Page 1

IMPORTANT:

specifications bef

oduct to the po

ore connecting the

wer source.

IPCP Pro Series • Setup Guide

Go to www.extron.com for the complete

user guide, installation instructions, and

pr

The Extron IPCPPro Series IPLink® Pro Control Processors integrate Ethernet connection into AV systems to allow users to

remotely control, monitor, and troubleshoot AV equipment, including display devices and switchers. All models include an

embedded web server. Depending on the model, an IPCPPro control processor can include multiple bidirectional serial ports,

relays, IR/serial ports, digital I/O, flex I/O, switched 12 VDC power output ports, a volume control port, or contact input ports for

use in applications that require control and monitoring of multiple devices within a large-scale AV system.

All models include an Extron eBUS port, which allows a variety of eBUS devices to be connected to a single control processor.

eBUS devices include an array of button panels as well as power and signal hubs. eBUS devices are automatically recognized by

the control processor and can be added or removed at any time.

The dual-NIC (network interface controller) models feature two network interfaces. One (at the LAN port) is for connection to the

corporate or “house” network. The second network interface (at the AVLAN port) is for dedicated control of local AV devices.

This guide provides instructions for an experienced installer to install an IPCPPro Series control processor and to create a basic

configuration.

Use the Extron Toolbelt software to discover and manage the IPCPPro control processor and other Extron control products.

Configure the control processor using Extron Global Configurator software running in Global Configurator Professional

(GCProfessional) or Global Configurator Plus (GC Plus) mode, or program the control processor using Extron Global Scripter(GS).

The IPCP integrates seamlessly with Extron GlobalViewer® Enterprise (GVE) software and Extron Control for Web, iOS, and

Android for remote control applications. These control processors support multiple TouchLink®Pro touchpanel interfaces over a

standard Ethernet network. Global Configurator and other useful software applications are available at www.extron.com.

Setup Checklist: How to Proceed With Installation

Get Ready

Familiarize yourself with the features of the control processor (see Front Panel Features — Single-NIC Models on page4,

Front Panel Features — Dual-NIC Models on page5, Rear Panel Features — Single-NIC Models on page6, and

Rear Panel Features — Dual-NIC Models on page7) and of any TouchLinkPro touchpanels that will be part of the

system.

Download and install the latest version of the following:

• Toolbelt software — for discovering the control processor and other control products, for managing core settings, and

for upgrading firmware if the need arises.

• Global Configurator (GC) software — for setting up and configuring the control system. GCProfessional and GCPlus

modes include a link to the Toolbelt software.

• Global Scripter software — for setting up and programming the control processor (as an alternative to GC)

• GUI Designer software — for designing layouts for Extron TouchLinkPro touchpanels and third party touch interfaces

• IPLinkPro device drivers — for use with GC, to make control of AV devices possible

• IR Learner Pro software — for use with models that have IR receiver ports, to create your own IR drivers using the

remote control of an AV device, if drivers are not already available from Extron

All are avail able from www.extron.com (see Locating Software, Firmware, and Driver Files on the Extron Website on page14).

Obtain network information for the unit from the network administrator. You will need the following details for each IPLinkPro

device:

DHCP setting (on or off) Subnet mask Username

Device (IPCP Pro, TouchLinkPro, IPLPro) LAN IPaddress Gateway IP address Passwords

AVLAN IPaddress (for dual-NIC models)

Write down the MAC address of each network interface card (NIC) on each IPLinkPro device to be used.

1

Page 2

IPCP Pro Series • Setup Guide (Continued)

Obtain model names and setup information for devices the IPCP will control.

Each control processor comes with a factory-installed Secure Sockets Layer (SSL) security certificate. If you intend to install

a different SSL certificate, contact your IT department to obtain the certificate or for instructions on how to obtain one. See

“Secure Sockets Layer (SSL) Certificates” in the IPCPProSeries User Guide for requirements and guidelines regarding SSL

certificates.

Mount and Cable All Devices

Mount the unit to a rack or furniture (see Mounting on the next page).

Cable devices to the control processor (see Cabling and Features on page 8).

Connect power cords and power on all the devices.

Set Up the Control Processor and Touchpanels for Network Communication

For single-NIC models: Connect the PC that you will use for setup, the LAN port of the control processor, and the touchpanels

to the same Ethernet network. For control processor LAN connections, see Control, Bidirectional — LAN and AV LAN

(Ethernet) on page4.

For dual-NIC models: Connect the PC that you will use for setup, the control processor, and the touchpanels to the network. For

control processor LAN and AV LAN connections, see Control, Bidirectional — LAN and AV LAN (Ethernet) on page4.

Start Toolbelt and use it to set the IP address, subnet, gateway IP address, DHCP status, and related settings. See the

flowchart in Network Communication Setup on the next page.

NOTE: When setting up DHCP during network configuration or if using a host name instead of an IP address, the user

must enter a qualified host name (Username.HostName.Domain). For example: somename.extron.com.

Configure or Program the Control Processor and Touchpanels

The most basic steps are outlined below in the recommended order.

NOTE: See the Toolbelt Help File, Global Configurator Help File, Global Scripter Help File, and GUI Designer Help File as

needed for step-by-step instructions and detailed information. The help file for GC includes an introduction to the software

and how to start a project and configuration.

If TouchLinkPro or third party touchpanels are part of the system, start and use GUI Designer to design, save, and build the

graphical user interface (GUI) layout for the touchpanels.

NOTE: To redeem (activate) a LinkLicense™, go to www.extron.com//llredeem and follow the online instructions.

