Page 1

User's Manual

Digital High Voltage Insulation Tester

Model 380375

Page 2

Warranty

EXTECH INSTRUMENTS CORPORATION warrants this instrument to be free of defects

in parts and workmanship for one year from date of shipment (a six month limited

warranty applies on sensors and cables). If it should become necessary to return the

instrument for service during or beyond the warranty period, contact the Customer

Service Department at (781) 890-7440 ext. 210 for authorization or visit our website at

www.extech.com (click on Contact Extech and go to Service Department to request an

RA number). A Return Authorization (RA) number must be issued before any product is

returned to Extech. The sender is responsible for shipping charges, freight, insurance

and proper packaging to prevent damage in transit. This warranty does not apply to

defects resulting from action of the user such as misuse, improper wiring, operation

outside of specification, improper maintenance or repair, or unauthorized modification.

Extech specifically disclaims any implied warranties or merchantability or fitness for a

specific purpose and will not be liable for any direct, indirect, incidental or consequential

damages. Extech's total liability is limited to repair or replacement of the product. The

warranty set forth above is inclusive and no other warranty, whether written or oral, is

expressed or implied.

Introduction

Congratulations on your purchase of Extech’s High Voltage Insulation Tester. This device

has four voltage test ranges (up to 5kV) and measures insulation resistance to 250GΩ.

This professional meter, with proper care, will provide years of safe reliable service.

Safety

1. Circuits under test must be de-energized and isolated before connections are made.

2. Circuit connections must not be touched during a test.

3. After insulation tests, capacitors must be discharged.

4. Test leads (including alligator clips) must be in good working order, clean and without

broken or cracked insulation.

