Page 1

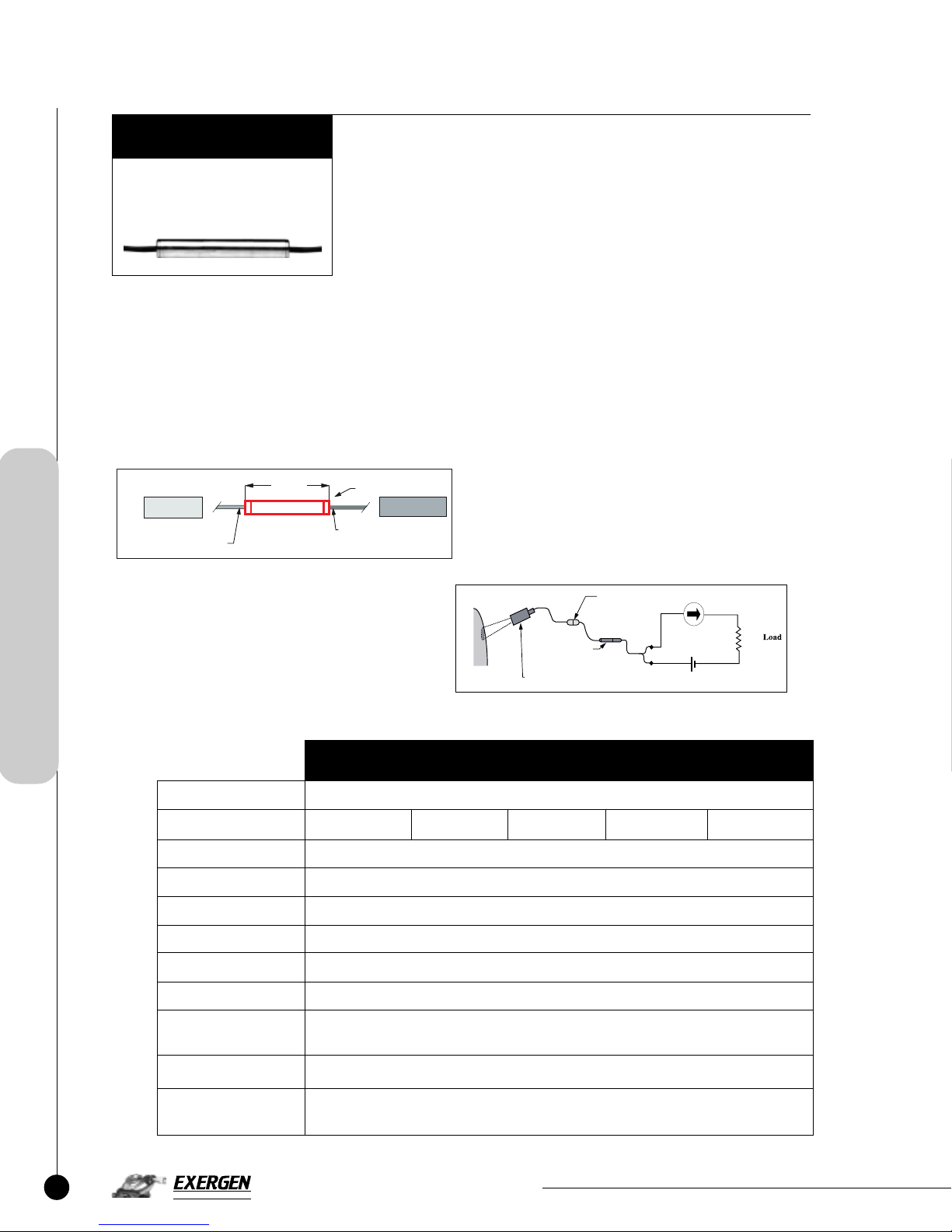

Transmitter

IRt/c.XMTR

In-Line Pre-Calibrated 4-20

mA Transmitter

The t/c.XMTR is specifically designed to interface any model IRt/c by a

simple thermocouple connector or splice. The two wire current loop can

be used in any conventional 4-20mA, 0-5V or 0-10V circuit that is scaled

for the temperature range of interest.

For OEMs, IRt/c sensors and t/c.XMTR can be supplied pre-wired

together.

· Use any existing wiring, for easy low cost installation

· Use existing PLC, computer or controller inputs

· In line design requires no mechanical support

· Pre-calibrated for IRt/c type, no span or zero adjustment necessary

· Hermetically sealed construction exceeds NEMA 4, 4X, IP65, 66,

67

· Stainless Steel construction can withstand harsh environments

IRt/c Accessories

IRt/c Side

3 ft (1 m) 26 AWGstranded

twisted shielded pair

thermocouple wire.

