Page 1

EXERGEN

51 Water Street • Watertown, MA 02472

Phone: 617-923-9900 Fax: 617-923-9911

www.exergen.com

e-mail: industrial@exergen.com

DX SERIES

Handheld Infrared

Thermometers

User’s Guide

Page 2

Page 3

Table of Contents

Chapter One - Welcome to Infrared Thermometry . . . .1

1.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . .1

1.2 Product Features . . . . . . . . . . . . . . . . . . . . . . .1

1.3 Models and Ordering Information . . . . . . . . . . .1

Chapter Two - Operation . . . . . . . . . . . . . . . . . . . . . . .2

2.1 DX Controls . . . . . . . . . . . . . . . . . . . . . . . . . . .2

2.2 To Change Display Measurement Units . . . . . .2

2.3 To Change Mode of Operation . . . . . . . . . . . . .3

2.4 Temperature Measurements . . . . . . . . . . . . . . .3

2.4.1 General Operation . . . . . . . . . . . . . . . . .3

2.4.2 Temperature Measurement of

Moving Targets . . . . . . . . . . . . . . . . . .4

2.4.3 High Temperature Targets . . . . . . . . . . .4

2.5 MAX Mode Temperature Measurements . . . . . .4

2.5.1 General Operation . . . . . . . . . . . . . . . . .4

2.6 SCAN Mode Temperature Measurements . . . . .5

2.6.1 General Operation . . . . . . . . . . . . . . . . .5

Chapter Three - Measurement Tips . . . . . . . . . . . . . . . .5

3.1 Optimizing Target Area Measurements . . . . . . .5

3.2 Measuring Metallic Targets . . . . . . . . . . . . . . . .6

3.3 Optimizing AESC Measurements for

NIST Traceability . . . . . . . . . . . . . . . . . . . . . . .6

3.4 Measuring Transparent Materials . . . . . . . . . . .6

3.5 Measuring Wet or Icy Surfaces . . . . . . . . . . . . .6

Chapter Four - Maintentance . . . . . . . . . . . . . . . . . . . . .7

4.1 Battery Replacement . . . . . . . . . . . . . . . . . . . .7

4.2 Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

4.3 Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

4.4 Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Chapter Five - Troubleshooting . . . . . . . . . . . . . . . . . . .7

5.1 Diagnostic Codes . . . . . . . . . . . . . . . . . . . . . . .7

5.2 Troubleshooting Measurement Difficulties . . . . .9

Chapter Six - DX™ Specifications . . . . . . . . . . . . . . . . .9

Chapter Seven - Warranty . . . . . . . . . . . . . . . . . . . . . . .10

Page 4

Chapter One - Welcome to Infrared

Thermometry

1.1 Introduction

Exergen Corporation, the world's leading manufacturer of

infrared temperature systems, presents the low cost DX

Series™ of hand held infrared thermometers. These dualpurpose systems function as both NIST traceable temperature calibrators and thermal scanning devices. Make fast,

accurate, and reliable temperature measurements using

advanced non-contact IR technology.

Meet your company's product quality conformance needs

with the DX's patented Automatic Emissivity Compensation

System (AECS). In this mode, the unit will provide precision temperature measurements of spot targets, without

knowing the target's emissivity value, and without errors

caused by other sources of incident radiation. Since the

DX is NIST traceable, it can function as a primary temperature calibrator for other temperature measuring devices,

serving your corporate quality instrument calibration programs. Operate the DX in SCAN mode, for thermal scanning measurements over a range of target temperatures.

Thermal Scanning is very useful in many applications such

as evaluating insulation, monitoring machinery, and inspecting electrical equipment. Or the DX may be operated in the

MAX mode where the highest temperature measured while

monitoring is presented.

This manual provides complete instructions on how to operate and use your DX--to provide fast, accurate, reliable

temperature measurements for your application needs.

1.2 Product Features

Designed for ease of use and measurement flexibility, the

DX features:

• Dual purpose, AECS as well as MAX and SCAN

measurement modes

• Measurement resolution to 0.1 °F or 0.1°C

• Factory calibration for precise results

• A 10 second display reading hold

• Internal self test and error diagnostic codes to insure

proper function

1.3 Models and Ordering Information

DX 501 -50 to 550°F (-45 to 287°C) Unit includes a 9 V

DC Alkaline Battery and DX Instruction Manual.

Also available with a Remote Sensor, RS232

Digital Output and an Analog Output.