Using GC, create a new GCProfessional or GCPlus project and configure the control processor and other IP Link Pro

devices. The configuration tells the control processor:

• how its ports function • what to monitor

• how to control other products • when to do things

• which touchpanels to interact with • whom to notify, how, and under what circumstances

Configure ports on the control processor.

Select device drivers and link them to each serial, IR/serial, or Ethernet port.

Select settings (serial protocol, relay behavior, digital I/O or flex I/O settings) as needed.

Add eBUS devices and set them up:

Ensure that the hardware address set on each device is distinct and matches the address used in the configuration.

Assign button functions as desired.

Set up monitors, schedules, macros, and local variables.

Add touchpanels and set them up:

• Upload the GUI configuration to the touchpanels using Global Configurator.

• Assign any appropriate functions, monitors, or schedules to the touchpanels and their buttons.

If not using GC Professional or GC Plus, use Global Scripter to program the control system as desired.

Program ports on the control processor.

• Program each serial, IR/serial, or Ethernet port.

• Program relay behavior, digital I/O, and flex I/O settings as needed.

2

Page 3

Add eBUS devices and set them up:

• Ensure that the hardware address (eBUS ID) set on each device is distinct and matches the address programmed

for it in the IPCP.

• Program button functions as desired.

Add touchpanels and set them up:

• Upload the GUI configuration to the touchpanels.

• Program the touchpanel buttons.

Save and build the project.

Upload the system configuration to the control processor.

Test and Troubleshoot

Test the system. (See the IPCPProUser Guide for an outline of the system testing procedure.)

Make adjustments to wiring or configuration as needed.

Network Communication Setup

Network setup is essential prior to configuration. Use the following flowchart as a guide to setting up the control processor for

network use.

Network Communication Setup

Connect the PC and the LAN port or AV LAN

port of the control processor to

the same network.

Apply power to all devices.

Open the Toolbelt software from within

Global Congurator (GC Professional or

GC Plus mode) or as the stand-alone

Toolbelt displays a list of all Extron control

devices connected to the network.

Using the MAC address, locate the desired

control processor in the list and select it.

For each NIC (LAN, or LAN and AV LAN), use

the Set IP feature in Toolbelt or use the

Toolbelt

feature to enter the IP address and

subnet address, then congure other

network settings as needed.

Figure 1. Network Setup

application.

Start Device Discovery.

Manage > Network Settings tab

Mounting

Securely mount the control processor and other devices and attach cables using the wiring section (see Cabling and Features

on page8) as a wiring guide. Optional 1U rack shelves and furniture mounting bracket kits are available for use with the control

processor. Read the instructions and UL guidelines that come with the rack shelf or mounting kit for installation procedures. See the

product-specific page at www.extron.com for a list of compatible accessories for mounting your control processor.

3

Page 4

IPCP Pro Series • Setup Guide (Continued)

Power

Power

Power

IPCP Pro Single-NIC Embedded Control Processor

Panels and Locations of Features

Location and quantity of LEDs and corresponding connectors vary by model, but the functions and port wiring are identical

across models for each port type.

Front Panel Features — Single-NIC Models

(within another device)

COM

RTS

eBUS

S

LIMIT

OVER

CTS

Tx

Rx

IR/S

2231

RELAYS

I/O

3142314

21

IR/

eBUS

LEDs

COM

(Serial)

LEDs

Serial

LEDs

COM

RTS

LED

Reset Button

(recessed)

eBUS

S

LIMIT

R

OVER

CTS

Tx

Rx

IR/S

1

2

Digital

I/O

LEDs

I/O RELAYS

2

314

Relay

LEDs

IPCP PRO 250

1

2

IR Receiver

eBUS LEDs

COM

RTS

eBUS

CTS

S

Tx

Rx

LIMIT

Tx

Rx

OVER

COM (Serial)

LEDs

COM

LED

LED

R

Reset

Button

(recessed)

R

Switched

12 VDC

LEDs

SWITCHED

12 VDC

21

LIMIT

43 12345678

OVER

1000

LINK

IR

ACT

IR/S

RTS

CTS

Tx

Rx

LAN/

Network

LEDs

Digital I/O LEDs

RELAYS

I/O

2

314

2231

IR/Serial

LEDs

IR/SERIAL RELAYS FLEX

2134

5 678

21

314

Relay

LEDs

5 678213 4

Flex I/O

LEDs

I/O

2134

IPCP PRO 350

IR

IR Receiver

eBUS LEDs

IPCP PRO 550

eBUS

S LIMIT

OVER

1000

LINK

ACT

IR

LAN

12

1000

LINK

ACT

3

LAN/

Network

LEDs

NOTE: Numbers adjacent to LEDs correspond to the like-numbered rear panel ports.

Figure 2. Front Panels: IPCP Pro Series Single-NIC, Rack Mountable Models

NOTES:

• For reset mode information, see the IPCPProSeries User Guide.

• The Reset button and power LED for the IPCPPro embedded control processors are located next to the rear panel

connectors.

• The embedded control processors do not have an IR learning sensor.

4

15˚ 15˚

2–12"

(4–30 cm)

1 2 3

4 5 6

7 809

IR Receiver

IR Learning

Angle and

Distance

Page 5

Front Panel Features — Dual-NIC Models

eBUS LEDs

Power

LIMIT

eBUS

OVER

Rx

CTS

RTS

Tx

ERROR

LINK

BUSY

COM

I/O

RELAYS

IR/S

12 121

COM

(Serial)

LEDs

IR/

Serial

LEDs

eBUS

LEDs

Relay

LEDs

Digital

I/O

LEDs

IPCP Pro Dual-NIC Embedded Control Processor

(within another device)

This section shows the front panel of a representative dual-NIC model, not all models.

