eXact PipeCut 220E Operating Instruction

EN Operating Instructions 5-16

FR Conseils d'emploi 17-28

ES Instrucciones de manejo 29-40

Exact PipeCut 220E System

Blade information for Exact PipeCut saws

TCT (tungsten carbide tip) saw blades are for cutting steel, copper, aluminium and all kind

of plastics. TCT blades can be sharpened.

Cermet (ceramic alloy tip) saw blades are for cutting stainless steel, acid proof materials,

steel, copper, aluminium and all kind of plastics. Cermet blades can be sharpened.

Diamond blades are for cutting cast iron only. Diamond blades can not be sharpened.

220E speed control recommendations:

Stainless steel 4

Steel 5

Cast-iron 6

Informations sur les lames des scies Exact PipeCut

Les lames de scie TCT (à pointe de carbure de tungstène) sont utilisées pour couper acier ,

cuivre, aluminium et toute sorte de plastiques. Les lames TCT peuvent être affûtées.

Les lames de scie Cermet (à pointe en alliage céramique) sont utilisées pour couper acier

inoxydable, matériaux anti-acide, acier, cuivre, aluminium et toute sorte de plastiques. Les

lames Cermet peuvent être affûtées.

Les lames Diamond sont utilisées pour couper de la fonte seulement. Les lames Diamond

ne s’affûtent pas.

Recommandations du réglage de la vitesse du modèle 220E:

Acier inoxydable 4

Acier 5

Fonte 6

Información sobre cuchillas para sierras Exact PipeCut

Las hojas de sierra TCT (con punta de carburo de tungsteno) están diseñadas para cortar

acero, cobre, aluminio y cualquier tipo de plástico. Las hojas TCT se pueden afilar.

Las hojas de sierra Cermet (con punta de aleación de cerámica) están diseñadas para

cortar acero inoxidable, materiales a prueba de ácidos, acero cobre, aluminio y cualquier

tipo de plástico. Las hojas Cermet se pueden afilar.

Las hojas de Diamond están diseñadas para cortar hierro fundido exclusivamente. Las

hojas de Diamond no se pueden afilar.

Recomendaciones sobre la velocidad en 220E:

Acero inoxidable 4

Acero 5

Hierro fundido 6

2

A

3

1.

2.

3.

4.

5.

6.

7.

