Page 1

HDMI Transmitters

DTP T HWP 232/332 D

DTP T UWP 232/332 D

HDMI Twisted Pair Extender Transmitters

User Guide

68-2547-01 Rev. A

03 14

Page 2

Safety Instructions

Safety Instructions • English

WARNING: This symbol, , when used on the product, is intended to

alert the user of the presence of uninsulated dangerous voltage within the

product’s enclosure that may present a risk of electric shock.

ATTENTION: This symbol, , when used on the product, is intended

to alert the user of important operating and maintenance (servicing)

instructions in the literature provided with the equipment.

For information on safety guidelines, regulatory compliances, EMI/EMF

compatibility, accessibility, and related topics, see the Extron Safety and

Regulatory Compliance Guide, part number 68-290-01, on the Extron website,

www.extron.com.

Instructions de sécurité • Français

AVERTISSEMENT: Ce pictogramme, , lorsqu’il est utilisé sur le

produit, signale à l’utilisateur la présence à l’intérieur du boîtier du produit

d’une tension électrique dangereuse susceptible de provoquer un choc

électrique.

ATTENTION: Ce pictogramme, , lorsqu’il est utilisé sur le produit, signale

à l’utilisateur des instructions d’utilisation ou de maintenance importantes

qui se trouvent dans la documentation fournie avec le matériel.

Pour en savoir plus sur les règles de sécurité, la conformité à la réglementation,

la compatibilité EMI/EMF, l’accessibilité, et autres sujets connexes, lisez les

informations de sécurité et de conformité Extron, réf. 68-290-01, sur le site

Extron, www.extron.com.

Sicherheitsanweisungen • Deutsch

WARNUNG: Dieses Symbol auf dem Produkt soll den Benutzer darauf

aufmerksam machen, dass im Inneren des Gehäuses dieses Produktes

gefährliche Spannungen herrschen, die nicht isoliert sind und die einen

elektrischen Schlag verursachen können.

VORSICHT: Dieses Symbol auf dem Produkt soll dem Benutzer in der

im Lieferumfang enthaltenen Dokumentation besonders wichtige Hinweise

zur Bedienung und Wartung (Instandhaltung) geben.

Weitere Informationen über die Sicherheitsrichtlinien, Produkthandhabung,

EMI/EMF-Kompatibilität, Zugänglichkeit und verwandte Themen finden Sie in

den Extron-Richtlinien für Sicherheit und Handhabung (Artikelnummer

68-290-01) auf der Extron-Website, www.extron.com.

Instrucciones de seguridad • Español

ADVERTENCIA: Este símbolo, , cuando se utiliza en el producto,

avisa al usuario de la presencia de voltaje peligroso sin aislar dentro del

producto, lo que puede representar un riesgo de descarga eléctrica.

ATENCIÓN: Este símbolo, , cuando se utiliza en el producto, avisa

al usuario de la presencia de importantes instrucciones de uso y

mantenimiento recogidas en la documentación proporcionada con el

equipo.

Para obtener información sobre directrices de seguridad, cumplimiento

de normativas, compatibilidad electromagnética, accesibilidad y temas

relacionados, consulte la Guía de cumplimiento de normativas y seguridad de

Extron, referencia 68-290-01, en el sitio Web de Extron, www.extron.com.

Инструкция по технике безопасности • Русский

ПРЕДУПРЕЖДЕНИЕ: Данный символ, , если указан на продукте,

предупреждает пользователя о наличии неизолированного опасного напряжения

внутри корпуса продукта, которое может привести к поражению электрическим

током.

ВНИМАНИЕ: Данный символ, , если указан на продукте,

предупреждает пользователя о наличии важных инструкций

по эксплуатации и обслуживанию в руководстве,

прилагаемом к данному оборудованию.

Для получения информации о правилах техники безопасности,

соблюдении нормативных требований, электромагнитной

совместимости (ЭМП/ЭДС), возможности доступа и других

вопросах см. руководство по безопасности и соблюдению

нормативных требований Extron на сайте Extron: www.extron.com,

номер по каталогу - 68-290-01.

Chinese Simplified(简体中文)

警告: 产品上的这个标志意在警告用户该产品机壳内有暴露的危险 电压,有触电危险。

注意: 产品上的这个标志意在提示用户设备随附的用户手册中有

重要的操作和维护(维修)说明。

关于我们产品的安全指南、遵循的规范、EMI/EMF 的兼容性、无障碍

使用的特性等相关内容,敬请访问 Extron 网站 www.extron.com,参见

Extron 安全规范指南,产品编号 68-290-01。

Chinese Traditional( )

警告: 若產品上使用此符號,是為了提醒使用者,產品機殼內存在著

可能會導致觸電之風險的未絕緣危險電壓。

注意 若產品上使用此符號,是為了提醒使用者。

有關安全性指導方針、法規遵守、EMI/EMF 相容性、存取範圍和相關主題的詳

細資訊,請瀏覽 Extron 網站:www.extron.com,然後參閱《Extron 安全性與

法規遵守手冊》,準則編號 68-290-01。

Japanese

警告: この記 号 が製品上に表示されている場合は、筐体内に絶縁されて

いない高電圧が流れ、感電の危険があることを示しています。

注意: この 記号 が製品 上に表 示されてい る場合は、本機 の取扱説明 書に 記載さ れてい

る重要な 操作と保 守(整 備)の 指示につ いてユーザーの 注意 を喚起 するものです。

安全上のご注意、法規厳守、EMI/EMF適合性、その他の関連項目に

つ い て は 、エ クスト ロン の ウ ェ ブ サ イト www.extron.com よ り 『 Extron Safety

and Regulatory Compliance Guide』 ( P/N 68-290-01) をご覧ください。

Korean

경고: 이 기호 가 제품에 사용될 경우, 제품의 인클로저 내에 있는 접지되지 않은 위험한

전류로 인해 사용자가 감전될 위험이 있음을 경고합니다.

주의: 이 기호 가 제품에 사용될 경우, 장비와 함께 제공된 책자에 나와 있는 주요 운영 및

유지보수(정비) 지침을 경고합니다.

안전 가이드라인, 규제 준수, EMI/EMF 호환성, 접근성, 그리고 관련 항목에

대한 자세한 내용은 Extron 웹 사이트(www.extron.com)의 Extron 안전 및

규제 준수 안내서, 68-290-01 조항을 참조하십시오.

Page 3

FCC Class A Notice

This equipment has been tested and found to comply with the limits for a Class A digital

device, pursuant to part15 of the FCC rules. The ClassA limits provide reasonable

protection against harmful interference when the equipment is operated in a commercial

environment. This equipment generates, uses, and can radiate radio frequency energy

and, if not installed and used in accordance with the instruction guide, may cause harmful

interference to radio communications. Operation of this equipment in a residential area is

likely to cause interference. This interference must be corrected at the expense of the user.

ATTENTION: The Twisted Pair Extension technology works with shielded twisted pair

(STP) cables only. To ensure FCC Class A and CE compliance, STP cables and STP

connectors are also required.

For more information on safety guidelines, regulatory compliances, EMI/EMF compatibility,

accessibility, and related topics, see the “Extron Safety and Regulatory Compliance Guide”

on the Extron website.

Copyright

© 2014 Extron Electronics. All rights reserved.

Trademarks

All trademarks mentioned in this guide are the properties of their respective owners.

The following registered trademarks®, registered service marks

(SM)

, and trademarks

(TM)

are the property of

RGBSystems, Inc. or Extron Electronics:

Registered Trademarks

AVTrac, Cable Cubby, CrossPoint, eBUS, EDID Manager, EDID Minder, Extron, Flat Field, GlobalViewer, Hideaway, Inline, IPIntercom,

IPLink, Key Minder, LockIt, MediaLink, PlenumVault, PoleVault, PowerCage, PURE3, Quantum, SoundField, SpeedMount, SpeedSwitch,

SystemINTEGRATOR, TeamWork, TouchLink, V-Lock, VersaTools, VN-Matrix, VoiceLift, WallVault, WindoWall, XTP, and XTP Systems

Registered Service Mark

AAP, AFL (Accu-Rate Frame Lock), ADSP (Advanced Digital Sync Processing), Auto-Image, CDRS (Class D Ripple Suppression), DDSP (Digital

Display Sync Processing), DMI (Dynamic Motion Interpolation), DriverConfigurator, DSPConfigurator, DSVP (Digital Sync Validation Processing),

FastBite, FOXBOX, IP Intercom HelpDesk, MAAP, MicroDigital, ProDSP, QS-FPC (QuickSwitch Front Panel Controller), Scope-Trigger, SIS,

Simple Instruction Set, Skew-Free, SpeedNav, Triple-Action Switching, XTRA, ZipCaddy, ZipClip

(SM)

: S3 Service Support Solutions

Trademarks (™

(®)

)

Page 4

Conventions Used in this Guide

Notifications

The following notifications are used in this guide:

CAUTION: A caution indicates a situation that may result in minor injury.