DX 1001 0 to 1000°F (-18 to 538°C) Unit includes a 9 V

DC Alkaline Battery and DX Instruction Manual.

Also available with a Remote Sensor, RS232

Digital Output and an Analog Output.

DX 1201 0 to 1207°F (86 to 653°C) Unit includes a

Remote Sensor, 9 V DC Alkaline Battery and DX

Instruction Manual. Also available with an RS232

Digital Output and an Analog Output.

1

Page 5

DX 1601 0 to 1600°F (86 to 871°C) Unit includes a

Remote Sensor, 9 V DC Alkaline Battery and DX

Instruction Manual. Also available with an RS232

Digital Output and an Analog Output.

Chapter Two - Operation

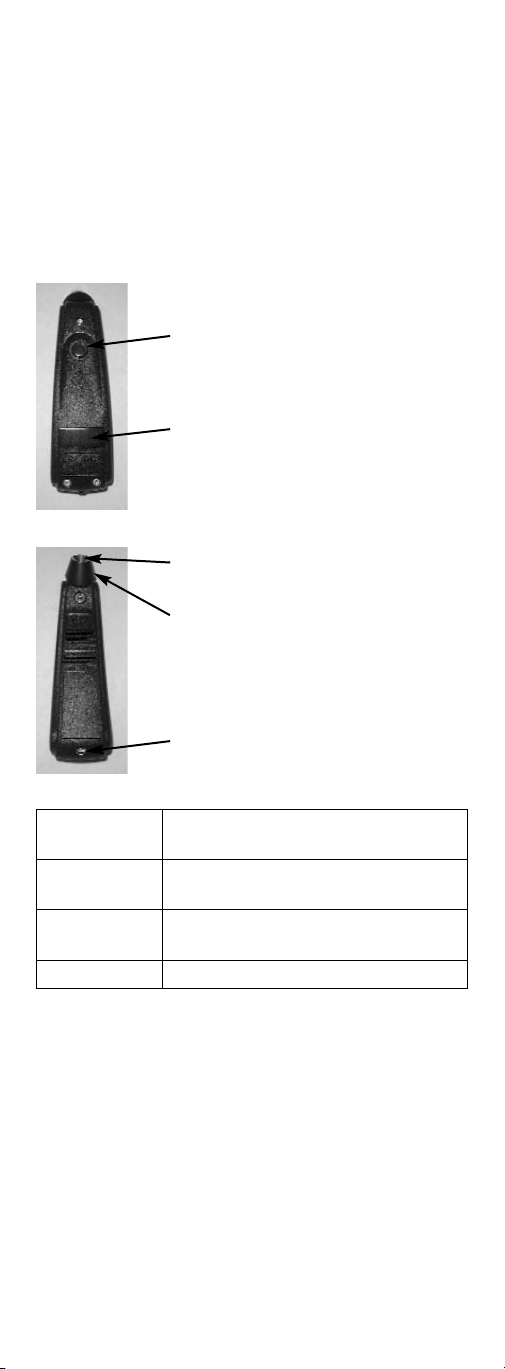

2.1 DX Controls

2.2 To Change Display Measurement Units

The DX Models come from the factory displaying temperature in units of Fahrenheit. To display readings in units of

Celsius, perform the following steps:

1. Remove the screw from the underside of the case.

2. Remove the cover, exposing the battery area.

3. Locate the push button switch as shown in the picture.

4. With the unit off (display is blank), push the push button in.

5. Holding the push button in, turn the unit on with the

MEASUREMENT button.

LED Display

MEASUREMENT

button

LED Display

Sensor Window

AECS Cup

Battery Cover

Screw

Displays target temperature and diagnostic codes

Measurement

button

To turn on and start temperature measurement

Nosepiece

w/AECS cup

Sensor window

Automatic emissitivity compensation

system nosepiece to contact target

Sensor viewing area for IR detector

2

Page 6

The instrument now reads in °C instead of °F. To return to

the original setting, simply repeat the process.

2.3 To Change Mode of Operation

The DX Models come from the factory operating in the MAX

mode. To change to the SCAN mode perform the following

steps:

1. Remove the screw from the underside of the case.

2. Remove the cover, exposing the battery area.

3. Locate the slide switch as shown in the picture.

4. Change the position of the slide switch from 1 to ON.

The unit will now operate in the SCAN mode. ON Î SCAN,

1 Î MAX.

2.4 Temperature Measurements

2.4.1 General Operation

CAUTION... SHOCK HAZARD

DO NOT TOUCH THE INSTRUMENT

TO ELECTRICAL CONDUCTORS*

The DX™ measures temperature very quickly. To obtain an

accurate measurement, it is only necessary to touch the

surface for a fraction of a second.