4

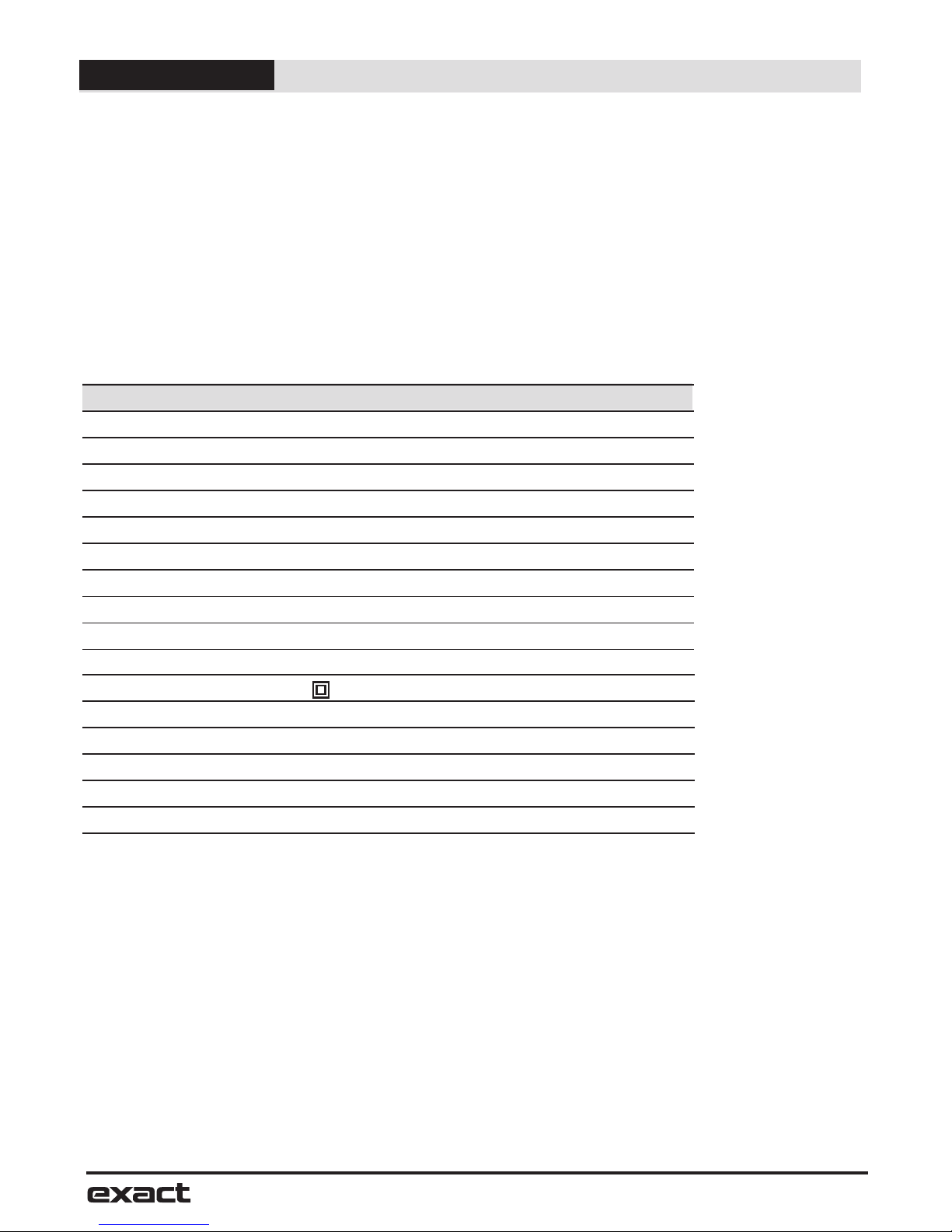

120 V 25 ft 50 ft 100 ft 150 ft

7,6 m 15,2 m 30,5 m 45,7 m

240 V 50 ft 100 ft 200 ft 300 ft

15,2 m 30,5 m 61,0 m 91,4 m

AWG AWG AWG AWG

0-6 A 18 16 16 14

6-10 A 18 16 14 12

10-12 A 16 16 14 12

12-16 A 14 12

Total length of chord

Longueur totale de la rallonge

Longitud total del cable

Not recommended

Non recommandé

No recomendado

Ampere rating

Courant

Amperios

Extension chord sets minimum gauge

Calibre (gauge) minimal pour les cordons de rallonges

Calibre (gauge) mínimo para juegos de cables

Contents

5

english

Contents

Technical data

Package contents

Safety

Safety instructions

Operation

Functional description

Product features

Before operating the tool

Connection to the mains power supply

Precise setting of the cutting point

Setting the pipe on supports

Attaching the pipe saw to the pipe

Piercing the pipe wall

Sawing around a pipe

Overload protection

Straightness of cut and adjusting wheel

Installing and changing the saw blade

Service and maintenance instructions

Environment /Disposal

Guarantee/Guarantee conditions

Tips for users

Exploded view (separate attachment)

6.

6.

7.

10.

10.

11.

11.

11.

11.

12.

12.

12.

13.

13.

14.

14.

16.

16.

16.

Definitions: Safety guidelines

The definitions below describe the level of severity for each signal word. Please read the manual and pay

attention to these symbols.

DANGER: Indicates an imminently hazardous situation which, if not avoided, will result in death or

serious injury.

WARNING: Indicates a potentially hazardous situation which, if not avoided, could result in death or

serious injury.

CAUTION: Indicates a potentially hazardous situation which, if not avoided, may result in minor or

moderate injury.

NOTICE: Indicates a practice not related to personal injury which, if not avoided, may result in

property damage.

Denotes risk of electric shock.

The label on your tool or this manual may include symbols. The symbols and their definitions are

listed on page 41.

Operating, safety, and servicing instructions

Please read this operating, safety , and servicing instructions carefully before using

the pipe saw. Also store this instruction book somewhere accessible to everyone using

the pipe saw. In addition to these instructions, always follow the official work, health

and safety regulations. The Exact PipeCut 220E is meant for professional use only .

Technical data

Kuva A

Information

6

Pipecut 220E

120 / 60 Hz

9.2 A

1600-3500 /min

2.5 min ON / 7.5 min OFF (S3 25%)

5.51” (140 mm)

2.44” (62 mm)

13.2 lbs (6,0 kg)

0.6”- 8.6” (15 mm –220 mm)

0.23” (6 mm)

0.55” (14 mm)

