Page 1

User's Manual

Datalogging Sound Level Meter

Model 407764

Range: 30dB to 130dB

•

4-digit LCD Display with 0.1dB resolution

•

A and C Frequency Weighting

•

RS-232 PC Interface with

•

128,000 point datalogger an d

Date / Time Stamp

Auto-Ranging

•

Introduction

Congratulations on your purchase of Extech’s Datalogging Sound Level Meter. The meter is

capable of performing all your noise measurements needs in addition to it’s capabilities for data

acquisition (direct data storage to a PC) or datalogging (data storage to internal memory for

later download). Data storage enables the user to save data, analyze data and generate

reports. This professional meter, with proper care, will provide years of safe reliable service.

Page 2

Specifications

Applicable Standards IEC651 Type 2, ANSI S1.4 Type 2

Accuracy ±1.5dB (under reference conditions)

Frequency range 31.5Hz - 8KHz

Measuring level 30 - 130dB

Frequency weighting A and C

Microphone 0.5” Electret condenser microphone

Display 4-digit LCD

Resolution: 0.1dB

Display period: 0.5 sec.

Bargraph 50dB scale (1dB steps). Display period: 50mS; Auto-ranging:

100dB scale, 2dB steps

Sampling rate 50mS

Memory size 128,000 records / 255 sets (non-volatile memory)

Datalogging sample rate 1 to 86,400 seconds per record

Time weighting FAST: 125mS, SLOW: 1 sec.

MAX Maximum reading held

Level ranges 30-80dB, 40-90dB, 50-100dB, 60-110 dB, 70-120dB, 80-130dB

(Total of 6 ranges)

Auto range 30 to 130dB

Linearity range 50dB

Alarm function OVER indicator for readings higher than high limit.

UNDER indicator for readings lower than low limit.

AC output 0.707 Vrms at Full Scale

Output impedance approx. 600Ω

DC output 10mV / dB

Output impedance approx. 100Ω

Power supply Four 1.5V ‘AA’ batteries

Battery life Approx. 30 hrs continuous operation

AC adap ter Voltage: 6VDC

Voltage Ripple: < 100mVpp

Supply Current: > 100mADC

Socket: Pin Ground

Casing: Positive

External Diameter: 3.5mm

Operating temperature 32 to 104

Operating humidity 10 to 80%RH

Storage temperature 14 to 140

o

F (0 to 40oC)

o

F (-10 to 60oC)

Storage humidity 10 to 80%RH

Memory size 128,000 data records with Date and Time Stamping

RS-232 Interface Baud rate: 9600bps

Dimensions 10.4 x 2.8 x 1.4” (265 × 72 × 35mm

Weight Approx. 11.5 oz. (358g) including battery

Accessories Batteries, carrying case, screwdriver, windscreen, 3.5mm plug, RS-232

cable , Windows

TM

compatible software.

Safety symbols

Meter is protected throughout by double insulation or reinforced

insulation.

