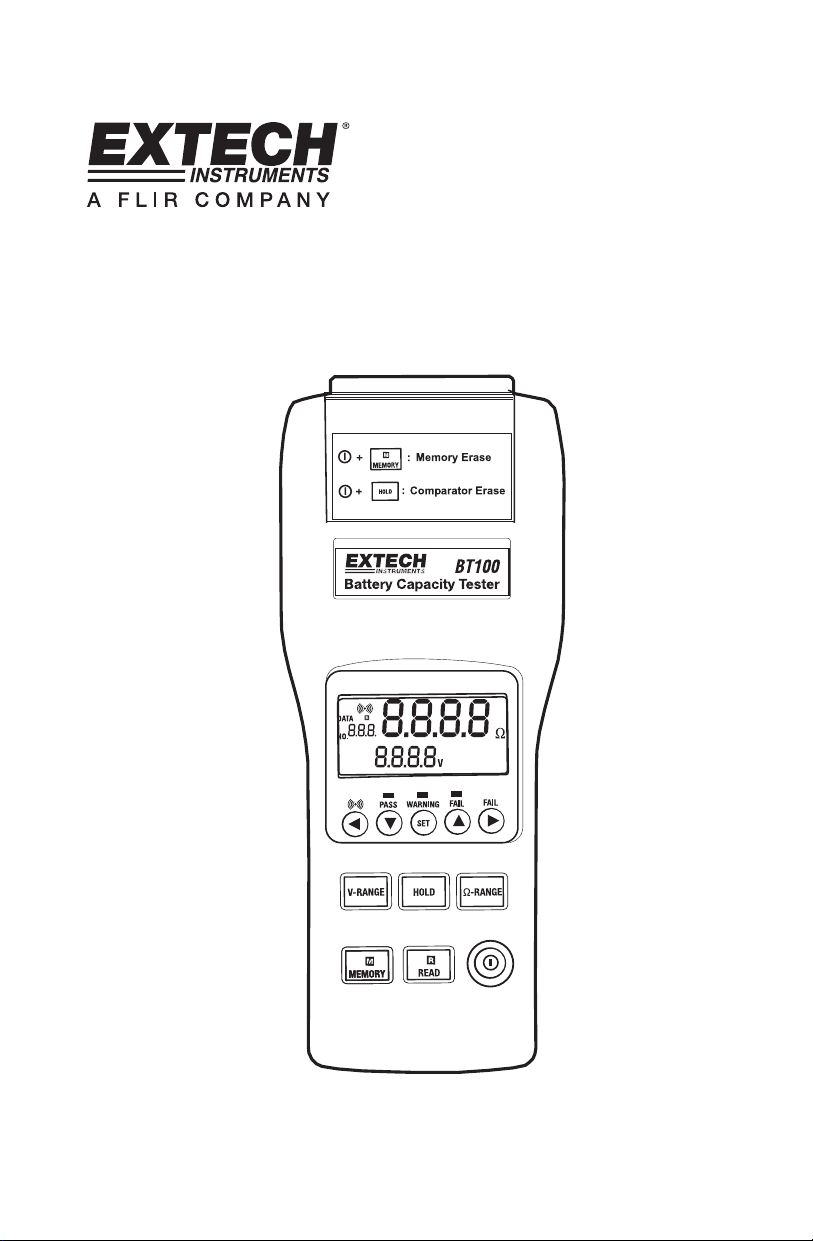

Page 1

User's Guide

Battery Capacity Tester

Model BT100

Page 2

Introduction

The Battery Tester is designed for measuring the internal resistance and output voltage of

batteries including lead storage cell, nickel-cadmium battery, lithium-ion battery and nickelmetal hydride battery.

AC four-terminal method to eliminates lead resistances and contact resistances and

yield the most accurate results.

1kHz test current with up to 10µΩ resistance resolution.

Dual display simultaneously indicates the internal resistance and voltage of the

battery.