/ II

YES

YES

YES

YES

YES

Model

Voltage

Current

No-Load speed

Intermittent operation

Blade diameter

Mounting bore

Weight

Range of use Ø

Max. pipe wall steel

Max. pipe wall plastics

Protection class

Spindle lock

Speed preselection

Constant electronic control

Overload Protection

Reduced starting current

english

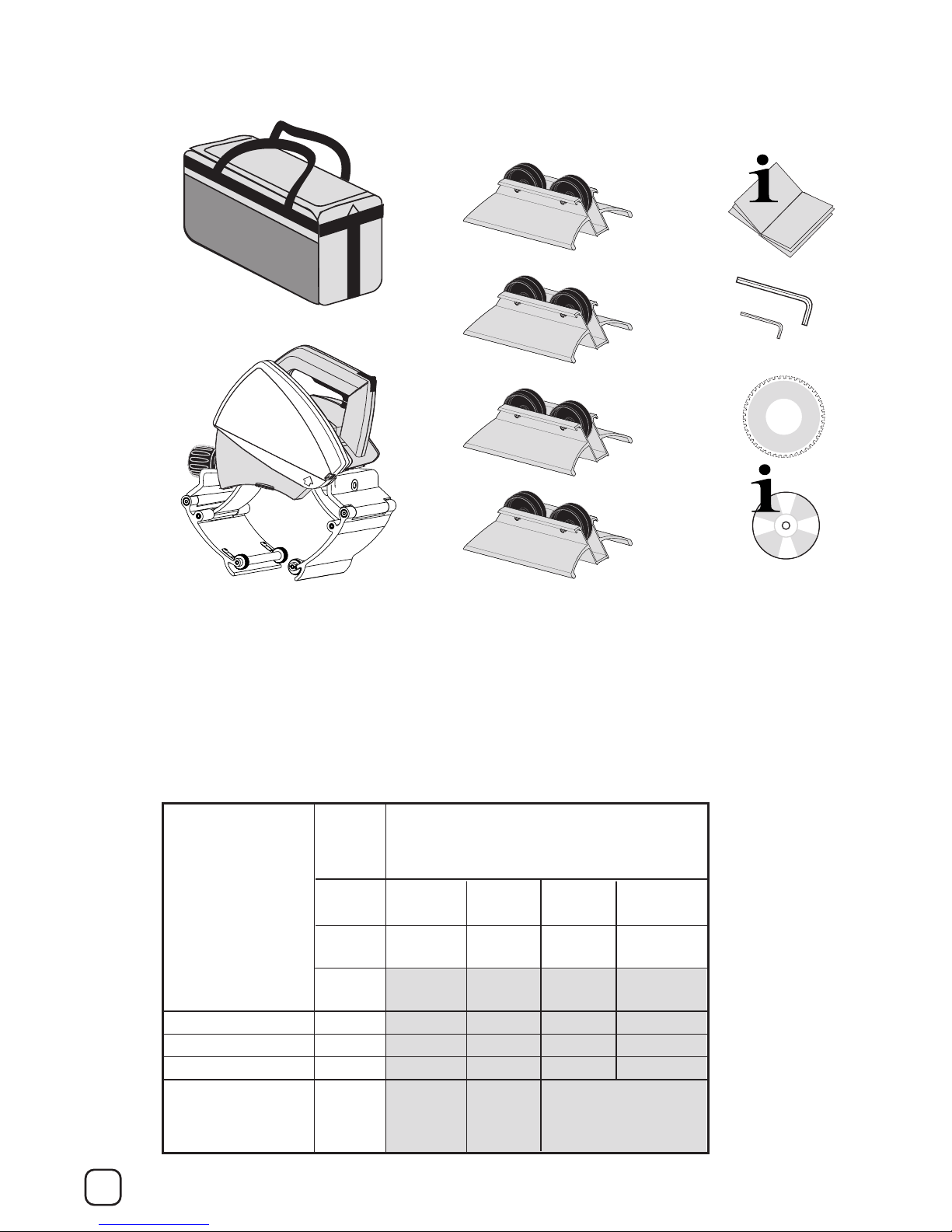

Exact PipeCut 220E pipecutting system,

Package contents:

Please check the package contains the following items (page4):

1. Pipecutting System case

2. Exact PipeCut 220E pipe saw

3. Cutting supports 4x

4. Operating instructions

5. Hex socket key 5 mm and 2 mm fitted to the machine

6. TCT blade 140 x 62 fitted on the machine

7. DVD-video disc with instructions

7

Safety

General power tool safety

warnings

WARNING: Read all safety warnings and

all instructions. Failure to follow the

warnings and instructions may result in

electric shock, fire and/or serious injury

Save all warnings and instructions for future

reference.

The term “power tool” in the warnings refers to your

mains-operated (corded) power tool or batteryoperated (cordless) power tool.

1. Work area safety

a) Keep work area clean and well lit. Cluttered

or dark areas invite accidents.

b) Do not operate power tools in explosive

atmospheres, such as in the presence of

flammable liquids, gases or dust. Power tools

create sparks which may ignite the dust or fumes.

c) Keep children and bystanders away while

operating a power tool. Distractions can cause

you to lose control.

2. Electrical safety

a) Power tool plugs must match the outlet. Never

modify the plug in any way. Do not use any

adapter plugs with earthed (grounded) power

tools. Unmodified plugs and matching outlets

will reduce risk of electric shock.

b) A void body cont act with earthed or grounded

surfaces, such as pipes, radiators, ranges

and refrigerators. There is an increased risk of

electric shock if your body is earthed or grounded.

c) Do not expose power tools to rain or wet

conditions. Water entering a power tool will

increase the risk of electric shock.

d) Do not abuse the cord. Never use the cord

for carrying, pulling or unplugging the power

tool. Keep cord away from heat, oil, sharp

edges and moving parts. Damaged or entangled

cords increase the risk of electric shock.

e) When operating a power tool outdoors, use

an extension cord suitable for outdoor use.

Use of a cord suitable for outdoor use reduces

the risk of electric shock.

f) If operating a power tool in a damp location

is unavoidable, use a residual current device

(RCD) protected supply . Use of an RCD reduces

the risk of electric shock.

3. Personal safety

a) Stay alert, watch what you are doing and use

common sense when operating a power tool.

Do not use a power tool while you are tired

or under the influence of drugs, alcohol or

medication. A moment of inattention while

operating power tools may result in serious

personal injury.

b) Use personal protective equipment. Always

wear eye protection. Protective equipment such

as dust mask, non-skid safety shoes, hard hat,

or hearing protection used for appropriate

conditions will reduce personal injuries.

c) Prevent unintentional starting. Ensure the

switch is in the off-position before connecting

to power source, picking up or carrying the

tool. Carrying power tools with your finger on

the switch or energising power tools that have

the switch on invites accidents.

d) Remove any adjusting key or wrench before

turning the power tool on. A wrench or a key

left attached to a rotating part of the power tool

may result in personal injury.

e) Do not overreach. Keep proper footing and

balance at all times. This enables better control

of the power tool in unexpected situations.

f) Dress properly. Do not wear loose clothing

or jewellery. Keep your hair, clothing and

gloves away from moving parts. Loose clothes,

jewellery or long hair can be caught in moving

parts.

g) If devices are provided for the connection of

dust extraction and collection facilities, ensure

these are connected and properly used. Use

of dust collection can reduce dust-related hazards.

