Page 1

User Manual

Model 381295 and 381295-220

5MHz Dual Channel

True RMS Handheld Oscilloscope

Page 2

Table of Contents

Introduction ........................................................................................ 3

Main Features .........................................................................................................3

Safety................................................................................................... 3

Safety Precautions .................................................................................................. 3

Safety Symbols .......................................................................................................3

Quick-Start Manual.............................................................................4

Power on and off ..................................................................................................... 4

Division, Trigger and Function key..........................................................................4

Input Terminals ........................................................................................................4

Command (F1-F4), Arrow, Backlight and Help key ................................................. 4

Primary Menu Map..................................................................................................5

Positioning the waveform on the screen .................................................................5

Division key map ..................................................................................................... 6

Changing Vertical (A/div or B/div) division ..............................................................7

Changing Horizontal division................................................................................... 7

Trigger key map ......................................................................................................8

Trigger level control................................................................................................. 8

Function key map....................................................................................................9

Specifications...................................................................................10

General Specifications ..........................................................................................10

Oscilloscope Function ........................................................................................... 11

Digital Multimeter Functions..................................................................................12

Product Description.........................................................................14

LCD Area............................................................................................................... 14

Keys Area..............................................................................................................15

Terminal Area ........................................................................................................17

Operation .......................................................................................... 18

Powering the Meter ............................................................................................... 18

Changing Backlight ...............................................................................................18

Making Selections in a Menu ................................................................................18

Frequency measurements for CHA....................................................................... 19

Freezing the screen ..............................................................................................19

Changing the Graphic Representation..................................................................20

Acquiring the Waveform........................................................................................21

Triggering on a Waveform..................................................................................... 22

Setting Trigger level (on NORmal trigger mode)...................................................22

Making a single acquisition ................................................................................... 23

Setting Trigger mode (Tmode) .............................................................................. 23

Setting AUTO Trigger Level .................................................................................. 24

Setting Normal Trigger mode ................................................................................ 24

Setting Trigger Slope............................................................................................. 25

Storing and Recalling Screens..............................................................................25

Storing Screen.......................................................................................................25

Recalling Screen ................................................................................................... 26

PC Interface and Datalogging Sof tware......................................... 27

Maintaining the Meter ......................................................................30

Battery Replacement........................................................................................... 269

Appendices....................................................................................... 32

Troubleshooting guide........................................................................................... 32

Warranty, Repair, and Technical Support….............................…...32

2

381295 V1.4V 10/06

Page 3

Introduction

Main Features

• Rechargeable batteries and AC Adaptor:

Model 381295 (120V, 60Hz)

Model 381295-220 (240V, 50Hz)

• RS-232C PC interface for viewing, saving, and printing measurement and

waveform data.

• Dual Channel operation plus Auto Calibration features.

• Automatic settings for horizontal and vertical divisions.

• DC to 5MHz bandwidth

• Built-in auto ranging True-RMS digital MultiMeter

• Auto ranging

• Data hold and run modes.

• Backlit display with Low battery indication.

• Display Type: Super-Twist 132 x 128 pixels.

• Designed to comply with safety standards: UL3111 and CSA C22.2 No.1010-1

Safety

Attention

Carefully read the following safety information before using this instrument.

Safety Precautions

Specific warning and caution statements, where they apply, will be found throughout the

manual.

A ‘Caution’ identifies conditions and actions that may damage the instrument. A

‘Warning’ identifies conditions and actions that pose hazard(s) to the user.

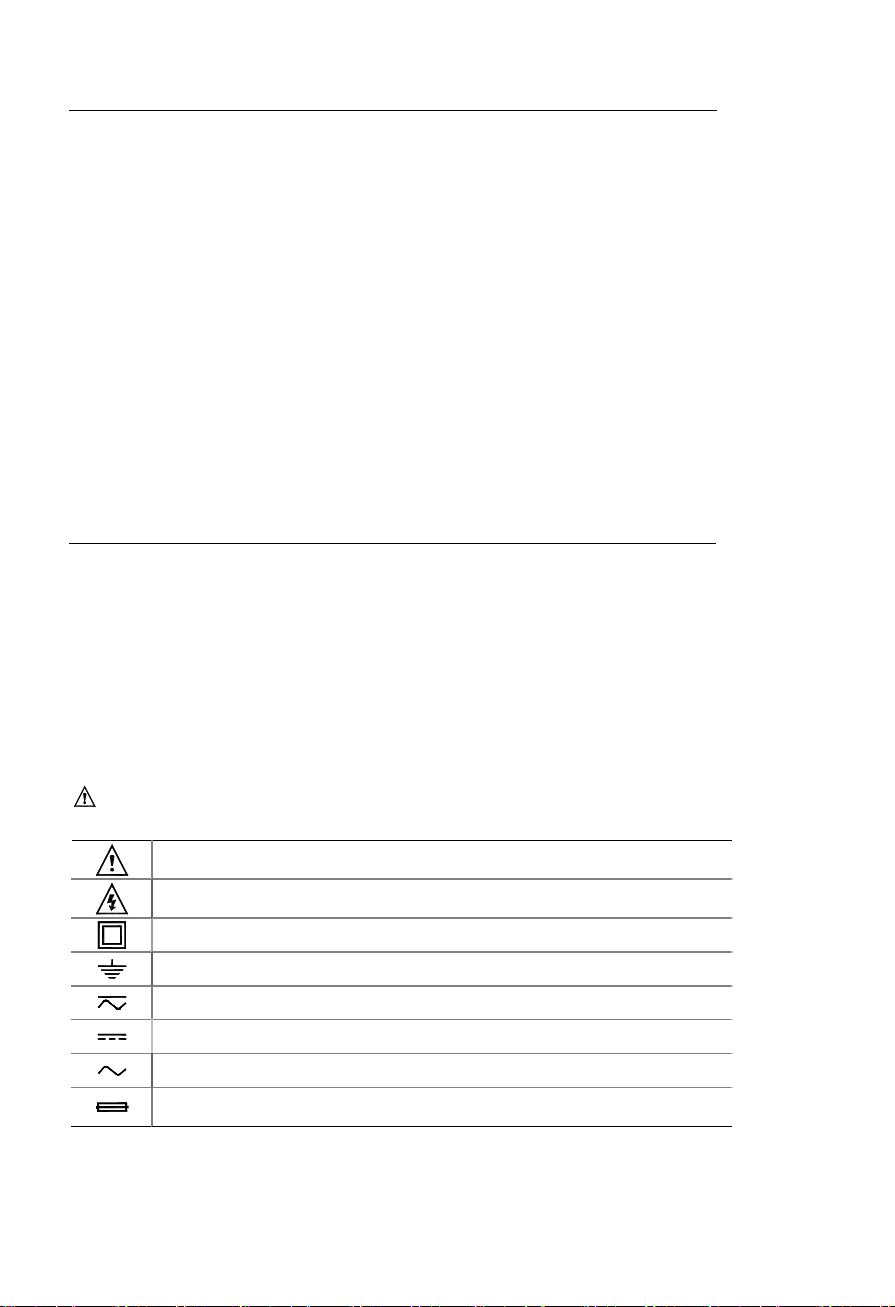

Symbols used on this instrument and in this manual are explained in the next table.

