Page 1

IMPORTANT:

IMPORTANT:

Go to www.extron.com for the complete

user guide, installation instructions, and

specifications before connecting the

IPCP Pro PCS1xi • Setup Guide

The Extron IPCPProPCS1xi Power and Device Control Processor integrates Ethernet

connection into AV systems to allow users to remotely control and monitor AV

equipment, including display devices and switchers. The IPCPProPCS1xi features a

controllable, 100-240 VAC, 50-60 Hz, AC power outlet for remote power management of

a connected device. A 10amp circuit breaker provides overcurrent protection.

The AC power button, located on the front panel, allows manual control of

the AC power output port. A front panel security lockout mode (executive

mode) can be used to disable the button if the unit is installed in an

unsecured environment where access is undesirable.

The IPCPProPCS1xi includes an embedded web server, a bidirectional

serial port, an IR/serial port, digital I/O ports, and a LAN port for use in

applications that require control and monitoring of multiple devices within an AV system. It also includes an Extron eBUS® port,

which allows a variety of eBUS devices to be connected to a single control processor. eBUS devices include an array of button

panels as well as power and signal hubs. eBUS devices are automatically recognized by the control processor and can be added

or removed at any time.

To discover and manage the IPCP and other Extron control products, use Extron Toolbelt® software. Configure the control

processor using Extron Global Configurator® software (Global Configurator Professional [GCProfessional] or Global Configurator

Plus [GC Plus]), or program the control processor using Extron Global Scripter®(GS). The IPCP integrates seamlessly with Extron

GlobalViewer® Enterprise (GVE) software and Extron Control apps for remote control applications. These control processors

support multiple TouchLink®Pro touchpanel interfaces and Network Button Panels (NBPs) over a standard Ethernet network. The

software applications are available at www.extron.com.

Users can view AC current value and circuit breaker status and access Extron Control from the IPCP embedded web page.

This guide provides instructions for an experienced installer to install the control processor and to create a basic configuration.

product to the power source.

CAUTION: This product is intended for indoor use only.

ATTENTION : Ce produit est exclusivement adapté à un usage intérieur.

NOTE: The IPCPProPCS1xi is intended to be used with Extron Electronics products only.

Setup Checklist: How to Proceed With Installation

ATTENTION:

• Installation and service must be performed by experienced personnel.

• L’installation et l’entretien doivent être effectués par du personnel expérimenté.

Get Ready

Familiarize yourself with the features of the control processor (see Front Panel Features on page4, Rear Panel

Features on page4) and of any TouchLinkPro touchpanels or button panels that will be part of the system.

Download and install the latest version of the following:

• Toolbelt software — for discovering the control processor and other control products on the network, for managing

core settings, and for upgrading firmware when needed.

• Global Configurator (GC) software — for configuring the control system

• Global Scripter software — for programming the control processor (as an alternative to GC)

• GUI Designer software — for designing layouts for Extron TouchLinkPro touchpanels and third party touch interfaces

• IPLinkPro device drivers — for use with GC, to make control of AV devices possible

All are avail able from www.extron.com (see Locating Software, Firmware, and Driver Files on the Extron Website on page9).

Obtain network information for the unit from the network administrator. You need the following details for each

Extron Pro series Ethernet-enabled device:

DHCP client setting (on or off) Subnet mask Username

Device (IPCP Pro, TouchLinkPro, IPLPro, NBP) LAN IPaddress Gateway IP address Passwords

Write down the MAC address of each IPLinkPro device to be used.

Obtain model names and setup information for devices the IPCP will control.

1

Page 2

IPCP Pro PCS1 xi • Setup Guide (Continued)

Each control processor comes with a factory-installed Secure Sockets Layer (SSL) security certificate. If you intend to install

a different SSL certificate, contact your IT department to obtain the certificate or for instructions on how to obtain one.

See “Secure Sockets Layer (SSL) Certificates” in the IPCPProSeries User Guide for requirements and guidelines regarding

SSL certificates. IEEE 802.1X authentication is also supported once enabled (see “IEEE 802.1X Certificates” in the

IPCPProQxi and xi Series User Guide for details).

Mount and Cable All Devices

Mount the unit to a rack or furniture (see Mounting on the next page).

Cable devices to the control processor (see Cabling and Features on page 5).

Connect power cords and power on all the devices.

Set Up the Control Processor, Touchpanels, and Network Button Panels for Network Communication

Connect the PC that you will use for setup, the LAN port of the control processor, and the touchpanels or network button

panels to the same Ethernet network. For control processor LAN connections, see Control, Bidirectional — LAN (Ethernet)

on page6.

Start Toolbelt and use it to set the IP address, subnet, gateway IP address, DHCP status, and related settings (see the

flowchart in Network Communication Setup on the next page).

NOTE: When setting up DHCP during network configuration or if using a host name instead of an IP address, the user

must enter a qualified host name (Username.HostName.Domain). For example: somename.extron.com.

Configure or Program the Control Processor, Touchpanels, and Network Button Panels

The most basic steps are outlined below in the recommended order.

NOTE: See the Toolbelt Help File, Global Configurator Help File, Global Scripter Help File, and GUI Designer Help File as

needed for step-by-step instructions and detailed information. The help file for GC includes an introduction to the software

and how to start a project and configuration.

If TouchLinkPro or third party touchpanels are part of the system, start and use GUI Designer to design, save, and build the

graphical user interface (GUI) layout for the touchpanels.

NOTE: To redeem (activate) a LinkLicense

®

, go to www.extron.com//llredeem and follow the online instructions.

Using GC, create a new GCProfessional or GCPlus project and configure the control processor and other IP Link Pro

devices. The configuration tells the control processor:

• How its ports function • What to monitor

• How to control other products • When to do things

• Which touchpanels to interact with • Whom to notify, how, and under what circumstances

Configure ports on the control processor:

Select device drivers and link them to each serial, IR/serial, or Ethernet port.

Select settings (serial protocol, digital I/O settings, AC output settings) as needed.

Add eBUS devices and set them up:

Ensure that the hardware address set on each device is distinct and matches the address used in the configuration.

Assign button functions as desired.

Add Network Button Panels (NBPs) and set them up. Assign button functions as desired.

Set up monitors, schedules, macros, and local variables.

Add touchpanels and set them up:

• Upload the GUI configuration for the touchpanels to the project within GC Professional or GC Plus.

• Assign any appropriate functions, monitors, or schedules to the touchpanels and their buttons.

If not using GC Professional or GC Plus, use Global Scripter to program the control system as desired.