ATTENTION: Attention indicates a situation that may damage or destroy the product or

associated equipment.

NOTE: A note draws attention to important information.

Software Commands

Commands are written in the fonts shown here:

^AR Merge Scene,,Op1 scene 1,1 ^B 51 ^W^C

[01] R 0004 00300 00400 00800 00600 [02] 35 [17] [03]

E X! *X1&* X2)* X2#* X2! CE}

NOTE: For commands and examples of computer or device responses mentioned

in this guide, the character “0” is used for the number zero and “O” is the capital

letter “o.”

Computer responses and directory paths that do not have variables are written in the font

shown here:

Reply from 208.132.180.48: bytes=32 times=2ms TTL=32

C:\Program Files\Extron

Variables are written in slanted form as shown here:

ping xxx.xxx.xxx.xxx —t

SOH R Data STX Command ETB ETX

Selectable items, such as menu names, menu options, buttons, tabs, and field names are

written in the font shown here:

From the File menu, select New.

Click the OK button.

Specifications Availability

Product specifications are available on the Extron website, www.extron.com.

Page 5

Contents

Introduction............................................................ 1

About this Guide ................................................. 1

About the DTP T HWP D and DTP T UWP D

Extenders .......................................................... 1

Twisted Pair Cable Advantages ....................... 2

Transmission Distance .................................... 2

Features ............................................................. 3

Installation and Operation .................................. 4

Mounting the Transmitter .................................... 4

UL and Safety Guidelines ................................ 4

Site Preparation and Wall Box Installation ....... 5

Mud Ring Installation ...................................... 6

Final Installation .............................................. 7

DTP T HWP 232 and 332 D Connections ........... 8

Front Panel ..................................................... 8

Rear Panel ...................................................... 9

DTP T UWP 232 and 332 D Connections ......... 10

Front Panel ................................................... 10

Rear Panel .................................................... 11

TP Cable Termination and

Recommendations .......................................... 12

Power Supply Wiring ........................................ 13

RS-232 and IR Connector Wiring ..................... 14

Remote RS-232 and Contact Closure

Connector ................................................... 14

IR Control Connector .................................... 14

Over DTP RS-232 Connector ....................... 14

Operation ......................................................... 15

Transmitter LEDs .......................................... 15

System Operation ......................................... 15

Remote Control ................................................... 16

Contact Closure Control ................................... 16

Simple Instruction Set Control .......................... 17

Host-to-Extender Communications ............... 17

Extender-Initiated Messages ......................... 17

Error Responses ........................................... 17

Timeout ........................................................ 17

Using the Command and Response Table .... 18

Command and Response Table for SIS

Commands ................................................. 20

Reference Information ...................................... 24

Decora Template Dimensions ........................... 24

vDTP T HWP/UWP 232/332 D Transmitters • Contents

Page 6

Page 7

Introduction

Transmitter

• About this Guide

• About the DTP T HWP D and DTP T UWP D Extenders

• Features

About this Guide

This guide provides instructions for experienced, professional installers to install, operate,

and configure the Extron DTP T HWP D and DTP T UWP D family of High-Definition

Multimedia Interface (HDMI®) and VGA Extenders.

Terms Used in this Guide

The terms “extender” and “transmitter” are used interchangeably in this guide to refer to all

of the DTP T HWP D and DTP T UWP D models.

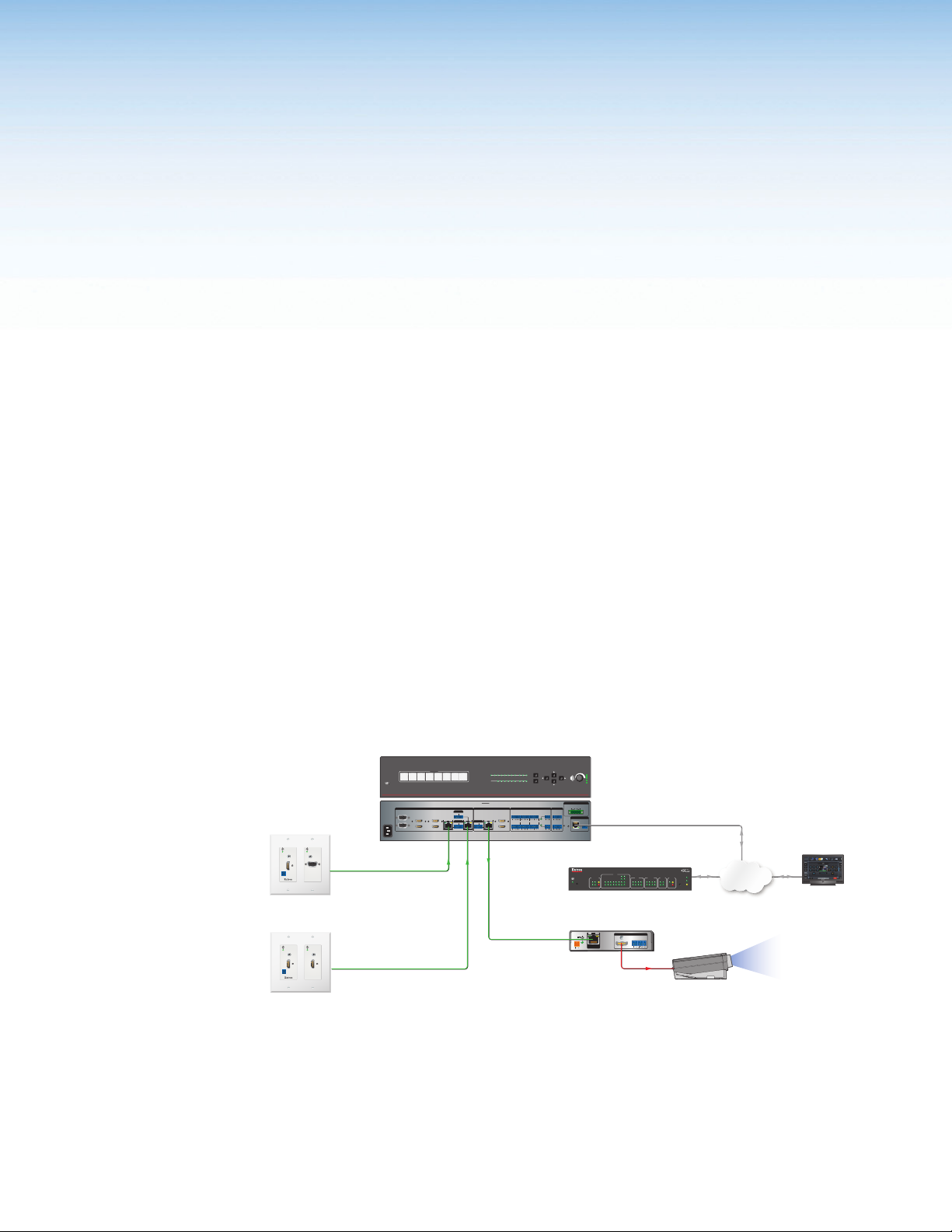

About the DTP T HWP D and DTP T UWP D Extenders

The Extron DTP T HWP D and DTP T UWP D extenders are a family of HDMI and

VGA transmitters (see figure 1) that are housed in enclosures that can be mounted in

Underwriters Laboratories (UL®) standard wall boxes with Decora®-style faceplates. Paired

with a compatible DTP 230 or 330 receiver, they extend the usable distance of HDMI digital

video, VGA analog video (UWP models only), and RS-232 or IR control signals over one

shielded twisted pair (STP) cable. The extenders also route audio.

