Page 1

User's Guide

Digital Stroboscope Tachometer

Model 461830 and Model 461831

Page 2

Warranty

EXTECH INSTRUMENTS CORPORATION warrants this instrument to be free of defects

in parts and workmanship for one year from date of shipment (a six month limited

warranty applies on sensors and cables). If it should become necessary to return the

instrument for service during or beyond the warranty period, contact the Customer

Service Department at (781) 890-7440 ext. 210 for authorization or visit our website at

www.extech.com (click on ‘Contact Extech’ and go to ‘Service Department’ to request an

RA number). A Return Authorization (RA) number must be issued before any product is

returned to Extech. The sender is responsible for shipping charges, freight, insurance

and proper packaging to prevent damage in transit. This warranty does not apply to

defects resulting from action of the user such as misuse, improper wiring, operation

outside of specification, improper maintenance or repair, or unauthorized modification.

Extech specifically disclaims any implied warranties or merchantability or fitness for a

specific purpose and will not be liable for any direct, indirect, incidental or consequential

damages. Extech's total liability is limited to repair or replacement of the product. The

warranty set forth above is inclusive and no other warranty, whether written or oral, is

expressed or implied.

Introduction

Congratulations on your purchase of the Extech Digital Stroboscope Tachometer. This

device measures the speed of moving parts such as gears, fans, propellers, centrifuges,

and pumps. The stop-motion action of this instrument permits the visual inspection of

moving parts. Careful use of this instrument will provide years of reliable service.

Model 461830/461831 Version 2.2 November 2003

2

Page 3

Safety

This symbol, adjacent to another symbol or terminal, indicates the user must refer

to the manual for further information.

This symbol, adjacent to a terminal indicates that, under normal use, hazardous

WARNING: Do not look directly at the Strobe’s Xenon lamp or its reflector.

WARNING: This device causes moving objects to appear still. Take precautions against

accidental contact with moving objects.

CAUTION: Do not touch the flash tube.

voltages may be present

Model 461830/461831 Version 2.2 November 2003

3

Page 4

Specifications

General Specifications

Circuit

Exclusive one-chip LSI circuit with crystal time base

Display 4-digit (10,000 count; 0 to 9999) LED display

Measurement unit RPM (revolutions or rotations per minute) is the speed of the

Operating Temperature 32 to 122oF (0 to 50oC)

Operating Humidity < 80% RH

Power Supply 110VAC (461830) or 220VAC (461831) 50/60Hz ±10%

Power Consumption <25 watts @ 115V

Weight 2.2 lbs. (1kg)

Dimensions 8.3 x 4.8 x 4.8" (21 x 12 x 12cm)

Housing construction Impact resistant plastic with plastic lens and mirrored reflectors

Electrical Specifications

Measurement Range

Resolution 0.1 (<1000 RPM/FPM)

Accuracy ± (0.05% + 1 digits)

Sampling Time 1 second

Strobe Flash adjust range LOW: 100 to 1,000 RPM/FPM

Strobe Flash tube type Xenon lamp

Strobe Flash duration 60 to 1000 microseconds

Strobe Flash Energy 4 Watt-Seconds (Joules)

Strobe Beam Angle 80o

Strobe Flash Color White 6500oK

Notes: Replace the Xenon lamp when readings appear irregular. To prolong the Xenon lamp

life and ensure safe operation, please adhere to the following recommendations.

• A 30-minute use limit < 3000rpm and 5-minute use limit > 3000rpm exists. Do not use

the instrument for periods longer than specified otherwise damage to the instrument

may result.

• Always permit a 10-minute cool-down between cycles.

• Do not touch the Xenon flash tube.

moving device under test which equals the FPM rate (strobe

flashes per minute)

100 to 10,000 RPM/FPM

1 (1000 to 9999 RPM/FPM)

10 (10,000 RPM/FPM)

