EWS Series, CWL Series, EWS-1035 LTD, EWS-1054, EWS-1354 Care And Use Manual

...

Care and Use Manual

Tank EWS/CWL Series Appliances

Information Provided for the Proper Set-Up, Installation and

Start-Up of the following Appliances:

EWS Series of Whole Home Filtration and Physical Conditioning:

EWS-1035 LTD, EWS-1054, EWS-1354, EWS-1354-HF, EWS1354-11/2”

CWL Series of Whole Home Filtration:

CWL-1035 LTD, CWL-1054, CWL-1354, CWL-1354-HF, CWL-1354-11/2”

4.2-1

ALL PRODUCT PROUDLY MANUFACTURED AND ASSEMBLED IN THE USA

To the Consumer:

Retain this Care & Use Manual for Maintenance and Information

You Must Register this Product - It is a Requirement for Warranty

www.EWSWATER.com office: 702-256-8182 (m-f; 8:30-4:30, pst) fax: 702-256-3744 customerservice@ewswater.com

4.2-2

SOFTENER DISCLAIMER:

Softeners do not filter. They simply exchange naturally-found calcium and magnesium (hardness) minerals for either sodium or potassium chloride. Please note

drinking softened water must be avoided, in addition,

there can be warranty issues with certain product and

finishes, and bans or restrictions due to the environmental impact of the brine discharge. If the “slippery” or

“silky” feeling and the perceived benefits are preferred,

install to the inlet to the water heater(s) for use on hot

water only.

WA TER FILTRA TION T O THE WHOLE HOME:

Most homes on “city” water simply require the correct

Whole Home Water Filtration Appliance installed on

the homes’ main service line.

Complete installation of any EWS or CWL Whole Home

Unit can be as easy for a professional contractor as

the installation of a water heater.

Specify by size of main water service line after homes’

shut-off valve. Options for smaller or larger homes,

usage and/or other conditions. The correct application

eliminates the need and expense of a “soft water loop”

which would bypass salt-softened water to any drinking water or hose bibs

www.EWSWATER.com office: 702-256-8182 (m-f; 8:30-4:30, pst) fax: 702-256-3744 customerservice@ewswater.com

Table of Contents

INSTALLATION SUMMARY AND INDEX

OF YOUR WHOLE HOME W ATER FIL TRATION APPLIANCE

EWS Series - Summary Product Information 4

CWL Series - Summary Product Information 5

INST ALLA TION SUMMARY - 12 STEPS 6

GENERAL INFORMA TION AND PRE-INST ALLA TION CHECKLIST 7

EWS & CWL 1035, 1054, 1354

Schematic 8

Installation Instructions 9-11

EWS & CWL -1354-HF

Schematic 12

Installation Instructions 13-15

4.2-3

EWS & CWL -1354-11/2”

Schematic 16

Installation Instructions 17-19

Start-Up Procedure for All Units 20-23

HOW TO MAINTAIN YOUR SYSTEM

ADJUSTING THE BACKWASH SETTINGS 24

Replacement of Media - EWS Units 26-27

Replacement of Media - EWS Units 28-29

Cleaning of Empty Housings, RSR Control Valve, Booster Pump (if applicable) 20

Warranty 30-31

Terms and Conditions of Sale 32

A Quick Reference of Systems and Combinations for Various Applications 33

EWS Series Tearsheet - Environmental Water Systems #1 Since 1987 34-35

www.EWSWATER.com office: 702-256-8182 (m-f; 8:30-4:30, pst) fax: 702-256-3744 customerservice@ewswater.com

4.2-4

The EWS Series - The Environmental Water System

Whole Home Water Filtration and Physical Conditioning Appliances

EWS-1354

EWS-1354-HF

EWS Series - Summary Product Information

Model#: EWS-1354

Whole Home Water Filtration and Physical Conditioning Appliance.

The EWS-1354 is the most popular system sold for use on 3/4” to 1’” water main

service lines for continuous flow rates up to 15 gpm.

Replacement Kit Code: POE-11

or Complete Tank with Kit: POE-11-T

Model#: EWS-1354-HF

Whole Home Water Filtration and Physical Conditioning Appliance.