OUTPUTS

INPUTS

1

2 3 4 5 6 7 8 A B C

OUTPUTS

LL1R R

A

HDMI

L2

L4

R

B

XTP DTP 24 Cable

230 '

MENU

ENTER

AUDIO INPUTS

OUTPUTS

L5R

12

+48V

MIC/LINE

VARIABLE

L6

LR

R

R

2

+48V

DTP HDMI 230 Rx

VOLUME

IN1608

SCALING PRESENTATION SWITCHER

AMPLIFIED OUTPUT

2x25W(8Ω)/2x50W(4Ω)

L3R

CLASS 2 WIRING

REMOTE

LAN

RESET

RS-232

TxRx

IPCP 505

R

IPCP 505

POWER

12V

0.7A MAX

G

COM

RTS

SWITCHED

12VDC

LIMIT

2

TXRXTX

1 2345678

314

OVER

SIG LINK

DTP IN

FLEX

IR/S

CTS

RX

5162738

OUTPUTS

AUDIO

LR

100

RELAY

eBUS

I/O

ACT LIMIT

4

2

4

LINK

IR

ACT

OVER

5162314

738

Ethernet

Network

TLP 1000TV

HDMI

SIGNAL

HDCP

IN1608 SA

OVER DTP

RS-232 IR

C

TxRx Tx RxG

8

SIG LINK

SIG LINK

OVER DTP

OVER DTP

RS-232 IR

RS-232 IR

DTP OUT

TxRx TxRxG

DTP IN

TxRx TxRxG

Projector

AUTO SW

AUDIO IN

AUDIO IN

HDCP

1

VGA IN

HDMI IN

CONFIG

IR OUT

G

S

Extron

DTP T UWP 232 D Tx

Transmitter

AUTO SW

AUDIO IN

AUDIO IN

HDCP

HDCP

1

1

2

HDMI IN

HDMI IN

CONFIG

IR OUT

G

S

Extron

DTP T HWP 232 D Tx

1 2 3 4 5 6 7 8

CONFIG

Extron

1

CONFIGURABLE

100-240V ~ -- A MAX

2

50/60 Hz

IN1608

XTP DTP 24 Cable

230 '

XTP DTP 24 Cable

230 '

INPUTS

INPUTS

5

3

7

SIG LINK

HDMI

HDMI

6

4

DTP IN

Figure 1. A Typical Transmitter and Receiver Application

DTP T HWP/UWP 232/332 D Transmitters • Introduction 1

Page 8

DTP T HWP D and DTP T UWP D systems consist of a transmitter (Tx) and a receiver

(Rx). The transmitters and corresponding compatible receivers are sold separately. Each

purchased transmitter is shipped with a single external desktop 12 VDC power supply that

accepts 100 to 240 VAC, 50-60 Hz input. A single power supply connected to either the

transmitter or a compatible receiver can power both units through the twisted pair cable that

links the units.

Twisted Pair Cable Advantages

Twisted pair cable is much smaller, lighter, more flexible, and less expensive than coaxial

or HDMI cable. These transmitter and receiver twisted pair (TP) products make cable runs

simpler and less cumbersome. Termination of the cable with RJ-45 connectors is simple,

quick, and economical (see TP Cable Termination and Recommendations on page 12

for more information).

NOTE: Do not use Extron UTP23SF-4 Enhanced Skew-Free AV UTP cable or STP201

cable to link the transmitter and receiver. The DTP T HWP and UWP 232 and 332 do

not work properly with these cables.

Control communications

The RS-232 or infrared (IR) communications are pass-through only. The transmitter and

receiver do not generate or respond to these signals.

Transmission Distance

The maximum transmission distance is determined by the resolution of the signal and the

twisted pair cable, graphics card, and display used in the system.

• DTP T HWP and UWP 232 D transmitters can transmit 720p, 1080i or 1080p HDTV

video signals up to 230 feet (70 m) over STP cable.

• DTP T HWP and UWP 332 D transmitters can transmit 720p, 1080i or 1080p HDTV

video signals up to 330 feet (100 m) over STP cable.

DTP T HWP/UWP 232/332 D Transmitters • Introduction 2

Page 9

Features

Transmits single link HDMI-D signals over one STP cable — Twisted pair cables

provide an economical, easily installed cable solution.

Transmits single link HDMI-D and VGA signals over one STP cable (UWP models)

— Twisted pair cables provide an economical, easily installed cable solution.

Supports DDC and HDCP transmission — The transmitters fully support long distance

transmission of the DDC and HDCP signals.

Control communications pass-through — Bidirectional RS-232 or IR control signals

can be transmitted alongside the HDMI signal, so that the remote display can be controlled

without the need for additional cabling.

Audio routing — The transmitters also route unbalanced stereo audio.

Wall-mountable enclosures

External 100 VAC to 240 VAC, 50-60 Hz, international power supply — Included with

transmitters.

Remote powering of the transmitter or receiver — Only one power supply is necessary

to power both devices.

DTP T HWP/UWP 232/332 D Transmitters • Introduction 3

Page 10

Installation and Operation

This section describes the installation and the operation of the extenders, including:

• Mounting the Transmitter

• DTP T HWP 232 and 332 D Connections

• DTP T UWP 232 and 332 D Connections

• TP Cable Termination and Recommendations

• Power Supply Wiring

• RS-232 and IR Connector Wiring

• Operation

Mounting the Transmitter

ATTENTION:

• Installation and service must be performed by authorized personnel.

• The installation must conform to national and local building, electrical, and safety

codes and to the size requirements of the wall plate.

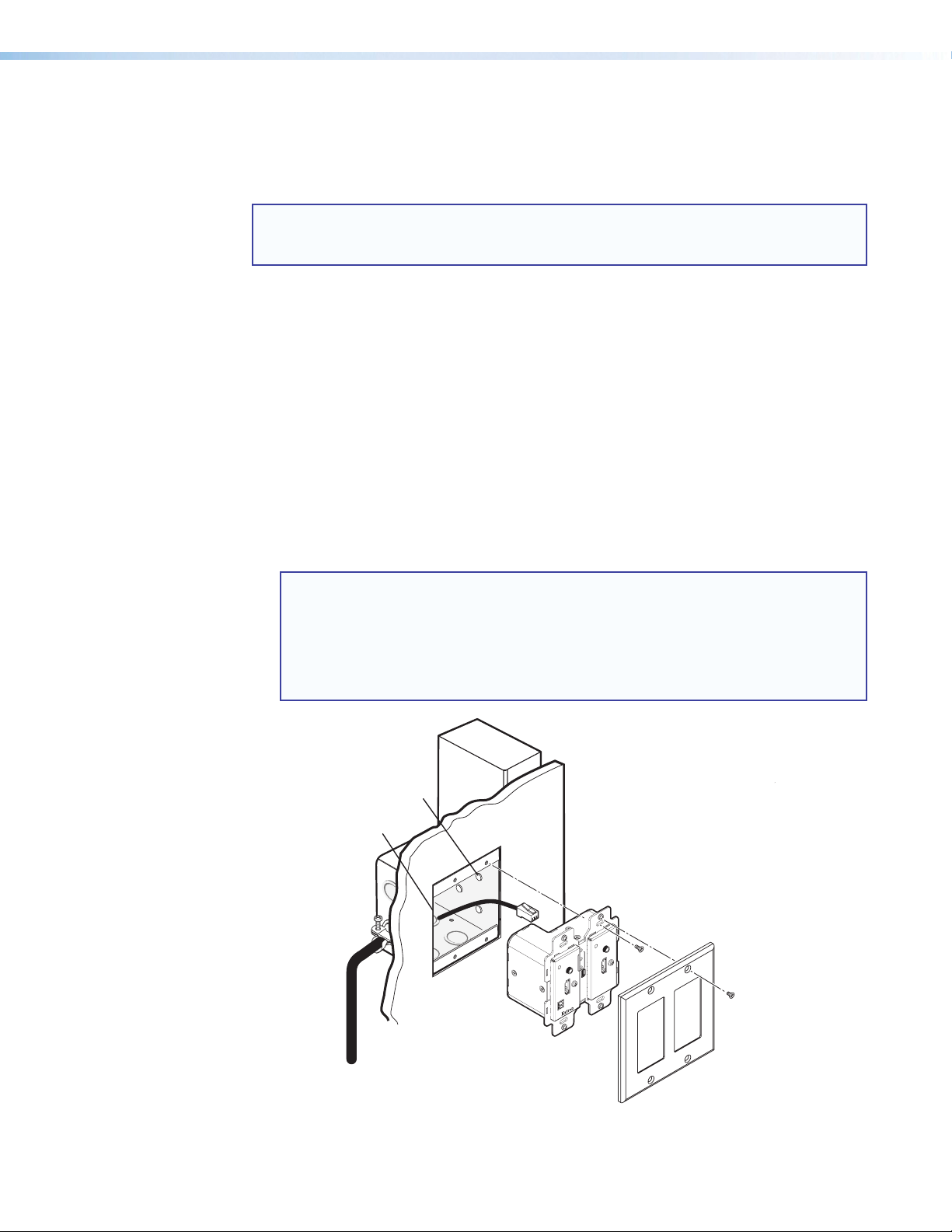

The transmitters can be installed in a two-gang electrical wall box, or with a mud ring, with a

Decora wall plate cover (supplied).

