Page 1

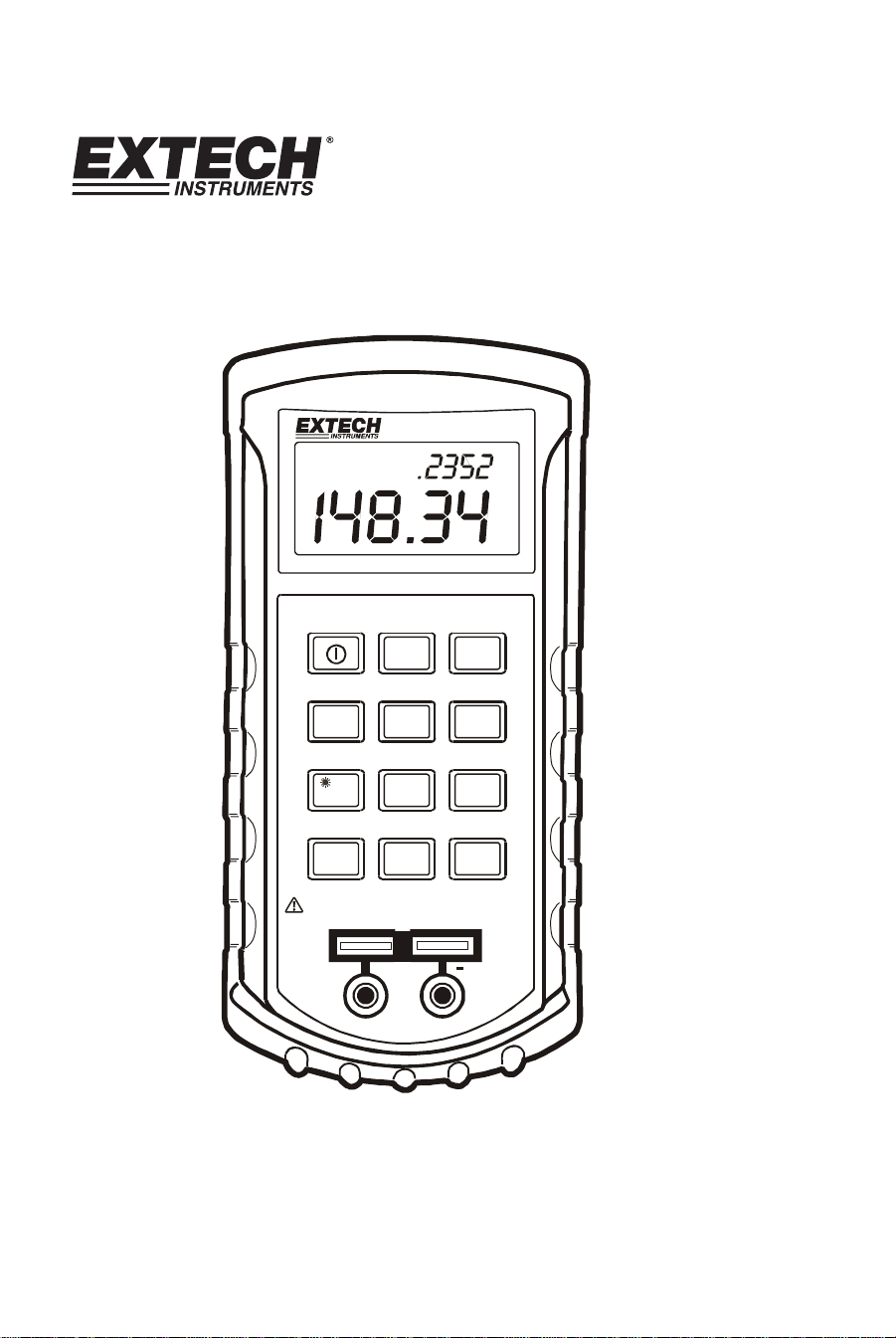

User's Guide

Passive Component LCR Meter

Model 380193

LCR M eter 380193

APO

AUTO

c

123

RANGE L/C/R Q/D/R

456

>2sec

HOLD

789

REL

PAL

-0 ENTER

L/C/R Q/D/R

MIN

MAX

Hi / Lo

LIMITS

D

1kHz

F

µ

SET

TOL

DO NOT APPLY VOLTAGE TO TERMINALS

DISCHARGE CAPACITOR BEFORE T E S TING

+

AUTO-POWER OFF

Page 2

INTRODUCTION

Congratulations on your purchase of Extech's Model 380193 LCR meter. This meter will

accurately measure capacitors, inductors and resistors using the test frequencies of

120Hz and 1 kHz. The dual display will simultaneously display the associated quality

factor, dissipation or resistance value using a series or parallel equivalent circuit.

