Page 1

User's Guide

Mini Multimeter

with Non-Contact Voltage Detector (NCV)

Model EX320

Page 2

Introduction

Congratulations on your purchase of the Extech 320 MultiMeter. The EX320 offers AC/DC

Voltage, AC/DC Current, Resistance, Diode, and Continuity testing plus a built-in non-contact

Voltage Detector. Proper use and care of this meter will provide many years of reliable

service.

Safety

This symbol adjacent to another symbol, terminal or operating device

indicates that the operator must refer to an explanation in the Operating

Instructions to avoid personal injury or damage to the meter.

WARNING

CAUTION

MAX

600V

SAFETY INSTRUCTIONS

This meter has been designed for safe use, but must be operated with caution. The rules

listed below must be carefully followed for safe operation.

1. NEVER apply voltage or current to the meter that exceeds the specified maximum:

Function Maximum Input

V DC or V AC 600V AC and DC

mA AC/DC 200mA DC/AC

A AC/DC 10A DC/AC (for 30 seconds max. every 15 minutes

Resistance, Diode Test, Continuity 250V DC/AC

2. USE EXTREME CAUTION when working with high voltages.

3. DO NOT measure voltage if the voltage on the "COM" input jack exceeds 600V above earth ground.

4. NEVER connect the meter leads across a voltage source while the function switch is in the current,

resistance, or diode mode. Doing so can damage the meter.

5. ALWAYS discharge filter capacitors in power supplies and disconnect the power when making resistance

or diode tests.

6. ALWAYS turn off power and disconnect test leads before opening the covers to replace the fuse or battery.

7. NEVER operate the meter unless the back cover and the battery and fuse covers are in place and fastened

securely.

8. If the equipment is used in a manner not specified by the manufacturer, the protection provided by the

equipment may be impaired.

This WARNING symbol indicates a potentially hazardous situation, which

if not avoided, could result in death or serious injury.

This CAUTION symbol indicates a potentially hazardous situation, which

if not avoided, may result damage to the product.

This symbol advises the user that the terminal(s) so marked must not be

connected to a circuit point at which the voltage with respect to earth

ground exceeds 600V.

This symbol adjacent to one or more terminals identifies them as being

associated with ranges that may, in normal use, be subjected to

particularly hazardous voltages. For maximum safety, the meter and its

test leads should not be handled when these terminals are energized.

This symbol indicates that a device is protected throughout by double

insulation or reinforced insulation.

