User's Guide

Visit us at www.TestEquipmentDepot.com

200A Mini Clamp + DMM

Model 380941

• Large 3 3/4 digit LCD display with 40 segment bargraph

• Continuity and Frequency Measurements

• One touch DCA zero adjust

• MIN/MAX and Data Hold functions

• 0.9” (23mm) Jaw diameter

99 Washington Street

Melrose, MA 02176

Fax 781-665-0780

TestEquipmentDepot.com

Introduction

Congratulations on your purchase of Extech’s DC/AC Clamp Meter. This professional meter,

with proper care, will provide years of safe reliable service.

Specifications

General Specifications

Display 3-3/4 (4000 count) Digit LCD with 40 segment bargraph

Functions ACA, DCA, ACV, DCV, Resistance, Frequency, Continuity

Polarity “-“ indicates negative polarity

Current sensor Hall effect sensor type

Overload indication Left blinking digit

DCA zero adjust One touch zero key

Display rate 2 readings/second (20 readings/second for bargraph)

Battery Two 1.5V AA batteries

Operating temp. 40F to 1220F (-100C to 500C)

Operating Humidity < 85% RH

Power consumption Approximately 10mA DC

Weight 8 oz. (225g) including battery

Dimensions 7 x 1.75 x 1.25” (178 x 45 x 32mm) (HWD)

Jaw opening 0.9” (23mm)

Standards IEC 1010 Category III 300V, Category II 600V

Range Specifications

Function Range Resolution. Accuracy Overload

DC Current

AC Current

DC Voltage 400V 0.1V ±(1.0% +2dgts) 1000VDC

Resistance

Frequency 100 to 10k 0.01Hz ±0.5% ±2dgts Sensitivity;

40A 10mA ±(1.0% +2dgts) 400A DC

0 to 150A 100mA ±(1.0% +2dgts) 400A DC

150 to 200A 100mA ±(2.2% +2dgts) 400A DC

50/60Hz 40 to 400Hz

40A 10mA ±(1.0% +3dgts) ±(1.5% +4dgts) 400A AC

0 to 150A 100mA ±(1.0% +3dgts) ±(1.5% +4dgts) 400A AC

150 to 200A 100mA ±(2.2% +3dgts) ±(2.5% ±4dgts) 400A AC

50/60Hz 40 to 400Hz AC Voltage

400V 0.1V ±(1.5% +2dgts) ±(2.0% +4dgts) 800V AC

40 to 400Ω

0.1 ±(1.0% +2dgts)

2

Beep <38Ω

2V, 0.1A AC

380941 Ver. 2.2 03/05

protect

600V AC

600V AC

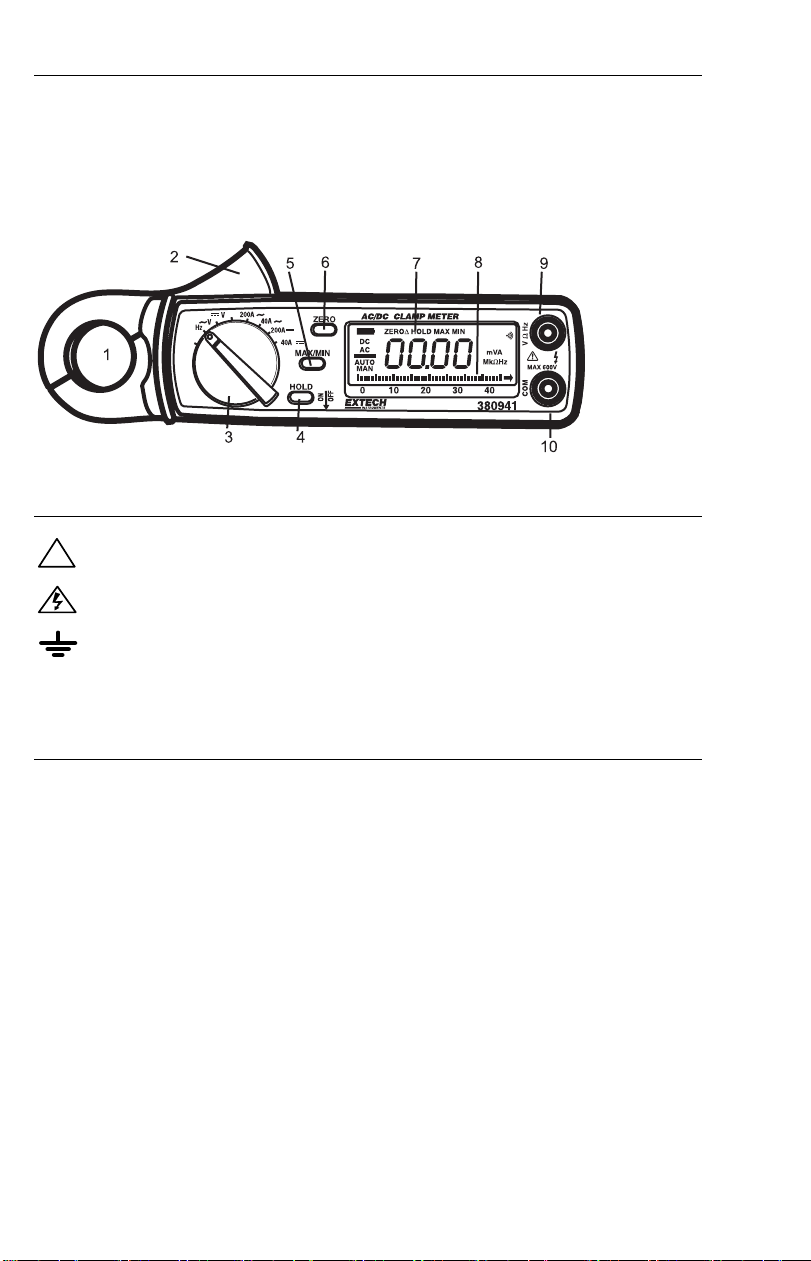

Front Panel Description

1. Current sense jaw

2. Measurement Trigger

3. Function switch

4. Data Hold key

5. Max Min key

6. One-touch DCA zero key

7. LCD Display

8. 40 segment bargraph display

9. Positive input terminal for V, HZ and Ω

10. COM terminal

International Symbols

Caution ! Refer to the explanation in this Manual

!

