Page 1

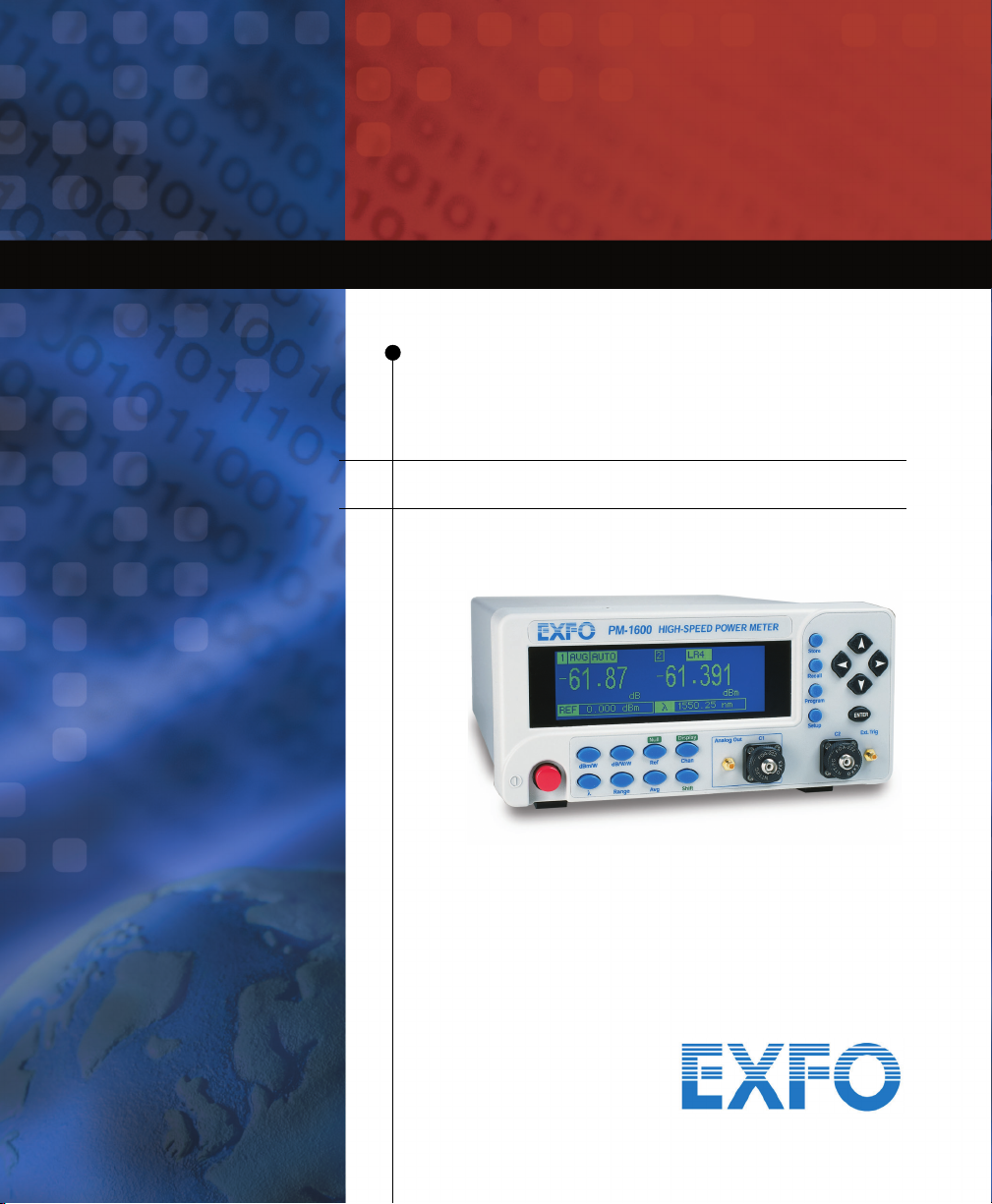

High-Speed Power Meter

PM-1600

User Guide

Page 2

P/N: 1034911

CORPORATE

HEADQUARTERS

EXFO AMERICA 4275 Kellway Circle, Suite 122 Addison TX, 75001 USA

EXFO EUROPE Le Dynasteur

EXFO ASIAPACIFIC

TOLL-FREE (USA and Canada) 1 800 663-3936

www.exfo.com · info@exfo.com

© 2004 EXFO Electro-Optical Engineering Inc. All rights reserved. Printed in Canada.

400 Godin Avenue Vanier (Quebec) G1M 2K2 CANADA

10/12, rue Andras Beck

151 Chin Swee Road

#03-29, Manhattan House

Tel.: 1 418 683-0211 · Fax: 1 418 683-2170

Tel.: 1 972 836-0100 · Fax: 1 972 836-0164

92366 Meudon la Forêt Cedex FRANCE

Tel.: +33.1.40.83.85.85 · Fax: +33.1.40.83.04.42

SINGAPORE 169876

Tel.: +6563338241 · Fax: +6563338242

Page 3

High-Speed Power Meter

PM-1600

User Guide

P/N: 1034911

March 2002

If the equipment described herein

bears the symbol, the said

equipment complies with the

applicable European Union

Directive and Standards mentioned

in the Declaration of Conformity.

High-Speed Power Meter

PM-1600

User Guide

P/N: 1034911

March 2002

If the equipment described herein

bears the symbol, the said

equipment complies with the

applicable European Union

Directive and Standards mentioned

in the Declaration of Conformity.

Page 4

All rights reserved. No part of this publication may be reproduced, stored in

a retrieval system, or transmitted in any form, be it electronically,

mechanically, or by any other means such as photocopying, recording, or

otherwise, without the prior written permission of EXFO Electro-Optical

Engineering Inc. (EXFO).

Information provided by EXFO is believed to be accurate and reliable.

However, no responsibility is assumed by EXFO for its use nor for any

infringements of patents or other rights of third parties that may result from

its use. No license is granted by implication or otherwise under any patent

rights of EXFO.

EXFO’s Commerce And Government Entities (CAGE) code under the North

Atlantic Treaty Organization (NATO) is 0L8C3.

The information contained in this publication is subject to change without

notice.

© 2002 EXFO Electro-Optical Engineering Inc.

Words that EXFO considers trademarks have been identified as such.

However, neither the presence nor absence of such identification affects

the legal status of any trademark.

Units of measurement in this document conform to SI standards and

practices.

All rights reserved. No part of this publication may be reproduced, stored in

a retrieval system, or transmitted in any form, be it electronically,

mechanically, or by any other means such as photocopying, recording, or

otherwise, without the prior written permission of EXFO Electro-Optical

Engineering Inc. (EXFO).

Information provided by EXFO is believed to be accurate and reliable.

However, no responsibility is assumed by EXFO for its use nor for any

infringements of patents or other rights of third parties that may result from

its use. No license is granted by implication or otherwise under any patent

rights of EXFO.

EXFO’s Commerce And Government Entities (CAGE) code under the North

Atlantic Treaty Organization (NATO) is 0L8C3.

The information contained in this publication is subject to change without

notice.

© 2002 EXFO Electro-Optical Engineering Inc.

Words that EXFO considers trademarks have been identified as such.

However, neither the presence nor absence of such identification affects

the legal status of any trademark.

Units of measurement in this document conform to SI standards and

practices.

Page 5

Contents

High-Speed Power Meter iii

Contents

Certification Information......................................................................................................... vi

1 Introducing the PM-1600 High-Speed Power Meter .................................. 1

Front Panel...............................................................................................................................2

Back Panel................................................................................................................................3

RS-232 Connector Pinout .........................................................................................................4

2 Safety Information ....................................................................................... 5

Safety Conventions ..................................................................................................................5

General Safety Information ......................................................................................................6

Laser Safety Information ..........................................................................................................6

Electrical Safety Information ....................................................................................................7

3 Getting Started with Your High-Speed Power Meter ................................. 9

Turning the PM-1600 On and Off.............................................................................................9

Selecting a Menu or a Menu Option ......................................................................................10

Nulling Electrical Offsets ........................................................................................................11

4 Acquiring Power Measurements ............................................................... 13

Setting a Display Mode ..........................................................................................................13

Measuring Absolute Power ....................................................................................................14

Measuring Relative Power ......................................................................................................16

Measuring Corrected Power...................................................................................................19

Displaying Averaged Measurement........................................................................................22

Setting Measurement Range..................................................................................................22

Viewing Statistics...................................................................................................................24

Managing the Wavelength List ..............................................................................................25

Setting a Correction Factor ....................................................................................................30

Setting Display Resolution......................................................................................................32

Setting Refresh Rate...............................................................................................................34

Setting Sampling Rate............................................................................................................35

Choosing a Number of Measurements for Averaging ............................................................36

Saving a Setup Configuration ................................................................................................37

Recalling a Setup Configuration.............................................................................................38

Resetting the PM-1600 ..........................................................................................................39

5 Storing and Recalling Power Measurements ........................................... 41

Storing Power Measurements Manually.................................................................................41

Recalling Manually Stored Power Measurements ...................................................................42

Erasing Manually Stored Power Measurements......................................................................43

Contents

High-Speed Power Meter iii

Contents

Certification Information......................................................................................................... vi

1 Introducing the PM-1600 High-Speed Power Meter .................................. 1

Front Panel...............................................................................................................................2

Back Panel................................................................................................................................3

RS-232 Connector Pinout .........................................................................................................4

2 Safety Information ....................................................................................... 5

Safety Conventions ..................................................................................................................5

General Safety Information ......................................................................................................6

Laser Safety Information ..........................................................................................................6

Electrical Safety Information ....................................................................................................7

3 Getting Started with Your High-Speed Power Meter ................................. 9

Turning the PM-1600 On and Off.............................................................................................9

Selecting a Menu or a Menu Option ......................................................................................10

Nulling Electrical Offsets ........................................................................................................11

4 Acquiring Power Measurements ............................................................... 13

Setting a Display Mode ..........................................................................................................13

Measuring Absolute Power ....................................................................................................14

Measuring Relative Power ......................................................................................................16

Measuring Corrected Power...................................................................................................19

Displaying Averaged Measurement........................................................................................22

Setting Measurement Range..................................................................................................22

Viewing Statistics...................................................................................................................24

Managing the Wavelength List ..............................................................................................25

Setting a Correction Factor ....................................................................................................30

Setting Display Resolution......................................................................................................32

Setting Refresh Rate...............................................................................................................34

Setting Sampling Rate............................................................................................................35

Choosing a Number of Measurements for Averaging ............................................................36

Saving a Setup Configuration ................................................................................................37

Recalling a Setup Configuration.............................................................................................38

Resetting the PM-1600 ..........................................................................................................39

5 Storing and Recalling Power Measurements ........................................... 41

Storing Power Measurements Manually.................................................................................41

Recalling Manually Stored Power Measurements ...................................................................42

Erasing Manually Stored Power Measurements......................................................................43

Page 6

Contents

iv PM-1600

6 Programming Acquisitions .........................................................................45

Programming Data Acquisitions.............................................................................................45

Programming Timed Acquisitions ..........................................................................................46

Programming Triggered Acquisitions .....................................................................................49

Saving a Program Configuration ............................................................................................53

Recalling a Program Configuration ........................................................................................54

7 Performing Typical Tests with Your PM-1600 ............................................55

Performing Absolute Power Measurements ...........................................................................56

Measuring Insertion Loss .......................................................................................................57

Testing Instrument Linearity ...................................................................................................58

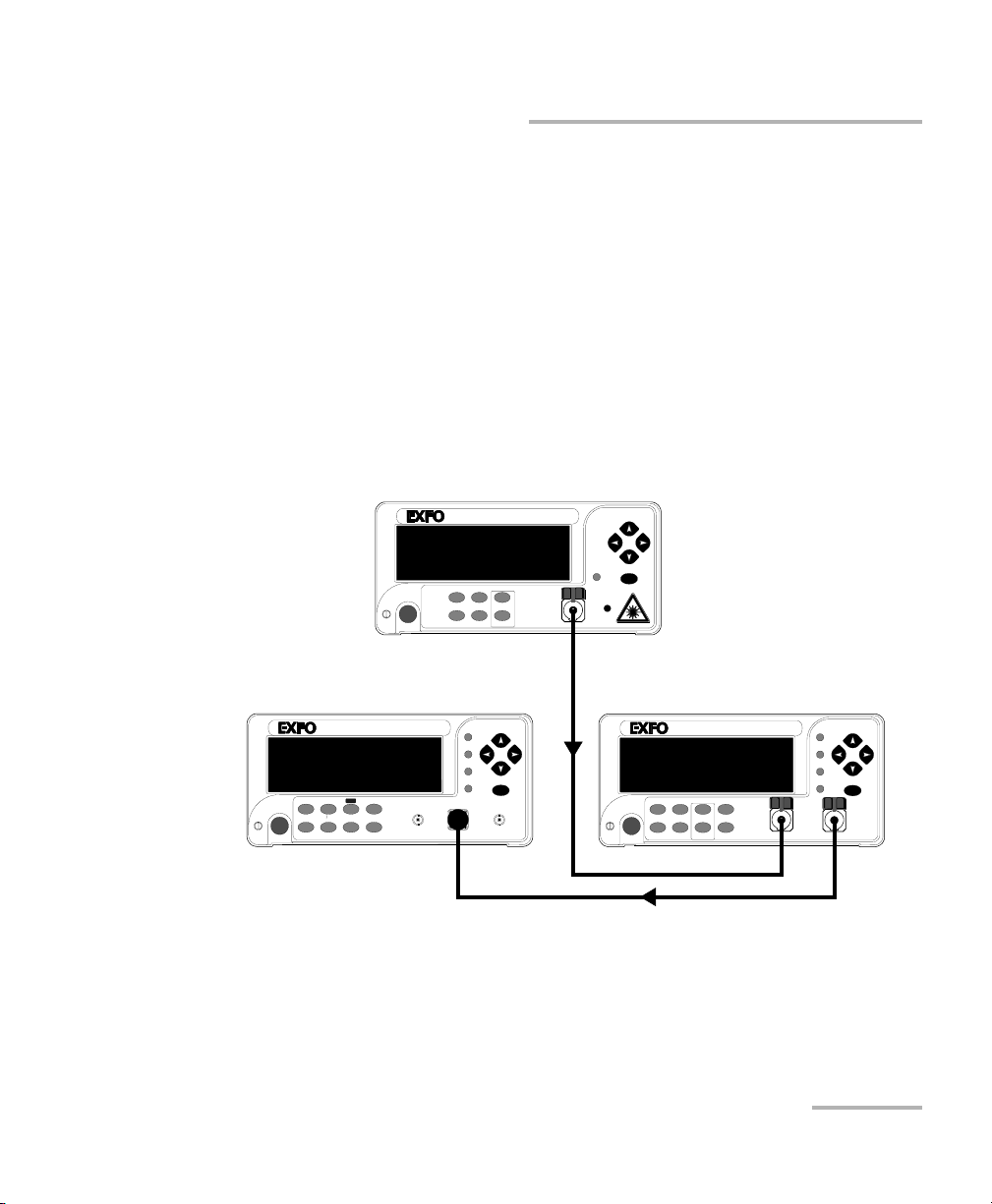

Characterizing an Optical Switch ...........................................................................................60

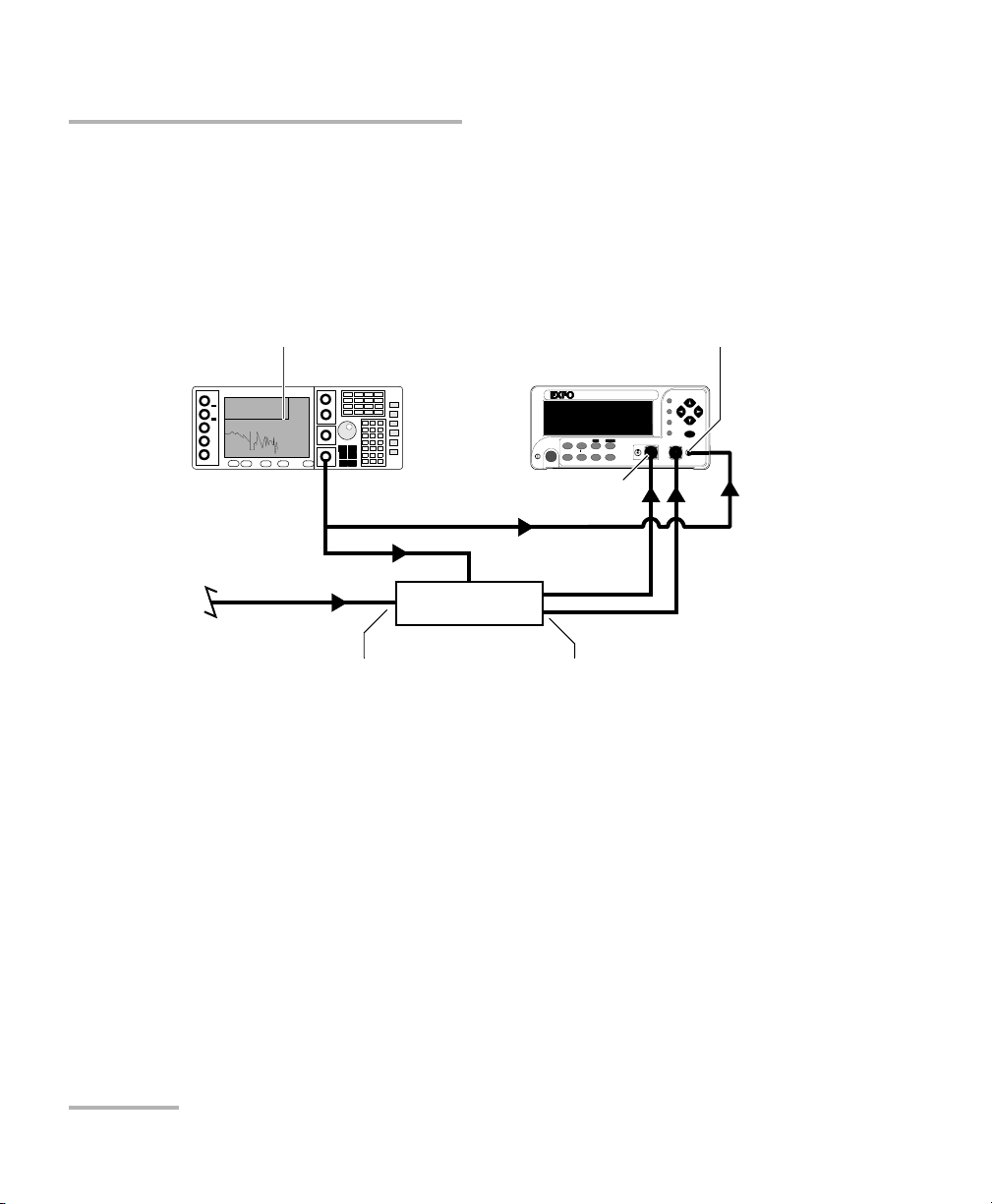

Using the External Trigger ......................................................................................................63

