Page 1

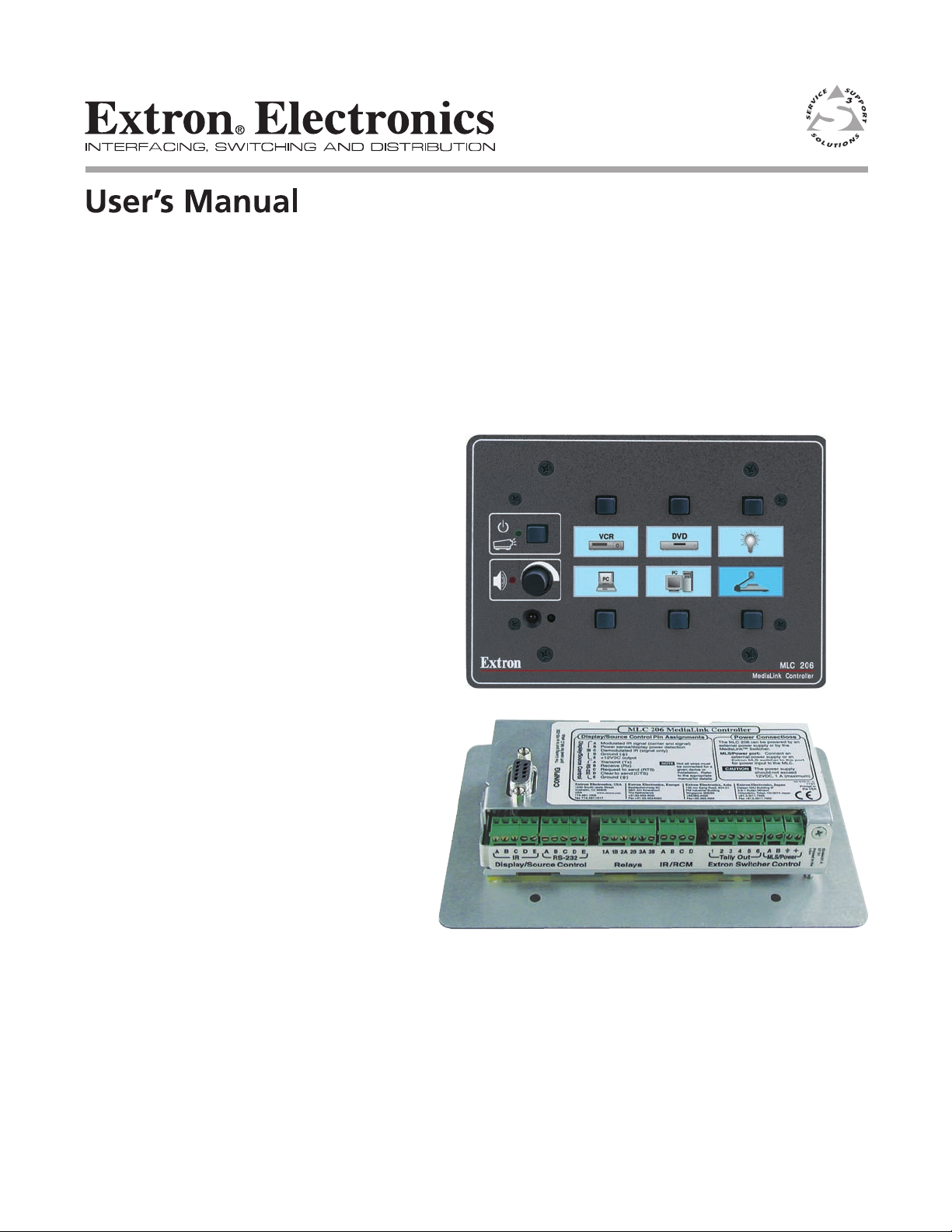

MLC 206, MLC 206 AAP,

MLC 206 EC, MLC 206 AAP EC

MediaLink™ Controllers

68-601-01 Rev. B

Printed in the USA

11 02

Page 2

Precautions

Safety Instructions • English

This symbol is intended to alert the user of important operating and maintenance

(servicing) instructions in the literature provided with the equipment.

This symbol is intended to alert the user of the presence of uninsulated dangerous

voltage within the product's enclosure that may present a risk of electric shock.

Caution

Read Instructions • Read and understand all safety and operating instructions before using the

equipment.

Retain Instructions • The safety instructions should be kept for future reference.

Follow Warnings • Follow all warnings and instructions marked on the equipment or in the user

information.

Avoid Attachments • Do not use tools or attachments that are not recommended by the equipment

manufacturer because they may be hazardous.

Consignes de Sécurité • Français

Ce symbole sert à avertir l’utilisateur que la documentation fournie avec le matériel

contient des instructions importantes concernant l’exploitation et la maintenance

(réparation).

Ce symbole sert à avertir l’utilisateur de la présence dans le boîtier de l’appareil de

tensions dangereuses non isolées posant des risques d’électrocution.

Attention

Lire les instructions• Prendre connaissance de toutes les consignes de sécurité et d’exploitation avant

d’utiliser le matériel.

Conserver les instructions• Ranger les consignes de sécurité afin de pouvoir les consulter à l’avenir.

Respecter les avertissements • Observer tous les avertissements et consignes marqués sur le matériel ou

présentés dans la documentation utilisateur.

Eviter les pièces de fixation • Ne pas utiliser de pièces de fixation ni d’outils non recommandés par le

fabricant du matériel car cela risquerait de poser certains dangers.

Sicherheitsanleitungen • Deutsch

Dieses Symbol soll dem Benutzer in der im Lieferumfang enthaltenen

Dokumentation besonders wichtige Hinweise zur Bedienung und Wartung

(Instandhaltung) geben.

Dieses Symbol soll den Benutzer darauf aufmerksam machen, daß im Inneren des

Gehäuses dieses Produktes gefährliche Spannungen, die nicht isoliert sind und

die einen elektrischen Schock verursachen können, herrschen.

Achtung

Lesen der Anleitungen • Bevor Sie das Gerät zum ersten Mal verwenden, sollten Sie alle Sicherheits-und

Bedienungsanleitungen genau durchlesen und verstehen.

Aufbewahren der Anleitungen • Die Hinweise zur elektrischen Sicherheit des Produktes sollten Sie

aufbewahren, damit Sie im Bedarfsfall darauf zurückgreifen können.

Befolgen der Warnhinweise • Befolgen Sie alle Warnhinweise und Anleitungen auf dem Gerät oder in

der Benutzerdokumentation.

Keine Zusatzgeräte • Verwenden Sie keine Werkzeuge oder Zusatzgeräte, die nicht ausdrücklich vom

Hersteller empfohlen wurden, da diese eine Gefahrenquelle darstellen können.

Warning

Power sources • This equipment should be operated only from the power source indicated on the

product. This equipment is intended to be used with a main power system with a grounded

(neutral) conductor. The third (grounding) pin is a safety feature, do not attempt to bypass or

disable it.

Power disconnection • To remove power from the equipment safely, remove all power cords from

the rear of the equipment, or the desktop power module (if detachable), or from the power

source receptacle (wall plug).

Power cord protection • Power cords should be routed so that they are not likely to be stepped on or

pinched by items placed upon or against them.

Servicing • Refer all servicing to qualified service personnel. There are no user-serviceable parts

inside. To prevent the risk of shock, do not attempt to service this equipment yourself because

opening or removing covers may expose you to dangerous voltage or other hazards.

Slots and openings • If the equipment has slots or holes in the enclosure, these are provided to

prevent overheating of sensitive components inside. These openings must never be blocked by

other objects.

Lithium battery • There is a danger of explosion if battery is incorrectly replaced. Replace it only

with the same or equivalent type recommended by the manufacturer. Dispose of used batteries

according to the manufacturer's instructions.

Avertissement

Alimentations• Ne faire fonctionner ce matériel qu’avec la source d’alimentation indiquée sur

l’appareil. Ce matériel doit être utilisé avec une alimentation principale comportant un fil de

terre (neutre). Le troisième contact (de mise à la terre) constitue un dispositif de sécurité :

n’essayez pas de la contourner ni de la désactiver.

Déconnexion de l’alimentation• Pour mettre le matériel hors tension sans danger, déconnectez tous

les cordons d’alimentation de l’arrière de l’appareil ou du module d’alimentation de bureau (s’il

est amovible) ou encore de la prise secteur.

Protection du cordon d’alimentation • Acheminer les cordons d’alimentation de manière à ce que

personne ne risque de marcher dessus et à ce qu’ils ne soient pas écrasés ou pincés par des

objets.

Réparation-maintenance • Faire exécuter toutes les interventions de réparation-maintenance par un

technicien qualifié. Aucun des éléments internes ne peut être réparé par l’utilisateur. Afin

d’éviter tout danger d’électrocution, l’utilisateur ne doit pas essayer de procéder lui-même à ces

opérations car l’ouverture ou le retrait des couvercles risquent de l’exposer à de hautes tensions

et autres dangers.

Fentes et orifices • Si le boîtier de l’appareil comporte des fentes ou des orifices, ceux-ci servent à

empêcher les composants internes sensibles de surchauffer. Ces ouvertures ne doivent jamais

être bloquées par des objets.

Lithium Batterie • Il a danger d'explosion s'll y a remplacment incorrect de la batterie. Remplacer

uniquement avec une batterie du meme type ou d'un ype equivalent recommande par le

constructeur. Mettre au reut les batteries usagees conformement aux instructions du fabricant.

Vorsicht

Stromquellen • Dieses Gerät sollte nur über die auf dem Produkt angegebene Stromquelle betrieben

werden. Dieses Gerät wurde für eine Verwendung mit einer Hauptstromleitung mit einem

geerdeten (neutralen) Leiter konzipiert. Der dritte Kontakt ist für einen Erdanschluß, und stellt

eine Sicherheitsfunktion dar. Diese sollte nicht umgangen oder außer Betrieb gesetzt werden.

Stromunterbrechung • Um das Gerät auf sichere Weise vom Netz zu trennen, sollten Sie alle

Netzkabel aus der Rückseite des Gerätes, aus der externen Stomversorgung (falls dies möglich

ist) oder aus der Wandsteckdose ziehen.

Schutz des Netzkabels • Netzkabel sollten stets so verlegt werden, daß sie nicht im Weg liegen und

niemand darauf treten kann oder Objekte darauf- oder unmittelbar dagegengestellt werden

können.

Wartung • Alle Wartungsmaßnahmen sollten nur von qualifiziertem Servicepersonal durchgeführt

werden. Die internen Komponenten des Gerätes sind wartungsfrei. Zur Vermeidung eines

elektrischen Schocks versuchen Sie in keinem Fall, dieses Gerät selbst öffnen, da beim Entfernen

der Abdeckungen die Gefahr eines elektrischen Schlags und/oder andere Gefahren bestehen.

Schlitze und Öffnungen • Wenn das Gerät Schlitze oder Löcher im Gehäuse aufweist, dienen diese

zur Vermeidung einer Überhitzung der empfindlichen Teile im Inneren. Diese Öffnungen dürfen

niemals von anderen Objekten blockiert werden.

Litium-Batterie • Explosionsgefahr, falls die Batterie nicht richtig ersetzt wird. Ersetzen Sie

verbrauchte Batterien nur durch den gleichen oder einen vergleichbaren Batterietyp, der auch

vom Hersteller empfohlen wird. Entsorgen Sie verbrauchte Batterien bitte gemäß den

Herstelleranweisungen.

Instrucciones de seguridad • Español

Este símbolo se utiliza para advertir al usuario sobre instrucciones importantes de

operación y mantenimiento (o cambio de partes) que se desean destacar en el

contenido de la documentación suministrada con los equipos.

Este símbolo se utiliza para advertir al usuario sobre la presencia de elementos con

voltaje peligroso sin protección aislante, que puedan encontrarse dentro de la caja

o alojamiento del producto, y que puedan representar riesgo de electrocución.

Precaucion

Leer las instrucciones • Leer y analizar todas las instrucciones de operación y seguridad, antes de usar

el equipo.

Conservar las instrucciones • Conservar las instrucciones de seguridad para futura consulta.

Obedecer las advertencias • Todas las advertencias e instrucciones marcadas en el equipo o en la

documentación del usuario, deben ser obedecidas.

Evitar el uso de accesorios • No usar herramientas o accesorios que no sean especificamente

recomendados por el fabricante, ya que podrian implicar riesgos.

Advertencia

Alimentación eléctrica • Este equipo debe conectarse únicamente a la fuente/tipo de alimentación

eléctrica indicada en el mismo. La alimentación eléctrica de este equipo debe provenir de un

sistema de distribución general con conductor neutro a tierra. La tercera pata (puesta a tierra) es

una medida de seguridad, no puentearia ni eliminaria.

Desconexión de alimentación eléctrica • Para desconectar con seguridad la acometida de

alimentación eléctrica al equipo, desenchufar todos los cables de alimentación en el panel trasero

del equipo, o desenchufar el módulo de alimentación (si fuera independiente), o desenchufar el

cable del receptáculo de la pared.

Protección del cables de alimentación • Los cables de alimentación eléctrica se deben instalar en

lugares donde no sean pisados ni apretados por objetos que se puedan apoyar sobre ellos.

Reparaciones/mantenimiento • Solicitar siempre los servicios técnicos de personal calificado. En el

interior no hay partes a las que el usuario deba acceder. Para evitar riesgo de electrocución, no

intentar personalmente la reparación/mantenimiento de este equipo, ya que al abrir o extraer las

tapas puede quedar expuesto a voltajes peligrosos u otros riesgos.

Ranuras y aberturas • Si el equipo posee ranuras o orificios en su caja/alojamiento, es para evitar el

sobrecalientamiento de componentes internos sensibles. Estas aberturas nunca se deben obstruir

con otros objetos.

Batería de litio • Existe riesgo de explosión si esta batería se coloca en la posición incorrecta. Cambiar

esta batería únicamente con el mismo tipo (o su equivalente) recomendado por el fabricante.

Desachar las baterías usadas siguiendo las instrucciones del fabricante.

Page 3

Table of Contents

Chapter 1 • Introduction .......................................................................................................1-1

About the MLC 206 ............................................................................................................ 1-2

Features and Options........................................................................................................ 1-2

Standard features .............................................................................................................. 1-2

Options and accessories..................................................................................................... 1-2

MediaLink System Application Examples ..............................................................1-3

Chapter 2 • Installation .......................................................................................................... 2-1

Installation Overview ....................................................................................................... 2-2

UL Requirements ................................................................................................................. 2-2

Installation Procedures .................................................................................................... 2-3

Preparing the site and installing the wall box ................................................................. 2-3

Replacing faceplates and labels ........................................................................................ 2-4

Replacing the faceplate ...................................................................................................... 2-4

Replacing labels .................................................................................................................. 2-5

Rear/bottom panel cable connections .............................................................................. 2-6

Display (projector) and source control connections ......................................................... 2-6

Room/relay control connections ........................................................................................ 2-8

Accessory control connections ........................................................................................... 2-8

Extron switcher control connections ............................................................................... 2-10

Pinout guide..................................................................................................................... 2-13

Application diagram ........................................................................................................2-14

Mounting the MLC .......................................................................................................... 2-14

Mounting the MLC to an electrical box or mud ring ..................................................... 2-15

Mounting the MLC to a wall or furniture ....................................................................... 2-16

Rack mounting the MLC ................................................................................................... 2-16

Mounting the MLC in a Euro Channel............................................................................. 2-17

Chapter 3 • Operation ............................................................................................................. 3-1

Projector Control.................................................................................................................3-2

Projector control memory ................................................................................................. 3-2

Secondary mode and special projector functions ............................................................ 3-2

Front Panel Features and Operation ......................................................................... 3-2

Optional Control Modules and MLA-Remote ....................................................... 3-5

Chapter 4 • Serial Communication................................................................................. 4-1

RS-232 Programmer’s Guide .......................................................................................... 4-2

Host-to-MLC communications ...........................................................................................4-2

MLC-initiated messages ...................................................................................................... 4-2

Error responses .................................................................................................................... 4-2

Using the command/response tables ................................................................................. 4-3

Symbol definitions ........................................................................................................ 4-3

Command/response table for SIS commands ................................................................... 4-3

Command/response table for special function SIS commands ........................................ 4-5

MediaLink Controllers • Table of Contents

i

Page 4

Table of Contents, cont’d

Command/response table for advanced instructions

(for the Windows

Control Software for Windows

®

-based control program)..................................................................... 4-8

®

.................................................................................. 4-9

Installing the software ...................................................................................................... 4-9