Comparator function with storage of up to 99 sets of resistance and voltage values for

battery deterioration characterization.

Pin type and alligator type 4-terminal Kelvin leads for quick and accurate resistance

measurements.

Memory capacity to store up to 999 manually stored data points or up to 9600 points

stored using interval datalogging.

RS232 PC port and Windows compatible software.

Warranty

EXTECH INSTRUMENTS CORPORATION warrants the basic instrument to be free of defects in parts and

workmanship for one year from date of shipment (a six month limited warranty applies on sensors and cables). If it

should become necessary to return the instrument for service during or beyond the warranty period, contact the

Customer Service Department at (781) 890-7440 EXTENSION 210 for authorization or visit www.extech.com

more information. A Return Authorization (RA) number must be issued before any product is returned to

Extech. The sender is responsible for shipping charges, freight, insurance and proper packaging to prevent

damage in transit. This warranty does not apply to defects resulting from action of the user such as misuse,

improper wiring, operation outside of specification, improper maintenance or repair, or unauthorized modification.

Extech specifically disclaims any implied warranties or merchantability or fitness for a specific purpose and will not

be liable for any direct, indirect, incidental or consequential damages. Extech's total liability is limited to repair or

replacement of the product. The warranty set forth above is inclusive and no other warranty, whether written or

oral, is expressed or implied.

for

2

Version 2.1 7/09

Page 3

Specifications

Measuring method: Resistance (AC four-terminal method).

A/D conversion: Dual slope method.

Display: Dual display LCD and LEDs (comparator output).

Sampling rate: 1 set (resistance & voltage measurements)/second.

Open-Circuit terminal voltage: 3.5Vpp max.

Input over range: “OL” display.

Low battery detection:

Test current fault detection: “- - - -” display.

Auto power off: After approximately 30 minutes.

Zero (Relative) function: Circuit offset voltage is displayed as 0V.

Hold function: Display is held.

Beeper function: Audible output for warning and fail results (can be

Comparator settings: Resistance High and Low limits and voltage

Number of comparator settings: 99 sets.

Comparator output: LEDs for pass (green), warning (yellow) and fail

Resistance

Voltage

Lo Warning Warning Fail

Hi PASS Warning Fail

display.

turned on and off).

threshhold point.

(red) results, audible tone for warning and fail.

Lo IN Hi

Manual Data logging: 999 sets.

Continuous Data logging: 9600 sets.

Operating environment: 32 to 104°F (0

Storage environment: 14 to 122°F (-10

Power source: Six AA size 1.5V batteries. (AC adaptor (output

9VDC) is optional)

Maximum power consumption: 1.0VA

Continuous operating time: 7 hours approx.

Maximum altitude value usable: 2000m or less.

Size: 9.8x3.9x1.7” (250×100×45mm)

Weight: 1.1 lbs (500g) approx. (including batteries)

Accessories: Test Leads, Instruction Manual, Batteries.

Option: AC adaptor (9V DC output).

3

°

to 40

°

°C)

80%RH (non-condensing)

to 50

°C)

80%RH (non-condensing)

