E-Z-GO FREEDOM, FREEDOM HP LE, FREEDOM SE, FREEDOM LE, SHUTTLE 2+2 Owner's And Service Manual

...

28681-G01-FR

OWNER’S MANUAL & SERVICE GUIDE

MANUEL D’EXPLOITATION

ET D’ENTRETIEN

GASOLINE POWERED FLEET GOLF CARS & PER-

VOITURETTES DE GOLF INDUSTRIELLES

A ESSENCE & VEHICULES PRIVES

A PARTIR DES MODELES DE L’ANNEE 2002

SNAL VEHICLES

STARTING MODEL YEAR 2002

REVISED 10-10-02

Mise à jour le 10-10-02

SAFETY

r

For any questions on material cont ained in this manual, conta ct an aut horized representative for clarification.

Read and understand all lab els located on the vehicle. Always replac e any dama ged or missing labels.

On steep hills it is possible for vehicles to coast at greater than normal speeds encountered on a flat surface. To pre-

vent loss of vehicle control and possible serious injury, speeds should be limited to no more than the maximum speed

on level ground. See GENERAL SPECIFICATIONS. Limit speed by applying the servi ce brake.

Catastrophic damage to the drivetrain components due to excessive speed may result from driving the vehicle above

specified speed. Damage caused by excessive speed may cause a loss of vehicle control, is costly, is considered

abuse and will not be covered under warranty.

Use extra caution when towing the vehicle(s). Do not tow a single vehicle at speeds in excess of 12 mph (19 kph). Do

not tow more than three vehicles at a time. Do not exceed 5 mph (8 kph) while towing multiple vehicles. Towing the

vehicle at above the recommended speed may result in personal injury and/or damage to the vehicle and other property.

Signs similar to the ones illustrated should be used to warn of situations that coul d result in an unsafe condition.

BATTERY WARNING

Battery posts,

terminals and related

accessories contain

lead and lead compounds,

chemicals known

to cause cancer and

reproductive harm.

WASH HANDS

AFTER HANDLING!

BATTERIES

AND RELATED PARTS

CONTAIN LEAD

WASH HANDS

AFTER HANDLING!

WARNING: Battery posts, terminals and related

accessories contain lead and lead compounds,

chemicals known to cause cancer and reproductive harm.

Be sure that this manual remains as part of the permanent service record should the vehicle be sold.

NOTES, CAUTIONS AND WARNINGS

Throughout this guide NOTE, CAUTION and WARNING

will be used.

A NOTE indicates a condition that should be

observed.

A CAUTION indicates a condition that

may result in damage to the vehicle.

A WARNING indicates a

! !

hazardous condition that

could result in severe

injury or death.

! !

quantities, to cause cancer, birth defects, or other

reproductive harm.

The exhaust emissions of this vehicles’ engine

complies with regulations set forth by the Environmental Protection Agency (EPA) of the United States of

America (USA) at time of manufacture. Significant fines could

result from modifications or tampering with the engine, fuel,

ignition or air intake systems.

Engine exhaust from this

product contains chemicals known, in certain

!

<

14

˚

25

%

DO NOT

DRIVE ACROSS

SLOPES IN

EXCESS OF 14˚

Observe these NOTES, CAUTIONS and WARNINGS;

be aware that servicing a vehicle requires mechanical

skill and a regard for conditions that could be hazardous.

Improper service or repair may damage the vehicle or

render it unsafe.

(NOTES, CAUTIONS AND WARNINGS CONTINUED ON INSIDE OF BACK COVER)

Battery posts, terminals

! !

and related accessories

contain l ead and lead

compounds. Wash hands after handling.

This spark ignition system meets all require-

ments of the Canadian Interference-Causing

Equipment Regulations.

Ce système d'allumage par étincelle de véhicule respecte

toutes les exigences du Règlement sur le matériel brouilleu

du Canada.

OWNER’S MANUAL

AND SERVICE GUIDE

GASOLINE POWERED

FLEET GOLF CARS

& PERSONAL VEHICLES

FLEET GOLF CAR

FREEDOM

™

FREEDOM™ SE

™

FREEDOM

FREEDOM

FREEDOM

FREEDOM

™

™

SHUTTLE

TEXTRON Golf, Turf & Specialty Products reserves the right to make design changes without obligatio n to make these changes on units previous ly so ld and the

informat i on contained in this manual is subject to change without notic e.

TEXTRON Golf, Turf & Specialty Products is not liable for errors in t hi s manual or for incidental or consequential damages that result from the use of the material in

this manual.

LE

™

HP

HP SE

HP LE

™

2+2

CUSTOMER SERVICE DEPARTMENT IN USA PHONE: 1-800-241-5855 FAX: 1-800-448-8124

Owner’s Manual and Service Guide

Page i

GENERAL INFORMATION

This vehicle has been designed and manufactured in the United States of America (USA) as a ‘World Vehicle’. The Standards

and Specifications listed in the followin g te xt originate in the USA unless othe rwise indicated.

The use of non Original Equipment Manufacturer (OEM ) ap pr oved parts may void the warranty.

Overfilling battery may void the warranty.

Tampering with or adjusting the go vernor to permit vehicle to operate at abov e factory specifications will void the vehicle

warranty.

When servicing e ngines, all ad justm ents an d rep laceme nt co m ponents m ust be per origi nal vehi cle spec ifica tions i n or der to

maintain the United States of America Federal and State emission certific at ion applicable at the time of manuf acture.

BATTERY PROLONGED STORAGE

All batteries will self discharge over time. The ra te of self di sch ar ge va rie s dep endin g on th e ambie nt te mp er a ture and th e age

and condition of the batte ries .

A fully charged battery wi ll not freeze in winter temperatur es unless the temperatur e fal ls below -7 5° F (-60° C ) .

Page ii

Owner’s Manual and Service Guide

TABLE OF CONTENTS

SAFETY ........ .. ............ .................... ............ .................... ............ .................... ....... Ins ide covers

NOTES ........................................................................................................................................ ii

SAFETY INFORMATION............................................................................................................ v

BEFORE IN ITIAL USE .............. ........... ..................... ........... ..................... ........... ..................... 1

Fig. 1 Initial Service Chart .........................................................................................................1

CONTROLS AND INDICATORS ...............................................................................................1

KEY/LIGHT SWITCH ...........................................................................................................................................1

DIRECTION SELECTOR .....................................................................................................................................2

CHOKE . .............. ............... .............. .............. ............ .............. .............. ............... ...............................................2

FUEL GAUG E ... .. ............... .............. .............. .......................... .............. ............... ...............................................2

LOW OIL PRESSURE INDICATOR LIGHT .........................................................................................................2

ACCELERATOR PEDAL .....................................................................................................................................2

COMBINATION BRAKE AND PA R K BRAKE PEDAL ....... ... ... .......................... .............. .......................... ..........3

HORN ...... ....................... .............................................. .................................. .....................................................3

OPERATING THE VEHICLE ..................................................................................................... 3

RUN-IN ................................................................................................................................................................4

COLD START I NG ......................... ............... .............. .............. .......................... .............. ....................................4

STARTING AN D DRIVING ............................ ............... ......................... ............... .............. .................................4

STARTING THE VEHICLE ON A HILL ................................................................................................................4

COASTING ............... ................. ............... ................. ................. ................. ............... .........................................5

FUEL ................... ............... .............. .............. .......................... .............. ............... ...............................................5

BATTERY .............. ................................... ............................................. ..............................................................5

LABELS AND PICTOGRAMS .............................................................................................................................5

SUN TOP AND W IND S H IE L D ... ... ............... .............. .............. .......................... .............. ............... .....................5

VEHICLE CLEANING AND CARE .................................. .. .... .. ........................ .. .... .. ..................6

VEHICLE CLEANING ..........................................................................................................................................6

VEHICLE CARE PRODUCTS ................................................................................................. ... .........................6

REPAIR .......... ............ ......... ........... ............ ......... ........... ............ ........... ......... ............ ................ 7

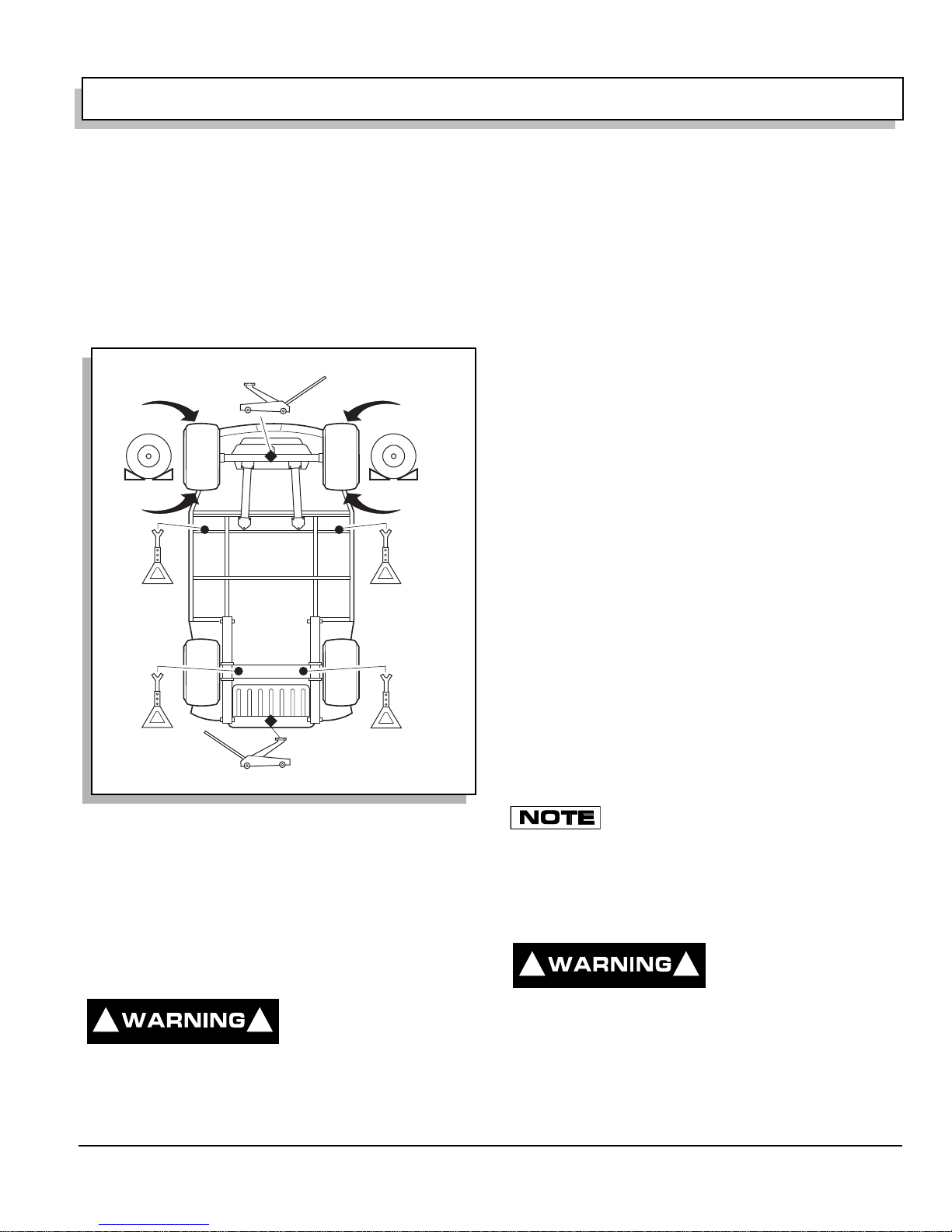

LIFTING THE VEHICLE ......................................................................................................................................7