Using the Analog Output.......................................................................................................65

8 Controlling the PM-1600 Automatically or Remotely ...............................67

Setting Up the PM-1600 for Remote Control .........................................................................68

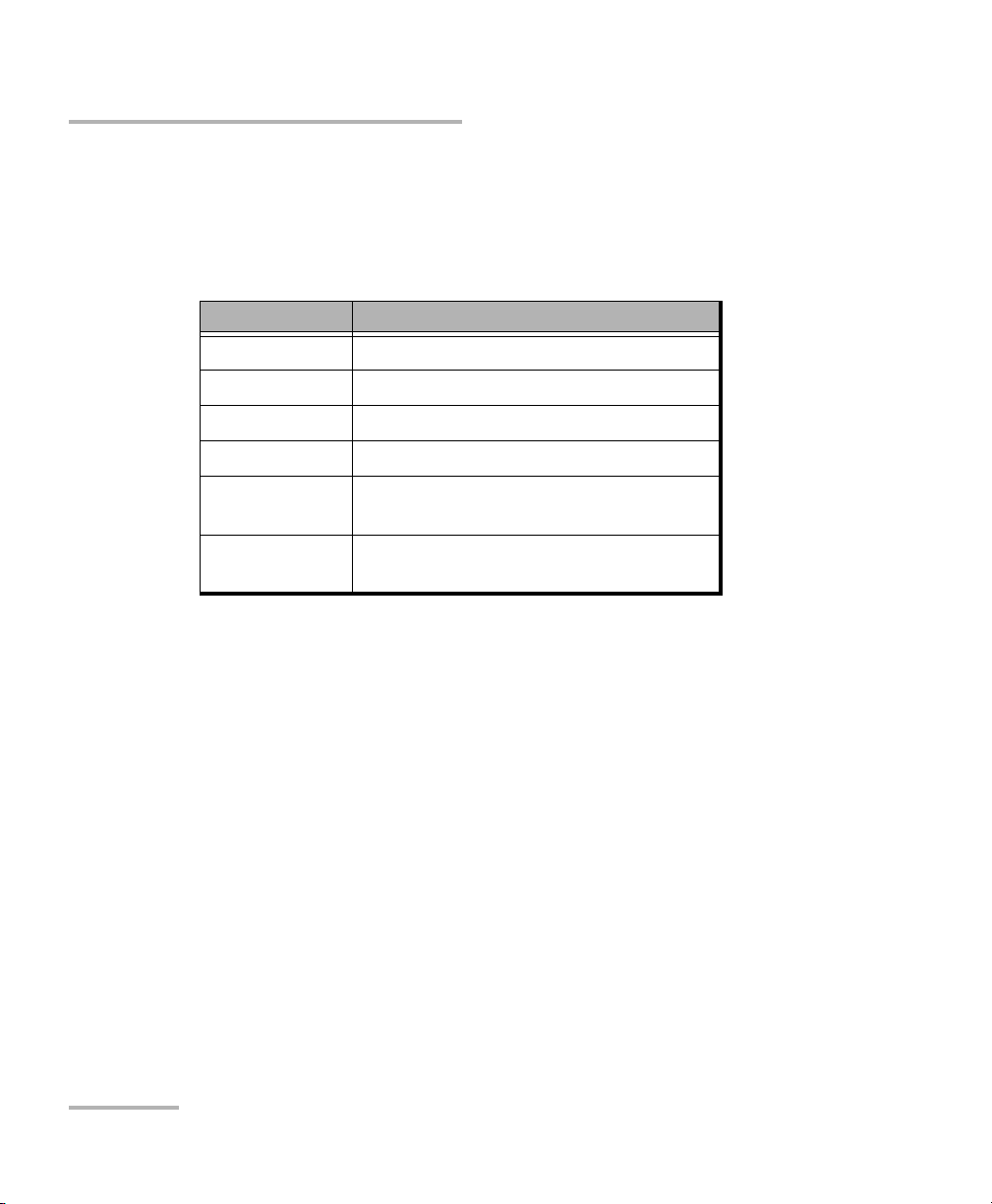

Communication Parameters...................................................................................................69

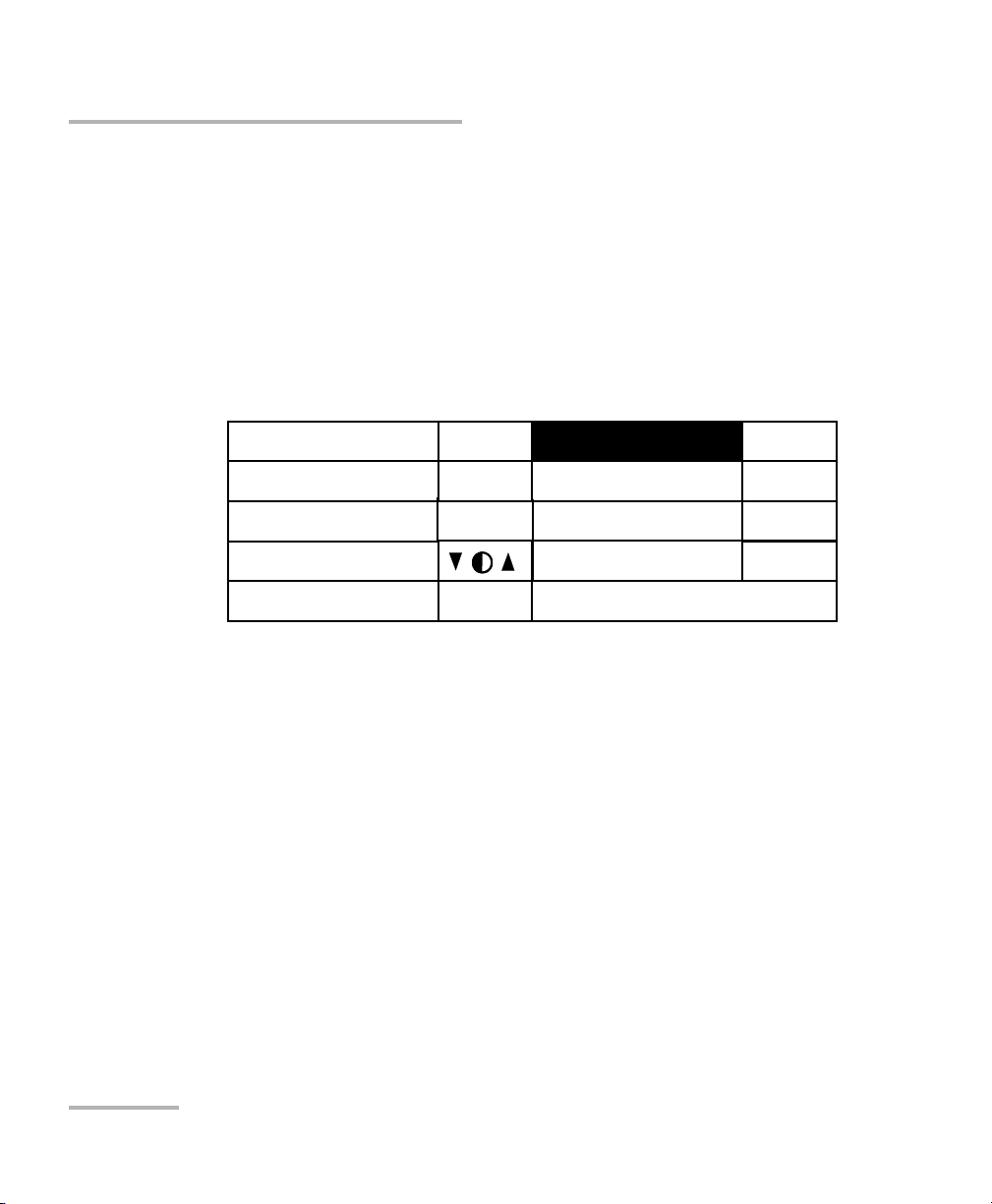

Standard Status Data Structure..............................................................................................70

Command Structure...............................................................................................................72

General Commands—Quick Reference...................................................................................73

Specific Commands—Quick Reference ...................................................................................75

Error Messages.......................................................................................................................80

SCPI Management Errors (System Errors) ...............................................................................81

PM-1600 Error Messages .......................................................................................................82

9 Customizing the PM-1600 Display .............................................................83

Setting Backlight....................................................................................................................83

Setting Display Contrast.........................................................................................................84

Choosing Video Mode............................................................................................................84

10 Maintenance ................................................................................................87

Cleaning the Front Panel........................................................................................................87

Cleaning Fixed Connectors .....................................................................................................88

Cleaning Connectors Equipped with EUI/EUA Adapters .........................................................90

Cleaning EUI/EUA Adapters....................................................................................................92

Cleaning Detector Ports .........................................................................................................94

Cleaning the Analog Output and External Trigger Ports.........................................................95

Replacing the Fuse .................................................................................................................96

Recalibrating the Unit ............................................................................................................97

Software Upgrade..................................................................................................................97

Contents

iv PM-1600

6 Programming Acquisitions .........................................................................45

Programming Data Acquisitions.............................................................................................45

Programming Timed Acquisitions ..........................................................................................46

Programming Triggered Acquisitions .....................................................................................49

Saving a Program Configuration ............................................................................................53

Recalling a Program Configuration ........................................................................................54

7 Performing Typical Tests with Your PM-1600 ............................................55

Performing Absolute Power Measurements ...........................................................................56

Measuring Insertion Loss .......................................................................................................57

Testing Instrument Linearity ...................................................................................................58

Characterizing an Optical Switch ...........................................................................................60

Using the External Trigger ......................................................................................................63

Using the Analog Output.......................................................................................................65

8 Controlling the PM-1600 Automatically or Remotely ...............................67

Setting Up the PM-1600 for Remote Control .........................................................................68

Communication Parameters...................................................................................................69

Standard Status Data Structure..............................................................................................70

Command Structure...............................................................................................................72

General Commands—Quick Reference...................................................................................73

Specific Commands—Quick Reference ...................................................................................75

Error Messages.......................................................................................................................80

SCPI Management Errors (System Errors) ...............................................................................81

PM-1600 Error Messages .......................................................................................................82

9 Customizing the PM-1600 Display .............................................................83

Setting Backlight....................................................................................................................83

Setting Display Contrast.........................................................................................................84

Choosing Video Mode............................................................................................................84

10 Maintenance ................................................................................................87

Cleaning the Front Panel........................................................................................................87

Cleaning Fixed Connectors .....................................................................................................88

Cleaning Connectors Equipped with EUI/EUA Adapters .........................................................90

Cleaning EUI/EUA Adapters....................................................................................................92

Cleaning Detector Ports .........................................................................................................94

Cleaning the Analog Output and External Trigger Ports.........................................................95

Replacing the Fuse .................................................................................................................96

Recalibrating the Unit ............................................................................................................97

Software Upgrade..................................................................................................................97

Page 7

Contents

High-Speed Power Meter v

11 Troubleshooting ....................................................................................... 101

Finding Information on the EXFO Web Site..........................................................................102

Contacting the Technical Support Group .............................................................................103

Transportation......................................................................................................................104

12 Warranty ................................................................................................... 105

General Information.............................................................................................................105

Liability ................................................................................................................................106

Exclusions ............................................................................................................................106

Certification .........................................................................................................................106

Service and Repairs ..............................................................................................................107

EXFO Service Centers Worldwide .........................................................................................108

A Technical Specifications ........................................................................... 109

B Remote Control (SCPI) Commands ......................................................... 111

General Commands..............................................................................................................111

Specific Commands..............................................................................................................118

Index ............................................................................................................... 147

Contents

High-Speed Power Meter v

11 Troubleshooting ....................................................................................... 101

Finding Information on the EXFO Web Site..........................................................................102

Contacting the Technical Support Group .............................................................................103

Transportation......................................................................................................................104

12 Warranty ................................................................................................... 105

General Information.............................................................................................................105

Liability ................................................................................................................................106

Exclusions ............................................................................................................................106

Certification .........................................................................................................................106

Service and Repairs ..............................................................................................................107

EXFO Service Centers Worldwide .........................................................................................108

A Technical Specifications ........................................................................... 109

B Remote Control (SCPI) Commands ......................................................... 111

General Commands..............................................................................................................111

Specific Commands..............................................................................................................118

Index ............................................................................................................... 147

Page 8

Certification Information

vi PM-1600

Certification Information

F.C.C. Information

Electronic test equipment is exempt from Part 15 compliance (FCC) in

the United States, but EXFO makes reasonable efforts to ensure this

compliance.

Information

Electronic test equipment is subject to the EMC Directive in the European

Union. The EN61326 standard prescribes both emission and immunity

requirements for laboratory, measurement, and control equipment.

This unit has been tested and found to comply with the limits for a Class A

digital device. Please refer to the Declaration of Conformity.

CSA Information

This unit received CSA certification under the model name “GO”. The CSA

Certificate Number is 162451. The “C-US” indicator adjacent to the CSA

Mark signifies that the product has been evaluated to the applicable

ANSI/UL and CSA Standards, for use in the United States and Canada.

Independent Laboratory Testing

This unit has undergone extensive testing according to the European Union

Directive and Standards. All pre-qualification tests were performed

internally, at EXFO, while all final tests were performed externally, at an

independent, accredited laboratory. This guarantees the unerring

objectivity and authoritative compliance of all test results.

➤ Use of shielded remote I/O cables, with properly grounded shields and

metal connectors, is recommended in order to reduce radio frequency

interference that may emanate from these cables.

Certification Information

vi PM-1600

Certification Information

F.C.C. Information

Electronic test equipment is exempt from Part 15 compliance (FCC) in

the United States, but EXFO makes reasonable efforts to ensure this

compliance.

Information

Electronic test equipment is subject to the EMC Directive in the European

Union. The EN61326 standard prescribes both emission and immunity

requirements for laboratory, measurement, and control equipment.

This unit has been tested and found to comply with the limits for a Class A

digital device. Please refer to the Declaration of Conformity.

CSA Information

This unit received CSA certification under the model name “GO”. The CSA

Certificate Number is 162451. The “C-US” indicator adjacent to the CSA

Mark signifies that the product has been evaluated to the applicable

ANSI/UL and CSA Standards, for use in the United States and Canada.

Independent Laboratory Testing

This unit has undergone extensive testing according to the European Union

Directive and Standards. All pre-qualification tests were performed

internally, at EXFO, while all final tests were performed externally, at an

independent, accredited laboratory. This guarantees the unerring

objectivity and authoritative compliance of all test results.

➤ Use of shielded remote I/O cables, with properly grounded shields and

metal connectors, is recommended in order to reduce radio frequency

interference that may emanate from these cables.