Input Protection Limits

Model EX320 - Version 4.0 –05/2006 2

Page 3

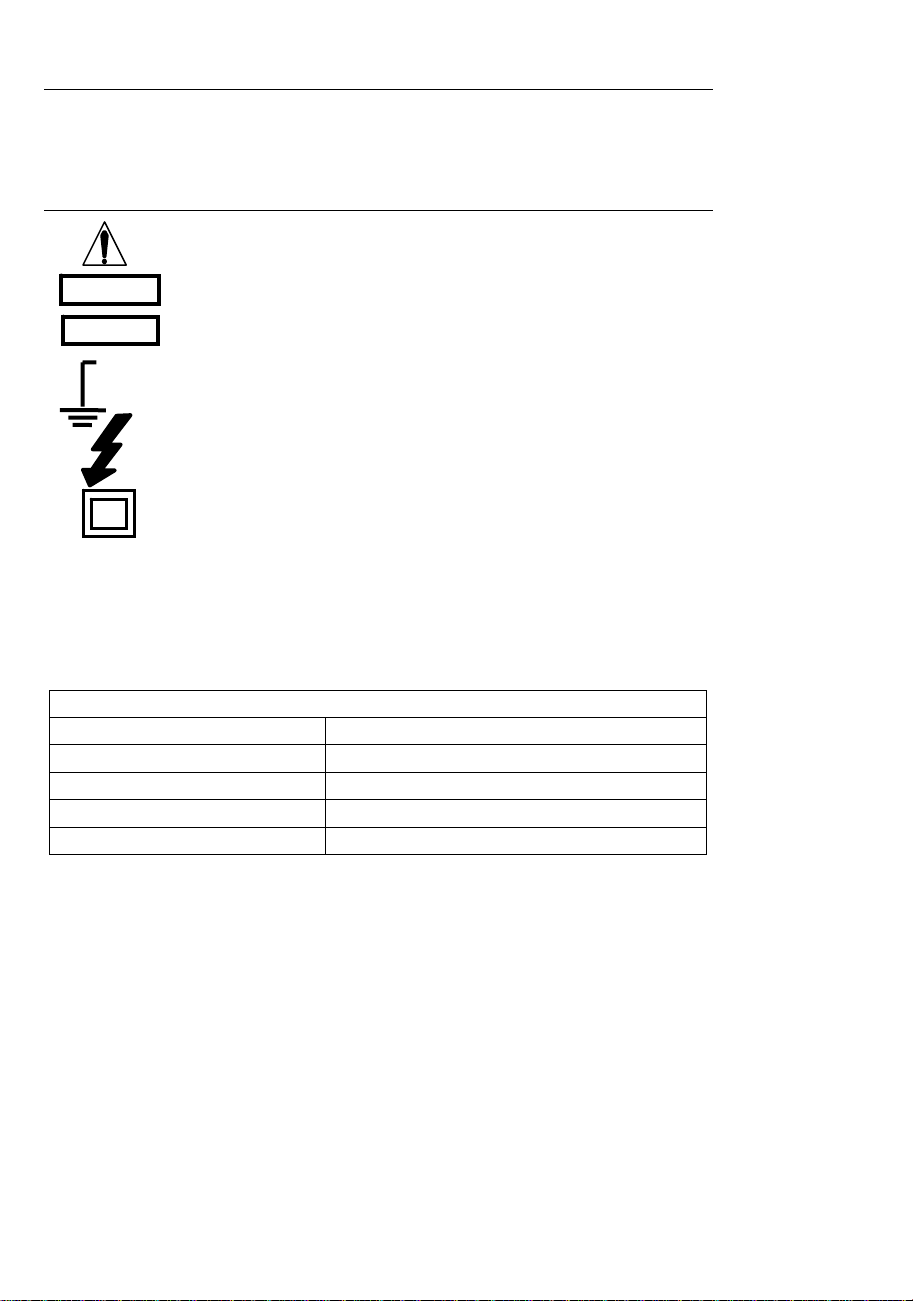

Controls and Jacks

1. AC Voltage Detector Sensor

2. AC Voltage Detector indicator light

3. LCD display

4. MAX push-button

5. MODE button

6. Non-contact AC Voltage Detector test

button

7. Rotary function dial

8. 10 ampere test lead jack

9. COM test lead jack

10. Test lead jack for voltage, milli-amp, microamp, & resistance functions

11. RANGE button

12. HOLD button

13. Protective rubber holster (must be

removed to access the rear battery

compartment)

Display Symbols and Annunciators

•))) Continuity

Diode test

Battery status

µ micro (10

m milli (10-3) (volts, amps)

k kilo (10

M mega (10

V Volts

A Amps

Ω Ohms

AC Alternating current

DC Direct current

HOLD Display hold

AUTO Autoranging

MAX Highest reading

C, F Temperature units

-6

) (amps)

3

) (ohms)

6

) (ohms)

1

2

3

4

5

13

12

11

6

7

10A

for

30sec.

8

MAX

every

15min.

FUSED

10

9

Model EX320 - Version 4.0 –05/2006 3

Page 4

Operating Instructions

WARNING: Risk of electrocution. High-voltage circuits, both AC and DC, are very

dangerous and should be measured with great care.

1. ALWAYS turn the function switch to the OFF position when the meter is not in use.

2. Press the HOLD button to freeze a displayed reading

NOTE: On some low AC and DC voltage ranges, with the test leads not connected to a

device, the display may show a random, changing reading. This is normal and is caused

by the high-input sensitivity. The reading will stabilize and give a proper measurement

when connected to a circuit.