Temperature at 4 mA

Temperature at 20 mA 150°F (65°C) 500°F (260°C) 1000°F (540°C) 2000°F (1100°C) 3000°F (1650°C)

Accuracy ±0.1% F.S.conversion of thermocouple mV input to mA output

Speed of Response 160 msec (10Hz bandwidth)

Operating Range 32 to 158°F (0 to 70°C)

3.4 (86)

.50 (12,7)

∅

Loop Side

10 ft (3 m) 22 AWG

stranded twisted pair wire.

J150

K150

J500

K500

t/c.XMTR

Any Model IRt/c

J1200

K1200

32°F (0°C)

t/c connector

4 - 20 mA

12 - 36 VDC

K2100 S3000

1000 Ohm

Max

Temperature Drift <0.02% F.S.per °C

Output Noise <1nv rms (100Hz bandwidth)

Input Break Indication Upscale: goes to >20 mA

Power Supply @ Load

StorageTemperature

Weight

Housing

4848

48

4848

CORPORATION

51 Water Street, Watertown, MA 02172 USA

800-422-3006 • 617-923-9900 • Fax 617-923-9911

12 VDC minimum @10; to 22 VDC minimum @1K

-85 to 257°F (-65 to 125°C)

2.4 oz (68 g) with cables

Stainless steel, hermetically sealed, meets or exceeds all applicable NEMA ratings, housing

electrically isolated from signal.

