Page 1

INSTRUCTION MANUAL

Model 380973

True RMS AC Clamp-on DMM

• True RMS AC measurements enable

precision distorted or non-sinusoidal

waveform measurements

• Peak Hold and Data Hold

• Selectable temperature measurement units

• Frequency measurements using the current

jaws or using the test leads.

1. INTRODUCTION

Congratulations on your purchase of Extech’s 380973 True RMS AC Clamp-on DMM. This

professional meter, with proper care, will provide years of safe reliable service.

1 380973 Ver. 1.01 8 /99

Page 2

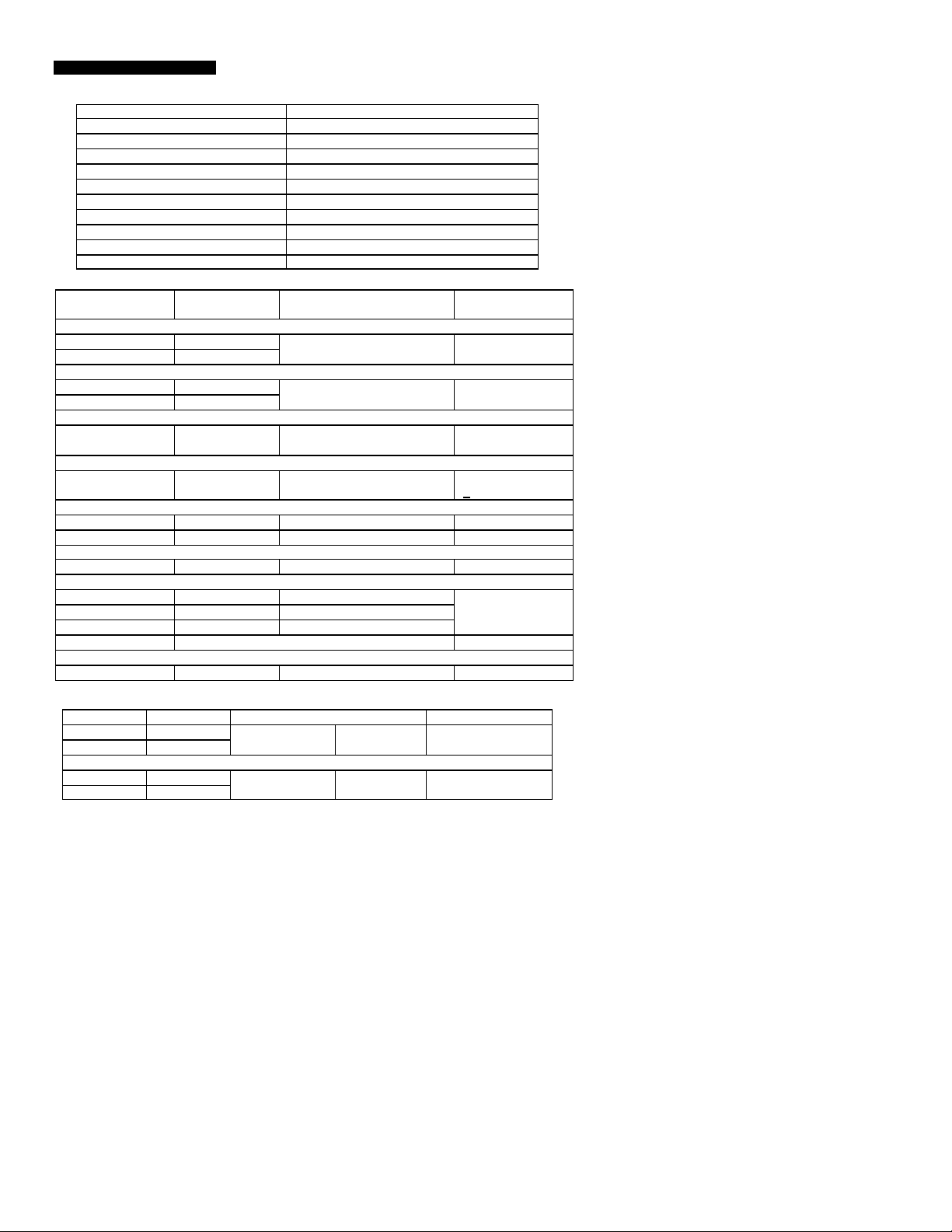

2. SPECIFICATIONS

2.1 General Specifications

Clamp jaw opening diameter 1.6” (40mm)

