Page 1

USER GUIDE

PON POWER METER

PPM-350B

NETWORK TESTING

Advanced Test Equipment Rentals

www.atecorp.com 800-404-ATEC (2832)

®

E

s

t

a

b

l

i

s

h

e

d

1

9

8

1

Page 2

ii

Copyright © 2006 EXFO Electro-Optical Engineering Inc. All rights reserved. No part

of this publication may be reproduced, stored in a retrieval system or transmitted in

any form, be it electronically, mechanically, or by any other means such as

photocopying, recording or otherwise, without the prior written permission of EXFO

Electro-Optical Engineering Inc. (EXFO).

Information provided by EXFO is believed to be accurate and reliable. However, no

responsibility is assumed by EXFO for its use nor for any infringements of patents or

other rights of third parties that may result from its use. No license is granted by

implication or otherwise under any patent rights of EXFO.

EXFO’s Commerce And Government Entities (CAGE) code under the North Atlantic

Treaty Organization (NATO) is 0L8C3.

The information contained in this publication is subject to change without notice.

Trademarks

EXFO’s trademarks have been identified as such. However, the presence or

absence of such identification does not affect the legal status of any trademark.

Units of Measurement

Units of measurement in this publication conform to SI standards and practices.

Patents

The PPM-350B is the subject of International Patent Appln. No. WO 2005/036783;

EXFO’s Universal Interface is protected by US patent 6,612,750.

Page 3

PPM-350B iii

Contents

Certification Information ................................................................................. iv

1 Introducing the PPM-350B PON Power Meter ......................... 1

Main Features ................................................................................................... 1

Available Models .............................................................................................. 3

Power Sources .................................................................................................. 3

Typical Applications .......................................................................................... 3

2 Safety Information ................................................................... 4

Electrical Safety Information ............................................................................. 4

Conventions ...................................................................................................... 4

3 Getting Started with Your PPM-350B PON Power Meter ........ 5

Turning the Unit On and Off ............................................................................. 5

Activating Automatic Shutdown (Auto-Off) ...................................................... 6

Installing the EXFO Universal Interface (EUI) ..................................................... 7

Cleaning and Connecting Optical Fibers ........................................................... 8

4 Configuring Thresholds and Correction Factors ..................... 9

5 Testing with Your PPM-350B PON Power Meter .................... 10

Nulling Electrical Offsets ................................................................................. 10

Viewing Correction Factors ............................................................................. 11

Selecting a Threshold Set ................................................................................11

Testing in Pass/Fail Mode or in Normal Mode .................................................. 13

Measuring Loss Between Two Points ............................................................... 16

6 Maintenance ............................................................................ 18

Cleaning EUI Connectors ................................................................................18

Replacing Disposable Alkaline Batteries .......................................................... 20

Recalibrating the Unit ..................................................................................... 20

Verifying Thresholds ....................................................................................... 21

Verifying the LEDs and LCD ............................................................................. 21

Recycling and Disposal (Applies to European Union Only) .............................. 22

7 Troubleshooting ...................................................................... 23

Solving Common Problems ............................................................................. 23

Error Codes and Descriptions .......................................................................... 24

Contacting the Technical Support Group ........................................................ 25

Finding Information on the EXFO Web Site .................................................... 26

Transportation ................................................................................................ 26

8 Warranty .................................................................................. 27

General Information ....................................................................................... 27

Liability ........................................................................................................... 27

Exclusions ....................................................................................................... 28

Certification .................................................................................................... 28

Service and Repairs ......................................................................................... 29

EXFO Service Centers Worldwide .................................................................... 30

A Technical Specifications .......................................................... 31

Page 4

Certification Information iv

Certification Information

F.C.C. Information

Electronic test equipment is exempt from Part 15 compliance (FCC) in the United

States. However, compliance verification tests are systematically performed on

most EXFO equipment.

Information

Electronic test equipment is subject to the EMC Directive in the European Union.

The EN61326 standard prescribes both emission and immunity requirements for

laboratory, measurement, and control equipment. This unit has undergone

extensive testing according to the European Union Directive and Standards.

Application of Council Directive(s): 73/23/EEC - The Low Voltage Directive

89/336/EEC - The EMC Directive

Manufacturer’s Name: EXFO ELECTRO-OPTICAL ENG.

Manufacturer’s Address: 400 Godin Avenue

Vanier, Québec

Canada G1M 2K2

(418) 683-0211

Equipment Type/Environment: Industrial Scientific Equipment

Trade Name/Model No.: PPM-350B PON Power Meter

Standard(s) to which Conformity is Declared:

EN 61326:

1997/ A2:

2001

Electrical Equipment for Measurement, Control and Laboratory

Use - EMC Requirements

EN 55022:

1998/ A1:

2000

Limits and methods of measurement of radio disturbance

characteristics of information technology equipment

I, the undersigned, hereby declare that the equipment specified above conforms to the above Directive and

Standards.

Manufacturer

Signature:

Full Name: Stephen Bull, E. Eng

Position: Vice-President Research and

Development

Address: 400 Godin Avenue Vanier, Quebec,

Canada

Date: September 15, 2004

DECLARATION OF CONFORMITY

Page 5

PPM-350B 1

1 Introducing the PPM-350B

PON Power Meter

The PPM-350B PON Power Meter was designed to suit FTTP testing needs and to be

easy to use for people who are not necessarily familiar with fiber optics.