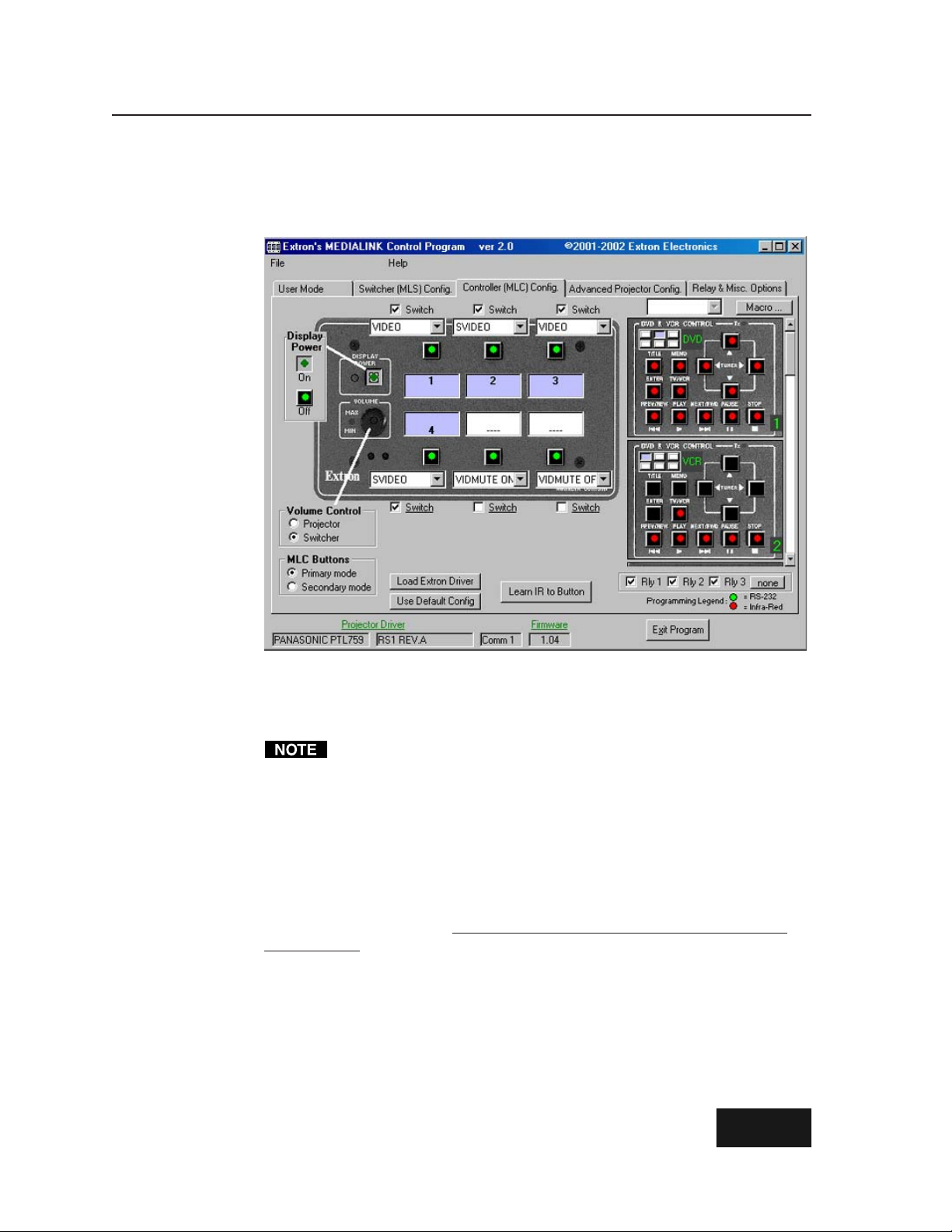

Using the control program ................................................................................................ 4-9

User Mode ......................................................................................................................... 4-10

Special features ........................................................................................................... 4-10

Switcher (MLS) Config ...................................................................................................... 4-11

Controller (MLC) Config ................................................................................................... 4-12

Load Extron Driver ...................................................................................................... 4-12

Use Default Config ...................................................................................................... 4-12

Primary and secondary modes.................................................................................... 4-13

Display Power on/off................................................................................................... 4-13

Volume control settings.............................................................................................. 4-13

IR learning ................................................................................................................... 4-14

Associating IRCM-DV+ modules with MLC inputs..................................................... 4-15

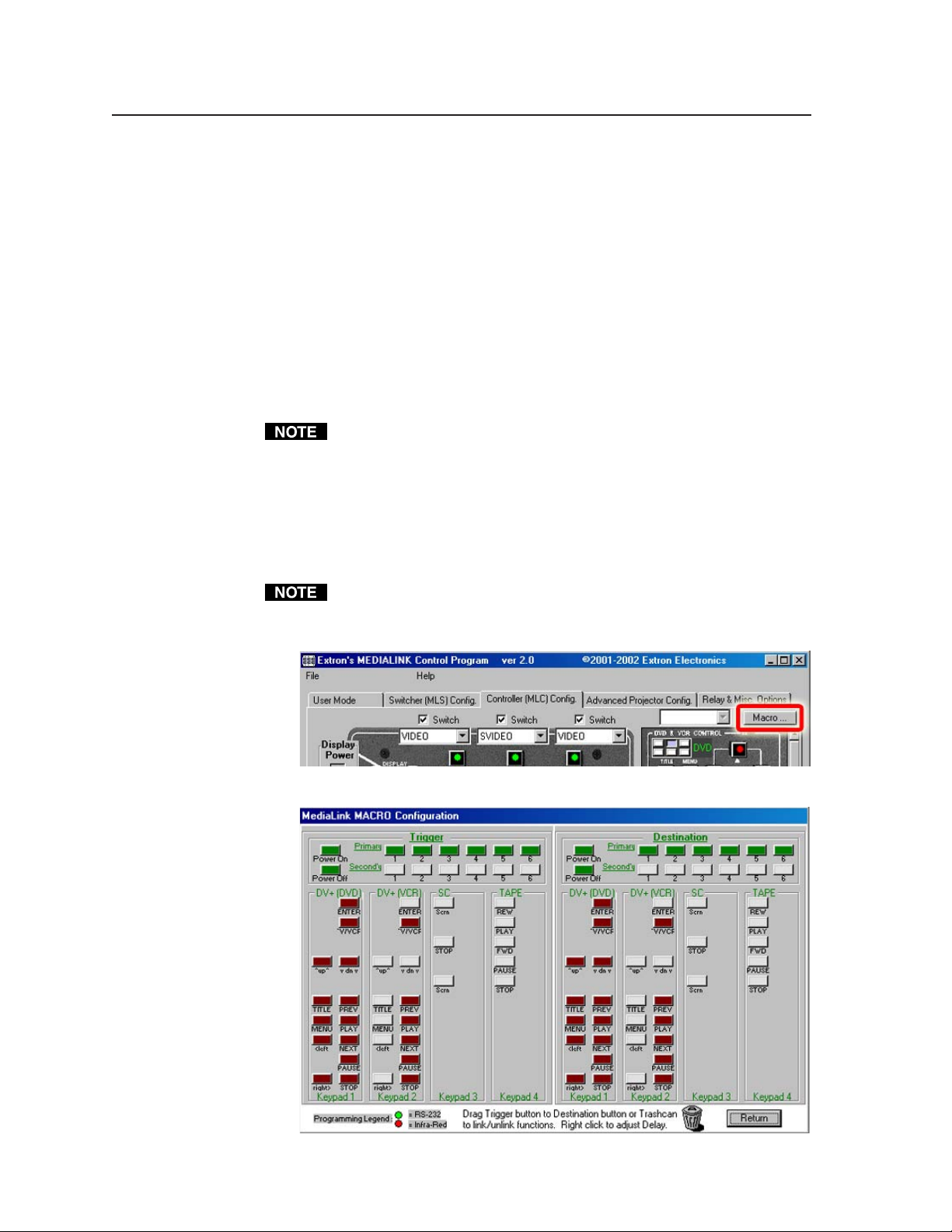

Macros: associating MLC and control module buttons with each other................. 4-16

Advanced Projector Config .............................................................................................. 4-20

Relay & Misc. Options ....................................................................................................... 4-22

Special features ........................................................................................................... 4-22

Saving and restoring configurations .............................................................................. 4-24

Using the help program .................................................................................................. 4-24

Downloading and using projector drivers...................................................................... 4-24

Key to file names ............................................................................................................. 4-25

Using the emulation mode ............................................................................................. 4-26

Appendix A • Specifications, Part Numbers, and Accessories.................... A-1

Specifications....................................................................................................................... A-2

Part Numbers and Accessories ......................................................................................... A-3

Included Parts.................................................................................................................... A-3

Accessories......................................................................................................................... A-3

Cables ................................................................................................................................ A-4

Appendix B • Dimensions, Templates, Replacements, and Upgrades ....B-1

Dimensions ............................................................................................................................B-2

Templates ................................................................................................................................ B-3

Replacements and Upgrades.........................................................................................B-5

Firmware Replacement ...................................................................................................... B-5

All trademarks mentioned in this manual are the properties of their respective owners.

68-601-01 Rev. B

Printed in the USA

11 02

ii MediaLink Controllers • Table of Contents

Page 5

MediaLink™ Controllers

Chapter One

1

Introduction

About the MLC 206

Features and Options

MediaLink System Application Examples

Page 6

Introduction

About the MLC 206

The Extron MediaLink™ Controller (MLC 206) provides infrared (IR) and RS-232

remote control of a display device, contact closure control of items in a room, tally

outputs, and MediaLink Switcher control. Some models of Extron system

switchers can also be set as a peripheral switcher to the controller.

The MLC 206 is designed for use with audiovisual equipment in sites such as a

small classroom or boardroom. The MLC 206 comes with a 3-gang faceplate, the

MLC 206 AAP has a 5-gang faceplate, and the MLC 206 EC and MLC 206 AAP EC

have Euro Channel-mountable faceplates. A variety of optional faceplates are also

available.

“MLC”, “MLC 206”, and “controller” are used interchangeably in this manual to

refer to the MediaLink controller unit, no matter which faceplate is attached to it.

Most examples in this manual show the MLC 206 (3-gang size). The cabling,

operation and setup are identical for all models; the models differ only in how they

are mounted.

Features and Options

Standard features

Illuminated display — A button’s label is illuminated brightly when the button is

Projector control — Using downloadable, one-way RS-232 or IR driver, IR learning,

Room control — Items in a room, such as room lights, a screen, a projector lift, and

Secure enclosure — Ideal for installations in high traffic areas, the MLC is

Inactivity timer — The MLC can be set to automatically shut off the projector after

Audio volume adjustment — The audio system volume can be attenuated via a

selected and dimly when it is not selected.

or user-defined RS-232 commands, the MLC 206 can turn a projector’s (or

display’s) power on and off and also select between the projector’s inputs.

You can also create RS-232 commands for special functions such as focus and

zoom features.

other devices can be controlled via the MLC’s contact closure relays.

designed to prevent label alteration. Its backlit labels are not accessible after

installation.

a user-defined period.

rotary control. The MLC can be configured to adjust the volume on either the

projector or an optional MediaLink switcher.

Options and accessories

Remote control — The optional MLA-Remote provides infrared remote control of

the MLC unit from up to 30 feet away.

Expandability — An optional switcher can be attached in order to expand the

number of inputs to the projector.

Optional faceplates for a variety of mounting locations — The controller can

easily be mounted in a standard equipment rack, in a wall in an electrical

box, in a Euro Channel, in a Hoffman box, or in a lectern or other furniture.

Control modules — By connecting and setting up optional IR control modules, the

MLC can also be used to control video sources such as VCRs and DVD

players. Control modules are also available for controlling features of a

MediaLink Switcher (MLS) or for directly controlling the room control relays.

MediaLink Controllers • Introduction1-2

Page 7

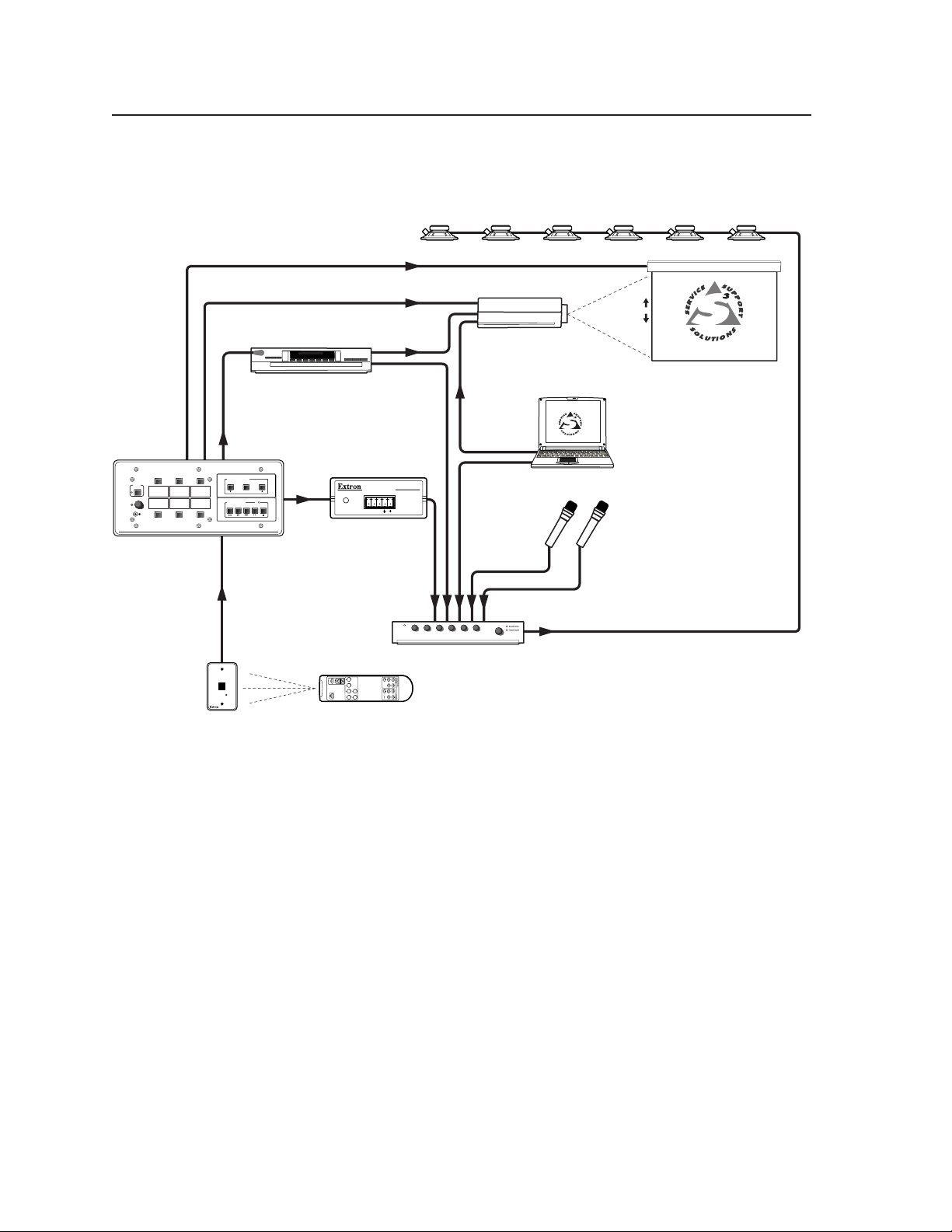

MediaLink System Application Examples

Extron

MLC 206 AAP

Control Module(s)

DISPLAY

POWER

DVD

VCR

VOLUME

Portable

PC

MAX/

MIN

Extron

IR Control

IR Emitter

DVD

VCR

Controller

Tx

VCR CONTROL

REW PLAY FWD PAUSE STOP

Tx

DVD CONTROL

REW PLAY NEXT PAUSE STOP

MLC 206 AAP

MediaLink Controller

&

Relay Control

RS-232

Control

Audio/

Video

Projector

VCRDVD

MAC

TUNER

123456

Extron

MediaLink Switcher

WORK

CELL CAMERA

DOC

RGB

Composite

S-video

Control

MENU NEXT

Audio

Audio

VOLUME

ADJUST

MLS 306

MediaLink Switcher

SIGNAL

IR LINK

DVD

Audio Amp.

MLA-RemoteIR Link

1-3MediaLink Controllers • Introduction

Page 8

Introduction, cont’d

Relay Control

DISPLAY

POWER

AUX.

VCR

VIDEO

VOLUME

AUX.

MAX/

PC

RGB

MIN

Extron

Extron

MLC 206 AAP

Control Module

IMAGE

MUTE

AUTO

SYNC

IR Link

IR

Emitter

SCREEN POSITION

DOWN UPSTOP

VCR CONTROL

REW PLAY FWD PAUSE STOP

IR

Control

SIGNAL

IR LINK

RS-232 Control

RS-232

Tx

MLC 206 AAP

MediaLink Controller

VCR

Extron

MLA VC10

MLA-Remote

POWER/

STATUS

MLC/RS-232

POWER

A B

Video

Audio

MLA-VC10

Control

Video

Audio

Audio Amplifier

Projector

Laptop

Microphones

MediaLink Controllers • Introduction1-4

Page 9

MediaLink™ Controllers

Chapter Two

2

Installation

Installation Overview

UL Requirements

Installation Procedures

Page 10

Installation

Installation Overview

To install and set up a MediaLink Controller, follow these steps:

CAUTION

If applicable, prepare the installation site: cut a hole in the wall/furniture,

1

install the electrical box or mud ring, and prepare the cables. Instructions are

included in this manual and/or with the optional faceplate, mounting device,

or wall box. See “Preparing the site and installing the wall box” in this

chapter.