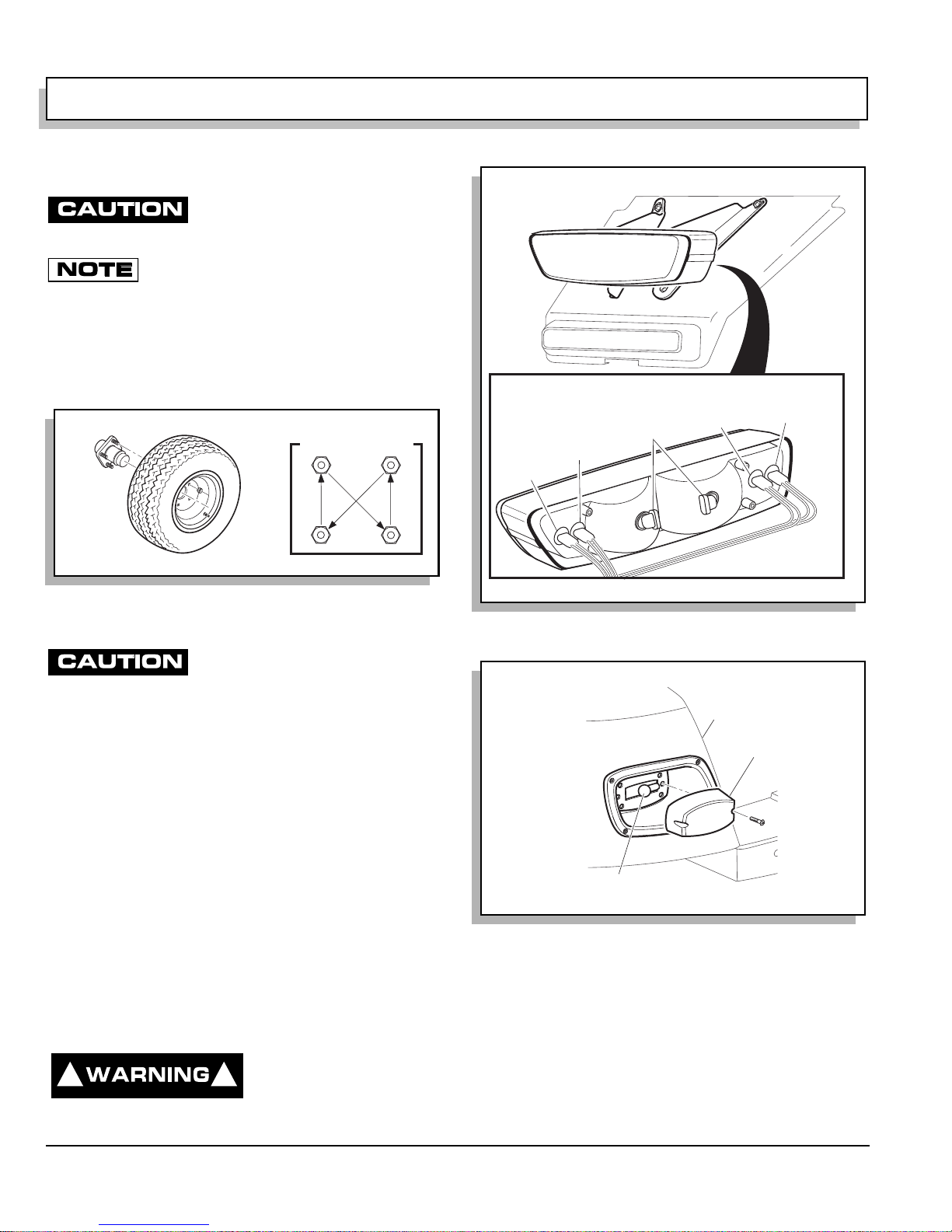

WHEELS AND TIRES .................. .......................... .............. .......................... .............. .......................................7

LIGHT BULB REPLACEMENT ............................................................................................................................8

FUSE REPLAC E M E N T ........ .. ... ............... ......................... ............... .............. .............. .......................................8

VEHICLE WITH A DISCHARGED BATTERY .....................................................................................................8

TRANSPORTING VEHICLE ...................................................................................................... 9

TOWING ..... .............. ................. .................. ................. .............. ................. ................. .......................................9

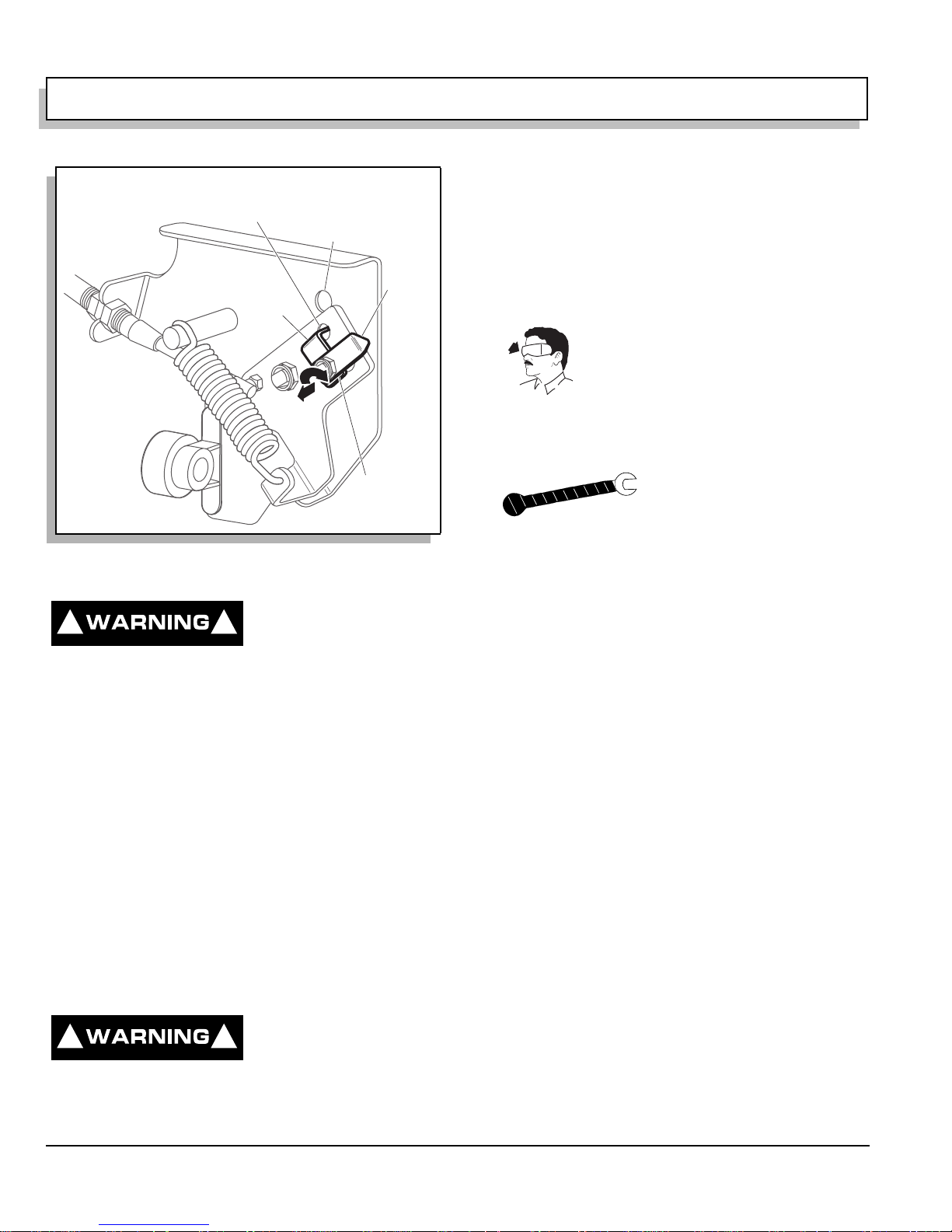

NEUTRAL LOCK ...............................................................................................................................................10

HAULING . ........... ............ ........ ............ ........... ............ ........ ............ ........... ............ ........ .....................................10

SERVICE AND MAINTENANCE ..................................................... .. .... .......................... .... ....11

SERIAL NUMBER PLATE LOCATION ..............................................................................................................11

Fig. 2 Key/Light Switch, Low Oil Pressure Light and Fuel Gauge ............................................2

Fig. 3 Direction Selector ...........................................................................................................2

Fig. 4 Choke .............................................................................................................................2

Fig. 5 Accelerator and Brake Controls ......................................................................................3

Fig. 6 Horn Button .....................................................................................................................3

Fig. 7 Check Oil Level on Dipstick ............................................................................................4

Fig. 8 Fueling ............................................................................................................................5

Fig. 9 Lifting the Vehicle ...........................................................................................................7

Tire Repair .......................... .............. ............... ......................... ............... .............. .................................7

Wheel Installation ...................................................................................................................................8

Fig. 10 Wheel Installation .........................................................................................................8

Fig. 11 Headlight, Turn Signal & Marker Light Bulb Replacement ...........................................9

Fig. 12 Tail and Brake Light Bulb Replacement .......................................................................9

On Rear Axle ........................................................................................................................................10

Fig. 13 Neutral Lock on Rear Axle ..........................................................................................10

On Direction Selector ............................................................................................................................10

Fig. 14 Neutral Lock on Direction Selector .............................................................................10

Owner’s Manual and Service Guide

Page iii

TABLE OF CONTENTS

Early Produ ct io n ........ ... ... .............. .............. ............... .............. .......................... .................................. 11

Fig. 15 Serial Number Plate Location - Early Production ....................................................... 11

Late Produc ti on ......................................... .............. .............. .............. .......................... ....................... 11

Fig. 16 Serial Num b e r Pla te Lo ca ti o n - Late Pr o duc t ion ............. ... .............. .......................... 12

PERIODIC SERVICE SCHEDULE .................................................................................................................. 13

TIRE INSPE CT IO N .. ... .. ............... .............. .............. .......................... .............. ............... .................................. 15

CHECKING THE OIL LEVEL ............................................................................................................................ 15

CHANGIN G TH E OIL .. .............. .............. .......................... .............. ............... .............. ..................................... 15

STARTER/ GENERATOR BE LT TENSION ...... ... .............. .......................... .............. .......................... .............. 17

BATTERY CLEANING ...................................................................................................................................... 18

BRAKES ........................................................................................................................................................... 19

AIR INTAKE AND COOLING FINS ................................................................................................................... 20

REAR AXLE . ... .......................... .............. ............... ......................... ............... ................................................... 20

AIR CLEANER INSPECTION AND REPLACEMENT ....................................................................................... 20

LUBRICA TION ......... .............. .............. ............ .............. .............. ............... ........... ........................................... 21