UL and Safety Guidelines

The following UL guidelines pertain to the installation of the Decora transmitters into a wall

or furniture.

• These units are not to be connected to a centralized DC power source or used beyond

their rated voltage range.

• These units must be installed in UL Listed wall boxes.

• These units must be installed with conduit in accordance with National Electrical Code.

DTP T HWP/UWP 232/332 D Transmitters • Installation and Operation 4

Page 11

Site Preparation and Wall Box Installation

Wa

flush with edge of box.

Choose a location that allows cable runs without interference. Allow enough depth for both

the wall box and the cables. Install the cables into the wall, furniture, or conduits before

installing the wall plate.

NOTE: The extender units are very deep and have connectors on the back side. Extron

recommends a 2-gang wall box which has a depth of at least 3.0 inches (7.6 cm) to

accommodate the connectors and cables.

To install a new wall box, perform steps 1 through 9. If a suitable wall box is already

installed, perform steps 6 through 9 on the next page. UL Listed wall boxes are

recommended.

1. If a wall box is not available to use for a template, use the Decora Template

Dimensions on page 24 to create a template. If installing directly into furniture, cut out

the center portion of the template.

2. Place the wall box (or the full size template) against the installation surface, and mark

the opening guidelines.

3. Cut out the material from the marked area.

4. Insert the wall box into the opening. The rear connectors on the box or wall plate should

fit easily into the opening. Enlarge or smooth the edges of the opening if needed.

5. Secure the wall box with nails or screws, leaving the front edge flush with the outer wall

or furniture surface (see figure 2).

NOTES:

• If attaching the wall box to wood, use four #8 or #10 screws or 10-penny

nails. A minimum of 0.5 inch (1.3 cm) of screw thread must penetrate the

wood.

• If attaching the wall box to metal studs or furniture, use four #8 or #10

self-tapping sheet metal screws or machine bolts with matching nuts.

Wall Stud

Screws or

Cable

Clamp

Nails

AUDIO IN

AUTO SW

HDCP

1

HDMI IN

AUDIO IN

CONFIG

HDMI IN

IR OUT

S

G

ll opening is

Signal Output

Cable

Extron

DTP HWP 232 D

Decora Faceplate

Figure 2. Installing the Wall Box and Mounting the Unit

DTP T HWP/UWP 232/332 D Transmitters • Installation and Operation 5

Page 12

6. Feed the twisted pair cables and, if applicable, the power cables through the opening

and through the wall box punch-out holes, securing them with cable clamps to provide

strain relief.

NOTES:

• In order to fit in the wall box, the twisted pair cables and RJ-45 connectors

• One power supply can power both the transmitter and the receiver, so only

7. Trim back and insulate exposed cable shields with heat shrink to reduce the chance of

short circuits.

To prevent short circuits, the outer foil shield can be cut back to the point where the

cable exits the cable clamp.

8. Connect the cables to the rear of the unit.

9. Connect front panel devices (see “Front Panel” on pages 8 and 10 for connector

details), restore the power supply, and test the transmitter and receiver system. Make

any cabling adjustments before final installation, as the cables will be inaccessible

afterwards.

Mud Ring Installation

1. Using the mud ring as a guide, mark the edges and cut out the material within the

marked area.

2. Insert the mud ring into the opening, rotate and secure the locking arms with the

supplied screws shown in figure 3.

3. Follow steps 6 through 9 of “Site preparation and wall box installation” above, and

Final Installation on the next page.

should not have a boot installed.

one unit needs a power supply (see Power Supply Wiring on page 13).

Wall

Wall Mounting

Mudring

Figure 3. Installing the Mud Ring

DTP T HWP/UWP 232/332 D Transmitters • Installation and Operation 6

Page 13

Final Installation

After testing and making any adjustments, do the following:

1. At the power outlet, unplug the power supply.

2. Mount the transmitter into the wall box or mud ring and attach the supplied Decora

faceplate to the unit (see figure 2 on page 5).

3. At the power outlet, reconnect the power supply. This powers up both units.

NOTE: One power supply can power both the transmitter and the receiver (see

Power Supply Wiring on page 13).

DTP T HWP/UWP 232/332 D Transmitters • Installation and Operation 7

Page 14

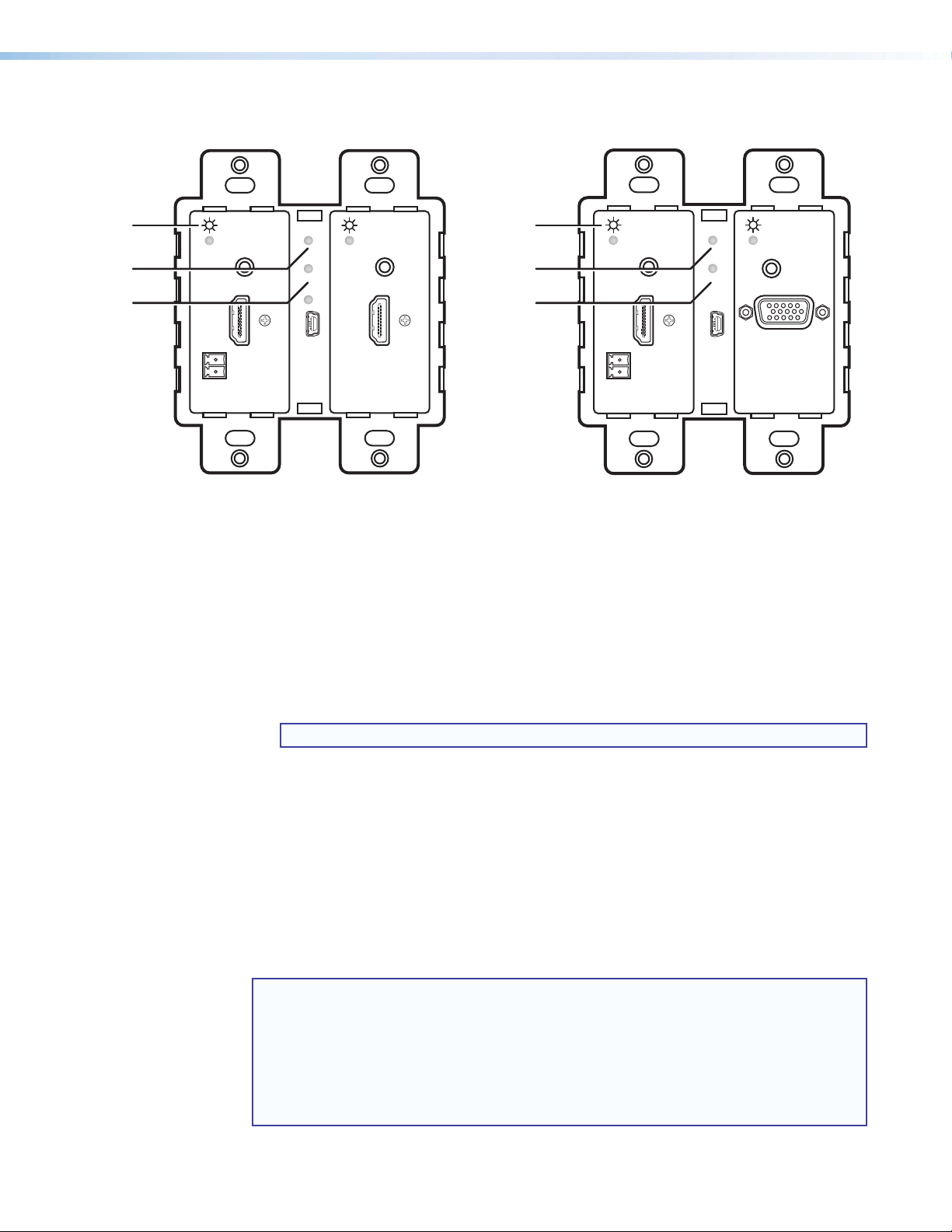

DTP T HWP 232 and 332 D Connections

AUTO SW

CONFIG

IR OUT

HDMI IN

AUDIO IN

S

G

HDCP

1

AUDIO IN

VGA IN

Extron

E

B

AA

Sleeve ( )

Tip

Front Panel

AUTO SW

AUDIO IN

HDCP

1

A

HDMI IN

2

AUDIO IN

A

HDMI IN

B

D

IR OUT

CONFIG

S

G

B

C

Extron

Figure 4. DTP T HWP 232 and 332 D Front Panel Connectors

A Audio input connector — Connect an unbalanced stereo audio source to this 3.5 mm

mini stereo jack. Figure 5 shows how to wire the audio plug.