The included RS-232c PC interface feature with Data Acquisition permits the user to

capture readings to a PC for data storage, viewing, printing, and exporting to spreadsheet

for graphing and other data manipulation tasks.

This meter is shipped fully tested and calibrated and, with proper use, will provide years of

reliable service.

International Safety Symbols

Safety Precautions

Caution ! Refer to the explanation in this Manual

!

Caution ! Risk of electric shock

Earth (Ground)

1. Make sure any covers or battery doors are properly closed and secured.

2. Always remove the test leads before replacing the battery or fuses.

3. Inspect the condition of the test leads and the meter itself for any damage before

operating the meter. Repair or replace any damage before use.

4. To reduce the risk of fire or electric shock, do not expose this product to rain or

moisture.

5. Do not exceed the maximum rated input limits.

6. Always discharge capacitors and remove power from the device under test before

performing Inductance, Capacitance, or Resistance.

7. Remove the battery from the meter if the meter is to be stored for long periods.

2

380193 V2.1 5/07

Page 3

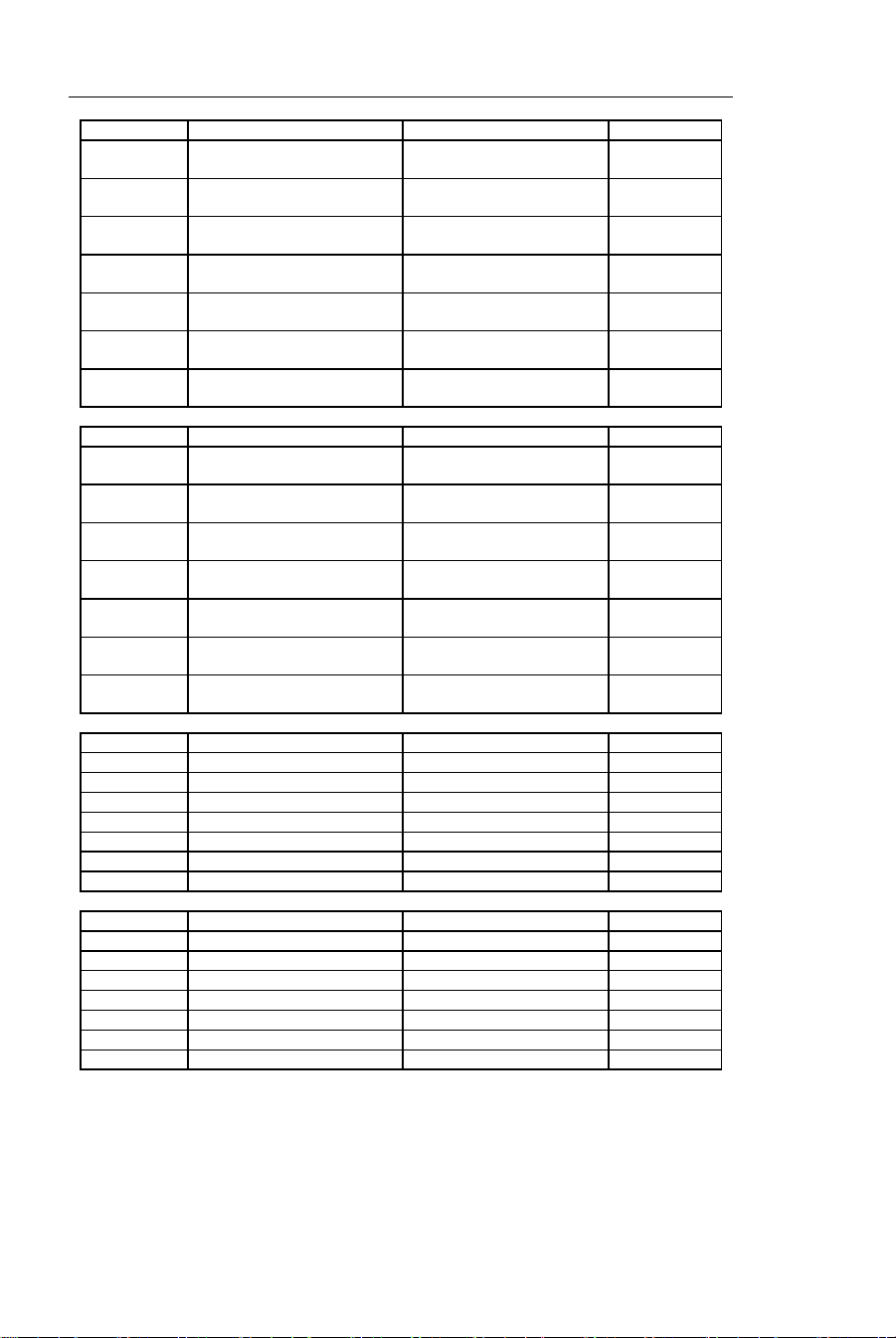

SPECIFICATIONS

Capacitance @ 120Hz

Range Cx accuracy DF accuracy Note

9.999mF ±(5.0% rdg + 5d)

(DF<0.1)

1999.9µF ±(1.0% rdg + 5d)

(DF<0.1)

199.99µF ±(0.7% rdg + 3d)

(DF<0.5)

19.999µF ±(0.7% rdg + 3d)

(DF<0.5)

1999.9nF ±(0.7% rdg + 3d)

(DF<0.5)

199.99nF ±(0.7% rdg + 5d)

(DF<0.5)

