Page 1

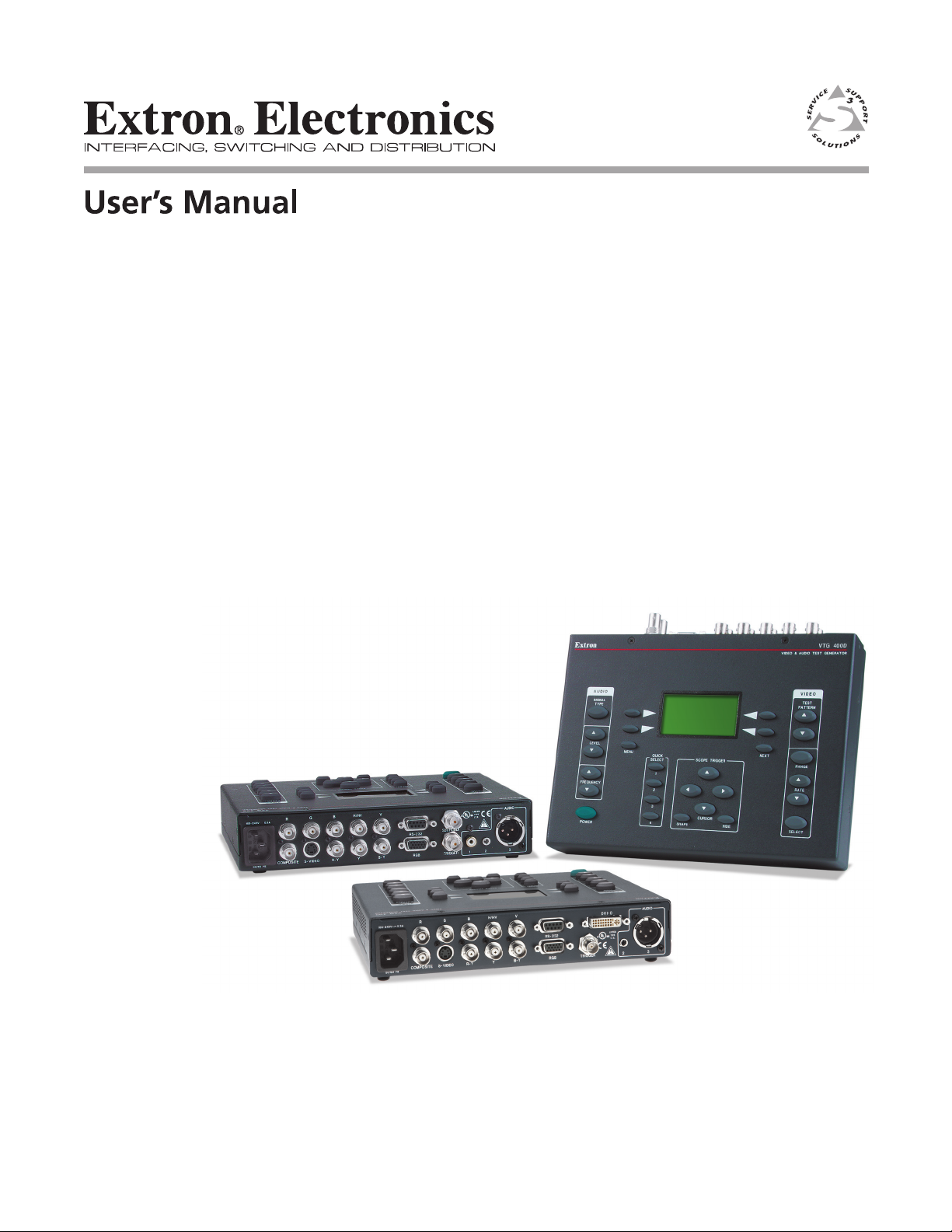

VTG 400D/400 DVI

Programmable Video and Audio Test Generator

68-786-01 Rev. C

04 09

Page 2

Precautions

Safety Instructions • English

This symbol is intended to alert the user of important operating and maintenance

(servicing) instructions in the literature provided with the equipment.

This symbol is intended to alert the user of the presence of uninsulated dangerous

voltage within the product’s enclosure that may present a risk of electric shock.

Caution

Read Instructions • Read and understand all safety and operating instructions before using the equipment.

Retain Instructions • The safety instructions should be kept for future reference.

Follow Warnings • Follow all warnings and instructions marked on the equipment or in the user

information.

Avoid Attachments • Do not use tools or attachments that are not recommended by the equipment

manufacturer because they may be hazardous.

Consignes de Sécurité • Français

Ce symbole sert à avertir l’utilisateur que la documentation fournie avec le matériel

contient des instructions importantes concernant l’exploitation et la maintenance

(réparation).

Ce symbole sert à avertir l’utilisateur de la présence dans le boîtier de l’appareil

de tensions dangereuses non isolées posant des risques d’électrocution.

Attention

Lire les instructions• Prendre connaissance de toutes les consignes de sécurité et d’exploitation avant

d’utiliser le matériel.

Conserver les instructions• Ranger les consignes de sécurité afin de pouvoir les consulter à l’avenir.

Respecter les avertissements • Observer tous les avertissements et consignes marqués sur le matériel ou

présentés dans la documentation utilisateur.

Eviter les pièces de xation • Ne pas utiliser de pièces de fixation ni d’outils non recommandés par le

fabricant du matériel car cela risquerait de poser certains dangers.

Sicherheitsanleitungen • Deutsch

Dies es Symbol soll dem Benut zer in der im Liefer umfang ent haltenen

Dokumentation besonders wichtige Hinweise zur Bedienung und Wartung

(Instandhaltung) geben.

Dieses Symbol soll den Benutzer darauf aufmerksam machen, daß im Inneren des

Gehäuses dieses Produktes gefährliche Spannungen, die nicht isoliert sind und

die einen elektrischen Schock verursachen können, herrschen.

Achtung

Lesen der Anleitungen • Bevor Sie das Gerät zum ersten Mal verwenden, sollten Sie alle Sicherheits-und

Bedienungsanleitungen genau durchlesen und verstehen.

Aufbewahren der Anleitungen • Die Hinweise zur elektrischen Sicherheit des Produktes sollten Sie

aufbewahren, damit Sie im Bedarfsfall darauf zurückgreifen können.

Befolgen der Warnhinweise • Befolgen Sie alle Warnhinweise und Anleitungen auf dem Gerät oder in der

Benutzerdokumentation.

Keine Zusatzgeräte • Verwenden Sie keine Werkzeuge oder Zusatzgeräte, die nicht ausdrücklich vom

Hersteller empfohlen wurden, da diese eine Gefahrenquelle darstellen können.

Warning

Power sources • This equipment should be operated only from the power source indicated on the product. This

equipment is intended to be used with a main power system with a grounded (neutral) conductor. The

third (grounding) pin is a safety feature, do not attempt to bypass or disable it.

Power disconnection • To remove power from the equipment safely, remove all power cords from the rear of

the equipment, or the desktop power module (if detachable), or from the power source receptacle (wall

plug).

Power cord protection • Power cords should be routed so that they are not likely to be stepped on or pinched by

items placed upon or against them.

Servicing • Refer all servicing to qualified service personnel. There are no user-serviceable parts inside. To

prevent the risk of shock, do not attempt to service this equipment yourself because opening or removing

covers may expose you to dangerous voltage or other hazards.

Slots and openings • If the equipment has slots or holes in the enclosure, these are provided to prevent

overheating of sensitive components inside. These openings must never be blocked by other objects.

Lithium battery • There is a danger of explosion if battery is incorrectly replaced. Replace it only with the

same or equivalent type recommended by the manufacturer. Dispose of used batteries according to the

manufacturer’s instructions.

Avertissement

Alimentations• Ne faire fonctionner ce matériel qu’avec la source d’alimentation indiquée sur l’appareil. Ce

matériel doit être utilisé avec une alimentation principale comportant un fil de terre (neutre). Le troisième

contact (de mise à la terre) constitue un dispositif de sécurité : n’essayez pas de la contourner ni de la

désactiver.

Déconnexion de l’alimentation• Pour mettre le matériel hors tension sans danger, déconnectez tous les cordons

d’alimentation de l’arrière de l’appareil ou du module d’alimentation de bureau (s’il est amovible) ou

encore de la prise secteur.

Protection du cordon d’alimentation • Acheminer les cordons d’alimentation de manière à ce que personne ne

risque de marcher dessus et à ce qu’ils ne soient pas écrasés ou pincés par des objets.

Réparation-maintenance • Faire exécuter toutes les interventions de réparation-maintenance par un technicien

qualifié. Aucun des éléments internes ne peut être réparé par l’utilisateur. Afin d’éviter tout danger

d’électrocution, l’utilisateur ne doit pas essayer de procéder lui-même à ces opérations car l’ouverture ou le

retrait des couvercles risquent de l’exposer à de hautes tensions et autres dangers.

Fentes et orices • Si le boîtier de l’appareil comporte des fentes ou des orifices, ceux-ci servent à empêcher

les composants internes sensibles de surchauffer. Ces ouvertures ne doivent jamais être bloquées par des

objets.

Lithium Batterie • Il a danger d’explosion s’ll y a remplacment incorrect de la batterie. Remplacer uniquement

avec une batterie du meme type ou d’un ype equivalent recommande par le constructeur. Mettre au reut les

batteries usagees conformement aux instructions du fabricant.

Vorsicht

Stromquellen • Dieses Gerät sollte nur über die auf dem Produkt angegebene Stromquelle betrieben werden.

Dieses Gerät wurde für eine Verwendung mit einer Hauptstromleitung mit einem geerdeten (neutralen)

Leiter konzipiert. Der dritte Kontakt ist für einen Erdanschluß, und stellt eine Sicherheitsfunktion dar. Diese

sollte nicht umgangen oder außer Betrieb gesetzt werden.

Stromunterbrechung • Um das Gerät auf sichere Weise vom Netz zu trennen, sollten Sie alle Netzkabel

aus der Rückseite des Gerätes, aus der externen Stomversorgung (falls dies möglich ist) oder aus der

Wandsteckdose ziehen.

Schutz des Netzkabels • Netzkabel sollten stets so verlegt werden, daß sie nicht im Weg liegen und niemand

darauf treten kann oder Objekte darauf- oder unmittelbar dagegengestellt werden können.

Wartung • Alle Wartungsmaßnahmen sollten nur von qualiziertem Servicepersonal durchgeführt werden.

Die internen Komponenten des Gerätes sind wartungsfrei. Zur Vermeidung eines elektrischen Schocks

versuchen Sie in keinem Fall, dieses Gerät selbst öffnen, da beim Entfernen der Abdeckungen die Gefahr

eines elektrischen Schlags und/oder andere Gefahren bestehen.

Schlitze und Öffnungen • Wenn das Gerät Schlitze oder Löcher im Gehäuse aufweist, dienen diese zur

Vermeidung einer Überhitzung der empndlichen Teile im Inneren. Diese Öffnungen dürfen niemals von

anderen Objekten blockiert werden.

Litium-Batterie • Explosionsgefahr, falls die Batterie nicht richtig ersetzt wird. Ersetzen Sie verbrauchte

Batterien nur durch den gleichen oder einen vergleichbaren Batterietyp, der auch vom Hersteller

empfohlen wird. Entsorgen Sie verbrauchte Batterien bitte gemäß den Herstelleranweisungen.

Instrucciones de seguridad • Español

Este símbolo se utiliza para advertir al usuario sobre instrucciones importantes

de operación y mantenimiento (o cambio de partes) que se desean destacar en el

contenido de la documentación suministrada con los equipos.

Este símbolo se utiliza para advertir al usuario sobre la presencia de elementos con

voltaje peligroso sin protección aislante, que puedan encontrarse dentro de la caja

o alojamiento del producto, y que puedan representar riesgo de electrocución.

Precaucion

Leer las instrucciones • Leer y analizar todas las instrucciones de operación y seguridad, antes de usar el

equipo.

Conservar las instrucciones • Conservar las instrucciones de seguridad para futura consulta.

Obedecer las advertencias • Todas las advertencias e instrucciones marcadas en el equipo o en la

documentación del usuario, deben ser obedecidas.

Evitar el uso de accesorios • No usar herramientas o accesorios que no sean especificamente recomendados

por el fabricante, ya que podrian implicar riesgos.

安全须知 • 中文

这个符号提示用户该设备用户手册中有重要的操作和维护说明。

这个符号警告用户该设备机壳内有暴露的危险电 压,有触电危险。

注意

阅读说明书 • 用户使用该设备前必须阅读并理解所有安全和使用说明。

保存说明书 • 用户应保存安全说明书以备将来使用。

遵守警告 • 用户应遵守产品和用户 指南上的所有安全和 操作说明。

避免追加 • 不要使用该产品厂商没有推荐的工具或追加设备,以避免危险。

Advertencia

Alimentación eléctrica • Este equipo debe conectarse únicamente a la fuente/tipo de alimentación eléctrica

indicada en el mismo. La alimentación eléctrica de este equipo debe provenir de un sistema de distribución

general con conductor neutro a tierra. La tercera pata (puesta a tierra) es una medida de seguridad, no

puentearia ni eliminaria.

Desconexión de alimentación eléctrica • Para desconectar con seguridad la acometida de alimentación eléctrica

al equipo, desenchufar todos los cables de alimentación en el panel trasero del equipo, o desenchufar el

módulo de alimentación (si fuera independiente), o desenchufar el cable del receptáculo de la pared.

Protección del cables de alimentación • Los cables de alimentación eléctrica se deben instalar en lugares donde

no sean pisados ni apretados por objetos que se puedan apoyar sobre ellos.

Reparaciones/mantenimiento • Solicitar siempre los servicios técnicos de personal calicado. En el interior no

hay partes a las que el usuario deba acceder. Para evitar riesgo de electrocución, no intentar personalmente

la reparación/mantenimiento de este equipo, ya que al abrir o extraer las tapas puede quedar expuesto a

voltajes peligrosos u otros riesgos.

Ranuras y aberturas • Si el equipo posee ranuras o orificios en su caja/alojamiento, es para evitar el

sobrecalientamiento de componentes internos sensibles. Estas aberturas nunca se deben obstruir con otros

objetos.

Batería de litio • Existe riesgo de explosión si esta batería se coloca en la posición incorrecta. Cambiar esta

batería únicamente con el mismo tipo (o su equivalente) recomendado por el fabricante. Desachar las

baterías usadas siguiendo las instrucciones del fabricante.

警告

电源 • 该设备只能使用产品上标明的电源。 设备必须使用有地线的供电系统供电。 第三条线

(地线)是安全 设施,不能 不用或跳过 。

拔掉电源 • 为安全地从设备拔掉电源,请拔掉所有设备后或桌面电源的电源线,或任何接到市

电系统的电 源线。

电源线保护 • 妥善布线, 避免被 踩踏,或重物 挤压。

维护 • 所有维修必须由认证的维修人员进行。 设备内部没有用户可以更换的零件。为避免出

现触电危险不要自己试图打开设备盖子维修该设备。

通风孔 • 有些设备机壳 上有通风槽或孔,它们是用来防止机内敏感元件过热。 不 要用任何东

西挡住通风 孔。

锂电池 • 不正确的更换电池会有爆炸的危险。必须使用与厂家推荐的相同或 相近型号的电池。

按照生 产厂的建议处 理废弃电池。

Page 3

FCC Class A Notice

N

N

This equipment has been tested and found to comply with the limits for a Class A digital

device, pursuant to part 15 of the FCC Rules. These limits are designed to provide reasonable

protection against harmful interference when the equipment is operated in a commercial

environment. This equipment generates, uses and can radiate radio frequency energy and,

if not installed and used in accordance with the instruction manual, may cause harmful

interference to radio communications. Operation of this equipment in a residential area is

likely to cause harmful interference, in which case the user will be required to correct the

interference at his own expense.

This unit was tested with shielded cables on the peripheral devices. Shielded cables must be

used with the unit to ensure compliance.

This device complies with Part 15 of the FCC Rules. Operation is subject to the following two

conditions: (1) this device may not cause harmful interference, and (2) this device must accept

any interference received, including interference that may cause undesired operation.

Page 4

Page 5

Table of Contents

Chapter 1 • Introduction ...................................................................................................... 1-1

About this Manual ............................................................................................................ 1-2

About the VTG 400D/400 DVI ...................................................................................... 1-2

Other Features .................................................................................................................... 1-2

Chapter 2 • Installation and Operation...................................................................... 2-1

Application Example ........................................................................................................ 2-2

Tabletop or Desktop Placement ................................................................................ 2-2

Rear Panel Connectors and Cabling ........................................................................ 2-3

Connecting Audio Outputs .......................................................................................... 2-5

RCA connector................................................................................................................... 2-5

XLR connector ................................................................................................................... 2-5

Mini stereo plug ............................................................................................................... 2-5

Top Panel Features ............................................................................................................ 2-6

Audio Testing Features ................................................................................................... 2-8

Selecting audio signals .................................................................................................... 2-8

Setting the audio level .................................................................................................... 2-9

Setting the audio frequency ........................................................................................... 2-9

Menus, Configuration, and Adjustments .......................................................... 2-10

Moving through menus by using front panel controls ............................................. 2-10

Menu overview ............................................................................................................... 2-11

Audio Setup menu ......................................................................................................... 2-12

Audio Setup submenu (1 of 5) .......................................................................................... 2-12

Audio level units .......................................................................................................... 2-12

Output 2 enable .......................................................................................................... 2-12

Audio Setup submenu (2 of 5) .......................................................................................... 2-12

Burst interval ............................................................................................................... 2-12

Burst on ........................................................................................................................2-13

Audio Setup submenu (3 of 5) .......................................................................................... 2-13

F. Sweep Start Freq ......................................................................................................2-13

F. Sweep Stop Freq ....................................................................................................... 2-13

Audio Setup submenu (4 of 5) .......................................................................................... 2-13

F. Sweep Format .......................................................................................................... 2-13

F. Sweep Direction ....................................................................................................... 2-13

Audio Setup submenu (5 of 5) .......................................................................................... 2-13

Audio Mute .................................................................................................................. 2-13

Square Wave Auto Attenuate.................................................................................... 2-13

Video Setup menu .......................................................................................................... 2-14

Video Setup submenu (1 of 4) .......................................................................................... 2-14

RGB sync format .......................................................................................................... 2-14

Raster border ............................................................................................................... 2-14

Video Setup submenu (2 of 4) .......................................................................................... 2-14

On-Screen Display ........................................................................................................2-14

Video Setup submenu (3 of 4) .......................................................................................... 2-15

VTG 400D/400 DVI • Table of Contents

i

Page 6

Table of Contents, cont’d

Autosequence Mode ................................................................................................... 2-15

Autosequence Interval ................................................................................................2-15

Video Setup submenu (4 of 4) .......................................................................................... 2-15

RGB Color Channel Enable .......................................................................................... 2-15

Advanced Setup menu ................................................................................................... 2-16

Advanced Setup submenu (1 of 4) ................................................................................... 2-16

Time-out interval ......................................................................................................... 2-16

Screensaver Mode .......................................................................................................2-17

Advanced Setup submenu (2 of 4) ................................................................................... 2-17

LCD Display Contrast ...................................................................................................2-17

LCD Backlight ...............................................................................................................2-17

Advanced Setup submenu (3 of 4) ................................................................................... 2-17

Internal Temperature ................................................................................................. 2-18

Native Rate for DVI Device .........................................................................................2-18

Advanced Setup submenu (4 of 4) ................................................................................... 2-18

System Reset ...............................................................................................................2-18

System Reset Confirm .................................................................................................2-18

Exit menu ........................................................................................................................ 2-18

Additional Functions ..................................................................................................... 2-18

Top panel security lockout (button lock mode) .......................................................... 2-18

Quick select buttons ....................................................................................................... 2-20

Video output range and rate buttons .......................................................................... 2-21

Test pattern selection buttons ....................................................................................... 2-22

Invert/special features functions ......................................................................................2-22

Adjusting the video level of test patterns ................................................................... 2-23

Scope-Trigger buttons .................................................................................................... 2-23

Chapter 3 • Serial Communication ................................................................................ 3-1

RS-232 Programmer’s Guide ........................................................................................ 3-2

Host-to-VTG communications .......................................................................................... 3-2

Video test generator-initiated messages .......................................................................... 3-2

Error responses ................................................................................................................... 3-2

Using the command/response tables ................................................................................. 3-3

Symbol definitions ...............................................................................................................3-3

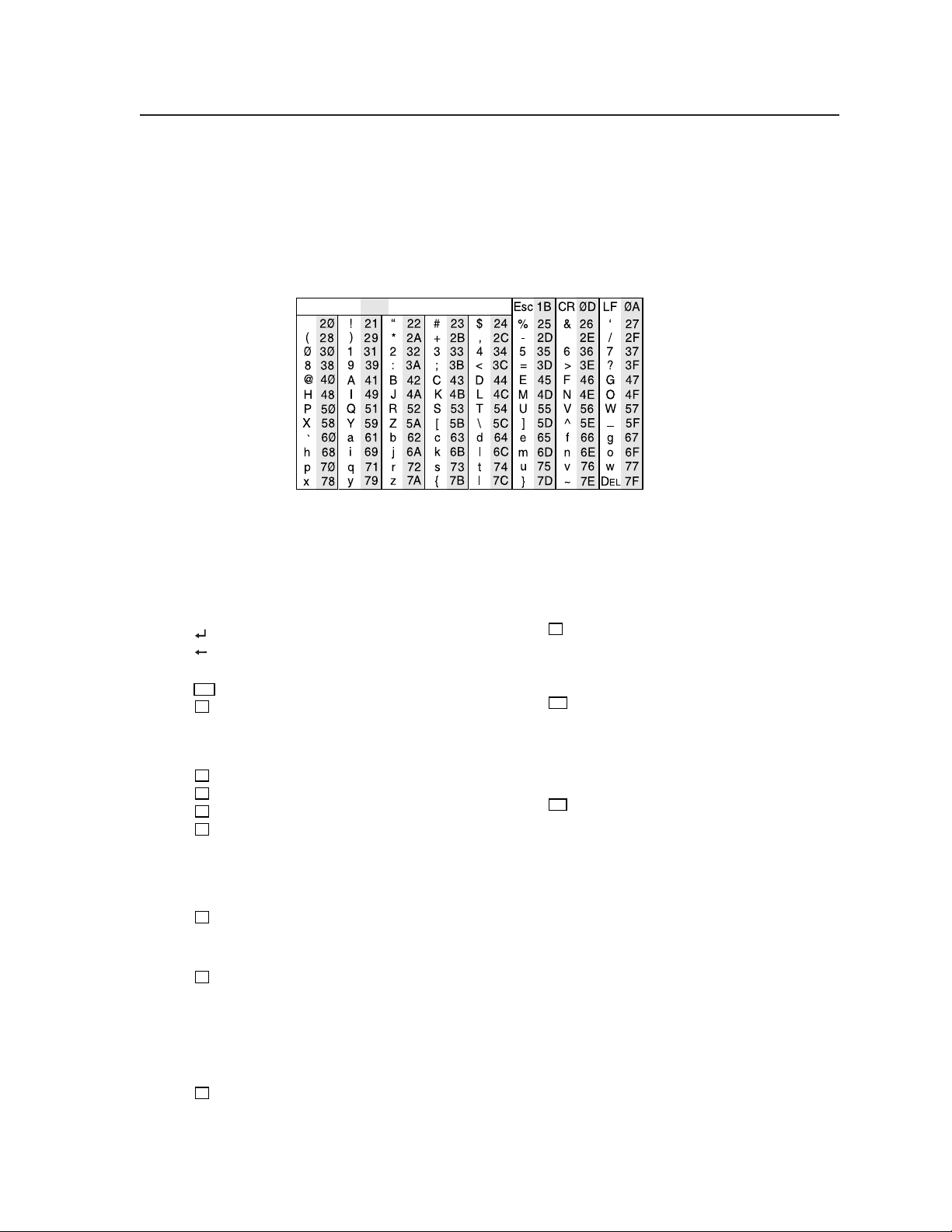

Command/response table for SIS commands..................................................................... 3-6

