Extron electronics eBUS EBP 106P D, eBUS EBP 103 D, eBUS EBP 105 D, eBUS EBP 106 D, eBUS EBP 108 D Setup Manual

...Page 1

Product Category

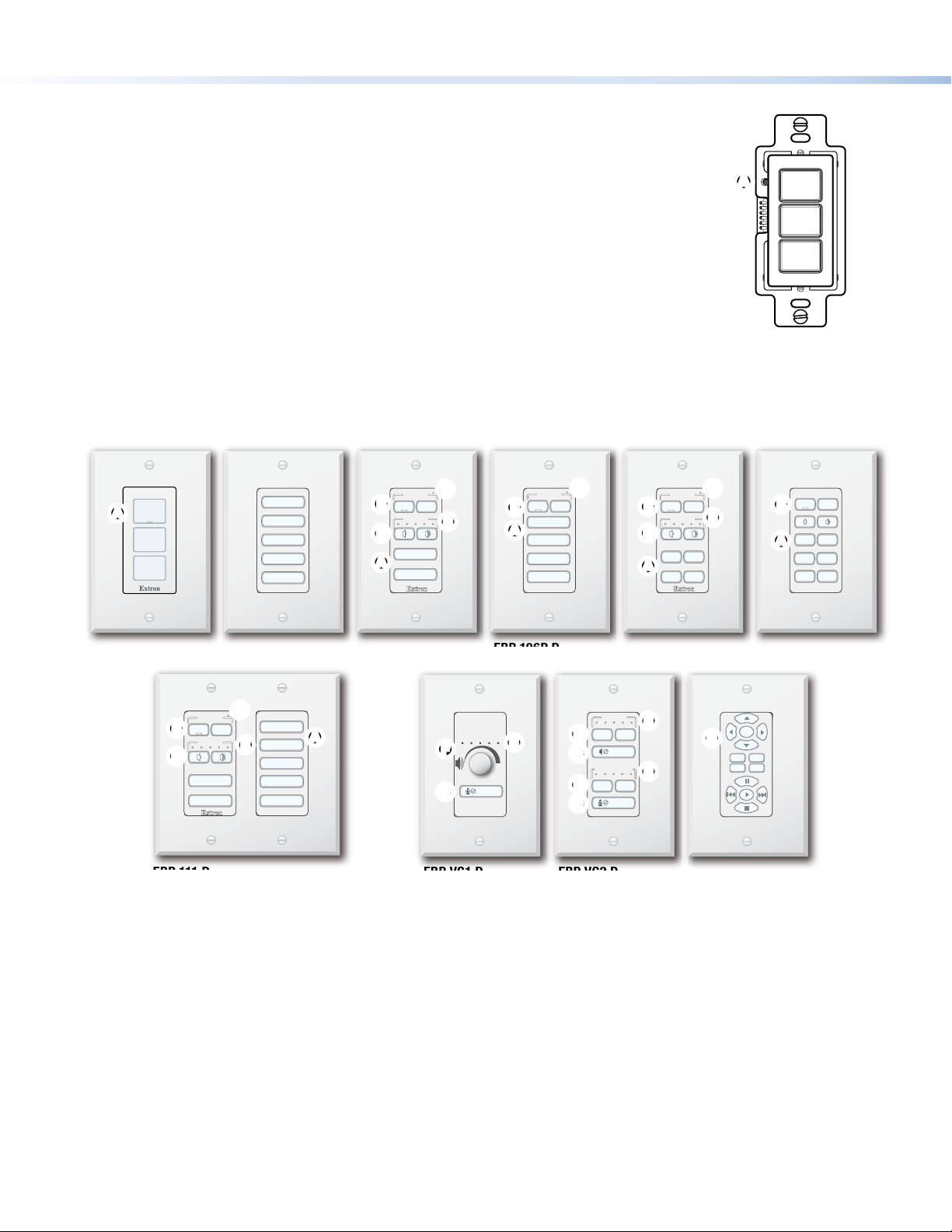

EBP 105 D Rear View

EBP 103 D Rear View

EBP 103 D Side View

EBP 105 D Side View

eBUS® Button Panel Decorator-Style Series • Setup Guide

Overview

Extron offers a range of eBUS Button Panels (EBPs)in the decorator-style form factor that can be mounted in walls or furniture

in any standard US 1-gang opening. Each panel is a fully customizable AV system control interface for use with Extron IPCPPro

Series control processors. Individual EBPs are easily congured and can be connected with other panels to provide control for

large and complex AV systems.

NOTE: These products are only for use with Extron UL Listed IPCP Pro control processors.

Each EBP button panel has two eBUS ports that support power and communications between the IPCPPro control processor

and eBUS devices. Up to eight eBUS devices such as EBP button panels can be connected to the control processor and to each

other in various cabling topologies. Cabling topology refers to the physical layout of cabling interconnections between devices

in a network such as an eBUS system. eBUS systems can include daisy chain, star, or hybrid (a combination of both) system

topologies (see the eBUS Technology Reference Guide, available on www.extron.com, for basic diagrams). Every device must

have a unique identication address (eBUS ID) within the system.

Setup involves setting eBUS ID DIP switches on the EBPs, then using Extron GlobalCongurator® Plus and Professional

software, the Toolbelt utility, or Global Scripter® programming software, to congure the control processor. Once congured, the

AV system can be controlled from any of its EBPs.

This guide provides basic instructions for an experienced installer to install the EBP decorator-style series button panels.

For more details on the EBPs, see the eBUS Technology Reference Guide, available on www.extron.com. For details on

conguration or programming, see the software help les.

EBP Rear and Side Panel Features

Figure 1 shows the side and rear views of the EBP 105 D and the rear view of the EBP 103 D. The EBP 105 D side features are

very similar for all EBP decorator-style models except the EBP 103 D. The EBP 105 D rear features are the same for all EBP

decorator-style models except the EBP 103 D.