Version 2.1 7/09

Page 4

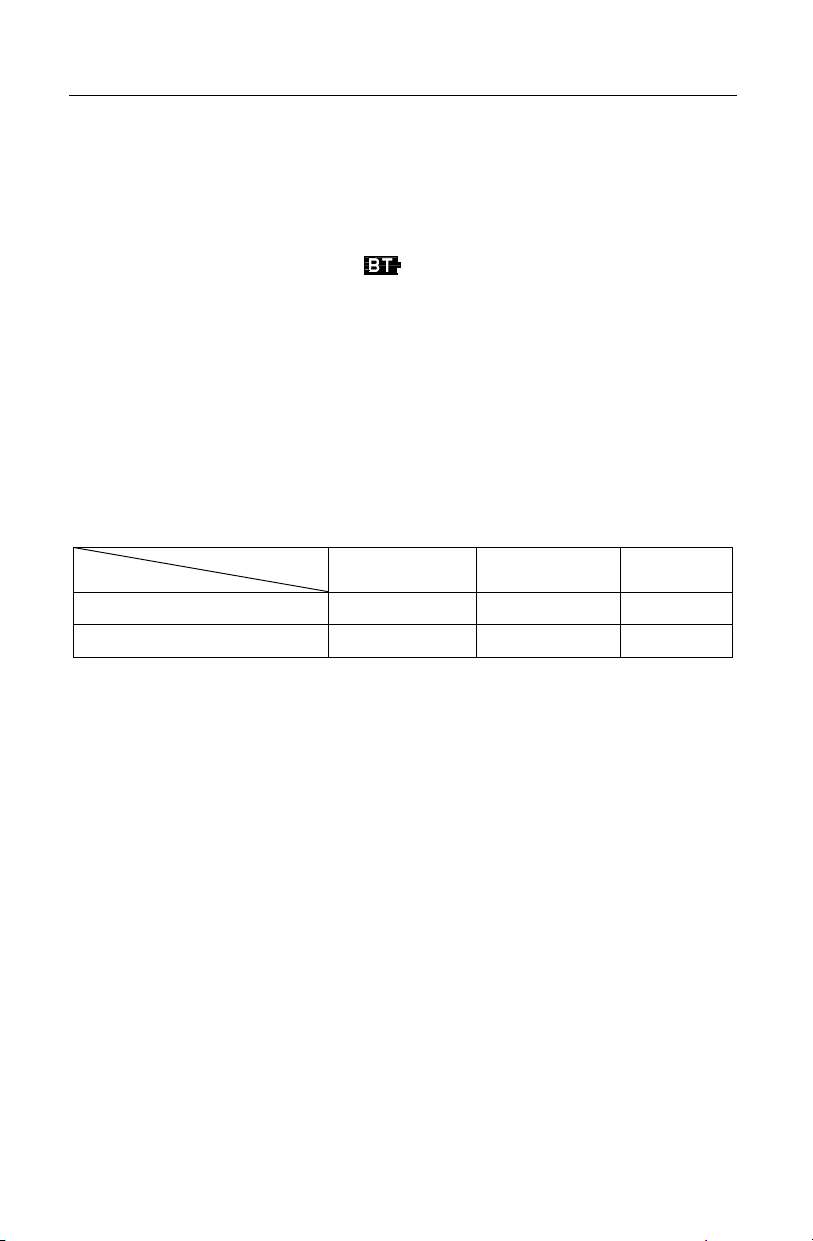

Electrical Specifications

Conditions to guarantee accuracy:

Temperature: 23

Humidity: 80%RH or less (non-condensing).

Zero adjustment: After zero adjustment for each range.

Resistance measurement

Temperature coefficient: (

Measuring current frequency: 1KHz

Measuring burden voltage:

Range Resolution Measurement current Accuracy

40mΩ 10µΩ 37.5mA approx.

°C ± 5°

±

0.1% rdg ± 0.5digits)/°C

±

10%

1.5mVAC

400mΩ 100µΩ 3.75mA approx.

4Ω 1mΩ 375µA approx.

40Ω 10mΩ 37.5µA approx.

Voltage Measurement

Temperature coefficient (

Range Resolution Accuracy

4V 1mV

40V 10mV

Maximum Input Voltage: 50VDC maximum, No AC voltage input, , 60VDC and AC

maximum between input terminals and ground.

Do not exceed the maximum permissible input voltage to the measurement terminal. This

could result in injury or damage to the unit.