CE Complies with EMC

2

Model 407764 Version 2.1 9/07

Page 3

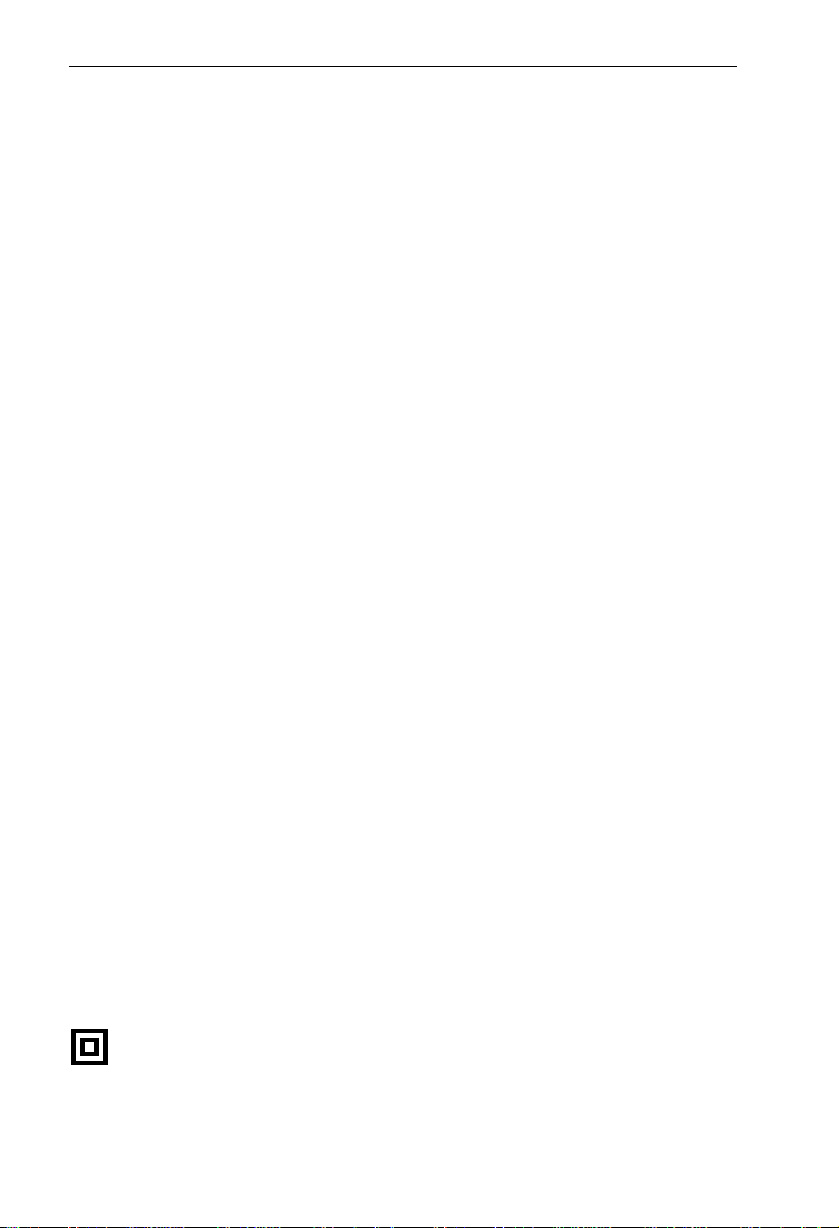

Meter Description

1. Microphone

2. Display

3. Power switch

4. Level range control switch

5. MAX hold switch

6. Frequency weighting switch

7. Response time select switch

8. AC output terminal

9. DC output terminal

10. CAL (calibration) pot.

11. External DC 6V power

12. RS-232 interface connector

13. Battery cover

14. Tripod mounting screw

15. Wind-screen

(Figure 1)

Display Description

1. Range selection

2. Date information

3. SPL: Instantaneous sound pressure level

4. Low-Battery

5. MAX: Maximum SPL value is held

6. Data recording

7. Measurement value

8. Memory full

9. Units

10. Frequency weighting (A/C)

11. TIME function

12. 50dB level (Bargraph)

13. Over range

14. SLOW time response

15. FAST time response

16. Under range

(Figure 2)

3

Model 407764 Version 2.1 9/07

Page 4

Measurement Preparation

Read the following safety information before attempting to operate the meter

•

Use the meter only as specified or the meter's built-in protection may be impaired.

•

Maintenance & Cleaning

Service not covered in this manual should be performed by qualified personnel

•

Periodically wipe the case with a dry cloth. Do not use abrasives or solvents.

•

Battery Replacement

When the battery voltage drops to a critical level, the

symbol appears on the LCD. Replace

batteries as soon as possible after the battery symbol appears. The batteries (4 AA) are located

in the rear battery compartment. Remove the single Philips head screw (center rear) for access

to the batteries.

Measurements

Default Configuration

1. The meter's default configuration is as follows: 40 to 90dB, 'A' Frequency Weighting, and

'FAST' Response Time

2. The LCD will reflect the meter's configuration.

Measurement Considerations

1. Use a windscreen to cover the microphone in windy conditions.

2. Calibrate the meter often, especially if the meter has not been used for a long time.

3. Do not store/operate the meter in high temperature/humidity for long periods of time.

4. Keep the meter and the microphone dry.

5. Avoid severe vibration when using the meter.

6. Remove the battery when the meter will be stored for long periods of time.

Frequency Weighting

Change the Frequency Weighting by pressing the 'A/C' button. The 'A' or 'C' icon will display on

the right-hand area of the LCD.