Program ports on the control processor.

• Program each serial, IR/serial, or Ethernet port.

• Program digital I/O settings, AC output settings as needed.

Add eBUS devices and set them up:

• Ensure that the hardware address (eBUS ID) set on each device is distinct and matches the address programmed

for it in the IPCP.

• Program button functions as desired.

2

Page 3

Add Network Button Panels and set them up. Program button functions as desired.

Add touchpanels and set them up:

Upload the GUI configuration for the touchpanels to the project.

Program functions, monitors, or schedules to the touchpanels and their buttons.

Save the GC or GS project.

Build and upload the system configuration to the control processor and other system devices.

Test and Troubleshoot

Test the system (see the IPCPProQxi and xi Series User Guide for an outline of the system testing procedure).

Make adjustments to wiring or configuration as needed.

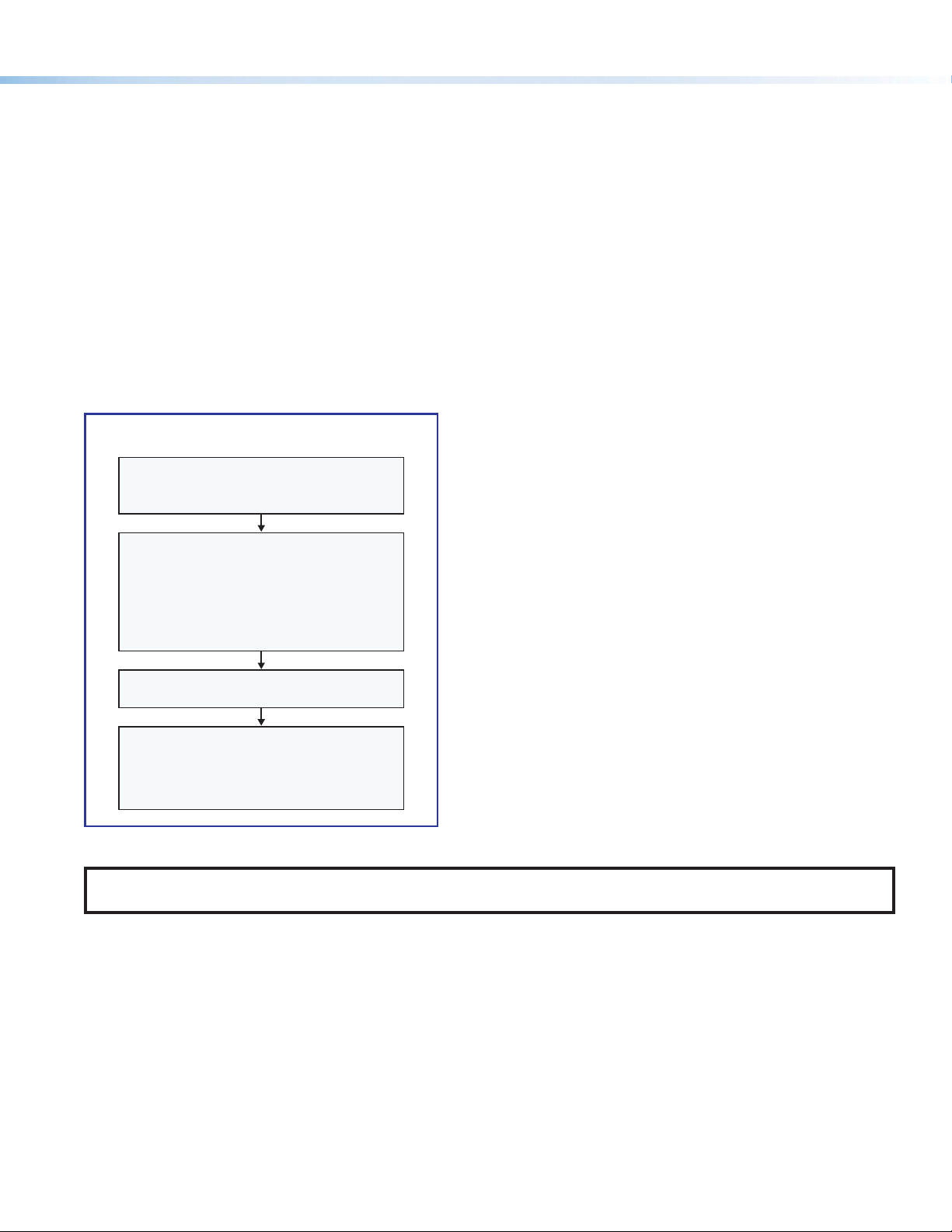

Network Communication Setup

Network setup is essential prior to configuration. Use the following flowchart as a guide to setting up the control processor for

network use.

Network Communication Setup

Connect the PC and the LAN port of the

control processor to the same network.

Apply power to all devices.

Open the Toolbelt software from within

Global Congurator (GC Professional or

GC Plus mode) or as the stand-alone

Toolbelt displays a list of all Extron control

devices connected to the network.

application.

Start Device Discovery.

Using the MAC address, locate the desired

control processor in the list and select it.

Use the Set IP feature in Toolbelt or use the

Toolbelt

Figure 1. Network Setup

Manage > Network Settings tab

feature to enter the IP address and

subnet address, then congure other

network settings as needed.

NOTE: If using 802.1X security, see the Extron 802.1X Technology Reference Guide and the Toolbelt Help file for additional

details on system setup.

Mounting

Securely mount the control processor and other devices and attach cables using the wiring section (see Cabling and Features

on page5) as a wiring guide. Optional 1U rack shelves and furniture mounting bracket kits are available for use with the control

processor. Read the instructions and UL guidelines that come with the rack shelf or mounting kit for installation procedures.

See the product-specific page at www.extron.com for a list of compatible accessories for mounting your control processor.