±

0.1%rdg±0.5digits)/

DANGER

°C

±

(0.1% reading ± 6digits)

±

(1% reading ± 10digits)

4

Version 2.1 7/09

Page 5

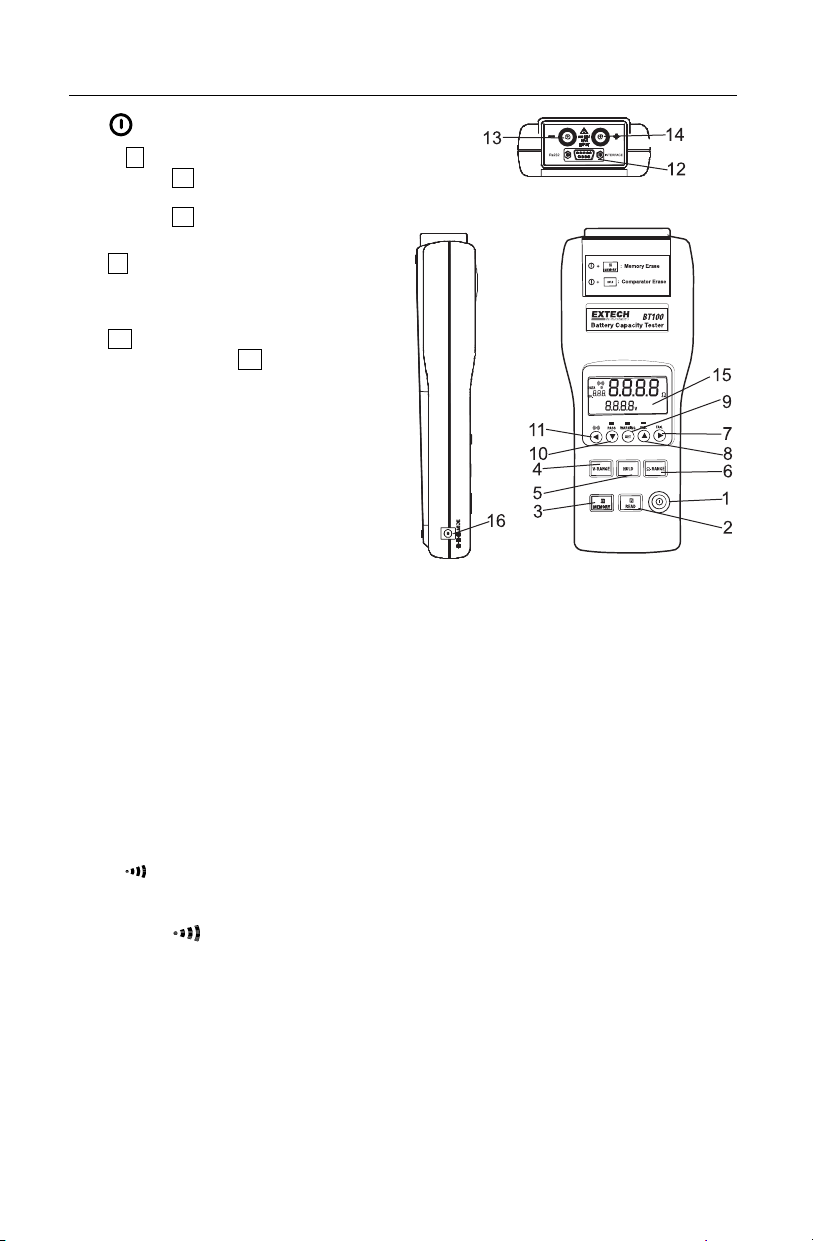

Meter Description

1.

2. R READ button:

3. M MEMORY button:

4. V-RANGE button: Select the voltage

5. HOLD button:

6. Ω - RANGE button: Select the resistance range. (40mΩ, 400mΩ, 4Ω, 40Ω)

7. REL button:

8. button : Press button to increase the displayed value.

9. SET button:

10. button: Press button to decrease the displayed value.

11.

12. RS-232 connector: PC interface connector.

13. – Input jack: For connecting with the black test lead plug.

14. + Input jack: For connecting with the red test lead plug.

15. LCD display

16. AC adaptor input

Power button: Power on /off

Press R button to show the manual

logged readings.

Press R READ button again to stop

reading.

Under the manual logging mode, the

tester stores each single set of logged

reading to the memory by pressing

M MEMORY button.