The EWS-1354-HF has a High Flow 1” MNPT solid brass body valve specified for use

on 11/4’” water main service lines for greater continuous flow rates up to 22 gpm.

Replacement Kit Code: POE-12

or Complete Tank with Kit: POE-12-T

EWS-1354-11/2”

EWS-1054

EWS-1035-LTD

Model#: EWS-1354-11/2”

Whole Home Water Filtration and Physical Conditioning Appliance.

The EWS-1354-11/2” has a 11/2” FNPT solid brass body valve specified for use on

larger 11/2’” water main service lines for greater continuous flow rates

up to 50 gpm.

Replacement Kit Code: POE-13

or Complete Tank with Kit: POE-13-T

Model#: EWS-1054

Whole Home Water Filtration and Physical Conditioning Appliance.

The EWS-1054 is the smaller version of the EWS-1354 for use on softer water below

15 grains (or 250 ppm or mg/l of water hardness). For use on 3/4” to 1’” water main

service lines for continuous flow rates up to 15 gpm.

Replacement Kit Code: POE-10

or Complete Tank with Kit: POE-10-T

Model#: EWS-1035-LTD

Whole Home Water Filtration and Physical Conditioning Appliance.

Specialty unit measuring only 44” tall for limited usage and space. For use on softer

water below 15 grains (or 250 ppm or mg/l of water hardness), Limit no more than 2

baths, 4 people, and one water heater. For use on 3/4” to 1’” water main service

lines for continuous flow rates up to 15 gpm.

Replacement Kit Code: POE-9

or Complete Tank with Kit: POE-9-T

Applicable to most municipally-treated water. Well water needs to be properly and completely tested before the specification of any filtration and

treatment system(s). Any EWS System can be combined with EWS softeners (hot-side only) and/or additional EWS sink filtration product based on

consumer preference, need, and/or based on the local water conditions. Larger units available. Any questions please inquire with EWS, Inc.

www.EWSWATER.com office: 702-256-8182 (m-f; 8:30-4:30, pst) fax: 702-256-3744 customerservice@ewswater.com

CWL Series - Summary Product Information

The CWL Series

The Other Standard in Whole Home Water Filtration

Model#: CWL-1354

Whole Home Water Filtration Appliance.

The CWL-1354 is the most popular system sold for use on 3/4” to 1’” water main

service lines for continuous flow rates up to 15 gpm.

Replacement Kit Code: POE-5

or Complete Tank with Kit: POE-5-T

Model#: CWL-1354-HF

Whole Home Water Filtration Appliance.

The CWL-1354-HF has a High Flow 1” MNPT solid brass body valve specified for use

on 11/4’” water main service lines for greater continuous flow rates up to 22 gpm.

Replacement Kit Code: POE-5

or Complete Tank with Kit: POE-5-T

4.2-5

CWL-1354

CWL-1354-HF

Model#: CWL-1354-11/2”

Whole Home Water Filtration Appliance.

The CWL-1354-11/2” has a 11/2” FNPT solid brass body valve specified for use on

larger 11/2’” water main service lines for greater continuous flow rates

up to 50 gpm.

Replacement Kit Code: POE-5

or Complete Tank with Kit: POE-5-T

Model#: CWL-1054

Whole Home Water Filtration Appliance.

The CWL-1054 is the smaller version of the CWL-1354 for use on smaller homes

and applications of no more than 2 baths, 4 people, and one water heater. For use

on 3/4” to 1’” water main service lines for continuous flow rates up to 15 gpm.

Replacement Kit Code: POE-4

or Complete Tank with Kit: POE-4-T

Model#: CWL-1035-LTD

Whole Home Water Filtration Appliance.

Specialty unit measuring only 44” tall for limited usage and space. Limit no more

than 2 baths, 4 people, and one water heater. For use on 3/4” to 1’” water main

service lines for continuous flow rates up to 15 gpm.