5. When servicing, use only specified replacement parts.

6. Environmental conditions:

• Indoor use only; Installation category II

• Pollution degree 2

• Altitude up to 2000 meters

• Relative Humidity 80% max.; Temperature 0 to 40

o

C

International Safety Symbols

Caution, refer to this manual before using this meter

Dangerous Voltages; risk of electric shock

Meter is protected throughout by double or reinforced insulation

2

380375 V1.5 3/04

Page 3

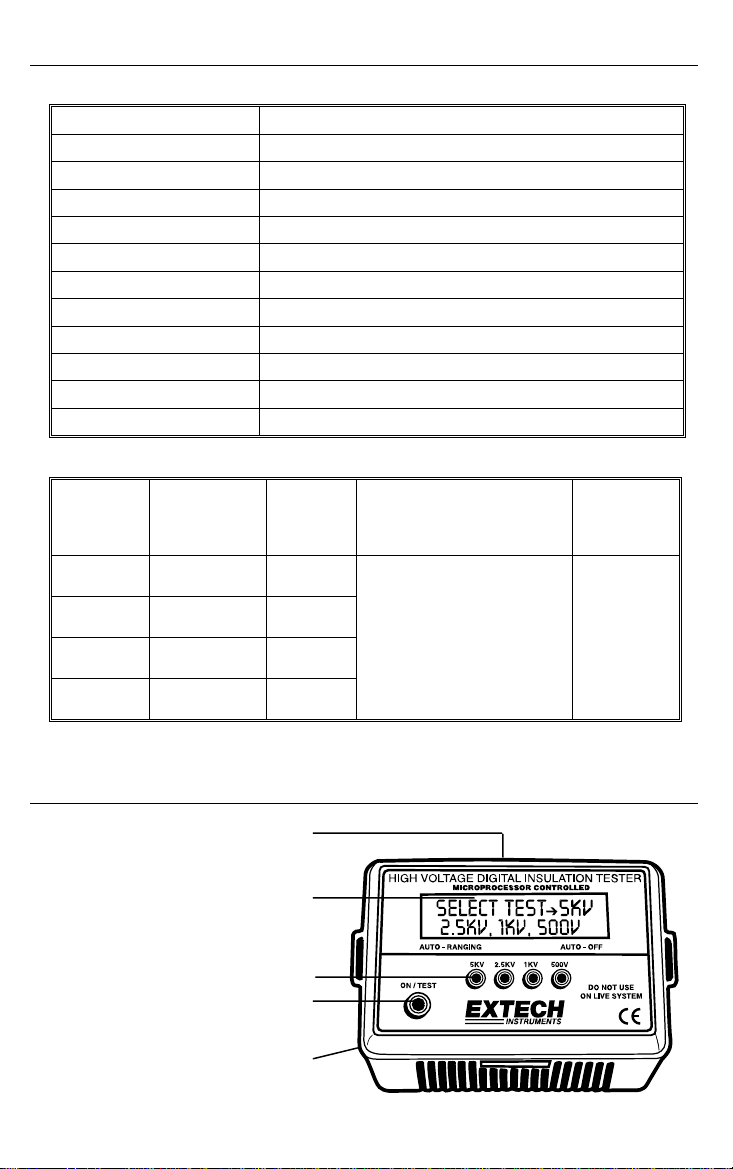

Specifications

General specifications

Display 2 x 16 character alphanumeric multi-function dot matrix

Range selection Automatic ranging

Bargraph Displays voltage ramp, soak, and decay

Automatic discharge After automatic & manual stop or upon completion of test

Low battery indicator "Replace battery" displayed when battery voltage is low

Power source Eight 1.5V AA cells; Battery life 40 hrs (no load at 5kV)

Auto Power off After 30 minutes

Enersave

Operating conditions 32 to 104oF (0 to 40oC); < 80% RH

Storage conditions 14 to 140oF (-10 to 60oC); < 80% RH

Dimensions 4.7 x 6.7 x 3.7” (120 x 170 x 95mm)

Weight 1.94 lbs (880g)

Range Specifications

Test

Voltage

TM

mode Shorter test time to conserve battery life

Resistance

Ranges

Short

Circuit

Accuracy Resolution

Current

500V DC

1000V DC

2500V DC

5000V DC

0 to 25 GΩ

0 to 50 GΩ

0 to 125 GΩ

0 to 250 GΩ

Meter Description

1. Test lead jacks compartment

2. Dot Matrix Display

3. Voltage test buttons

4. ON / TEST button

5. Battery compartment is

located on bottom of unit

1mA

1mA

1mA

1.6 mA

1

\

2

3

4

5

0 to 50GΩ: ± 3% reading

50 to 250GΩ: ± 5% reading

3

1kΩ

380375 V1.5 3/04

Page 4

Operation

Note: Ensure that the circuit under test does not include devices or components that can

be damaged by 5000VDC; such devices include power factor correction capacitors, low

voltage mineral insulated cables, electronic light dimmers, ballasts and starters for

fluorescent lamps.

Connecting the Test Leads to the meter

The Black (Earth) and Red (Line) test leads connect to the meter in the lead compartment

located on the back of the meter (the meter jacks are color coded). NOTE: The Green

(Guard) lead is typically not used. Do not connect this test lead to the meter unless

absolutely certain it is going to be used. For more information, continue reading this

Operation section and the Applications section to follow.

Connecting the Test Leads to the device under test

The Black (Earth) lead is connected to the conductive material. The Red (Line) lead is

connected to the insulating material. The Green (Guard) lead is at the same potential as

the negative terminal (0V) and, when required, is used to prevent erroneous readings by

removing parallel leakage paths from the measurement.

