Page 1

User's Guide

Oyster Meter

pH-Conductivity-TDS-Salinity-ORP(mV)

Model 341350A

Page 2

INTRODUCTION

Congratulations on your purchase of the Extech's Oyster Series meter. This device measures

pH, Conductivity, TDS, ORP and Salinity. These meters are intended for routine laboratory

and field testing. Accurate measurements are provided in a battery operated, portable meter

with a hinged display that can be adjusted to any viewing angle.

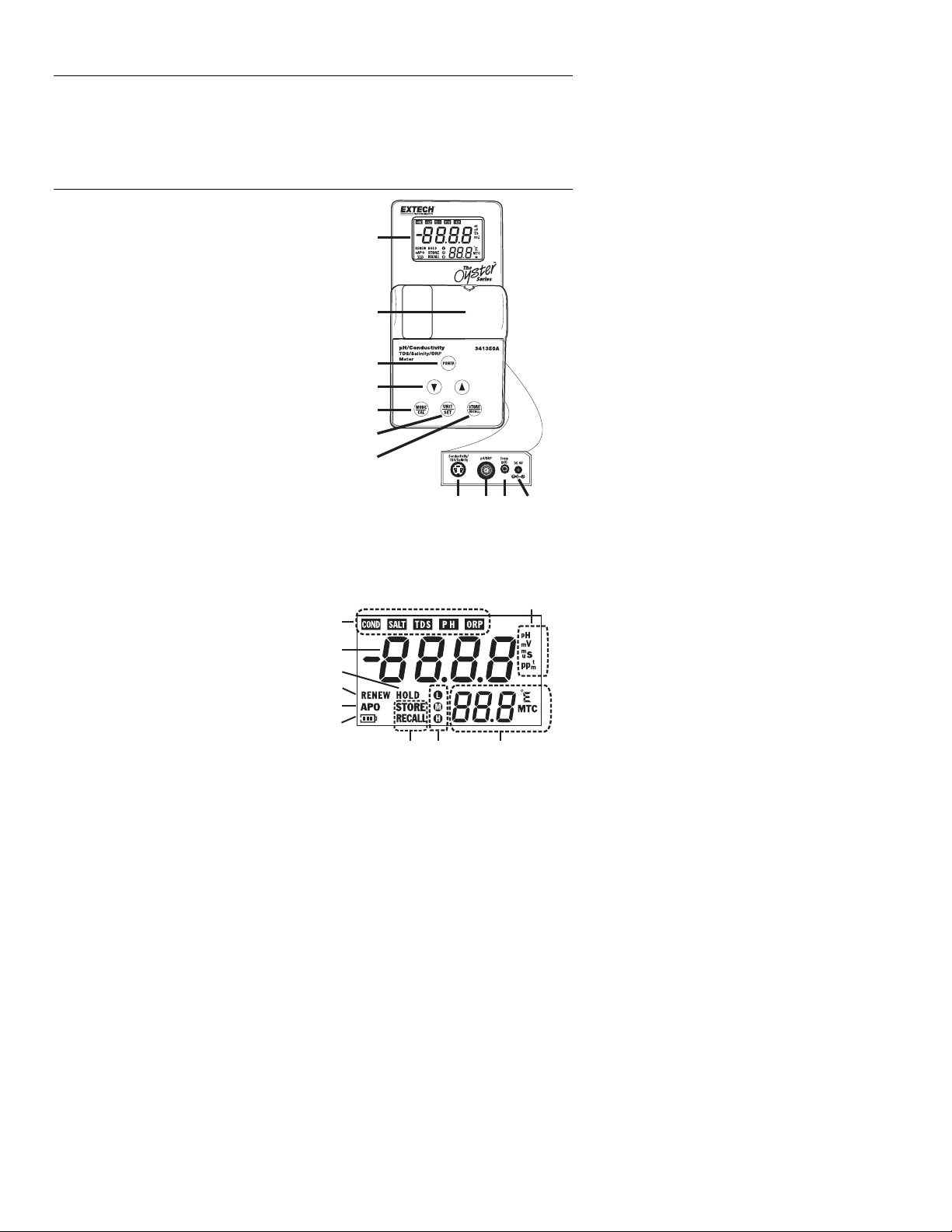

METER DESCRIPTION

Front and Side panels

1. LCD display

2. Battery compartment

3. Power button

4. Up/Down arrow buttons

5. MODE/CAL button

6. UNIT/SET button

7. STORE/RECALL button

8. Connector, Conductivity probe

9. Connector, pH probe

10. Connector, Temperature probe

11. Connector, AC adapter

Display

1. Mode indicators

2. Primary display

3. Data held indicator

4. Probe renew indicator

