Page 1

INSTRUCTION MANUAL

Model 403380

Autoranging DMM ProbeMeterTM

• Measures voltage, resistance, frequency,

capacitance, temperature, and duty cycle.

• Back lit LCD with Autorange and full function

displays

• Audible continuity and diode tests

1. INTRODUCTION

Congratulations on your purchase of Extech’s Autoranging DMM ProbemeterTM. This

professional meter, with proper care, will provide years of safe reliable service.

1 403380 Ver. 1.01 7/99

Page 2

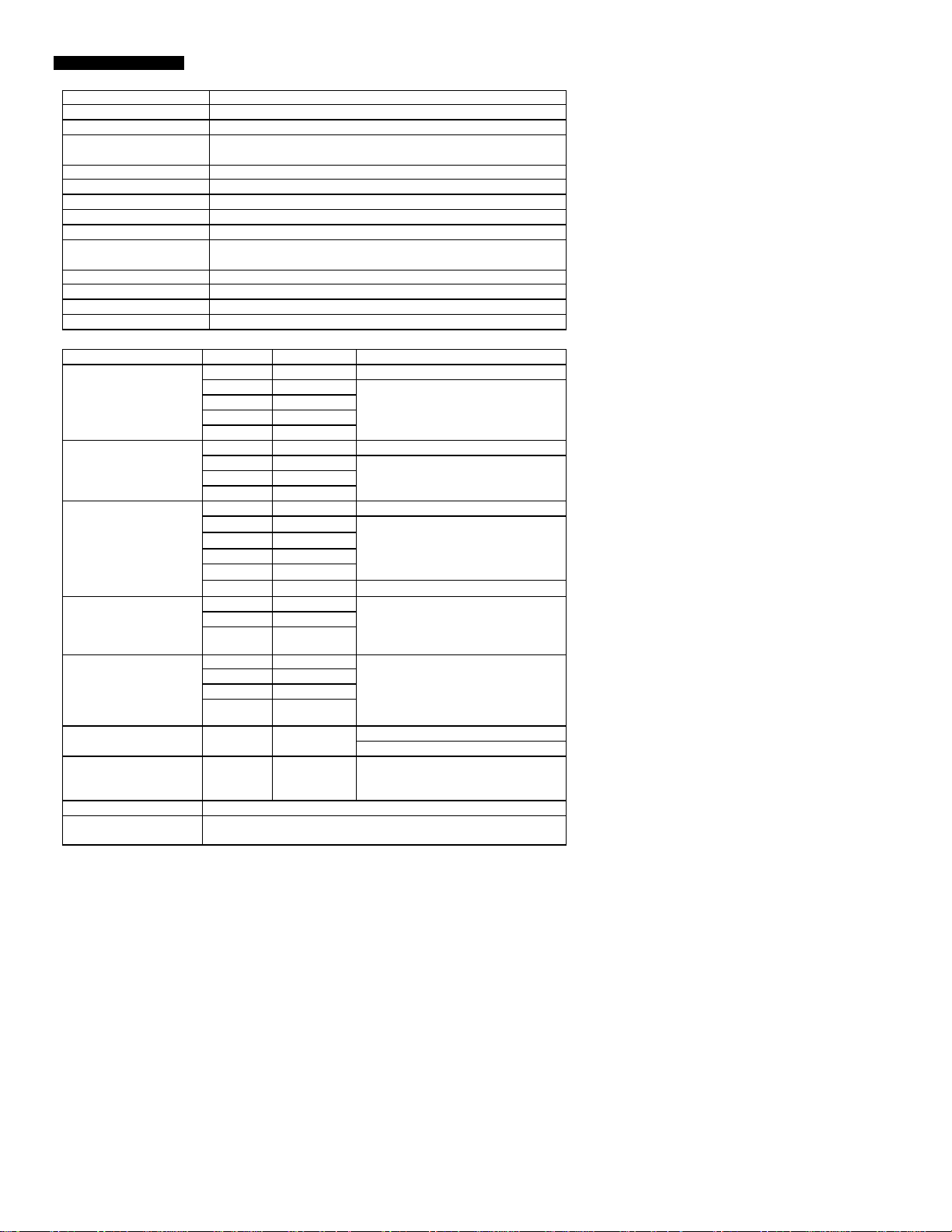

2. SPECIFICATIONS

2.1 General Specifications

Display 2500 count backlit LCD

Polarity Automatic, positive implied, negative polarity indication

Overrange "OL" or "-OL" is displayed

Low battery indication The low battery icon is displayed when the battery voltage

drops below the operating level

Measurement rate 2.5 times per second, nominal

Operating conditions 32 oF to 104oF (0 to 40oC) at <70% relative humidity

Storage Temperature -4oF to 140oF (-20 to 60oC), 0 to 80% R.H.

Accuracy Stated accuracy at 73.4oF ±9oF, <75% relative humidity

Auto Power off After 30 minute period of non-use

Safety EN61010-1 protection class II over-voltage category

(CAT II 600V) pollution degree 2

Power 4 x 1.5V (AAA size) batteries

Battery life 500 hours typical with alkaline

Dimensions 6.7 (H) x 1.7 (W) x 1.6 (D)” (170mm x 44mm x 40mm)