CWL-1354-11/2”

CWL-1054

Replacement Kit Code: POE-3

CWL-1035-LTD

or Complete Tank with Kit: POE-3-T

Applicable to most municipally-treated water. Well water needs to be properly and completely tested before the specification of any filtration and

treatment system(s). Any EWS System can be combined with EWS softeners (hot-side only) and/or additional EWS sink filtration product based on

consumer preference, need, and/or based on the local water conditions. Larger units available. Any questions please inquire with EWS, Inc.

www.EWSWATER.com office: 702-256-8182 (m-f; 8:30-4:30, pst) fax: 702-256-3744 customerservice@ewswater.com

4.2-6

All Units - Important

IF YOU ONLY READ ONE PAGE IN THIS MANUAL - THIS IS IT !!!

INSTALLATION SUMMARY - 12 STEPS

Step 1:

Locate the following: **Main Water Supply Line, Drain Access, Electrical Outlet and Clearances.

Caution: **Avoid soft water loops that bypass cold side kitchen sink(s) from these applications.

Step 2:

Check the incoming Water Pressure. Maximum water pressure not to exceed 65 psi.

Install a pressure regulator (PRV) if the water pressure exceeds or can surge above 65 psi.

Step 3:

Place the tank at the point of installation, making sure the tank is level (tanks have self-leveling bases) and

on a solid floor, note sp ace necessary to complete the inst allation. Inside or Out side? See details.

Step 4:

Caution: Since handling and moving the unit may loosen the valve head - make sure to Check and Hand

Tighten V alve Head on the Tank. Hand Tighten the Valve Head in a Clockwise Direction. Make sure tank

cover or plastic dome, if applicable does not interfere or cut into the connection.

Step 5:

Identify Water Main Supply and plumb inlet (supply) and outlet (filtered) into the unit following the directional

arrows molded onto the valve body. Plumb the unit with the bypass and the male yoke included, or for larger

brass valved units, a bypass must be plumbed. Do not cross-connect or plumb backwards. See detailed

installation schematics and the helpful information in this manual.

Step 6:

Connect a backwash drain line (minimum 1/2” or 3/4” ) based on application and provide an air gap.

Step 7:

Partially Open Inlet V alve Only.

Keep outlet valve closed. (Larger brass valved units, keep plumbed bypass valve closed).

Step 8:

Plug the unit into an electrical outlet. Be sure the outlet is dedicated and unswitched.

An outlet that cannot be turned “on” or “off.”

Step 9:

Set the time of day on the valve display . The valve will read or flash between the time of day and the

remaining days before the next automatic backwash.

Step 10:

Backwash and Flush the system properly and completetly until the drain water runs clear.

Step 11:

Open Outlet V alve slowly (Larger valved units, keep plumbed byp ass valve closed).

Check all plumbing connections

Step 12:

Run hot/cold water throughout the home (at every tap) to flush pipes and water heaters to prepare unit for

usage. You are done.

Fill Tank Slowly. Once t ank is filled, completely open inlet valve.

A typical installation no more difficult then a water heater. Just simply follow the proper set-up, installation

and start-up and if you have any questions call our offices and we would be glad to help in any way.

For additional details regarding line pressure, outside installations or other topics,

please review the troublshooting section at the back of this service guide

www.EWSWATER.com office: 702-256-8182 (m-f; 8:30-4:30, pst) fax: 702-256-3744 customerservice@ewswater.com

All Units - Important

4.2-7

GENERAL INFORMATION AND PRE-INSTALLATION CHECKLIST

Verify: All components are included with the unit and were not damaged in shipping.

Caution: Do not attempt to install any system using defective or damaged components. Do not install any

system that has been misapplied.

Warning: When plumbing, use protective eyewear to prevent possible eye injury due to flying objects.

When using an open flame and/or hot materials, take the necessary precautions for you and the

environment to prevent burns, burning and/or fires.

Water Pressure and Flow Rate:

A minimum of 35 PSI (40 PSI for Iron units) and 8 GPM for 1035 & 1054 units/12 GPM for 1354 units is

required for backwash valve to operate effectively. Water pressure not to exceed or to surge in excess of a

maximum of 65 PSI for the system. Unsure of pressure or it’s ability to surge? A pressure reducing valve

(PRV) becomes an insurance policy and is recommended for this and many other products that limit high

pressure in your home.