SPARK PLUGS ................................................................................................................................................. 21

DIRECTION SELECTOR (Dual Cable system) ................................................................................................ 22

PROLONGED STORAGE ................................................................................................................................ 22

HARDWARE ....................... ................................... ............................................. .............................................. 22

CAPACITIES AND REPLACEMENT PARTS ................................................................................................... 23

GENERAL SPECIFICATIONS.................................................................................................. 25

TXT GASOLINE - FLEET .................................................................................................................................. 26

TXT GASOLINE - FREEDOM™ ........................................................................................................................ 27

TXT GASOLINE - FREEDOM™ SE .................................................................................................................. 28

TXT GASOLINE - FREEDOM™ LE................................................................................................................... 29

TXT GASOLINE - FREEDOM™ HP.................................................................................................................. 30

TXT GASOLI N E - FRE ED O M ™ H P SE .............. ... .............. .......................... .............. .............. ............. .......... 31

TXT GASOLI N E - FRE ED O M ™ H P LE...... .............. ............... ......................... ............... .............. .................... 32

TXT GASOLINE - SHUTTLE™ 2+2................................................................................................................... 33

LIMITED WARRANTIES...........................................................................................................37

DOMESTIC W AR RANTY ............. .............. .............. .......................... .............. ............... .............. .................... 38

Fig. 17 Periodic Service Schedule ......................................................................................... 13

Fig. 18 Clean Entire Dipstick ............. .................. ............................ .................. .....................15

Fig. 19 Check Oil Level on Dipstick ....................................................................................... 15

Fig. 20 Oil Viscosity Chart ...................................................................................................... 16

Fig. 21 Clean Top of Engine ........... ......... ............................ ......... ......... ............................ .... 16

Fig. 22 Remove Oil Filter ....................................................................................................... 16

Fig. 23 Clean Oil Filter ................... ......... ........................... .................................................... 16

Fig. 24 Blowing Out Oil Filter ................................................................................................. 16

Fig. 25 Add Engine Oil ........................................................................................................... 17

Fig. 26 Checking Belt Tension with Gauge ............................................................................ 17

Fig. 27 Checking Belt Tension Manually ................................................................................ 17

Adjusting the Belt ................................................................................................................................. 18

Fig. 28 Adjusting Belt Tension ............................................................................................... 18

Fig. 29 Preparing Acid Neutralizing Solution .......................................................................... 18

Periodic Brake Test for Mechanical Brakes ......................................................................................... 19

Fig. 30 Typical Brake Performance Test ................................................................................ 19

Fig. 31 Cleaning Ai r Intake ............................... ......... ......... .......... ......... ......... ......... ............... 20

Fig. 32 Cleaning the Cooling Fins ......................... ......... .................. ......................................20

Checking th e Lu b ric an t Le ve l ........ ... ... .............. .............. ............... .............. .......................... .............. 20

Fig. 33 Add, Check and D r ain Rear Axle Lubric ant .......... ..................................................... 20

Cleaning th e Air F ilt er El e men t ....................................... ............... .......................... .............. . ............. 21

Fig. 34 Air Cleaner ................................................................................................................. 21

Fig. 35 Lubrication Points - Early Production ......................................................................... 21

Fig. 36 Lubrication Points - Late Production .......................................................................... 21

Fig. 37 Shift Cable Adjustment ............................................................................................... 22

Fig. 38 Torque Sp e ci fic a tio ns .......................... .............. .............. ............... ......................... ...23

Fig. 39 Capacities and Replacement Parts ............................................................................ 23

Fig. 36 Vehicle Dimensions.....................................................................................................34

Fig. 37 Vehicle Dimensions, Incl ine Specifications and Turning Clearance Diamet er............ 35

Page iv

Owner’s Manual and Service Guide

TABLE OF CONTENTS

INTERNAT IO N A L WAR RANTY (2002).......... ... ... .............. ............... .............. .......................... .........................39

INTERNAT IO N A L WAR RANTY (2003).......... ... ... .............. ............... .............. .......................... .........................40

FEDERAL EMIS SION COMPONE N T D EF EC T W AR RA N T Y .... .............. .......................... .............. ............... ..41

CALIFORNIA EMISSIO N CO NT R O L W ARRANTY STAT E M ENT.... ... .. ... .......................... .......................... ..... 4 3

DECLARATION OF CONFORMITY (EUROPE ONLY)............................................................47

FLEET GOLF C AR ( 20 0 0)..... .............. .............. ............... .............. .......................... .............. ............................48

FREEDOM™ GOLF CAR (2000) .......................................................................................................................49

FREEDOM™ HP GO L F CAR (200 0 ) ............. ............... .............. .............. ............... .............. ............................50

SHUTTLE 2+ 2 (200 0 ).............. ............... .............. .......................... .............. .......................... ............................51

FLEET AND FR EE D O M ™ GO LF CAR (20 0 2)...................... .......................... .............. ............... ......................52

SHUTTLE 2+ 2 (200 2 ).............. ............... .............. .......................... .............. .......................... ............................53

LABELS AND PICTOGRAMS.................................................................................. Appendix A

Owner’s Manual and Service Guide

Page v

N

TABLE OF CONTENTS

otes:

Page vi

Owner’s Manual and Service Guide

SAFETY INFORMATION

This manual has been designed to assist in maintaining the vehicle in accordance with procedures developed by the

manufacturer. Adherence to these procedures and troubleshooting tips will ensure the best possible service from the product.

To reduce the chance of personal i nj ury or property damage, the fol low in g m ust be carefully observed:

GENERAL

Many vehicles are us ed for a variety of tasks beyond the or iginal intended use of the veh icle; therefore, it is impossi ble to

anticipate and wa rn against every possible combin at io n of circumstances that may oc cu r. No warnings can take the place of

good common sense and prudent driving practices.

Good commo n sense and prudent driving practices do m ore to prevent acci dents and injury than all of the warnings and

instructions combined. The manufacturer strongly suggests that all users and maintenance personnel read this entire manual

paying particular attention to the CAU TIONS and WARNINGS con tained ther ei n.

If you have any questions regarding this vehicle, contact your closest representative or write to the address on the back cover

of this publication, Attention: Pro duct Service Department.

TEXTRON Golf, Turf & Specialty Products reserves the right to make design changes without obligation to make these

changes on units previousl y sold and the informatio n conta in ed in th is ma nual is subject to change without notice.

TEXTRON Golf, Turf & Specialty Products is not liable for error s in this manual or for inc idental or consequen tial damages

that result from the use of the m at er i al in this m anual.

This vehicle conform s to th e cur re nt appl i cab le stand ar d(s ) for saf ety and performance requir em ents .

These vehicles are designed and manufactured for off-road use. They do not conform to Federal Motor Vehicle Safety

Standards of the United States of America (USA) and are not equippe d for operation o n public streets. Some communities

may permit these veh ic le s to be operated on their streets on a lim ited b asis and in accordance w ith local ordinances.

Refer to GENERAL SPEC I FI CATIONS for vehicle seating capacity.

Never modify the vehicle in any way that will alter the weight distribution of the vehicle, decrease its stability or

increase the speed beyond the factory specification. Such modifications can cause serious personal injury or death.

Modifications that increase the speed and/or weight of the vehicle will extend the stopping distance and may reduce the

stability of the vehicle. Do not make any such modifications or changes. The manufacturer prohibits and disclaims

responsibility for any such modifications or any oth er alter at io n w hi ch would adversely affect the saf et y of the vehicl e.

Vehicles that are capable of higher speeds must limit their speed to no more than the speed of other vehicles when used in a

golf course environment. Additionally, speed should be further moderated by the environmental conditions, terrain and

common sense.

Always:

• Use the vehicle in a responsible manner and maintain the vehicle in safe operating condition.

• Read and observe all warnings and operation inst ruction labels affixed to the vehicle.

• Follow all safety rules established in the area where the vehicle is being operated.

• Reduce speed to compensate for poor terrain or conditions.

• Apply service brake to control speed on steep grades.

• Maintain adequate distance between vehicles.

• Reduce speed in wet areas.

• Use extreme caution when approaching sharp or blind turns.

• Use extreme caution when driving over loose terrain.

GENERAL OPERATION

Owner’s Manual and Service Guide

Page vii

SAFETY INFORMATION

• Use extreme caution in areas where pedestrians are present.

MAINTENANCE

Always:

• Maintain the vehicle in accordance with the manufacturer’s periodic service schedul e.

• Ensure that repairs are performed by those that are trained and qualified to do so.

• Follow the manufacturer’s maintenance procedures for the vehicle. Be sure to disable the vehicle before performing

any maintenance. Disabling includes removing the key from the key switch and removal of a battery wire.

• Insulate any tools used within the bat tery area in order to prevent sparks or battery explosion caused by shorting the

battery terminals or associated wiring. Remove the battery or cover exposed terminals with an insulating material.

• Use specified replacement parts. Never use replace men t parts of lesser quali ty.

• Use recommended tools.

• Determine that tools and procedures not specifically recommended by the manufacturer will not compromise the

safety of personnel nor jeopar dize the safe operation of the vehicl e.

• Support the vehicle using wheel chocks and jack stands. Never get under a vehicle that is supported by a jack. Lift

the vehicle in accordance with the manufacturer’s instructions.

• Empty the fuel tank or plug fuel hoses to prevent fuel leakage.

• Maintain the vehicle in an area away from exposed flame or persons who are smoki ng.

• Be aware that a vehicle that is not performing as designed is a potential hazard and must not be operated.

• Test driv e the vehicle after any repairs or maintenance. Al l t ests must be conducted in a safe ar ea that is free of both

vehicular and pedestrian traffic.

• Replace damaged or missing warning, caution or information labels.

• Keep complete records of the maintenance history of the vehicle.

The manufacturer cannot anticipate all situations, therefore people attempting to maintain or repair the vehicle must have the

skill and expe rience to re cogni ze and prot ect the msel ves f rom po tent ial situ ations t hat could resu lt in s evere perso nal injur y

or death and d amage to the vehicle. Use e xtreme caution and, if u nsure as to the potential fo r injury, refer the repair or

maintenance to a qualified mechanic.

VENTILATION

Always store gasol in e vehicles in a well ventilated are a . Ventilation prevents gasoline fumes from acc um ulat i ng.

Never fuel a vehicle in an area that is subject to flame or spark. Pay particular attention to na tural gas or propane wa ter

heaters and furnac es.

Never work a round or operate a vehicle in an environment that do es not ventilate exhaust ga ses from the area. Carb on

monoxide is a dangerous gas that can ca use unconsciousness and is potentially leth al.

Page viii

Owner’s Manual and Service Guide

SAFETY INFORMATION

Owner’s Manual and Service Guide

Page ix

Notes:

SAFETY INFORMATION

Page x

Owner’s Manual and Service Guide

SAFETY INFORMATION

Read all of manual to become thoroughly familiar with this vehicle. Pay part icu lar at tention to all Notes, Cautions and Warnings

GENERAL

The following tex t is pr ovided as recomm en ded by part II of

American Society of Mechanical Engineers / American

National Standards Institute (ASME/ANSI ) B56.8- 1988. Th e

manufacturer strongly endorses the contents of this

specification.