Page 2

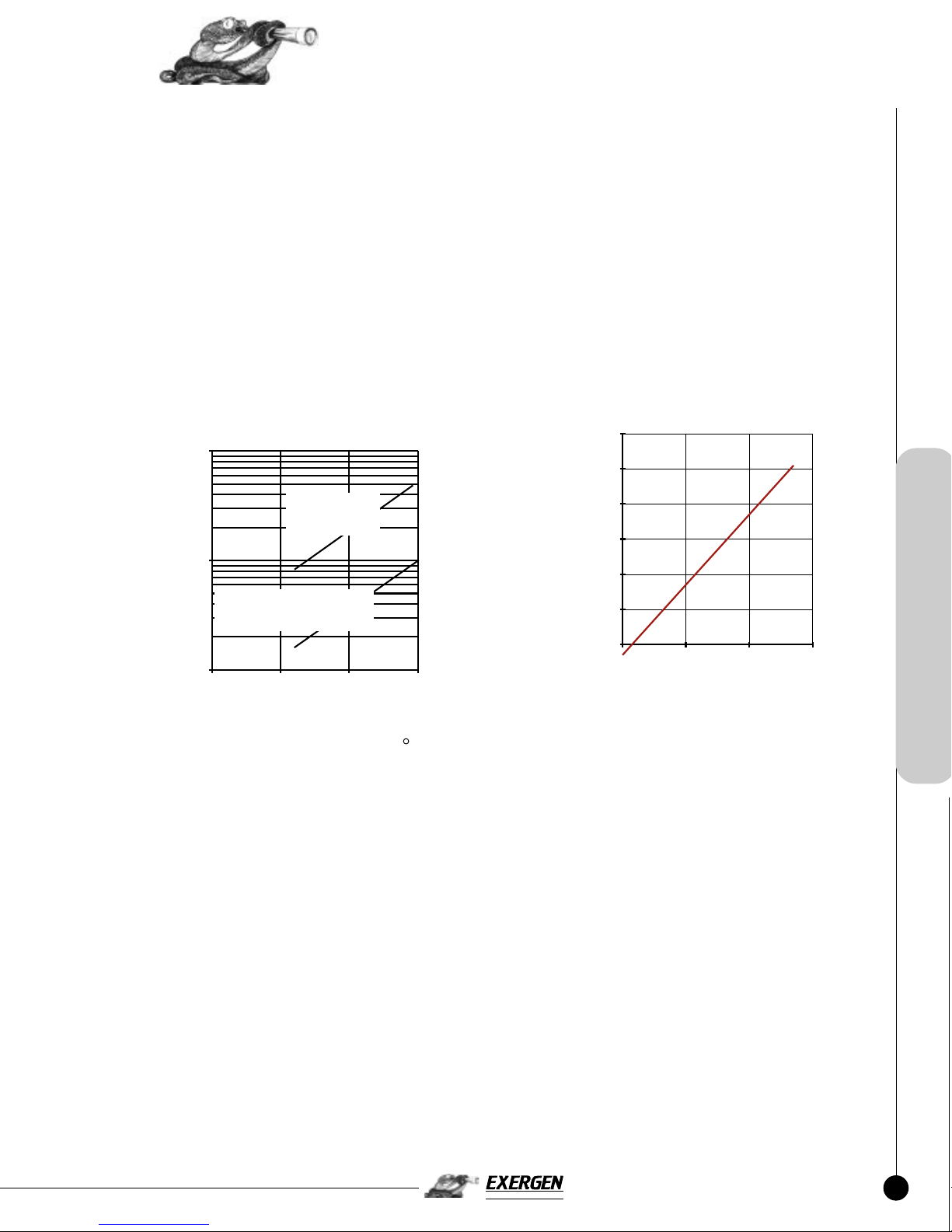

IRt/c for Ambient >100

Up to 450°F (230°C), air alone can provide sufficient cooling with the Cooling Jacket Kit. As the Air Cooling

Chart illustrates, considerably less air is required to cool an IRt/c with a CJK-1 or CJK-2, than an IRt/c.5. For

this reason, the IRt/c is recommended for hot areas if it is possible to bring the sensor close to the target.

The air cooling chart extends above the recommended 450°F (230°C), and can be used there, but caution is

advised due to the possible effects of hot spots.

If air consumption is of concern, or if ambient temperatures are above 450°F (230°C), water cooling is recommended. A small amount of purge air is also recommended when water cooling (see Tech Note #15).

0

C Cooling Requirements

Air Cooling Chart

90

100

(psig)

10

CJK-1 or CJK-2

1

0 200 400 600

Ambient Temperature (

Chart applies to standard ovens. For

forced convection ovens, multiply air

pressure by 3, or add external sleeve

with insulating stagnant air gap.

180°C

IRt/c.xxx*

F

700

(kPa)

70

7

)

1000

0.01

Pressure (psig)

0.001

Air Flow Requirements

100

IRt/c Accessories

10

1

0.1

0.01 0.1 1 10

Flow (SCFM)

Air pressure required to cool IRt/c with CJK-1 or

CJK-2 at various ambient temperatures,

compared

to requirement for IRt/c models with built-in

air cooling.

*All other IRt/c’s with built-in air cooling.

To estimate air flow requirements, select the

pressure required from the Air Cooling Chart, and

read air flow above.