Battery type 9V

Range Selection Manual

Display 3 ¾ digit (4000 count) LCD

Overload Indication ‘OL’ displays on LCD

Low Battery Indication ‘BT’ displays on LCD

Sampling rate 2.5 readings/sec

Operating Temp. / RH 32 to 104oF (0oC to 40oC); <80%

Storage Temp. / RH 14 to 140oF (-10oC to 60oC); <70%

Dimensions 9 x 3 x 1.5” (228 x 76 x 39mm)

Weight 12.4 oz. (385g)

2.2 Electrical Specifications

Resolution Accuracy

Overload Protect

(% of reading + digits))

AC Current (True RMS)

400A 0.1A

±(2.0% + 5d) (40 to 450Hz) 800A rms

600A 1A

AC Voltage (True RMS)

400V 0.1V

600V 1V

±(1.2% + 5d) (40 to 450Hz) 660V rms

input imp. 1MΩ

DC Voltage

600V 1V ±(0.75% + 2d) 660V rms

input imp. 1MΩ

Resistance

4KΩ 0.001kΩ

±(1.0% + 5d) 660V rms

< 3.2VDC open cir

Frequency

4KHz (clamp test) 1Hz ±(0.5%rdg + 5d) 800A (sensitiv.5A)

4KHz (lead test) 1Hz ±(0.5%rdg + 5d) 660V (sensitiv.1V)

Capacitance

2000uF 1uF ±(3% + 5d) 250V rms

Type-K Therm.

-20 to 300oC 1oC ±(2% + 3oC)

660 Vrms

300 to 1200oC 1oC ±(3.5% + 2oC)

-4 to 2192oF 1oF ±(3% + 8oF)

Continuity Buzzer <40 ohms (oc V=3V, sc A=0.8mA) 660 V rms

Diode Test

3V 0.001V ±(1%rdg + 2d) 660V rms

2.3 100mS PEAK HOLD (True RMS) Specifications

AC Voltage Resolution Accuracy (of reading) Overload

400V 0.1V

±(1.5% + 10d) 50 to 60Hz 660V rms

600V 1V

AC Current

400A 0.1A

±(2.0% + 10d) 50 to 60Hz 800A rms

600A 1A

SPECIFICATION NOTE: Accuracy is tested in a 64 to 82oF (18 to 28oC) <80% Relative

Humidity environment. The accuracy specs apply to measurements taken in the largest

circle inside the clamp jaw (refer to the diagram in Section 3).