Weight 4.5 oz. (140g) including batteries.

2.2 Function Specifications

Function Range Resolution Accuracy

DC Volts

Input impedance: 10MΩ

Overload protection:

600VAC/DC

AC Volts (50-500Hz)

Input impedance: 10MΩ

Overload protection:

600VAC/DC

Resistance

Open ckt. V: 0.4VDC

Overload protection:

500VAC/DC

Capacitance

(Autoranging)

Overload protection:

250mV 100uV ±(0.25% rdg + 5dgts)

2.5V 1mV

±(0.25% rdg + 1dgt)

25V 10mV

250V 0.1V

600V 1V

250mV 100uV not specified

2.5V 1mV

±(0.75% of rdg + 4dgts)

250V 0.1V

600V 1V

250Ω 0.1Ω

2.5kΩ 1Ω

±(0.3% rdg + 3dgts)

±(0.3% rdg + 1dgts)

25kΩ 10Ω

250kΩ 0.1kΩ

2.5MΩ 1kΩ

25MΩ 10kΩ

250nF 0.1nF

±(3.5% rdg + 4 dgts)

±(5.0% rdg + 10dgts)

2.5uF 1nF

25uF 10nF

500VAC/DC

Frequency

(Autoranging)

Sensitivity: 1.0V min.

Overload protection:

500VAC/DC

(Type K thermocouple)

Duty Cycle (2Hz-1kHz)

Overload protection:

5Hz 0.001Hz

±(0.05% rdg + 2dgts).

50Hz 0.01Hz

500Hz 0.1Hz

5kHz 1Hz

-4oF to

2498oF

0.1oF/1oF

±(2.0% rdg + 6oF) –4oF to 923oF Temperature

±(3.0% rdg + 4oF) 923oF to 2498oF

10%-90% 0.1% ±5dgts@2Vrms min

Pulse Width : 50uSec

500VAC/DC

Continuity

Audible alert <100Ω; Overload protection: 500VDC/AC

Diode Accuracy: ±(3.0% rdg + 3dgts); Resolution: 1mV.

Test current: 0.25A ±0.2mA; Test voltage: <1.6V.