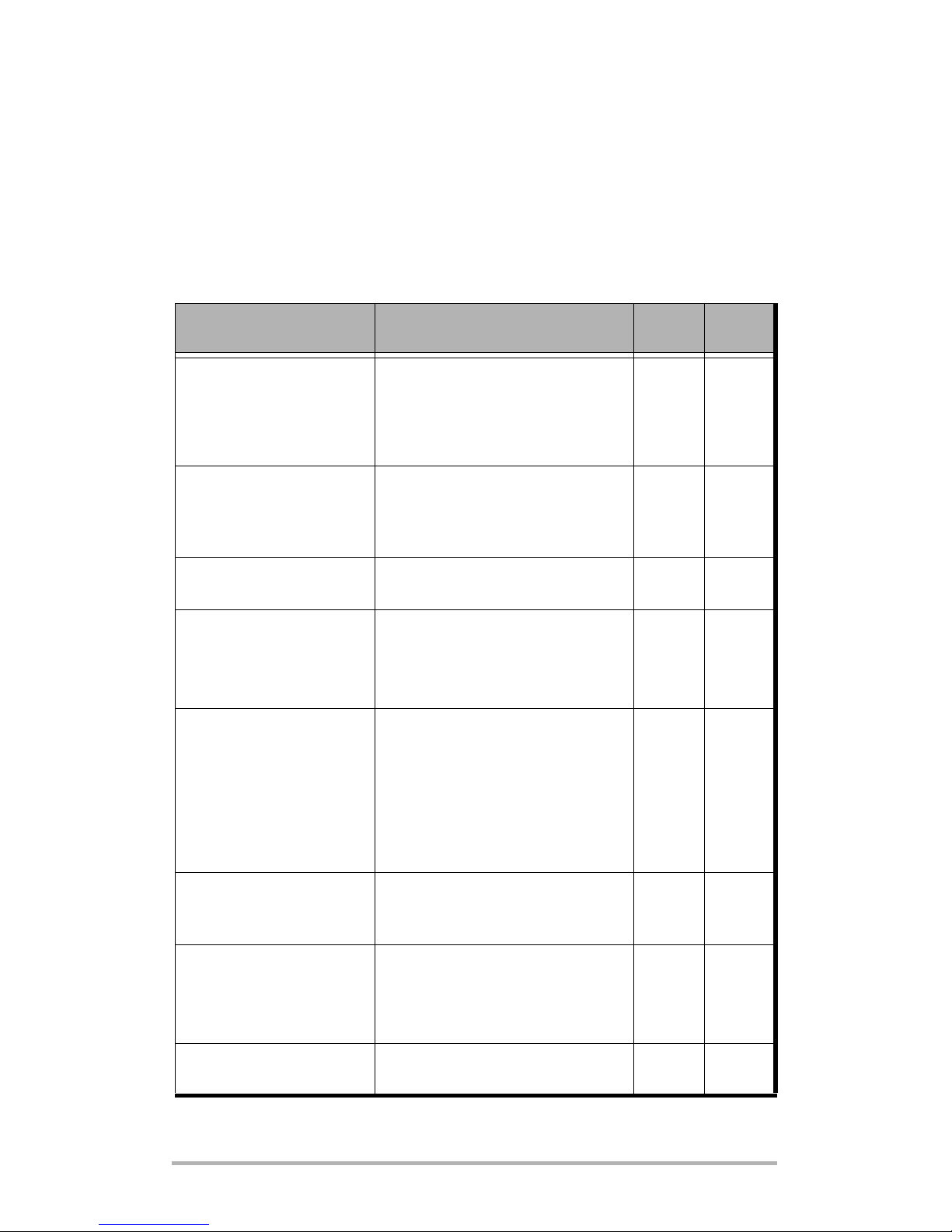

Main Features

Details

1-port

Models

2-port

Models

Supports:

³ 1310 nm (ONT)

³ 1490 nm (OLT)

³ 1550 nm (video)

On 2-port models,

³ Port 1: 1310 nm (ONT)

³ Port 2: 1490 nm (OLT)/

1550 nm (video)

XX

Pass-through device (spy

mode): does not block

communication between

ONT and OLT

X

Allows triple-play testing

(voice, video and data)

XX

Measures each signal

independently

³ Optical network terminal

(ONT): 1310 nm

³ Central office (CO): 1490 and

1550 nm

XX

Measures optical power of

any type of signal

³ Continuous (e.g., TV signal at

1550 nm)

³ Framed (e.g., ATM, Ethernet at

1490 nm or 1310 nm)

³ All baud rates (e.g., 155 Mbps,

1 Gpps; synchronous or

asynchronous)

X

X

X

X

X

X

Measures all signals

simultaneously

Only way to measure ONT signal

(ONT does not transmit when

disconnected)

X

Features visual Pass/Fail

indicators

³ One indicator (LED) per

wavelength

³ All 3 signal status are displayed

simultaneously

XX

X

Displays all power levels

simultaneously

X

Page 6

Introducing the PPM-350B PON Power Meter 2

Contains up to 10 different

threshold sets

³ You can select any of the

predefined threshold sets

³ You can configure thresholds

on a computer and transfer

them to your PPM-350B PON

Power Meter via RS-232

XX

Automatically shuts down

after 10 minutes of idle

time (auto-off)

XX

Details

1-port

Models

2-port

Models

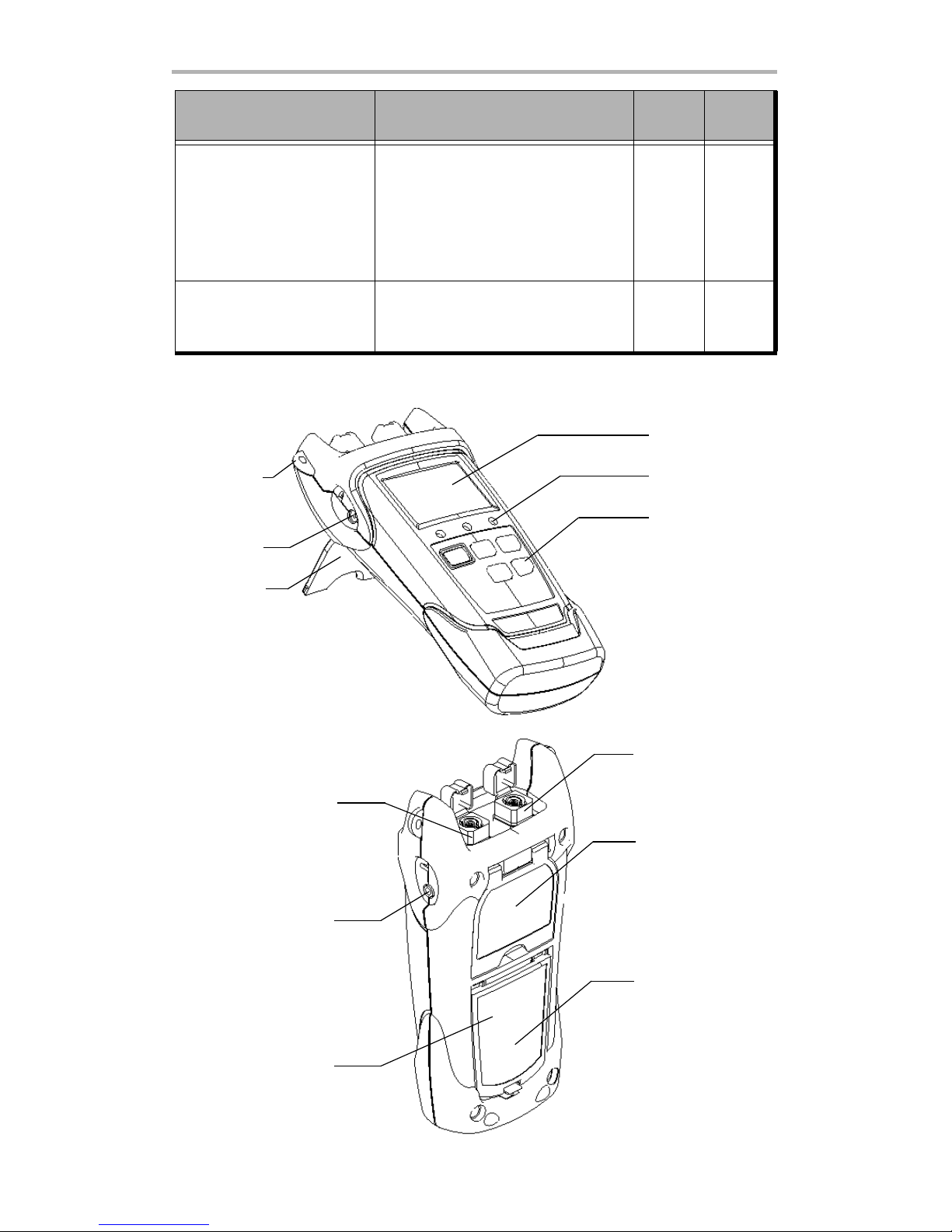

Liquid crystal

display (LCD)

DC connector

Keypad

Stand

Shoulder

strap eyelet

Status LEDs

Quick reference

label

RS-232 connector

On 1-port models:

ONT and OLT/video port

On 2-port models:

OLT/video port

Serial number

(under the stand)

Battery compartment

(3 alkaline batteries)

ONT port (on 2-port

models only)

Page 7

PPM-350B 3

Available Models

The PPM-350B PON Power Meter is offered in one- and two-port configurations with

normal or extended measurement range. The extended range allows testing at the

central office and before the splitter.

Some models support relative-power measurement allowing you to measure loss

between two locations.

Power Sources

The PPM-350B PON Power Meter operates with the following power sources:

³ AC adapter (connected to standard power outlet—indoor use only)

³ AA alkaline batteries (automatically take over if you unplug the AC adapter)

The icon also indicates the battery charge.

Typical Applications

You can use your PPM-350B PON Power Meter during service activation (at ONT) or

to troubleshoot passive optical networks (at ONT, drop terminal, fiber distribution

hub or CO).