D

AA

BB

ID

ERROR

COM

+V +S -S G+V +S -S G

STATUS

ERROR

PWR LOAD = X.XW

LINK

eBUS

Figure 1. EBP 105 D and EBP 103 D Rear and Side Views.

eBUS connectors (2 ports) — The four-pole captive screw connectors use the Extron eBUS protocol to connect the panel to

A

a controller and to other panels (see Step 5: Cable All Devices on page 9).

Status LEDs — Provide diagnostic information about the connection, communication, and power status of the panels.

B

z The EBP 103 D has amber, red, and green LEDs.

z All other EBP decorator-style models have a single green LED.

For more information about how the LEDs are used for troubleshooting, see Step 7: Test and Troubleshoot on page 11.

DIP switches — Up to eight devices can be connected to one control processor. Each device connected to the same control

C

processor must have a unique eBUS ID, which is set using DIP switches (see Step 4: Set the eBUS ID on page 6).

Reset button — Resets the rmware to the factory installed version (see To reset the firmware on the next page).

D

D

CC

AA

BB

+V +S -S G

+S -S G

+V

eBUS

PWR LOAD = 1.5W

DD

C

C

1

Page 2

eBUS Button Panel Decorator-Style Series • Setup Guide (Continued)

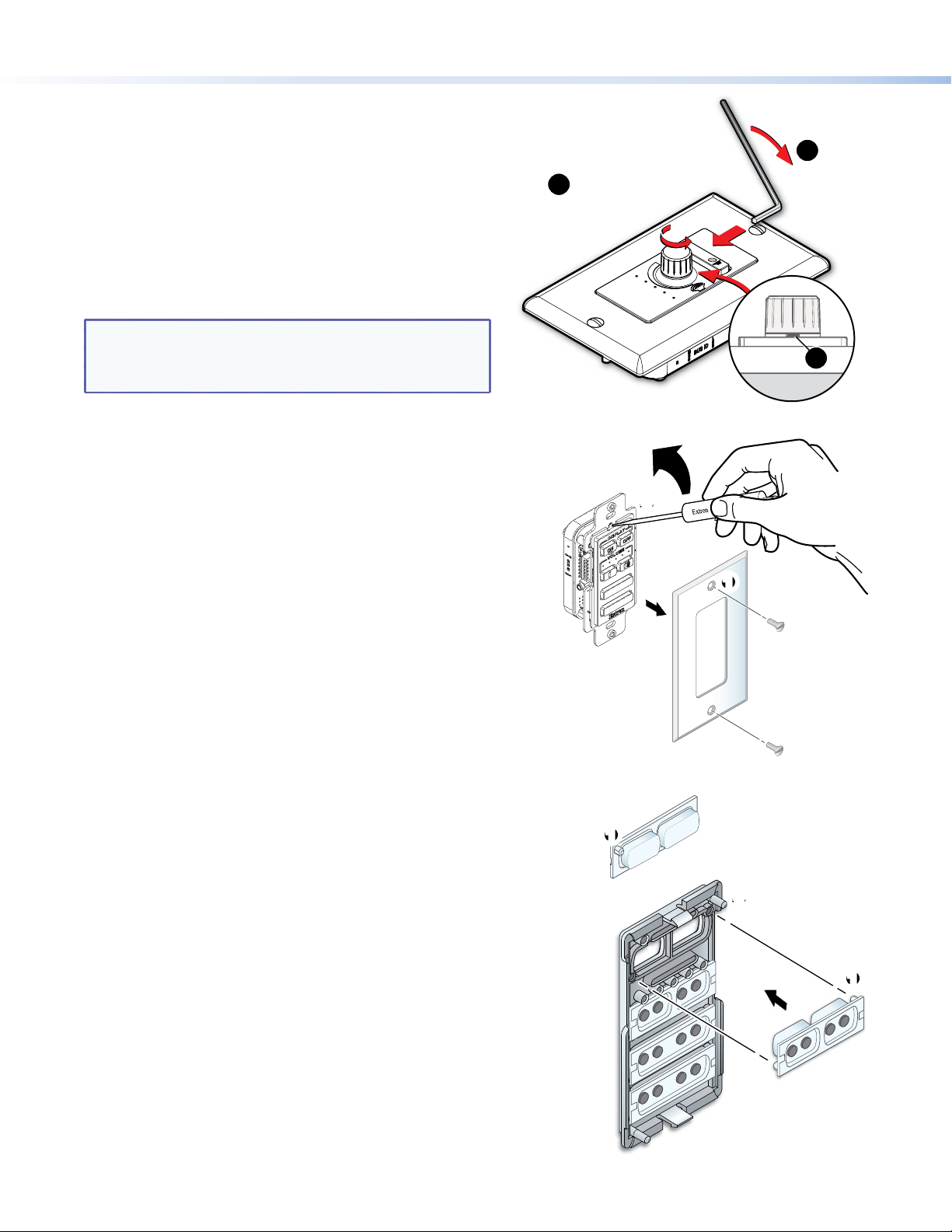

EBP 111 D

EBP VC1 D EBP VC2 D

EBP NAV D

To reset the firmware

The Reset button (see gure 2, A) for the EBP 103 D can only be accessed from the front of

the unit, after removing the frame (see Remove the frame and bezel on page 4).

For all models:

1. Disconnect the eBUS cable that is providing power.

2. While reconnecting power, press and hold down the Reset button (see gure 1,

gure 2, A).

3. Release the Reset button 1 second after reconnecting power. During the reset process,

the front panel buttons are not lit. When the eBUS Status LED lights, the reset process

is complete, and the EBP is functioning normally. For the EBP 103 D, the green Link

LED lights to show that the EBP is functioning normally.