4. Power tool use and care

a) Do not force the power tool. Use the correct

power tool for your application. The correct

power tool will do the job better and safer at the

rate for which it was designed.

b) Do not use the power tool if the switch does

not turn it on and off. Any power tool that cannot

be controlled with the switch is dangerous and

must be repaired.

c) Disconnect the plug from the power source

from the power tool before making any

adjustments, changing accessories, or storing

power tools. Such preventive safety measures

reduce the risk of starting the power tool

accidentally.

d) Store idle power tools out of the reach of

children and do not allow persons unfamiliar

with the power tool or these instructions to

operate the power tool. Power tools are

dangerous in the hands of untrained users.

e) Maintain power tools. Check for misalignment

or binding of moving parts, breakage of p art s

and any other condition that may affect the

power tool’s operation. If damaged, have the

power tool repaired before use. Many accidents

are caused by poorly maintained power tools.

f) Keep cutting tools sharp and clean. Properly

maintained cutting tools with sharp cutting edges

are less likely to bind and are easier to control.

g) Use the power tool, accessories and tool bits

etc. in accordance with these instructions,

taking into account the working conditions

and the work to be performed. Use of the

power tool for operations different from those

intended could result in a hazardous situation.

english

8

Safety

5. Service

Have your power tool serviced by a qualified

repair person using only identical

replacement parts. This will ensure that the

safety of the power tool is maintained.

Safety warnings for circular

saws

a) DANGER: Keep hands away from

cutting area and the blade. Keep your

second hand on motor housing. If

both hands are holding the saw, they cannot be

cut by the blade.

b) Do not reach underneath the workpiece. The

guard cannot protect you from the blade below

the workpiece.

c) Never hold the workpiece being cut in your

hands or across your leg. Secure the

workpiece to a stable platform. It is important

to support the work properly to minimize body

exposure, blade binding, or loss of control.

d) Hold the power tool only by the insulated

gripping surfaces when performing an

operation where the cutting tool may contact

hidden wiring or its own cord. Contact with a

“live” wire will also make exposed metal parts of

the power tool “live” and shock the operator.

e) Always use blades with correct size and shape

(diamond versus round) of arbour holes.

Blades that do not match the mounting hardware

of the saw will run eccentrically, causing loss of

control.

f) Never use damaged or incorrect blade

washers or bolt. The blade washers and bolt

were specially designed for your saw, for optimum

performance and safety of operation.

g) When blade is binding, or when interrupting

a cut for any reason, release the trigger and

hold the saw motionless in the material until

the blade comes to a complete stop. Never

attempt to remove the saw from the work or

pull the saw backward while the blade is in

motion. Investigate and take corrective actions

to eliminate the cause of blade binding.

h) When restarting a saw in the workpiece,

centre the saw blade in the kerf and check

that saw teeth are not engaged into the

material. If saw blade is binding, it may walk up

from the workpiece as the saw is restarted.

i) Do not use dull or damaged blades.

Unsharpened or improperly set blades produce

narrow kerf causing excessive friction and blade

binding.

j) Use extra caution when making a “plunge

cut” into existing walls or other blind areas.

The protruding blade may cut objects that can

cause kickback.

k) Check lower guard for proper closing before

each use. Do not operate the saw if lower

guard does not move freely and close

instantly. Never clamp or tie the lower guard

into the open position. If saw is accidentally

dropped, lower guard may be bent. Raise the

lower guard with the retracting handle and make

sure it moves freely and does not touch the blade

or any other part, in all angles and depths of cut.

l) Check the operation of the lower guard.

If the guard and the spring are not operating

properly, they must be serviced before use.

Lower guard may operate sluggishly due to

damaged parts, gummy deposits, or a build-up

of debris.

m)Do not reach into the saw dust ejector with

your hands. They could be injured by rotating

parts.

n) Do not work overhead with the saw. In this

manner you do not have sufficient control over

the power tool.

o) Do not operate the power tool stationary. It

is not designed for operation with a saw table.

p) Do not use high speed steel (HSS) saw blades.

Such saw blades can easily break.

q) When working with the machine, always hold

it firmly with both hands and provide for a

secure stance. The power tool is guided more

secure with both hands.

r) Secure the workpiece. A workpiece supported

by pipe holders is held more secure than by

hand.

s) Always wait until the machine has come to

a complete stop before placing it down. The

tool insert can jam and lead to loss of control

over the power tool.

t) Never use the machine with a damaged cable.

Do not touch the damaged cable and pull

the mains plug when the cable is damaged

while working. Damaged cables increase the

risk of an electric shock.

Safety instructions for plunge

type saws

a) Check guard for proper closing before each

use. Do not operate the saw if guard does not

move freely and enclose the blade instantly.

Never clamp or tie the guard with the blade

exposed. If saw is accidentally dropped, guard

may be bent. Check to make sure that guard

moves freely and does not touch the blade or

any other part, in all angles and depths of cut.

b) Check the operation and condition of the

guard return spring. If the guard and the spring

are not operating properly , they must be serviced

before use. Guard may operate sluggishly due

to damaged parts, gummy deposits, or a buildup of debris.

english

9

Safety

c) Assure that the guide plate of the saw will

not shift while performing the “plunge

cut” when the blade bevel setting is not at

90°. Blade shifting sideways will cause binding

and likely kick back.

d) Always observe that the guard is covering

the blade before placing saw down on bench

or floor. An unprotected, coasting blade will

cause the saw to walk backwards, cutting

whatever is in.

Additional specific safety rules

The pipe saw must never be used in the following

cases, if:

• There is water or another liquid, explosive gases

or poisonous chemicals inside the pipe to be cut.

• The power switch is faulty.

• The power cable is faulty,

• The blade is bent.

• The blade is blunt or in poor condition.

• The plastic components are cracked or have parts

missing.

• The gripper unit is not properly tightened around

the pipe or if it is warped.

• The blade guard cover or moving blade guard

has been damaged or removed from the machine.

• The locking mechanisms do not work properly

(UNLOCK-button).

• The pipe saw has become wet.

When using the pipe saw, the following factors

must always be taken into consideration:

• Support tubes to minimise the risk of blade

pinching.

• Ensure that the pipe to be cut is empty.

