Page 1

User's Manual

AC Clamp Meter + Phase Rotation Tester

Model 380974

Introduction

Congratulations on your purchase of the Extech 380974 AC Clamp Meter + Phase

Rotation Tester. This professional 1000A Clamp meter also provides phase rotation

testing where motor direction (clockwise or counter-clockwise) and phase sequences

(L1, L2, & L3) can be displayed. Careful use of this meter will provide years of reliable

service.

Hz

CAT III

CAT III

600V

600V

Page 2

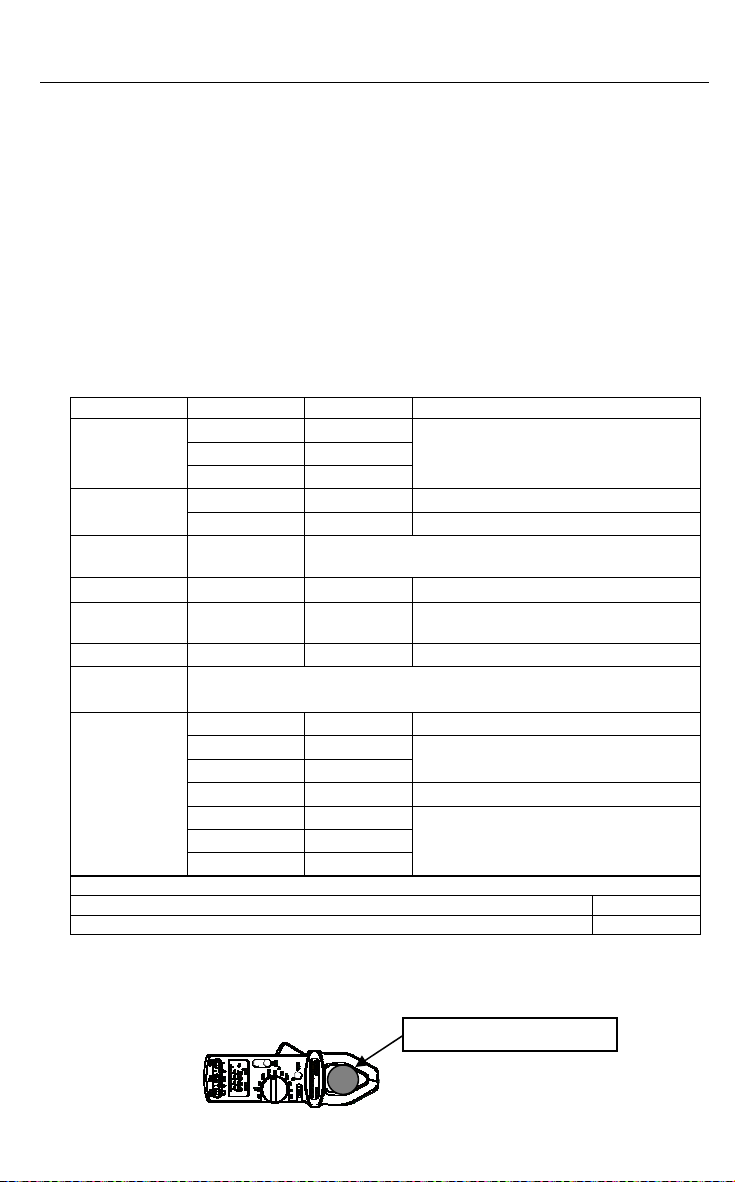

Specifications

Clamp jaw size 1.6” (40mm)

Battery type 9V

Range Selection Manual

Display 3 ¾ digit (4000 count) multi-function LCD with 40-

Overload Indication ‘OL’ displays on LCD

Power 9V battery (200 hour life typical)

Low Battery Indication Battery icon displays on LCD

Auto Power Off After 30 minutes (feature can be disabled)