Note: With ‘A’ weighting selected, the meter responds like the human ear (boosting and cutting

the noise amplitude over the frequency spectrum - see Appendix). ‘A’ weighting is used for

environmental measurements, OSHA regulatory testing, law enforcement, and workplace

design. Select ‘C’ weighting for flat response measurements (no boost or cut). ‘C’ weighting is

suitable for the sound level analysis of machines, engines, etc. Most OSHA related testing is

performed using 'A' Weighting and SLOW Response Time settings.

Response Time

Change the Response Time by pressing the 'FAST/SLOW' button. The 'FAST' or 'SLOW' icon

will display on the upper area of the LCD.

Note: Select FAST to capture noise peaks and noises that occur very quickly. In FAST mode,

the meter responds in 200ms. Select the SLOW Mode (meter responds in 500ms) to monitor a

sound source that has a reasonably consistent noise level or to average quickly changing

levels. Selection of Fast or Slow is determined by the application and any directives or

standards related to that application.

Auto/Manual Range

Press the LEVEL button up arrow to scroll through the following ranges: 30-80dB, 40-90,

50-100dB, 60-110, 70-120, 80-130 and 30-130dB (auto). The displa y will reflect the range for

each button press.

Use Auto Range when the noise source is relatively steady. Use one of the Manual

Notes:

ranges may be required if the dB levels are changing over a wide range.

4

Model 407764 Version 2.1 9/07

Page 5

Operation

1. Power the meter and select the desired Response Time (Fast or Slow) and Frequency

Weighting (A or C).

2. Select the desired range.

3. Hold the instrument comfortably in hand or position on tripod. Point the microphone

toward the noise source, the sound pressure level will be displayed on the meter’s LCD

display.

4. When MAX (maximum hold) mode is selected by pressing the MAX key, the instrument

captures and holds the maximum noise level reading on the display. Press the MAX key

again to clear the MAX reading.

Calibration

Note that a Sound Level Calibrator is required. Set up the meter as listed in Step 1 below.

To calibrate the meter;

1. Display: SPL (dBA)

Response Time: FAST

Disable the MAX function

Range: 70 to 120dB.

2. Insert the microphone carefully into the sound

level calibrator.

3. Power the calibrator and adjust the Sound Level Meter’s

CAL potentiometer (as shown in figure at right) to match

the Calibrator’s output.

4. Typically, a Sound Level Calibrator will supply 94dB

or 114dB at 1KHz. Adjust the Sound Level Meter’s CAL

potentiometer for a 94dB or 114dB LCD display

(Figure-3)

