EXFO Power Blazer 88000 Series, Power Blazer 88200NGE, Power Blazer 8880, Power Blazer 8870, Power Blazer 88400NGE User Manual

...Page 1

HIGH-SPEED MULTISERVICE TEST MODULE

Power Blazer

88000 Series

User Guide

Page 2

Copyright © 2014–2018 EXFO Inc. All rights reserved. No part of this

publication may be reproduced, stored in a retrieval system or transmitted

in any form, be it electronically, mechanically, or by any other means such

as photocopying, recording or otherwise, without the prior written

permission of EXFO Inc. (EXFO).

Information provided by EXFO is believed to be accurate and reliable.

However, no responsibility is assumed by EXFO for its use nor for any

infringements of patents or other rights of third parties that may result from

its use. No license is granted by implication or otherwise under any patent

rights of EXFO.

EXFO’s Commerce And Government Entities (CAGE) code under the North

Atlantic Treaty Organization (NATO) is 0L8C3.

The information contained in this publication is subject to change without

notice.

Trademarks

EXFO’s trademarks have been identified as such. However, the presence

or absence of such identification does not affect the legal status of any

trademark.

Units of Measurement

Units of measurement in this publication conform to SI standards and

practices.

Patents

Dual Test Set/Bi-Directional testing is protected by US patent 9,432,206 and

equivalents in other countries.

Feature(s) of this product is/are protected by one or more of: US design

patent D798,171 and equivalent(s) in other countries.

May 2, 2018

Document version: 4.0.0.1

ii 88000 Series

Page 3

Contents

Certification Information ........................................................................................................x

1 Introducing the High-Speed Multiservice Test Module .............................. 1

Features ..................................................................................................................................1

Technical Specifications ...........................................................................................................2

Conventions ............................................................................................................................3

2 Safety Information ....................................................................................... 5

Additional Laser Safety Information .......................................................................................7

Installation Instruction Warnings ............................................................................................8

3 Getting Started .......................................................................................... 11

Inserting and Removing Test Modules .................................................................................11

Inserting and Removing Transceiver Adaptors (TA) ..............................................................12

Turning On the Unit ..............................................................................................................14

Starting the Module Application ...........................................................................................15

4 Physical Interfaces and LEDs ..................................................................... 17

Port Availability on the 88000 Series ...................................................................................20

Transceivers ..........................................................................................................................24

RJ45 ......................................................................................................................................24

BNC ......................................................................................................................................25

SMB ......................................................................................................................................25

LEDs ......................................................................................................................................25

5 Graphical User Interface Overview ............................................................ 27

Main Application Window ...................................................................................................27

Main Window .......................................................................................................................27

Navigation Buttons ...............................................................................................................28

Status Bar ...........................................................................................................................28

Title Bar ...............................................................................................................................31

Global Indicator ....................................................................................................................31

Test Control .........................................................................................................................33

Test Menu ............................................................................................................................33

Application Buttons .............................................................................................................34

Zoomed-In/Zoomed-Out Views .............................................................................................37

Arrow Buttons .....................................................................................................................37

Keyboard Usage ...................................................................................................................38

Power Blazer iii

Page 4

6 Test Setup - Test Applications ....................................................................41

iOptics ..................................................................................................................................42

iSAM .....................................................................................................................................43

Multi-Channel OTN ...............................................................................................................44

OTN BERT ..............................................................................................................................45

OTN-SONET/SDH BERT ..........................................................................................................47

SONET/SDH BERT ..................................................................................................................50

DSn/PDH BERT ......................................................................................................................53

SONET/SDH - DSn/PDH BERT ................................................................................................55

NI/CSU Emulation ................................................................................................................58

EtherSAM (Y.1564) ................................................................................................................59

RFC 2544 ..............................................................................................................................61

RFC 6349 ..............................................................................................................................63

EtherBERT .............................................................................................................................64

Traffic Gen & Mon ................................................................................................................66

Smart Loopback ....................................................................................................................68

Through Mode ......................................................................................................................70

TCP Throughput ....................................................................................................................71

Carrier Ethernet OAM ..........................................................................................................72

Cable Test .............................................................................................................................74

1588 PTP ...............................................................................................................................75

SyncE ....................................................................................................................................76

Wander .................................................................................................................................77

FC BERT ................................................................................................................................78

CPRI/OBSAI BERT ..................................................................................................................79

7 Selecting and Starting a Test .....................................................................81

Intelligent Apps ....................................................................................................................81

Transport Test Applications ...................................................................................................85

Ethernet Test Applications ....................................................................................................87

Sync Test Applications ...........................................................................................................89

Fibre Channel Test Application ..............................................................................................91

Wireless Test Application ......................................................................................................93

iv 88000 Series

Page 5

8 Test Setup - Test Configurator, Timer, and System .................................. 95

Test Configurator Overview .................................................................................................100

Modify Structure Button ....................................................................................................108

Signal Auto-Detect ............................................................................................................131

1588 PTP ............................................................................................................................132

BERT and Unframed BERT ...................................................................................................139

Cable Test ..........................................................................................................................145

CFP4/CFP8/QSFP/SFP/SFP+/SFP28 .......................................................................................147

Clock ..................................................................................................................................148

EtherBERT, FC BERT, BERT (CPRI/OBSAI), and Unframed BERT .............................................155

EtherSAM - Burst ...............................................................................................................163

EtherSAM - Global .............................................................................................................165

EtherSAM - Ramp ..............................................................................................................169

External Reference .............................................................................................................171

Fibre Channel .....................................................................................................................172

Frequency ...........................................................................................................................175

FTFL/PT and PT ...................................................................................................................177

GFP-F/GFP-T ........................................................................................................................181

Interface (Ethernet, Packet Sync, Fibre Channel, and Wireless) ..........................................182

Labels ................................................................................................................................196

Link OAM ...........................................................................................................................198

Local Details (iSAM) ...........................................................................................................200

MAC/IP/UDP .......................................................................................................................204

Network .............................................................................................................................220

Network Details (iSAM) ......................................................................................................226

ODU Channels - Global ......................................................................................................237

Optical Device Under Test (iOptics) ....................................................................................245

Remote Details (iSAM) .......................................................................................................248

RFC 2544 - Global ..............................................................................................................252

RFC 2544 - Subtests ...........................................................................................................255

RFC 6349 ...........................................................................................................................264

S-OAM and MPLS-TP OAM .................................................................................................267

Services - Global ................................................................................................................277

Services - Profile .................................................................................................................280

Signal (Transport) ..............................................................................................................287

Signal - Signal Configuration (DSn/PDH) ............................................................................294

Signal - Signal Configuration (OTN) ...................................................................................302

Signal - Signal Configuration (SONET/SDH) ........................................................................307

Smart Loopback .................................................................................................................311

Streams - Global ................................................................................................................313

Streams - Profile ................................................................................................................315

SyncE .................................................................................................................................323

Power Blazer v

Page 6

System ...............................................................................................................................325

TA-SFP28 ............................................................................................................................326

TCP Throughput .................................................................................................................327

Test Sequence (iOptics) ......................................................................................................329

Timer .................................................................................................................................330

Traces (OTN) ......................................................................................................................332

Traces (SONET/SDH) ...........................................................................................................336

Wander ..............................................................................................................................338

9 Test Results ................................................................................................341

Alarms/Errors Overview .......................................................................................................344

Analysis - MTIE/TDEV .........................................................................................................417

Analysis - Time Error / Time Interval Error ..........................................................................419

FTFL/PT and PT ...................................................................................................................421

GFP-F/GFP-T ........................................................................................................................423

Graph (RFC 2544) ..............................................................................................................426

Labels ................................................................................................................................427

Link OAM ...........................................................................................................................428

Logger ...............................................................................................................................432

Messages ...........................................................................................................................434

MPLS .................................................................................................................................436

OTL-SDT ..............................................................................................................................437

Performance Monitoring ....................................................................................................439

PTP Stats ............................................................................................................................446

Quality Level (1588 PTP) ....................................................................................................448

Quality Level (SyncE) ..........................................................................................................450

S-OAM and MPLS-TP OAM .................................................................................................452

SDT (Multi-Channel OTN) ...................................................................................................457

Service Configuration - Burst .............................................................................................459

Service Configuration - Ramp ............................................................................................460

Service Performance ..........................................................................................................462

Streams - Frame Loss / Out-of-Sequence ............................................................................464

Streams - Jitter ...................................................................................................................464

Streams - Latency ..............................................................................................................465

Streams - Throughput / Customer Frame Throughput ........................................................466

Summary ...........................................................................................................................467

Summary (1588 PTP) .........................................................................................................474

Summary (Cable Test) ........................................................................................................479

Summary (EtherSAM) ........................................................................................................485

Summary (FC BERT) ............................................................................................................488

Summary (iOptics) .............................................................................................................491

Summary (iSAM) ................................................................................................................493

vi 88000 Series

Page 7

Summary (Link OAM) .........................................................................................................497

Summary (Multi-Channel OTN) ..........................................................................................499

Summary (NI/CSU Emulation) ............................................................................................501

Summary (RFC 2544) .........................................................................................................502