IMPORTANT

If the battery level becomes too low, the unit turns itself off.

Extended-range model

Page 8

Safety Information 4

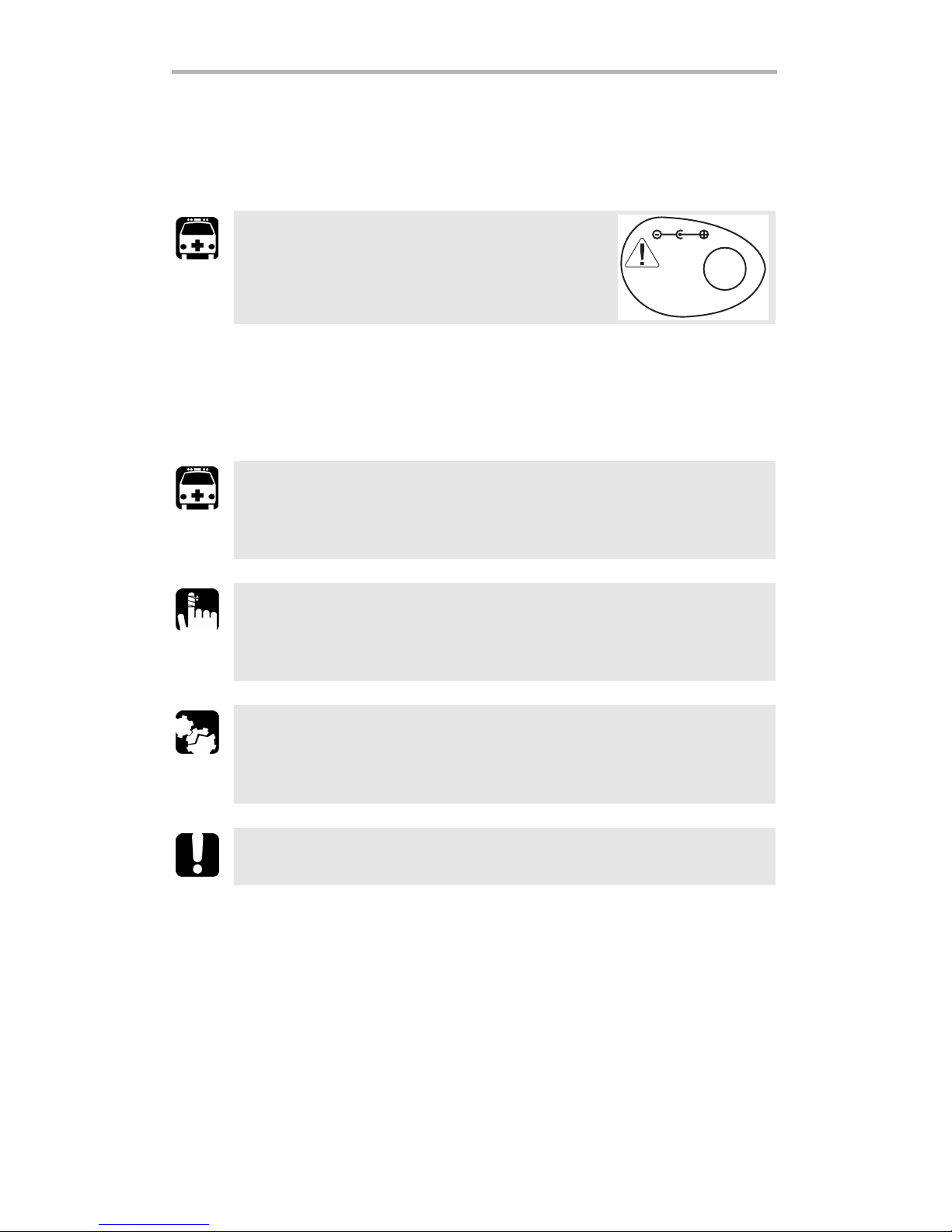

2 Safety Information

Electrical Safety Information

Conventions

Before using the product described in this manual, you should understand the

following conventions:

WARNING

Use the AC adapter provided with this product

indoors only.

WARNING

Indicates a potentially hazardous situation which, if not avoided,

could result in death or serious injury. Do not proceed unless you

understand and meet the required conditions.

CAUTION

Indicates a potentially hazardous situation which, if not avoided,

may result in minor or moderate injury. Do not proceed unless you

understand and meet the required conditions.

CAUTION

Indicates a potentially hazardous situation which, if not avoided,

may result in component damage. Do not proceed unless you

understand and meet the required conditions.

IMPORTANT

Refers to information about this product you should not overlook.

Q

S

T

5

1

9

A

150 mA

6 -16 V DC

Page 9

PPM-350B 5

3 Getting Started with Your

PPM-350B PON Power

Meter

Turning the Unit On and Off

When you turn the PPM-350B PON Power Meter off, it saves the current mode

(Pass/Fail or Normal) and threshold set. On models supporting relative-power

measurement, unit and reference values are also kept in memory.

Note: Offset nulling values are always returned to factory settings.

To t u r n t h e un i t on :

Press . The unit displays EXFO for a few seconds and vertical bars move at the

top of the display, indicating the initialization is in progress. You may use your unit

immediately under normal conditions. The unit is in Pass/Fail or Normal mode,

depending on which mode was used last time.

To turn the unit off:

From Pass/Fail or Normal modes (not threshold selection mode or correction factor

mode), hold down a few seconds.

IMPORTANT

If you remove batteries (and the AC adapter is unplugged), the unit

will turn off without saving the above values.

If batteries are low (and the AC adapter is unplugged), the unit will

save the above values and turn off.

