Expobar BREWTUS IV, BREWTUS IV-R, BREWTUS IV-P Supplemental Instructions

1

EXPO

BAR

BREWTUS IV

Supplemental Instructions

for all

Expo

barBrewtus IV machines

Rotary Pump

(IV-R)

, Vibration Pump

(IV),Plumbable Vibration Pump (IV

-P)www.wholelattelove.com

888.411.5282

2

Congr

atulation

s

on the purchase of your new Brewtus

IV

. The Expo

barBrewtus

is a

very unique machine that is designed to provide you with the ultimate in brewing

temperature control and

,

there

fore, the best coffee extraction

.

Please read both the manufacturer

’s

instructions

as well as these supplemental

instructions

thoroughly before you start brewing.

Note:

Do not plug in the machine or perform any other start

-

up procedures until

you’ve read the

instructions.

Both boiler

s

must be primed

upon

start up or t

he heating

element in the bre

w

boiler

may be damaged.

Upon s

tartup,

make sure

the brew

-

group lever

is raised to

the up

position until water comes out of the brew group.

The steam boiler will fill on its own

using the machine

’

s controls.

Index

1.

Unpacking

the Machine

2.

Controls and Programming

3.

Water and D

rain Line Connections

4.

Incoming Water Pressure

5.

Brew Pressure Adjustments

6.

Accessories

7.

Initial Start

-

Up Instructions

8.

Water Softener Instructions

9.

Coffee Preparation

10.

Advanced Brewing and Operational Techniques

11.

Steaming and Frothing

12.

Dispensing Hot Water

13.

Cleaning the Brewing Components

14.

Cleaning the Housing

15.

Trouble Shooting Guide

16.

Recipes

17.

Coffee Education

and Terminology

18.

Cautions

3

1.

Unpacking the machine.

The Brewtus

IV is a very heavy machine

(over 60lbs

),so please use

cau

tion

when

unpacking the unit

.

To remove the Brewtus, turn

the box upside down, open the bottom

four flaps,

then

turn the box right

-

side-up and lift the box straight up. Then

,

lay the

machine down on its side and remo

ve the top layer of foam. C

arefully remo

ve the

machine from the bottom layer of foam. It is easier to have a second pers

on helping you

with the removal process,

as the machine is heavy and the bottom layer of foam may

stick to the machine.

2.