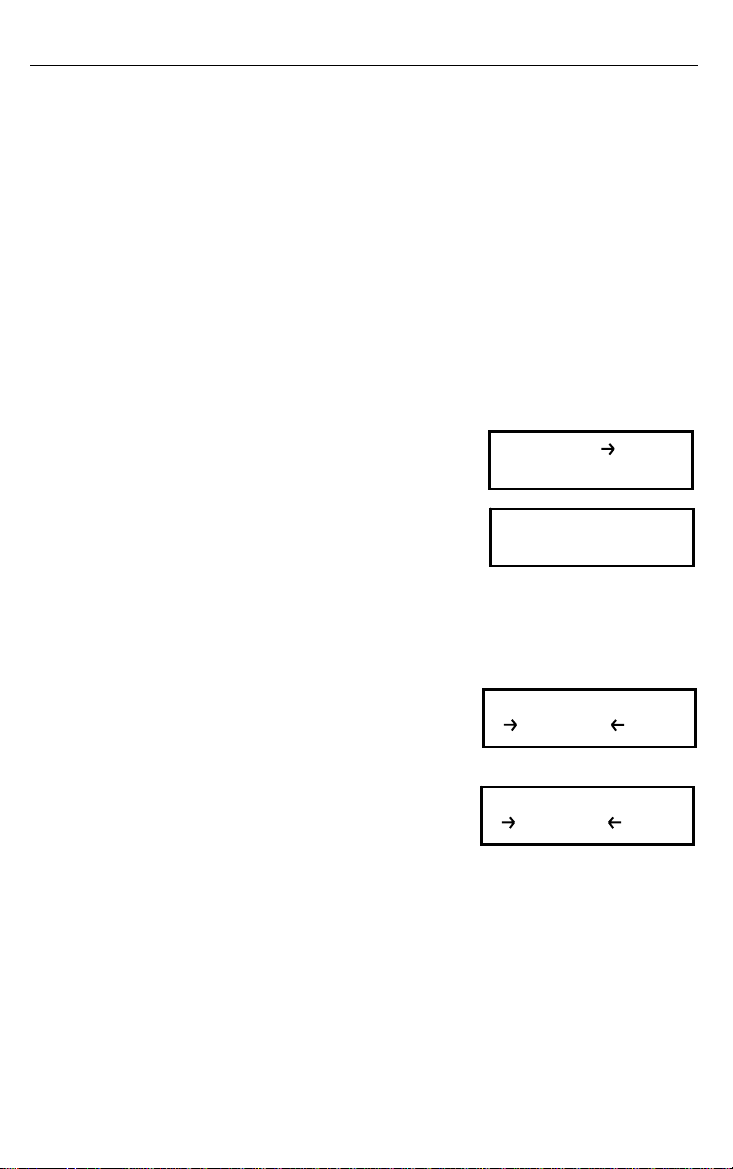

Insulation Resistance Measurements

1. Connect the test leads to the meter and the device under test.

2. Press the ON / TEST button to turn the unit on. The

unit will display the turn-on screens and then stop at

the “Select Test” display.

3. Select the desired test voltage by pressing the 500V,

1KV, 2.5KV, or 5KV button. The screen will briefly

display the selected test voltage and then will proceed

to the “Connect Leads Testing for LIVE” display. If the

circuit is “live” the display will indicate “Live Warning… Circuit Live” and the meter will

beep. If this occurs, remove the test leads and press the ON / TEST button.

4. Press the ON / TEST button to apply the voltage and begin the test. The meter will

beep every 2 seconds which indicated high voltage is on the test leads and the meter

will intermittently buzz while the high voltage is being generated.

5. On the display, elapsed test time appears on the

upper right, the resistance reading appears on the

upper left, the selected voltage is shown on the lower

right and the bar graph indicates the actual voltage

present on the test leads.

6. At the completion of the test the meter will discharge

the device under test and the display “HOLD”. Do not

remove the test leads until the bargraph disappears

(complete discharge) and “HOLD” appears in the display.

7. The meter automatically discharges the system at the end of the test. The test ends

when one of the following occurs.

a. After approximately 10 seconds in the Enersave

b. After approximately 100 seconds in the continuous mode.

c. When the red ON / TEST button is pressed.

Select Test 5kV

2.5kV, 1kV, 500V

Connect Leads

Testing for LIVE

R= 108.2MΩ 6.5s

0

██████ 500V

R= 128.4MΩ 7.4s

0

HOLD 500V

TM

mode.

4

380375 V1.5 3/04

Page 5

The Enersave

Enersave

10 seconds. Enersave

TM

Mode

TM

conserves battery life by reducing the test time from 100 seconds to approx.

TM

is the default mode of operation. To disable EnersaveTM press

and hold the ON / TEST button for three seconds to begin a test.

Bargraph Voltage Display

The bargraph represents the voltage present on the test leads as it charges, soaks, and

discharges. The bargraph appears on the lower portion of the display during tests.

Automatic Low Resistance Detect

If the display shows the message “LOW MΩ”, the test should be interrupted immediately

by pressing the ON / TEST button. This message indicates that the insulation under test

has broken down and the meter is trying to inject a high potential onto a short circuit.

Elapsed Timer

The test duration is indicated on the display. This is particularly useful in determining

whether an insulating material under test will break down in a given amount of time.

Manual Test STOP

To stop a test in progress, press the ON / TEST button. The test will immediately end and

the system will automatically discharge.

Automatic Test STOP

The test automatically stops after 100 seconds if the meter is not in the Enersave

When in the Enersave

TM

mode, the test automatically stops after approx. 10 seconds.

TM

mode.