Warning

To avoid electrical shock, use only the supplied power supply.

See explanation in manual

Dangerous Voltage

Double Insulation (Protection Class)

Earth (Ground)

Either AC or DC

DC – Direct Current

AC – Alternating Current

Fuse

3

381295 V1.4V 10/06

Page 4

Quick-Start

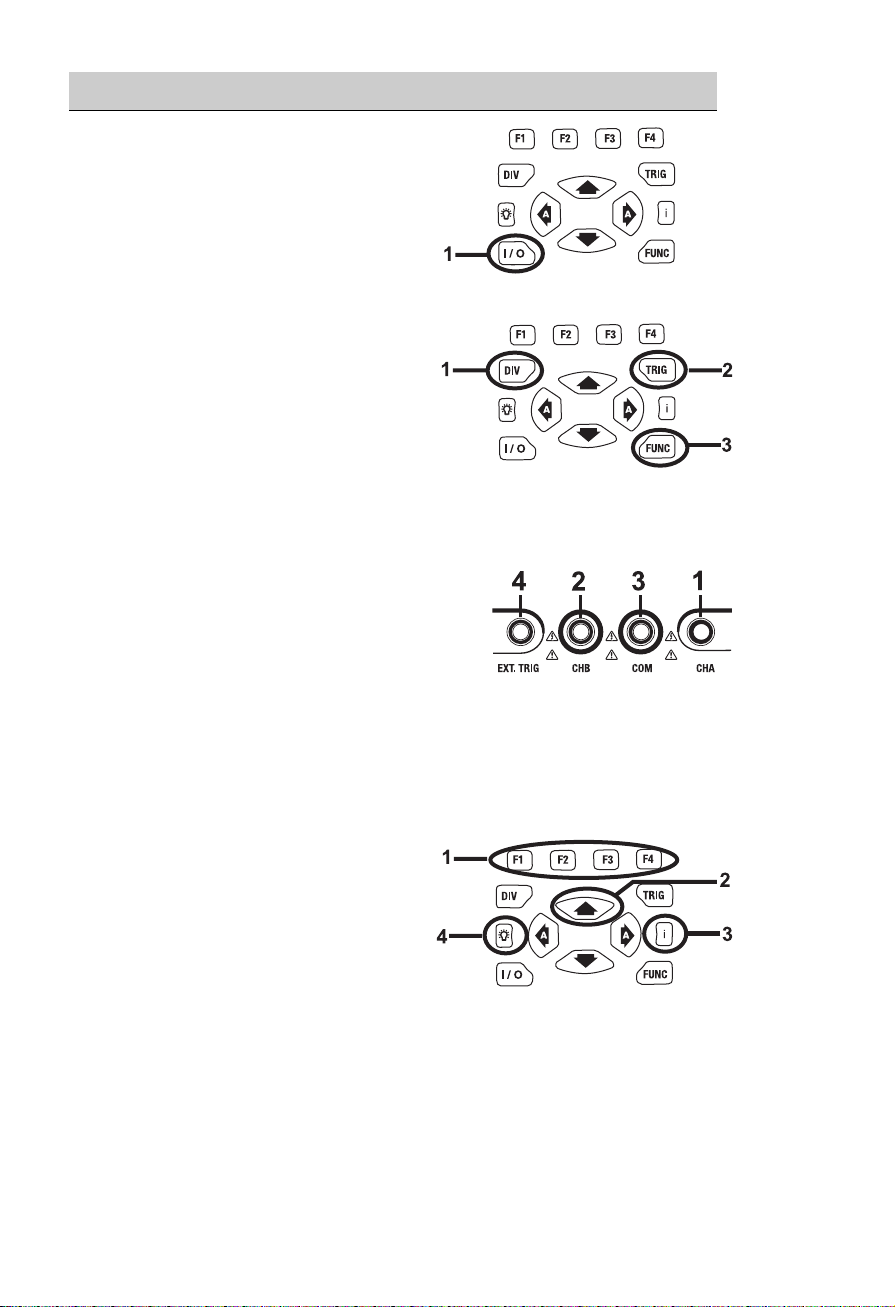

Power On and Off

1.Pressing and holding this button for 2 to 3

seconds will turn the unit on. Pressing this

button again will turn the power off.

Division, Trigger and Fu nction key

1 Division key:

Adjusts vertical division or Horizontal

division.

2 Trigger key:

Adjusts Trigger level.

Selects Single shot mode.

Selects trigger setup.

3 Function key:

Selects Scope Setup.

Selects general setup.

Input Terminals

1 Channel A:

Always use the red channel A input for single

input measurements.

2 Channel B:

For measuring two signals, use Channel B with

Channel A.

3 Common:

Use the black common as signal ground for low frequency measurements and for

ACV, DCV, Ohm, and Continuity measurements.

4 External trigger:

The EXT.TRIG input accepts external trigger signals.

Command (F1-F4), Arrow, Backlight and Help key

1

Function Command keys:

F1 through F4 are command ‘soft’ keys.

Their functions change with each screen.

2 Four arrow keys:

These keys serve as the primary means

of navigating the instrument’s menus and

operating displays.

3 Help key:

General information for the meter is available with a press of this key.

4 Display back light:

Press this button to turn on the backlight. To turn the back light off, press this button

again.