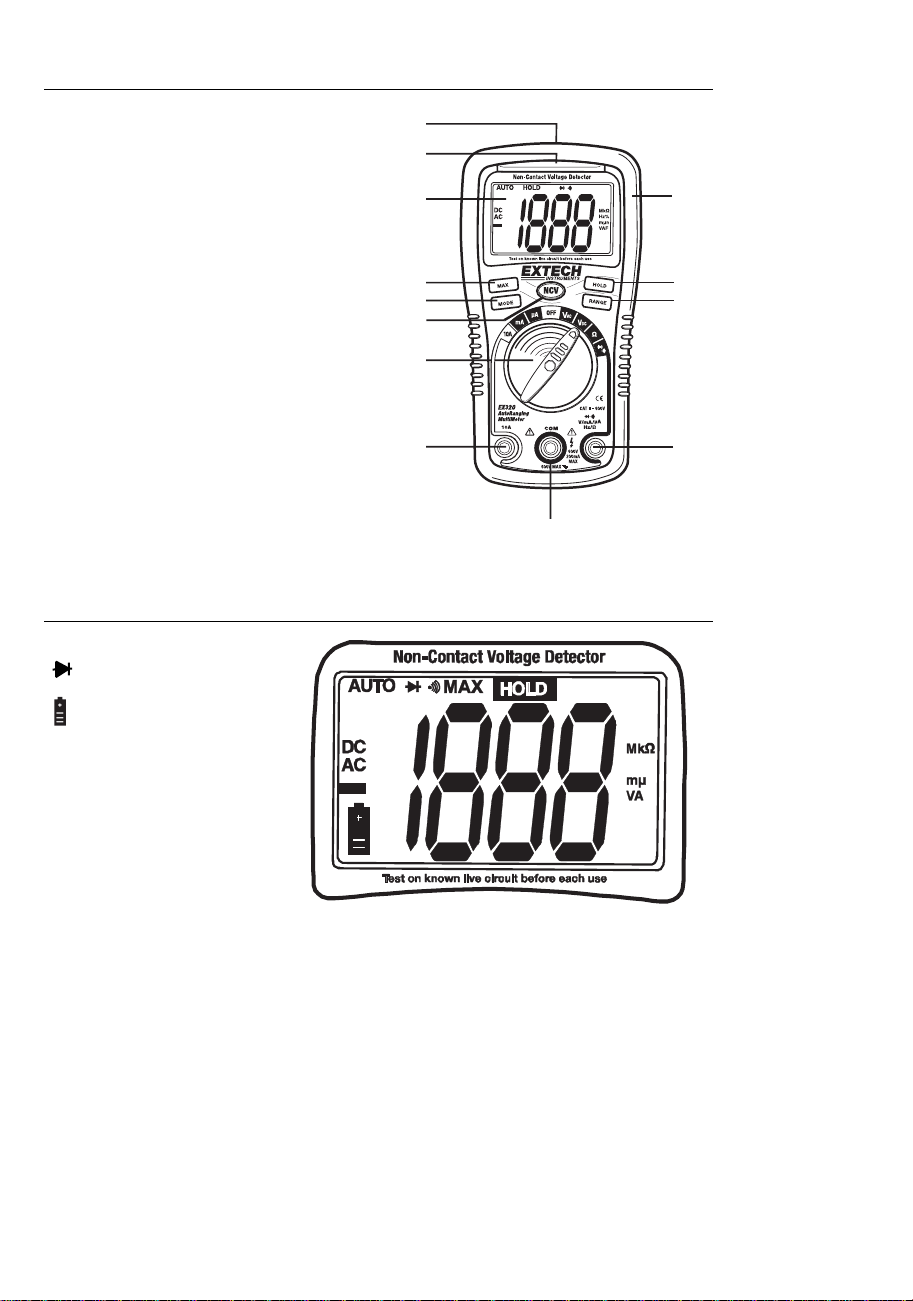

NON-CONTACT AC VOLTAGE DETECTOR

The EX320 can detect the presence of AC voltage (from 100 to 600VAC) simply by being

held very near to a voltage source.