Water Temperature Range:

Feed water temperature not to exceed 95°F or be allowed to go below 40°F . Protect unit from exceeding high

temperatures and never allow unit, its’ drain line and any water to freeze. Must avoid any thermal expansion

from water heaters

Electrical:

An uninterrupted alternating current (A/C) supply is required. Please make sure your voltage supply is compatible with your unit before installation.

Existing Plumbing:

Condition of existing plumbing should be free from lime and iron buildup. Piping that is built up heavily and

clogged with lime and/or iron should be replaced. Problem with iron? Our separate iron filter unit should be

installed ahead of any other unit. Old galvinized or combinations of plumbing materials can cause water

issues and conditions. Pre-existing conditions may affect initial effectiveness of any product.

Location of Tank, Drain and Electrical:

Units can be installed, almost anywhere. Inside or outside. However, use your common sense. Valves are

water resistant, not water proof. Protect any system from the elements. Review issues on water flow rates

and pressure, and environmental and water temperature ranges. The tank should have access to the supply

water, provide filtered water to the home, be located close to a clean working drain, have an electrical outlet

available, and be connected according to all local plumbing codes.

By-Pass Valves:

Larger brass valved units and all Iron Units are required to be plumbed with an bypass and unions (see

installation schematics). Some units (CWL/EWS-1035 LTD, CWL/EWS-1054, CWL/EWS-1354) come complete with a dual-port bypass and male yoke that is required to use for a simple installation.

Drain Connection:

Nominal drain line and drain size on 1035/1054/1354 (non-iron) units should be a minimum of 1/2”. Larger

1 1/2” brass valves require 3/4” drain line. Any drain line exceeding 20’ in length and/or expected to flow over 5’

above the height of the drain port requires an increase in drain line size by an additional 1/4” to either 3/4” or

1”. Install, non-restrictive, check valve in drain line, if drain water is expected to flow over 5’ above the height

of the drain port. Never restrict the backwash drain water flow.Teflon tape is the only sealant to be used on the

drain fitting.

All plumbing should be done in accordance with all local plumbing codes.

All the information that you may need is in this product manual and available on the web.

Identify the unit you are installing and follow the detailed, Set-Up, Installation and S tart-Up of that unit.

WARNING: IMPROPER INSTALLATION WILL RESULT IN THE VOIDING OF ANY WARRANTY.

www.EWSWATER.com office: 702-256-8182 (m-f; 8:30-4:30, pst) fax: 702-256-3744 customerservice@ewswater.com