• Ensure that the blade is correctly installed.

• Ensure that the diameter and thickness of the

blade are suitable for the pipe saw and that the

blade is suitable for the rpm-range of the machine.

• Never use sideways force to stop the blade, always

allow the blade to stop freely.

• Check the attachments of the blade guards.

• Never use excessive force when using the pipe

saw.

• Never use the pipe saw to lift the pipe while it is

still attached to the pipe.

• Avoid overloading the electric motor.

• Always follow the safety and operating instructions

and current regulations.

Air vents often cover moving parts and should

be avoided. Loose clothes, jewellery or long hair

can be caught in moving parts.

Accessories must be rated for at least the speed

recommended on the tool warning label. Accessories

running over rated speed can fly apart and cause

injury . Accessory ratings must always be above tool

speed as shown on tool nameplate.

WARNING: ALWAYS wear proper

personal hearing protection that

conforms to ANSI S12.6 (S3.19) during use. Under

some conditions and duration of use, noise from

this product may contribute to hearing loss. When

working with various materials, the sound level may

vary and at times exceed the 85 dB(A) limit. Always

use ear protectors to protect yourself.

WARNING: ALWAYS use safety glasses.

Everyday eyeglasses are NOT safety

glasses. Always use safety goggles to prevent injury

to your eyes from particles thrown up when using

the pipe saw. Also use face or dust mask if cutting

operation is dusty (cast iron cutting). ALWAYS

WEAR CERTIFIED SAFETY EQUIPMENT:

• ANSI Z87.1 eye protection (CAN/CSA Z94.3),

• ANSI S12.6 (S3.19) hearing protection,

• NIOSH/OSHA/MSHA respiratory protection.

WARNING: ALWAYS use safety gloves

as the edges of cut pipes are sharp and

can cause cuts.

WARNING: Some dust created by power

sanding, sawing, grinding, drilling, and

other construction activities contains chemicals

known to cause cancer, birth defects or other

reproductive harm. Some examples of these

chemicals are:

• lead from lead-based paints,

• crystalline silica from bricks and cement and other

masonry products, and

• arsenic and chromium from chemically-treated

lumber (CCA).

Your risk from these exposures varies, depending

on how often you do this type of work. To reduce

your exposure to these chemicals: work in a well

ventilated area, and work with approved safety

equipment, such as those dust masks that are

specially designed to filter out microscopic particles.

Avoid prolonged contact with dust from power

sanding, sawing, grinding, drilling, and other

construction activities.

Wear protective clothing and wash exposed

areas with soap and water. Allowing dust to get

into your mouth, eyes, or lay on the skin may promote

absorption of harmful chemicals.

WARNING: Use of this tool can generate

and/or disbursedust, which may cause

serious and permanent respiratory orother injury .

Always use NIOSH/OSHA approved respiratory

protection appropriate for the dust exposure.

Direct particles away from face and body.

english

10

Safety, Operation

Extension cords

An extension cord must have adequate wire size

(AWG or American Wire Gauge) for safety. The

smaller the gauge number of the wire, the greater

the capacity of the cable, that is 16 gauge has more

capacity than 18 gauge. An undersized cord will

cause a drop in line voltage resulting in loss of

power and overheating. When using more than one

extension to make up the total length, be sure each

individual extension contains at least the minimum

wire size. The following table shows the correct size

to use depending on cord length and nameplate

ampere rating. If in doubt, use the next heavier

gauge. The smaller the gauge number , the heavier

the cord.(see page 4).

Motor

Be sure your power supply agrees with nameplate

marking. As little as 10% lower voltage can cause

loss of power and can result in overheating. All

Exact Tools products are factory-tested; if this tool

does not operate, check the power supply.

WARNING: Accessories must be rated

for at least the speed recommended on

the tool warning label. Accessories running over

rated speed can fly apart and cause injury.

Accessory ratings must always be above tool speed

as shown on tool nameplate.

DANGER: Avoid contact with the blade

teeth to prevent personal injury

Functional Description

Read all safety warnings and all instructions.

Failure to follow the warnings and instructions may

result in electric shock, fire and/or serious injury.

Intended Use

PipeCut 220E:

The PipeCut 220E pipe saw is intended for use as

a pipe fitter’s tool at the installation site. The PipeCut

220E pipe saw can only be used to cut round pipes,

with a diameter of 0.6”-8.6” (15-220mm) and a

maximum wall thickness of 0,23” (6 mm) with steel

and other ferrous and non-ferrous materials and

0,55” (14 mm) with plastics. The PipeCut 220E pipe

saw can be used to cut all normal pipe materials,

such as steel, stainless steel, cast iron, copper,

aluminium and plastic. PipeCut 220E pipe saw is

intended for short, intermittent use. The machine

may be loaded for 2.5 minutes during a 10-minute

period (S3 25 %). PipeCut 220E pipe saw is not

intended for use in industrial production. Use pipe

holders to support pipe.

Product Features

While reading the operating instructions, unfold the

graphics page for the machine and leave it open.

This page is folded under the cover of this manual

(page 3). The following numbering of the product

features refers to this illustration.