3

Page 4

IPCP Pro PCS1 xi • Setup Guide (Continued)

CCCCCCCC

AAAAAAAA BBBBBBBB

D

DDDDDDD

FFFFFFFFEEEEEEEE GGGGGGGG

H

HHHHHHH

COM (Serial) LEDs

Digital

I/O LEDs

Reset Button

and LED

Breaker

eBUS

Network

IR/

Serial

POWER

BREAKER

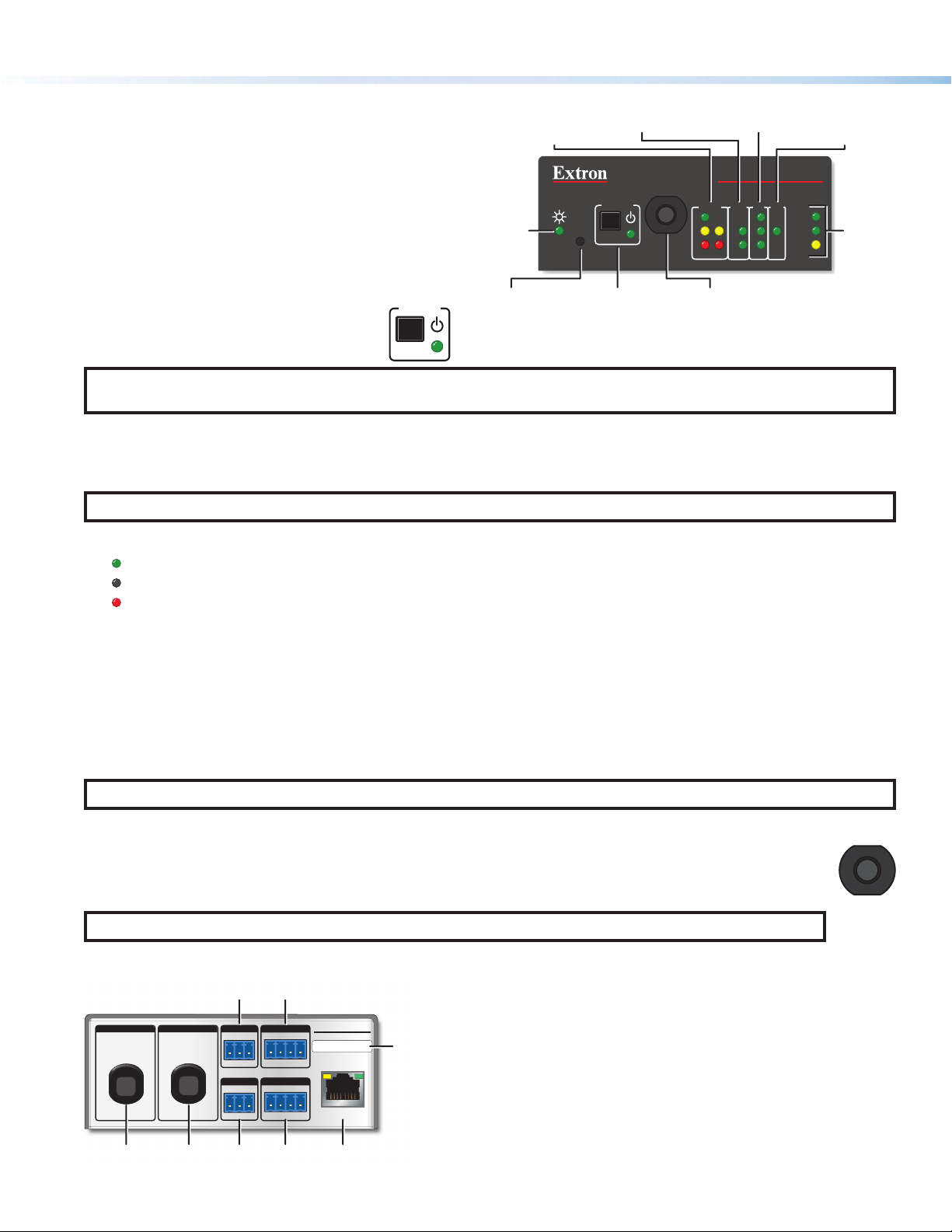

Panels and Locations of Features

Front Panel Features

LEDs

LED

See figure 2 at right for the front panel features and their

locations.

The LED indications are described and shown in Cabling

and Features (starting on the next page) paired with

descriptions of the corresponding ports. For reset button and

reset mode information, see the IPCPProSeries User Guide.

Power button (switch) and LED

The front panel power button (switch) provides

a convenient way to manually turn switched

AC power output on or off for the rear panel

O

T

10

S

S

E

R

P

BREAKER

Power

LED

(recessed)

POWER

R

AC Power Button

Figure 2. IPCP Pro PCS1xi Front Panel

IPCP PRO PCS1 xi

R

E

eBUS

S

E

L

T

LIMIT

B

E

OVER

Circuit

COM

Tx

Rx

I/O IR/S

1

2

3

1000

LINK

ACT

LAN/

LEDs

AC power output cable.

NOTE: The button is not a safety disconnect device. In case of an emergency, disconnect AC power from the power input

(appliance inlet) of the connected equipment.

The IPCPProPCS1xi can be configured (using Global Configurator or Global Scripter) to monitor the power output condition

and to alert users in the event of a power fault interruption. The IPCPProPCS1xi can be set up to monitor the circuit breaker and

also the current load at the switched AC power output port. The AC current value and circuit breaker status are shown in the IPCP

embedded web page. Power output can also be toggled on and off using a control in the embedded web page.

NOTE: The power output state setting persists after and is retained during a power cycle.

LED indications for power output state

• Lit green: power output is enabled.

• Off (dark): power output is disabled.

• Lit red: a fault condition is detected, and power output is disabled.

Front panel lockout (executive mode)

To prevent unauthorized use, this button can be locked (disabled) via a front panel lockout mode (executive mode) that can be

enabled or disabled by one of two methods:

• Using software, as part of the configuration or when programming actions, monitors or schedules

• Holding down the power button switch for 3 seconds

The power LED blinks three times to indicate the lockout mode has been enabled or disabled.

When the front panel is locked, if the Power button is pressed, the power LED blinks three times to indicate that the button is

locked, and the unit does not change power states as a result of the button press.

4

NOTE: The executive mode state (on or off) persists after and is retained during a power cycle.

Circuit breaker

The front panel features a 10 A rated circuit breaker. When a fault condition occurs, the breaker is triggered, which

stops power output. This condition can be monitored and the system can be configured (using available commands)

to send an alert e-mail or perform some other action. After you correct the cause of the overcurrent condition, press

the Breaker button to manually reset the circuit breaker.

NOTE: The circuit breaker and the Reset button are not affected by front panel lockout (executive mode) settings.