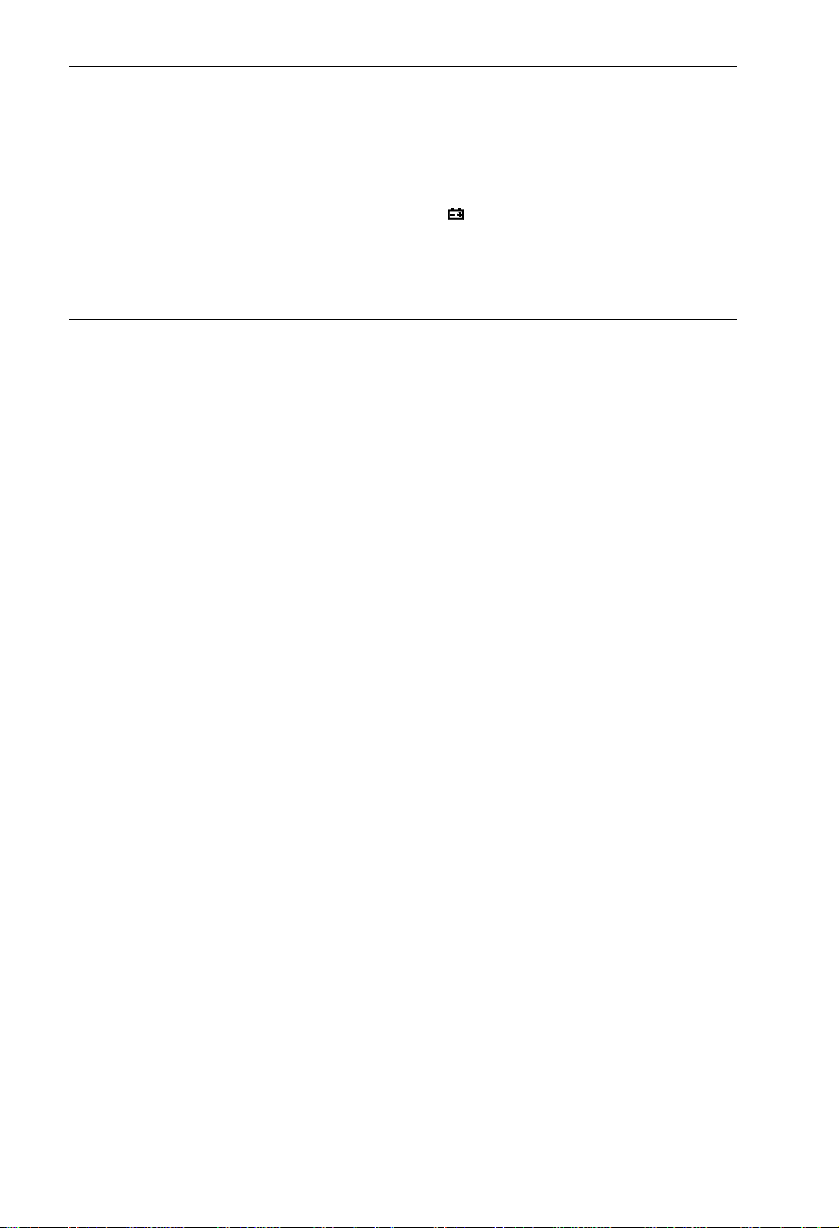

Analog output

The 407764 has two analog output jacks located on its right side; one for AC and one for DC.

For DC, the meter transmits 10mv / dB. For AC the full scale value is 0.707V. The output

impedance is 600Ω for AC and 100Ω for DC.

The supplied 3.5mm stereo mini-plug can be used to assemble a cable to connect to either of

the meter’s analog output jacks. When using a stereo plug, like the one supplied, short the Tip

and the Ring (see diagram below). Ground (negative) connects to the Sleeve while the positive

signal is taken from the Tip/Ring. For mono plugs, ground connects to the Sleeve while the

positive signal is taken from the Tip. The meter output can then be transmitted to a chart

recorder, datalogger, or other data storage device.

(Figure 4)

Stereo

Sleeve

Ring

Tip

5

Model 407764 Version 2.1 9/07

Mono

Sleeve

Tip

Page 6

DataLogging

The internal memory of the meter can store up to 128,000 reading in up to 255 recording

sessions (called sets). Prior to beginning data storage, the meter’s real time clock and the

datalogger’s sample rate must be set using the supplied software. The clock is set in the

Control Panel window and the sample rate is set in the Logger window.

1. Set the real time clock (if required).

2. Set the sample rate (if required).

3. To record data, press & hold the RECORD key for 3 seconds until the “RECORD” symbol

flashes once per second on the LCD. Press the Record key again to stop recording data.

4. If the recording memory is full, the “FULL” symbol will appear on the LCD.

5. To clear the recording memory press and hold the RESET key and power the meter. The

LCD will show the “dEL” icon letting the user know that the datalog memory has been

cleared.

6. To Download or Record data via a PC refer to the PC Interface section below.

PC Interface

Connecting the Meter to a PC

Refer to Figure 5. Connect the 9-pin male connector to the Sound Level Meter, and connect the

9-pin female connector to the 9-pin COM1 PC port.

PC Requirements (figure 5)

• 486 IBM compatible PC or better

• One 3.5" high density disk drive

• Available serial port.

• 4M Bytes H.D. storage space

• EGA or VGA monitor

• Windows 95, 98, 2000, NT, XP Operating System

• 3-button or 2-button Microsoft compatible

mouse. At least a 486 PC is recommended

for displaying all software windows with a

fast sampling rate (such as 1 second). If a 386/25 PC is used, you can only open one

window (LIST, GRAPH, ANALOG) at a time when using fast sampling rates.