Remove the faceplate. See “Replacing faceplates and labels” in this chapter.

2

Make and install labels. See “Replacing faceplates and labels” in this chapter.

3

Reinstall the original faceplate or attach a different faceplate to the MLC. See

4

“Replacing faceplates and labels” in this chapter.

For an MLC 206 AAP EC or an optional faceplate with spaces for installing

5

Extron Architectural Adapter Plates (AAPs), attach the AAPs to the faceplate.

Attach cables to the rear of the MLC and to the projector, room devices,

6

optional control modules (IRCMs, ACMs, RCMs), optional IR Link,

IR Emitters or IR Broadcaster, and optional switcher. See “Rear/bottom panel

cable connections” in this chapter. If applicable, also attach cables to the back

of the optional AAP plates.

Connect power cords and turn on all the devices, including the MLC.

7

Configure the controller by using the included Windows®-based control

8

software or Simple Instruction Set™ commands. See chapter four.

Test the system: press the MLC’s buttons, watch the display, and listen to the

9

audio output to determine whether the output devices are responding

correctly (powering on/off, switching inputs). If not, ensure that all devices

are plugged in and receiving power. Check the cabling; make adjustments as

needed.

Installation and service must be performed by authorized personnel only. UL

Listed electrical boxes are recommended. See “UL Requirements” below.

Attach the MLC to the wall, furniture, equipment rack, or Euro Channel.

10

A. Disconnect the MLC’s power supply at the source end (not at the MLC).

B. Disconnect the other devices’ power.

C. Secure the faceplate onto the UL-approved electrical wall box, the mud

ring, the wall or furniture, the rack, or the Euro Channel. See

“Mounting the MLC” in this chapter.

D. Restore power to the MLC and to the connected devices.

UL Requirements

The Underwriters Laboratories (UL) requirements listed below pertain to the

installation of the MLC into a wall or furniture.

1. This unit is not to be connected to a centralized DC power source or used

beyond its rated voltage range.

2. This unit must be installed in a UL listed junction box.

3. This unit must be installed in accordance with the National Electrical Code.

The Extron P/S 100 and other Extron power supplies may be used with the

MLC.

The UL approved electrical wall box (junction box) is not included with the

MLC; the installer is responsible for obtaining and installing the box.

MediaLink Controllers • Installation2-2

Page 11

Installation Procedures

The MLC can be installed into a wall, a Euro Channel, or furniture, or, if an optional

faceplate is used, it can be mounted directly in furniture or an equipment rack.

Follow the instructions appropriate to the mounting option you have selected.

Templates for optional faceplates are not detailed in this manual.

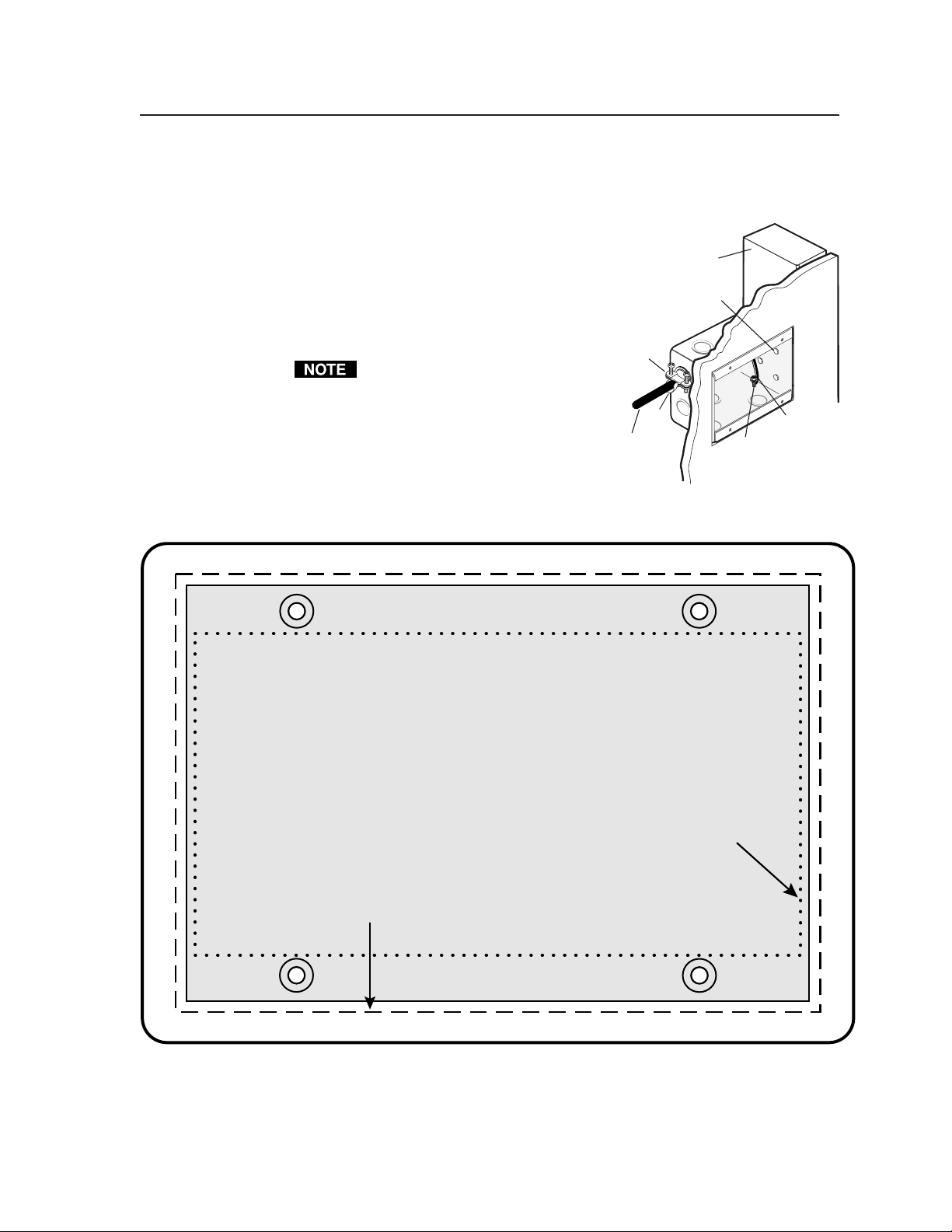

Preparing the site and installing the wall box

Choose a location that will allow cable runs without interference. Allow enough

depth for both the wall box and the cables. You may need to install the cables into

the wall, furniture, or conduits before installing the controller.

The installation must conform to national and local electrical codes and to the

equipment’s size requirements. Dimensional drawings of the MLC 206 and

MLC 206 AAP and actual-size cut-out templates are provided in appendix B of this

manual. Templates for the optional faceplates are included with each faceplate.

Installation using a UL listed wall box is recommended for most mounting options,

but mud rings or a Euro Channel can be used instead.

• The MLC 206 includes a three-gang faceplate, the MLC 206 AAP includes a fivegang faceplate with space for Extron AAPs. Each can be installed in a standard

electrical wall box that is at least 1.75” deep. Mud rings are also available.

• The EC models (MLC 206 EC, MLC 206 AAP EC) can be installed in a standard

Euro Channel.

• Optional faceplates are available that accept the MLC 206 and also have openings

for Extron AAPs. Some optional faceplates can be installed into various sizes

of standard electrical wall boxes. Other optional faceplates are designed to be

directly mounted into a lectern or other furniture.

1a. If you are using a wall box or installing a MLC using a lectern mounting

faceplate, make a 100% size photocopy of the cut-out template that

corresponds to the faceplate you are using, and cut out the center portion of it

as indicated on the template.

1b. If you are using a mud ring, use the template that came with the mud ring.

Cut out the indicated center portion.

2. Place the template (or the wall box or mud ring) against the installation

surface, and mark the guidelines for the opening on the wall or furniture.

3. Cut out the wall/furniture material from the marked area.

4. Check the opening size by inserting the wall box, mud ring, or MLC into the

opening. The box or mud ring (if used) and/or MLC should fit easily into the

opening. Enlarge or smooth the edges of the opening if needed.

5. Feed cables through the wall box punch-out holes, and secure them with cable

clamps to provide strain relief.

6. Exposed cable shields (braids or foil) are

potential sources of short circuits. Trim back

and/or insulate shields with heat shrink.

To prevent short circuits, the outer

foil shield can be cut back to the point

where the cable exits the cable clamp.

Both braided and foil shields should

be connected to an equipment ground

at the other end of the cable.

Grounding outer braided and foil shields

Wall Stud

Wall Box

Screws or Nails

Flush with

Wall Surface

2-3MediaLink Controllers • Installation

Page 12

Installation, cont’d

7a. If you are using a wall box, insert the wall box into the opening, and attach it

Wall Stud

Wall Box

Screws or Nails

Attaching a wall box to a wall stud

If attaching the wall box to wood, use four #8 or #10 screws or 10-penny nails.

A minimum of 1/2 inch (1.3 cm) of screw threads must penetrate the wood.

If attaching the wall box to metal studs or furniture, use four #8 or #10 selftapping sheet metal screws or machine bolts with matching nuts.

7b. If you are using a mud ring, follow the directions, if any, that came with the

mud ring to attach the clips that fasten the ring to the wall or furniture.

8. If desired, replace the faceplate and/or input labels.

9. Cable and test the MLC before fastening it into the wall box, mud ring, or

furniture.

to the wall stud/furniture with

nails or screws, leaving the front

edge flush with the outer wall or

furniture surface. The illustration

applies to all sizes of wall boxes.

Flush with

Wall Surface

Replacing faceplates and labels

The MLC’s faceplate and the backlit input selection labels can be replaced. You can

replace the standard faceplate with an optional lectern mounting, rack mounting, or

wall mounting MLM faceplate for installation into a variety of locations. The

MLC 206 is shown in the following examples, but the instructions apply to all

models.

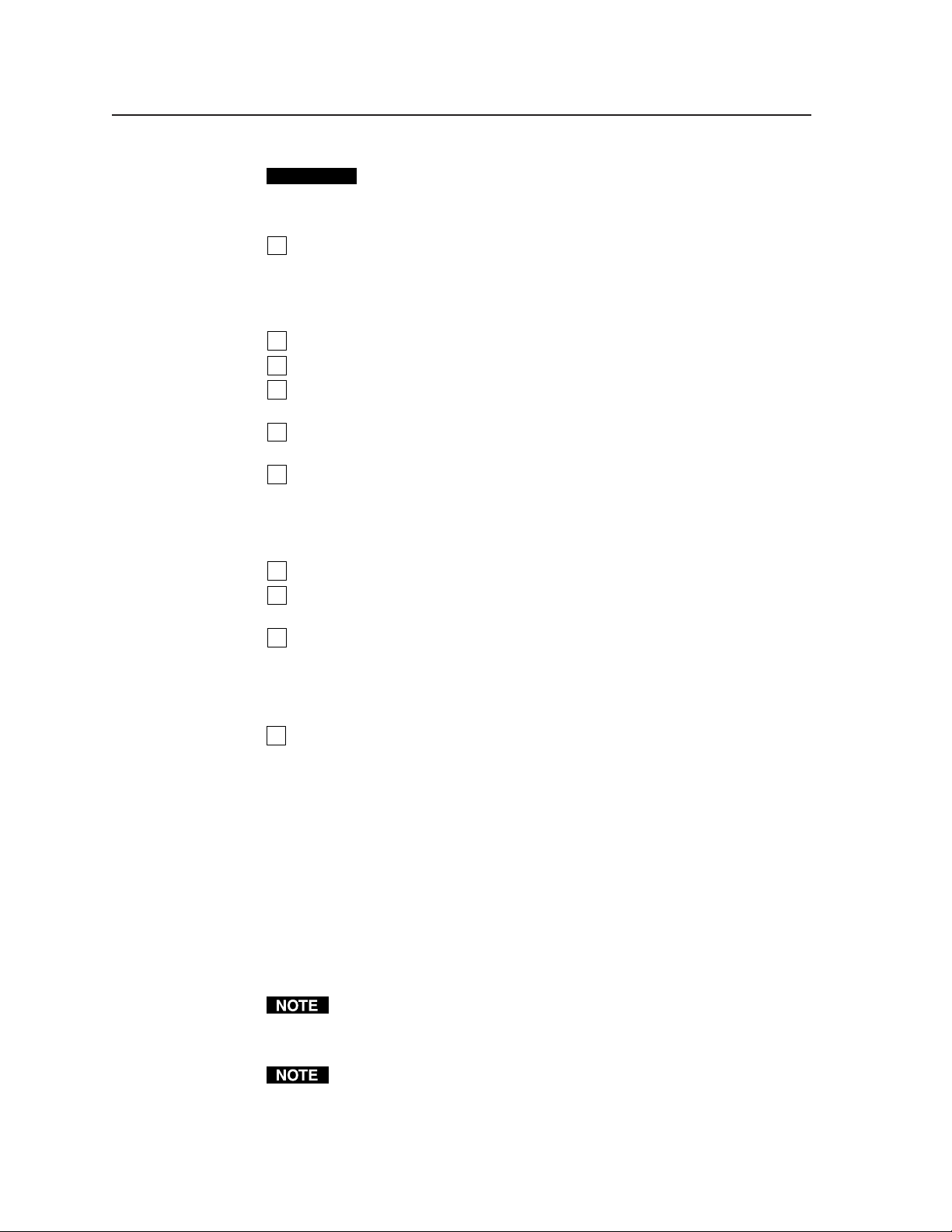

Replacing the faceplate

1. Use a small Philips screwdriver to remove the four faceplate attachment

screws marked 1 in the

picture at right, and keep them

for later use.

Do not remove these screws

while the MLC is installed

in a wall or furniture, or the

controller may fall down

into the wall/furniture or

wall box.

2. Lift the faceplate off the MLC.

3. Align the openings in the new faceplate with the controller’s buttons, knobs,

and LEDs, and place the new faceplate on the MLC.

4. Replace the four screws removed in step one, and hand tighten them.

1

1

Extron

DISPLAY

POWER

VCR DVD Laptop

VOLUME

MAX/

MIN

MediaLink Controller

1

1

MLC 206

MediaLink Controllers • Installation2-4

Page 13

Replacing labels

The backlit input selection labels are inaccessible once the MLC is installed into a

wall or furniture. The faceplate must be removed to gain access to the labels.

1. Use a small Philips screwdriver to remove the four faceplate attachment

screws, and keep them for later use.

2. Lift the faceplate off the MLC.

3. Lift off the transparent, protective, plastic window that covers the labels.

4. Lift off the transparent, rectangular label you want to replace, being careful

not to damage the circuits beneath it. You may need to use a small, flat

bladed screwdriver to gently pry the label out.

Window Labels

DVD

Plastic Window

Faceplate

VCR

DISPLAY

Extron

POWER

VOLUME

MAX/

MIN

r

MLC 206

k Controlle

MediaLin

Remove four screws.

5. Detach one of the preprinted labels or one of the blank labels from the sheet of

labels that is included with the MLC 206. Remove the protective film from the

front of the label. To create customized labels, use a label maker, such as a

Brother® P-touch®, and clear label material to print text to place on the blank

labels.

6. Insert the new label into the opening from which the other label was removed.

7. Repeat steps four through six for each label you wish to replace.

8. Place the plastic window back onto the MLC to cover the labels.

9. Align the openings in the faceplate with the buttons, knobs, and LEDs of the

MLC, and place the faceplate on the MLC.

