eXact PipeCut+Bevel 280 Pro Series, PipeCut+Bevel 360 Pro Series, PipeCut+Bevel 460 Pro Series Operating Instructions Manual

English

EN

Operating Instructions

PipeCut+Bevel 280 Pro Series

360 Pro Series

460 Pro Series

These instructions are translation of the original instructions written in Finnish language.

All instructions are available on web-site: exacttools.com/manuals

Patents: US 7,257,895, JP 4010941, EP 1301311, FI 108927, KR 10-0634113

English

2

Exact PipeCut+Bevel 280 / 360 / 460 Pro Series

Data of Exact PipeCut saw blades

1. Exact TCT saw blades are for cutting steel,

copper, aluminum and all kind of plastics pipe

materials. Exact TCT saw blades can be

sharpened.

2. Exact CERMET saw blades are for cutting

stainless steel, acid proof materials, steel,

copper, aluminum and all kind of plastic pipe

materials. Exact CERMET saw blades can be

sharpened.

3. Exact CERMET ALU saw blades are for cutting

all kind of aluminum and plastic pipe materials.

Exact CERMET ALU saw blades can be

sharpened.

4. Exact TCT P blades are for cutting all kind of

plastic pipe materials. Exact TCT P saw blades

can be sharpened.

5. Exact DIAMOND X discs are for cutting Cast or

Ductile Iron only. Exact DIAMOND X discs

cannot be sharpened.

280 Pro Series / 360 Pro Series / 460 Pro Series

speed control recommendations:

Stainless steel I

Steel II

Cast-iron II

Plastics II

Declaration of Conformity

We declare under our sole responsibility that the pipe cutting machines

Exact PipeCut+Bevel 280 / 360 / 460 Pro Series

Described under” Technical Data” are in conformity with the following standards or standardization

documents:

IEC 62841-1:2014, IEC 62841-2-5:2014, EN 62841-1:2015, EN 62841-2-5:2014, EN 55014-1,

EN 55014-2, EN 61000-3-2, EN 61000-3-3

These instructions are translation of the original instructions written in Finnish

For more information, please contact Exact Tools at the following address:

The technical file is available at the address underneath:

The person authorized to compile the technical file:

Seppo Makkonen, chairman of the board (seppo.makkonen@exacttools.com)