4

381295 V1.4V 10/06

Page 5

Quick-Start

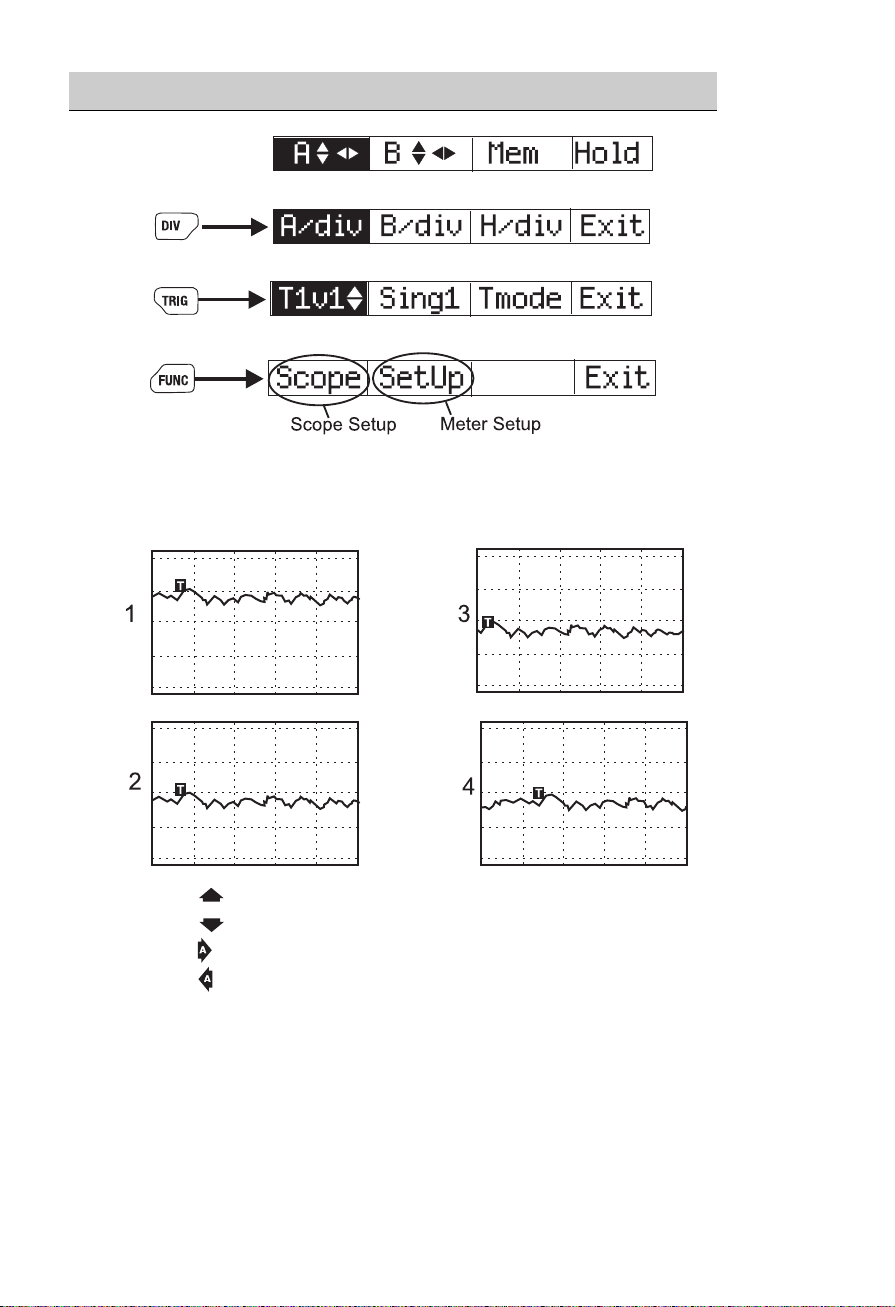

Primary Menu Map

Default Menu

Division Menu

Trigger Menu

Function Menu

Positioning the Waveform on the Screen

1. Pressing

2. Pressing

3. Pressing

4. Pressing

¸

moves the waveform up.

moves the waveform down.

moves the waveform left.

moves the waveform right.

5

381295 V1.4V 10/06

Page 6

Quick-Start

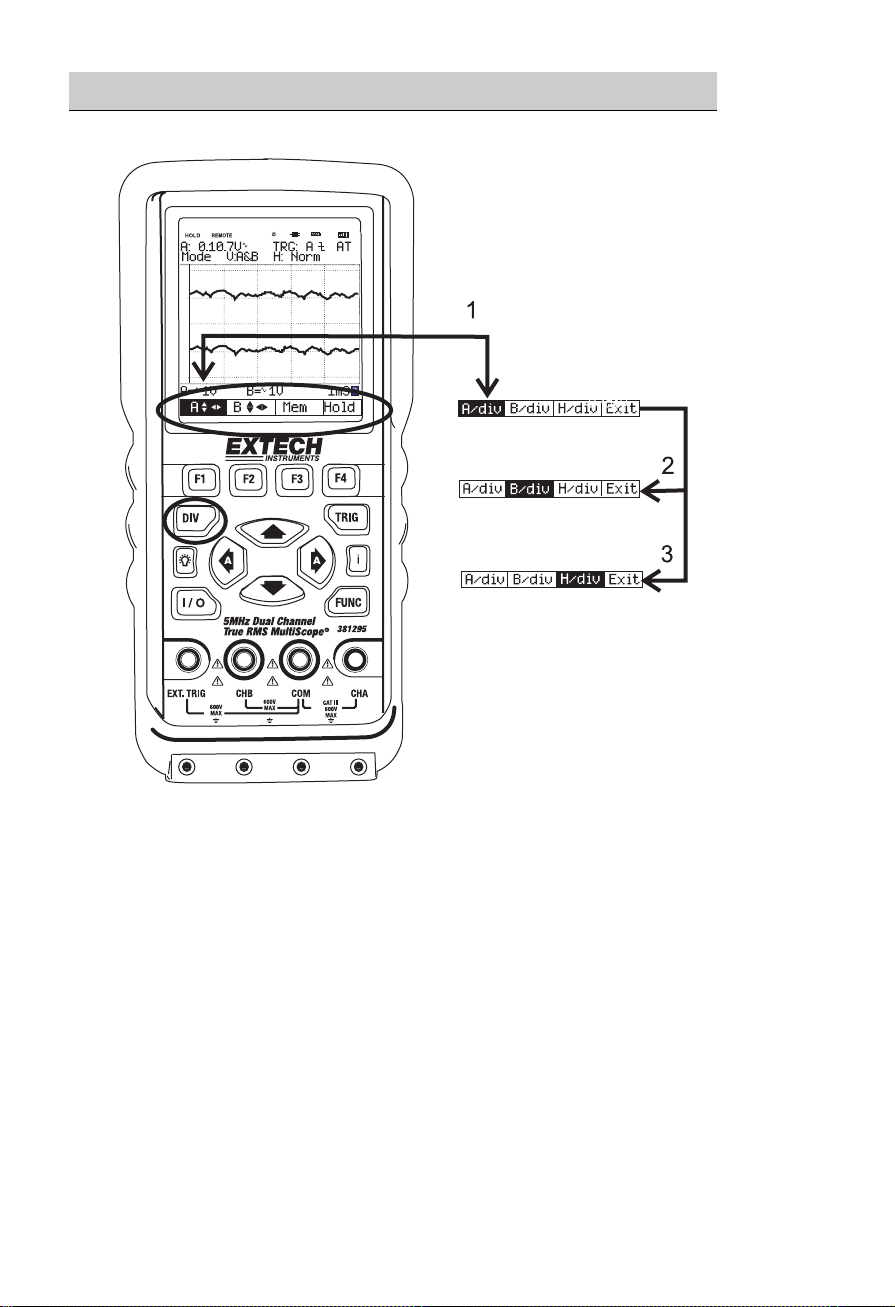

Division key map

1

Pressing DIV calls up the default division menu.

2 Press F2 to control the Channel B Vertical Division.

3 Press F3 to change the Horizontal Division.

4 Press F4 to exit.

6

381295 V1.4V 10/06

Page 7

Quick-Start

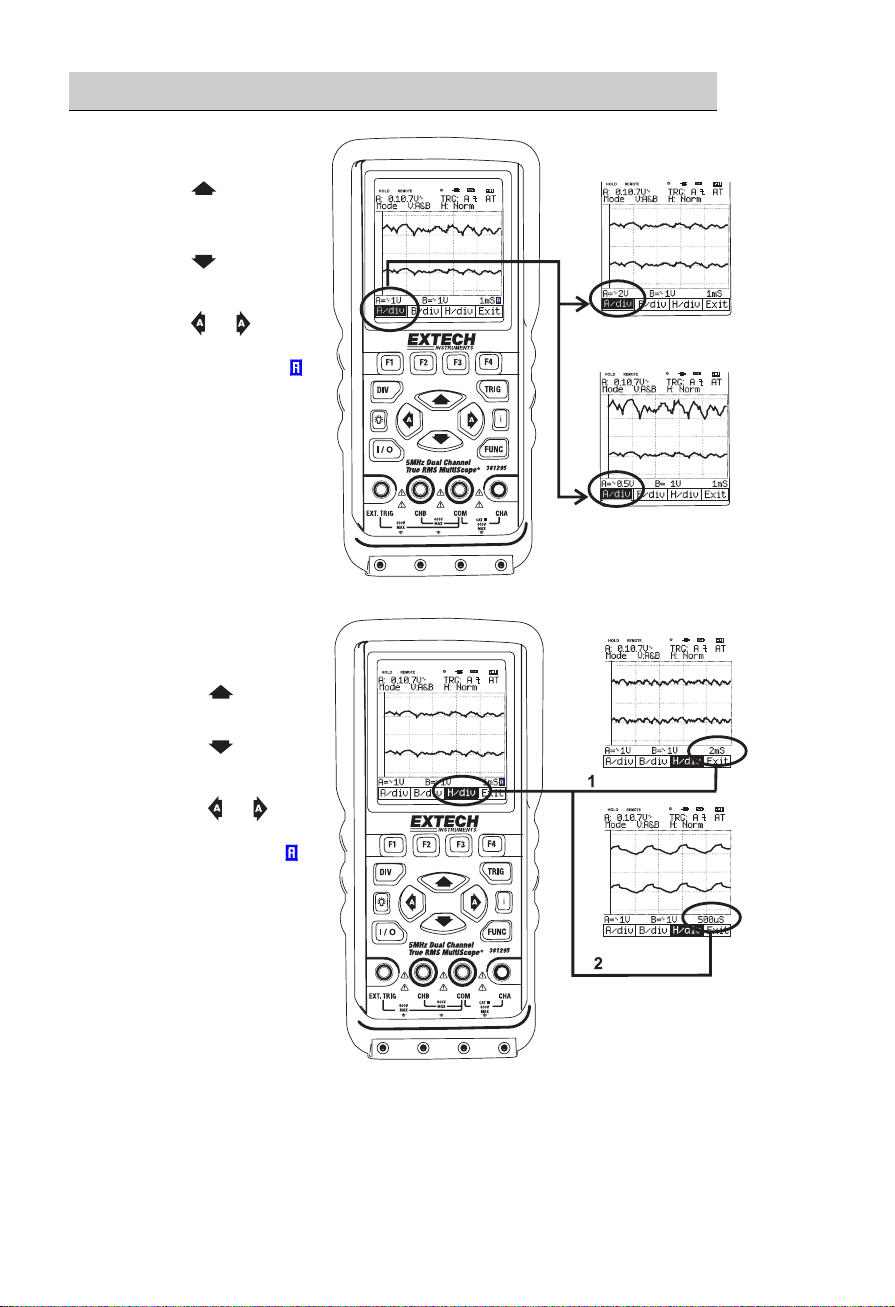

Changing Ve rtical (A/div or B/div) division

1 Pressing increases

CHA vertical division

(A/div).

2 Pressing

CHA vertical division

(A/div).

3 Pressing

change Div from

MANUAL to AUTO(

Changing Horizontal

division

1 Pressing increases

Horizontal division

(H/div).

2 Pressing

decreases Horizontal

division (H/div).

3 Pressing

change Div from

MANUAL to AUTO(

decreases

or will

).

or will

).

7

381295 V1.4V 10/06

Page 8

Quick-Start

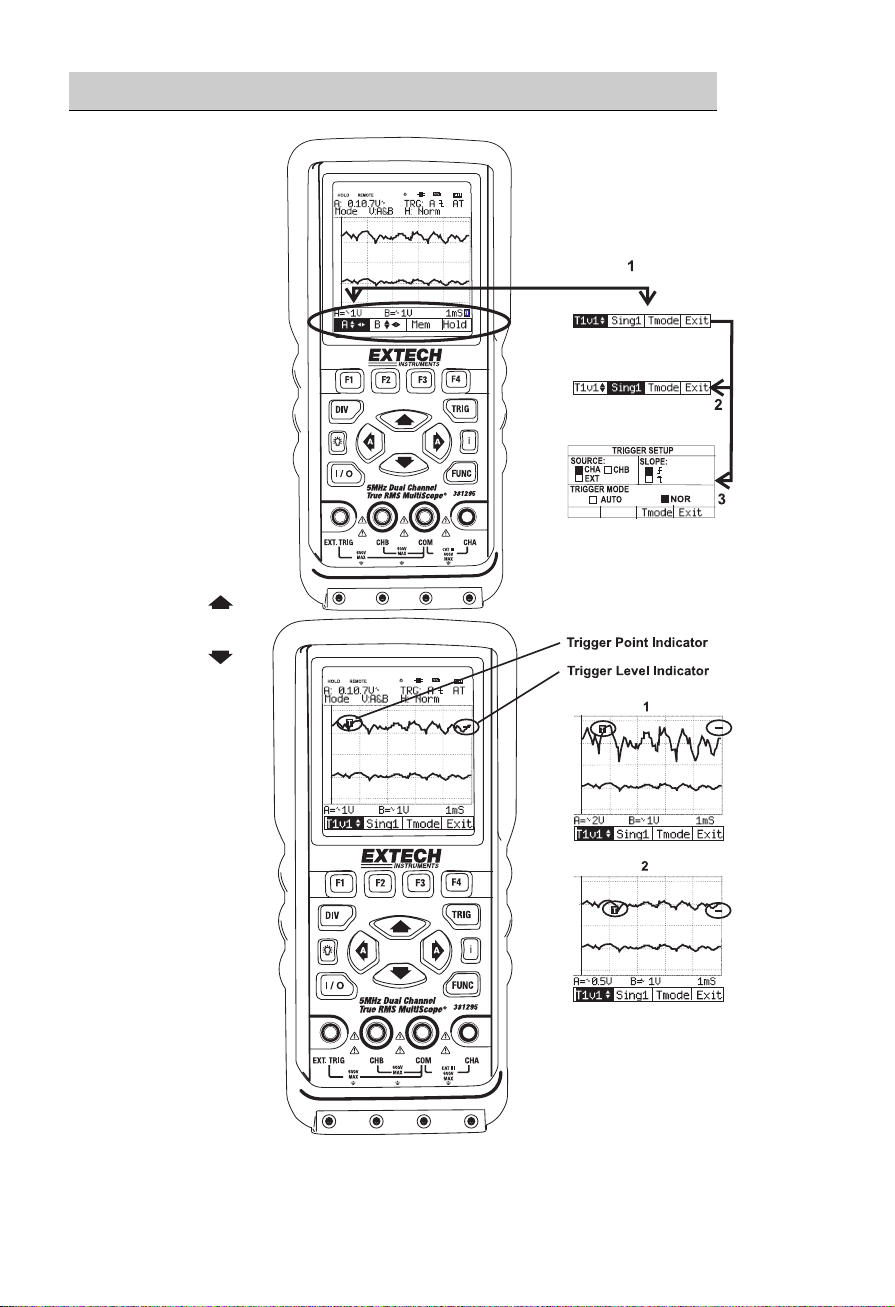

Trigger key map

1

Press TRIG to

display the

TRIGGER

default menu.