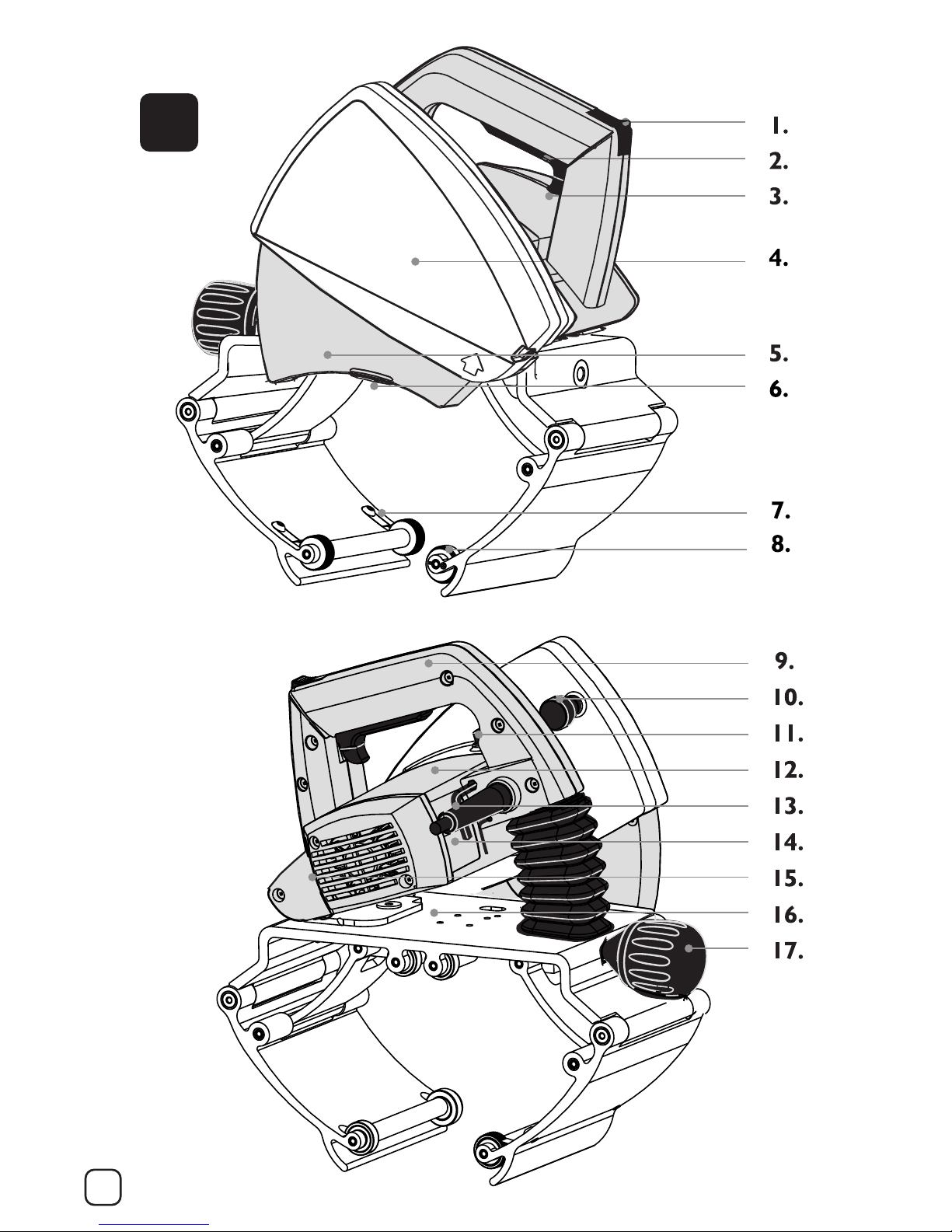

1. UNLOCK button

2. Power switch

3. Power-switch locking lever

4. Blade-guard cover

5. Moving blade-guard

6. Edge of moving blade-guard

7. Braking wheels

8. Adjusting wheel

9. Operating handle

10. Blade-guard screw

11. Spindle-lock button

12. Motor unit

13. Blade key and (key for the

adjusting wheel)

14. Rating plate

15. Overload protection or rpm

regulator

16. Gripper unit

17. Gripper adjustment handle

english

11

Exact PipeCut 220E

pipecutting system

operating instructions

Before operating the tool

Ensure that the motor unit is in the upright position.

The yellow mark of the UNLOCK button is visible.

Check that the blade is correctly fitted, in good

condition and suitable for the material to be cut.

Ensure the pipe saw guide wheels rotate.

Ensure the support wheels rotate.

Check the operation of the lower blade guard.

Ensure the pipe is empty.

If plastic pipes have been cut with the pipe saw

(resulting in long, statically charger slivers), open

the blade guard cover, and clean carefully the lower

blade guard and the entire pipe saw.

Connection to the mains power supply

Ensure that the mains voltage is the same as

indicated on the rating plate (Figure A/14). Connect

the pipe saw to the power outlet only after having

checked this.

Precise setting of the cutting point

When you mark the cutting point on the pipe to be

cut, deduct 1 inch from the required dimension

(Easy-to-remember rule: The cutting mark location

requires a measurement of - 1”.)(Figure C)