4.2-8

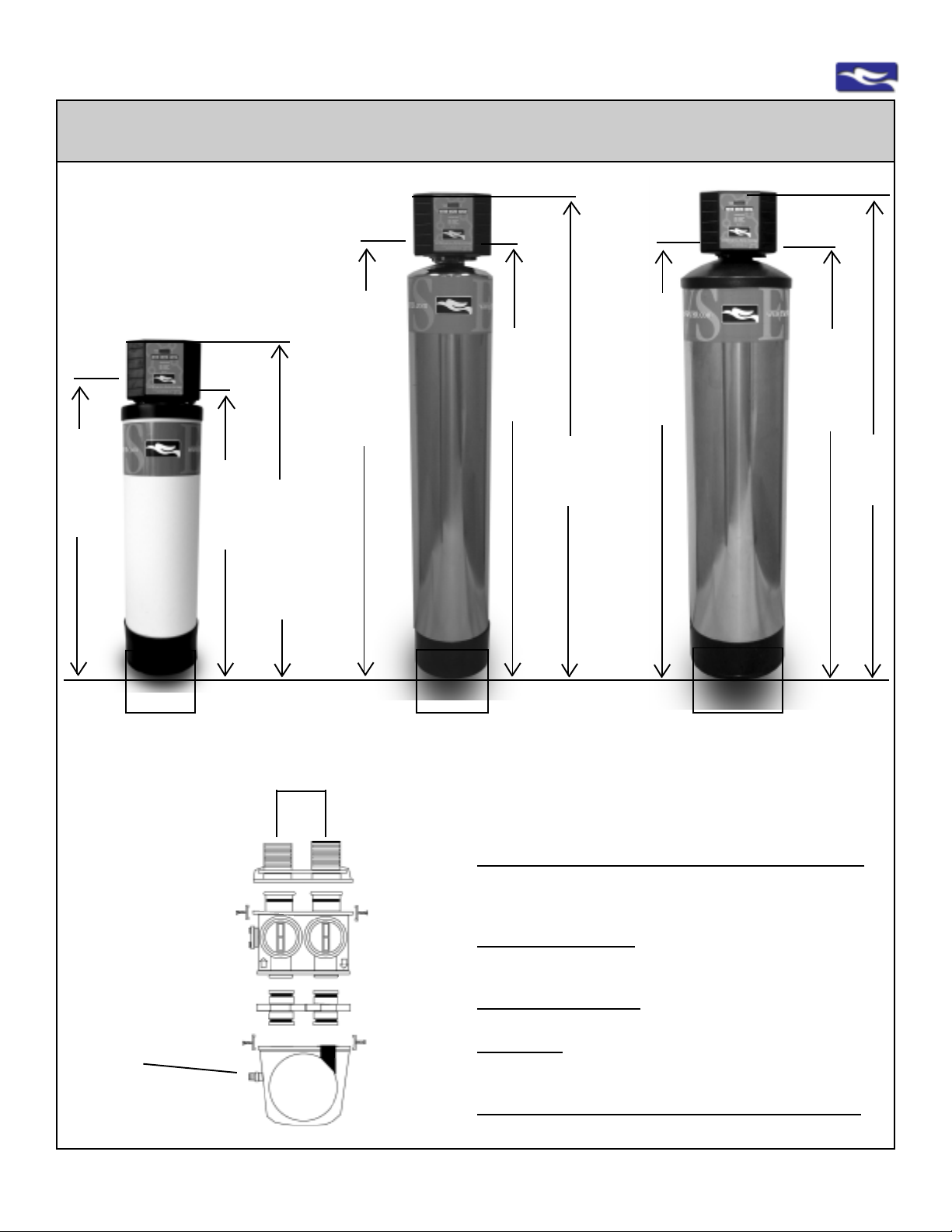

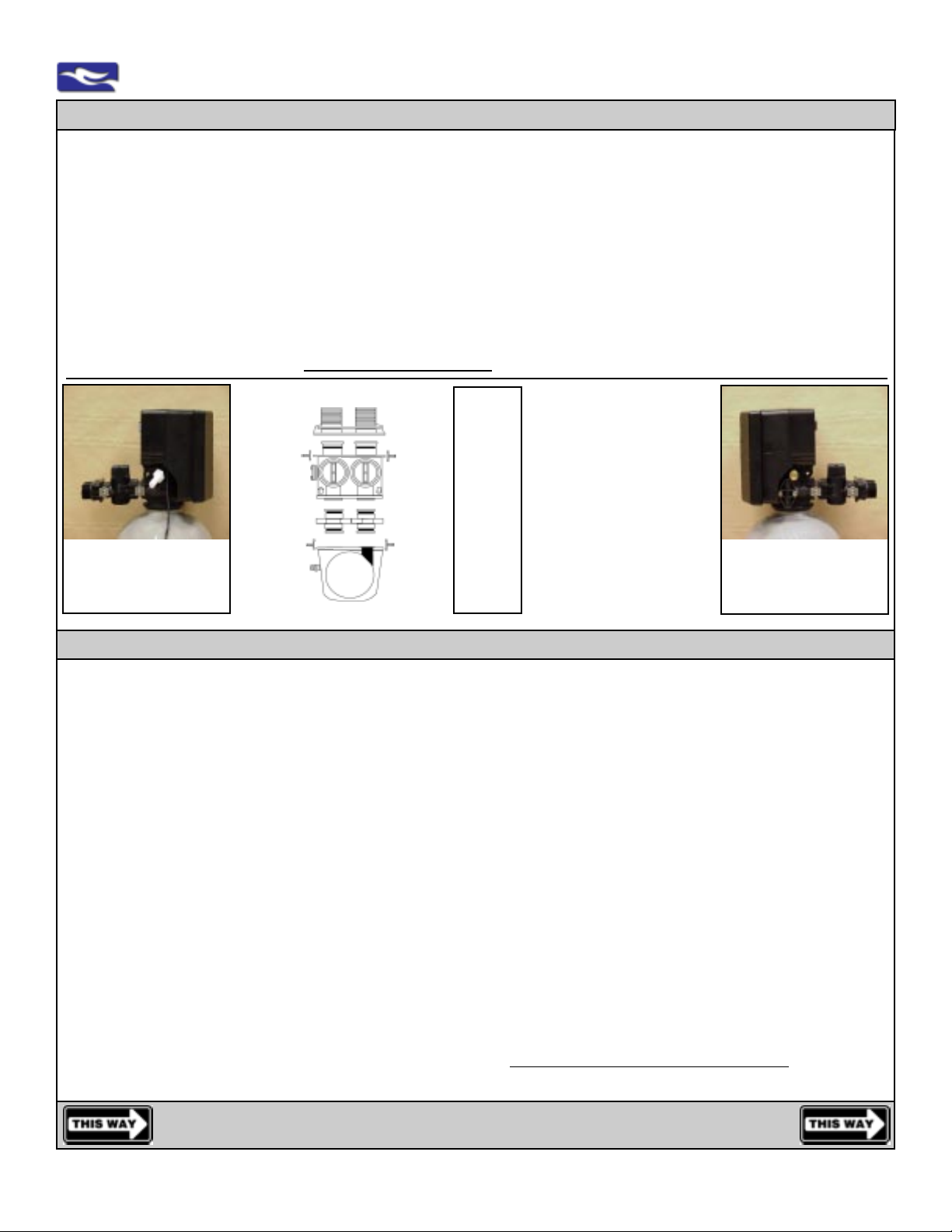

EWS & CWL 1035, 1054, 1354

Set-Up and Installation Schematic for the following Units:

EWS-1035 LTD, EWS-1054, EWS-1354; CWL-1035 LTD, CWL-1054, CWL-1354

EWS/CWL-1035 LTD

drain

line

38 3/4”

on

center

water

inlet/outlet

37 1/2”

on center

overall

height

44”

EWS/CWL-1054

drain

line

57 1/2”

on

center

water

inlet/outlet

56 1/4”

on center

overall

height

62 1/2”

EWS/CWL-1354**

drain

line

58”

on

center

water

inlet/outlet

56 3/4”

on center

overall

height

63”

10”

back of valve:

Yoke

Dual-Port

Bypass V alve

Dual Male

outlet

side:

to the

home

filtered

left

2”cc

inlet

side:

supply

from

main

right

Connectors

Drain

Port

top

view:

front: valve face

www.EWSWATER.com office: 702-256-8182 (m-f; 8:30-4:30, pst) fax: 702-256-3744 customerservice@ewswater.com

10”

**CWL/EWS-1354 has a grey tank adaptor

that allows for installation of valve on 13x54

tank and adds 1/2” Due to tank and base

variances overall dimensions +/- 1”

EWS/CWL-1035 L TD, EWS/CWL-1054, EWS/CWL-1354