2 403380 Ver. 1.01 7/99

Page 3

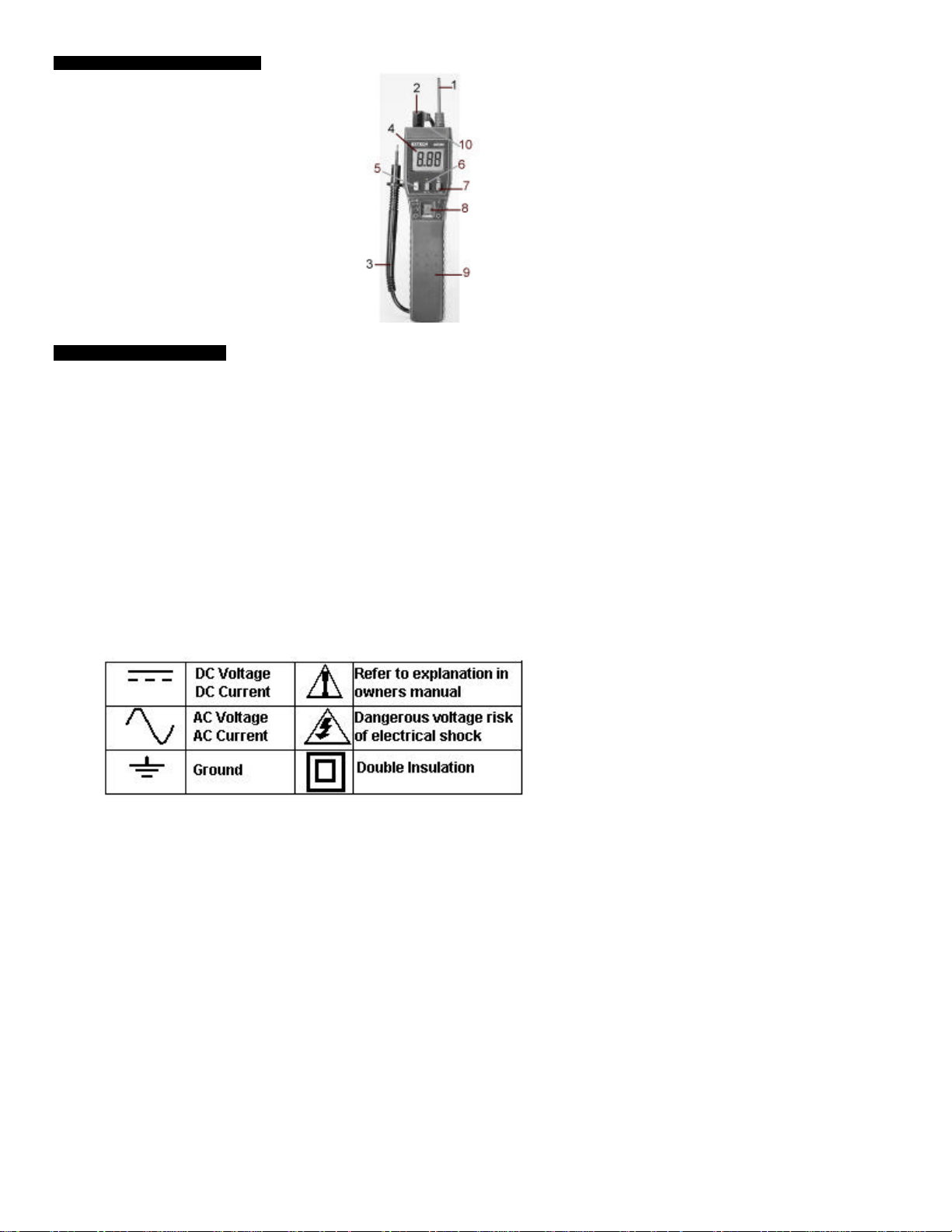

3. FRONT PANEL DESCRIPTION

1 Positive test lead (in meter jack)

2 Negative test lead (in meter jack)

3 Negative test lead (test end)

4 LCD Display

5 Select key

6 Temperature, duty cycle, Hz key

7 Data Hold / Backlight key

8 Function switch

9 Handle

10 Thermocouple input socket (top)

4. SAFETY INFORMATION

The following safety information must be observed to insure maximum personal safety

during the operation of this meter:

1. Do not use the meter if the meter/test leads appear damaged or if you suspect that the

meter is not operating properly.