Page 9

Certification Information

High-Speed Power Meter vii

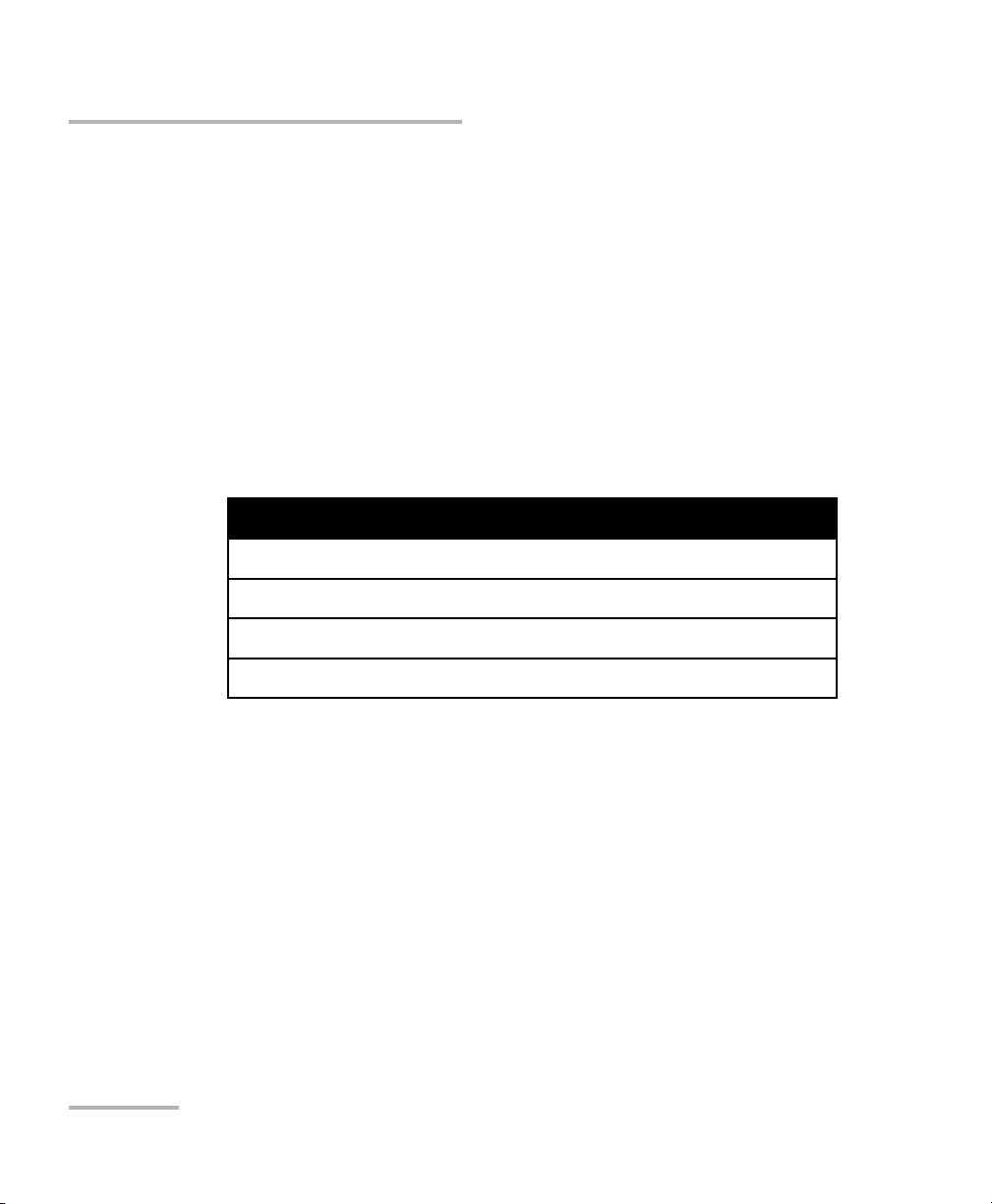

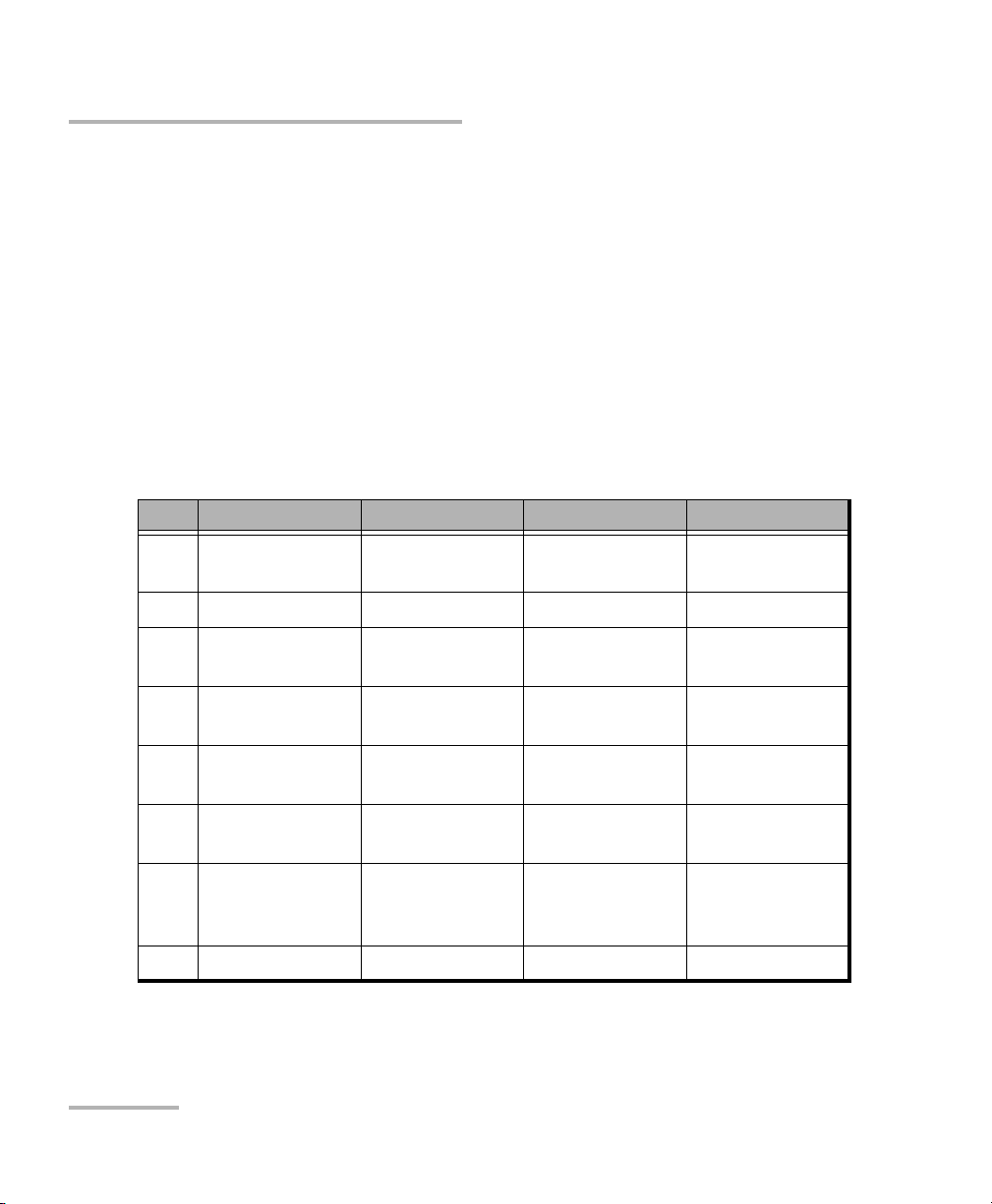

Application of Council Directive(s): 73/23/EEC - The Low Voltage Directive

89/336/EEC - The EMC Directive

Manufacturer’s Name: EXFO ELECTRO-OPTICAL ENG.

Manufacturer’s Address: 465 Godin Avenue

Vanier, Quebec

Canada G1M 3G7

(418) 683-0211

Equipment Type/Environment: Industrial Scientific Equipment

Trade Name/Model No.: PM-1600 High-Speed Power Meter

Year of Conformity Assessment: 2001

Stan dard(s) to whic h Conformi ty is Dec lared:

EN 61010-1:1993/

A2:1995

Safety Requi remen ts f or Elec trica l Eq uipm ent for Meas ureme nt, Cont rol, and

Laboratory Us e, P art 1: Ge neral Req uirem ents.

EN 55022:1994/

A2:1997

Limi ts an d Met hods of Me asurem ent o f Rad io Di sturbance Charac terist ics o f

Information Technology Equipment.

EN 50082-1:1997 Gen eric Immunit y fo r Re side ntial, Commer cial , an d Li ght Indu strial Environment

I, the undersigned, hereby declare that the equipment specified above conforms to the above Directive and Standards.

Man ufac turer

Signature:

Full Name: Stephen Bull, E. Eng

Position: Vice-President Research and

Development

Address: 465 Godin Avenue Vanier, Quebec,

Canada

Date: November 15, 2001

DECLARATION OF CONFORMITY

Certification Information

High-Speed Power Meter vii

Application of Council Directive(s): 73/23/EEC - The Low Voltage Directive

89/336/EEC - The EMC Directive

Manufacturer’s Name: EXFO ELECTRO-OPTICAL ENG.

Manufacturer’s Address: 465 Godin Avenue

Vanier, Quebec

Canada G1M 3G7

(418) 683-0211

Equipment Type/Environment: Industrial Scientific Equipment

Trade Name/Model No.: PM-1600 High-Speed Power Meter

Year of Conformity Assessment: 2001

Stan dard(s) to whic h Conformi ty is Dec lared:

EN 61010-1:1993/

A2:1995

Safety Requi remen ts f or Elec trica l Eq uipm ent for Meas ureme nt, Cont rol, and

Laboratory Us e, P art 1: Ge neral Req uirem ents.

EN 55022:1994/

A2:1997

Limi ts an d Met hods of Me asurem ent o f Rad io Di sturbance Charac terist ics o f

Information Technology Equipment.

EN 50082-1:1997 Gen eric Immunit y fo r Re side ntial, Commer cial , an d Li ght Indu strial Environment

I, the undersigned, hereby declare that the equipment specified above conforms to the above Directive and Standards.

Man ufac turer

Signature:

Full Name: Stephen Bull, E. Eng

Position: Vice-President Research and

Development

Address: 465 Godin Avenue Vanier, Quebec,

Canada

Date: November 15, 2001

DECLARATION OF CONFORMITY

Page 10

Page 11

High-Speed Power Meter 1

1 Introducing the PM-1600

High-Speed Power Meter

The PM-1600 High-Speed Power meter provides all the performance you

need to increase your testing efficiency. With its high sampling rate and fast

stabilization time, the PM-1600 is ideal for system monitoring and

high-density WDM component characterization and assembly.

The PM-1600 is available with one or two detectors. Each power channel

(detector) is independently controlled (except for the acquisition

frequency) and can achieve a sampling rate of up to 4096 Hz.

Power transitions of up to 95 dB will stabilize within 15 ms. Faster

stabilization time will be achieved with reduced dynamic range.

Stabilization within 1 ms is possible when the gain of the detector

amplification stage is manually locked on a specific scale (“Manual

Range”).

Power measurement acquisitions can be electrically synchronized with the

external trigger input or optically synchronized by programming a power

level threshold.

In addition to the standard, 1 mm InGaAs detector, the PM-1600 power

meter series offers a new detector option, the PM-1600W wide-area

detector. This power meter, equipped with a 3 mm diameter InGaAs

detector, offers excellent repeatability for in-process testing of components

before they are connectorized. Also, this large detector option improves the

stabilization time of the module over the complete dynamic range.

Particularly user-friendly with its state-of-the-art technology display, the

PM-1600 features absolute power (in watts or dBm) and relative power

(dB or W/W) measurements, manual data storage, and programmed data

acquisition. The PM-1600 is particularly suited for the most demanding

laboratory, qualification, and manufacturing applications. It can be

remotely controlled through a GPIB or RS-232 interface.

High-Speed Power Meter 1

1 Introducing the PM-1600

High-Speed Power Meter

The PM-1600 High-Speed Power meter provides all the performance you

need to increase your testing efficiency. With its high sampling rate and fast

stabilization time, the PM-1600 is ideal for system monitoring and

high-density WDM component characterization and assembly.

The PM-1600 is available with one or two detectors. Each power channel

(detector) is independently controlled (except for the acquisition

frequency) and can achieve a sampling rate of up to 4096 Hz.

Power transitions of up to 95 dB will stabilize within 15 ms. Faster

stabilization time will be achieved with reduced dynamic range.

Stabilization within 1 ms is possible when the gain of the detector

amplification stage is manually locked on a specific scale (“Manual

Range”).

Power measurement acquisitions can be electrically synchronized with the

external trigger input or optically synchronized by programming a power

level threshold.

In addition to the standard, 1 mm InGaAs detector, the PM-1600 power

meter series offers a new detector option, the PM-1600W wide-area

detector. This power meter, equipped with a 3 mm diameter InGaAs

detector, offers excellent repeatability for in-process testing of components

before they are connectorized. Also, this large detector option improves the

stabilization time of the module over the complete dynamic range.

Particularly user-friendly with its state-of-the-art technology display, the

PM-1600 features absolute power (in watts or dBm) and relative power

(dB or W/W) measurements, manual data storage, and programmed data

acquisition. The PM-1600 is particularly suited for the most demanding

laboratory, qualification, and manufacturing applications. It can be

remotely controlled through a GPIB or RS-232 interface.