Control Software for Windows

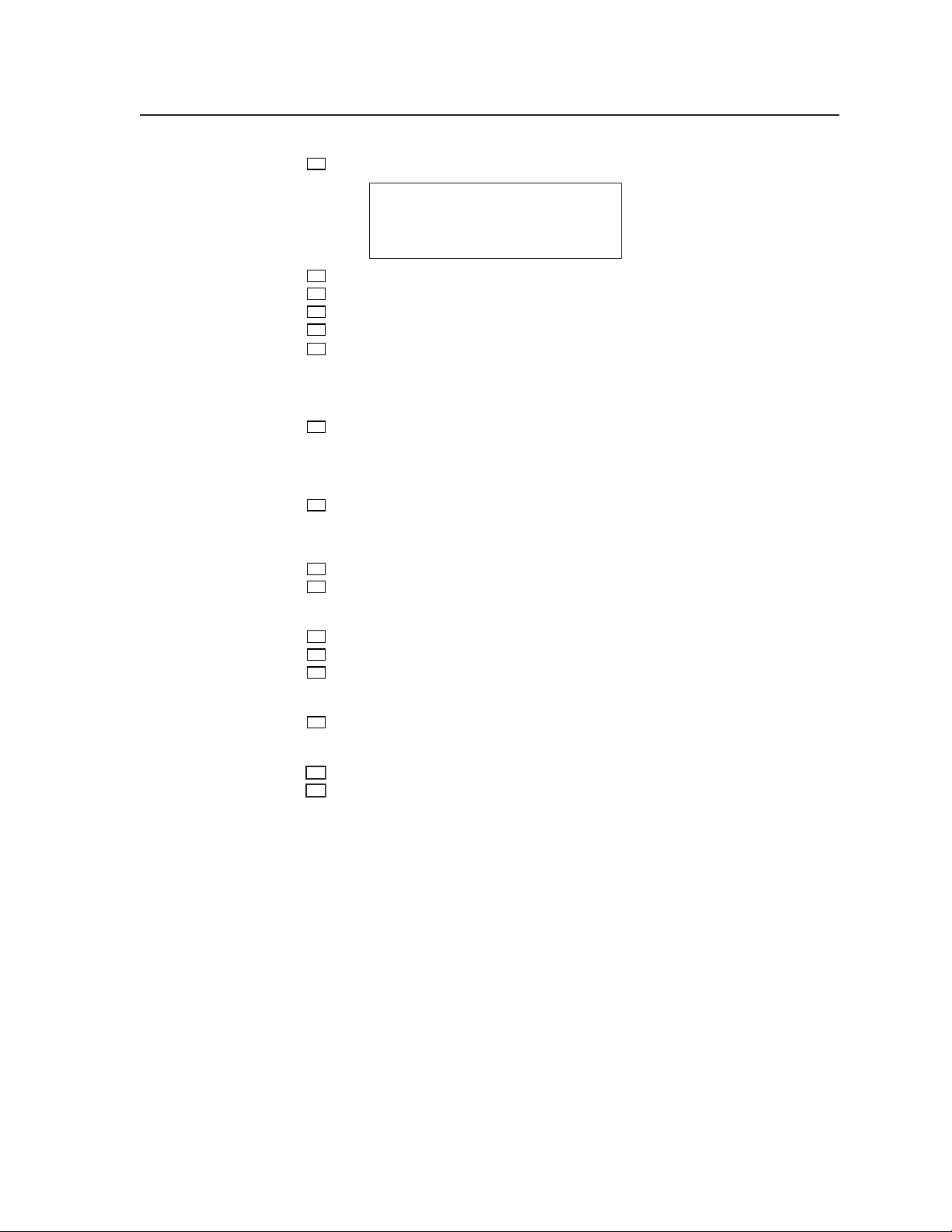

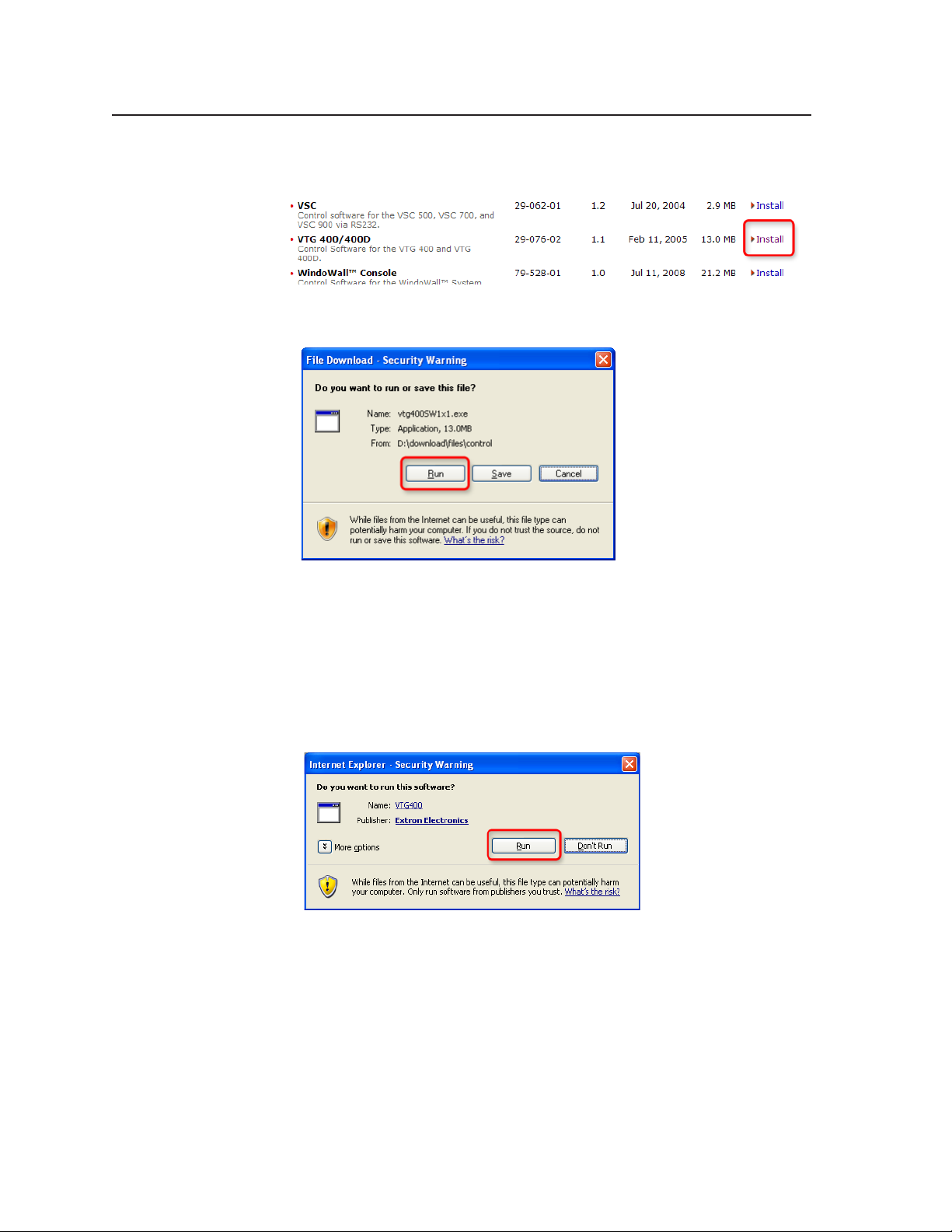

Installing the software ................................................................................................... 3-11

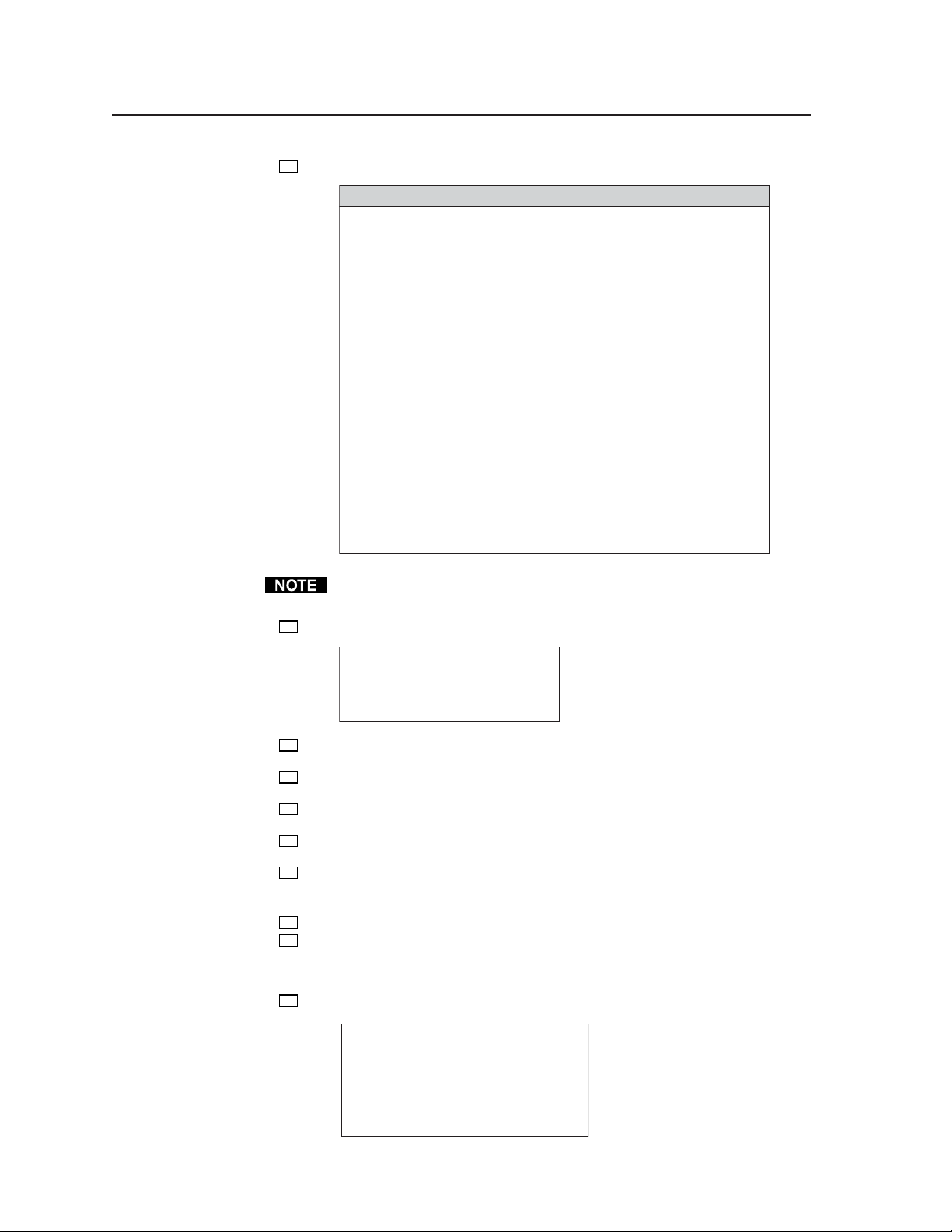

Downloading the VTG 400 software from the Web ................................................... 3-13

Starting the control program ........................................................................................ 3-14

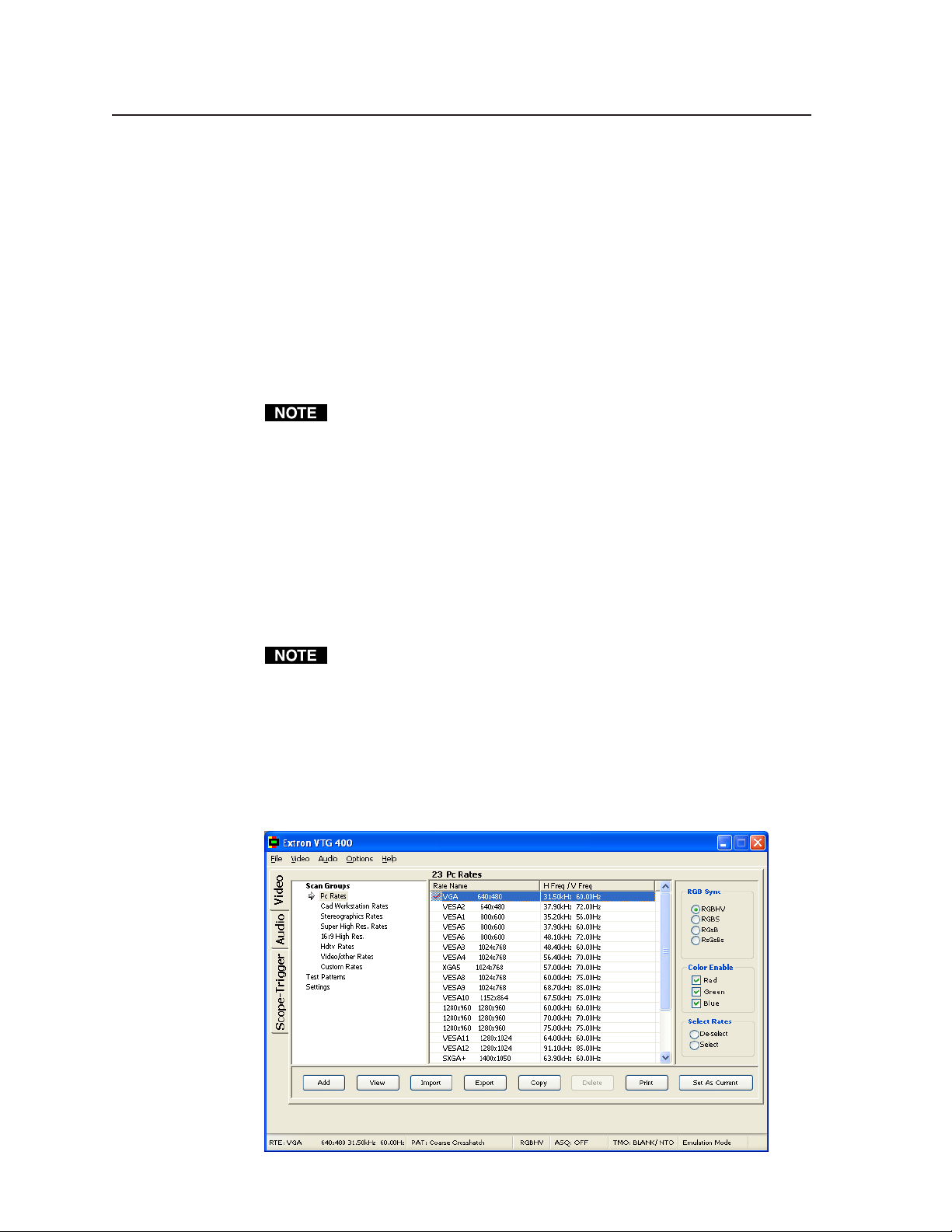

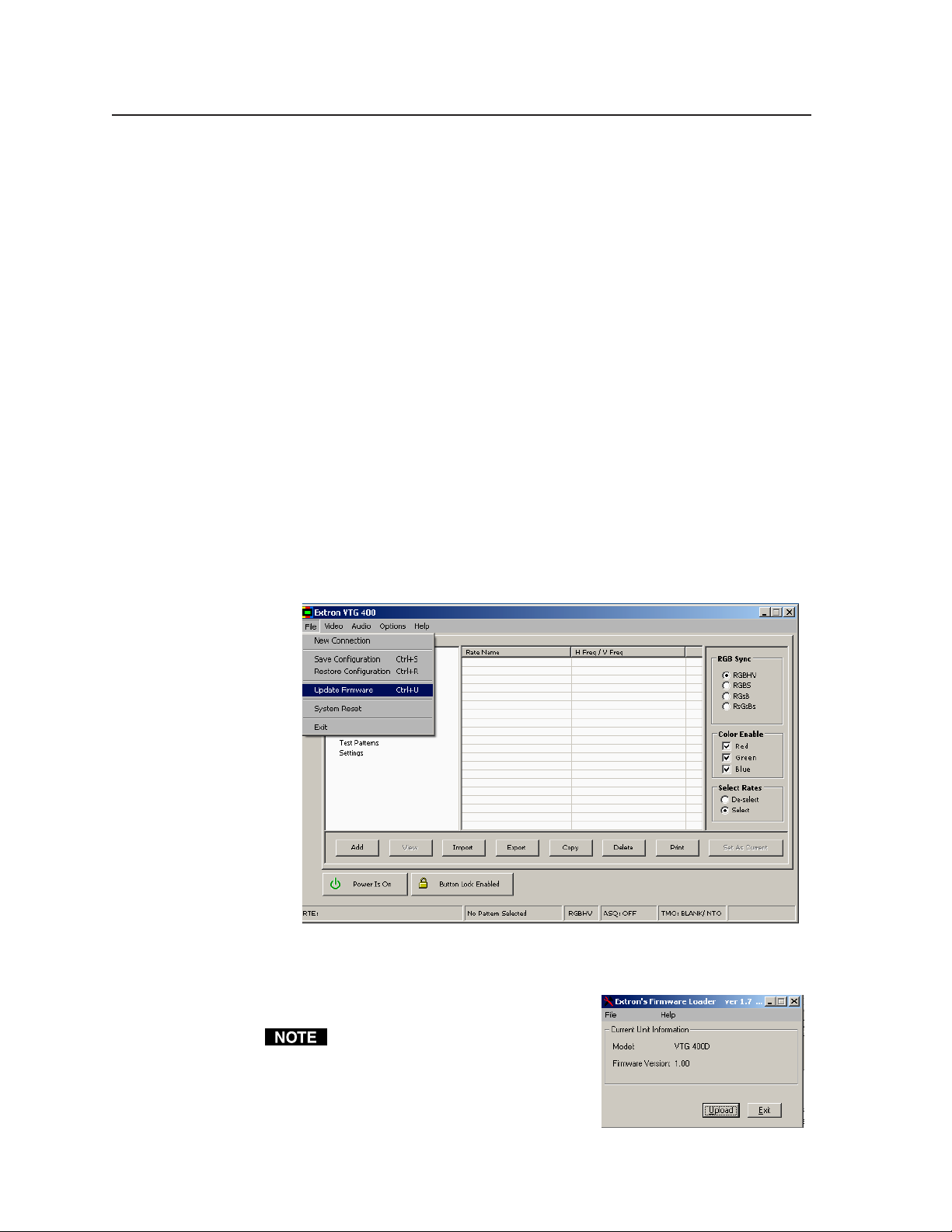

Drop-down menus .......................................................................................................... 3-15

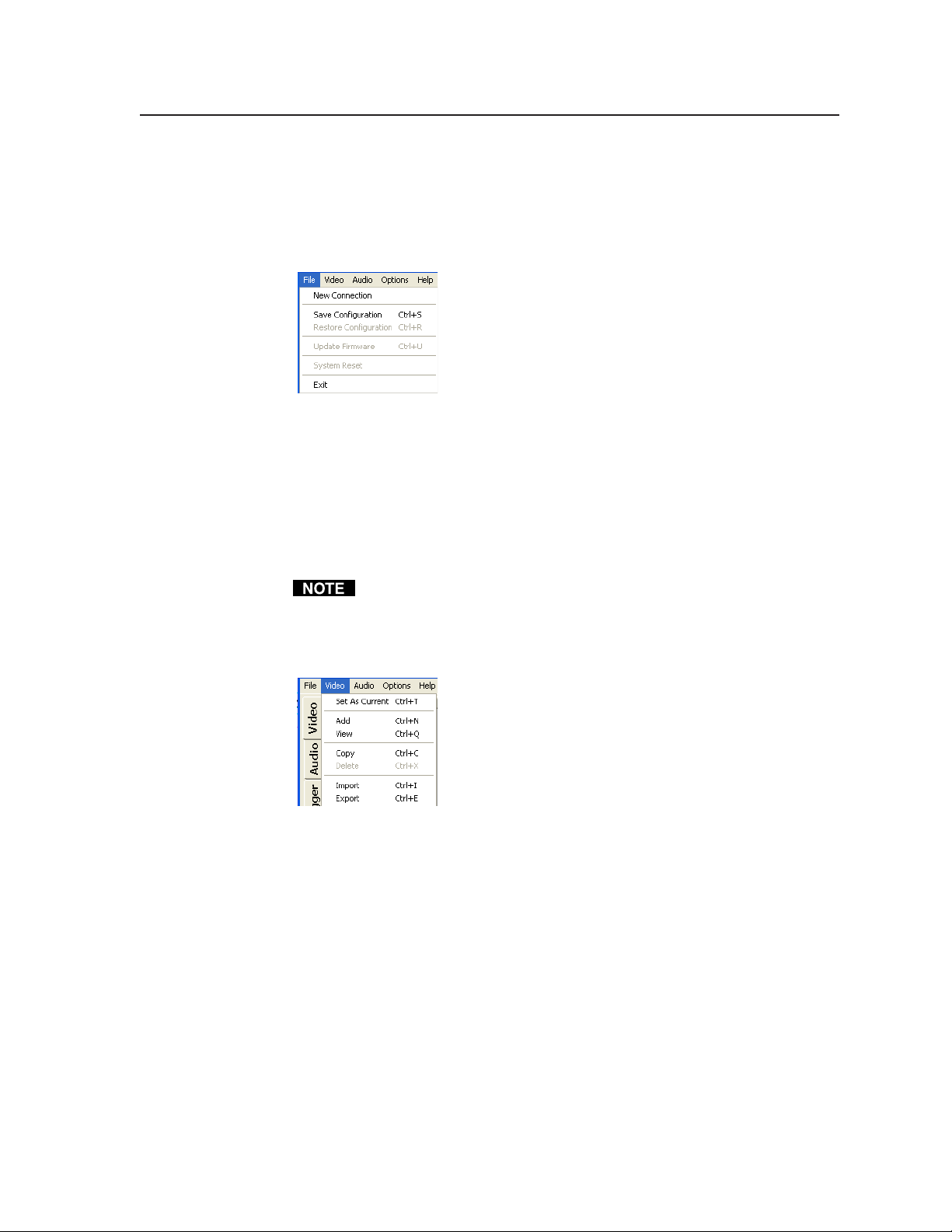

File menu ........................................................................................................................... 3-15

Video menu ....................................................................................................................... 3-15