WARNING: Test the AC voltage detector on a known live circuit before each use.

WARNING: Before using the meter in the AC Voltage Detector mode, verify that the battery

is fresh by confirming characters appear on the LCD when the function dial is turned to any

position. Do not attempt to use the meter as an AC Voltage Detector if the battery is weak

or bad.

NON-CONTACT VOLTAGE (NCV)

The NCV function works on any rotary switch position.

1. Test the detector on a known live circuit before use.

2. Press and hold the NCV button for the duration of the test.

The meter will beep once when the button is pushed.

3. Hold the top of the meter very close to the voltage source

as shown.

4. If voltage is present, the rim of the LCD display will flash a

bright orange and an audible warning will sound.

Model EX320 - Version 4.0 –05/2006 4

Page 5

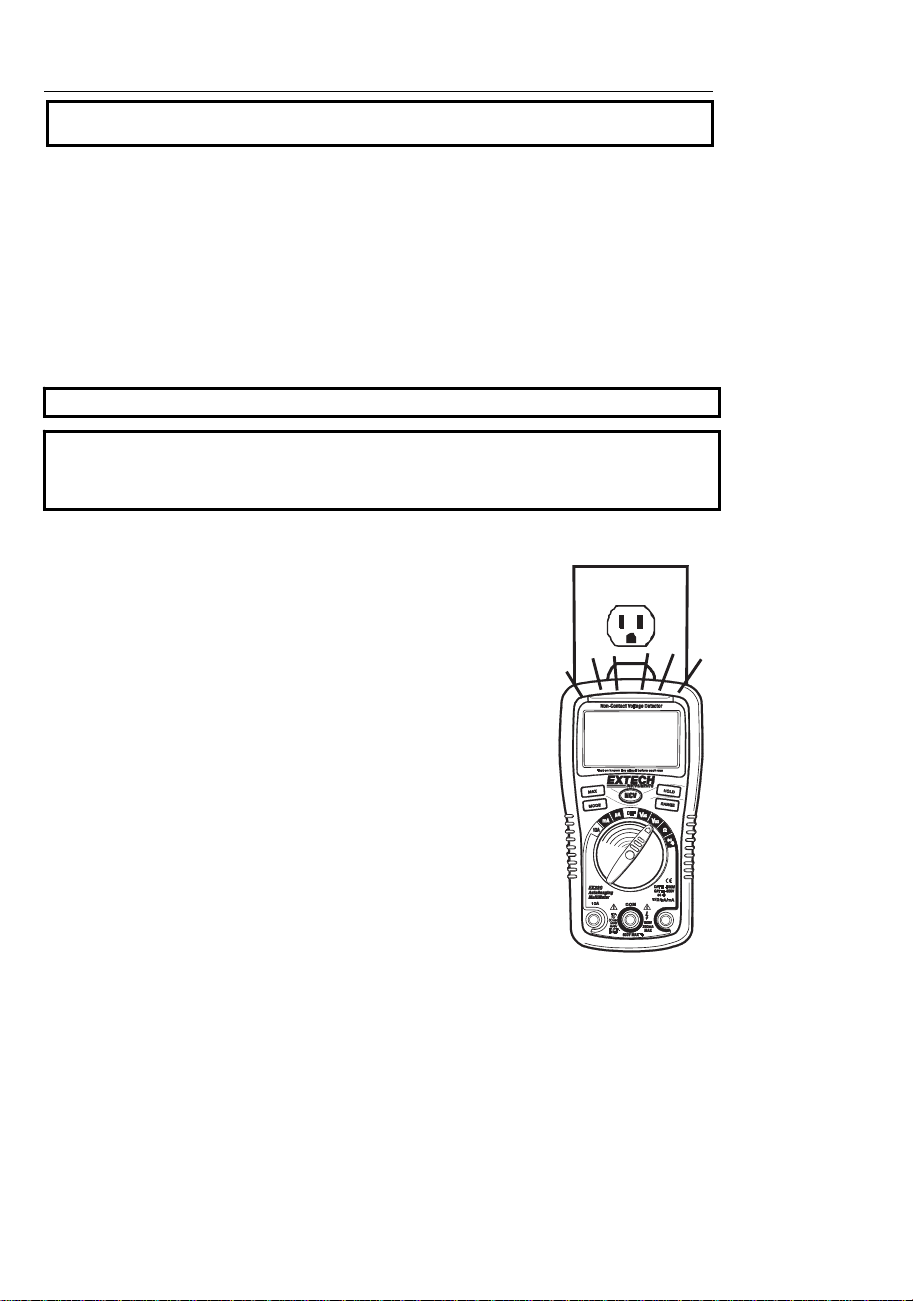

AC VOLTAGE MEASUREMENTS

WARNING: Risk of Electrocution. The probe tips may

not be long enough to contact the live parts inside

some 240V outlets for appliances because the contacts

are recessed deep in the outlets. As a result, the

reading may show 0 volts when the outlet actually has

voltage on it. Make sure the probe tips are touching the

metal contacts inside the outlet before assuming that

no voltage is present.

CAUTION: Do not measure AC voltages if a motor on

the circuit is being switched ON or OFF. Large voltage

surges may occur that can damage the meter.

1. Set the function switch to the VAC position.

2. Insert the black test lead banana plug into the

negative COM jack. Insert the red test lead

banana plug into the positive V jack.

3. Touch the black test probe tip to the neutral

side of the circuit.

4. Touch the red test probe tip to the “hot” side of

circuit.

5. Read the voltage in the display.

DC VOLTAGE MEASUREMENTS

CAUTION: Do not measure DC voltages if a motor on the circuit is being switched ON or

OFF. Large voltage surges may occur that can damage the meter.

1. Set the function switch to the VDC position.