CORPORATION

51 Water Street, Watertown, MA 02172 USA

800-422-3006 • 617-923-9900 • Fax 617-923-9911

4949

49

4949

Page 3

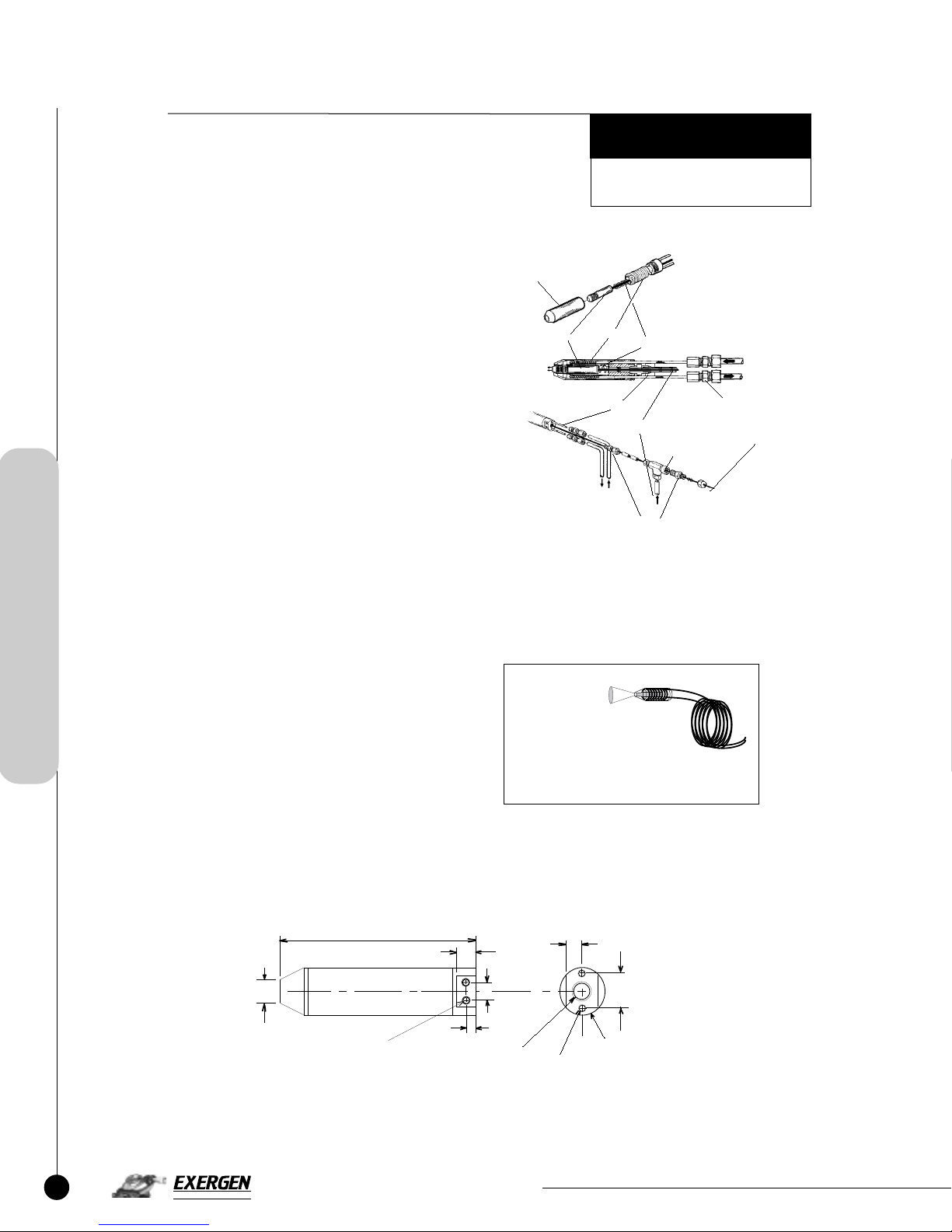

A convenient and inexpensive kit makes it possible

to use the IRt/c with air, water, or both for service in

harsh environments. Measuring only 1" x 4.16" (25 x

106 mm) overall, the CJK-1 is physically small

enough to fit into tight areas and closely monitor

process temperatures from the optimum position - up

close. With its all stainless steel housing, it can

withstand the harshest environments.

Extraordinarily efficient in design, the CJK requires

only .05 gpm (190 cc/min) of water and 0.1 CFM

(3000 cc/min) of air to protect an IRt/c at 1000°F

(540°C).

All Stainless Steel Housing

IRt/c.2

Purge Air Out

Cooling Jacket Kits

CJK-1

for IRt/c, IRt/c.3X, IRt/c.1X

Water/Air Cooling

WaterCoil

1/8" (3,2) Tubing

Spring

Purge Air In

Female Run Tee

Reducing Union

1/4 to 1/8

Thermocouple Wire

WaterIn

WaterOut

IRt/c Accessories

Features

• Small size - 1" dia. x 4.16" lg. (25 x 106mm)

• Stainless steel housing

• Seamless copper monotube cooling coil

• Complete equipment for air cooling and/or

water cooling

• Air purge included

• Super-efficient design for low air and water use

• Fits IRt/c, IRt/c.1X, IRt/c.3X

• Water cooling to 1000°F (540°C) with as little

as 0.05 gpm (190 cc/min) and 0.1 CFM (3000

cc/min) of air

CJK-1 Housing Dimensions

4.16 (105,6)

.595 (15,1)

Male Connector

Water Cooling Configuration.

All fittings required are supplied.

Water flow > .05 gpm (190 cc/min).

The water

cooling system

consists of a

seamless monotube, in order

to eliminate the possibility of

leaking joints. For convenience, the

seamless tubing extends 3 ft (1 m) from

the rear of the housing.

CJK-1

.44 (11,1)

.500 (12,7)

.372 (9,44)

.75 (19,05)

5050

50

5050

CORPORATION

51 Water Street, Watertown, MA 02172 USA

800-422-3006 • 617-923-9900 • Fax 617-923-9911

6-32 TappedHoles-4

.22 (5,56)

1/8 NPT

1.00 (25,4) O.D.

