EWS FUGAC200, FUGAC300, FUGAC350, UU350, FUGAC250 Care And Use Manual

...

EWS, Inc. / Environmental Water Systems

Care and Use Manual

Drinking W ater Filtration Systems

Information Provided for the Proper Set-Up, Installation and

Start-Up of the following Filtration Systems

T wo-Stage Undercounter Drinking W ater Filtration Units:

FUGAC200, FUGAC250, UU250

Three-Stage Undercounter Drinking W ater Filtration Units:

FUGAC300, FUGAC350, UU350

In-Line Filtration Unit:

FUGAC150

4.1-1

ALL PRODUCT PROUDLY MANUFACTURED AND ASSEMBLED IN THE USA

Retain this Care & Use Manual for Maintenance and Information

You Must Register this Product - It is a Requirement for Warranty

www.EWSWATER.com office: 702-256-8182 (m-f; 8:30-4:30, pst) fax: 702-256-3744 customerservice@ewswater.com

To the Consumer:

4.1-2

EWS, Inc. / Environmental Water Systems

A Special Message to Our Customers,

EWS, Inc. and Environmental Water Systems would like to thank you for your consideration in selecting from our

comprehensive list of residential filtration and conditioning product.

We recommend that you take the time to read the information that pertains to your product as you begin to use it.

The information in this manual is designed to assist your installer to set-up, install and start-up your system properly.

In addition, the information contained in this manual is designed to provide the consumer, the most comprehensive

information on this series of product.

Please contact us if you have any questions, comments or additions to the information provided.

Sincerely,

Customer Service at EWS, Inc.

EWS, Inc. and Environmental Water Systems

9101 W. Sahara A ve., Suite 105-J8

Las Vegas, NV. 891 1 7

Office: 702-256-8182 Available Monday through Friday , 8:30 - 4:30 Pacific S tandard Time

Fax: 702-256-3744 Dedicated and A vailable 24/7

E-Mail: customerservice@ewswater.com

Web Site: www .ewswater .com

Installation of the Filtration System - Please Read the Enclosed Information

Please take the time to familiarize yourself with the unit you are about to install. The Table of Content s will point to

specific instructions for the simple step-by-step instructions for;

Installation of a Dispenser/Faucet

Placement or Locating the Water System

Inlet Supply Water Connection

Connection of Tubing from Supply and to Dispenser/Faucet

System St art-Up and Operation Procedures

You may need the following for proper installation:

• Teflon tape • Work Gloves • Safely Glasses • Knife or scissors

• Adjustable Wrench • Pliers • Screwdriver; straight & phillips • Drill & drill bits

WARNING: V erify that all components are included with the unit and were not lost, misplaced, or damaged in shipping

or handling. Any damage in shipping needs to be reported to the shipping company.

WARNING: Do not attempt to install this system using defective or damaged components. Check and inspect, inlet and

outlet fittings and any other connections on this system that might have been damaged during shipping and handling. Check

all these components again upon installation and start-up for any hidden issues. All plumbing should be done in accordance

with all local plumbing codes. Water Pressure: minimum 25psi, maximum 65p si. Water Temperature Range (cold supply

only): not to exceed 1 10°F or below 40°F. Electrical (if applicable): an uninterrupted a/c supply, (if applicable): make sure

voltage supply is compatible with your unit prior to install

WARRANTY: Warranty Registration of this product is required to have a warranty. A proper inst allation and start-up will

save you time, money and hassles, and is also required for warranty purposes. Any issue as a result of improper application,

set-up, installation and/or start-up will void any warranty .

www.EWSWATER.com office: 702-256-8182 (m-f; 8:30-4:30, pst) fax: 702-256-3744 customerservice@ewswater.com