2. Insert the black test lead banana plug into the

negative COM jack. Insert the red test lead

banana plug into the positive V jack.

3. Touch the black test probe tip to the negative

side of the circuit. Touch the red test probe tip to

the positive side of the circuit.

4. Read the voltage in the display.

Model EX320 - Version 4.0 –05/2006 5

Page 6

AC / DC CURRENT MEASUREMENTS

CAUTION: Do not make current measurements at 10 Amps for longer than 30 seconds.

Exceeding 30 seconds may cause damage to the meter and/or the test leads.

1. Insert the black test lead banana plug into the negative COM jack.

2. For current measurements up to 2000µA, set the function switch to the µA position

and insert the red test lead banana plug into the mA/µA jack

3. For current measurements up to 200mA, set the function switch to the mA position

and insert the red test lead banana plug into the mA/µA jack.

4. For current measurements up to 10A, set the function switch to the 10A range and

insert the red test lead banana plug into the 10A jack.

5. Use the MODE button to select AC or DC current.

6. Remove power from the circuit under test, then open up the circuit at the point

where you wish to measure current.

7. Touch the black test probe tip to the negative side of the circuit. Touch the red test

probe tip to the positive side of the circuit.

8. Apply power to the circuit.

9. Read the current in the display.

Model EX320 - Version 4.0 –05/2006 6

Page 7

RESISTANCE MEASUREMENTS

WARNING: To avoid electric shock, disconnect power

to the unit under test and discharge all capacitors

before taking any resistance measurements. Remove

the batteries and unplug the line cords.

1. Set the function switch to the Ω position.

2. Insert the black test lead banana plug into the

negative COM jack. Insert the red test lead

banana plug into the positive Ω jack.

3. Touch the test probe tips across the circuit or

component under test. It is best to disconnect

one side of the circuit under test so the rest of

the circuit will not interfere with the resistance

reading.

