Page 1

complete user guide and installation

instructions befor

oduct to the power sou

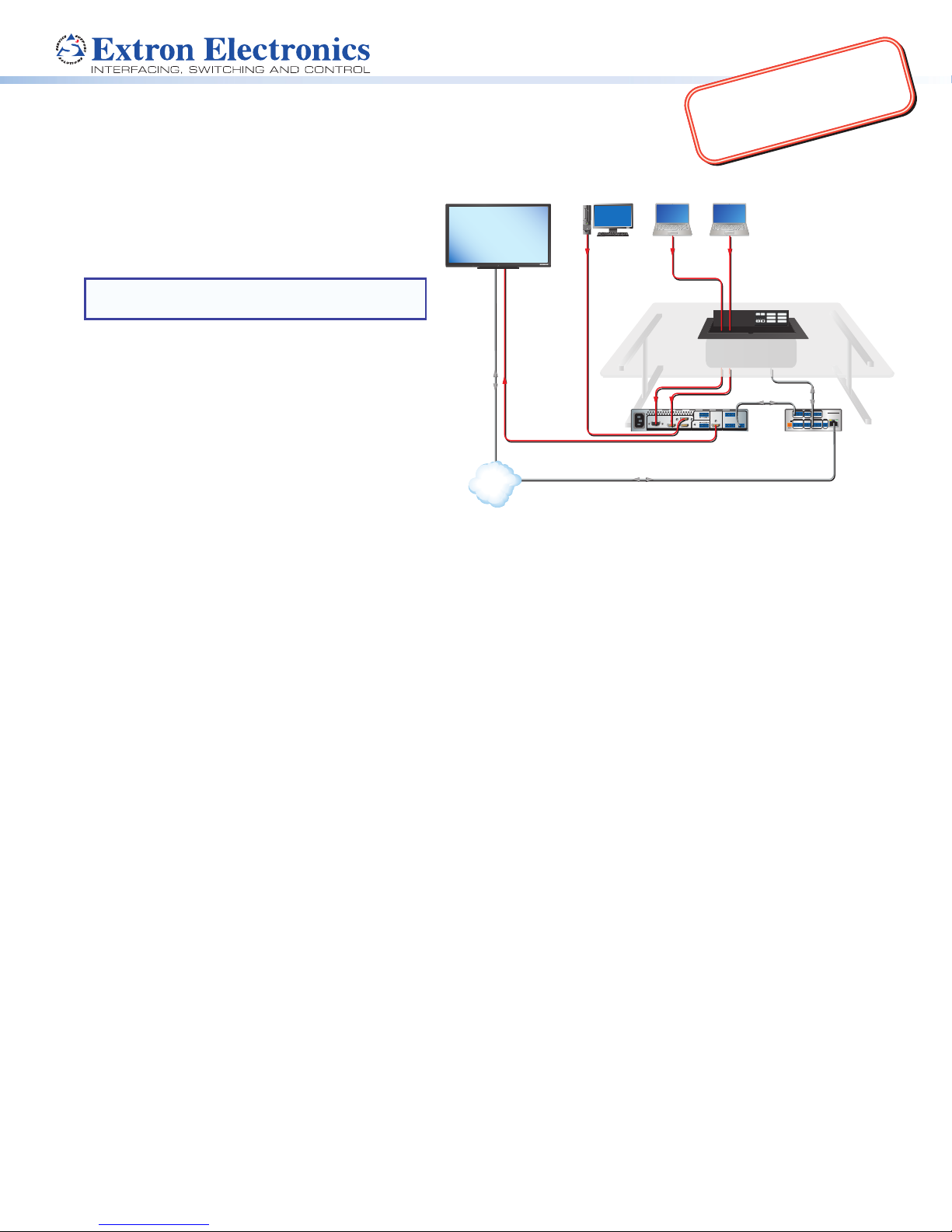

EBP 1200C Cable Cubby Enclosure

Display with Speakers

Laptop Laptop

Computer

with eBUS® Button Panel • Setup Guide

Product Category

m

o

c

.

n

o

IMPORTANT:

Go to www.extron.com for the

pr

r

t

x

e

.

w

w

w

e connecting the

rce.

The Extron EBP1200C is a Cable Cubby® 1200 with an

MODEL 80

integrated eBUS button panel to combine convenient

AV and data connectivity with a fully customizable AV

system control interface for use with Extron IPCPPro

Series Control Processors.

NOTE: These products are only for use with Extron

UL Listed IPCP Pro control processors.

FLAT PANEL

HDMI

VGA

HDMI

Extron

EBP 1200C

Cable Cubby eBUS

Button Panel

ON

OFF

PC

HDMI

LAPTOP

VGA

MUTE

AUX VIDEO

Extron

This guide provides basic instructions for an

experienced installer to install an EBP1200C Cable

Cubby button panel:

• Setup Checklist

• Installing the EBP 1200C Cable Cubby

• Connecting to the eBUS System

For more details on eBUS, see the eBUS Technology

Reference Guide, available on www.extron.com. For

details on conguration, see the software help les.

Setup Checklist

Figure 1. EBP 1200C Application Diagram

Ethernet

Network

TCP/IP

HDMI

100-240V ~ --A MAX

HDMI HDMI3

21CONFIGURABLE

HDMI4

INPUT REMOTE

50-60 Hz

Extron

IN1604 HD

Four Input Scaler

Ethernet

OUT

IN

12

LR

L

R

AUDIOOUTPUT

3214+V

TALLY OUT

HDMI

CONTACT IN

1234G

RS-232

RS-232

TxRx G

Extron

IPCP Pro 250

IP Link Pro

Control Processor

Step 1 — Planning

Download and install the latest version of the software, rmware, and device drivers needed to congure the IPCPPro

and control the connected AV products. See the IPCPPro Series User Guide (available at www.extron.com) for details on

software and drivers.

Obtain network information (IP addresses, passwords, DHCP settings, and the like) and the MAC address for the control

processor.

Obtain model names, drivers, and setup information for AV devices.

Determine which eBUS cabling topologies to use and obtain cables, mounting hardware, and any power supplies or hubs

required by that conguration.

Make sure you are familiar with all the Included parts (see the next page) and have all the necessary tools for installing the

Cable Cubby.

Before cutting a hole in any furniture, select the best location for the EBP 1200C.

• Ensure that the product is oriented so that the lid opens in the desired direction.

• Ensure there is enough space for all the system cables and components, including cable retractors, if they are to be

installed.