D

or

AA

RESET

SOURCE

1

M

B

S

SOURCE

2

B

SS

L

SOURCE

3

Extron

EBP Front Panel Features

All buttons are backlit with LEDs to identify the active button. Inactive buttons can be backlit

dimly to help identify them in low ambient lighting.

The buttons and encoders must be congured or programmed to carry out their functions. Use

Global Congurator Plus and Professional and Toolbelt to congure the EBP buttons and LEDs

or use Global Scripter to program the EBP buttons and LEDs.

DISPLAY

DISPLAY

C

SOURCE 1

AAA

SOURCE 2

SOURCE 3

EBP 103 D

DISPLAY

ON OFF

B

B

D

D

VOLUME

AUTO IMAGE

A/V MUTE

LAPTOP

DOC CAM

EBP 105 D

C

C

LAPTOP

EE

DOC CAM

PC

DVD

VIDEO

PC

AA

HDMI

VGA

B

B

D

D

AA

EBP 106 D

ON

VOLUME

VIDEO

C

OFF

E

E

PC

F

F

G

G

EBP 106P D

VOLUME

MUTE

B

B

AA

E

E

ON

OFF

PC

LAPTOP

VIDEO

DOC CAM

C

C

D

D

G

G

D

D

G

G

VOLUME

– +

MUTE

MICROPHONE

– +

MUTE

DISPLAY

ON OFF

B

B

VOLUME

D

D

PC VIDEO

AA

LAPTOP MUTE

EBP 108 D

E

E

E

E

Figure 2. EBP 103 D with Front

Panel Removed

C

C

E

E

H

H

ENT

CH +

TITLE

CH −

INFO

ON OFF

BB

PC LAPTOP

AA

DOC

CAM

HDMIVGA

EBP 110 D

VIDEO

Figure 3. EBP Decorator-style Series Front Panels

Function buttons — The EBP 103 D has three backlit dual-color buttons. The top button has a nub that can be felt with the

A

nger tips. All other panels have backlit soft-touch buttons.

Power buttons — Control the power to the display device. The On button has a nub that can be felt with the nger tips.

B

Transmit LED — Present on certain models only, the Transmit LED blinks once when any button is pressed.

C

Volume control

Volume buttons — Present on certain models only, the Volume buttons increment or decrement audio volume.

D

Volume LED meter — Present on certain models only, the Volume LED meter lights to indicate the volume level.

E

Volume rotary encoder — Present on certain models only, the volume rotary encoder increments or decrements audio

F

volume.

Mute button — Present on certain models only, the Mute button toggles between audio mute and unmute. You can congure

G

the Mute button so that it is backlit red when muted and white when unmuted for a visual indication of the status.

Video control

Transport control buttons — Used to control a DVD or Blu-ray player.

H

2

Page 3

Product Category

Planning the System and Installation

When planning to install an eBUS system, consider how many EBP button panels to use, maximum cable distance, cabling

topology, and mounting. See the eBUS Technology Reference Guide for more information about eBUS topologies.

Installation

Step 1: Get Ready

Use the following check list to prepare for the installation.

Download and install the latest versions of the software, rmware, and device drivers needed to congure or program the

IPCPPro to control the connected AV products. See the IPCPPro Series User Guide (available at www.extron.com) for

details on software and drivers.

Obtain network information (IP addresses, passwords, DHCP settings, and the like) and the MAC address for the control

processor.

Obtain model names, drivers, and setup information for AV devices.

Determine which eBUS cabling topologies to use and obtain cables, mounting hardware, and any power supplies or

hubs required by that conguration.

Step 2: Prepare the Installation Site

ATTENTION:

• Installation and service must be performed by authorized personnel only.

• L’installation et l’entretien doivent être effectués par le personnel autorisé uniquement.

• Extron recommends installing the EBP into a grounded, UL Listed electrical junction box.

• Extron recommande d’installer le EBP dans un boîtier d’encastrement électrique mis à la terre, listé UL.

• If the EBP will be installed into ne furniture, it is best to hire a licensed, bonded craftsperson to cut the access hole

and perform the physical installation so the surface will not be damaged.

• S’il est prévu d’installer le EBP dans du beau mobilier, il est préférable de faire appel à un artisan autorisé et qualié

pour couper le trou d’accès et réaliser l’installation de telle façon que la surface ne soit pas endommagée.

• Follow all national and local building and electrical codes that apply to the installation site.

• Respectez tous les codes électriques et du bâtiment, nationaux et locaux, qui s’appliquent au site de l’installation.

NOTE: For the installation to meet UL requirements and to comply with National Electrical Code (NEC), the EBP must be

installed in a UL Listed junction box (not included with the EBP). The end user or installer must furnish the junction box.

Americans with Disabilities Act (ADA) compliance

When planning where to install these devices, you may need to consider factors affecting accessibility of the button panel such

as height from the oor, distance from obstructions, and how far a user must reach to press the buttons. For guidelines, see

sections 307 (“Protruding Objects”) and 308 (“Reach Ranges”) of the 2010 ADA Standards for Accessible Design available at

http://www.ada.gov/regs2010/2010ADAStandards/2010ADAStandards.pdf.

Site preparation

All of the EBP decorator-style series models, except the EBP 111 D, t any standard 1-gang US wall opening. The EBP 111 D ts

any standard 2-gang US wall opening. All devices ship with a mud ring of the correct size. In addition, Extron offers an assortment

of optional ULListed in-wall junction boxes, external wall boxes (EWBs), and surface or tabletop mounting boxes that can be

used with the eBUS button panels (see www.extron.com).

Step 3: Change the Buttons (Optional)

You can replace any combination of faceplate, buttons, or rotary encoder, depending on the model. You can order replacement or

custom buttons using the Custom Button Builder at www.extron.com.

To replace the buttons:

1. If required, remove the rotary encoder knob (EBP VC1 D only) (see Remove the rotary encoder knob on the next page).

2. Remove the wallplate (all models) (see To reset the firmware on the previous page).

3. Replace the buttons (all models except the EBP 103 D) (see Replace buttons for panels except the EBP 103 D on the next

page).

4. Replace the button labels (EBP 103 D) (see Replace button labels for the EBP 103 D on page 5).

3

Page 4

eBUS Button Panel Decorator-Style Series • Setup Guide (Continued)

h

Module

Remove the rotary encoder knob

(EBP VC1 only)

The EBP VC1 D has a rotary encoder knob. Before replacing

buttons, remove the encoder, as shown here.

1. Turn the rotary encoder knob (gure 4,

hex screw holding the knob in place (2).

2. Insert the provided 0.05 inch Allen wrench and turn the

wrench in the direction shown (3) to loosen the screw.

3. Pull the knob straight out to remove it.

Once the encoder knob is removed, the frame and bezel can be

removed and the buttons replaced as described in the following

sections.

NOTE: To replace the knob, align the ridge on the inside

of the knob with the groove in the metal knob assembly

underneath. Press the knob straight down so that the

magnet in the knob secures it to the unit.

) to expose the

1

Remove the frame and bezel

(All models)

1. To remove the frame, remove the two screws holding the frame

to the module (gure 5, 1).

2. To separate the bezel from the module, insert a small at-

bladed screw driver into the notch at the top of the bezel.

Release the catch holding the bezel to the module (2).

3. Repeat step 2 to release the catch at the bottom of the bezel.

4. Tilt the top of the bezel forward as you remove it to prevent the

buttons falling out.

1

Turn the rotary encoder

to expose the screw.

MUTE

VOLUME

Figure 4. Removing the Rotary Encoder (EBP VC1 D only)

2

2

Bezel

11

3

Use an Allen wrenc

to loosen the screw.

2

Replace buttons for panels except the EBP 103 D

This section applies to all EBP decorator models except the

EBP 103 D (see Replace button labels for the EBP 103 D on the

next page).

1. From the front of the bezel, press the button or button pair to

be replaced backward through its slots in the faceplate until the

membrane containing the button is free.

2. If required, remove all the buttons and replace the bezel.

3. On the back of the bezel, insert the replacement button or button

pair into the appropriate slots. Ensure the text is in the correct

orientation. Align the two pegs in the button membrane (see

gure 6, 1) with the holes located at opposite corners of the

empty space in the faceplate.

4. Press the two buttons into the faceplate until the pegs on the

membrane are seated in the corresponding holes (2).

5. Repeat steps 1 through 4 for any other buttons that you want to

replace.

6. Snap the bezel into place on the module.

7. Reattach the frame, using the two screws removed in

step 1 of Remove the frame and bezel, above.

8. EBP VC1 D only: Replace the rotary encoder knob

by reversing the procedure that was described

above in Remove the rotary encoder knob.

4

EBP 106 D

Frame

Figure 5. Releasing the Faceplate

11

MUTE

LAPTOP

22

Figure 6. Replacing the Buttons

1

1

Page 5

Replace button labels for the EBP 103 D

Separate the

two-piece button

her

fuser

Base

1

You can replace one or more of the labels within the buttons.

Some button labels ship with the unit. You can create and

print your own customized labels using Extron Button Label

Generator software.

To change a label, follow these instructions.

1. Remove the frame and bezel (see the previous page).

2. Gently separate the button cap from its white diffuser:

insert the end of the provided Extron removal tool into the

corner notch and gently twist the tool (see gure 7, 1).

3. Remove the label insert from the button cap.

TIP: If the insert does not come out easily, use a piece

of sticky tape to pull it out of the button cap.

4. Select one of the button labels from the printed label

sheets included with the unit. Remove the label from its

backing and remove the clear, protective lm from the

label.

5. Insert the button label into the button cap (

6. Align the cap with the white diffuser and press the clear

cap into place on the button.

7. Reattach the frame and bezel to the EBP by reversing the

process described in Remove the frame and bezel on the

previous page.

2

).

Product Category

TEXT

Dif

2

Insert

button label.

Button

Lens Cap

Removal

Tool

e at the corner.

Figure 7. Replacing Button Labels on the EBP 103 D

5

Page 6

eBUS Button Panel Decorator-Style Series • Setup Guide (Continued)

M

BUS ID

Step 4: Set the eBUS ID

Up to eight devices can be connected to one control processor. In order for

the control processor to be successfully congured, each device connected to

the same control processor must have a unique six-bit, eBUS ID, which is set

with the DIP switch assembly on the side panel of the EBP (gure 8, 1). If two

or more modules have the same eBUS ID, address conicts may cause one or

more of the panels to not be recognized by the IPCPPro control processor.

Various combinations of the six DIP switches being set to On or Off, provide 64

addresses: 0 is a reserved eBUS ID and the congurable eBUS ID range is 1

through 63 (see the table on the two following pages). The section below shows

an example of binary to decimal conversion.

eBUS ID Setup

Dip Switch

ON

S

B

1 2

4

3

56

L

S

Slide

B

Position

Decimal

1

Off

Off

5

4

2

=32

2

2

=16

3

Off

Off

3

2

2

=8

5

4

On

2

1

2

=4

=2

2

Off

0

Figure 8. Decorator-style eBUS

6

=1

11

Panel DIP Switches

Figure 9. eBUS ID Setup

Add the decimal numbers for each of the DIP switches that are set to On to obtain the address of the device. In gure 9, only DIP

switch 5 is on and the rest are off, which means the address for the device in gure 9 is 0+0+0+0+2+0 = 2.

NOTES:

• Any address can be used except address 0 (binary: 000000), which is reserved (as the address of the controller) and

may not be used.

• Switch 1 (on the left) is the highest value (32, the most signicant bit) and is labelled MSB.

• Switch 6 (on the right) is the lowest value (1, the least signicant bit) and is labelled LSB.