Setting the pipe on supports

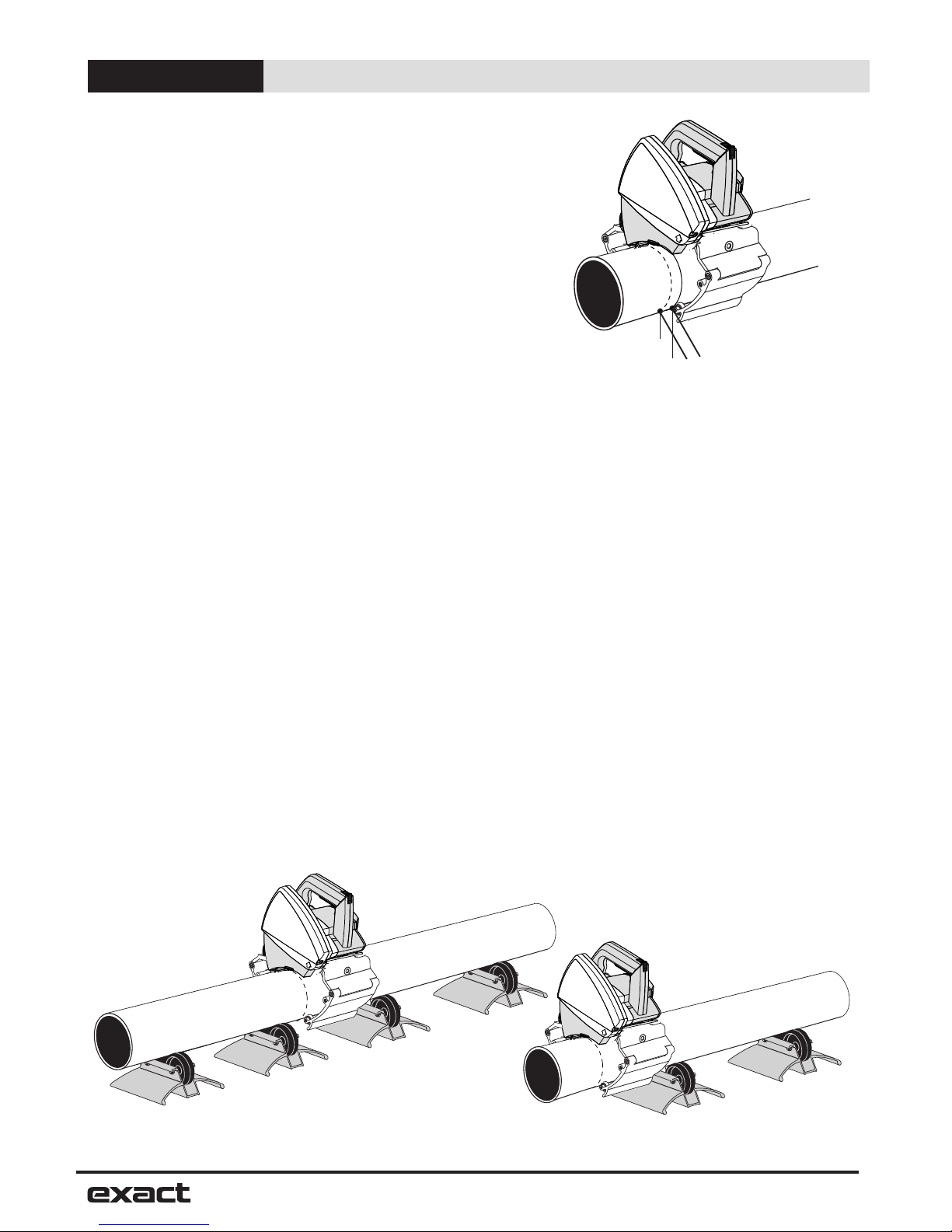

Use the system supports when cutting pipes. This

will ensure safe working and optimum result. Work

on flat surface. Place the pipe on two supports so

that the cutting point is between the supports. Place

two more support under both ends of the pipe. Check

that all support wheel contact the pipe (adjust if

required e.g. with pieces of lumber) (Figure B).

When cutting short pipes (10” or less) place the

supports so that the cutting point is outside supports

(Figure D). Support the pipe with your left leg, if

required. Proper arrangements will prevent the blade

from jamming as the pipe is cut through.

Fig C

Fig B

Fig D

Operation

english

1”