For exact surface temperature measurements that are NIST

traceable, use the following procedure:

1. Press and hold the MEASURE button.

2. The display will briefly show [8888].

3. Touch the nosepiece to the target surface.

4. The display may or may not change, but the "beeping"

sound will indicate that measurements are being

made.

5. Record the temperature from the display.

6. Release the MEASURE button. The last reading will

remain locked on the display for 10 seconds after

releasing the button.

*If the target is electrical equipment, Exergen manufactures

the Model E Microscanner instruments for safe andconvenient inspection of electrical equipment. Contact Exergen

for more information on the Model E line of instruments and

electrical inspection. If the surface is metallic, be sure to

mark it as described in the Measurement Tips section in

Chapter Three.

ºF/ºC Switch

MAX/SCAN Switch

3

Page 7

2.4.2 Temperature Measurement of Moving

Targets

To measure moving targets that are not possible to touch,

use the following procedure:

1. Press and hold the MEASURE button.

2. The display will briefly show [8888].

3. Bring the nosepiece as close as possible to the target,

preferably within 1/32 inch (1 mm). **

4. The display may or may not change, but the "beeping"

sound will indicate that measurements are being

made.

5. Record the temperature from the display.

6. Release the MEASURE button. The last reading will

remain locked on the display for 10 seconds after

releasing the button.

** If the surface is metallic, be sure to mark it as described

in the Measurement Tips section in Chapter Three.

2.4.3 High Temperature Targets

When using the DX™ to measure high temperature targets,

above 100 °F, quickly touch the target's surface -- one second is long enough to get an accurate reading.

Follow the procedures described above under 2.4.1

General Operation (see pg. 5). If the DX makes contact

with a hot surface for an extended time (10 seconds or

more) the target will conduct heat. Although this will not

harm the unit, the indicated temperature may be a few

degrees too high. Allow a few minutes between readings

for the nosepiece to cool down and stabilize.

If the DX makes contact with a hot surface and an error

message [HI] shows on the display remove the instrument

from the object immediately.

2.5 MAX Mode Temperature Measurements

Use this measurement mode when making contact with the

target or when the target is large. The DX is a wide-angle

thermal scanner with a fixed emissivity of 0.9. The target's

temperature is continuously displayed and updated 10

times per second for as long as you hold the MEASURE

button down.

The DX displays the average temperature of everything

within the sensor's field of view measurement area. The

size of the measuring area depends on the distance of the

device from the target. The DX has a 1:1 field of view,

which means that this unit will measure a 1"diameter target

area when the device is 1" from the target.

2.5.1 General Operation

For continuous temperature measurement of a target or for

temperature measurement at a distance, use the following

procedure.

1. Determine the appropriate measurement distance from

your desired target. Best measurements are made

when the DX is in contact with the target.

2. Make sure the MODE switch is on MAX.

3. Point the nosepiece at the target.

4. Press and hold the MEASURE button.

4

Page 8

5. Record the temperature from the display.

6. Release the MEASURE button. The last reading will

remain locked on the display for 10 seconds after

releasing the button.

2.6 SCAN Mode Temperature Measurements

Use this measurement mode for thermal scanning of a target or when measuring targets located at a distance. The

DX is a wide-angle thermal scanner with a fixed emissivity

of 0.9. The target's temperature is continuously displayed

and updated 10 times per second for as long as you hold

the MEASURE button down.

The DX displays the average temperature of everything

within the sensor's field of view measurement area. The

size of the measuring area depends on the distance of the

device from the target. The DX has a 1:1 field of view,

which

means that this unit will measure a 1"diameter target area

when the device is 1" from the target.

2.6.1 General Operation

For continuous temperature measurement of a target or for

temperature measurement at a distance, use the following

procedure.

1. Determine the appropriate measurement distance from

your desired target.

2. Make sure the MODE switch is on SCAN.

3. Point the nosepiece at the target.

4. Press and hold the MEASURE button.

5. Record the temperature from the display.

6. Release the MEASURE button. The last reading will

remain locked on the display for 10 seconds after

releasing the button.