PART II

FOR THE USER

4 GENERAL SAFETY PRACTICES

4.1 Introduction

4.1.1 Like other machines, carriers can cause injury

if improperly used or maintained. Part II contains broad

safety practices applicable to carrier operations. Before

operation, the user shall establish such additional specific safety practices as may reasonably be required for

safe operation.

4.2 Stability

4.2.1 Experience has shown that this v ehicle , which

complies with this standard, is stable when properly

operated and when operated in accordance with specific

safety rules and practices established to meet actual

operating terrain and conditions. However, improper

operation, faulty maintenance, or poor housekeeping

may contribute to a condition of instability and defeat the

purpose of the standard. Some of the conditions which

may affect stability are failure of the user to follow safety

practices; also, ground and floor conditions, grade,

speed, loading, the operation of the carrier with improper

loads, battery weight, dynamic and static forces, and the

judgement exercised by the carrier operator.

(a) The user shall train carrier operators to adhere

strictly to the operating instructions stated in this Standard.

(b) The user shall survey specific operating conditions

and environment, and establish and train carrier operators to comply with additional, specific safety practices.

4.3 Nameplates, Markings, Capacity, and Modifica-

tions

4.3.1 The user shall maintain in a legible condition

all nameplates, warnings, and instructions which are

supplied by the manufacturer.

4.3.2 The user shall not perform any modification or

addition which affects capacity or safe operation, or

make any change not in accordance with the owner’s

manual without the manufacturer’s prior written authorization. Where authorized modifications have been made,

the user shall ensure that capacity, operation, warning,

and maintenance instruction plates, tags, or decals are

changed accordingly.

4.3.3 As required under paras. 4.3.1 or 4.3.2, the

manufacturer shall be contacted to secure new nameplates, warnings, or instructions which shall then be

affixed in their proper place on the carrier.

4.4 Fuel Handling and Storage

4.4.1 The user shall supervise the storage and han-

dling of liquid fuels (when used) to be certain that it is in

accordance with appropriate paragraphs of American

National Standards Institute/National Fire Protection

Association (ANSI/NFPA) 505 and ANSI/NFPA 30.

4.4.2 Storage and handling of liquefied petroleum

gas fuels shall be in accordance with appropriate paragraphs of ANSI/NFPA 505 and ANSI/NFPA 58. If such

storage or handling is not in compliance with these standards, the user shall prevent the carrier from being used

until such storage and handling is in compliance with

these standards.

4.5 Changing and Charging Storage Batteries for

Electric Personnel and Burden Carriers

4.5.1 The user shall require battery changing and

charging facilities and procedures to be in accordance

with appropriate parag raphs of ANSI/NFPA 505.

4.5.2 The user shall periodically inspect facilities

and review procedures to be certain that appropriate

paragraphs of ANSI/ NFPA 505, are strictly complied wi th,

and shall familiarize carrier operators with it.

4.6 Hazardous Locations

4.6.1 The user shall determine the hazard classifi-

cation of the particular atmosphere or location in which

the carrier is to be used in accordance with ANSI/NFPA

505.

4.6.2 The user shall permit in hazardous areas only

those carriers approved and of the type required by

ANSI/NFPA 505.

4.7 Lighting for Operating Areas

4.7.1 The user, in accordance with his responsibility

to survey the environment and operati ng condit ions, shall

determine if the carrier requires lights and, if so, shall

Owner’s Manual and Service Guide

Page xi

SAFETY INFORMATION

Read all of manual to become thoroughly f amiliar with th is vehicle. Pay particular attention to all Notes, Cautions and Warnings

equip the carrier with appropriate lights in accordance

with the manufacturer’s recommenda ti ons.

4.8 Control of Noxious Gases and Fumes

4.8.1 When equipment powered by internal com-

bustion engines is used in enclosed areas, the atmosphere shall be maintained within limits specified in the

American Conference of Governmental Industrial

Hygienists publication, “Threshold Limit Values for

Chemical Substances and Physical Agents in the Workroom Environment”. This shall be accomplished by ventilation provided by the user, and/or the installation, use,

and proper maintenance of emission control equipment

recommended or provided by the manufacturer of the

equipment.

4.9 Warning Device(s)

4.9.1 The user shall make periodic inspections of

the carrier to be certain that the sound-producing and/or

visual device(s) are maintained in good operating condition.

4.9.2 The user shall determine if operating conditions require the carrier to be equipped with additional

sound-producing and/or visual devices and be responsible for providing and maintaining such devices, in accordance with the manufacturer’s recommendations.

5 OPERATING SAFETY RULES AND

PRACTICES

5.1 Personnel and Burden Carrier Operator

Qualifications

5.1.1 Only persons who are trained in the proper

operation of the carrier shall be authorized to operate the

carrier. Operators shall be qualified as to visual, auditory,

physical, and mental ability to safely operate the equipment according to Section 5 and all other applicable

parts of this Standard.

5.2 Personnel and Burden Carrier Operators’

Training

5.2.1 The user shall conduct an operators’ training

program.

5.2.2 Successful completion of the operators’ training program shall be required by the user before operation of the carrier. The program shall be presented in its

entirety to all new operators and not condensed for those

claiming previous experience.

5.2.3 The user should includ e in the op erators ’ tra in-

ing program the following:

(a) instructional material provided by the manufac-

turer;

(b) emphasis on safety of passengers, material loads,

carrier operator, and other employees;

(c) general safety rules contained within this Standard

and the additional specific rules determined by the user

in accordance with this Standard, and why they were formulated;

(d) introduction of equipment, control locations and

functions, and explanation of how they work when used

properly and when used improperly, and surface conditions, grade, and other conditions of the environment in

which the carrier is to be operated;

(e) operational per formance t est s and e valuati ons during, and at completion of, the program.

5.3 Personnel and Burden Carrier Operator

Responsibility

5.3.1 Operators shall abide by the following safety

rules and practices in p aras. 5.4, 5.5, 5.6, and 5.7.

5.4 General

5.4.1 Safeguard the pedestrians at all times. Do not

drive carrier in a manner that woul d endanger anyone.

5.4.2 Riding on the carrier by pers ons other t han the

operator is authorized onl y on per sonnel seat (s ) provi ded

by the manufacturer. All parts of the body shall remain

within the plan view outline of the carrier.

5.4.3 When a carrier is to be left unattended, stop

carrier, apply the parking brake, stop the engine or turn

off power, turn off the control or ignition circuit, and

remove the key if provided. Block the wheels if machine

is on an incline .

5.4.4 A carrier is considered unattended when the

operator is 25 ft. (7.6 m) or more from the carrier which

remains in his view, or whenever the operator leaves the

carrier and it is not within his view. When the operator is

dismounted and within 25 ft. (7.6 m) of the carrier still in

his view, he still must have controls neutralized, and the

parking brake(s) set to prevent movement.

5.4.5 Maintain a safe distance from the edge of

ramps and platforms.

5.4.6 Use only approved carriers in hazardous locations, as defined in the appropriate safety standards.

5.4.7 Report all accidents involving personnel,

Page xii

Owner’s Manual and Service Guide

SAFETY INFORMATION

Read all of manual to become thoroughly familiar with this vehicle. Pay part icu lar at tention to all Notes, Cautions and Warnings

building structures , and equipment.

5.4.8 Operators shall not add to, or modify, the car-

rier.

5.4.9 Carriers shall not be parked or left unattended

such that they block or obstruct fire aisles, access to

stairways, or f ire equipment.

5.5 Traveling

5.5.1 Observe all traff ic regulati ons, i ncludi ng autho-

rized speed limits. Under normal traffic conditions keep

to the right. Maintain a safe distance, based on speed of

travel, from a carrier or vehicle ahead; and keep the carrier under control at all times.

5.5.2 Yield the right of way to pedestrians, ambulances, fire trucks, or other carriers or vehicles in emergency situations.

5.5.3 Do not pass another carrier or vehicle traveling in the same direction at intersections, blind spots, or

at other dangerous locations .

5.5.4 Keep a clear view of the path of travel,

observe other traffic and personnel, and maintain a safe

clearance.

5.5.5 Slow down or stop, as conditions dictate, and

activate the sound-producing warning device at cross

aisles and when visibili ty i s obstructed at other locatio n s.

5.5.6 Ascend or descend grades slowly.

5.5.7 Avoid turning, if possible, and use extreme

caution on grades, ramps, or inclines; normally travel

straight up and down.

5.5.8 Under all travel conditions the carrier shall be

operated at a speed that will permit it to be brought to a

stop in a safe manner.

5.5.9 Make starts, stops, turns, or direction reversals in a smooth manner so as not to shift the load,

endanger passengers, or overturn the carrier.

5.5.10 Do not indulge in dangerous a ctivi ties , such as

stunt driving or horseplay.

5.5.11 Slow down when approaching, or on, wet or

slippery surfaces .

5.5.12 Do not drive carrier onto any elevator unless

specifically authorized to do so. Approach elevators

slowly, and then enter squarely after the elevator car is

properly leveled. Once on the elevator, neutralize the

controls, shut off power, and set parking brakes. It is

advisable that all other personnel leave the elevator

before a carrier is allowed to enter or exit.

5.5.13 Avoid running over loose objects, potholes,

and bumps.

5.5.14 To negotiate turns, reduce speed to improve

stability, then turn hand steering wheel or tiller in a

smooth, sweeping motion.

5.6 Loading

5.6.1 Handle only stable and safely arranged loads.

When handling off-center loads which cannot be centered, operate with extra caution.

5.6.2 Handle only loads within the capacity of the

carrier as specified on the nameplate.

5.6.3 Handle loads exceeding the dimensions used

to establish carrier capacity with extra caution. Stability

and maneuverability may be adversely affected.

5.7 Operator Care of Personnel and Burden

Carriers

5.7.1 At the beginning of each shift during which the

carrier will be used, the operator shall check the carrier

condition and inspect the tires, warning devices, lights,

battery(s), speed and directional controllers, brakes, and

steering mechanism. If the carrier is found to be in need

of repair, or in any way unsafe, the matter shall be

reported immediately to the designated authority and the

carrier shall not be operated until it has been restored to

safe operating conditio n.

5.7.2 If during operation the carrier becomes unsafe

in any way, the matter shall be reported immediately to

the designated authority, and the carrier shall not be

operated until it has been restored to safe operating condition.

5.7.3 Do not make repairs or adjustments unless

specifically authorized to do so.

5.7.4 The engine shall be stopped and the operator

shall leave the carrier whi le refueling.

5.7.5 Spillage of oil or fuel shall be carefully and

completely absorbed or evaporated and fuel tank cap

replaced before st arting engine.

5.7.6 Do not operate a carrier with a leak in the fuel

system or battery(s).

5.7.7 Do not use open flames for checking electrolyte level in storage battery(s) or liquid level in fuel tanks.

6 MAINTENANCE PRACTICES

6.1 Introduction

Owner’s Manual and Service Guide

Page xiii

SAFETY INFORMATION

Read all of manual to become thoroughly f amiliar with th is vehicle. Pay particular attention to all Notes, Cautions and Warnings

6.1.1 Carriers may become hazardous if maintenance is neglected. Therefore, maintenance facilities,

trained personnel, and procedures shall be provided.