10. Replace the four screws removed in step 1, and hand tighten them.

2-5MediaLink Controllers • Installation

Page 14

Installation, cont’d

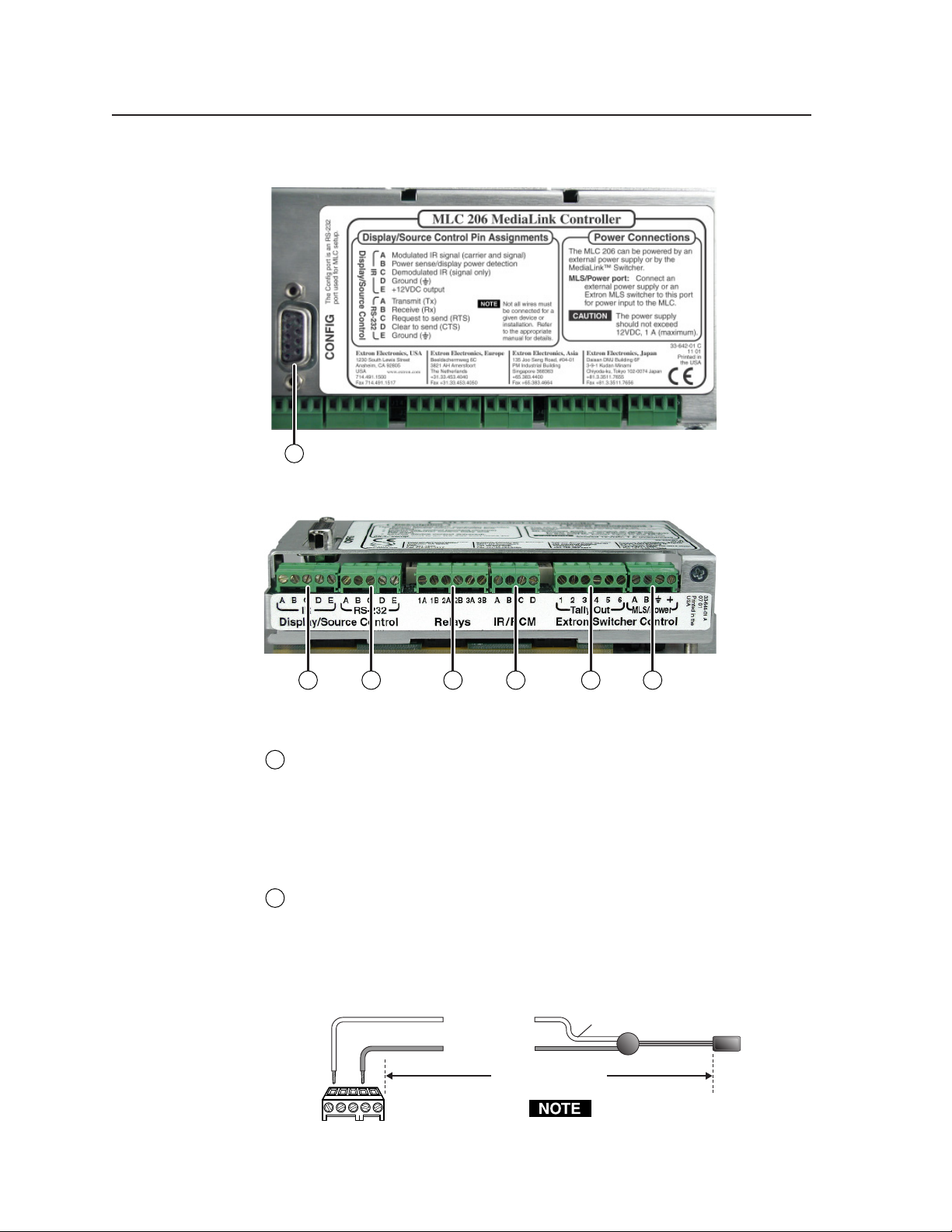

Rear/bottom panel cable connections

1

MLC 206 rear view

3 42 6 75

MLC 206 bottom view

Configuration port — This port is used for system configuration and for

1

loading control files into the MLC. Connect a host computer, third party

control system, or a terminal such as a personal digital assistant to the MLC

via this rear panel 9-pin HD female RS-232 connector. Commands and drivers

can be downloaded into or uploaded from the MLC via this port. See chapter

four for details about the setup software and downloading drivers.

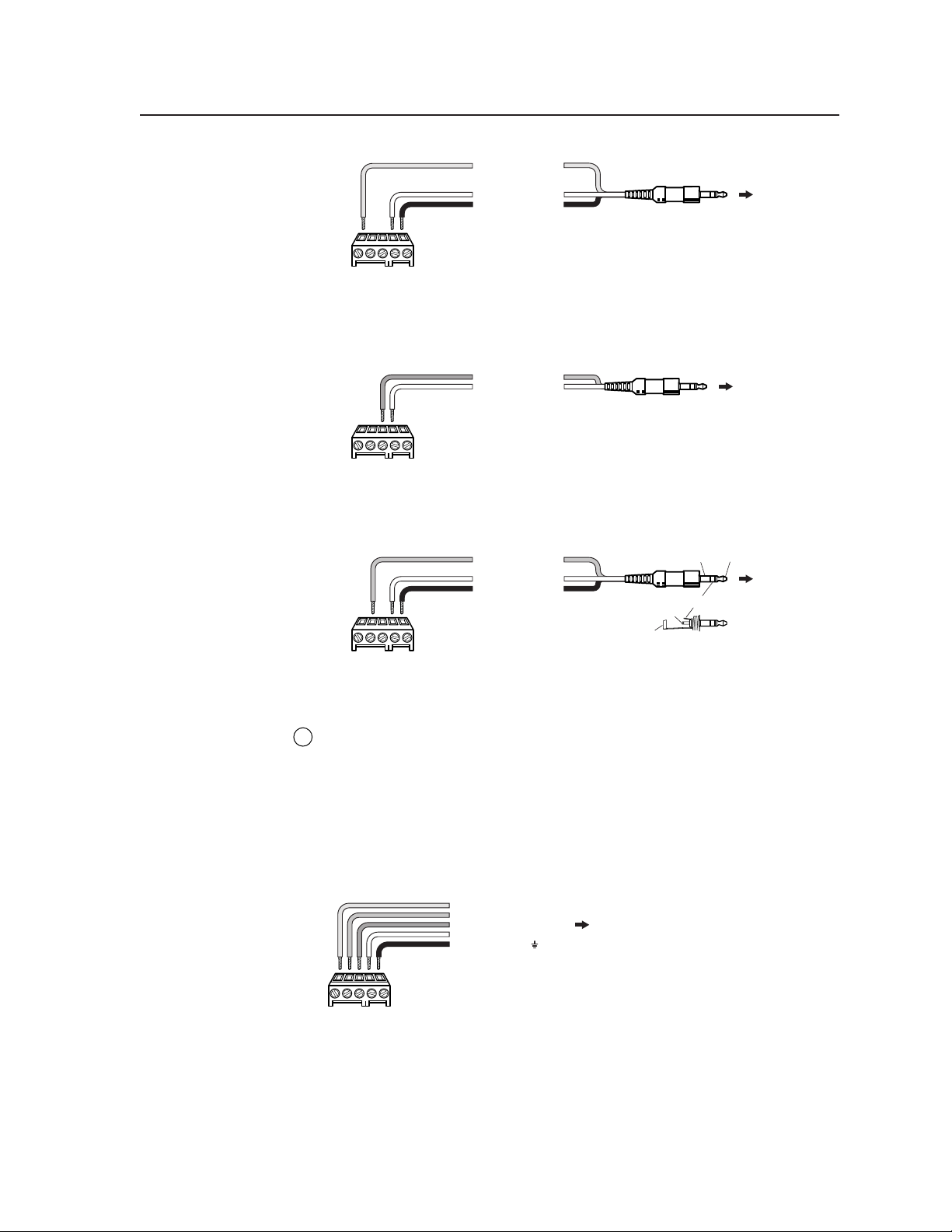

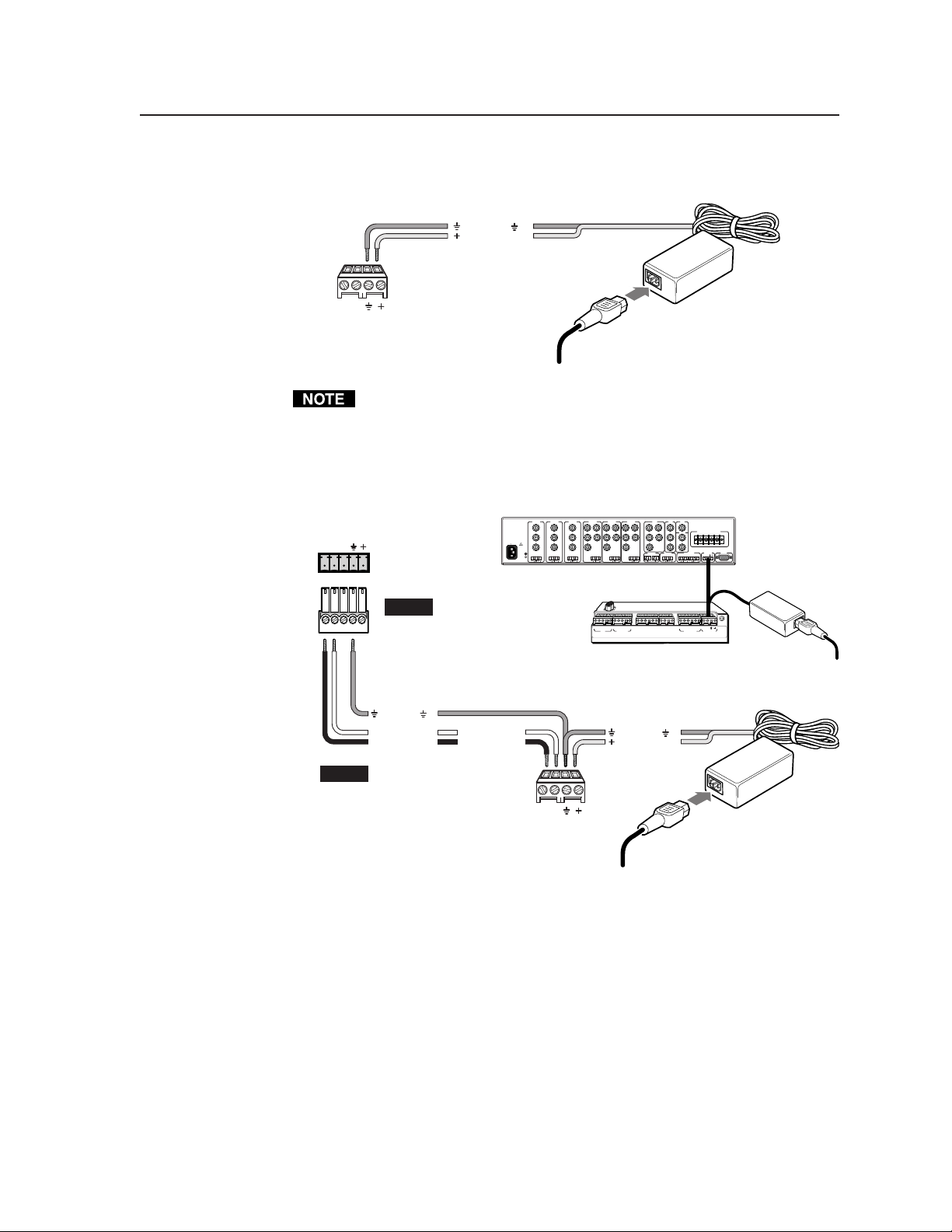

Display (projector) and source control connections

IR Display/Source Control connector — Infrared control signals are sent to

2

A/V devices via accessories connected to this port. Connect Extron

IR Emitters or an IR Broadcaster to this 3.5 mm, 5-pole direct insertion captive

screw connector so display and/or source devices can be controlled via

infrared commands from the MLC. Up to four IR Emitters can be connected

to the MLC via this connector at one time. Wire the connector as shown in the

following illustrations.

Modulated IR

BCDE

A

IR

MLC

IR control

port

A

Ground

D

110 feet (33.5 m) maximum

White striped wire only

Place the head of each IR Emitter

over or directly adjacent to the

controlled device’s IR receiver.

IR

Emitter

Connect

up to 4 IR

Emitters

(max.).

MediaLink Controllers • Installation2-6

Page 15

Modulated IR

A

Ground

D

+12VDC output

E

MLC

IR control

BCDE

A

port

IR

For the IR Broadcaster with emitter port

To IR Broadcaster

with Emitter port

(#60-272-02)

To the projector's

wired remote port

(Connector type and

pin configurations may

vary depending on the

projector model.)

BCDE

A

MLC

IR control

port

Demodulated IR

C

Ground

D

IR

For a wired projector remote port

Tip

(+12VDC)

To Display Power

Sensor

(#60-271-01)

BCDE

A

MLC

IR control

port

Power sense

B

Ground

D

+12VDC output

E

Tip (+12VDC)

Sleeve (Gnd)

Sleeve (Gnd)

Ring (power sense)

IR

For a projector current/power sensor

RS-232 Display/Source Control connector — The MLC sends out RS-232

3

commands via this port for controlling a projector or a peripheral Extron

system switcher. Guides for peripheral system switchers to the MLC and for

controlling specific models of projectors are available on the Extron Web site.

Connect a cable between the projector and this 3.5 mm, 5-pole direct insertion

captive screw connector for RS-232 projector control. Use the illustration

below as a guide to wiring the connector. Wiring will vary depending on the

projector model. In most cases only the transmit (Tx) and ground connections

will be needed.

Transmit (Tx)

A

Receive (Rx)

B

Request to send (RTS)

C

Clear to send (CTS)

D

Ground ( )

E

To the

display/projector's

RS-232 port

MLC

RS-232

control

BCDE

A

port

RS-232

We recommend using the UC 50’ universal projector control cable (for this

connection. One end of the cable is terminated with a female 9-pin D

connector, and the other end is unterminated. The UC 50’ pin assignments

are as shown in the following illustration. Refer to the projector’s manual for

the projector’s pin assignments in order to determine which of the cable’s

wires to connect to which of the MLC’s RS-232 pins.

2-7MediaLink Controllers • Installation

Page 16

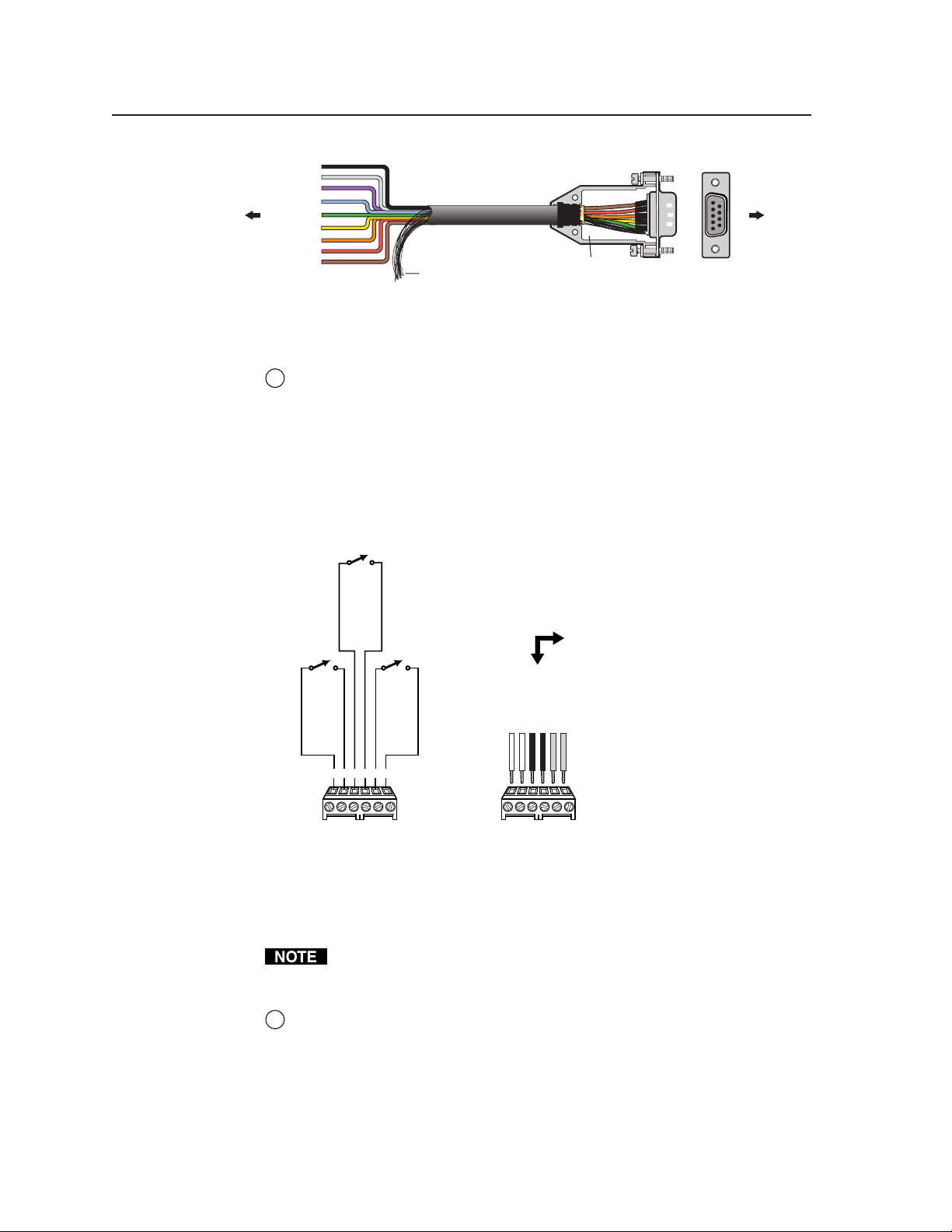

Installation, cont’d

9

Black

8

Grey

Purple

7

Blue

To the

MLC 206

Orange

Room/relay control connections

6

5

Green

4

Yellow

3

2

Red

1

Brown

Pin #Color

Relay connector — This 3.5 mm, 6 pole direct insertion captive screw

4

connector provides three relays. Via the included software, these relays can

be set to control items in the room (such as lights, screens, and projector lifts)

when the display/projector is being powered up or down. They can also be

associated with other buttons. See chapters three (operation) and four (serial

communication) for details.