EWS, Inc. / Environmental Water Systems

Table of Contents

INST ALLATION SUMMARY AND INDEX

OF YOUR DRINKING WATER FILTRATION SYSTEM

Placement or Locating the Dispenser/Faucet (2 & 3 Stage Units Only) 4

Installation of the Supplied Dispenser/Faucet (2 & 3 S tage Unit s Only) 5

Dispenser/Faucet Q & A 6

Placement or Locating the Water System 7

Inlet Supply Water Connection

Basic Supplied Connection 8

Preferred Connection 9

Connection of T ubing from Supply and to Dispenser/Faucet 10

4.1-3

System Start-Up and Operation Procedures 11

HOW TO MAINTAIN YOUR SYSTEM

Replacement of Filter Cartridges 12

Replacement of UV Lamp (if applicable) 13

Optional Disinfection Procedure of Empty Unit 13

GENERAL INFORMATION

Water Fitration Systems Included in this Care and Use Manual 14

FILTER REPLACEMENTS AND ORDERING

Filter and UV Lamp Replacements 16

Ordering Filters, UV Lamp Replacements, and Parts 17

Trouble Shooting Guide 18

Schematics 20

Warranty 24

Terms and Conditions of Sale 26

www.EWSWATER.com office: 702-256-8182 (m-f; 8:30-4:30, pst) fax: 702-256-3744 customerservice@ewswater.com

4.1-4

EWS, Inc. / Environmental Water Systems

Placement or Locating the Dispenser/Faucet

Step by step instructions to mount and secure the supplied dispenser/faucet

Professional Installation is Strongly Recommended

Note:

Dispenser/Faucet Not Included with In-Line Units. Sold separately, or use existing or other dispenser.