Such facilities may be on or off the pre mises.

6.2 Maintenance Procedures

6.2.1 Maintenance and inspection of all carriers

shall be performed in conformance with the manufacturer’s recommendations and the following pract ices.

(a) A scheduled preventive maintenance, lubrication,

and inspection system shall be followed.

(b) Only qualified and authorized personnel shall be

permitted to maintain, repair, adjust, and inspect carriers.

(c) Before undertaking maintenance or repair, follow

the manufacturer’s recommendations for immobilizing

the carrier.

(d) Block chassis before worki ng underneath it.

(e) Before disconnecting any part of the engine fuel

system of a gasoline or diesel powered carrier with gravity feed fuel systems, be sure shutoff va lve is closed, and

run engine until fuel syst em is depl eted and engine stops

running.

(f) Before disconnecting any part of the engine fuel

system of LP gas powered carriers, close the LP gas cylinder valve and run the engine until fuel in the system is

depleted and the engine stops runni ng.

(g) Operation to check performance of the car rier shall

be conducted in an authorized area where safe clearance exists.

(h) Before commencing operation of the carrier, follow

the manufacturer’s instructions and recommended procedures.

(i) Avoid fire hazards and have fire protection equipment present in the work ar ea. Do not use an open flame

to check level or leakage of fuel, battery electrolyte, or

coolant. Do not use open pans of fuel or flammable

cleaning fluids for cleaning parts.

(j) Properly ventilate the work area.

(k) Handle LP gas cylinders with care. Physical damage, such as dents, scrapes, or gouges, may dangerously weaken the tank and make it unsafe for use.

(l) Brakes, steering mechanisms, speed and directional control mechanisms, warning devices, lights, governors, guards, and safety devices shall be inspected

regularly and maintained in a safe operating condition.

(m) Special carriers or devices designed and

approved for hazardous area operation shall be

inspected to ensure that maintenance preserves the original approved safe operating features.

(n) Fuel systems shall be chec ked for l eak s and condition of parts. If a leak is found, action shall be taken to

prevent the use of the carrier until the leak has been

eliminated.

(o) The carrier manufa cturer’s capaci ty, operation, and

maintenance instruction plates, tags, or decals shall be

maintained in legible condition.

(p) Batteries, motors, speed and directional controllers, limit switches, protective devices, electrical conductors, and connections shall be inspected and maintained

in conformance with manufacturers recommended procedures.

(q) Carriers shall be kept in a clean condition to minimize fire hazards and facilitate detection of loose or

defective parts.

(r) Modifications and additions which affect capacity

and safe machine operation shall not be performed by

the customer or user without manufacturer’s prior written

authorization; where authorized modifications have been

made, the user shall ensure that capacity, operation,

warning, and maintenance instruction plates, tags, or

decals are changed accordingly.

(s) Care shall be taken to ensure that all replacement

parts are interchangeable with the original parts and of a

quality at least equal to that provided in the original

equipment.

End of ASME/ANSI B56.8 - 1988 Text

Page xiv

Owner’s Manual and Service Guide

SAFETY INFORMATION

Read all of manual to become thoroughly familiar with this vehicle. Pay part icu lar at tention to all Notes, Cautions and Warnings

GENERAL

The following tex t is pr ovided as recomm en ded by part II of

American National Standards Institute/National Golf Car

Manufacturers As sociation (ANSI/NGCMA ) Z130.1 - 1993.

The manufacturer, as a member of the NGCMA, strongly

endorses the contents of this specification.

PART II

MAINTENANCE AND OPERATIONS

5. GENERAL SAFETY PRACTICES

5.1. Introduction

Like other machines, golf cars can cause inj ury if improperly used or maintained. This section contains broad

safety practices recommended for safe golf car operations. Before operation, the controlling party should

establish suc h additional specific safety practices as may

be reasonably required for safe operations.

Experience has shown that golf cars which comply with

the provisions stated in Part II of this Standard are safe

when properly operated in accordance with the safety

and operation warnings affixed to every gol f car. The safe

operation is enhanced when the golf cars are operated

within a specific set of operation instructions, safety rules

and practices established to meet actual operating terrain and conditions.

The safety information contained in Part II is intended to

provide the controlling party with basic safety information

and to encourage the controlling party to implement a

golf car safety program.

It is suggested and recommended that Part II be

reprinted in the golf car manufacturer’s operation and

service manuals to encourage safe operations and practices at the controlling party’s facility.

5.2.1. Steep Grade

In areas where steep grades exist, golf car operations

should be restricted to the designated golf car pathways

where possible, and shall be identified with a suitable

warning giving the following information: “Warning, steep

grade, descend slowly with one foot on brake.”

5.2.2. Wet Areas

Wet grassy areas may cause a golf car to lose traction

and may affect stability. Wet areas shall be chained or

roped off to prevent golf car operat ions or be identi fied by

a suitable warning not to operate golf cars in this area

due to wet terrain.

5.2.3. Sharp Turns, Blind Corners, Bridge

Approaches

Sharp turns, blind spots, bridge approaches and other

potentially hazardous areas shall be either chained or

roped off to prevent golf car operations or identified with

a suitable warning to the operator of the nature of the

hazard and stating the proper precautions to be taken to

avoid the hazard.

5.2.4. Loose Terrain

Loose terrain may cause a golf car to lose traction and

may affect stability. Areas of loose terrain should be

repaired if possible, or chained or roped off to prevent

golf car operation or identified by a suitable warning to

operators not to operate golf cars in this area due to

loose terrain or possible hazardous conditions.

5.2.5. Golf Car/Pedestrian Interference Areas

5.2. Safety Survey

The controlling party shall perform a safety survey periodically, and as conditions warrant to their premises, to

identify areas where golf cars should not be operated

and to identify possible hazards.

Areas where pedestrians and golf cars interfere shall be

avoided whenever possible by rerouting the golf car traffic or the pedestrian traffic to eliminate the interfer ence. If

elimination of the interference is not possible or is highly

impractical, signs shall be erected warning pedestrians

of the golf car traffic and golf car operators of the pedestrian traffic and to drive slowly and use extreme caution.

Owner’s Manual and Service Guide

Page xv

SAFETY INFORMATION

Read all of manual to become thoroughly f amiliar with th is vehicle. Pay particular attention to all Notes, Cautions and Warnings

6. MAINTENANCE

6.1. Introduction

6.1.1. Golf cars may become hazardous if maintenance

is neglected or improperly performed. Therefore maintenance facilities, trained personnel and procedures in

accordance with the manufacturer’s recommendations

should be provided by the control ling party.

6.2. Preventive Maintenance

A regularly scheduled inspection and preventive maintenance program in accordance with the manufacturer’s

recommendations should be established. Such a program will be a valuable tool in providing the golfing

patron with a safe, properly operating golf car and

thereby help to avoid accidents.

6.2.1. Personnel

Only qualified, trained and authorized personnel shall be

permitted to inspect, adjust and maintain golf cars.

liters per car per charge. Because of the highly volatile

nature of hydrogen gas and its propensity to rise and

accumulate at the ceiling in pockets, a minimum of 5 air

changes per hour is recommended. The controlling party

shall consult applicable fir e and safet y codes for the specific ventilation levels required as well as the use of

explosion proof electrical apparatus.

6.2.4. Maintenance Procedures

All maintenance shall be performed in accordance with

the manufacturer’s recommended maintenance procedures as outlined in the manufacturer’s operation and

service manuals.

6.2.5. Maintenance Safety Procedures

All maintenance shall be performed in accordance with

the manufacturer’s recommended safety procedures as

outlined in the manufacturer’s operation and service

manuals. The following list of recommended safety procedures are general in nature and in no way supersede

the manufacturer’s specific instructions.

6.2.2. Parts and Materials

Only manufacturer’s recommended replacement parts

and materials shall be used.

6.2.3. Ventilation

Maintenance and storage areas shall be properly ventilated to avoid fire hazards in accordance with applicable

fire codes and ordinances.

6.2.3.1. Ventilation for gasoline powered golf cars shall

be provided to remove flammable vapors, fumes and

other flammable materials. Consult applicable fire codes

for specific levels of ventilation.

6.2.3.2. Ventilation for electric powered golf cars shall

be provided to remove the accumulation of flammable

hydrogen gas emitted during the charging process. The

amount of hydrogen gas emitted depends upon a number of factors such as the condition of the batteries, the

output rate of the battery charger and the amount of time

the batteries are on charge. Hydrogen emissions are

generally considered to be in the area of 10 to 20 cubic

6.2.5.1. Follow manufacturer’s instructions for immobilizing golf car before beginning any maintenance.

6.2.5.2. Block chassis before working underneath golf

car.

6.2.5.3. Before disconnecting any part of the fuel system, drain the system and turn all shut off valves to the

‘OFF’ position to prevent leakage or accumulation of

flammable fuels in the work area.

6.2.5.4. Avoid fire hazards and have fire protection

equipment available.

6.2.5.5. Before performing any maintenance on an electric golf car, disable the electrical system in accordance

with the manufacturer’s instructions.

6.2.5.6. Use only properly insulated tools when working

on electrically powered golf car s or around batteries.

6.2.5.7. Brakes, ste ering mechani sms, warning devices,

Page xvi

Owner’s Manual and Service Guide

SAFETY INFORMATION

Read all of manual to become thoroughly familiar with this vehicle. Pay part icu lar at tention to all Notes, Cautions and Warnings

governors and all other safety devi ces shall be inspected

and maintained in a safe and proper operating condition

and shall not be modified as supplied by the manufacturer.

6.2.5.8. After each maintenance or repair the golf car

shall be driven by qualified, trained and authorized personnel to ensure proper operation and adjustment.

6.2.5.9. Driving golf car to check for proper operation

and adjustment aft er repair shall be performed in an area

that is free of vehicular and pedestrian traffic.

6.2.5.10.Record all maintenance performed in a maintenance record log by date, name of person performing

maintenance and type of maintenance. Controlling party

management should periodically inspect maintenance

log to ensure currency and completenes s of entries.

7. FUELS HANDLING AND STORAGE/

BATTERY CHARGING

7.1. The controlling party shall supervise the storage

and handling of liquid fuels in accordance with appli cable

fire and safety requirements.

7.2. Storage and handling of liquefied petroleum gas

fuels shall be in accordance with American Gas Association recommendations and applicable fire safety requirements.

7.3. The controlling party shall require battery changing and charging facilities and procedures to be in accordance with applicable ordinances or regulations (also

see paragraph 6.2.3.2).

7.4. The controlling party shall periodically inspect

facilities and review procedures to be certain that the

procedures in paragraphs 6.2.3.2 and 7.3 are being followed.

6.2.5.11. Provide operator comment cards to assist in

identifying non-periodic maintenance needs for specific

golf cars.

6.2.6. The controlling party shall maintain in a legible

condition all nameplates, warnings and instructions

which are supplied by the manufacturer.

6.2.7. The controlling party shall not perf orm any modification or addition which affects capacity or safe operation, or make any change not in accordance with the

owner’s manual without the manufacturer’s prior written

authorization. Where autho rized modi ficat ions have been

made, the controlling party shall ensure that capacity,

operation, warning and maintenance instruction plates,

tags or decals are changed accordingly.