2 380973 Ver. 1.01 8 /99

Page 3

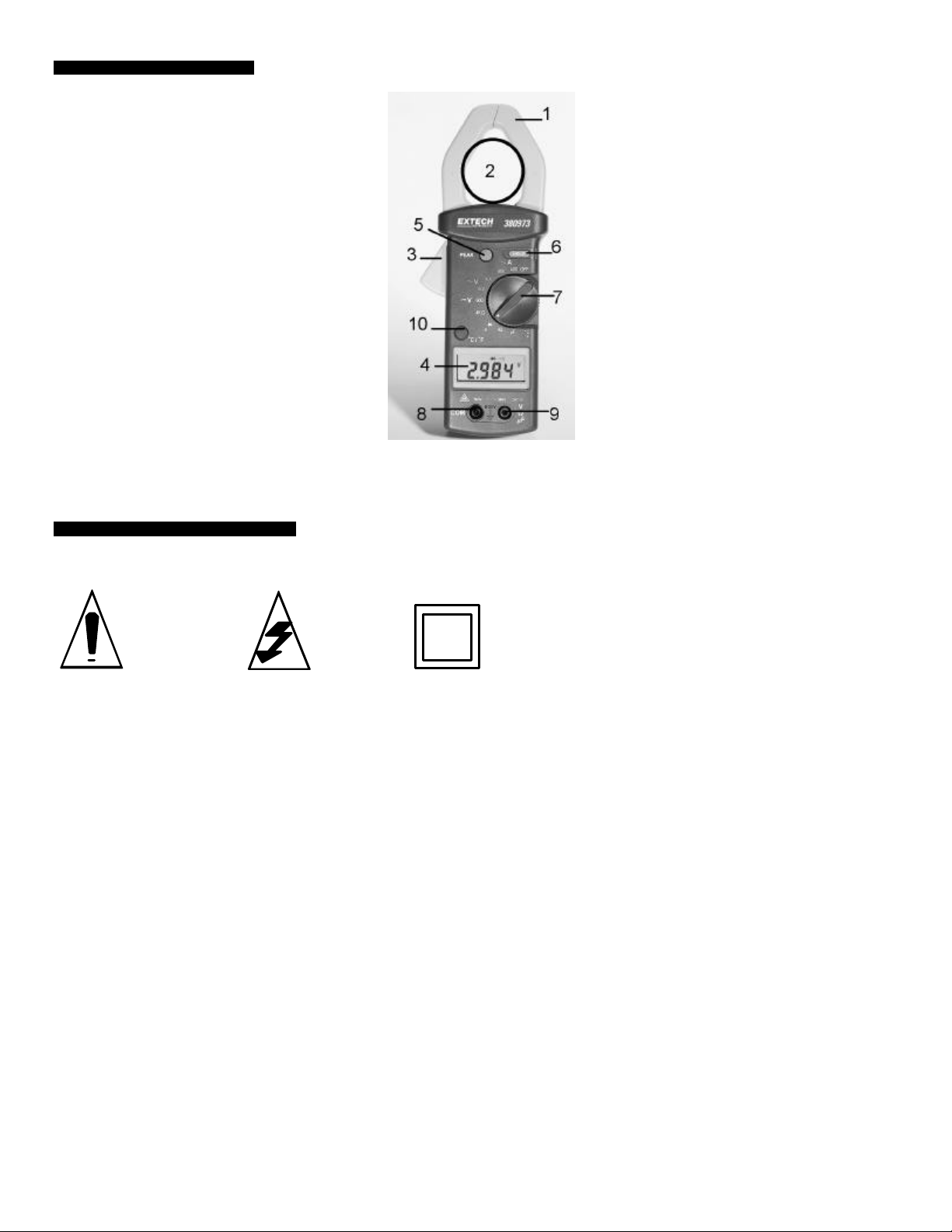

3. FRONT PANEL DESCRIPTION

1 Clamp jaw

2 Clamp measurement area

3 Jaw trigger – Press to open transformer jaw

4 LCD Display – Displays data, units, polarity,

decimal, peak/data hold icons, overload and low

battery indication.

5 Peak Hold key – Press to activate, press again to

deactivate.

6 Data Hold key - Press to activate, press again to

deactivate.

7 Rotary selector switch – Powers meter while

selecting function and range.

8 Negative input terminal – Black test lead

connection (COM).

9 Positive input terminal – Red test lead connection

for voltage, resistance, frequency, capacitance,

temperature, diode, and continuity tests.

10 Temperature units select key – Press to select

desired units

4. INTERNATIONAL SAFETY SYMBOLS

CAUTION:

Refer to

documentation

CAUTION:

Risk of

Electrical

Double

Insulation

Shock

3 380973 Ver. 1.01 8 /99

Page 4

5. OPERATION

5.1 True RMS Measurements

The 380973 incorporates True RMS technology meaning that non-sinusoidal (triangle,

sawtooth, etc.) or distorted waveforms can be measured more accurately than averaging

meters. The degree of distortion that the meter can accurately measure is determined by

the ‘crest factor’ of a waveform (ratio of peak value to rms value).

5.2 Measurement Preparation

1. Use the Rotary Selector switch (7) to select the appropriate range and function. Ensure

that the selected range is suitable for the measurement to be taken.

2. If the measured current is higher than the selected range for long periods of time,

overheating can result which may damage the meter.

3. Do not measure current on high voltage conductors (> 600V).

5.3 AC Current Measurements

WARNING: Ensure that all test leads are disconnected

from the meter’s terminals before proceeding.

1. Set the Rotary Selector switch to the 400 or 600 Amps

AC (~) range.

2. Clamp the transformer jaw around one of the

conductors under test. Open the jaw via the jaw trigger

(3). Ensure that the clamp closes completely around

the conductor.

3. Read the displayed measurement value on the display.

5.4 DC Voltage Measurements

Warning: Maximum DC input voltage is 600V. To avoid

electrical shock or damage to the instrument, do not attempt

to measure any voltage exceeding this limit.

1. Set the Rotary Selector switch to the 600Volts DC (----)

range.

2. Connect the black test lead to the COM terminal and red

test lead to the V/Ω/uF terminal.

3. Connect the test leads to the circuit, component, or other

device under test (refer to figure at right).

4. Read the displayed measurement value on the LCD.

5.5 AC Voltage Measurements

Warning: Maximum AC input voltage is 600V. To avoid

electrical shock or damage to the instrument, do not attempt

to measure any voltage exceeding this limit.

1. Set the Rotary Selector switch to the AC Volts (~) range.

2. Connect the black test lead to the COM terminal and red

test lead to the V/Ω/uF terminal.

3. Connect the test leads to the circuit, component, or other

device under test (refer to figure at right).

4. Read the displayed measurement value on the LCD.

4 380973 Ver. 1.01 8 /99

Page 5

5.6 Frequency Measurements

Note: Clamp (ammeter) and test lead (voltage) frequency measurements can both be

made. Check the specifications for differences in sensitivity. When reading frequency via

the clamp jaw the current must be at least 5A (minimum threshold).

1. Set the Rotary Selector switch to the Hz function.

2. Connect the black test lead to the COM terminal and red test lead to the V/Ω/uF terminal

and connect the other ends of the test leads to the circuit, component, or other device

under test for test lead measurements; otherwise use the clamp jaw for current

measurements.

3. Read the displayed measurement value on the LCD.

5.7 Resistance Measurements

Warning: Before attempting any in-circuit resistance measurements remove power from

the circuit under test and discharge any capacitors.

1. Set the Rotary Selector switch to the Ω function.

2. Connect the black test lead to the COM terminal and red test lead to the V/Ω/uF terminal

and connect the other ends of the test leads to the circuit, component, or other device

under test.

3. Read the displayed measurement value on the LCD.

5.8 Capacitance Measurements

Warning: Discharge capacitors and circuit before testing.

1. Set the Rotary Selector switch to the uF function.

2. Remove at least one leg of a capacitor from its circuit before testing.

3. Connect the black test lead to the COM terminal and red test lead to the V/Ω/uF terminal

and connect the other ends of the test leads to the circuit, component, or other device

under test.

4. If measuring a polarity sensitive electrolytic capacitor, touch red test lead to the positive

side of the cap. and the black test lead to the negative side.

5. Read the displayed measurement value on the LCD.

5.9 Temperature Measurements

1. Set the Rotary Selector switch to the “C / F” function.

2. Set the temperature units with the temperature units key.

3. Insert the type-K thermocouple adapter into the meter (positive end to the V/Ω/uF meter

terminal).

4. Insert the thermocouple into the thermocouple adapter.

5. Secure the beaded end of the K-type thermocouple to the surface to be measured.

6. Read the displayed temperature value on the LCD.

5.10 Continuity Measurements

Warning: Before attempting any in-circuit measurements remove power from the circuit

under test and discharge any capacitors.