HIGH: 1000 to 10,000 RPM/FPM

Model 461830/461831 Version 2.2 November 2003

4

Page 5

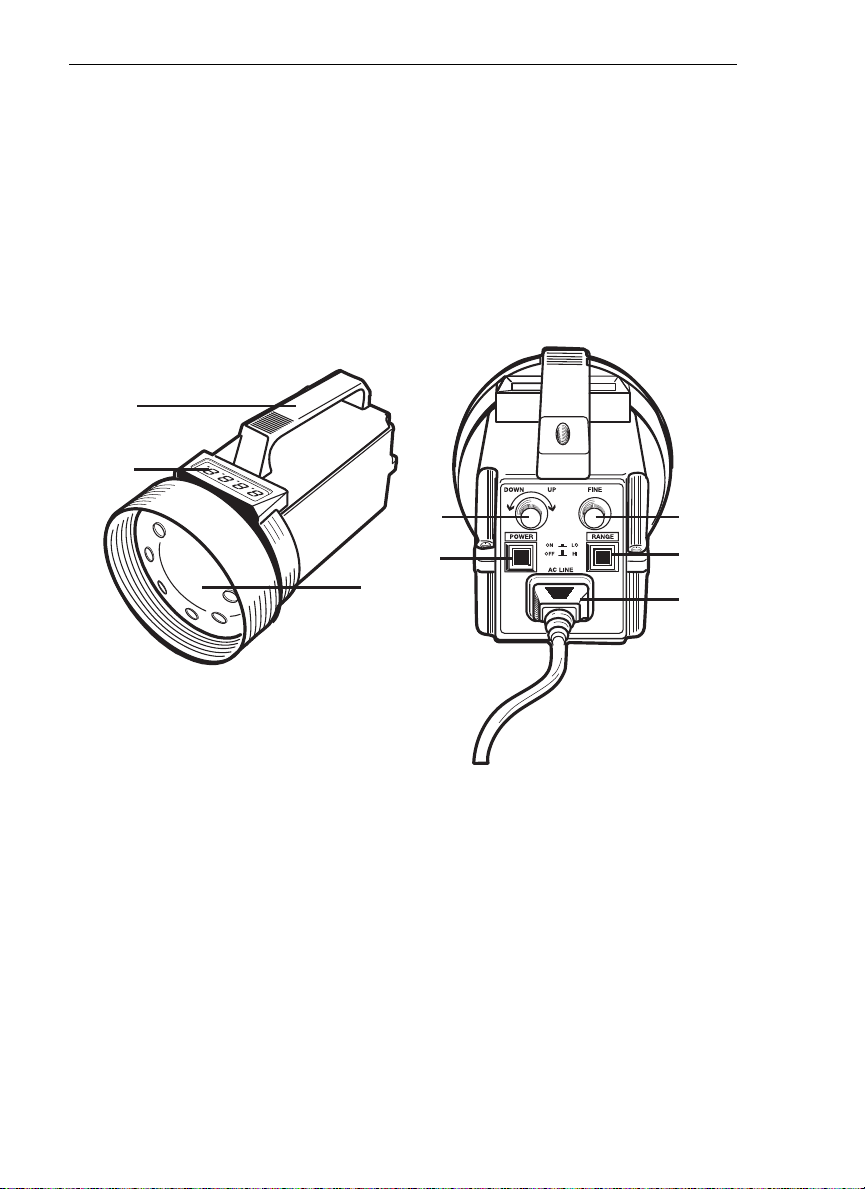

Meter Description

3

2

1. Xenon lamp

2. LED Display

3. Grip handle

4. COARSE adjust knob

5. FINE adjust knob

6. Power ON/OFF switch

7. Range Select Switch

8. AC power cord and jack

4

5

67

1

8

Model 461830/461831 Version 2.2 November 2003

5

Page 6

Operation

Powering the instrument

1. Plug the supplied power cable into the instrument’s power cable jack.

2. Plug the other end of the cable into an appropriate AC power source. The Model

461830 requires 110VAC and the 461831 requires 220VAC. Do not plug the device

into an incorrect power source otherwise damage to the instrument will result.

3. Use the ON/OFF switch to turn the instrument on or off.

Speed (RPM) Measurements

1. Remove power to the device under test so that it is stationary.

2. Affix a reflective mark or place a small piece of the supplied reflective tape on the

device under test.

3. Point the Stroboscope’s beam toward the reflective mark.

4. Use the ‘FINE’ and ‘COARSE’ adjustment knobs to synchronize or "stop" the motion of

the reflective mark (read the ‘Display Notes’ section below).

5. Read the RPM value on the LED display.

Range Adjustments

1. While measuring, use the RANGE button to select the range as desired

2. The LOW range is used for measurements below 1,000 RPM. The HIGH range is used

for measurements above 1,000 RPM.

Model 461830/461831 Version 2.2 November 2003

6

Page 7

Display Notes for Speed Measurements

Care must be taken to ensure that the reflective mark is providing a 1:1 measurement.

Check that there is only one mark and not two, four, or more stationary marks on the object

under test.

Two or more stopped marks indicate a ‘harmonic’ measurement (2:1, 3:1, 4:1 etc.) and the

instrument will display double, triple, or quadruple the actual speed. A useful method of

avoiding harmonic measurements is to adjust the FINE/COARSE knobs until two images

(reflective marks) appear and then lower the flash rate (via COARSE/FINE knobs) until a

single, stationary image appears. This will be the actual speed.

