Page 1

D501

Microscanner

D-Series

D501-RS

™

High-Performance Models

Instruction Manual

Page 2

Welcome to Infrared!

Exergen’s high-performance microprocessor-based infrared thermometers

have been designed to provide you with new dimensions of accuracy and

versatility. They literally put the power and speed of infrared in your hand!

By combining computer calibration and advanced software technology with

our patented Automatic Emissivity Compensation System, this generation

of Microscanner™ D-Series provides precision temperature measurements

over a wide range of environmental and target temperatures.

For added versatility, your high-performance Microscanner™

D-Series features:

• Full range resolution to 0.1 °F or °C

• SCAN, MAX and MIN modes of operation

• A 10-second display lock

• An audible beeper to signal functional or conditional changes

• Fahrenheit/Celsius Conversion

This manual provides complete instructions on how to operate and use

your Microscanner - the fastest, most accurate instrument for measuring

temperature available.

Table of Contents

Operation and Controls 1

Understanding How Your Microscanner™ Operates 2

Taking Exact Temperature Measurements 3

Moving Targets 3

High Temperature Targets 4

Thermal Scanning 5

Measuring Relative Humidity 6

Display Messages 7

Helpful Hints 8

Maintenance 9

Troubleshooting 10

Warranty & Repair 10

Specifications 11

Page 3

Operations and Controls

Your high-performance Microscanner™ D-Series is equipped with an ON/OFF

power pushbutton and a mode selector switch. The mode selector switch allows

you to choose one of three modes of operation: SCAN, MAX or MIN.

On/Off, Lock and Reset:

• TO TURN the unit ON, PUSH and HOLD the ON/OFF power pushbutton.

The display will momentarily read 8888, an indication that the microprocessor is performing its self-diagnostic testing. After the test, the unit will

measure and display temperature in the selected mode of operation for

as long as the power button is depressed.

• RELEASE the power pushbutton TO LOCK the display on the last reading.

A single beep will audibly indicate that the display is locked. The instrument will hold the last reading on the display for 10 seconds before it

automatically turns itself OFF.

• To RESET the display and initiate a new set of readings, PUSH the power

pushbutton at any time.

Operation Mode:

• SCAN - In the SCAN mode, the target’s instantaneous temperature is

continuously displayed and updates 10 times per second for as long as

you hold the power button down. After you release the power button, the

display will lock on the last temperature measured and hold that reading

for 10 seconds.

• MAX - In the MAX mode, the display will lock on the highest temperature

measured for as long as you hold the power button down. Each time a

new peak temperature is measured or repeated an audible beep will

sound. After you release the power button, the display will lock on the

maximum recorded temperature and hold that reading for 10 seconds.

• MIN - In the MIN mode, the display will lock on the lowest temperature

measured for as long as you hold the power button down. Each time

a new low temperature is measured or repeated, an audible beep will

sound. After you release the power button, the display will lock on the

minimum recorded temperature and hold that reading for 10 seconds.

1

Page 4

Understanding How Your

Microscanner™ Operates

The ability of an infrared thermometer to measure an accurate temperature depends

on the following:

1. The ability of the object’s surface to emit heat.

In general, infrared thermometers can easily measure non-metallic surfaces

because they emit most of their potential heat. Metallic surfaces, on the

other hand, are poor emitters and require special treatment before infrared

thermometers can accurately measure their tem perature. Fortunately, that

special treatment is simple and can be easily accomplished by mark ing the

metallic surface you wish to measure with a non-metallic substance such as

paint, grease, oil or even transparent tape. We recom mend marking metallic

surfaces with a solid paint marker.* To make things easy, Exergen provides a

marker with each unit.

* It is only necessary to mark an area slightly larger than your Microscanner’s nosepiece. In the MAX

or MIN mode you may want to check several points over an area. In this case, it may be more efficient

to coat the entire area with a non-metallic finish.

2. The ability of the instrument to properly detect and interpret the

object’s emitted heat signal.

Measuring and interpreting an object’s emitted heat signal can be complex.

Once again, Exergen’s innovative design makes it simple.

If you look at the Microscanner’s nosepiece, you will see that it is really

a small reflective cup with the sensor’s window at its base. When the

Microscanner’s nosepiece touches the surface of an object, that reflective

cup automatically controls what the sensor sees by eliminating variables

such as target emissivity and extraneous radiation. Patented by Exergen as

our Automatic Emissivity Compensation System (AECS), this unique design

ensures ac curate readings every time.

2

Page 5

Taking Exact Temperature

Measurements

CAUTION...Shock Hazard.

Do Not Touch the Instrument to

Electrical Conductors*

The Microscanner™ D-Series measures tem perature very quickly.