2 Press F2 for

Single shot mode.

3 Press F3 for

TRIGGER

SETUP.

4 Press F4 to exit.

Trigger level control

1 Pressing

increases the

Trigger level.

2 Pressing

decreases the

Trigger level.

8

381295 V1.4V 10/06

Page 9

Quick-Start

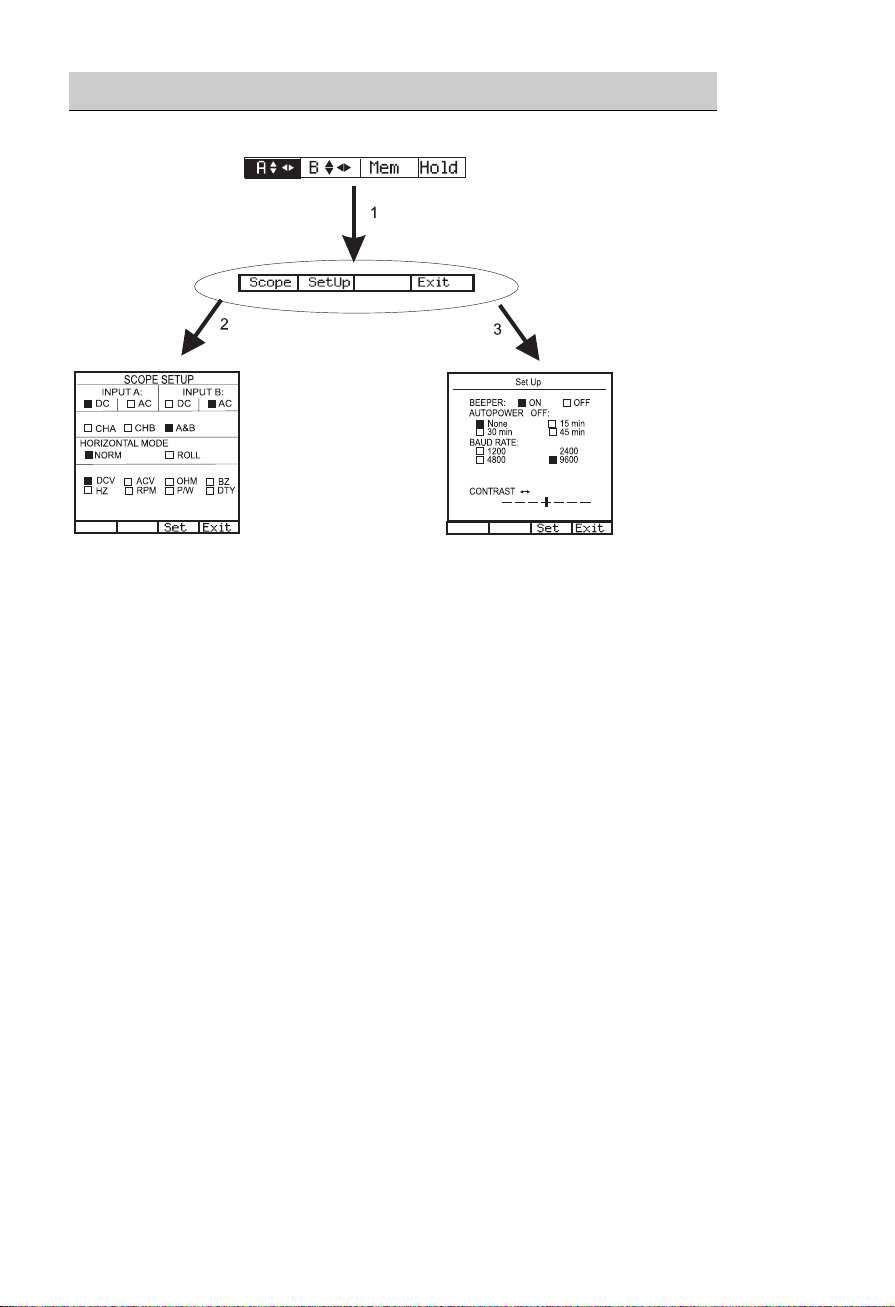

Function key map

1 Press FUNC to display the FUNCtion default menu.

2 Press F1 for SCOPE SETUP.

3 Press F2 for General SETUP. Press F4 to exit.

9

381295 V1.4V 10/06

Page 10

Specifications

General Specifications

Operational Temperature: +32°F to +122°F (0°C to +50°C)

Operational Relative Humidity: < 75%

Storage conditions: -4°F to 140°F (-20°C to +60°C); < 75%RH

Temperature Coefficient: 0.1 x (Specified Accuracy) per °C for temperature

Max. Voltage Input and Ground: DC or AC 600Vrms

Basic DC Accuracy: 0.3%

Scope Bandwidth: 5 MHz

MultiMeter AC Bandwidth: 20 kHz

Power Supply: Ni-MH Battery 4.8V (1.2V x 4 cell)

Battery Life: 4 Hours with Backlight OFF, 3 Hours with Backlight

Battery Charge Time: 3 Hours approx.

AC Adaptor/Charger: Class-2 transformer,

Display Type: Super-Twist 132 x 128 pixels

Equipment Dimensions: 3.5” (90mm) width x 7.7” (195mm) depth x 1.6”

Equipment Weight: 1.0 lbs

<64.4°F (18°C) to >82.4°F (28°C)

ON

Input: 120V AC 60Hz (381295)

Input: 240V AC 50Hz, (381295-220)

Output: 9V DC 1A

(40mm) height

. (460g) approx.

