Extech CG204 Instruction Manual

User's Guide

Extech CG204

Coating Thickness Tester

CG204-EU-EN V2.0 2/11

2

Introduction

Congratulations on your purchase of the Extech CG204 Coating Thickness Tester. The

CG204 is a portable meter designed for non-invasive coating thickness measurements.

The meter uses two measurement methods: magnetic induction (for ferrous metal

substrates) and eddy current (for non-ferrous metal substrates).

The meter is easily configured using the intuitive push-button programming menu. Five (5)

film reference samples and two (2) metal substrates are provided. The meter is also

equipped with a USB PC interface port and PC software.

Proper use and care of this meter will provide many years of reliable service.

Description

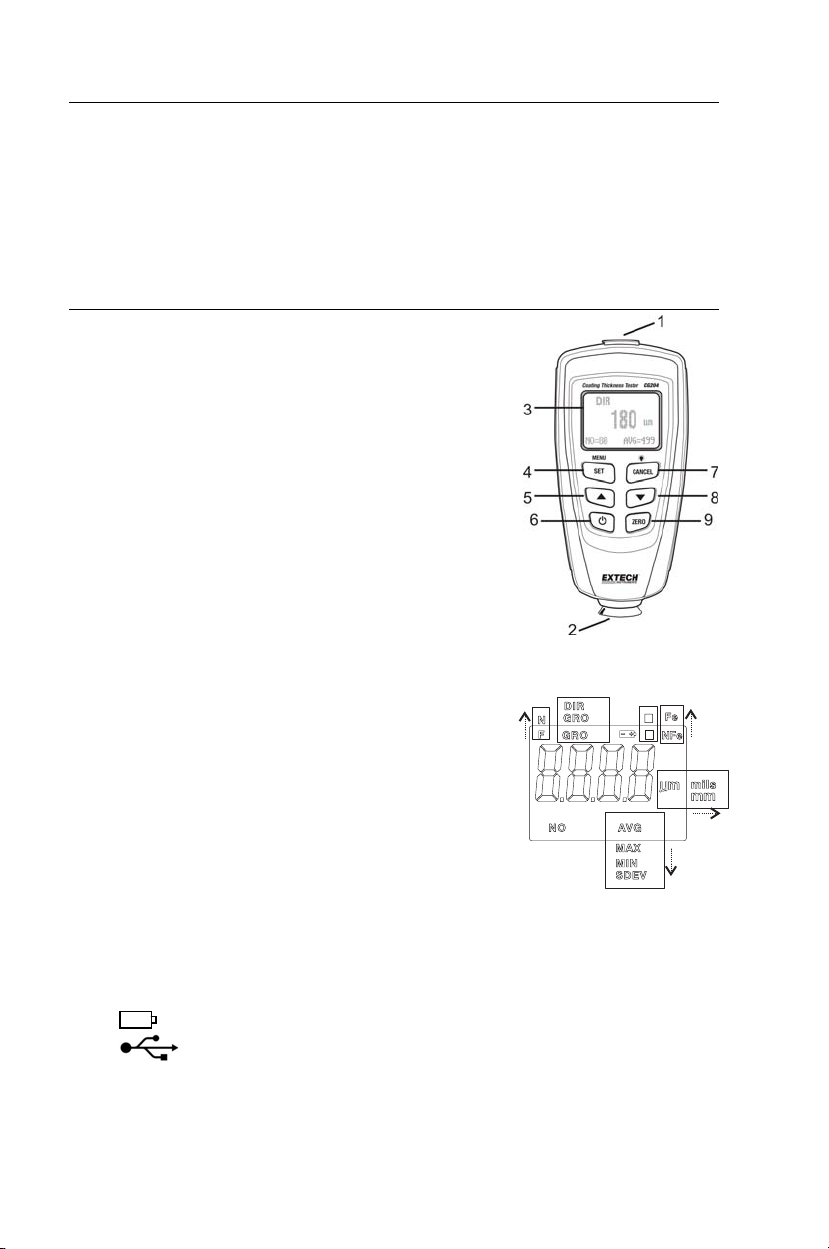

Meter Description

1. USB jack for PC interface

2. Measurement probe

3. Backlit LCD display

4. SET /OK /YES /MENU /SELECT button

5. UP /LEFT ARROW button

6. Power ON/OFF button

7. CANCEL /ESC /NO /BACK button (menu mode)

and Backlight ON/OFF (normal mode)

8. DOWN ARROW /RIGHT button

9. ZERO calibration button

Note: Battery compartment on rear of meter

Display Icon Description

NFe Non-ferrous metals

Fe Ferrous metals

AUTO Automatic substrate recognition

F or N Calibration icons

DIR DIRECT mode

GRO1…4 GROUP Mode

μm Micrometers unit of measure

mils mils = millimeters * 2.54/100

mm Millimeters unit of measure

AVG Average reading

MIN Minimum reading

MAX Maximum reading

SDEV Standard Deviation reading

NO Number of data points

Low battery

USB Connection

Note: The unit of measure icon flashes when in the CONTINUOUS mode of operation.

The unit of measure icon is stable when in the SINGLE mode of operation.

L

H

1

=

=

[AUT

O]

[NOALRRM]

cal n o(1 or 2)

zero n o(yes)

CG204-EU-EN V2.0 2/11

3

Quick Start Instructions

Meter Power

Press the power button to switch the meter ON. The display will switch ON. If the

display does not switch ON, replace the batteries.

Measurements

Use the supplied film references and zero reference metal substrates to learn how the

meter operates before moving to a professional application. The round metal substrate is

the ferrous (magnetic) substrate and the rectangular shaped metal substrate is the non-

ferrous (non-magnetic) substrate. The meter automatically senses ferrous or non-ferrous

substrates.

1. Place a reference film (250μm, for example) on the round, ferrous substrate.

2. Place the spring-loaded meter sensor against the reference film.

3. In the single mode the meter will emit an audible tone indicating that the

measurement has been taken.

4. In the continuous mode the display will continually measure and update the display

5. The LCD will show the reading (250μm) at the center of the display area.

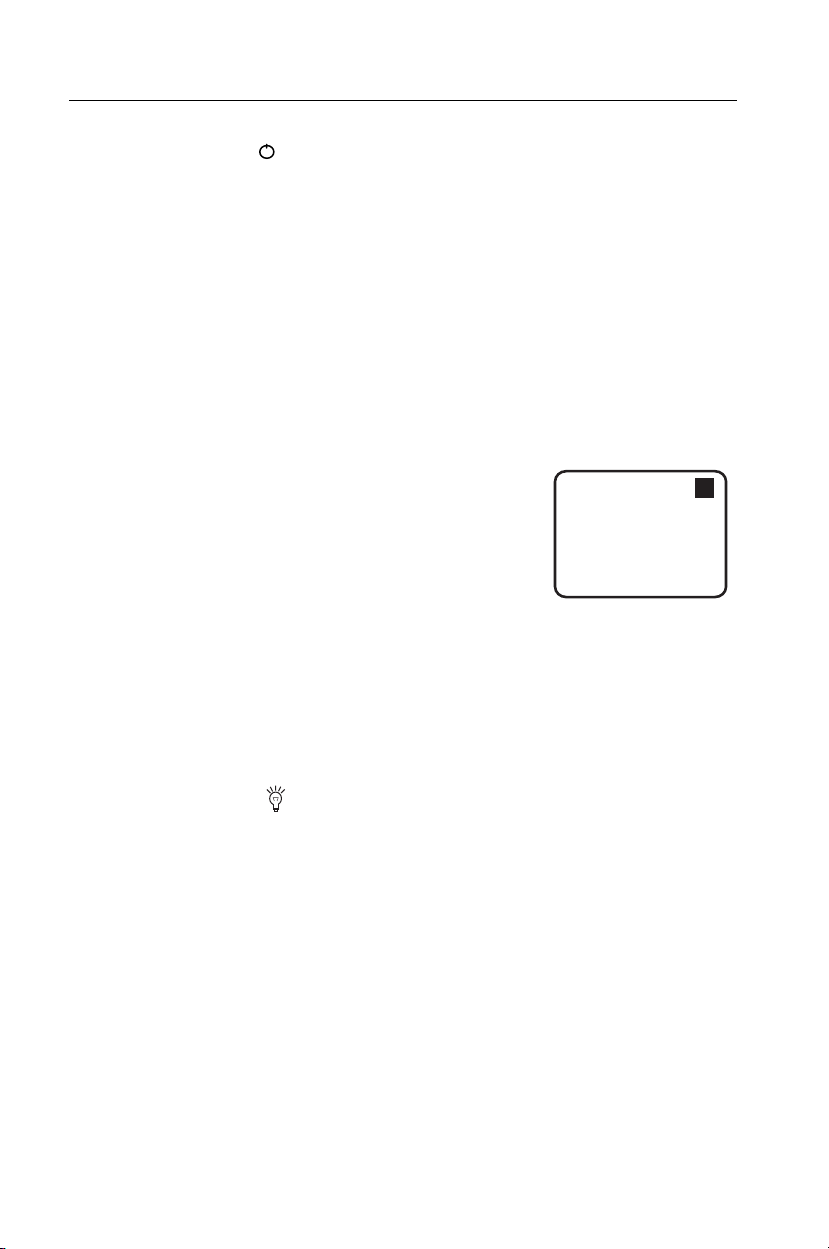

6. A typical display will also show the following:

• NO = 1 (reading number one) on the lower left of

the LCD

• AVG = 250μm (running average) on the lower right

• DIR = DIR mode of operation on the upper left

• Fe = Ferrous substrate on the upper right of the

LCD

Experiment with the remaining reference films and the substrate before using the meter

professionally.

Automatic Power OFF

In order to conserve battery life, the meter will automatically turn off after approximately 3

minutes. To defeat this feature use the programming menu detailed in the next section

(menu parameter AUTO POWER OFF under OPTIONS).

LCD Backlight Button

The LCD is equipped with backlighting for easier viewing, especially in dimly lit areas.

Press the backlight button to turn the backlight on. Press again to turn the backlight off. To

enable/disable the LCD backlighting, use the BACKLIGHT parameter under OPTIONS in

the programming menu.

Factory Default Reset

To restore the meter to its original factory default settings:

1. Turn the meter OFF.

2. Press and hold the ZERO button while switching the meter ON.

3. When the meter powers up, the display will prompt for a YES or NO.

4. Press the SET button for YES or the CANCEL button for NO.

5. Note that all data in all memory locations will be erased, in addition to statistics,

calibration values, and alarm limits.

DIR

um

AVG=250

NO=1

250

Fe

CG204-EU-EN V2.0 2/11

4

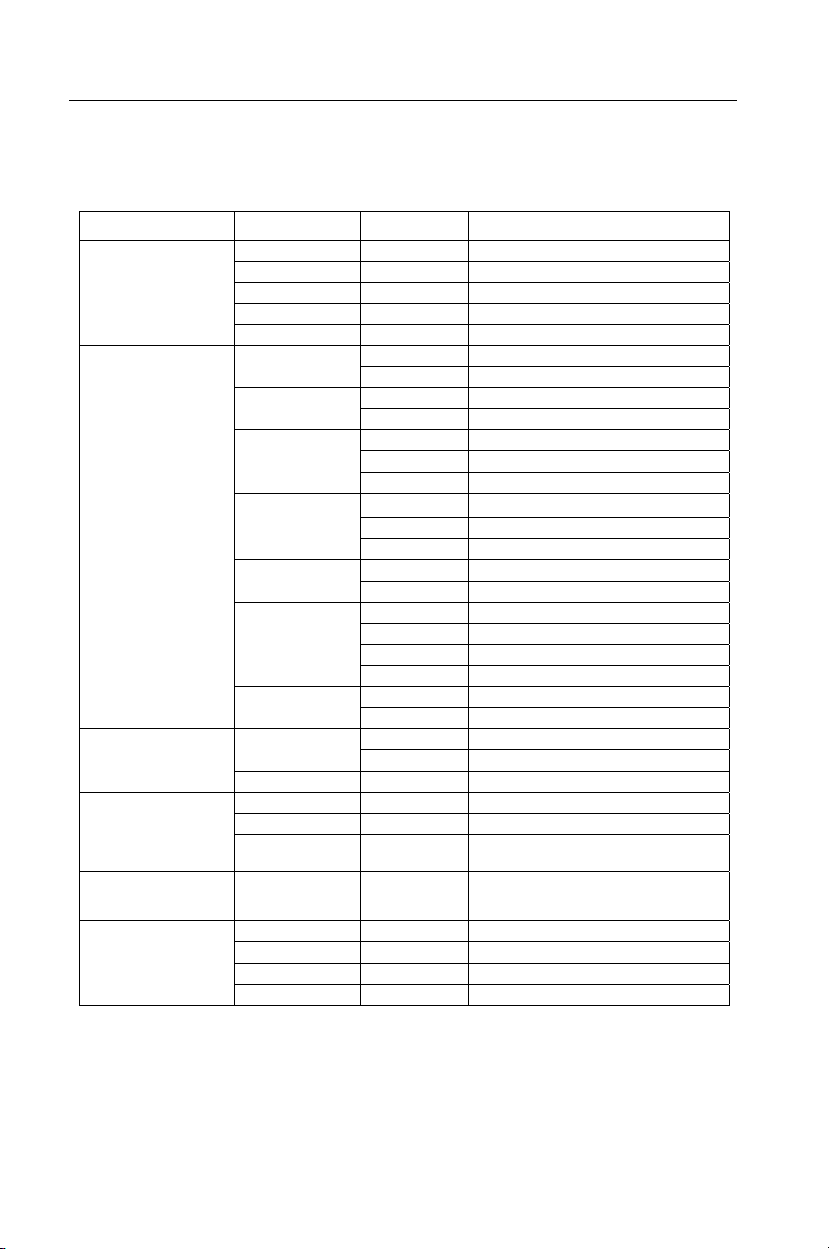

Programming Menu

The meter can be configured and calibrated through simple button presses in the

programming menu. Press the MENU button to access the menu and refer to the menu

‘tree’ below. The menu uses UP/DOWN, SELECT, BACK, & ESC presses for navigation

and selection. In the table below the factory default settings are in bold with an asterisk.

Each parameter is explained in detail in the subsequent sections.

Top level Sub level 1 Sub level 2 Notes

AVG* Average of a series of readings

MIN Lowest of a series of readings

MAX Highest of a series of readings

NO Number of sampled readings

STATISTICAL VIEW

SDEV Standard deviation of a series

Single* One reading at a time

Measure mode

Continuous Continuous measurements

Direct* Readings are not stored in groups

Working mode

Group 1…4 Store readings in groups

Auto* Meter automatically selects mode

Fe Ferrous measurement mode

Probe used

No Fe Non-ferrous measurement mode

μm*

Micrometers

mils Mils = mm * 2.54 / 100

Unit settings

mm Millimeters

ON* Enables backlight operation

Backlight

OFF Disables backlight operation

AVG* Average of a series of readings

MAX Lowest of a series of readings

MIN Highest of a series of readings

LCD Statistics

SDEV Standard deviation of a series

Enable* Allows auto power off to operate

OPTIONS

Auto Power OFF

Disable Defeats the auto power off feature

High Limit High Alarm alerts user when reached

Limit settings

Low Limit Low Alarm alerts user when reached

LIMIT

Delete Limits Clear the alarm limit values

Current Data Delete current data

All Data Delete all stored data

DELETE

Group Data

Delete data stored data plus alarm

and calibration data

MEASUREMENT

VIEW

View stored data in all groups

Enable Allow calibration access

Disable Lock out the calibration mode

Delete Zero N Clear the zero cal. data (non-ferrous)

CALIBRATION

Delete Zero F Clear the zero cal. data (ferrous)

NOTE: Disable the Auto Power OFF feature before lengthy programming to avoid

inconvenient automatic power down while programming.

CG204-EU-EN V2.0 2/11

5

STATISTICAL VIEWS Menu

1. Press the MENU button to access the programming menu

2. Press SELECT to choose STATISTCAL VIEW

3. Use the UP and DOWN buttons to scroll through the AVERAGE, MINIMUM,

MAXIMUM, NUMBER OF DATA, and SDEV (Standard Deviation) values for the stored

readings.

4. ‘NO DATA’ will display if no readings are available for the meter to analyze. Stored

readings will clear when the meter powers down unless the GROUP feature is used

(refer to GROUP function explanation later in this section).

5. Press the BACK and then the ESC soft-keys to return to the normal operating mode.

OPTIONS Menu

1. Press the MENU button to access the programming menu

2. Use the DOWN ARROW button to scroll down to OPTIONS

3. Press SELECT to choose OPTIONS

4. Use the UP and DOWN buttons to scroll to the MEASURE MODE, WORKING MODE,

PROBE USED, UNIT SETTINGS, BACKLIGHT, LCD STATISTICS, AND AUTO

POWER OFF parameters. Use the SELECT soft-key to select the desired parameter.

Each parameter is detailed below:

a. Measure Modes

Select CONTINUOUS or SINGLE under MEASURE MODES in the OPTIONS Menu

using the arrow buttons and the SELECT soft-key.

In the CONTINUOUS measurement mode the meter displays a running average of

readings as they are taken. Note that the audible measurement ‘beep’ is not active in

this mode.

In the SINGLE measurement mode measurements are taken one at a time. Single

mode measurement readings are accompanied by an audible tone.

b. Working Modes

Select DIRECT or GROUP 1, 2, 3, or 4 under WORKING MODES in the OPTIONS

Menu using the arrow buttons and the SELECT soft-key.

In DIRECT mode, individual readings are logged to memory. When power is switched

off or if the meter is switched to GROUP mode, all DIRECT readings will be cleared.

However, the statistical analysis data will remain. The statistical analysis utility can

evaluate up to 80 readings. When the memory is filled, new readings will replace old

readings. Lastly, this mode has its own calibration and alarm limit values.

In GROUP mode each group memory can store a maximum of 80 readings and 5

statistical values. Calibration and alarm limit values can be individually set and stored

for each group. When the memory is filled, measurements will continue to be taken but

readings will no longer log (previously logged readings are not affected); in addition,

statistical data will no longer update. If desired, the group data, statistical values,

calibration data, and alarm limit values can be deleted using the programming menu.

Loading...

Loading...