Use the software to specify momentary or latching contact. All the relays are

normally open, and the minimum rating is 24V, 1 A. See the following

diagrams of the relays and connector wiring, and refer to the screen,

projector lift, or AC controller manufacturer’s wiring guide.

UC Cable

Shield

Connector Shell

UC 50', 100', 200' Cable Color Codes

1

6

To the

projector

9

5

Normally open (2B)

Normally open (2A)

Normally open (1B)

Normally open (1A)

1A

1A

Relays

Normally open (3B)

Normally open (3A)

3B1B 2A 2B 3A

3B1B 2A 2B 3A

MLC 206 Relays

Accessory control connections

The MLC contains three relays, so you may install a maximum of one

RCM-SC or one RCM-SCLT in a system with an MLC. Refer to the Relay

Control Modules User’s Manual.

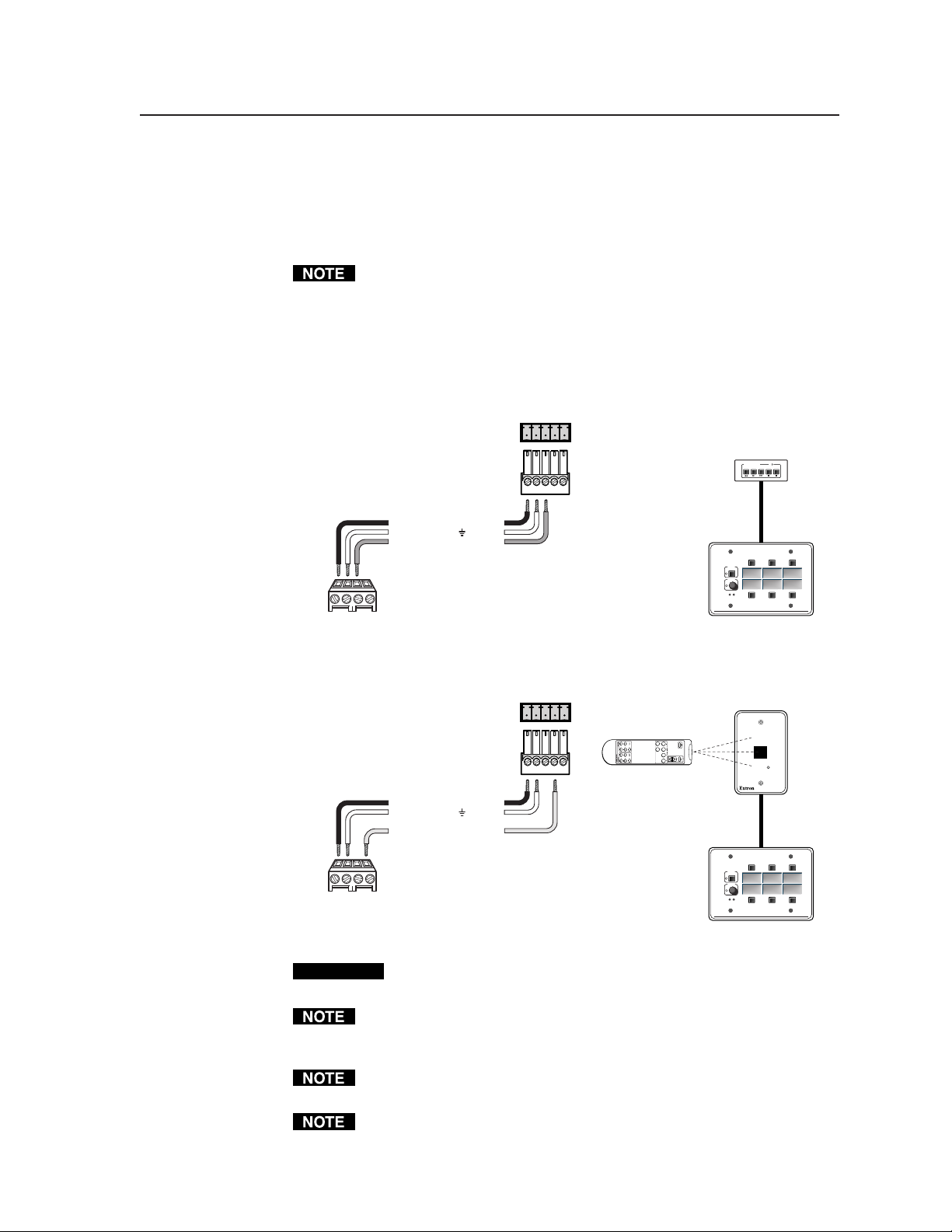

IR/RCM connector — Connect an optional IR Link signal repeater and/or

5

optional control modules (such as an Extron IRCM-VCR, IRCM-DVD,

IRCM-DVD+, IRCM-Tape, or an ACM, or RCM control module) here. The

IR Link receives infrared signals from the MLA Remote and sends them

directly to the MLC, allowing the MLA Remote to be used out of the line of

sight of and/or at a greater distance from the MLC than would be possible if

the IR Link were not used.

1A

Relay 1, pin B

Relay 1, pin A

Relay 2, pin A

Relays

Relay 2, pin B

Relay 3, pin A

3B1B 2A 2B 3A

To / from

room control

equipment

Relay 3, pin B

MediaLink Controllers • Installation2-8

Page 17

The control modules are Architectural Adapter Plate modules that can be

connected to the MLC to control devices such as VCR, tape, or DVD players,

or provide limited control of an optional MLS 306/506 Series switcher, or

other devices. Up to four control modules (in addition to the IR Link) can be

connected to the MLC, though the connector can hold wires for only 2-3 items

at a time, so you may wish to daisy chain the control modules together.

You must also set the control modules’ rear DIP switches so each control

module has a unique address number.

Wire the MLC’s IR/RCM 3.5 mm, 4-pole direct insertion captive screw

connector as shown in the following illustrations. Refer to the Control Modules

User’s Manual or the Relay Control Modules User’s Manual for information on

setting an address for each device. An Extron Comm-Link cable (see

appendix A for part numbers) is recommended.

A

+12VDC

Ground ( )

B

Control signal (IRCM)

MLC

/

RCM

IR

port

A

B

CC

ABCD

IR / RCM

MLC 206 to a control module

ABCD

IR / RCM

A

+12VDC

Ground ( )

B

Modulated IR (IR Link)

D

MLC

/

IRCM

IR

port

A

B

D

MLC 206 to an IR Link

ABCDE

ABCDE

Control

module

connector

IR Link

connector

MLA-Remote

IRCM control

module(s)

Extron

Extron

Total distance

from MLC:

150' (45.7 m)

max.

Tx

VCR CONTROL

REW PLAY FWD PAUSE STOP

DISPLAY

POWER

VCR DVD Laptop

VOLUME

MAX/

MIN

MLC 206

Total distance

from MLC:

150' (45.7 m) max.

SIGNAL

IR LINK

IR Link

IR signal

repeater

DISPLAY

POWER

VCR DVD Laptop

VOLUME

MAX/

MIN

MLC 206

MediaLink Controller

MediaLink Controller

MLC 206

MLC 206

CAUTION

Polarity is important. If the IR/RCM connector wiring specified in the

diagram is not followed, the equipment may be damaged.

Connect a maximum of one (1) IR Link. Do not connect more than one

IR Link (either in parallel or in series). Also, do not connect more than four

(4) control modules to the MLC.

The MLC contains three relays, so you may install a maximum of one

RCM-SC or one RCM-SCLT in a system with an MLC.

The control modules are not hot swappable. When you add or remove a control

module, you must cycle (disconnect, then reconnect) the MLC’s power before

the MLC can recognize the new module and the configuration change.

2-9MediaLink Controllers • Installation

Page 18

Installation, cont’d

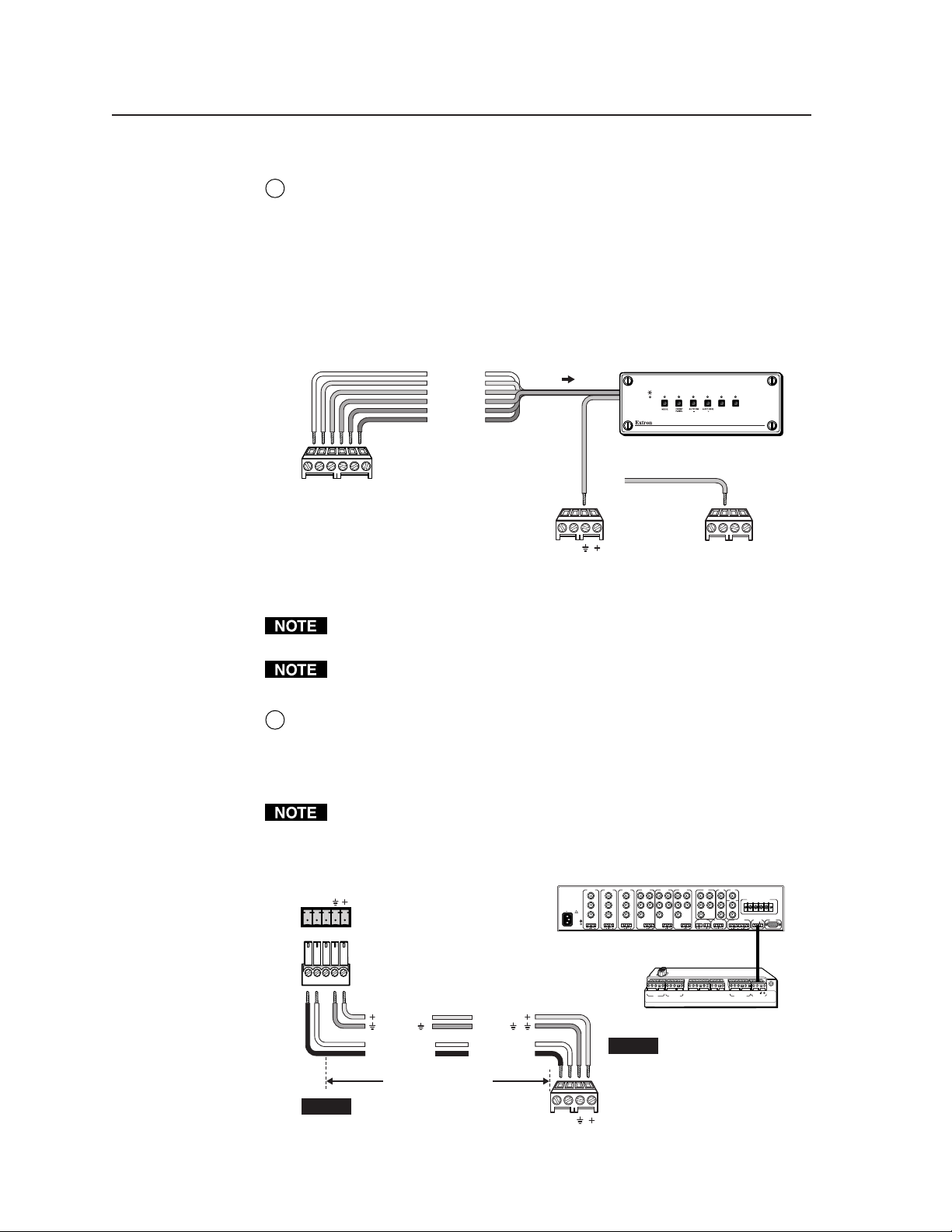

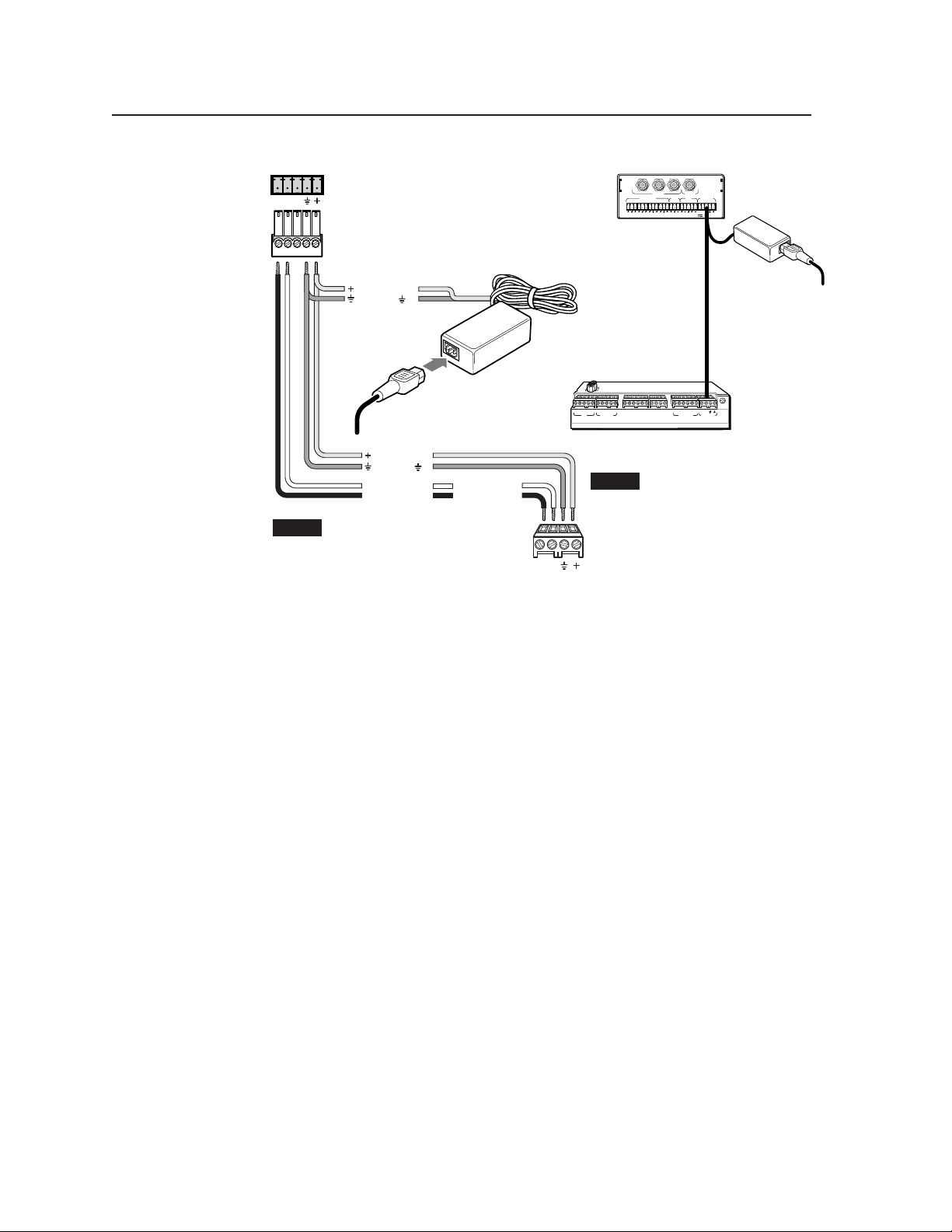

Extron switcher control connections

Contact closure Tally Out(put) connector — To effectively add more A/V

6

inputs to a projector, you aren’t limited to using a MediaLink switcher. If

desired, attach an Extron switcher that accepts contact closure control to this

3.5 mm, 6 pole direct insertion captive screw connector. Each pin corresponds

to a switcher front panel button. When a tally pin is selected, the pin changes

from a high (5V) to a low (0V) state. This momentary high-to-low change can

be used to trigger switching on various contact closure controllable Extron

switchers.

Wire the connector as shown here.

Input 1

1

Input 2

2

Input 3

3

Input 4

4

Input 5

5

Input 6

6

Connect the switcher's

contact closure

1

62345

ground pin to a

ground on the MLC.

To any

contact closure-

controllable

Extron switcher

123456

or

Tally Out

MLC

MLS/Power

AB

MLS / Power

port

ABCD

IR / RCM

MLC 206 Contact Closure Control

You must connect the ground pin of the switcher’s connector to a ground

connection on the MLC.

Only Extron switchers can be peripheral to the MLC via this tally output

contact closure connector.

MLS/Power connector — Connect a cable between this 3.5 mm, 4-pole direct

7

insertion captive screw connector and an optional Extron MLS switcher for

RS-232 control of the switcher and to provide power from the switcher to the

MLC. See the following diagram. With Extron Comm-Link cable, the

switcher and controller can be up to 250 feet (76.2 m) apart.