Controls and Programming

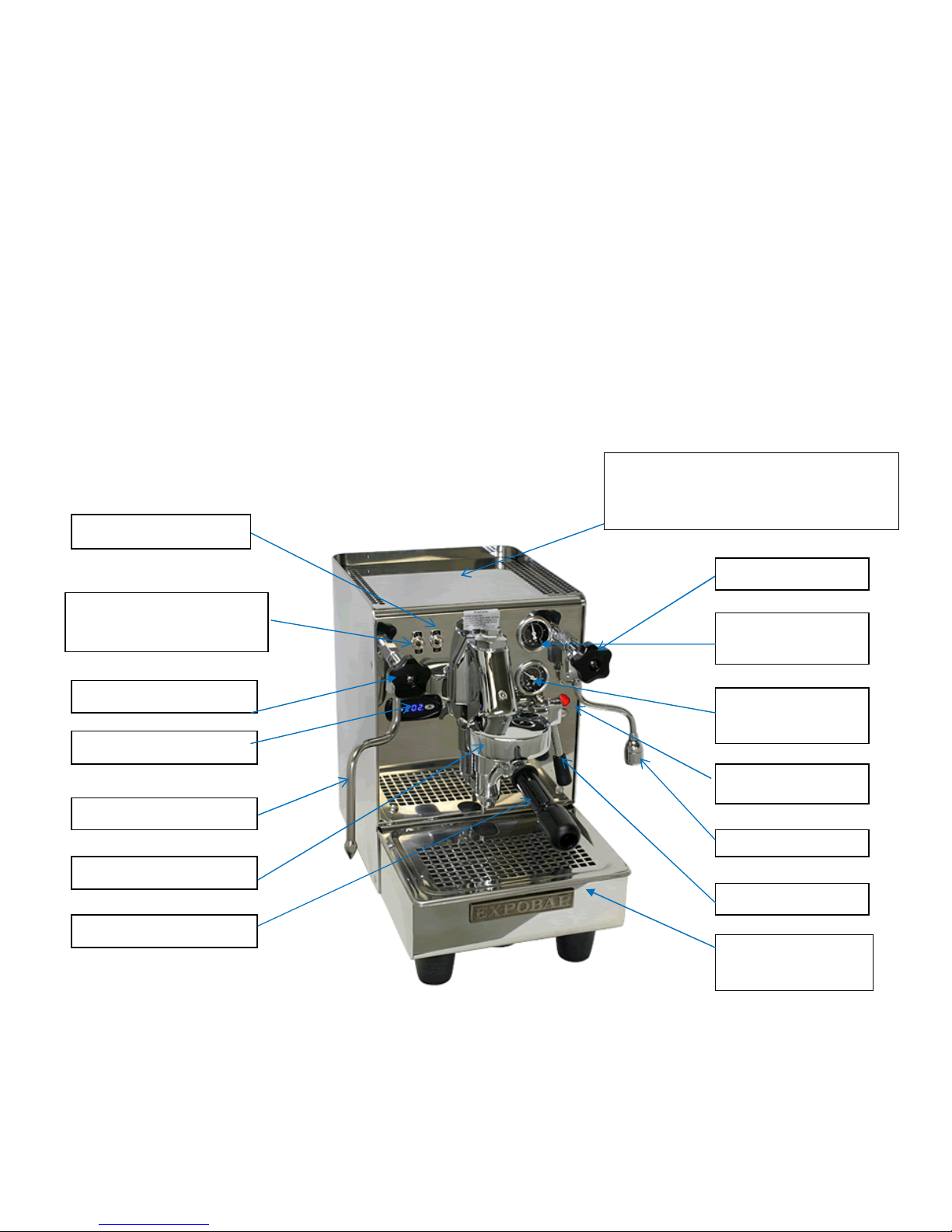

Control Lever

Main Power Switch

PID Control Pane

l

Steam Boiler Light

Hot-Water Knob

Hot Water Wand

Steam Boiler

Pressure Gauge

No-Burn Steam Wand

Steam Boiler On/Off

Switch

E61 Brew Group

Cup Warmer and Reservoir A

ccess

forBrewtus

M

odels

E

quipped with a

Water R

eservoir.

Removable Drip

T

ray

Portafilter handle

Brew Pressure

Gauge

Steam Knob

4

Control Lever

The lever on the front of the machine controls a valve inside of the brew group and it

also controls the pump for brewing. The lever has three positions

:

raised, mid

-

level

and

lowered

.

1.

Raised

: When in the up position

,

the pump

turns on for brewing and the valve

inside the brew group opens and allows water to flow over the coffee.

2.

Mid-Level

:

This position is o

nly used for

coffee pre

-

infusion.

Do not leave the

lever in the middle position when

the machine is not in use or

idle.When

the

lever is

in the middle position

, the pump is

off but the pressure in the brew

group has not been released

,

so do not remove the portafilter.

3.

Lowered

: When the lever is lowered, the

pump

is

off and any water pressure

left on the coffee is released

and deposited into the drip tray through the tube

at

the bottom of the brew group.

Always

set

the lever to the down position

before removing the portafilter from the brew group

.

Main Power Switch

The main power switch is located on the top left side of

the front of the machine.

When turned on

,

the

Brewtus

will automatically start heating up and the water level

control system will

ensure

that the steam boiler is full of water. Note: When the main

power switch is turned on

, the pump may activate

for a few

seconds

,

even if the steam

boiler is full.

Steam B

oiler Switch

When in the

OFF

position

,

the steam boiler will

be inactive

. Only the brew boiler will

heat up. This will allow for a quicker

warm

up for when you only want to brew.

Steam Boiler Light

This

light goes on whenever the heating elem

ent in the steam boiler is on.

It is

perfectly normal for this light to go on and off with or without any discernable pattern

when the machine is in use.

Steam Pressure Gauge

This pressure gauge shows the pressure i

nside the steam boiler. The pressure come

s

set from the factory at

1.3 to 1.4

Bars. This is the proper boiler pressure and there

should be no need to make any adjustments. The needle on the pressure gauge will go

down during steaming

and

quickly rise up as

the steam boiler heating element is

activated.