COM

LED

RTS

eBUS

LIMIT

OVER

CTS

Tx

Rx

R

LINK

BUSY

ERROR

IR/S

2231

I/O

314

RELAYS

2

21

314

1000

LINK

IR

IPCP PRO 360

AV LAN

3

12

ACT

LAN

Reset

Button

(recessed)

COM (Serial)

LEDs

IR/Serial

LEDs

Figure 3. IPCPPro360 Front Panel (Dual-NIC)

Digital I/O

LEDs

Relay

LEDs

IR

Receiver

AV LAN

LEDs

LAN

LEDs

5

Page 6

IPCP Pro Series • Setup Guide (Continued)

I

I

IPCP Pro Single-NIC

Embedde

Cont

(w

de

Rear Panel Features — Single-NIC Models

d

rol Processor

ithin another

vice)

R

COM 1

GTx Rx

RTSCTS

IR/SERIAL

1SG2

COM 2COM 3

SG

DDDEEEE IIII

D

DIGITAL I/O

GTx Rx GTx Rx

RELAYS

2143CC

1234G

+V +S -S G

PWR OUT = 6W

eBUS

JJJJFFFF GGGG

1

23

LLLL

POWER

12V

1.0A MAX

A

AAA

Tx Rx

COM 1

G

VOL

VCG

KKKK

RTSCTS

DDDDEEEE

COM 2

Tx Rx

RELAYS

G

C12

IIII

DIGITAL I/O

3

12 4G

eBUS

-S+V +S G

PWR OUT = 6W

J

JJJ

IPCP Pro 250

IPCP PRO 250

MAC: 00-05-A6-XX-XX-XX

S/N: ####### E######

IR/S

SG

LAN

F

L

FFFGGGG

LLL

M

MMM

PCP Pro 350

POWER

12V

1.0A MAX

AAAA

PCP Pro 550

100-240V ~ 50-60Hz

1.2A MAX

Figure 4. IPCPPro Single-NIC Control Processors Rear Panels

Power input connector (external power supply)

A

Power input connector (internal power supply)

B

Switched 12 VDC power output ports

c

3-pole COM ports (RS-232-only)

D

5-pole COM ports (RS-232/RS-422/RS-485)

E

IR/serial output ports

F

Relay ports

G

EEE

COM 1

GTx Rx

RTSCTS

IR/SERIAL

1SG2

F

FFF

SWITCHED 12 VDC

40W MAX TOTAL

DDDDE

COM 2 COM 3

GTx Rx GTx Rx

RELAYS

2143CC

SG

G

GGG

1 1 2 3 7

2 1 2

TxRx GTxRxG TxRx GTxRxG SGSG SGSG

3 4

C

CCCBBBB DDDD EEEE HHHH

4 5 6

TxRx GTxRxG TxRx GTxRxG

I

III

DIGITAL I/O

1 234G

eBUS

+V +S -S G

PWR OUT = 6W

J

JJJ

RTSCTS

8

RTSCTS

3 4

5 6

7 8

SGSG SGSG

F

FFF

M

MMM

00-05-A6-XX-XX-XX

MAC: 00-05-A6-XX-XX-XX

S/N: ####### E######

1 2

3 4

5 6

7 83214G

GGGG

Flex I/O ports (digital input/output or analog input)

H

Digital I/O ports (digital input/output)

I

Volume control port

K

eBUS ports

J

LAN connectors and LEDs (Ethernet)

L

MAC address

M

IPCP PRO 350

LAN

123

L

LLL

J

JJJ

eBUS

IPCP PRO 550

LAN

L

LLL

PWR OUT = 12W

+V +S -S G

FLEX I/ORELAYSIR/SERIALCOM12 VDC

00-05-A6-XX-XX-XX

MAC: 00-05-A6-XX-XX-XX

S/N: ####### E######

M

MMM

6

Page 7

Rear Panel Features — Dual-NIC Models

I

This section shows rear panels of some representative dual-NIC models.

IPCP Pro 255

POWER

12V

1.0A MAX

AAAA

Tx Rx

COM 1

G

VOL

VCG

KKKK

RTSCTS

DDDDEEEE

COM 2

Tx Rx

RELAYS

DIGITAL I/O

G

12 4G

C12

3

eBUS

-S+V +S G

PWR OUT = 6W

JJJ

J

IR/S

SG

FFFGGGG

F

LLLIIII

L

MAC: 00-05-A6-XX-XX-XX

S/N: ####### E######

MAC: 00-05-A6-XX-XX-XX

S/N: ####### E######

NNN

N

LAN

LAN

MMMM

AV

PCP Pro 360

100-240V ~ 1.5A MAX

50-60 Hz

BBBB

Figure 5. IPCP Pro Dual-NIC Control Processors Rear Panels

Power input connector (external power supply)

A

Power input connector (internal power supply)

B

3-pole COM ports (RS-232-only)

D

5-pole COM ports (RS-232/RS-422/RS-485)

E

IR/serial output ports

F

Relay ports

G

EEE

COM 1

GTx Rx

RTSCTS

IR/SERIAL

1SG2

SG

F

FFF GGGG

DDDDE

COM 2 COM 3

GTx Rx GTx Rx

RELAYS

2143CC

I

III

DIGITAL I/O

1 234G

eBUS

+V +S -S G

PWR OUT = 6W

J

JJJ

IPCP PRO 360

00-05-A6-XX-XX-XX

MAC: 00-05-A6-XX-XX-XX

S/N: ####### E######

12

AV LAN

PWR

PoE+ OUT PoE+ OUT

N

NNN

Digital I/O ports (digital input/output)

I

Volume control port

K

eBUS ports

J

LAN connectors and LEDs (Ethernet)

L

MAC addresses

M

AV LAN connector and LEDs (Ethernet)

N

IPCP AV LAN

PWR

00-05-A6-XX-XX-XX

MAC: 00-05-A6-XX-XX-XX

S/N: ####### E######

3

IPCP LAN

LAN

LLLL

M

MMM

The following ports are not shown in figure 5 but are available in some dual-NIC models such as the IPCPPro555.