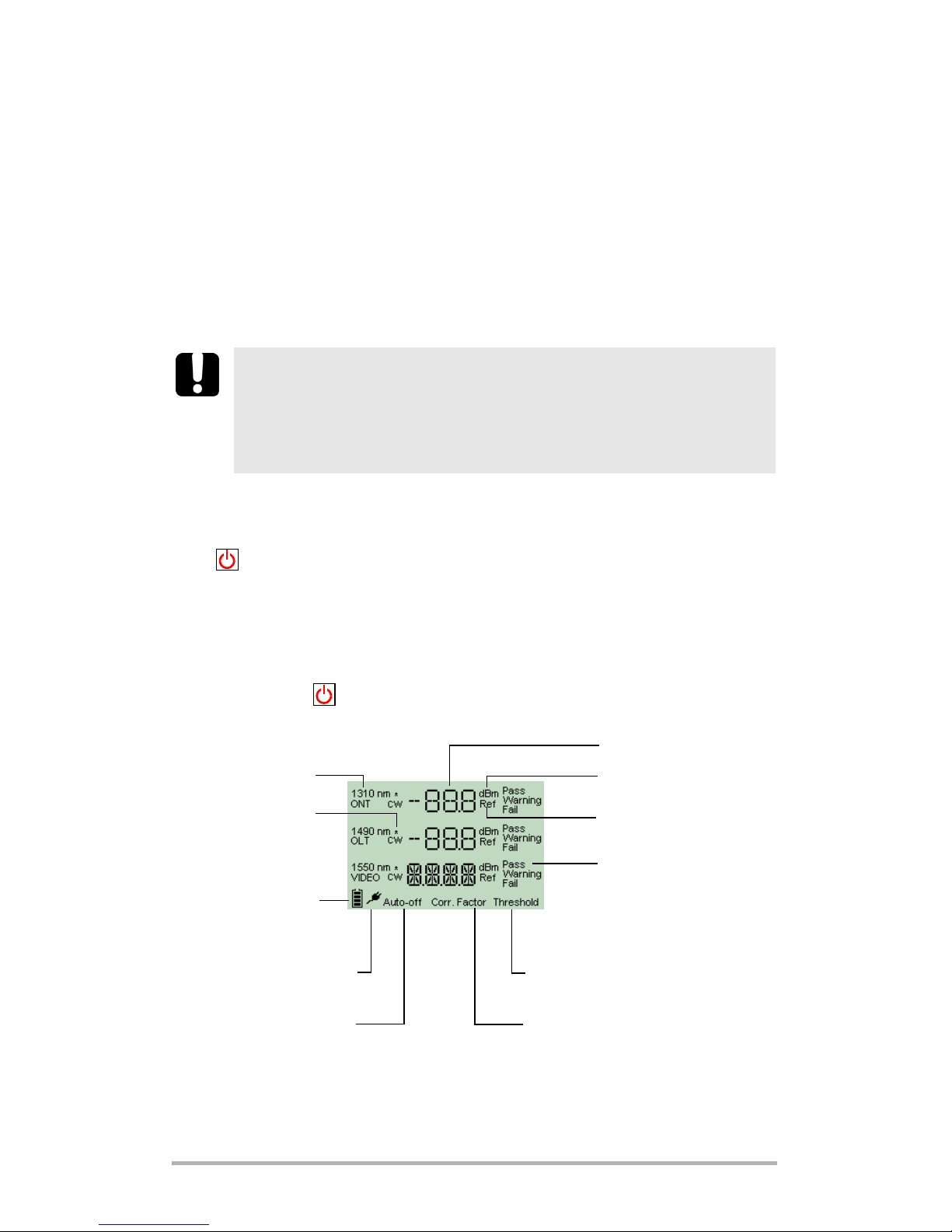

Batteries in use

(with level;

blinking when

weak)

Status

Signal (wavelength)

Power level

Reference values displayed

(models supporting this

feature)

Display

Auto-off activated

AC adapter plugged in

Units

Correction factors displayed

Threshold selection mode

activated

Correction

factor not

equal to 0 dB

Page 10

Getting Started with Your PPM-350B PON Power Meter 6

Activating Automatic Shutdown (Auto-Off)

When auto-off is activated, the unit will turn itself off

after 10 minutes of idle time.

Auto-off is activated by default when you turn unit on.

To deactivate/reactivate auto-off:

Press .

PRESS: Turns unit on

Controls auto-off

Exits special modes

HOLD: Turns unit off

PRESS: Switches between

measurement units and

deactivates Pass/Fail mode

HOLD: Displays correction factors

PRESS: Displays reference values for a few

seconds, then switches units to dB and

deactivates Pass/Fail mode.

HOLD: Sets input power as reference power

for all wavelengths

Accesses threshold selection

mode

Activates/deactivates Pass/Fail mode

(not possible during nulling, threshold

verification, LEDs/LCD verification)

Keypad (models that can measure relative power)

PRESS: Turns unit on

Controls auto-off

Exits special modes

HOLD: Turns unit off

PRESS: Switches between ONT and

OLT/video signals (on 1-port models)

HOLD: Displays correction factors

Accesses threshold selection

mode

PRESS: Activates/deactivates Pass/Fail mode

(not possible during nulling, threshold

verification, LEDs/LCD verification)

Keypad (other models)

Page 11

PPM-350B 7

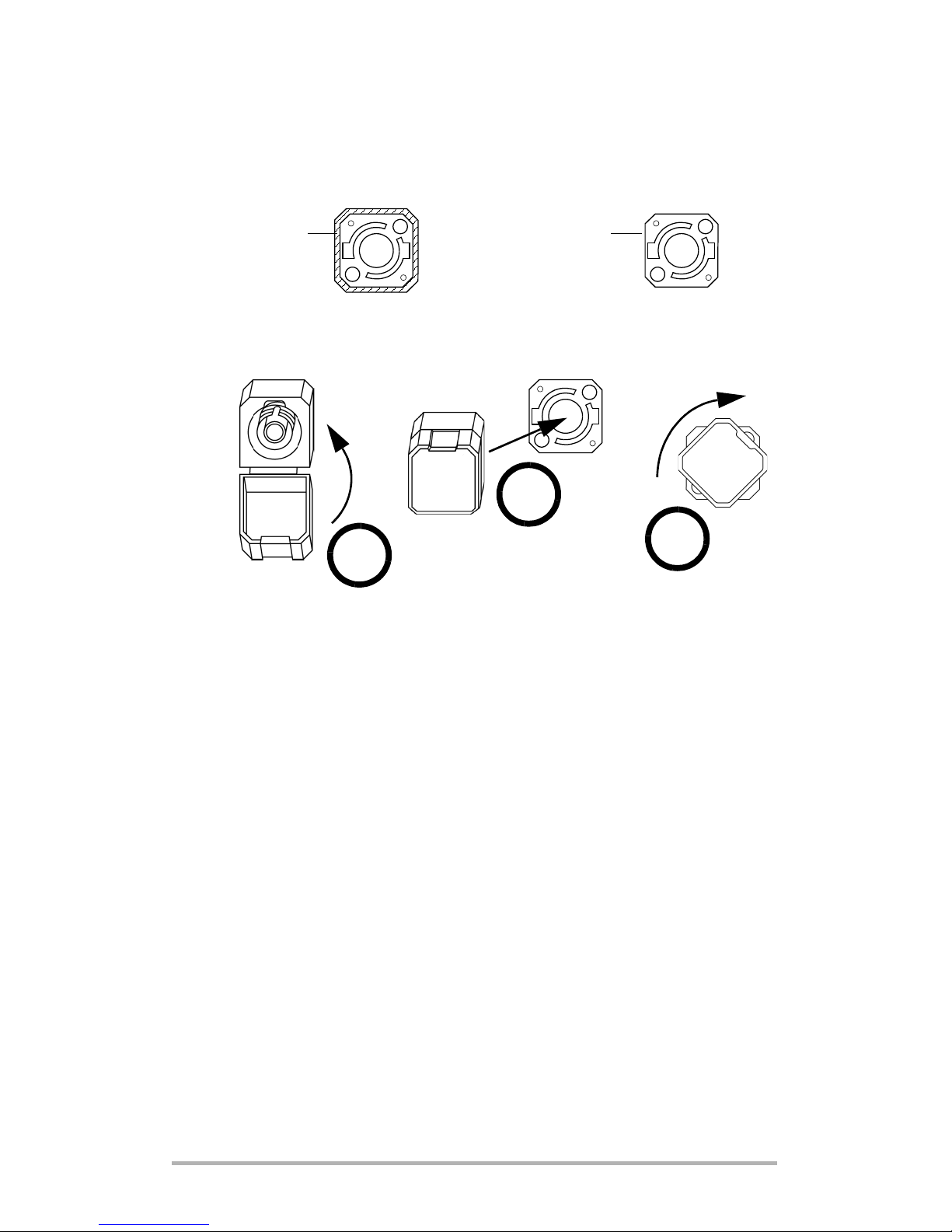

Installing the EXFO Universal Interface (EUI)

The EUI fixed baseplate is available for connectors with angled (APC) or non-angled

(UPC) polishing. A green border around the baseplate indicates that it is for

APC-type connectors, as shown below:

To install an EUI connector adapter onto the EUI baseplate:

1. Hold the EUI connector adapter so the dust cap opens downwards.

2. Close the dust cap in order to hold the connector adapter more firmly.

3. Insert the connector adapter into the baseplate.

4. While pushing firmly, turn the connector adapter clockwise on the baseplate to

lock it in place.

Bare metal

(or blue border)

indicates UPC option

Green border

indicates APC

option

2

4

3

Page 12

Getting Started with Your PPM-350B PON Power Meter 8

Cleaning and Connecting Optical Fibers

To connect the fiber-optic cable to the port:

1. Clean the fiber ends as follows:

1a. Gently wipe the fiber end with a lint-free swab dipped in isopropyl alcohol.

1b. Use compressed air to dry completely.

1c. Visually inspect the fiber end to ensure its cleanliness.

2. Carefully align the connector and port to prevent the fiber end from touching the

outside of the port or rubbing against other surfaces. If your connector features

a key, ensure that it is fully fitted into the port’s corresponding notch.

3. Push the connector in so that the fiber-optic cable is firmly in place, thus

ensuring adequate contact.

If your connector features a screwsleeve, tighten the connector enough to firmly

maintain the fiber in place. Do not overtighten, as this will damage the fiber and

the port.

Note: If your fiber-optic cable is not properly aligned and/or connected, you

will notice heavy loss and reflection.

IMPORTANT

To ensure maximum power and to avoid erroneous readings:

³ Always clean fiber ends as explained below before inserting

them into the port. EXFO is not responsible for damage or errors

caused by bad fiber cleaning or handling.

³ Ensure that your patchcord has appropriate connectors. Joining

mismatched connectors will damage the ferrules.

Page 13

PPM-350B 9

4 Configuring Thresholds

and Correction Factors

Your PPM-350B PON Power Meter offers 3 correction factors (one per wavelength)

and up to 10 threshold sets. On a properly calibrated PPM-350B PON Power Meter,

correction factors are set to 0 dB.

Correction factors are added to the measured values. For this reason, once the

correction factors are applied, your PPM-350B PON Power Meter may display “HI” or

“LO”, indicating the power levels are no longer within the unit’s power limits.

If you need to define correction factors of more than 1 dB or less than –1 dB to

compensate for inaccuracies, it may be a good idea to send your PPM-350B PON

Power Meter for recalibration (see Recalibrating the Unit on page 20). This will

ensure the results remain accurate.

The Handheld Data Transfer (provided on your CD) enables you to create new

threshold sets and correction factors or modify values retrieved from your PPM-350B

PON Power Meter. For more information, refer to Handheld Data Transfer online

help.

IMPORTANT

Both threshold sets and correction factors will be transferred to your

unit. Previous values will be lost.

Page 14

Testing with Your PPM-350B PON Power Meter 10

5 Testing with Your

PPM-350B PON Power

Meter

In this chapter, some instructions are identified as “Models measuring relative

power”. A quick way to confirm that your unit can measure relative power is to

verify if the keypad has a button.

Nulling Electrical Offsets

Temperature and humidity variations affect the performance of electronic circuits

and optical detectors. Nulling the electrical offsets eliminates these effects. Your unit

has been designed not to require offset nulling under normal operation, but you

should perform it whenever environmental conditions change significantly or when

measuring very low power values.

Note: Factory-defined values will be reinstated when you turn the unit off.

To perform an offset nulling:

³ [Models measuring relative power] Hold down

and a few seconds.

³ [Other models] Hold down and a

few seconds.

The unit displays NULL and vertical bars move at

the top of the display, indicating the nulling is in progress.

Note: Keypad is disabled during the operation.

The unit will then return to your previous mode (Pass/Fail or Normal).

IMPORTANT

If light reaches the detector when nulling offsets, LIGH appears on

the display and the nulling is not performed. You will need to press a

key to return to the previous display.

dBm/

dB

dBm/

dB

REF/

SEL

Threshold Select

Page 15

PPM-350B 11

Viewing Correction Factors

Applying a correction factor to measured power compensates for known power

gains or losses, or inaccuracies at specific wavelengths.

By default, correction factors

are set to 0 dB, because

properly calibrated units do not

require any correction factor.

Correction factors are added to

the values that are read. For this

reason, once the correction

factors are applied, your

PPM-350B PON Power Meter may display “HI” or “LO”, indicating the power levels

are no longer within the unit’s power limits.

Note: The unit takes correction factors into account in both Pass/Fail and

Normal modes.

To modify correction factors, you must use the Handheld Data Transfer (refer to the

Handheld Data Transfer online help).

To view correction factors on your unit:

1. [Models measuring relative power] Hold down

for a few seconds.

[Other models] Hold down for a few

seconds.

The unit displays correction factors (one per

wavelength).

2. Press to return to your previous mode (Pass/Fail or Normal).

Selecting a Threshold Set

You can select which threshold set will be used to determine the Pass/Warning/Fail

status. Your unit contains up to 10 threshold sets, but only one set can be selected at

a time.

A threshold set comprises three wavelengths (1310, 1490 and 1550 nm), each of

them having specific threshold values for pass, warning and fail.

Note: Thresholds are used in Pass/Fail mode only.

You can view thresholds directly on your unit. To modify threshold values, you must

use the Handheld Data Transfer (refer to the Handheld Data Transfer online help).

Correction

factor not

equal to 0 dB

Signal (wavelength)

dBm/

dB

Select

Page 16

Testing with Your PPM-350B PON Power Meter 12

To select a threshold set:

1. Press . The unit enters the threshold

selection mode and displays the current

threshold set. If the threshold name has more

than 4 characters, it will scroll automatically.

2. Press to switch between available

threshold sets.

3. If desired, display the Pass/Warning/Fail values of the threshold set as follows:

3a. Hold down for a few seconds. The

unit displays threshold values of the first

wavelength that has not been deactivated.

3b. Press to switch to next wavelength.

Note: If a wavelength has been deactivated via

the Handheld Data Transfer (refer to the

Handheld Data Transfer online help), the

unit displays no threshold values.

3c. Press to return to threshold selection mode.

4. [Models measuring relative power] Press to make the displayed threshold

set the current one.

[Other models] Press to make the displayed threshold set the current

one.

The unit returns to Pass/Fail mode.

5. Press to exit without selecting a new threshold set. The unit returns to your

previous mode (Pass/Fail or Normal).

Threshold set number

Current threshold set indicators

Threshold set name

Threshold

Threshold

Signal (wavelength)

Threshold

Threshold

REF/

SEL

Select

Page 17

PPM-350B 13

Testing in Pass/Fail Mode or in Normal Mode

³ Pass/Fail mode: status is indicated directly (screen and LEDs). Status is

determined according to the current threshold set (see Selecting a Threshold

Set on page 11).

³ Normal mode: only the power levels are shown and LEDs are off.

Note: If the result is greater than the Pass threshold, the word Fail and the LED

will flash. If the result is lower than the Fail threshold, the unit will only

display Fail and the LED will not flash.

Note: On 1-port units, you will only see values at 1490 nm and 1550 nm.

At startup, the unit is in the same mode that was used during last test session.

You may activate the Pass/Fail mode at any time (except during nulling, threshold

verification, and LEDs and LCD verification).

Pass/Fail Normal

Signal (wavelength)

Power levels (dBm; dB only

possible with models

measuring relative power)

Status

LEDs are on:

Green (Pass),

Yellow (Warning), Red (Fail)

Correction factor not

equal to 0 dB

When power is outside unit’s power limits

(see Technical Specifications on page 31)

Power levels (dBm only)

Page 18

Testing with Your PPM-350B PON Power Meter 14

To test in Pass/Fail or Normal mode with a 1-port model:

1. Clean your fibers properly as explained in Cleaning and Connecting Optical

Fibers on page 8.

2. Connect as shown:

3. Tu r n unit on.

4. Press to select OLT/video signal.

5. If you want to test in Pass/Fail mode:

³ Ensure that LEDs are on. If not, press .

³ Ensure that the desired threshold set is selected (see Selecting a Threshold

Set on page 11).

Results are now available.