2. This meter is not recommended for high voltage industrial use; for example, not for

measurements of 440 VAC or 600 VAC industrial power mains. The unit is intended

for use with low energy circuits to 600V AC/DC or high energy circuit to 250VAC or DC.

3. Use caution when working > 60V dc / 30V ac rms. Such voltages pose a shock hazard.

4. When using the probes, keep your fingers behind the finger guards on the probes.

5. Measuring voltage which exceeds the limits of the meter may cause damage and

expose the operator to a shock hazard. Always respect the voltage limits as stated on

the meter.

6. If the equipment is used in a manner not specified by the manufacturer, the protection

provided by the instrument may be impaired.

7. Refer to the following International Safety Symbols

3 403380 Ver. 1.01 7/99

Page 4

5. PREPARATION FOR MEASUREMENT

Before attempting measurements, read the Safety Information in Section 4. Always

examine the instrument for damage, contamination (excessive dirt, grease, etc.) and

defects. Examine the test leads for cracked or frayed insulation. If any abnormal

conditions exist do not attempt any measurements.

5.1 Auto Power-OFF mode

If unused for about 30 minutes, the meter will power down automatically. To disable

Auto Power-OFF mode, press the SELECT key while powering the meter.

5.2 Backlight / Data-Hold key

Press this key briefly to activate the Data Hold mode. The "H" annunciator will appear on

the LCD and the measurement data will freeze. Press and hold this key for 2 seconds to

turn the LCD backlighting on. Briefly press the key to return to normal display. To turn

the Backlight off press and hold again for 2 seconds.

5.3 Function Switch

Lower position (O) is power off mode, center position is voltage mode, and top position

is diode, continuity, capacitance, temperature, and resistance mode.

5.4 SELECT key

Press the yellow SELECT key to choose AC or DC volts when the voltage mode is

selected via the FUNCTION key. Press the SELECT key to choose the desired

measurement function when the FUNCTION switch is set to the

diode/continuity/ohms/capacitance mode. For reference, observe the display icons as

each mode is selected.

5.5 Hz, oF, % key

When the Function switch is in the upper position

(diode/continuity/ohms/capacitance/temperature modes), the Hz (frequency), oF

(Temperature), % (Duty Cycle) key permits the user to select the temperature function. If

the FUNCTION switch is set to the voltage position, the Hz/oF/% key permits the

selection of Frequency, Duty Cycle, or Voltage. Observe the LCD function icons to be

sure of which function is currently selected.

4 403380 Ver. 1.01 7/99

Page 5

6. OPERATION

6.1 Voltage Measurements

1. Connect the red test lead to the "V" jack and the black test lead to the "COM" jack.

2. Set the FUNCTION switch to voltage and press the yellow Select key to choose AC

or DC (the AC icon will appear on the LCD, the DC mode is implied).

3. Connect the test leads to the device or circuit being measured.

4. For dc, a (-) sign is displayed for negative polarity; positive polarity is implied.

6.2 Frequency Measurements

1. Set the FUNCTION switch to voltage and press the Hz/%/oF key to scroll through

the voltage/frequency/duty cycle modes. Select Frequency (Hz will appear on the

LCD).

2. Connect the red test lead to the "V" jack and the black test lead to the "COM" jack.

3. Connect the test leads to the point of measurement and read the LCD.

6.3 Duty Cycle Measurements

1. Set the FUNCTION switch to voltage and press the Hz/%/oF key to scroll through

the voltage/frequency/duty cycle modes. The % mode represents duty cycle.

2. Connect the red test lead to the "V " jack and the black test lead to the "COM" jack.

3. Connect the test leads to the point of measurement. The display will indicate 0.1%

to 99.9% duty cycle.