5. Auto Power Off indicator

6. Low battery indicator

7. Memory status indicators

8. Calibration status indicators

9. Temperature display

10. Unit indicators

1

2

3

4

5

6

7

891011

10

1

2

3

4

5

6

7

89

2

341350A V1.1 1/09

Page 3

OPERATING INSTRUCTIONS

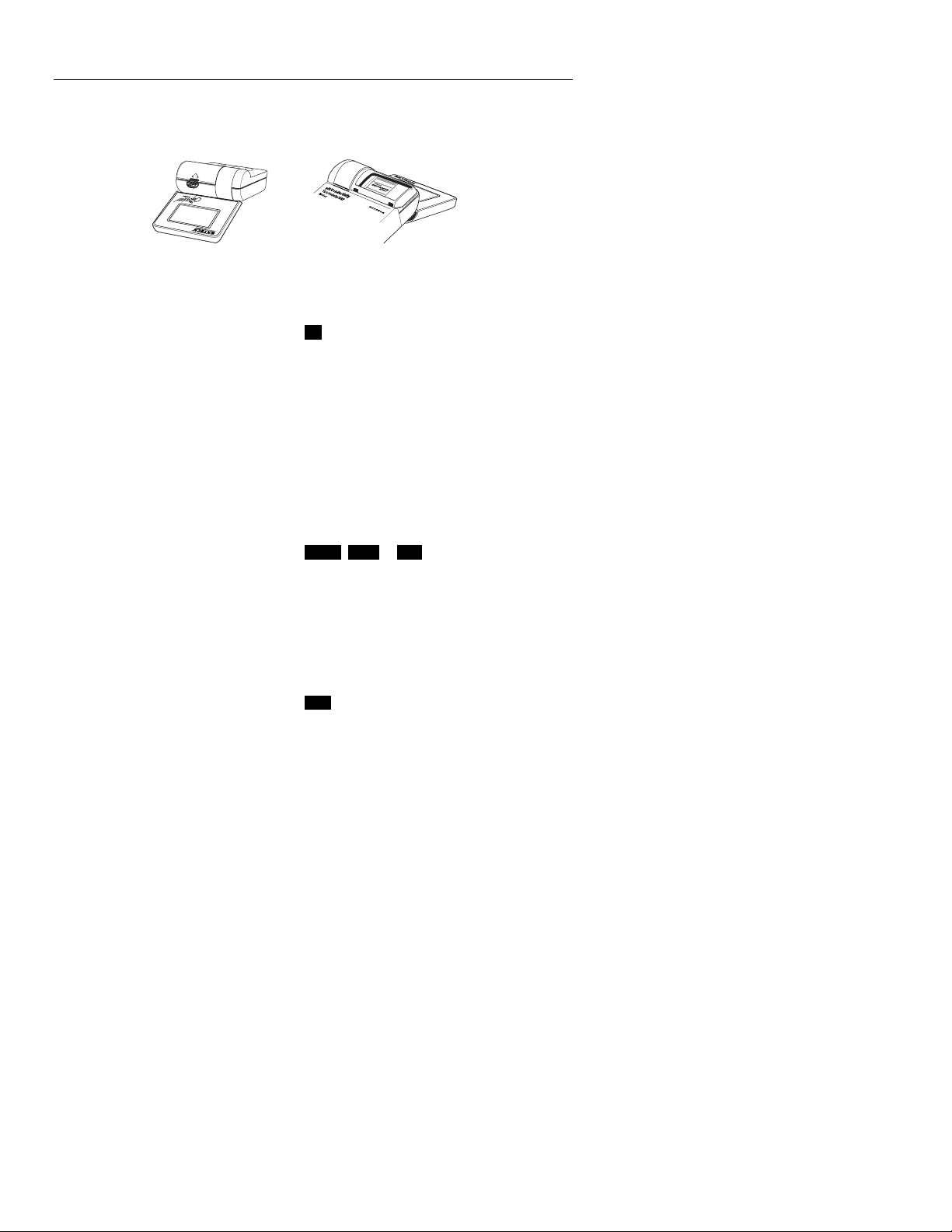

Battery Installation/Replacement

Open the battery cover by inserting a small coin into the latch slot and pressing downward.

The cover will release in the direction of the arrow. Install the new battery and replace the

cover.

pH Measurements

1. Press the POWER button to turn the meter on. (the meter will cycle through a self

check)

2. Press the MODE/CAL button until the PH icon is on.

3. Press the UNIT/SET button to select ºC or ºF.

4. Connect the pH electrode to the side pH BNC connector.

5. Adjust the ▲▼buttons to the temperature of the solution (or use the external

temperature probe).