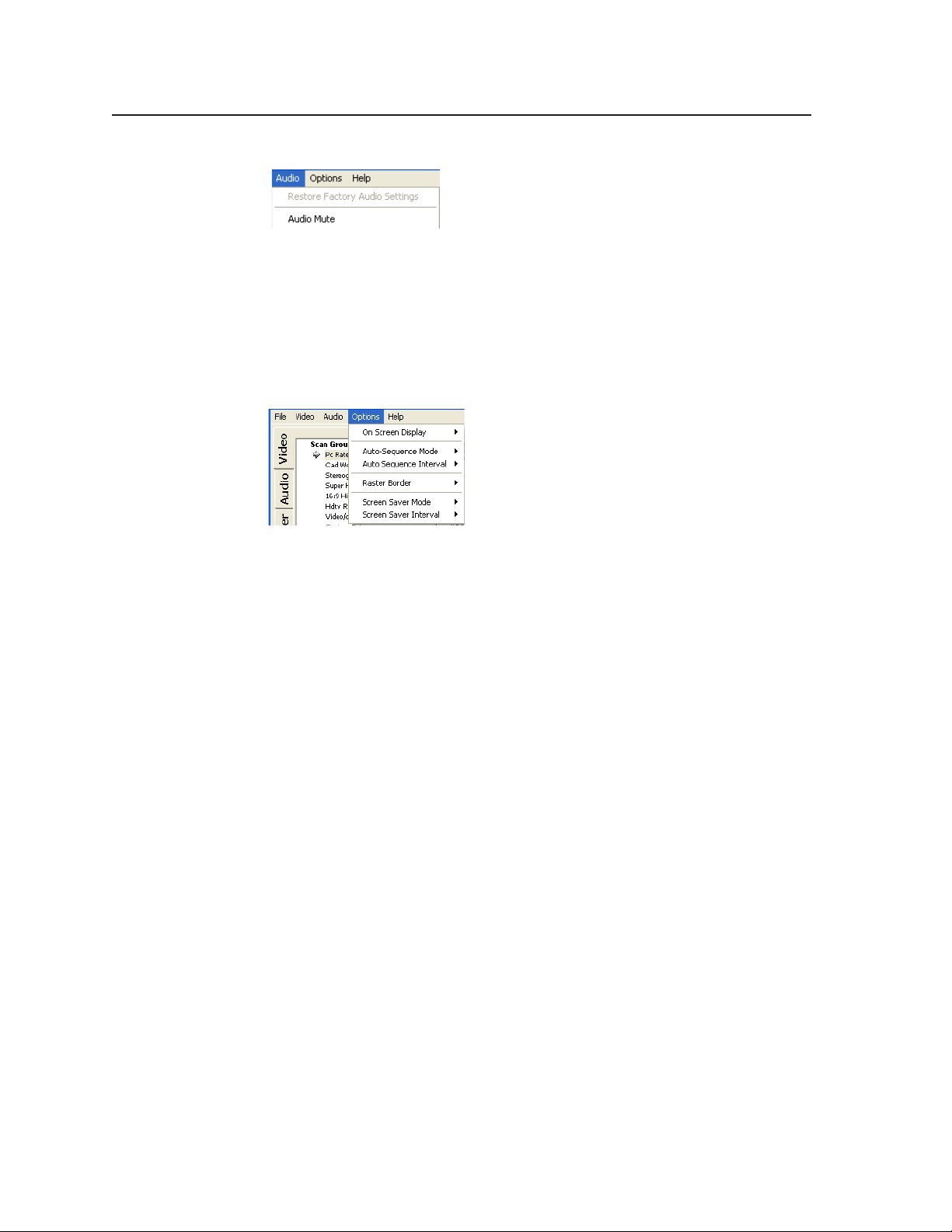

Audio menu .......................................................................................................................3-15

Options menu .................................................................................................................... 3-16

Help menu .........................................................................................................................3-16

Video tab ......................................................................................................................... 3-16

Scan Groups screen ........................................................................................................... 3-16

®

............................................................................. 3-11

ii VTG 400D/400 DVI • Table of Contents

Page 7

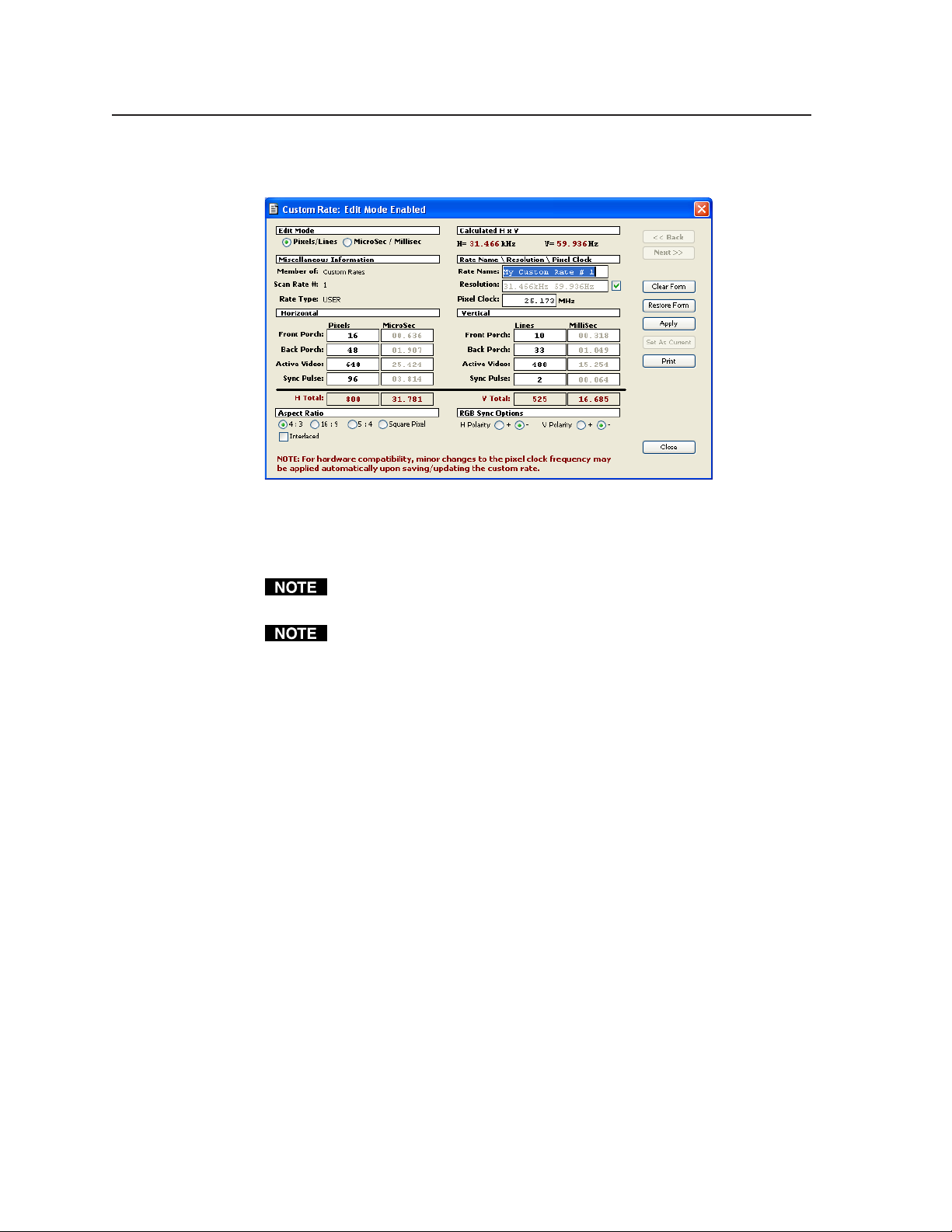

Test Patterns screen .......................................................................................................... 3-21

Settings screen ..................................................................................................................3-22

Audio tab ......................................................................................................................... 3-23

Scope-Trigger tab ............................................................................................................ 3-24

Power/Status button ....................................................................................................... 3-25

Button Lock/Status button ............................................................................................ 3-25

Using the help program ................................................................................................. 3-25

Using the Emulation Mode .............................................................................3-26

Firmware Upgrade Through the Extron Web Site ......................................... 3-28

Downloading the latest firmware to the PC ............................................................... 3-28

Uploading the firmware from the PC to the VTG 400D/400 DVI .............................. 3-28

Appendix A • Reference Materials ............................................................................... A-1

Specifications ..................................................................................................................... A-2

Included Parts ..................................................................................................................... A-4

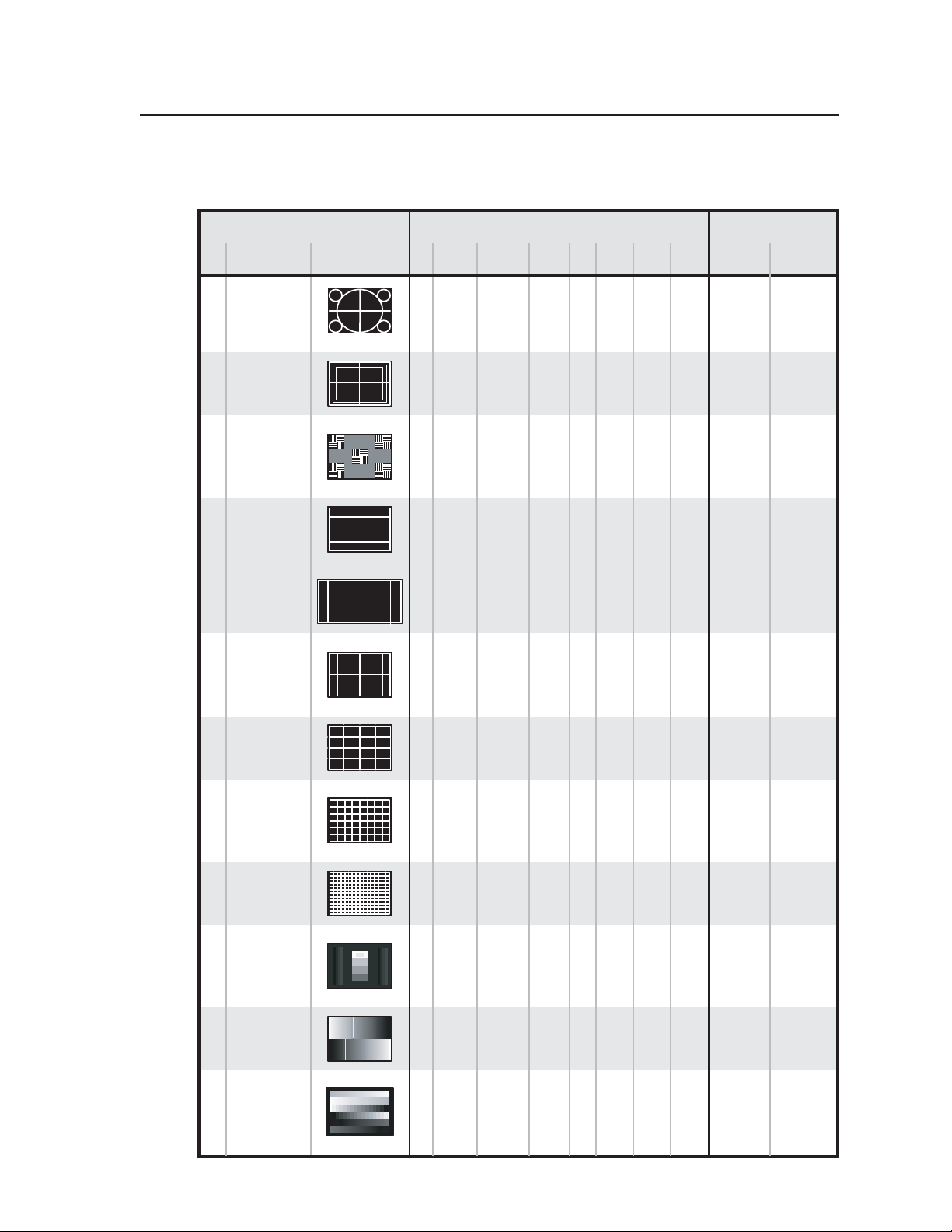

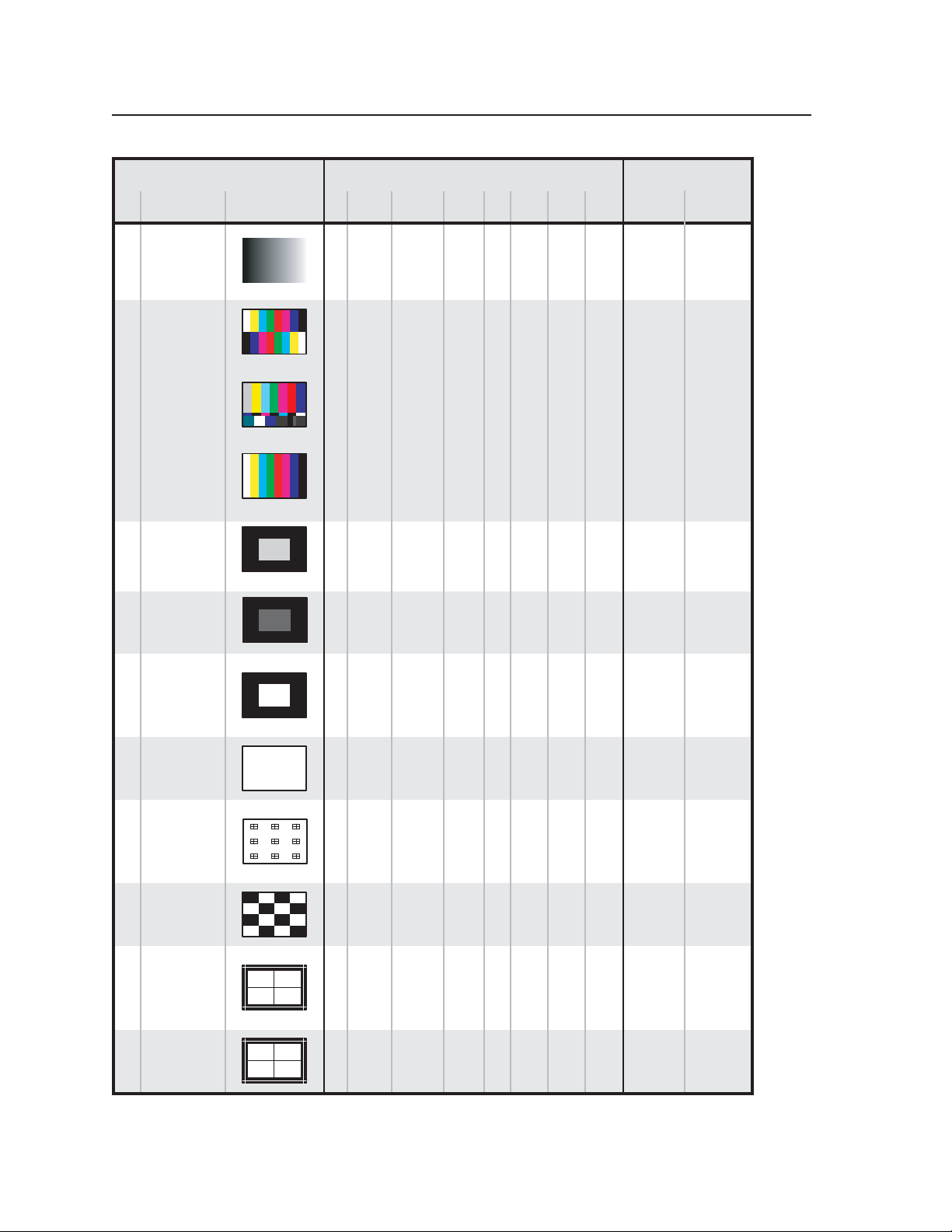

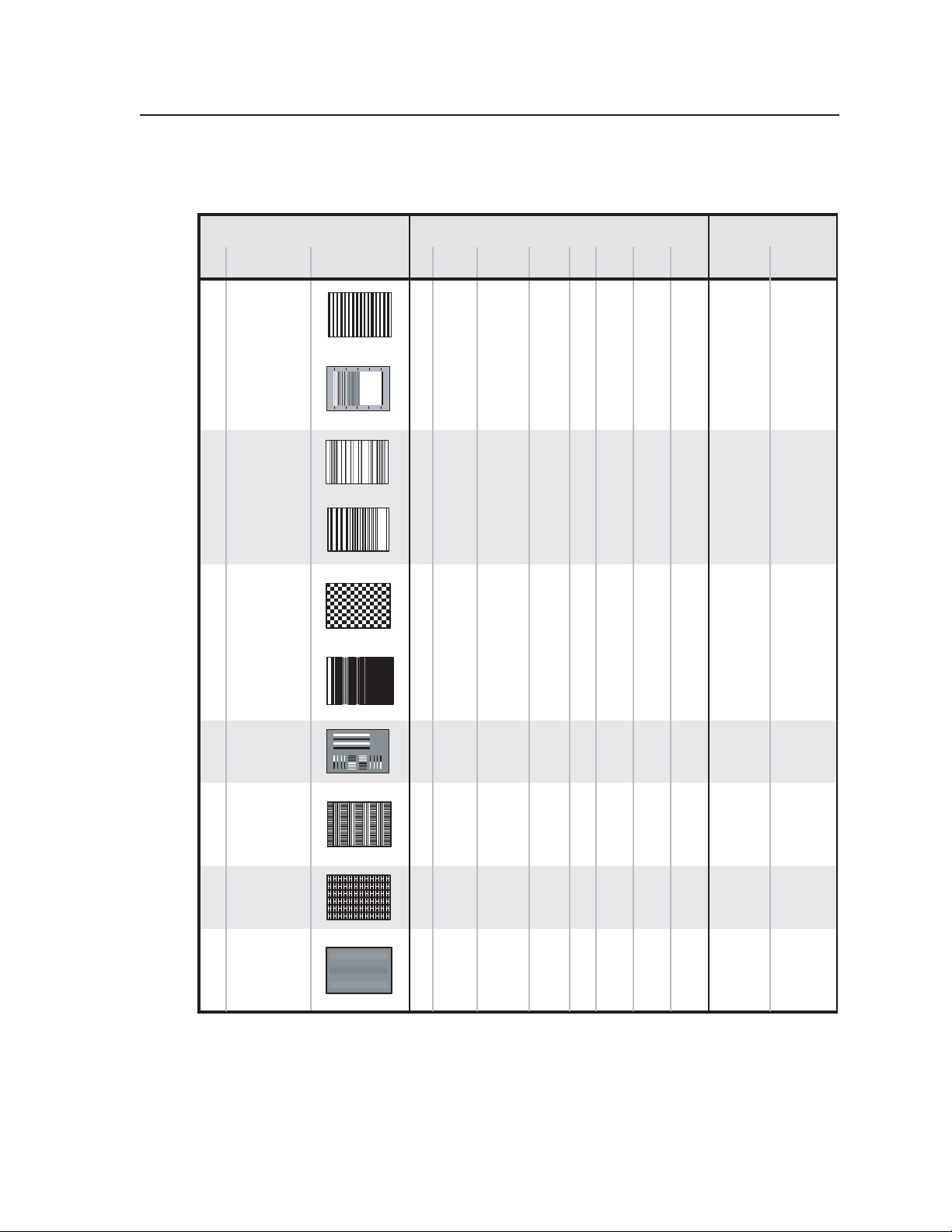

Test Patterns Chart .......................................................................................................... A-5

Test Patterns in Detail ................................................................................................... A-8

1. Circles ............................................................................................................................ A-8

2. Safe Area (5%/10%)..................................................................................................... A-8

3. Focus ............................................................................................................................. A-8

4. 16:9 Crop (4:3 rates)..................................................................................................... A-9

4:3 Crop (16:9 rates) .................................................................................................. A-9

5. Rectangle/Square Crosshairs ....................................................................................... A-9

6. 4x4 Crosshatch ............................................................................................................. A-9

7. Coarse Crosshatch ........................................................................................................ A-9

8. Fine Crosshatch .......................................................................................................... A-10

9. PLUGE .......................................................................................................................... A-10

Setting Black Level ........................................................................................................... A-10

Contrast Gain ................................................................................................................... A-11

10. 32-Level Split Grayscale .......................................................................................... A-11

11. Extreme Grayscale ................................................................................................... A-11

12. Ramp ......................................................................................................................... A-12

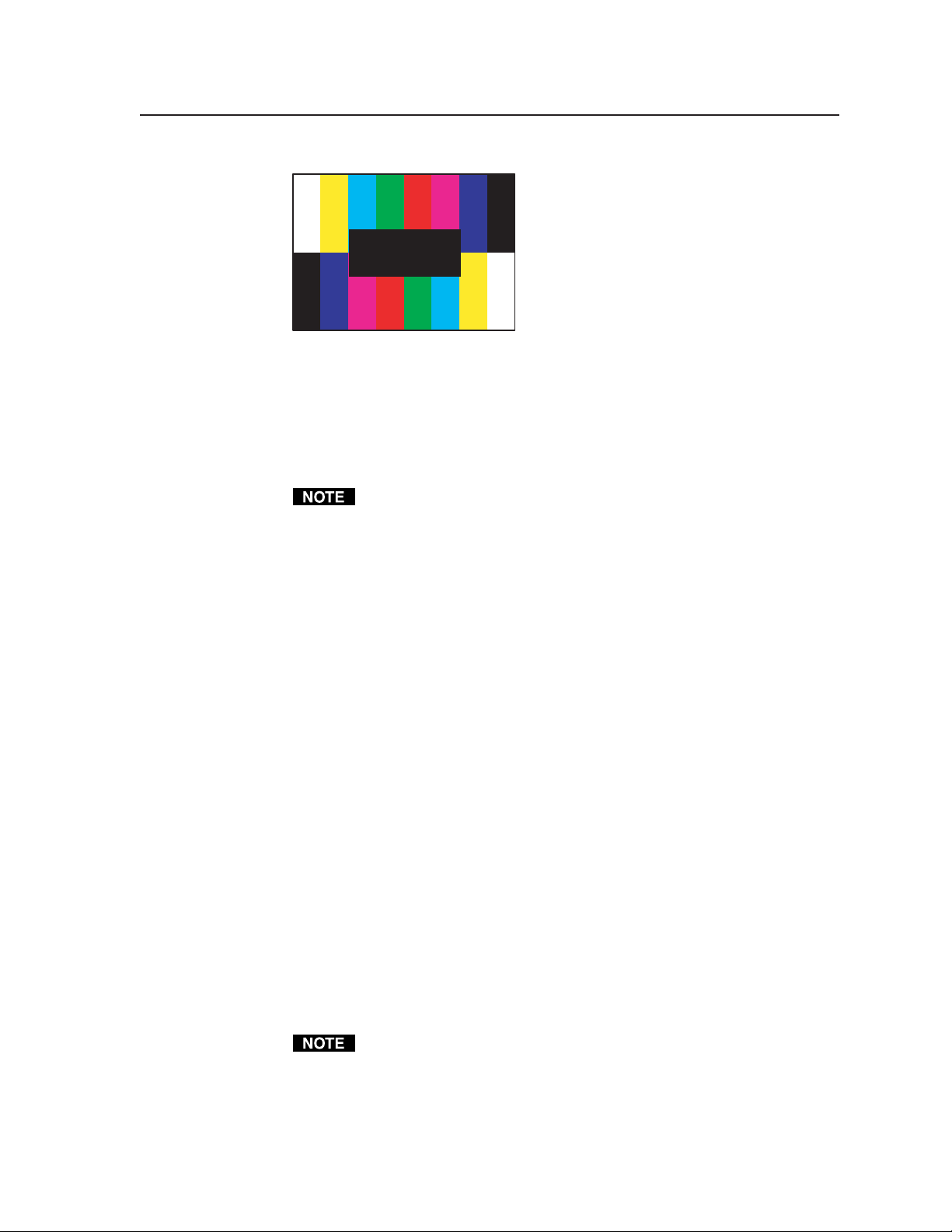

13. Color Bars (8-color split) ......................................................................................... A-12

SMPTE Color Bars (with PLUGE pattern) ............................................................... A-12

EBU Color Bars (8-color full bars) .......................................................................... A-13

14. Window 80% ........................................................................................................... A-13

15. Window 20% ........................................................................................................... A-14

16. Window (variable level) ......................................................................................... A-14

17. Flat Field ................................................................................................................... A-14

18. Flat Field with Targets ............................................................................................ A-14

19. Checkerboard ........................................................................................................... A-15

20. Bounce (automatic) ................................................................................................. A-15

21. Bounce (manual toggle) ......................................................................................... A-15

22. Alternating Pixels (1 on, 1 off) ............................................................................... A-16

Frequency Sweep .................................................................................................... A-16

23. Graphics Multiburst ................................................................................................. A-16

VTG 400D/400 DVI • Table of Contents

iii

Page 8

Table of Contents, cont’d

Multiburst ................................................................................................................ A-16

24. Alternating Pixels (2-dimensional) ........................................................................ A-17

Multipulse ................................................................................................................ A-17

NTSC Multipulse ............................................................................................................... A-17

PAL Multipulse.................................................................................................................. A-18

25. Transient Response .................................................................................................. A-18

26. Contrast Transfer Function (CTF) ............................................................................ A-19

27. H Pattern ................................................................................................................... A-19

28. Hum Bar Detect ........................................................................................................ A-20

VTG 400D/400 DVI Video Output Scan Rate Table ........................................ A-21

All trademarks mentioned in this manual are the properties of their respective owners.

iv VTG 400D/400 DVI • Table of Contents

68-786-01 Rev. C

04 09

Page 9

VTG 400D/400 DVI

Chapter One

1

Introduction

About this Manual

About the VTG 400D/400 DVI

Other Features

Page 10

Introduction

About this Manual

This manual discusses how to set up and operate the Extron VTG 400D/400 DVI

programmable video test generator.