Service Line Size: 3/4” - 1”; Service Flow Rate: 15 gpm

Drain Line Size: min: 1/2”

(see drain connection for proper specifications)

Installed Dimensions:

See diagrams for specific units

Dry Weight: 1035 - 80lbs, 1054 - 125lbs, 1354 - 165lbs.

Plumbing Clearances:

Minimum of 18” from front of unit to back wall for plumbing

Drain Flow:

restricted up to 4 gpm (1035, 1054), up to 7 gpm (1354)

Factory Set: maximum of 18 minutes every 3rd day

Bypass and male threaded 1” MNPT yoke (included)

Required to be installed with valve

13”

EWS & CWL 1035, 1054, 1354

Go to next for pages to:

Step 1 PREPARE FOR INSTALLATION:

Step 2 UNBOX UNIT:

CHECK TANK AND VALVE AND

LOCATE BYPASS AND MALE YOKE:

Step 3 PLUMBING LINE CONNECTIONS:

Step 4 DRAIN CONNECTIONS:

After Steps 1 through 4 are completed you must go to:

Step 5 - GO TO SYSTEM START-UP PROCEDURES

4.2-9

Notes:

www.EWSWATER.com office: 702-256-8182 (m-f; 8:30-4:30, pst) fax: 702-256-3744 customerservice@ewswater.com

4.2-10

EWS & CWL 1035, 1054, 1354

1 - PREPARE FOR INST ALLA TION:

Check the Following:

Main Water Supply Line, Drain Access, Electrical Outlet, and Clearances to comlepte the inst all.