6.4 Resistance Measurements

1. Set the FUNCTION switch to the Ω position.

2. Remove power from the equipment under test.

3. Connect the red test lead to the "V" jack and the black test lead to the "COM" jack.

4. Touch the probes to the test points and read the resistance display.

6.5 Diode Tests

1. Set the FUNCTION switch to the diode position.

2. Remove power from the equipment under test.

3. To scroll through the continuity/diode/capacitance/resistance modes, press the

yellow SELECT key. Select diode by observing the diode symbol on the LCD while

scrolling.

4. Touch probes to the diode (Red lead to Anode, Black lead to Cathode of diode). A

correct forward-voltage drop is about 0.6V (silicon diode) or 0.3V (germanium).

5. Reverse the probes. If the diode is good, "OL" will display. If the diode is shorted,

".000" or another small number will display. If the diode is open, "OL" is displayed,

in both directions.

6. If a diode’s junction is measured in circuit and a low reading is obtained, the

junction may be shunted by a resistance of less than 1k. In this case the diode

must be disconnected from the circuit for accurate testing.

6.6 Continuity Measurements

1. Set the FUNCTION switch to the continuity position (same position as diode).

2. Remove power from the equipment under test.

3. To scroll through the continuity/diode/capacitance/resistance modes, press the

SELECT key.

4. Connect the test leads to the two points for which continuity is to be tested. The

audible tone will sound if the resistance is less than approximately 100 Ω.

5 403380 Ver. 1.01 7/99

Page 6

6.7 Capacitance Measurements

1. Set the FUNCTION switch to the capacitance position.

2. Remove power from the equipment under test.

3. To scroll through continuity/diode/capacitance/resistance modes, press the SELECT

key.

4. Discharge capacitors before trying to measure them.

5. Connect the "+" lead to the "V" jack and the "-" lead to the "COM" jack.

6. Touch the test leads to the capacitor, observing polarity of electrolytic capacitors,

and read the capacitance value on the LCD.

6.8 Temperature Measurements

1. Set the FUNCTION switch to the "oF" position and press the "oF” key to toggle the

ohms/oF modes.

2. Connect a Type-K thermocouple to the jack on the instrument. Place the probe or

thermocouple tip on or in the material to be measured and read the temperature on

the display.

6 403380 Ver. 1.01 7/99

Page 7

7. MAINTENANCE

7.1 Battery Replacement

Power is supplied by four 1.5V (AAA size) batteries. The low battery icon (symbol of a

battery on lower left corner of LCD) appears on the LCD display when replacement is

necessary. To replace the batteries, remove the rear screw and open the battery

compartment with your thumb. Remove and replace with fresh batteries. Reinstall

battery compartment cover.

7.2 Cleaning

Periodically wipe the case with a damp cloth and detergent, do not use abrasives or

solvents.

8. CALIBRATION / REPAIR SERVICES

Extech offers complete repair and calibration services for all of the products we sell. For

periodic calibration, NIST certification or repair of any Extech product, call customer

service for details on services available. Extech recommends that calibration be performed

on an annual basis to insure calibration integrity.

9. WARRANTY

EXTECH INSTRUMENTS CORPORATION warrants this instrument to be free of defects in parts and

workmanship for one year from date of shipment (a six month limited warranty applies on sensors and

cables). If it should become necessary to return the instrument for service during or beyond the warranty

period, contact the Customer Service Department at (781) 890-7440 for authorization. A Return

Authorization (RA) number must be issued before any product is returned to Extech. The sender is

responsible for shipping charges, freight, insurance and proper packaging to prevent damage in transit.

This warranty does not apply to defects resulting from action of the user such as misuse, improper wiring,

operation outside of specification, improper maintenance or repair, or unauthorized modification. Extech

specifically disclaims any implied warranties or merchantability or fitness for a specific purpose and will not

be liable for any direct, indirect, incidental or consequential damages. Extech's total liability is limited to

repair or replacement of the product. The warranty set forth above is inclusive and no other warranty,

whether written or oral, is expressed or implied.

7 403380 Ver. 1.01 7/99

Loading...

Loading...