Page 12

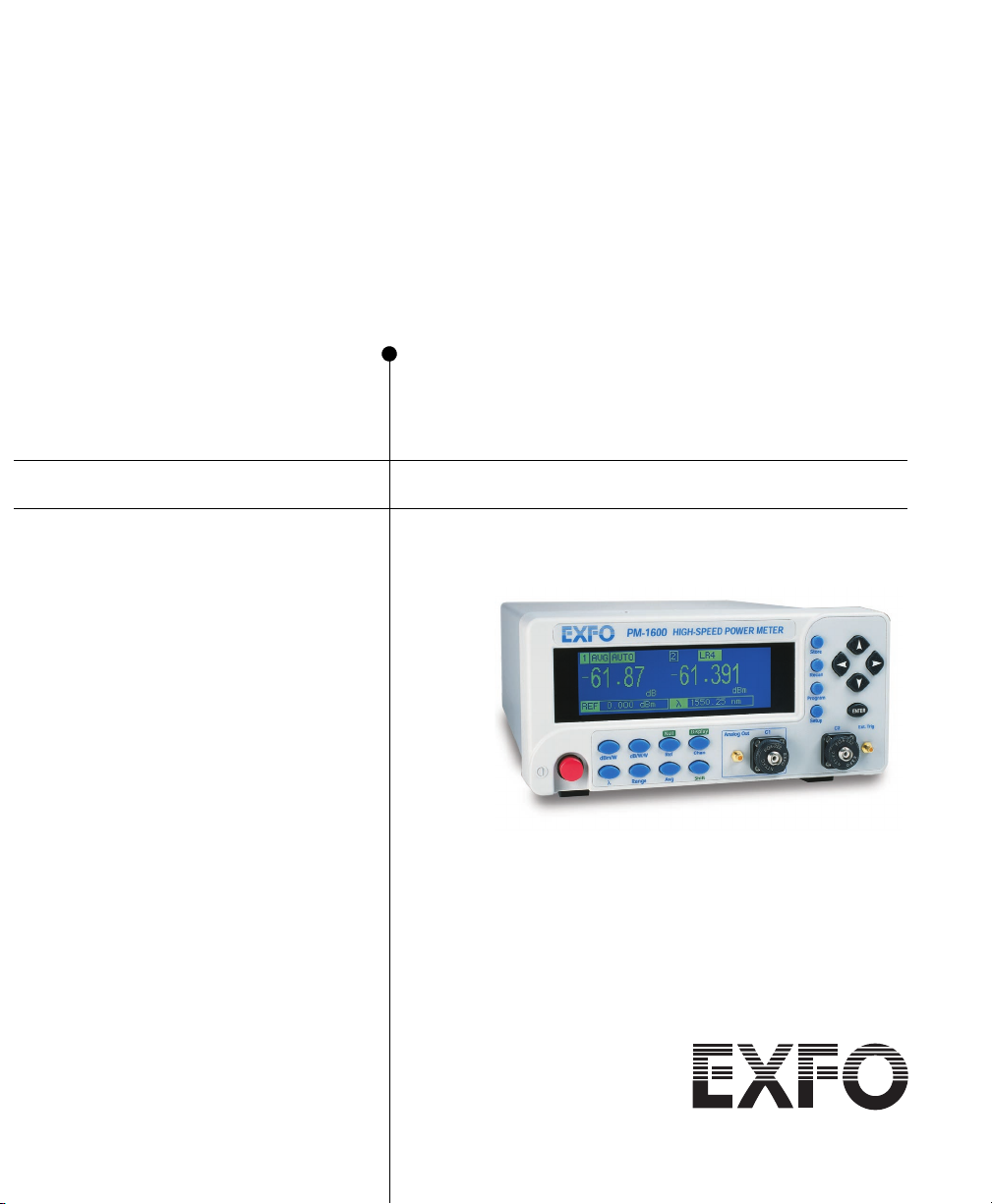

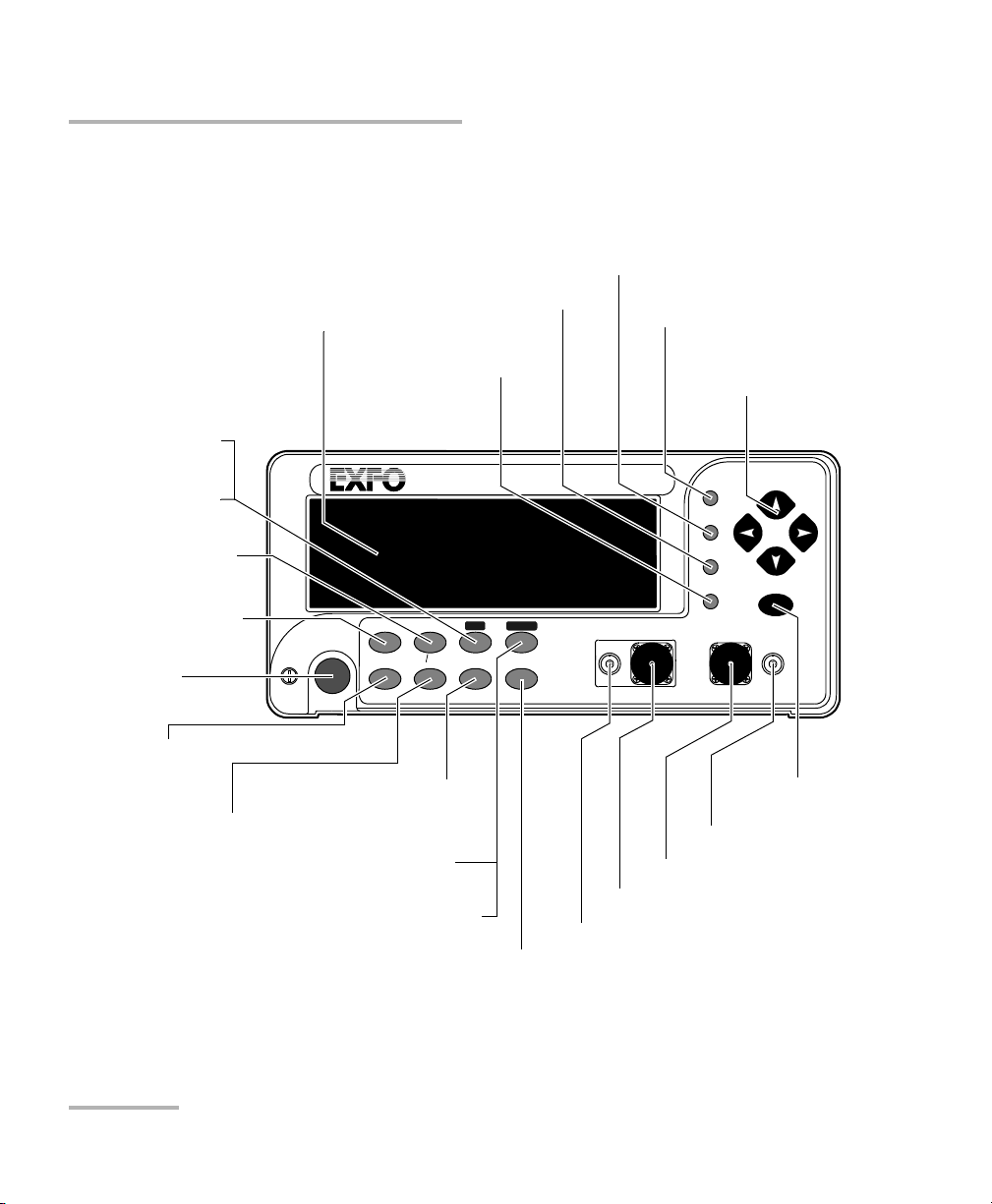

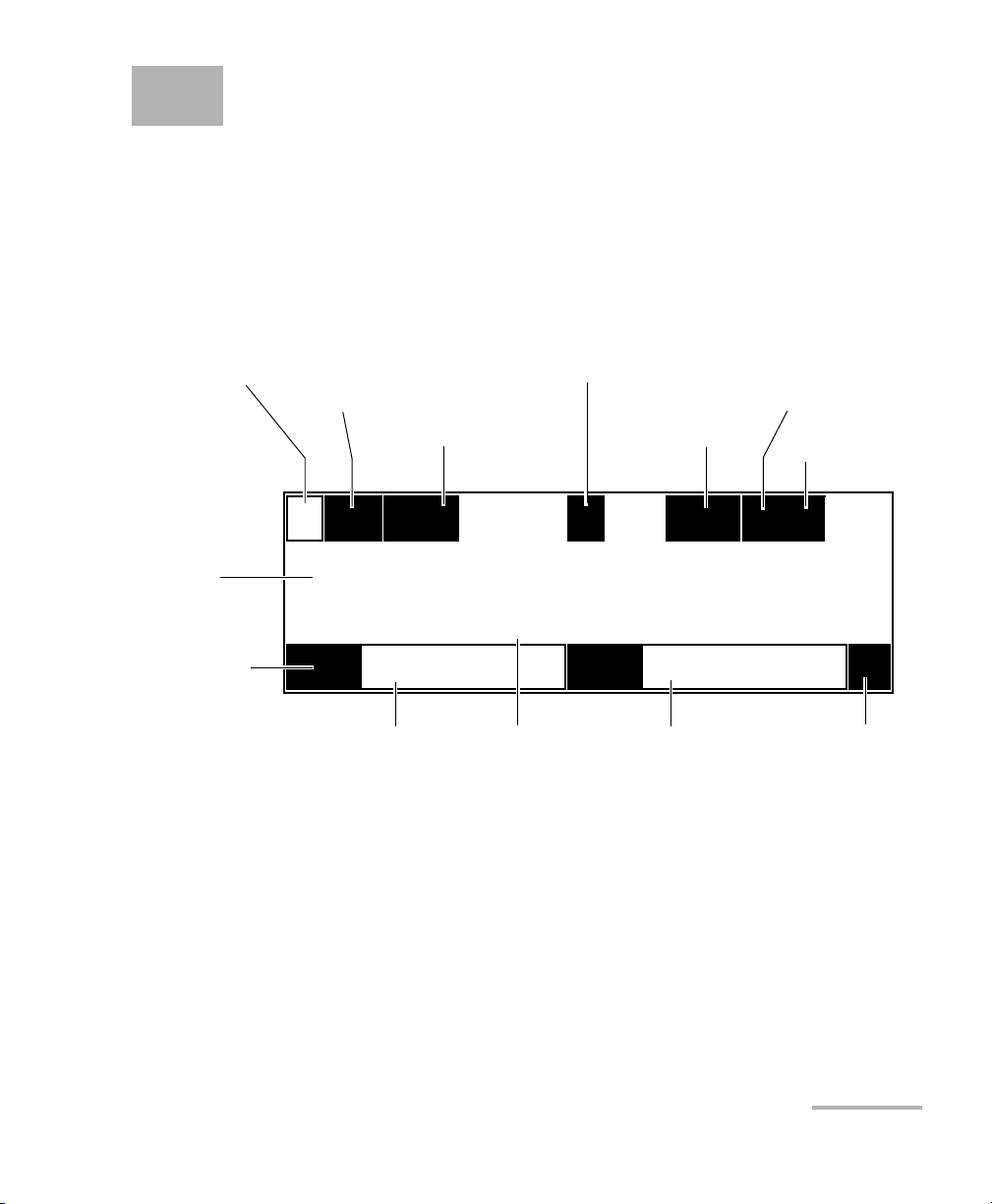

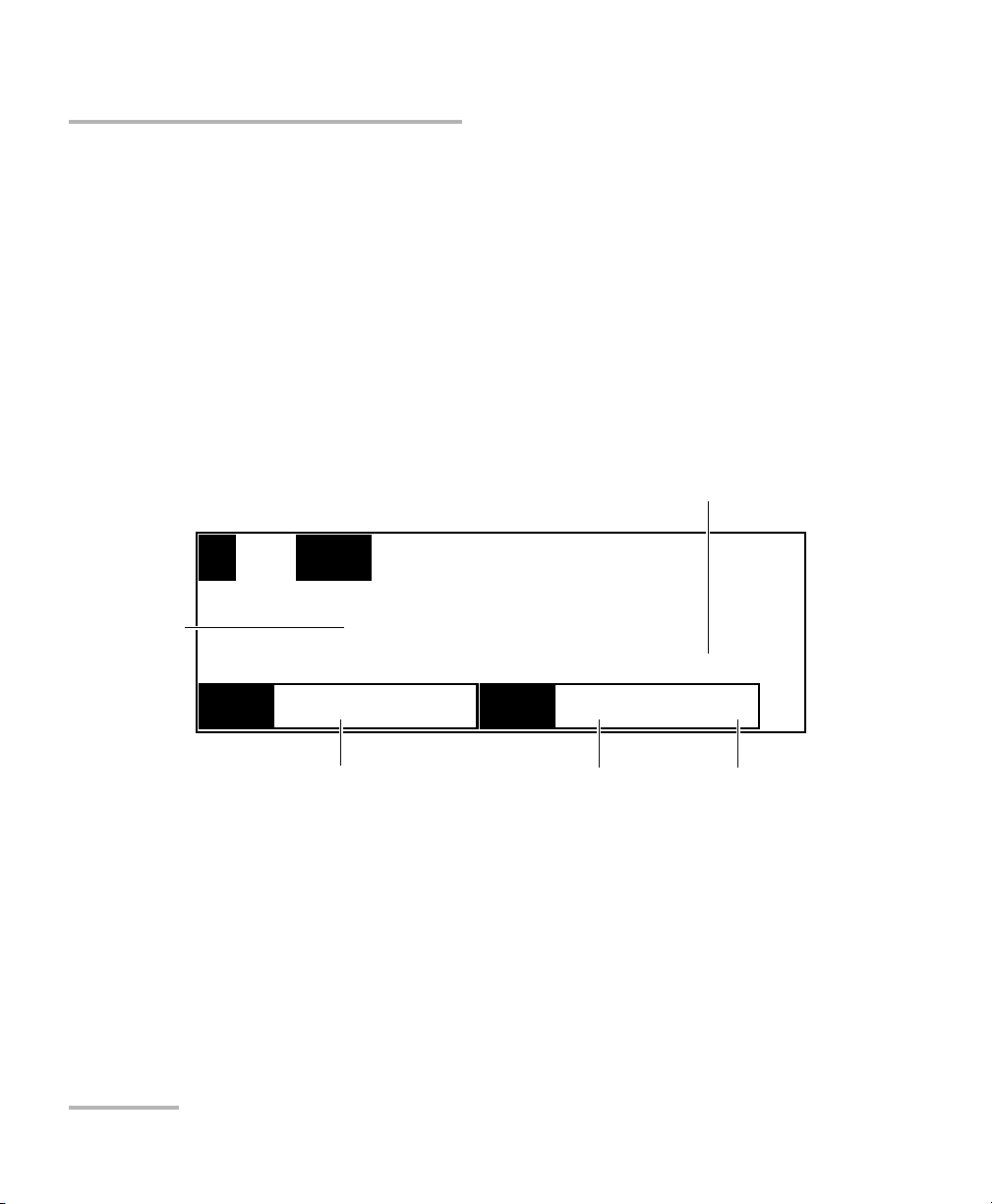

Introducing the PM-1600 High-Speed Power Meter

2 PM-1600

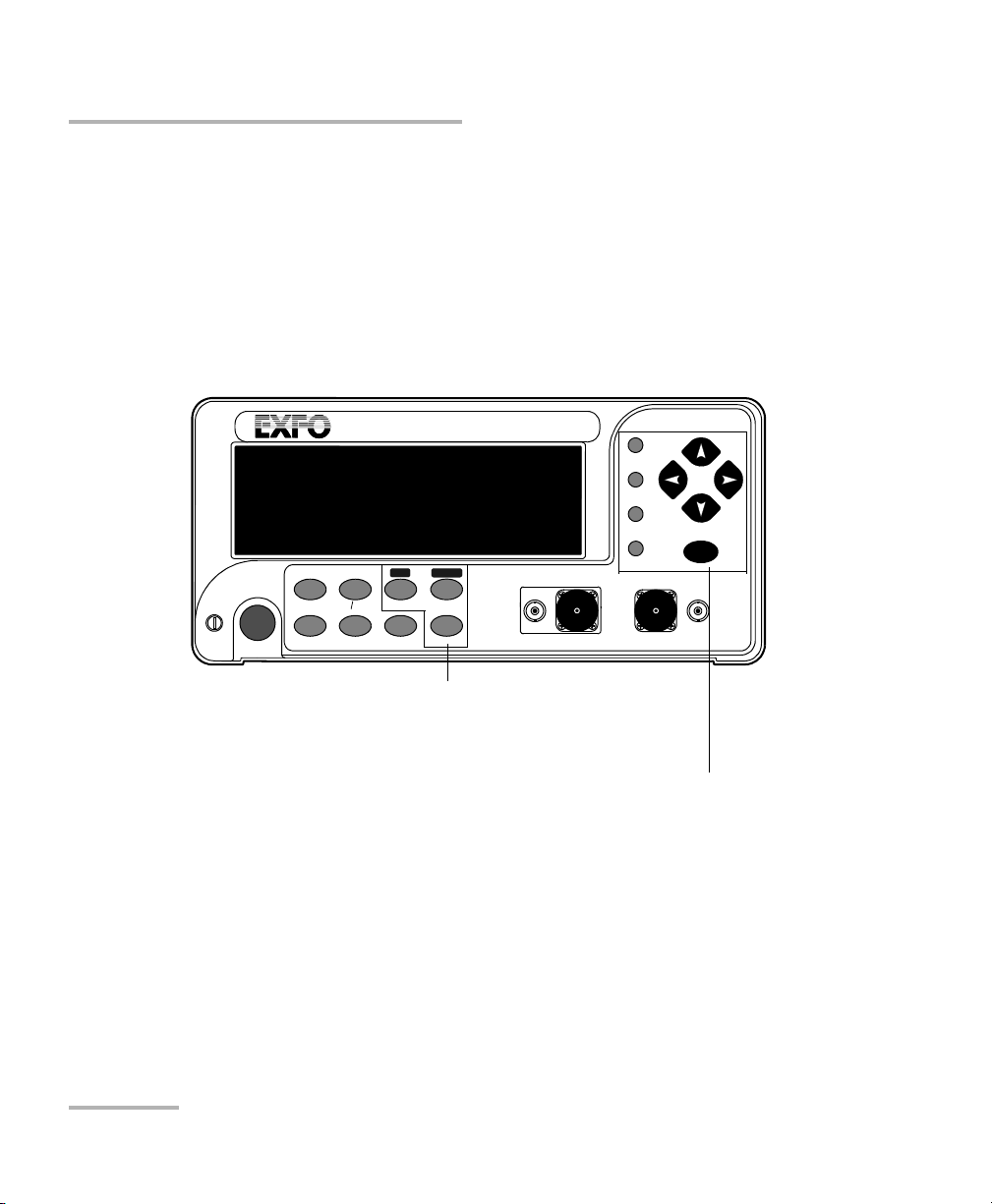

Front Panel

Front Panel

Note: Your PM-1600 may slightly differ from the above illustration.

HIGH-SPEED POWER METER

PM-1600

dB W/W

ENTER

dBm/W Ref

Null

Chan

Range

λ

Avg Shift

Store

Recall

Program

Setup

Analog Out

C1 C2

Ext. Trig

Display

Channel #2 detector port

Relative mode control

see page 16

Power range control

see page 22

Store menu access

see page 41

Confirmation

button

Absolute mode control

see page 14

Average mode control

see page 22

Wavelength control

see page 11

Arrow buttons for

menu navigation and

parameter settings

Recall menu access

see page 42

Program menu access

see page 46

Setup menu access

see page 18

External trigger port

Secondary function control

Channel #1 detector port

Analog output port

On/off button

Display

Channel control (PM-1620)

see page 13

Display mode control

see page 13

Offset nulling control

see page 11

Reference control

see page 16

Introducing the PM-1600 High-Speed Power Meter

2 PM-1600

Front Panel

Front Panel

Note: Your PM-1600 may slightly differ from the above illustration.

HIGH-SPEED POWER METER

PM-1600

dB W/W

ENTER

dBm/W Ref

Null

Chan

Range

λ

Avg Shift

Store

Recall

Program

Setup

Analog Out

C1 C2

Ext. Trig

Display

Channel #2 detector port

Relative mode control

see page 16

Power range control

see page 22

Store menu access

see page 41

Confirmation

button

Absolute mode control

see page 14

Average mode control

see page 22

Wavelength control

see page 11

Arrow buttons for

menu navigation and

parameter settings

Recall menu access

see page 42

Program menu access

see page 46

Setup menu access

see page 18

External trigger port

Secondary function control

Channel #1 detector port

Analog output port

On/off button

Display

Channel control (PM-1620)