Brew Pressure Gauge

This pressure gauge

display

s

the current

brew pressure.

Steam Knob (Left

S

ide of

M

achine)

When this knob is turned counter clockwise

,

the steam valve is opened

and high

-

pressure steam

w

ill

be dispensed

through the steam wand.

5

Hot Water K

nob (

Right Side of M

achine)

When this knob is turned counter clockwise

,

hot water and some steam

will be

dispensed through the

hot water wand.

Note

:

Exercise

caut

ion when using this

function;

boiling

wat

er exiting from the hot water wand can cause severe burns.

Steam Wand

Use this wand for fr

othing and steaming your milk.

Theno-

burn wand has been

insulated to remain cool to the touch

.

E61 Brew Group

The brew group will become very hot

. A

lways use caut

ion while working with the

machine.

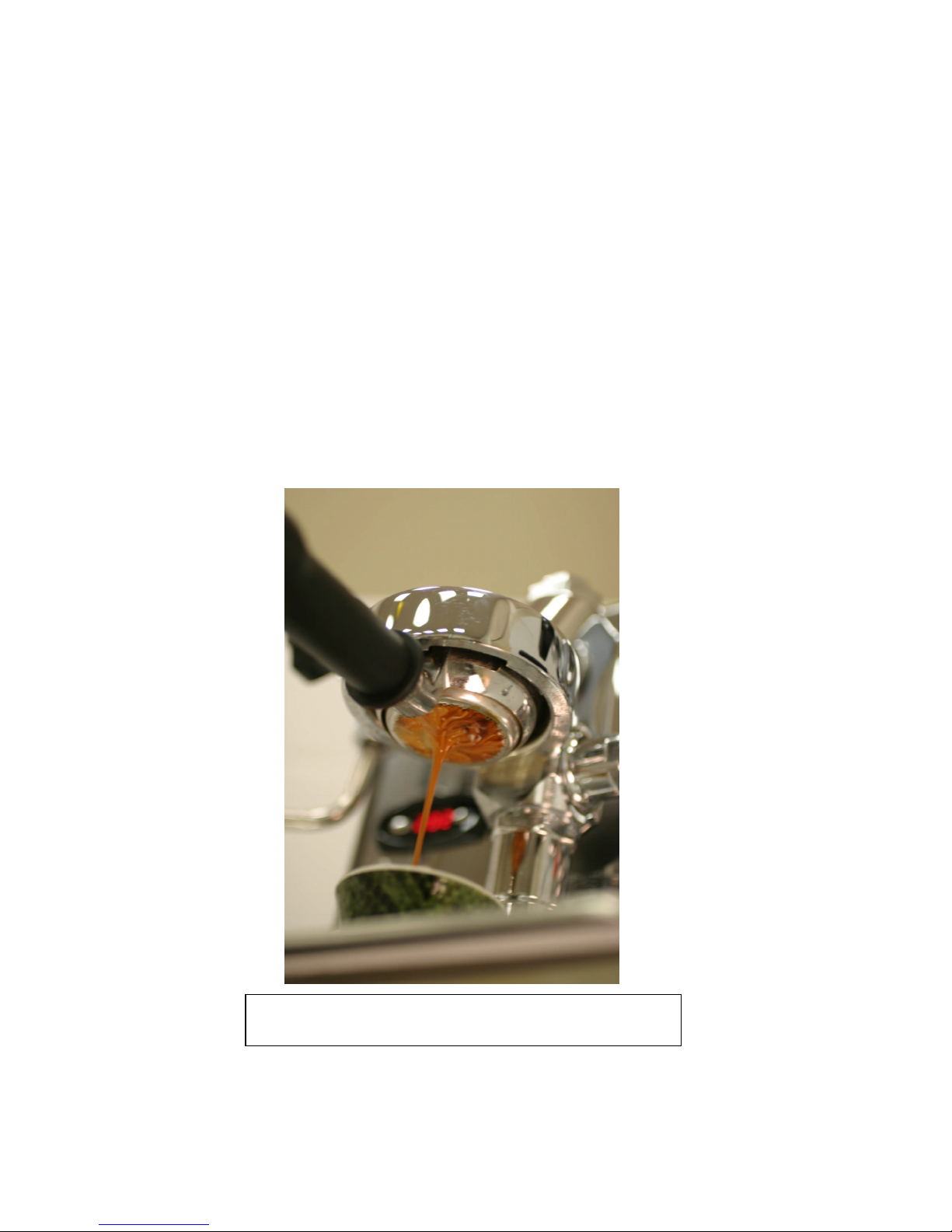

Optional Bottomless Portaf

ilter with a triple shot basket.