Location of T ank: Units can be installed, almost anywhere. Inside or outside. However , use your common sense. V alves

may be water resistant, not water proof. Protect any system from the elements. Review issues on water flow rates and

pressure, and environmental and water temperature ranges. The tank should have access to the supply water, provide

filtered water to the home, be located close to a clean working drain, have an electrical outlet available, and be connected

according to all local plumbing codes.

Water Temperature Range: Feed water temperature not to exceed 110°F or be allowed to go below 40°F. Protect unit

from exceeding high temperatures and direct sunlight, and never allow unit, the drain line and any water to freeze.

Electrical: An uninterrupted alternating current (A/C) supply is required. The system is ideally located within 4-6 feet of a

1 10 volt outlet to allow the unit to be plugged in. A 24 volt motor and transformer is available for longer electrical runs (use

10-2 regular lamp gauge wire). The 24 volt transformer must be located inside.

Existing Plumbing: Condition of existing plumbing should be free from lime and iron buildup. Piping that is built up heavily

and clogged with lime and/or iron should be replaced. Problem with iron? Our separate iron filter unit should be installed

ahead of any other unit. Old galvinized or combinations of plumbing materials can cause water issues and conditions.

Drain Connection: Nominal drain line and drain size on 1035/1054/1354 (non-iron) units should be a minimum of 1/2”.

Any drain line exceeding 20’ in length and/or expected to flow over 5’ above the height of the drain port requires an increase

in drain line to 3/4”. Install, non-restrictive, check valve in drain line, if drain water is expected to flow over 5’ above the height

of the drain port. Never restrict the backwash drain water flow.Teflon tape is the only sealant to be used on the drain fitting.

Check Incoming Water Pressure and Flow Rates: A minimum of 35 PSI and 8 GPM for 1035 & 1054 unit s/12 GPM

for 1354 units is required for backwash valve to operate effectively . W ater pressure not to exceed or to surge in excess of

a maximum of 65 PSI for the system. Unsure of pressure or it’s ability to surge? A pressure reducing valve (PRV), or limiting

pressure to 65 PSI is recommended for this and many other kitchen and bath products in your home. Automatic valve is

rated for 100 PSI and the tank is rated for 150 PSI, however the overall system with various connections has limitations to

excessive pressure. Water pressure measuring 65 PSI during the day may surge to over 100 PSI at night when the

automatic backwash occurs.

Install (often required by code) a pressure regulator (PRV) if the water pressure exceeds or can surge above 65 PSI.

2 - UNBOX UNIT : CHECK T ANK AND V AL VE AND LOCATE BYP ASS AND MALE YOKE:

1) PLACE THE T ANK WHERE YOU W ANT TO INST ALL THE UNIT.

Make sure the tank is level and on a firm base. Black bases on tanks are glued-on and self-leveling. If necessary , lift t ank

and tap the part of the base to floor , in order to level unit. T ake note of the clearances necessary to complete the inst allation.

2) CHECK AND TIGHTEN V AL VE HEAD ON THE T ANK.

Hand Tighten the V alve Head in a Clockwise Direction. Make sure the stainless tank cover or plastic dome (1354 unit s) does

not interfere or cut into the connections.

WARNING: S tainless covers are non-functional, if “dinged” in handling, turn to good side.

3) CONNECT BYP ASS VAL VE AND MALE YOKE TO V A LVE HEAD.

Make sure bypass valves are facing up. Keep bypass valve level (horizontal). Do not put, up or downward, and/or sideways

pressure on bypass valve, this will not allow nipples and o-rings to seat squarely and completely and over time could cause

under pressure connection failure.

3 - PLUMBING LINE CONNECTIONS:

1) IDENTIFY THE MAIN W A TER SUPPL Y .

Do Not Assume. You may have to perform “the old bucket test” to determine where the water is coming from.