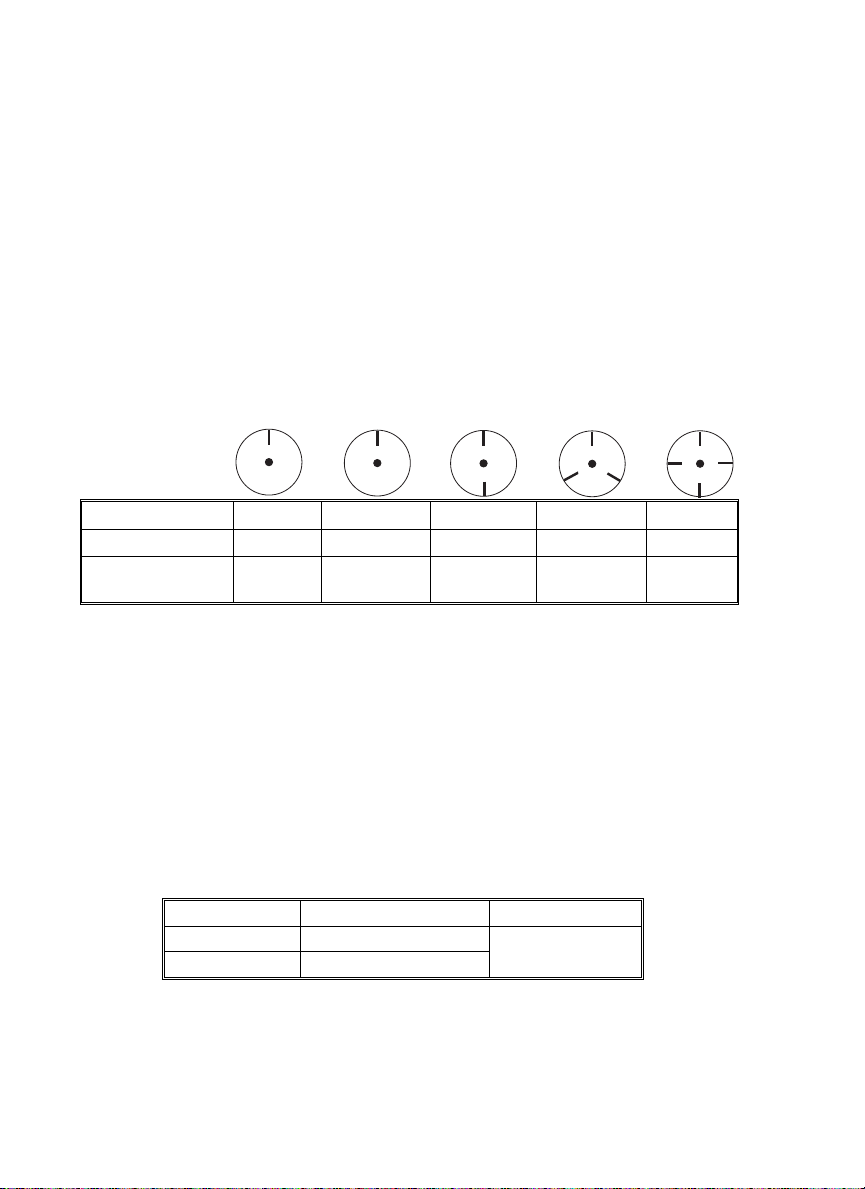

In the example below, a rotating shaft is affixed with one piece of reflective tape. The

illustrations below represent several possible images that would appear when the strobe

beam is pointed to the shaft.

If more than one reflective mark appears (as in columns 3, 4, and 5 below) the image is

showing a ‘harmonic’. The bold column (column 2) shows the actual speed of the shaft.

Column 1 shows a harmonic whereby the actual speed is divided in half. Because of this, it

is good practice to adjust the ‘FINE’ and ‘COARSE’ knobs until you can see the ‘doubled

harmonic’ (Column 3) and then the ‘halved harmonic’ (Column 1) and then find the setting

in-between (Column 2 in bold).

Shaft speed 1000rpm 1000rpm 1000rpm 1000rpm 1000rpm

Strobe flash rate 500rpm 1000rpm 2000rpm 3000rpm 4000rpm

Visible reflective

marks

Note that the LED display has an AUTO RANGE INDICATOR (flashing decimal at the far

right) that appears when the readings are over 10,000 RPM. In these cases, multiply the

displayed reading by 10.