• Up = on = 1, Down = off = 0

The following table shows the factory default eBUS IDs and the corresponding addresses for the decorator-style models. These

IDs can be changed to any valid value.

Model Address eBUS ID

EBP 103 D 23 010111

EBP 105 D 2 000010

EBP 106 D 1 000001

EBP 106P D 13 001101

EBP 108 D 7 000111

EBP 110 D 8 001000

EBP 111 D 9 001001

EBP NAV D 18 010010

EBP VC1 D 17 010001

EBP VC2 D 15 001111

The table on the following two pages shows the DIP switch settings for all 64 possible addresses.

6

Page 7

Product Category

Setting eBUS ID Numbers

In the table below, a DIP switch setting shown as 0 is equivalent to Off. A DIP switch setting shown as 1 is equivalent to On.

NOTE: The ID number 0 (switch setting 000000) is reserved for the control processor and cannot be used by an eBUS device.

DIP Switch Setting

1 2 3 4 5 6 1 2 3 4 5 6

ON

M

S

B

1 2

ON

M

S

B

1 2

ON

M

S

B

1 2

ON

M

S

B

1 2

ON

M

S

B

1 2

ON

M

S

B

1 2

ON

M

S

B

1 2

ON

M

S

B

1 2

ON

M

S

B

1 2

ON

M

S

B

1 2

ON

M

S

B

1 2

ON

M

S

B

1 2

ON

M

S

B

1 2

ON

M

S

B

1 2

ON

M

S

B

1 2

56

4

3

56

4

3

56

4

3

56

4

3

56

4

3

56

4

3

56

4

3

56

4

3

56

4

3

56

4

3

56

4

3

56

4

3

56

4

3

56

4

3

56

4

3

0 0 0 0 0 0

L

S

B

0 0 0 0 0 1

L

S

B

0 0 0 0 1 0

L

S

B

0 0 0 0 1 1

L

S

B

0 0 0 1 0 0

L

S

B

0 0 0 1 0 1

L

S

B

0 0 0 1 1 0

L

S

B

0 0 0 1 1 1

L

S

B

0 0 1 0 0 0

L

S

B

0 0 1 0 0 1

L

S

B

0 0 1 0 1 0

L

S

B

0 0 1 0 1 1

L

S

B

0 0 1 1 0 0

L

S

B

0 0 1 1 0 1

L

S

B

0 0 1 1 1 0

L

S

B

Decimal

Value

0

1

2

3

4

5

6

7

8

9

10

11

12

13

14

DIP Switch Setting

ON

M

S

B

1 2

ON

M

S

B

1 2

ON

M

S

B

1 2

ON

M

S

B

1 2

ON

M

S

B

1 2

ON

M

S

B

1 2

ON

M

S

B

1 2

ON

M

S

B

1 2

ON

M

S

B

1 2

ON

M

S

B

1 2

ON

M

S

B

1 2

ON

M

S

B

1 2

ON

M

S

B

1 2

ON

M

S

B

1 2

ON

M

S

B

1 2

56

4

3

56

4

3

56

4

3

56

4

3

56

4

3

56

4

3

56

4

3

56

4

3

56

4

3

56

4

3

56

4

3

56

4

3

56

4

3

56

4

3

56

4

3

0 0 1 1 1 1

L

S

B

0 1 0 0 0 0

L

S

B

0 1 0 0 0 1

L

S

B

0 1 0 0 1 0

L

S

B

0 1 0 0 1 1

L

S

B

0 1 0 1 0 0

L

S

B

0 1 0 1 0 1

L

S

B

0 1 0 1 1 0

L

S

B

0 1 0 1 1 1

L

S

B

0 1 1 0 0 0

L

S

B

0 1 1 0 0 1

L

S

B

0 1 1 0 1 0

L

S

B

0 1 1 0 1 1

L

S

B

0 1 1 1 0 0

L

S

B

0 1 1 1 0 1

L

S

B

Decimal

Value

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

7

Page 8

eBUS Button Panel Decorator-Style Series • Setup Guide (Continued)