Test at the premises

Te s t j u m pe r

Drop cable

Bulkhead connector

OLT/Video signal

Test at the drop terminal

Tes t j u m p e r

OLT/Video signal

Splitter’s output pigtail

Bulkhead connector

Tes t j u m p e r

Test at the f iber d istribution hub (FDH)

Select

P/F

mode

Page 19

PPM-350B 15

To test in Pass/Fail or Normal mode with a 2-port model:

1. Clean your fibers properly as explained in Cleaning and Connecting Optical

Fibers on page 8.

2. Connect as shown:

3. Tu r n unit on.

4. If you want to test in Pass/Fail mode:

³ Ensure that LEDs are on. If not, press .

³ Ensure that the desired threshold set is selected (see Selecting a Threshold

Set on page 11).

Results are now available.

Test at the premises

Tes t j u m p e r

ONT port

Tes t j u m p e r

OLT/video port

Drop cable

Bulkhead connector

Test at the drop terminal

Tes t j u m p e r

ONT port

Tes t j u m p e r

OLT/video port

Bulkhead connector

Drop cable

ONT port

Tes t j u m p e r

OLT/video port

Splitter’s output pigtail

Bulkhead connector

Te s t j u m pe r

Test at the fiber distribution hub (FDH)

P/F

mode

Page 20

Testing with Your PPM-350B PON Power Meter 16

Measuring Loss Between Two Points

You can measure loss between two locations using a single PPM-350B PON Power

Meter.

Note: This type of test is only possible with models measuring relative power.

To measure loss between two points:

1. Clean your fibers properly as explained in Cleaning and Connecting Optical

Fibers on page 8.

2. At location A, connect as shown:

Test at the premises

Tes t j u m p e r

ONT port

Tes t j u m p e r

OLT/video port

Drop cable

Bulkhead connector

Test at the drop terminal

Tes t j u m p e r

ONT port

Tes t j u m p e r

OLT/video port

Bulkhead connector

Drop cable

ONT port

Tes t j u m p e r

OLT/video port

Splitter’s output pigtail

Bulkhead connector

Te s t j u m pe r

Test at the fiber distribution hub (FDH)

Page 21

PPM-350B 17

3. Tu r n unit on.

4. Hold down for a few seconds to take reference

(all 3 wavelengths simultaneously).

5. If desired, press once to view reference values.

6. Press to select dB. You should see 0 dB at

each wavelength.

7. When you are done, disconnect and turn unit off.

8. Repeat steps 1 to 3 at location B, using the same PPM-350B PON Power Meter.

9. Press to select dB.

Results are displayed.

REF/

SEL

REF/

SEL

dBm/

dB

Signals (wavelengths)

Relative power at each wavelength

(loss between location A and B)

dBm/

dB

Page 22

Maintenance 18

6 Maintenance

To help ensure long, trouble-free operation:

³ Always clean fiber-optic connectors before using them.

³ Keep the unit free of dust.

³ Clean the unit casing and front panel with a cloth slightly dampened with water.

³ Store unit at room temperature in a clean and dry area. Keep the unit out of

direct sunlight.

³ Avoid high humidity or significant temperature fluctuations.

³ Avoid unnecessary shocks and vibrations.

³ If any liquids are spilled on or into the unit, turn off the power immediately and

let the unit dry completely.

Cleaning EUI Connectors

Regular cleaning of EUI connectors will help maintain optimum performance. There

is no need to disassemble the unit.

To clean EUI connectors:

1. Remove the EUI from the instrument to expose the connector baseplate and

ferrule.

2. Moisten a 2.5 mm cleaning tip provided by EXFO with one drop of isopropyl

alcohol (alcohol may leave traces if used abundantly).

3. Slowly insert the cleaning tip into the EUI adapter until it comes out on the other

side (a slow clockwise rotating movement may help).

WARNING

Use of controls, adjustments and procedures for operation and

maintenance other than those specified herein may result in

hazardous radiation exposure.

IMPORTANT

If any damage occurs to internal connectors, the module casing will

have to be opened and a new calibration will be required.

Push

Turn

Pull

Page 23

PPM-350B 19

4. Gently turn the cleaning tip one full turn, then continue to turn as you withdraw

it.

5. Repeat steps 3 to 4 with a dry cleaning tip.

Note: Make sure you don’t touch the soft end of the cleaning tip.

6. Clean the ferrule in the connector port as follows:

6a. Deposit one drop of isopropyl alcohol on a lint-free wiping cloth.

6b. Gently wipe the connector and ferrule.

6c. With a dry lint-free wiping cloth, gently wipe the same surfaces to ensure

that the connector and ferrule are perfectly dry.

6d. Verify connector surface with a portable fiber-optic microscope

(e.g., EXFO’s FOMS) or fiber inspection probe (e.g., EXFO’s FIP).

7. Put the EUI back onto the instrument (push and turn clockwise).

8. Throw out cleaning tips and wiping cloths after one use.

IMPORTANT

Since isopropyl alcohol is not absolutely pure, it may leave residues

if used abundantly or left to evaporate (about 10 seconds).

Avoid contact between the tip of the bottle and the wiping cloth,

dry the surface quickly, and use a bottle that distributes only a drop

of alcohol at a time.

WARNING

Verifying the surface of the connector WHILE THE UNIT IS ACTIVE

WILL result in permanent eye damage.

3

4

5

Page 24

Maintenance 20

Replacing Disposable Alkaline Batteries

Your unit requires three AA alkaline batteries.

Note: The provided AC adapter is not a charger.

To replace disposable alkaline batteries:

1. Turn off the unit (if the AC adapter is plugged in, you

may replace batteries while unit is on).

2. Open the battery compartment door located at the

back of the unit.

3. Replace batteries, respecting the polarity as shown.

4. Close the battery compartment door.

Recalibrating the Unit

Manufacturing and service center calibrations are based on the ISO/IEC 17025

Standard, which states that calibration documents must not contain a

recommended calibration interval, unless this has been previously agreed upon

with the customer.

Validity of specifications depends on operating conditions. For example, the

calibration validity period can be longer or shorter depending on the intensity of use,

environmental conditions and unit maintenance. You should determine the

adequate calibration interval for your unit according to your accuracy requirements.

Under normal use, EXFO recommends calibrating your unit every year.

Note: The FlexCare warranty program includes Calibration/Verification

packages (see Service and Repairs on page 29).

To view the last calibration date:

1. Hold down and press at the same

time. The unit displays the main embedded

software version.

2. Press to display the calibration date of the

unit.

3. Press to return to your previous mode (Pass/Fail

or Normal).

WARNING

Do not throw batteries into fire or water and do not short-circuit

the batteries’ electrical contacts.

+

+

+

YearMonth/Day

Threshold

Threshold

Page 25

PPM-350B 21

Verifying Thresholds

You can verify the threshold values to ensure that your unit will function normally

with any of the available threshold sets.

If a problem is detected, error code 12 will be displayed. If you turn the unit off

without correcting the problem, the error code will be displayed once the unit is

turned on again. For more information, see Error Codes and Descriptions on

page 24.

To verify thresholds:

Hold down and a few seconds. The

unit displays CHKS and vertical bars move at the top of

the display, indicating the verification is in progress.

Note: Keypad is disabled during this operation.

The unit will then return to your previous mode

(Pass/Fail or Normal).

Verifying the LEDs and LCD

You can verify that the LEDs function normally and that the screen can display all the

elements properly. The unit must be in Pass/Fail or Normal mode to perform the

verification.

To verify the LEDs and LCD:

1. Hold down and a few seconds. The unit

displays TEST and vertical bars move at the top of

the display, indicating the verification is in progress.

The three LEDs will light up briefly in the following

order: green, yellow, red. Once LEDs are turned off,

all the screen segments will be displayed at the

same time, allowing you to verify them.

Note: Keypad is disabled during the operation.

2. Press any key to return to your previous mode (Pass/Fail or Normal).

P/F

mode

Threshold

P/F

mode

Page 26

Maintenance 22

Recycling and Disposal (Applies to European

Union Only)

³ Unless otherwise noted in a separate agreement between EXFO and a

customer, distributor or commercial partner, EXFO will cover costs related to

the collection, treatment, recovery and disposal of end-of-lifecycle waste

generated by electronic equipment introduced after August 13, 2005 to an

European Union member state with legislation regarding Directive 2002/96/EC.

³ Except for reasons of safety or environmental benefit, equipment manufactured

by EXFO, under its brand name, is generally designed to facilitate dismantling

and reclamation.

For complete recycling/disposal procedures and contact information, visit the EXFO

Web s ite at www.exfo.com/recycle.

Recycle or dispose of your product (including electric and electronic

accessories) properly, in accordance with local regulations. Do not

dispose of it in ordinary garbage receptacles.

This equipment was sold after August 13, 2005 (as identified by the

black rectangle).

Page 27

PPM-350B 23

7 Troubleshooting

Solving Common Problems

Problem Possible Cause Solution

One of the LEDs remains

off.

OR

One of the LEDs remains

green or red even if the

status is Warning.

LED is burnt.

Verify LEDs (see Verifying

the LEDs and LCD on

page 21).

Contact EXFO.

Pressing the button

does not activate Pass/Fail

mode.

³ Unit is currently

nulling offsets,

verifying thresholds or

verifying LEDs and

LCD.

³ Let the unit complete

the operation.

If the unit was

verifying LEDs and

LCD, press any key to

return to your previous

mode (Pass/Fail or

Normal).

³ The current threshold

set contains an

unusable (corrupted)

value.

³ See Error Codes and

Descriptions on

page 24.

³ No threshold sets have

been defined.

³ See Error Codes and

Descriptions on

page 24.

The threshold set name is

not displayed correctly.

Name contains characters

that your unit cannot

display. Unsupported

characters are replaced

with dashes, spaces or

“+”.

Rename the threshold set

using only supported

characters:

³ 0 through 9

³ A through Z (both

lowercase and

uppercase)

³ - (dash) + / . < = > ?

[ \ ] _ (underscore)

and space

For more information on

renaming threshold sets,

see Configuring

Thresholds and Correction

Facto rs on page 9.

P/F

mode

Page 28

Troubleshooting 24

Error Codes and Descriptions

³ ER: error code displayed until you press a key.

³ WR: warning code displayed for 3 seconds, then unit returns to normal.

[1-port models] In

Pass/Fail mode, only the

battery charge and the

auto-off indicators are

displayed.

You selected O N T

(1310 nm), but this signal

has been deactivated in

the current threshold set

(see Selecting a Threshold

Set on page 11).

[1-port models]

Impossible to see the

current wavelength(s) and

the corresponding LED(s)

is (are) off.

The signal is deactivated

(see Selecting a Threshold

Set on page 11).

Reactivate the signal (see

Configuring Thresholds

and Correction Factors on

page 9).

[2-port models] In

Pass/Fail mode,

Impossible to see all

wavelengths and some of

the LEDs are off.

At least one signal is

deactivated (see Selecting

a Threshold Set on

page 11).

Error

Code

Description Solution

LIGH Light detected while nulling offsets.

Nulling is not performed.

Correctly place protective cap on

ports, then retry. If the problem

persists, contact EXFO.

ER 12/16 Threshold values are not usable

(corruption problem).

Would occur:

³ during unit initialization

³ after threshold verification (see

Verifying Thresholds on page 21)

³ after threshold set selection

Download new threshold sets to

your unit. For more information,

see Configuring Thresholds and

Correction Factors on page 9.

ER 13 EEPROM corrupted (would occur

during unit initialization).

Unit must be recalibrated.

Contact EXFO.

WR 23 No threshold sets have been defined.

Pass/Fail mode cannot be activated.

Download new threshold sets to

your unit. For more information,

see Configuring Thresholds and

Correction Factors on page 9.

Problem Possible Cause Solution

Page 29

PPM-350B 25

Contacting the Technical Support Group

To obtain after-sales service or technical support for this product, contact EXFO at

one of the following numbers. The Technical Support Group is available to take your

calls from Monday to Friday, 7:30 a.m. to 8:00 p.m. (Eastern Time in North America).

To accelerate the process, please have information such as the name and the serial

number (see the product identification label—an example is shown below), as well

as a description of your problem, close at hand.

You may also be requested to provide the embedded software’s version numbers.

To display the embedded software version:

1. Hold down and press at the same

time. The unit displays the main software version.

2. Press to return to your previous mode

(Pass/Fail or Normal).

Technical Support Group

400 Godin Avenue

Quebec (Quebec) G1M 2K2

CANADA

1 866 683-0155 (USA and Canada)

Tel.: 1 418 683-5498

Fax: 1 418 683-9224

support@exfo.com

Ver.

Mfg.

date

P/N

S/N

Made in Canada QST442B

465 Godin Avenue

Vanier (Quebec) G1M 3G7 CANADA

**************** A

January 2003

542392-3D

PPM-35XB-XX

Model Connector code

Threshold

Page 30

Troubleshooting 26

Finding Information on the EXFO Web Site

The EXFO Web site provides answers to frequently asked questions (FAQs)

regarding the use of your PPM-350B PON Power Meter.

To access FAQs:

1. Ty pe http://www.exfo.com in your Internet browser.

2. Click on the Support tab.

3. Click on FAQs and follow the on-screen instructions. You will be given a list of

questions pertaining to your subject.

The EXFO Web site also provides the product’s most recent technical specifications.

Transportation

Maintain a temperature range within specifications when transporting the unit.

Transportation damage can occur from improper handling. The following steps are

recommended to minimize the possibility of damage:

³ Pack the unit in its original packing material when shipping.

³ Avoid high humidity or large temperature fluctuations.

³ Keep the unit out of direct sunlight.

³ Avoid unnecessary shock and vibration.

Page 31

PPM-350B 27

8 Warranty

General Information

EXFO Electro-Optical Engineering Inc. (EXFO) warrants this equipment against

defects in material and workmanship for a period of one year from the date of

original shipment. EXFO also warrants that this equipment will meet applicable

specifications under normal use.

During the warranty period, EXFO will, at its discretion, repair, replace, or issue

credit for any defective product, as well as verify and adjust the product free of

charge should the equipment need to be repaired or if the original calibration is

erroneous. If the equipment is sent back for verification of calibration during the

warranty period and found to meet all published specifications, EXFO will charge

standard calibration fees.

THIS WARRANTY IS IN LIEU OF ALL OTHER WARRANTIES EXPRESSED, IMPLIED,

OR STATUTORY, INCLUDING, BUT NOT LIMITED TO, THE IMPLIED WARRANTIES OF

MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE. IN NO EVENT

SHALL EXFO BE LIABLE FOR SPECIAL, INCIDENTAL, OR CONSEQUENTIAL

DAMAGES.

Liability

EXFO shall not be liable for damages resulting from the use of the product, nor shall

be responsible for any failure in the performance of other items to which the

product is connected or the operation of any system of which the product may be a

part.

EXFO shall not be liable for damages resulting from improper usage or unauthorized

modification of the product, its accompanying accessories and software.

IMPORTANT

The warranty can become null and void if:

³ unit has been tampered with, repaired, or worked upon by

unauthorized individuals or non-EXFO personnel.

³ warranty sticker has been removed.

³ case screws, other than those specified in this guide, have been

removed.

³ case has been opened, other than as explained in this guide.

³ unit serial number has been altered, erased, or removed.