Make sure the whole facility is on the line. Some cold water lines (kitchen, island, wet bar sinks, refrigerators, ice

makers) may have been plumbed separately , if previously plumbed for (salt) softened water . Y ou may have to recapture

those lines by replumbing that manifold. Or, capture the main water supply before the byp assed or “looped” away lines,

usually found at, or after , the main water shut off. However , some plumbing designs prevent this ideal installation. A sink

(point of use) filtration unit can be used for that missed location.

www.EWSWATER.com office: 702-256-8182 (m-f; 8:30-4:30, pst) fax: 702-256-3744 customerservice@ewswater.com

EWS & CWL 1035, 1054, 1354

4.2-11

3 - PLUMBING LINE CONNECTIONS - Continued:

Hose bibs are unnecessary to capture unless required by consumer. Irrigation (which should tee-of f prior to the home’s

main water supply) uses a lot of water and this connection should be discouraged. It puts an unnecessary burden on the

unit and the media.

2) USING THE CONNECTED BYP ASS VAL VE AND 1” MALE NPT YOKE.

3) PLUMB INLET (supply) AND OUTLET (filtered) INTO THE UNIT.

Follow the directional arrows molded onto the valve body and bypass. See pictures below for; top/front/back and left/

right views to prevent plumbing the unit backwards. Teflon tape is the only sealant to used on any of our fittings.

NO Heat, No Torch; Leave at least 12” between the male yoke and any solder joints. Failure to do this could cause

interior damage. Consider flexible stainless (1”FNPT x 1”FNPT (3/4” if your application) and at least 18” in length) connected to copper male adapters, or some other applicable connection - no heat, saves time, neat install, if applicable

code to your application.

4) WARNING: ONCE PLUMBED, DO NOT TURN ON W ATER, UNTIL YOU BEGIN START -UP PROCEDURES.

Outlet (filtered) Side:

left side view of valve and

drain port with included

drain adaptor, bypass and

male yoke

outlet

side:

to the

home

filtered

left

top

view

back:

inlet

side:

supply

from

main

right

front:

Yoke

1” MNPT

Dual

Port

Bypass

O-Ring

Connect

Valve

Head

Required use of dual-port,

full flow, noryl bypass with

1” MNPT yoke.

•Shuts off water to/from the

unit

•No additional plumbing for

media replacement or maintenance

•Less costly plumbing in-

stallation, easier start-ups,

non-corrosive

Inlet (supply) Side:

right side view of valve with

included bypass and male

yoke

4 - DRAIN CONNECTIONS:

1) LOCA TE DRAIN PORT ON THE LEFT (OUTLET) SIDE OF THE V AL VE HEAD.

Inserted into valve drain port is a flow control housing (male o-ringed insert x 1/2” FNPT) which is locked in by the retainer clip

The flow control housing has a flow washer which determines the restricted flow rate (4 gpm - 1035 and 1054, 7 gpm - 1354).

2) DO NOT OVERTIGTHEN CONNECTIONS. IMPORT ANT TO READ THE FOLLOWING:

Nominal drain line and drain size should be a minimum of 1/2”. Drain line exceeding 20’ in length and/or drain water that is

expected to flow over 5’ above the height of the drain port requires a 3/4” line and drain. Install, non-restrictive, check valve in

drain line, if drain water is expected to flow over 5’ above the height of the drain port . Never restrict the backwash drain

water flow.

A drain adapter or hose barb has been supplied and is loosely connected awaiting final installation. You may use this or

any other applicable adaptor or connector depending on your drain line.Care must be taken when screwing in any connection to

the flow control housing, not to crush piece and distort the flow washer, crucial to the ef fective backwashing of the system.

Flexible tubing, poly tubing or any hose must be clamped (do not overtighten) and do not allow any tubing to kink.

Hard piping of drain line: NO Heat, NO Torch, leave at least 12” between drain port and any solder joints - remember to

use a union (a quick disconnect feature) for future servicing applications. Therefore, the system will require no replumbing.

Teflon tape is the only sealant to be used on any drain fitting.

3) LOCA TE A SUIT ABLE PLACE TO DRAIN.

A suitable place to drain the water must be available. