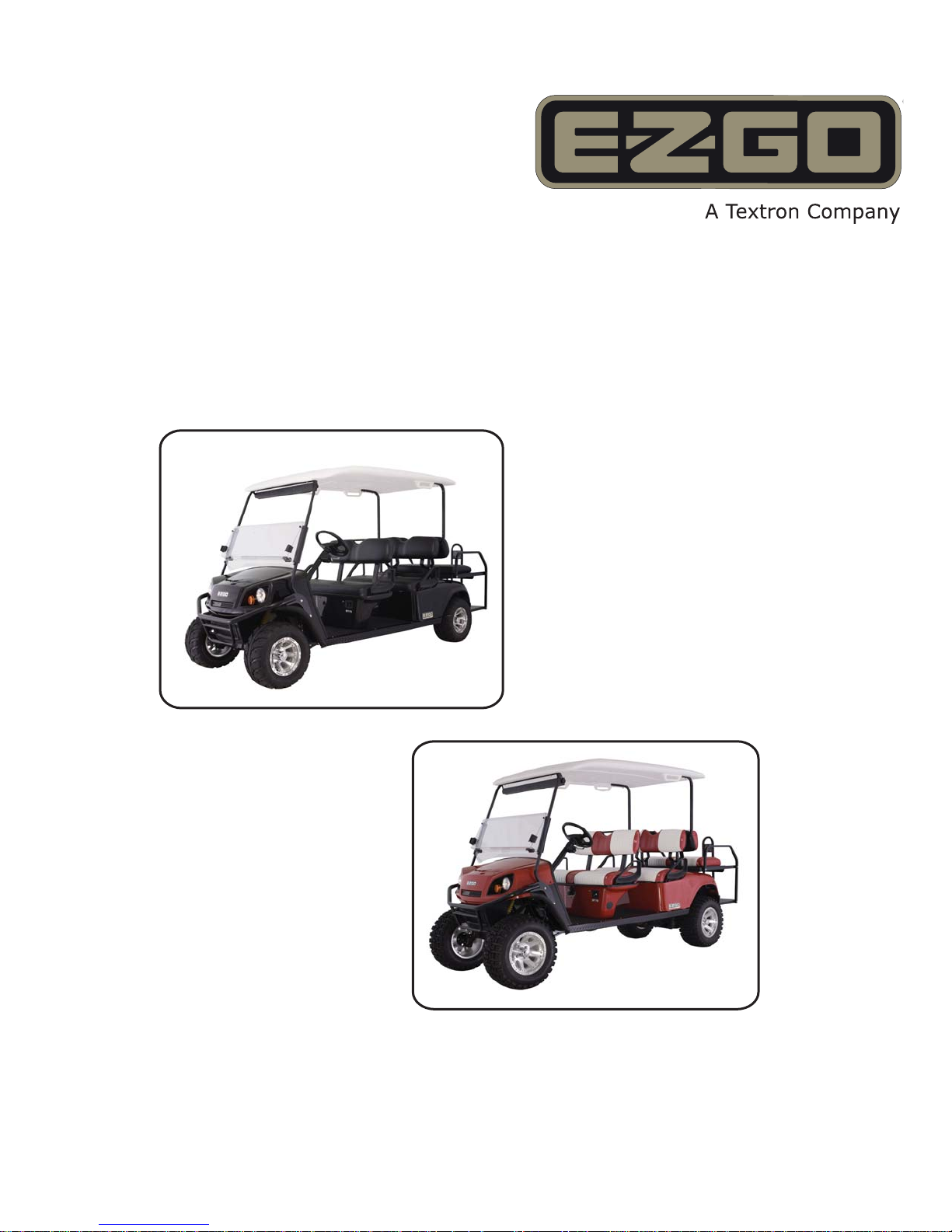

Ezgo EXPRESS L6 2012, EXPRESS S6 2012 Technician's Repair And Service Manual

625610

TECHNICIAN’S REPAIR AND SERVICE MANUAL

ELECTRIC POWERED UTILITY VEHICLE

625621

REVISED AUGUST 2012 ISSUED JUNE 2012

SAFETY

WASH HANDS

AFTER HANDLING!

Battery posts,

terminals and related

accessories contain

lead and lead compounds,

chemicals known

to cause cancer and

reproductive harm.

BATTERY WARNING

WASH HANDS

AFTER HANDLING!

WARNING: Battery posts, terminals and related

accessories contain lead and lead compounds,

chemicals known to cause cancer and reproductive harm.

BATTERIES

CONTAIN LEAD

AND RELATED PARTS

!

25

DO NOT

DRIVE ACROSS

SLOPES IN

EXCESS OF 14˚

NOTICE

NOTICE

NOTICE

For any questions on material contained in this manual, contact an authorized representative for clarification.

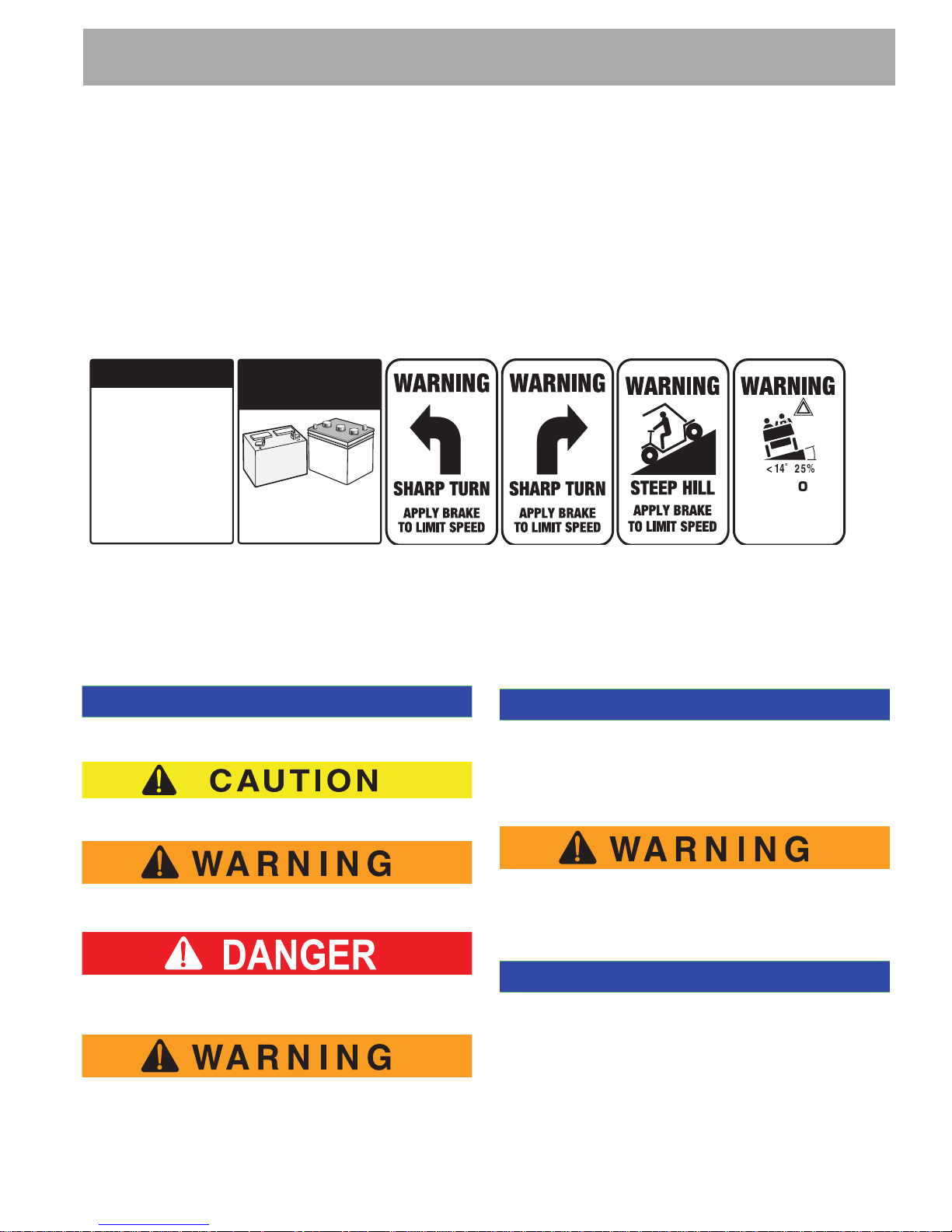

Read and understand all labels located on the vehicle. Always replace any damaged or missing labels.

On steep hills it is possible for vehicles to coast at greater than normal speeds encountered on a flat surface. To prevent loss of vehicle control and possible serious injury, speeds should be limited to no more than the maximum speed

on level ground. See GENERAL SPECIFICATIONS. Limit speed by applying the service brake.

Catastrophic damage to the drivetrain components due to excessive speed may result from driving the vehicle above

specified speed. Damage caused by excessive speed may cause a loss of vehicle control, is costly, is considered

abuse and will not be covered under warranty.

For towing/transporting vehicle, refer to “TRANSPORTING VEHICLE”.

Signs similar to the ones illustrated should be used to warn of situations that could result in an unsafe condition.

Be sure that this manual remains as part of the permanent service record should the vehicle be sold. Throughout this

guide NOTICES, CAUTION and WARNING will be used.

Observe these NOTICES, CAUTIONS and WARNINGS; be aware that servicing a vehicle requires mechanical skill

and a regard for conditions that could be hazardous. Improper service or repair may damage the vehicle or render it

unsafe.

A NOTICE indicates a condition that should be observed.

The exhaust emissions of this vehicles’ engine complies with

regulations set forth by the Environmental Protection Agency

(EPA) of the United States of America (USA) at time of manufacture. Significant fines could result from modifications or

tampering with the engine, fuel, ignition or air intake systems.

Indicates a hazardous situation which, if not avoided,

could result in minor or moderate injury.

Battery posts, terminals and related accesso-

Indicates a hazardous situation which, if not

avoided, could result in death or serious injury.

ries contain lead and lead compounds. Wash

hands after handling.

Indicates a hazardous situation which, if

not avoided, will result in death or serious

injury.

This spark ignition system meets all requirements of the

Canadian Interference-Causing Equipment Regulations.

Engine exhaust from this product contains

chemicals known, in certain quantities, to

cause cancer, birth defects, or other reproductive harm.

(NOTICES, CAUTIONS AND WARNINGS CONTINUED ON INSIDE OF BACK COVER)

Ce système d'allumage par étincelle de véhicule respecte

toutes les exigences du Règlement sur le matériel brouilleur

du Canada.

SERVICE AND REPAIR MANUAL

ELECTRIC POWERED

UTILITY VEHICLES

EXPRESS L6

EXPRESS S6

STARTING MODEL YEAR 2012

E-Z-GO Division of TEXTRON Inc. reserves the right to incorporate engineering and design changes to products in this Manual, without obligation to

include these changes on units leased/sold previously.

The information contained in this Manual may be revised periodically by E-Z-GO, and therefore is subject to change without notice.

E-Z-GO DISCLAIMS LIABILITY FOR ERRORS IN THIS MANUAL, and E-Z-GO SPECIFICALLY DISCLAIMS LIABILITY FOR INCIDENTAL AND CON-

SEQUENTIAL DAMAGES resulting from the use of the information and materials in this Manual.

TO CONTACT US

NORTH AMERICA:

TECHNICAL ASSISTANCE & WARRANTY PHONE: 1-800-774-3946, FAX: 1-800-448-8124

SERVICE PARTS PHONE: 1-888-GET-EZGO (1-888-438-3946), FAX: 1-800-752-6175

INTERNATIONAL: PHONE: 001-706-798-4311, FAX: 001-706-771-4609

Repair and Service Manual

Page i

GENERAL INFORMATION

This vehicle has been designed and manufactured in the United States of America (USA) as

a ‘World Vehicle’. The Standards and Specifications listed in the following text originate in

the USA unless otherwise indicated.

The use of non Original Equipment Manufacturer (OEM) approved parts may void the

warranty.

Tampering with or adjusting the governor to permit vehicle to operate at above factory

specifications will void the vehicle warranty.

When servicing engines, all adjustments and replacement components must be per original

vehicle specifications in order to maintain the United States of America Federal and State

emission certification applicable at the time of manufacture.

BATTERY PROLONGED STORAGE

All batteries will self discharge over time. The rate of self discharge varies depending on the

ambient temperature and the age and condition of the batteries.

A fully charged battery will not freeze in winter temperatures unless the temperature falls

below -75° F (-60° C).

BATTERY DISPOSAL

Lead-acid batteries are recyclable. Return whole scrap batteries to distributor, manufacturer

or lead smelter for recycling. For neutralized spills, place residue in acid-resistant

containers with absorbent material, sand or earth and dispose of in accordance with local,

state and federal regulations for acid and lead compounds. Contact local and/or state

environmental officials regarding disposal information.

Page ii

Repair and Service Manual

TABLE OF CONTENTS

TITLE PAGE

SAFETY .......................................................................................................................Inside Covers

GENERAL INFORMATION...............................................................................................................ii

SAFETY INFORMATION ................................................................................................................. v

TITLE SECTION

GENERAL INFORMATION & ROUTINE MAINTENANCE ..............................................................A

SAFETY ...........................................................................................................................................B

BODY...............................................................................................................................................C

WHEELS AND TIRES......................................................................................................................D

FRONT SUSPENSION AND STEERING ........................................................................................E

ELECTRONIC SPEED CONTROL ..................................................................................................F

MOTOR........................................................................................................................................... G

BATTERIES AND CHARGING.........................................................................................................H

BATTERY CHARGER...................................................................................................................... J

BRAKES...........................................................................................................................................K

ELECTRICAL SYSTEM ................................................................................................................... L

REAR SUSPENSION......................................................................................................................M

REAR AXLE......................................................................................................................

WEATHER PROTECTION...............................................................................................................P

HANDHELD DEVICE...................................................................................................................... Q

TROUBLESHOOTING.....................................................................................................................R

LIGHTING PROTECTION AND GROUNDING................................................................................S

GENERAL SPECIFICATIONS .........................................................................................................T

...............N

Repair and Service Manual

Page iii

NOTES:

TABLE OF CONTENTS

Page iv

Repair and Service Manual

SAFETY INFORMATION

Read all of Section B and this section before attempting any procedure. Pay particular attention to Notices, Cautions, Warnings and Dangers.

This manual has been designed to assist the owner-operator in maintaining the vehicle in accordance with

procedures developed by the manufacturer. Adherence to these procedures and troubleshooting tips will ensure the

best possible service from the product. To reduce the chance of personal injury and/or property damage, the

following instructions must be carefully observed:

GENERAL

Many vehicles are used for a variety of tasks beyond the original intended use of the vehicle; therefore it is impossible

to anticipate and warn against every possible combination of circumstances that may occur. No warnings can take

the place of good common sense and prudent driving practices.

Good common sense and prudent driving practices do more to prevent accidents and injury than all of the warnings

and instructions combined. The manufacturer strongly suggests that the owner-operator read this entire manual

paying particular attention to the CAUTIONS and WARNINGS contained therein. It is further recommended that

employees and other operators be encouraged to do the same.

If you have any questions, contact your closest representative or write to the address on the back cover of this

publication, Attention: Customer Care Department.

E-Z-GO Division of Textron reserves the right to make design changes without obligation to make these changes on

units previously sold and the information contained in this manual is subject to change without notice.

E-Z-GO Division of Textron is not liable for errors in this manual or for incidental or consequential damages that result

from the use of the material in this manual.

This vehicle conforms to the current applicable standard for safety and performance requirements.

These vehicles are designed and manufactured for off-road use. They do not conform to Federal Motor Vehicle

Safety Standards and are not equipped for operation on public streets. Some communities may permit these vehicles

to be operated on their streets on a limited basis and in accordance with local ordinances.

With electric powered vehicles, be sure that all electrical accessories are grounded directly to the battery (-) post.

Never use the chassis or body as a ground connection.

Refer to GENERAL SPECIFICATIONS for vehicle seating capacity.

Never modify the vehicle in any way that will alter the weight distribution of the vehicle, decrease

its stability, increase the speed or extend the stopping distance beyond the factory specification.

Such modifications can result in serious personal injury or death.

Modifications that increase the speed and/or weight of the vehicle will extend the stopping distance and may reduce

the stability of the vehicle. Do not make any such modifications or changes. The manufacturer prohibits and disclaims responsibility for any such modifications or any other alteration which would adversely affect the safety of the

vehicle.

Vehicles that are capable of higher speeds must limit their speed to no more than the speed of other vehicles when

used in a golf course environment. Additionally, speed should be further moderated by the environmental conditions,

terrain and common sense.

Repair and Service Manual

Page v

SAFETY INFORMATION

Read all of Section B and this section before attempting any procedure. Pay particular attention to Notices, Cautions, Warnings and Dangers.

GENERAL OPERATION

B

ALWAYS:

use the vehicle in a responsible manner and maintain the vehicle in safe operating condition.

read and observe all warnings and operation instruction labels affixed to the vehicle.

follow all safety rules established in the area where the vehicle is being operated.

reduce speed to compensate for poor terrain or conditions.

apply service brake to control speed on steep grades.

maintain adequate distance between vehicles.

reduce speed in wet areas.

use extreme caution when approaching sharp or blind turns.

use extreme caution when driving over loose terrain.

use extreme caution in areas where pedestrians are present.

MAINTENANCE

ALWAYS:

maintain your vehicle in accordance with the manufacturer’s periodic service schedule.

ensure that mechanics performing repairs are trained and qualified to do so.

follow the manufacturer’s directions if you do any maintenance on your vehicle. Be sure to disable the vehicle before

performing any maintenance. Disabling includes removing the key from the key switch and removal of a battery wire.

insulate any tools used within the battery area in order to prevent sparks or battery explosion caused by shorting the

battery terminals or associated wiring. Remove the batteries or cover exposed terminals with an insulating material.

check the polarity of each battery terminal and be sure to rewire the batteries correctly.

use specified replacement parts. Never use replacement parts of lesser quality.

use recommended tools.

determine that tools and procedures not specifically recommended by the manufacturer will not compromise the safety

of personnel nor jeopardize the safe operation of the vehicle.

support the vehicle using wheel chocks and safety stands. Never get under a vehicle that is supported by a jack. Lift

the vehicle in accordance with the manufacturer’s instructions.

Never attempt to maintain a vehicle in an area where exposed flame is present or persons are smoking.

be aware that a vehicle that is not performing as designed is a potential hazard and must not be operated.

The manufacturer cannot anticipate all situations, therefore people attempting to maintain or repair the vehicle must

have the skill and experience to recognize and protect themselves from potential situations that could result in severe

personal injury or death and damage to the vehicle. Use extreme caution and, if unsure as to the potential for injury,

refer the repair or maintenance to a qualified mechanic.

Page vi

Repair and Service Manual

SAFETY INFORMATION

Read all of Section B and this section before attempting any procedure. Pay particular attention to Notices, Cautions, Warnings and Dangers.

B

ALWAYS:

test drive the vehicle after any repairs or maintenance. All tests must be conducted in a safe area that is free of both

vehicular and pedestrian traffic.

replace damaged or missing warning, caution or information labels.

keep complete records of the maintenance history of the vehicle.

VENTILATION

Hydrogen gas is generated in the charging cycle of batteries and is explosive in concentrations as low as 4%.

Because hydrogen gas is lighter than air, it will collect in the ceiling of buildings necessitating proper ventilation. Five

air exchanges per hour is considered the minimum requirement.

Never charge a vehicle in an area that is subject to flame or spark. Pay particular attention to natural gas or propane

gas water heaters and furnaces.

Use a dedicated circuit for each battery charger. Do not permit other appliances to be plugged into the receptacle

when the charger is in operation.

Chargers must be installed and operated in accordance with charger manufacturers recommendations or applicable

electrical code (whichever is more restrictive).

B

Repair and Service Manual

Page vii

SAFETY INFORMATION

Read all of Section B and this section before attempting any procedure. Pay particular attention to Notices, Cautions, Warnings and Dangers.

Notes:

Page viii

Repair and Service Manual

GENERAL INFORMATION & ROUTINE MAINTANENCE

TABLE OF CONTENTS FOR SECTION ‘A’

SECTION TITLE PAGE NO.

SERIAL NUMBER LOCATION ................................................................................. A - 1

TRANSPORTING VEHICLE ..................................................................................... A - 1

Towing ............................................................................................................. A - 1

Hauling ............................................................................................................. A - 1

SERVICING THE ELECTRIC VEHICLE.................................................................... A - 1

ROUTINE MAINTENANCE ...................................................................................... A - 2

REAR AXLE.............................................................................................................. A - 2

BRAKES ................................................................................................................... A - 2

TIRES........................................................................................................................ A - 2

LIGHT BULB REPLACEMENT ................................................................................. A - 2

VEHICLE CLEANING AND CARE ............................................................................ A - 2

VEHICLE CARE PRODUCTS ................................................................................... A - 3

SUN TOP AND WINDSHIELD .................................................................................. A - 3

HARDWARE ............................................................................................................. A - 4

TORQUE SPECIFICATIONS .................................................................................... A - 4

PERIODIC SERVICE SCHEDULE ............................................................................ A - 5

LIST OF ILLUSTRATIONS

Fig. 1 Initial Service Chart ..................................................................................... A - 2

Fig. 2 Lubrication Points ........................................................................................ A - 2

Fig. 3 Torque Specifications .................................................................................. A - 4

Fig. 4 Periodic Service Schedule ........................................................................... A - 5

Repair and Service Manual

Page A-i

GENERAL INFORMATION & ROUTINE MAINTANENCE

Read all of Section B and this section before attempting any procedure. Pay particular attention to Notices, Cautions, Warnings and Dangers

Notes:

Page A-ii

Repair and Service Manual

GENERAL INFORMATION & ROUTINE MAINTANENCE

Read all of Section B and this section before attempting any procedure. Pay particular attention to Notices, Cautions, Warnings and Dangers.

SERIAL NUMBER LABEL

LOCATION

Two serial number and manufacture date code label are

on the vehicle. One is placed on the body below the

front, driver side of the seat. The other is located on the

chassis under the seat.

Design changes take place on an ongoing basis. In

order to obtain correct components for the vehicle, the

manufacture date code, serial number and vehicle

model must be provided when ordering service parts.

TRANSPORTING VEHICLE

Towing

This vehicle is not designed to be towed.

It is recommended that the vehicle be moved by placing

the entire vehicle on a trailer, flatbed truck or other

suitable transport.

Hauling

To reduce the possibility of severe injury or

death while transporting vehicle:

Secure the vehicle and contents.

Never ride on vehicle being transported.

Always remove windshield before

transporting.

Maximum speed with sun top installed is

50 mph (80 kph).

If the vehicle is to be transported at highway speeds,

the sun top must be removed and the seat bottom

secured. When transporting vehicle below highway

speeds, check for tightness of hardware and cracks in

sun top at mounting points. Always remove windshield

when transporting. Always check that the vehicle and

contents are adequately secured before transporting.

The rated capacity of the trailer or truck must exceed

the weight of the vehicle (see GENERAL SPECIFICATIONS for vehicle weight) and load plus 1000 lbs. (454

kg). Lock the park brake and secure the vehicle using

ratchet tie downs.

SERVICING THE ELECTRIC

VEHICLE

To prevent severe injury or death, resulting

from improper servicing techniques, observe

the following Warnings:

Do not attempt any type of servicing operations before reading and understanding all

notes, cautions and warnings in

this manual.

Any servicing requiring adjustments to be

made to the powertrain while the motor is

running must be made with both drive

wheels raised.

Wear eye protection when working on the vehicle. In particular,

use care when working around

batteries, or using solvents or

compressed air.

To reduce the possibility of causing an

electrical arc, which could result in a battery explosion, turn off all electrical loads

from the batteries before removing any

heavy gauge battery wires.

To prevent the possibility of motor

disintegration, never operate vehicle at full

throttle for more than 4 - 5 seconds while

vehicle is in a “no load” condition.

It is in the best interest of both vehicle owner and servicing dealer to carefully follow the procedures recommended in this manual. Adequate preventive

maintenance, applied at regular intervals, is the best

guarantee for keeping the vehicle both dependable and

economical.

Before a new vehicle is put into operation, it is recommended that the items shown in the INITIAL SERVICE

CHART be performed (Ref. Fig. 1).

Vehicle batteries must be fully charged before initial

use.

Repair and Service Manual

Page A-1

GENERAL INFORMATION & ROUTINE MAINTANENCE

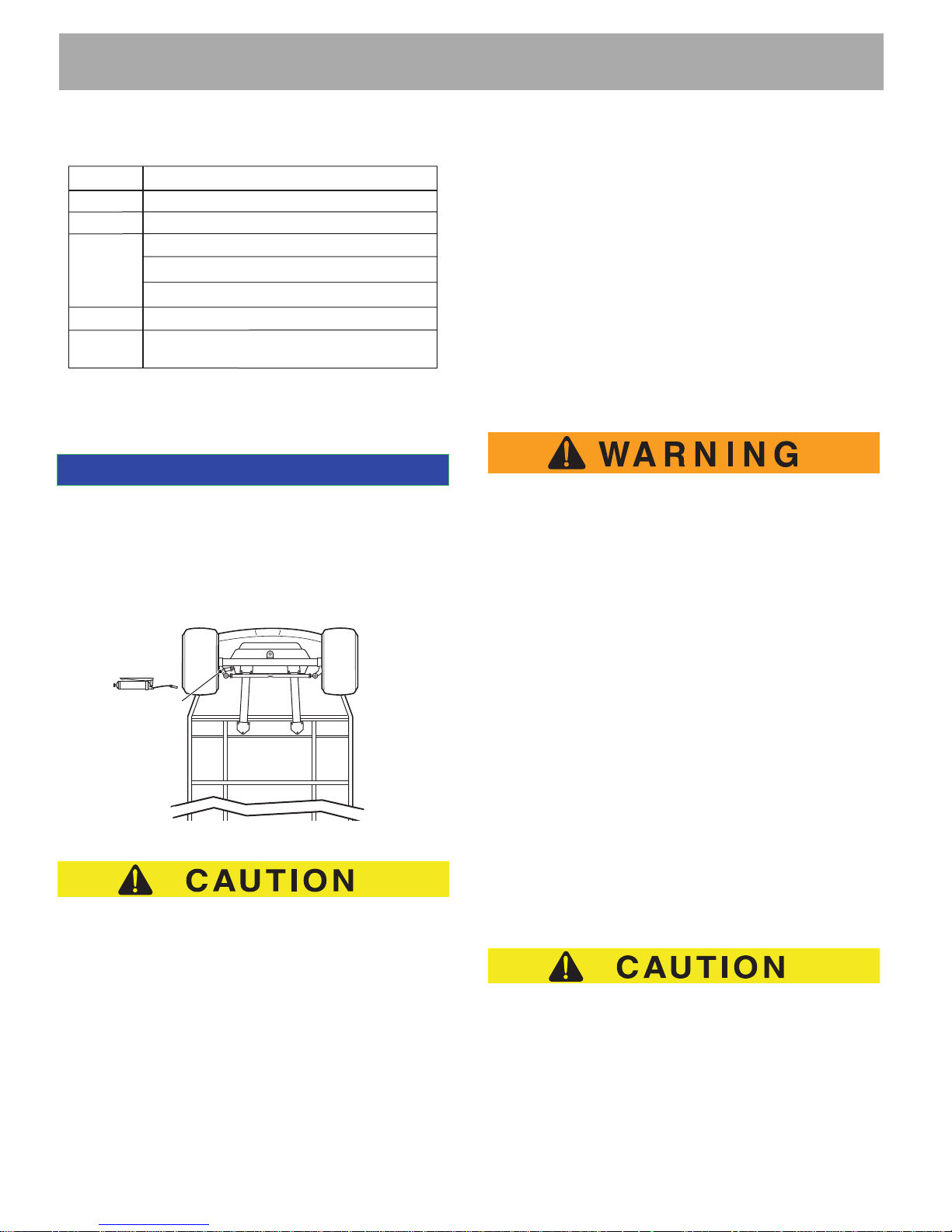

ITEM SERVICE OPERATION

Batteries Charge batteries

Seats Remove protective plastic covering

Brakes Check operation and adjust if necessary

Establish acceptable stopping distance

Check hydraulic brake fluid level

Tires Check air pressure (see SPECIFICATIONS)

Portable Remove from vehicle and properly mount

Charger

NOTICE

Rack

Ball

Joint

Read all of Section B and this section before attempting any procedure. Pay particular attention to Notices, Cautions, Warnings and Dangers.

REAR AXLE

B

The only maintenance required for the first five years is

the periodic inspection of the lubricant level. The rear

axle is provided with a lubricant level check/fill plug

located on the bottom of the differential. Unless leakage

is evident, the lubricant need to be only replaced after

five years. The procedure to follow for checking the rear

axle lubricant level is in the REAR AXLE section.

BRAKES

After the vehicle has been put into service, it is recom-

Fig. 1 Initial Service Chart

ROUTINE MAINTENANCE

mended that the brakes be checked daily by performing

a brake test.

Some maintenance items must be serviced more frequently on

vehicles used under severe driving conditions.

This vehicle will give years of satisfactory service

provided it receives regular maintenance. Refer to the

Periodic Service Schedule for appropriate service intervals (Ref. Fig. 4). Refer to Lubrication Point for

appropriate lubrication location (Ref. Fig. 2).

Fig. 2 Lubrication Points

Do not use more than three pumps of grease for each

grease fitting at any one time- Excess grease may

cause grease seals to fail or grease migration into

areas that could damage components.

To prevent severe injury or death resulting

from operating a vehicle with improperly operating brake system, the braking system must

be properly maintained. All driving brake tests

must be done in a safe location with regard for

the safety of all personnel.

For information on conducting a brake test, refer to

BRAKES section.

TIRES

Tire condition should be inspected per the Periodic

Service Schedule. Inflation pressures should be

checked when the tires are cool. Be sure to reinstall

valve dust cap after checking or inflating. For additional

information, refer to WHEELS AND TIRES section.

LIGHT BULB REPLACEMENT

Refer to ELECTRICAL SYSTEM for information regarding light bulb replacement.

VEHICLE CLEANING AND CARE

Putting more than three pumps of grease in a grease fitting could damage grease seals and cause premature

bearing failure.

Page A-2

When pressure washing vehicle, do not use pressure in

excess of 700 psi (4826 kPa). To prevent cosmetic

damage, do not use any abrasive or reactive solvents

to clean plastic parts.

It is important that proper techniques and cleaning

materials be used. Using excessive water pressure may

Repair and Service Manual

GENERAL INFORMATION & ROUTINE MAINTANENCE

Read all of Section B and this section before attempting any procedure. Pay particular attention to Notices, Cautions, Warnings and Dangers.

cause damage to seals, plastics, the electrical system,

body finish or seat material. Do not use pressure in

excess of 700 psi (4826 kPa) to wash vehicle.

Normal cleaning of vinyl seats and plastic or rubber trim

require the use of a mild soap solution applied with a

sponge or soft brush and wipe with a damp cloth.

Removal of oil, tar, asphalt, shoe polish, etc. will require

the use of a commercially available vinyl/rubber cleaner.

The painted surfaces of the vehicle provide attractive

appearance and durable protection. Frequent washing

with lukewarm or cold water is the best method of

preserving those painted surfaces.

Do not use hot water, strong soap or harsh chemical

detergents.

Rubber parts should be cleaned with non-abrasive

household cleaner.

Occasional cleaning and waxing with non-abrasive

products designed for ‘clear coat’ automotive finishes

will enhance the appearance and durability of the

painted surfaces.

Corrosive materials used as fertilizers or for dust control

can collect on the underbody of the vehicle. These

materials will accelerate corrosion of underbody parts. It

is recommended that the underbody be flushed occasionally with plain water. Thoroughly clean any areas

where mud or other debris can collect. Sediment packed

in closed areas should be loosened to ease its removal,

taking care not to chip or otherwise damage paint.

SUN TOP AND WINDSHIELD

B

The sun top does not provide protection from

roll over or falling objects.

The windshield does not provide Complete

protection from tree limbs or flying objects.

The sun top and windshield are designed for weather

protection only.

Clean with lots of water and a clean cloth. Minor

scratches may be removed using a commercial plastic

polish or Plexus plastic cleaner available from Service

Parts Department.

VEHICLE CARE PRODUCTS

To help maintain the vehicle, there are several products

available through local Distributors, authorized

Branches, or the Service Parts Department.

• Touch-up paint specially formulated to match

vehicle colors for use on TPE (plastic) bodies

(P/N 28140-G** and 28432G**).

• Multi-purpose Battery Protectant formulated to

form a long-term, flexible, non-tacky, dry coating

that will not crack, peel or flake over a wide

temperature range (P/N 606312).

• Multi-purpose Hand Cleaner is an industrial

strength cleaner containing no harsh solvents, yet

gently lifts grease off hands. May be used with or

without water (P/N 607636).

• Battery Maintenance Kit for complete battery

cleaning and watering, with battery maintenance

instructions (P/N 25587G01).

• Plexus plastic cleaner and polish removes minor

scratches from windshield (P/N 606314).

Repair and Service Manual

Page A-3

GENERAL INFORMATION & ROUTINE MAINTANENCE

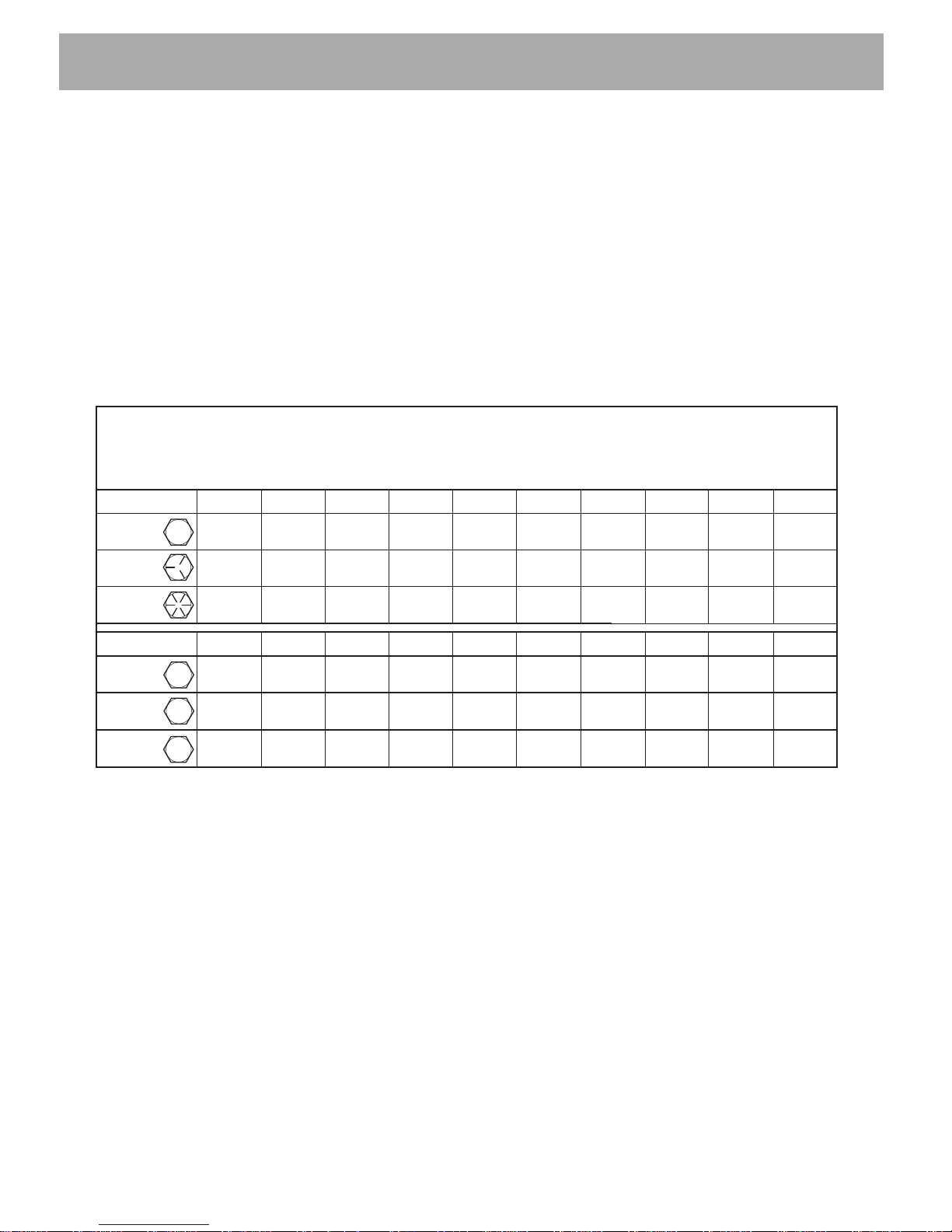

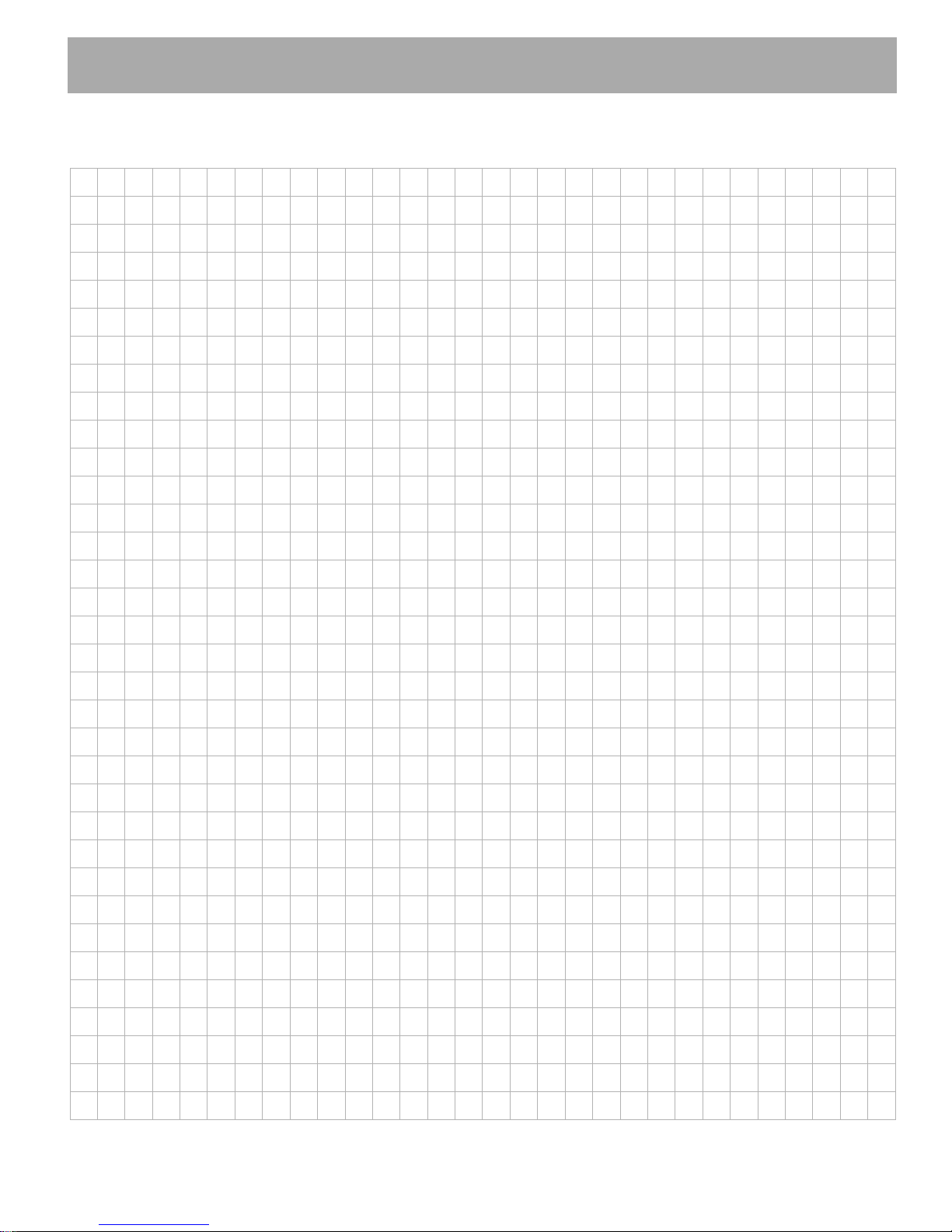

ALL TORQUE FIGURES ARE IN FT. LBS. (Nm)

BOLT SIZE

Grade 2

1/4" 5/16" 3/8" 7/16" 1/2" 9/16" 5/8" 3/4" 7/8" 1"

Unless otherwise noted in text, tighten all hardware in accordance with this chart.

This chart specifies 'lubricated' torque figures. Fasteners that are plated or lubricated when

installed are considered 'wet' and require approximately 80% of the torque required for 'dry' fasteners.

4

(5)

8

(11)

15

(20)

24

(33)

35

(47)

55

(75)

75

(102)

130

(176)

125

(169)

190

(258)

Grade 5

Grade 8

6

(8)

13

(18)

23

(31)

35

(47)

55

(75)

80

(108)

110

(149)

200

(271)

320

(434)

480

(651)

6

(8)

18

(24)

35

(47)

55

(75)

80

(108)

110

(149)

170

(230)

280

(380)

460

(624)

680

(922)

BOLT SIZE

Class 5.8

(Grade 2)

M4 M5 M6 M8 M10 M12 M14

1

(2)

2

(3)

4

(6)

10

(14)

20

(27)

35

(47)

55

(76.4)

Class 8.8

(Grade 5)

2

(3)

4

(6)

7

(10)

18

(24)

35

(47)

61

(83)

97

(131)

Class 10.9

(Grade 8)

3

(4)

6

(8)

10

(14)

25

(34)

49

(66)

86

(117)

136

(184)

5.8

8.8

10.9

Read all of Section B and this section before attempting any procedure. Pay particular attention to Notices, Cautions, Warnings and Dangers.

HARDWARE

B

Periodically the vehicle should be inspected for loose

fasteners. Fasteners should be tightened in accordance

with the Torque Specifications table (Ref. Fig. 3).

Use care when tightening fasteners and refer to the

Technician’s Repair and Service Manual for specific

torque values.

TORQUE SPECIFICATIONS

Generally, two grades of hardware are used in the

vehicle.

• Grade 5 hardware can be identified by the three

marks on the hexagonal head.

• Unmarked hardware is Grade 2.

Page A-4

Fig. 3 Torque Specifications

Repair and Service Manual

GENERAL INFORMATION & ROUTINE MAINTANENCE

Read all of Section B and this section before attempting any procedure. Pay particular attention to Notices, Cautions, Warnings and Dangers.