6. If required, calibrate the electrode. (see pH Calibration)

7. Place the electrode in the sample solution and read the pH value on the display.

8. When all measurements have been taken, unplug the electrode and rinse in distilled

water, shake and store in the wetting cap or a pH 4 buffer solution.

Conductivity/TDS/Salt Measurements

1. Press the POWER button to turn the meter on.

2. Press the MODE/CAL button until the COND, SALT or TDS icon is on.

3. Connect the conductivity electrode to the side conductivity connector.

4. If required, calibrate the electrode. (see Conductivity Calibration)

5. Place the electrode in the sample solution and read the value on the display.

6. When finished, unplug the electrode and rinse in distilled water.

ORP (mV) Measurements

1. Press the POWER button to turn the meter on.

2. Press the MODE/CAL button until the ORP icon is on.

3. Connect the ORP electrode to the side ORP BNC connector.

4. Place the electrode in the sample solution and read the mV value on the display.

5. When all measurements have been taken, unplug the electrode and rinse in distilled

water.

3

341350A V1.1 1/09

Page 4

Data Memory

25 readings can be stored to and recalled from the internal memory.

Storing readings

1. With the reading on the display, momentarily press the STORE/RECALL button. The

STORE and HOLD display icons will appear on the LCD and the reading will freeze.

2. Momentarily press the STORE/RECALL button again to confirm and return to the

normal operation mode.

3. Up to 25 readings can be stored in this fashion.

Recalling Readings

1. Press and hold the STORE/RECALL button. The RECALL icon and the memory

location number will appear followed by the data in the displayed memory location. .

2. Press the ▼or ▲button to scroll through the memory locations and to view the stored

data.

3. Momentarily press the STORE/RECALL button to exit the Recall Readings mode.

End will appear in the display and then the meter will return to the normal

measurement mode.

Clearing the memory

With the meter on, press and hold the ▼ and ▲ buttons for 2 seconds. CLr will appear on

the display indicating that the memory has been erased.

Temperature Units

Press the UNIT button to switch between a ºF or ºC display.

Manual Temperature Compensation

In the pH mode, the solution temperature can be set by using the optional external

temperature probe or by adjusting the temperature display when the probe is not used.

Press the ▲▼buttons to set the temperature when MTC icon is displayed. The

Conductivity probe has a built-in temperature sensor so manual temperature

compensation does not apply for those measurements.

Auto Power off (APO)

The meter is equipped with an Automatic Power Off feature. The meter will turn off 10minutes after the last button-press. This feature can be disabled by pressing and holding

the POWER button for 2 seconds (the APO display icon indicates that this feature is

enabled). Next time the meter is powered up, Auto Power off will be engaged again.

Reset to Default settings

The meter can be reset to its factory default configuration by following these steps.

1. With the meter OFF, press and hold the POWER and STORE/RECALL buttons

simultaneously until dFLt rSt appears in the display.

2. Release the buttons and the meter will continue with a normal startup.

3. Default values include: Calibration values, Conductivity mode, ºC, MTC, APO and

RENEW off.

4

341350A V1.1 1/09

Page 5

pH Calibration (1, 2, or 3 points)

A two point calibration with a buffer of 7 plus 4 or 10 (whichever is nearest to the expected

sample value) is always recommended. A one point calibration (choose the value closest

to the expected sample value) or a three point calibration is also valid. For best accuracy,

always calibrate at the sample temperature. Frequency of calibration is dependent on how

often the meter is used, care of the electrode and strength of the samples tested. Typically,

it is recommended that calibration be performed once a day or before each use if the meter

is not used on a daily basis.

1. Connect the pH probe and place it into a pH7 buffer.

2. Press the POWER button to turn the meter on and press the MODE/CAL button until

the PH icon appears. (Note: disable the Auto Power Off feature to avoid an automatic

power off during calibration)

3. If MTC icon appears next to the temperature display, press the ▼ or ▲ buttons to set

the temperature of the pH buffer. If the optional temperature probe is used, insert the

probe into the buffer solution.

4. Press and HOLD the MODE/CAL button until the display begins to flash 7.00. The

meter automatically recognizes the buffer and calibrates itself to that value. At the end

of the calibration cycle, SA and End will briefly appear on the display and then the

meter returns to the normal operating mode

5. When a calibration is performed, the calibration icons

be cleared (calibration data is not erased) and will be replaced when a successful

calibration is performed for each buffer within one power on cycle. These icons

indicate what calibration levels were last performed. They do not indicate how

recently the calibration was performed or if the calibrations are still valid.