Caution ! Risk of electric shock

Earth (Ground)

Safety

This meter has been designed to be safe in use, but the operator must use caution in its

operation. The rules listed below should be carefully followed for safe operation.

1. NEVER apply voltage or current to the meter that exceeds the specified maximum:

2. USE EXTREME CAUTION when working with high voltages.

3. DO NOT measure voltage if the voltage on the "COM" input jack exceeds 500V above

earth ground.

4. NEVER connect the meter leads across a voltage source while the function switch is in

the current, resistance or diode mode. Doing so can damage the meter.

5. ALWAYS discharge filter capacitors in power supplies and disconnect the power when

making resistance or diode tests.

6. ALWAYS turn off the power and disconnect the test leads before opening the back to

replace the fuse or batteries.

7. NEVER operate the meter unless the back cover and the battery/fuse door are in pla ce

and fastened securely.

3

380941 Ver. 2.2 03/05

Test Equipment Depot - 800.517.8431 - 99 Washington Street Melrose, MA 02176

FAX 781.665.0780 - TestEquipmentDepot.com

Operation

AC Current Measurements

WARNING: To avoid electric shock, disconnect the test leads from the meter before

making current measurements.

1) Set the Function switch to the 40 or 200A AC range.

2) Press the jaw trigger and clamp around, fully enclosing a single conductor. Do not

allow a gap between the two halves of the jaw.

3) Read the ACA value on the LCD.

DC Current Measurements

WARNING: To avoid electric shock, disconnect the test leads from the meter before

making current measurements.

1) Set the Function switch to the 40 or 200A DC range.

2) Press the DCA zero key to null the meter display.

3) Press the Trigger to open the current sense Jaw.

4) Fully enclose the conductor to be measured. Do not allow a gap between the two

halves of the jaw.

5) Read the DCA value on the LCD.

AC Voltage Measurements

WARNING: To avoid electric shock or damage to the meter, do not make any voltage

measurements that exceed the maximum specified.

1) Set the Function switch to the VAC position.

2) Insert the test leads to the meter as follows: Red lead to “V,Hz,Ω” terminal; Black

lead to the COM input.

3) With the pointed end of the test le ads measure voltage. Remember that voltage

measurements are made in parallel with the device or circuit under test.

4) Read the ACV value on the LCD.

DC Voltage Measurements

WARNING: To avoid electric shock or damage to the meter, do not make any voltage

measurements that exceed the maximum specified.

1) Set the Function switch to the VDC position.

2) Insert the test leads to the meter as follows: Red lead to “V,Hz,Ω” terminal; Black

lead to the COM input.

3) With the pointed end of the test le ads measure voltage. Remember that voltage

measurements are made in parallel with the device or circuit under test.

4) Read the DCV value on the LCD.

Resistance and Continuity Measurements

WARNING: To avoid electric shock or damage to the meter, remove power to the circuit

under test and discharge all capacitors.

1) Set the Function switch to the Ω position.

2) Insert the test leads to the meter as follows: Red lead to “V,Hz,Ω” terminal; Black

lead to the COM input.

3) With the pointed end of the test le ads measure resistance. Remember that

resistance measurements are made in parallel with the device or circuit under test.

4) Read the resistance value on the LCD.

5) If the resistance is less than 40Ω, the continuity beeper will sound.

4

380941 Ver. 2.2 03/05

Frequency Measurements

1) Ensure that at least 0.1A AC is detectable with an ACA measurement before

measuring Frequency.

2) Set the Function switch to the Hz position.

3) Press the Trigger to open the Jaw and fully enclose the conductor to be measured. If

line frequency is being measured, enclose only one line of the source (ensure first

that there is current present).

4) Read the Frequency measurement on the LCD in Hz.

Special Features

Relative Measurements

1) Press the Zero key and the present measurement will Zero.

2) All subsequent measurements are displayed with respect to the zeroed reading. For

example, if a 20A reading is zeroed and a 30A reading is subsequently measured,

the LCD will display 10A.

3) To return to normal operation, press and hold the zero key for 2 seconds.

4) Note that Relative mode is not available if MIN/MAX mode is enabled.

Data Hold

To freeze the current reading on the LCD, press the Data Hold key. To release the Data

Hold function and return the meter to normal operation, press the Data Hold key again.

MIN/MAX Readings

Pressing the MIN/MAX key allows the meter to display ONLY the highest and the lowest

readings encountered. Press the MIN/MAX key once to view the minimum reading,

press it again to view the maximum reading. Note that the meter will only change its

displayed reading when a measurement is taken higher than the previous MAX or lower

than the previous MIN readings. The HOLD display icon (along with the MIN or MAX

icon) will appear on the LCD in MIN/MAX mode Pressing the MIN/MAX key a 3

returns the meter to normal operation.

rd

time

Back to the Extech 380941 Product Page

Visit us at www.TestEquipmentDepot.com

5

380941 Ver. 2.2 03/05

Test Equipment Depot - 800.517.8431 - 99 Washington Street Melrose, MA 02176

FAX 781.665.0780 - TestEquipmentDepot.com

Loading...

Loading...