Chapter Three - Measurement Tips

3.1 Optimizing Target Area Measurements

When performing a continuous thermal scan of a target, or

measuring a target located at a distance, proper target

alignment will help assure accurate results. Since the DX's

sensor measurement area is fixed at a field of view of 1 to

1, it is important to properly determine the best measuring

distance from the target, to optimize the reading. A field of

view of 1 to 1 means that the DX’s viewing area is 1" diameter for 1" distance from target. Optimize optical alignment,

so that the DX views only the target and does not overlap

the measurement area. See Figure below for examples of

proper optical alignment.

5

POOR POOR GOOD

Page 9

3.2 Measuring Metallic Targets

In general, infrared thermometers can easily measure nonmetallic surfaces because they emit most of their potential

heat. Metallic surfaces, on the other hand, are poor emitters and require special treatment before infrared thermometers can accurately measure their temperature.

Fortunately, that special treatment is simple and can be

easily accomplished by marking the metallic surface you

wish to measure with a non-metallic substance such as a

solid paint marker. Other substances such as grease, oil,

or tape may also be used. It is only necessary to mark an

area slightly larger that the DX nosepiece, when operating

in AECS mode. When operating in MAX or SCAN modes,

mark the appropriate target area for the measuring distance

from the target, based on a 1 to 1 Field of View.

3.3 Optimizing AESC Measurements for

NIST Traceablity

If you look at the DX's nosepiece, you will see that it is really a small reflective cup with the sensor's window at its

base. When the DX's nosepiece touches the surface of an

object, that reflective cup automatically controls what the

sensor sees by eliminating variables such as target emissivity and extraneous radiation. Patented by Exergen as

the Automatic Emissivity Compensation System (AECS),

this unique design ensures accurate readings every time.

To optimize results, make sure that the nosepiece is flush

with the target when possible, so that the reflective cone

can complete trap out any light or incident radiation from

the environment.

3.4 Measuring Transparent Materials

Although transparent materials pass visible light, many visibly transparent materials are opaque in the infrared and

can be directly measured by the DX.

To test for infrared transparency, touch the DX to the target's surface and pass a heat source such as your hand or

a penlight through the sensor's field of view on the other

side of the material. If the DX responds to the heat source,

the material is transparent in the infrared, and requires

marking the surface for proper measurement. Mark the

surface with an opaque non-metallic coating, such as paint

or grease.

Alternatively, place a shiny metallic object, such as aluminum foil, behind the transparent material. The shiny

metal will reflect the target's heat back to the DX.

3.5 Measuring Wet or Icy Surfaces

Wet or icy surfaces may interfere with the DX's readings.

Water and other liquids are good targets, but evaporation

lowers their surface temperatures.

Frost forms on a surface at the freezing point of water.

Frozen foods or similar targets will form frost unless the

environment is controlled. If frost forms, the DX will measure the temperature of the frost instead of the object's temperature.

Melting ice will read slightly higher than 32 °F (0°C)

because the instrument actually measures the air condensing on the ice, a reaction that generates a small amount of

6

Page 10

heat. As long as the ice is not melting, the DX will accurately read its temperature.

To make an accurate target measurement, remove any ice

or moisture before measuring.

Chapter Four - Maintenance

The high-performance DX is a rugged and durable instrument, designed for long term performance reliability.

4.1 Battery Replacement

Open the instrument's cover to access the battery by loosening the screw on the back of the instrument. Remove the

old battery and replace it with one fresh, 9 V alkaline battery. Align the battery contacts as indicated on the case.

4.2 Cleaning

The only maintenance required involves keeping the sensor

window clean. This window, located at the base of the

nosepiece's reflective cup, is made of a special crystal that

passes infrared heat. Dirt, greasy films, or moisture on the

window will interfere with the passage of infrared heat and

affect the accuracy of the instrument.

If necessary, clean the sensor window and reflective cup

with a cotton swab dipped in alcohol. Periodic cleaning is a

good practice.

4.3 Storage

When not in use, store the DX in a container, to protect the

unit from dirt and dust. Do not store the unit in areas of

extreme heat, cold, or humidity. If not using the DX for a

long period, remove the battery from the unit.

4.4 Calibration

The DX is factory calibrated under high quality standards.

Because there are no mechanical adjustments, the instrument is able to maintain its calibration through vibration and

normal use. No field calibration is necessary.

Chapter Five - Troubleshooting

5.1 Diagnostic Codes

The high-performance DX™ continuously monitors its ability

to produce accurate temperature readings. If either the target's temperature or the unit's ambient temperature

exceeds the operational limits, the display will default to an

error message.

The battery voltage is also monitored. A low battery is indicated by a separate error code. The unit will continue to

operate as long as accuracy can be assured. If the battery

drops below 5.7 volts, the battery is considered "dead" and

the display defaults to [----].