Summary (RFC 6349) .........................................................................................................505

Summary (S-OAM and MPLS-TP OAM) ...............................................................................508

Summary (SyncE) ...............................................................................................................513

Summary (TCP Throughput) ...............................................................................................516

Summary (Traffic Gen & Mon) ...........................................................................................519

Summary (Wander) ............................................................................................................521

Traces - OTN .......................................................................................................................525

Traces - SONET/SDH ...........................................................................................................527

Traffic - Ethernet ................................................................................................................528

Traffic - Flow Control .........................................................................................................531

Traffic - Graph ....................................................................................................................533

Traffic - OAM, S-OAM, and MPLS-TP OAM .........................................................................534

Window Sweep ..................................................................................................................536

WIS ....................................................................................................................................537

10 Test Functions ........................................................................................... 539

40/100G/400G Advanced - CFP4/CFP8/QSFP Control ..........................................................542

40/100G/400G Advanced - Lanes Mapping & Skew ...........................................................545

APS ....................................................................................................................................550

Client Offset ......................................................................................................................553

FDL - Bit-Oriented Message ................................................................................................556

FDL - Performance Report Message ...................................................................................560

FEAC ..................................................................................................................................563

Filters .................................................................................................................................567

Packet Capture ...................................................................................................................571

GCC BERT ...........................................................................................................................577

GMP ..................................................................................................................................579

OH - GFP-F/GFP-T ................................................................................................................580

OH - OTN ...........................................................................................................................585

OH - SONET/SDH ................................................................................................................591

Ping & Trace Route .............................................................................................................605

Pointer Adjustment ............................................................................................................610

RTD ....................................................................................................................................620

RTD/RTT (CPRI/OBSAI Framed L2) .......................................................................................623

S-OAM Link Trace ...............................................................................................................626

Signaling Bits .....................................................................................................................628

Spare Bits ...........................................................................................................................630

Traffic Scan ........................................................................................................................632

Power Blazer vii

Page 8

11 Test Control ...............................................................................................635

Discover Remote Button ....................................................................................................636

Inject Button .......................................................................................................................639

Laser Button .......................................................................................................................639

Lpbk Tool Button (Loopback Tool) ......................................................................................640

Report Button ....................................................................................................................647

Reset Button .......................................................................................................................652

Save/Load Button ...............................................................................................................653

Start/Stop|TX Button ..........................................................................................................657

12 Power Failure Recovery ............................................................................659

Enabling Power Failure Recovery .........................................................................................660

When Using the Test Timer .................................................................................................661

13 Maintenance ..............................................................................................663

Cleaning LC/SC/MPO-24 Connectors ...................................................................................664

Battery Safety Information .................................................................................................664

Recalibrating the Unit .........................................................................................................665

Recycling and Disposal .......................................................................................................666

14 Troubleshooting ........................................................................................667

Solving Common Problems .................................................................................................667

Contacting the Technical Support Group ............................................................................668

Transportation ....................................................................................................................668

15 Warranty ....................................................................................................669

General Information ...........................................................................................................669

Liability ...............................................................................................................................670

Exclusions ...........................................................................................................................671

Certification ........................................................................................................................671

Service and Repairs .............................................................................................................672

EXFO Service Centers Worldwide ........................................................................................673

A Specifications ............................................................................................675

viii 88000 Series

Page 9

B Glossary .................................................................................................... 677

Acronym List .......................................................................................................................677

10G Ethernet Client ............................................................................................................694

1588 PTP .............................................................................................................................697

CPRI ...................................................................................................................................703

Ethernet Cables .................................................................................................................708

G.709 Optical Transport Network (OTN) ............................................................................710

Generic Framing Procedure (GFP) ......................................................................................727

MPLS Labels ........................................................................................................................739

OBSAI ................................................................................................................................740

SONET/DSn/SDH/PDH ..........................................................................................................745

SyncE ..................................................................................................................................755

Unicast/Multicast Addresses for Ethernet OAM ..................................................................757

VLAN ID and Priority ...........................................................................................................758

C Remote ToolBox ....................................................................................... 759

Overview .............................................................................................................................759

Remote ToolBox Installation ................................................................................................761

Starting and Using the Remote ToolBox Application ..........................................................762

Applications for... ...............................................................................................................764

Index .............................................................................................................. 765

Power Blazer ix

Page 10

Certification Information

Certification Information

North America Regulatory Statement

This unit was certified by an agency approved in both Canada and the

United States of America. It has been evaluated according to applicable

North American approved standards for product safety for use in Canada

and the United States.

Electronic test and measurement equipment is exempt from FCC part 15,

subpart B compliance in the United States of America and from ICES-003

compliance in Canada. However, EXFO Inc. makes reasonable efforts to

ensure compliance to the applicable standards.

The limits set by these standards are designed to provide reasonable

protection against harmful interference when the equipment is operated in

a commercial environment. This equipment generates, uses, and can

radiate radio frequency energy and, if not installed and used in accordance

with the user guide, may cause harmful interference to radio

communications. Operation of this equipment in a residential area is likely

to cause harmful interference in which case the user will be required to

correct the interference at his own expense.

Modifications not expressly approved by the manufacturer could void the

user's authority to operate the equipment.

x 88000 Series

Page 11

Certification Information

European Community Declaration of Conformity

Warning: This is a class A product. In a domestic environment, this product

may cause radio interference in which case the user may be required to

take adequate measures.

The full text of the EU declaration of conformity is available at the following

Internet address: www.exfo.com/library.

Laser

Your instrument is a Class 1 laser product in compliance

with standards IEC 60825-1: 2007/2014 and 21 CFR

1040.10, except for deviations pursuant to Laser Notice

No. 42, dated December 18, 1989.

Power Blazer xi

Page 12

Page 13

1 Introducing the High-Speed

Multiservice Test Module

Turnkey field-test solution for deploying, validating, and troubleshooting

networks up to 400G.

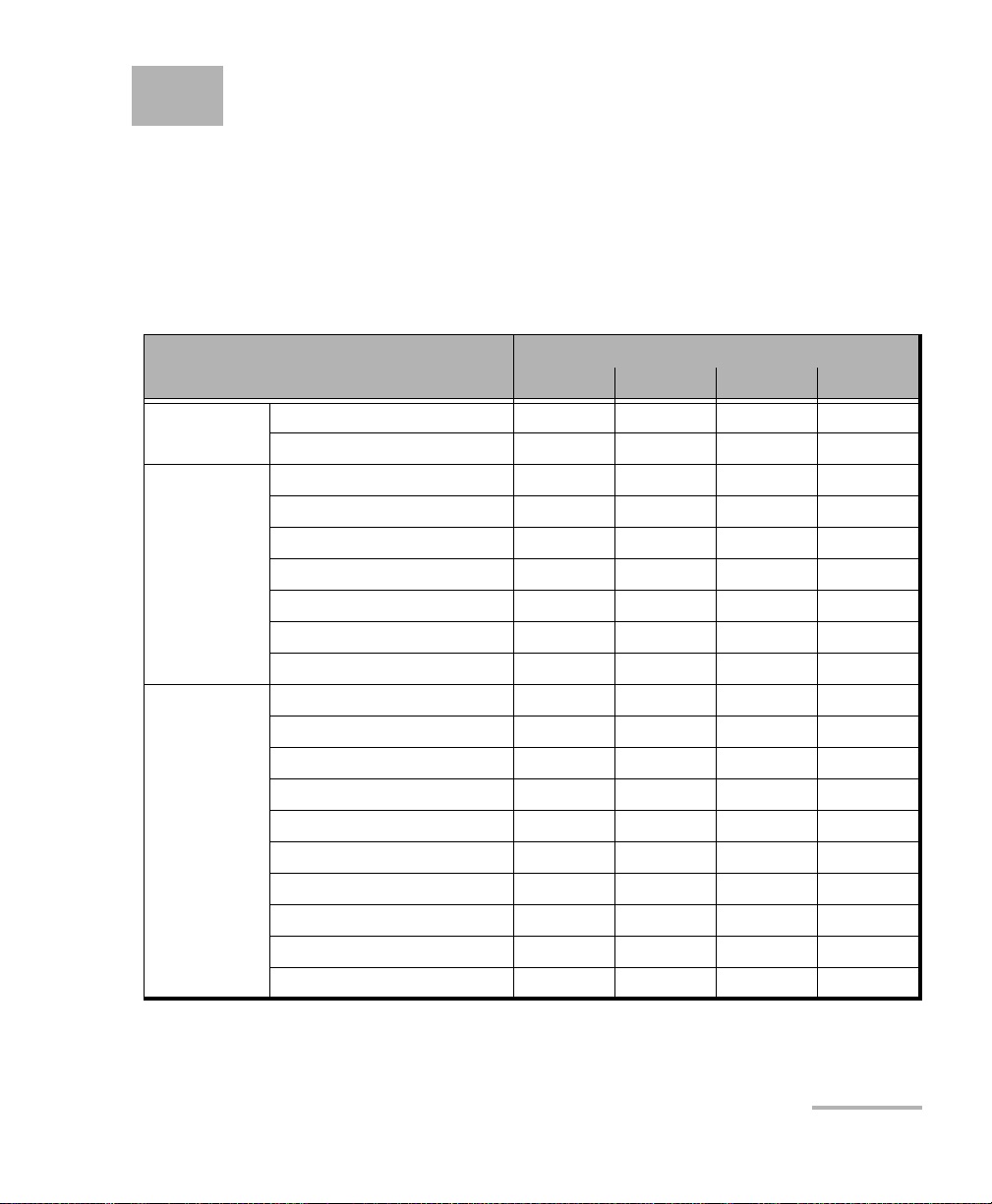

Features

Features

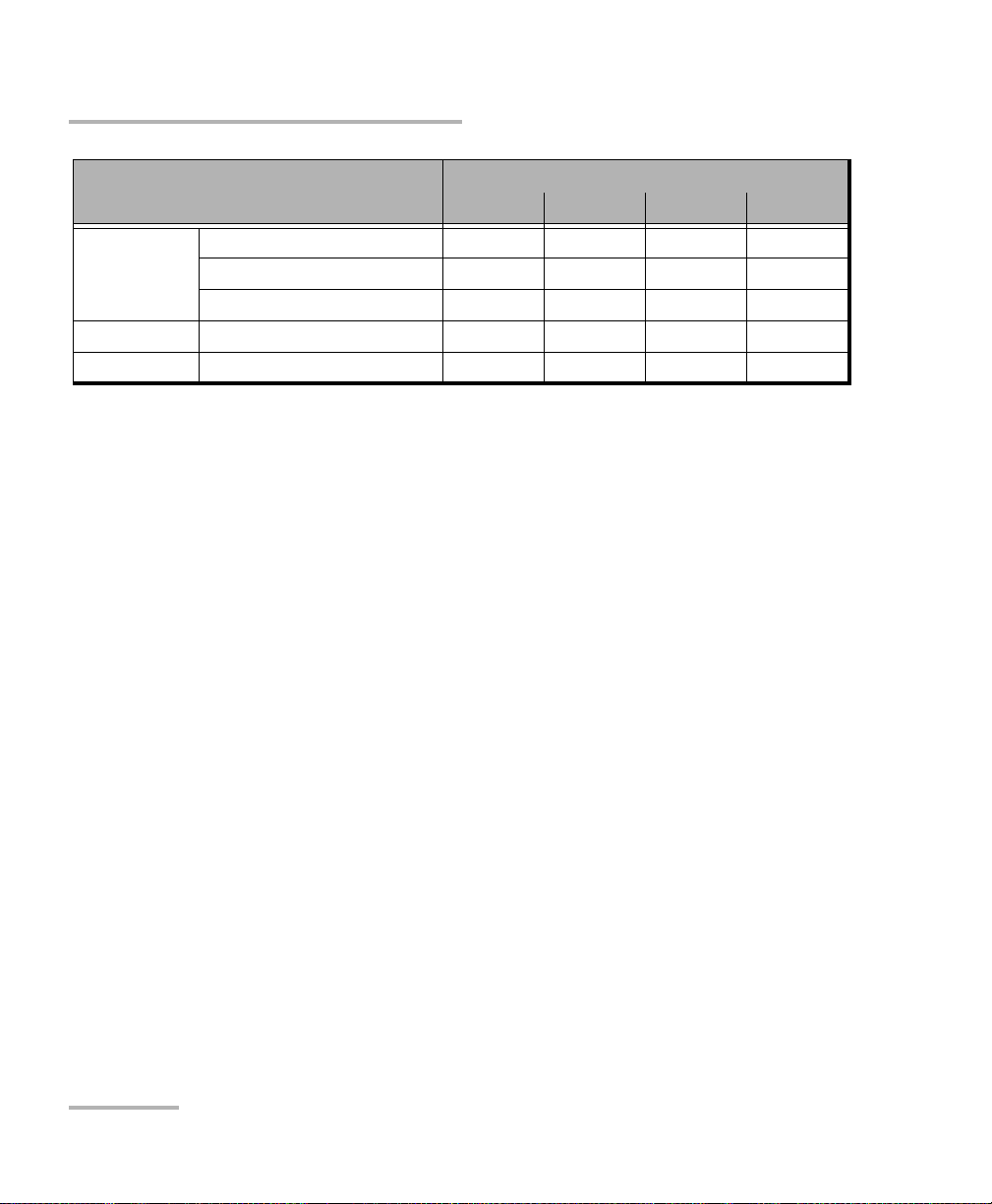

88200NGE 88260 88400NGE 8870/8880

Intelligent Apps. iOptics X - X X

iSAM X - - X

Transport Multi-Channel OTN X - - -

OTN BERT X - - X

SONET/SDH BERT X - - X

OTN-SONET/SDH BERT X - - X

DSn/PDH BERT - - - X

SONET/SDH - DSn/PDH BERT - - - X

NI/CSU - - - X

Ethernet EtherSAM (Y.1564) X - - X

RFC 6349 X - - X

RFC 2544 X X - X

EtherBERT X X X X

Traffic Gen & Mon X X - X

Smart Loopback X X - X

Through Mode X - - X

TCP Throughput X - - X

Carrier Ethernet OAM X - - X

Cable Test - - - X

Model

Power Blazer 1

Page 14

Introducing the High-Speed Multiservice Test Module

Technical Specifications

Features

88200NGE 88260 88400NGE 8870/8880

Packet Sync 1588 PTP X - - X

SyncE X - - X

Wander - - - 8880

Fibre Channel FC BERT X - - X

Wireless CPRI/OBSAI BERT X - - X

Model

Technical Specifications

To obtain this product’s technical specifications, visit the EXFO Web site at

www.exfo.com.

2 88000 Series

Page 15

Introducing the High-Speed Multiservice Test Module

Conventions

Before using the product described in this guide, you should understand

the following conventions:

WARNING

Indicates a potentially hazardous situation which, if not avoided,

could result in death or serious injury. Do not proceed unless you

understand and meet the required conditions.

CAUTION

Indicates a potentially hazardous situation which, if not avoided,

may result in minor or moderate injury. Do not proceed unless you

understand and meet the required conditions.

CAUTION

Indicates a potentially hazardous situation which, if not avoided,

may result in component damage. Do not proceed unless you

understand and meet the required conditions.

Conventions

IMPORTANT

Refers to information about this product you should not overlook.

Power Blazer 3

Page 16

Page 17

2 Safety Information

WARNING

Do not install or terminate fibers while a light source is active.

Never look directly into a live fiber and ensure that your eyes are

protected at all times.

WARNING

The use of controls, adjustments and procedures, namely for

operation and maintenance, other than those specified herein may

result in hazardous radiation exposure or impair the protection

provided by this unit.

WARNING

If the equipment is used in a manner not specified by the

manufacturer, the protection provided by the equipment may be

impaired.

WARNING

Use only accessories designed for your unit and approved by EXFO.

For a complete list of accessories available for your unit, refer to its

technical specifications or contact EXFO.

Power Blazer 5

Page 18

Safety Information

When you see the following symbol on your unit , make sure

that you refer to the instructions provided in your user

documentation. Ensure that you understand and meet the required

conditions before using your product.

When you see the following symbol on your unit , it indicates

that the unit is equipped with a laser source, or that it can be used

with instruments equipped with a laser source. These instruments

include, but are not limited to, modules and external optical units.

Other safety instructions relevant for your product are located

throughout this documentation, depending on the action to

perform. Make sure to read them carefully when they apply to your

situation.

IMPORTANT

IMPORTANT

IMPORTANT

6 88000 Series

Page 19

Safety Information

Additional Laser Safety Information

Additional Laser Safety Information

This product employs Class 1 Laser transceivers.

WARNING

When the LASER LED is on or flashing, the module is transmitting an

optical signal on the transceiver ports.

Note: Refer to the platform’s user guide for additional test equipment safety

information and ratings.

Power Blazer 7

Page 20

Safety Information

Installation Instruction Warnings

Installation Instruction Warnings

When you use the unit outdoors, ensure that it is protected from

liquids, dust, direct sunlight, precipitation, and full wind pressure.

Except for the dual Bantam connector and the RJ-48C port, all

telecom (electrical) interfaces are SELV (Safety Extra Low Voltage)

circuitry intended for intra-building use only.

For the dual Bantam connector and the RJ-48C ports, use only No.

26 AWG or larger telecommunication line cord to reduce the risk of

fire.

CAUTION

CAUTION

CAUTION

CAUTION

No user serviceable parts are contained inside. Contact the

manufacturer regarding service of this equipment.

IMPORTANT

All wiring and installation must be in accordance with local building

and electrical codes acceptable to the authorities in the countries

where the equipment is installed and used.

WARNING

Use only accessories designed for your unit and approved by EXFO.

8 88000 Series

Page 21

Safety Information

Installation Instruction Warnings

CAUTION

Electrostatic Discharge (ESD) Sensitive Equipment:

Plug-in modules can be damaged by static electrical discharge. To

minimize the risk of damage, dissipate static electricity by touching

a grounded unpainted metal object

before removing, inserting, or handling the module.

before connecting or disconnecting cables to/from the module.

before inserting or removing a transceiver to/from the module.

Power Blazer 9

Page 22

Page 23

3 Getting Started

If the module has been purchased at the same time as the platform, the

module is pre-installed with the appropriate software version.

Number of Dedicated Modules per Platform

The following table lists the maximum number of dedicated modules that

can run simultaneously on each platform.

Platform 88200NGE 88260NGE 88400NGE 8870/8880

FTB-2 NA NA NA 2

FTB-2 Pro 2 2 NA 2

FTB-4 Pro 4 4 1

LTB -8 8 8 2 8

a. The platform needs to be connected to a power outlet since this module requires too

much power to run on battery power.

Inserting and Removing Test Modules

CAUTION

There is no need to turn off your unit before inserting or removing

FTBx- modules.

However, inserting/removing modules without following the

instructions provided in the platform user documentation could

result in the following consequences, depending on the operation

underway when the modules are inserted/removed:

a

4

unexpected behavior of the test applications,

instability of the system,

or cause irreparable damage to your modules.

Note: Refer to the platform user guide for more information on how to

insert/remove a module into/from the platform.

Power Blazer 11

Page 24

Getting Started

Screw

Handle

Inserting and Removing Transceiver Adaptors (TA)

Inserting and Removing Transceiver

Adaptors (TA)

CAUTION

There is no need to turn off your unit before inserting or removing

TA modules.

However, inserting/removing TA modules without following the

instructions provided in this user documentation could result in the

following consequences, depending on the operation underway

when the modules are inserted/removed:

unexpected behavior of the test applications,

instability of the system,

or cause irreparable damage to your TA modules.

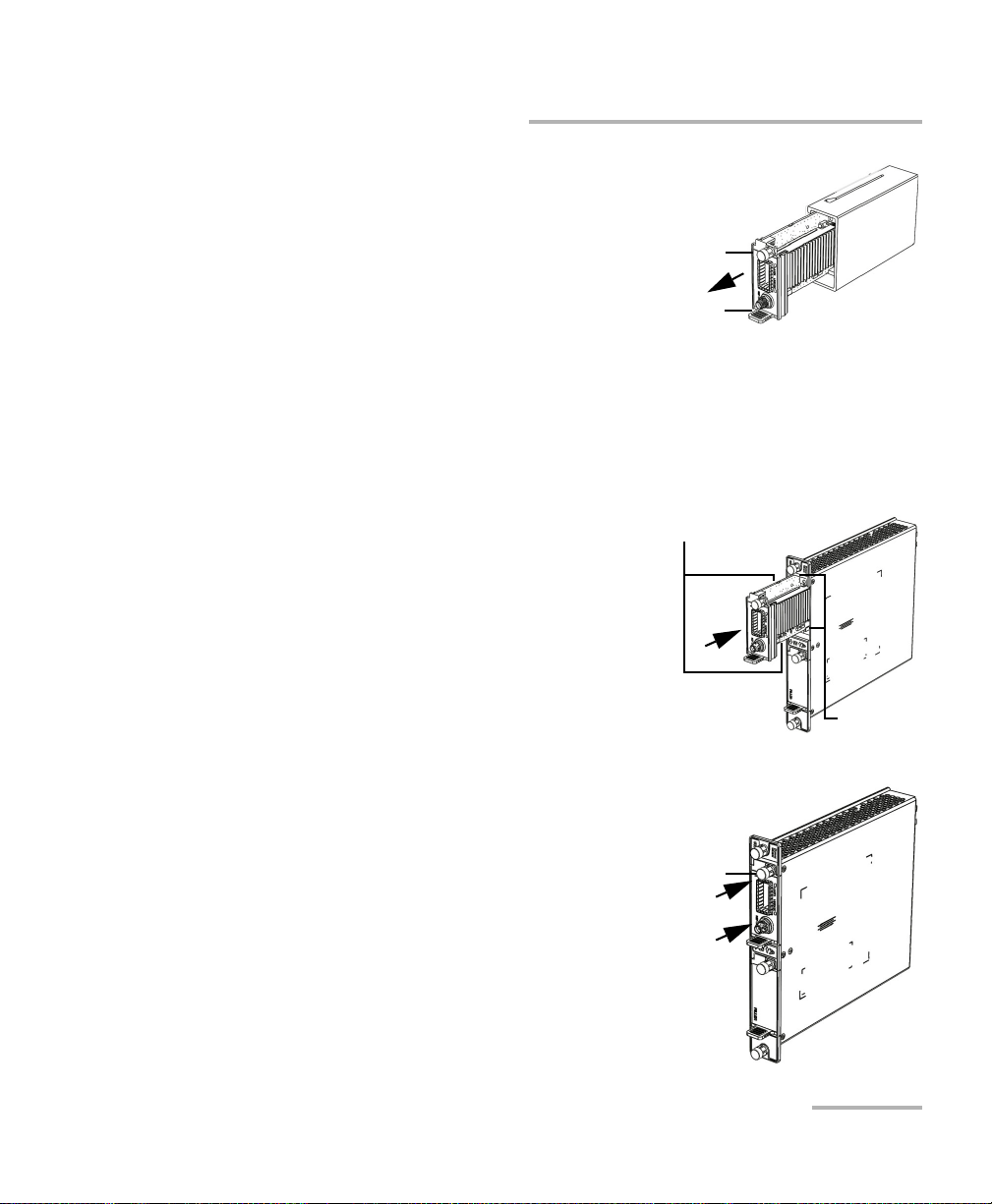

To insert a TA module into the FTBx-88260 module:

1. Position the FTB-x-88260 module so that its faceplate is facing you.

2. Remove the FILLER (protective

cover) from the FTBx-88260.

Turn the retaining screw

counterclockwise until it is

loose.

Hold the FILLER by the handle

and/or the retaining screw and

pull it out.

12 88000 Series

Page 25

Inserting and Removing Transceiver Adaptors (TA)

Screw

Handle

Protruding edges

Grooves

Press on

the edge

Screw

3. Remove the TA module from its

packaging:

3a. Turn the retaining screw

counterclockwise until it is

loose.

3b. Hold the TA module by the

handle and/or the retaining

screw (NOT by the connectors)

and pull it out. Don‘t throw away the TA packaging, it is

recommended to insert the TA module into its packaging when

carrying the TA outside the FTBx-88260 module.

4. Insert the TA module into the FTBx-88260 module:

4a. Take the TA module and place it

so that the connector pins are at

the back as shown below.

The identification sticker and

the protruding edges are on the

left side.

Getting Started

4b. Insert the protruding edges of

the module into the grooves of

the receptacle’s module port.

4c. Push the TA module all the way

to the back of the receptacle by

pressing firmly on the left edge

of the TA module until it is fully

inserted.

4d. Turn the retaining screw

clockwise until it is tightened.

This will secure the TA module

into its “seated” position.

Power Blazer 13

Page 26

Getting Started

Screw

Handle

Tur ning On the Unit

To remove a TA module from the FTBx-88260 module:

1. Position the FTB-x-88260 module so

2. Turn the retaining screw

3. Hold the TA module by the handle

Pulling out a TA module by its connectors could seriously damage

both the TA module and connectors. Always pull out a TA module

by its retaining screw, and/or the handle.

4. Cover the empty FTBx-88260’s receptacle with the supplied FILLER.

that its faceplate is facing you.

counterclockwise until it is loose.

and/or the retaining screw (NOT by

the connectors) and pull it out.

CAUTION

CAUTION

Failure to reinstall the FILLER over an empty receptacle will result in

ventilation problems.

Turning On the Unit

Turn on the platform. Refer to the platform user guide for more

information.

14 88000 Series

Page 27

Getting Started

Starting the Module Application

Starting the Module Application

The module can be configured and controlled by starting the application(s)

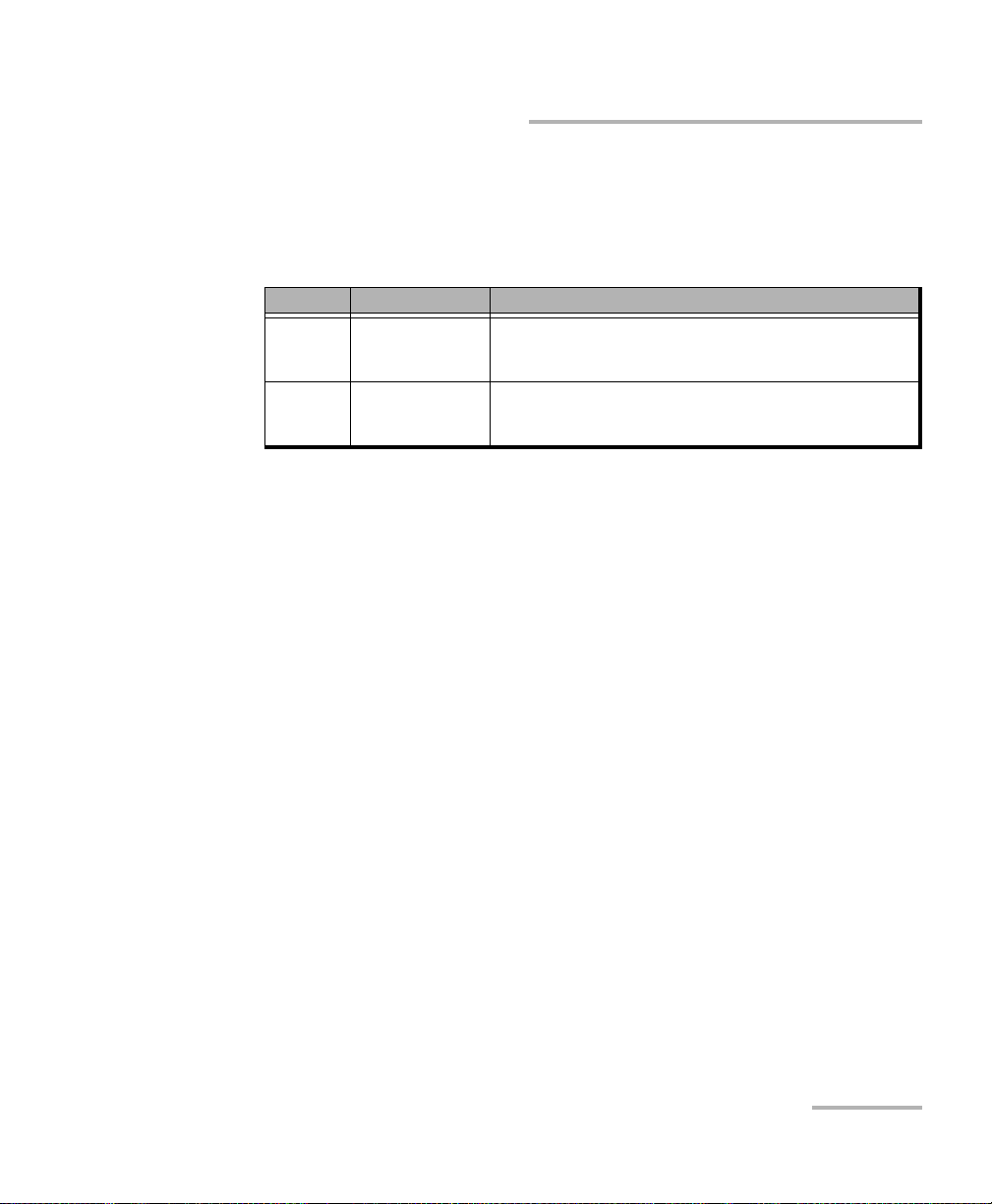

as described in the following table.

Module Application Comment

88200NGE

88260

88400NGE

8880

8870

a. Only the OpticalRF application is available on RTU-2.

b. No supported on FTB-2.

To start the application:

From Too lBo x X tap the desired application button.

Power Blazer

Power Blazer

a

OpticalRF

BBU-Emulation

b

Only one application can run at once.

b

Note: Refer to the respective user guides for more information on OpticalRF, and

BBU-Emulation applications.

Power Blazer 15

Page 28

Page 29

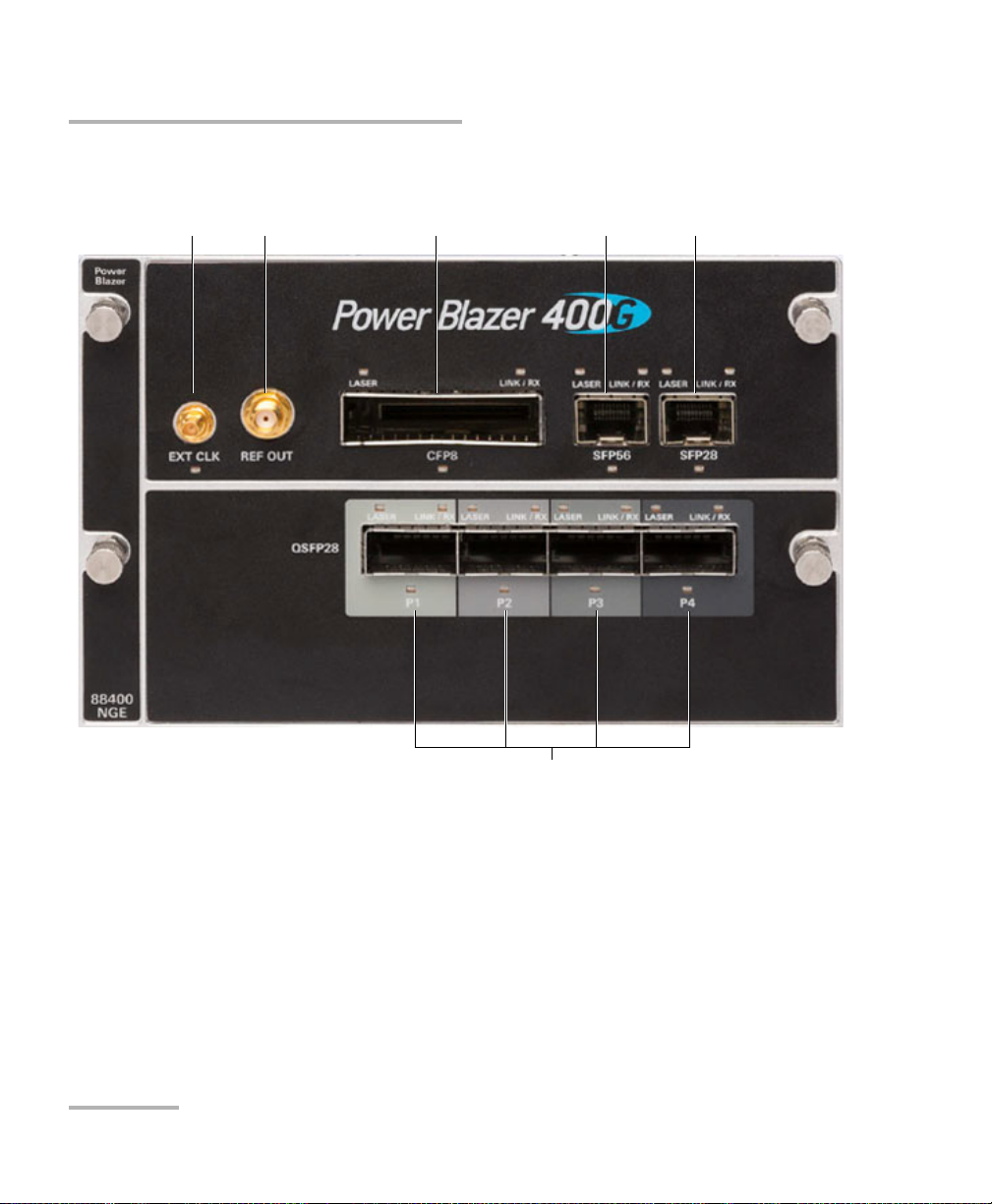

4 Physical Interfaces and LEDs

CFP41 QSFP1 EXT LCK REF OUT SFP+1

1. Laser radiation emitted from this port when LASER LED is on.

1. Laser radiation emitted from this port when LASER LED is on.

Port A Port B FTBx-88260

Port A1

1

TA-SFP28 Port A21 Port B11 Port B21

This section describes all connectors (ports) and LEDs available on the

88000 Series.

CAUTION

To prevent exceeding the maximum input/output power level,

please refer to this product’s technical specifications at

www.exfo.com.

FTBx-88200NGE

FTBx-88260 and TA-SFP28

Power Blazer 17

Page 30

Physical Interfaces and LEDs

QSFP281

1. Laser radiation emitted from this port when LASER LED is on.

EXT CLK REF OUT CFP81 SFP561 SFP281

FTBx-88400NGE

18 88000 Series

Page 31

FTBx-8870/8880

SFP+

1

P2

1. Laser radiation emitted from this port when LASER LED is on.

SFP+

1

P1

RJ45

P1

RJ48C BANTAM BNC

TX/RX2

BNC

RX

DUPLEX

LINK/ACT

LINK/RX

LASER

BNC

EXT CLK

Physical Interfaces and LEDs

Power Blazer 19

Page 32

Physical Interfaces and LEDs

Port Availability on the 88000 Series

Port Availability on the 88000 Series

88200NGE

The following table shows the list of available ports as well as a description

and the signals supported on the module.

Port

Labelled

SFP+ Optical IN/OUT port SFP/SFP+

CFP4 Optical IN/OUT port CFP4

QSFP

(QSFP+ or

QSFP28)

REF OUT Electrical port SMA for eye

EXT CLK Electrical port SMB for

a. Only OTU4 (4 Lanes) and 100GE (4 Lanes) are supported.

b. Only parallel interfaces are supported.

c. Available for Dual Test Set - One-Way Latency measurement mode.