6.2.8. As required under paragraphs 6.2.6 and 6.2.7 the

manufacturer shall be contacted to secure new nameplates, warnings or instructions which shall then be

affixed in their proper place on the golf car.

8. OPERATING SAFETY RULES AND

PRACTICES

8.1. Operator Qualifications

8.1.1. Only authorized persons shall be allowed to oper-

ate golf cars. It is recommended that no persons be

allowed to operate golf cars except those persons who

posses a valid motor vehicle driver’s license.

8.1.2. The controlling party shall display the operation

and safety instructions as recommended by the golf car

manufacturers and the golf course safety rules in a conspicuous place near the golf car rental area or golf car

pick-up area. It is also recommended, as with all motor

vehicles, that the warning “Do not ope rate golf cars when

under the influence of alcohol or drugs.” be posted in a

conspicuous location.

Owner’s Manual and Service Guide

Page xvii

N

SAFETY INFORMATION

Read all of manual to become thoroughly f amiliar with th is vehicle. Pay particular attention to all Notes, Cautions and Warnings

otes:

Page xviii

Owner’s Manual and Service Guide

OPERATION AND SERVICE INFORMATION

Read all of manual to becom e th oroughly fam iliar with this vehicle. Pa y pa rt i cular attention to all Notes, Cautions and Warnings

Thank you for purchasing this vehicle. Before driving the

vehicle, we ask you to spend some time reading this

Owner’s Manual and Service Guide. This guide contains the

information that will assist you in maintaining this highly

reliable vehicle. Some i llustrations may show item s that are

optional for your vehicle. This guid e covers the ope ration of

several vehicles; therefore, some pictorial views may not

represent your ve hicle. Physical differences i n controls will

be illustrated.

This vehicle has been designed and manufactured as a

‘World Vehicle’. Some countries have individual

requirements to compl y with their specifications; therefor e,

some sections may not apply in your country.

Most of the service procedures in this guide can be

accomplished using common automotive hand tools.

Contact your serv ic e representative on servicing the vehicle

in accordance with the Pe riodi c Service Schedule.

Service Parts Manuals and Technician’s Repair and Se rvice

Manuals are available from a local Distributor, an authorized

Branch or the Service Parts Department. When ordering

parts or requesting information for your vehicle, provide

vehicle model, ser ial nu m ber and m anufacture date code.

BEFO R E INITIA L USE

Read, understand and follow the safety label on the

instrument panel . Be sure you unders tand how to operate

the vehicle, its equipment and how to use it safely.

Maintaining good per fo rmance depends to a la rg e ext en t on

the operator.

Hydrogen gas is generated

! !

concentration of hydrogen gas is explosive and could

cause severe injury or death. Charging must take place in

an area that is adequately ventilated (minimum of 5 air

exchanges per hour).

To reduce the cha nce of bat ter y ex plo sion th at cou ld r esu lt

in severe injury or death, never smoke around or charge

batteries in an area that has open flame or electrical

equipment that could cause an electrical arc.

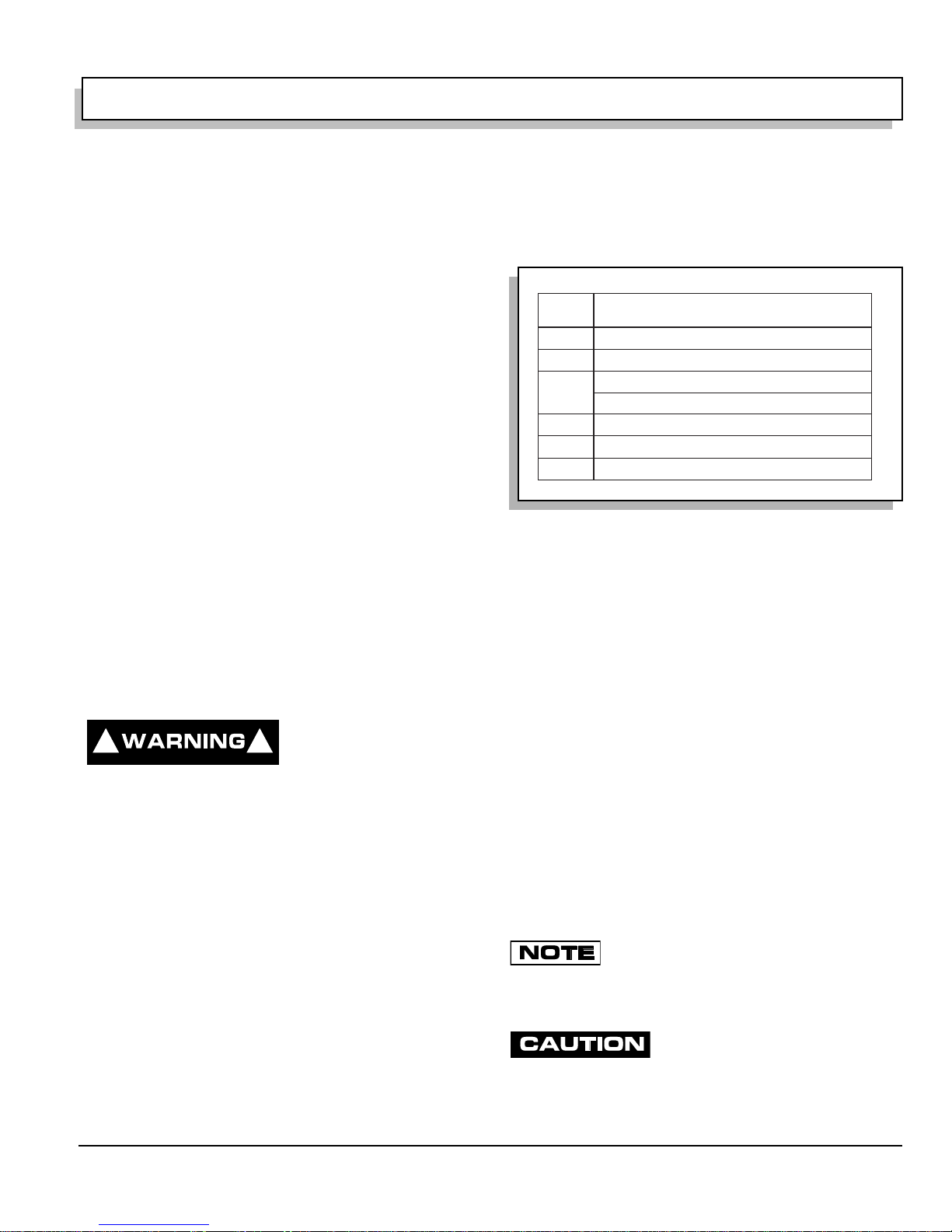

Before a new vehicle is put into operat ion, the items shown

in the INITIAL SERVICE CHART must be performed (Ref.

Fig. 1 on page 1).

V ehicle battery must be f ully cha rged before ini t ial use .

Check for correct tire inflation. See GENERAL

SPECIFICATIONS.

Check for oil or fuel leaks that could have developed in

shipment from the factory.

as a natural part of the lead

acid battery charging

process. A 4%

Determine and record braking distance required to stop

vehicle for future brak e per f or ma nce tests.

Remove the protective clear plastic, that protect the seat

bottom and back rest during shipping, before placing the

vehicle in service.

ITEM SERVICE OPERATION

Battery Charge battery

Seats Remove protective plastic covering

Brakes Check operation and adjust if necessary

Establish acceptable stopping distance

Tires Check air pressure (see SPECIFICATIONS)

Fuel Fill tank with correct fuel

Engine Check oil level

Ref Isc 2

Fig. 1 Initial Service Chart

CONTROLS AND INDICA T O RS

Vehicle controls and indicators consist of:

• key/light switch

• directi on selector

• choke

• fuel gauge

• low oil pressure indicator light

• accelera tor pe dal

• combination service and

park brake pedal

• horn

KEY/LIGHT SWITCH

Located on the dash panel, this switch enables the basic

electrical system of the vehicle to be turned on and off by

turning the key. To prevent inadvertent operation of the

vehicle when left unattend ed, the key should be turned to

the ‘OFF’ position and rem ov ed ( R ef . Fig. 2 on page 2) .

If the vehicle is equipp ed with lights, the key switch has a

position to operate the m , indicated by the light icon.

If the vehicle is equipped with factory installed

custom accessories, some accessories remain

operational with the key switch in the ‘OFF’ position.

DIRECTION SELECTOR

To reduce the possibility of component

damage, the vehicle must be completely

stopped before moving the direction

selector.

Owner’s Manual and Service Guide

Page 1

OPERATION AND SERVICE INFORMATION

OFF

ON

F

UEL

R

R

R

Read all of manual to become thoroughly f amiliar with th is vehicle. Pay particular attention to all Notes, Cautions and Warnings