Installing the Windows Application Program

Follow the instructions on the disk for installation. When installing the software, please use the

Visual Basic version (VB) on installation CD.

6

Model 407764 Version 2.1 9/07

Page 7

Software Control Panel Description

METER SIMULATION

The left side of the Control Panel window provides a replica of the meter’s front panel and

display.

MAX: Hold and update maximum value

A/C A/C weighting selection

RESET Reboot and clear the data memory

F/S Fast/Slow selection

REC Enable datalogging

LEVEL Set range

DATA ACQUISITION CONTROLS and DISPLAYS

MIN: Displays the minimum value recorded

MAX: Displays the maximum value recorded

TIME: Displays the Real Time Clock Setting

SAMPLING TIME Display of data acquisition sampling rate (Fig 7)

PC SAMPLING: Opens data acquisition sampling rate selection box. (Datalogging

<--RESET-->: Resets the MIN and MAX stored readings

SYSTEM TIME SET: Sets the meter’s clock to the value of the pc clock

SAVE AS: Opens the data file storage window (*.dat)

OPEN FILE: Opens the data file retrieve window (*.dat) (Fig.8)

FILE NAME: Displays name and location of data acquisition file

START RECORDING: After opening a file, click to start recording.

STOP RECORDING: Stop recording and close the file

EXIT Close program

(Figure-7) (Figure-8)

Selecting the datalog sample rate Opening a datalog file (*.dat)

The Control Panel (Figure 6)

sample rate is set in the MEMORY “Logger” window)

7

Model 407764 Version 2.1 9/07

Page 8

DISPLAY SELECTIONS

(Figure-9) (Figure-10)

GRAPH LIST

(Figure 11)

ANALOG

Logger Window (memory setup/ data download)

The Logger window sets the sample rate of the meter’s internal memory and provides the

controls to download display and save stored data.

MEMORY Displays memory size

REMAINING Displays amount of

TIME OF METER When clicked,

ID CODE Numeric Identification

SAMPLING Datalogger sample

NUMBER OF SETS Click on the bar to download the stored data

TIME OF RECORDING Click on the bar to display sets downloaded. Click on a set to select

NUMBERS OF REC Displays the number of records (data points) in the selected set.

SHOW DATA Display, Save or Graph data from selected set

unused memory

downloads and

displays the meter’s

date and time

code. Enter the code

in the box and click on

the bar to store the

code.

rate. Enter the sample

rate in the box (in

seconds) and click on

the SAMPLING bar to store the value.

data for display

8

Model 407764 Version 2.1 9/07

Page 9

DATA DOWNLOAD PROCEDURE

1. Click the MEMORY icon in the Control Panel screen.

2. Click the NUMBERS OF SETS button, the number of sets will appear.

3. Click on the TIME OF RECORDING button to view each recorded set.

4. Click on a SET in the TIME OF RECORDING box. The number of records in the set will

appear and the data will be downloaded from meter to PC. Save to disk if desired.

5. Click the SHOW DATA button for details on each record. Figure 13 shows the data list.

Select SAVE, PRINT, GRAPH, or EXIT from the menu choices.

Note: In the example for Figure 12, there are 3 sets of recorded data in memory. Set No. 3 has

15 records. Note: If you need to change the ID CODE or the SAMPLING time, click on the

desired parameter, type the changes and click on the bar.

(Figure-13) – List of datalogged set (Figure-14) – Graph of datalogged set

(Figure-15) – Selecting a range of datalogged records

9

Model 407764 Version 2.1 9/07

Page 10

Calibration / Repair Services

Extech offers complete repair and calibration services for all of the products we sell. For

periodic calibration, NIST certification or repair of any Extech product, call customer service for

details on services available. Extech recommends that calibration be performed on an annual

basis to insure calibration integrity.