Press and hold M MEMORY button

for 2 seconds to enter continuous

logging mode. Press again to stop

logging.

range. (4V, 40V)

Press HOLD button to freeze or unfreeze

the displayed reading.

Press and hold HOLD button for 2

seconds to enter the interval time setting

mode for continuous data logging.

Press button to move the cursor to the right.

Press REL (Relative) button to zero the reading.

Press SET button to switch the comparator mode on or off.

Press and hold the SET button for 2 seconds to enter the comparator-setting mode.

Press again to store the setting in memory.

Button:

Press button to move the cursor to the left.

Press

button to turn the beeper on or off.

5

Version 2.1 7/09

Page 6

Display Description

1. Measured resistance reading (High or Low limit of resistance on the comparator

settings)

2. Measured voltage reading (High or Low limit of voltage on the comparator settings).

3. The assigned number of comparator: 99 sets

4. The location for the manual logged data.

5. Symbols:

mΩ: Milliohm (resistance).

V: Voltage.

HOLD : Hold function.

COMP : Comparator function enabled.

: Low-Battery

:

Beeper enabled

DATA R : Manual datalogging enabled.

M : Continuous datalogging enabled (Flashes when data is stored).

INTV: Interval time settings of continuous datalogging function. (1~255

COMP.SET : Comparator settings.

HIGH: High limit setting of the comparator resistance & voltage.

LOW: Low limit setting of the comparator resistance.

LED Display Indicators

PASS (green LED): Battery complies with the high limit of comparator.

WARNING (yellow LED) Battery is beginning to deteriorate.

FAIL (red LED): Battery has failed.

These indications will appear when the High and Low comparator limits for internal resistance and

the comparator threshold value for voltage are all set.

seconds).

6

Version 2.1 7/09

Page 7

Basic Operation

Preparation

The following safety information must be observed to ensure maximum personal safety

during the operation of this tester.

To avoid electric shock when replacing the batteries first disconnect the leads from the

object to be measured.

Check the battery polarity carefully when inserting the batteries.

Be sure to dispose of used batteries properly.

1. Remove the battery cover.

2. Insert the batteries into the battery compartment.

WARNING

Do not attempt to measure DC voltage exceeding 50V. Do not attempt to

measure AC voltages. This could result in injury or damage to the unit.

Do not attempt to measure the voltage of a generator. This would result in an

AC voltage being applied to the voltage generating output terminals, which is

dangerous.

After measuring a high voltage battery, before continuing to measure a low

voltage battery first short the measurement leads together. This will discharge

the DC-elimination capacitor which is connected across the leads. Otherwise

an excess voltage may be applied to the low voltage battery, which is

dangerous.

Test Leads

Two sets of test leads are supplied with the meter. Both sets provide 4 terminal Kelvin

connections which eliminates lead resistance and probe contact resistance from the

measurement. Use of either the alligator or press-probe is determined by the measurement

application.

7

Version 2.1 7/09

Page 8

Operation

Connect the red test lead to the “+” jack and the black test lead to the “-” jack.

1. Press Power

2. Connect the red test probe to the positive battery terminal, and the black test probe to

the negative battery terminal.

3. Use the V-RANGE and Ω-RANGE buttons to select the desired voltage and resistance

ranges.

4. Read the battery internal resistance and DC voltage directly from the display.

Note : When the measured DC voltage or battery internal resistance value is over range,

“OL” is displayed.

When the AC test current faults, “- - - -” will be displayed.

REL Zero Adjust

The REL function zeros the selected range of resistance and voltage. The reading

displayed when the REL button is pressed will be taken as zero and will be used to

calibrate subsequent measurements.

1. Short the 4 tips of red and black test leads probe terminals.

2. Press REL button. The display shows R , then the resistance and voltage value is zero,

connect the test leads probe to the battery to be tested.

3. The zero adjustment is valid only for the currently selected range, as long as the power

remains on.

button to turn on the tester.