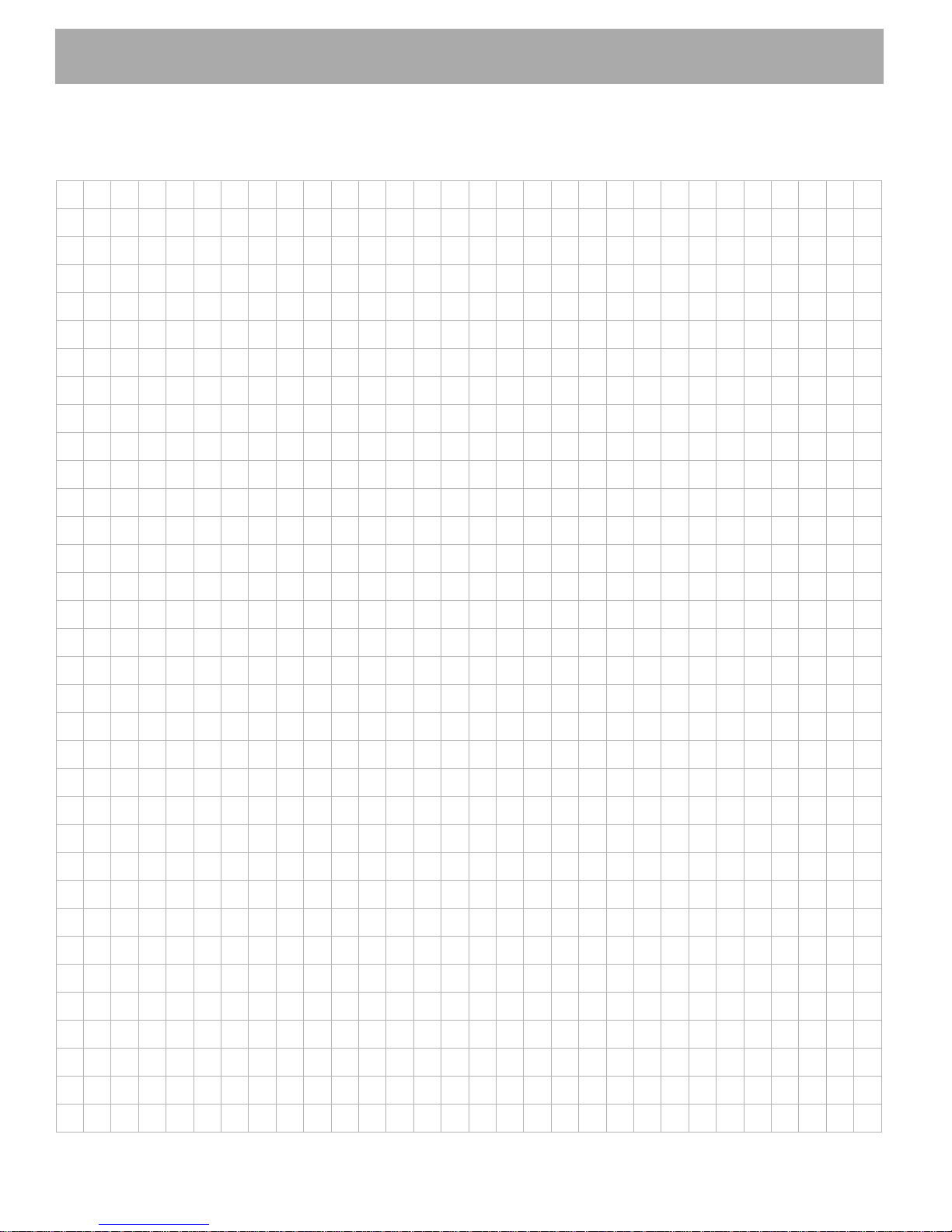

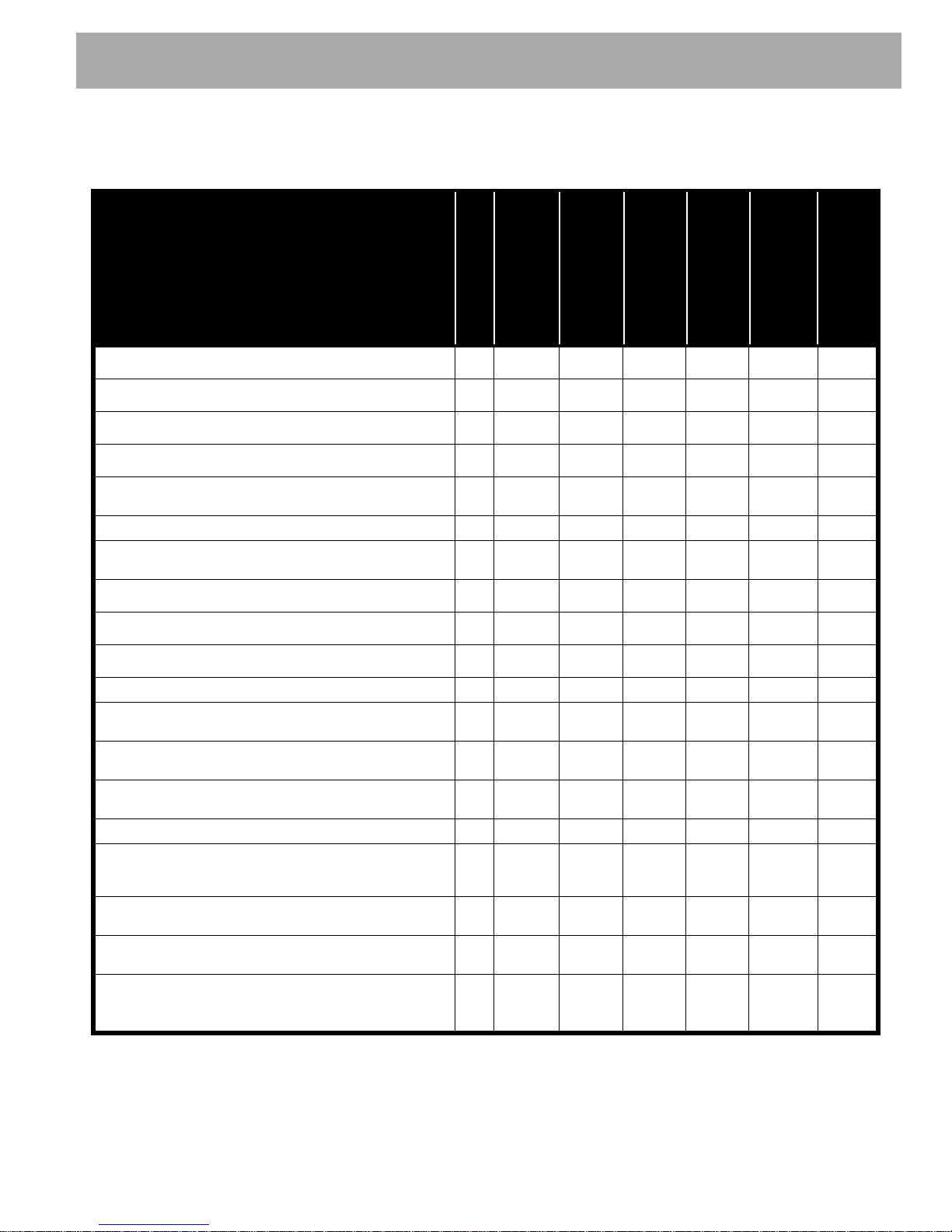

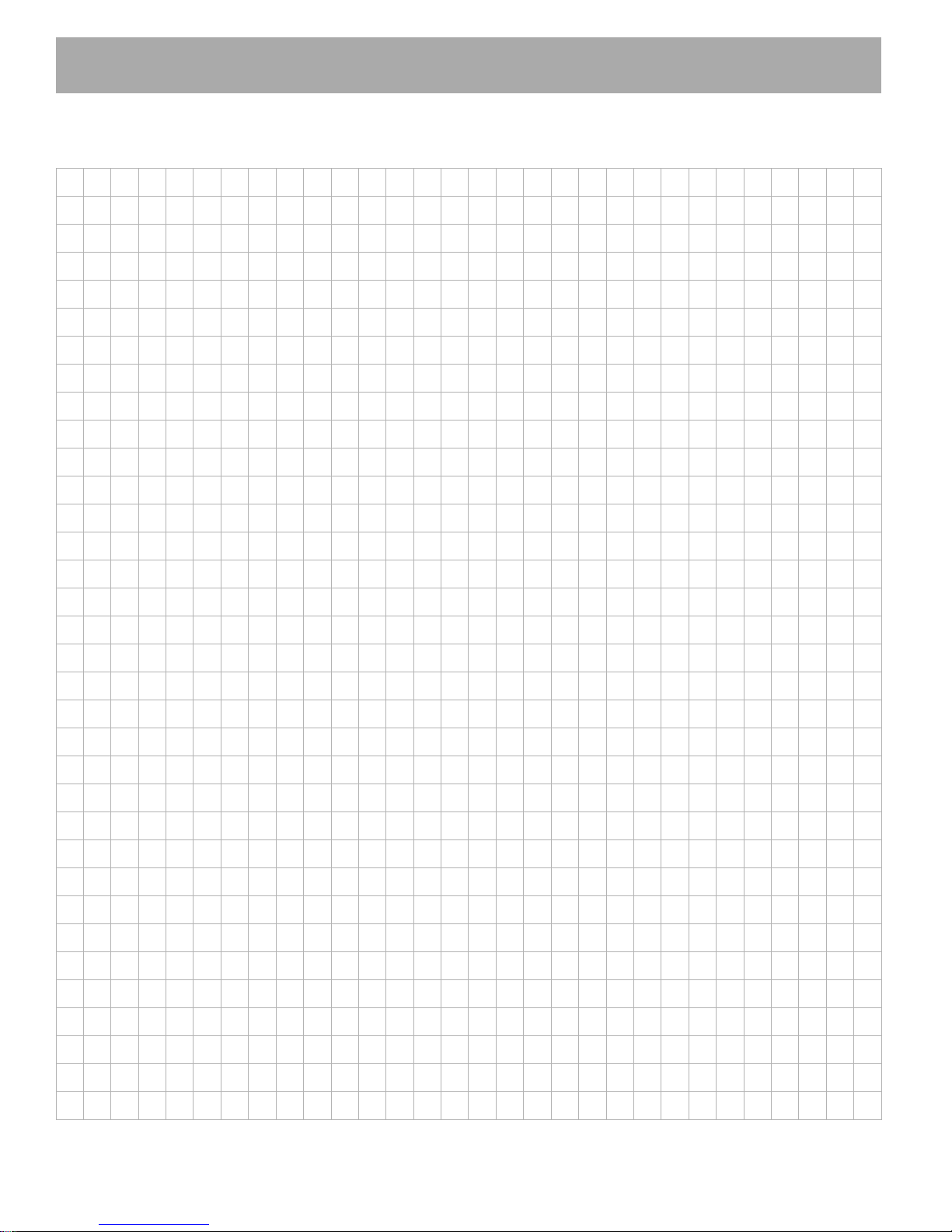

PERIODIC SERVICE SCHEDULE

- CHECK C&A - CHECK & ADJUST CL - CLEAN R - REPLACE

REMARKS

20 rnds/20 hrs

100 miles/160 kms

before each use

DAILY

Tires - pressure, condition of tires & rims

Hardwares and Fasteners - loose or missing

Reverse Warning Indicator

Overall Vehicle Condition

Batteries - state of charge, condition, loose terminals,

corrosion, hold down & hardware

Batteries* - check electrolyte level, fill if required C&A C&A C&A C&A

Brakes - smooth operation of pedal, Fluid , stopping

distance

Brakes - aggressive stop test, does brake hold on a hill

MONTHLY

60 rnds/60 hrs

300 miles/500 kms

QUARTERLY

125 rnds/125 hrs

600miles/1000 kms

SEMI-ANNUAL

CL CL CL CL

B

250 rnds/250 hrs

1200miles/2000 kms

ANNUAL

5 YEARS

PAGE

Accelerator - smooth operation

Wiring - loose connections, broken or missing insulation

Charger Receptacle - clean connections CL CL CL CL

Steering Assembly - excessive play, loose or missing

hardware

Tie Rods - excessive play, bent rods, loose or missing

hardware

Rear Axle - oil leakage, noise, loose or missing

hardware

Rear Axle - drain & replace fluid R

Front Suspension - strut oil leakage, excessive play in

hubs or kingpins, worn bushings, loose or missing

hardware

Front Wheel Alignment - unusual tire wear, missing lug

nuts.

Rear Suspension - shock oil leakage, worn bushings,

loose or missing hardware

Motor Coupling - Add Anti - Sieze compound

(Apporx 1 tablespoon)

Fig. 4 Periodic Service Schedule

C&A C&A C&A

20,000

AMPHrs

*Use only distilled or purified water that is free of contaminants to fill batteries.

Repair and Service Manual

Page A-5

GENERAL INFORMATION & ROUTINE MAINTANENCE

Read all of Section B and this section before attempting any procedure. Pay particular attention to Notices, Cautions, Warnings and Dangers.

Notes:

Page A-6

Repair and Service Manual

SAFETY

TABLE OF CONTENTS FOR SECTION ‘B’

SECTION TITLE PAGE NO.