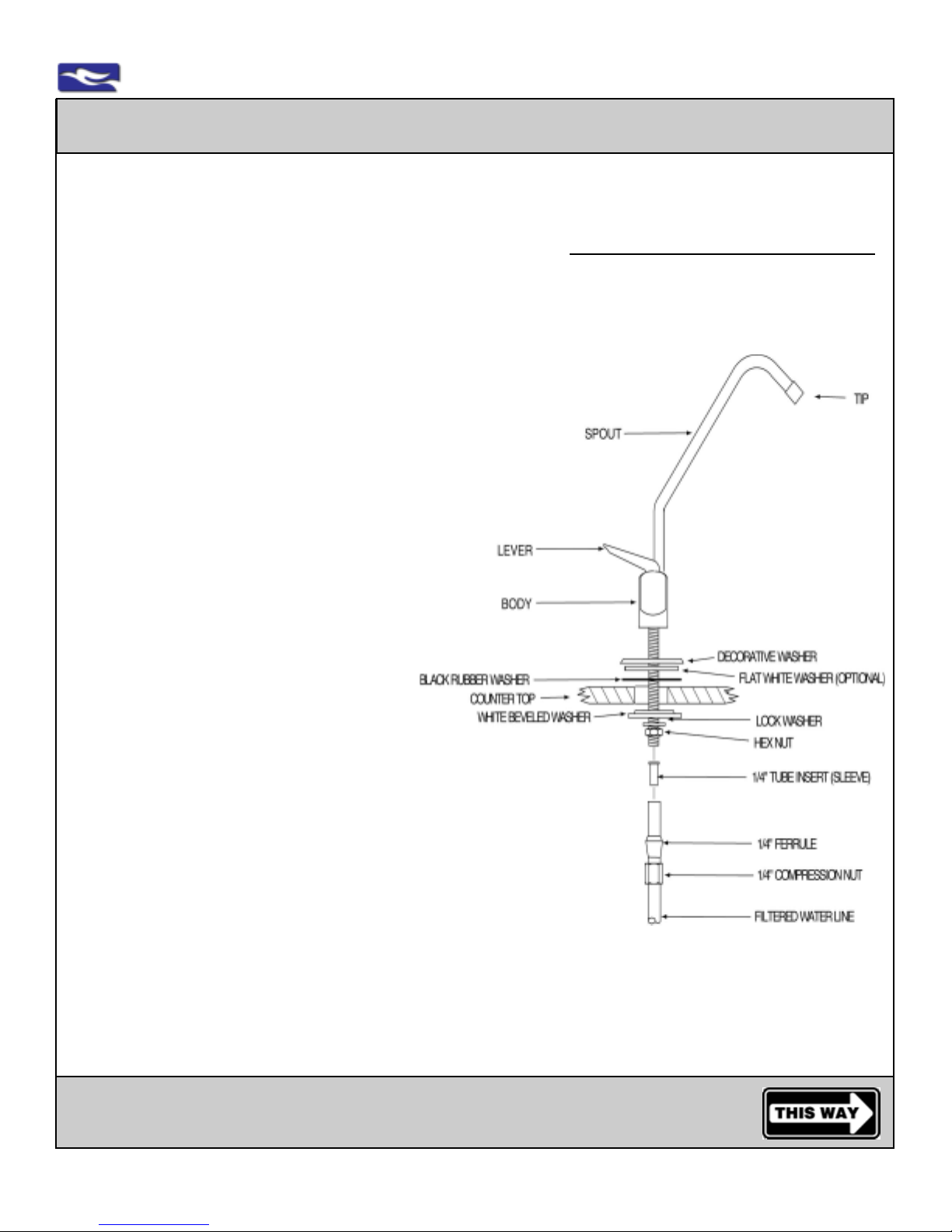

Step 1: Locate Faucet Parts Bag (2 and 3-Stage Units Only)

Parts Included: faucet body with handle, faucet spout with tip, decorative washer, black rubber

washer, white beveled washer, lock washer, hex nut, 1/4” tube insert sleeve,

Included 1/4” plastic compression ferrule, 1/4” compression nut

Optional Part: flat white washer (for use under decorative washer depending on hole/application)

Preferred - Select a standard sink location to mount the faucet.

It is recommended that the faucet be placed in a hole provided on most sinks similar to the ones used for a

sprayer, soap dispenser and/or dishwasher air gap. If the hole or sp ace is unavailable, an alternative location

will be required: MINIMUM HOLE REQUIRED 1/2”, MAXIMUM 1 3/8”

Option A: On the sink. This option is to drill a new hole into the sink rim itself, if space allows.

Option B: On the countertop next to a sink. This option is to position the faucet spout in the

correct location to drain into the sink. This requires a clearance around the faucet

both above and below the countertop. Use the supplied dispenser as a template or

see the enclosed dispenser schematic and dispenser dimensions.

Prepare to drill the hole using the dispenser as a template.

• Sinks can be made of, but not limited to, stainless steel, copper, porcelain/steel, enamel/cast iron,

man-made surfaces, stone, concrete, and/or materials known or unknown at this time.

• Countertops can be made of, but not limited to, or be a combination of, natural stone, enamel,

porcelain, concrete, wood, metals and/or man-made materials known or unknown at this time.

CAUTION: Please consult with the sink or countertop manufacture, supplier, fabricator, or

installer for proper drilling techniques and methods.

EXTREME CARE MUST BE T AKEN IN DRILLING THE HOLE FOR ANY SURF ACE. THE SURFACE MA TERIALS OF SINKS AND COUNTERTOPS CAN CHIP OR CRACK. THE MANUFACTURER ASSUMES NO

RESPONSIBILITY FOR ANY DAMAGE RESUL TING FROM THIS INST ALLA TION.

WARNING: USE SAFETY GLASSES OR OTHER EYE PROTECTION WHEN GRINDING OR

DRILLING TO PREVENT POSSIBLE EYE INJUR Y DUE T O FL YING PARTICLES.

Installation of the Supplied Dispenser/Faucet

www.EWSWATER.com office: 702-256-8182 (m-f; 8:30-4:30, pst) fax: 702-256-3744 customerservice@ewswater.com

Follow Steps 2 through 12

EWS, Inc. / Environmental Water Systems

4.1-5

Installation of the Supplied Dispenser/Faucet (2 & 3-Stage Units Only)

Step by step instructions to mount and secure the supplied dispenser/faucet

If using another faucet, please review the instructions included with that product**

Above the Surface

Step 2:

Place decorative washer to bottom of faucet body

(optional: place flat white washer under decorative washer)

Step 3:

Place black rubber washer below decorative washer

(or below optional flat white washer)

Step 4:

Place faucet stem through hole and center

Below the Surface

Step 5:

Insert white beveled washer, bevel side up to

fit snugly into a (1 3/8”) pre-drilled hole or flat side

up depending on the application

Step 6:

Place lock washer on this white beveled washer

Step 7:

Spin hex nut onto faucet stem and

tighten hex nut and washers into place

Step 8:

Slide 1/4” compression nut (threads up)

onto 1/4” filtered line

Step 9:

Slide 1/4” plastic compression ferrule, long side

down onto filtered water tube. Ferrule will seat into

compression nut

Step 10:

Insert 1/4” tube insert sleeve into 1/4” filtered water line

Step 11:

Insert 1/4” blue (filtered water) tube into faucet stem. Leave

other end available for system interconnection

Step 12:

Thread 1/4” compression nut onto faucet stem and tighten

Enclosed Dispenser/Faucet Dimensions***

Height: from deck to top of dispenser 8”

from deck to tip of dispenser 6 1/4”

Reach: from center of dispenser to tip 6”

Hole: minimum required 1/2”

maximum 1 3/8”

CAUTION: Do not overtigthen fittings

Note: Spout pulls out from faucet body and has 2 o-rings at base. Insert completely into bottom of faucet body to prevent

leaking. Spount swivels to direct water. Handle and tip can be removed. Handle can be locked up in open position.

** Other faucets check with specifications. ***All dimensions are approximate.

Go to the Placement or Locating the Water System

www.EWSWATER.com office: 702-256-8182 (m-f; 8:30-4:30, pst) fax: 702-256-3744 customerservice@ewswater.com

4.1-6

EWS, Inc. / Environmental Water Systems

Dispenser/Faucet Q & A

Q: I do not want to drill any extra holes or use a separate dispenser/faucet - what can I do?

A: An alternative to installing and using the dispenser/faucet is to consider a direct connection to your

existing kitchen (cold side) faucet. Connect the supply from the cold water angle stop to feed/inlet side of the

filtration system as directed in this manual. Then connect the filtered/outlet side to the cold feed side of the

kitchen faucet. Special fiitings, that are readily available to the plumbing professional, will be required to fit this

application based on line size and materials used.

WARNING: This is not a preferred method due to a more complicated install, lower flow rates to your

kitchen faucet and most importantly, the possibility of water quality issues as a result of the

aerator at the end of the kitchen faucet not intended for filtered water.

Note: There will be a diminishment in your flow rate to the cold side of the faucet (kitchen faucet

has a flow rate of up to 2.3 gallons per minute and the filtered water is delivered up to 1 gallon

per minute). To get filtered water you must be sure you have the faucet to the cold side only.

This application or option may not be applicable for reverse osmosis systems.

Q: I would like to use another dispenser/faucet?

A: Based on many styles and finishes, a consumer may have another dispenser they would like to use.

No problem, all these items have universal or industry standard fittings, or if not, can be easily adapted to fit.

Note: EWS, Inc. includes a standard chrome, long-reach, lead-free faucet with white handle and tip.

Options: EWS provides the following options to match other items at an additional charge;

Change your white tip and handle to black

Change your faucet to the following finshes; white faucet (with white tip and handle), satin

nickel, polished nickel, polished brass, or oil rubbed bronze (all with black handle and tip).

Inquire with your local EWS, Inc. distributor, contact an authorized internet distributor or visit us

on the web (see page 4.1-17 for more details).

Q: Can we connect the filtered water up to other devices?

A: Y es, simply connect by a “T” connection, the filtered water line to any inst ant hot, chiller , ice-maker,

refrigerator, etc. Regarding flow rate, be mindful of too many (3 or more) connections and/or any length

limitations in excess of 15 feet to any item that may create issues with delivery rates. See our Point of Entry ,

Whole Home Appliances to filter all the fixtures within the home.

Note: Spout pulls out from faucet body and has 2 o-rings at base. Insert completely into bottom of faucet

body to prevent leaking. Spount swivels to direct water. Handle and tip can be removed. Handle

can be locked up in open position.