DIP Switch Setting

1 2 3 4 5 6 1 2 3 4 5 6

ON

M

S

B

1 2

ON

M

S

B

1 2

ON

M

S

B

1 2

ON

M

S

B

1 2

ON

M

S

B

1 2

ON

M

S

B

1 2

ON

M

S

B

1 2

ON

M

S

B

1 2

ON

M

S

B

1 2

ON

M

S

B

1 2

ON

M

S

B

1 2

ON

M

S

B

1 2

ON

M

S

B

1 2

ON

M

S

B

1 2

ON

M

S

B

1 2

ON

M

S

B

1 2

ON

M

S

B

1 2

56

4

3

56

4

3

56

4

3

56

4

3

56

4

3

56

4

3

56

4

3

56

4

3

56

4

3

56

4

3

56

4

3

56

4

3

56

4

3

56

4

3

56

4

3

56

4

3

56

4

3

0 1 1 1 1 0

L

S

B

0 1 1 1 1 1

L

S

B

1 0 0 0 0 0

L

S

B

1 0 0 0 0 1

L

S

B

1 0 0 0 1 0

L

S

B

1 0 0 0 1 1

L

S

B

1 0 0 1 0 0

L

S

B

1 0 0 1 0 1

L

S

B

1 0 0 1 1 0

L

S

B

1 0 0 1 1 1

L

S

B

1 0 1 0 0 0

L

S

B

1 0 1 0 0 1

L

S

B

1 0 1 0 1 0

L

S

B

1 0 1 0 1 1

L

S

B

1 0 1 1 0 0

L

S

B

1 0 1 1 0 1

L

S

B

1 0 1 1 1 0

L

S

B

Decimal

Value

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

DIP Switch Setting

ON

M

S

B

1 2

ON

M

S

B

1 2

ON

M

S

B

1 2

ON

M

S

B

1 2

ON

M

S

B

1 2

ON

M

S

B

1 2

ON

M

S

B

1 2

ON

M

S

B

1 2

ON

M

S

B

1 2

ON

M

S

B

1 2

ON

M

S

B

1 2

ON

M

S

B

1 2

ON

M

S

B

1 2

ON

M

S

B

1 2

ON

M

S

B

1 2

ON

M

S

B

1 2

ON

M

S

B

1 2

56

4

3

56

4

3

56

4

3

56

4

3

56

4

3

56

4

3

56

4

3

56

4

3

56

4

3

56

4

3

56

4

3

56

4

3

56

4

3

56

4

3

56

4

3

56

4

3

56

4

3

1 0 1 1 1 1

L

S

B

1 1 0 0 0 0

L

S

B

1 1 0 0 0 1

L

S

B

1 1 0 0 1 0

L

S

B

1 1 0 0 1 1

L

S

B

1 1 0 1 0 0

L

S

B

1 1 0 1 0 1

L

S

B

1 1 0 1 1 0

L

S

B

1 1 0 1 1 1

L

S

B

1 1 1 0 0 0

L

S

B

1 1 1 0 0 1

L

S

B

1 1 1 0 1 0

L

S

B

1 1 1 0 1 1

L

S

B

1 1 1 1 0 0

L

S

B

1 1 1 1 0 1

L

S

B

1 1 1 1 1 0

L

S

B

1 1 1 1 1 1

L

S

B

Decimal

Value

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

8

Page 9

Product Category

+

G

S

+S

+V

Step 5: Cable All Devices

Attach cables using the diagrams in this section as a guide. Connect a 4-pole captive screw connector to each end of the cable,

wiring both ends as shown in gure 7. In most cases the EBPs are powered by the IPCPPro control processor that provides the

eBUS signal. Power is carried on the V+ pin of each eBUS connection.

The four connectors are:

z +V — carries 12 VDC power from the controller, active hub, or power supply

z +S — carries the positive data signal

z -S — carries the negative data signal

z G — ground

Extron STP20-2/1000 or STP20-2P/1000 cable is recommended for eBUS connections.

12 VDC

+ Signal

-

Signal

Ground

Drain Wires (2)

Figure 10. Basic eBUS Connector Wiring and Cable Color Code

Red

Green

White

Black

NOTES:

• The two eBUS ports are interchangeable: either port can be used to connect the device to a controller or EBDB

distribution hub and either can be used to daisy-chain the device to another EBP.

• Connect up to eight eBUS devices for each IPCP Pro control processor.

• Wire the connectors in the same way at both ends.

• Do NOT power an EBP from more than one power source.

• Do not exceed a total of 1000 feet (305 meters) of cable for connections between the IPCP Pro and all the EBP panels.

• Power is provided by the IPCP Pro. If additional power is required, use a PS 1220EB power supply and distribution

hub, or an Extron PS series desktop power supply. If more than one power source is used in a system, make sure that

the devices powered by the rst source are isolated from the devices powered by the second source by disconnecting

the +V pin appropriately (see figure 11 on the following page).

ATTENTION:

• Always use a power supply supplied or specied by Extron. Use of an unauthorized power supply voids all regulatory

compliance certication and may cause damage to the supply and the end product.

• Utilisez toujours une source d’alimentation fournie ou recommandée par Extron. L’utilisation d’une source

d’alimentation non autorisée annule toute conformité réglementaire et peut endommager la source d’alimentation ainsi

que le produit nal.

• If not provided with a power supply, this product is intended to be supplied by a UL Listed power source marked

“Class2” or “LPS” and rated output 12VDC, minimum 1.0A.

• Si le produit n’est pas fourni avec une source d’alimentation, il doit être alimenté par une source d’alimentation

certiée UL de classe 2 ou LPS, avec une tension nominale 12 Vcc, 0,5 A minimum.

• Unless otherwise stated, the AC/DC adapters are not suitable for use in air handling spaces or in wall cavities.

• Sauf mention contraire, les adaptateurs CA/CC ne conviennent pas à une utilisation dans les espaces d’aération ou

dans les cavités murales.

• The installation must always be in accordance with the applicable provisions of National Electrical Code ANSI/

NFPA70, article725 and the Canadian Electrical Code part1, section16. The power supply shall not be permanently

xed to building structure or similar structure.

• Cette installation doit toujours être conforme aux dispositions applicables du Code américain de l’électricité (National

Electrical Code) ANSI/NFPA 70, article 725, et du Code canadien de l’électricité, partie1, section16. La source

d’alimentation ne devra pas être xée de façon permanente à la structure de bâtiment ou à d’autres structures

similaires.

-

9

Page 10

eBUS Button Panel Decorator-Style Series • Setup Guide (Continued)

C

G

R

12V

G

S

CTS

3

G

G

C

S

G

N

MAC: 00-05-A6

XX

S/

#

EBP

V

C

G

PO

12V

1.0

G

Tx

R

S

CTS

3

2

4

G

G

TxR

C

1

2

S

G

M

X

S/

#

EBP

EBPs that are relatively far from the control processor (see the eBUS Technology Reference Guide on www.extron.com for

details) can be connected to an optional Extron PS1220EB eBUS power supply and distribution hub, or an Extron PS series

desktop power supply as shown in the following diagrams.

T

POWE

1.0A MAX

IPCP Pro

COM 1

RRT

VOL

COM 2

Tx

RELAYS

DIGITAL I/O

eBUS

-S+V +S G

PWR OUT = 6W

X

IPCP PRO 250

-XX-XX-

N: ####### E#####

IR/S

LA

ATTENT ION: Do NOT connect the

power pin to any device that is already

powere d by the IPC P Pro control

processor or by an additional power

supply.