NOTICES, CAUTIONS WARNINGS AND DANGERS..............................................B - 1

IMPORTANT SAFETY WARNING ............................................................................B - 1

MODIFICATIONS TO VEHICLE ................................................................................B - 1

GENERAL MAINTENANCE ......................................................................................B - 1

BEFORE SERVICING THE VEHICLE .......................................................................B - 1

Additional Warnings.......................................................................................... B - 2

BATTERY REMOVAL & INSTALLATION .................................................................B - 3

LIFTING THE VEHICLE ............................................................................................B - 4

LIST OF ILLUSTRATIONS

Fig. 1 Battery Connections ....................................................................................B - 3

Fig. 2 Lifting the Vehicle .......................................................................................B - 4

Repair and Service Manual

Page B-i

SAFETY

Read all of Section B and this section before attempting any procedure. Pay particular attention to Notices, Cautions, Warnings and Dangers.

Notes:

Page B-ii

Repair and Service Manual

SAFETY

NOTICE

DANGER

Read all of Section B and this section before attempting any procedure. Pay particular attention to Notices, Cautions, Warnings and Dangers.

B

NOTICES, CAUTIONS, WARNINGS

AND DANGERS

Throughout this manual, the following NOTICES,

CAUTIONS, WARNINGS and DANGERS are used. For

the protection of all personnel and the vehicle, be aware

of and observe the following:

A NOTICE indicates a condition that should be observed.

A CAUTION indicates a condition that may result in

damage to the vehicle or surrounding facilities.

A WARNING indicates a hazardous condition

which could result in serious injury or death.

Indicates a hazardous situation which, if

not avoided, will result in death or serious

injury.

IMPORTANT SAFETY WARNING

Always use the appropriate tools listed in the tool list

and wear approved safety equipment.

MODIFICATIONS TO VEHICLE

To prevent personal injury or death to the

operator or passenger(s), do not make

changes to the weight distribution or the

center of gravity which could make the vehicle

unstable or prone to roll over.

Do not modify the vehicle in any manner that will change

the weight distribution of the vehicle.

GENERAL MAINTENANCE

To prevent severe injury or death resulting

from improper servicing techniques, observe

the following Warnings:

Do not attempt any type of servicing

operations before reading and understanding

all notes, cautions and warnings in this

manual.

B

In any product, components will eventually fail to

perform properly as the result of normal use, age, wear

or abuse. It is virtually impossible to anticipate all

possible component failures or the manner in which

each component may fail.

Be aware that a vehicle requiring repair indicates that

the vehicle is no longer functioning as designed and

therefore should be considered potentially hazardous.

Use extreme care when working on any vehicle. When

diagnosing, removing or replacing any components that

are not operating correctly, take the time to consider the

safety of yourself and others around you if the

component should move unexpectedly.

Some components are heavy, spring loaded, highly

corrosive, explosive or may produce high amperage or

reach high temperatures. Battery acid and hydrogen gas

could result in serious bodily injury to the technician/

mechanic and bystanders if not treated with utmost

caution. Be careful not to place hands, face, feet or

body in a location that could expose them to injury

should an unforeseen situation occur.

When any maintenance procedure or inspection is

performed, it is important that care be exercised to

insure the safety of the technician/mechanic or

bystanders and to prevent damage to the vehicle.

Always read and understand the entire relevant manual

section (chapter) before attempting any inspection or

service.

BEFORE SERVICING THE VEHICLE

Before attempting to inspect or service a vehicle, be

sure to read and understand the following warnings:

To prevent personal injury or death, observe

the following:

Before working on vehicle, remove all

jewelry (watches, rings, etc.).

Be sure that no loose clothing or hair can

Repair and Service Manual

Page B-1

SAFETY

Read all of Section B and this section before attempting any procedure. Pay particular attention to Notices, Cautions, Warnings and Dangers.

become caught in the moving parts of the

B

powertrain.

Use care not to contact hot objects.

Any servicing requiring adjustments to be

made to the powertrain while the motor is

running must be made with both wheels

raised.

To prevent the possibility of motor

disintegration, never operate vehicle at full

throttle for more than 4 - 5 seconds while

vehicle is in a “no load” condition.

Wear OSHA approved clothing and eye

protection when working on anything that

could expose the body or eyes to potential

injury. In particular, use care when working

with or around batteries, compressed air or

solvents.

Always turn the key switch to ‘OFF’ and

remove the key before disconnecting a live

circuit.

When connecting battery cables, pay particular attention to the polarity of the battery

terminals. Never confuse the positive and

negative cables.

The parking ‘PARK’ brake should always

be set, except for cases where the powertrain must be allowed to rotate or service is

being performed on the brake system.

If repairs are to be made that will require

welding or cutting, the batteries must be

removed.

Additional Warnings

Before working on the electrical system, be sure to read

and understand the following warnings that pertain to

electrical system repair or maintenance.

To prevent battery explosion that could result

in severe personal injury or death, keep all

smoking materials, open flame or sparks away

from the batteries.

Hydrogen gas is generated in the charging

cycle of batteries and is explosive in

concentrations as low as 4%. Because

hydrogen gas is lighter than air, it will

collect in the ceiling of buildings

necessitating proper ventilation. Five air

exchanges per hour is considered the

minimum requirement.

Be sure that the key switch is off and all

electrical accessories are turned off before

starting work on vehicle.

Batteries should always be removed before

any servicing or repairs that could generate

sparks.

Never disconnect a circuit under load at a

battery terminal.

Batteries are heavy. Use

proper lifting techniques when

moving them. Always lift the

battery with a commercially

available battery lifting device.

Use care not to tip batteries

when removing or installing

them; spilled electrolyte can

cause burns and damage.

The electrolyte in a storage battery is an

acid solution which can cause severe burns

to the skin and eyes. Treat all electrolyte

spills to the body and eyes with extended

flushing with clear water. Contact a

physician immediately.

Wear eye protection when

working on the vehicle. In particular, use care when working

around batteries, or using

solvents or compressed air.

Any electrolyte spills should be neutralized

with a solution of 1/4 cup (60 ml) sodium

bicarbonate (baking soda) dissolved in

1 1/2 gallons (6 liters) of water and flushed

with water.

Wrap wrenches with

vinyl tape to prevent the

possibility of a dropped

wrench from ‘shorting

out’ a battery, which could result in an

explosion and severe personal injury or

death.

Aerosol containers of battery terminal

protectant must be used with extreme

care. Insulate metal container to prevent

can from contacting battery terminals which

could result in an explosion.

Page B-2

Repair and Service Manual

SAFETY

NOTICE

+

-

+

-

+

-

+

-

+

-

+

-

Front of Vehicle

BL+ to

Solenoid

+

-

+

-

To

Charger

BL- to Bon ESC

Read all of Section B and this section before attempting any procedure. Pay particular attention to Notices, Cautions, Warnings and Dangers.

should be present. If any corrosion is found, it should be

immediately removed with a putty knife and wire brush.

The area should be washed with a solution of sodium

bicarbonate (baking soda) and water and thoroughly

Overfilling batteries may result in electrolyte being

expelled from the battery during the charge cycle.

Expelled electrolyte may cause damage to the vehicle

and storage facility.

BATTERY REMOVAL &

INSTALLATION

Tool List Qty.

Insulated wrench, 1/2" ................................................. 1

Socket, 1/2" ................................................................. 1

Ratchet ........................................................................ 1

Battery carrier.............................................................. 1

Torque wrench (in. lbs.)............................................... 1

In the following text, there are references to removing/installing

bolts etc. Additional hardware (nuts, washers etc.) that are

removed must always be installed in its original position unless

otherwise specified. Nonspecified torques are as shown in

table contained in Section “A”.

Before any electrical service is performed on PDS model

vehicles, the Run-Tow/Maintenance switch must be

placed in the ‘Tow/Maintenance’ position.

dried before priming and painting with a corrosion

resistant paint.

Place batteries into the battery rack. Install the battery

hold downs and tighten to 45 - 55 in. lbs. (5 - 6 Nm)

torque, to prevent movement but not tight enough to

cause distortion of the battery cases.

Inspect all wires and terminals and clean any corrosion

from the battery terminals or the wire terminals with a

solution of sodium bicarbonate (baking soda) and wire

brush if required.

Aerosol containers of battery terminal

protectant must be used with extreme care.

Insulate metal container to prevent can from

contacting battery terminals which could result

in an explosion.

Use care to connect battery cables as shown in the

following illustration (Ref. Fig. 1). Connect the positive

(+) battery cable first, other battery connecting cables,

and then connect the negative (-) cable last. Ensure

that all battery terminals are installed with crimp up.

Tighten the battery post hardware to 90 - 100 in. lbs.

(10 - 11 Nm). Protect the battery terminals and battery

cable terminals with a commercially available

protective coating.

B

B

If a power wire (battery, motor or controller) is disconnected for any reason on the PDS model vehicle, the

Run-Tow/Maintenance switch must be left in the ‘Tow/

Maintenance’ position for at least 30 seconds after the

circuit is restored.

Turn vehicle key to ‘OFF’ and remove. Insure all optional

electrical accessories are turned OFF.

Using an insulated wrench, remove the negative (-)

cable first, the positive (+) cable and then all other

cables from the vehicle batteries. Remove the battery

hold down by removing the hardware and lifting the

retainer from the batteries.

Remove the batteries using a commercial battery

carrier.

If the batteries have been cleaned and any acid in the

battery rack area neutralized on a regular basis, no

corrosion to the battery racks or surrounding area

Repair and Service Manual

Fig. 1 Battery Connections

Page B-3

SAFETY

View from Underside of Vehicle

Center of

Front Axle

Flat Portion

of Frame

Outside End

of Rear Axle

Read all of Section B and this section before attempting any procedure. Pay particular attention to Notices, Cautions, Warnings and Dangers.

LIFTING THE VEHICLE

B

Tool List Qty.

Floor jack .....................................................................1

Jack stands.................................................................. 4

Chocks......................................................................... 4

Some servicing operations may require the vehicle to be

raised.

To prevent possible injury or death resulting

from a vehicle falling from a jack, be sure the

vehicle is on a firm and level surface. Never

get under a vehicle while it is supported by a

jack. Use jack stands and test the stability of

the vehicle on the stands. Always place chocks

in front and behind the wheels not being

raised. Use extreme care since the vehicle is

extremely unstable during the lifting process.

When lifting the vehicle, position jack stands only in the

areas indicated.

To raise the entire vehicle, install chocks in front and

behind each front wheel (Ref. Fig. 2). Center jack under

the rear frame crossmember. Raise vehicle and locate a

jack stand under outer ends of rear axle.

Lower the jack and test the stability of the vehicle on the

two jack stands.

Fig. 2 Lifting the Vehicle

Place the jack at the center of the front axle. Raise the

vehicle and position jack stands under the inner frame

member as indicated.

Lower the jack and test the stability of the vehicle on the

four jack stands.

If only the front or rear of the vehicle is to be raised,

place the chocks in front and behind each wheel not

being raised in order to stabilize the vehicle.

Lower the vehicle by reversing the lifting sequence.

Page B-4

Repair and Service Manual

SAFETY

Read all of Section B and this section before attempting any procedure. Pay particular attention to Notices, Cautions, Warnings and Dangers.

Notes:

Repair and Service Manual

Page B-5

SAFETY

Read all of Section B and this section before attempting any procedure. Pay particular attention to Notices, Cautions, Warnings and Dangers

Notes:

Page B-6

Repair and Service Manual

BODY

TABLE OF CONTENTS FOR SECTION ‘C’

SECTION TITLE PAGE NO.

BODY.............................................................................................................................C - 1

General................................................................................................................................. C - 1

BODY COMPONENT REPLACEMENT........................................................................C - 1

Instrument Panel Replacement ............................................................................................ C - 5

Cowl Replacement ............................................................................................................... C - 5

Front Fascia Replacement ................................................................................................... C - 5

Rocker Panel Replacement.................................................................................................. C - 5

Front Seat Pod Replacement ............................................................................................... C - 6

Rear Body Replacement ...................................................................................................... C - 6

Foot Rest Replacement........................................................................................................ C - 7

Rear Bumper Replacement .................................................................................................. C - 7

Front Seat Replacement....................................................................................................... C - 7

Front Facing Rear Seat ........................................................................................................ C - 7

Rear Facing Rear Seat......................................................................................................... C - 8

Cargo Bed Replacement ...................................................................................................... C - 8

Seat/Cargo Bed Latch .......................................................................................................... C - 8

PAINTING......................................................................................................................C - 8

Minor Scratches.................................................................................................................... C - 8

Larger Scratches .................................................................................................................. C - 9

Complete Panel Repair ........................................................................................................ C - 9

LIST OF ILLUSTRATIONS

Fig. 1 Drill Out Metal Rivet .............................................................................................................. C - 1

Fig. 2 Body Components (Front) ..................................................................................................... C - 2

Fig. 3 Body Components (Seats and Rear) .................................................................................... C - 3

Fig. 4 Body Components (Cargo Box and Seat Foot Rest) ............................................................ C - 4

Repair and Service Manual

Page C-i

BODY

Read all of Section B and this section before attempting any procedure. Pay particular attention to Notices, Cautions, Warnings and Dangers.

NOTES:

B

Page C-ii

Repair and Service Manual

BODY

NOTICE

Read all of Section B and this section before attempting any procedure. Pay particular attention to Notices, Cautions, Warnings and Dangers.

B

BODY

In the following text, there are references to removing/i nstalling

bolts etc. Additional hardware (nuts, washers etc.) that are

removed must always be installed in their original positions

unless otherwise specified. Non-specified torques are as

shown in the table in Section A.

General

To prevent possible injury or death from battery

explosion. Batteries should always be removed

before any servicing that will generate sparks. It

is important to use a sharp drill bit when removing the rivets on the side of the vehicle. Extreme

care must be used when drilling out the rivets

located in the front of the body and the bottom

side of the body. Excessive pressure could

result in the drill bit being forced through the

body panel and penetrating a component. As

extra protection, it is recommended that a protective piece of sheet metal be placed between

the battery and the rivet. Use of a drill depth

stop will provide additional protection.

In general, body component replacement can be accomplished with a minimum of specialized tools. Most body

components are held in place with conventional removable hardware (nuts, bolts, washers and screws). Some

components are mounted with ‘pop’ rivets which require

that the rivet head be removed in order to push out the

shank of the rivet. The rivet head is easily removed by

drilling into the head with a sharp drill bit that is slightly

larger than the shank of the rivet (Ref. Fig. 1). Care must

be exercised when drilling to prevent the drill from being

forced through and damaging compo nent s wher e it could

damage components located immediately behind the

rivet. The best way to prevent this from occurring is to use

a sharp drill bit that requires very little pressure to cut successfully and to place a piece of protective sheet metal

between the surface being drilled and components

directly behind it.

Drill Out Rivet

Pop Rivet

Fig. 1 Drill Out Metal Rivet

Head Only

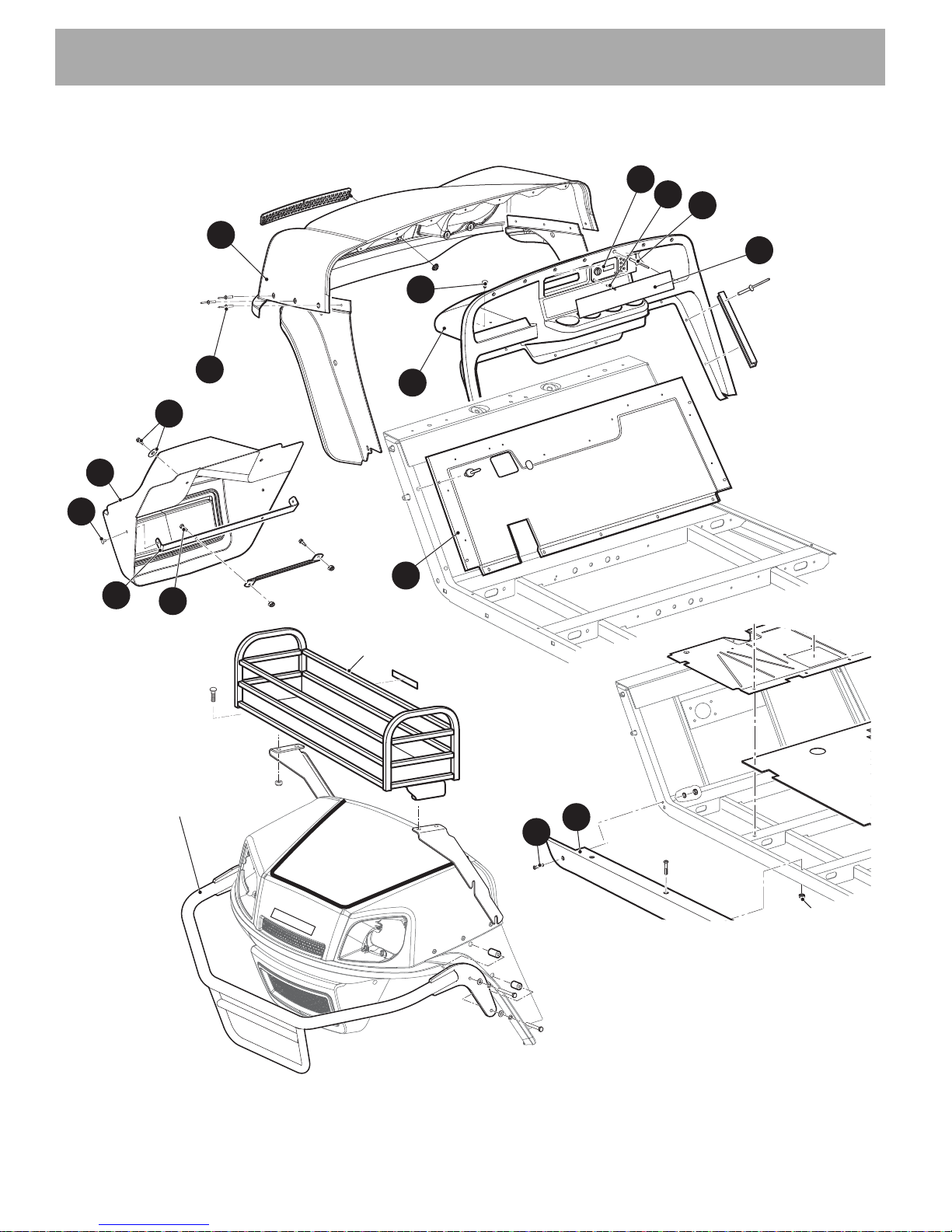

BODY COMPONENT REPLACEMENT

The body components can be replaced by removing the

securing hardware, replacing the component and securing with hardware in the same orientation as removed.

The illustrations on the following pages indicate the

assembly methods for the various components.

B

Repair and Service Manual

Page C-1

BODY

48

16

5

1

8

7

BRUSH GUARD

FRONT BASKET

4

6

9

10

11

28

143

139

144

145

141

Read all of Section B and this section before attempting any procedure. Pay particular attention to Notices, Cautions, Warnings and Dangers.

B

Page C-2

Fig. 2 Body Components (Front)

Repair and Service Manual

Loading...

Loading...