Left (+)

Ring

Right (

-

)

Figure 5. Audio Input Connector Wiring

NOTE: The extenders do NOT embed analog audio onto the HDMI signal. This

analog audio signal is transmitted simultaneously with audio embedded within the

HDMI signal.

B HDMI input connector — Connect an HDMI cable between this port and the HDMI

output port of the digital video source.

C Mini USB port — Connect a male USB mini-B cable to this port for SIS configuration

and firmware updates.

D IR output connector — Connect an IR device to this 2-pole, 3.5 mm captive screw

pass-through connector for IR control (see RS-232 and IR Connector Wiring on page

14 to properly wire the IR connector).

DTP T HWP/UWP 232/332 D Transmitters • Installation and Operation 8

Page 15

Rear Panel

E

0.9

POWER

12V

+–

A MAX

A

Tx Rx G

R

DTP

B

RS-232

Tx Rx

CONTACT

G12

A/S

SIG LINK

DTP OUTREMOTEOVER

C

D

Figure 6. DTP T HWP 232 and 332 D Rear Panel Connectors

A DC power input connector — Plug the included external 12 VDC power supply into

either this 2-pole connector (see Power supply wiring on page 13 to wire the power

connector) or the power input connector on the receiver (see the user guide of your

respective receiver for more information).

B Over DTP control port — Connect an RS-232 device to this 3-pole, 3.5 mm captive

screw connector for pass-through RS-232 control (see RS-232 and IR Connector

Wiring on page 14 to properly wire the RS-232 connector).

C Remote (RS-232 and contact closure) control port — Connect an RS-232 device,

contact closure device, or both to this 5-pole, 3.5 mm captive screw connector to

control switching on the unit (see RS-232 and IR Connector Wiring on page 14 to

properly wire the Remote connector).

• RS-232 — To control the unit through this port, connect an RS-232 device and

configure it as follows: 9600 baud rate, 8 data bits, 1 stop bit, no parity.

• Contact — Momentarily short pins 1 or 2 to ground (G) to select the corresponding

input. Connect pins 1 and 2 to ground (G) to set the unit to auto switch mode. The

device will select the highest active input.

D DTP Out port — Connect one end of the twisted pair cable to the RJ-45 connector

on the transmitter (see TP Cable Termination and Recommendations on page 12

to properly wire the RJ-45 connectors). Connect the opposite end of the cable to the

appropriate receiver.

ATTENTION: Do not connect this device to a telecommunications or computer

data network.

E Reset button — Use an Extron Tweeker or small screwdriver to press and hold the

recessed button for 6 seconds while the extender is running to perform a factory reset.

DTP T HWP/UWP 232/332 D Transmitters • Installation and Operation 9

Page 16

DTP T UWP 232 and 332 D Connections

AA

Front Panel

AUTO SW

AUDIO IN

HDCP

1

AUDIO IN

VGA IN

C

D

B

E

IR OUT

HDMI IN

S

G

CONFIG

Extron

Figure 7. DTP T UWP 232 and 332 D Front Panel Connectors

A Audio input connector — Connect an unbalanced stereo audio source to this 3.5 mm

mini stereo jack (see figure 5 on page 8 for wiring details).

NOTE: The extenders do NOT embed analog audio onto the HDMI signal. This

analog audio signal is transmitted simultaneously with audio embedded within the

HDMI signal.

B HDMI input connector — Connect an HDMI cable between this port and the HDMI

output port of the digital video source.

C VGA input connector — Connect a VGA cable between this port and the output port

of the video source.

D Mini USB port — Connect a male USB mini-B cable to this port for SIS configuration

and firmware updates.

E IR output connector — Connect an IR device to this 2-pole, 3.5 mm captive screw

pass-through connector for IR control (see RS-232 and IR Connector Wiring on page

14 to properly wire the IR connector).

DTP T HWP/UWP 232/332 D Transmitters • Installation and Operation 10

Page 17

Rear Panel

E

0.9

POWER

12V

+–

A MAX

A

Tx Rx G

R

DTP

B

RS-232

Tx Rx

CONTACT

G12

A/S

SIG LINK

DTP OUTREMOTEOVER

C

D

Figure 8. DTP T UWP 232 and 332 D Rear Panel Connectors

A DC power input connector — Plug the included external 12 VDC power supply into

either this 2-pole connector (see Power supply wiring on page 13 to wire the power

connector) or the power input connector on the receiver (see the User Guide of your

respective receiver for more information).

B Over DTP control port — Connect an RS-232 device to this 3-pole, 3.5 mm captive

screw connector for pass-through RS-232 control (see RS-232 and IR Connector

Wiring on page 14 to properly wire the RS-232 connector).

C Remote (RS-232 and contact closure) control port — Connect an RS-232 device,

contact closure device, or both to this 5-pole, 3.5 mm captive screw connector to

control switching on the unit (see RS-232 and IR Connector Wiring on page 14 to

properly wire the Remote connector).

• RS-232 — To control the unit through this port, connect an RS-232 device and

configure it as follows: 9600 baud rate, 8 data bits, 1 stop bit, no parity.

• Contact — Momentarily short pins 1 or 2 to ground (G) to select the corresponding

input. Connect pins 1 and 2 to ground (G) to set the unit to auto switch mode. The

device will select the highest active input.

D DTP Out port — Connect one end of the twisted pair cable to the RJ-45 connector

on the transmitter (see TP Cable Termination and Recommendations on page 12

to properly wire the RJ-45 connectors). Connect the opposite end of the cable to the

appropriate receiver.

ATTENTION: Do not connect this device to a telecommunications or computer

data network.

E Reset button — Use an Extron Tweeker or small screwdriver to press and hold the

recessed button for 6 seconds while the extender is running to perform a factory reset.

DTP T HWP/UWP 232/332 D Transmitters • Installation and Operation 11

Page 18

TP Cable Termination and Recommendations

TP Wires

Pins:

Figure 9 details the recommended termination of both ends of TP cables with RJ-45

connectors in accordance with the TIA/EIA-T568B wiring standard.

12345678

Figure 9. TP Cable Termination

NOTE: Do not use Extron UTP23SF-4 Enhanced Skew-Free AV UTP cable or STP201

cable to link the transmitter and receiver. The DTP T HWP D and DTP T UWP D family

of transmitters do not work properly with these cables.

Supported cables —

The DTP T HWP D and DTP T UWP D family of transmitters are compatible with shielded

twisted pair cables (F/UTP, SF/UTP, and S/FTP).

TIA/EIA

Pin

Wire color

White-orange

1

Orange

2

3

White-green

4

Blue

5

White-blue

Green

6

7

White-brown

8

Brown

T568-B

Cable recommendations —

Extron recommends using the following practices to reduce transmission errors and achieve

full transmission distances up to 230 feet (70 m) on the 232 models or 330 feet (100 m) on

the 332 models.

• Use the following Extron XTP DTP 24 SF/UTP cables and DTP 24 connectors for the

best performance:

• XTP DTP 24/1000 Non-Plenum 1000’ (305 m) spool 22-236-03

• XTP DTP 24P/1000 Plenum 1000’ (305 m) spool 22-235-03

• XTP DTP 24 Plug Package of 10 101-005-02

• If not using XTP DTP 24 cable, at a minimum, Extron recommends 24 AWG, solid

conductor, STP cable with a minimum bandwidth of 400 MHz.