+ Signal

-

Signal

Ground

100-240V 50-60Hz

Power Input

(100-240 VAC,

50-60 Hz)

0.6A MAX

-S+V +S G-S+V +S G-S+V +S G

eBUS 24 WATTS MAX

-S+V +S G-S+V +S G -S+V +S G

X

Tie drain wires

to ground.

PS 1220EB

+12 VDC

+ Signal

-

Signal

Ground

• Connect up to ve (5) eBUS

endpoint devices to the PS 1220EB.

• Wire the connectors the same at both

ends.

• All ports are identical and

interchangeable.

3/16" (5 mm) Max.

Figure 11. Cabling an eBUS System with an PS 1220EB Power Supply and Distribution Hub

eBUS Connections

eBUS

+

V

+

S G

–

S

+

V

+

S G

–

S

COM 1

A MAX

xRT

WER

VOL

IPCP Pro

COM 2

x

RELAYS

DIGITAL I/O

1

eBUS

-S+V +S G

PWR OUT = 6W

IPCP PRO 250

IR/S

+

V

+

eBUS

S G

–

S

+

V

+

S G

–

S

AC: 00-05-A6-XX-XX-X

N: ####### E#####

3/16" (5 mm) Max.

Tie drain wires to ground.

External Power Supply

(12 VDC, 1.5 A max.)

Ground

-

Signal

+ Signal

Ground

-

Signal

+ Signal

+12 VDC

+12 VDC input

Figure 12. Cabling EBP Panels with an Extron PS Series Desktop Power Supply

– Return

Ground

all Devices

+

V

+

eBUS

S G

–

S

+

V

+

S G

–

S

EBP

RidgedSmooth

NOTE:

supply before connecting it to the EBP.

Check the polarity of the power

NOTE: Although the rear panel for the EBP 103 D is different from the rear panel shown in gures 11 and 12, power and eBUS

cables are connected in exactly the same way.

10

Page 11

Product Category

Step 6: Configure the System

EBPs are shipped with pre-labelled buttons in place but these buttons do not have any functions associated with them until

they are congured with Global Congurator or programmed with Global Scripter. See the Global Configurator Help File or the

Global Scripter Help File for step-by-step instructions and detailed information.

Step 7: Test and Troubleshoot

1. Verify that the DIP switches on the EBPs are set to the desired address on each device and that there are no eBUS ID

conicts in the system (see Step 4: Set the eBUS ID on page 6).

2. The eBUS status LEDs (see figure 1,

eBUS ID address conicts.

The EBP 103 D has three LEDs:

z Off — If all three LEDs are off, the device is not receiving power.

z Amber LED— Lights solidly when the device is receiving power but communication with the control processor is not

conrmed.

z Red LED— Lights solidly when there is an eBUS ID address conict.

z Green LED — Lights solidly when power and communication are both conrmed.

All other decorator-style panels have a single green LED that provides information as follows:

z Off — The device is not receiving power.

z Slow blink (1 blink per second)— The device is receiving power but communication with the control processor is not

conrmed.

z Fast blink (2 blinks per second) — There is an eBUS ID address conict.

z Lights solidly — Power and communication are both conrmed.

3. Verify that cables to and from the EBPs are wired the same at each end (pin 1 to pin 1, pin 2 to pin 2, and so forth).

4. Test the system.

z Press buttons on the EBPs and ensure the buttons light as desired and that the appropriate control commands or

functions are triggered.

z Ensure that the audio output responds correctly to the volume knob or button. Also ensure that the volume LEDs light

correctly as you increase or decrease the audio gain.

5. Make adjustments to wiring, eBUS ID address, or system conguration as needed. Remember that the rear panel ports

and DIP switches will not be accessible after the EBP is mounted. If needed, upload a revised conguration to the control

processor.

If you have questions during installation and setup, call the ExtronS3 Sales & Technical Support Hotline or the ExtronS3

Control Systems Support Hotline (1.800.633.9877).

, on page 1) provide information about power and communication status and

B

11

Page 12

eBUS Button Panel Decorator-Style Series • Setup Guide (Continued)

Step 8: Mount the EBPs

EBP panels can be installed directly into the wall using a 1-gang or 2-gang (EBP 111D) wall mounting bracket (mud ring) or a

UL Listed junction box. Figures 13 (below) and 14 (on the next page) show how to mount a 1-gang EBP. Use the same procedure

to mount the two-gang EBP 111 D.

ATTENTION:

• All electrical installation should be performed by qualied personnel in accordance with local and national building

codes, re and safety codes, and local and national electrical codes.

• Toute installation électrique devrait être effectuée par un personnel qualié, conformément aux codes du bâtiment, aux

codes incendie et sécurité, et aux codes électriques locaux et nationaux.

Before mounting:

1. Decide where to locate the panel. Take into consideration the position of wall studs and windows that could obstruct cable

runs.

NOTES:

• For 1-gang products the hole is 3.61 inches (92 mm) H x 2.13 inches (54 mm) W.

• For the EBP 111 D (2-gang) the hole is 3.61 inches (92 mm) H x 3.97 inches (100 mm) W.

• EBP products ship with a wall mounting bracket (mud ring). Electrical junction boxes must be purchased

separately. Ensure the junction box is the correct size for the EBP.

• The EBP VC1 D is deeper than other decorator-style panels and has a front panel rotary encoder that protrudes

from the wall more than the buttons of the other models.

• Allow at least 1.44 inches (37 mm) depth in the wall or furniture for cables.

• The EBP VC1 D front panel, including the rotary encoder, extends 0.77 inches (20 mm) from the wall.

2. If required, install an electrical junction box by following the instructions provided by the manufacturer.

To install a wall mounting bracket, see steps 1-3 of “Mounting with a wall mounting bracket,” below.