19.999nF ±(1.0% rdg + 5d)

(DF<0.1)

Capacitance @ 1kHz

Range Cx accuracy DF accuracy Note

999.9µF ±(5.0% rdg + 5d)

(DF<0.1)

199.99µF ±(1.0% rdg + 3d)

(DF<0.5)

19.999µF ±(0.7% rdg + 3d)

(DF<0.5)

1999.9nF ±(0.7% rdg + 3d)

(DF<0.5)

199.99nF ±(0.7% rdg + 5d)

(DF<0.5)

19.999nF ±(0.7% rdg + 5d)

(DF<0.1)

1999.9pF ±(1.0% rdg + 5d)

(DF<0.1)

Inductance @ 120Hz

Range Lx accuracy (DF<0.5) DF accuracy (DF<0.5) Note

10000H Not specified Not specified

1999.9H ±(1.0%rdg + Lx/10000 + 5d) ±(2.0%rdg + 100/Lx + 5d) after open cal

199.99H ±(0.7%rdg + Lx/10000 + 5d) ±(1.2%rdg + 100/Lx + 5d)

19.999H ±(0.7%rdg + Lx/10000 + 5d) ±(1.2%rdg + 100/Lx + 5d)

1999.9mH ±(0.7%rdg + Lx/10000 + 5d) ±(1.2%rdg + 100/Lx + 5d)

199.99mH ±(1.0%rdg + Lx/10000 + 5d) ±(3.0%rdg + 100/Lx + 5d) after short cal

19.999mH ±(2.0%rdg + Lx/10000 + 5d) ±(10%rdg + 100/Lx + 5d) after short cal

Inductance @ 1kHz

Range Lx accuracy (DF<0.5) DF accuracy (DF<0.5) Note

1999.9H Not specified Not specified

199.99H ±(1.0%rdg + Lx/10000 + 5d) ±(1.2%rdg + 100/Lx + 5d) after open cal

19.999H ±(0.7%rdg + Lx/10000 + 5d) ±(1.2%rdg + 100/Lx + 5d)

1999.9mH ±(0.7%rdg + Lx/10000 + 5d) ±(1.2%rdg + 100/Lx + 5d)

199.99mH ±(0.7%rdg + Lx/10000 + 5d) ±(1.2%rdg + 100/Lx + 5d)

19.999mH ±(1.2%rdg + Lx/10000 + 5d) ±(5.0%rdg + 100/Lx + 5d) after short cal

1999.9µH ±(2.0%rdg + Lx/10000 + 5d) ±(10%rdg + 100/Lx + 5d) after short cal

Note: Where Lx or Cx is the the C or L reading in the display without range indication.

i.e. For a reading of 18.888, use 18888 as the factor.

±(10%rdg + 100/Cx + 5d)

(DF<0.1)

±(2%rdg + 100/Cx + 5d)

(DF<0.1)

±(0.7%rdg + 100/Cx + 5d)

(DF<0.1)

±(0.7%rdg + 100/Cx + 5d)

(DF<0.1)

±(0.7%rdg + 100/Cx + 5d)

(DF<0.1)

±(0.7%rdg + 100/Cx + 5d)

(DF<0.5)

±(2.0%rdg + 100/Cx + 5d)

(DF<0.1)

±(10%rdg + 100/Cx + 5d)

(DF<0.1)

±(2.0%rdg + 100/Cx + 5d)

(DF<0.5)

±(0.7%rdg + 100/Cx + 5d)

(DF<0.1)

±(0.7%rdg + 100/Cx + 5d)

(DF<0.1)

±(0.7%rdg + 100/Cx + 5d)

(DF<0.1)

±(0.7%rdg + 100/Cx + 5d)

(DF<0.1)

±(2.0%rdg + 100/Cx + 5d)

(DF<0.1)

after short cal

after short cal

after open cal

after open cal

after short cal

after short cal

after open cal

after open cal

3

380193 V2.1 5/07

Page 4

Resistance

A

Range accuracy (1kHz & 120Hz) Note

10.000MΩ

1.9999MΩ

199.99kΩ

19.999kΩ

1.9999kΩ

199.99Ω

0.020 to 19.999Ω

±(2.0%rdg + 8d) after open cal*

±(0.5%rdg + 5d) after open cal*

±(0.5%rdg + 3d)

±(0.5%rdg + 3d)

±(0.5%rdg + 3d)

±(0.8%rdg + 5d) after short cal

±(1.2%rdg + 8d) after short cal

*Note: For resistance readings above 1MΩ, series and parallel impedances may affect

readings (especially at 1kHz). This effect is often noticed on decade resistance boxes

where the AC measured value can vary from the DC calibrated value. Use fixed value

low inductance resistors (film or equivalent) for high resistance calibration or certification.

Note: In the 20Ω range, effective readings must be over 20 counts.

Test Frequency (accuracy) 122.88Hz (±4Hz) and 1kHz (±4Hz)

Display: Dual 4 ½ digit backlit LCD

Overload indication: “OL”

Low battery indication:

Measurement rate: One time per second

Auto-power off: After 10 minutes of inactivity

Operating environment: 32

Storage environment: 14

o

F to 122oF (0oC to 50oC), < 80% RH

o

F to 140oF (-20oC to 60oC), < 80% RH, battery removed

Power: 9V battery or optional external 12V-15V @ 50mA (approx.)

Fuse 0.1A/250V fast blow

Dimensions: 7.56x3.6x2.1” (19.2x9.1x5.25cm)

Weight: 12.9oz (365gm)

METER DESCRIPTION

1. Q/D/R display

2. L/C/R display

3. Keypad

4. Test fixture

5. Input jacks

6. External power input

7. Protective holster

8. Battery compartment (rear)

6

7

1

2

3

8

4

5

4

LCR Meter 380193

APO

AUTO

D

PAL

c

-0 ENTER

L/C/R Q/D/R

123

RANGE L/C/R Q/D/R

456

>2sec

MIN

SET

HOLD

MAX

789

Hi / Lo

REL

TOL

LIMITS

DO NOT APPLY VOLTAGE TO TERMINALS

DISCHARGE CAPACITOR BEFO RE TESTING

+

UTO-POWER OFF

380193 V2.1 5/07

1kHz

F

µ

Page 5

Display Symbols and Annunciators

APO Auto Power Off 1KHz 1kHz test frequency

R Recording mode active 120Hz 120Hz test frequency

6

MAX Maximum reading M Mega (10

MIN Minimum reading K kilo (10

AVG Average reading p pico (10

)

3

)

-12

)

AUTO AutoRanging active n nano (10-9)