• Terminate cables with shielded connectors to the TIA/EIA-T568B standard.

• Use no more than two pass-through points, which may include patch points, punch

down connectors, couplers, and power injectors. If these pass-through points are

required, use shielded couplers and punch down connectors.

NOTE: When using STP cable in bundles or conduits, consider the following:

• Do not exceed 40% fill capacity in conduits.

• Do not comb the cable for the first 20 meters, where cables are straightened,

aligned, and secured in tight bundles.

• Loosely place cables and limit the use of tie wraps or Velcro®.

• Separate twisted pair cables from AC power cables.

DTP T HWP/UWP 232/332 D Transmitters • Installation and Operation 12

Page 19

Power Supply Wiring

AA

NOTES:

• Only one power supply is required. A single power supply connected to either unit

• A power supply is included with each individually-packaged transmitter.

Figure 10 shows how to wire the connector. Snap the provided ferrite bead onto the DC

power cable, between the power supply and the connector on the unit.

in the pair powers both units.

3/16"

(5 mm) Max.

Smooth

SECTION A–A

Power Supply

Output Cord

Ridges

Captive Screw

Connector

Figure 10. Power Connector Wiring

CAUTION: Failure to follow these instructions may result in injury.

The two power cord wires must be kept separate while the power supply is plugged

in. Remove power before wiring.

ATTENTION:

• Always use a power supply supplied and or specified by Extron. Use of an

unauthorized power supply voids all regulatory compliance certification and may

cause damage to the supply and the end product. Unless otherwise stated, the

AC/DC adapters are not suitable for use in air handling spaces or in wall cavities.

The installation must always be in accordance with the applicable provisions of

National Electrical Code ANSI/NFPA 70, article 725 and the Canadian Electrical

Code part 1, section 16. The power supply shall not be permanently fixed to

building structure or similar structure.

• Power supply voltage polarity is critical. Incorrect voltage polarity can damage

the power supply and the unit. The ridges on the side of the cord (see figure 10)

identify the power cord negative lead.

• To verify the polarity before connection, plug in the power supply with no load and

check the output with a voltmeter.

• The length of the exposed (stripped) copper wires is important.

The ideal length is 3/16 inch (5 mm). Longer bare wires can short together.

Shorter wires are not as secure in the connectors and could be pulled out.

NOTE: Do not tin the power supply leads before installing them in the direct insertion

connector. Tinned wires are not as secure in the connectors and could be pulled out.

DTP T HWP/UWP 232/332 D Transmitters • Installation and Operation 13

Page 20

RS-232 and IR Connector Wiring

Connected RS-232 and

or contact closure control

or contact closure control

REMOTE

d

S

Signal

OVER DTP

ansmit pin on connected unit

Remote RS-232 and Contact Closure Connector

Wire the rear Remote RS-232 and contact closure connector as shown in figure 11.

Tx/Rx

Pins

21

G

RxTx

RS-232 Contact

Figure 11. RS-232 and Contact Closure Connector Wiring

IR Control Connector

Wire the front panel IR control connector as shown in figure 12.

Contact Closure Device Pins

Pin 2 f

Pin 1 f

Ground

Transmit pin on connected unit

Receive pin on connected unit

G

Groun

Figure 12. IR Out Connector Wiring

Over DTP RS-232 Connector

Wire the rear Over DTP RS-232 connector as shown in figure 13.

Ground

Tr

Tx Rx G

Figure 13. Over DTP Connector Wiring

NOTE: Do not tin the wires before installing them in the direct insertion connector.

Tinned wires are not as secure in the connectors and could be pulled out.

Receive pin on connected unit

DTP T HWP/UWP 232/332 D Transmitters • Installation and Operation 14

Page 21

Operation

Front Panel

Front Panel

A

AUDIO IN

B

HDMI IN

C

IR OUT

Extron

DTP T HWP 232/332 D

Transmitter LEDs

AUTO SW

HDCP

1

AUDIO IN

A

AUDIO IN

AUTO SW

HDCP

1

AUDIO IN

B

2

HDMI IN

HDMI IN

VGA IN

C

CONFIG

S

G

IR OUT

S

G

Extron

DTP T UWP 232/332 D

Figure 14. Transmitter LED Indicators

A Power LEDs — Two-color front panel LEDs on the transmitters light to indicate signal

and power status as follows:

Amber — The unit is receiving power but there is no signal on the associated input.

Green — The unit is receiving power and a signal is present on the associated

input.

CONFIG

NOTE: Both inputs on the transmitters have their own separate LEDs.

B Auto Switch LED — Lights green when auto switch is active (see “Contact” of item

C

on pages 9 and 11).

C HDCP LEDs — Lights green when HDMI input has been authenticated on the source

device.

System Operation

After the transmitter, the receiver, and their connected devices are powered up, the system

is fully operational. If any problems are encountered, ensure all cables are routed and

connected properly.

NOTES:

• Ensure that the video source and display are properly connected to the transmitter

and receiver pair, and that the transmitter, the receiver, and the display have power

applied before power is applied to the video source. If all other devices are not

turned on before the video source, the image may not appear.

• Input switching can only be performed via auto switching, RS-232, or contact

closure through the rear panel connectors.

DTP T HWP/UWP 232/332 D Transmitters • Installation and Operation 15

Page 22

Remote Control

This section includes:

• Contact Closure Control

• Simple Instruction Set Control

The DTP T HWP D and DTP T UWP D family of transmitters can be remotely controlled via

their front panel configuration (USB) port, rear panel Remote RS-232 port, and rear panel

Remote Contact port. Remote control devices can be:

• A host device such as a computer or control system and the Extron Simple Instruction

Set (SIS)

• A contact closure device such as an Extron KP 6 Keypad Control or a Show Me video

cable

Contact Closure Control

The rear panel Remote port provides a way to select an input to the extender using

a remote contact closure device. The contact closure pin assignments are detailed in

“Contact” of item C on pages 9 and 11.

To select a different input number using a contact closure device, momentarily short the pin

for the desired input number to ground. To force one of the inputs to be always selected,

leave the short to ground in place.

DTP T HWP/UWP 232/332 D Transmitters • Remote Control 16

Page 23

Simple Instruction Set Control

The DTP T HWP D and DTP T UWP D family of extenders can be remotely controlled using

SIS commands from a host device such as a computer or control system via its rear panel

Remote RS-232 port (see item C on pages 9 and 11) or front panel Configuration (USB)

port (see item C on page 8, and D on page 10).

The default serial port protocol of the port is as follows:

• 9600 baud • No parity • 8 data bits

• No flow control • 1 stop bit

Host-to-Extender Communications

SIS commands consist of one or more characters per field. No special characters are

required to begin or end a command character sequence. When a command is valid, the

extender executes the command and sends a response to the host device. All responses

from the extender to the host end with a carriage return and a line feed (CR/LF = ]), which

signals the end of the response character string. A string is one or more characters.

Extender-Initiated Messages

When a local event occurs, such as a front panel operation, loss or restoration of an input

signal, or an error condition, the extender responds by sending a message to the host.

Examples of the extender-initiated messages are listed below:

© Copyright 20yy, Extron Electronics DTP T HWP 232 D, Vx.xx, 60-nnnn-nn

The extender issues the copyright message when it first powers on. Vx.xx is the firmware

version number and 60-nnnn-nn is the part number.

Inn All

]

The extender also sends the Inn message whenever the selected input is changed. n is the

input number. A 0 in the n field indicates no input is selected.

]

Error Responses

When the extender receives a valid SIS command, it executes the command and sends a

response to the host device. If the extender is unable to execute the command because the

command is invalid or it contains invalid parameters, the extender returns an error response

to the host. The error response codes are:

E01 — Invalid input channel number (out of range)

E06 — Invalid channel change

E10 — Invalid command

E13 — Invalid parameter

Timeout

Pauses of 10 seconds or longer between command ASCII characters result in a timeout.

The command operation is aborted with no other indication.

DTP T HWP/UWP 232/332 D Transmitters • Remote Control 17

Page 24

Using the Command and Response Table

ASCII to Hex Conversion Table

Space

The command and response table begins on page 20. Symbols are used throughout the

table to represent variables in the command and response fields. Command and response

examples are shown throughout the table. The ASCII to HEX conversion table below is for

use with the command and response table.