Other faucets check with specifications.

All dimensions are approximate.

www.EWSWATER.com office: 702-256-8182 (m-f; 8:30-4:30, pst) fax: 702-256-3744 customerservice@ewswater.com

EWS, Inc. / Environmental Water Systems

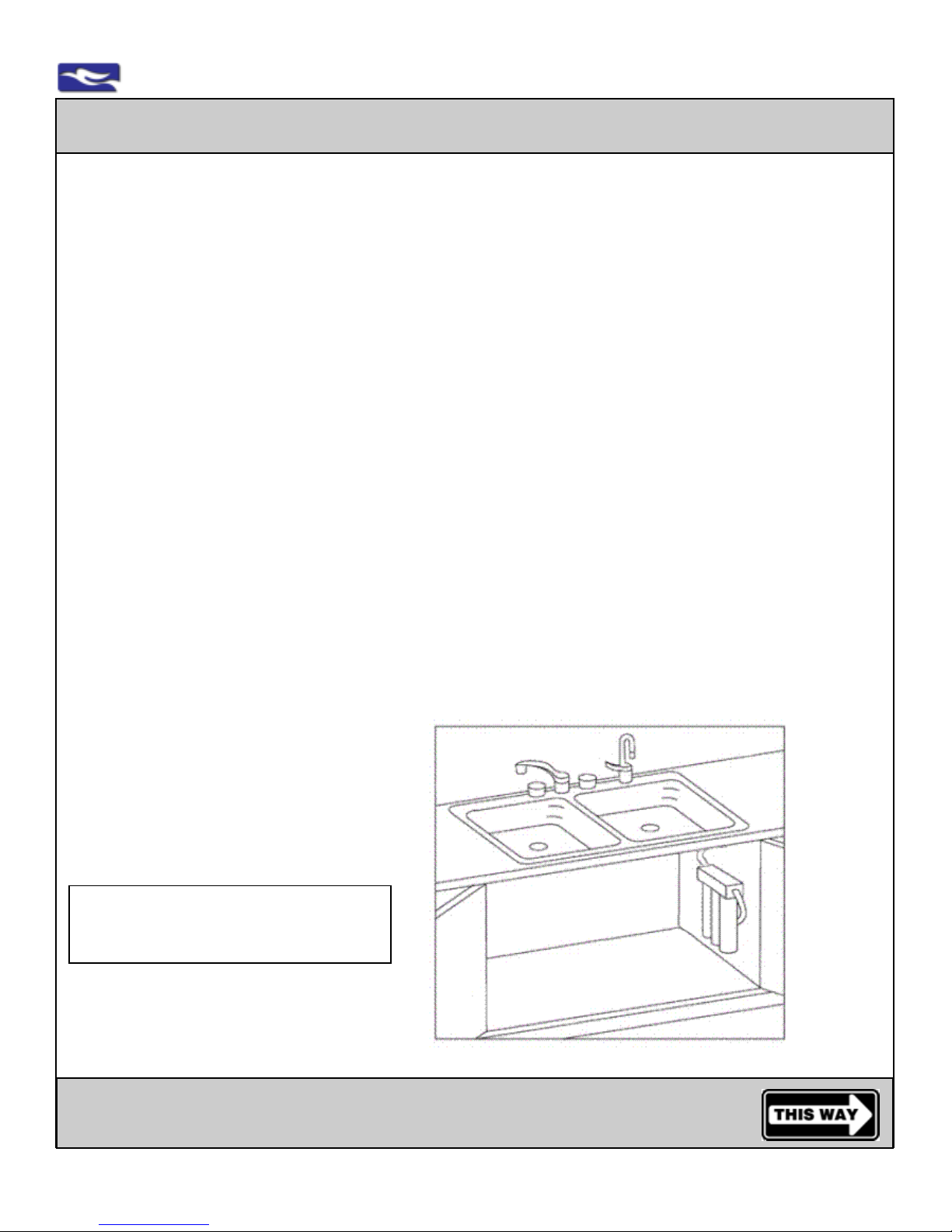

Placement or Locating the Water System

Simply place the water system on a level floor, cabinet bottom or horizontal surface.

Always assume for enough space and tubing to remove, move and/or adjust

for filter replacement and maintenance.

If mounting the system to a wall, cabinet side or other vertical surface,

Please see the following;

Step 1: All filter cartridges for the system are preinstalled. If the unit is installed in a permanent

hanging position, a minimum clearance of 2” will be required to allow filter replacement.

Step 2: Mark pilot holes using the bracket as a template.

Step 3: Using a drill bit or punch, drill a hole or punch as a starter hole to catch the mounting

screws.

WARNING: AL TERNA TIVE F ASTENING METHOD MA Y BE REQUIRED FOR PLASTER BOARD,

P ARTICLE BOARD OR SIMILAR MA TERIAL INSTALLA TION. USE SAFETY GLASSES

OR OTHER EYE PROTECTION TOPREVENT POSSIBLE EYE INJURY DUE TO

FL YING P ARTICLES.

4.1-7

Step 4: Set mounting screws (provided) with screw driver. Leave a 1/4” gap between the screw

head and mounting surface to allow the bracket to slide on easily .

Step 5: Slide the bracket over the screws and hang the unit. Make sure unit is level.

Now make the connections of tubing to/from the system.

Helpful Hint:

Find the enclosed Sp anner Wrench that

Kitchen Faucet

Dispenser/Faucet

of filtered water

came with the unit and place it on top of

the bracket.

When finished, roll up this Service Guide

and place on top with wrench.

Take a note of the Model # and WQA

Serial # for the required warranty registration of this unit.

This Service Guide and the wrench will

Filtered Water to

Dispenser/Faucet

Mounted to Wall

(option shown) or

Placed on level floor

Outlet

Inlet from

Cold Inlet/Supply

Connection

(angle stop not

shown)

come in very handy when it’s time for

filter replacement.

Go to the Inlet Supply W ater Connection

www.EWSWATER.com office: 702-256-8182 (m-f; 8:30-4:30, pst) fax: 702-256-3744 customerservice@ewswater.com