The commands issued from this port are standard Extron SIS™ commands,

and they follow the Extron switcher protocol (9600 baud rate, 8-bit, 1 stop bit,

no parity). The commands sent via the MLS/Power connector are fixed and

cannot be altered. See page 3-3 for additional details.

MLC/IR

ABC

MediaLink

Switcher

rear panel

MLC/IR port

INPUT 1

INPUT 2

INPUT 3

INPUT 4

VIDEO

VIDEO

RH/

RH/

R-Y

R-Y

HV

V

Y

Y

G

G

B-Y

B-Y

B

C

B

LR LR LR

C

100-240V 0.2A 50/60 Hz

.5A MAX

VIDEO

R-Y

Y

B-Y

C

L LRR LR

MLS 506MA Rear Panel

INPUT 5

HV

V

RH/

G

B

YUV

INPUT 6

HV

VIDEO

RGB

RH/

R-Y

HV

S-VIDEO

Y

Y

V

V

G

B

C

B-Y

AUX/MIXEFFECTS

FIXED VARIABLE

SENDLRRETURN

LR

LR

SW 6 AR MX

MLC

/

IRCM

IR

port

MONO AMPLIFIED OUTPUT

4 ohm

COMM 8 ohm 70V

MLC/IR RS232

AUDIO OUT

ABC

LRLR

CONTACT CLOSURE

33-644-01 A

07 01

Printed in the

123456

Tally Out

MLS

Extron Switcher Control

USA

/Power

+12VDC

Ground ( )

B

Receive (Rx)

A

Transmit (Tx)

Ground ( )

Transmit (Tx)

Receive (Rx)

250 feet (76.2 m) maximum

NOTE If you use cable that has a

drain wire, tie the drain wire

to ground at both ends.

+12VDC

B

A

AB

MLS / Power

NOTE

MLC

MLS/Power

port

ABCDE ABC

DE ABC ABD

1A 1B 2A 2B3A 3B

IR

RS-232

Display/Source Control

Relays IR/RCM

MLC 206 Bottom Panel

The switcher provides

power to the controller.

Connecting an MLC 206 to a MediaLink Switcher

MediaLink Controllers • Installation2-10

Page 19

If you are not using an optional switcher, connect an external power supply

(12VDC, 1 A maximum) to this port to power the MLC as shown in the

following diagram.

Ground ( )

+12VDC input

An external

power supply

(12VDC, 1A max.)

AB

MLC

MLS/Power

port

MLS / Power

Connecting an MLC 206

Ground all devices

to an external power supply

Check the power supply’s polarity before connecting it to the MLC.

If you choose to power the MLC from a separate external power supply rather

than from a MLS 306/506/506 MA/506 SA or MLS 100 Series switcher, you

must connect a ground wire between the MLS and the MLC, as shown in the

following diagrams.

MLC/IR

ABC

MediaLink

Switcher

rear panel

MLC/IR port

NOTE

Ground ( )

B

Receive (Rx)

A

Transmit (Tx)

INPUT 1

INPUT 2

VIDEO

VIDEO

R-Y

R-Y

Y

Y

100-240V 0.2A 50/60 Hz

B-Y

B-Y

C

C

L LRR LR

.5A MAX

MLS 506MA Rear Panel

If using an external

power supply (instead of

the MLS) to power the

MLC, you must connect

a ground wire between

the MLC and MLS.

Transmit (Tx)

Receive (Rx)

B

A

INPUT 3

VIDEO

Y

C

INPUT 4

INPUT 5

RH/

RH/

R-Y

HV

HV

V

V

G

G

B-Y

B

B

LR LR LR

ABCDE ABC

IR

RS-232

Display/Source Control

MLC 206 Bottom Panel

+12VDC input

INPUT 6

RGB

RH/

RH/

HV

V

G

G

B

B

SENDLRRETURN

LR

DE ABC ABD

1A 1B 2A 2B 3A 3B

Relays IR/RCM

Ground ( )

HV

V

YUV

R-Y

Y

B-Y

AUX/MIXEFFECTS

LR

VIDEO

MONO AMPLIFIED OUTPUT

S-VIDEO

COMM 8 ohm 70V

Y

C

AUDIO OUT

FIXED VARIABLE

LRLR

123456

Tally Out

Extron Switcher Control

4 ohm

MLC/IR RS232

ABC

MLS

/Power

CONTACT CLOSURE

Printed in the

USA

33-644-01 A

07 01

External

Power Supply

NOTE If you use cable that has a

drain wire, tie the drain wire

to ground at both ends.

Connecting an MLC 206

to a MediaLink Switcher and

an external power supply

AB

MLS / Power

MLC

MLS/Power

port

Ground all devices

External

Power Supply

(12VDC, 1A max.)

2-11MediaLink Controllers • Installation

Page 20

Installation, cont’d

POWER

AB

MLS100Series

Switcher

MLC/RS-232

Power Port

+12VDC input

Ground ( )

Ground all devices

+12VDC

Ground ( )

Receive (Rx)

B

A

Transmit (Tx)

NOTE If you use cable that has a

drain wire, tie the drain wire

to ground at both ends.

Connecting an MLC 206

to a MediaLink

VersaTools Switcher and an external power supply

External

Power Supply

(12VDC, 1A max.)

Transmit (Tx)

Receive (Rx)

B

A

AB

MLS / Power

3

2

1

INPUTS

OUTPUT

AUDIO INPUTS

OUT

AUX/MIX

LR

CONTROL/

4

LR

MONO

POWER

A

B

12V .5A MAX

LR

MLS 103 V

2

1

3

LR

LR

MLS 103 V

Rear Panel

250 ft

(76.2 m)

max.

ABCDE ABC

DE ABC ABD

IR

RS-232

Display/Source Control

1A 1B 2A 2B 3A 3B

Relays IR/ RCM

123456

Tally Out

MLS

Extron Switcher Control

MLC 206 Bottom Panel

NOTE You must connect a

ground wire between

the MLC and MLS.

MLC 206's

MLS/Power

Port

/Power

33-644-01 A

07 01

Printed in the

USA

External

Power Supply

MediaLink Controllers • Installation2-12

Page 21

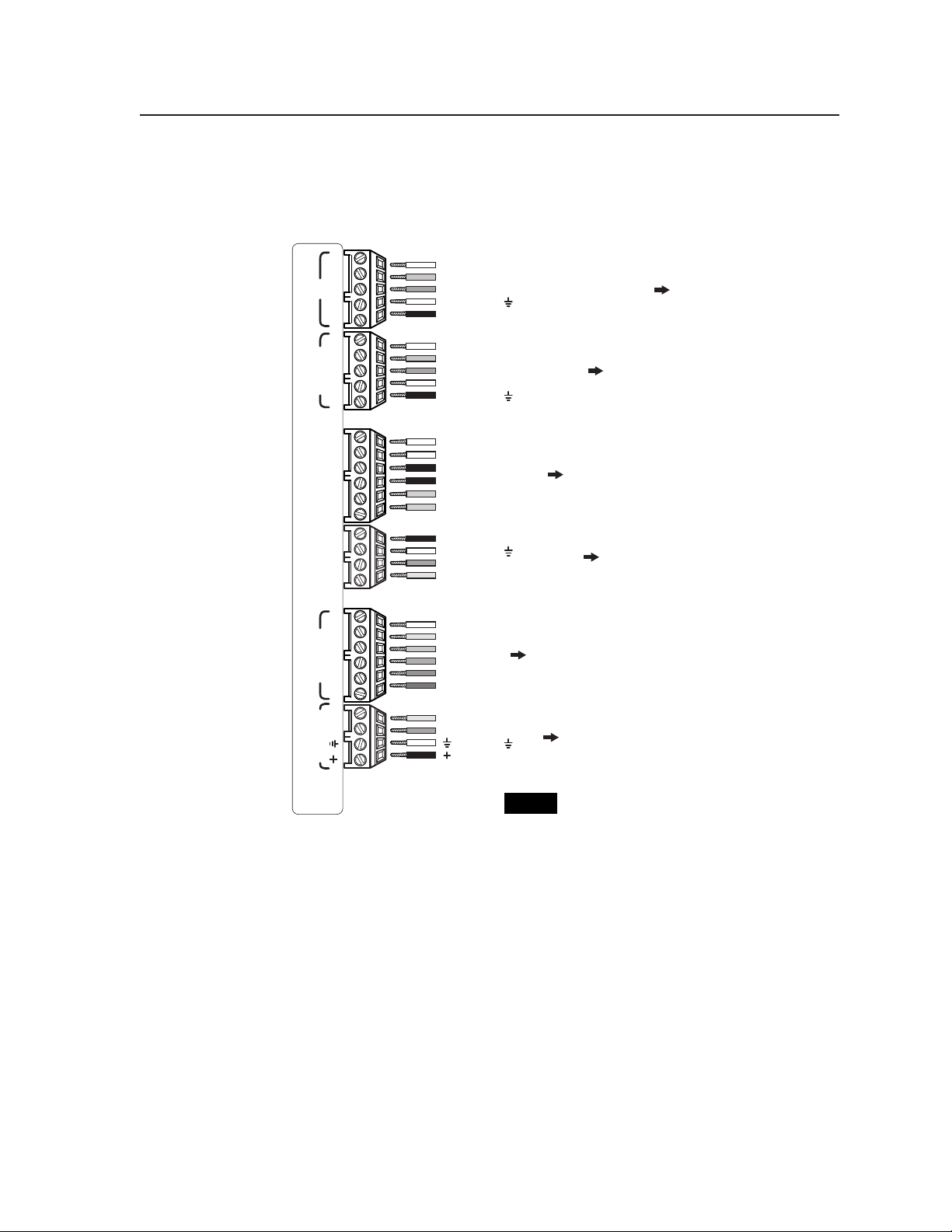

ABCDE ABC

IR

Display/Source Control

Extron Switcher Control

Relays IR /RCM

RS-232

DE ABC ABD

1A 1B 2A 2B 3A 3B

123456

Tally Out

MLS

/Power

33-644-01 A

07 01

Printed in the

USA

+12VDC output

Modulated IR signal (carrier & signal)

Power sense/display power detection

Demodulated IR (signal only)

Ground ( )

E

D

C

B

A

Ground ( )

Transmit (Tx)

Receive (Rx)

Request to send (RTS)

Clear to send (CTS)

E

D

C

B

A

Ground ( )

+12VDC input

Receive (Rx)

Transmit (Tx)

B

A

C

Modulated IR (IR Link)

+12VDC output

Control signal (IRCM)

Ground ( )

D

B

A

Input 2

Input 1

Input 3

Input 4

Input 5

Input 6

6

5

4

3

2

1

Relay 1, pin B

Relay 1, pin A

Relay 2, pin A

Relay 2, pin B

Relay 3, pin A

Relay 3, pin B

1A

3B

1B

2A

2B

3A

To the

display/projector's

RS-232 port

To an IR Link

and/or MediaLink

Control Module(s)

To any contact closurecontrollable Extron switcher

To/from

room control

equipment

To/from a MediaLink Switcher

or

an external 12VDC, 1A power supply

To IR Emitter(s),

an IR Broadcaster,

the projector's wired

remote port, and/or a

Display Power Sensor

MediaLink Controller (MLC 206) bottom panel connector pinouts

NOTE Not all wires must be connected for a

given device or installation. Refer to

the appropriate manual for details.

Pinout guide

The illustration below summarizes the pin assignments of all of the MLC’s bottom

panel connectors that are covered in detail on pages 2-6 to 2-12.

2-13MediaLink Controllers • Installation

Page 22

Installation, cont’d

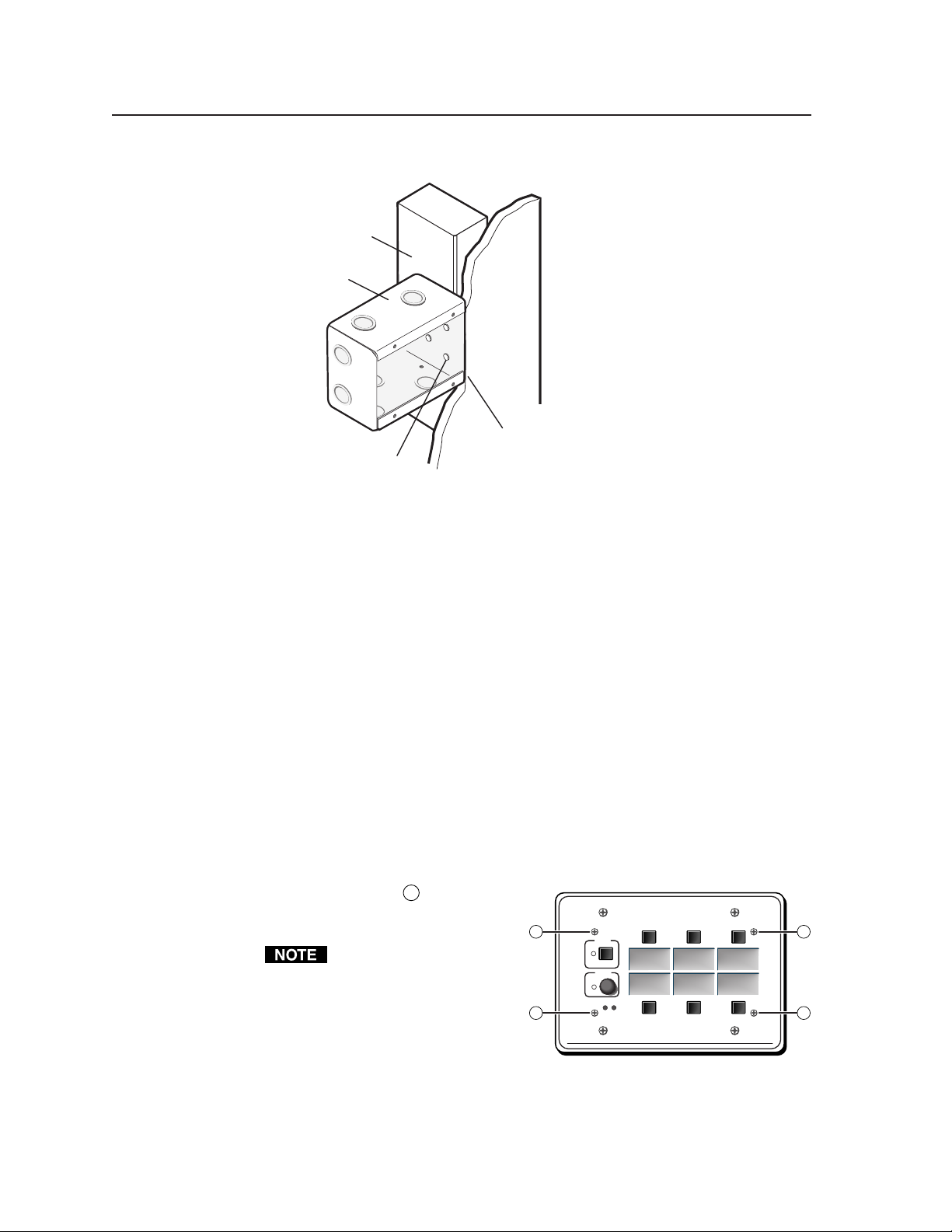

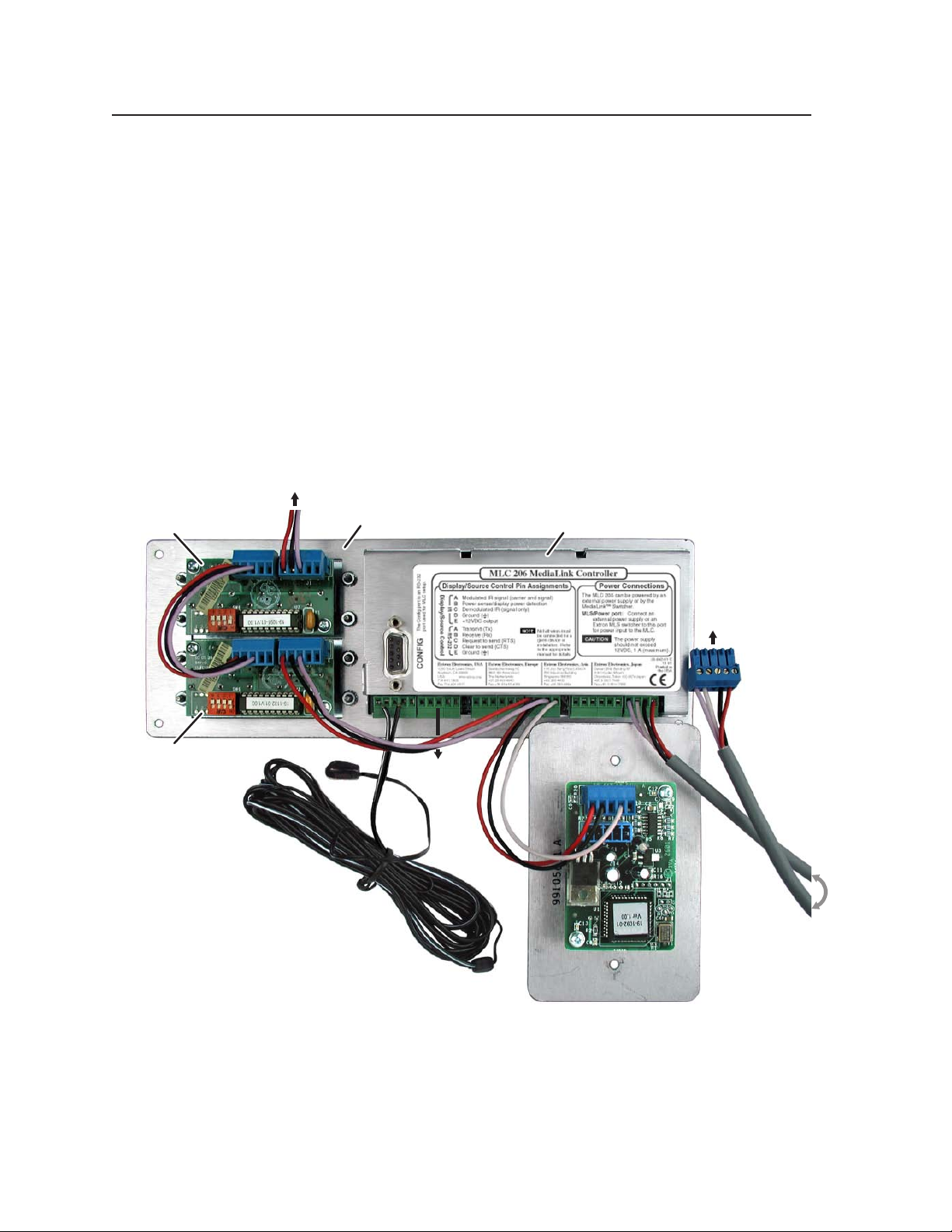

Application diagram

An example of one way to connect accessories to the controller is shown in the

photo below. The Config port is not shown with an RS-232 cable attached because

that connection is only required during setup.