10

381295 V1.4V 10/06

Page 11

Oscilloscope Function

Horizontal

Sample Rate

Record Length

Sample / Division 25

Modes Single shot, Roll, Normal

Accuracy 0.01%

Sweep Rate 1uS to 5S in 1, 2, 5 sequence

25 MS/s (Dual CH mode)

50 MS/s (Single CH mode)

512 single shot mode

256 in all modes

Vertical

Bandwidth 5MHz

Resolution 8 Bit

Channels Dual

Coupling AC, DC

Input impedance

Accuracy ±3% reading + 0.1 x range; (“0” reference at center scale)

Max. Input Volts DC or AC 600Vrms

Volts / Division 50 mV to 500V in 1, 2, 5 sequence

1 MΩ

Triggering

Type CHA, CHB, External

Coupling AC, DC

Slope

Internal Trigger

Sensitivity

Rising (↑) or Falling (↓) edge

2 / 20 Division

Waveform Memory

Waveform Memory 16 Screen shots

11

381295 V1.4V 10/06

Page 12

Digital MultiMeter Function

DC V

Scope

V/Div

50m,100m,200m 500mV 0.1mV

500m, 1, 2 5V 0.001V

5, 10, 20 50V 0.01V

50, 100, 200 500V 0.1V

500 1000V 1V

DMM

Range

Resolution Accuracy Impedance

±(0.3%+3)

±(0.5%+5)

AC V

+5)

Accuracy (Hz)

±(2.5%

±(2%+5)

Scope

V/Div

50m,100m,200m 300mV 0.1mV

500m, 1, 2 3V 0.001V

5, 10, 20 30V 0.01V

50, 100, 200 300V 0.1V

500 750V 1V

DMM

Range

Resol.

50~450 0.45k~5k 5k~20k

±(0.75%

OHM

Range Resolution Accuracy Over Load Protection

5 kΩ 0.001 kΩ

50 kΩ 0.01 kΩ

500 kΩ 0.1 kΩ

5 MΩ 0.001 MΩ

±(0.5%+5)

±(0.75%+10)

600V DC or

Continuity Buzzer

Test Voltage Threshold Over Load Protection

1.7V 100 digits 600V DC or AC rms

Frequency

Range Resolution Accuracy Overload protection

100 Hz 0.01 Hz

1 kHz 0.0001 kHz

10 kHz 0.001kHz

100 kHz 0.01kHz

1 MHz 0.0001MHz

10 MHz 0.001MHz

±(0.05%+5)

12

381295 V1.4V 10/06

+5)

N/A

AC rms

600V DC

or AC rms

1 MΩ

Imped.

1 MΩ

Page 13

RPM

Range Resolution Accuracy

240 - 60,000 1 RPM ±(0.05%+5)

Pulse Width

% Duty

Range

2uS-500mS (Pulse Width > 2uS)

Range

25% - 75%

13

381295 V1.4V 10/06

Page 14

Product Description

In this section, the LCD, front panel buttons, controls and terminals are described.

LCD Area

The screen is divided into five areas: INDICATOR, READING, WAVEFORM,

SETTING and MENU areas. Refer to the Figure below.

[LCD Display]

1) Indicator

▪ HOLD: Freezes displayed reading

▪ REMOTE: RS-232 PC interface indicator

▪ BACKLIGHT(

▪ Charging LINE(

▪ BATTERY(

▪ BUZZER(

2) Primary Numerical Field (DMM Function): Displays numerical readings

3) Trigger selection: Channel A, B and External

3-1) Trigger level indicator

3-2) Trigger Cursor

4) Trigger Slope: Rising or Falling edge

5) Trigger mode: Normal or AUTO

6) Channel mode status

Verticle mode: CHA, CHB, A&B

Horizontal mode: Normal, Roll

7) Memory Address: 0 to 15

8) Live Scope Display (Channel A): Displays real time waveforms and freezes held

captures.

9) Channel B

10) Channel A Vertical Division

11) Channel B Vertical Division

12) Horizontal Division (Time base)

13) Command Menu Field

): Backlight indicator

): Charging Battery indicator

): Low battery indicator

): Buzzer indicator

14

381295 V1.4V 10/06

Page 15

Keys Area

14) Command Menu keys

The F1 – F4 soft keys’ functions change with each display screen.

Default (Command Menu)

A/div B/div H/div Exit

15)

Arrow keys: Use the arrow keys to highlight an item.

Press to move the cursor upward. This button also increases the value of a

selection.

Press to move the cursor downward. This button also decreases the value of a

selection.

Move the cursor to the left with this button.

Pressing this button changes Vertical division or horizontal division from MANUAL

to AUTO.

Move the cursor to the right with this button.

Pressing this button changes Vertical division or horizontal division from MANUAL

to AUTO.

16) DIV Division key: Set Channel A and B Horizontal Division

A/div B/div H/div Exit

15

381295 V1.4V 10/06

Page 16

7) TRIG Trigger key: Set Trigger level, Single mode and Setup

Tlvl

Singl Tmode Exit

F1 F2 F3 F4

F3

TRIGGER SETUP

SOURCE:

■ CHA □ CHB

□ EXT

TRIGGER MODE:

□ AUTO ■ NOR

Set Exit

F1 F2 F3 F4

18) Back Light Key: Activates Back Light for the LCD, Toggles backlight ON and

19)

20) I/O Power switch: Turns the instrument ON or OFF (hold for 3 seconds to turn on)

OFF.

i Help key: Provides meter model number, firmware version, serial number,

calibration date and manufacture date.

21) FUNC Function Key: Set Scope, Auto Scope and Setup of the METER

Scope Setup Exit

F1 F2 F3 F4

Scope Setup

FUNCF1 (Scope)

SLOPE:

□

■

SCOPE SETUP

INPUT A: INPUT B:

■ DC □ AC ■ DC □ AC

VERTICAL MODE:

□ CHA □ CHB □ A&B

HORIZONTAL MODE:

■ NORM □ ROLL

MEASUREMENTS A:

■ DCV □ ACV □ OHM □ BZ

□ HZ □ RPM □ P/W □ DTY

Set Exit

F1 F2 F3 F4

16

381295 V1.4V 10/06

Page 17

Terminal Area

22) Terminals description

The METER provides 4 input jacks.

① CHA: Channel A

Use the red channel A terminal for all single input measurements.

② COM: Common

Use the black COMMON terminal as signal ground for DCV, ACV, Ohm, Continuity,

frequency and RPM measurements.

③ CHB: Channel B

When measuring two signals, use channel B and channel A.

④ EXT. TRIG

External trigger.

17

381295 V1.4V 10/06

Page 18

Operation

Powering the METER

Follow the steps below to power the Meter from a standard ac outlet.

1. Insert Power Adaptor into AC outlet.

2. Connect the Power Adaptor to the Meter.

3. I/O Turn the Meter on by holding this button for about 3 seconds.

4. The meter powers up configured as it was at last power down.

Changing Backlight

1. Press Backlight ON.

2. Press Backlight OFF.

Note: Using the meter without the backlight increases battery life by 1 hour

approximately.

Selecting items in a Menu

Follow steps ① through ⑤ to open a menu and choose an item.

Press FUNC to open the FUNCTION menu.

Scope SetUp Exit

F1 F2 F3 F4

Press F1 to open the Scope Setup menu.