Check all relevant regulations (see the next page).

eBUS

COM 1

COM 2

DIGITAL I/O

IPCP PRO 250

G

TxRx RTSCTS

G

TxRx

1 2 3 4 G

POWER

RELAYS

eBUS

IR/S

VOL

12V

1 2 C

VCG

--A MAX

+V+S-SG

S G

PWR OUT = 6W

LAN

Step 2 — Cutting the Table

Decide on the method for cutting a hole in the table (see Cutting the Table on page 3).

Verify that you have the correct cut-out template and dimensions (see Cutting the Table on page 3).

Step 3 — Setting the eBUS ID Address

All eBUS devices connected to the same control processor must have a unique eBUS ID address. This requires access to the

DIP switches on the bottom panel of the EBP 1200C and it is more convenient to set the address before the EBP 1200C is

installed in the table (see Setting the eBUS ID Address on page 10).

1

Page 2

EBP 1200C • Setup Guide (Continued)

34

89

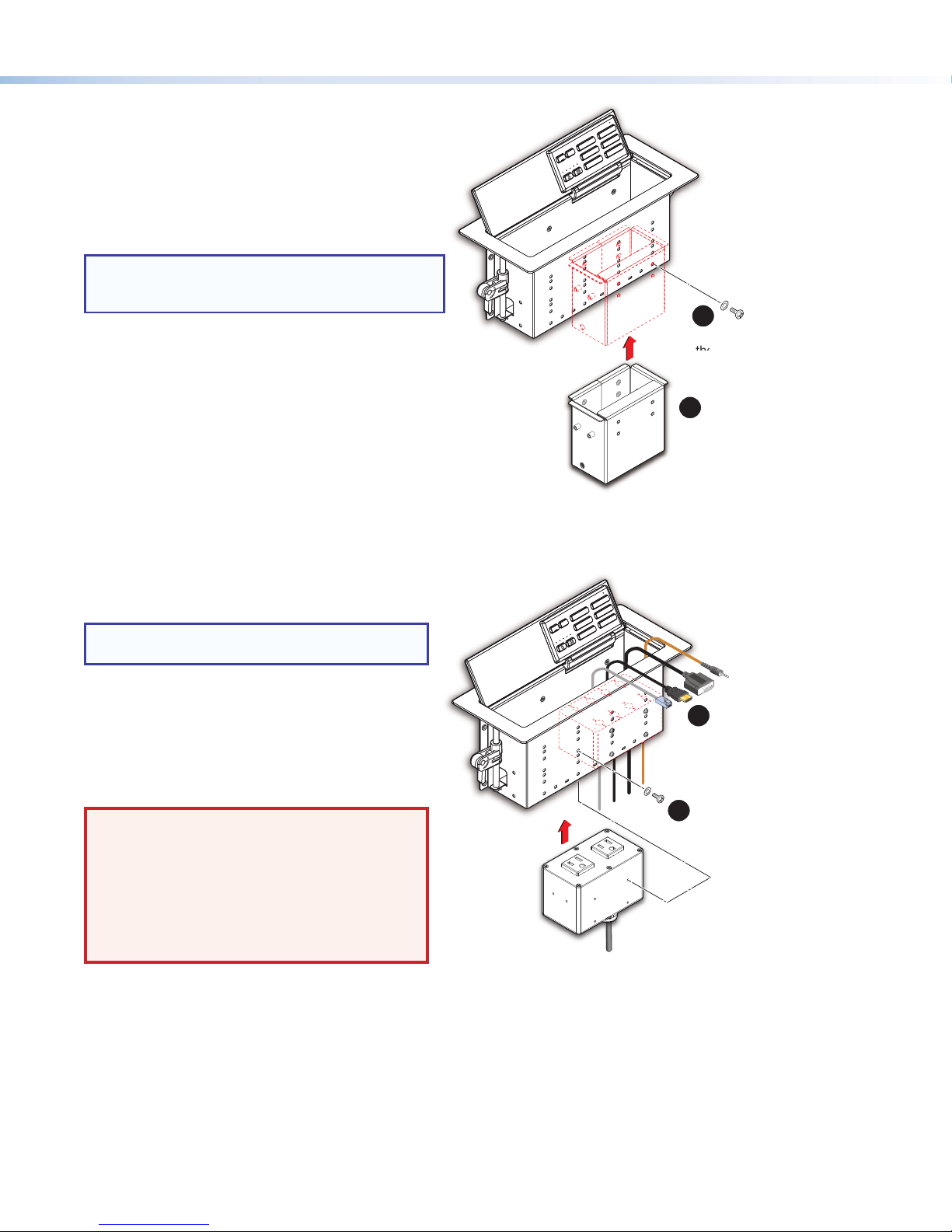

Step 4 — Mounting the EBP 1200C

Connectivity modules allow you to populate the Cable Cubby enclosure with a combination of AAP™ devices, cable

pass-throughs, retractors, or power modules. The EBP 1200C accommodates your choice of any two modules, allowing you

to customize the device to meet your specic needs.

The AAP module and cable pass-through module require some assembly before they can be installed in the EBP 1200C.

Install the modules.

Mount the EBP 1200C.

Install the retractors.

Route the cables.

Step 5 — Changing the Buttons

The EBP 1200C ships with a set of buttons installed and some additional blank buttons ship with the unit. You can order

others from www.extron.com. To replace one or more of the individual buttons, see Changing Buttons on page 9

Step 6 — Connecting to the eBUS System

Connect the EBP 1200C to an eBUS device or control processor.

Congure the system.

Test and troubleshoot.