Cutting mark

Cutting point

Attaching the pipe saw to the pipe

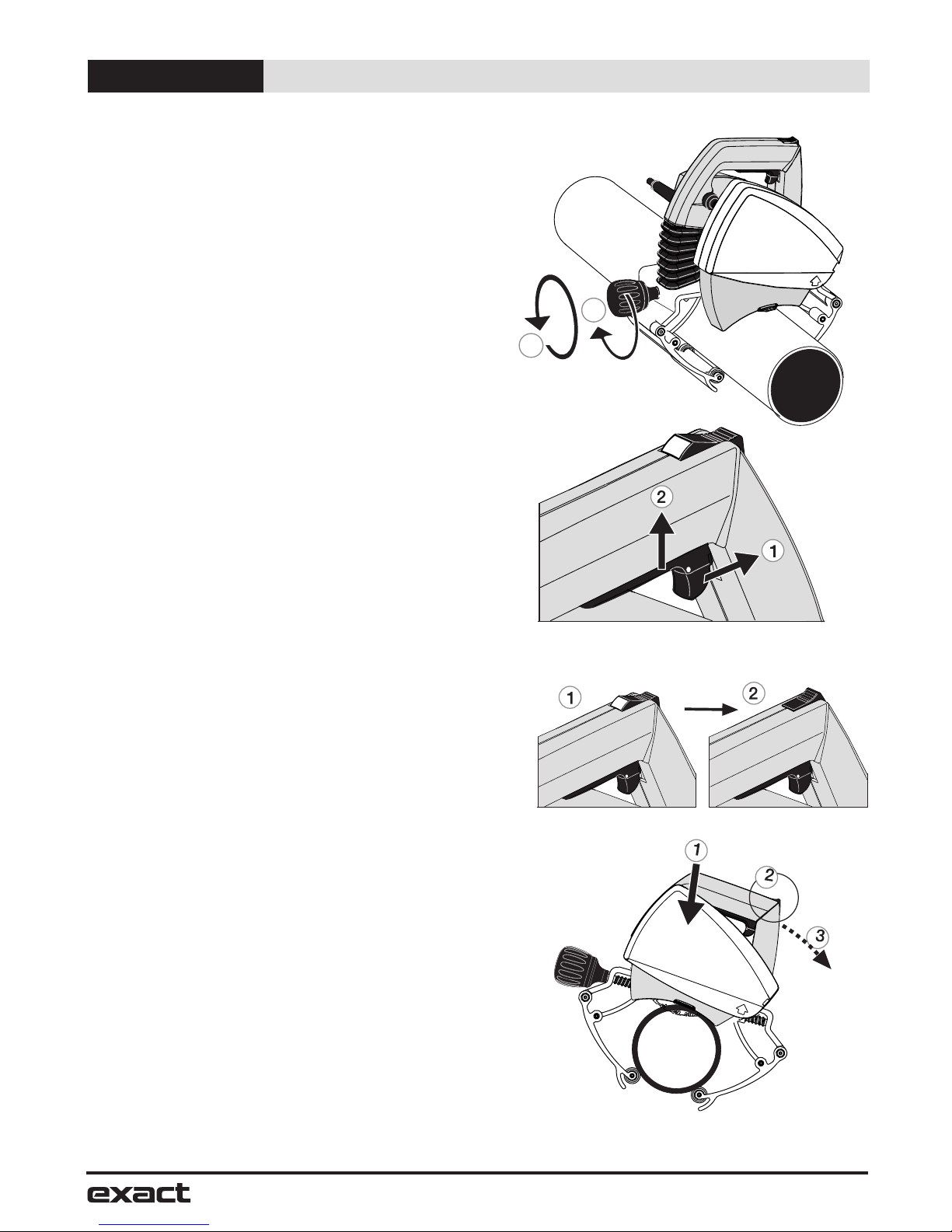

Open the pipe saw's gripper unit enough to suit the

diameter of the pipe by rotating the adjustment

handle located at the rear of the saw (Fig. E/1).

Position the pipe saw on top of the pipe so that the

edge of the lower blade guard is at the cutting mark.

Fasten the pipe saw to the pipe by turning the gripper

adjustment handle until the gripper grips firmly the

pipe to be cut (Figure E/2). Hold the pipe in place

and ensure that pipe saw moves freely in the direction

the pipe is fed. For sake of safety ensure the pipe

saw leads are to the left of the pipe saw. The pipe

saw is now ready for cutting.

Piercing the pipe wall

Grip the gripper firmly with your right hand and place

your left foot on top of the pipe approximately 20”

from the pipe saw. T urn the saw until it leans slightly

forward (Figure H). When starting the motor, first

of all release the power-switch locking lever (Fig

F/1) and push the power switch all the way down

(Fig F/2). Before starting to saw, wait until the blade

reaches full speed. Pierce the pipe wall by pressing

pipe saw operating handle downwards slowly and

evenly until the blade has cut through the pipe wall

(at this stage the pipe must not rotate) and the motor

unit is locked in the sawing position (Fig H/1).. Look

at the UNLOCK button during the piercing operation.

When UNLOCK button is locked, i.e. the yellow

mark disappears (Fig G), pipe saw is locked in the

sawing position, and you can safely start sawing

around the pipe.

Sawing around the pipe

Start sawing by feeding the pipe saw forward and

fix the pipe with your left foot (Fig H/3).. After that

release the pipe (remove your left foot from the pipe)

and turn the pipe saw backwards, whereby the pipe

will also be rotated backwards (Fig J). Start a new

feeding movement, and feed continuously forward

ca. 1/6 of the pipe's circumference. Repeat until the

pipe is cut off (Fig K).

Select the feeding speed as per the material and

the thickness of the wall. Too high speed can damage

the blade, overload the pipe saw and give a poor

sawing result.

12

Operation

Fig E

Fig F

Fig G

Fig H

english

2

1

When the pipe is cut off, push the UNLOCK button

forward until the yellow mark is visible and the locking

is released (Fig L/1). Now raise the motor unit to

starting position (Fig L/2). Release the power switch

(Fig L/3). When the blade is stationary, remove the

pipe saw from the pipe by loosening the gripped

handle (Fig L/4). Ensure that the moving lower bladeguard is lowered into safety position.

Should there be problems during piercing or sawing,

abnormal sounds or vibrations due to which you have

to interrupt sawing before the pipe is cut through,

release the blade by pushing the UNLOCK button

forward until the UNLOCK button is released, and lift

the motor unit up. Once the problem is cleared, start

sawing again.

Never start the motor, when the motor unit is locked

in sawing position or teeth of the blade contact the

pipe to be sawn.

Overload protection and spin-speed regulator

There is a spin-speed regulator in model 220E. A

suitable spin speed is selected, determined by the

material to be sawed. There is also an automatic

overload protection in the regulator.

In the case of overload: Release the power switch

(Fig L/3). Push the UNLOCK button forward until the

yellow mark is visible and the locking is released (Fig

L/1). The electronics circuit limits the current and stops

the motor. When the motor stops due the overload,

the red light on the pipe cutter is turned on. The pipe

cutter has to cool down while the electronics percepts

the internal temperature. The motor will not start (even

the red light turned off) until the switch is released

and pressed once more time or plug disconnect and

reconnect. The red light indicates to the user that the

machine was overloaded.

The indicator light in question turns on for a moment

every time the motor is started. This in normal and

does not require any actions.

Straightness of cut and adjusting wheel

The cut is affected by many factors, e.g. the size of

the pipe, the material, the wall thickness, the quality

of the pipe's surface, the roundness, welded seams,

blade condition, feed rate, operator's experience.

13

Operation

Fig J

Fig K

Fig L

Fig M

english

4

1/6

Gap to left Gap to right

Loading...

Loading...