This system includes an MLC mounted in an optional faceplate (MLM-LAAP) that

holds two control modules (IRCMs, ACMs, and/or RCMs), and an additional

control module is connected to the upper IRCM and mounted in another location.

An IR Link infrared repeater shares the IR/RCM port with the control modules (a

much longer cable than the one shown here would be used). IR Emitters are

connected to the MLC for controlling a VCR, DVD player, tape player or other

source device, and/or projector. An RS-232 connection to the projector could be

made from the adjacent RS-232 Display/Source Control port. Note the wiring on

both ends of the cable that connects the MLC’s MLS/Power port to an MediaLink

Switcher (MLS).

To 1–2 additional

IR Control Modules

(IRCMs)

IRCM #2

rear view

IRCM #1

rear view

MLM faceplate

IR Emitter

(Connect 1 per

each IRCM.)

RS-232

projector

connection

MLC 206 rear view

To an

MLS

switcher

Mounting the MLC

Once the system has been cabled, configured (see chapter four), and tested, the

controller can be installed in the wall, furniture, equipment rack, or Euro Channel.

MediaLink Controllers • Installation2-14

IR Link Infrared Repeater

rear view

Page 23

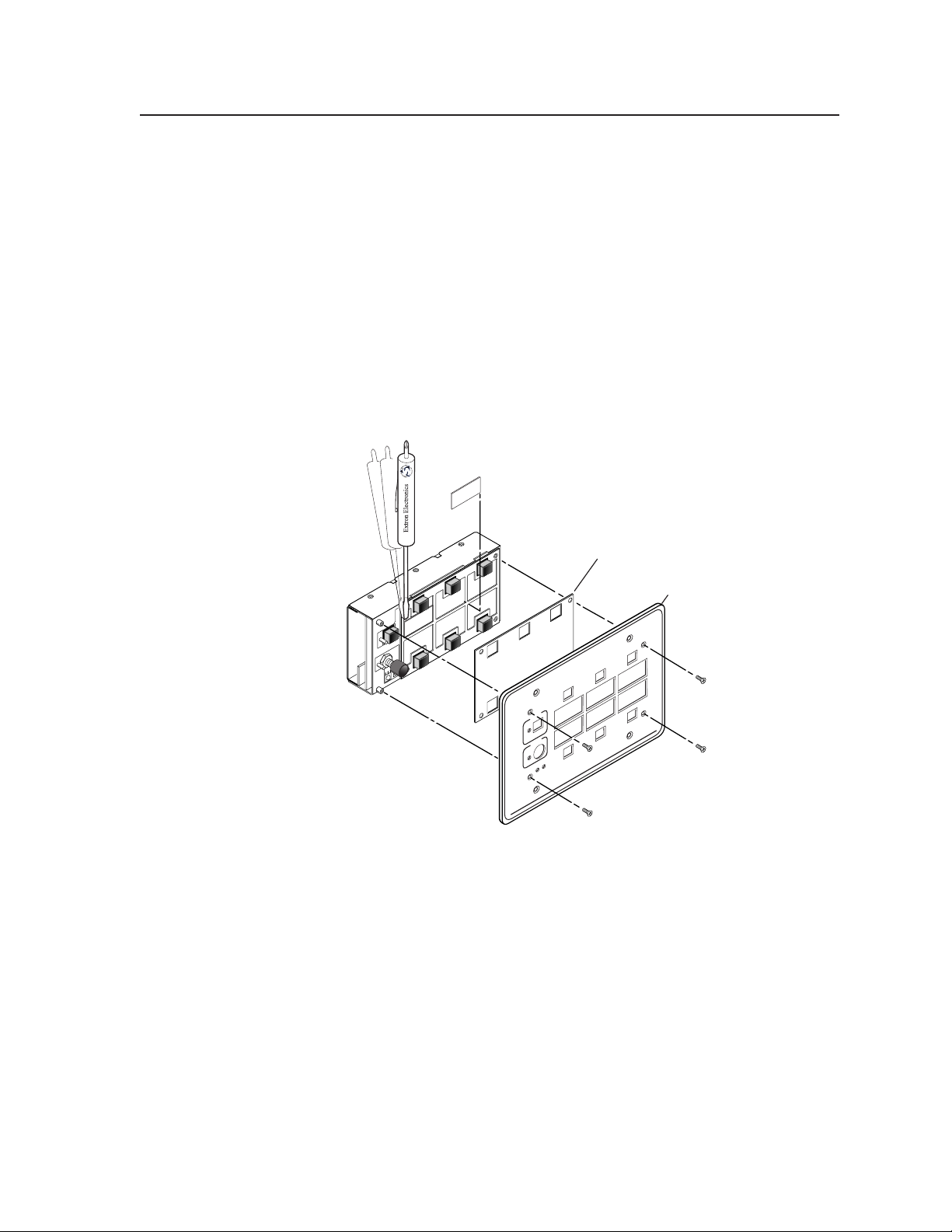

Mounting the MLC to an electrical box or mud ring

Detail A

0.75" #6-32 Screw

Backing Clip

Backing Clip

Sheet Rock

Sheet Rock

Mounting Bracket

Mounting Bracket

Detail B

1.25" #6-32 Screw

Backing Clip can

be in either orientation.

See Detail A or Detail B.

MLC 206

Extron

MediaLink Controller

MLC 206

DISPLAY

POWER

VOLUME

MAX/

MIN

VCR

DVD

Laptop

1. With power disconnected at the source, insert the MLC into the wall or furniture.

2. Mount the MLC to the wall box or mud ring mounting bracket with the

provided machine screws (as shown in the following illustrations), or attach it

directly to the furniture with wood or metal screws.

If the MLC (and any accessories such as control modules or an IR Link) is not

mounted to a grounded metal wall box,

• Ground each faceplate directly to an earth ground. Or...

• Tie each faceplate to it’s circuit board and power supply via a ground pin on

one of the connectors.

not tie a product’s faceplate to both a separate earth ground and the circuit

Do

ground (via a connector pin). If you tie a product to two different ground

sources, you may introduce ground loops or other grounding-related problems

into the system.

Cable

Clamp

Installation

Cable

Extron

Y

DISPLA

POWER

VOLUME

MAX/

MIN

DVD

VCR

MLC 206

Laptop

MLC 206

MediaLink Controller

Mounting the MLC to an electrical box or mud ring

2-15MediaLink Controllers • Installation

Page 24

Installation, cont’d

Mounting the MLC to a wall or furniture

1. Attach the optional lectern mounting faceplate to the MLC with machine

screws, as described on page 2-4 in “Replacing faceplates and labels” in this

chapter.

2. With power disconnected at the source, insert the MLC into the wall or

furniture.

3. Fasten the MLC and faceplate directly to the furniture or wall using wood

screws.

Rack mounting the MLC

1. Attach the optional rack mounting faceplate to the MLC with machine screws,

as described on page 2-4 in “Replacing faceplates and labels” in this chapter.

2. With power disconnected at the source, fasten the MLC and faceplate to the

rack using the supplied machine screws as shown in the following

illustration.

If the MLC (and any accessories such as control modules or an IR Link) is not

mounted to a grounded metal wall box,

• Ground each faceplate directly to an earth ground. Or...

• Tie each faceplate to it’s circuit board and power supply via a ground pin on

one of the connectors.

not tie a product’s faceplate to both a separate earth ground and the circuit

Do

ground (via a connector pin). If you tie a product to two different ground

sources, you may introduce ground loops or other grounding-related problems

into the system.

MediaLink

Laptop

DVD

VCR

DISPLAY

POWER

VOLUME

MAX/

MIN

Rack mounting the MLC

MediaLink Controllers • Installation2-16

Page 25

Mounting the MLC in a Euro Channel

1. With power disconnected at the source, insert the MLC 206 EC or

MLC 206 AAP EC into the Euro Channel. For wider types of Euro Channels,

you may need to insert a spacer plate first.

2. Mount the controller to the Euro Channel by attaching the faceplate to the two

backing plates using four #4-40 mounting screws. See the illustration below.

Make sure that the EuroChannel is grounded to an earth ground before

completing the installation.

Auxiliary

Video

Document

Camera

DVD

MediaLink

Lectern

Computer

VCR

Laptop

DISPLAY

POWER

VOLUME

MAX/

MIN

Backing Plate

Euro Channel

Mounting the MLC 206 EC or MLC 206 AAP EC to a Euro Channel

2-17MediaLink Controllers • Installation

Page 26

Installation, cont’d

MediaLink Controllers • Installation2-18

Page 27

MediaLink™ Controllers

Chapter Three

3

Operation

Projector Control

Front Panel Features and Operation

Optional Control Modules and MLA Remote

Page 28

Operation

Projector Control

Projector control memory

The MLC 206 can control a projector or other display device by using IR or RS-232

control. The MLC must be configured for projector control in one of the following

ways before it will send commands to the projector:

• An IR or an RS-232 driver file can be downloaded from a disk or the Extron Web

site into the MLC.

• RS-232 command strings can be entered directly from a host computer using the

supplied Windows-based software.

• IR commands can be entered directly from an IR remote control into the MLC

through IR learning. IR learning is convenient for installing new or updated

commands into the MLC in the field.

See chapter four and the MediaLink Control Program software for details on

setting up the MLC and for downloading, programming, or learning projector

control commands.

Each time a new projector driver is downloaded into the MLC, all previously

downloaded drivers (IR or RS-232) and user-defined RS-232 commands will be

replaced (overwritten or deleted) by the new driver. Similarly, entering a userdefined RS-232 command will cause the previously downloaded or user-defined

command to be replaced.

Secondary mode and special projector functions

The MLC has additional memory (up to 32 bytes per input selection button) for

storing commands for special projector functions such as zooming, focusing,

displaying color bars, or muting sound. These commands must be stored and the

MLC must be set up (see chapter four) to associate each command with a specific

input selection button. See the next page for LED and button names/numbers and

locations.

Follow these steps to execute the secondary mode commands:

1. Press input selection buttons three and four for three seconds to access the

secondary mode. The Display Power LED blinks rapidly while the secondary

mode is active.

2. While the secondary mode is active, press and release an input selection

button to send out the command that has been associated with it. The

button’s label blinks each time an input selection button is pressed and a

command is sent out.

The previously selected input remains active and will not change/switch while

the MLC is in the secondary mode.

3. To exit secondary mode, either press input selection buttons three and four

for three seconds and release them, or allow the MLC approximately ten

seconds of inactivity to time out to the regular (primary) mode.

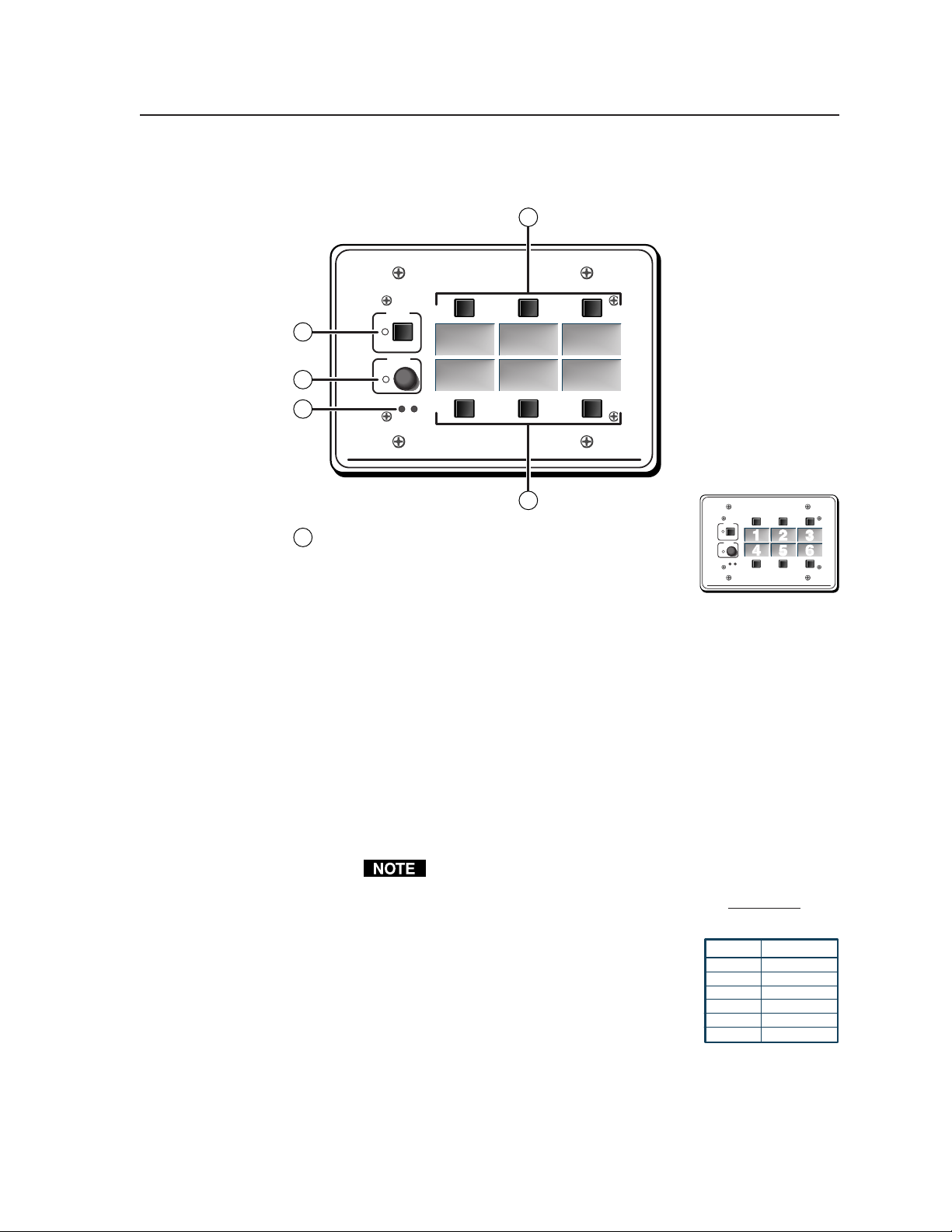

Front Panel Features and Operation

Each of the front panel buttons can have more than one function. A button may

serve one purpose in regular use (in primary mode), but can have another function

that is accessible only when the MLC is in secondary mode. See 1 in the

following picture.

Many features must be set up in order to function. See chapter four, “Serial

Communication”, for information about the MediaLink Control Program,

which you must use to set up many features of the MLC 206.

MediaLink Controllers • Operation3-2

Page 29

The MLC 206 is shown in the following examples, but the features and operation

are the same for all MLC models.