H Data hold active µ micro (10

SET SET mode m milli (10

-6

)

-3

)

TOL Tolerance mode H Henry (inductance units)

PAL Parallel equivalent circuit F Farad (capacitance units

SER Series equivalent circuit Ω Ohms (resistance units)

D Dissipation factor Upper limit

Q Quality factor Lower limit

R Resistance Relative mode

L Inductance Low battery

C Capacitance % Tolerance (percentage)

5

380193 V2.1 5/07

Page 6

OPERATING INSTRUCTIONS

CAUTION: Measuring a DUT (device under test) in a live circuit will produce false readings

and may damage the meter. Always remove power and isolate the component from the

circuit to obtain an accurate reading.

CAUTION: Do not apply voltage to the input terminals. Discharge capacitors before testing

Note: Measurement considerations for resistance <0.5 ohms.

1. Use positive contact alligator clips.

2. Perform a SHORT calibration zero to remove stray impedances.

3. Clean the DUT leads / contacts of oxidation or film to minimize contact resistance.

Power

1. Press the power key to turn the meter on or off

2. Auto-Power OFF (APO)

If the keypad is inactive for 10 minutes, the meter will automatically shut down. If this

occurs, press the key to resume operation.

3. Auto-Power Off disable.

To disable the auto-power off feature, from the off position, press and hold the power

on key until “APO OFF” appears in the display. Auto-Power Off will also be disabled

if the MIN MAX record mode is used or if the meter is powered by an external power

supply.

Frequency Selection

Press the FREQ key to select either 120Hz or 1kHz as the test frequency. The frequency

selected appears in the display.

Generally, 120Hz will be used for large electrolytic capacitors and 1kHz used for most

other tests.

Parallel/Series Selection

Press the PAL SER key to select either a parallel (PAL) or series (SER) equivalent circuit.

The selected mode will appears as “SER” or “PAL” in the display.

This mode defines the R loss of an inductor or capacitor as a series loss or a parallel loss.

Generally, high impedances are measured in the parallel mode and low impedances are

measured in the series mode.

Range Selection

The meter turns on in the autoranging mode with “AUTO” indicated in the display. Press

the RANGE key and the “AUTO” indicator will disappear. Each press of the RANGE key

will now step through and hold the available ranges for the parameter selected. To exit the

manual range mode, press and hold the RANGE key for 2 seconds.

6

380193 V2.1 5/07

Page 7

Inductance, Capacitance, Resistance Selection

The L/C/R key selects the primary parameter measurement function. Each press of the

key will select either inductance (L), capacitance (C) or resistance (R) along with the

proper units of H (henries), F (farads) or

Quality, Dissipation, Resistance Selection

The Q/D/R key selects the secondary parameter measurement function. Each press of the

key will select either the quality (Q) or dissipation (D) indicators or resistance (Ω) units in

the small secondary display.

Hold and Backlight Selection

The HOLD >2sec key selects the Hold feature and also enables the display backlight.

Press the key and the H indicator will appear in the display and the last reading will

“freeze” in the display. Press the key again and the reading will begin to update again.

Press and Hold the key for 2 seconds and the display backlight will turn-on. To extinguish

the backlight, press and hold the key again for 2 seconds or wait 1 minute for it to

automatically disable.

Minimum, Maximum and Average Selection

The MAX MIN key selects the recording function. Press the key and the “R“ indicator will

appear in the display and the meter will begin recording the minimum, maximum and

average measured values. When this mode is entered, the auto power off and the function

keys are disabled.

Max-Min operation

1. Set all the function parameters for the test.

2. Press the MAX MIN key. The “R“ indicator will appear and a “beep” will sound after

approximately six seconds. Two “beeps” will sound every time the max or min is

updated.

3. Press the MAX MIN key. The “MAX” indicator and the maximum recorded value will

appear in the display

4. Press the MAX MIN key. The “MIN” indicator and the minimum recorded value will

appear in the display

5. Press the MAX MIN key. The “MAX - MIN” indicator and the difference between the

maximum - minimum value will appear in the display

6. Press the MAX MIN key. The “AVG” indicator and the average of the recorded

values will appear in the display.

7. Press and hold the MAX MIN key for 2 seconds to exit the mode.

Notes:

The average value is a true average and averages up to 3000 values. If the 3000 limit is

exceeded, the AVG indicator will flash and no further averaging will take place. The max

and min values will continue to update.

If the HOLD key is pressed during min max recording, the recording is halted until the

HOLD key is pressed again.

Relative Mode

The relative mode displays the difference between the measured value and the value of a

stored reference.

1. Press the REL key to enter the Relative mode.

2. The value in the display when the REL key is pressed will become the stored

reference value and the display will indicate zero or a value close to zero (since the

measured value and the reference value are the same at this point).

3. All subsequent measurements will be displayed as a value relative to the stored

value.

4. The reference value may also be a value that was stored into memory using the

SET Relative procedure (see the Setting a Relative Reference paragraph).

5. To use the SET relative value, press the SET key while in the Relative mode.

6. To exit the Relative mode, press and hold the REL key for 2 seconds.

Ω (ohms) in the main large display.

7

380193 V2.1 5/07

Page 8

Hi / Lo Limits Mode

The Hi / Lo limits mode compares the measured value to the stored high and low limit

values and gives an audible and visible indication if the measured value is outside the

limits. See the setting Hi/Lo limits paragraph below to store the limits in memory.

1. Press the Hi/Lo LIMITS key to enter the mode. The display will briefly show the

stored upper limit with the “ “ indicator and then the stored lower limit with the “ “

indicator before displaying the measured value.

2. The meter will sound an audible tone and blink the upper or lower limit indicator if

the measured value is outside the limits.

3. The meter will ignore an “OL” overload reading.

4. Press the Hi/Lo LIMITS key to exit the mode.

% Tolerance Mode

The % Tolerance Limits mode compares the measured value to a % high and low limit

based on a stored reference value and gives an audible and visible indication if the

measured value is outside the limits. Any % limit can be entered in the SET % Limit mode

(see paragraph below) or standard 1%, 5%, 10% and 20% symmetrical limits can be

selected directly in the % Tolerance mode.

1. Press the TOL key to enter the mode. The display will briefly show the stored

reference value in the main display and the small display will indicate the %

difference between the measured value and the reference value. See the SET %

Limit paragraph to change the reference value.

2. Press the TOL key to step through and select the 1, 5, 10 or 20% settings. The

selected % will briefly appear in the small display.

3. Previously stored user defined % limits are accessed by pressing the SET key.

4. The meter will sound an audible tone and blink the upper or lower limit indicator if

the measured value is outside the limits.

5. Press and hold the TOL key for 2 seconds to exit the mode.

Set Limits and Open/Short Calibration Selection

The SET key is used to; 1. Set Hi/Lo limits, 2. Set % limits, 3. Set Tolerance reference

value and 4. Perform the Open / Short calibration. The SET mode can only be activated if

no other function is active.

Entering the SET mode

1. Power ON and press the SET key.

2. The display will clear, “SEt“ will appear in the small display and a flashing TOL

and flashing indicators will appear in the display.

3. The 5 keys that are now active are; Power, SET, REL, Hi/Lo, and TOL

Open and Short Calibration

The Open and Short function removes stray parallel and series fixture impedances from

the measured value. This feature improves accuracy for very high or low impedances.

(Note: Remove any leads from the meter during this procedure. Leaving them connected

will add impedance to the circuit causing the calibration to fail indicated by OUT UAL

appearing on the display.)

1. Press the SET key 2 times and the display will indicate “CAL OPEn”.

2. Remove any devices or test leads and press “ENTER” (PAL SER). After several

seconds the calibration will complete and display “CAL SHrt”.

3. Short circuit the test fixture and press “ENTER” (PAL SER). After several seconds

the calibration will complete and the meter will return to normal operation.

4. Press the “SET” to bypass either the open or short calibration.

8

380193 V2.1 5/07

Page 9

Setting Absolute Hi/Lo Limits

The Hi/Lo limits set allows the user to enter an upper and lower limit value into memory

for comparison to the measured value.

1. Press the SET key and then the Hi / Lo LIMITS key. The upper limit “ “ indicator

will flash and the previously stored upper limit will appear with the first digit flashing.