Throughout this manual the terms “VTG”, “video test generator”, and

“VTG 400D/400 DVI” are used interchangeably to refer to the same products.

About the VTG 400D/400 DVI

The Extron VTG 400D and VTG 400 DVI are advanced, programmable, and

upgradeable video and audio test generators that deliver accurate, wide

bandwidth video signals and high performance audio test signals. These test

generators are professional quality reference tools for setup, performance

evaluation, calibration, and troubleshooting audio and video systems.

The VTG 400D/400 DVI offers a comprehensive array of video test patterns, as

well as a suite of audio reference signals. Video is output simultaneously as

RGB, component video, S-video, and composite video. An SDI and HDSDI

output is included with the VTG 400D. A DVI-D output is included with the

VTG 400 DVI.

The VTG is designed to provide a wide variety of reference signal types. A total

of 113 output scan rates are available for high resolution computer video, as well

as HDTV, NTSC, and PAL. Up to 183 additional rates can be programmed into

the VTG.

A powerful and innovative feature is the Scope-Trigger

which enables analysis of a selected area within the video image using an

oscilloscope. Scope-Trigger greatly simplifies and speeds up oscilloscope

setup for video signals by using a specially generated trigger signal precisely

timed to a user-defined target location on the image.

™

output (patent pending),

Other Features

Video output connectors — RGB, composite, and component video are output

via BNC connectors or a 15-pin HD connector (RGB). S-video is output

from a 4-pin mini DIN connector. SDI/HDSDI (VTG 400D) is output via a

BNC connector. DVI-D (VTG 400 DVI) is output via a DVI-I connector.

Audio output connectors — Audio outputs are via a 3-pin XLR connector for

balanced audio, a 3.5 mm phone jack for unbalanced left and right audio,

and an RCA jack (except the VTG 400 DVI) for unbalanced audio.

Scope-Trigger cursor — The Scope-Trigger cursor may be visible or invisible. If

visible, the cursor may be either a crosshair or single pixel and can be

positioned anywhere within the video signal using the directional cursor

buttons.

RS-232 remote control — The VTG can be remotely controlled by a host

computer via an RS-232 control port utilizing Extron’s Simple Instruction

Set (SIS

control software.

Flash-upgradeable firmware — The VTG’s firmware can be updated using the

Windows-based Control program via the RS-232 port.

Nonvolatile memory — The VTG retains its configuration settings after the

video test generator has been powered off.

™

) of basic ASCII commands or through the Windows®-based

VTG 400D/400 DVI • Introduction1-2

Page 11

VTG 400D/400 DVI

Chapter Two

2

Installation and Operation

Application Example

Tabletop or Desktop Placement

Rear Panel Connectors and Cabling

Connecting Audio Outputs

Top Panel Features

Audio Testing Features

Menus, Configuration, and Adjustments

Additional Functions

Page 12

Installation and Operation

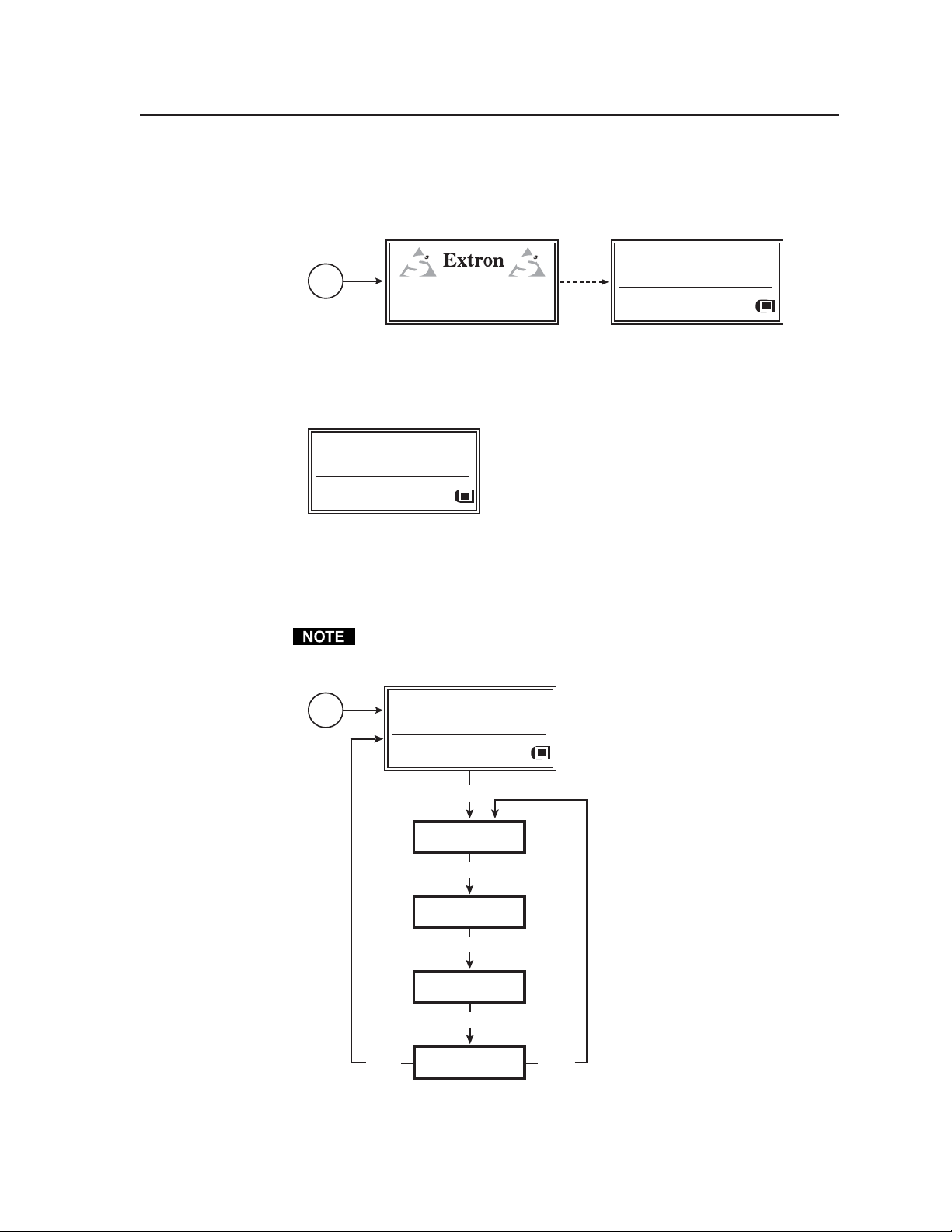

Application Example

The illustration below is one example of implementing the VTG 400D.

Extron 15 pin HD

VGA Cable

3

AUDIO

FREQUENCY

TRIGGER

1

2

AUDIO

SIGNAL

TYPE

LEVEL

ON/OFF

I.T.E.

1T23

LISTED

MENU

RS-232

SDI/HDSDI

A/V SETUP:

Audio Level Units

dBu

dBV mV

Freq. Sweep Speed:

1.5 sec

QUICK

SCOPE-TRIGGER

SELECT

1

2

3

CURSOR

SHAPE HIDE

4

COMPOSITE

S-VIDEO R-Y Y B-Y RGB

R G B H/HV V

VTG 400

PROGRAMMABLE VIDEO TEST GENERATOR

VIDEO

TEST

PATTERN

RANGE

NEXT

RATE

SELECT

50-60Hz

100-240V 0.3A

Extron

VTG 400D

Video Test Generator

Tabletop or Desktop Placement

For tabletop or desktop placement, install the self-adhesive rubber feet/pads

(provided) onto the four corners of the bottom of the enclosure

VTG 400D/400 DVI • Installation and Operation2-2

Page 13

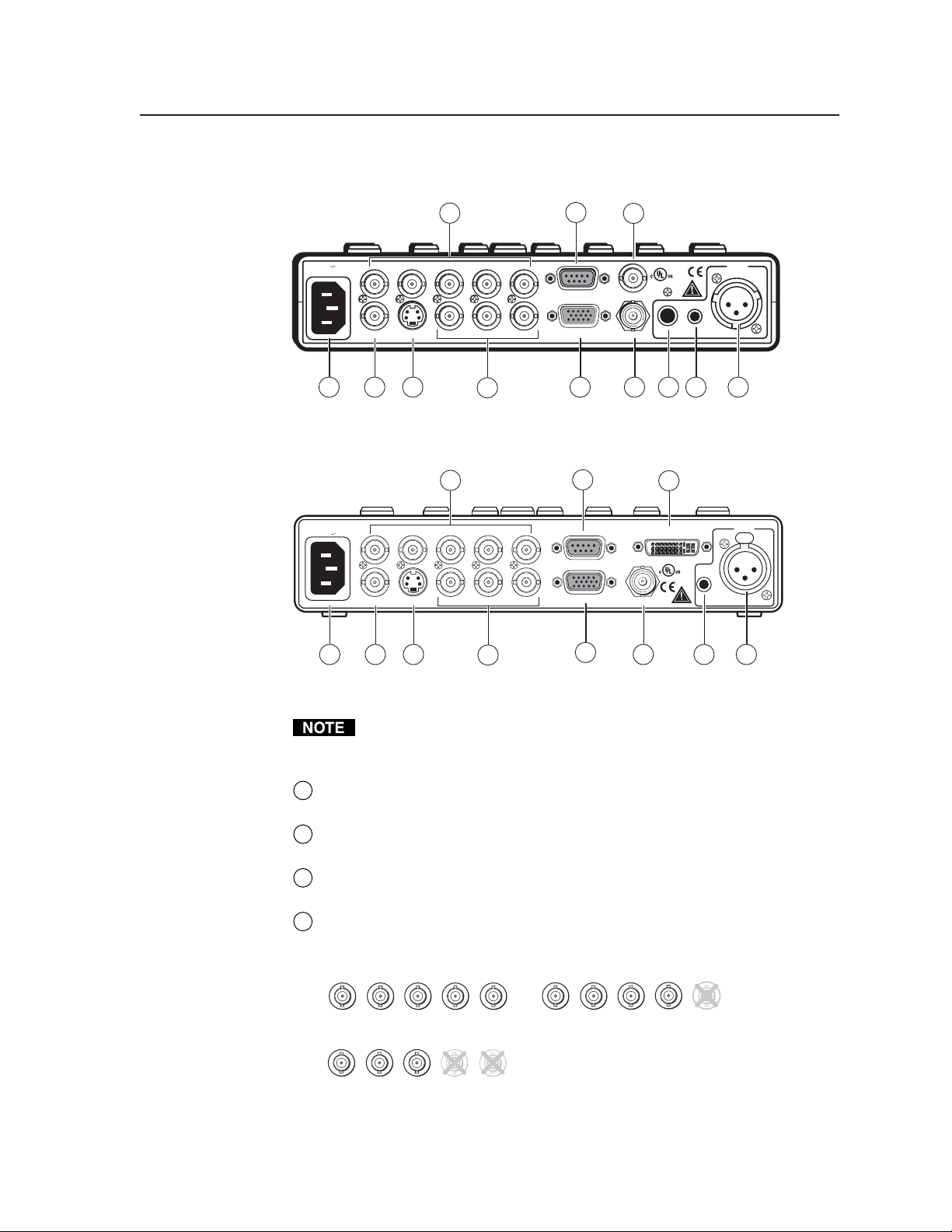

Rear Panel Connectors and Cabling

4

100-240V 0.3A

50-60Hz

1 2 3 6 9 10 11 12

R G B H/HV V

COMPOSITE

S-VIDEO R-Y Y B-Y RGB

5

7

RS-232

8a

SDI/HDSDI

TRIGGER

LISTED

1T23

I.T.E.

2

1

VTG 400D rear panel connectors

100-240V 0.3A

COMPOSITE

50-60Hz

1 2 3

4

RGBH/HVV

S-VIDEO R-Y Y B-Y

5

7

RS-232

RGB

6

8b

DVI-D

LISTED

1T23

I.T.E.

TRIGGER

9 11 12

AUDIO

3

AUDIO

23

VTG 400 DVI rear panel connectors

RGB video, component video, composite video, S-video, SDI/HDSDI

(VTG 400D only), and DVI-D (VTG 400 DVI only) video are output

simultaneously.

AC power connector — Plug a standard IEC power cord into the connector

1

to connect the VTG to a 100 to 240 VAC, 50-60 Hz power source.

Composite video output connector — Composite video is output through

2

this BNC connector.

S-video output connector — S-video is output through this 4-pin mini DIN

3

connector.

RGB computer video output connectors — Connect a display device to the

4

five female BNC connectors for RGBHV, RGBS, RGsB, or RsGsBs video

output, as follows:

/HV

R

B

G

H

RGBHV output

/HV

R

B

G

H

RGsB, RsGsBs output

V

R

G

RGBS output

V

/HV

B

V

H

2-3VTG 400D/400 DVI • Installation and Operation

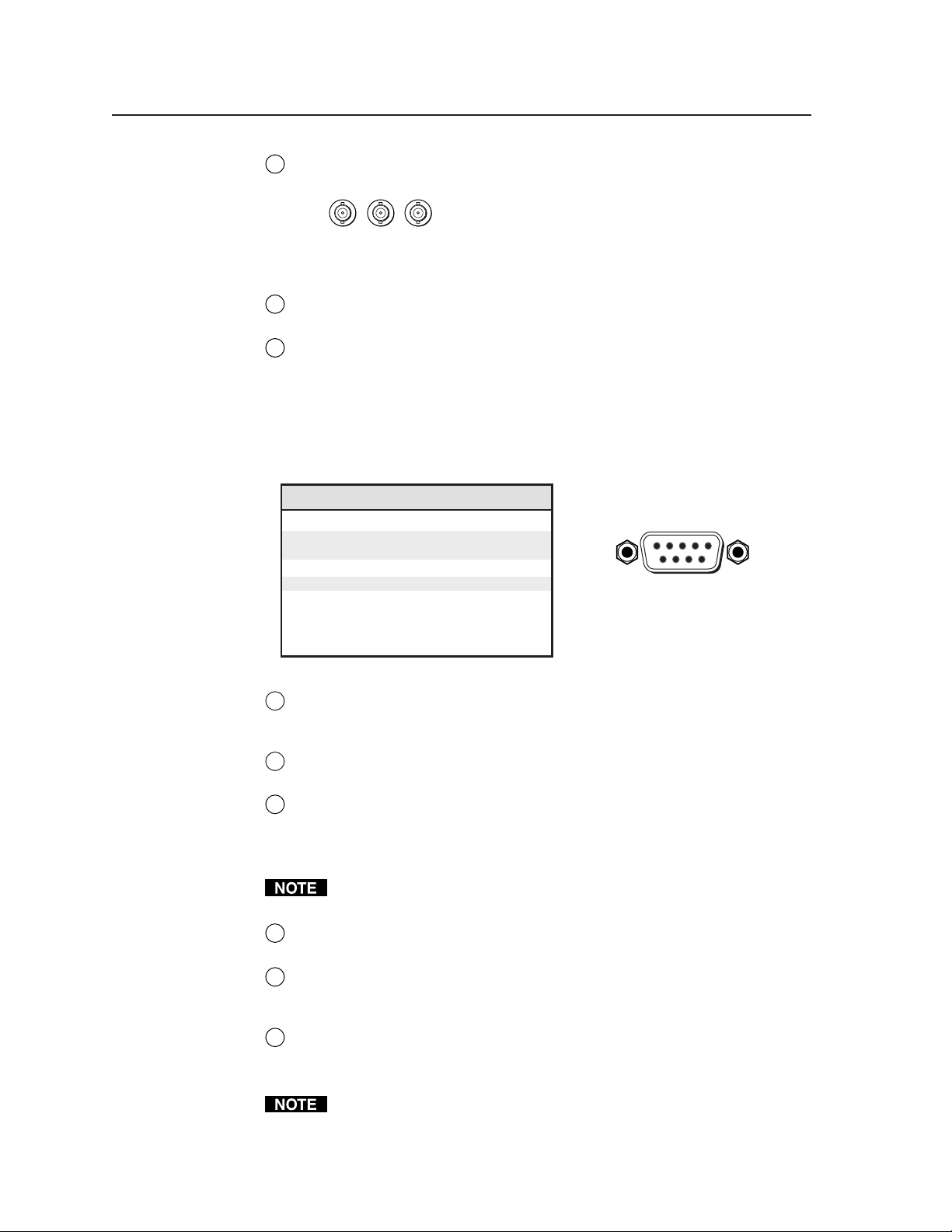

Page 14

Installation and Operation

DB9 Pin Locations

Female

51

96

R-Y, Y, B-Y component video output connectors — Connect a display

5

device to the three female BNC connectors for component video output:

R-Y

Component video output

(R-Y, Y, B-Y)

15-pin RGB output connector — RGBHV, RGBS, RGsB, and RsGsBs are

6

B-Y

Y

output through this 15-pin HD connector.

RS-232 port — This 9-pin female D connector provides for two-way RS-232

7

communication. See chapter three, “Serial Communication”, for

information on how to install and use the control software and SIS

commands.

The default protocol is 9600 baud, 1 stop bit, no parity, and no flow control.

The rear panel RS-232, 9-pin connector has the following pin assignments:

Pin RS-232 function Description

1 – No connection

2 Tx Transmit data

3 Rx Receive data

4 – No connection

5 Gnd Signal ground

6 – No connection

7 – No connection

8 – No connection

9 – No connection

SDI/HDSDI serial digital interface output connector (VTG 400D only) —

8a

Connect an output device to the SDI/HDSDI component output female

BNC.

DVI-I output connector (VTG 400 DVI only) — Connect an output device

8b

to receive the DVI-D signal from the female DVI-I output connector.

Trigger output connector — Connect an oscilloscope to this female BNC

9

connector when using an oscilloscope to align its display to a specific point

in the video waveform.

The oscilloscope’s external trigger needs to be configured to accept a TTL

level (0 to 5 V) signal.

RCA jack (Audio output 1) — Unbalanced mono audio is output from this

10

female jack. See the note below.

3.5 mm mini stereo phone jack (Audio output 2) — Unbalanced mono

11

audio on both left and right channels is output from this female mini phone

jack. See the note below.

XLR audio output connector (Audio output 3) — Balanced mono audio is

12

output from this 3-pin male connector.

See Connecting Audio Outputs later in this chapter for audio wiring

instructions.

VTG 400D/400 DVI • Installation and Operation2-4

Page 15

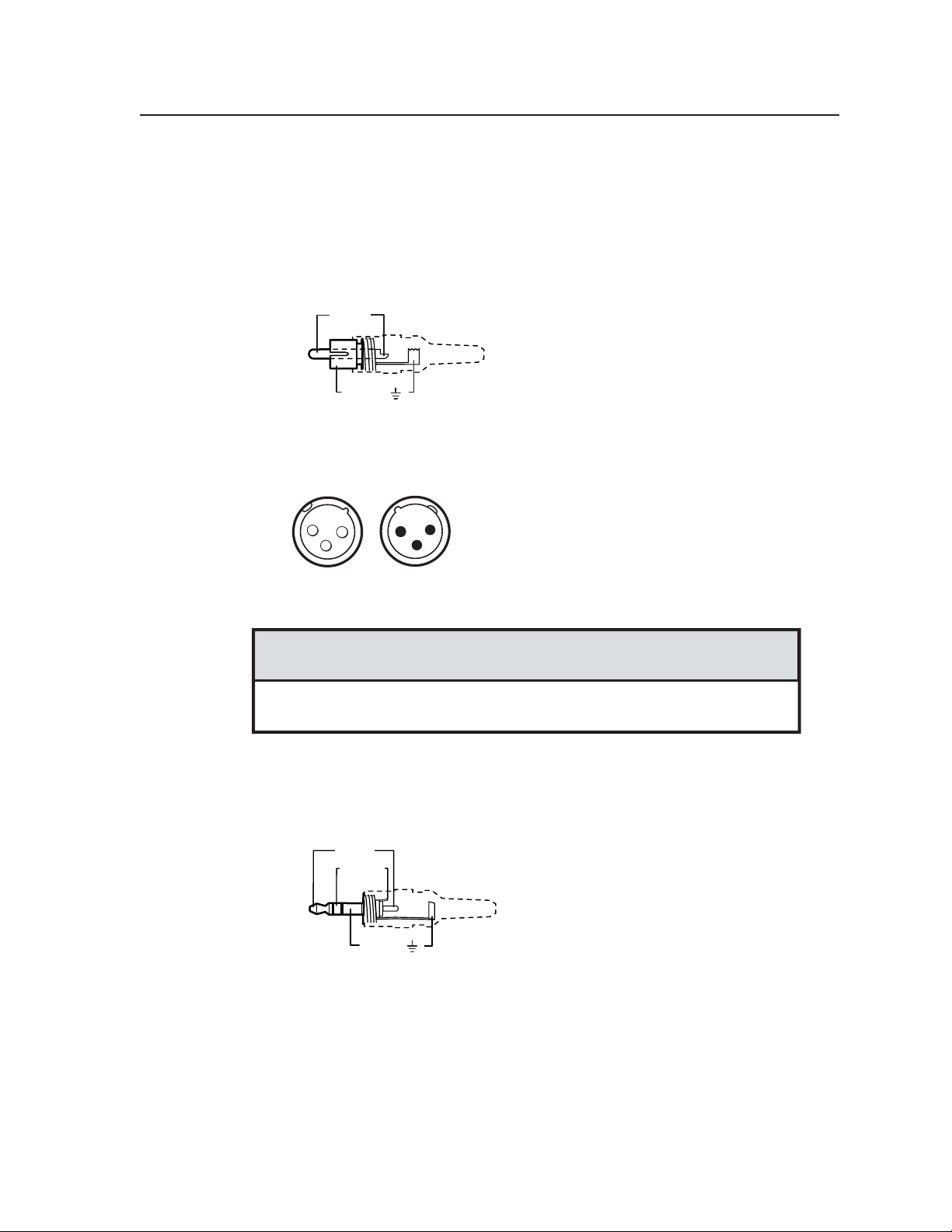

Connecting Audio Outputs

The VTG has three types of audio output connectors: an RCA jack

(VTG 400D only), a 3-pin XLR connector, and a 3.5 mm mini stereo phone jack.