Description Supported Signal(s)

Ethernet 100/1000 Mbit/s, 10 Gbit/s optical

transceiver

transceiver

Optical IN/OUT port QSFP+

transceiver

Optical IN/OUT port QSFP28

transceiver

diagram clock signal

generation

external clock synchronization

a

b

a

Ethernet 10/100/1000 Mbit/s electrical (using active copper SFP)

Fibre Channel 1X, 2X, 4X, 8X, 10X, 16X

CPRI 1.2, 2.4, 3.1, 4.9, 6.1, 9.8 Gbit/s

OBSAI 1.5, 3.1, 6.1 Gbit/s

OC-1/STM-0, OC-3/STM-1, OC-12/STM-4, OC-48/STM-16,

OC-192/STM-64

OTU1, OTU2, OTU1e, OTU2e, OTU1f, OTU2f.

Ethernet 100 Gbit/s

OTU4

Ethernet 40 Gbit/s

OTU3e2, OTU3e1, OTU3

Ethernet 100 Gbit/s

OTU4

DS1/1.5M, E1/2M, 2MHz, 1PPS

c

20 88000 Series

Page 33

Physical Interfaces and LEDs

Port Availability on the 88000 Series

88260

The following table shows the list of Transceiver Adapter (TA) supported on

each port of the FTBx-88260 module.

Port

Labelled

A TA left port TA-SFP28

B TA right port TA-SFP28

Description Supported Transceiver Adapter (TA)

The following table shows the list of port as well as a description and the

signals supported on each Transceiver Adapter (TA).

TA Description

TA-SFP28 Dual SFP28 1 Ethernet 25 Gbit/s optical

a. The ports are listed/referred as follows in the GUI: Port, FTBx-88260‘s port (A or B), TA port (1 or 2), and

connector type; for example Port A1 - SFP28.

Port

Labelled

2

a

Supported Signal(s)

Power Blazer 21

Page 34

Physical Interfaces and LEDs

Port Availability on the 88000 Series

88400NGE

The following table shows the list of available ports as well as a description

and the signals supported on the module.

Port

Labelled

SFP28a

a

Optical IN/OUT port SFP56

SFP56

a

QSFP28

(P1, P2, P3,

and P4)

CFP8 Optical IN/OUT port CFP8

REF OUT Electrical port SMA for eye

EXT CLK

a. Future use.

a

Electrical port SMB for

Description Supported Signal(s)

Optical IN/OUT port SFP28

transceiver

transceiver

Optical IN/OUT port QSFP28

transceiver

transceiver

diagram clock signal

generation

external clock synchronization

Ethernet 100/1000 Mbit/s, 10 Gbit/s, 25 Gbit/s optical

Ethernet 50 Gbit/s

Ethernet 40 Gbit/s, 100 Gbit/s

Ethernet 400 Gbit/s

DS1/1.5M, E1/2M, 2MHz, 1PPS

22 88000 Series

Page 35

Physical Interfaces and LEDs

Port Availability on the 88000 Series

8870/8880

The following table shows the list of available ports as well as a description

and the signals supported for each module.

Connector Labelled Description and supported signal(s)

Bantam BANTAM

TX/RX2

RX

BNC BNC

TX/RX2

BNC

RX

BNC

EXT CLK

RJ45 RJ45 P1 Ethernet 10/100/1000 Mbit/s electrical X X

RJ48C RJ48C DS1/1.5M, E1/2M X X

SFP/SFP+ SFP+ P1

or

SFP+ P2

SFP+ P1 OC-1/STM-0, OC-3/STM-1, OC-12/STM-4, OC-48/STM-16,

SFP+ P2 Ethernet 10/100/1000 Mbit/s electrical (using active copper

TX and RX: DS1/1.5M, E1/2M

RX2: DS1/1.5M

Clock IN/OUT: DS1/1.5M, E1/2M, 2 MHz

TX: E1/2M, E3/34M, DS3/45M, STS-1e/STM-0e/52M, E4/140M,

STS-3e/STM-1e/155M

RX2: DS3, 2 MHz, 10 MHz

Clock OUT: DS1/1.5M, E1/2M, 2 MHz

E1/2M, E3/34M, DS3/45M, STS-1e/STM-0e/52M, E4/140M,

STS-3e/STM-1e/155Mk, 1PPS

Clock IN: DS1/1.5M, E1/2M, 2 MHz, 10 MHz, 1 PPS

Clock IN: DS1/1.5M, E1/2M, 2 MHz, 1 PPS X -

1PPS, 2 MHz, 10 MHz - X

Clock IN: DS1/1.5M, E1/2M, 2 MHz - X

Clock OUT: DS1/1.5M, E1/2M, 2 MHz - X

Ethernet 100 Mbit/s, 1000 Mbit/s,10 Gbit/s LAN/WAN optical

CPRI 1.2, 2.4, 3.1, 4.9, 6.1, 9.8 Gbit/s

OBSAI 1.5, 3.1, 6.1 Gbit/s

Fibre Channel 1X, 2X, 4X, 8X, 10X

OC-192/STM-64

OTU1, OTU2, OTU1e, OTU2e, OTU1f, OTU2f

b

SFP)

a

Module

8870 8880

-X

-X

-X

XX

XX

XX

a. Port SFP+ P2 is used with OC-192/STM-64 in Decoupled (TX≠RX) mode.

b. Available as a second port when the test application requires two ports.

Power Blazer 23

Page 36

Physical Interfaces and LEDs

Transceivers

Transceivers

Carefully connect optical fibre cables to the transceiver IN and OUT ports.

To ensure good signal quality, make sure that the optical fibre connector is

fully inserted into the optical connector port.

To prevent exceeding the maximum input power level please use an

attenuator when a loopback configuration is used.

Before inserting an optical module into the interface receptacle,

inspect the receptacle to make sure nothing is inside.

Use only EXFO supported transceivers. Refer to www.exfo.com for

the list of supported transceivers. Using non-supported transceivers

can affect the performance and accuracy of the test.

CAUTION

CAUTION

WARNING

Note: Do not replace the transceiver while the test is running to avoid distorting

results. First stop the test, replace the transceiver, select the connector type

(refer to Modify Structure Button on page 108), and then restart the test.

RJ45

The electrical port is RJ45 for category 5 unshielded twisted pair (UTP).

Refer to Ethernet Cables on page 708 for cable specifications.

24 88000 Series

Page 37

Physical Interfaces and LEDs

BNC

Connector type is BNC for coaxial 75-ohm cable connection. An adapter

cable (BNC to Bantam) is required for Bantam external clock connection

(not supplied).

SMB

The connector type is SMB for coaxial 75-ohm cable connection. An

adapter cable (SMB to Bantam) is required for Bantam connection (not

supplied).

LEDs

LASER red LED is on when the module is emitting an optical laser

signal.

LINK/RX green LED is on when the link is up, off when the link is down,

and flashing when frames are transmitted and/or received.

BNC

DUPLEX green LED is on for Full Duplex mode, off for Half Duplex

mode, and flashing when collisions are detected.

Port blue LED is on when this port is selected for the test, and flashing

when this port is selected for clock input.

Power Blazer 25

Page 38

Page 39

5 Graphical User Interface

Main

Window

Te st

Control

Tes t M en u

Application

Buttons

Status Bar

Global

Indicator

Title Bar

Overview

This chapter describes the Power Blazer Series graphical user interface.

Main Application Window

The following main application window is displayed when the Power

Blazer application is started.

Main Window

The main window is used to setup a test and to view the test status and

results.

Power Blazer 27

Page 40

Graphical User Interface Overview

Navigation Buttons

Navigation Buttons

Navigation buttons appear when there is not enough room on one page to

display all available test applications. The left and right arrow buttons allow

respectively accessing the previous or next window. The buttons in

between the left and right arrow buttons allow directly selecting the

window for the type of test application listed.

Status Bar

The status bar displays the following information.

Icon

and/or text

Test icon Icon representing the active test application. All

P1, P2, P3, P4 Port identification number: Port x All

A1, A2, B1,

B2

TX/RX, TX, RX Indicates the direction of the signal per port. Transport,

Interface/

Signal

(BTS) or

(RRH)

LINK Green arrow: Link up.

Port identification number composed of the port of the FTBx-88260

module (A or B) and the TA port (1 or 2)

The interface or signal rate per port: 1GE Optical, 40G, OTU1,

OTU2, OTU3, etc.

BTS: Emulation mode is Base Station

RRH: Emulation mode is Remote Radio Head

Red arrow: Link down.

Gray arrow: Awaiting incoming data to provide a status.

Description Test Application

All (FTBx-88260)

Wander (DS1/E1)

All

CPRI/OBSAI BERT

All

CPRI/OBSAI BERT

28 88000 Series

Page 41

Graphical User Interface Overview

Status Bar

Icon

and/or text

Description Test Application

PTP For G.8265.1:

Green arrow: Signaling requests granted.

Red arrow: Request denied, session canceled, or no reply.

Gray arrow: Pending, inactive, or link down.

Refer to Negotiation Status on page 475 for more information.

For G.8275.1:

Green arrow: Announce, Sync, and Follow-up are received according

with their respective interval.

Red arrow: Announce, Sync, or Follow-up are not received.

Gray arrow: Pending.

ESMC Green arrow: ESMC valid information frame received.

Red arrow: No ESMC valid information frames received.

Gray arrow: Pending state.

Refer to ESMC Monitoring on page 321 for more information.