Warranty

EXTECH INSTRUMENTS CORPORATION warrants this instrument to be free of d efects in parts

and workmanship for one year from date of shipment (a six month limited warranty applies on

sensors and cables). If it should become necessary to return the instrument for service during or

beyond the warranty period, contact the Customer Service Department at (781) 890-7440 ext. 210

for authorization or v isit our we bsite at ww w.extech.co m (clic k on C ont a ct Ex tec h and g o to Serv ic e

Department to request an RA number). A Return Authorization (RA) number must be issued before

any product is returned to Extech. The sender is responsible for shipping charges, freight, insurance

and proper packaging to pr event damag e in transit. This warr anty does not ap ply to defects resulting

from action of the user s uch as misus e, improp er wiring, o peratio n outs ide of spec ificatio n, improper

maintenance or repair, or unauthorized modification. Extech specifically disclaims any implied

warranties or merchantability or fitness for a specific purpose and will not be liable for any direct,

indirect, incidental or consequential damages. Extech's total liability is limited to repair or

replacement of the prod uct. The warr anty set forth ab ove is inclusive an d no other warra nty , whether

written or oral, is expressed or im pl ied.

Technical support: Extension 200; E-mail: support@extech.com

Repair & Returns: Extension 210; E-mail: repair@extech.com

Product specifications subject to change without notice

For the latest version of this User’s Guide, Software updates, and other

up-to-the-minute product information, visit our website:

Extech Instruments Corporation, 285 Bear Hill Rd., Waltham, MA 02451

Copyright © 2005 Extech Instruments Corporation. All rights reserved

including the right of reproduction in whole or in part in any form.

Support line (781) 890-7440

www.extech.com

10

Model 407764 Version 2.1 9/07

Page 11

Appendix - Typical ‘A’ Weighted Sound Levels

50 HP Siren (100')

Jet take-off (200')

Riveting machine

Subway (20')

Pneumatic drill (50')

Vacuum cleaner (10')

Large store

Small office

Residential area (night)

Whisper (5')

Threshold of hearing

130

110

90

70

50

30

10

140

120

Chain saw

100

Boiler room

80

Freight train (100')

Speech (1')

60

Large Office

Residence

40

Sound studio

20

0

11

Model 407764 Version 2.1 9/07

Page 12

Software Protocol

Data Protocol Baud rate: 9600bps

Byte1 Byte2 Byte3 Byte4 Byte5

02 Status Function 03

Leading byte Ending byte

Status Byte2

Bit7 Bit6 Bit5 Bit4 Bit3 Bit2 Bit1 Bit0

0 Fast C Normal Normal Normal 0 0 0 30-80

1 Slow A Max Full Rec 0 0 1 40-90

0 1 0 50-100

0 1 1 60-110

1 0 0 70-120

1 0 1 80-130

1 1 0 30-130

1 1 1

Function Byte3

Bit7 Bit6 Bit5 Bit4 (x10

0 Normal Normal Normal

2

) Bit3-0 (x10)

00-19

1 OVER UNDER BT

Function Byte4

Bit7-4 (x 10

0

0

) Bit3-0 (x10-1)

00-99

1

Command Protocol

Set time and date - Send 7 bytes

D YY MM dd hh mm ss

leading byte year month date hour min sec

Set sampling rate – Send 3 bytes

Set ID code – Send 3 bytes

Get software version – Output “V” - Receive 1 byte (0 – 255)

Get system argument – Output “Y” – Receive 10 bytes

ID Code

2bytes

Get time and date – Output “C” - Receive 6 bytes (YY+MM+dd+hh+mm+ss)

Receive 6 bytes (Sets+YY+MM+dd+hh+mm+ss+Status+Sample rate+Records)

Get Record – Output “K”+N records”

Receive (YY+MM+dd+hh+mm+ss+Status+Sampling rate+Records+1

record+…+nth record)

Erase Command: “EEE” (3 bytes) Set MAX spl; “M” (1 byte)

Switch Fast/Slow: “F” (1 byte) Stop Recording: “T” (1 byte)

Switch A/C: “A” (1 byte) Start Recording: “S” (1 byte)

Switch range: “U” (up), “P” (down) (1 byte)

W high byte low byte

leading byte 1 – 65535 sec

X high byte low byte

leading byte 1 – 65535

Version

1 byte

ID code

1 byte

Data sets

1 byte

Last address

3 bytes

Sample rate

2 bytes

st

record+2nd

12

Model 407764 Version 2.1 9/07

Loading...

Loading...