3. Disconnect power from all devices at the source and run the cables through the wall or furniture.

4. Connect the cables to the EBP rear panel (see EBP Rear and Side Panel Features on page 1).

5. If you have not already done so, set the DIP switches to give the panel a unique eBUS ID (see Step 4: Set the eBUS ID on

page 6).

Mounting with a wall mounting bracket (mud ring)

1. Mark the position of the hole on the wall in

the desired location. Use a level to ensure

hole is marked at the correct angle.

2. Use a drywall saw to cut a hole (

3. Insert the mounting bracket into the hole.

Use a screwdriver to turn and tighten the

locking arms until they clamp the mud

ring to the mounting surface (2). Do not

overtighten.

4. Use the two provided Phillips head screws to

secure the module to the mounting bracket

(3).

5. Use the two screws provided to secure the

frame to the module (4).

1

).

Wall

11

2

2

Wall Mounting

Bracket

3

3

4

4

12

EBP 106 D

Frame

Figure 13. Mounting with a Wall Mounting Bracket

Page 13

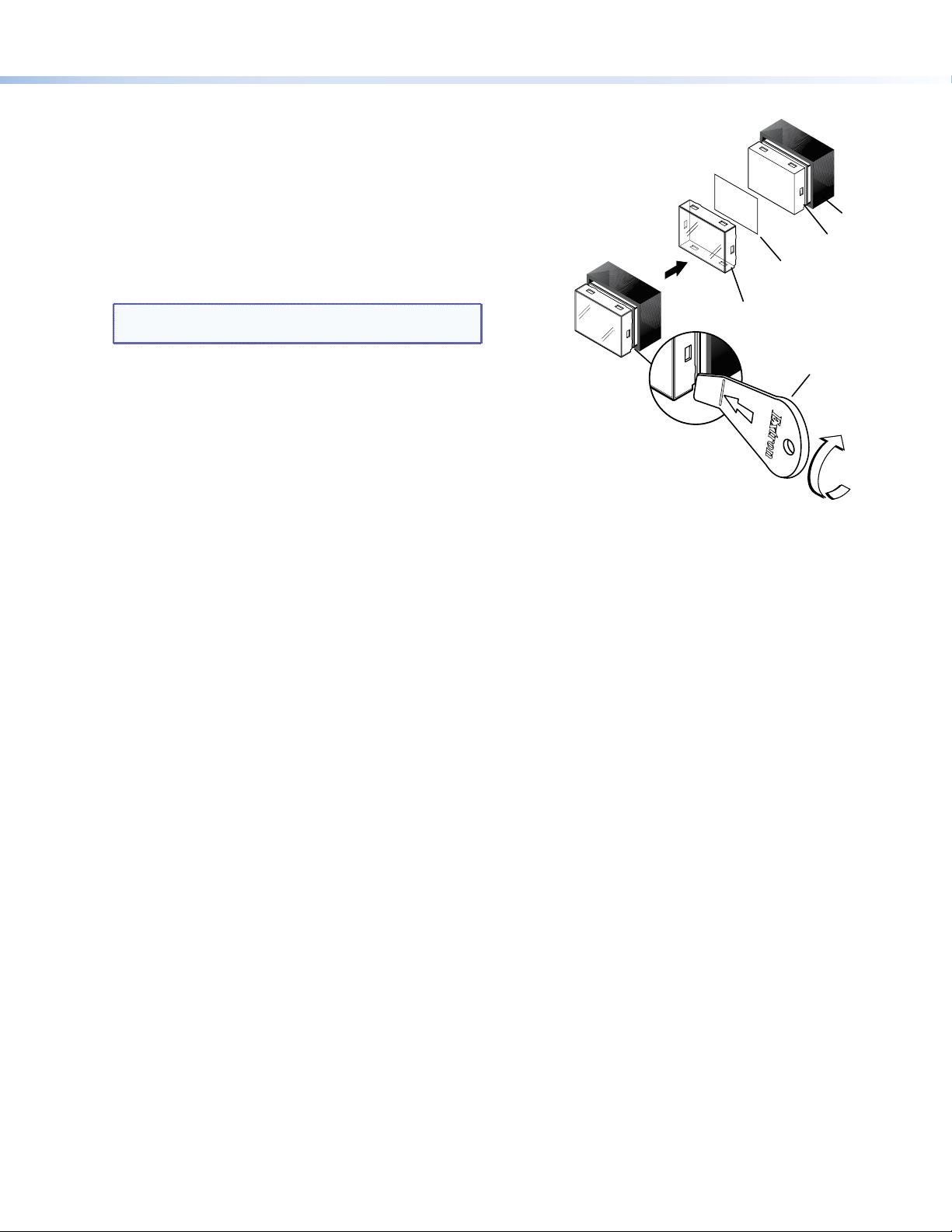

Mounting with a UL Listed Electrical Junction Box

Electr

Ju

Bo

Electr

Ju

Bo

1. Install the junction box by following the instructions provided by the manufacturer.

2. Use the two provided Phillips head screws to secure the module to the junction box (

3. Use the two screws provided to secure the frame to the module (

4

).

33

ical

nction

x

4

4

3

Product Category

).

Frame

Figure 14. Mounting with a UL Listed Electrical Junction Box

Removing Decorator-Style EBPs

If you need to remove a decorator-style EBP from where it has been mounted, follow these steps:

1. Remove the two screws holding the frame to the module (see gure 13,

2. Remove the two screws holding the module to the junction box or wall mounting bracket (

3. Remove the unit from the wall (

) and remove the eBUS cables from the rear panel connectors.

3

1

).

22

ical

nction

x

33

1

1

2

).

Frame

Figure 15. Removing the EBP 106 D

13

Page 14

eBUS Button Panel Decorator-Style Series • Setup Guide (Continued)

© 2016 - 2018 Extron Electronics All rights reserved. All trademarks mentioned are the property of their respective owners. www.extron.com

14

68-1449-50 Rev. D

03 18

Loading...

Loading...