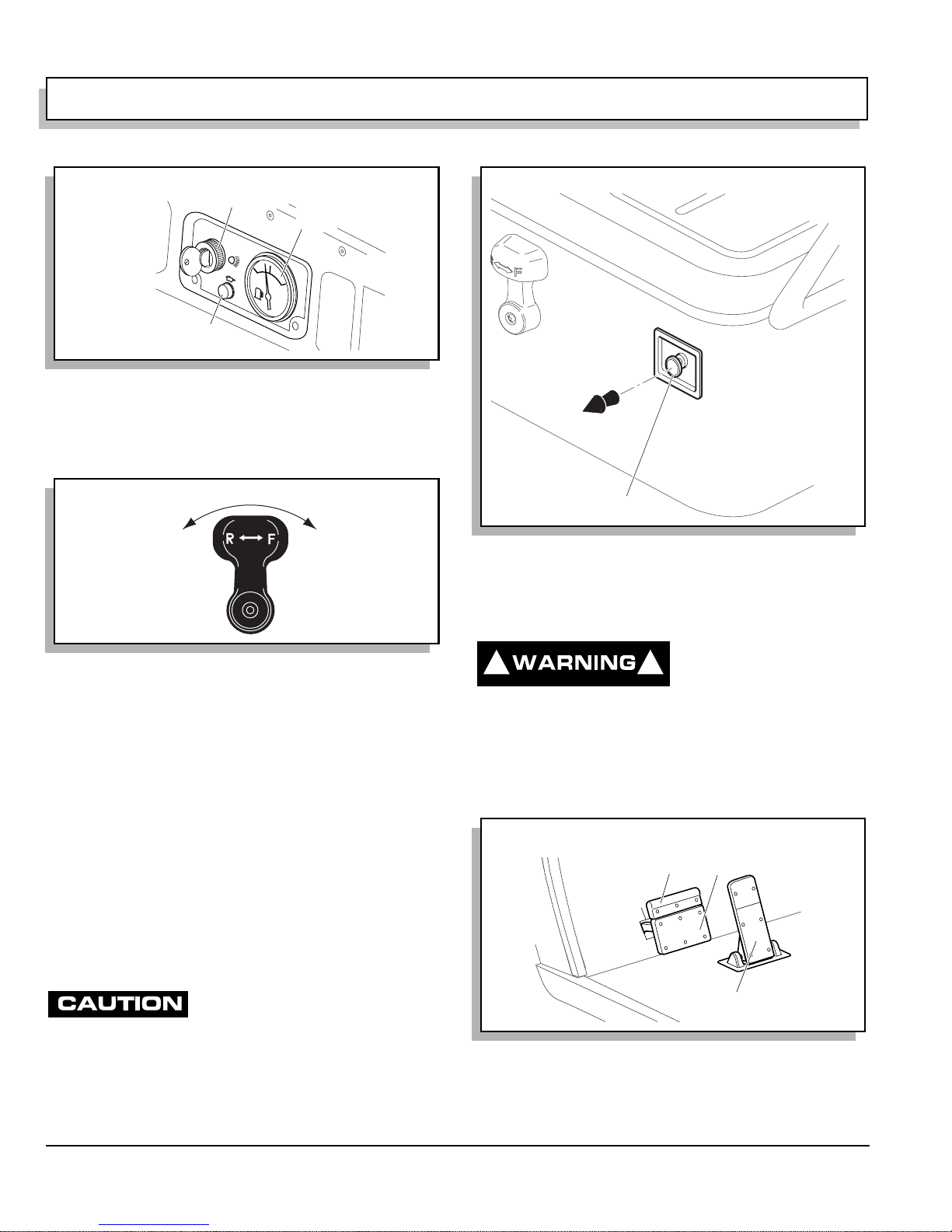

Low Oil Pressure

ef Kes 2

Key/Light Switch

OFF

ON

Indicator Light

Fuel

Gauge

E

F

Fig. 2 Key/Light Switch, Low Oil Pressure Light and

Fuel Gauge

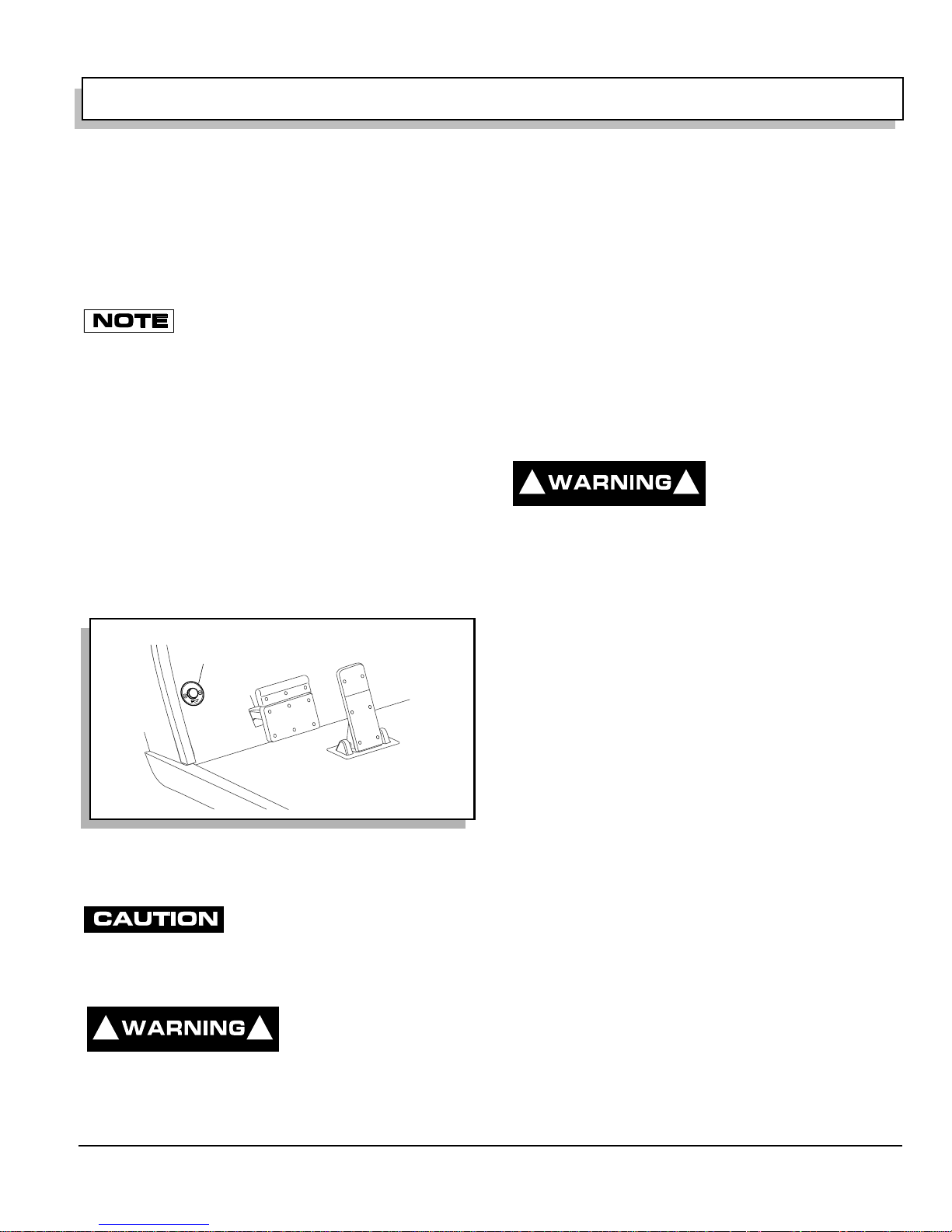

Located on the seat support panel, this lever permits the

selection of either ‘F’ (forward) or ‘R’ (reverse) (Ref. Fig. 3

on page 2). Vehicle should be left in ‘F’ when unattend ed.

Reverse

ef Dsl 2

Forward

Fig. 3 Direction Selector

CHOKE

The choke is used to aid cold starting ( Ref. Fig. 4 o n page

2). See COLD ST ARTING section for operating instructions.

FUEL GAUGE

The fuel gauge (if equipped) will either be located on the

dash panel (elec tric) (Ref. Fig. 2 on page 2) or directl y on

the fuel tank (mechanical).

LOW OIL PRESSURE INDICATOR LIGHT

A low oil pressure indicator light is located on the dash panel

(Ref. Fig. 2 on page 2). The light illuminates when the oil

pressure is low. Check oil level. If oil level is between ADD

and FULL mark on dipstick, a mechanical problem exists

within the engine and the vehicle must not be driven.

Contact a local distribu to r or authorized branch.

Ref Chk 1

Choke

Fig. 4 Choke

check oil pressur e. If oil light does no t com e on, co ntinue to

use vehicle.

ACCELERATOR PEDAL

Unintentional movement of

! !

move which could result in severe injury or death.

With the key switch ‘ON’, depressing the accelerator pedal

starts the engine. When the pedal is released, the engine

will stop (Ref. Fig. 5 on page 2) . To s top the vehicle more

quickly, depress the service brake.

the accelerator pedal will

releas e the pa rk br ak e an d

may cause the vehicle t o

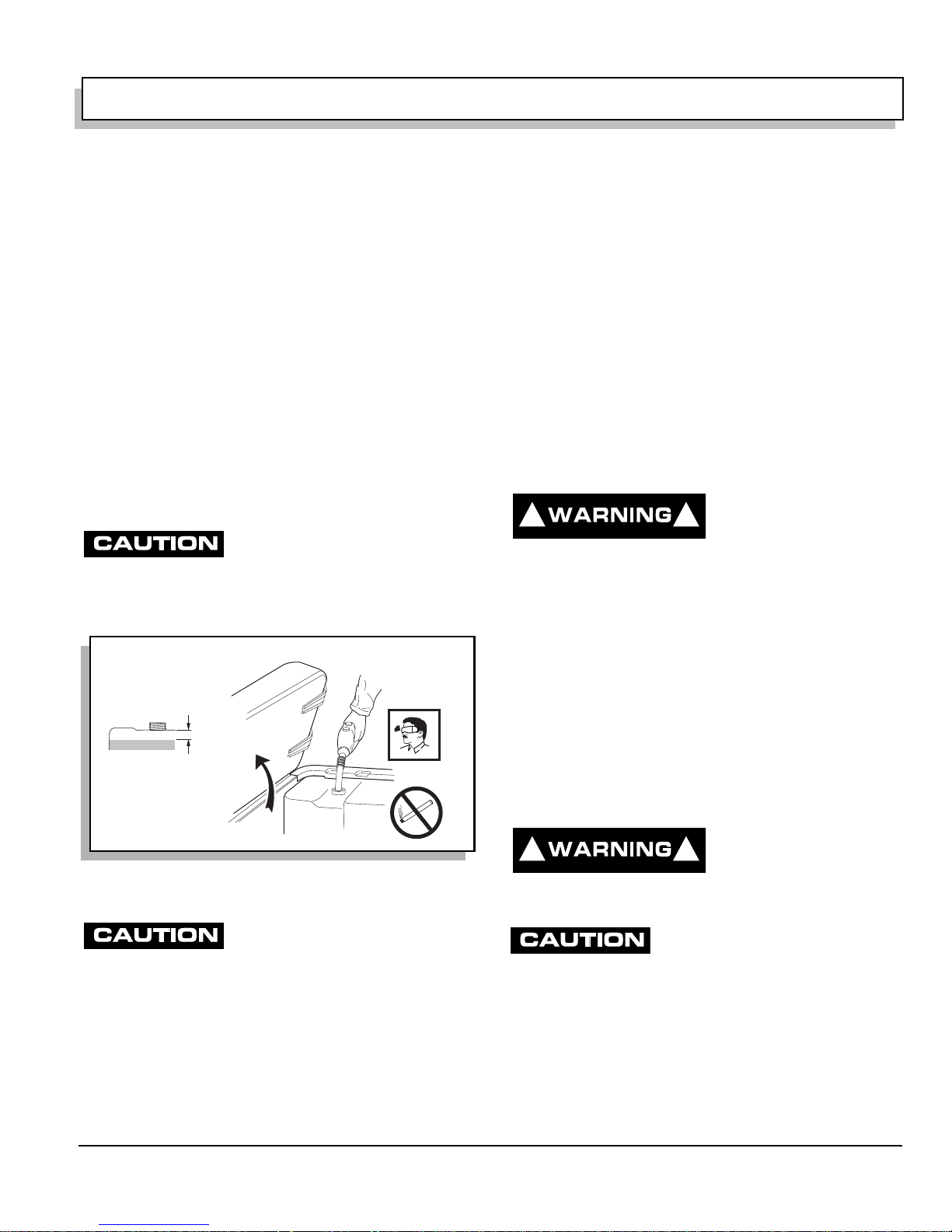

Park

Brake

Service

Brake

PARK

To prevent engine damage, do not

operate engine until oil pressure is

corrected. Do not overfill engine. Too

much oil may cause smoking or allow oil to enter the air filter

enclosure.

If oil level is below ADD mark on dipstick, add oil to bring

level to FULL mark. Drive vehicle a short distance and

Page 2

ef Abc 1

Accelerator

Fig. 5 Accelerator and Brake Controls

If key switch is ‘ON’ and park brake is set, depressing the

accelerator inadvertently will release the park brake and will

Owner’s Manual and Service Guide

OPERATION AND SERVICE INFORMATION

Read all of manual to become thoroughly familiar with this vehicle. Pay part icu lar at tention to all Notes, Cautions and Warnings

cause the vehicle to move which could cause severe inj ury

or death.