Planning

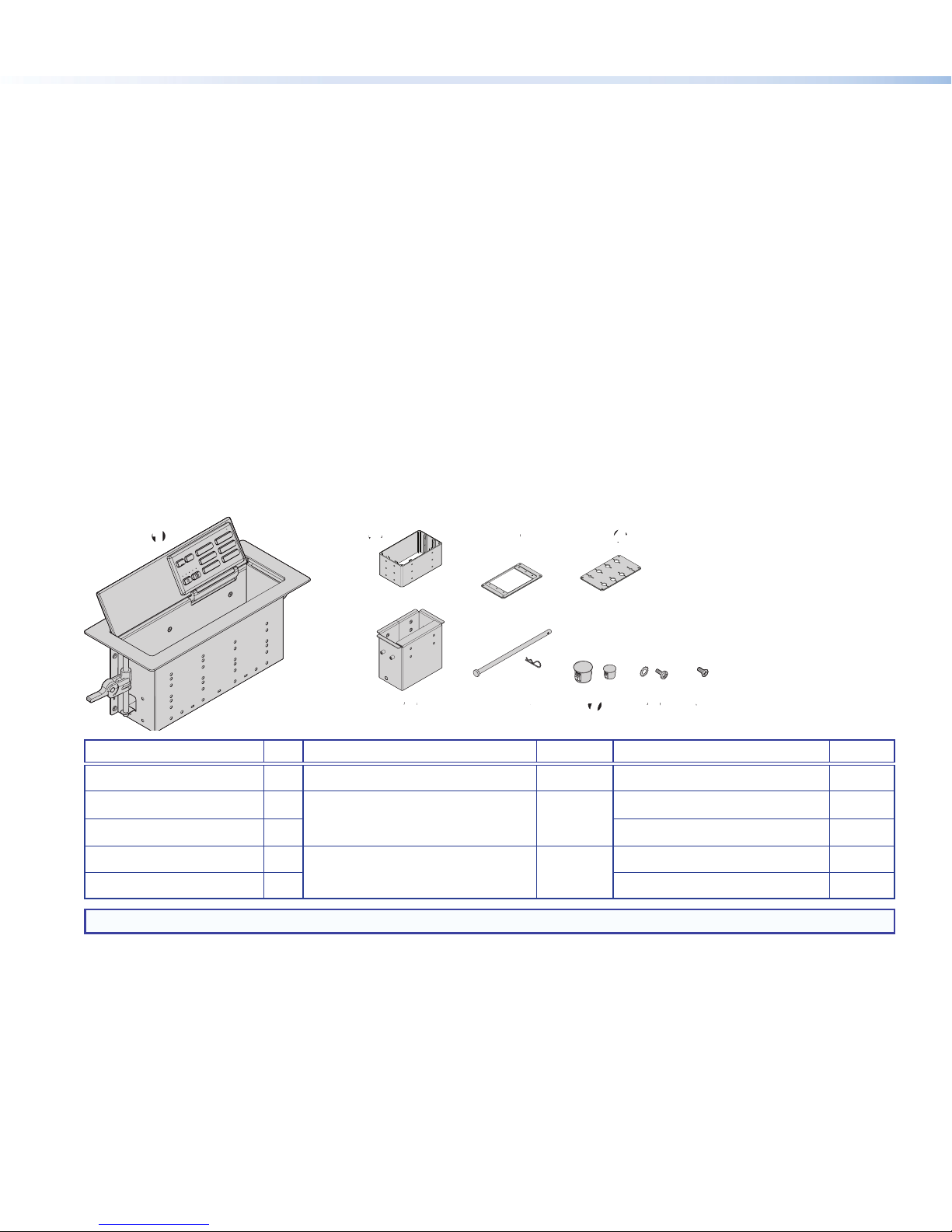

Included parts

11223

21-525-01LF

e

HDMI

VGA

PC

OFF

AUX VIDEO

LAPTOP

ON

MUTE

e

5

566778

4

9

Item Qty Item Qty Item Qty

EBP 1200C

1

Connectivity Bracket

2

AAP Frame Plate

3

Cable Grommet Plate

4

Retractor Bracket

5

1

1*

1 Extron removal tool (not shown) 1

1

1 Blank buttons (not shown) 1

Retractor Pin and Clip

6

Hole Plugs

7

#6 Pan-head Mounting Screws

8

and Star Washers

1

6 (3/8")

2 (1/4")

8 Extron Tweeker (not shown) 1

#4-40 Module Screws

9

NOTE: *A single connectivity bracket is provided. It can be used with either the AAP frame plate or the cable grommet plate.

Figure 2. EBP 1200C Included Parts

Check all relevant regulations

• Ensure the installation complies with local, state, and national building and electrical codes.

• Ensure the installation complies with the Americans with Disabilities Act or other accessibility requirements. When planning

where to install these devices, you may need to consider factors affecting accessibility of the button panel such as height

from the oor, distance from obstructions, and how far a user must reach to press the buttons.

For guidelines, see sections 307 (“Protruding Objects”) and 308 (“Reach Ranges”) of the 2010 ADA Standards for Accessible

Design available at http://www.ada.gov/regs2010/2010ADAStandards/2010ADAStandards.pdf.