2. Set the value of the flashing digit by pressing the appropriate numeric key. The

adjustment selection will then proceed through each digit from left to right.

3. Press the - 0 key after the last digit is set to change the value of the sign to negative

or positive.

4. Press the “ENTER” key to store the value and continue on to the lower limit

adjustment.

5. The lower limit “ “ indicator will flash and the previously stored lower limit will

appear.

6. Adjust the limits as described for the upper limit and press the “ENTER” key when

complete.

Setting % Tolerance Limits

The % tolerance set allows the user to enter an upper and lower percentage limit into

memory for comparison of the measured value to a reference value.

1. Press the SET key and then the TOL key. The “TOL” indicator will flash and the

previously stored reference will appear with the first digit flashing.

2. To adjust the reference, set the value of the flashing digit by pressing the

appropriate numeric key. The adjustment selection will then proceed through each

digit from left to right.

3. Press the “ENTER” key to store the value and continue on to the % upper limit

adjustment. The upper limit “ “ indicator will flash and the previously stored upper

% limit will appear.

4. Adjust the % limit as described for the reference value and press the “ENTER” key

when complete. The lower limit “ “ indicator will flash and the previously stored

lower % limit will appear.

5. Adjust the lower % limit and press “ENTER” when complete.

Setting a Relative Reference

The relative set allows the user to store a relative reference value into memory for later

use in the REL mode.

1. Press the SET key and then the REL key. The “ ” indicator will flash and the

previously stored reference will appear with the first digit flashing.

2. To adjust the reference, set the value of the flashing digit by pressing the

appropriate numeric key. The adjustment selection will then proceed through each

digit from left to right.

3. Press the - 0 key after the last digit is set to change the value of the sign to negative

or positive.

4. Press the “ENTER” key to store the reference value.

9

380193 V2.1 5/07

Page 10

PC INTERFACE

The Model 380193 LCR Meter includes a PC interface feature for use with the supplied

Windows

Instructions for use of the PC interface are included on the supplied Program Disk and are

beyond the scope of this operation manual. For complete details and instructions refer to

the HELP file on the supplied Program Disk.

TM

software. The interface allows the user to:

View measurement data in real time on the PC

Save, Print, and Export measurement data.

Set standard and high / low limits for data analysis

Generate calibration reports in spreadsheet format

Plot SPC (statistical process control) analyses

Database compatibility (supports ODBC) for use with: SQL server, Access

and other database utilities

TM

Warranty

EXTECH INSTRUMENTS CORPORATION warrants this instrument to be free of defects

in parts and workmanship for one year from date of shipment (a six month limited warranty

applies to sensors and cables). If it should become necessary to return the instrument for

service during or beyond the warranty period, contact the Customer Service Department at

(781) 890-7440 ext. 210 for authorization or visit our website www.extech.com for contact

information. A Return Authorization (RA) number must be issued before any product is

returned to Extech. The sender is responsible for shipping charges, freight, insurance and

proper packaging to prevent damage in transit. This warranty does not apply to defects

resulting from action of the user such as misuse, improper wiring, operation outside of

specification, improper maintenance or repair, or unauthorized modification. Extech

specifically disclaims any implied warranties or merchantability or fitness for a specific

purpose and will not be liable for any direct, indirect, incidental or consequential damages.

Extech's total liability is limited to repair or replacement of the product. The warranty set

forth above is inclusive and no other warranty, whether written or oral, is expressed or

implied.

Calibration and Repair Services

Extech offers repair and calibration services for the products we sell. Extech also

provides NIST certification for most products. Call the Customer Care Department for

information on calibration services available for this product. Extech recommends that

annual calibrations be performed to verify meter performance and accuracy.

Technical Support: Extension 200; E-mail: support@extech.com

Repair & Returns: Extension 210; E-mail: repair@extech.com

Product specifications subject to change without notice

For the latest version of this User Guide, Software updates, and other

up-to-the-minute product information, visit our website: www.extech.com

Extech Instruments Corporation, 285 Bear Hill Road, Waltham, MA 02451

Copyright © 2007 Extech Instruments Corporation

All rights reserved including the right of reproduction in whole or in part in any form.

Support line (781) 890-7440

10

380193 V2.1 5/07

,

Loading...

Loading...