see page 13

Display mode control

see page 13

Offset nulling control

see page 11

Reference control

see page 16

Page 13

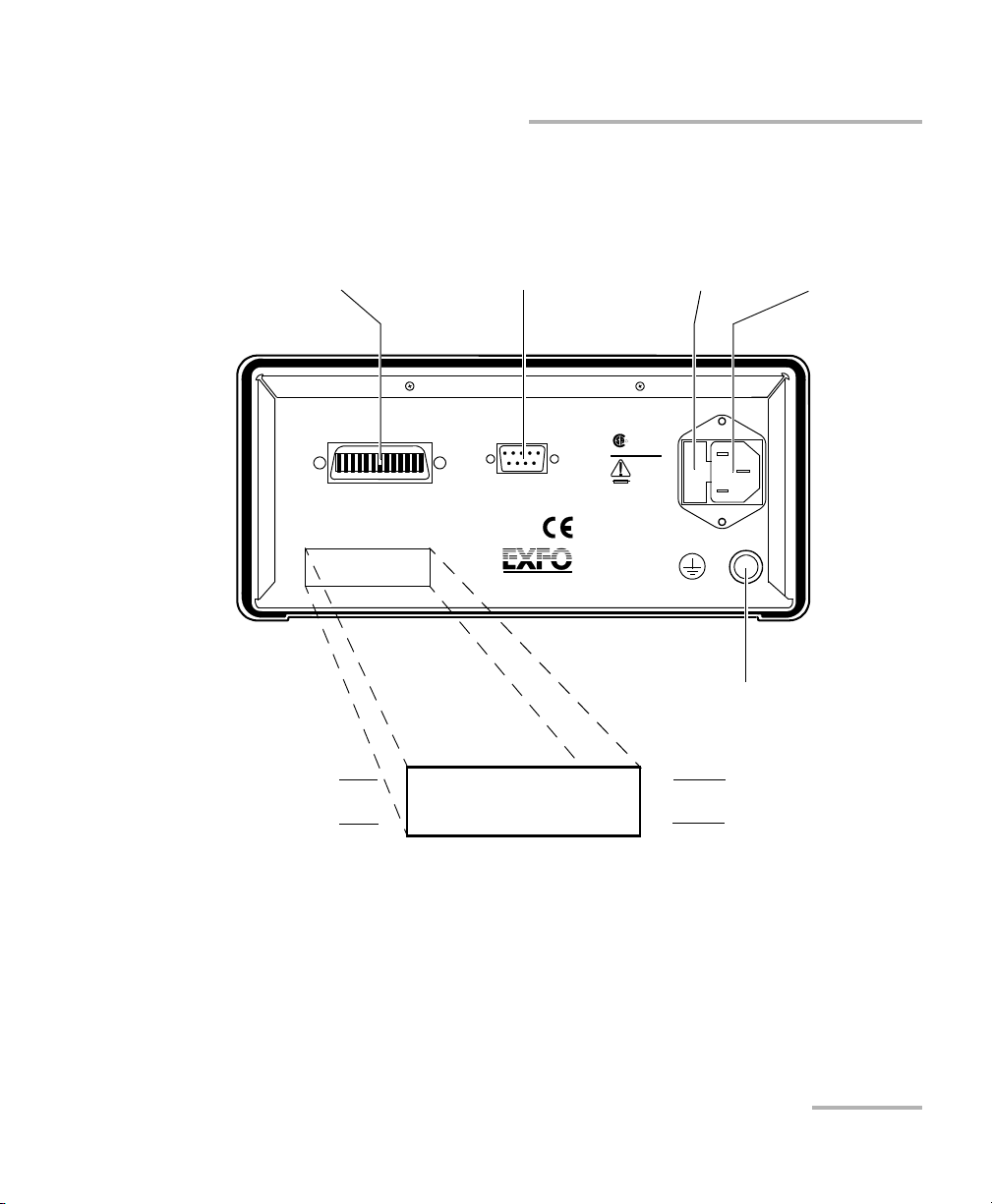

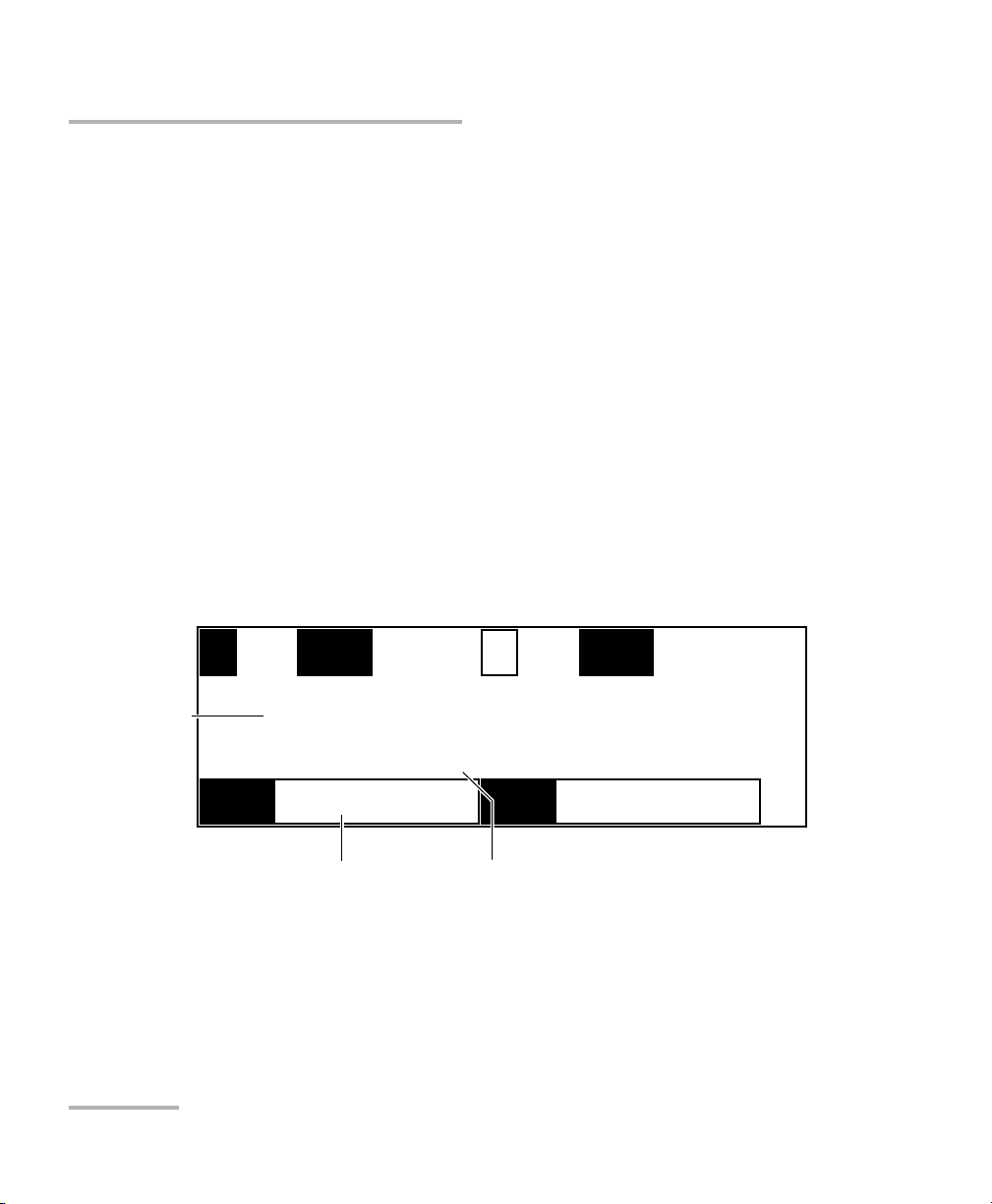

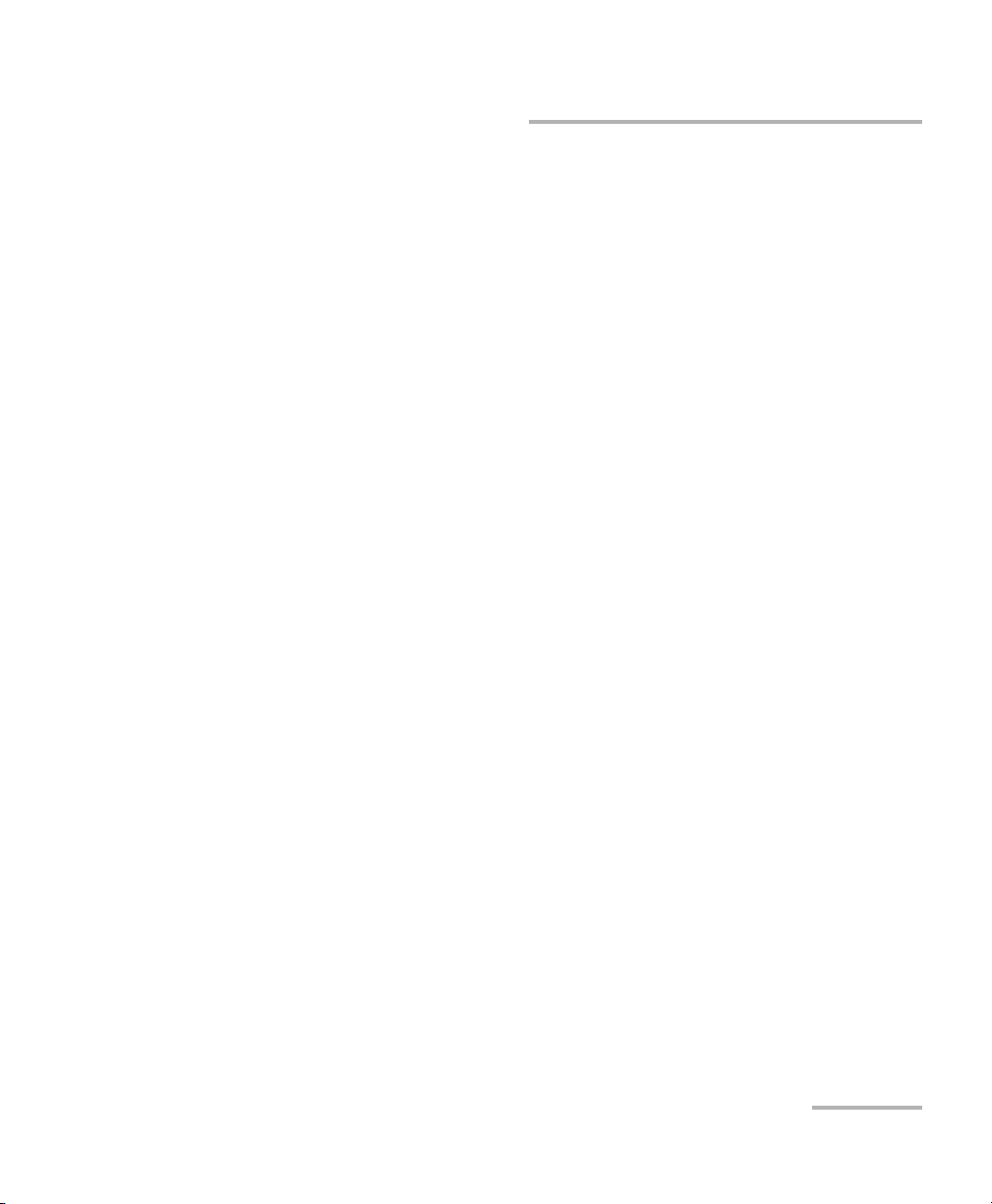

Introducing the PM-1600 High-Speed Power Meter

High-Speed Power Meter 3

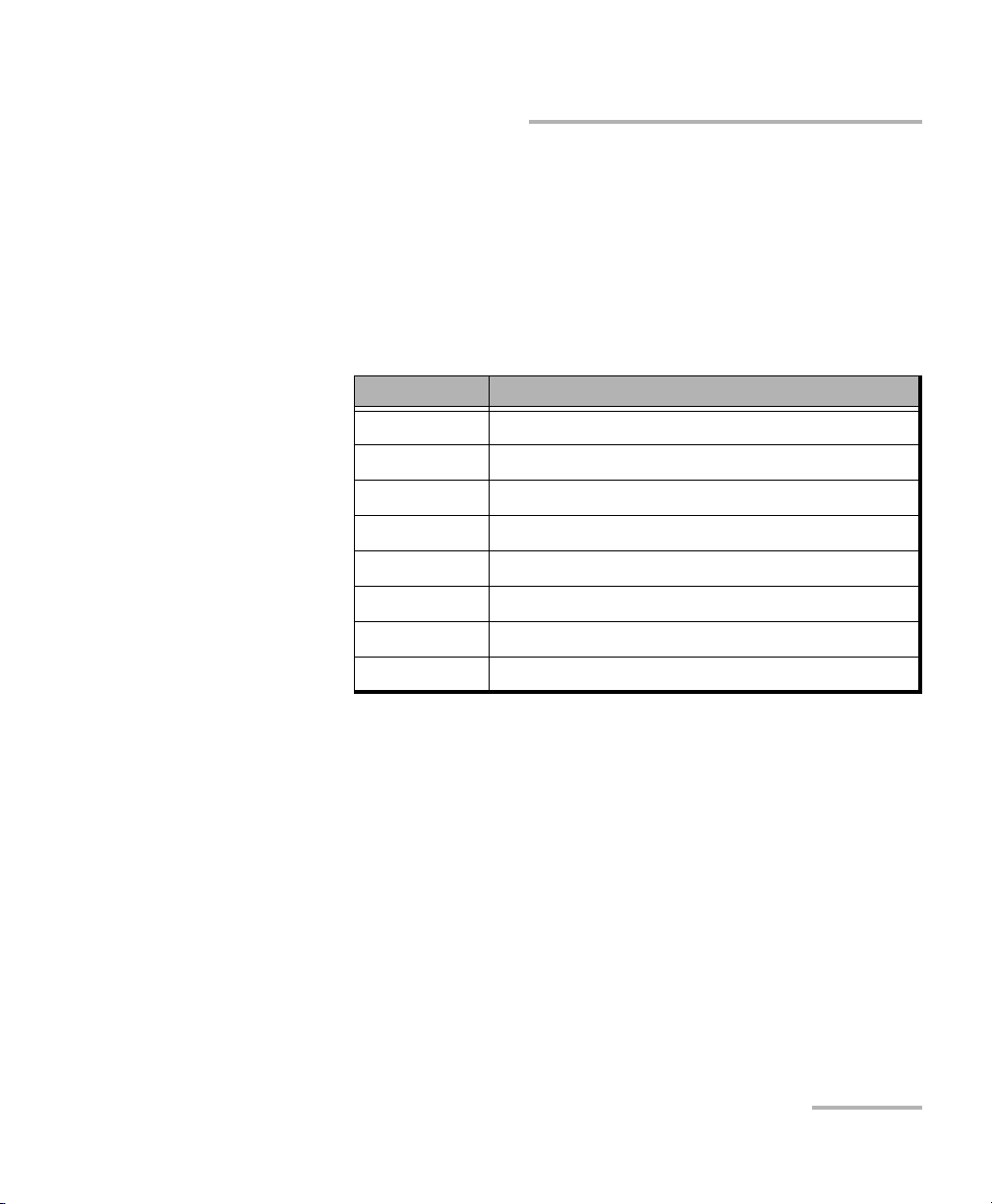

Back Panel

Back Panel

Note: Your PM-1600 may slightly differ from the above illustration.

Ver.

Serial port (RS-232 DTE)

see page 4

Fuse holder

see page 96

Power inlet

see page 8

GPIB port

see page 67

Electro-Optical Engineering

465 Godin Ave.

Vanier, Que., Canada G1M 3G7

R

GPIB IEEE 488.2

SH1, AH1, T6, L4, SR1, RL1, PP0, DC1, DT1, C0, E2

This device complies with part 15 of the FCC rules. Operation is

subject to the following two conditions: (1) this device may not cause

harmful interference and (2) this devic e must accept any interference

received, including interference that may cause undesired operation.

Made in Canada

P/N

S/N

Ver.

Mfg.

date

QST-151E

Serial Port

MODEL: GO

LR107723

100-240 V

50/60 Hz

2 A

F2AL250 V

Ground

PM-1623

12345-AB

A-2.0

November 2001

CUS

P/N

S/N

Mfg.

date

Part number

Serial number

Version number

Manufacturing

Introducing the PM-1600 High-Speed Power Meter

High-Speed Power Meter 3

Back Panel

Back Panel

Note: Your PM-1600 may slightly differ from the above illustration.

Ver.

Serial port (RS-232 DTE)

see page 4

Fuse holder

see page 96

Power inlet

see page 8

GPIB port

see page 67

Electro-Optical Engineering

465 Godin Ave.

Vanier, Que., Canada G1M 3G7

R

GPIB IEEE 488.2

SH1, AH1, T6, L4, SR1, RL1, PP0, DC1, DT1, C0, E2

This device complies with part 15 of the FCC rules. Operation is

subject to the following two conditions: (1) this device may not cause

harmful interference and (2) this devic e must accept any interference

received, including interference that may cause undesired operation.

Made in Canada

P/N

S/N

Ver.

Mfg.

date

QST-151E

Serial Port

MODEL: GO

LR107723

100-240 V

50/60 Hz

2 A

F2AL250 V

Ground

PM-1623

12345-AB

A-2.0

November 2001

CUS

P/N

S/N

Mfg.