8

2

Page 3

Product Category

Installing the EBP 1200C Cable Cubby

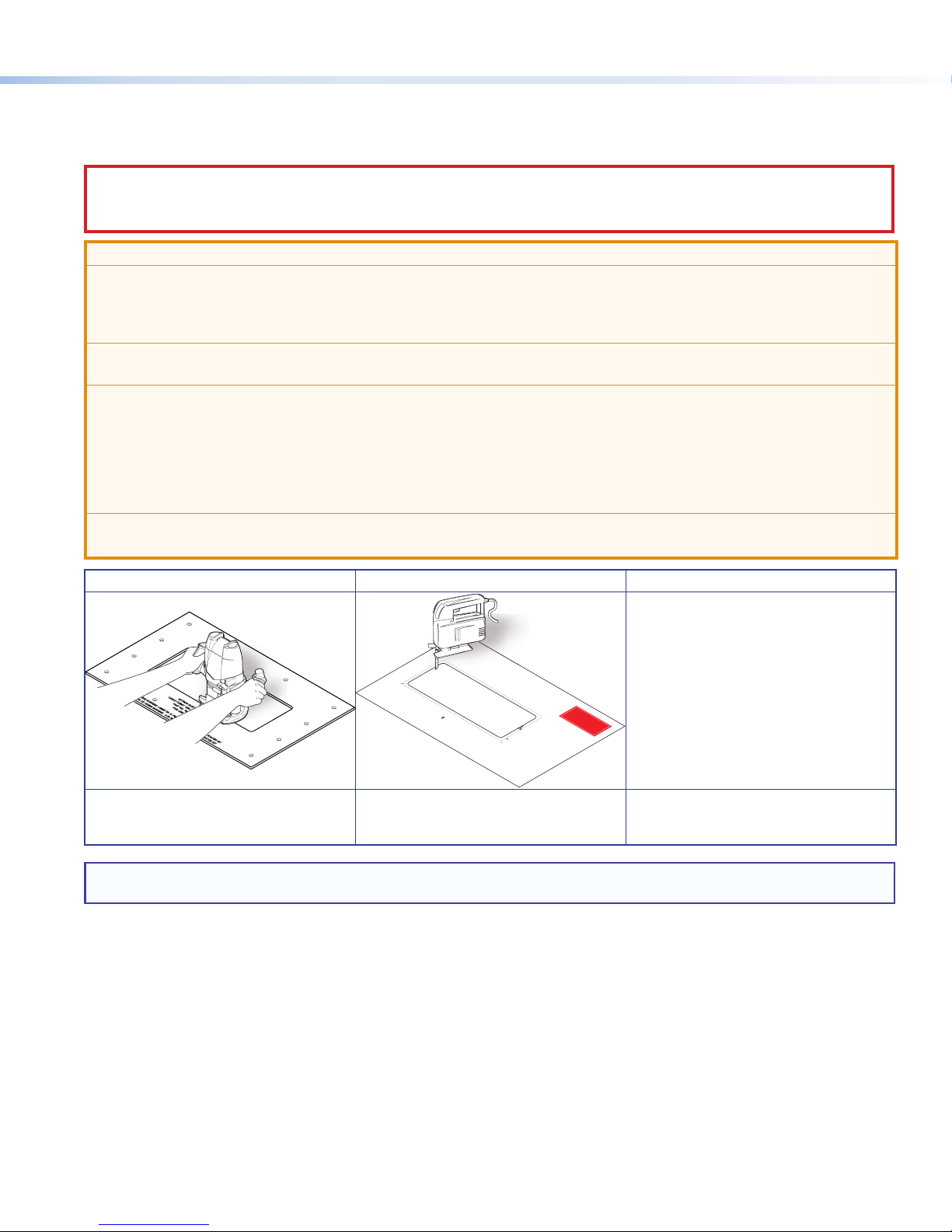

Cutting the Table

CAUTION: Wear safety glasses when operating power equipment. Failure to comply can result in eye injury.

ATTENTION : Portez des lunettes de sécurité lorsque vous utilisez l’équipement électrique. Ne pas respecter cela peut

conduire à une blessure à l’oeil.

ATTENTION:

• The opening in the table for the Cable Cubby should be cut only by licensed and bonded craftspeople. Exercise care

to prevent scarring or damaging the furniture.

• L’ouverture dans la table pour le CableCubby devrait être coupée seulement par des artisans autorisés et qualiés.

Faites attention à ne pas faire de marques sur le meuble et à ne pas l’endommager.

• Follow all national and local building and electrical codes that apply to the installation site.

• Respectez tous les codes électriques et du bâtiment, nationaux et locaux, qui s’appliquent au site de l’installation.

• Use the appropriate metal Extron routing template or refer to the surface cutout dimensions before cutting a hole in

the furniture or other surface. Pay special attention to the direction the unit will face. The connector access side is

underlined (see CNC Wood Router below). Extron is not responsible for miscut mounting holes.

• Utilisez le gabarit de détourage métallique approprié ou reportez-vous aux dimensions de découpe de la surface

indiquées ci-après avant de découper le meuble ou la surface. Faites particulièrement attention à la directions dans

laquelle l’unité sera dirigée. Le côté pour accéder au connecteurs est souligné (voir CNC Wood Router ci-dessous).

Extron ne sera pas responsable des erreurs de coupe.

• Ensure the table surface is at least 0.50 inch (1.27 cm) thick.

• Assurez vous que la surface de la table est au moins 1,27 cm (0,50 pouce) d’épaisseur.

Hand Router and Routing Template Jigsaw and Paper Cut-out Template CNC Wood Router

If using a CNC wood router or other

precise machinery, use the exact

cut-out dimensions:

Cut-O

Cable Cubby 1200

ut Template for the Extron

Cu

0.

tOut

25"

Radius:

(

0.6 cm)

User Access

Visit www.extron.com for the

EBP 1200C routing template part

number and instructions.

The cut-out template and

dimensions are available online at

www.extron.com.

and EBP 1200C

Trim Ring

Lip

Outer Ed

(Do

g

not cut th

e

of Fro

i

s l

i

n

P/N 68-

2

4

72-01

Page Size: 11" x 17"

Print Scale 1:1

Do not Shrink

1. Confirm the produc

2. Remove the s

(gray) from the

3. Me

4

. Mark the

furniture

asure the

wil

5. Double check

urfac

l be

pos

then cut

t to be

c

t

e

e

where the

utout and template

install

mplate

cut-out are

ition on the

installe

ed.

the ope

.

t

Ca

he dimensions

d.

a

ble Cubby

ning.

.

1200

n

t Bezel

e.)

Re

v

. C

and position,

User Access Width

10.00" (25.40 cm)

Depth

4.00" (10.16 cm)

NOTE: The metal router guide must be purchased separately. It is reusable and should not be discarded when the installation

is complete.

3

Page 4

EBP 1200C • Setup Guide (Continued)

e the AAP plate on the connectivity brackets,

Secure up to three single-space

AAPs in the AAP plate.

Secure the AAP plate on the connectivity brackets,

using four of the provided module screws.

#4-40 Nut with

Captive Washer

Insert cables through the bottom of the connectivity bracket.

Connect cables to the AAPs.