strictly for illustration purposes only

4.1-8

EWS, Inc. / Environmental Water Systems

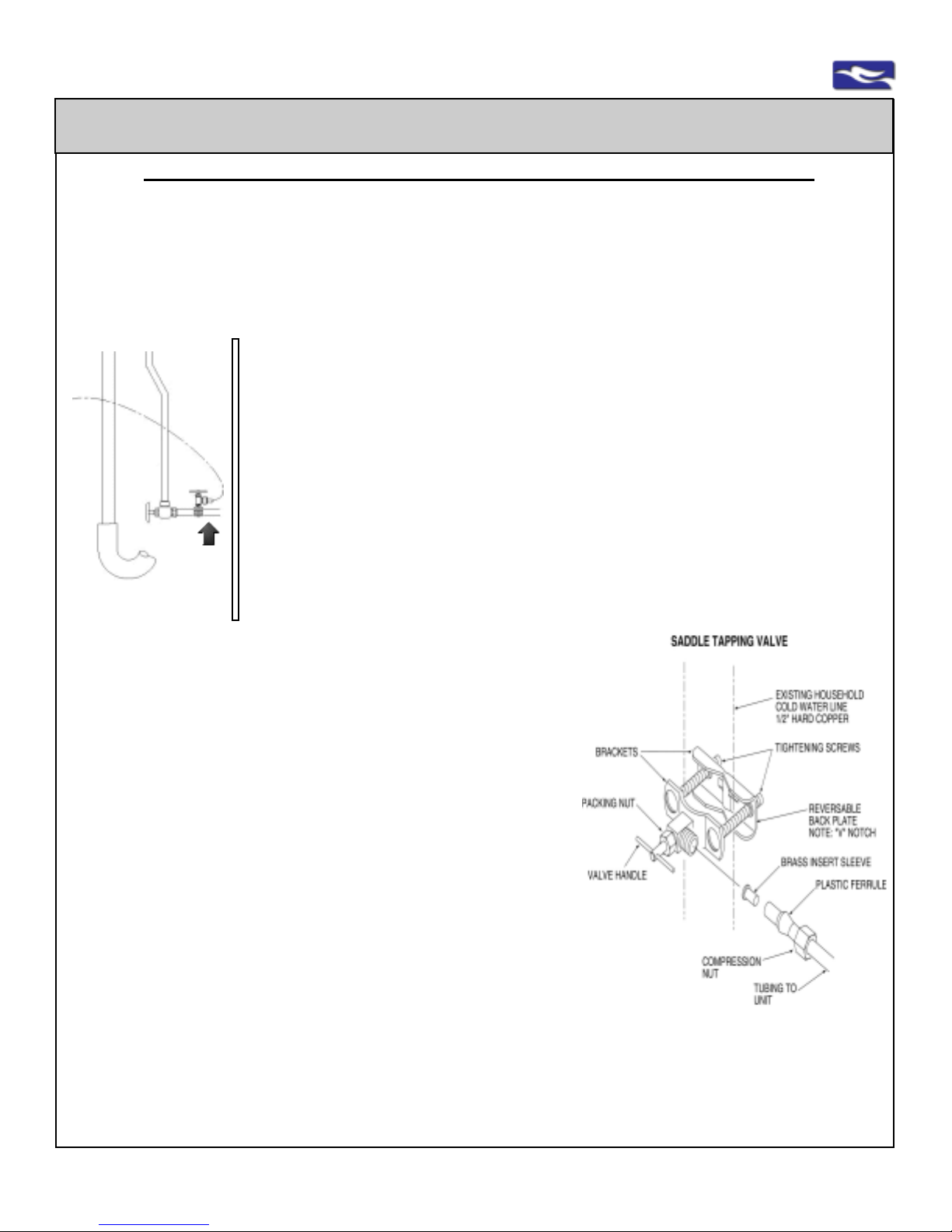

Basic Inlet Supply Water Connection **

Professional Installation Using a Preferred Connection is Strongly Recommended

**This unit is supplied with a saddle tapping valve and should be considered a basic connection for copper , steel or brass

3/8” to 1/2” O.D. pipe prior to the angle stop shut-off of the cold water line to the kitchen faucet. This should be considered

a “do-it-yourself” connection which is not applicable in many situations and may not meet local codes.

A qualified plumber should choose to make the inlet supply water connection by a more preferred method.

Instructions from the bag containing the supplied saddle tapping valve, if applicable

Step 1: From parts bag locate: saddle tapping valve and 4’ of 1/4” tubing, color coded: red or orange (supply line to unit).

wall

angle

stop

cold

supply

to

kitchen

faucet

saddle

tapping

valve

pipe for

install

and

clearance

from wall

supply

tube

to

filtration

unit

drain

and

trap

Step 4: Loosely assemble saddle tapping valve on pipe

A: For all 3/8 O.D. pipe, use side of bracket with side projections

toward or against pipe to prevent distortion of tubing.

B: For all 1/2 O.D. pipe, use “V” side of bracket with that notch

toward or against pipe.

Step 5: T ighten screws evenly . Make sure brackets are parallel,

then tighten firmly until the valve is not moving on the pipe.

CAUTION: Do not over tighten fittings.

Step 6: Connect the 1/4” plastic tubing to the saddle tapping

valve by following these instructions:

A: Slide 1/4” compression nut over plastic tubing with threads toward the

saddle tapping valve.

B: Slide 1/4” plastic ferrule over plastic tubing with long tapered side

toward saddle tapping valve.

C: Place 1/4” brass insert sleeve into the end of the 1/4” or orange/red

plastic tubing.

D: Insert orange/red tubing into saddle tapping valve. Leave other end

available for system interconnection

E: Tighten compression nut onto saddle tapping valve.

Step 2: Locate cold water line that feeds your existing faucet. Determine if there is enough

space to install the saddle tapping valve on the hard line between the wall and the angle

stop.

CAUTION: USE ONL Y COLD WATER LINE. NOT INTENDED FOR SUPPLY BY HOT

WATER.