date

Part number

Serial number

Version number

Manufacturing

Page 14

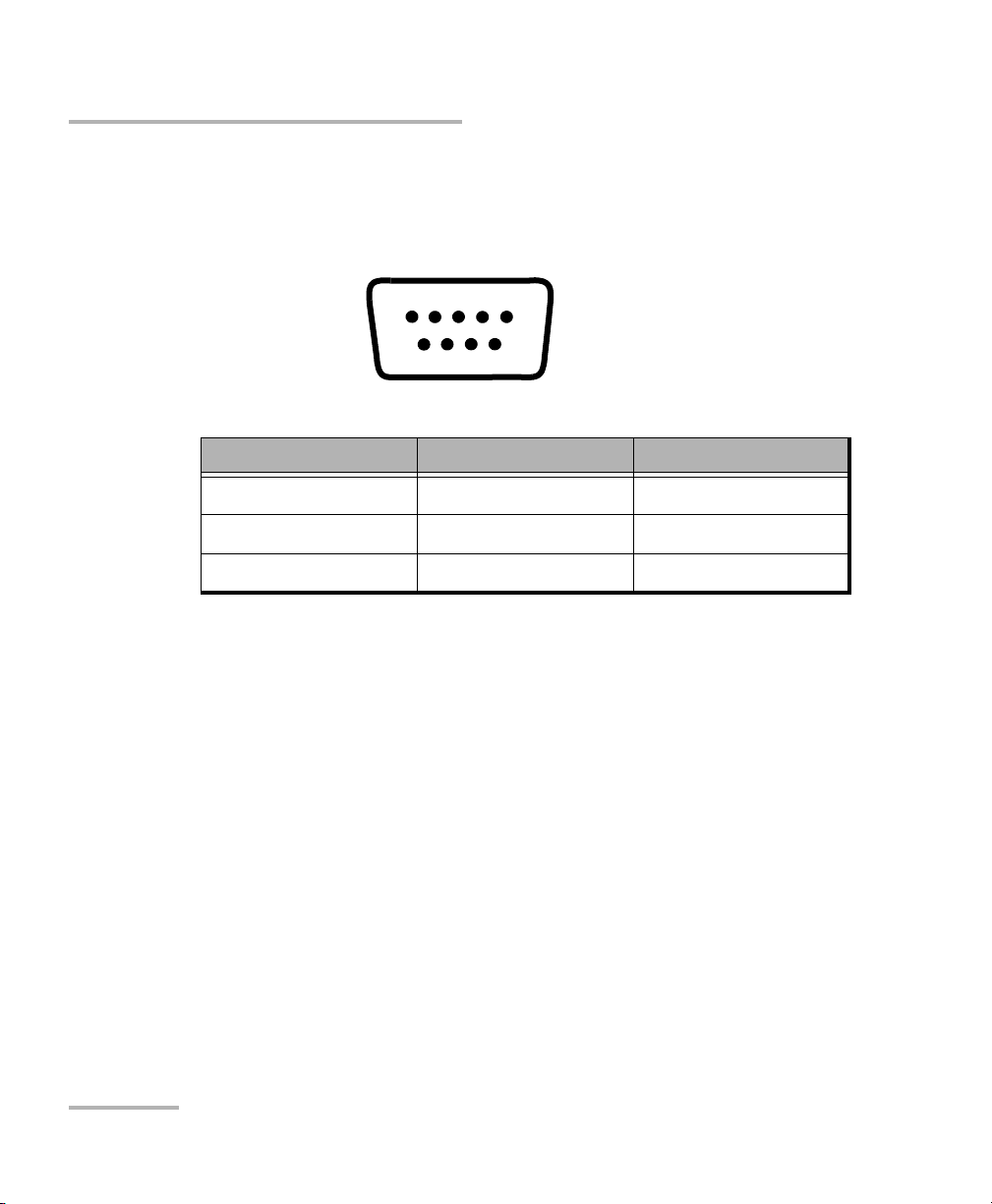

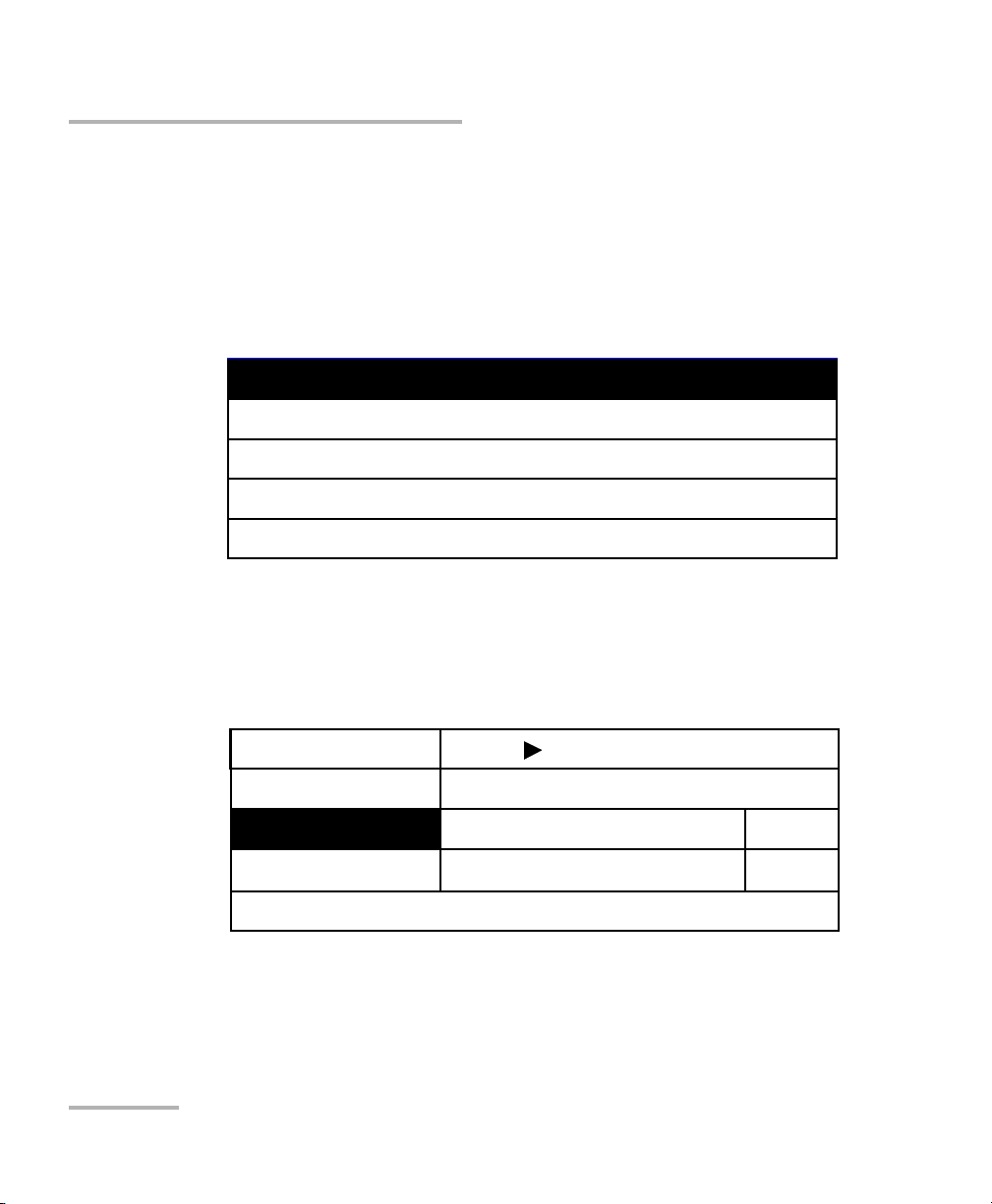

Introducing the PM-1600 High-Speed Power Meter

4 PM-1600

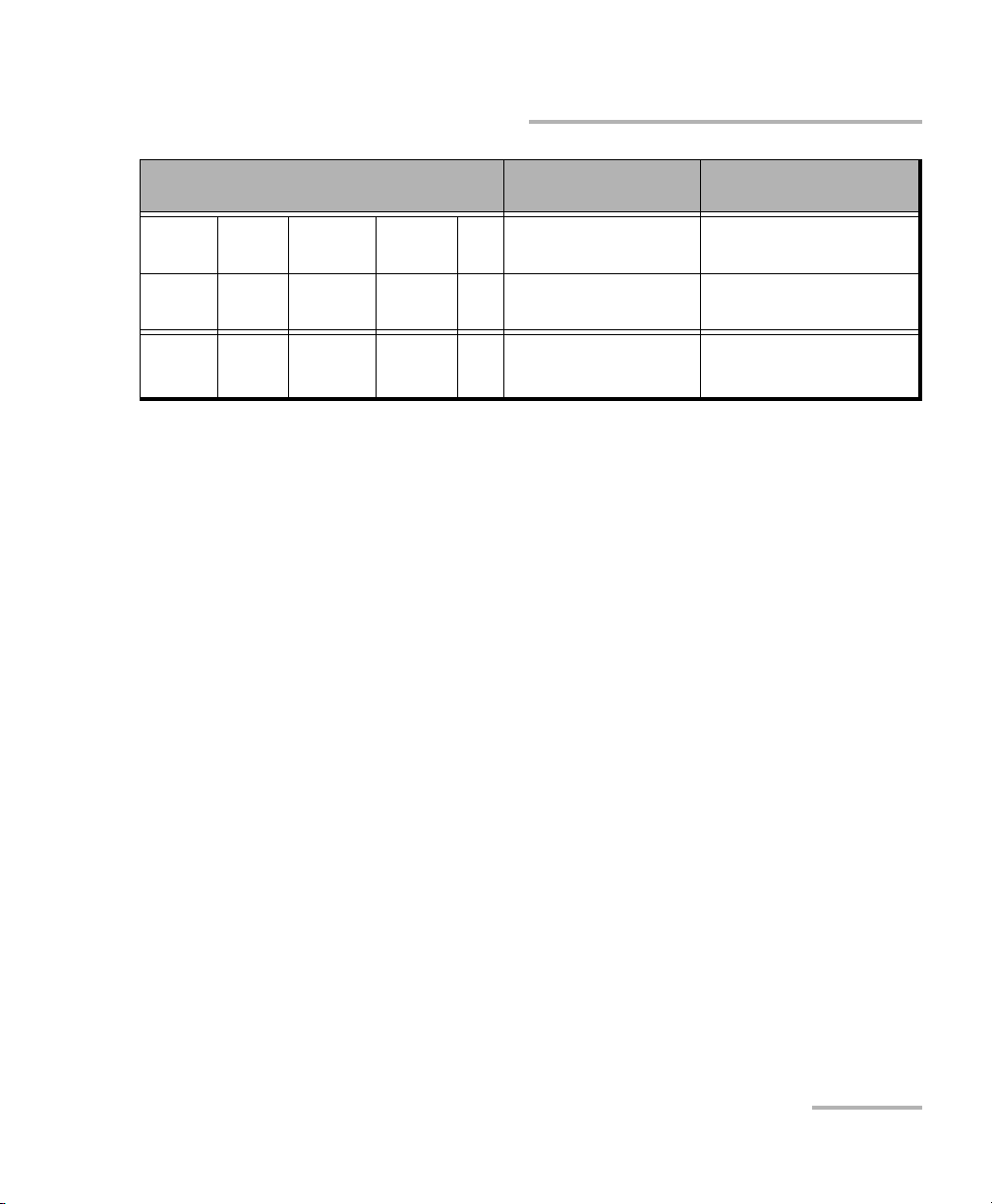

RS-232 Connector Pinout

RS-232 Connector Pinout

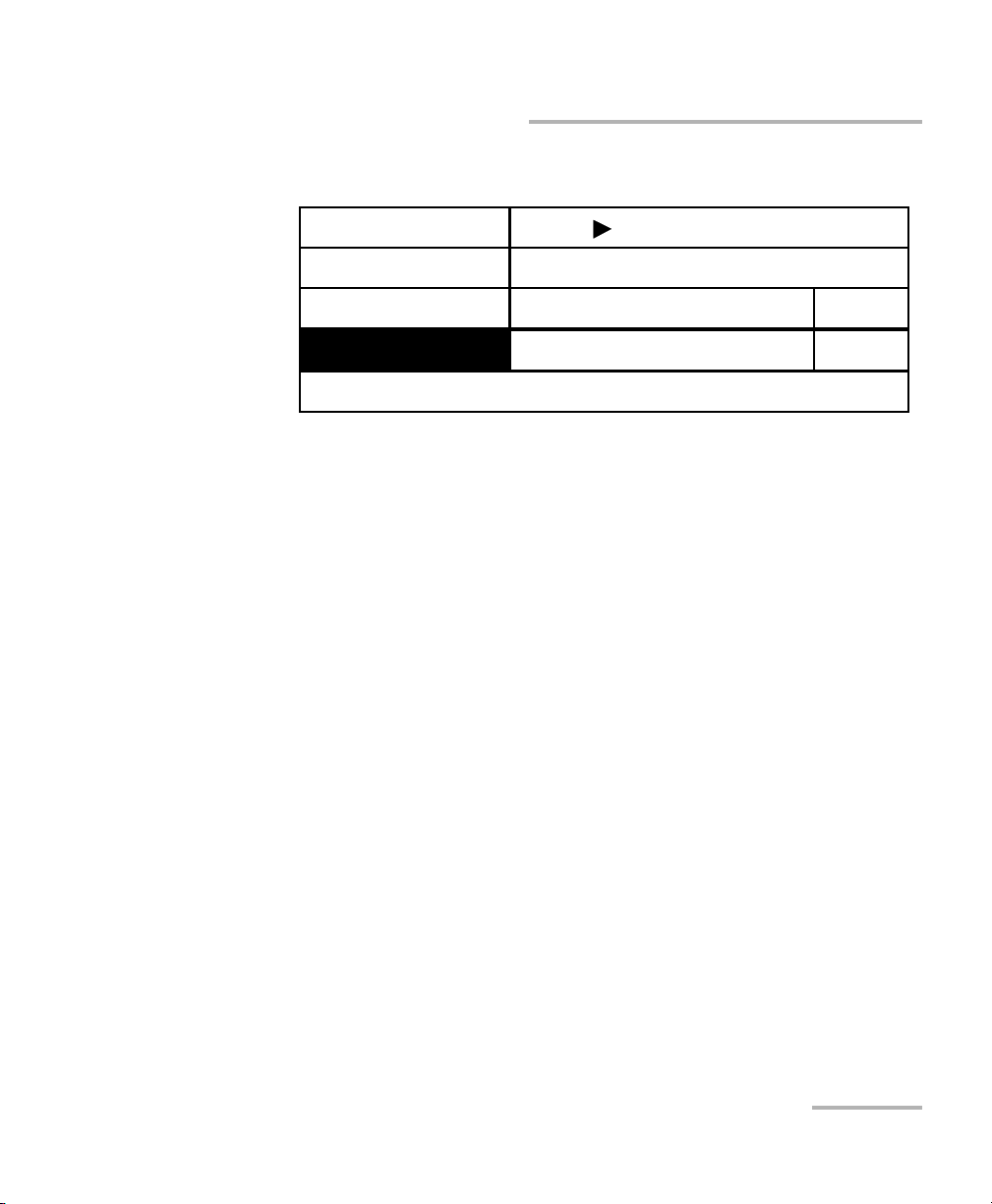

The RS-232 connector (serial port) at the back of the PM-1600 uses a DTE

pinout configuration.

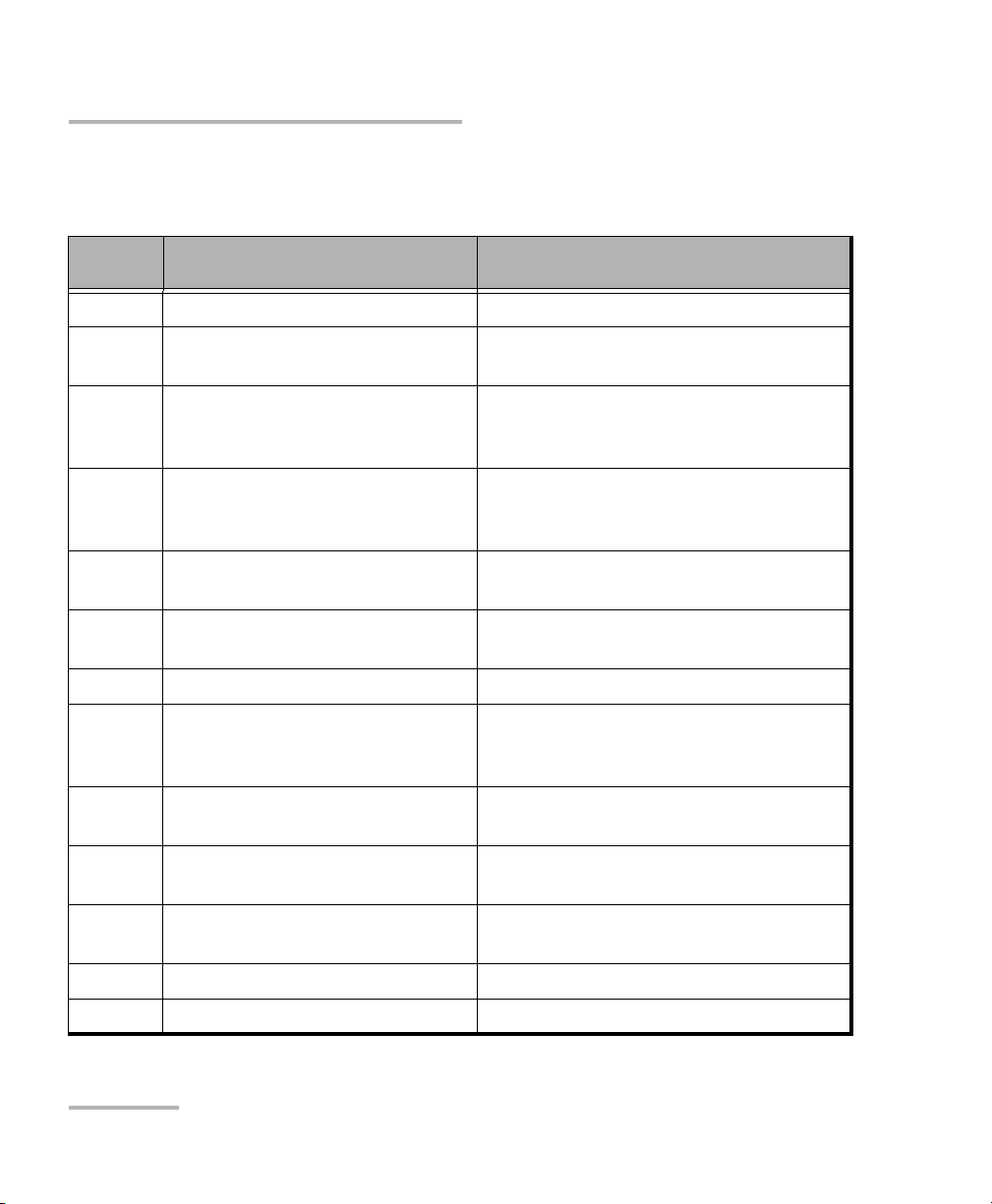

Pin Description Direction

2 Receive (Rx) Input

3 Transmit (Tx) Output

5 Signal ground (Gnd) —

1234 5

6789

Introducing the PM-1600 High-Speed Power Meter

4 PM-1600

RS-232 Connector Pinout

RS-232 Connector Pinout

The RS-232 connector (serial port) at the back of the PM-1600 uses a DTE

pinout configuration.

Pin Description Direction

2 Receive (Rx) Input

3 Transmit (Tx) Output

5 Signal ground (Gnd) —

1234 5

6789

Page 15

High-Speed Power Meter 5

2 Safety Information

Safety Conventions

You should understand the following conventions before using the product

described in this manual:

WARNING

Refers to a potential personal hazard. It requires a

procedure which, if not correctly followed, may result

in bodily harm or injury. Do not proceed beyond a

WARNING unless you understand and meet the

required conditions.

CAUTION

Refers to a potential product hazard. It requires a

procedure which, if not correctly followed, may result

in component damage. Do not proceed beyond a

CAUTION unless you understand and meet the

required conditions.

IMPORTANT

Refers to any information regarding the operation of

the product which you should not overlook.

High-Speed Power Meter 5

2 Safety Information

Safety Conventions

You should understand the following conventions before using the product

described in this manual:

WARNING

Refers to a potential personal hazard. It requires a

procedure which, if not correctly followed, may result

in bodily harm or injury. Do not proceed beyond a

WARNING unless you understand and meet the

required conditions.

CAUTION

Refers to a potential product hazard. It requires a

procedure which, if not correctly followed, may result

in component damage. Do not proceed beyond a

CAUTION unless you understand and meet the

required conditions.

IMPORTANT

Refers to any information regarding the operation of

the product which you should not overlook.

Page 16

Safety Information

6 PM-1600

General Safety Information

General Safety Information

The following safety precautions must be observed during the operation

and servicing of the units. Failure to comply with these precautions or with

specific indications elsewhere in this manual violates safety standards of

intended use of the unit. EXFO assumes no liability for the user's failure to

comply with these requirements.

➤ This unit is intended for indoor use only.

➤ Unit covers cannot be removed during operation.

➤ The unit must be positioned in a way not to block the ventilation holes

located on each side of the unit.

➤ Installation of replacement parts or modification of the unit should be

carried out by authorized personnel only.

Laser Safety Information

WARNING

Use of controls or adjustments or performance of procedures other

than those specified herein may result in hazardous radiation

exposure.

WARNING

Do not install or terminate fibers while a laser source is active.

Never look directly into a live fiber and ensure that your eyes are

protected at all times.

Safety Information

6 PM-1600

General Safety Information

General Safety Information

The following safety precautions must be observed during the operation

and servicing of the units. Failure to comply with these precautions or with

specific indications elsewhere in this manual violates safety standards of

intended use of the unit. EXFO assumes no liability for the user's failure to

comply with these requirements.

➤ This unit is intended for indoor use only.

➤ Unit covers cannot be removed during operation.

➤ The unit must be positioned in a way not to block the ventilation holes

located on each side of the unit.

➤ Installation of replacement parts or modification of the unit should be

carried out by authorized personnel only.

Laser Safety Information

WARNING

Use of controls or adjustments or performance of procedures other

than those specified herein may result in hazardous radiation

exposure.

WARNING

Do not install or terminate fibers while a laser source is active.

Never look directly into a live fiber and ensure that your eyes are

protected at all times.

Page 17

Safety Information

High-Speed Power Meter 7

Electrical Safety Information

Electrical Safety Information

➤ Before powering on the unit, all grounding terminals, extension cords,

and devices connected to it should be connected to a protective

ground via a ground socket. Any interruption of the protective

grounding is a potential shock hazard and may cause personal injury.

➤ Whenever the ground protection is impaired, the unit is not to be used

and must be secured against any accidental or unintended operation.

➤ Only fuses with the required rated current and specified type

(IEC, 250 V, 2 A, fast blow,5 mm x 20 mm (0.197 in x 0.787 in)) may be

used for replacement. Do not use repaired fuses or short-circuited fuse

holders.

➤ Any adjustments, maintenance, and repair of opened units under

voltage should be avoided and carried out only by skilled personnel

aware of the hazards involved. Do not attempt internal service or

adjustment unless another person qualified in first aid is present. Do

not replace any components while power cable is connected.

➤ Operation of any electrical instrument around flammable gases or

fumes constitutes a major safety hazard.

➤ Capacitors inside the unit may be charged even if the unit has been

disconnected from its electrical supply.

AC Requirements

The PM-1600 can operate from any single-phase AC power source between

100 V and 240 V (50 Hz/60 Hz). The maximum input current is 2 A.

Safety Information

High-Speed Power Meter 7

Electrical Safety Information

Electrical Safety Information

➤ Before powering on the unit, all grounding terminals, extension cords,

and devices connected to it should be connected to a protective

ground via a ground socket. Any interruption of the protective

grounding is a potential shock hazard and may cause personal injury.

➤ Whenever the ground protection is impaired, the unit is not to be used

and must be secured against any accidental or unintended operation.

➤ Only fuses with the required rated current and specified type

(IEC, 250 V, 2 A, fast blow,5 mm x 20 mm (0.197 in x 0.787 in)) may be

used for replacement. Do not use repaired fuses or short-circuited fuse

holders.

➤ Any adjustments, maintenance, and repair of opened units under

voltage should be avoided and carried out only by skilled personnel

aware of the hazards involved. Do not attempt internal service or

adjustment unless another person qualified in first aid is present. Do

not replace any components while power cable is connected.

➤ Operation of any electrical instrument around flammable gases or

fumes constitutes a major safety hazard.

➤ Capacitors inside the unit may be charged even if the unit has been

disconnected from its electrical supply.

AC Requirements

The PM-1600 can operate from any single-phase AC power source between

100 V and 240 V (50 Hz/60 Hz). The maximum input current is 2 A.

Page 18

Safety Information

8 PM-1600

Electrical Safety Information

Power Cable

The PM-1600’s power cable is its disconnecting device.

The PM-1600 uses an international safety standard three-wire power cable.

This cable serves as a ground when connected to an appropriate AC power

receptacle. The type of power cable supplied with each unit is determined

according to the country of destination.

Only qualified electricians should connect a new plug if needed. The color

coding used in the electric cable depends on the cable. New plugs should

meet the local safety requirements and include the following features:

➤ adequate load-carrying capacity

➤ ground connection

➤ cable clamp

➤ If the unit is to be powered via an auto-transformer for voltage

reduction, the common terminal must be connected to the grounded

power source pole.

➤ Insert the plug into a power outlet with a protective ground contact. Do

not use an extension cord without a protective conductor.

➤ Before powering on the unit, the protective ground terminal of the unit

must be connected to a protective conductor using the unit power

cord.

➤ Do not tamper with the protective ground terminal.

WARNING

To avoid electrical shock, do not operate the unit if there are signs

of damage to any part of the outer surface (covers, panels, etc.).

To avoid serious injury, the following precautions must be observed

before powering on the unit.

Safety Information

8 PM-1600

Electrical Safety Information

Power Cable

The PM-1600’s power cable is its disconnecting device.

The PM-1600 uses an international safety standard three-wire power cable.

This cable serves as a ground when connected to an appropriate AC power

receptacle. The type of power cable supplied with each unit is determined

according to the country of destination.

Only qualified electricians should connect a new plug if needed. The color

coding used in the electric cable depends on the cable. New plugs should

meet the local safety requirements and include the following features:

➤ adequate load-carrying capacity

➤ ground connection

➤ cable clamp

➤ If the unit is to be powered via an auto-transformer for voltage

reduction, the common terminal must be connected to the grounded

power source pole.

➤ Insert the plug into a power outlet with a protective ground contact. Do

not use an extension cord without a protective conductor.

➤ Before powering on the unit, the protective ground terminal of the unit

must be connected to a protective conductor using the unit power

cord.

➤ Do not tamper with the protective ground terminal.

WARNING

To avoid electrical shock, do not operate the unit if there are signs

of damage to any part of the outer surface (covers, panels, etc.).

To avoid serious injury, the following precautions must be observed

before powering on the unit.

Page 19

High-Speed Power Meter 9

3 Getting Started with Your

High-Speed Power Meter

Turning the PM-1600 On and Off

To turn the unit on or off, use the red button in the lower left corner of the

front panel.

When you turn on the unit, it beeps twice and performs a self-test, while

displaying startup information as well as the software version number.

Before taking any measurements, it is recommended that you null the

detector offsets (see Nulling Electrical Offsets on page 11).

When the unit is turned off, the following items remain in non-volatile

memory:

➤ manually stored data

➤ reference values

➤ remote-control settings

➤ shortlisted wavelengths

➤ customized settings

➤ saved configurations (up to three setup configurations and up to three

program configurations)

Note: To ensure the power is completely turned off, disconnect the power cord.

IMPORTANT

Before turning the PM-1600 on, please read the Safety Information

on page 5.