Power level The received optical signal status:

Green with “Power”: Power level in range

Yellow: Power level out-of-range

Red with “LOS”: Loss of signal

b

.

b

a

.

.

Red with “Power”: Power level is close to damage.

Gray: The operational range value is either not available or not

supplied by the transceiver.

Laser ON

b

. The laser icon is not displayed when the laser is offa. The

laser icon is only displayed for optical interfaces. The laser is ON by

default when the test is created. The laser control is not affected when

turning off the laser by generating a LOS for example. Refer to Laser

Button on page 643.

The status of the received signal pattern per port:

Green: Pattern is synchronized.

Red: Loss of pattern.

Gray: Test is not running (EtherBERT test or EoOTN client) or the No

Pattern Analysis (Live) check box is selected.

Connection established between two testing units in Dual Test Set

(DTS), EXFO|Worx Interop, or in Loop Up mode.

Connection not established between two testing units in Dual Test Set

(DTS), EXFO|Worx Interop, or in Loop Up mode.

1588 PTP

SyncE, Wander

All except Cable Test

All

Tra nsp ort

EtherBERT

Fibre Channel

Wireless

Ethernet

Ethernet

Power Blazer 29

Page 42

Graphical User Interface Overview

Status Bar

Icon

and/or text

Description Test Application

Remote unit is busy (locked) in EXFO|Worx Interop operation mode. Ethernet

Loopback Tool enabled on the port unused by the main test

application.

Clock synchronization signal clock. The clock icon is followed by the

clock mode: INT for Internal, EXT for External RCV for Recovered,

or BKP for Backplane. AUTO is displayed for dual port test when a

different clock is used on each port.

Green: Clock Synchronized.

Red: Loss of clock.

Indicates a manual change in the OH bytes transmitted. Not displayed

when using the default OH values.

Remote PC connection established with the Power Blazer. N/A

The test is in loopback mode. Not displayed when not in loopback

mode.

Alarm/error is currently injected. Not displayed when there is no

alarm/error injection.

Ethernet

Tra nsp ort

Ethernet

Fibre Channel

Wireless

Tra nsp ort

NI-CSU Emulation

Tra nsp ort

EtherBERT

Carrier Ethernet OAM

Fibre Channel

Wireless

a. For all lanes for parallel interface.

b. For at least one lane for parallel interface.

The following status are also displayed:

Battery/AC icons, available on FTB platforms, indicate the battery level

and if the platform is connected to an AC power source. Refer to the

platform user guide for more information.

Date and Time indicate the current date and time.

30 88000 Series

Page 43

Graphical User Interface Overview

Global

Alarm

Tes t T i mer

Global indicator area

History

Current

Timer

Global

Verdict

Title Bar

The Title Bar displays the module’s slot number in brackets, the software

application name and the minimize, maximize, and close buttons.

Global Indicator

The global indicator area displays the global pass/fail verdict, global alarm,

and the test duration.

Title Bar

The global indicator area can be maximized for distant viewing. Tap

anywhere within the global indicator area to display a maximized view. Tap

again to exit the maximized view.

Power Blazer 31

Page 44

Graphical User Interface Overview

Global Indicator

Global Verdict

Reports the global test verdict status when supported by the test

application and enabled (when applicable).

Verdict Description

PAS S PA SS is displayed with a green background when all result values meet the configured threshold

criteria.

FAIL FAIL is displayed with a red background when any result value does not meet the configured

threshold criteria or when a specific alarm is detected (refer to each test application for additional

information).

“--” “--” is displayed with a gray background when at least one of the following conditions is met:

- Pass/Fail verdict is not enabled

- there is no defined criterion

- the test has not run yet.

Global Alarm

Indicates the current and history alarm/error status of the test.

Background

color

Gray Current -- No test result available.

Green Current No Alarm No alarm/error has occurred in the last second.

Red Current Alarms or the name of the alarm. An alarm/error occurred in the last second.

Amber History No current alarm/error but at least one

Alarm/

Error

History

History No alarm/error has occurred during the test.

History

Text displayed Description

alarm/error has occurred during the test.

32 88000 Series

Page 45

Graphical User Interface Overview

Test Timer

The test timer without the timer icon indicates the time elapsed since the

beginning of the test. No timer action is active. The test timer format is

“day hour:minute:second”.

Timer

The timer icon with Armed indicates that a start time is active.

The timer icon with the Test Timer indicates that a duration and/or a stop

time is active.

Test Control

Note: Refer to Te st Cont r ol on page 635 for more information.

Test Menu

Test C o n tr ol

The test menu displays the following buttons:

Setup allows configuring the selected test. Refer to Test Setup - Test

Configurator, Timer, and System on page 95 for more information.

Results allows viewing test results. Refer to Test Results on page 341

for more information.

Functions allows configuring additional test functions (refer to Te st

Functions on page 539).

Power Blazer 33

Page 46

Graphical User Interface Overview

Application Buttons

Application Buttons

Help (?) displays the help information related to the content of the

active main window. It is also possible to navigate through the

remainder of the help information.

Exit (x) closes the application.

About (i) mainly displays the product version details and technical

support information.

Module Details button displays the module details such as its ID, Serial

Number, Software Product Version, etc.

View Licence Agreement button displays the details of the product

licence agreement.

Software Options button displays the list of software options.

Note: For information on how to install and activate software options, refer to the

platform User Guide. The Power Blazer application must be restarted once

a new software option is installed in order to activate it.

Software Option Description

10electrical Ethernet 10Base-T electrical interface

100optical Ethernet 100Base-FX optical interface

100electrical Ethernet 100Base-TX electrical interface

GigE_Electrical Ethernet 1000Base-T electrical interface

GigE_Optical Ethernet 1000Base-X optical interface

10G_LAN Ethernet 10G LAN optical interface

10G_WAN Ethernet 10G WAN optical interface

25GE Ethernet 25G

40GE Ethernet 40G

100GE Ethernet 100G

400GE Ethernet 400G

OTU4 Optical Transport Unit-4 (111.81 Gbit/s)

OTU3-e1-e2 Optical Transport Unit-3 Overclocked (44.571/44.583 Gbit/s)

OTU3 Optical Transport Unit-3 (43.018 Gbit/s)

34 88000 Series

Page 47

Graphical User Interface Overview

Application Buttons

Software Option Description

OTU2-1f-2f Optical Transport Unit-2 Overclocked (11.270/11.317 Gbit/s)

OTU2-1e-2e Optical Transport Unit-2 Overclocked (11.049/11.096 Gbit/s)

OTU2 Optical Transport Unit-2 (10.7 Gbit/s)

OTU1 Optical Transport Unit-1 (2.7 Gbit/s)

40G 39.81312 Gbit/s (SONET/SDH)

9953M 9.953 Gbit/s (SONET/SDH)

2488M 2.488 Gbit/s (SONET/SDH)

622M 622 Mbit/s (SONET/SDH)

155M 155 Mbit/s (SONET/SDH)

52M 52 Mbit/s (SONET/SDH)

FC-1X Fibre Channel 1X

FC-2X Fibre Channel 2X

FC-4X Fibre Channel 4X

FC-8X Fibre Channel 8X

FC-10X Fibre Channel 10X

FC-16X Fibre Channel 16X

CPRI-1.2G CPRI 1.2288 Gbit/s

CPRI CPRI 2.4576 Gbit/s and 3.072 Gbit/s

CPRI-4.9G CPRI 4.9152 Gbit/s

CPRI-6.1G CPRI 6.144 Gbit/s

CPRI-9.8G CPRI 9.8304 Gbit/s

DP-CPRI Dual Port CPRI

OBSAI-1.5G OBSAI 1.536 Gbit/s

OBSAI OBSAI 3.072 Gbit/s

OBSAI-6.1G OBSAI 6.144 Gbit/s

ETH-CAPTURE Ethernet Frame Capture

ETH-OAM Carrier Ethernet OAM test application

TRAFFIC-SCAN Traffic Scan

LINK-OAM Link OAM

TST-OAM Test Over Service OAM

DUAL-PORT Dual Port Test

DP_40-100GE Dual Port at 40/100GE

RFC6349 RFC 6349 test application (up to 10GE)

RFC6349_40-100GE RFC 6349 test application (40/100GE)

RFC6349-EXFOWorx EXFO|Worx Interop Operation Mode

Power Blazer 35

Page 48

Graphical User Interface Overview

Application Buttons

Software Option Description

DTS-NAT NAT traversal for DTS applications

ADV-FILTERS Advanced filtering

MPLS MPLS Encapsulation (up to 10GE)

MPLS_40-100GE MPLS Encapsulation (40/100GE)

EoE Ethernet over Ethernet Encapsulation (up to 10GE)

EoE_40-100GE Ethernet over Ethernet Encapsulation (40/100GE)

PBBTE Provider Backbone Bridge Encapsulation (up to 10GE)

PBBTE_40-100GE Provider Backbone Bridge Encapsulation (40/100GE)

IPv6 Internet Protocol Version 6 (IPv6) (up to 10GE)

IPv6_40-100GE Internet Protocol Version 6 (IPv6) (40/100GE)