Rear Panel Features

Power input (attached cable) — Powers the IPCPProPCS1xi,

IPCP Pro PCS1 xi

COM

Tx Rx

IR/S

SG

G

PWR OUT = 6W

DIGITAL I/O

1 2 3 G

eBUS

-S+V +S G

INPUT

100-240V ~ 10A MAX

50-60Hz

100-240V ~ 10A MAX

OUTPUT

50-60Hz

Figure 3. IPCPProPCS1xi Rear Panel

IPCP PRO PCS1 xi

MAC: 00-05-A6-XX-XX-XX

S/N: ####### E######

LAN

A

next page

AC power output (attached cable) — Provides switched

B

(controlled) AC power output to another device, next page

3-pole COM port (RS-232-only), page 6

c

Digital I/O ports (digital input/output), page 7

D

IR/serial output port, page 6

E

eBUS port, page 7

F

LAN connector and LEDs (Ethernet), page 6

G

MAC address, page 6

H

O

R

T

E

10

S

10

E

S

T

S

E

R

P

Page 5

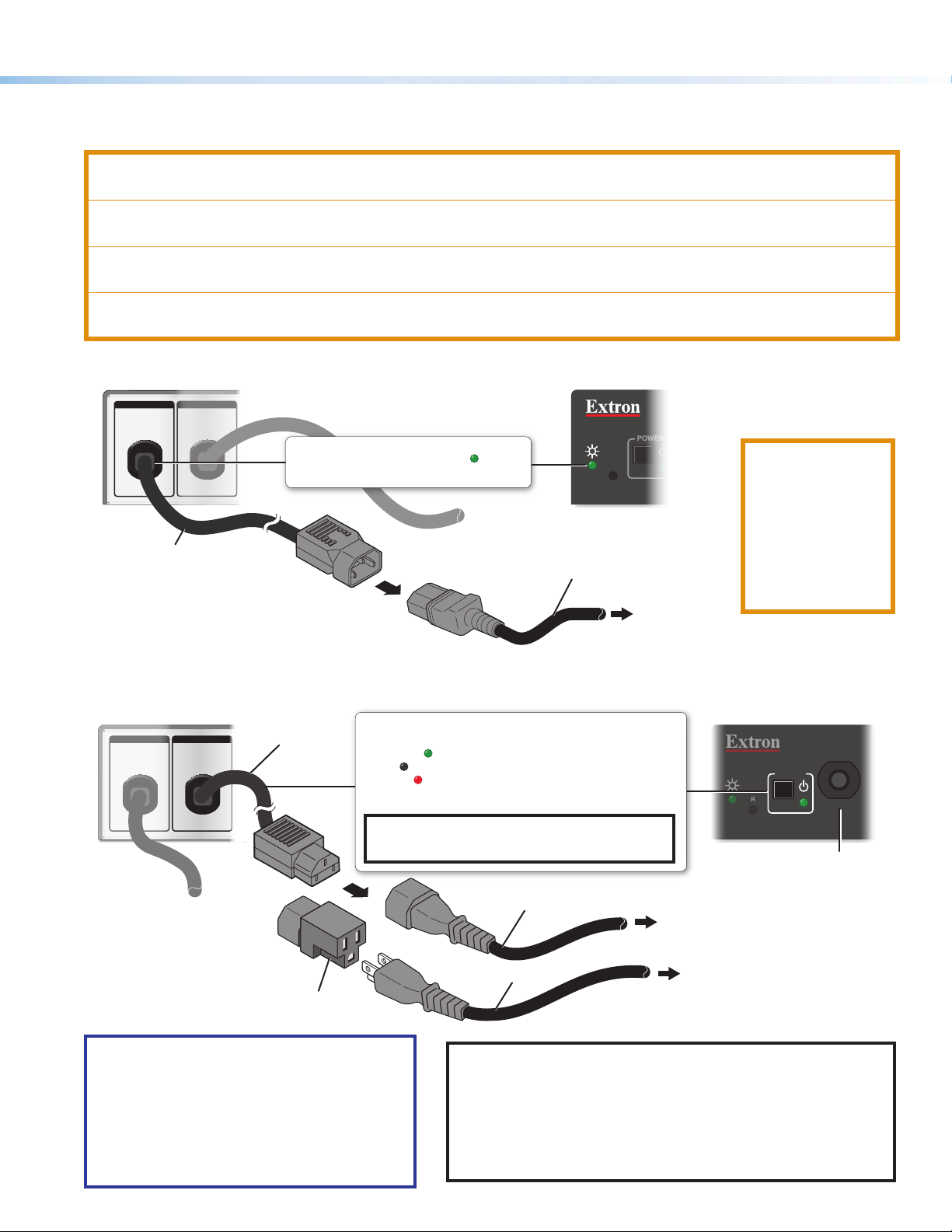

Cabling and Features

POWER

R

Attach cables using the following wiring diagrams as a guide. Full details are available in the IPCPProQxi and xi Series User Guide.

CAUTION:

ATTENTION :

• Total length of the power cord including the small pigtail shall not be less than 1.5m or more than 4.5m.

• La longueur totale du câble d’alimentation, cordon compris, ne doit pas être inférieure à 1,5 m ou supérieure à 4,5m.

• Always use the power cord provided with the unit.

• Veillez à toujours utiliser le câble d’alimentation fourni avec l’unité.

• Should you need to use a different power cord, consult Extron Electronics prior to using the cord.

• Si vous devez utiliser un autre câble d’alimentation, contactez Extron Electronics avant d’utiliser ce câble.