Step 3: Shut off the main water supply to the house and open the faucet to relieve water

pressure in the hard pipe. NOTE: Shutting the angle stop only , still leaves water in that pipe.

Shut the main supply .

CAUTION: Do not turn valve handle before or while installing the “saddle tapping valve”.

Make sure the piercing lance does not protrude beyond the rubber gasket. Failure to do this

may result in damage to the piercing needle.

NOTE: For Copper Pipe - go directly to #4.

For Steel or Brass Pipe - follow A, B, C below, then go to #4

A: Drill a 3/16” hole in pipe. Use a hand drill to avoid shock hazard.

B: Turn handle to expose lance beyond the rubber gasket no more than 3/16”.

C: Place body of valve over hole so the lance fits into the hole

CAUTION:

Do not over

tighten fittings.

Step 7: Be sure the packing nut is tight, then turn the handle of the saddle tapping valve clockwise

until it is firmly seated. NOTE: For Copper Pipe - the pipe is now pierced.

HINT: Back the end of the piercing lance out, turning the handle counter-clockwise. Then re-insert by turning the handle

of the saddle tapping valve clockwise until it is again firmly seated. This will clear any possible debris that can

block piercing lance and water flow.

Step 8: Turn the handle counter-clockwise to open the valve for water supply . Keep main line shut of f and proceed with

the remainder of the installation and start-up.

www.EWSWATER.com office: 702-256-8182 (m-f; 8:30-4:30, pst) fax: 702-256-3744 customerservice@ewswater.com

EWS, Inc. / Environmental Water Systems

4.1-9

Preferred Inlet Supply Water Connection - All Applications

Professional Installation Using a Preferred Connection is Strongly Recommended

A qualified plumber should choose to connect the inlet supply water supply by a more preferred connection. ***

The Preferred Inlet Supply Water Connection is Applicable in All Applications and Codes

Replace the Angle Stop with a Proper 3-Way Fitting:

There are a number of options to properly install any one of these drinking water filtration systems.

Identify the cold water supply line and then you will need to know;

• Size or O.D. diameter of pipe or tubing

• Pipe material (hard or sof t copper, steel, brass, stainless, PVC, plastic, etc...)

• The existing angle stop or fitting will assist in determining the proper 3-way angle stop or fitting needed for

your specific application

A more preferred method to connect the inlet supply line is to shut off

the water main and replace the entire angle stop. This will have a connection from the house main water line, a connection to the cold water

side to the kitchen sink faucet and a much better connection for the

inlet supply to the filtration unit. This will provide one fitting with a shut

off to the kitchen faucet and a shut off to the filtration system. The

replacement of the angle stop is a better plumbing connection and any

number of fittings can be used for the correct application under any

circumstances.

Examples of common connections and fittings available:

• OPTIONS:

1/2” IPS x 3/8” compression x 1/4” compression

3-way angle stop

• OPTIONS:

1/2” compression x 3/8” compression x 1/4” compression

3-way angle stop

Note:

Be sure one outlet is 1/4” compression

for the water filter 1/4” inlet/supply tubing

drain

and

trap

Example:

new 3-way

angle stop or

fitting

kitchen faucet supply

shut

off

cold water

supply pipe

to kitchen

faucet

connection

1/4” filtration

unit supply

connection

wall

water flow

main water

supply pipe

Proper installation is dependent on your specific application and the concept of proper installation is universal.

Locate the supply , shut off your main water supply , install the proper connections

and follow the remaining instructions in this manual.

***EWS, Inc. can not anticipate all the different locations, applications and materials used by your builder and/

or plumbing contractor regarding your household or sink piping, therefore we offer a generic and common fitting

with proper instructions. A qualified plumber , plumbing supply location, or hardware store will have no problem

with alternative parts and advice necessary to install your unit.

Go to the Connections of Tubing to and from System

www.EWSWATER.com office: 702-256-8182 (m-f; 8:30-4:30, pst) fax: 702-256-3744 customerservice@ewswater.com

Loading...

Loading...