RCA connector

Unbalanced mono audio is output from this connector. Wire the RCA connector

as shown here.

Tip (+)

Sleeve ( )

XLR connector

Balanced mono audio is output from this connector. Wire the female XLR

connector as shown here.

1

3-pin

Male

2

3

3

2

3

3-pin

Female

3

1

3-pin XLR Pin Configuration

Application Pin 1 Pin 2 Pin 3

Balanced audio (std.) ground (shield) positive (+) negative (-)

(on sending/female connector) (hot/live) (cold/return)

Mini stereo plug

Unbalanced mono audio on both left and right channels is output from this

connector. Wire the mini phone plug as shown here.

Tip (L)

Ring (R)

Sleeve ( )

2-5VTG 400D/400 DVI • Installation and Operation

Page 16

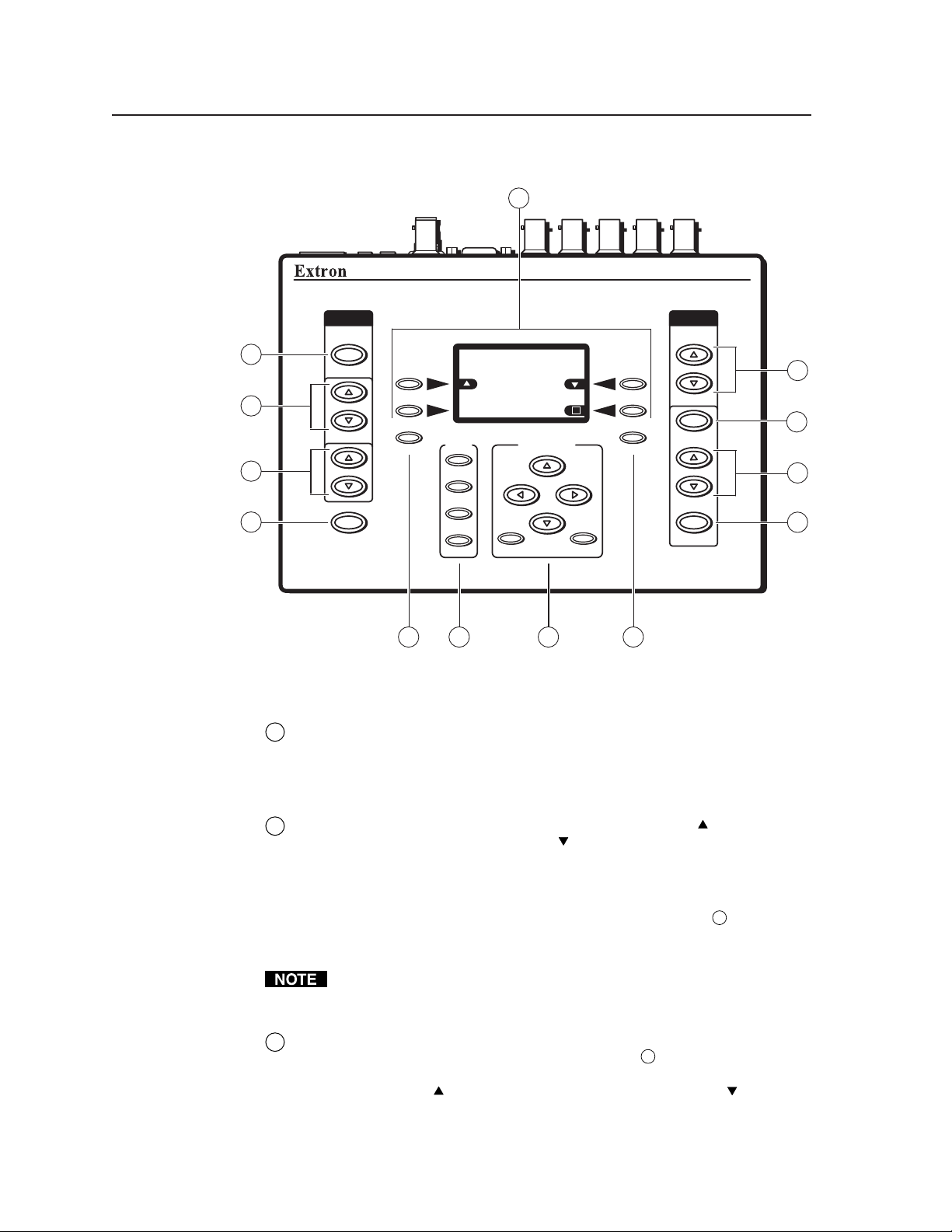

Installation and Operation, cont’d

Top Panel Features

13

AUDI O

SIGNAL

TYPE

1

RES: NTSC 720X485

FRQ:15.70kHz 60/30Hz

Checkerboard 100%

2

3

LEVEL

MENU

FREQUENCY

4

POWER

SIG:Pink noise FRQ:N/A

LEV:-18dBu 97.6mV

QUICK

SELECT

1

2

3

4

6 75 8

VTG 400D/400 DVI top panel features

SCOPE-TRIGGER

CURSOR

SHAPE HIDE

VIDEO

TEST

PATTERN

RANGE

RATE

SELECT

VTG 400

VIDEO & AUDIO TEST GENERATOR

NEXT

9

10

11

12

Audio signal type (Signal Type) — Press this button to select from among

1

seven different audio test signals: pink noise, white noise, sine wave,

square wave, frequency sweep, polarity test, and sine burst. The signal type

is indicated on the LCD display. See Selecting audio signals later in this

chapter.

Audio output signal level adjustment (Level) — Press the button to

2

increase the RMS signal level and the

button to decrease the RMS signal

level. See the Audio Setup menu section in this chapter to specify either dBu

or dBV as the signal level unit. The level setting is indicated on the LCD

display.

The audio output level settings for all audio signal types (see

1

above) are

retained after the VTG is powered off. The default setting is -28 dBu for

polarity test and -10 dBu for all other signal types.

If the Level buttons are held down for more than one second, the VTG

automatically advances through the level adjustment in the direction

indicated by the button.

Audio frequency adjustment (Frequency) — When the audio signal type

3

is either sine wave, square wave, or sine burst (see

1

above), the audio

frequency can be adjusted from 20 Hz to 20 kHz (sine) or 20 Hz to 5 kHz

(square). Press the

button to increase the frequency and the button to

decrease the frequency. The adjustment is in 1/12 octave steps. See Setting

the audio frequency later in this chapter. The audio frequency is indicated on

the LCD display.

VTG 400D/400 DVI • Installation and Operation2-6

Page 17

If the Frequency buttons are held down for more than one second, the VTG

automatically advances through the frequency adjustment in the direction

indicated by the button.

Power — Power up or power down the VTG by holding down the Power

4

button for one second.

Menu — Press this button to enter the main menus and to move from menu

5

to menu.

Quick Select — Press these buttons to save and recall up to four user-

6

defined presets of current audio settings, video settings, or all settings. See

Quick select buttons later in this chapter.

Scope Trigger adjustment — Press the cursor buttons to position the

7

oscillosope’s trigger point, press the Shape button to toggle between a

crosshair or single pixel on-screen cursor, and press the Hide button to

make the cursor visible or invisible. See Scope trigger buttons in this chapter.

Next — Press this button to enter a specific submenu of a selected main

8

menu.

Video test pattern (Test Pattern) — Press the or button to select from

9

among 28 different test patterns. See Selecting a Video Test Pattern later in

this chapter.

Video output range (Range) — Pressing this button will display the video

10

output range menu. See Video output range menu later in this chapter.

Video output rate (Rate) — Press the or button to select from among

11

113 different output rates. See Video output range and rate buttons in this

chapter.

If the Rate buttons are held down for more than one second, the VTG

automatically advances through the video output rate adjustment in the

direction indicated by the button.

Select video settings (Select) — Press this button to accept the specified

12

video settings for the signal range (

LCD display and four arrow selection ( , ) buttons — View this

13

) and output rate ( 11 ).

10

five-row liquid crystal display to read the VTG status, menus, and options.

Use the four arrow selection buttons on either side of the LCD to select

function option icons, as shown in the example below.

AUDIO SETUP: <5 of 5>

Audio Mute:

ON

Square Wave Auto Attenuate

Press arrow selection buttons adjacent

to the function option icons. See the

table of Function Option Icons on the

right.

OFF

ON

OFF

Each arrow selection button is assigned to the adjacent function on the LCD

display. The following table identifies the different function option icons.

The VTG’s backlight times out after 10 seconds of button inactivity.

Pressing any button except the power button turns the backlight back on.

2-7VTG 400D/400 DVI • Installation and Operation

Page 18

Installation and Operation, cont’d

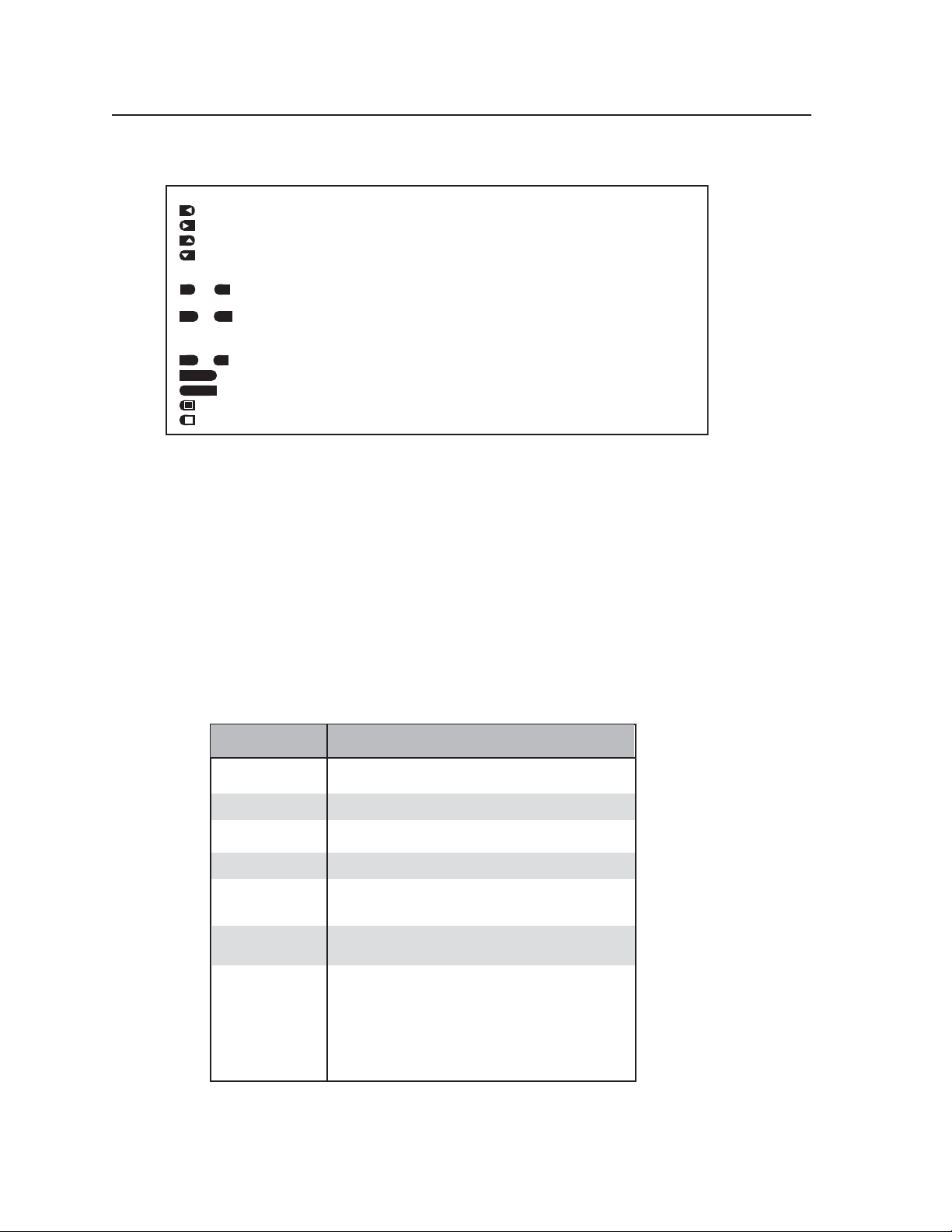

Function Option Icons

Cursor movement and option selection

— Press the button next to this icon to move the cursor left or select an option at the left of the LCD.

— Press the button next to this icon to move the cursor right or select an option at the right of the LCD.

— Press the button next to this icon to increment or scroll up to the next selection.

— Press the button next to this icon to decrement or scroll down to the previous selection.

State indication and option selection

ON

or — This icon indicates the function is on/active. Press the button next to this icon to toggle the

OFFONOFF

or — This icon indicates the function is off/not selected. Press the button next to this icon to toggle

Option selection

or — Press the button next to this icon to select “yes” or “no”.

YES

SAVE

SAVE

CANCEL

— Press the button next to this icon to invert the test pattern.

— Press the button next to this icon to return the test pattern from the inverted state to the original state.

Audio Testing Features

The VTG can selectively output seven different audio signal formats. The audio level can also be

selected from a range of levels available for each audio format.

Depending on the audio signal format, the audio frequency may be selected from a range of

values.

See the Top Panel Features section earlier in this chapter for button descriptions.

“on” state to “off”.

the “off” state to “on”.

NO

— Press the button next to this icon to save the current settings.

— Press the button next to this icon to cancel (not save) the current settings.

Selecting audio signals

The following table summarizes the seven audio signal formats available through the VTG.

Pressing the Signal Type button repeatedly scrolls through the signals and displays the signal type

on the LCD.

AUDIO

SIGNAL FORMAT

Pink Noise

White Noise

Sine Wave

Square Wave

Frequency Sweep

Polarity test

Sine Burst

Generates a sine wave of a specified frequency that is gated

on and off for fixed intervals. Used in testing the transient

response of audio systems.

• The burst interval is defined by the total number of cycles

(on and off) in each repeating period.

• The burst on duration is defined by the number of cycles

in the interval where the sine wave is turned on.

See the burst signal example below.

Random noise that has constant energy per octave.

Used in loudspeaker testing and calibration.

Random noise that has an equal energy distribution

across all frequencies between 20 Hz and 20 kHz.

Used in detecting distortion. The frequency can be set

from 20 Hz to 20 kHz (in 1/12 octave steps).

Square wave signal with 50% duty cycle and no DC offset.

The frequency can be set from 20 Hz to 5 kHz.

Varies the frequency of a sine wave signal continuously

over the specified frequencies. Used to detect driver

defects and mechanical sources of distortion.

Pulsed waveform (1 Hz pulse, positive-going, pulse width =

1ms, duty cycle = 0.1%) used in verifying the polarity of

audio wiring.

DESCRIPTION

VTG 400D/400 DVI • Installation and Operation2-8

Page 19

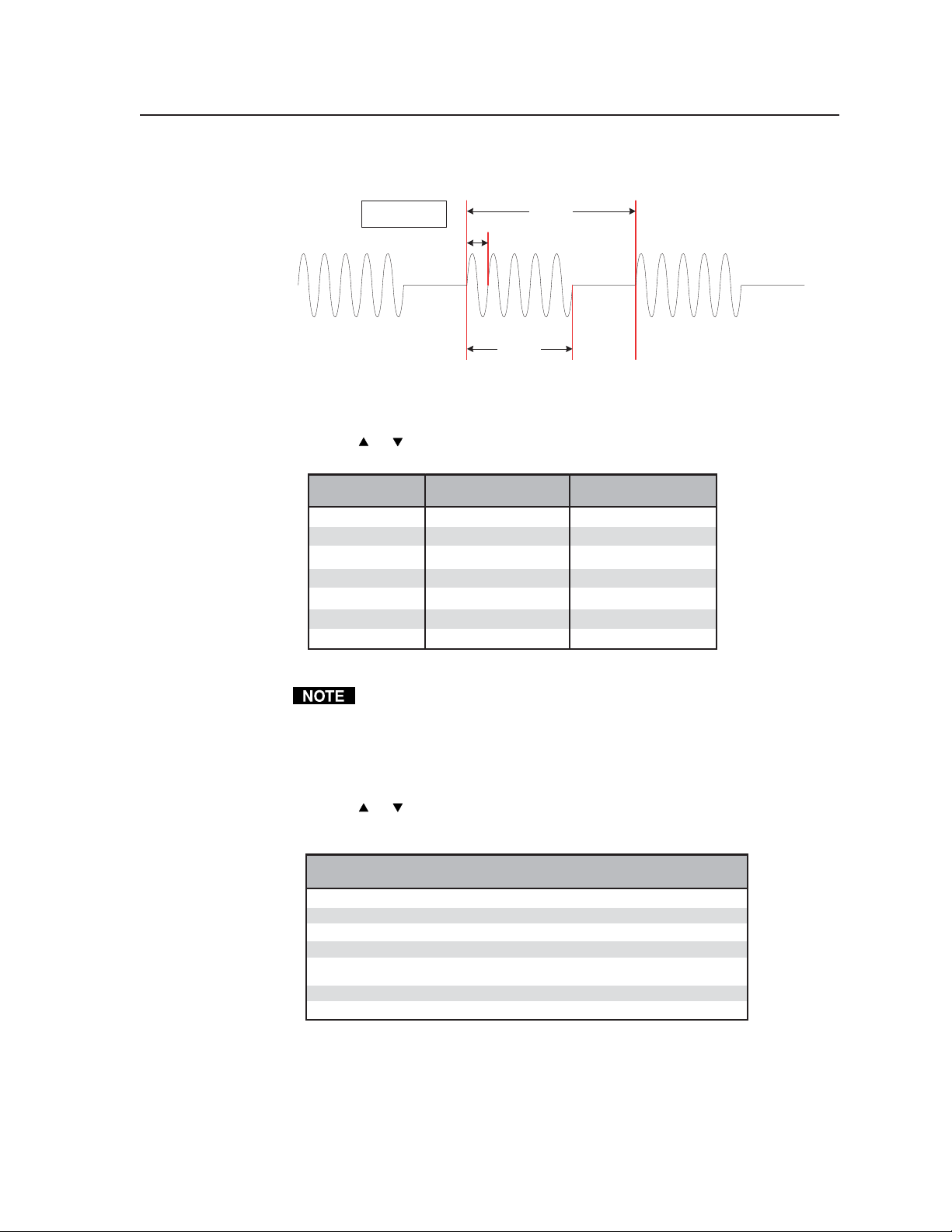

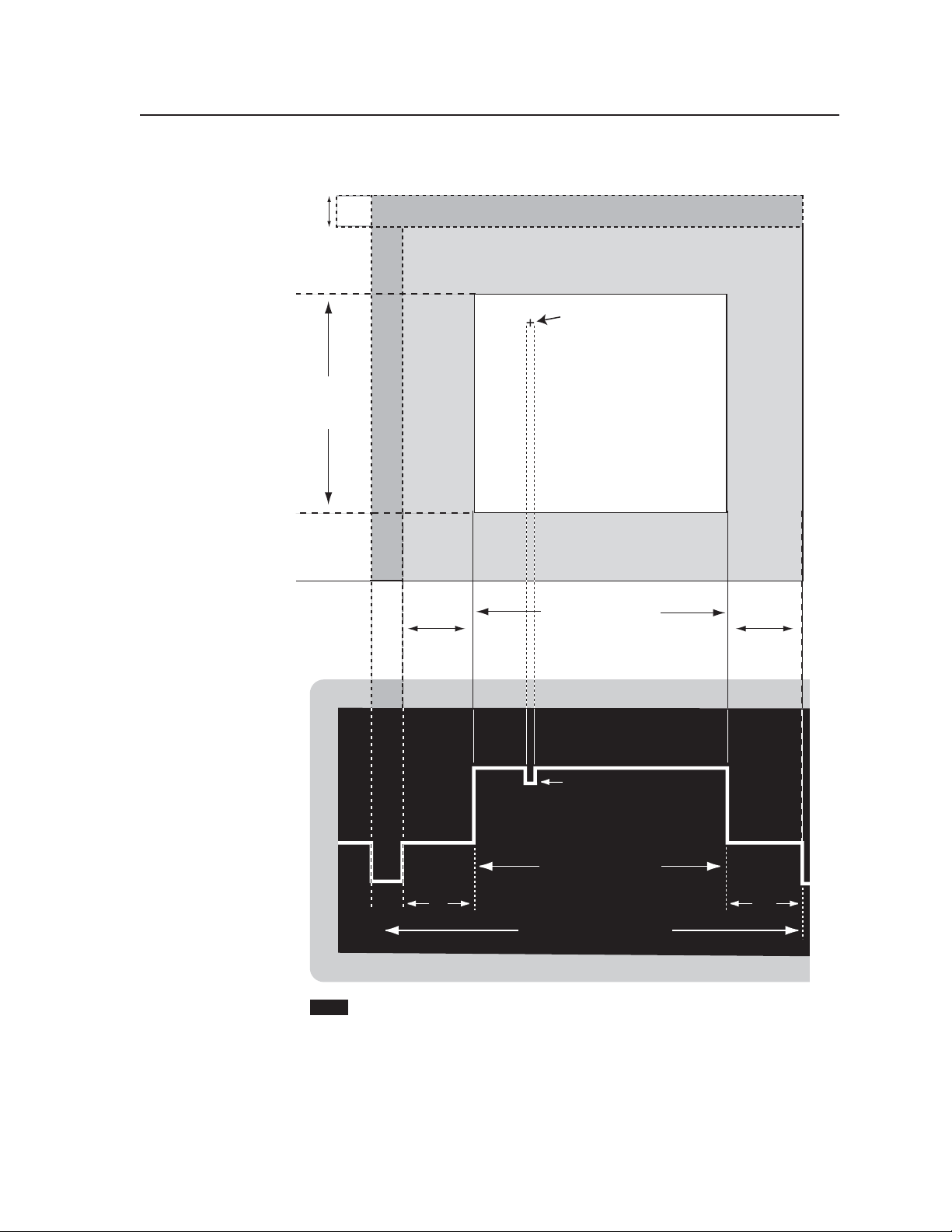

An example of the sine burst signal is shown in the following illustration:

Interval

= 8 Cycles

Burst On

= 5 Cycles

Burst Frequency

= 1 / Cycle

1

Cycle

Audio

Signal Format Audio Frequencies

Pink Noise N/A

White Noise N/A

Sine Wave 20 Hz through 20 kHz (see the following Audio Range chart)

Square Wave 20 Hz through 5 kHz (see the following Audio Range chart)

Frequency Sweep Sweep speed (in seconds): 120, 90, 60, 30, 20, 10, 9.0, 8.0, 7.0, 6.0,

5.0, 4.0, 3.0, 2.0, 1.0

Polarity Test 1 Hz

Sine Burst 20 Hz through 20 kHz (see the following Audio Range chart)

Setting the audio level

The audio level for each audio signal type is selected from a range of values

using the

Audio Audio Level Range Audio Level Range

Signal Format (in dBu increments) (in dBV increments)

Pink Noise -4 dBu to -72 dBu -6 dBV to -74 dBV

White Noise +6 dBu to -72 dBu +4 dBV to -74 dBV

Sine Wave +6 dBu to -72 dBu +4 dBV to -74 dBV

Square Wave +6 dBu to -72 dBu +4 dBV to -74 dBV

Frequency Sweep +6 dBu to -72 dBu +4 dBV to -74 dBV

Polarity Test -14 dBu to -72 dBu -16 dBV to -74 dBV

Sine Burst +6 dBu to -72 dBu +4 dBV to -74 dBV

or Level buttons. The following table lists the range of values.