Power input connector (internal power supply)

B

Switched 12 VDC power output ports

c

Flex I/O ports (digital input/output or analog input)

H

7

Page 8

IPCP Pro Series • Setup Guide (Continued)

Smooth

Rear

Front Panel

Lights if total power drawn

Lights if total power drawn

Cabling and Features

Attach cables using the following wiring diagrams as a guide. Full details are available in the IPCPPro Series User Guide.

ATTENTION:

• Installation and service must be performed by experienced personnel.

• L’installation et l’entretien doivent être effectués par du personnel expérimenté.

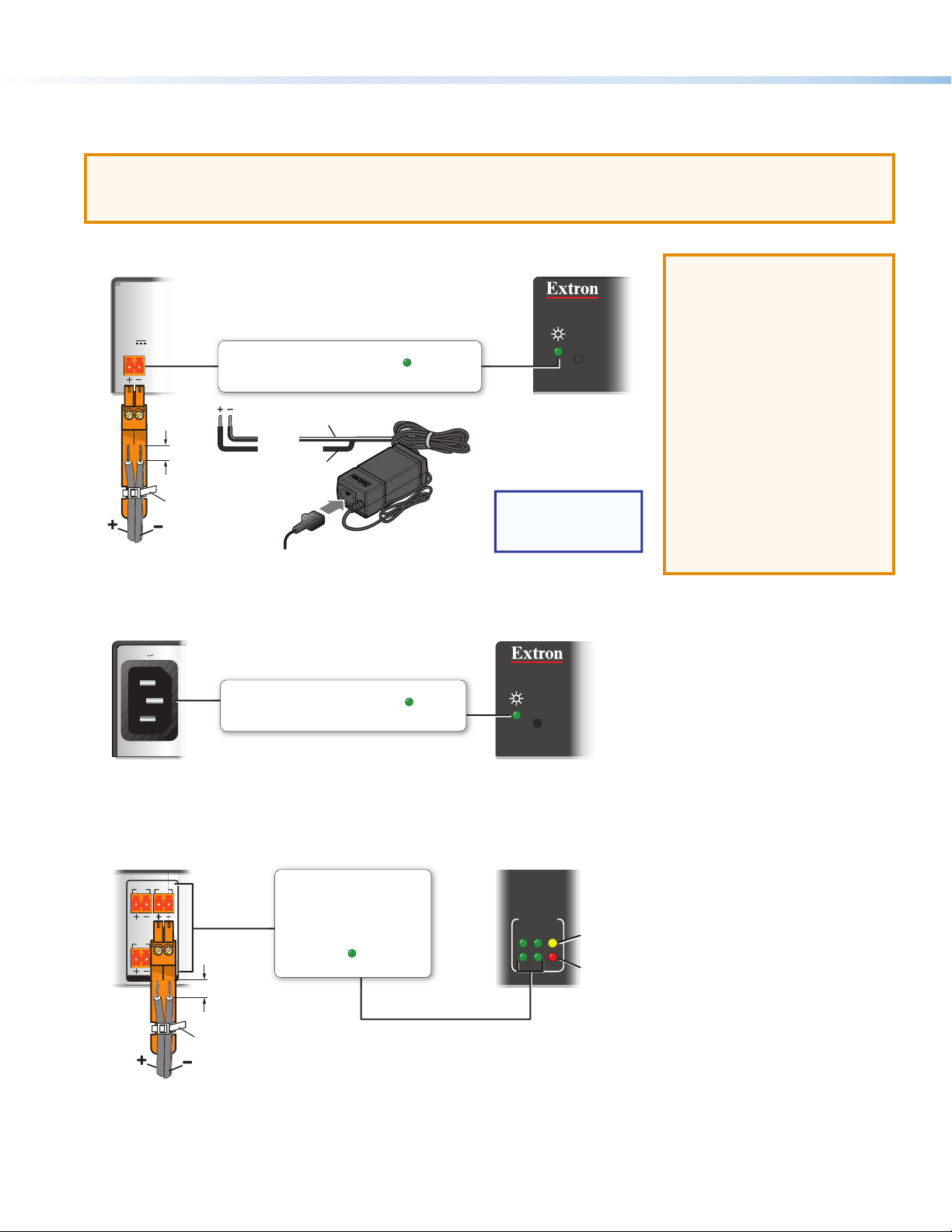

Power Input — External

POWER

12V

x.xA MAX

Tie Wrap

Ridged

3/16"

(5 mm)

Max.

Power Input, External Power Supply

• Connect to

included 12 VDC

power supply.

– Return

+12 VDC input

Power Input — Internal

100-240V 50-60Hz

Power Input, Internal Power Supply

• Connect to 100 to

240 VAC.

1.2A MAX

Panel

• Front panel LED ( ) blinks during

boot-up and remains lit when the

IPCP is powered and operational.

Ridged

Smooth

1A MAX

100-240V 50-60Hz

• Front panel LED ( ) blinks

during boot-up and remains lit

when the IPCP receives power.

External

12 VDC

Power Supply

Ground

all devices.

R

Front Panel

NOTE:

Check the polarity

of the power supply

before connecting it to

the IPCP.