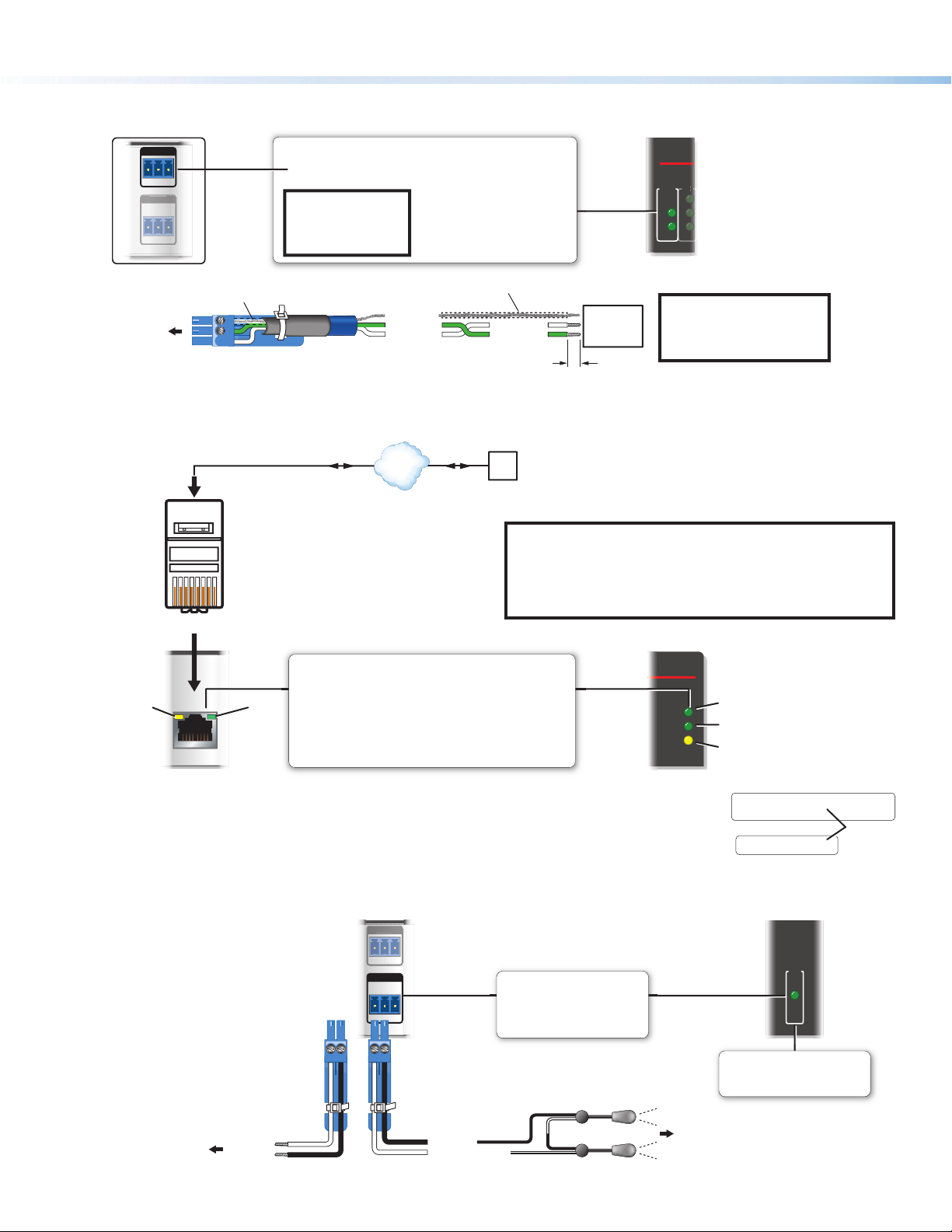

Power Input — Internal

INPUT

100-240V ~ 10A MAX

50-60Hz

Rear Panel

6 inch (152 mm)

IEC Input Cable

OUTPUT

100-240V ~ 10A MAX

50-60Hz

Power Input, Internal Power Supply

• Connect to

100 to 240 VAC.

• Front panel LED ( ) blinks

during boot-up and remains lit

when the IPCP receives power.

Power Output — Switched AC Power Output

Switched 100-240 VAC, 10 A (Max.) Power Output

• Front panel Power LED appears:

• Lit green ( ) when power output is enabled (unit outputs power)

• Off ( ) when power output is disabled (power output is off)

• Lit red ( ) when a power output overcurrent condition is detected

(the circuit breaker has been tripped) and power output is disabled.

• Front panel Power button controls power output availability.

NOTE: The front panel power switch is not a safety disconnect

device. In case of emergency, disconnect AC power from the

power input (appliance inlet) of the connected equipment.

or

INPUT

100-240V ~ 10A MAX

50-60Hz

Rear

Panel

OUTPUT

100-240V ~ 10A MAX

50-60Hz

6 inch (152 mm)

IEC Output Cable

NEMA 5-15R

Adapter

IEC Power Cord

IEC Power Cord

Edison Power Cord

R

Front Panel

To a 100 - 240 VAC

power source

(main power)

Power input port

on an AV device

(international)

Power input port

on an AV device

CAUTION: Always

disconnect the

product from the

wall plug.

ATTENTION:

Veillez à toujours

déconnecter le

produit de la

prise murale.

POWER

Front

Panel

(USA)

O

R

T

E

10

S

E

S

T

S

E

R

P

BREAKER

Circuit Breaker

(power output

overcurrent

protection)

ATTENTION:

• When using the NEMA5-15R receptacle

adapter, connect the equipment only to a

nominal 120VAC electrical supply source.

• Lorsque vous utilisez la prise de courant

NEMA5-15R, veillez à ne connecter le

dispositif qu’à une source d’alimentation

nominale de 120Vca.

NOTES:

• Within the United States of America use a power supply cord

with conductors that are a minimum diameter of 18 AWG.

• For international installations, use a power supply cord with

conductors that are a minimum of 1.0mm2.

• Make sure that the device being controlled can support an AC

power cycle.

5

Page 6

IPCP Pro PCS1 xi • Setup Guide (Continued)

S

G

/S

S

I/O

3/16" (5 mm) max.

Front Panel

Rear Panel

P

RJ-45

Connector

eceived.