Displayed levels are for high impedance loads. For 600 ohm loads, there is

a -0.7 dB (unbalanced) / -1.3 dB (balanced) difference between the displayed

and actual levels.

Setting the audio frequency

The audio frequency for each audio signal type is selected from a range of values

using the or Audio Frequency buttons and observing the LCD. The

following tables list the available frequencies.

2-9VTG 400D/400 DVI • Installation and Operation

Page 20

Installation and Operation, cont’d

Audio Range

20 Hz

21.2 Hz

22.4 Hz

23.6 Hz

25 Hz

26.5 Hz

28 Hz

30 Hz

31.5 Hz

33.5 Hz

35.5 Hz

37.5 Hz

40 Hz

42.5 Hz

45 Hz

47.5 Hz

50 Hz

53 Hz

56 Hz

60 Hz

63 Hz

67 Hz

71 Hz

75 Hz

80 Hz

85 Hz

90 Hz

95 Hz

100 Hz

106 Hz

112 Hz

118 Hz

125 Hz

132 Hz

140 Hz

150 Hz

160 Hz

170 Hz

180 Hz

190 Hz

200 Hz

212 Hz

224 Hz

236 Hz

250 Hz

265 Hz

280 Hz

300 Hz

315 Hz

335 Hz

355 Hz

375 Hz

400 Hz

425 Hz

450 Hz

475 Hz

500 Hz

530 Hz

560 Hz

600 Hz

630 Hz

670 Hz

710 Hz

750 Hz

800 Hz

850 Hz

900 Hz

950 Hz

1.0 kHz

1.06 kHz

1.12 kHz

1.18 kHz

1.25 kHz

1.32 kHz

1.40 kHz

1.50 kHz

1.60 kHz

1.70 kHz

1.80 kHz

1.90 kHz

2.00 kHz

2.12 kHz

2.24 kHz

2.36 kHz

2.50 kHz

2.65 kHz

2.80 kHz

3.00 kHz

3.15 kHz

3.35 kHz

3.55 kHz

3.75 kHz

4.00 kHz

4.25 kHz

4.50 kHz

4.75 kHz

5.00 kHz

5.30 kHz

5.60 kHz

6.00 kHz

6.30 kHz

6.70 kHz

7.10 kHz

7.50 kHz

8.00 kHz

8.50 kHz

9.00 kHz

9.50 kHz

10.00 kHz

10.60 kHz

11.20 kHz

11.80 kHz

12.50 kHz

13.20 kHz

14.00 kHz

15.00 kHz

16.00 kHz

17.00 kHz

18.00 kHz

19.00 kHz

20.00 kHz

Menus, Configuration, and Adjustments

VTG configuration and adjustments are performed by using top panel controls

and the menus that are displayed on the VTG’s LCD screen. The VTG can also

be controlled via either the Extron Simple Instruction Set (SIS™) commands or the

Windows-based control program (see chapter three for details).

Moving through menus by using front panel controls

Menu button — Press the Menu button to activate menus and to scroll to the

main menus. After 15 seconds of inactivity, the VTG times out and returns

to the default menu cycle.

Next button — Press the Next button to move between the submenus of a

selected main menu.

If a submenu is exited by pressing an audio or video adjustment button, the

NEXT button can be pressed from the default screen to return to that same

submenu.

Arrow selection (

the submenu options and to make selections. Refer to the flowcharts in this

chapter and to specific sections for explanations of cursor button selections.

, ) buttons — Use these buttons to scroll through

VTG 400D/400 DVI • Installation and Operation2-10

Page 21

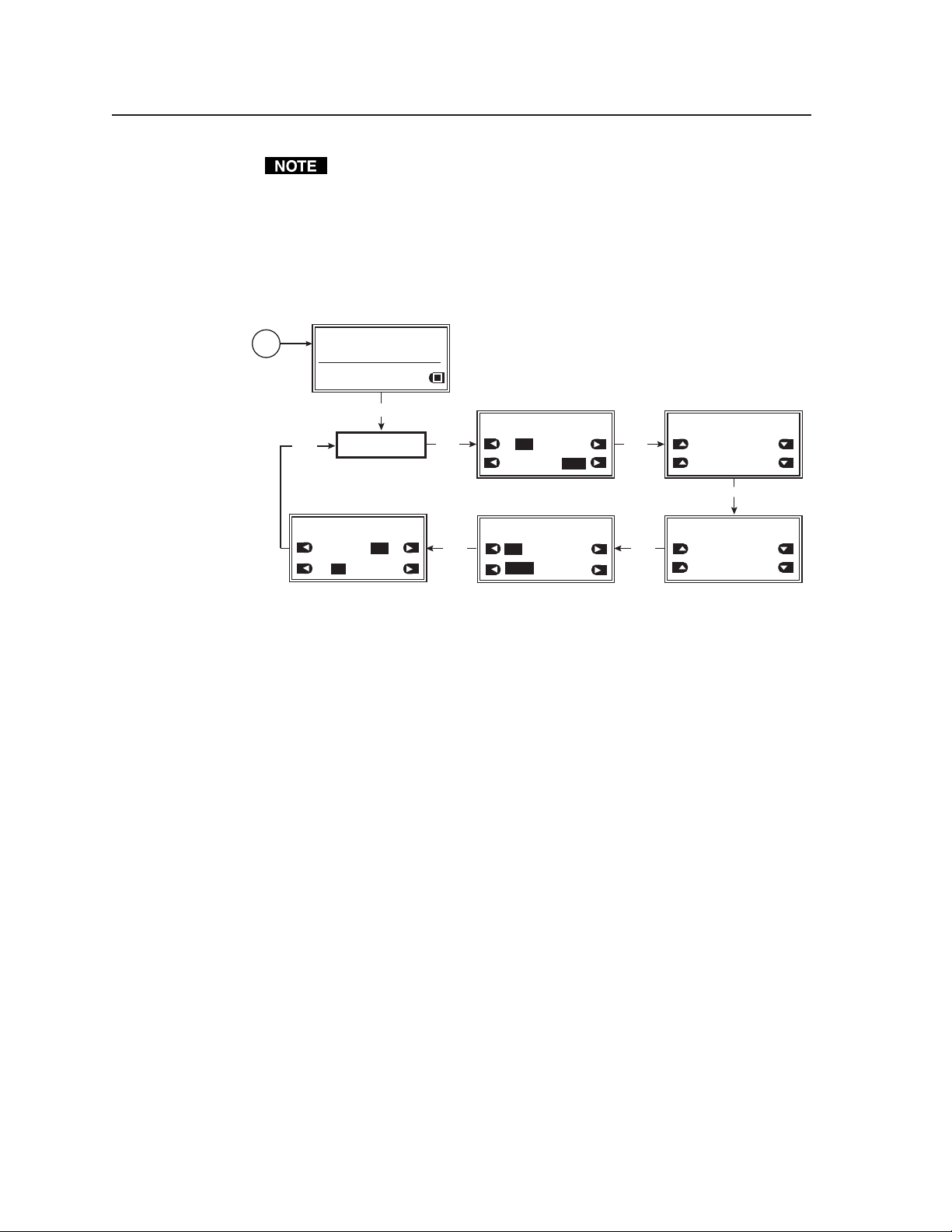

Menu overview

The default screen appears on the LCD when the unit is first powered on, as

shown here.

Power

on

Default menus during initial power up

If no top panel buttons are pressed within a 15-second timeout period, the

following menu is displayed. Both audio and video information are displayed.

RES: VGA 640x480

FRQ: 31.50kHz 60.00Hz

PAT: Fine Crosshatch

SIG: Pink noise FRQ: N/A

LEV: -10 dBu 245mV

Default menu after 15-second timeout

The main menus are shown in the following flowchart. The main menus for the

VTG 400D and VTG 400 DVI are identical. Use the Menu button to scroll

between main menus.

60-564-01 Ver. 1.00

VTG 400

VIDEO TEST GENERATOR

3 sec.

RES: VGA 640x480

FRQ: 31.50kHz 60.00Hz

PAT: Fine Crosshatch

SIG: Pink noise FRQ: N/A

LEV: -10 dBu 245mV

Power

on

From any menu or submenu, after 15 seconds of inactivity the VTG saves all

adjustment settings, and times out to the default screen.

RES: VGA 640x480

FRQ: 31.50kHz 60.00Hz

PAT: Fine Crosshatch

SIG: Pink noise FRQ: N/A

LEV: -10 dBu 245mV

MENU

AUDIO

SETUP

MENU

VIDEO

SETUP

MENU

ADVANCED

SETUP

MENU

NEXT

EXIT MENU

Press "NEXT" button

MENU

Main menus for the VTG

2-11VTG 400D/400 DVI • Installation and Operation

Page 22

Installation and Operation, cont’d

If you press the Menu button while a submenu is active, the next main menu

becomes active. For example, the menu changes from an Audio Setup

submenu (see the following menu) to the Video Setup main menu.

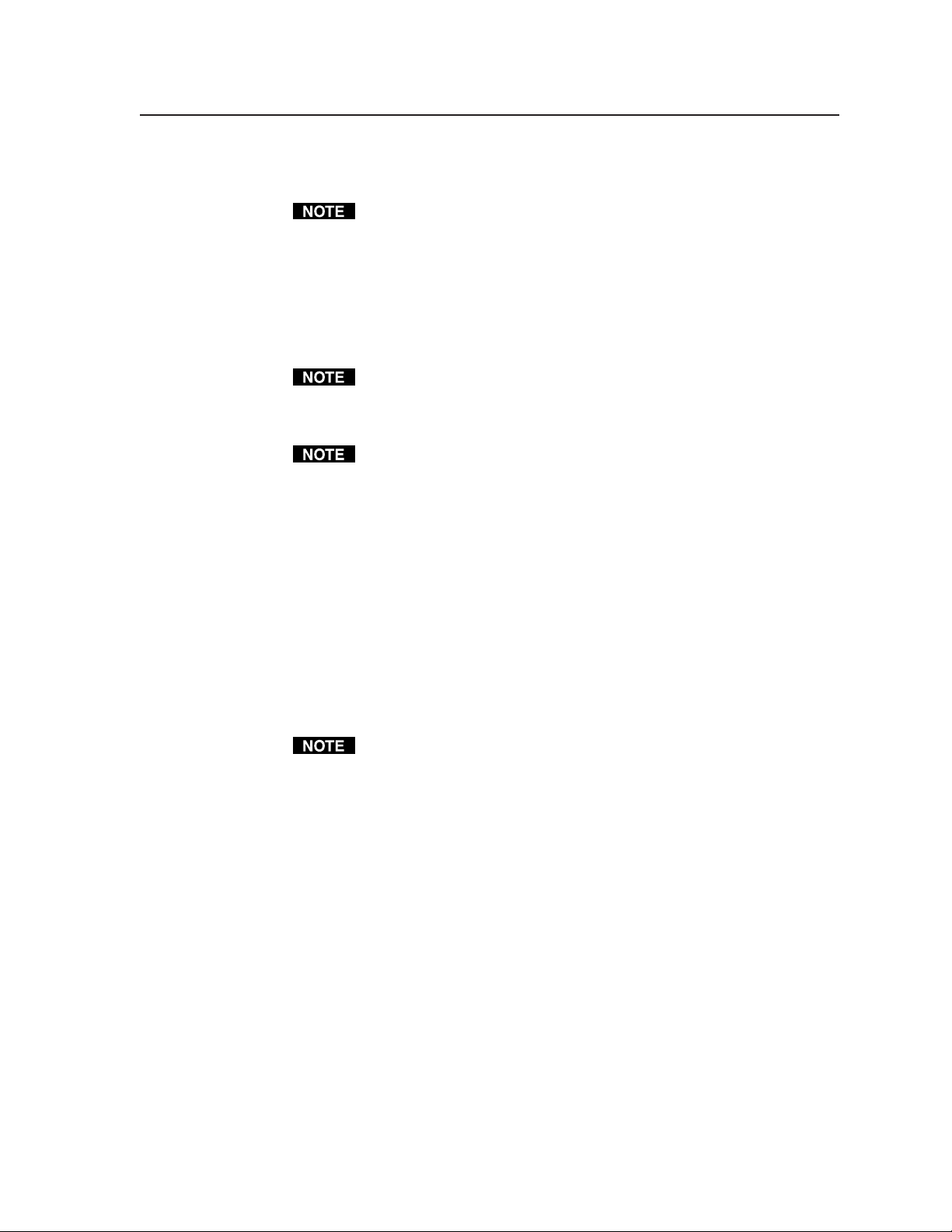

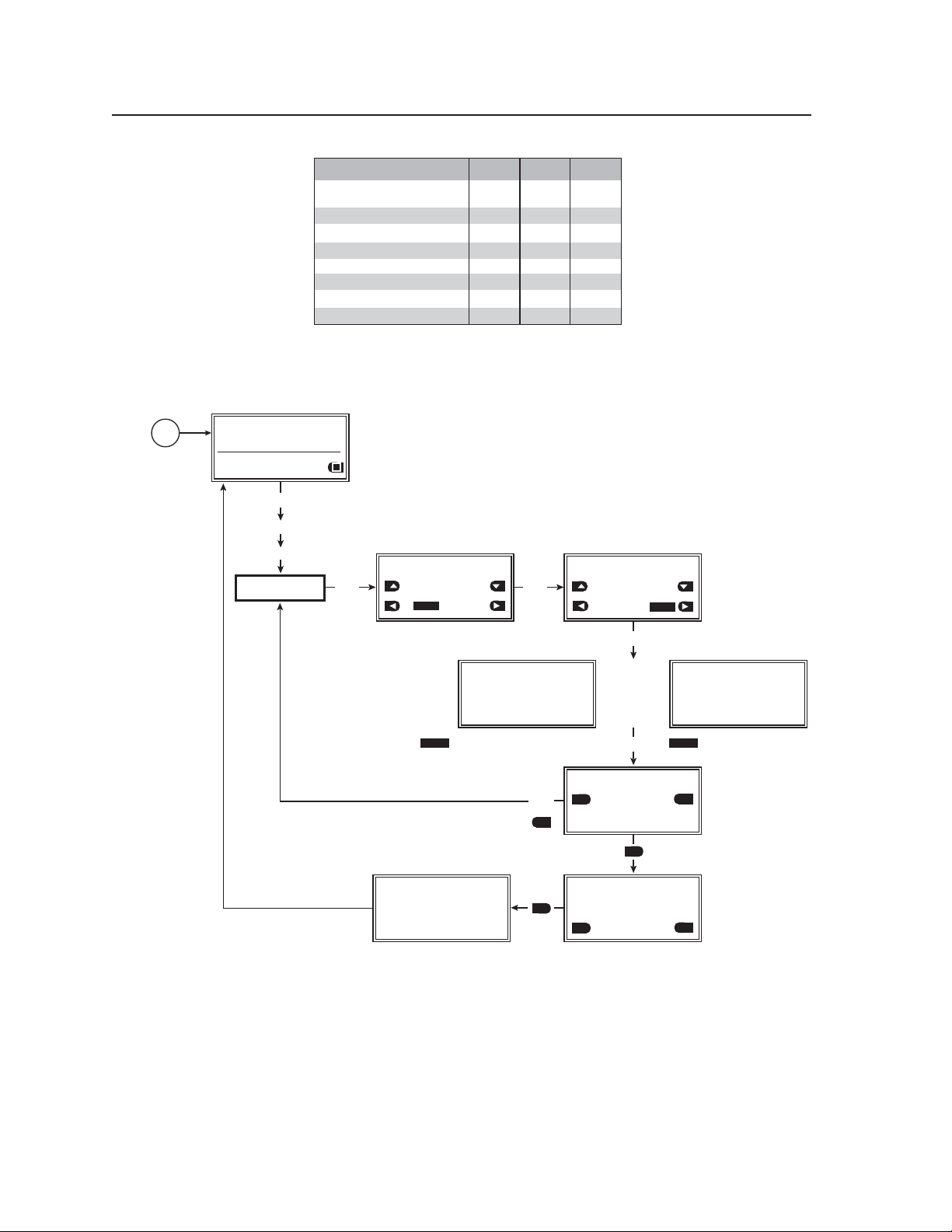

Audio Setup menu

The following flowchart illustrates the Audio Setup menu system. Pressing the

Next button displays the audio setup submenus.

Power

on

RES: VGA 640x480

FRQ: 31.50kHz 60.00Hz

PAT: Fine Crosshatch

SIG: Pink noise FRQ: N/A

LEV: -10 dBu 245mV

MENU

NEXT

AUDIO SETUP: <5 of 5>

Audio Mute:

ON

Square Wave Auto Attenuate

AUDI O

SETUP

OFF

ON

OFF

AUDIO SETUP: <1 of 5>

Audio Level Units:

NEXT

dBV

Output 2 Enable:

L+R Left

AUDIO SETUP: <4 of 5>

F. Sweep Format:

Log Linear

F. Sweep Direction:

Lo->Hi Hi->Lo

dBu

Right

AUDIO SETUP: <2 of 5>

Burst Interval

NEXT

00001 Cycle

Burst On

00001 Cycle

AUDIO SETUP: <3 of 5>

F. Sweep Start Freq:

NEXTNEXT

20.0 Hz

F. Sweep Stop Freq:

112 Hz

Audio setup menu

Audio Setup submenu (1 of 5)

Audio level units are specified from this submenu. The output channel(s) of

Audio output 2 is (are) also specified.

Audio level units

Specify the audio level unit for the VTG to display. Choose from among the

following unit types:

NEXT

• dBu (default)

• dBV

Output 2 enable

Specify the audio channel(s) to be output from Audio output 2 (3.5 mm mini

stereo phone jack). Specify from among the following channels:

• L+R [left and right] (default)

• Left

• Right

Audio Setup submenu (2 of 5)

The interval of the burst cycles and the amount of cycles in each burst are

specified from this submenu.

Burst interval

Specify the number of cycles per burst interval (0 through 65,535 cycles).

VTG 400D/400 DVI • Installation and Operation2-12

Page 23

Burst on

Specify the number of active cycles in each burst (0 through 65,535 cycles).

The number of active cycles in a burst must always be less than or equal to

the total number of cycles in an interval.

Audio Setup submenu (3 of 5)

The starting and ending frequencies of the frequency sweep audio test signal are

specified from this submenu.

F. Sweep Start Freq

Specify the frequency sweep start frequency (20.0 Hz through 19.0 kHz).

The start frequency can never be set greater than the stop frequency.

F. Sweep Stop Freq

Specify the frequency sweep stop frequency (21.2 Hz through 20.0 kHz).

The stop frequency can never be set lower than the start frequency.

Audio Setup submenu (4 of 5)

The format and direction of the frequency sweep audio test signal are specified

from this submenu.

F. Sweep Format

• Log (default) – sweep logarithmically (more time spent in the lower

frequencies)

• Linear – sweep linearly (equal time spent in each frequency)

F. Sweep Direction

• Lo->Hi – sweep from the start frequency to the stop frequency

• Hi->Lo – sweep from the stop frequency to the start frequency

See the Audio Setup submenu (3 of 5) earlier in this chapter.

Audio Setup submenu (5 of 5)

To prevent damage to connected audio equipment, audio muting and the

automatic attenuation of the square wave signal can be specified from this

submenu.

Audio Mute

• ON – enable audio muting

• OFF (default) – disable audio muting

Square Wave Auto Attenuate

• ON – automatically attenuate the square wave signal to -40 dBu when

toggling through the audio signals

• OFF (default) – disable automatic attenuation of the square wave signal

2-13VTG 400D/400 DVI • Installation and Operation

Page 24

Installation and Operation, cont’d

Video Setup menu

The following flowchart describes the Video Setup menu.

Power

on

RES: VGA 640x480

FRQ: 31.50kHz 60.00Hz

PAT: Fine Crosshatch

SIG: Pink noise FRQ: N/A

LEV: -10 dBu 245mV

MENU

MENU

VIDEO

SETUP

VIDEO SETUP: <1 of 4>

RGB Sync Format

NEXT

RGBHV

Raster Border:

ON

VIDEO SETUP: <4 of 4>

RGB Color Channel Enable:

NEXT

ON

RED GREEN

ON

BLUE

OFF

NEXT

ON

NEXT

Video Setup menu

Video Setup submenu (1 of 4)

The RGB sync format and a raster border are specified from this submenu.

RGB sync format

Specify the RGB sync format.

• RGBHV (default)

• RsGsBs

• RGsB

• RGBS

VIDEO SETUP: <2 of 4>

On-Screen Display:

ON

VIDEO SETUP: <3 of 4>

Auto Sequence Mode:

ON

Auto Sequence Interval:

15 seconds

OFF

NEXT

OFF

Raster border

A one-pixel-wide white border around the edge of the active area can be enabled

(on) or disabled (off).