(Not included with machine)

6

Control Panel with PID Temperature Control

ThePID controller was

designed a

nd

programmed

exclusively

for the Expo

barBrewtus. Fahrenheit temperatures are

adjustable

in

one

-

degree

increments.

The

PID control

display

s

the

brewing temperature

and can be

used t

o adjust brew

-

boiler

temperature. It does not a

ffect

the steam boiler

,

which is controlled by a pressure stat.

Display functions:

1.

Upon

startup,

the digital displ

ay will show

the current brew boiler

temperature,

minus an offset factor.

2.

The small LED light will blink

,

as it sends power to the brew boiler.

Note: The steam boi

ler heats up first, which

will take about 8 to

10

minutes

.

Afterwards, the brew boiler wil

l turn on. Both b

oilers will not operate at the same

time.

Changing the Brewing Boiler Temperature

1.

Push and release the “Down Arrow” (left button), the display will

show

“PRG.”

2.

Push the “Up Arrow” and release. Then

, press

the UP

and

DOWN

arrows to

set

to your desired temperature.

It may take up to 5 or 10 minutes before the

new temperature is achieved.

To Turn off the Brew Boil

er

(the only reason t

o do this is if you just want to

steam milk

or dispense hot water

without brewing

)

Press

the UP arrow

f

or 2 seconds

;

the display

will

show “Off.”

To turn the brew boiler

back on

,

push

and hold the

UP arrow

for3seconds.

Steam boiler adjustments

:

We do not recommend maki

ng any adjustments to the

steam

-

boiler pressure. It is set to cycle between 1.2 and 1.4

Bars.Down Arrow for Temperature Control Adjustment

Boiler Temperature

Display

Up Arrow for Temperature Con

trol

Boiler Operation Light

7

3.

Water and Drain Line Connections

Water Line Connection

s for

Brewtus

-IVModels Equipped

with

a

Rotar

y pump

or

Vibration Pump with P

lumb K

it

The water line supplied with the machine is 3/8” braided stainless steel

and it

may vary in

length

.Itw

ill

include

a 3/8”

male

flair

fitting

for you to hook onto

.

Depending on your

water quality

,

you may want a good water f

ilter to condition your water, which will

help

with machine longevity. The taste of the coff

ee is affected by your water.

Drain Line Connection

(On Brewtus

-IVwith Drain L

ine)

Thedrain line measu

res 57” long from the drain pan. It

has an in

side diameter of 3/4

”

and an outside diameter of

7/8

”. You will want to have an open dr

ain line stand pipe

for it to drop into.

T

he end

of

the drain line

should not

be below the surface of the

water in the stand pipe or it may back up.

The drain pan supplied does not have a hole

it because many customers do not want to hook up the drain line

. If yo

u hook up a

drain line, drill a 1/4

” hole in the center of the drain pan.