G

TxR

CO

Rear Panel Front Panel

Two Single IR Emitters

Source Device

S/N: ####### E######

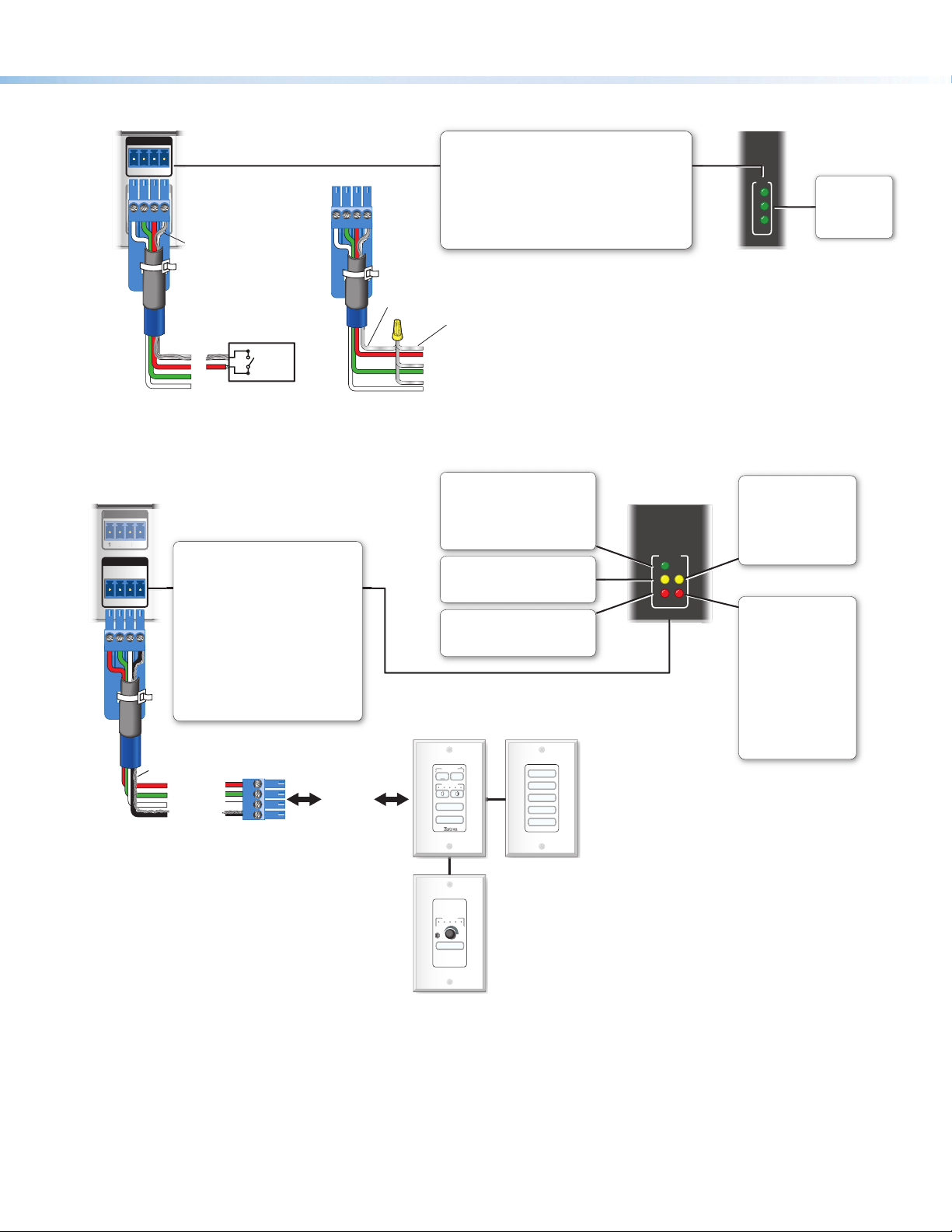

Control, Bidirectional — Serial (COM)

COM

Tx Rx

IR

3-pole COM

G

(RS-232)

NOTE: The 3-pole

COM port

supports software

Serial (COM) Port

Select protocol via software.

COM port default protocol:

• 9600 baud

• 8 data bits • 1 stop bit

• no parity • no ow control

IPCP

COM

Tx

Rx

1

2

3

ow control only.

To 3-pole

COM port

Heat Shrink

Over Shield Wires

G

Rx

Tx

Ground

Receive

Transmit

Heat Shrink

Receive (Rx)

Transmit (Tx)

Strip wires

RS-232-

Controllable

Device

NOTE:

Control, Bidirectional — LAN (Ethernet)

Insert Twisted

Rear

Panel

Activity

LED

Pins:

LAN

12345678

Pair Wires

Link

LED

Ethernet

Default protocol, public ports:

• IPCP IP address: 192.168.254.250

• Gateway IP address: 0.0.0.0

• Subnet mask: 255.255.255.0

• DNS address: 127.0.0.1

• DHCP client: off

• Link speed and duplex level: autodetected

• Data rates: 10/100/1000Base-T

The control processor is assigned a unique user hardware ID number (MAC address,

for example, 00-05-A6-05-1C-A0). You may need this address during control processor configuration.

A label that indicates the MAC address is located on the rear or side panel of the unit.

TCP/IP

Network

LAN (Ethernet)

PC

NOTE: The factory configured passwords for this device

have been set to the device serial number. Passwords

are case sensitive. Performing a Reset to Factory

Defaults reset (see Reset Modes: a Brief Summary on

page8) sets the passwords to extron.

Front Panel

RO PCS1 xi

Default login

credentials:

• Username:

admin or

user

• Password:

extron

1000

LINK

ACT

If you use cable that

has a drain wire, tie the

drain wire to ground at

both ends.

1000 Mbps

Connection

Network is

active.

Data is being

sent/r

00-05-A6-XX-XX-XX

MAC: 00-05-A6-XX-XX-XX

S/N: ####### E######

MAC: 00-05-A6-XX-XX-XX

MAC

Address

Control, Unidirectional — IR/Serial

To a Projector,

Panel Display, or the

Wired IR Remote or

RS-232 Port of a

6

IR or RS-232

Output

Ground

M

IR/S

SG

or

Unidirectional

IR

Output options:

• IR (30 kHz to 300 kHz,

• Unidirectional RS-232

Ground

G

IR Output Signal

S

IR/Serial Ports

with or without carrier signals)

(-)

(+)

(-)

(-)

(+)

(+)

To the IR Receiver of a

Projector, Display, or

IR/Serial LED

Lights when signals are

transmitted on the IR/serial port.