• ON

• OFF (default)

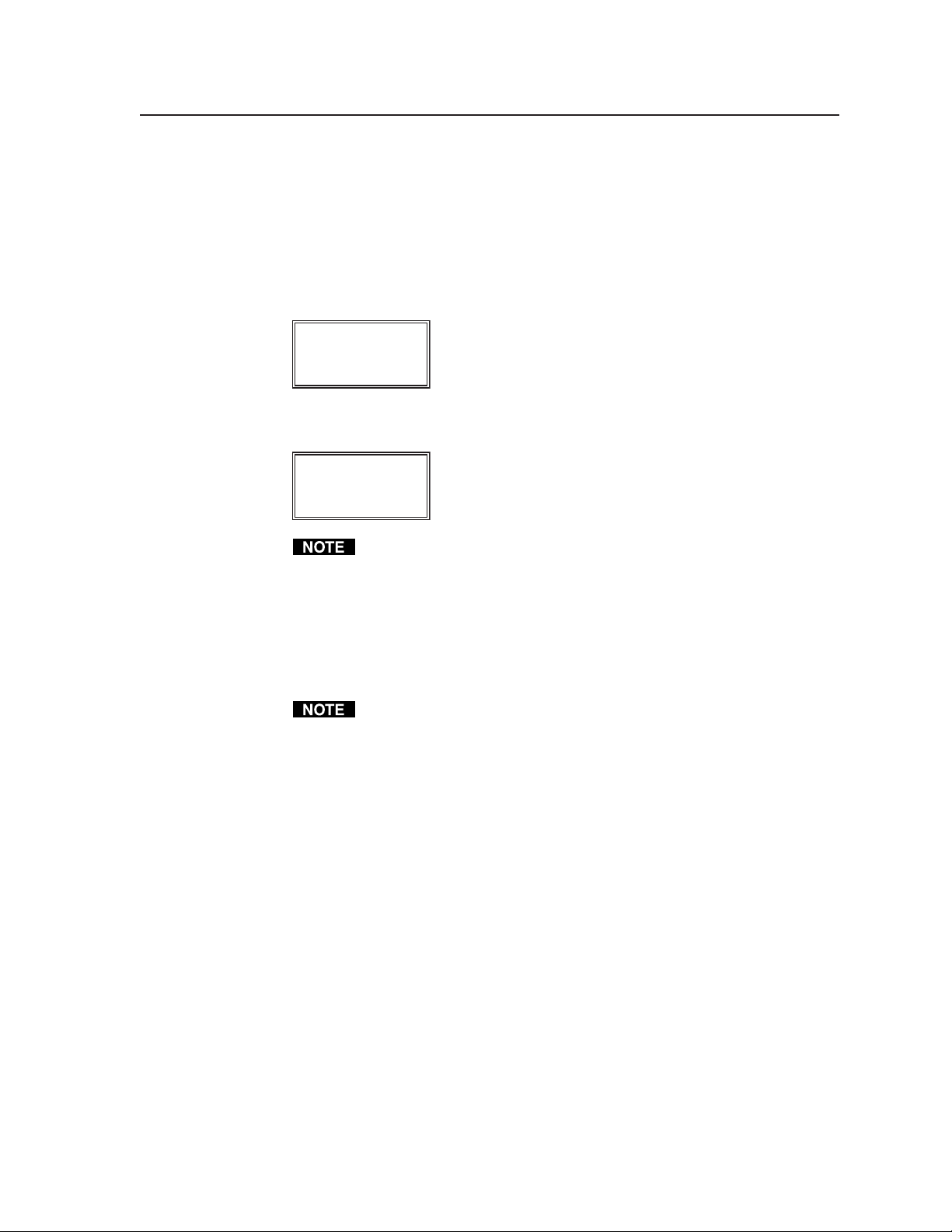

Video Setup submenu (2 of 4)

The test pattern’s on-screen display can be enabled (on) or disabled (off) from

this submenu.

On-Screen Display

• ON

• OFF (default)

When set ON and a new output rate is activated, the VTG displays the rate

type, rate frequency, and resolution for 4 seconds. The text is identical to

what is displayed on the VTG’s LCD display and appears as white text in a

black box centered on the test pattern. See the following example

illustration.

VTG 400D/400 DVI • Installation and Operation2-14

Page 25

Res: VESA3 1024x768

FRQ: 48.40 kHz 60.00 Hz

Video Setup submenu (3 of 4)

Test pattern autosequence mode and autosequence interval are selected from this

submenu. Test pattern autosequence mode specifies whether to step through the

test patterns in a predetermined sequence. Test pattern autosequence interval

specifies how long each test pattern in the autosequence mode will be displayed.

The predetermined sequence of test patterns is specified via RS-232

commands or the Windows-based control program. By default, all test

patterns are selected for autosequence. See chapter 3, Serial

Communication.

Autosequence Mode

The mode can be enabled (on) or disabled (off).

• ON

• OFF (default)

Autosequence Interval

There are 3 options for the interval:

• 15 seconds (default)

• 30 seconds

• 60 seconds

Video Setup submenu (4 of 4)

To specify particular colors in the test patterns, the individual color channels can

be toggled on or off from this submenu. See the following table of possible color

combinations.

RGB Color Channel Enable

Specify each color as enabled (on) or disabled (off).

• RED (default = ON)

• GREEN (default = ON)

• BLUE (default = ON)

This adjustment affects only the RGB outputs (BNCs and HD15 connector).

2-15VTG 400D/400 DVI • Installation and Operation

Page 26

Installation and Operation, cont’d

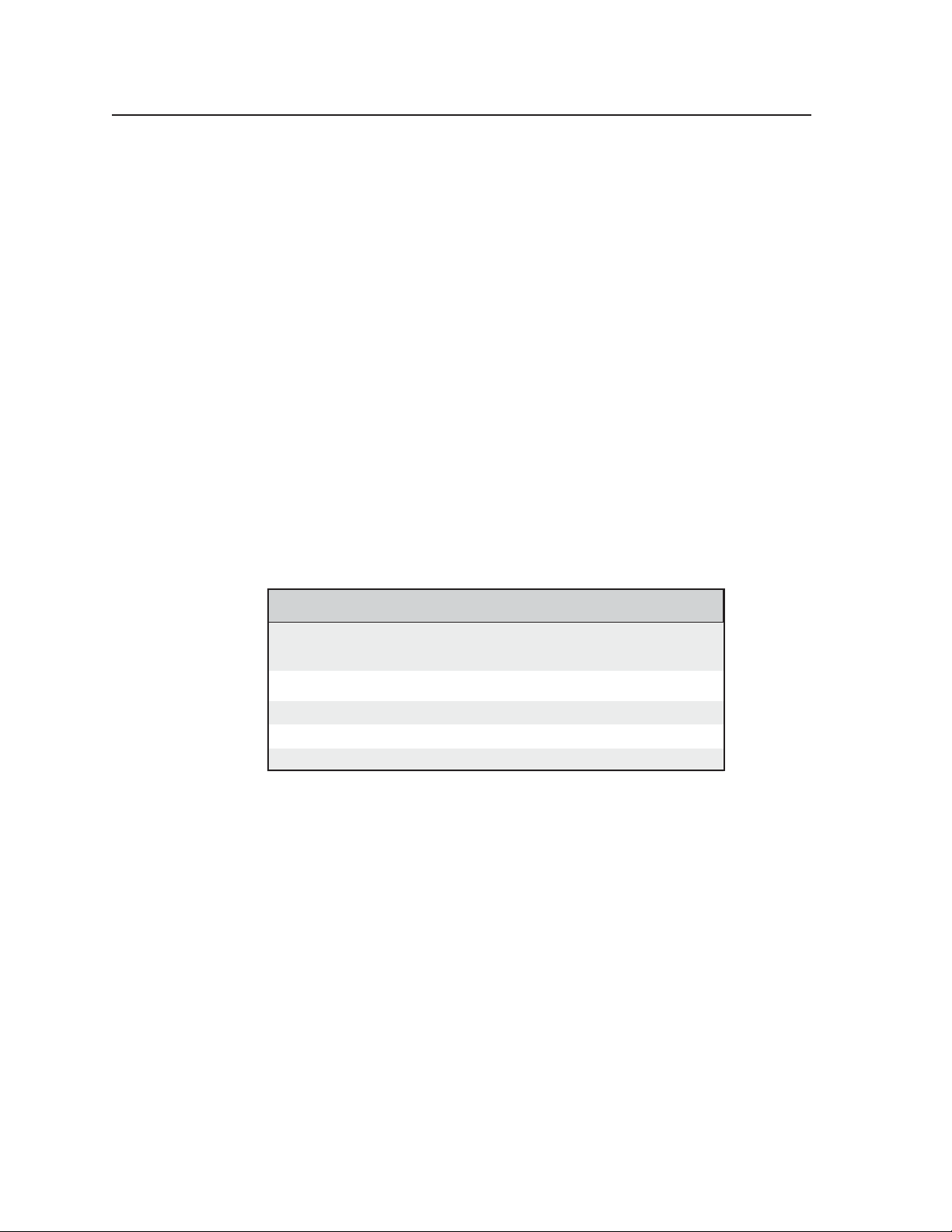

Color Combinations R G B

Black

Blue

Green

Cyan

Red

Magenta

Yellow

White

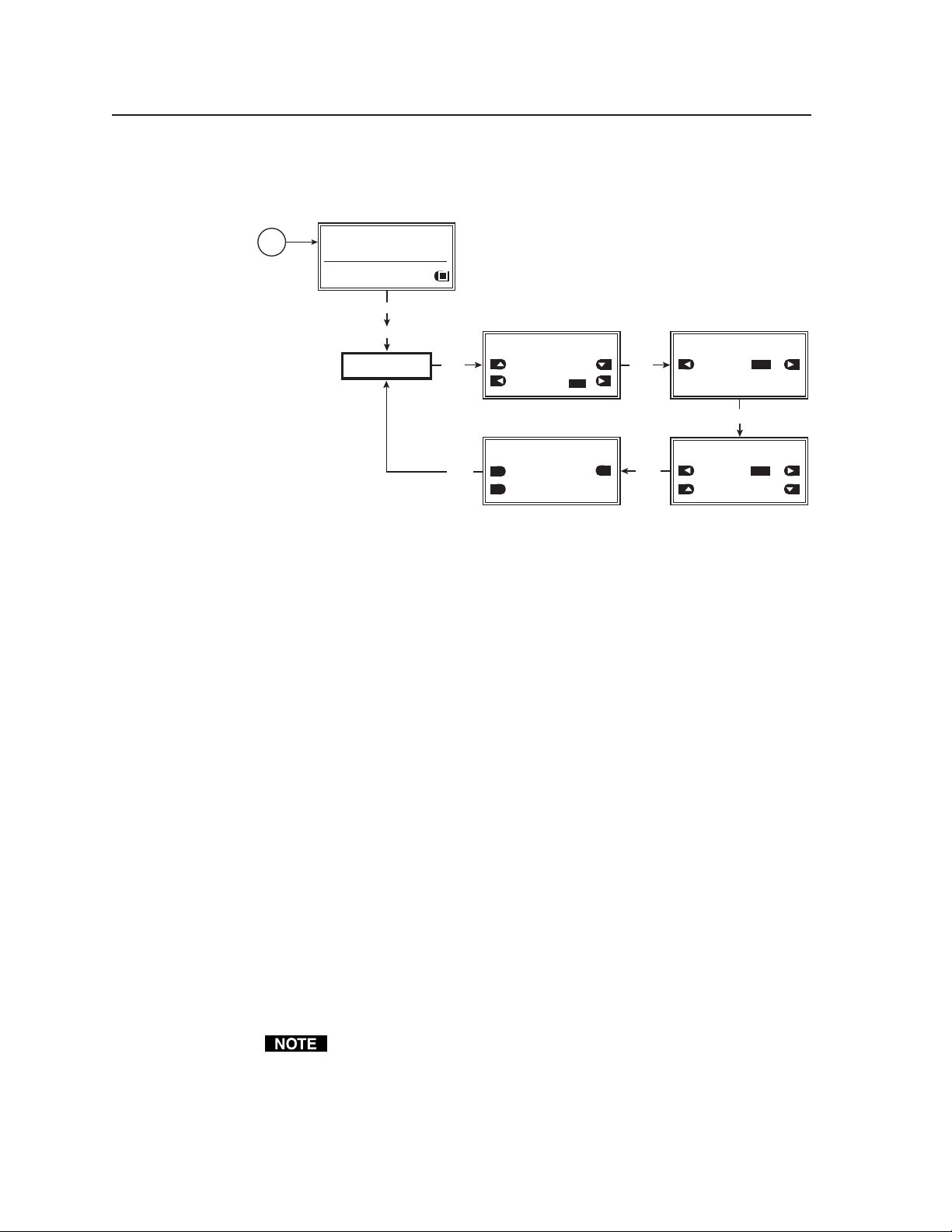

Advanced Setup menu

The following flowchart describes the Advanced Setup menu.

off

off

off

off

on

on

on

on

off

off

on

on

off

off

on

on

off

on

off

on

off

on

off

on

Power

on

RES: VGA 640x480

FRQ: 31.50kHz 60.00Hz

PAT: Fine Crosshatch

SIG: Pink noise FRQ: N/A

LEV: -10 dBu 245mV

MENU

MENU

MENU

ADVANCED

SETUP

ADVANCED SETUP: <1 of 4>

Time-out Interval:

NEXT

Never timeout

Screensaver Mode:

Cycle

Blank

ADVANCED SETUP: <3 of 4>

Internal Temperature:

-32.0F -00C

All models except the VTG 400 DVI display

NOTE

the menu above.

NEXT

NEXT

ADVANCED SETUP: <2 of 4>

LCD Display Contrast:

038

LCD Backlight:

Always On

NEXT

– OR –

(see notes below)

NEXT

ADVANCED SETUP: <4 of 4>

YES

YES

SYSTEM RESET

or

NO

YES

YES

Auto

ADVANCED SETUP: <3 of 4>

Internal Temperature:

-32.0F -00C

Native Rate For DVI Device

1600x1200 @60 Hz

Only the VTG 400 DVI displays the

NOTE

menu above.

NO

Unit Reset to

Factory Default

ADVANCED SETUP: <4 of 4>

YES

SYSTEM RESET

YES

CONFIRM!

NO

Advanced Setup menu

Advanced Setup submenu (1 of 4)

The screensaver timeout interval can be specified and the screensaver mode can

be set to either a blank (black)/muted screen or a cycle of test patterns from this

submenu.

Time-out Interval

Specify the screensaver timeout interval:

VTG 400D/400 DVI • Installation and Operation2-16

Page 27

• 5 minutes

• 10 minutes

• 15 minutes

• 30 minutes

• Never time out (default — screensaver is not activated)

The following LCD display message is updated approximately every 38 seconds

starting with the timeout interval selected.

Time-out in:

00:18 minutes

After the timeout interval has has elapsed, the following LCD message is

displayed.

SCREEN SAVER

ACTIV E

The timeout timer is reset whenever any VTG button is pressed.

Screensaver Mode

The screensaver mode can be set to a blank (black) screen or the mode can be set

to cycle through all valid test patterns in 4-second intervals for the video type.

• Blank (default)

• Cycle

In blank screen mode, the sync remains active even while the video is muted.

Refer to the Test Pattern Chart in appendix A for the table of available test

patterns and their features.

Advanced Setup submenu (2 of 4)

The VTG’s LCD display features an adjustable contrast setting and a backlight.

LCD Display Contrast

• 000 through 063, select a setting while observing the LCD

LCD Backlight

The LCD backlight on the VTG can be set to remain on or to automatically turn

off after 10 seconds of inactivity.

• Always On

• Auto (default)

Advanced Setup submenu (3 of 4)

The VTG’s LCD displays the internal board temperature of the VTG in degrees

Celsius and degrees Fahrenheit.

The native rate for a DVI device connected to the VTG 400 DVI is displayed on

the LCD. This information is detected from the EDID generated by the attached

DVI device.

2-17VTG 400D/400 DVI • Installation and Operation

Page 28

Installation and Operation, cont’d

Internal Temperature

• -67° to +257°F (-55° to +125°C)

Native Rate for DVI Device

• The preferred resolution of the device connected to the DVI connector

(VTG 400 DVI only).

Advanced Setup submenu (4 of 4)

The VTG can be reset to default settings from this submenu.

System Reset

• YES

• NO

Selecting “YES” displays a confirmation menu.

System Reset Confirm

• YES

• NO

Selecting “YES” resets the VTG to factory default settings.

A system reset does not affect any stored custom rates. Those rates are not

overwritten.

Exit menu

The following flowchart describes the Exit menu. Pressing the Next button from

this menu causes the VTG to return to the default screen.

Power

on

RES: VGA 640x480

FRQ: 31.50kHz 60.00Hz

PAT: Fine Crosshatch

SIG: Pink noise FRQ: N/A

LEV: -10 dBu 245mV

MENU MENU MENU

Exit menu

Additional Functions

The VTG 400 has several functions that are not accessible through the Menu and

Next buttons.

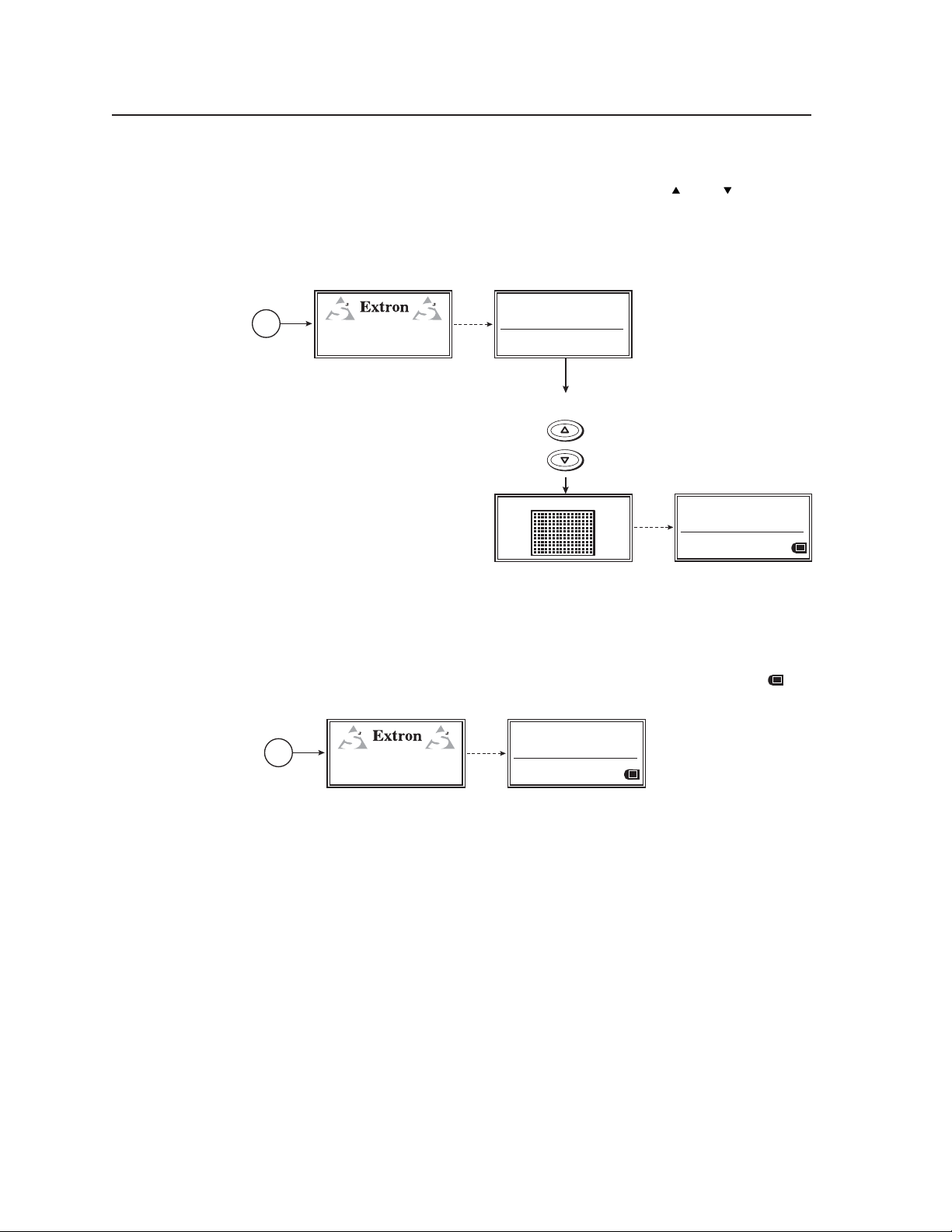

Top panel security lockout (button lock mode)

To prevent accidental changes to settings, simultaneously press and hold the

Audio Signal Type button and the Video Test Pattern up cursor ( ) button for

about two seconds to enable the VTG’s button lock mode. See the following

illustration.

Button lock mode locks all top panel functions. When button lock mode is active,

all functions and adjustments can still be made through RS-232 control. For

details on RS-232 control, see chapter 3.

To disable button lock mode, simultaneously press and hold the Audio Signal

Type button and the Video Test Pattern up cursor (

seconds.

MENU

EXIT MENU

Press "NEXT" button

) button for about two

NEXT

VTG 400D/400 DVI • Installation and Operation2-18

Page 29

Power

on

VTG 400

VIDEO TEST GENERATOR

60-564-01 Ver. 1.00

3 sec.

RES: VGA 640x480

FRQ: 31.50kHz 60.00Hz

PAT: Fine Crosshatch

SIG: Pink noise FRQ: N/A

LEV: -10 dBu 245mV

Button lock mode

Button Lock

Enabled!

O

Button Lock

Disabled!

O

TEST

PATTERN

TEST

PATTERN

SIGNAL

TYPE

Simultaneously press both buttons for

two seconds to enable button lock mode

SIGNAL

TYPE

Simultaneously press both buttons for

two seconds to disable button lock mode

2-19VTG 400D/400 DVI • Installation and Operation

Page 30

Installation and Operation, cont’d

Quick select buttons

Up to four video and/or audio settings can be saved by pressing one of the four

top panel Quick Select buttons for two seconds until the Quick Select Setup menu

appears. The following menu flowchart illustrates this process.

Power

on

VTG 400

VIDEO TEST GENERATOR

60-564-01 Ver. 1.00

3 sec.

Press any Quick Select

button for 2 seconds.

RES: VGA 640x480

FRQ: 31.50kHz 60.00Hz

PAT: Fine Crosshatch

SIG: Pink noise FRQ: N/A

LEV: -10 dBu 245mV

QUICK

SELECT

Settings Saved

to Button #1

SAVE

Select

SAVE

QUICK SELECT SETUP #1

Configuration to store:

Video settings

Save changes:

SAVE

SAVE

?

Press either arrow selection button adjacent to

the or selectors to save either the

Audio settings, Video settings, or All settings

(both audio and video).

Press the arrow selection button adjacent to

SAVE

the selector to save the setting(s)

to a Quick Select button or press the arrow

selection button adjacent to the

selector to cancel the operation and not save

the setting(s) to a Quick Select button.

CANCEL

CANCEL

Select

CANCEL

Quick Select Setup menu

The audio and/or video settings are saved when the Save selector

SAVE

(

approximately 15 seconds or if the Cancel selector (

) is chosen. Nothing is saved if the menu times out after

CANCEL

) is chosen.

To recall a previously saved configuration, press the associated Quick Select

button that was used to save the configuration. The recalled configuration

overwrites only the corresponding current settings. The following illustration is

an example of the LCD screen response after recalling Quick Select button 1:

Settings Recalled

for Button #1

SAVE

VTG 400D/400 DVI • Installation and Operation2-20

Page 31

Video output range and rate buttons

Pressing the Video Range button selects from among eight output range

categories. Pressing the

chosen output range. The output rates are displayed two at a time on the LCD.