Live Circuit Warning

If the test leads are connected to a live circuit when testing, a warning beeper will sound

and the meter will display “Live Warning…Circuit Live…”. In this case, correct the problem

and retest.

Automatic Discharge

At the end of a test, the meter automatically discharges the high voltage. The automatic

discharge status is reflected on the display. During discharge the beeper will sound and,

when completely discharged, the HOLD icon appears on the display.

Auto OFF

The meter will automatically turn off after approximately 30 minutes of operation.

5

380375 V1.5 3/04

Page 6

Applications

Measuring Power Tools and Small Appliances

For small appliances, connect the Black (EARTH) lead to conductors and the Red (LINE)

lead to insulating material.

For single or double insulated power tools, one lead should be connected to the device’s

chuck, blade, etc. and the other lead to one of the AC power cord conductors (test both

conductors in turn). Refer to the power tool application diagram below.

Connect the BLACK

lead to the chuck

Testing Motors

AC Motors

Disconnect the motor from the line by:

If the main switch is opened, and the

motor also has a motor-starter, then

the starter must be held in the ON position. With the main switch opened, the measured

resistance will include the resistance of the motor wire and all other components between

the motor and the main switch. If a weakness is indicated, the motor and other

components should be checked individually. If the motor is disconnected at the motor

terminals, connect the RED lead to the grounded motor housing and the BLACK lead to

one of the motor leads.

DC Motors

1. Disconnect the motor from the line.

2. To test the brush rigging, field coils and armature, connect the RED lead to the

3. If the resistance measurement indicates a weakness, raise the brushes off of the

Testing Single Conductor Cables

1. Completely disconnect the cable

2. Connect the test leads to the

a. Disconnecting the wires from the

motor terminals or

b. Opening the main switch

grounded motor housing and the BLACK lead to the brush on the commutator.

commutator and separately test the armature, field coils and brush rigging by

connecting one lead to each individually, leaving the other connected to the grounded

motor housing. This also applies to DC Generators.

under test from its source and

destination.

cable as shown at right.

AC

Plug

For 2 or 3 prong plugs, connect the

RED lead to one conductor at a time

Connect BLACK lead

to the motor leads

Connect RED lead

to grounded housing

Core Insulation Sheath Covering

EARTH GUARD LINE

6

380375 V1.5 3/04

Page 7

Testing Multi Conductor Cables

g

1. Completely disconnect the

cable under test from its

source and destination.

2. Refer to the diagrams at

right for three possible

tests.

Transformer Testing

Transformer tests are performed with the transformer completely disconnected from the

line and the load. Note that the case ground should not be removed.

The five tests listed below will completely test a single-phase transformer. Note that at

least 1 minute should be allowed between each test.

1. High voltage winding to low voltage winding and ground

2. Low voltage winding to high voltage winding and ground

3. High voltage winding to low voltage winding (pictured below)

4. High voltage winding to ground

5. Low voltage winding to ground

Connect the

BLACK lead here

EARTH

LINE

EARTH

LINE

GUARD

GUARD

LINE

EARTH

Connect the

RED lead here

Testing one

conductor to

all of the

conductors

Testing one

conductor

to earth

Testing one

conductor to

all conductors

round

minus

7

380375 V1.5 3/04

Page 8

Maintenance

Battery Replacement

When ‘REPLACE BATTERY’ appears on the display, replace the eight 1.5V ‘AA’ batteries.

1. Ensure that the meter is powered down and that the test leads are not connected

2. Close the instrument cover and turn the instrument upside down

3. Remove the phillips head screw located on the bottom of the meter

4. Remove the battery compartment cover

5. Replace the eight batteries ensuring proper polarity

6. Affix the rear cover and secure the rear screw

Cleaning

Periodically wipe the case with a dry cloth. Do not use solvents or abrasives to clean this

instrument.

Repair and Calibration

Extech offers complete repair and calibration services for all of the products we sell. For

periodic calibration, NIST certification or repair of any Extech product, call customer

service for details on services available. Extech recommends that calibration be performed

on an annual basis to insure calibration integrity.

Copyright ©

including the right of reproduction in whole or in part in any form.

Repair/Returns: Ext. 210; Email: repair@extech.com

Support Hotline (781) 890-7440

Tech support: Ext. 200; Email: support@extech.com

Website: www.extech.com

2002 Extech Instruments Corporation. All rights reserved

8

380375 V1.5 3/04

Loading...

Loading...