Source Device

IR/S

Page 7

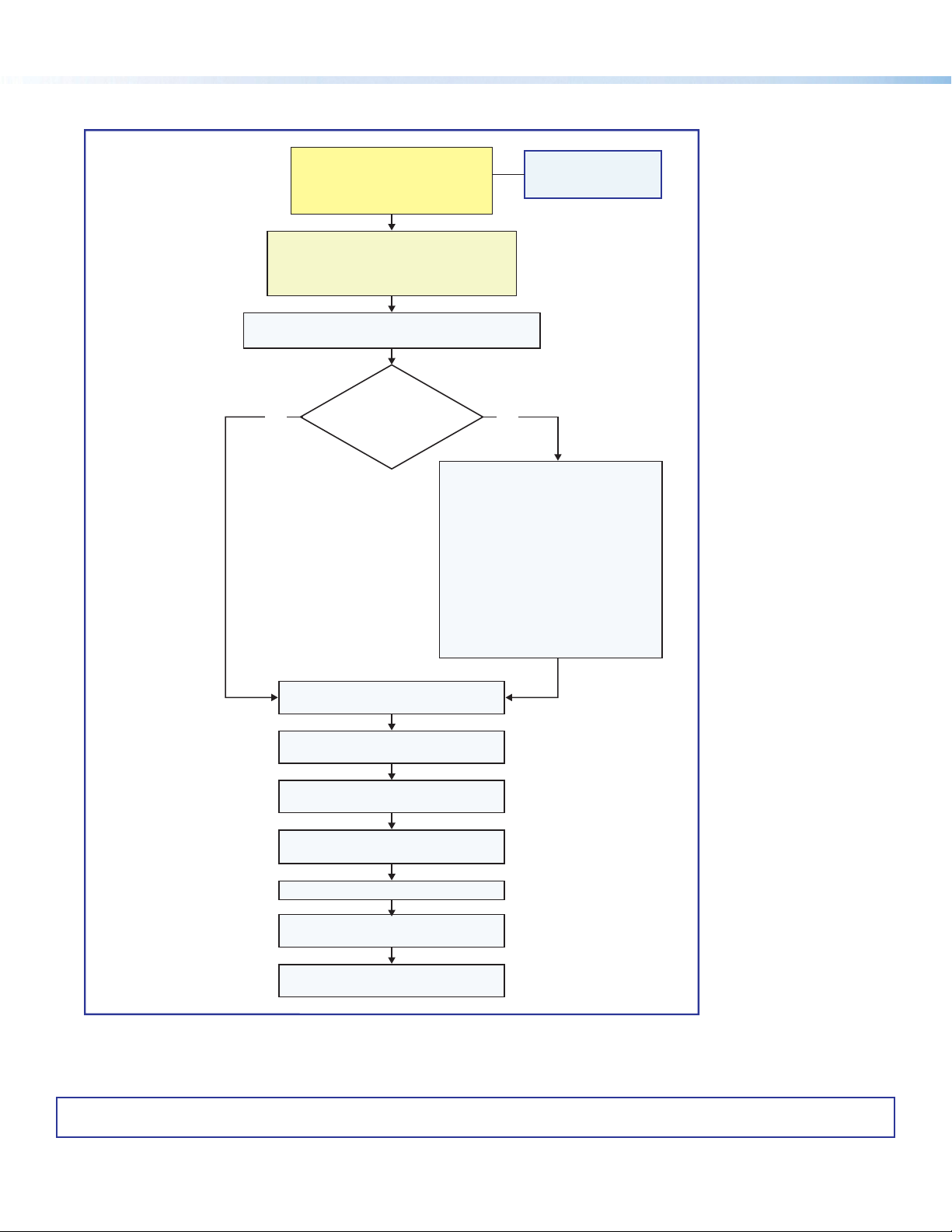

Control, Unidirectional — Digital I/O

P

W

-S+SG

BUS

eBUS

1

Device 1

3

G

DIGITAL I

/O

Rear Panel Front Panel

I/O

3

12 G

WR OUT = 6

Heat

Shrink

Over

Shield

Wires

G

3

2

Switch,

Sensor

Control — eBUS

Ground

Digital I/O (digital input/output)

Congure each port as a digital input or output,

with or without +5 VDC pull-up.

Use these ports to:

• Monitor or trigger events and functions (toggle relays,

issue commands, send e-mail), once congured.

• Power LEDs or other devices that accept a

TTL signal.

Wire

Nut

Share the same ground among

I/O connections.

Device 3

Device 2

(Switches, sensors,

LEDs, relays, or

similar items)

I/O

1

2

3

Digital I/O

LEDs

Light when the

corresponding

ports are active.

Rear Panel

eBUS

-S+V +S G

PWR OUT = 6W

eBUS Accessory Port

Connect the rst eBUS device to this

port, then connect other eBUS devices

and accessories to that device in the

desired topology (daisy chain, star, or

combination).

• Wire the connectors the same at

both ends for every eBUS device.

• See the eBUS Technology Reference

Guide for the recommended distance

from the control processor to the last

eBUS device and maximum quantity

of devices per control processor.

• The IPCP Pro can provide power to

the button panel devices.

Drain Wires

+V

+12 VDC

+S

+ Signal

-S

- Signal

G

Ground

eBUS port

on an

eBUS device

(button

panel or

similar

device)

eBUS Link LED (green)

Lights steadily and remains lit

when the unit detects connected

eBUS devices, there are no ID

conicts, and eBUS rmware is

not currently being synchronized.

eBUS Busy LED (amber)

Blinks while eBUS rmware is

being synchronized.

eBUS Error LED (red)

Blinks if the unit detects an

eBUS ID conict.

DISPLAY

OFF

ON

VOLUME

PC

VIDEO

VOLUME

LAPTOP

DOC CAM

PC

DVD

VIDEO

Front Panel

eBUS

L

B

E

LIMIT

OVER

eBUS Limit LED

(amber)

Lights steadily and

remains lit while the

eBUS port uses the

maximum threshold

power.

eBUS Overload LED

(red)

Lights steadily when the

eBUS port exceeds

maximum threshold

power usage and enters

the fault state.

During this fault state,

eBUS port power is

shut down until the

power usage falls back

below the threshold.

The Over LED remains

lit during the fault state.

MUTE

(Continued on the next page)

7

Page 8

IPCP Pro PCS1 xi • Setup Guide (Continued)

+

V

+

S

G

–

S

Tie drain wires to ground.

X

EBDB MINI

Rear Panel

(or use

an EBDB

10-port hub)

ATTENTION:

• Do NOT connect the power pin to

any device that is already powere d

by the IPCP Pro control processor

or by an addi ti onal power supply.

• NE connectez PAS la broche

d'alimentati on à un appa reil déjà

alimenté par le processeur de

contrôle IPCP Pro ou par une autre

eBUS DISTRIBUTION HUB

+

V G-S+S+V G-S+S+V G-S+S

X

G-S+S

• Connect up to four (4) eBUS devices to the

EBDB Mini eBUS Distribution Hub.

•Wire the connectors the same at both ends.

G-S+S

+V

G-S+S

+V

+V

+S

-

S

G

IPCP Pro

Rear Panel

+12 VDC

+ Signal

-

Signal

Ground

eBUS

PWR OUT = 6W

eBUS Connections

3/16" (5 mm) Max.

Tie drain wires to ground.

-S+V +S G

+

V

+

S

–

S

G

eBUS port on an

EBP or other

eBUS endpoint

device

source d'alimentation.

G-S+S

Powered

G-S+S

eBUS

device(s)

+V

Reset Modes: a Brief Summary

The IP Link Pro control processors offer the following reset modes:

• Run Factory Boot Code: Press and hold the front panel Reset button while applying power to the unit. Keep holding the

button down until the Power LED blinks twice, or for 6 seconds, then release the button. The

LED blinks slowly during bootup. The control processor runs the factory boot code (rather than

full firmware). Upload new firmware to the unit (see “Updating the Firmware” in the user guide

for details).