1

3

2

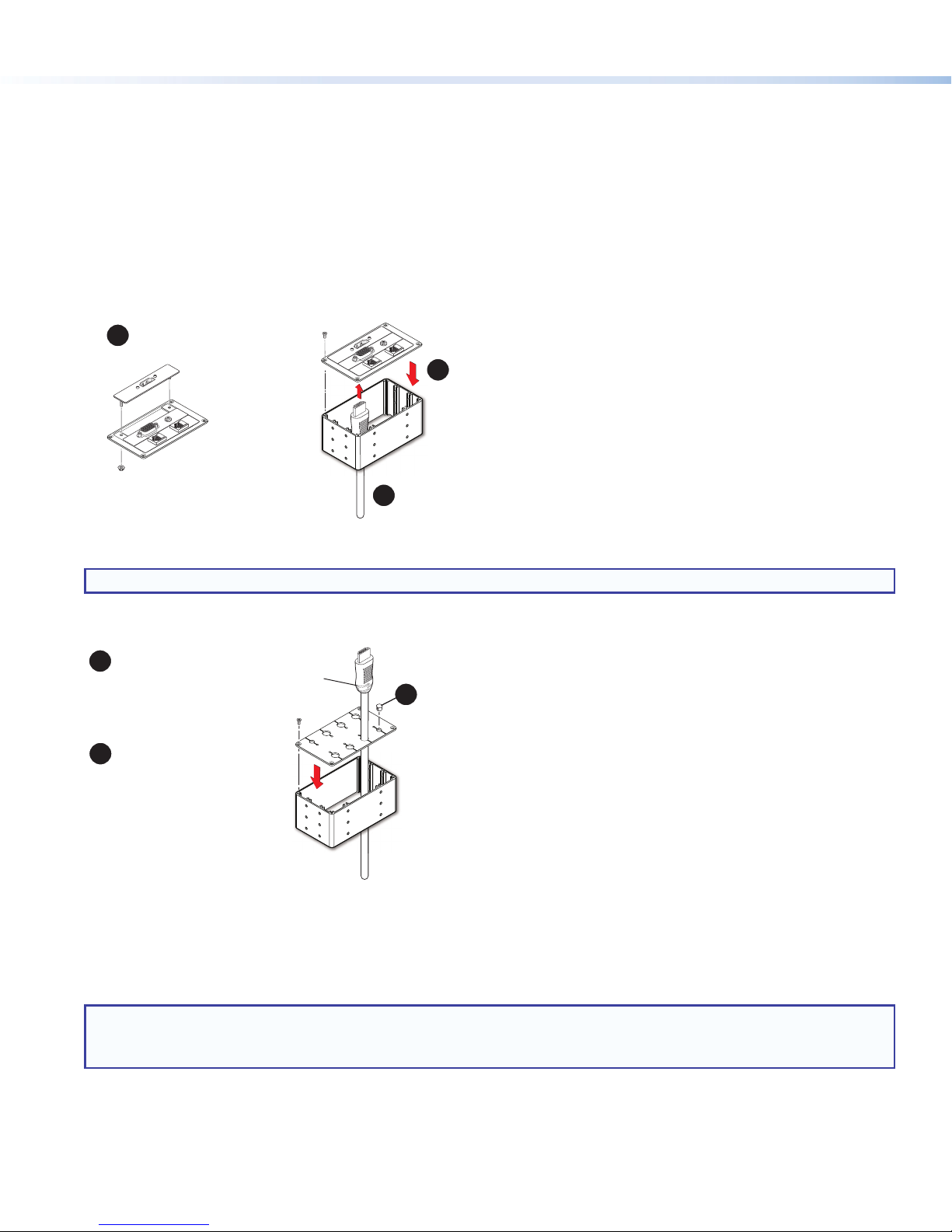

Mounting the EBP 1200C

A variety of modules allow you to populate the Cable Cubby enclosure with a combination of AAPs, cable pass-through,

retractors, or power modules. The EBP 1200C accommodates your choice of any two modules, allowing you to customize the

device to meet your specic needs.

Assemble the Connectivity Modules of your Choice

The EBP 1200C is provided with a single connectivity bracket that can be used with either the AAP frame plate or the cable

grommet plate. Follow the steps below to assemble the connectivity modules of your choice before they can be mounted into the

EBP 1200C.

AAP module

The AAP module accommodates up to three single-space AAPs.

Secure up to three single-space

1

AAPs in the AAP plate.

Secur

3

using four of the provided module screws.

#4-40 Nut with

Captive Washer

Insert cables through the bottom of the connectivity bracket.

2

Connect cables to the AAPs.

Figure 3. Assembling the AAP Module

NOTE: After assembling the AAP module, proceed to Install the Modules below.

Cable pass-through module

The cable pass-through module accommodates up to eight AV cables.

1

Insert cables through the bottom of

the connectivity bracket and into the

holes of the grommet plate.

You may need to bend the

plate gently to slide the cable

past the slot opening.

2

Secure the grommet plate on the

connectivity bracket, using four

of the provided module screws.

Figure 4. Assembling the Cable Pass-through Module

Install the Modules

Determine where the modules are installed in the Cable Cubby. Any combination of two modules can be installed. The modules

can be installed on either side of the enclosure and at various heights.

3

Snap the included

hole plugs into any

unused holes.

NOTES:

• Ensure that there is enough room above the modules for the Cable Cubby lid to close completely.

• Use a screwdriver to secure the modules with the screws.

4

Page 5

Retractor bracket

ews with star washers. Tighten

Se

e and

ews

Use the retractor bracket to mount retractors in the Cable

Cubby enclosure. The retractor bracket accommodates

up to three Retractor Series/2 or Retractor Series/2

XL cable retraction modules. The retractors must be

purchased separately.

If you require retractors, insert the retractor bracket as

shown in gure 5.

Product Category

HDMI

VGA

PC

OFF

AUX VIDEO

LAPTOP

ON

MUTE

e

NOTE: Do not mount the retractors in the retractor

bracket until after the Cable Cubby is mounted

(see Install the Retractors on page 7).

Install retractor ller modules (see www.extron.com) in

any unused retractor mounting spaces.

Optional retractor brackets (see www.extron.com) each

accommodate two cable retraction modules. These

brackets must be purchased separately. They are sold

in pairs and allow the cable retractors to be mounted at

the outer edges of the enclosure with one of the other

modules mounted centrally.

Figure 5. Install the Retractor Bracket

AAP module, cable pass-through module and power module

Insert the modules into the cable cubby as shown in

gure 6.

NOTE: Extron recommends mounting the power

module on the left side of the enclosure.

AC power and AC+USB power modules are available

for US, Europe, and other major world markets. They

must be purchased separately (see www.extron.com).

Most AC power modules provide two unswitched AC

outlets.

The AC+USB power modules provide one or two AC

outlets and two USB power outlets.

WARNING: Risk of Electric Shock. To ensure

proper electrical grounding, use the

provided #6-32 mounting screws with the

star washers.

AVERTISSEMENT : Risque de choc électrique.

An d’assurer une mise à la terre correcte,

utilisez les xations de mise à la terre #6-32 et

les rondelles en étoile fournies.

Figure 6. Install the Connectivity and Power Modules

21-525-01LF

e

2

Secure the bracket using four of

the provided pan-head mounting

scr

the screws using a screwdriver.

1

Insert the bracket as shown.

The bracket may be installed on the

left or right side of the enclosur

at the lowest height.

HDMI

VGA

PC

OFF

AUX VIDEO

LAPTOP

ON

MUTE

e

Insert the modules

1

into the Cable Cubby.

21-525-01LF

e

Secure the modules using

2

four of the provided

pan-head mounting scr

and star washers.

125V~ 12A MAX TOTAL

5

Page 6

EBP 1200C • Setup Guide (Continued)

into the hole to test the t.

nd

face of

h

e

ON

OFF

PC

LAPTOP

MUTE

AUX VIDEO

VGA

HDMI

is rmly seated in the table.

the Cable Cubby.

21-526-0

21-526-0

Locking

plate

Mount the EBP 1200C

TIP: Before mounting the EBP 1200C, you should set the eBUS ID address, since this requires access to the DIP switches,

which are on the bottom of the unit (see Setting the eBUS ID Address on page 10).

Insert the EBP 1200C enclosure into

the table

CAUTION: The anged edges of the top

of the surface enclosure are sharp.

These edges are also soft and may be

easily nicked or bent. Exercise caution

when handling the enclosure to prevent

personal injury or damage to the

enclosure.

ATTENTION : Les extrémités à brides

du haut de la surface du boîtier sont

aiguisées. Ces extrémités sont aussi

lisses et peuvent facilement être coupées

ou pliées. Soyez prudents lorsque vous

manipulez le boîtier an d’éviter de

l’endommager ou de vous blesser.

1

Remove the plastic strips and

astic strips a

lm on the surface of the

Cable Cubby.