4. Read the resistance in the display.

CONTINUITY CHECK

WARNING: To avoid electric shock, never measure continuity on circuits or wires that

have voltage on them.

1. Set the function switch to the

position.

2. Insert the black lead banana plug into the

negative COM jack.

3. Insert the red test lead banana plug into

the positive jack.

4. Use the MODE button to view the icon

on the display.

5. Touch the test probe tips to the circuit or

wire under test.

6. If the resistance is less than

approximately 100Ω, the audible signal

will sound. If the circuit is ‘open’ (bad), the

display will indicate “OL”.

Model EX320 - Version 4.0 –05/2006 7

Page 8

DIODE TEST

1. Set the function switch to the position.

2. Insert the black test lead banana plug into the

negative COM jack and the red test lead

banana plug into the positive jack.

3. Use the MODE button to view the icon on

the display.

4. Touch the test probes to the diode under test.

Forward voltage will typically indicate 0.400 to

0.700V. Reverse voltage will indicate “OL”.

Shorted devices will indicate near 0V and an

AUTO-MANUAL RANGE SELECTION

MAX MODE

open device will indicate “OL” in both polarities.

When the meter is first turned on, it automatically goes into the Auto Range mode. This

automatically selects the best range for the measurements being made and is generally

the best mode for most measurements. For measurement situations requiring that a range

be manually selected, perform the following:

1. Press the RANGE key. The AUTO display indicator will turn off.

2. Press RANGE to step through the available ranges until the desired range is

selected.

3. To exit the Manual Ranging mode and return to Auto Range mode, press and hold

the RANGE key for 2 seconds.

Press the MAX button (the MAX icon will appear on the LCD). The meter will now only

display the highest reading during a test. Each time a higher reading is encountered, the

display will update. Press the MAX button again to exit this mode.

Model EX320 - Version 4.0 –05/2006 8

Page 9

Maintenance

WARNING: To avoid electric shock, disconnect the test leads from any source of voltage

before removing the back cover or the battery or fuse covers.

WARNING: To avoid electric shock, do not operate your meter until the battery and fuse

covers are in place and fastened securely.

This MultiMeter is designed to provide years of dependable service, if the following care

instructions are performed:

1. KEEP THE METER DRY. If it gets wet, dry it immediately.

2. USE AND STORE THE METER IN NORMAL TEMPERATURES. Temperature

extremes can shorten the life of the electronic parts and distort or melt plastic parts.

3. HANDLE THE METER GENTLY AND CAREFULLY. Dropping it can damage the

electronic parts or the case.

4. KEEP THE METER CLEAN. Wipe the case occasionally with a damp cloth. DO

NOT use chemicals, cleaning solvents, or detergents.

5. USE ONLY FRESH BATTERIES OF THE RECOMMENDED SIZE AND TYPE.

Remove old or weak batteries so they do not leak and damage the unit.

6. IF THE METER IS TO BE STORED FOR A LONG PERIOD OF TIME, the battery

UL LISTED

The UL mark does not indicate that this product has been evaluated for its accuracy.

AUTO POWER OFF

The meter will automatically turn off after 15 minutes of inactivity. This will conserve battery

energy. To turn the meter on after an Auto Power OFF, simply turn the rotary switch to OFF

and then back to the desired setting.

should be removed to prevent damage to the unit.

Model EX320 - Version 4.0 –05/2006 9

Page 10

BATTERY INSTALLATION and LOW BATTERY INDICATION

WARNING: To avoid electric shock, disconnect the test leads from any source of voltage

before removing the battery cover.

LOW BATTERY INDICATION

The icon will appear in the lower left-hand corner of the display when the battery

voltage becomes low. Replace the batteries when this appears.