7

Page 11

If the [E-##] or [Err] error messages are displayed, the unit

will not function and must be returned to the factory for

repair. (See section on Warranty for return instruction).

The following charts summarize the fault condition, and the

associated indication.

5.2

Model DX 501 [LO] Target < -50 °F

(-45 °C)

Contact

Exergen

Model DX 1001 [LO] Target <0 °F (-

18 °C)

Use lower DX

Model DX 1201 [LO] Target <186 °F

(86 °C)

Use lower DX

Model DX 1601 [LO] Target <186 °F

(86 °C)

Use DX 501

or DX 1001

Low Target Temperature

Condition Error

Code

RemedyMeasurement

Fault

High Ambient

Temperature

[HI A] Ambient > 122

°F (50 °C)

Move to

alternate

location

Low Ambient

Temperature

[LO A] Ambient < 32

°F (0 °C)

Move to

alternate

location

Low Battery [N/A] Battery power

low

Replace

battery

Dead Battery [----] Dead battery Replace

battery

Other Errors

Condition Error

Code

RemedyMeasurement

Fault

Processing

Error

[E-##]

or [Err}

Internal fault

Repeat

measurement,

if error

remains,

contact

Exergen

8

Model DX 501 [HI] Target >550°F

(287 °C)

Use higher

DX

Model DX 1001 [HI] Target >1000

°F (538 °C)

Use higher

DX

Model DX 1201 [HI] Target >1207

°F (653 °C)

Use higher

DX

Model DX 1601 [HI] Target >1600

°F (871 °C)

Contact

Exergen

High Target Temperature

Condition Error

Code

RemedyMeasurement

Fault

Page 12

5.2 Troubleshooting Measurement

Difficulties

If you experience measurement problems, review the following troubleshooting steps:

Is the sensor window clean?

Clean the sensor window and reflective cup and repeat the

measurement.

Is the target's surface non-metallic?

Coat metallic surfaces with a non-metallic finish and repeat

the measurement.

Is the target's surface transparent?

Coat transparent surfaces with an opaque non-metallic finish and repeat the measurement.

Alternatively, put a shiny metallic surface such as aluminum

foil behind the transparent target and repeat the measurement.

Was the instrument's nosepiece in contact with the surface?

Touch the nosepiece flush to the target's surface and repeat

the measurement.

If after applying all of the above solutions, the instrument's

accuracy is still in question, contact Exergen for further

help.

Chapter Six - DX™ Specifications

Target Temperature Range

DX 501 -50 to 550°F (-45 to 287°C)

DX 1001 0 to 1000°C (-18 to 538°C)

DX 1201 186 to 1207°F (86 to 653°C)

DX 1601 186 to 1600°F (86 to 871°C)

Linearity Error

DX 501 ± 1% of reading

DX 1001 ±3% of reading

DX 1201 ±3% of reading

DX 1601 ±3% of reading

Emissivity Error

±1% of max. difference between target temperature and

instrument temperature when touching, for emissivity of 0.8

to 1.0

Minimum spot size diameter

Approx. 1/4" (6.4 mm)

Repeatability

± 0.1 °F/°C

NIST Traceablity

In AECS Mode

Display Resolution

0.1 °F or 0.1 °C

9

Page 13

Display Update

10 times/second

Measurement Response Time

Approximately 0.1 seconds

Field of View

1:1 0.63" (15.9 mm) Diameter Spot Area in AECS Mode

Spectral Sensitivity

2 to 20 microns

Battery

One 9 volt

Battery Life

5000 readings (10 seconds each)

Instrument Ambient Temperature

Operating Range: 32 to 122°F (0 to 50°C)

Storage Range: -22 to 140°F (-30 to 60°C)*

*Extended storage at temperature extremes will reduce battery life.

Chapter Seven - Warranty

Exergen warrants the DX to be free of defects in material

and workmanship for a period of one year from the date of

purchase, and will repair or replace the returned instrument

at no charge during the period. No other warranties are

implied.

If repair is required:

Contact the factory for a Return Material Authorization

(RMA) Number. Mark the RMA number on both the shipping box and the packing slip. Include a description of the

unit's problem. Ship the instrument prepaid. Exergen will

return ship prepaid. After you have received an RMA

Number, send to:

EXERGEN CORPORATION

Repair Department

RMA ________________

51 Water Street

Watertown, MA 02472

10

Page 14

Page 15

Page 16

Loading...

Loading...