2

Ensure that the

side clamps are

seated against the

enclosure.

e

the

HDMI

VGA

PC

OFF

AUX VIDEO

LAPTOP

ON

MUTE

e

3

Lower the Cable Cubby

If necessary, carefully

enlarge the opening.

Figure 7. Insert EBP 1200C Enclosure into the Table

Under the Table, Adjust the Side Clamps on the Enclosure

HDMI

VGA

PC

OFF

AUX VIDEO

LAPTOP

ON

MUTE

e

Lever

01LF

-

525

21

e

21-525-01LF

1

e

NOTE: To lower the side clamp, turn the lever down,

then press and hold the locking plate while sliding

down the clamp.

21-525-01LF

e

e

Rotate the side clamp

outward and ensure

that the lever is down.

Figure 8. Secure the Cable Cubby Enclosure

6

Slide the clamp all the

21 3

way up against the

bottom of the table.

Ensure the Cable Cubby

Raise the lever to secure

Page 7

Product Category

e

ON

OFF

PC

LAPTOP

MUTE

AUX VIDEO

VGA

HDMI

Insert the pin thr

Retractor mounting hole on

the side of the Cable Cubby

and Retractor assembly

. Do not

cables to the holes

Install the Retractors

Retractors can be installed in a vertical, angular, or horizontal orientation. No adjustment of the enclosure screws is needed if the

retractors are mounted vertically. To mount at an angle or horizontally, adjust the enclosure screws as shown below. When the

retractors are mounted horizontally, the retractor mechanism must be secured to the underside of the table (see Cable Retractor

Setup Guide, which is available at www.extron.com).

To secure the retractors in the retractor bracket, follow the instructions in gure 9.

Horizontal Mounting

Cable Release

Assembly

Remove two enclosure screws

(one on each side) from this position.

Then mount the Retractors as shown

at left.

3

2

ough the

.

1

Insert Retractors into

the Retractor bracket.

Figure 9. Installing Retractors

Secure the locking screw

4

on each Retractor

overtighten.

Route and Connect the Cables to Cable Cubby

Secure the clip

on the pin.

See the Cable Retractor Setup Guide, available

at www.extron.com, for additional steps.

Angular Mounting

Remove the two enclosure screws, as shown

above, and then follow this step:

Move the cable release assembly upward until

the angular mounting hole is visible. Reinstall the

enclosure screws in this hole (both sides).

CAUTION: Risk of Electric Shock.

This equipment must be grounded.

ATTENTION : Risque de choc

électrique. Cet équipement doit

être xé au sol.

Figure 10. Route and Connect AV Cables

Connect cables to the AV system

3

and connect the AC power cord.

NOTE: Ensure there is no tension

on the power cable.

Using zip ties, secure

2

on the bottom of the Cable Cubby.

For cable pass-through applications,

1

allow at least 36 inches (0.9 m) of cable

loop for each cable.

7

Page 8

EBP 1200C • Setup Guide (Continued)

BC

Connecting to the eBUS System

The EBP 1200C has two eBUS ports that support power and communication with an IPCPPro control processor. Up to eight

eBUS endpoint devices such as EBP button panels can be connected to the control processor and to each other in various

cabling topologies. These can include daisy chain, star, or hybrid system (a combination of both daisy chain and star) topologies

(see the eBUS Technology Reference Guide, available on www.extron.com, for basic diagrams). Every endpoint device must

have a unique identication address (bus ID) within the system.

Once the bus ID DIP switches are set on the EBPs, use Extron GlobalCongurator® (GC) Plus and Professional software, or

Global Scripter® programming, to congure the control processor. Once congured, the EBPs can control the AV system.

EBP Front Panel Features

NOTE: Use Global Congurator Plus and Professional to congure the EBP buttons and LEDs. Alternatively, use Global

Scripter to program the buttons and LEDs.

Cable Cubby lid — Tilts back to 130°. Friction washers

A

ensure the lid holds any angle set by the user.

A switch in the hinge activates the buttons when the lid

is fully open and deactivates them when the lid is closed

to prevent accidental button presses.

Power buttons — Are labelled ON and OFF and control

B

the power to the display device. The ON button has a

nub that can be felt with the nger tips.

Volume LED meter — Shows the volume level.

C

Volume buttons — Can be used to increment or

D

decrement audio volume. There is also a MUTE button

to the right.

Button panel removal slots — Use the Extron removal

E

tool in these slots to release the top of the panel when

replacing buttons.

Input and function buttons — If these buttons are

F

used to select an input, they can be congured as a

group to act in a mutually exclusive manner. However,

the buttons can also be congured to carry out separate

functions. In that case, they can be removed from the

input group and congured independently.

Transmit LED — Blinks once when any button is

G

pressed.

Button panel hinge — Holds the bottom of the panel in

H

place, allowing the panel to tilt forward when replacing

buttons.

AA

Figure 11. EBP 1200C Front Panel

BB

C

C

D

D

E

E

OFF

ON

F

F

PC

LAPTOP

MUTE

E

E

HDMI

VGA

AUX VIDEO

G

G

H

H

EBP Bottom Panel

DIP switches — Used to provide each unit connected to the same

A

control processor with a unique bus ID (see Setting the eBUS ID

Address on page 10).

eBUS connectors (2 blocks) — These four-pole captive screw

B

blocks connect the EBP 1200C to a controller and to other panels.

Status LEDs — These three LEDs are mutually exclusive (only one

C

LED lights at a time). When the unit is not receiving power, all three

LEDs are off.

• Link — lights green when power and communication with the control processor are both good.

• Com Error — lights amber when there is no communication with the control processor.

• ID Error — lights red when there is a bus ID conict.

Reset button — Resets the rmware to the factory installed version.

D

1. Disconnect the eBUS cable that is providing power.

2. Press and hold down the Reset button while reconnecting power. During the reset process, the front panel buttons are

not lit and the eBUS Link Status LED is lit.

After about 30 seconds, the front panel buttons are lit dimly and the unit rmware is restored to the original

factory-installed version. For information about updating the unit rmware, see the eBUS Technology Reference Guide.

8

AA

ON

CIT

M

PWR LOAD

S

= 2.0W

B

Figure 12. EBP 1200C Bottom Panel

1234 56

BUS ID

L

S

B

B

eBUS Status

+S -S -SG+V+SG

+V

C

LINK COM

ERRORID ERROR

D

D

RESET

Page 9

Product Category

OF

Extron

Extr

on

21-785-01LF

Changing Buttons

You can replace a faceplate or one or more of the individual buttons. Some additional blank buttons ship with the unit. You can

order standard or custom buttons from www.extron.com. To change the buttons:

11

Insert the Extron removal tool into one of the removal

3

3

2

2

HDMI

VGA

PC

OFF

ON

LAPTOP

MUTE

e

AUX VIDEO

11

slots in the top edge of the button panel.