1

DISPLAY

POWER

2

VOLUME

3

MAX/

MIN

4

VCR DVD Laptop

Extron

MLC 206

MediaLink Controller

1

DISPLAY

POWER

Input selection buttons and backlit labels — From

1

the upper left to lower right these buttons are

numbered 1 through 6. See chapter 2 for instructions

on how to replace the labels.

Extron

VOLUME

MAX/

MIN

Basic operation — Press and release an input selection button to select the

designated input on the projector or the optional Extron switcher. All

labels are lit while the MLC receives power. The selected (active) input’s

label is lit more brightly than those of the nonselected inputs. If the

display power is off, the label backlighting will turn off (go dark) after a

period of inactivity (if no buttons are pressed for a while).

If the MLC is used without an optional switcher and the MLC has been

set up for use with a projector, only the number of inputs that are

available on the projector will be selectable on the MLC. If an optional

Extron switcher is connected to the MLC, all six input selection buttons

will be selectable. Which buttons are and aren’t part of the switching

rotation can be determined/set by the projector driver or via the

Windows-based setup program. See pages 4-7 and 4-12 and the

MediaLink Control Program’s Help file for details.

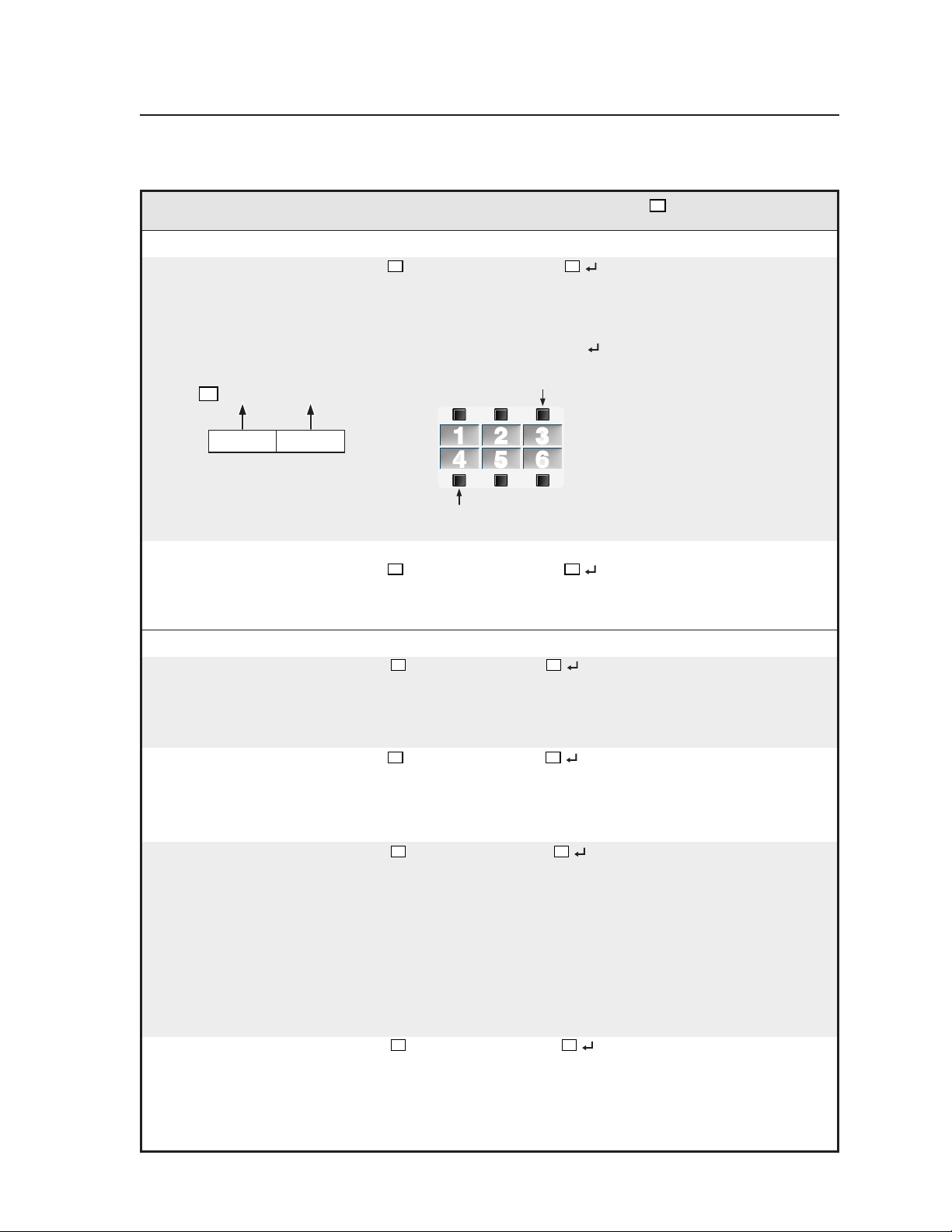

When an input selection button is part of the switching rotation,

pushing that button causes the MLC to send out an SIS input

change command via the MLS/Power connector in addition to

sending projector control commands out the Display/Source

Control IR or RS-232 ports.

The standard Extron SIS commands sent

via the MLS/Power connector are fixed

and cannot be altered. The command for

each input is shown at right.

Button Command

Input 1 1!

Input 2 2!

Input 3 3!

Input 4 4!

Input 5 5!

Input 6 6!

Additional and secondary functions —

IR/RS-232 command execution — Each input selection button can also

have IR commands or up to 32 bytes of RS-232 commands

associated with it. A command can be executed along with an

input switch by pressing the button while the MLC is in

primary mode. A different command can be executed by

123

456

MediaLink Controller

MLC 206

3-3MediaLink Controllers • Operation

Page 30

Operation, cont’d

pressing the button when the MLC is in the secondary mode or

via the Windows-based software.

The corresponding label flashes when a command associated with a

button is executed.

Relay triggering — A relay can be associated with a button. The relay

can be triggered by pressing a button only when the MLC is in

primary mode, or it can be triggered via the control software.

See pages 2-8, 4-3, 4-5, 4-10, 4-12, 4-22, and the note on page 4-18

for details.

If an input selection button is not part of the switching rotation

(does not cause input switching), the corresponding label flashes

when a momentary relay associated with a button is triggered, and

it lights steadily while a latching relay associated with the button

is active.

Secondary mode selection — If buttons 3 and 4 are simultaneously

pressed for three seconds, the MLC enters the secondary mode.

In this mode, input switching is temporarily disabled, and the

input selection buttons can be used to send various user-defined

RS-232 or IR commands to the projector (or other equipment).

Commands for special projector functions such as autosync,

focus, and zoom can be assigned to an input button and

executed when secondary mode is active.

While the secondary mode is active, the Display Power LED

blinks about twice per second. If a button is pressed in

secondary mode, the button’s label flashes briefly. Relays

cannot be triggered via the front panel when secondary mode is

active, only via the software.

To exit secondary mode, press and hold buttons 3 and 4, or

allow the MLC to time out to primary mode.

Display Power button and LED — The Display Power button has two blocks

2

of memory that can be programmed to store projector power-on and poweroff commands.

Basic operation — You must program the commands (see chapter four)

during MLC setup before this button will control the projector. To turn

the projector’s power on/off:

1. Press the Display Power button to turn the projector’s power on.

The MLC sends an RS-232 or IR power-on command to the

projector, the Display Power LED blinks for the period set for

power-up delay (refer to the Room & Misc. Options screen of the

control software for details), and then the LED remains steadily lit.

2. Once the projector is on, press and hold the Display Power button

for two seconds to turn the projector’s power off. The MLC sends a

power-off command to the projector, the LED blinks for the time set

for power-down delay, then the LED turns off. During the powerdown period, the MLC resends the power-off command.

The two-second press and hold period for Display Power Off can

be changed, via HyperTerminal only, to zero seconds by using a

special command (22 * X? #, where X? = 0 for a two-second delay,

or X? = 1 for no delay). See page 4-7.

The relays discussed in “Rear/bottom panel cable connections” in

chapter two can be turned on/off when the Display Power button is

pressed. Via the control software, each relay can also be associated with

MediaLink Controllers • Operation3-4

Page 31

either an input selection button or display power-up or display powerdown. See chapter two for information on the relays, and see chapter

four and the control software for details on changing settings for the relays.

Additional and secondary functions — While the secondary mode is active,

the Display Power LED blinks rapidly.

Volume adjustment knob and LED — Rotate this knob to adjust the audio

3

volume. The LED lights when the volume has reached the minimum or

maximum limit. The included control software lets you select whether this

knob will control the projector’s audio levels or the optional switcher’s audio

levels. If the knob controls the projector’s audio levels, the software allows

you to specify incremental adjustments or table-based adjustments. See the

MediaLink Control Software Help file for details.

IR signal pickup devices — These sensors allow for IR control of the MLC

4

and for IR learning. The IR remote control must be pointed directly at these

devices for best results. One device is an IR receiver that receives signals from

the MLA-Remote for controlling the MLC 206. The other is the IR learning

device. The MLC can “learn” commands in order to control the projector or

to control input devices such as a VCR or DVD players. IR learning of

projector control codes is only necessary if there are no RS-232 codes available

for that projector or if you need to customize the driver. The IR learning

procedure is discussed in the control software and later in this manual.

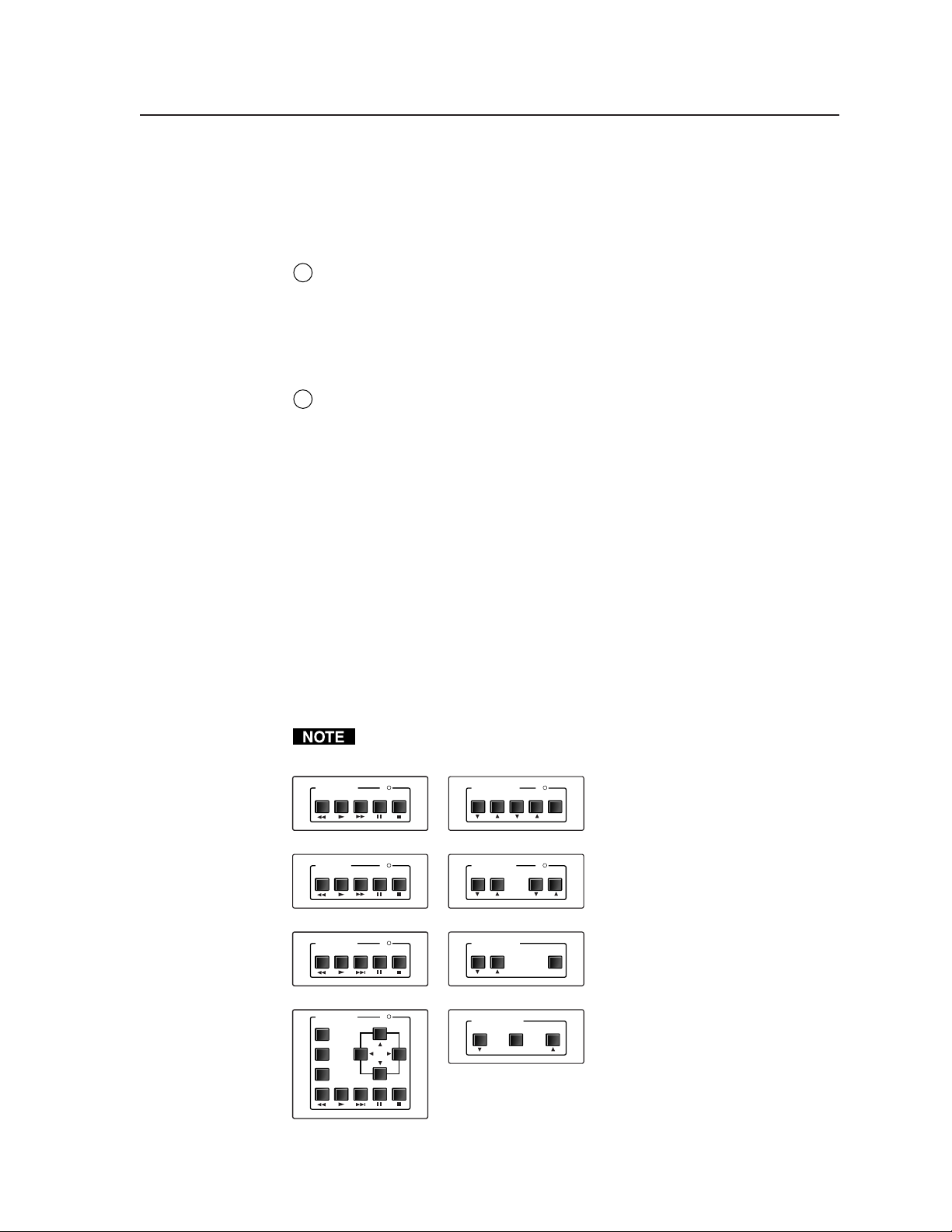

Optional Control Modules and MLA-Remote

The MLC has an additional thirty memory blocks in which IR or other commands

can be stored for control modules attached to the MLC. The MLC can “learn” IR

commands directly from a VCR’s, DVD’s, tape deck’s or other device’s remote

control. A learned command can be associated with each of the buttons on an

optional infrared control module (such as the Extron IRCM-VCR, IRCM-DVD,

IRCM-DVD+, IRCM-DV+, or IRCM-Tape) in order to allow limited control of

source devices. ACM control modules provide limited remote control of

adjustments to a peripheral MediaLink Switcher.

The control module must be connected to the MLC before you can perform IR

learning for the module’s buttons.

VCR CONTROL

REW PLAY FWD PAUSE STOP

Tx

MAX/

AUDIO CONTROL

INPUT LEVEL MIX LEVEL MUTE

MIN

A total of four control modules

(maximum) can be installed with

an MLC 206. Refer to the Control

IRCM-VCR

TAPE DECK

REW PLAY FWD PAUSE STOP

Tx

TONE CONTROL

BASS TREBLE

ACM-Level

MAX/

MIN

Modules User’s Manual and the

Relay Control Modules User’s

Manual for installation details.

See page 4-4 of this manual for

IRCM-Tape

DVD CONTROL

REW PLAY NEXT PAUSE STOP

IRCM-DVD

DVD CONTROL

MENU

TITLE

ENTER

PLAY NEXT PAUSE STOP

REW

IRCM-DVD+

ACM-Tone

Tx

Tx

ROOM CONTROL

SCREEN POSITION LIGHTING

ON / OFF

RCM-SCLT

SCREEN POSITION

DOWN UPSTOP

RCM-SC

special instructions for the

IRCM-DV+.

Optional IRCM, ACM, and RCM control modules

3-5MediaLink Controllers • Operation

Page 32

Operation, cont’d

The buttons on the optional MLA-Remote duplicate the

MLC’s front panel controls and also those of two Control

Modules (IRCMs) for normal operation. The MLA-Remote

can also be used to control a MediaLink Switcher (MLS). The

controller, control module, or switcher responds to commands

from the MLA-Remote as if the corresponding button or knob

were pressed or turned on the controller or switcher.

From a distance of no more than 30 feet and within 40° of the

axis, the MLA-Remote sends infrared (IR) signals to

• a MediaLink Controller via the controller’s front panel IR

pickup device or the IR pickup device of an optional IR

Link IR signal repeater.

• a MediaLink Switcher via a connected IR Link. The

switcher can receive signals from the MLA-Remote only

via an IR Link.

The MLA-Remote’s Display Power button and the VCR and

DVD control buttons will not function until commands have

been stored in the MLC’s memory. The MLA-Remote’s VCR

buttons control the first (lowest address numbered) IRCMVCR connected to the MLC. The DVD buttons control the

first (lowest address numbered) IRCM-DVD connected to the

MLC.

Commands are transmitted from the MLC’s Display/Source Control RS-232 port

(via hard wiring) and IR ports (via IR Emitters or optional IR Broadcaster) when the

corresponding button is pressed on the MLA-Remote or on the controller’s or

control module’s front panel. Refer to the Control Modules User’s Manual.

Setup operations cannot be performed from the

MLA-Remote.

The only control modules that can be controlled via the

MLA-Remote are the IRCM-VCR and IRCM-DVD.

MLA-Remote

IR remote control

MediaLink Controllers • Operation3-6

Page 33

MediaLink™ Controllers

Chapter Four

4

Serial Communication

RS-232 Programmer’s Guide

Control Software for Windows

Page 34

Serial Communication

DB9 Pin Locations

Female

51

96

The MLC can be remotely set up and controlled via a host computer or other

device (such as a control system) attached to the rear panel Configuration port.

The control device (host) can use either Extron’s Simple Instruction Set (SIS)

commands or the graphical control program for Windows.

The MLC uses a protocol of 9600 baud, 1 stop bit, no parity, and no flow control.

The rear panel RS-232 9-pin D connector has the following pin assignments:

Pin RS-232 function Description

1 – No connection

2TxTransmit data

3RxReceive data

4 – No connection

5 Gnd Signal ground