BATTERY REPLACEMENT

1. Disconnect the test leads from the meter.

2. Remove the protective rubber holster. See diagram.

3. Remove the Phillips head screw located on the lower back of the instrument.

4. Flip up the fuse/battery compartment cover to access the batteries. See diagram.

5. Gently remove batteries and install two new 1.5V ‘AAA’ batteries observing polarity.

6. Secure the fuse/battery compartment cover.

7. Place the protective rubber holster on the meter.

1. Removable Rubber Holster

2. Meter

3. Battery

4. Fuses

5. Compartment Cover

6. Rubber Holster

WARNING: To avoid electric shock, do not operate the meter until the battery is in place

and fastened securely.

REPLACING THE FUSES

WARNING: To avoid electric shock, disconnect the test leads from any source of voltage

before removing the fuse cover.

1. Disconnect the test leads from the meter.

2. Remove the protective rubber holster.

3. Remove the Phillips head screw located on the lower back of the instrument.

4. Flip up the fuse/battery compartment cover to access the fuses.

5. Gently remove the fuse(s) and install new fuse(s) into the holder(s).

6. Always use fuses of the proper size and value (200mA/250V fast blow for the mA /

µA ranges, 10A/250V fast blow for the A range).

7. Secure the fuse/battery compartment cover.

8. Place the protective rubber holster on the meter.

WARNING: To avoid electric shock, do not operate your meter until the fuse cover is in

place and fastened securely.

Model EX320 - Version 4.0 –05/2006 10

Page 11

Range Specifications

Function Range Resolution Accuracy

Non-contact AC

Voltage detector

DC Voltage

(V DC)

AC Voltage

(V AC)

(50/60Hz)

DC Current

(A DC)

AC Current

(A AC)

(50/60Hz)

Resistance

Notes:

Accuracy specifications consist of two elements:

• (% reading) – This is the accuracy of the measurement circuit.

• (+ digits) – This is the accuracy of the analog to digital converter.

Accuracy is stated at 65

100 to 600V Resolution & accuracy do not apply since the meter does

not display the voltage in this mode. The lamp at the top of

the meter’s display flashes when voltage is sensed and an

audible warning will sound.

200mV 0.1mV

±(0.5% reading + 2 digits)

2V 0.001V

20V 0.01V

±(1.0% reading + 2 digits)

200V 0.1V

600V 1V

200mV 0.1mV

±(1.5% reading + 2 digits)

±(1.0% reading + 30 digits)

2V 0.001mV

20V 0.01V

±(1.5% reading + 3 digits)

200V 0.1V

600V 1V

±(2.0% reading + 4 digits

200µA 0.1µA ±(1.0% reading + 3 digits)

2000µA 1µA

20mA 0.01mA

±(1.5% reading + 3 digits)

200mA 0.1mA

2A 0.001A

10A 0.01A

±(2.5% reading + 5 digits)

200µA 0.1µA ±(1.5% reading + 5 digits)

2000µA 1µA

20mA 0.01mA

±(1.8% reading + 5 digits)

200mA 0.1mA

2A 0.001A

10A 0.01A

±(3.0% reading + 7 digits)

200Ω 0.1Ω ±(1.2% reading + 4 digits)

2kΩ 1Ω

20kΩ 0.01kΩ

200kΩ 0.1kΩ

±(1.2% reading + 2 digits)

2MΩ 0.001MΩ

20MΩ 0.01MΩ ±(2.0% reading + 3 digits)

o

F to 83oF (18oC to 28oC) and less than 75% RH.

Model EX320 - Version 4.0 –05/2006 11

Page 12

General Specifications

Diode Test Test current of 0.3mA maximum, open circuit voltage 1.5V DC

Continuity Check Audible signal will sound if the resistance is less than 100Ω

Input Impedance 10MΩ (VDC & VAC)

AC Bandwidth 50 / 60Hz

Display 2000 count (0 to 1999) backlit LCD

Over-range indication “OL” is displayed

Auto Power Off After 15 minutes (approximately) of inactivity

Polarity Automatic (no indication for positive); Minus (-) sign for

Measurement Rate 2 times per second, nominal

Low Battery Indication “ ” is displayed if battery voltage drops below operating

Battery Two (2) 1.5V ‘AAA’ batteries

Fuses mA, µA ranges; 200mA/250V fast blow

Operating Temperature 32ºF to 122ºF (0ºC to 50ºC)

Storage Temperature -4

Operating Humidity Max 70% up to 87ºF (31ºC) decreasing linearly to 50% at

Storage Humidity <80% RH

Operating Altitude 7000ft. (2000meters) maximum.