6. Remove the electrode from the pH7 buffer, rinse in a rinse solution and insert it into

the pH4 or pH10 buffer solution.

7. Repeat step 4 for the second calibration point and then the third point if desired.

Note: If the output of the electrode falls outside predetermined limits, the meter will

cancel the calibration, indicate End and the RENEW icon will flash. This typically

happens when the electrode has aged and needs replacement.

Note: To avoid cross contamination, always rinse the electrode in a rinse solution

when changing from one buffer or sample to the next buffer or sample.

(pH10) (pH7) (pH4) will

5

341350A V1.1 1/09

Page 6

Conductivity (TDS & Salt) Calibration

Conductivity accuracy verification should be performed on a periodic basis. Once per

month is the recommended cycle for normal use. If calibration is required, a conductivity

standardizing solution must be obtained. The meter can be calibrated in any or all of the

three ranges. Standardizing solutions of 84µS/cm, 1413µS/cm or 12.88mS/cm

(12,880µS/cm) are used for the automatic calibration recognition procedure. No other

calibration values are permitted.

Calibration is always done in conductivity mode. Since salinity and TDS values are

calculated from conductivity values, this procedure also calibrates the Salinity and TDS

ranges.

1. Fill a sample cup with the standardizing solution.

2. Turn the meter ON and insert the electrode into the solution. Tap or move the

electrode in the sample to dislodge any air bubbles.

3. Press and hold the MODE/CAL button (approximately 2 seconds) until the main

display starts flashing.

4. The meter will automatically recognize and calibrate to the standardizing solution. At

the end of the calibration, the display will briefly indicate “SA”, “End” and then return

to the measurement mode.

Note: The “SA” will not appear if the calibration fails.

5. The “range calibrated” symbol will appear in the display for each range that is

calibrated during that power on cycle.

Low range, 84µS/cm

Medium range, 1413µS/cm

High range, 12.88mS/cm (12,880µS/cm)

Note: The meter allows for a 1, 2 or 3 point calibration. If calibration is done for more than

one point, the lowest value standard should be done first to obtain the best accuracy.

ORP Calibration

The ORP electrode does not require calibration.

Temperature (pH and Conductivity) Offset Calibration

This procedure allows for error correction of the external temperature probe (pH) or the

conductivity probe’s built-in temperature sensor.

1. Switch to pH or Conductivity (Salt/TDS) mode.

2. Place the temperature probe or conductivity cell in the sample and allow the

temperature reading to stabilize.

3. Press and hold the UNIT/SET button until the ºC or ºF icon begins flashing.

4. Adjust the ▼ or ▲ buttons to set the display to indicate the known temperature of the

sample.

5. Momentarily press the UNIT/SET button to save the change and return to the

measurement mode.

6

341350A V1.1 1/09

Page 7

pH Troubleshooting Chart

Symptom Cause Recommended Solution

Long response

time or reading

drift

Dry Bulb Long term storage without wetting Soak electrode tip in wetting cap filled

Static Charge Wiping electrodes Rinse electrode in 7.0 buffer and blot.

Same readings

in different

buffers and

samples

Erratic LCD

display

Notes on pH measurements and electrodes

1. The Electrode should be stored in its wetting cap until used. Use a pH 4 buffer solution

or tap water as the storage medium.

2. If bubbles are seen in the bulb area, hold the electrode by its cap and shake

downwards until bubbles are removed.

3. To improve speed of response, vigorously stir the electrode in the sample, buffer, or

rinse solution.

4. After exposure to a sample, buffer, or rinse solution, shake the electrode with a snap

motion to remove residual drops of solution.

5. When possible, use part of the next sample/buffer to be measured as a rinse solution,.

6. Keep buffers and samples at the same temperature to avoid temperature effects.

7. pH readings stabilize faster in some solutions than others; allow time to stabilize.

8. Electrodes deteriorate over time. If accuracy falls to 10% the electrode should be

cleaned. If no improvement is observed, replace the electrode.

Clogged Junction Soak in 4.07 M KCL @ 60oC for 30

Oil, paint, dyes, suspended solids

on sensor

Cracked or broken bulb Replace electrode. Use bulb guard.

Samples have low ionic strength

(lacks salt); e.g. distilled, deionized, boiled, lake water (high

pressure)

minutes

Rinse electrode alternately with

materials solvent then buffer 7.00

with 1ml 7.00 buffer for 24 to 48 hours

Do no wipe electrode.