R

ATTENTION:

• Always use a power

supply supplied or

specified by Extron. Use

of an unauthorized power

supply voids all regulatory

compliance certification and

may cause damage to the

supply and the unit.

• Utilisez toujours une source

d’alimentation fournie par

Extron. L’utilisation d’une

source d’alimentation non

autorisée annule toute

conformité réglementaire et

peut endommager la source

d’alimentation ainsi que

l’unité.

Power Output — Switched 12 VDC Power Output

1 2

SWITCHED 12 VDC

40W MAX TOTAL

3 4

Rear

Panel

12 VDC

3/16"

(5 mm)

Max.

Tie Wrap

8

Switched 12 VDC

Power Output

• Total output for all four ports

combined:

12 VDC, 40 watts (max.)

• Corresponding front panel

green LEDs ( ) light when

power is available at each port.

SWITCHED

12 VDC

21

LIMIT

OVER

43

Front

Panel

is 41-46 watts.

exceeds 47 watts.

Power output shuts off

until the user corrects the

overload.

Page 9

Control, Bidirectional — Serial (COM)

IR/SER

S

S

TTx

Y

Y

3

Rear

eceived.

Panels

(RS-232)

Serial (COM) Ports

Select protocol via software.

COM port default protocol:

• 9600 baud

• 8 data bits • 1 stop bit

• no parity • no ow control

COM 2 COM

G

GTx Rx Tx Rx

1 7

TxRx GTxRxG

or or

4

TxRx GTxRxG

COM 1

GTx Rx

RTSCTS

IAL

8

RTS

RTSCTS

CTS

5-pole COM

(RS-232, RS-422, RS-485)

NOTE: The 5-pole COM ports support both

3-pole COM

hardware and software ow control.

The 3-pole COM ports support software

ow control only.

To 5-pole

COM port

To 3-pole

COM port

Heat Shrink

Over Shield Wires

CTS

RTS

G Ground

Rx Receive

Tx

G

Ground

Rx

Receive

Tx

Transmit

Request to send

Transmit

Strip wires

3/16" (5 mm) max.

Heat Shrink

Receive (Rx)

Transmit (Tx)

Receive (Rx)

Transmit (Tx)

Projector, Panel

Display, PC, or Other

RS-232, RS-422, or

RS-485 Device

RS-232-

Controllable

Device

Clear to send

NOTE: If you use cable that has a drain wire, tie the drain wire to ground at both ends.

Front Panels

COM

Tx

Tx

Rx

Rx

12345678

1

RTS =

Request to Send

CTS = Clear to Send

Tx = Transmitting Data

Rx = Receiving Data

RTS

CTS

Tx

Rx

5-pole COM Pin Configurations

RS-232

Tx

Rx

Ground

RTS

CTS

RS-422

TxRx-

Ground

Tx+

Rx+

(pins 1 & 2

tied together)

(pins 4 & 5

tied together)

Pin

1 (Tx)

2 (Rx)

3 (G)

4 (RTS)

5 (CTS)

RTS

CTS

Tx

Rx

COM

231

RS-485

Data-

Ground

Data+

Control, Bidirectional — LAN and AV LAN (Ethernet)

Default port IP addresses and recommended connections vary depending on whether the IPCP is a single-NIC or dual-NIC

model.

Single-NIC models — LAN ports

Insert Twisted

RJ-45

Connector

Rear Panel,

Rack Mount

Models

12

Pair Wires

Pins:

LAN

12345678

Ethernet

or

Activity

LED

TCP/IP

Network

LAN

Link

LED

PC

Single-NIC LAN (Ethernet)

Default protocol, public ports:

• IPCP IP address: 192.168.254.250

• Gateway IP address: 0.0.0.0

• Subnet mask: 255.255.255.0

• DNS address: 127.0.0.1

• DHCP client: off

• Link speed and duplex level: autodetected

• Data rates: 10/100/1000Base-T

Default login

credentials:

• Username:

admin

• Password:

extron

NOTE: IPCPs with more than one LAN port function as

multiport, unmanaged network switches so you can

connect additional devices to the same network.

Front Panel,

Rack Mount

Models

1000

LINK

ACT

LAN

123

1000 Mbps

Connection

Network is

active.

Data is being

sent/r

9

Page 10

IPCP Pro Series • Setup Guide (Continued)

2

3

Y

Y

S/

E######

#

2

3

T

A L

AN

6-

XX-XX-X

X

S/

#

###

-

0

X

X

N

eceived.

6-

XX-XX-XX-X

X

S/

E######

#

00

--A6-

YY

S/

#

00-05-A6-XX-XX-XX

Dual-NIC models — LAN ports

Rear

Panels

PC

00

-05-A

N: ####### E###

Corporate

TCP/IP

Network

5-A6-XX-XX-

PoE+ OU

PCP AV LA

Ethernet

RJ-45

Connector

00-05-A6-XX-XX-XX

MAC: 00-05-A6-YY-YY-YY

S/N: ####### E######

oE+ OUT

Insert Twisted

Pair Wires

Pins:

12345678

IPCP LAN

LAN

Activity

LED

or

Ethernet

PC

Corporate

TCP/IP

Network

MAC: 00-05-A6-XX-XX-XX

S/N: ####### E######

MAC: 00-0-A6-Y-

N: #######

LAN

N

##

NOTE: IPCPs with more than one LAN or AV LAN port function as multiport, unmanaged

network switches so you can connect additional devices to the same network.