NOTE: Upper and lowercase text can be used interchangeably unless otherwise stated.

Symbol definitions

DTP T HWP 232/332 D and DTP UWP 232/332 D models

= Carriage return/line feed

]

= Carriage return (no line feed)

}

| = Pipe (can be used interchangeably with the } character)

• = Space

= Escape key

E

W = Can be used interchangeably with the E character

•

X! = Input number 0

X@ = Status 0 = off, disabled, or not detected

through 2 (0 = deselect input [break tie]. This results in the output being disabled.)

1 = HDMI, 2 = VGA (UWP models)

1 = on, enabled, or detected

X# = Auto switch mode 0 = disabled (default)

1 = enabled (highest active input has priority)

X$ = EDID See table 1 on page 22.

X% = Input HDCP status 0 = No source is detected

1 = Source is detected with HDCP

2 = Source detected without HDCP

X^ = Output HDCP status 0 = No sink is detected

1 = Sink is detected with HDCP support

2 = Sink is detected without HDCP support

X& = Transmitter name A text string of up to 24 alphanumeric characters and minus sign/hyphen (-).

No blank or space characters are permitted as part of a name. The first letter must a

letter, and the last character must not be a minus sign/hyphen (default is

DTP-T-HWP/UWP-232/332).

X* = Raw EDID data 128 or 256 bytes of hexadecimal data

X( = Video color bit depth mode 0 = Auto (default, based on sink EDID)

1 = force 8-bit

X1) = Analog input video format (UWP models only) 0 = Auto detect (default)

1 = RGB/VGA

2 = YUV/component video

X1! = Current EDID native resolutions and refresh rate in plain text

DTP T HWP/UWP 232/332 D Transmitters • Remote Control 18

Page 25

X1& = Verbose mode 0 = clear/none

1 = verbose mode (default)

2 = tagged responses for queries

3 = verbose mode and tagged for queries

X1( = Force VGA to DVI out (UWP models only) 0 = HDMI (default)

1 = force VGA input to be DVI output

X3) = Pixel phase value 0 to 63, default is 32

X3! = Total pixels value ±255 of default value (depends on input rate)

X3@ = Horizontal/Vertical start value 0 to 255 (default is 128)

DTP T HWP/UWP 232/332 D Transmitters • Remote Control 19

Page 26

Command and Response Table for SIS Commands

Command Function

Select and view input

Select an input

Example:

View input selection

Signal status

Request all signal status

HDCP status

View the HDCP status of a specific

input

View the HDCP status of both HDMI

inputs

View the output HDCP status

Auto switch status

View the auto switch status

HDCP Authorized device

Set HDCP authorization per input

Set HDCP authorization to all inputs

SIS Command

(Host to Unit)

X!

! InX!•All

1!

!

E

}

OLS

EIX!

E

IHDCP

E

OHDCP

E

AUSW

EEX!*X@

EEX@

}

HDCP

}

} X^]

} X#]

}

HDCP

}

HDCP

Response

(Unit to Host)

In01•All

X!]

Sig

HdcpI

HdcpI

HdcpEX!*

HdcpE

]

]

X@•X@*X@]

X%] X!

X%•X%]

X@] X!

X@]

Additional Description

Select input X! to transmit to the

connected receiver.

Select input 1.

Input X! is selected.

0 = not detected

1 = detected

(Example: Input 1 • Input 2 * Output

= input 1-2; X% = HDCP status

(HDMI inputs only)

0 = disabled (default)

1 = enabled (highest active input priority)

= input (1 or 2)

X@

= 0 (disabled) or 1 (enabled, default)

HDMI inputs only

View input HDCP authorization status

E

} X@•X@]

EHDCP

Input video format (VGA input only, UWP models only)

Set input video format

View current format

View auto-detected format

X1)

2*

\ Typ2*

2\

2*\

X1)

X1)

]

]

X1)

]

X1)

= 0 (HDMI, default) or 1 = force

VGA inputs to DVI output

View current format of input 2.

View auto-detected format of input

X1)

(

=1).

Force VGA DVI out (UWP models only)

Force VGA to DVI output

View VGA to DVI output

EX1(

E

VTPO

VTPO

}

}

X1(] X1(:

Vtpo

X1(]

= 0 (HDMI, default) or 1 (force VGA

inputs to be DVI output)

View VGA DVI out status.

DTP T HWP/UWP 232/332 D Transmitters • Remote Control 20

Page 27

Command Function

SIS Command

(Host to Unit)

Picture adjustment (RGB input only, UWP models only )

Set pixel phase value

Increment pixel phase value

Decrement pixel phase value

View pixel phase value

Set total pixels value

Increment total pixels value

Decrement total pixels value

View total pixels value

Set horizontal start value

Increment horizontal start value

Decrement horizontal start value

View horizontal start value

Set vertical start value

Increment vertical start value

Decrement vertical start value

View vertical start value

E2*X3)

E

2+PHAS

E

2-PHAS

E

2PHAS

E2*X3!

E

2+TPIX

E

2-TPIX

E

2TPIX

E2*X3@

E

2+HSRT

E

2-HSRT

E

2HSRT

E2*X3@

E2

+VSRT

E2

-VSRT

E2

VSRT

}

PHAS

}

}

} X3)

}

TPIX

}

}

} X3!

}

HSRT

}

}

} X3@

}

VSRT

}

}

} X3@

Response

(Unit to Host)

]

X3)

Phas2*

]

X3)

Phas2*

]

X3)

Phas2*

]

]

X3!

Tpix2*

]

X3!

Tpix2*

]

X3!

Tpix2*

]

]

X3@

Hsrt2*

]

X3@

Hsrt2*

]

X3@

Hsrt2*

]

]

X3@

Vsrt2*

]

X3@

Vsrt2*

]

X3@

Vsrt2*

]

Additional Description

X3)

= Pixel phase (0-63, default is 32)

X3!

= ±255 of default value (depends

on input rate)

X3@

= 0-255 (default is 128)

X3@

= 0-255 (default is 128)

DTP T HWP/UWP 232/332 D Transmitters • Remote Control 21

Page 28

Command Function

EDID Minder

NOTE: See table 1 for the EDID values.

SIS Command

(Host to Unit)

Response

(Unit to Host)

Additional Description

Assign EDID to an input

Save the EDID of the connected

display to a user location

View the EDID assignment

View/Read EDID in HEX format

View EDID native resolution

EAX!*X$

ESX$

EDID

EAX!

EDID

ERX!

EDID

ENX!

EDID

}

EDID

}

EdidAX!*

EdidS

} X$]

} X*]

} X1!]

X$]

X$]

Defaults: 50 (HDMI inputs), 03 (VGA

inputs)

Save EDID of display connected to the

output to the user store slot 66, 67, or 68.

Read data as text from the EDID assigned

and used on input X!.

Read out native resolution and refresh

rate from the EDID assigned to the

specified input in plain text.

Example: 1920x1200 @60Hz

Table 1. EDID Values

X$

Value

VGA – PC values

800x600 @ 60 Hz

01

1024x768 @ 60 Hz

02

1280x720 @ 60 Hz

03*

1280x768 @ 60 Hz

04

DVI – PC values

800x600 @ 60 Hz 21 1280x800 @ 60 Hz

17

1024x768 @ 60 Hz 22 1280x1024 @ 60 Hz

18

1280x720 @ 60 Hz 23 1360x768 @ 60 Hz

19

1280x768 @ 60 Hz 24 1366x768 @ 60 Hz

20

HDMI – PC values, with 2-channel audio

800x600 @ 60 Hz

33

1024x768 @ 60 Hz

34

1280x768 @ 60 Hz

35

1280x800 @ 60 Hz

36

HDMI – HDTV values, with 2-channel audio

47

48

49

480p @ 60 Hz

576p @ 50 Hz

720p @ 50 Hz

HDMI – HDTV values, with multi-channel audio

57

58

720p @ 50 Hz

720p @ 60 Hz

Output and user locations

X$

65

* Default for input 2 (VGA) on UWP models.

✝ Default for input 1 (HDMI) on HWP and UWP models and input 2 on HWP models.