8

Version 2.1 7/09

Page 9

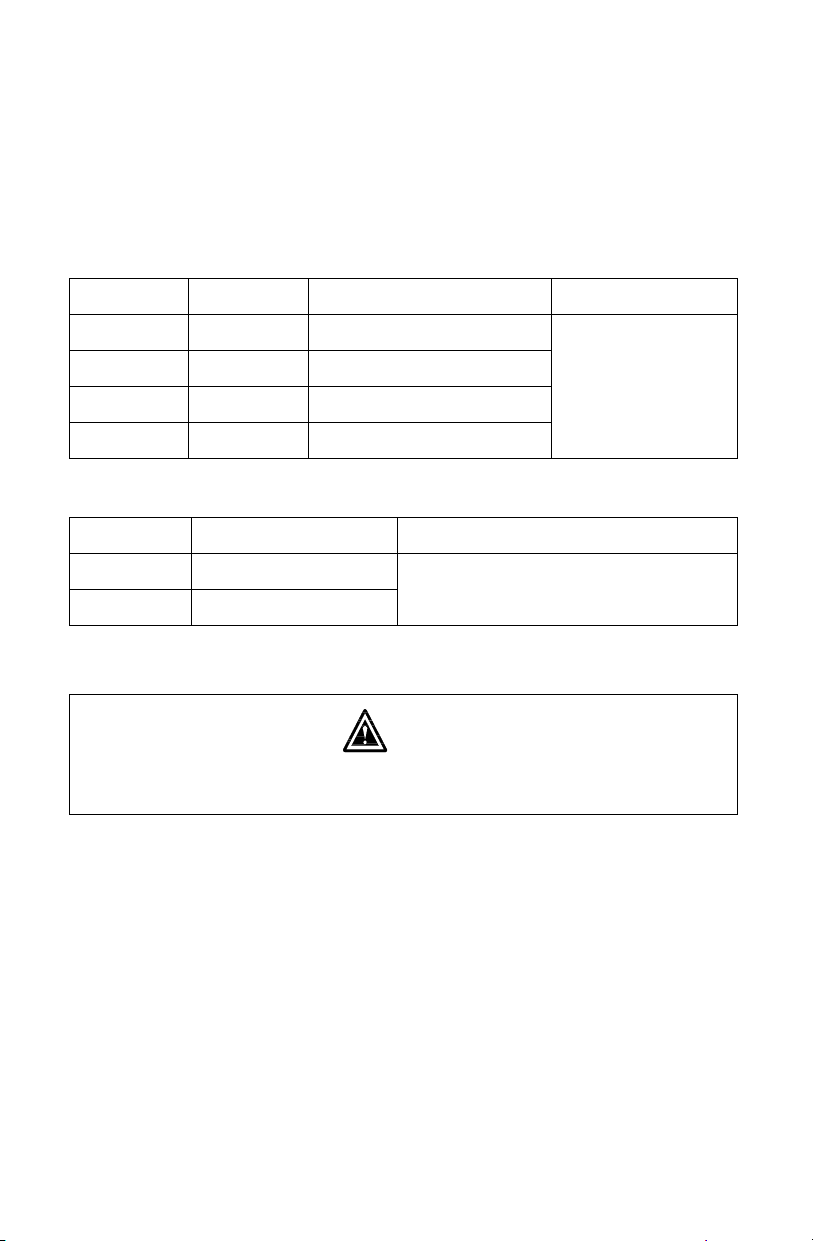

Comparator (99 sets)

The comparator function compares the measured values with preset High and Low limit

values for internal resistance and voltage level, and determines the range that the

measurement should fall into. Then, according to the following conditions, lights the

corresponding LED, and sounds a beeper under the WARNING and FAIL cases.

Comparator Settings

1. Press and hold the “SET” button for 2 seconds, the display will show COMP.SET

indicating the comparator mode is enabled.

2. Use the or button to change the comparator number from 01 up to 99.

3. Use the V-RANGE or Ω-RANGE button to set the desired voltage and resistance

measured range.