Display update rate 1.3 updates/second (digital display); 13.3

Operating Temperature / RH 32 to 122

Storage Temperature / RH 14 to 140

Dimensions/Weight 9 x 3 x 1.5” (228 x 76 x 39mm) / 13 oz. (370g)

Function Range Resolution Accuracy

AC Current

40A 0.01

400A 0.1A

1000A 1A

400V 0.1V ±(1.2% + 5d) (40 to 400Hz) AC Voltage

3-Phase

600V 1V ±(3.0% + 5d) (40 to 400Hz)

80V to 480V Frequency Response 40Hz to 400Hz

sequence

Resistance

40KΩ 10Ω

Frequency 4KHz 1Hz ±(0.5%rdg + 5d)

Capacitance 400uF 1uF ±(3% + 5d)

Continuity Audible alert <40 ohms

(open circuit < 3V, short circuit: 0.8mA)

PEAK HOLD

(Capture

time:

100ms)

AC Voltage Resolution Accuracy (of reading)

400V 0.1

600V 1V

AC Current

40A 0.01A

400A 0.1A

1000A 1A

Overload Protection

AC Current, Frequency (clamp) 1100A

AC Voltage, Sequence, Resistance, Capacitance, Frequency (leads) 600V rms

segment bargraph indication

updates/second (bargraph)

o

F (0oC to 50oC) / <80%

o

F (-10oC to 60oC) / <70%

(% of reading + digits)

±(2.0% + 5d)

Freq. range: 40 to 400Hz

±(1.0% + 5d)

Sensitivity: 10A (clamp), 30V (leads)

±(2.5% + 10d)

±(2.5% + 10d)

Specification notes: Accuracy is % of reading + number of digits at 64 to 82oF (18 to

o

C) <80% RH. The accuracy specs apply to measurements taken in the largest circle

28

inside the clamp jaw (see diagram).

Circle inside clamp jaws

2

Model 380974 V1.8 Sept 2003

Page 3

Safety Information

• Read the following safety information carefully before attempting to operate or service

the meter

• To avoid meter damage, do not exceed the maximum specified input limits

• Do not use the meter if the test leads appear damaged

• Use caution when working near bare conductors or bus bars

• Accidental contact with a conductor may cause electrical shock

• Use this meter only as specified in this manual, otherwise the protection provided by the

meter may become impaired

• Read the operation manual before use and follow all safety instructions

• Use caution when working with voltages that exceed 60VDC or 30VAC, such signals

pose a shock hazard

• Disconnect circuits under test from the main power supply and disconnect all loads

before taking resistance, capacitance, and continuity measurements

• Environmental Conditions:

1. Installation Category III

2. Pollution Degree 2

3. Altitude 2000 meters max.

4. Indoor use only

• International Safety Symbols:

CAUTION:

Ref er to

doc ume nt at io n

CAUTION:

Risk of

El e ct ri c al

Shock

3

Double

Insulation

Model 380974 V1.8 Sept 2003

Page 4

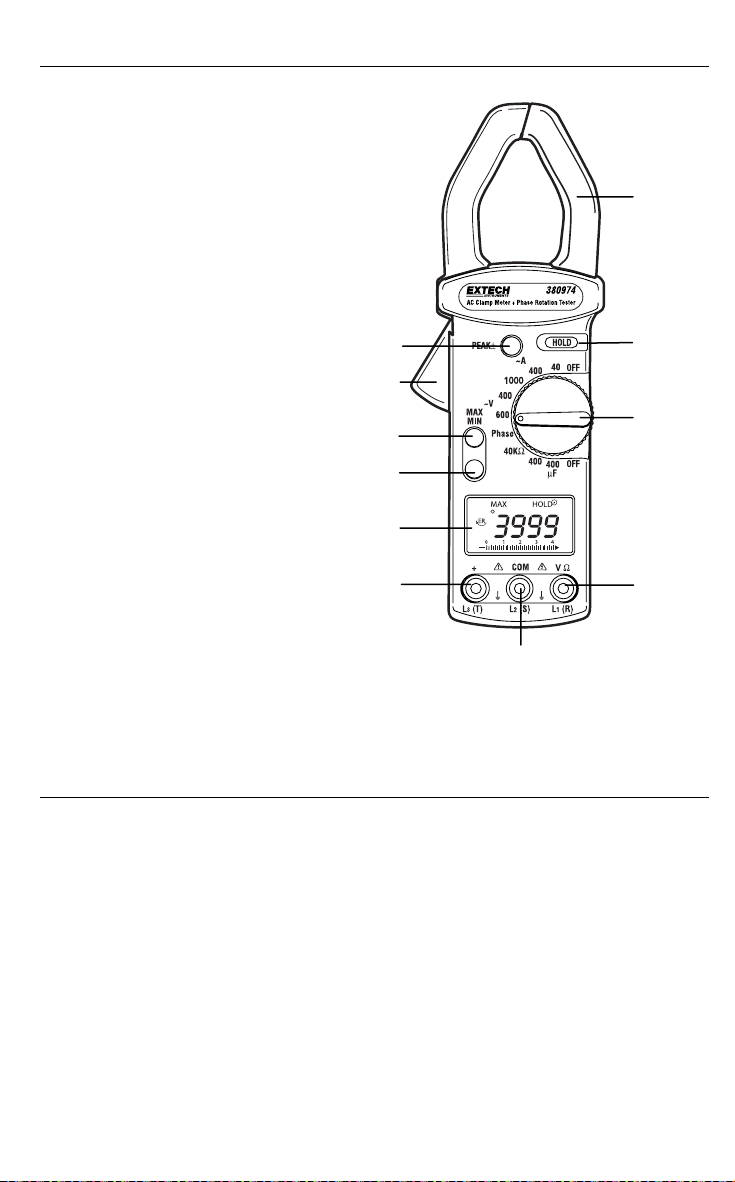

Meter Description

1. Transformer jaws

2. Jaw opening trigger

3. LCD Display

4. PEAK HOLD button

5. DATA HOLD button

6. Rotary select switch

7. COM or L2 (S) Input

8. VOLT/OHM or L1 (R) input

9. Positive, L3 (T), and CAP input

10. Frequency (Hz) button

11. MAX/MIN button

Automatic Shut-Off Feature

4

2

11

10

Hz

3

9

CAT III

CAT III

600V

600V

1

5

6

8

7

The meter shuts off automatically after 30 minutes to conserve energy. To defeat this feature:

1. Turn the meter off.

2. Hold down the PEAK or the MAX/MIN button while turning the meter on.

3. The Auto Power Off feature will now be disabled.

4. Note that when the meter is turned off the Auto Power Off feature is enabled again.

4

Model 380974 V1.8 Sept 2003

Page 5

Meter Operation

Measurement Preparation

1. Use the rotary selector switch to choose the appropriate range and function. Ensure

that the selected range matches the measurement to be taken.

2. If the measured current is higher than the selected range for long periods of time,

overheating can result which may damage the meter.