Source

Output (Auto)

X$

1280x800 @ 60 Hz

05

1280x1024 @ 60 Hz

06

1360x768 @ 60 Hz

07

1366x768 @ 60 Hz

08

1280x1024 @ 60 Hz

37

1360x768 @ 60 Hz

38

1366x768 @ 60 Hz

39

1400x1050 @ 60 Hz

40

✝

50

51

52

59

60

720p @ 60 Hz

1080i @ 50 Hz

1080i @ 60 Hz

1080i @ 50 Hz

1080i @ 60 Hz

X$

66

User setting 1

Value

Source

X$

1400x1050 @ 60 Hz

09

1440x900 @ 60 Hz

10

1600x900 @ 60 Hz

11

1600x1200 @ 60 Hz

12

1400x1050 @ 60 Hz

25

1440x900 @ 60 Hz

26

1600x900 @ 60 Hz

27

16001200 @ 60 Hz

28

1440x900 @ 60 Hz

41

1600x900 @ 60 Hz

42

1600x1200 @ 60 Hz

43

1680x1050 @ 60 Hz

44

1080p @ 50/25 Hz

53

54

55

61

62

1080p @ 50 Hz

1080p @ 60/24 Hz

1080p @ 50/25 Hz

1080p @ 50 Hz

X$

67

User setting 2

Value

Source

X$

1680x1050 @ 60 Hz

13

1920x1080 @ 60 Hz

14

1920x1200 @ 60 Hz

15

2048x1080 @ 60 Hz

16

1680x1050 @ 60 Hz

29

1920x1080 @ 60 Hz

30

1920x1200 @ 60 Hz

31

2048x1080 @ 60 Hz

32

1920x1200 @ 60 Hz

45

2048x1080 @ 60 Hz

46

56

63

64

1080p @ 60 Hz

1080p @ 60/24 Hz

1080p @ 60 Hz

X$

68

User setting 3

Value

Source

DTP T HWP/UWP 232/332 D Transmitters • Remote Control 22

Page 29

Command Function

SIS Command

(Host to Unit)

Response

(Unit to Host)

Additional Description

Video mute

Enable video mute

Disable video mute

View video mute status

1B

0B

B

Vmt1

Vmt0

X@]

]

]

Output no video signal.

Output selected video input.

Mute status = X@ (0 = off, 1 = on)

Video breakaway

Select program video input only

View currently selected video input

X!

% In

%

X!

X!]

] X! = input number

•

Vid

- 2 only

0

Analog audio mute

Mute or unmute analog audio

Read analog audio mute

X@

Z Amt

Z

X@] X@

X@]

= 0 (off, default), 1 (on)

Analog audio mute status = X@.

Analog audio breakaway

Select program audio input only

View currently selected audio input

X!

$ In

$

X!

X!]

] X! =

•

Aud

- 2 only (analog audio input)

0

Video output color bit depth

Set video color bit depth mode

View video color bit depth mode

EVX(

E

VBITD

}

BITD

} X(]

BitdV

X(]

= auto based on sink (default)

0

1 = force 8-bit

Device name

Set the device name

Set device name to factory default

View device name

EX&CN}

E

}

•

CN

Ipn

Ipn•DTP-T-xxx-xxx

ECN} X&]

X&]

•

]

Change the device name to X&.

Set device name to default.

(Example: DTP-T-HWP-232)

Reset

Reset to factory setting

E

ZXXX

}

Zpx

]

Reset to factory defaults.

Upload firmware

Upload

Information requests

Information request

Request part number

Query firmware version

Query firmware version w/build

E

I

N

Q

*Q

Upload

}

...go

]

Upl

InX!Vid•InX!Aud•Ausw

60-nnnn-nn

x.xx

x.xx.xxxx

]

]

]

]

Upl

displays after upload is

completed.

X#

X@

•

Vmt

X@]

•

Amt

See the Extron website,

www.extron.com, for part numbers.

Verbose mode

NOTE: If tagged responses are enabled (modes 2 and 3), all “view” commands return the prefix and the value, just as the “set”

commands do. For example, the view autoswitch mode (

Set verbose mode

Read verbose mode

EX1&CV}

ECV} X1&]

E

}

AUSW

) command returns “Ausw

X1&]

Vrb

X#]

” in verbose mode.

0 = clear/none

1 = verbose mode (default)

2 = tagged responses for queries

3 = verbose mode and tagged for queries

DTP T HWP/UWP 232/332 D Transmitters • Remote Control 23

Page 30

Reference

(10.87 cm

Template for the 2-gang

Information

This section includes Decora template dimensions for installation of the DTP T HWP D and

DTP T UWP D family of transmitters.

Decora Template Dimensions

To create a template, use the dimensions shown on figure 14.

NOTES:

• The drawing is not full size or to scale. DO NOT scale up or print to use as a

template.

• Full size templates are available online at www.extron.com.

mounting bracket

4.28"

)

3.06"

(7.78 cm)

4.26" (10.83 cm)

3.75" (9.53 cm)

Recommended

cut-out area

for the installation

surface.

SURFACE

CUT-OUT AREA

FOR WALL MOUNT

Top Panel

Figure 15. Decora Template Dimensions

DTP T HWP/UWP 232/332 D Transmitters • Reference Information 24

Page 31

Extron Warranty

Extron Electronics warrants this product against defects in materials and workmanship for a period of three years

from the date of purchase. In the event of malfunction during the warranty period attributable directly to faulty

workmanship and/or materials, Extron Electronics will, at its option, repair or replace said products or components,

to whatever extent it shall deem necessary to restore said product to proper operating condition, provided that it is

returned within the warranty period, with proof of purchase and description of malfunction to:

USA, Canada, South America,

and Central America:

Extron Electronics

1230 South Lewis Street

Anaheim, CA 92805

U.S.A.

Europe and Africa:

Extron Europe

Hanzeboulevard 10

3825 PH Amersfoort

The Netherlands

Japan:

Extron Electronics, Japan

Kyodo Building, 16 Ichibancho

Chiyoda-ku, Tokyo 102-0082

Japan

China:

Extron China

686 Ronghua Road

Songjiang District

Shanghai 201611

China

Asia:

Extron Asia Pte Ltd

135 Joo Seng Road, #04-01

PM Industrial Bldg.

Singapore 368363

Middle East:

Extron Middle East

Dubai Airport Free Zone

F12, PO Box 293666

United Arab Emirates, Dubai

Singapore

This Limited Warranty does not apply if the fault has been caused by misuse, improper handling care, electrical

or mechanical abuse, abnormal operating conditions, or if modifications were made to the product that were not

authorized by Extron.

NOTE: If a product is defective, please call Extron and ask for an Application Engineer to receive an RA (Return

Authorization) number. This will begin the repair process.

USA: 714.491.1500 or 800.633.9876 Europe: 31.33.453.4040

Asia: 65.6383.4400 Japan: 81.3.3511.7655

Units must be returned insured, with shipping charges prepaid. If not insured, you assume the risk of loss or damage

during shipment. Returned units must include the serial number and a description of the problem, as well as the

name of the person to contact in case there are any questions.

Extron Electronics makes no further warranties either expressed or implied with respect to the product and its quality,

performance, merchantability, or fitness for any particular use. In no event will Extron Electronics be liable for direct,

indirect, or consequential damages resulting from any defect in this product even if Extron Electronics has been

advised of such damage.

Please note that laws vary from state to state and country to country, and that some provisions of this warranty may

not apply to you.

Extron Headquarters

+1.800.633.9876 (Inside USA/Canada Only)

Extron USA - West Extron USA - East

+1.714.491.1500 +1.919.850.1000

+1.714.491.1517 FAX +1.919.850.1001 FAX

Extron Europe

+800.3987.6673

(Inside Europe Only)

+31.33.453.4040

+31.33.453.4050 FAX

© 2014 Extron Electronics All rights reserved. www.extron.com

Extron Asia

+65.6383.4400

+65.6383.4664 FAX

Extron Japan

+81.3.3511.7655

+81.3.3511.7656 FAX

Extron China

+86.21.3760.1568

+86.21.3760.1566 FAX

Extron Middle East

+971.4.299.1800

+971.4.299.1880 FAX

Extron Korea

+82.2.3444.1571

+82.2.3444.1575 FAX

Extron India

1.800.3070.3777

(Inside India Only)

+91.80.3055.3777

+91.80.3055.3737 FAX

Loading...

Loading...