Helsinki, 01.02.2018

Seppo Makkonen, chairman of the board Exact Tools Oy

Särkiniementie 5 B 64

FI-00210 Helsinki, Finland

English

3

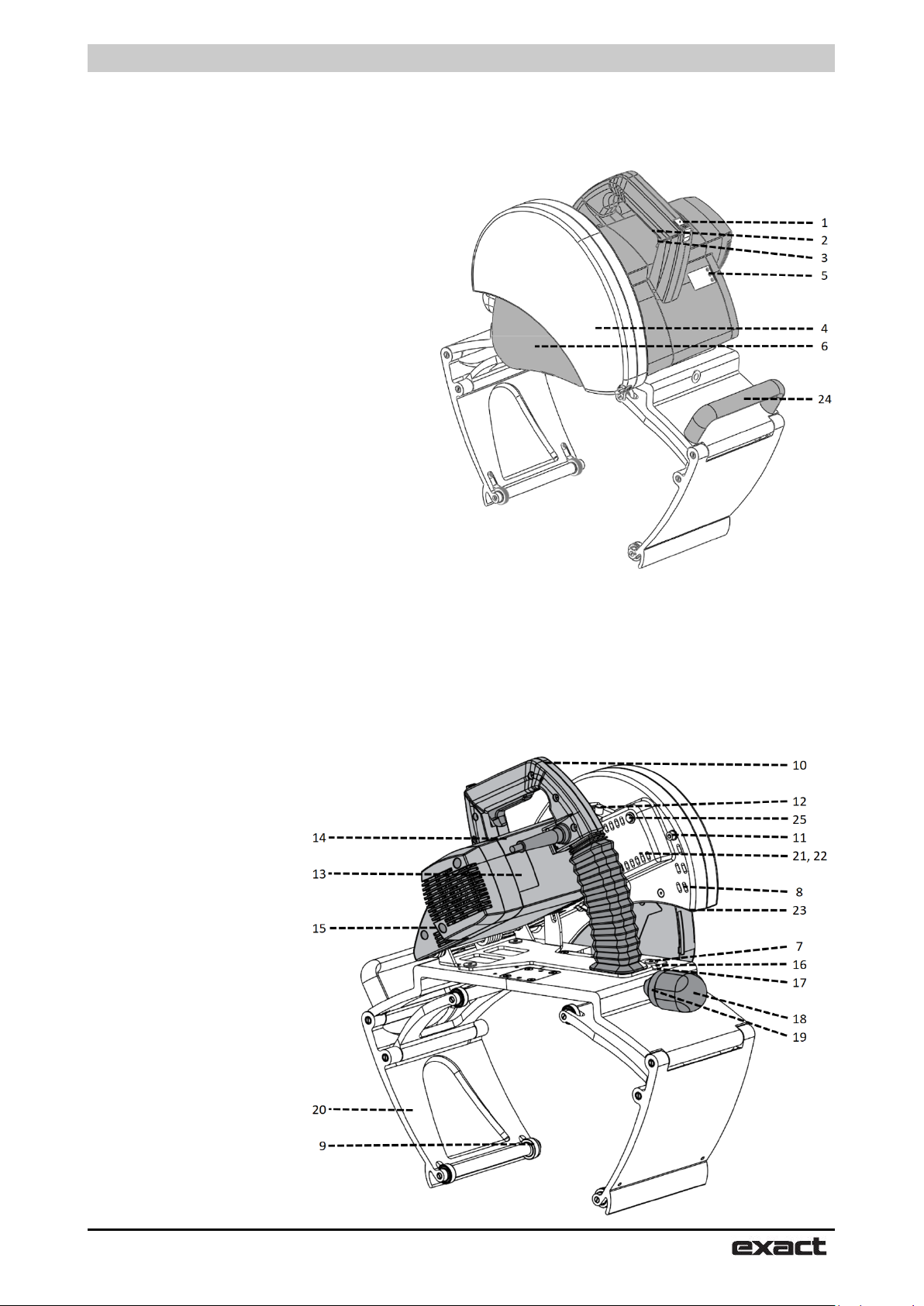

FIGURE A

1 Unlocking switch

2 Power switch

3 Power switch locking lever

(in front of the switch)

4 Blade guard cover

5 Overload indicator light

6 Moving blade-guard

7 Adjusting screws

8 Laser pointer box

9 Adjusting wheel

10 Handle

11 Blade guard screw

12 Lock pin

13 Plate

14 Motor unit

15 Blade RPM speed control

16 Adjustment arrow

17 Adjustment slot

18 Gripping device adjusting knob

19 Gripping device locking collar

20 Gripping device

21 Laser pointer batteries

(inside the blade protection)

22 Battery seat cover

(inside the blade protection)

23 Laser Pointer

(inside the blade protection)

24 Handle to carry the saw

25 Laser switch

English

4

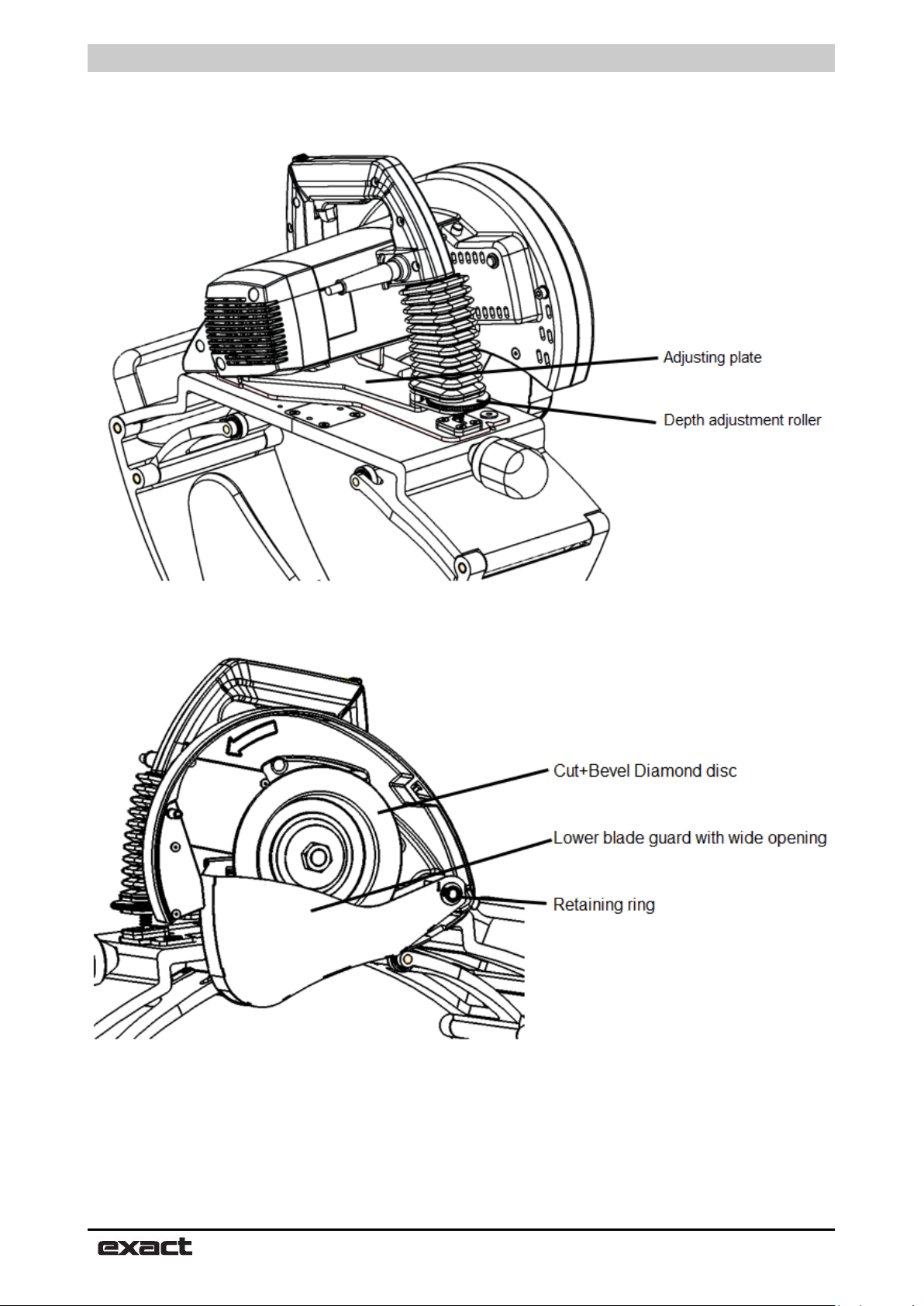

FIGURE A2

Package contents

English

5

Contents

Information

Technical data 6

Package contents 7

Safety

Safety instructions 8

Operation

Functional description 11

Product features 12

Before operating the tool 13

Connection to mains power supply 13

Setting the pipe on supports 13

Attaching the pipe saw to the pipe 13

Piercing the pipe wall 14

Cutting around the pipe 14

Overload protection and RPM adjustment 15

Explanation if indicator lights 15

Improving possible misalignment of the cut 15

Cutting result adjustment on Exact 16

PipeCut+Bevel 280 / 360 / 460 Pro Series

Installing and changing the blade 17

Maintenance and servicing instructions 17

Environment / disposal 18

Guarantee / guarantee conditions 18

Tips for using Exact PipeCut saws 18

Extra equipment 19

Theoretical cutting depths 19

Instructions updated 18.10.2019

Safety instructions

English

6

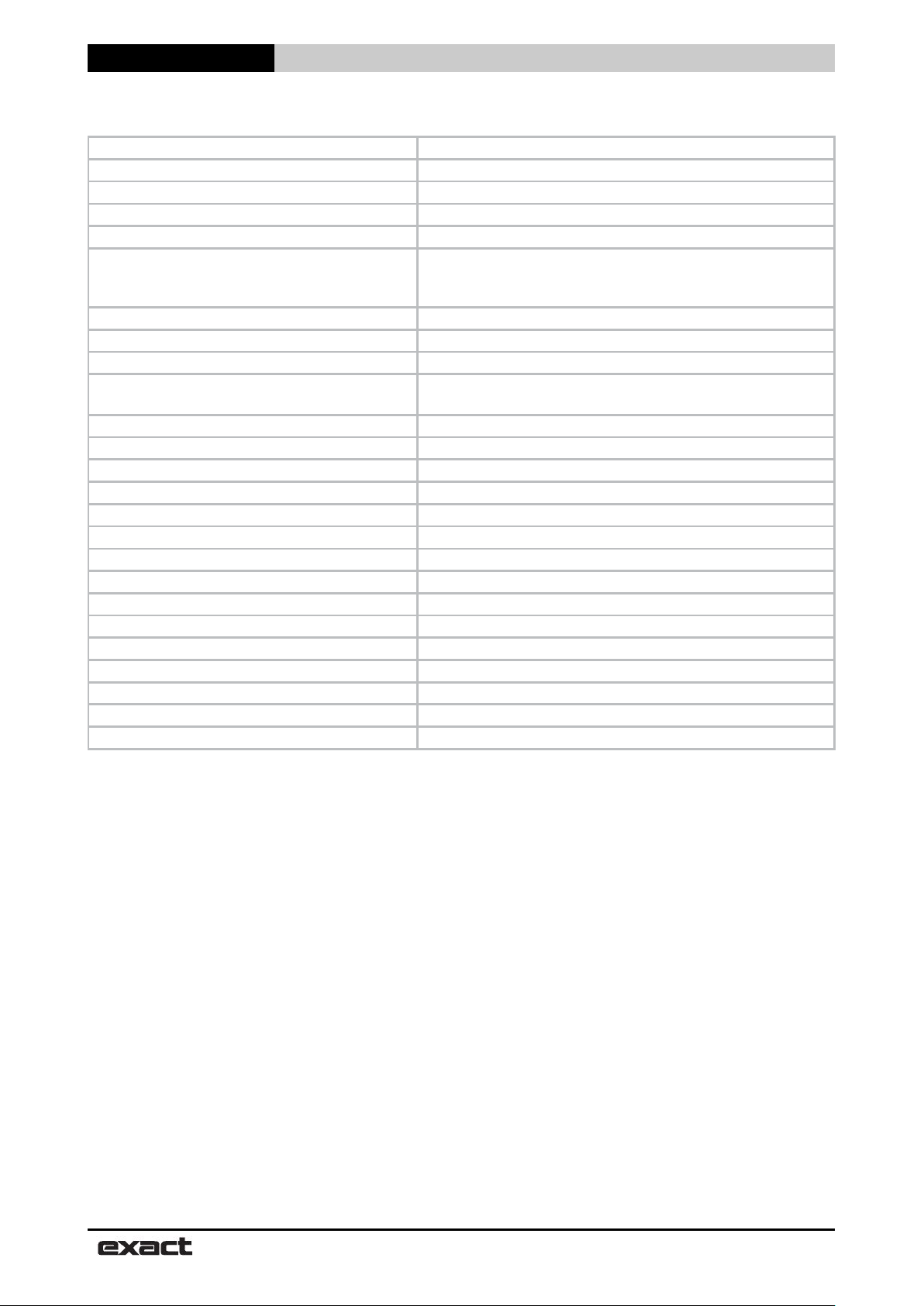

Voltage

230 V– 240 V / 50–60 Hz / 100 V–120 V 50–60Hz

Power

2500 W– 230 V– 240 V / 15 А-100 V– 120 V

No-load speed

I (low) = 1900/min, II (high) = 2885 /min

Blade diameter

140 mm (5.6"), 165 mm (6.50"), 180 mm (7.2"),190 mm (7.6")

Mounting bore

62 mm (2.44")

Weight

PipeCut+Bevel 280 Pro Series 16 kg (35 lbs),

PipeCut+Bevel 460 Pro Series 18,5 kg (42 lbs)

Range of use PipeCut+Bevel 280 Pro Series

40 mm–280 mm (1.6"–11")

Range of use PipeCut+Bevel 360 Pro Series

75 mm–360 mm (3.0"–16")

Range of use PipeCut+Bevel 460 Pro Series

100 mm–460 mm (4"–17.5")

Max. pipe wall, plastics and other soft materials

45 mm (1.8”) 280

Max. Pipe wall 230V, steel, iron

20 mm / 0.78”

Max. Pipe wall 120V, steel, iron

12 mm / 0.47”

Protection class

⧈ / II

Spindle lock

Yes

Speed preselection

Yes

Constant electronic control

Yes

Overload Protection

Yes

Reduced starting current

Yes

Vibration, A

”cutting metal”

3,2 m/s2

Vibration uncertainty, K

0,3 m/s2

LpA (sound pressure)

101,0 dB(A)

KpA (sound pressure uncertainty)

3 dB(A)

LWA (acoustic power)

112,0 dB(A)

KWA (acoustic power uncertainty)

3 dB(A)

Recommended generator capacity

4,9kVA for 230V, 3kVA for 100 V-120V

Exact PipeCut+Bevel 280 / 360 / 460 Pro Series

PipeCut+Bevel 360 Pro Series 17,5 kg (40 lbs),

50 mm (2.0”) 360 and 460

h,M

The values given are valid for nominal voltages [U] of 230/240 V. For lower voltage and models for specific countries, these values can vary.

Package contents

English

7

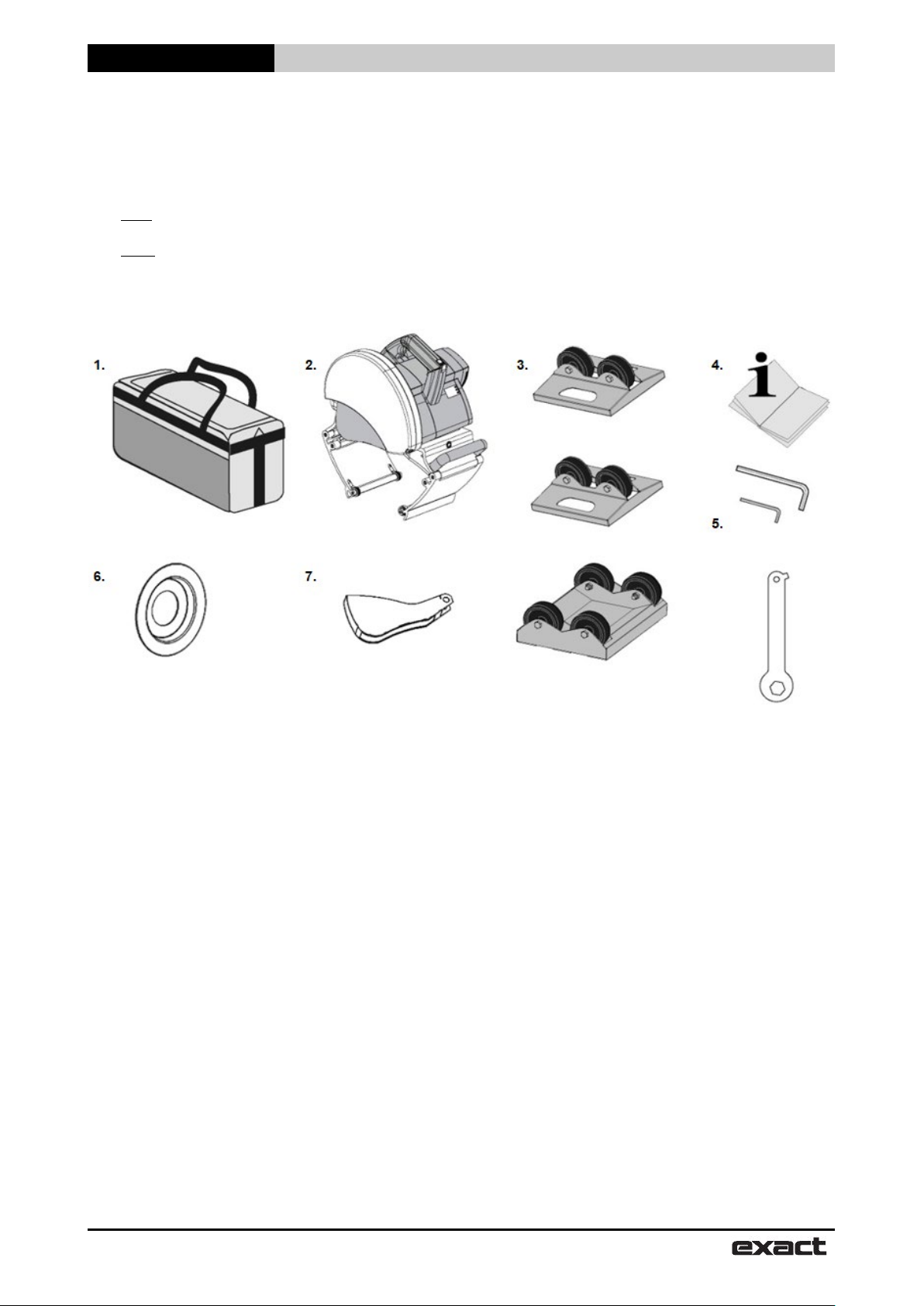

Exact PipeCut+Bevel 280 / 360 / 460 Pro Series pipe cutting systems

Package contents, please check that the package contains the following items:

1. Exact PipeCut System Shoulder Bag

2. Exact PipeCut+Bevel 280 / 360 / 460

3. Pipe Cutting supports 1 + 2 pcs. (280 4pcs aluminum)

4. Operating instructions

5. Allen key 2 pcs (5 mm and 2 mm) and blade adjusting key.

6. Exact Cut+Bevel Diamond disc 165

7. Lower blade guard with wide opening for Cut+Bevel Diamond disc

Pro Series pipe saw

Loading...

Loading...