Link

LED

Dual-NIC LAN

(Ethernet)

Default protocol, LAN

ports:

• LAN IP address:

192.168.253.250

• Gateway IP address:

0.0.0.0

• Subnet mask:

255.255.255.0

• DNS address: 127.0.0.1

• DHCP client: off

• Link speed and duplex

level: autodetected

• Data rates:

10/100/1000Base-T

Default login

credentials:

• Username: admin

• Password: extron

Front

Panels

1000

LINK

ACT

LAN

1

1000 Mbps

Connection

Network is

active.

Data is being

sent/r

Dual-NIC models — AVLAN ports

Ethernet

Insert Twisted

Pair Wires

RJ-45

Connector

Pins:

12345678

00-05-A6-XX-XX-XX

MAC: 00-05-A6-XX-XX-XX

S/N: ####### E######

AV LAN

21

PWR

PoE+ OUT PoE+ OUT

NOTE: IPCPs with more than one LAN or AV LAN

port function as multiport, unmanaged network

switches so you can connect additional

devices to the same network.

10

AV

Network

IPCP AV LAN

PWR

AC:

N: ####### E#####

3

PC

PC

AV

Network

Ethernet

Rear

Panels

MAC: 00-0-A

N: #######

##

-YY-

PCP LAN

LAN

or

Activity

LED

MAC: 00-05-A6-YY-YY-YY

S/N: ####### E######

LAN

AV

Link

LED

AV LAN (Ethernet)

Default protocol,

AV LAN:

• IP address:

192.168.254.250

• Gateway IP address:

0.0.0.0

• Subnet mask:

255.255.255.0

• DNS address: 127.0.0.1

• DHCP client: off

(disabled)

• DHCP server off

(disabled)

• Link speed and duplex

level: autodetected

• Data rates:

10/100/1000Base-T

Default login

credentials:

• Username: admin

• Password: extron

Front

Panels

1000

LINK

ACT

AV LAN

12

A

3

1000 Mbps

Connection

Network is

active.

Data is being

sent/received.

AV LAN DHCP Server

The AV LAN DHCP Server is disabled by default. It can be enabled to dyanmically assign

IP addresses to DHCP clients on the AV LAN.

Default protocol, AV LAN when

DHCP server is enabled:

• DHCP server IP address: 192.168.254.1

• Subnet mask: 255.255.255.0

• Gateway: 0.0.0.0

• DNS address: 192.168.254.1

• DHCP dynamic address range for client

devices: 192.168.254.100 -

192.168.254.149

• Maximum served addresses when

DHCP server is enabled: 50

• DHCP client address lease time: 24 hours.

To use DHCP in the AV LAN:

1. Using Toolbelt, enable the DHCP server

for the AV LAN within the control

processor (see the software or

programming help le for details).

2. Enable DHCP on each client AV device

(see the user guide for each product).

3. Connect client AV devices to the AV LAN.

Page 11

All models (single- or dual-NIC)

Two Single IR Emitters

Source Device

Relay 1

R

PoE+ OUT

Each NIC of the control processor is assigned a unique user hardware ID number (MAC address)

(for example, 00-05-A6-05-1C-A0). You may need this address during control processor

configuration. A label that indicates the MAC address is located on the rear or side panel of the unit.

00-05-A6-XX-XX-XX

MAC: 00-05-A6-XX-XX-XX

S/N: ####### E######

MAC: 00-05-A6-XX-XX-XX

S/N: ####### E######

MAC

Address

Some models, such as the IPCPPro360, offer Power over Ethernet+ (PoE+) output on RJ-45 connectors

labeled “PoE+ Out,” which can output a maximum of 30watts per port. The corresponding Power LED lights

when the port provides power. For details, see the Global Configurator Help file.

ATTENTION:

• Power over Ethernet (PoE) is intended for indoor use only. It is to be connected only to networks or

circuits that are not routed to the outside plant or building.

• L’alimentation via Ethernet (PoE) est destinée à une utilisation en intérieur uniquement. Elle doit

être connectée seulement à des réseaux ou des circuits qui ne sont pas routés au réseau ou au

bâtiment extérieur.

Control, Unidirectional — IR/Serial

IR/Serial Ports

Output options:

• IR (30 kHz to 300 kHz,

with or without carrier signals)

• Unidirectional RS-232

Ground

IR Output Signal

Light when signals are transmitted

on the corresponding IR/serial port.

(-)

(+)

(-)

(-)

(+)

(+)

To the IR Receiver of a

Projector, Display, or

Source Device

To a Projector,

Panel Display, or the

Wired IR Remote or

RS-232 Port of a

Rear Panels Front Panels

1 2

IR/SERIAL

1SG2

SG

IR or RS-232

Output

Ground

or or

SGSG SGSG

SGSG SGSG

5 6

IR/SERIAL

3 4

7 8

or

Unidirectional

IR

G

S

IR/S

1

2

IR/Serial LEDs

PW

IR/SERIAL

2134

5678

Control, Unidirectional — Relays

All relays

are

normally

Rear Panels

1 2

5 6

RELAYS

3 4

7 8

To Room

Control

Equipment

open.

Normally

or

Open (1)

RELAYS

2143CC

Open (2)

Normally

Common

Common

Common

Relay 2

• Connect devices for contact control.

Relays

• Do not exceed a total of 24V at 1A for each port.

Normally

To Room

Control

Equipment

Open

21C

Closed

21C

Front Panels

RELAYS

2134

5678

Relay LEDs

Light when the corresponding relays

are activated (tied to GND, closed).

11

Page 12

IPCP Pro Series • Setup Guide (Continued)

1

Device 1

Control, Unidirectional — Flex I/O or Digital I/O

Rear Panel Front Panel

DIGITAL I/O

1 234G

3214G

FLEX I/O

Heat

Shrink

Over

Shield

Wires

G

4

3

2

Switch,

Sensor

Ground

Wire

Nut

Device 4

Device 3

Device 2

Digital I/O (digital input/output)

Congure each port as a digital input or output,

with or without +5 VDC pull-up.