4. Press button one time, LOW and the left two digits of the low limit resistance

flashing. (Use the & buttons to select the desired value.)

5. Press button one time, the right two digits of the low limit resistance

(Use the and buttons to select the desired value.)

6. Press button one time, HIGH and the left two digits of the high limit resistance

flashing. (Use the and buttons to select the desired value.)

7. Press button one time, the right two digits of the high limit resistance

(Use the and buttons to select the desired value.)

8. Press button one time, the left two digits of the threshold voltage

(Use the and buttons to select the desired value.)

9. Press button one time, the right two digits of the threshold voltage

(Use the and buttons to select the desired value.)

10. Repeat step 2 to step 9 to set the next comparator number.

11. Press SET button again to exit from comparator setting mode.

Comparator Tables

Resistance

Voltage

Voltage Lo

Comparison

Value Hi

Low limit resistance High limit resistance

Lo Middle Hi

WARNING

Beeper

Pass

WARNING

Beeper

WARNING

Beeper

will be flashing.

will be flashing.

will be flashing.

will be flashing.

FAIL

Beeper

FAIL

Beeper

will be

will be

Comparator Start / Stop Controls

1. Press SET button to start comparator function, the COMP indication will appear on the

display, and the comparator will be operating once the measurements are taken.

2. Press and buttons to select the desired comparator number. The selected

comparator number remains in memory even when the power is turned off.

3. Press

and the beeper will sound with a WARNING or FAIL result. Press

disable the beeper.

4. Press SET button again to disable the comparator function.

button to set the beeper on, the indication will appear on the display,

button again to

9

Version 2.1 7/09

Page 10

Datalogging

Manual Data Logging (999 sets)

1. Log the reading one by one to the memory by pressing the M MEMORY button.

“DATA M NO XXX” will appear on the LCD for one sec. to indicate the memorized

location.

2. Press R READ button to review the logged readings. The display will show “DATA R

NO XXX”.

3. Press The and buttons to scroll through the logged readings.

4. Press R READ button again to stop viewing logged readings.

Continuous Data Logging

1. Press HOLD button for 2 seconds, the display will show INTV.

2. Using or button, select the desired interval time from 1 second to 255 seconds.

3. Press SET button to exit interval time setting.

4. Press M MEMORY button for 2 seconds to enter continuous logging mode, the display

will show M.

5. The M will flash every time a reading is stored.

6. Press M MEMORY button again to exit continuous logging mode.

7. Data stored using continuous datalogging can not be read directly on the tester’s

display, it must be downloaded to a PC using the supplied software.

Erasing Memory

When memory is full, “Full” symbol will appear on the display and logging will stop.

1. Press

2. Press and hold the MEMORY button, then press the

and all datalogged readings will be cleared from memory.

button to turn off the tester.

button. The display will indicate “CLr”

10

Version 2.1 7/09

Page 11

PC Software

The supplied software combines data acquisition and datalogger functionality.

In the Datalogger mode, the meter stores readings remotely

then, at a later time, the meter is connected to the PC and the readings are transferred

(addressed in this section).

In the Data Acquisition mode, the meter takes readings while connected

readings are taken, displayed, and stored all at the same time.

PC Requirements

• 486-33 IBM compatible PC or better

• CD-ROM drive

• Available serial port

• Windows 95, 98, 2000, NT, ME, or XP Operating System

Installing the Windows Application Program

1. Connect the BT100 to the serial PC port (COM1 or COM2) using the 9-pin female

connector to the 9-pin male serial PC port cable supplied.

2. Place the supplied software CD in the PC CD-ROM drive

3. Wait for “Autorun” to start and follow the on-screen instructions

4. If “Autorun” does not start, click on “Start” then “Run”. Type the drive letter of the CD-

ROM and :\VB\Disk1\Setup.exe and click OK (To install the LabVIEW version, type the

drive letter and :\LV\installer\Setup.exe and click OK).

5. Change the path if necessary or choose to install the program to its default location.

6. Launch the program by double clicking the program file in the location where it was

saved during installation.

7. Do not run the supplied software until the meter is properly connected to the PC.

Software Operation

Click “Start” on the Start menu, click “Programs” and then click on

“BatTester” to launch the program. The COM Port screen will

appear. Select COM1 or COM2 then click OK

The Battery Tester main screen will appear. On the lower right of the

screen, “COM1” or “COM2” will appear if a connection has been

accomplished. “NO COM” will appear if there is no connection.

The function of the Main screen icons are:

1. Opens the “Save As” dialog box to save data to a new file.

2. Opens the “Open” dialog box to open a saved file.

3. Opens the “Real Time List” display box for data acquisition mode.

4. Opens the “Real Time Graph” of the voltage and resistance for data.

5. Opens the “Real Time Sampling Rate” dialog box

6. Opens the “Data Logger” box and downloads the data.

7. Opens the “Manual Records” box and downloads the data.

(explained in previous section)

to the PC. The

11

Version 2.1 7/09

Page 12

Data Acquisition Mode

In the data acquisition mode, the meter is connected to the computer while taking readings.

At the same time the readings are taken, they are displayed and stored on the computer. The

readings can be displayed as a List, a Voltage graph or a Resistance graph.

Sampling Rate Setting for Data Acquisition Mode

The sampling rate for the data acquisition

mode can be set from 1 reading per

second to 1 reading every 86,400

seconds (1 sample every 24 hours).

Note: This sampling rate setting is for the

data acquisition mode only

datalogger mode, the sample rate is set

using the meter’s front panel controls as explained earlier in this manual.

. For

12

Version 2.1 7/09

Page 13

Datalogger Mode

The meter’s internal datalogger memory

stores readings in files. Each file is created

when a datalogging session is started and

then stopped using the MEMORY button

(described earlier). The Datalogger screen

lists each file (1, 2, 3,…) with the ohm range,

voltage range, sampling time and the number

of records stored in the file.

Click on one of the numbered files and the

“Input Starting Time” box appears. Enter the

exact time and date of the first reading in the

file. The software will then put a time and date stamp on all of the records in the file. The

data will automatically download at this time.

The recalled data can be viewed as a list or

graph and can be saved as file

READ Button

Data stored manually (single press of the MEMORY button on the meter)

can be downloaded by clicking the READ button. The data can be

viewed as a list, saved in a file or printed.

Excel spreadsheet import

Saved files may be imported into Excel. In the Excel import wizard select “Delimited”,

“TAB” and (”) as the text qualifiers.

13

Version 2.1 7/09

Page 14

Maintenance

Cleaning

1. Repairs or servicing not covered in this manual should only be performed by qualified

personnel.

2. Periodically wipe the case with a dry cloth. Do not use abrasives or solvents on this

instrument.

Do not use abrasives or solvents on this instrument.

Battery Check & Replacement

1. The

symbol will be displayed when the batteries need replacement.

2. a). Disconnect the test leads.

b).Turning off the tester.

c). Open the battery cover with a screw driver.

d). Replace the batteries

e). Replace and secure the battery cover.

Calibration and Repair Services

Extech offers complete repair and calibration services for all of the products we sell.

For periodic calibration, NIST certification on most products or repair of any Extech

product, call customer service for details on services available. Extech recommends that

calibration be performed on an annual basis to ensure calibration integrity.

Technical support: Extension 200; E-mail: support@extech.com

Repair & Returns: Extension 210; E-mail: repair@extech.com

Product specifications subject to change without notice

For the latest version of this User’s Guide, Software updates, and other

up-to-the-minute product information, visit our website: www.extech.com

Support line (781) 890-7440

Copyright © 2005 Extech Instruments Corporation (a FLIR company).

All rights reserved including the right of reproduction in whole or in part in any form.

14

Version 2.1 7/09

Loading...

Loading...