An accurate reading is almost instantaneous. It is only necessary to touch

the surface for a fraction of a second.

For exact surface temperature measurements, simply:

• Press the power button

• Touch the nosepiece to the target surface**

• Read the temperature on the LED display

• Release the power button

* Exergen manufactures specific instruments for safe and conve nient inspection of electrical

equipment. If electrical inspection is of particular importance, contact Exergen for more informa tion

relative to the dedicated electrical inspection instruments.

** If the surface is metallic, be sure to mark it as previously described (see pg. 2).

Taking Exact Temperature of

Moving Targets

For moving targets which are not possible to touch even for an instant, simply

• Set slide switch to MAX for targets warmer than ambient, or MIN for

targets cooler than ambient.

• Point at target

• Press the power button

• Bring nosepiece as close as possible to the target, preferably within

1/32 inch (1mm)

• Release power button

• Read the temperature

3

Page 6

High Temperature Targets

When using the D501 on high tem perature targets, momentarily touch the target’s

surface - a fraction of a second is long enough to get an accurate reading.

If these instruments are used in contact with a hot surface for an extended

time (10 seconds or more) the target’s heat will be conducted into the nosepiece. Although this will not harm the unit, the indicated temperature may be a

few degrees too high. If this happens, allow a few minutes between readings

for the nosepiece to cool down and stabilize.

If the instrument is used in contact with a hot surface and the display

message reads (HI), remove the instrument from the object immedi ately.

At a distance, the D-Series operates as a high-speed infrared

scanning thermometer.

Contact the nosepiece to the surface and the D-Series will display

an accurate surface temperature.

4

Page 7

Thermal Scanning

The high-performance Microscanner™ D-Series can also be used to

measure tempera tures at a distance.

When not touching or close to a surface:

• The Microscanner™ is a wide-angle ther mal scanner with a fixed

emissivity of .98.

• The displayed reading is an average tem perature of everything that the

sensor sees within its field of view.

Thermal scanning is very useful in many applications such as evaluating

insulation, monitoring machinery, and inspecting electrical equipment.

The MAX or MIN modes of operation can be particularly useful in thermal

scanning. The highest (or lowest) temperature measured dur ing a scan is

indicated by the audible beeper. Once a hot spot (or cold spot) is identified,

the exact temperature of that spot can be measured by touching the

surface as previously ex plained.

When using the D-Series as a scanner, keep the following in mind:

• The instrument’s field of view is 1:1. Also referred to as a distance-tospot ratio, 1:1 field of view means that the sensor sees a cir cular area

with a diameter equal to the distance between the sensor and target.

For example, at a 6-inch distance, the sensor sees a 6-inch diameter

spot; at a 10-foot distance, the sensor sees a 10-foot diameter spot.

• The Microscanner™ measures the average temperature of everything

in its field of view.

• A small hot spot may get lost in a large viewing area. The closer you

hold the instru ment to a surface, the better its target resolu tion.

5

Page 8

Measuring Relative Humidity with the

Microscanner™ D501

A unique benefit of the Microscanner™ D501 is its ability to measure wet

and dry bulb tem peratures faster and more accurately than ever before.

A Relative Humidity Kit is available as an accessory. Contact Industrial Sales

Customer Support for more information. This kit is comprised of a calculator

card and a tube of water. The calculator card incorporates two circular

membranes, an RH calculator and a Dew Point calculator.

The Microscanner™ is used to measure the wet bulb and dry bulb

temperatures of the atmo sphere. From these two temperatures, both the

relative humidity and the dew point can be calculated.

To calculate Relative Humidity:

1. Wet the absorbent membrane identified as WET with a few drops of water

(a small tube of tap water is provided with the kit).

2. Rapidly wave the card in the air for several seconds. This assures that the

water on the wet membrane is evaporating at its maximum rate.

3. With the Microscanner™ in the MIN mode, quickly measure the

temperature of the WET membrane immediately after you stop waving it.

This is the atmosphere’s wet bulb temperature.

4. Set the Microscanner™ in the SCAN mode and measure the DRY spot.

This is the atmo sphere’s dry bulb temperature.

5. Use the calculator card as directed to com pute the relative humidity and

dew point.

Fahrenheit to Celsius Conversion

The D501 Microscanners™ are equipped with a convenient method for

Fahrenheit/Celsius conversion:

1. Find the small hole on the left side of the red display filter.

2. Insert the end of a straightened paper clip into the hole and push to

activate the small switch underneath.

3. While holding the paper clip pressed into the switch, turn the instrument on

by pressing the red POWER ON button.

4. Remove the paper clip.

5. The instrument now reads °C instead of °F. To return to the original

setting, simply repeat the process. Each time you repeat the process, the

instrument switches between °F and °C.