10-32 TappedHoles- 2

Page 4

Cooling Jacket Kits

CJK-2

For IRt/c.3X only

Air Only Cooling

Features

• Cooling up to 750°F (450°C)

• Small size - 1" dia. x 3" lg. (76 x 25.4mm)

• Stainless steel housing

• Available with brass or stainless fittings

• Air purge included

• Ultra-efficient design for low air consumption

and maximum cooling efficiency

• Side venting for variable air flow

IRt/c Accessories

CORPORATION

51 Water Street, Watertown, MA 02172 USA

800-422-3006 • 617-923-9900 • Fax 617-923-9911

5151

51

5151

Page 5

MB-1

Multi-Purpose Mounting

Bracket

IRt/c Accessories

IRt/c Accessories

APK-1, APK-2

Pumps for Purge Air

APK-1 120 V A C

APK-2 12 VDC

The convenient Air Pump Kit allows for fast and easy installation of

an air source suitable for maintaining optical cleanliness of IRt/c’s in

dirty, dusty environments. Its air flow is sufficient to keep up to five

IRt/c.2, or one IRt/c.5 clean. Additionally, the air flow is sufficient to

allow an IRt/c.2 to operate in ambients up to 240°F (115°C). The

pump can be mounted on either horizontal or vertical surfaces.

Specifications:

•

Air Pump - 120VAC, 120 cu.in./min (1960cc/min). Available in

12VDC.

•

Vinyl Tubing - 10 ft (3m), .25" (6mm) OD, .17" (4mm) ID.

•

Standoff Mounts - allow pump to be secured vertically or

horizontally.

5252

52

5252

CORPORATION

51 Water Street, Watertown, MA 02172 USA

800-422-3006 • 617-923-9900 • Fax 617-923-9911

Page 6

•

Easy Installation of IRt/c, with up to 1000'

(300 m) Extension Cable

•

Connector Ground Protects Against Electrical

Noise Errors

•

Write-On Area for Easy Identification

•

Superior Mechanical Connection Prevents

Signal Loss due to Vibration or Wire Movement

•

Rugged Glass-Filled Nylon Shell Rated to

425°F (218°C)

•

High Purity Thermocouple

Alloy Pins and Sockets

•

Available in J, K, E, T Types

The new IRt/c miniature low noise

connectors are designed to provide

an easy connection of ground wires

to IRt/c’s and extension wire. The

drain wire of a 20 AWG twisted

shield cable or the shield of the

overbraided wire is crimped and

held in place by the internal

hardware. They have excellent

thermal and electrical characteristics

IRt/c Accessories

Connector Kit

Thermocouple Connectors

with Shield

to assure high accuracy. Each connector includes a

write-on insert and an external ground strap to

maintain the electrical connection of the ground wire

and strengthen the mechanical connection between

connectors.

(.8)

1/32

1/8

5/16

(7.9)

(3.2)

MALE

0.1 DIA.

(2.5)

3/16

(3.2)

(4.8)

3/32

5/16

(7.9)

Ground Strap

(31.8)

1-1/4

(2.4)

1/8

3/8

5/16

(9.5)

(7.9)

(36.5)

1-7/16

9/32

(7.1)

(16.7)

21/32

FEMALE

DIMENSIONS

IN INCHES

(mm)

IRt/c Accessories

•

Twisted Shielded Pair for High Noise Rejection

•

Can Be Used Up To 1000' (300 m) Length

•

FEP Teflon Jacket/Insulators Service Temperature to 392°F

(200°C)

•

Highest Accuracy - Thermocouple

Grade Wire

•

Available In J, K, E, T Types

Although commonly available thermocouple extension wire may be used with

IRt/c’s, twisted shielded pair wire is

preferred due to its much superior noise

rejection characteristics. This feature is

particularly important when using IRt/c’s

with long extensions in electrically noisy

environments, due to the relatively high

impedance of IRt/c’s compared to

ordinary thermocouples.

TeflonOuter Jacket

Tefloninsulators

Full Foil Shield

Shield Drain Wire

T/C Cable

Twisted Shielded Pair

Extension Cable

Type

J White

K Yellow

E Purple

T Blue

24 AWG Stranded Leads/

Thermocouple Grade

(-) Red

Twisted

CORPORATION

51 Water Street, Watertown, MA 02172 USA

800-422-3006 • 617-923-9900 • Fax 617-923-9911

5353

53

5353

Page 7

Gooseneck Mounting Kit

For fast and convenient mounting of IRt/c’s, especially for testing, the

Gooseneck Mounting Kit provides an inexpensive method to quickly

install an IRt/c directly on the production line. Its heavy duty design

provides excellent stiffness for reliable positioning. Clamps are fabricated

of aluminum for durable performance. The sensor clamp fits all IRt/c

models (the MB-1 Mounting Bracket is required for Adjustable IRt/c

models),

IRt/c Accessories

GMK-1

For fast, con venient testing

of IRt/c’s

5454

54

5454

CORPORATION

51 Water Street, Watertown, MA 02172 USA

800-422-3006 • 617-923-9900 • Fax 617-923-9911

Loading...

Loading...