8

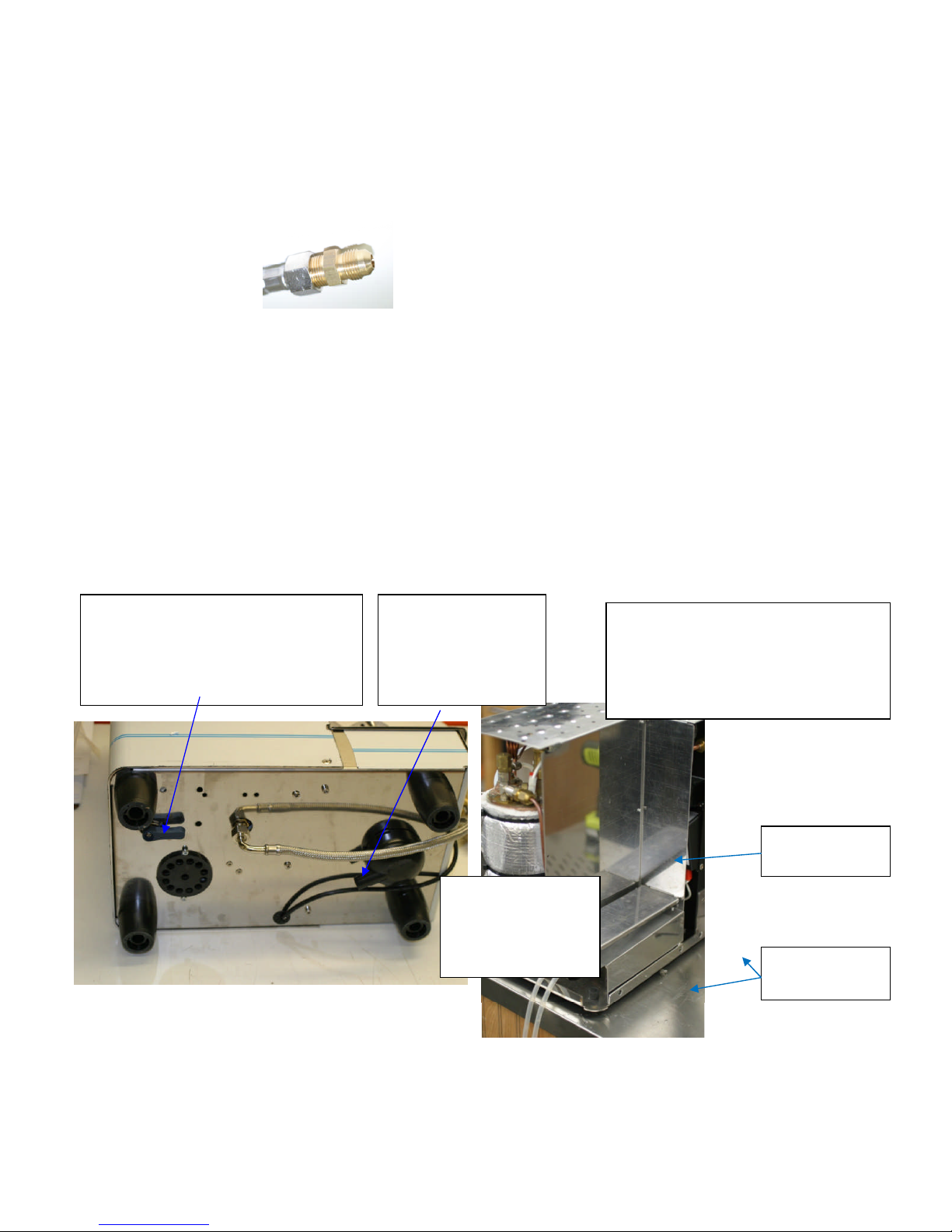

Water line Adapter:

The machine comes equipped with a braided stainless steel water line. Included is a brass

adapter that has a 3/8” male flair fitting. You will nee

d to use a 3/8” female flair fitting to

hook up to it.

Brewtus IV

-Pwith Plumbing K

it

and Reservoir

The Br

ewtus IV

-Pcan be used

either with a water line hookup or the included reservoir.

There is

a

lever on the bottom of the machine that you ca

n use t

o alternate between the

plumbed line and water reservoir

.

The machine will be shipped from Whole Latte Love

ready to use with the reservoir. If you want to use it with the water line hook up

, you will

have to move the control lever

and

the wires on the Mic

ro Switch that senses the weight

of the reservoir

as shown below.

Turn this lever forward for water line

connection and

back for reservoir

connection. (T

he image below shows

it set up for a water line).

The flexible drain

line that was

supplied with the

machine sli

des over

this fitting.

To access the micro

switch under

the

reservoir remove the housing (5

screws) and the reservoir holding

plate

(two Philips head screws and

two 3

mm A

llen screws)

UNPLUG the

machine when

performing any of

these functions

.

Two 3mm

Allen screws

Reservoir

holding plate

Loading...

Loading...