Use these ports to:

• Monitor or trigger events and functions (toggle relays,

issue commands, send e-mail), once congured.

• Power LEDs or other devices that accept a

TTL signal.

Flex I/O (digital input/output or analog input)

Congure each port as an analog input or as a digital

input or output with or without +5 VDC pull-up.

Share the same ground among

I/O connections.

(Switches, sensors,

LEDs, relays, or

similar items)

I/O

2

314

FLEX

I/O

21

34

Digital I/O

LEDs

Light when the

corresponding

ports are active.

Flex I/O LEDs

Light when the

corresponding

ports are active.

Control — eBUS

eBUS

+V +S -S G

PWR OUT = 6W

Rear Panels,

Rack Mount Models

PWR OUT = 12W

+V +S -S G

eBUS

Drain Wires

+V

+12 VDC

+S

+ Signal

-S

- Signal

G

Ground

eBUS Link LED (green)

Lights solid and remains lit when

the unit detects connected eBUS

devices, there are no ID conicts,

and eBUS rmware is not

currently being synchronized.

eBUS Busy LED (amber)

Blinks while eBUS rmware is

being synchronized.

eBUS Error LED (red)

Blinks if the unit detects an

eBUS ID conict.

eBUS Accessory Port

Connect the rst eBUS device to this port, then connect other

eBUS devices and accessories to that device in the desired

topology (daisy chain, star, or combination).

• Wire the connectors the same at both ends for every eBUS

device.

• See the eBUS Technology Reference Guide for the

recommended distance from the control processor to the

last eBUS device.

• The IPCP Pro can provide power to the button panel devices.

eBUS port

on an

eBUS device

(button

panel or

similar

device)

ON

DISPLAY

VOLUME

VIDEO

VOLUME

MUTE

OFF

PC

LAPTOP

DOC CAM

PC

DVD

VIDEO

eBUS

LINK

LIMIT

BUSY

ERROR

OVER

Front Panels,

Rack Mount Models

eBUS

SLIMIT

OVER

eBUS Limit LED

(amber)

Lights solid and remains

lit while the eBUS port

uses the maximum

threshold power.

eBUS Overload LED

(red)

Lights solid when the

eBUS port exceeds

maximum threshold

power usage and enters

the fault state.

During this fault state,

eBUS port power is

shut down until the

power usage falls back

below the threshold.

The Over LED remains

lit during the fault state.

eBUS Status LED (green)

LED is not lit — This indicates one of the following

conditions:

• No power is present.

• No eBUS devices are detected.

LED is blinking fast — An eBUS ID conict has

occurred: two devices have the same bus ID number.

LED is blinking slowly — A rmware update is in

progress: the control processor is synchronizing

rmware of the eBUS panel(s).

LED is lit solid — Power is present with conrmed

communication and there are no eBUS ID conicts

in the entire system.

12

Page 13

Tie drain wires to ground.

EBDB MINI

Reference voltage

V

Rear Panel

(or use

an EBDB

10-port hub)

eBUS DISTRIBUTION HUB

+

V G-S+S+V G-S+S+V G-S+S

• Connect up to four (4) eBUS devices to the

eBUS Connections

EBDB Mini eBUS Distribution Hub.

• Wire the connectors the same at both ends.

ATTENTIO N: Do NOT

connect the powe r pi n

to any device that is

already powered by the

IPCP Pro control

processor or by an

additional power supply.

Control — Volume

Rear Panel

VOL

VCG

Ground (Gnd)

G

Control voltage (variable output to amp from IPCP Pro) – This signal controls the amp volume.

C

Reference voltage input (from amplier) – This allows the IPCP Pro to detect when the amp is present.

V

X

Powered

eBUS

device(s)

Reference

voltage: ≤10 VDC

VCG

Control voltage output:

0 - 10 VDC

+V

G-S+S

G-S+S

eBUS

PWR OUT = 6W

+V

3/16" (5 mm) Max.

-S+V +S G

G-S+S

G-S+S

G-S+S

+V

+12 VDC

+V

+S

+ Signal

-

S

-

Signal

G

Ground

IPCP Pro

Rear Panel

Volume Control

This port can be used to control the volume and mute or

unmute the audio for Extron half rack width audio ampliers.

• Connect to an Extron audio amplier to permit volume

control via touchpanel controls, macros, or schedules.

• Do not exceed 10 VDC input voltage.

Congure the maximum and minimum voltage limits. Set

Soft Start mode off or on (default). Soft Start mode allows

volume to gradually increase from mute to the previous level

after muting or power-on to prevent loud audio bursts.

+

V

+

S G

–

S

Tie drain wires to ground.

eBUS port on an

EBP or other

eBUS endpoint

device

NOTE:

Use shielded

cable and place the

control processor as

close as possible to

the amplier to avoid

picking up background

noise via the cable.

Ideal cable length is

six feet (1.8 m) or less.