SCOPE SETUP

INPUT A: INPUT B:

■ DC □ AC ■ DC □ AC

VERTICAL MODE:

□ CHA □ CHB ■ A&B

HORIZONTAL MODE:

■ NORM □ ROLL

MEASUREMENTS A:

■ DCV □ ACV □ OHM □ BZ

□ HZ □ RPM □ P/W □ DTY

Set Exit

F1 F2 F3 F4

Use the arrow keys to highlight an item

Press F3 to select an item

Press F4 to Exit

18

381295 V1.4V 10/06

Page 19

Frequency measurement for CHA:

Plug the black test lead into the COM input jack and plug the red test lead into the CHA

input jack

Press FUNC to open the FUNCTION menu.

Scope SetUp Exit

F1 F2 F3 F4

Press F1 to open the Scope Setup menu.

SCOPE SETUP

INPUT A: INPUT B:

■ DC □ AC ■ DC □ AC

VERTICAL MODE:

□ CHA □ CHB □ A&B

HORIZONTAL MODE:

■ NORM □ ROLL

MEASUREMENTS A:

■ DCV □ ACV □ OHM □ BZ

□ HZ □ RPM □ P/W □ DTY

Set Exit

Press to Highlight Hz (□ Hz )

F3 Set

Exit

F4

Observe that Hz is now the main reading.

Holding (freezing) the display screen

You can freeze the screen (all readings and waveforms) at any time.

Default (Command Menu) Display:

A B

Mem Hold

F1 F2 F3 F4

F4 freeze the screen. Highlighted Hold appears at the bottom of the Command Menu

area.

A B

Mem Hold

F1 F2 F3 F4

F4 Resume your measurement

A B

Mem Hold

F1 F2 F3 F4

19

381295 V1.4V 10/06

Page 20

Changing the Graphic Representation

Changing the vertical division

DIV Open the Command Menu.

A/div

B/div H/div Exit

F1 F2 F3 F4

F1 or F2 Change the vertical division. (CH A or CH B)

Increase the vertical division, Div is changed to manual mode

Decrease the vertical division, Div is changed to manual mode.

or Change Div from Manual mode to AUTO mode

Changing the Time Base

DIV Open the Command Menu.

A/div B/div H/div Exit

F1 F2 F3 F4

F3 Change the Horizontal division

A/div B/div H/div Exit

F1 F2 F3 F4

Increase the number of periods.

Div is changed to manual mode

Decrease the number of periods.

Div is changed to manual mode

or Change Div from Manual mode to AUTO mode

20

381295 V1.4V 10/06

Page 21

Acquiring the Waveform

FUNC Open the FUNCTION menu.

Scope SetUp Exit

F1 F2 F3 F4

F1 Open the Scope Setup menu.

SCOPE SETUP

INPUT A: INPUT B:

■ DC □ AC ■ DC □ AC

VERTICAL MODE:

□ CHA □ CHB □ A&B

HORIZONTAL MODE:

■ NORM □ ROLL

MEASUREMENTS A:

■ DCV □ ACV □ OHM □ BZ

□ HZ □ RPM □ P/W □ DTY

Set Exit

F1 F2 F3 F4

Recording Slow Signals over a Long Period of Time

Highlight ROLL MODE.

F3 Set ROLL MODE.

F4 Exit.

The roll mode function supplies a visual log of waveform activity and is especially useful

when measuring lower frequency waveforms.

Note: ROLL MODE operates when the horizontal division is between 1s and 5s

Selecting AC-Coupling for INPUT A

Highlight AC for INPUT A.

F3 SET

F4 Exit.

21

381295 V1.4V 10/06

Page 22

Triggering on a Waveform

Triggering tells the Meter when to begin displaying a waveform. The instructions that

follow explain how to:

• Select a Channel

• Select rising or falling edge on which to trigger

• Define the condition for a new update of the waveform.

The display icons on the top line (right side) of the LCD identify the trigger parameters

currently used. Trigger icons on the screen indicate the trigger level and slope.

(1) Trigger Channel: Channel A or B

(2) Slope: rising or falling

(3) Trigger mode: Trigger setting mode

(Auto or Normal)

(4) Trigger Level indicator

(5) Trigger Cursor

(6) Command Menu: Trigger level

(7) Command Menu: Single shot

(8) Command Menu: Trigger mode (Setup)

Setting Trigger lev el (on NORmal trigger mode)

TRIG Open the Trigger menu

Tlvl

Singl Tmode Exit

F1 F2 F3 F4

Adjust the Trigger Level continuously. Observe the horizontal trigger icon on the

rightmost time division line.

F4 Exit.

22

381295 V1.4V 10/06

Page 23

Making a single acquisition

To catch single events, perform a single shot. (One time screen update.) To set up the

Meter for a single shot on the input Channel A waveform:

Connect the probe to the signal to be measured.

TRIG Open the Trigger menu

Tlvl

Singl Tmode Exit

F1 F2 F3 F4

F2 Highlight Singl (SINGLE SHOT)

Tlvl

Singl Tmode Exit

F1 F2 F3 F4

Meter performs a single shot. (One time screen update)

F2 Return to normal Trigger mode.

Setting Trigger mode (Tmode)

TRIG Open the Trigger menu

Tlvl

Singl Tmode Exit

F1 F2 F3 F4

F3 Open the Trigger Setup

TRIGGER SETUP

SOURCE:

■ CHA □ CHB

□ EXT

SLOPE:

□

■

TRIGGER MODE:

Set Exit

F1 F2 F3 F4

Highlight an ITEM.

F3 Set the ITEM.

F4 Exit.

□ AUTO ■ NOR

23

381295 V1.4V 10/06

Page 24

Setting AUTO Trigger Level

For fast trigger operation, use the AUTO trigger mode to trigger on

nearly all signals automatically. To optimize the trigger slope manually:

F3 Open the Trigger Setup

TRIGGER SETUP

SOURCE:

■ CHA □ CHB

□ EXT

TRIGGER MODE:

□ AUTO ■ NOR

Set Exit

F1 F2 F3 F4

Highlight AUTO.

F3 Set AUTO.

F4 Exit.

Setting Normal T rigger mode

Highlight NOR.

F3 Set NOR.

F4 Exit.

Adjust the Trigger Level continuously. Observe the horizontal trigger icon on the

rightmost time division line.

SLOPE:

□

■

24

381295 V1.4V 10/06

Page 25

Setting Trigger Slope

Highlight

F3 Set

F4 Exit.

or .

or . Trigger on either positive Slope or negative Slope of the chosen waveform.

or .

Storing and Recalling Screens

The meter can store setups and waveforms to memory for later recall. Sixteen (0-15) setup

and waveform memories are available.

Storing a Screen

F3 Open the memory (Mem) menu

Sto

Rcl

Exit

F1 F2 F3 F4

Memory field (M:00) appears at the top-right corner of the display area.

Select the memory address where the screen is to be stored.