3. Do not measure current on high voltage conductors (> 600V).

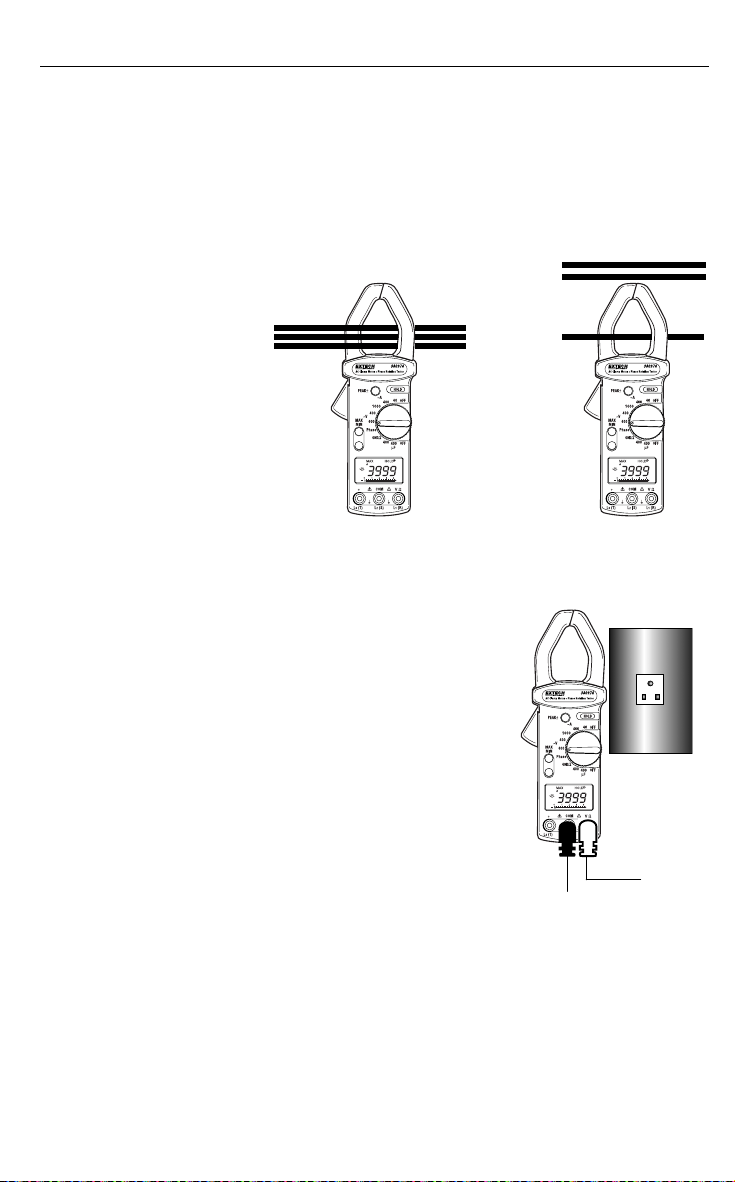

AC Current Measurements

Warning: Ensure that all test leads are disconnected from the meter’s terminals before

proceeding.

1. Set the Rotary selector

switch to the 40, 400 or

1000 Amps AC (~ A)

range.

2. Open the jaw via the

trigger and clamp

around one of the

conductors (see

diagram). Close clamp

completely around the

conductor.

3. Read the displayed

measurement value.

AC Voltage Measurements

Warning: Maximum AC

input voltage is 600V. To

avoid electrical shock or damage to the instrument, do not attempt to measure any voltage

exceeding this limit.

1. Set the rotary selector switch to AC Volts (~ V).

2. Connect the black test lead to the COM terminal and the

red test lead to the V/Ω terminal.

3. Connect the other ends of the test leads to the circuit,

component, or other device under test. See diagram.

4. Read the displayed measurement value on the LCD.

Frequency Measurements

Note: Current (with clamp) and voltage (with test leads)

frequency measurements are possible with this instrument. At

least 10A (minimum threshold) must be available when

measuring the frequency of a current signal with the clamp.

1. Set the rotary selector switch to a voltage or current

position. Then Press the Hz button.

2. For measuring the frequency of a voltage (using test

leads), connect the black test lead to the COM terminal

and the red test lead to the V/Ω terminal. Note that in the 400V range, the minimum

threshold is 30V.

3. Connect the other ends of the test leads to the circuit, component, or other device

under test

4. For measuring the frequency of a current signal (using the clamp), fully enclose the

conductor under test in the jaws.

5. Read the displayed measurement value on the LCD.

CAT III

CAT III

600V

600V

CAT III

CAT III

600V

600V

INCORRECT CORRECT

CAT III

CAT III

600V

600V

5

Model 380974 V1.8 Sept 2003

Loading...

Loading...