ODU0 OTN ODU0

ODUMUX ODU Multiplexing Payload Type 20 and 21

EoOTN Ethernet over Optical Transport Network

ODUflex OTN ODUflex

SONET Synchronous Optical Network

SDH Synchronous Digital Hierarchy

OTN-INTR-THRU OTN Intrusive Through Mode

SONETSDH-INTR-THRU SONET/SDH Intrusive Through Mode

MULTI-CH-OTN Multi-Channel OTN Test Application

OTN-MIX-MAPPING Mix-Mapping capability for Multi-Channel OTN

GCC-BERT GCC BERT

TCM Tandem Connection Monitoring STS/AU and VT/TU (SONET/SDH)

ETH-THRU Through Mode Test Application

iOptics Intelligent Pluggable Optic Test Application

iSAM Intelligent Service Activation Methodology

CABLE_TEST Cable Test Application

1588PTP 1588 Precision Time Protocol Test Application

G82751 ITU-T G.8275.1 Profile

SyncE Synchronous Ethernet Test Application

Wander Time Error / Wander Test Application

TCP-THPUT TCP Throughput Test Application

DSn Digital Signal

DS1-FDL DS1/1.5M Facility Data Link

DS3-FEAC DS3/45M Far-End Alarm and Control

DUALRX Dual RX

36 88000 Series

Page 49

Graphical User Interface Overview

Moves to the top of the list.

Moves one page up.

Moves one line up.

Moves one line down.

Moves one page down.

Moves to the end of the list.

Software Option Description

DS3-G747 ITU-T Recommendation G.747

PDH Plesiochronous Digital Hierarchy

NI-CSU NI/CSU Emulation

Zoomed-In/Zoomed-Out Views

Some configuration and result blocks give access to zoomed views

allowing more detailed configurations/results.

The block title contains the magnifier (+) icon when a zoomed view is

available.

To zoom-in, tap the magnifier (+) icon or anywhere on the block.

To zoom-out, tap on the magnifier (-) icon or anywhere on the block title.

Arrow Buttons

Zoomed-In/Zoomed-Out Views

Power Blazer 37

Page 50

Graphical User Interface Overview

Keyboard Usage

Keyboard Usage

The GUI pops up different keyboards to modify data. Following are the

usual keyboard keys:

Left arrow moves the cursor one position to the left.

Right arrow moves the cursor one position to the right.

Up arrow increases the value by one.

Down arrow decreases the value by one.

Del deletes the value at the cursor position.

Back deletes the value preceding the cursor position.

OK completes data entry.

Cancel closes the keyboard and discards the keyboard entry.

Previous... allows the selection of previously configured values. This

button is only available for certain fields like IP Address, MAC Address,

etc.

Note: For certain text fields, the GUI pops up or uses the unit’s on-screen

keyboard. Refer to the platform user guide for more information on how to

use it.

For full keyboard, the Back, Del, Shift, and Space bar keys have the same

functionality as a regular PC keyboard.

38 88000 Series

Page 51

Graphical User Interface Overview

Keyboard Usage

For multiplexing keyboard, tap on all mapped signals that have to be

added/removed to/from the test path.

A mapped signal with an orange background color is part of the test

path.

A mapped signal with a gray background color is not part of the test

path.

Power Blazer 39

Page 52

Graphical User Interface Overview

Keyboard Usage

The Trace message keyboard allows entering alphanumerical characters

(ITU T.50) required for J0/J1/J2/TTI Trace fields. Tap the Control

Characters button to access these characters.

ITU T.50 Characters

b7 to b1 Character Description b7 to b1 Character Description

000 0000 NUL Null 001 0000 DLE Data Link Escape

000 0001 SOH Start Of Heading 001 0001 DC1 Device Control 1

000 0010 STX Start of Text 001 0010 DC2 Device Control 2

000 0011 ETX End of Text 001 0011 DC3 Device Control 3

000 0100 EOT End Of Transmission 001 0100 DC4 Device Control 4

000 0101 ENQ Enquiry 001 0101 NAK Negative Acknowledge

000 0110 ACK Acknowledge 001 0110 SYN Synchronous idle

000 0111 BEL Bell 001 0111 ETB End of Transmission Block

000 1000 BS Backspace 001 1000 CAN Cancel

000 1001 HT Horizontal Tabulation 001 1001 EM End of Medium

000 1010 LF Line Feed 001 1010 SUB Substitute character

000 1011 VT Vertical Tabulation 001 1011 ESC Escape

000 1100 FF Form Feed 001 1100 IS4 Information Separator 4

000 1101 CR Carriage Return 001 1101 IS3 Information Separator 3

000 1110 SO Shift-Out 001 1110 IS2 Information Separator 2

000 1111 SI Shift-In 001 1111 IS1 Information Separator 1

40 88000 Series

Page 53

6 Test Setup - Test Applications

The Power Blazer offers the following test applications.

Type Application

Intelligent

Apps

Tra nsport OTN BERT X--X45

Ethernet EtherSAM (Y.1564) X--X59

Sync 1588 PTP X--X75

Fibre Channel FC BERT X--X78

Wireless CPRI/OBSAI BERT X--X79

iOptics X-X X42

iSAM X--X43

Multi-Channel OTN X---44

SONET/SDH BERT X--X50

OTN-SONET/SDH BERT X--X47

DSn/PDH BERT ---X53

SONET/SDH - DSn/PDH BERT ---X55

NI/CSU Emulation ---X58

RFC 6349 X--X63

RFC 2544 XX- X61

EtherBERT XXXX64

Traffic Gen & Mon XX- X66

Smart Loopback XX-X68

Through Mode X - - X 70

TCP Throughput X--X71

Carrier Ethernet OAM X--X72

Cable Test ---X74

SyncE X--X76

Wander ---888077

88200NGE 88260 88400NGE 8870 / 8880

Available on

Page

Power Blazer 41

Page 54

Test Setup - Test Applications

EXFO Module

iOptics

iOptics

iOptics test application provides a quick assessment of the proper

operation of an optical transceiver before using it in a network or test

environment. The validation is done by running sub-tests in addition to

monitoring transceiver power consumption and temperature. Result and

verdict are reported for each sub-test and monitoring task. Transceiver’s

manufacturing information is also automatically collected.

A fiber loopback patch cord is required to perform the test with applicable

attenuation included to protect the optical device. Bidirectional (single

fiber) transceivers are not supported since the iOptics test requires a

loopback.

Typical iOptics test application:

Supported Interfaces/Rates: 40G/100G/OTU3/OTU3e1/OTU3e2/OTU4

parallel interfaces and all serial interfaces up to 10G/OTU2f (refer to

Rate on page 245 for more information).

42 88000 Series

Page 55

Test Setup - Test Applications

Network

under test

(EVC)

Local Unit Remote Unit

EXFO Module EXFO Module

Manual or

Remote

Loopback

Network

under test

(EVC)

Local Unit Remote Unit

EXFO Module EXFO Module

EtherSAM

(DTS)

iSAM

iSAM is a simplified version of EtherSAM that is centered around addressing

turn-up of E-Line circuits (EVC). The objective of the test is to validate

Carrier Ethernet-based services key performance indicators defined in

MEF: Frame Delay (FD), Inter-Frame Delay Variation (IFDV), and Frame

Loss Ratio (FLR). In addition the RFC 6349 subtest can be enabled to

validate that the Ethernet service is able to properly carry TCP traffic.

The iSAM test has to be executed in conjunction with a remote module.

The remote module can be either in loopback configuration for

unidirectional testing or in EtherSAM Dual Test Set mode for bidirectional

testing.

The Dual Test Set test allows bi-directional testing between two

compatible modules providing independent results for each test direction.

The results from local-to-remote and remote-to-local are available on the

local testing unit.

iSAM

Typical iSAM test applications:

Supported Interfaces/Rates: 10M to 100G.

Power Blazer 43

Page 56

Test Setup - Test Applications

Network

under test

Testing Unit DUT Loopback

EXFO Module

Network

under test

Te s t ing U n it Te s t ing U n it

EXFO Module EXFO Module

Multi-Channel OTN

Multi-Channel OTN

The Multi-Channel OTN test application validates individual channel

connectivity with a device under test by allowing concurrent generation

and monitoring of all channels of a single or mixed ODUmux test structure.

Typical Multi-Channel OTN test applications:

Path/Mapping

The Multi-Channel OTN test application offers the following

path/mapping structures depending on the inserted CFP4/QSFP

transceivers and enabled options. Mixed mapping is available with the

OTN-MIX-MAPPING software option.

44 88000 Series

Page 57

Test Setup - Test Applications

Network

under test

Testing Unit DUT Loopback

EXFO Module

Network

under test

Te s t ing U n it Te s t ing U n it

EXFO Module EXFO Module

Testing Unit

EXFO Module

Network

under test

Network

under test

OTN BERT

Allows OTN (framed and unframed), OTN multiplexing, and EoOTN traffic

generation with specific test pattern for Bit Error Rate analysis.

Typical OTN BERT test applications:

OTN BERT

Path/Mapping

The OTN BERT test application offers the following path/mapping