F1 Store the actual screen

25

381295 V1.4V 10/06

Page 26

Recalling Screen

F3 Open the memory menu

Sto

Rcl

Exit

F1 F2 F3 F4

Memory field (M:00) appears at the topright corner of the display area.

Select the memory address from

which to recall the screen.

Recall the screen.

26

381295 V1.4V 10/06

Page 27

PC Interface and Datalogging Software

Introduction

With the Meter connected to a PC, measurements can be viewed on the computer

screen as they are taken. Graphical (scope) as well as numerical (DMM) data can be

viewed. Measurement data can then be stored in a file and/or printed. Data files can be

opened in spreadsheets as ‘text files’ if desired. The PC interface also allows the meter

to be remotely controlled using the on-screen virtual push-buttons.

Connecting the Meter to a PC

Connect the meter to the PC using the supplied communication cable. The TRS

(tip/ring/sleeve phono plug) end of the cable connects to the meter (top) and the 9-pin

end connects to the PC serial port.

Installing the Supplied Datalogging So ftware

Install the software by placing the supplied diskette in the PC floppy drive. Run the

SETUP.EXE file from the list of files on the diskette. Follow the on-screen instructions for

installation. The supplied software should be installed on the PC hard drive first and the

program should be launched from the version on the hard drive. Do not run the software

program straight from the supplied disk.

Main Software Screen

After the program is installed, open the program to view the main software screen:

27

381295 V1.4V 10/06

Page 28

Menu Bar in Main Software Window

The Menu Bar includes FILE, SETUP, and WINDOW selections, explained below:

FILE

Under FILE click on EXIT to close the program

SETUP

Under SETUP select COMM to choose the PC COMM port and the baud rate. Select

PRINTER to configure the line printer. Select COLOR to choose the display color

configuration.

WINDOW

Select DATALOGGER to open the Data View recording window (see below)

28

381295 V1.4V 10/06

Page 29

Communicating with the PC

Once the program is running and the meter is connected, shut the meter off and turn it

back on. This will initiate communication between the meter and PC.

Under the SETUP menu on the main software screen, select the appropriate Serial

Comm Port and Baud Rate and then click the OK button.

To select the sampling time (rate at which data points are recorded), click on the S /

TIME button and type the desired sampling time.

Open the Data View window by clicking the DATA LOGGER button on the main software

screen. Click the “START” button to begin recording. Press ‘STOP’ to end recording.

The data points should appear in the Data View window. If not, check that the proper

COMM PORT is selected under SETUP.

Once the datalogger is started and the data points are appearing in the Data View

window, the software program’s remote control virtual pushbuttons can be used.

Data View Window Operation

In the Data View window (shown above), the data points can be stored in a file using the

SAVE button. When the SAVE button is RED the program is storing readings in the file

shown in the OPEN FILE NAME field. Click on the SAVE button until the letters appear

in red, the readings are now being stored. When the SAVE button is not RED, readings

can still be viewed in the data list but the readings are not being saved.

To open a file of previously stored data, use the BROWSER button. When the file is

found and opened, use the LOAD button to recall the data points to the Data View

Window.

29

381295 V1.4V 10/06

Page 30

Maintaining the Meter

Cleaning the Meter

Clean the Meter with a damp cloth and a mild soap. Do not use abrasives, solvents, or

alcohol.

Storing the Meter

If you are storing the Meter for an extended period of time, charge the NI-MH battery

pack before storing. It is not necessary to remove the battery pack.

Replacing and Disposing of the NI-MH Battery Pack

Warning

To avoid electrical shock, remove the test leads and probes before replacing the battery

pack.

Note

This instrument contains a NI-MH battery pack. Do not dispose of this battery pack with

other solid waste. Used batteries should be disposed of by a qualified recycler or

hazardous materials handler.

To replace the battery pack:

1. Disconnect the test leads and probes both at the source and at the meter.

2. Loosen the screws with a screwdriver.

3. Lift the rear cover away from the Meter.

4. Take the battery pack out of the battery compartment.

5. Remove the battery plug from the connector.

6. Install a new battery pack.

7. Reinstall the rear cover and secure the screws.

30

381295 V1.4V 10/06

Page 31

Replacing the Battery

31

381295 V1.4V 10/06

Page 32

Appendices

Troubleshooting guide

If you experience a problem with the meter, try the corrective actions below before

concluding that the instrument needs repair.

1. Make sure you are using a fresh NI-MH battery pack or fully charged rechargeable

battery pack. If you are using the AC/DC power adapter, make sure the adapter is

plugged into an appropriate live power source.

2. If the buttons do not respond or the contrast is set such that the display is unreadable,

remove the power source while the instrument is on. Wait 15 minutes and then

restore power and retry.

3. If you still experience difficulty, check your connections and reread this instruction

manual.

4. If the meter’s display is frozen when trying to control the trigger level:

• In normal (NOR) mode, the trigger level must be the same level as the waveform.

The Meter does not trigger if the trigger level is set above or below the waveform

level.

• In Auto (AT) mode, the trigger level does not have to be adjusted.

• In rare cases, the instrument may require servicing. There are no internal user-

serviceable parts.

32

381295 V1.4V 10/06

Page 33

Warranty, Repair, and Technical Support

Warranty

EXTECH INSTRUMENTS CORPORATION warrants this instrument to be free of defects

in parts and workmanship for one year from date of shipment (a six month limited warranty

applies to sensors and cables). If it should become necessary to return the instrument for

service during or beyond the warranty period, contact the Customer Service Department at

(781) 890-7440 ext. 210 for authorization or visit our website www.extech.com for contact

information. A Return Authorization (RA) number must be issued before any product is

returned to Extech. The sender is responsible for shipping charges, freight, insurance and

proper packaging to prevent damage in transit. This warranty does not apply to defects

resulting from action of the user such as misuse, improper wiring, operation outside of

specification, improper maintenance or repair, or unauthorized modification. Extech

specifically disclaims any implied warranties or merchantability or fitness for a specific

purpose and will not be liable for any direct, indirect, incidental or consequential damages.

Extech's total liability is limited to repair or replacement of the product. The warranty set

forth above is inclusive and no other warranty, whether written or oral, is expressed or

implied.

Calibration and Repair Services

Extech offers repair and calibration services for the products we sell. Extech also provides

NIST certification for most products. Call the Customer Service Department for information

on calibration services available for this product. Extech recommends that annual

calibrations be performed to verify meter performance and accuracy.

Technical support: Extension 200; E-mail: support@extech.com

Repair & Returns: Extension 210; E-mail: repair@extech.com

Product specifications subject to change without notice

For the latest version of this User’s Guide, Software updates, and other

up-to-the-minute product information, visit our website: www.extech.com

Extech Instruments Corporation, 285 Bear Hill Rd., Waltham, MA 02451

Support line (781) 890-7440

All rights reserved including the right of reproduction in whole or in part in any form.

Copyright © 2005 Extech Instruments Corporation

33

381295 V1.4V 10/06

Loading...

Loading...