Carefully release the corner of the panel.

Repeat step 1 to release the opposite corner of

22

the panel.

Tilt the lid forward to prevent the buttons from

33

falling out.

Pull the top of the button panel forward. The

44

panel is attached to the lid with a hinge that

allows access to the buttons without the panel

4

4

7

5

5

7

66

Back of

Button Panel

££

¢

¢

9

9

£

£

HDMI

VGA

PC

OFF

ON

LAPTOP

MUTE

AUX VIDEO

e

¤¤

becoming completely detached.

You can now return the lid to the fully open position.

From the front of the panel, press the button

55

until it is free of the panel.

From the back of the button panel, insert the

66

replacement button into the appropriate slot.

Ensure the text is in the correct orientation.

Align the two pegs on the button with the holes

on the button panel.

Press the button into the faceplate until the

77

pegs on the button are seated securely in the holes.

Repeat steps 5-7 for any other buttons that

88

need to be replaced.

Tilt the lid forward to prevent the buttons from

99

falling out.

Tilt the lid and the button panel backwards.

¢¢

Press the top corners so that they snap back

££

into place, securely attaching the button panel

to the lid.

If the corners do not snap back easily, you

may need to adjust how the button panel is

seated in the hinge attaching it to the lid ( ).

¤¤

Figure 13. Replacing Buttons

9

Page 10

EBP 1200C • Setup Guide (Continued)

D

0W

T

US

D

OR

M

BUS ID

S

BUS ID

S

BUS ID

S

BUS ID

S

BUS ID

S

BUS ID

S

BUS ID

S

B

BUS ID

Setting the eBUS ID Address

Up to eight units can be connected to one control processor.

Each unit connected to the same control processor must

have a unique six-bit, binary eBUS ID (address), which is set

with the DIP switch assembly on the bottom panel of the

EBP 1200C (gure 14).

eBUS Status

eB

CIT

L

L

S

B

I

G

PWR LOAD

PWR LOA

= 2.

= 2.0W

ON

N

ON

M

M

S

S

B

B

B

1234 56

1234 56

BUS ID

BUS ID

Figure 14. DIP Switches on EBP 1200C Bottom Panel

If other modules have the same bus ID, address conicts

may cause one or more of the panels to not be recognized

by the IPCPPro control processor.

Set the bus identication DIP switches for each EBP button

panel in the system using the diagrams in this section as a

guide.

NOTES:

• By factory default, the EBP 1200C is set to

address 26 (binary: 011010), as shown in the

diagram below.

• Any address can be used except address

0 (binary: 000000). This is reserved as the

address of the controller and may not be used.

• Switch 1 (on the left) is the highest value (32,

the most signicant bit) and is labelled MSB.

• Switch 6 (on the right) is the lowest value (1,

the least signicant bit) and is labelled LSB.

• Up = on = 1, Down = off = 0

ON

S

B

1 2

CIT

L

S

B

56

4

3

tatus

LINK COM

LINK

ERR

ERRORID ERROR

Slide

I

ERROR

RESET

RESE

Example eBUS IDs

Address eBUS ID DIP Switch

0 000000*

*Reserved for

controller address

ON

M

S

B

1 2

CIT

56

4

3

BUS ID

1 000001

ON

M

S

B

1 2

CIT

56

4

3

BUS ID

2 000010

3 000011

4 000100

5 000101

6 000110

7 000111

ON

1 2

ON

1 2

ON

1 2

ON

1 2

ON

1 2

ON

1 2

CIT

56

4

3

CIT

56

4

3

CIT

56

4

3

CIT

56

4

3

CIT

56

4

3

CIT

56

4

3

L

S

B

L

S

B

L

S

B

L

S

B

L

S

B

L

S

B

L

S

B

L

S

B

10

8 001000

ON

1 2

CIT

L

S

B

56

4

3

Page 11

Product Category

+

Drain Wires

G

S

+S

+V

Cable All Devices

Attach cables using the diagrams in this section as a guide. Connect a 4-pole captive screw connector to each end of the cable,

wiring both ends as shown in gure 15. In most cases the EBPs are powered by the IPCPPro control processor that provides the

eBUS signal. Power is carried on the V+ pin of each eBUS connection.

The four connectors are:

• +V — carries 12 VDC power from the controller, active hub, or power supply

• +S — carries the positive data signal

• -S — carries the negative data signal

• G — ground

Extron STP20-2/1000 or STP20-2P/1000 cable is recommended for eBUS connections.

12 VDC

+ Signal

-

Signal

Ground

Figure 15. Basic eBUS Connector Wiring and Cable Color Code

For long cable runs, category cable can provide a convenient option for eBUS signals. For these applications, compatible 4-pole

captive screw to RJ-45 adapters are available at www.extron.com.

Extron recommends using shielded CAT6 cable.

Red

Green

White

Black

-

NOTES:

• The two eBUS blocks are interchangeable: either block can be used to connect the unit to a controller or EBDB and

either can be used to daisy-chain the unit to another EBP.

• Connect up to eight eBUS endpoint devices for each IPCP Pro control processor.

• Wire the connectors in the same way at both ends.

• See the eBUS Technical Reference Guide (available at www.extron.com) for information about the maximum cable

distance and power requirements for your eBUS system.

• Do NOT power an EBP from more than one power source.

ATTENTION:

• Always use a power supply supplied or specied by Extron. Use of an unauthorized power supply voids all regulatory

compliance certication and may cause damage to the supply and the unit.

• Utilisez toujours une source d’alimentation fournie par Extron. L’utilisation d’une source d’alimentation non autorisée

annule toute conformité réglementaire et peut endommager la source d’alimentation ainsi que l’unité.

• If not provided with a power supply, this product is intended to be supplied by a UL Listed power source marked

“Class2” or “LPS” and rated output 12VDC, minimum 1.0A.

• Si ce produit ne dispose pas de sa propre source d’alimentation électrique, il doit être alimenté par une source

d’alimentation certiée UL de classe 2 ou LPS et paramétré à 12VDC et 1,0A minimum.

• Unless otherwise stated, the AC/DC adapters are not suitable for use in air handling spaces or in wall cavities.

• Sauf mention contraire, les adaptateurs AC/DC ne sont pas appropriés pour une utilisation dans les espaces

d’aération ou dans les cavités murales.

• The installation must always be in accordance with the applicable provisions of National Electrical Code ANSI/

NFPA70, article725 and the Canadian Electrical Code part1, section16. The power supply shall not be permanently

xed to building structure or similar structure.