³ unit has been misused, neglected, or damaged by accident.

Page 32

Warranty 28

Exclusions

EXFO reserves the right to make changes in the design or construction of any of its

products at any time without incurring obligation to make any changes whatsoever

on units purchased. Accessories, including but not limited to fuses, pilot lamps,

batteries and universal interfaces (EUI) used with EXFO products are not covered by

this warranty.

This warranty excludes failure resulting from: improper use or installation, normal

wear and tear, accident, abuse, neglect, fire, water, lightning or other acts of nature,

causes external to the product or other factors beyond EXFO’s control.

Certification

EXFO certifies that this equipment met its published specifications at the time of

shipment from the factory.

IMPORTANT

EXFO will charge a fee for replacing optical connectors that were

damaged due to misuse or bad cleaning.

Page 33

PPM-350B 29

Service and Repairs

EXFO commits to providing product service and repair for five years following the

date of purchase.

To send any equipment for service or repair:

1. Call one of EXFO’s authorized service centers (see EXFO Service Centers

World wi de on page 30). Support personnel will determine if the equipment

requires service, repair, or calibration.

2. If equipment must be returned to EXFO or an authorized service center, support

personnel will issue a Return Merchandise Authorization (RMA) number and

provide an address for return.

3. If possible, back up your data before sending the unit for repair.

4. Pack the equipment in its original shipping material. Be sure to include a

statement or report fully detailing the defect and the conditions under which it

was observed.

5. Return the equipment, prepaid, to the address given to you by support

personnel. Be sure to write the RMA number on the shipping slip. EXFO will

refuse and return any package that does not bear an RMA number.

Note: A test setup fee will apply to any returned unit that, after test, is found to

meet the applicable specifications.

After repair, the equipment will be returned with a repair report. If the equipment is

not under warranty, you will be invoiced for the cost appearing on this report. EXFO

will pay return-to-customer shipping costs for equipment under warranty. Shipping

insurance is at your expense.

Routine recalibration is not included in any of the warranty plans. Since

calibrations/verifications are not covered by the basic or extended warranties, you

may elect to purchase FlexCare Calibration/Verification Packages for a definite

period of time. Contact an authorized service center (see EXFO Service Centers

World wi de on page 30).

Page 34

Warranty 30

EXFO Service Centers Worldwide

If your product requires servicing, contact your nearest authorized service center.

EXFO Headquarters Service Center

400 Godin Avenue

Quebec (Quebec) G1M 2K2

CANADA

1 866 683-0155 (USA and Canada)

Tel.: 1 418 683-5498

Fax: 1 418 683-9224

quebec.service@exfo.com

EXFO Europe Service Center

Le Dynasteur

10/12, rue Andras Beck

92366 Meudon la Forêt Cedex

FRANCE

Tel.: +33.1.40.83.85.85

Fax: +33.1.40.83.04.42

europe.service@exfo.com

EXFO China Service Center/

Beijing OSIC

Beijing New Century Hotel

Office Tower, Room 1754-1755

No. 6 Southern Capital Gym Road

Beijing 100044

P. R . C H I N A

Tel.: +86 (10) 6849 2738

Fax: +86 (10) 6849 2662

beijing.service@exfo.com

Page 35

PPM-350B 31

A Technical Specifications

IMPORTANT

The following technical specifications can change without notice.

The information presented in this section is provided as a reference

only. To obtain this product’s most recent technical specifications,

visit the EXFO Web site at www.exfo.com.

PPM-35XB-XX

Model

PPM-351B = PON power meter, one port BPON

PPM-352B = PON power meter, two ports BPON

PPM-352B-EG = PON power meter, two ports

BPON, E PON, GPON

PPM-352B-EG-ER = PON power meter, two ports, extended

range, BPON, E PON, GPON

Example: PPM-352B-EG-ER-EA-E UI-91

STANDARD ACCESSORIES

User guide, three AA batteries, wrist strap, PC threshold-transfer software,

RS-232 cable, alcohol cleaning pads.

GENERAL SPECIFICATIONS

Size (H x W x D) 185 mm x 100 mm x 55 mm (7 1/4in x 4 in x 2 1/8in)

Weight 0.4 kg (0.9 lb)

Temperature

operating −10 °C to 5 0 °C (14 °F to 122 °F)

storage −40 °C to 70 °C (−40 °F to 158 °F)

Relative humidity 0 % to 95 % non-condensing

Notes

1. Same connectors for b oth ports on two-ports version.

Connector

1

EI-EUI-28 = UPC/D IN 47256

EI-EUI-76 = UPC/ HMS-10/AG

EI-EUI-89 = UPC/FC narrow key

EI-EUI-90 = UPC/ST

EI-EUI-91 = UPC/SC

EI-EUI-95 = UPC/E-2000

EA-EUI-28 = AP C/DIN 47256

EA-EUI-89 = APC/ FC narrow key

EA-EUI-91 = AP C/SC

EA-EUI-95 = AP C/E-2000

PPM-351B PPM-352B PPM-352B-EG PPM-352B-EG-ER

BPON EPON/GPON

Power measurement range – pass zone 1490 nm 1 to −33 1 to −33 1 to −33 12 to −40

for continuous data stream (dBm) 1550 nm 15 to −36 15 to −36 15 to −36 252to −40

Burst mode measurement capability: Splitter to ONT Splitter to ONT Splitter to ONT CO to ONT

Burst mode measurement range2(dBm) 1310 nm 5.5 to −15 5.5 to −15 5.5 to −24 10 to –33 10 to −29

ORL3(dB) 1550 nm 55 55 55 55

Pass through insertion loss2(dB) 1.5 1.5 1.5 1.5

Spectral passband (nm) 1310 nm 1260 to 1360 1260 to 1360 1260 to 1360 1260 to 1360

1490 nm 1480 to 1500 1480 to 1500 1480 to 1500 1480 to 1500

1550 nm 1539 to 1565 1539 to 1565 1539 to 1565 1539 to 1565

Power uncertainty at calibrated 0.5 0.5 0.5 0.5

wavelengths

2, 4

(dB)

Refresh rate of display (Hz) 2.5 2.5 2.5 2.5

Calibrated wavelengths (nm) 1310, 1490, 1550 1310, 1490, 1550 1310, 1490, 1550 1310, 1490, 1550

Threshold sets 10 configurable threshold sets with threshold naming

Autonomy2(hours) > 30 > 30 > 30 > 30

Number of ports 1 2 2 2

Warranty and recommended 1 1 1 1

calibration interval (year)

Notes

1. At room temperature.

2. Typical.

3. For APC connectors. Typically

> 35 dB for UPC connectors.

4. Around –7 dBm, CW.

ORDERING INF ORMATION

Page 36

www.exfo.com · info@exfo.com

Printed in Canada (2006-03)

© 2006 EXFO Electro-Optical Engineering Inc. All rights reserved.

P/N: 1043827

CORPORATE

HEADQUARTERS

400 Godin Avenue Quebec (Quebec) G1M 2K2 CANADA

Tel.: 1 418 683-0211 · Fax: 1 418 683-2170

EXFO AMERICA 3701 Plano Parkway, Suite 160 Plano TX, 75075 USA

Tel.: 1 972 907-1505 ·

EXFO EUROPE Le Dynasteur

10/12, rue Andras Beck

92366 Meudon la Forêt Cedex FRANCE

Tel.: +33.1.40.83.85.85 · Fax: +33.1.40.83.04.42

EXFO ASIAPACIFIC

151 Chin Swee Road

#03-29, Manhattan House

SINGAPORE 169876

Tel.: +6563338241 · Fax: +6563338242

TOLL-FREE (USA and Canada) 1 800 663-3936

Loading...

Loading...