High-Speed Power Meter 9

3 Getting Started with Your

High-Speed Power Meter

Turning the PM-1600 On and Off

To turn the unit on or off, use the red button in the lower left corner of the

front panel.

When you turn on the unit, it beeps twice and performs a self-test, while

displaying startup information as well as the software version number.

Before taking any measurements, it is recommended that you null the

detector offsets (see Nulling Electrical Offsets on page 11).

When the unit is turned off, the following items remain in non-volatile

memory:

➤ manually stored data

➤ reference values

➤ remote-control settings

➤ shortlisted wavelengths

➤ customized settings

➤ saved configurations (up to three setup configurations and up to three

program configurations)

Note: To ensure the power is completely turned off, disconnect the power cord.

IMPORTANT

Before turning the PM-1600 on, please read the Safety Information

on page 5.

Page 20

Getting Started with Your High-Speed Power Meter

10 PM-1600

Selecting a Menu or a Menu Option

Selecting a Menu or a Menu Option

The PM-1600 is equipped with a new type of multifunctional, graphical

liquid crystal display (LCD) with increased brightness, readability, and

resolution that significantly improves both menu navigation and power

meter operation versatility.

For basic PM-1600 operation, simply press the control buttons at the bottom

of the display.

HIGH-SPEED POWER METER

PM-1600

dB W/W

ENTER

dBm/W Ref

Null

Chan

Range

λ

Avg Shift

Store

Recall

Program

Setup

Analog Out

C1 C2

Ext. Trig

Display

To access a secondary function, press Shift (SH

marker appears in the lower right corner of the

display), then press the desired control button.

To select a menu, press the matching menu

button. For more information, see Storing and

Recalling Power Measurements on page 41 and

Customizing the PM-1600 Display on page 83.

To select a menu option, use the up/down or

left/right arrow keys until the desired option is

highlighted, then confirm by pressing ENTER.

To exit a menu, use the up/down or left/right

arrow keys until Exit is highlighted, then press

ENTER. You c a n al so press the button that gave

access to the menu.

Getting Started with Your High-Speed Power Meter

10 PM-1600

Selecting a Menu or a Menu Option

Selecting a Menu or a Menu Option

The PM-1600 is equipped with a new type of multifunctional, graphical

liquid crystal display (LCD) with increased brightness, readability, and

resolution that significantly improves both menu navigation and power

meter operation versatility.

For basic PM-1600 operation, simply press the control buttons at the bottom

of the display.

HIGH-SPEED POWER METER

PM-1600

dB W/W

ENTER

dBm/W Ref

Null

Chan

Range

λ

Avg Shift

Store

Recall

Program

Setup

Analog Out

C1 C2

Ext. Trig

Display

To access a secondary function, press Shift (SH

marker appears in the lower right corner of the

display), then press the desired control button.

To select a menu, press the matching menu

button. For more information, see Storing and

Recalling Power Measurements on page 41 and

Customizing the PM-1600 Display on page 83.

To select a menu option, use the up/down or

left/right arrow keys until the desired option is

highlighted, then confirm by pressing ENTER.

To exit a menu, use the up/down or left/right

arrow keys until Exit is highlighted, then press

ENTER. You c a n al so press the button that gave

access to the menu.

Page 21

Getting Started with Your High-Speed Power Meter

High-Speed Power Meter 11

Nulling Electrical Offsets

Note: The PM-1600 will beep whenever the unit does not allow an operation.

Note: In this manual, the single-channel power meter is referred to as the

PM-1610 and the dual-channel power meter as the PM-1620.

Nulling Electrical Offsets

The Offset Nulling function provides a zero power measurement, thus

eliminating the effects of electronic dark current. For best results and

accuracy, ensure that offsets are nulled before each test session, each time

the unit is turned on, or whenever environmental conditions change while

the power meter is operating (temperature and humidity variations affect

the performance of optical detectors).

To perform a nulling,

1. Place the protective cap over the detector port on which a nulling has

to be performed.

IMPORTANT

Light must not reach the detector when nulling offsets.

When the PM-1600 is turned on after a cold start, allow the unit to

warm up for about 20 minutes (30 minutes for PM-1600W) until the

electronics stabilize and can meet announced optical specifications.

1

AUTO

λ

1310.00 nm

- - - - - - -

dBm

2

LR4 CF

1550.00 nm

1.26

W/W

SH

λ

Getting Started with Your High-Speed Power Meter

High-Speed Power Meter 11

Nulling Electrical Offsets

Note: The PM-1600 will beep whenever the unit does not allow an operation.

Note: In this manual, the single-channel power meter is referred to as the

PM-1610 and the dual-channel power meter as the PM-1620.

Nulling Electrical Offsets

The Offset Nulling function provides a zero power measurement, thus

eliminating the effects of electronic dark current. For best results and

accuracy, ensure that offsets are nulled before each test session, each time

the unit is turned on, or whenever environmental conditions change while

the power meter is operating (temperature and humidity variations affect

the performance of optical detectors).

To perform a nulling,

1. Place the protective cap over the detector port on which a nulling has

to be performed.

IMPORTANT

Light must not reach the detector when nulling offsets.

When the PM-1600 is turned on after a cold start, allow the unit to

warm up for about 20 minutes (30 minutes for PM-1600W) until the

electronics stabilize and can meet announced optical specifications.

1

AUTO

λ

1310.00 nm

- - - - - - -

dBm

2

LR4 CF

1550.00 nm

1.26

W/W

SH

λ

Page 22

Getting Started with Your High-Speed Power Meter

12 PM-1600

Nulling Electrical Offsets

2. If necessary, select the desired channel (in the case of a PM-1620) by

pressing Chan. In the above figure, channel #1 is currently selected.

3. Press Shift, then Null. The offset nulling process takes approximately

10 seconds. Once done, the unit returns to the previously active

operation state.

Note: If you are trying to perform an offset nulling with a protective cap

improperly tightened on the detector port, the message Light detected will

be briefly displayed. If so, ensure the protective cap is properly tightened

and restart the offset nulling.

Note: Offset nulling constants are retained until a new offset nulling is performed.

Getting Started with Your High-Speed Power Meter

12 PM-1600

Nulling Electrical Offsets

2. If necessary, select the desired channel (in the case of a PM-1620) by

pressing Chan. In the above figure, channel #1 is currently selected.

3. Press Shift, then Null. The offset nulling process takes approximately

10 seconds. Once done, the unit returns to the previously active

operation state.

Note: If you are trying to perform an offset nulling with a protective cap

improperly tightened on the detector port, the message Light detected will

be briefly displayed. If so, ensure the protective cap is properly tightened

and restart the offset nulling.

Note: Offset nulling constants are retained until a new offset nulling is performed.