• Cette installation doit toujours être en accord avec les mesures qui s’applique au National Electrical Code ANSI/

NFPA70, article725, et au Canadian Electrical Code, partie1, section16. La source d’alimentation ne devra pas être

xée de façon permanente à une structure de bâtiment ou à une structure similaire.

11

Page 12

EBP 1200C • Setup Guide (Continued)

S

X

#

S

6-

XX-XX-XX

#

Extron P/N 28-071-57LF)

EBPs that are relatively far from the control processor (see the eBUS Technology Reference Guide on www.extron.com for

details) can be connected to an optional Extron PS1220EB eBUS power inserter, or an Extron 12VDC desktop power supply as

shown in the following diagrams.

.0A MAX

COM 1

WER

TST

VOL

COM 2

RELAYS

DIGITAL I/O

eBUS

-S+V +S G

PWR OUT = 6W

IPCP PRO 250

AC: 00-05-A6-XX-XX-X

N: ####### E#####

IR/S

100-240V 50-60Hz

0.6A MAX

-S+V +S G-S+V +S G-S+V +S G

eBUS 24 WATTS MAX

-S+V +S G-S+V +S G -S+V +S G

eBUS Connections

• Connect up to ve (5) eBUS

endpoint devices to the PS 1220EB.

• Wire the connectors the same at both

ends.

• All ports are identical and

interchangeable.

IPCP Pro

X

Power Input

(100-240 VAC,

50-60 Hz)

ATTENT ION: Do NOT connect the

power pin to a ny device that is already

powere d by the IPC P Pro control

processor or by an additional power

suppl y.

+ Signal

-

Signal

Ground

Tie drain wires

to ground.

Figure 16. Powering an eBUS System with an PS 1220EB Power Inserter

M

PWR LOAD

S

= 2.0W

B

EBP 1200C

ATTENT ION: Do NOT connect the

power pin from th e IPCP Pro

control processor to a devi ce that

COM 1

x

WER

.0A MAX

TST

VOL

COM 2

x

x

RELAYS

DIGITAL I/O

eBUS

-S+V +S G

PWR OUT = 6W

IPCP PRO 250

IR/S

AC: 00-05-A

N: ####### E#####

IPCP Pro

EBP wall panel

is powe red by a sepa rate power

suppl y.

3/16" (5 mm) Max.

X

Tie drain wires to ground.

External Power Supply

(12 VDC, 1 A max.,

X

ON

1234 56

BUS ID

Ground

-

Signal

+ Signal

Ground

-

Signal

+ Signal

+12 VDC

PS 1220EB

+12 VDC

+ Signal

-

Signal

Ground

M

PWR LOAD

S

= 2.0W

B

EBP 1200C

eBUS Status

CIT

L

S

B

+S -S -SG+V+SG

+V

X

+12 VDC input

– Return

Ground

all Devices

3/16" (5 mm) Max.

ON

1234 56

BUS ID

eBUS Status

CIT

L

S

B

+S -S -SG+V+SG

+V

LINK COM

ERRORID ERROR

RESET

Smooth

Power Supply

Output Cord

RidgedSmooth

SECTION A–A

NOTE:

Check the polarity of the power

supply before connecting it to the EBP.

LINK COM

ERRORID ERROR

RESET

Ridges

G

AA

G

Figure 17. Powering an eBUS System with an Extron 12VDC, 1 A Power Supply

12

Page 13

Product Category

Configure the System

NOTE: EBPs are shipped with pre-labelled buttons in place but these buttons do not have any functions associated with them

until they are congured with Global Congurator or programmed with Global Scripter. See the Global Configurator Help

File or Global Scripter Help File as needed for step-by-step instructions and detailed information.

1. Create a new Global Congurator Plus or Professional project and congure the controller and any eBUS devices. The

conguration tells the control processor how its ports function; how to control other products; what to monitor; when to do

things; and whom to notify, how, and under what circumstances.

a. Congure ports on the control processor.

• Select device drivers and link them to each assigned port.

• Congure settings (serial protocol, relay behavior, digital input, volume control settings) as needed.

b. Set up monitors, schedules, macros, and local variables.

c. Set up the eBUS button panel buttons: assign appropriate commands and actions, macros, timers, local variables

monitors, or feedback to the buttons.

2. Save the project.

3. Build and upload the system conguration to the control processor.

NOTE: Once the Global Congurator project has been set up, you can use Global Scripter to program buttons and LEDs.

Test and Troubleshoot

1. Verify that the DIP switches on the EBPs are set to the desired address on each unit and that there are no DIP switch address

conicts in the system. If there is a bus ID conict, the ID Error status LED lights red (see EBP Bottom Panel on page 8).

2. Verify that cables to and from the EBPs are wired the same at each end (pin 1 to pin 1, pin 2 to pin 2, and so forth). If there is

no communication with the control processor, the Com Error status LED lights amber. If power and communication with the

control processor are both good, the Link status LED lights green (see EBP Bottom Panel on page 8).

3. Test the system.

• Press buttons on the EBPs and ensure the buttons light as desired and that the appropriate control commands or

functions are triggered.

• Ensure that the audio output responds correctly to the volume knob or button. Also ensure that the volume LEDs light

correctly as you increase or decrease the audio gain.

4. Make adjustments to wiring, bus ID address, or system conguration as needed. Remember that the rear panel ports and DIP

switches may not be accessible after the EBP is mounted. If needed, upload a revised conguration to the control processor.

If you have questions during installation and setup, you can le an online technical support request or call the ExtronS3 Control

Systems Support Hotline (1.800.633.9877).

13

Page 14

EBP 1200C • Setup Guide (Continued)

Extron Headquarters

+1.800.633.9876 (Inside USA/Canada Only)

Extron USA - West Extron USA - East

+1.714.491.1500 +1.919.850.1000

+1.714.491.1517 FAX +1.919.850.1001 FAX

© 2017 Extron Electronics All rights reserved. All trademarks mentioned are the property of their respective owners. www.extron.com

14

Extron Europe

+800.3987.6673

(Inside Europe Only)

+31.33.453.4040

+31.33.453.4050 FAX

Extron Asia

+65.6383.4400

+65.6383.4664 FAX

Extron Japan

+81.3.3511.7655

+81.3.3511.7656 FAX

Extron China

+86.21.3760.1568

+86.21.3760.1566 FAX

Extron Middle East

+971.4.299.1800

+971.4.299.1880 FAX

Extron Australia

+61.8.8113.6800

+61.8.8351.2511 FAX

Extron India

1800.3070.3777

(Inside India Only)

+91.80.3055.3777

+91.80.3055.3737 FAX

68-1449-52 Rev. A

05 17

Loading...

Loading...