Example:

Connecting to

Extron Amplifiers

VOL

VCG

IPCP Pro

Rear

Panel

Ground

G

Control voltage

C

XPA 1002

10V 50mA

G

GCV

MPA 401 Series

REMOTE

10V 50mA

STANDBY

10V 50mA

MPA 181T,

MP 101 Series

REMOTE

10V

VOL/MUTE

GCV

MPA 152MPA 152 Plus

REMOTE

GCV

C or

VOL/MUTE

10V 50mA

VOL/MUTE

V or 10V G or

NOTE: When audio mute is active,

the control processor sets output

voltage to

0 VDC, even if the

voltage range (minimum and

maximum voltage limits) has been

set to levels above zero, such as

2 V to 8 V.

13

Page 14

IPCP Pro Series • Setup Guide (Continued)

Reset Modes: a Brief Summary

The IP Link Pro control processors offer the following reset modes:

• Use Factory Firmware: Press and hold the front panel Reset button while applying power to the unit. Hold the button

down until the Power LED flashes twice, or for 6 seconds, then release the button. The control

processor enters factory firmware mode. For units with firmware prior to version 2.x, the LED

flashes quickly. Use this mode to revert to factory firmware in the event of a firmware failure.

• Project Recovery: See the IPCP Pro Series User Guide for instructions. Use this mode to recover the project in the

event of a lost user name and password.

• Reset All IP Settings: Press and hold the front panel Reset button for 6 seconds. After the Power LED flashes twice,

release and momentarily press the Reset button. Use this mode to reset all network settings to

factory default values without affecting user-loaded files.

• Reset to Factory Defaults: Press and hold the front panel Reset button for 9 seconds. After the Power LED flashes three

times, release and momentarily press the Reset button. Use this mode to return the control

processor to factory default settings.

For detailed information on each mode and its use, see the IPCP Pro Series User Guide at www.extron.com.

Resources

Obtaining Control Drivers

Extron provides an extensive selection of device drivers available on the Extron website. If the system requires a control driver

that is not already available, you have additional options:

• Request a new serial (RS-232) or Ethernet driver from Extron.

• Create your own custom IR device driver using IRLearnerPro software. Follow the directions in the IRLearnerPro Help file

to create a driver by using the remote control for that device and the IR receiver port on the front panel of the IPCPPro.

Obtaining Instructions, Information, and Assistance

A checklist of basic setup steps is provided at the beginning of this guide. For additional information see the help files and the

IPCPProSeries User Guide, available at www.extron.com.

If you have questions during installation and setup, call the ExtronS3 Sales & Technical Support Hotline or the ExtronS3

Control Systems Support Hotline (1.800.633.9877).

Locating Software, Firmware, and Driver Files on the Extron Website

There are three main ways to find software, firmware, and device drivers within www.extron.com:

• Via links from the web page for the specific product

• Via the Download Center page (Click on the Download tab at the top of any page within www.extron.com.)

• Via links from search results

NOTES:

• For some software you have the option to click the Download Now button to begin downloading the software file. For other

software there is a link for contacting an Extron support representative who can provide you access to the latest version.

To obtain Global Configurator (GCProfessional, GC Plus) software, you must have an Extron Insider account and

contact an Extron support representative. Extron provides training to our customers on how to use the software.

Access to Global Configurator Professional is available to users who successfully complete Extron Control Professional

Certification.

• New RS-232 and Ethernet drivers are required. You must use serial and Ethernet drivers developed specifically

for the IPLinkPro platform. With the exception of IR device drivers, drivers used for the previous generation

IPLink (non-Pro) control processors are not compatible.

14

Page 15

This page was intentionally left blank.

15

Page 16

IPCP Pro Series • Setup Guide (Continued)

Overall Configuration Procedure for the Control Processor

Within Global Configurator

(GC Professional or

GC Plus mode):

Configure the IP settings of

the control processor and the

TouchLink Pro touchpanels.

If desired or required, install a new

security certicate (via Toolbelt).

Create a new GC Professional or GC Plus project

and add the control processor to it.

Will

TouchLink Pro or

No Yes

third party touchpanels or

other user interfaces

be used?

Create GUI layouts for the

touchpanels or other interfaces:

1. Start GUI Designer.

2. Create GUI layout designs for each

TouchLink Pro, third party

touchpanel (with a TouchLink

Interface), or a computer or

mobile device (with LinkLicense).

3. Save and build the GUI layout le.

Or...

Download existing GUI layouts

from identical touchpanels.

See Network

Communication Setup

Communication Setup

Network

in this guide.

Congure ports on the

control processor.

Create monitors, schedules, timers,

macros, and local variables.

Add touchpanels or other interfaces

(if used) to the project.

Import GUI layouts and congure the

touchpanels or other interfaces.

Save the project.

Build and upload the conguration to

the control processor.

Test the system, make adjustments,

nalize conguration.

Figure 6. Overall Configuration Steps

If you have questions during installation and setup, you can call the Extron S3 Sales & Technical Support Hotline

or the Extron S3 Control Systems Support Hotline (1.800.633.9877).

Extron Headquarters

+1.800.633.9876 (Inside USA/Canada Only)

Extron USA - West Extron USA - East

+1.714.491.1500 +1.919.850.1000

+1.714.491.1517 FAX +1.919.850.1001 FAX

16

© 2017 Extron Electronics All rights reserved. All trademarks mentioned are the property of their respective owners. www.extron.com

Extron Europe

+800.3987.6673

(Inside Europe Only)

+31.33.453.4040

+31.33.453.4050 FAX

Extron Asia

+65.6383.4400

+65.6383.4664 FAX

Extron Japan

+81.3.3511.7655

+81.3.3511.7656 FAX

Extron China

+86.21.3760.1568

+86.21.3760.1566 FAX

Extron Middle East

+971.4.299.1800

+971.4.299.1880 FAX

Extron Australia

+61.8.8113.6800

+61.8.8351.2511 FAX

68-2438-50

Rev. D

06 17

Extron India

1800.3070.3777

(Inside India Only)

+91.80.3055.3777

+91.80.3055.3737 FAX

Loading...

Loading...