Page 23

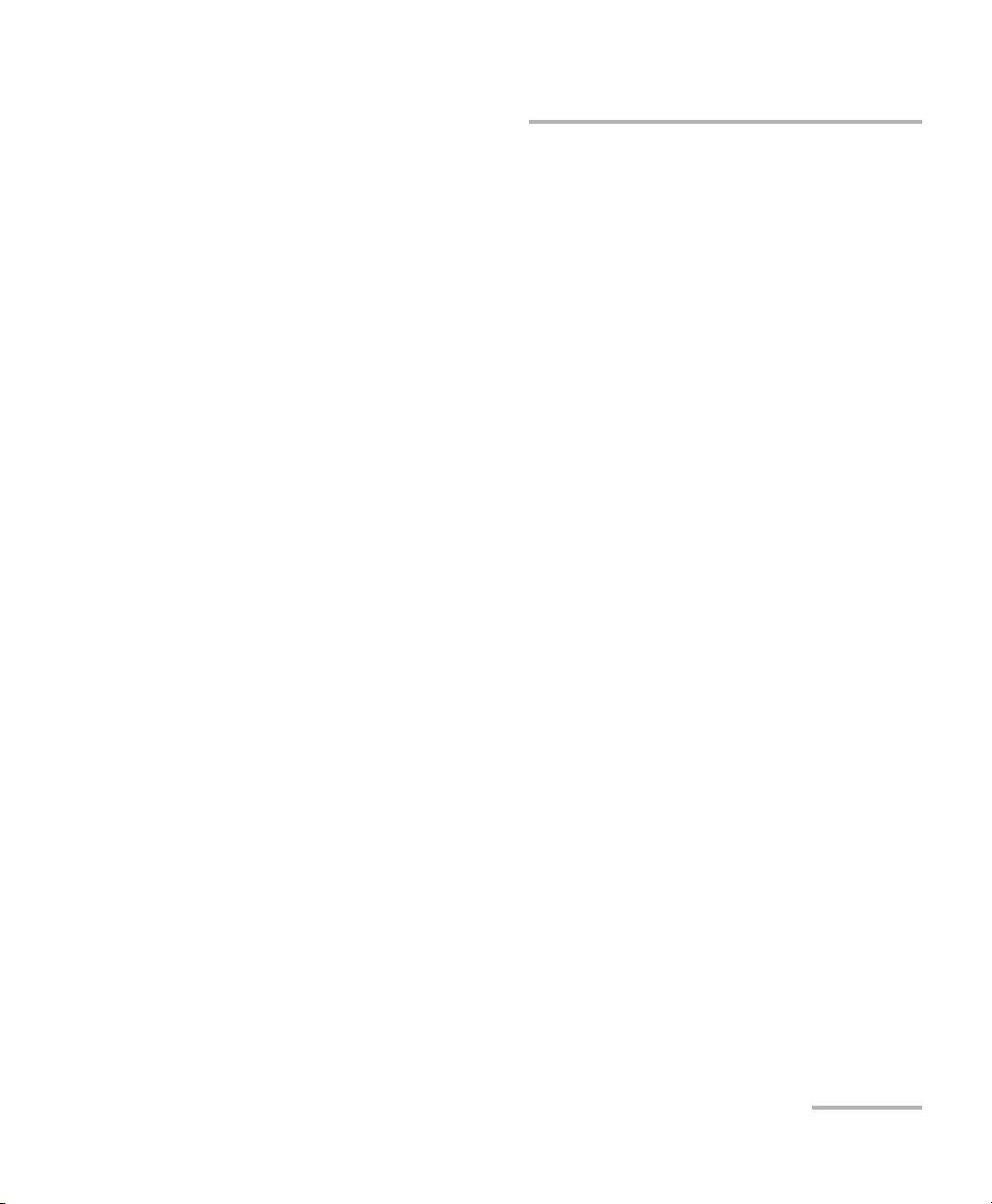

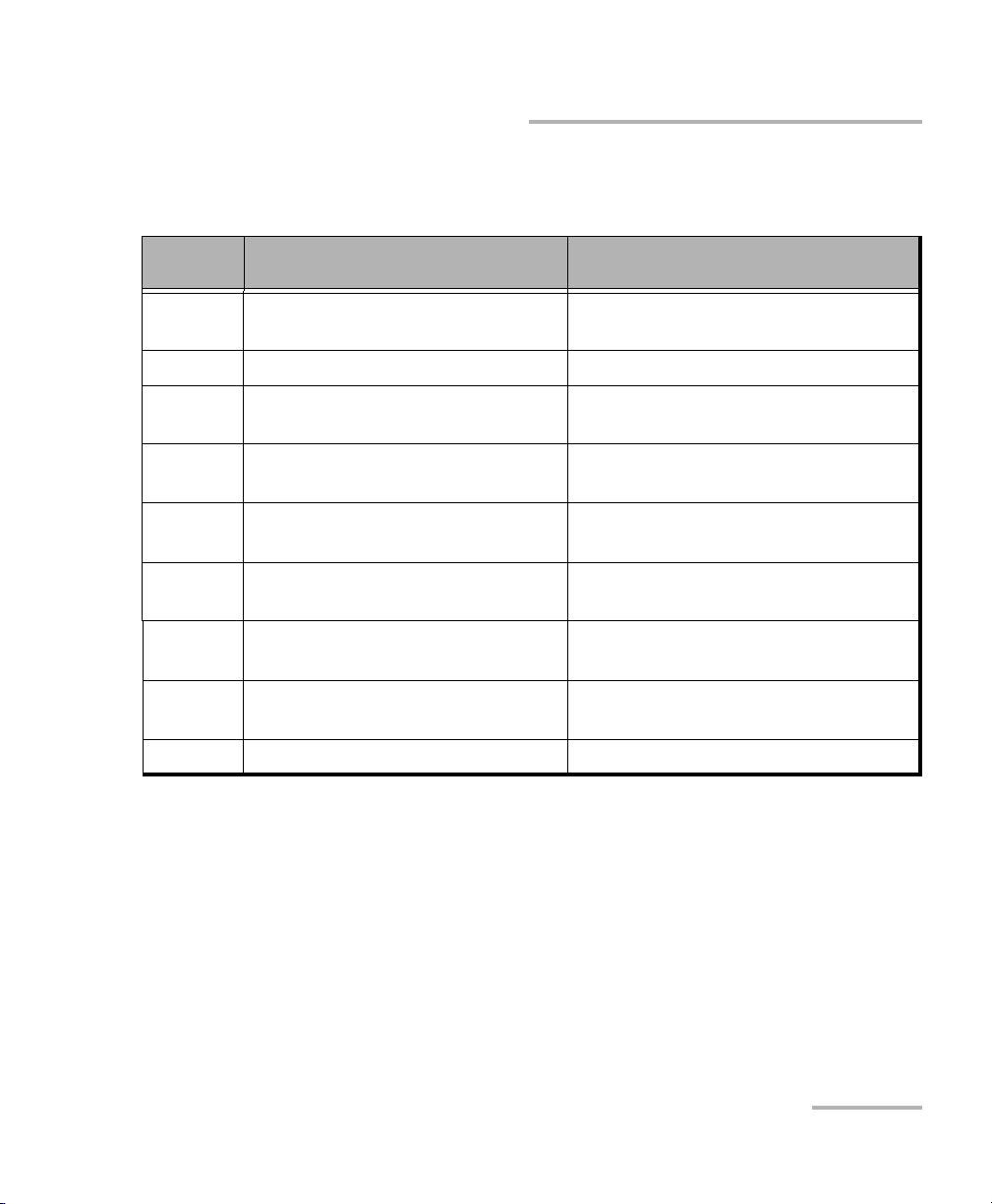

High-Speed Power Meter 13

4 Acquiring Power

Measurements

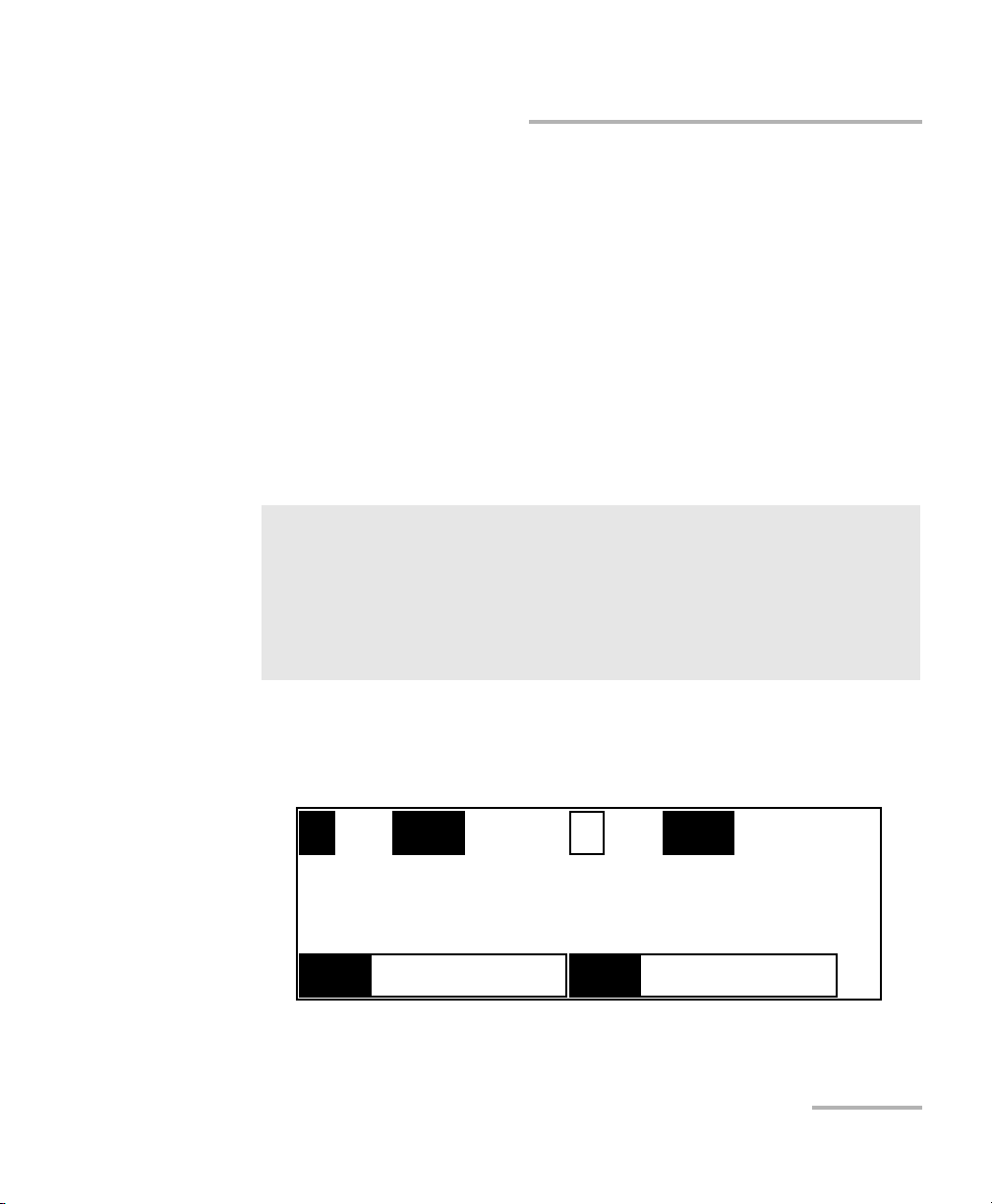

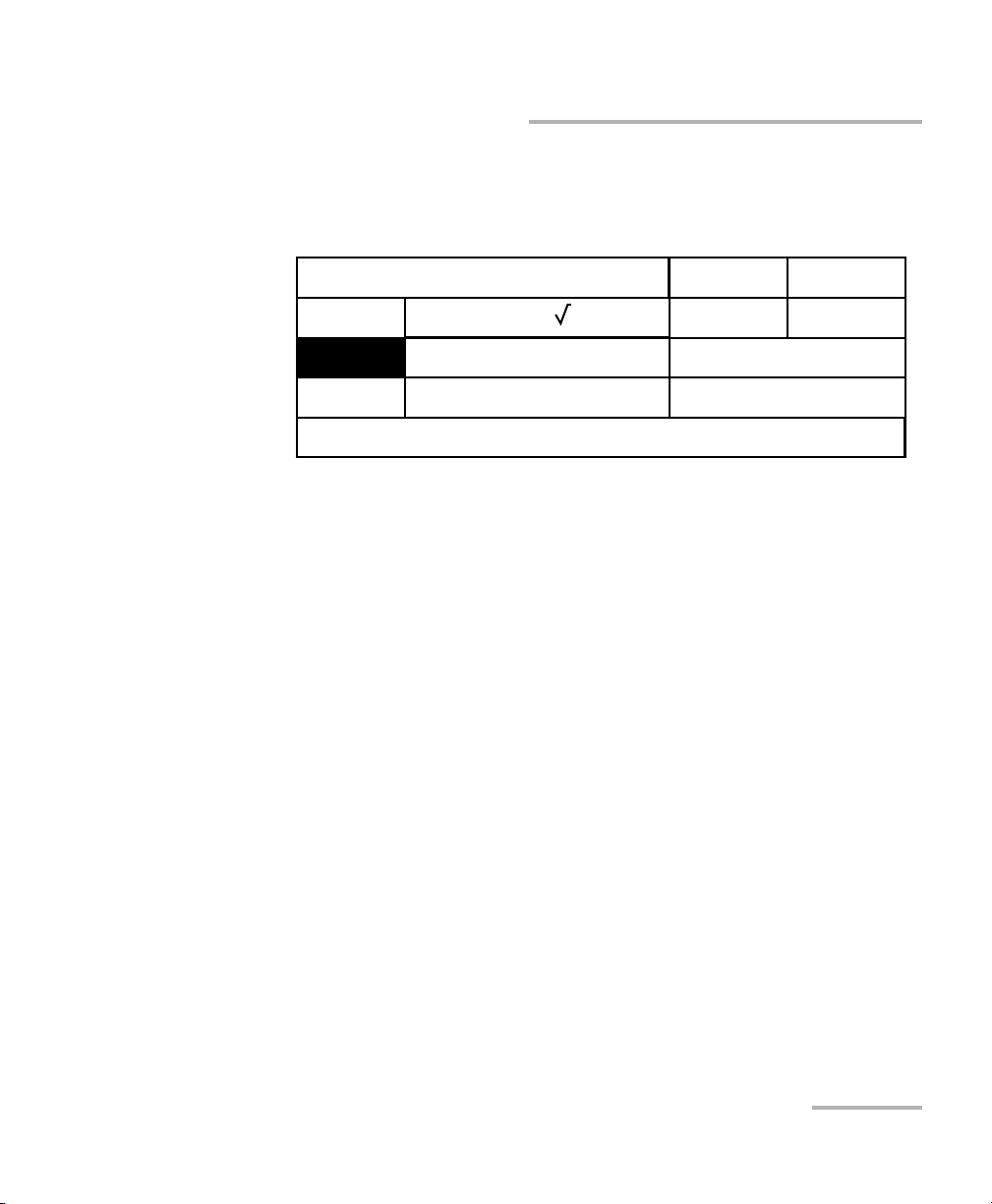

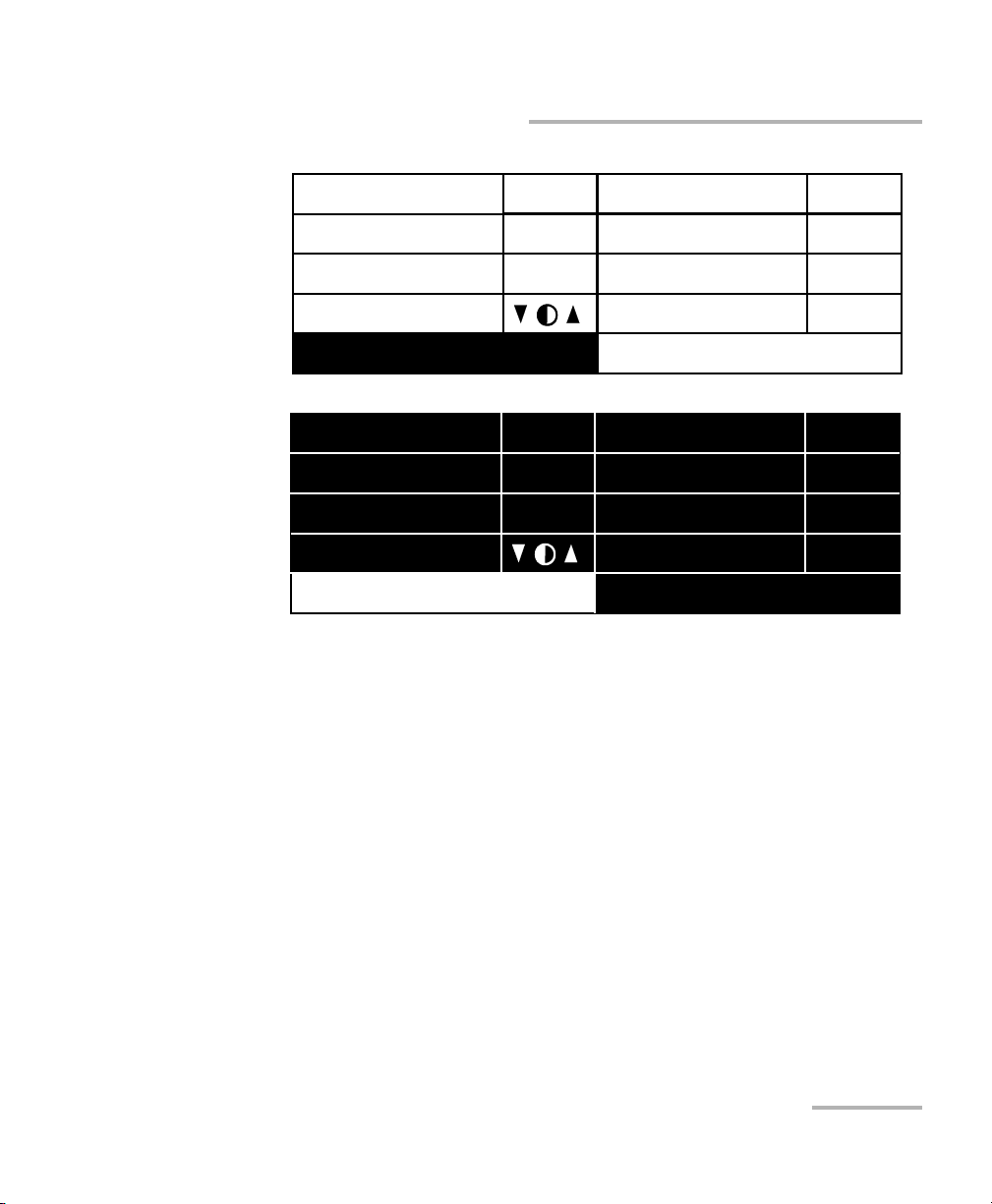

Setting a Display Mode

A typical display in power measurement mode might look as follows.

To set the display mode, i.e., the data type at the bottom of the display,

1. If necessary, select the desired channel (PM-1620) by pressing Chan.

The current wavelength is displayed for the active channel. In the

above figure, channel #2 is currently selected.

2. Press Shift, then Display. The current reference value is displayed for

the active channel (in dBm or W units, depending on the currently

selected measurement unit).

AVG1

AUTO

REF

-52.640 dBm

5.585

dB

2

LR4 CF

1310.26 nm

1.26

dB

Sensitivity range

(auto) active

Sensitivity range

(manual) active

Channel 1 display zone

Channel 2 display zone

Inactive channel

Active channel

Averaging

mode

active

Correction factor

active

Power

reading

Reference value

(channel #1)

Current unit

Current wavelength

(channel #2)

Secondary function

indicator

SH

λ

Display mode

tab

O

Offset

indicator

Current unit

High-Speed Power Meter 13

4 Acquiring Power

Measurements

Setting a Display Mode

A typical display in power measurement mode might look as follows.

To set the display mode, i.e., the data type at the bottom of the display,

1. If necessary, select the desired channel (PM-1620) by pressing Chan.

The current wavelength is displayed for the active channel. In the

above figure, channel #2 is currently selected.

2. Press Shift, then Display. The current reference value is displayed for

the active channel (in dBm or W units, depending on the currently

selected measurement unit).

AVG1

AUTO

REF

-52.640 dBm

5.585

dB

2

LR4 CF

1310.26 nm

1.26

dB

Sensitivity range

(auto) active

Sensitivity range

(manual) active

Channel 1 display zone

Channel 2 display zone

Inactive channel

Active channel

Averaging

mode

active

Correction factor

active

Power

reading

Reference value

(channel #1)

Current unit

Current wavelength

(channel #2)

Secondary function

indicator

SH

λ

Display mode

tab

O

Offset

indicator

Current unit

Page 24

Acquiring Power Measurements

14 PM-1600

Measuring Absolute Power

3. Press Shift a second time, then Display. The current correction factor

(CF) is displayed for the active channel (in dB or W/W units,

depending on the currently selected measurement unit).

4. Press Shift again, then Display. The Offset value (O) appears for the

active channel (in dB or W/W units, depending on the currently

selected measurement unit).

Note: On a PM-1610 single-channel power meter, two different data types

simultaneously appear at the bottom of the display. To select the desired

display mode, just press Display.

Measuring Absolute Power

When in absolute power, measured values are displayed in either dBm or

W units (pW, nW, µW, mW...) according to the power of the signal, and the

displayed value represents the absolute optical power reaching the

detector within specified uncertainty.

To display absolute power,

1. If necessary, select the desired channel (PM-1620). In the above figure,

channel #1 is currently selected.

1

AUTO

λ

1310.00 nm

-14.278

dBm

2

LR2 CF

1550.00 nm

1.26

W/W

SH

λ

Power reading

Current wavelength Measurement unit

Acquiring Power Measurements

14 PM-1600

Measuring Absolute Power

3. Press Shift a second time, then Display. The current correction factor

(CF) is displayed for the active channel (in dB or W/W units,

depending on the currently selected measurement unit).

4. Press Shift again, then Display. The Offset value (O) appears for the

active channel (in dB or W/W units, depending on the currently

selected measurement unit).

Note: On a PM-1610 single-channel power meter, two different data types

simultaneously appear at the bottom of the display. To select the desired

display mode, just press Display.

Measuring Absolute Power

When in absolute power, measured values are displayed in either dBm or

W units (pW, nW, µW, mW...) according to the power of the signal, and the

displayed value represents the absolute optical power reaching the

detector within specified uncertainty.

To display absolute power,

1. If necessary, select the desired channel (PM-1620). In the above figure,

channel #1 is currently selected.

1

AUTO

λ

1310.00 nm

-14.278

dBm

2

LR2 CF

1550.00 nm

1.26

W/W

SH

λ

Power reading

Current wavelength Measurement unit

Page 25

Acquiring Power Measurements

High-Speed Power Meter 15

Measuring Absolute Power

2. If necessary, press λ to select the appropriate wavelength from the

shortlist (see the section on viewing wavelength list on page 25).

Note: The wavelength may take some time to change on the display due to a low

refresh rate. To set the refresh rate, see Setting Refresh Rate on page 34.

3. Press dBm/W to display the absolute power of the signal received at

the detector port. The dBm/W button is also used to toggle between

dBm and W measurement units.

An absolute power measurement in negative W units indicates that

electrical offsets were improperly nulled. If so, repeat the offset nulling

(see Nulling Electrical Offsets on page 11).

Note: When ------- is displayed, the power level detected is below the lower

limit of the selected measurement range. When +++++++ is

displayed, the power level detected is above the upper limit of the selected

measurement range. See Setting Measurement Range on page 22.

When !!!!!!! is displayed, the displayed data is in transition (range was

changed in power measurement mode, with Autorange selected).

When *******is displayed, a programmed acquisition is running with

a high sampling rate.

Acquiring Power Measurements

High-Speed Power Meter 15

Measuring Absolute Power

2. If necessary, press λ to select the appropriate wavelength from the

shortlist (see the section on viewing wavelength list on page 25).

Note: The wavelength may take some time to change on the display due to a low

refresh rate. To set the refresh rate, see Setting Refresh Rate on page 34.

3. Press dBm/W to display the absolute power of the signal received at

the detector port. The dBm/W button is also used to toggle between

dBm and W measurement units.

An absolute power measurement in negative W units indicates that

electrical offsets were improperly nulled. If so, repeat the offset nulling

(see Nulling Electrical Offsets on page 11).

Note: When ------- is displayed, the power level detected is below the lower

limit of the selected measurement range. When +++++++ is

displayed, the power level detected is above the upper limit of the selected

measurement range. See Setting Measurement Range on page 22.

When !!!!!!! is displayed, the displayed data is in transition (range was

changed in power measurement mode, with Autorange selected).

When *******is displayed, a programmed acquisition is running with

a high sampling rate.

Page 26

Acquiring Power Measurements

16 PM-1600

Measuring Relative Power

Measuring Relative Power

Power measurements can be displayed as a deviation from an absolute

reference value. The relative power is particularly useful when performing

insertion loss measurements.

Relative power is displayed in dB when the reference value is measured in

dBm. If this is the case, the value will either be positive or negative since

the actual measured power is higher or lower than the reference power.

If the reference value is in W, the relative power will be displayed in W/W

units. The relative power will then represent the deviation ratio from the

reference.

In the example on the previous page, the measured power is 30.112 dB

higher than the reference value of −32.218 dBm. The absolute power is

−2.106 dBm.

To display relative power,

1. If necessary, select the desired channel (PM-1620).

2. If necessary, press

λ to select the appropriate wavelength from the

shortlist (see the section on viewing wavelength list on page 25).

1

AUTO

λ

1310.25 nm

30.112

CF

-32.218 dBm

dB

SH

Relative power

Current wavelength

Reference value

REF

Relative power unit

Reference unit

Acquiring Power Measurements

16 PM-1600

Measuring Relative Power

Measuring Relative Power

Power measurements can be displayed as a deviation from an absolute

reference value. The relative power is particularly useful when performing

insertion loss measurements.

Relative power is displayed in dB when the reference value is measured in

dBm. If this is the case, the value will either be positive or negative since

the actual measured power is higher or lower than the reference power.

If the reference value is in W, the relative power will be displayed in W/W

units. The relative power will then represent the deviation ratio from the

reference.

In the example on the previous page, the measured power is 30.112 dB

higher than the reference value of −32.218 dBm. The absolute power is

−2.106 dBm.

To display relative power,

1. If necessary, select the desired channel (PM-1620).

2. If necessary, press

λ to select the appropriate wavelength from the

shortlist (see the section on viewing wavelength list on page 25).

1

AUTO

λ

1310.25 nm

30.112

CF

-32.218 dBm

dB

SH

Relative power

Current wavelength

Reference value

REF

Relative power unit

Reference unit

Page 27

Acquiring Power Measurements

High-Speed Power Meter 17

Measuring Relative Power

3. Press dB/W/W until the display switches to relative mode in dB (where

the value displayed is equal to the absolute power minus the

previously stored reference power) or in W/W (where the value

displayed is the deviation ratio from the reference). Pressing dB/W

/W

again switches between dB and W/W measurement units for the

relative power and reference value.

When you access relative mode, the PM-1600 displays the last reference

value entered at the current wavelength (to view the reference value, set

the appropriate channel to reference display mode).

However, to display meaningful relative power readings, it is important to

have an appropriate reference value, using appropriate adapters and test

jumpers, and connecting the optical circuit being referenced to a detector

port.

Note: If you set a reference while a correction factor (CF) is active, the reference

measurement will take the correction factor into account.

To set a reference value, two choices are available.

Entering the Current Power as the Reference Value

To enter the current power,

1. If necessary, select the desired channel (PM-1620).

2. If necessary, press

λ to select the appropriate wavelength.

3. Press dBm/W to select the desired measurement unit.

4. Press Ref to use the current power value as the new reference.

Note: Pressing Ref switches the display to relative mode.

Acquiring Power Measurements

High-Speed Power Meter 17

Measuring Relative Power

3. Press dB/W/W until the display switches to relative mode in dB (where

the value displayed is equal to the absolute power minus the

previously stored reference power) or in W/W (where the value

displayed is the deviation ratio from the reference). Pressing dB/W

/W

again switches between dB and W/W measurement units for the

relative power and reference value.

When you access relative mode, the PM-1600 displays the last reference

value entered at the current wavelength (to view the reference value, set

the appropriate channel to reference display mode).

However, to display meaningful relative power readings, it is important to

have an appropriate reference value, using appropriate adapters and test

jumpers, and connecting the optical circuit being referenced to a detector

port.

Note: If you set a reference while a correction factor (CF) is active, the reference

measurement will take the correction factor into account.

To set a reference value, two choices are available.

Entering the Current Power as the Reference Value

To enter the current power,

1. If necessary, select the desired channel (PM-1620).

2. If necessary, press

λ to select the appropriate wavelength.

3. Press dBm/W to select the desired measurement unit.

4. Press Ref to use the current power value as the new reference.

Note: Pressing Ref switches the display to relative mode.

Page 28

Acquiring Power Measurements

18 PM-1600

Measuring Relative Power

Entering a Specific Reference Value

To enter a specific value,

1. If necessary, press

λ to select the appropriate wavelength.

2. Press dBm/W to select the desired measurement unit.

3. Press Setup to access the Setup menu.

4. Use the up/down arrow keys to select Channel 1 Setup or Channel 2

Setup, then press ENTER. The current channel settings are displayed.

5. Use the up/down arrow keys to select Reference.

5a. To clear the current reference, use the left/right arrow keys to

select Reset, then confirm by pressing ENTER.

System Setup

Wavelength List & Corr. Factor

Channel 1 Setup

Channel 2 Setup

Exit

Resolution

Averaging

Reference

002

−

68.975 dBm

3.0103 dB

(Active)

Reset

4

Exit Channel 1 Setup

Offset

100.000 dB

Reset

Acquiring Power Measurements

18 PM-1600

Measuring Relative Power

Entering a Specific Reference Value

To enter a specific value,

1. If necessary, press

λ to select the appropriate wavelength.

2. Press dBm/W to select the desired measurement unit.

3. Press Setup to access the Setup menu.

4. Use the up/down arrow keys to select Channel 1 Setup or Channel 2

Setup, then press ENTER. The current channel settings are displayed.

5. Use the up/down arrow keys to select Reference.

5a. To clear the current reference, use the left/right arrow keys to

select Reset, then confirm by pressing ENTER.

System Setup

Wavelength List & Corr. Factor

Channel 1 Setup

Channel 2 Setup

Exit

Resolution

Averaging

Reference

002

−

68.975 dBm

3.0103 dB

(Active)

Reset

4

Exit Channel 1 Setup

Offset

100.000 dB

Reset

Page 29

Acquiring Power Measurements

High-Speed Power Meter 19

Measuring Corrected Power

5b. To modify the current reference, press ENTER to select the

reference edit box, then use the left/right arrow keys to select the

desired sign and digit, and the up/down arrow keys to increase or