6

Page 9

The Display Messages

The high-performance D-Series Microscanner™ continuously monitors its

ability to pro duce accurate temperature readings. If either the target’s

temperature or the unit’s ambient temperature exceeds the operational

limits, the beeper will sound one beep per second and the LED display will

default to a display message.

For example, the D501 is designed to display temperature only if that

temperature is within its specified measure ment range. If the target

temperature is greater than 565°F (296°C), the display will read “HI.”

The battery voltage is also monitored. A low battery is indicated by a double

beep each second. Temperatures will continue to be displayed as long as

accuracy can be assured. If the battery drops below 5.7 volts the battery is

considered “dead” and the display defaults to [----].

If a problem is discovered during the initial self-diagnostic test, the instrument will display an error message (E-01), (E-02), etc. If any (E-##) error

message is displayed, the unit will not function and must be returned to the

factory for repair. (See section on Warranty for return instruction).

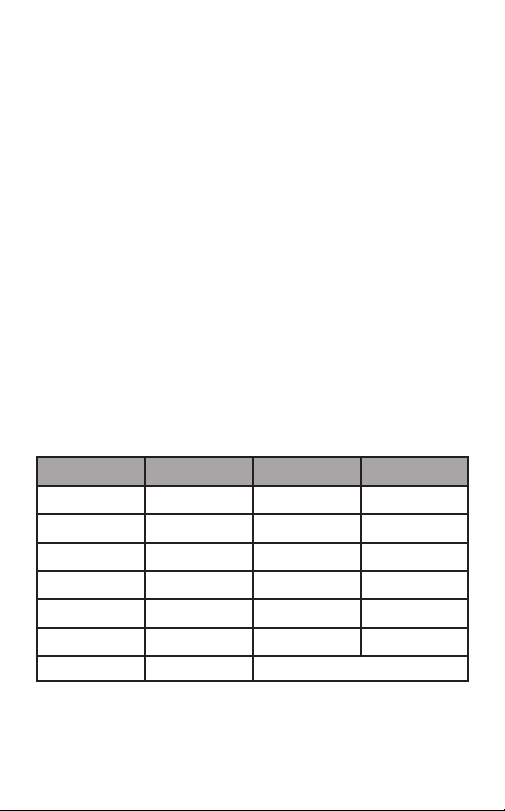

The following chart summarizes the fault conditions, and the

associated indications:

Condition Display Sound Range

High Target

Low Target

High Ambient

Low Ambient

Low Battery

Dead Battery

Processing Error

[HI] 1/sec >565°F (296°C)

[LO] 1/sec <-65°F (-54°C)

[HI A] 1/sec >122°F (50°C)

[LO A] 1/sec <32°F (0°C)

2/sec <6.2v

[----] 2/sec <5.7v

[E-##] Return Instrument to Exergen for Repair

7

Page 10

Helpful Hints

Although transparent materials pass vis ible light, many visible transparent

materials are opaque in the infrared and can be directly measured by the

Microscanner™ D-Series.

To test for infrared transparency, touch the Microscanner™ to the surface

and pass a heat source, such as your hand, through the sensor’s field of

view on the other side of the material. If the Microscanner™ responds to the

heat source, the material is transparent in the infrared.

To measure a transparent surface, use one of the following techniques:

1. Mark the surface with an opaque nonmetal lic coating.

2. Put a shiny metallic surface such as alumi num foil behind the transparent material. The shiny metal will reflect the transparent materi al’s heat

back to the Microscanner™.

Wet or icy surfaces may interfere with the Microscanner’s readings. Water

and other liquids are good targets, but evaporation lowers their surface

temperatures.

Frost forms on a surface at the freezing point of water. Frozen foods or

similar targets will form frost unless the environment is controlled. If frost

forms, the Microscanner™ will read the temperature of the frost instead of

the subsur face (object’s) temperature.

Melting ice will read slightly higher than 32°F (0°C) because the instrument

actually measures the air condensing on the ice, a reaction which generates

a small amount of heat. As long as the ice is not melting, the Microscanner™ will ac curately read its temperature. For true object temperature,

remove any ice or moisture before measuring.

8

Page 11

Maintenance

The high performance Microscanner™ D-Series products are rugged and

durable instruments. They are designed to be used as a tool with long

temperature measurement reliability.

• Calibration

Calibration is performed by a computer through an optical link with the

unit’s micro processor. Because there are no mechanical adjustments,

the instrument is able to maintain its calibration through normal use.