See the following illustration.

Power

on

VTG 400

VIDEO TEST GENERATOR

60-564-01 Ver. 1.00

and Video Rate buttons selects an output rate for the

RES: VGA 640x480

FRQ: 31.50kHz 60.00Hz

PAT: Fine Crosshatch

3 sec.

SIG: Pink noise FRQ: N/A

LEV: -10 dBu 245mV

Press the Range button to select from

among the following rate types:

• PC

• CAD Workstation

• Stereographic

• Super High Res.

• 16:9 High Res.

• HDTV

• Video/Other

• Custom

PC RATES

VESA12 1280x1024

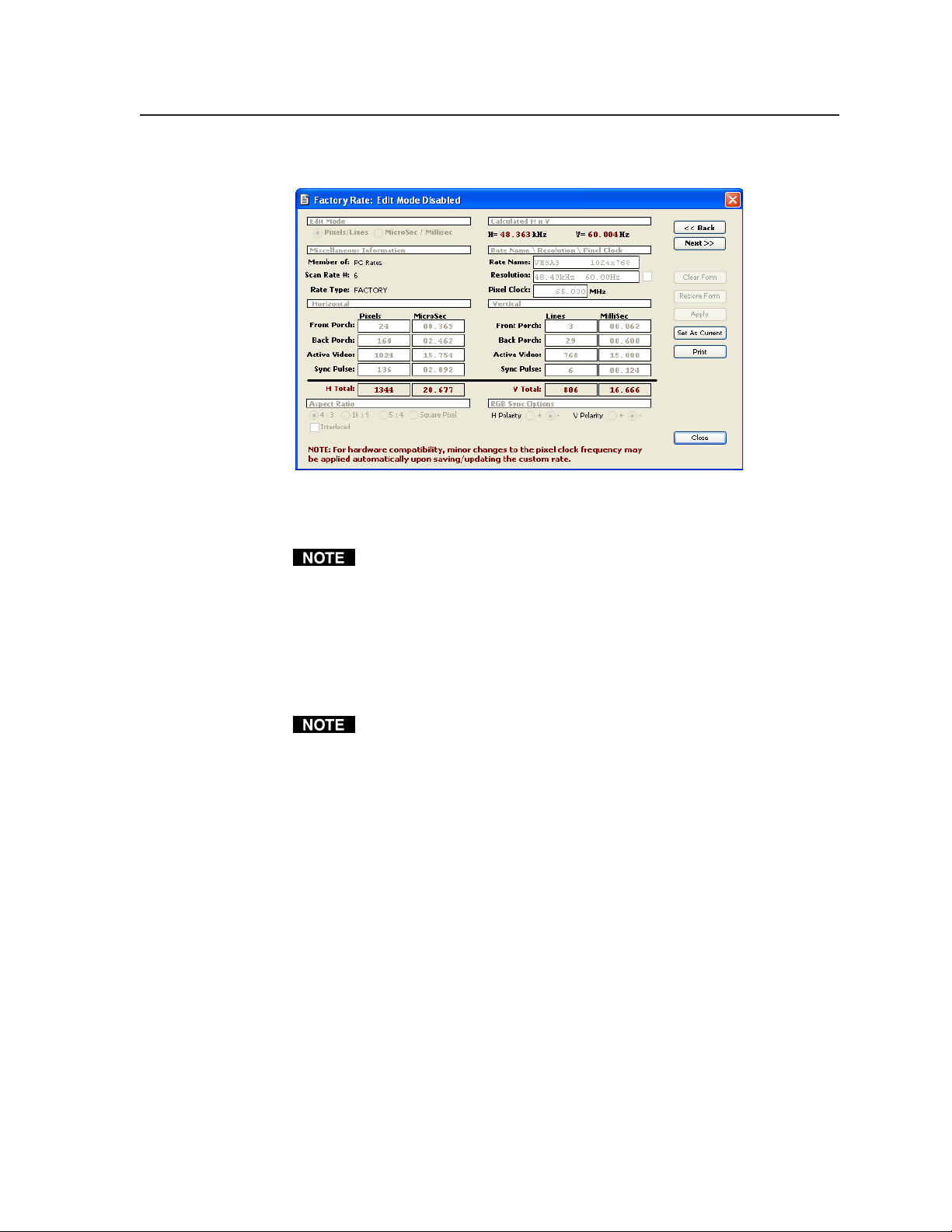

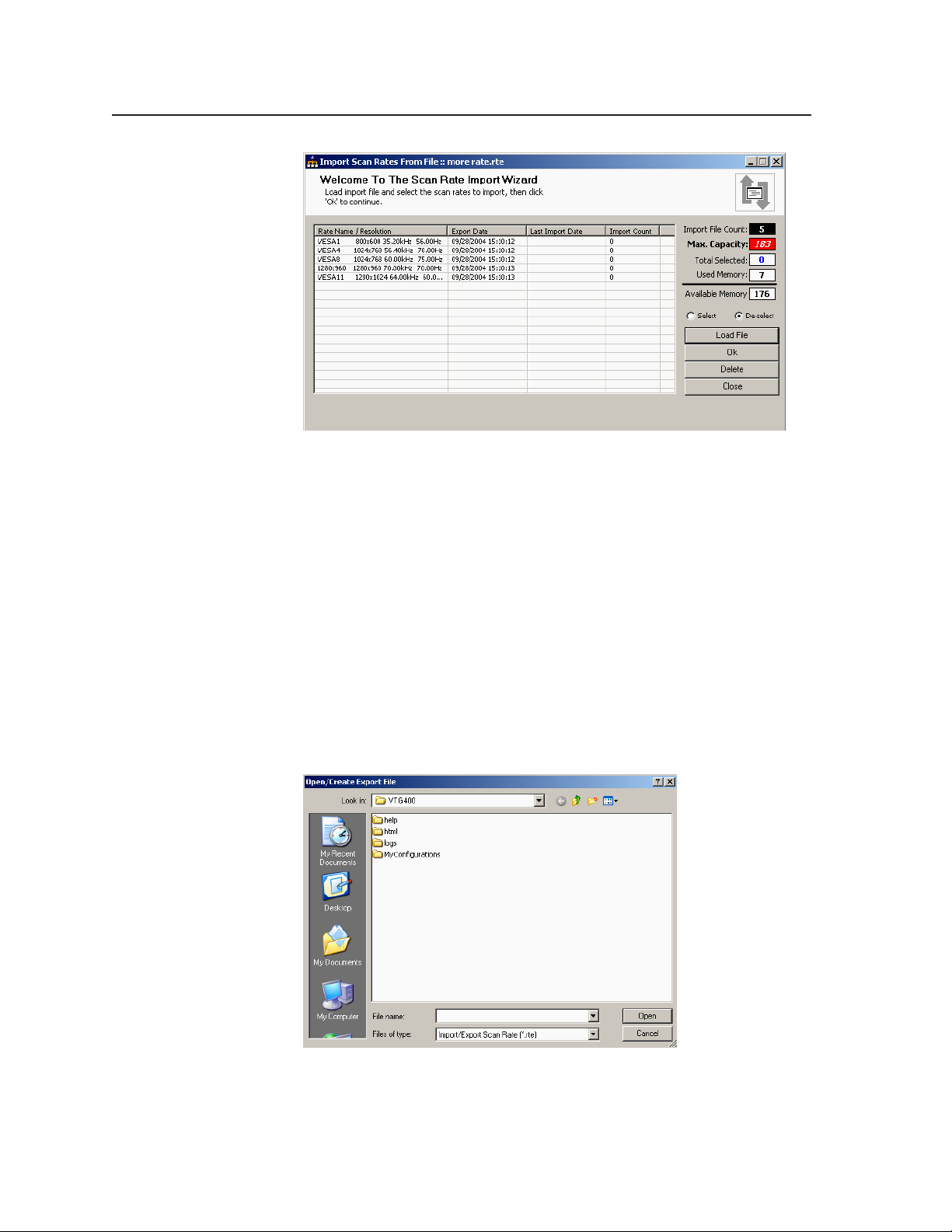

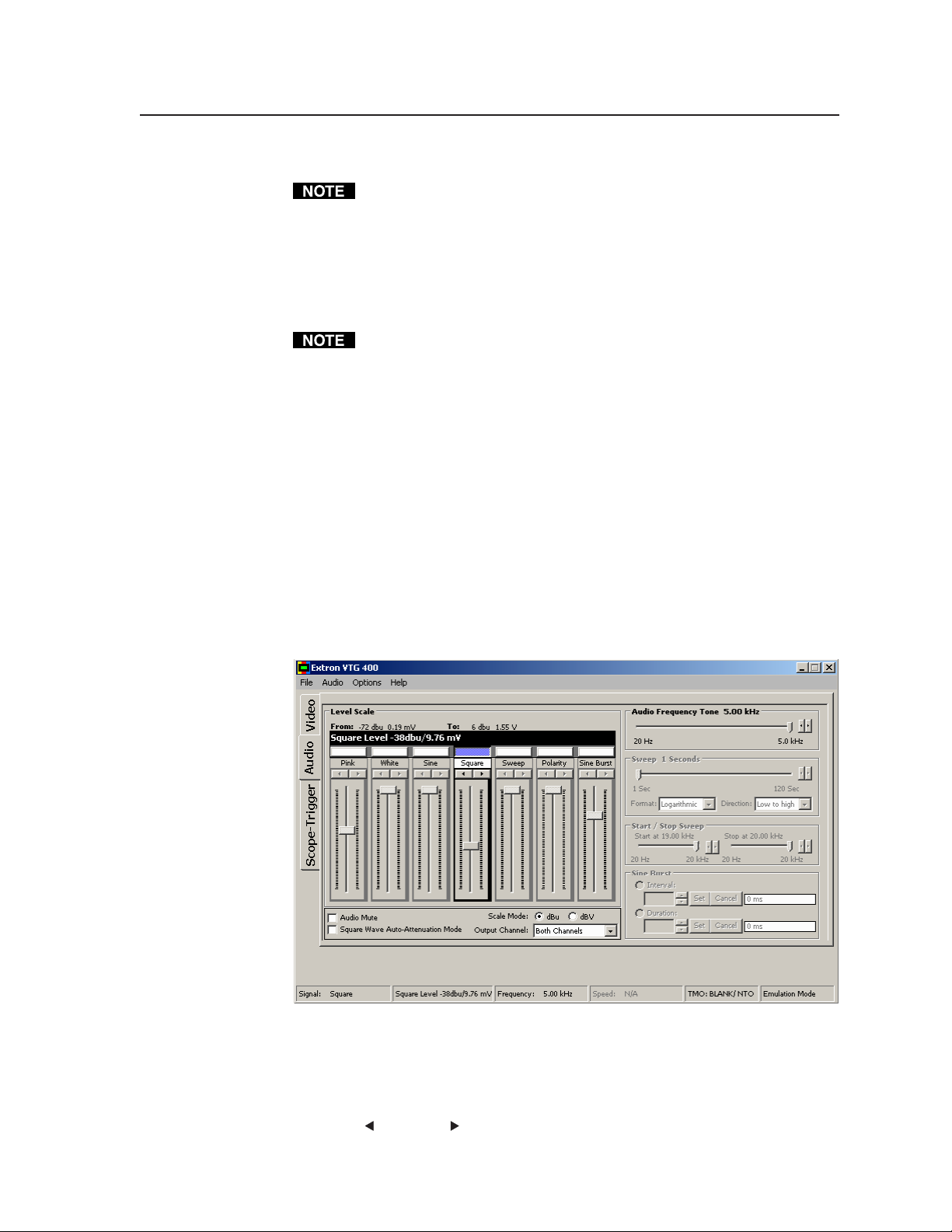

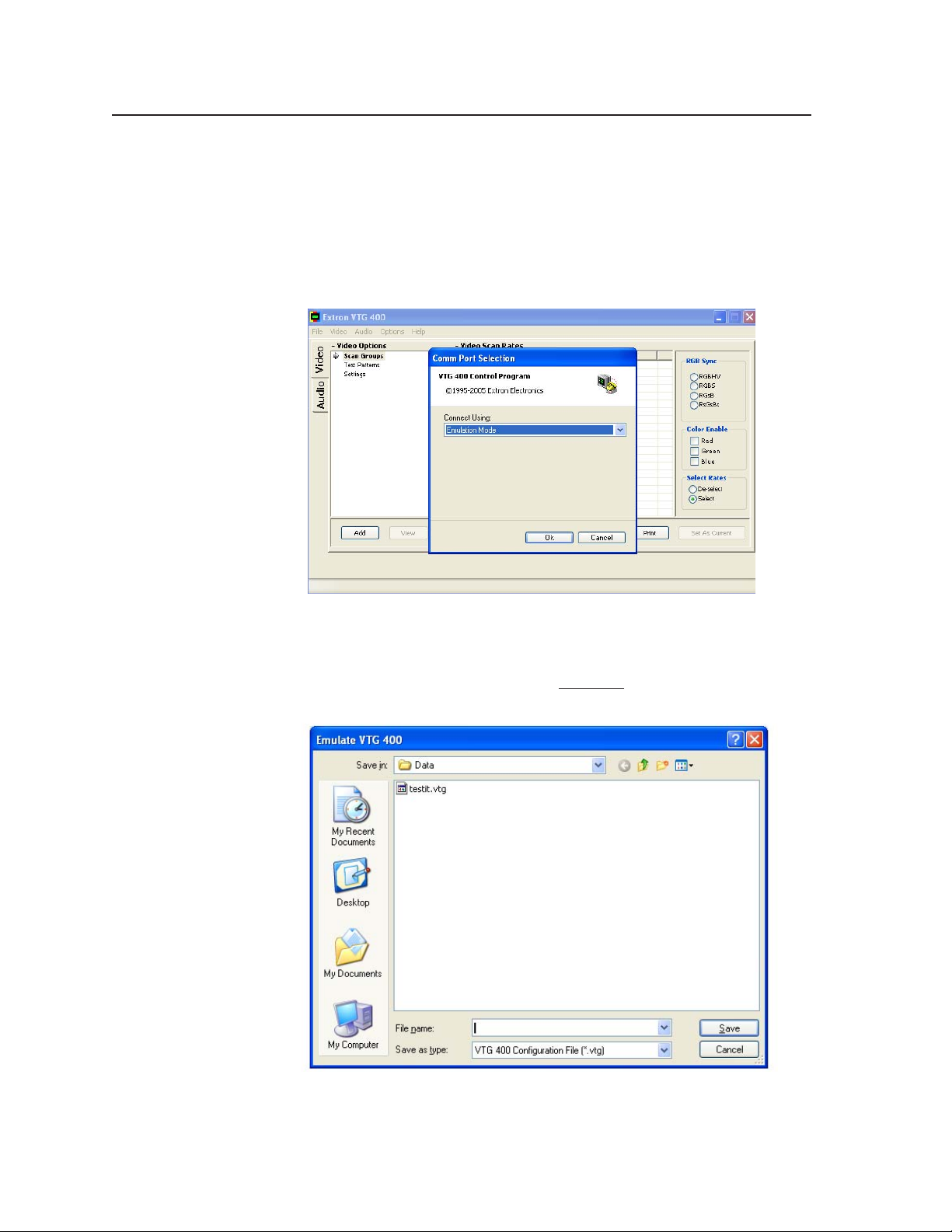

91.10kHz 85.00Hz

SXGA+ 1400x1050

63.90kHz 60.00Hz

RANGE

RATE

Use the Rate buttons to select the rate.

NOTE

Press the Select

button to activate the

selected rate.

SELECT

After pressing the Select button or after 15

seconds of inactivity, the VTG will return to

the default menu.

Video output range and rate selection buttons

After selecting the desired rate, press the Select button to activate the selected

rate.

The VTG returns to the default menu after pressing the Select button or after

15 seconds of inactivity.

2-21VTG 400D/400 DVI • Installation and Operation

Page 32

Installation and Operation, cont’d

Test pattern selection buttons

Depending on the currently selected video rate, pressing the and Video Test

Pattern selection buttons selects from up to 28 different video test patterns. The

newly selected test pattern displays for three seconds before returning to the

previous menu. See the following menu. Refer to the Test Patterns Chart in

appendix A for the table of available test patterns and their features.

RES: VESA6 800x600

Power

on

VTG 400

VIDEO TEST GENERATOR

60-564-01 Ver. 1.00

FRQ: 48.10kHz 72.00Hz

PAT: PLUGE

3 sec.

SIG: Pink noise FRQ: N/A

LEV: -18 dBu 97.6mV

Press any

Test Pattern

button.

TEST

PATTERN

Fine Crosshatch

RES: VESA6 800x600

FRQ: 48.10kHz 72.00Hz

PAT: Fine Crosshatch

3 sec.

SIG: Pink noise FRQ: N/A

LEV: -18 dBu 97.6mV

Test pattern selection buttons

Invert/special features functions

Certain test patterns, as indicated in the “Invert/Special” column of the Test

Patterns Chart, can be inverted, i.e., black becomes white and white becomes

black, by pressing the arrow selection button adjacent to the invert symbol

the LCD screen. See the following diagram.

RES: VESA6 800x600

Power

on

VTG 400

VIDEO TEST GENERATOR

60-564-01 Ver. 1.00

FRQ: 48.10kHz 72.00Hz

PAT: Bounce (Manual Toggle)

3 sec.

SIG: Pink noise FRQ: N/A

LEV: -18 dBu 97.6mV

Press the invert button to

activate/deactivate the Invert/Special

functions of specific test patterns.

The following test patterns feature the invert function:

• Circles

• Safe area

• 16:9 crop

• 4:3 crop

• Rectangle/square crosshairs

• 4x4 crosshatch

• Coarse crosshatch

• Fine crosshatch

• Ramp

• Checkerboard

• H pattern

on

VTG 400D/400 DVI • Installation and Operation2-22

Page 33

The following test patterns have a special feature function using the invert

button:

• SMPTE Bars — This pattern toggles blue mode on and off.

• Bounce (manual toggle) — Toggles the center window on and off. This

pattern does not invert the entire pattern.

• Contrast transfer function — This test pattern toggles the vertical lines

between always on and blinking.

Refer to the Test Patterns in Detail section in appendix A of this manual.

Adjusting the video level of test patterns

From the default cycle menu, the video level of specific test patterns can be

adjusted in 1% increments (1 IRE) from 0 through 100% (0 to 100 IRE). Currently,

there are six test patterns that support this adjustable level feature.

• Window (variable level)*

• Flat field*

• Flat field with targets*

• Checkerboard*

• Contrast transfer function

• Hum bar detect

* These test patterns have globally adjustable video levels, i.e., a change to one

results in an identical change to all of the others.

Adjusting the level of the contrast transfer function test pattern results in

changes to the contrast ratio percentage rather than the video level. The

hum bar detect and contrast transfer function levels are saved

independently, so changes to other patterns’ video levels do not affect these

two patterns.

Use the adjacent arrow selection buttons to adjust the video level, as shown here

in the example display.

RES: VESA8 1024x768

FRQ: 60.00kHz 75.00Hz

Checkerboard 0%

SIG: Freq. Sweep SPD:9.0 sec

LEV: -09 dBu 275mV

Refer to the Test Pattern Chart in appendix A for the table of available test

patterns and their features.

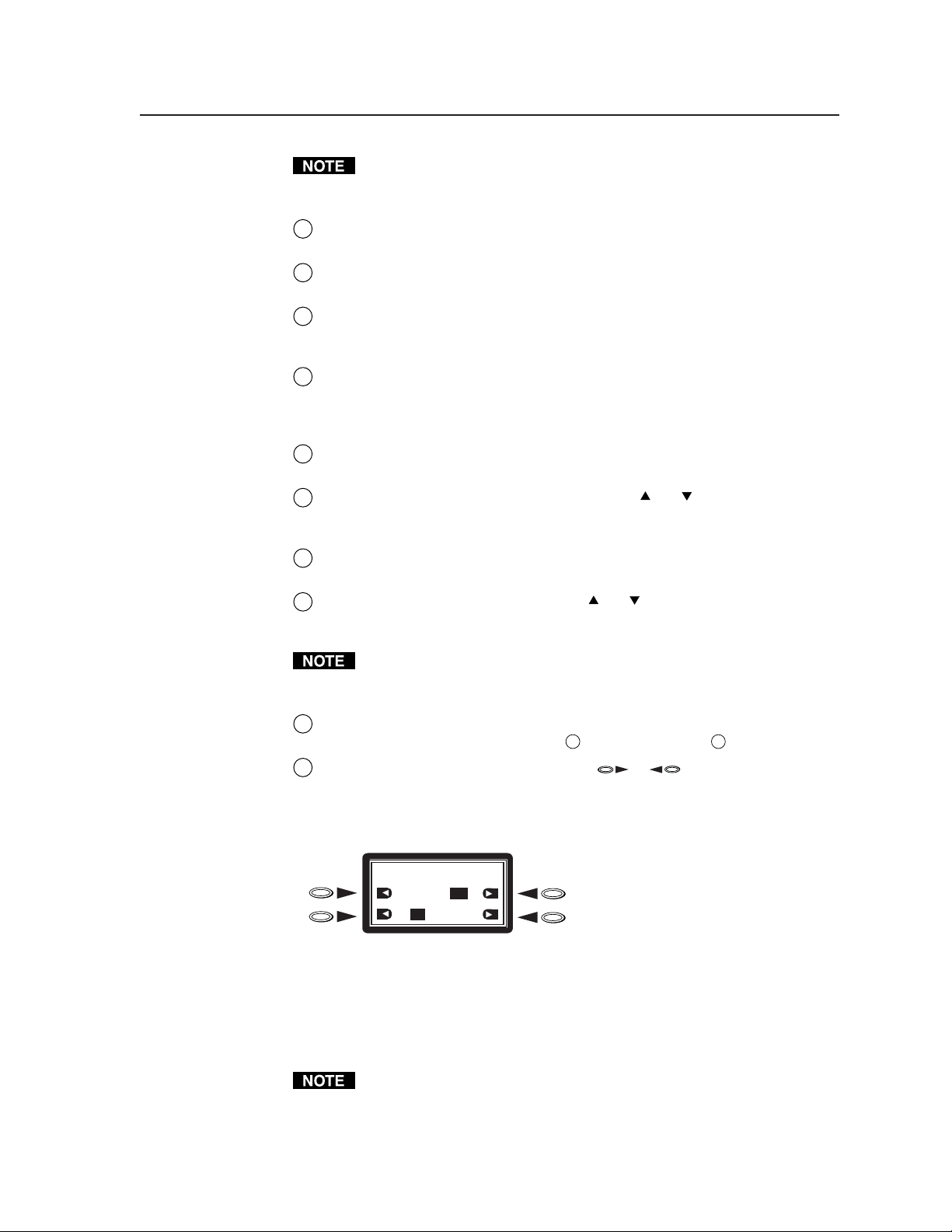

Scope-Trigger buttons

A unique feature of the VTG 400 is the ability to locate a trigger point at a specific

pixel location on an oscilloscope’s signal display.

When a Scope Trigger button is pressed, the LCD displays the Scope-Trigger

menu, as shown in the following figure. The cursor’s location is given in

coordinates (x, y) relative to the active area, as well as the total area of the

screen display. The range of the coordinates is dependent on the scan rates.