Depressing the accele ra to r p eda l will release the par k brake

if it is engaged. This is a feature to assure the vehicl e is not

driven with the park brake engaged. Depressing the

accelerator p edal is not the pr eferred method o f releasing

the park brake.

Depressing the lower section of the brake

pedal is the preferred method of releasing the

park brake to assure the longest service life of brake

components.

COMBINATION BRAKE AND PARK BRAKE

PEDAL

The brake pedal incorporates a park brake feature (Ref. Fig.

5 on page 2). To engage, push down on the upper section of

the pedal until it loc ks in place. The park brake will releas e

when the service brak e pedal is depressed. Use the lower

section of the brake pedal to operate the service brake

system.

HORN

The horn is operate d by pus hing the h orn but ton loc ated on

the floor to the left of the brake pedal (Ref. Fig. 6 on page 3).

Horn

R

N

O

H

PARK

conditions and the environmental factors which effect

the terrain and the ability to control the vehicle.

Use extra care an d reduced speed when drivi ng on

poor surfaces, such as loose dirt, wet grass, gravel,

etc.

Stay in designated areas and avoid extremely rough

terrain.

Maintain a safe speed when driving down hill. Use

service brake to co nt ro l spe ed wh en tra veling do wn an

incline. A sudden stop or change of direction may

result in loss of control.

Slow down befo re and dur ing tu rns. All t urns s hould

be made at reduced speed.

Never drive vehicle up, down, or across an incline that

exceeds 14° (25% grade).

To reduce the possibility of

! !

severe injury or death

resulting from improper

vehicle operation, the

following warnings must be observed:

Refer to GENERAL SPECIFICATIONS for seating

capacity.

Depressing accel erator pedal will release foot

operated park brake and may cause inadve rtent

vehicle movemen t. Turn the key to th e ‘OFF’ posi tion

whenever the vehicle is parked.

To prevent inadvertent movement when the vehicle is

to be left unattended, enga ge the park brake, move

direction selector to forward position, turn key to

‘OFF’ position and remove key.

Ref Hor 1

Fig. 6 Horn Button

OPERAT ING THE VEHICLE

Improper use of the vehicle or the lack of

proper maintenance may result in damage

or decreased performance.

Read and understand the following warnings before

attempting to operat e th e vehicle.

To reduce the possibility of

! !

following warnings must be observed:

When driving vehicle, consider the terrain , traffic

severe injury or death

resulting from loss of

vehicle control, the

Make sure that the direction selector is in correct

position before attempting to start the vehicle.

Always bring the vehi cle to a comple te stop before

shifting the direction selecto r.

Do not take vehicle out of ‘gear’ while in motion

(coast).

Check the area behind the vehicle before operating in

reverse.

All occupants must be seated. Keep ent ire body inside

vehicle and hold on while vehicle is in motion.

RUN-IN

Check for oil or fuel leaks that could have developed in

shipment from th e factor y. Avoid full throttle starts and rapid

acceleration until the engine has achieved operating

temperature.

All engines consu me more oil than normal during the f irst

hours of operation. As internal moving parts are run-in, oil

Owner’s Manual and Service Guide

Page 3

OPERATION AND SERVICE INFORMATION

Ref

Read all of manual to become thoroughly f amiliar with th is vehicle. Pay particular attention to all Notes, Cautions and Warnings

consumption should gradually decrease until the rate of

consumption stabilizes.

Check the oil level per the Periodic Service Schedule (Ref.

Fig. 17 on page 12). Add oil if the level on the dipstick

indicates that oil is in the add oil range (Ref . Fig. 7 on page

4).

Do not overfill engin e. Too much oil may

cause smoking or allow oil to enter the air

filter enclosure.

Both the oil dipstick and fill cap must be in

place before operating the engine. Failure to

install the dipstick and fill cap will result in oil becoming

contaminated and/or being discharged into the engine

compartment.

The oil should be changed in accordance with the Periodic

Service Schedule wh ile the engine is warm. See SERVICE

AND MAINTENANCE for checking oil level and changing oil

procedures.

Dsk 1

Maximum oil level

DO NOT OVERFILL

Add

oil

Fig. 7 Check Oil Level on Dipstick

Safe

operating range

Full

COLD STARTING

Starting a cold engine may require use of the choke.

Depress the acce lerator approximately 1" ( 2.5 cm) or until

the starter just begins to operate. Pull the choke out if

required. Accelerate slowly and push the choke in

completely when the engine runs smoothly.

Do not allow the starter to operate

continuously for more than 10 seconds.

Allow 30 seconds between starting

attempts. If the vehicle does not start on the third attempt, turn the

key switch off, set the park brake and determine the cause of the

problem.

If the vehicle had been running and the engine does not

start within 10 seconds , us e th e chok e.

STARTING AND DRIVING

To reduce the possibility of

! !

release service brake until engine has started.

roll-back which could

result in severe injury or

vehicle dama ge, do not

To operate vehicle:

• Apply the service brake, place the key in the key

switch and turn it to the ‘ON’ position.

• Move the direction selector to the direction desired.

• Release the park brake by depressing the service

brake pedal until the park brake releases.

• Slowly depress the accelerator pedal to start the

engine. Release service brake when engine starts.

• When the ac celerator pedal is released, the ignitio n

circuit is de- energize d a nd th e engine stops. To stop

the vehicle more qui ckly, depress the service b rake

pedal.

When the direction selector is in the reverse

position, a warning signal will sound to indicate

that the vehicle is ready to run in reverse.

STARTING THE VEHICLE ON A HILL

To reduce the possibility of

! !

roll-back which could

result in severe injury or

vehicle dama ge, do not

release service brake until engine has started.

Do not hold vehicle on hill by using

accelerator and engine. This will cause

premature and excessive wear to drive

train components.

To reduce the possibility of perm anent damage t o the drive

system, it is important to prevent exc essive roll-back when

starting the vehicle on a hil l.

Place left foot on service bra ke and release the par k brake.

Depress accelera tor with right foot and release the service

brake by lifting left foot.

COASTING

To reduce the possibility of

! !

severe injury or death from

coasting at above

recommended speeds, limit

speed with service brake.

On steep hills, it is possible for the vehicle to coast at

greater than normal speeds encountered on a flat surface.

To reduce the possible loss of vehicle control and severe

drivetrain damage, speeds should be limited to no more

than the maximum governed speed on level ground (see

GENERAL SPECIFICATIONS). Limit speed by applying

service brake.

FUEL

To reduce the possibility of

! !

severe injury or death from

improper fuel handling:

Page 4

Owner’s Manual and Service Guide

OPERATION AND SERVICE INFORMATION

Read all of manual to become thoroughly familiar with this vehicle. Pay part icu lar at tention to all Notes, Cautions and Warnings

Do not smoke near the fuel tank.

Do not refuel near open flam e or electr ical ite ms wh ich

could produce a spark.

Always handle gasoline in a well ventilated area.

Always wear eye protection to protect against

splashed fuel and fuel vapors.

Always allow adequate space for the expansion of

gasoline. Leave at least 1" (2.5 cm) space below

bottom of filler neck.

Inspect fuel cap, tank and other components for leaks

or deterioration that co uld cause a hazardous

condition.

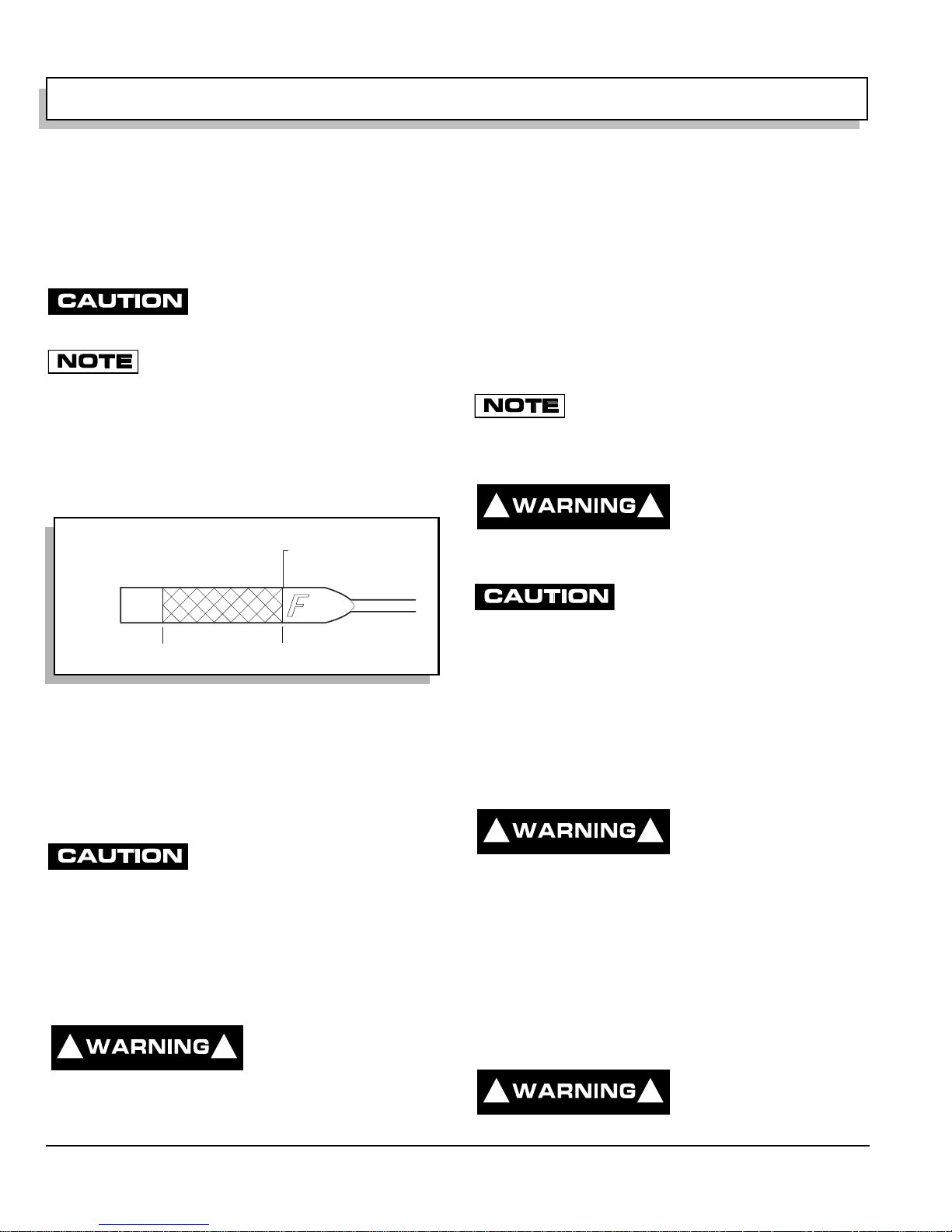

The fuel tank is located under the seat on the passenger

side of the vehicle (Ref. Fig. 8 on page 5). Fill the tank with

fresh, clean, automotive grade gasoline (Ref. Fig. 39 on

page 22). High alt itude or heav y use/load app lications may

benefit from higher oc tane gasoline.