• Use this mode to temporarily boot up the unit running only the factory boot code, then

install the desired firmware.

• Use this in the event that a firmware update has failed or if incompatibility issues arise with

user-loaded firmware.

NOTES:

• Do not continue to operate the control processor using only the factory boot code.

The unit requires a full firmware package in order to be fully operational. If you want

to use the firmware version with which the unit shipped, you must upload that version

again (see the Global Configurator Help File or Toolbelt Help File for firmware upload

instructions).

• To return the unit to the firmware version that was running prior to the reset, cycle

power to the unit instead of installing new firmware.

• Project Recovery: See the IPCP Pro Qxi and xi Series User Guide for instructions. Use this mode to recover the

project in the event of a lost user name and password.

• Run/Stop Program: Hold down the Reset button for about 3 seconds, until the Power LED blinks once. Release

and press the Reset button momentarily (for <1second) within 1second. (Nothing happens

if the momentary press does not occur within 1second.) The LED blinks 2 times if scripts and

systems are starting. The LED blinks 3 times if they are stopping. This mode allows you to

• Toggle DHCP Client: Press the Reset button five times (consecutively). Release the button. Do not press the button

restart any programs stopped by an IP settings reset.

within 3seconds following the fifth press. Use this mode to enable or disable the DHCP client

for the LAN port.

• The Reset LED blinks 6 times if the DHCP client is enabled.

• The Reset LED blinks 3 times if the DHCP client is disabled.

NOTES:

• By default DHCP is off for the LAN port and the unit uses a static IP address.

• If DHCP has been enabled, when you disable DHCP, the unit reverts to using the previously-

set static IPaddress.

8

Page 9

• Reset All IP Settings: Press and hold the front panel Reset button until the Power LED blinks once at 3 seconds and

twice at 6 seconds. Release and momentarily press the Reset button within 1 second. The

LED blinks 3 times in quick succession upon successful reset.

Use this mode to reset all network settings to factory default values without affecting

user-loaded files. This reset mode also stops any running programs

authentication.

turning DHCP off.

Lastly, this mode resets the settings for both LAN and AV LAN ports, including

and disables 802.1X

• Reset to Factory Defaults: Press and hold the front panel Reset button for 9 secondsuntil the Power LED blinks once

at 3 seconds, twice at 6 seconds, and thrice at 9 seconds. Release and momentarily press

the Reset button within 1 second. The

successful reset.

Use this mode to return the control processor to factory default settings. This mode also

deletes all user-loaded files and configurations

in the event logs table. User-loaded digital certificates are deleted. The unit continues to run the userloaded firmware.

For detailed information on each mode and its use, see the IPCP Pro Qxi and xi Series User Guide at www.extron.com.

Power LED blinks 4 times in quick succession upon

(except LinkLicense files), and it clears messages

Resources

Obtaining Control Drivers

Extron provides an extensive selection of device drivers available on the Extron website. If the system requires a control driver

that is not already available, you can request a new serial (RS-232), IR, or Ethernet driver from Extron.

The IPCPProPCS1xi does not support IR learning. However, if you have another model of IPCPProxi, IPCPPro, or IPLPro

control processor, one that includes an IR receiver port, you can create your own custom IR device driver using IR Learner Pro

software. Follow the directions in the IR Learner Pro Help File to create a driver by using the remote control for that device and the

IR receiver port on the front panel of the control processor.

Obtaining Instructions, Information, and Assistance

A checklist of basic setup steps is provided at the beginning of this guide. For additional information see the help files and the

IPCPProQxi and xi Series User Guide, available at www.extron.com.

If you have questions during installation and setup, call the ExtronS3 Sales & Technical Support Hotline or the ExtronS3

Control Systems Support Hotline (1.800.633.9877).

Locating Software, Firmware, and Driver Files on the Extron Website

There are three main ways to find software, firmware, and device drivers within www.extron.com:

• Via links from the web page for the specific product

• Via the Download Center page (Click on the Download tab at the top of any page within www.extron.com.)

• Via links from search results

NOTES:

• For some software you have the option to click the Download Now button to begin downloading the software file. For other

software there is a link for contacting an Extron support representative who can provide you access to the latest version.

To obtain Extron control product software, you must have an Extron Insider account. Extron provides training to our

customers on how to use the software. Access to the full features of Global Configurator Professional is available to

those who successfully complete Extron Control Professional Certification.

• IPLinkPro Series RS-232 and Ethernet drivers are required. You must use serial and Ethernet drivers

developed specifically for the IPLinkPro platform. With the exception of IR device drivers, drivers used for the

previous generation IPLink (non-Pro) control processors are not compatible.

9

Page 10

IPCP Pro PCS1 xi • Setup Guide (Continued)

Overall Configuration Procedure for the Control Processor

Within Global Configurator

(GC Professional or

GC Plus mode):

Create a new GC Professional or GC Plus project

No Yes

Configure the IP settings

of the control processor,

NBP network button panels, and

TouchLink Pro touchpanels.

If desired or required, use

Toolbelt or other software to congure

security settings for 802.1X, SSL.

Upload security certicates, private keys.

and add the control processor to it.

Will

TouchLink Pro or

third party touchpanels or

other user interfaces

be used?

Create GUI layouts for the

touchpanels or other interfaces:

1. Start GUI Designer.

2. Create GUI layout designs for each

TouchLink Pro, third party

touchpanel (with a TouchLink

Interface), or a computer or

mobile device (with LinkLicense).

3. Save and build the GUI layout le.

Or...

Download existing GUI layouts

from identical touchpanels.

Network

See Network

Communication Setup

Communication Setup

on page 3.

Congure ports on the

control processor.

Create monitors, schedules, timers,

macros, and local variables.

Add touchpanels, other interfaces, or

button panels (if used) to the project.

Import GUI layouts and congure the

touchpanels or other interfaces.

Save the project.

Build and upload the conguration to

the control processor.

Test the system, make adjustments,

nalize conguration.

Figure 4. Overall Configuration Steps

For information on safety guidelines, regulatory compliances, EMI/EMF compatibility, accessibility, and related topics, see the

Extron Safety and Regulatory Compliance Guide on the Extron website.

10

© 2021 - Extron All rights reserved. www.extron.com

All trademarks mentioned are the property of their respective owners.

Worldwide Headquarters: Extron USA West, 1025 E. Ball Road, Anaheim, CA 92805, 800.633.9876

68-3496-52

Rev. A

02 21

Loading...

Loading...