Visually inspecting a moving object (stop-motion)

When the speed of the moving object matches the flash rate of the stroboscope, the

moving object appears still. Measure the speed of a moving object as described in the

previous sections to obtain a stop-motion. Once stop-motion is achieved, the FINE adjust

knob is used to vary the viewing perspective of the object under test for visual inspection.

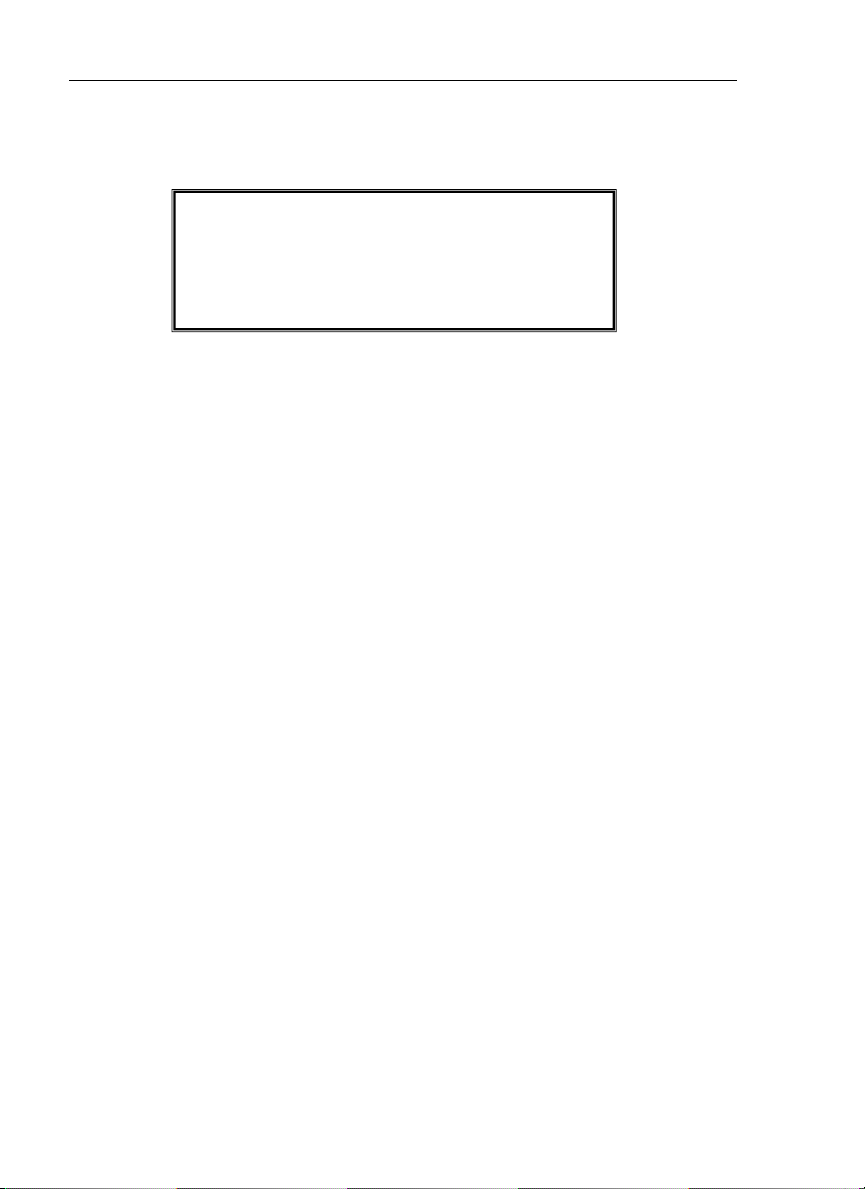

Important note on Test Durations

The Xenon lamp used in this instrument has time restrictions on usage. If the specified test

times and cool-off periods (shown in the table below) are not observed, damage to the

instrument can result and the life span of the lamp can be shortened.

< 3,000 rpm 30 minutes

> 3,000 rpm 5 minutes

1 1 2 3 4

RPM Max. Operating Time Cool-Off Time

10 minutes

Model 461830/461831 Version 2.2 November 2003

7

Page 8

Calibration and Repair Services

Extech offers repair and calibration services for the products we sell. Extech also provides

NIST certification for most products. Call the Customer Service Department for information

on calibration services available for this product. Extech recommends that annual

calibrations be performed to verify meter performance and accuracy.

All rights reserved including the right of reproduction in whole or in part in any form.

Support Hotline (781) 890-7440

Tech support: Ext. 200; Email: support@extech.com

Repair/Returns: Ext. 210; Email: repair@extech.com

Website: www.extech.com

Copyright © 2003 Extech Instruments Corporation

Model 461830/461831 Version 2.2 November 2003

8

Loading...

Loading...