1. Set the Rotary Selector switch to the diode/continuity function (diode symbol).

2. Connect the black test lead to the COM terminal and red test lead to the V/Ω/uF

terminal and connect the other ends of the test leads to the circuit, component, or other

device under test.

3. When the resistance measured is lower than 40Ω, the meter will sound an audible tone.

5 380973 Ver. 1.01 8 /99

Page 6

5.11 Diode Measurements

Warning: Before attempting any in-circuit measurements remove power from the circuit

under test and discharge any capacitors.

1. Set the Rotary Selector switch to the diode/continuity function (diode symbol).

2. Connect the black test lead to the COM terminal and red test lead to the V/Ω/uF

terminal.

3. Connect the red test lead to the anode side of the diode, and the black test lead to the

cathode side of the diode under test.

4. Read the forward voltage value on the LCD.

5. If the test leads are connected in reverse of step 3 above, the meter should read open

circuit voltage if the diode is in working condition.

5.12 Peak Hold / Data Hold Modes

1. Peak Hold allows the meter to capture fast voltage or current peaks.

2. Data Hold freezes the reading on the display when the Data Hold key is pressed.

3. Set the Rotary Selector switch to the AC Voltage or Current function position for Peak

Hold measurements. For Data Hold, set the switch to any function position.

4. Set the clamp meter to the Peak Hold or Data Hold mode by pressing the Peak Hold or

Data Hold key once.

5. The display will now indicate “P” for Peak Hold or ‘H’ for Data Hold.

6. For Peak Hold, the display will show the maximum peak of a measured signal surge. For

example, in-rush current during a motor start-up can be easily detected using Peak Hold

mode. For Data Hold, the LCD reading is frozen.

7. To return to normal operation press the Peak or Data Hold key again.

6. MAINTENANCE

6.1 Battery Replacement

Warning: To prevent electrical shock or hazard, remove power to the meter and remove

the test leads before removing back cover.

1. The meter displays ‘BT’ when the battery voltage falls critically low. Replace battery as

soon as possible when this icon appears on the meter LCD.

2. Set the rotary switch to the OFF position and remove all test leads.

3. Unscrew the three back cover screws to access the battery compartment. Note that the

screw nearest the meter jaw is a shorter machined screw. Be sure to install the same

screws in the same screw holes after replacing battery.

4. Replace battery and reinstall back cover.

6.2 Cleaning

Warning: To avoid electrical shock or damage to the meter, do not allow water or other

liquids to enter the meter case. Remember to remove power and test leads before

opening meter case.

Periodically wipe the case with a damp cloth and mild detergent. Do not use abrasives or

solvents.

6 380973 Ver. 1.01 8 /99

Page 7

7. CALIBRATION / REPAIR SERVICES

Extech offers complete repair and calibration services for all of the products we sell. For

periodic calibration, NIST certification or repair of any Extech product, call customer

service for details on services available. Extech recommends that calibration be performed

on an annual basis to insure calibration integrity.

8. WARRANTY

EXTECH INSTRUMENTS CORPORATION warrants this instrument to be free of defects in parts and

workmanship for one year from date of shipment (a six month limited warranty applies on sensors and

cables). If it should become necessary to return the instrument for service during or beyond the warranty

period, contact the Customer Service Department at (781) 890-7440 for authorization. A Return

Authorization (RA) number must be issued before any product is returned to Extech. The sender is

responsible for shipping charges, freight, insurance and proper packaging to prevent damage in transit.

This warranty does not apply to defects resulting from action of the user such as misuse, improper wiring,

operation outside of specification, improper maintenance or repair, or unauthorized modification. Extech

specifically disclaims any implied warranties or merchantability or fitness for a specific purpose and will not

be liable for any direct, indirect, incidental or consequential damages. Extech's total liability is limited to

repair or replacement of the product.

The warranty set forth above is inclusive and no other warranty, whether written or oral, is expressed or

implied.

Copyright © 1999 Extech Instruments Corporation. All rights reserved including the

right of reproduction in whole or in part in any form.

7 380973 Ver. 1.01 8 /99

Loading...

Loading...