Avoid plunging electrode to bottom of

container and spinning bars. A

wetting cap will protect bulb between

measurements.

For each 50 ml of sample add 1 drop

(50uL) of SAT.KCL No alteration in

pH will occur by inert KCL.

Notes on the Conductivity/TDS/Salt Cell

1. Cell Storage: On sheathed cells, replace the sheath over the cell when storing. For

non-sheathed versions, soak the cell tip in de-ionized water for storage.

2. Cell Cleaning: After each use, the cell tip should be rinsed with de-ionized water. If

solids build up inside the cell carefully remove with a cotton swab soaked in solvent

taking care not to touch the metal parts of the inner cell.

7

341350A V1.1 1/09

Page 8

SPECIFICATIONS

Ranges Resolution Accuracy

pH 0.00 to 14.00pH 0.01pH ± 0.02pH

Conductivity

TDS 0.0 to 134.0ppm

Salinity 0.0 to 100.0ppm

ORP -1500 to 1500mV 1mV ± 3mV

Temperature 32 to 194ºF

Display 9999 count LCD

MTC temperature range 32.0 to 194.0ºF (0.0 to 90.0ºC)

pH calibration points 4.00, 7.00 and 10.00pH

Conductivity calibration points 84.0µS, 1413µS, 12.88mS

TDS conversion ratio 0.67 fixed

Salinity conversion ratio 0.5 fixed

Auto Power OFF 10 minutes, with disable

Overrange indication “OL”

Operating Temperature 41ºF to 104ºF (5ºC to 40ºC)

Storage Temperature -4ºF to 140ºF (-20ºC to 60ºC)

Operating Humidity Max 80% up to 87ºF (31ºC) decreasing linearly to

Storage Humidity <80%

Operating Altitude 7000ft. (2000meters) maximum.

Power 9V alkaline battery or AC adapter

Dimensions 4.7x3.8x1.8” (118x96x45mm) closed

Weight 12oz. (340g)

0.0 to 200.0µS

200 to 2000µS

2.00 to 20.00mS

134 to 1340ppm

1.34 to 13.40ppt

100 to 1000ppm

1.00 to 10.00ppt

0.0 to 90.0ºC

0.1µS

1µS

0.01mS

0.1ppm

1ppm

0.01ppt

0.1ppm

1ppm

0.01ppt

0.1º ≤ 99.9º

1º ≥ 100º

50% at 104ºF (40ºC)

± 2% FS

(calculated from Conductivity)

(calculated from Conductivity)

± 2ºF/1ºC (meter+probe)

8

341350A V1.1 1/09

Page 9

MAINTENANCE

Calibration / Repair Services

Extech offers complete repair and calibration services for all of the products we sell. For

periodic calibration or repair of any Extech product, call customer service for details on

services available. Extech recommends that calibration be performed on an annual basis

to insure calibration integrity.

WARRANTY

EXTECH INSTRUMENTS CORPORATION (a FLIR company) warrants this instrument to be free of defects

in parts and workmanship for one year from date of shipment (a six month limited warranty applies on

sensors and cables). If it should become necessary to return the instrument for service during or beyond the

warranty period, contact the Customer Service Department at (781) 890-7440 ext. 210 for authorization or

visit our website at www.extech.com

RA number). A Return Authorization (RA) number must be issued before any product is returned to Extech.

The sender is responsible for shipping charges, freight, insurance and proper packaging to prevent damage

in transit. This warranty does not apply to defects resulting from action of the user such as misuse, improper

wiring, operation outside of specification, improper maintenance or repair, or unauthorized modification.

Extech specifically disclaims any implied warranties or merchantability or fitness for a specific purpose and

will not be liable for any direct, indirect, incidental or consequential damages. Extech's total liability is limited

to repair or replacement of the product. The warranty set forth above is inclusive and no other warranty,

whether written or oral, is expressed or implied.

Copyright © 2009 Extech Instruments Corporation (a FLIR company)

All rights reserved including the right of reproduction in whole or in part in any form.

Technical support: Extension 200; E-mail: support@extech.com

Repair & Returns: Extension 210; E-mail: repair@extech.com

Product specifications subject to change without notice

For the latest version of this User Guide, Software updates, and other

up-to-the-minute product information, visit our website: www.extech.com

Extech Instruments Corporation, 285 Bear Hill Road, Waltham, MA 02451

(click on Contact Extech and go to Service Department to request an

Support line (781) 890-7440

9

341350A V1.1 1/09

Page 10

10

341350A V1.1 1/09

Loading...

Loading...