Weight 9.17 oz (260g) (includes holster).

Size 5.8” x 2.9” x 1.6” (147 x 76 x 42mm) (includes holster)

Safety

This meter is intended for indoor use and protected, against

Approvals CE, UL

PER IEC1010 OVERVOLTAGE INSTALLATION CATEGORY

OVERVOLTAGE CATEGORY I

Equipment of OVERVOLTAGE CATEGORY I is equipment for connection to circuits in

which measures are taken to limit the transient overvoltages to an appropriate low level.

Note – Examples include protected electronic circuits.

OVERVOLTAGE CATEGORY II

Equipment of OVERVOLTAGE CATEGORY II is energy-consuming equipment to be

supplied from the fixed installation.

Note – Examples include household, office, and laboratory appliances.

OVERVOLTAGE CATEGORY III

Equipment of OVERVOLTAGE CATEGORY III is equipment in fixed installations.

Note – Examples include switches in the fixed installation and some equipment for

industrial use with permanent connection to the fixed installation.

OVERVOLTAGE CATEGORY IV

Equipment of OVERVOLTAGE CATEGORY IV is for use at the origin of the installation.

Note – Examples include electricity meters and primary over-current protection equipment

typical

negative

voltage

A range; 10A/250V fast blow

o

F to 140oF (-20oC to 60oC)

122ºF (50ºC)

the users, by double insulation per EN61010-1 and IEC610101 2nd Edition (2001) to CAT II 1000V & CAT III 600V; Pollution

Degree 2. The meter also meets UL 61010-1, Second Edition

(2004), CAN/CSA C22.2 No. 61010-1, Second Edition (2004),

and UL 61010B-2-031, First Edition (2003)

Model EX320 - Version 4.0 –05/2006 12

Page 13

Warranty

EXTECH INSTRUMENTS CORPORATION warrants this instrument to be free of defects in parts and

workmanship for one year from date of shipment (a six month limited warranty applies on sensors and

cables). If it should become necessary to return the instrument for service during or beyond the warranty

period, contact the Customer Service Department at (781) 890-7440 ext. 210 for authorization or visit our

website at www.extech.com. A Return Authorization (RA) number must be issued before any product is

returned to Extech. The sender is responsible for shipping charges, freight, insurance and proper packaging

to prevent damage in transit. This warranty does not apply to defects resulting from action of the user such

as misuse, improper wiring, operation outside of specification, improper maintenance or repair, or

unauthorized modification. Extech specifically disclaims any implied warranties or merchantability or fitness

for a specific purpose and will not be liable for any direct, indirect, incidental or consequential damages.

Extech's total liability is limited to repair or replacement of the product. The warranty set forth above is

inclusive and no other warranty, whether written or oral, is expressed or implied.

Calibration and Repair Services

Extech offers complete repair and calibration services for most of the products we sell. For

periodic calibration, NIST certification or repair for most Extech products, call customer

service for details. Extech recommends that calibration be performed on an annual basis to

ensure calibration integrity.

All rights reserved including the right of reproduction in whole or in part in any form.

Technical support: Extension 200; E-mail: support@extech.com

Repair & Returns: Extension 210; E-mail: repair@extech.com

Product specifications subject to change without notice

For the latest version of this User’s Guide, Software updates, and other

up-to-the-minute product information, visit our website: www.extech.com

Extech Instruments Corporation, 285 Bear Hill Rd., Waltham, MA 02451

Copyright © 2005 Extech Instruments Corporation.

Support line (781) 890-7440

Model EX320 - Version 4.0 –05/2006 13

Loading...

Loading...