• Cleaning

The only maintenance required is to keep the sensor window clean. This

window, located at the base of the nosepiece’s reflective cup, is made of

a special crystal which passes infrared heat. Dirt, greasy films or moisture

on the win dow will interfere with the passage of infrared heat and affect

the accuracy of the instrument. If necessary, clean the sensor window

and reflective cup with a cotton swab dipped in alcohol or water. Periodic

cleaning is a good practice. When not in use, store in a clean environment.

• Battery

The battery is accessed by removing the instrument’s cover. Loosen the

four screws on the body of the instrument to remove the cover.

9

Page 12

Troubleshooting

If the accuracy of the measurement is in ques tion, check the following:

Is the sensor window clean?

Check the sensor window and reflective cup for cleanliness and remeasure.

Is the target’s surface non-metallic?

Coat metallic surfaces with a non-metallic finish and remeasure.

Is the target’s surface transparent?

• Coat transparent surfaces with an opaque non-metallic finish and

remeasure.

• Put a shiny metallic surface such as aluminum foil behind the

transparent target and remeasure.

Was the instrument’s nosepiece in contact with the surface?

Touch the nosepiece flush to the target’s surface and remeasure.

If after applying all of the above solutions the instrument’s accuracy is still

in question, contact Exergen for further directions.

Warranty

Exergen warrants the Microscanner™ D-Series to be free of defects in

material and workmanship for a period of one year from the date of

purchase, and will repair or replace the returned instrument (at Exergen’s

discretion) at no charge during the period. No other warranties are implied.

If repair is required:

• Contact the factory for a Return Material Authorization (RMA) Number.

• Mark the RMA number on both the shipping box and the packing slip.

• Include a description of the unit’s problem.

• Ship the instrument prepaid. Exergen will return ship prepaid.

• After you have received an RMA Number, send to:

Exergen Corporation

Repair Department

400 Pleasant Street

Watertown, MA 02472 U.S.A.

10

Page 13

Specifications

Target Temperature Range

D501: -50°F to 550°F or -45°C to 287°C

Absolute accuracy for any non-metallic, non transparent surface

+/- (1 + 0.02 (Reading less ambient)) deg F

+/- (0.6 + 0.02 (Reading less ambient)) deg C

Minimum spot size diameter Approx. ¼” (6.4mm)

Repeatability +/- .02% of absolute temperature

Display Resolution 0.1°F or 0.1°C

Display Update 10 times /second

Response Time Constant 60 mSec

Field of View 1:1 (53 degrees)

Spectral Sensitivity 2 to 20 microns

Battery One 9 volt alkaline

Battery life 5000 readings (10 seconds each)

Instrument Ambient Temperature

Operating Range: 32° to 122 °F (0° to 50 °C)

Storage Range: -22° to 140 °F (-30° to 60 °C)*

*Extended storage at temperature extremes will reduce battery life.

11

Page 14

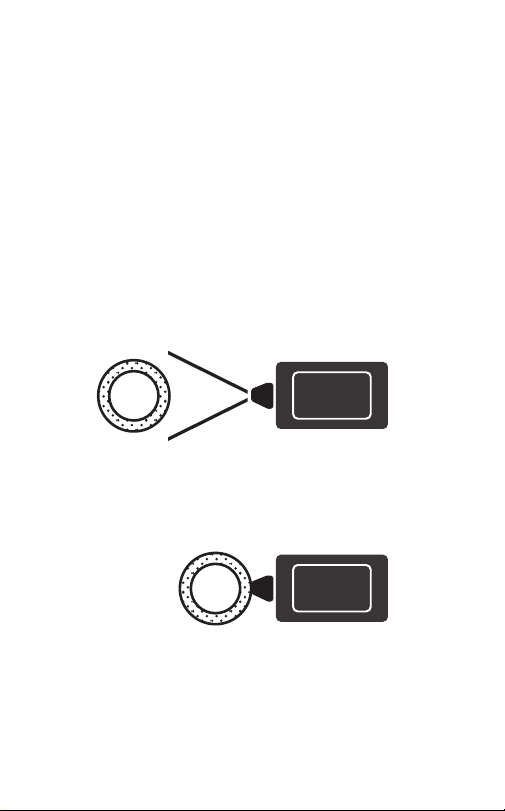

Microscanner™ D-Series - Features Overview

Model D501

Sensor Window

Nosepiece with

Reflective Cup

(AECS)

Mode

Selector

Switch

On/Off Power

Pushbutton

High-impact

ABS Case

Digital LED

Display

Page 15

Microscanner™ D-Series - Features Overview

Model D501-RS

Remote

Sensor

Probe

Page 16

Microscanner™ D-Series

Exergen Corporation

400 Pleasant Street

Watertown, MA 02472 U.S.A.

617-923-9900

www.exergen.com

818098 Rev 3

Loading...

Loading...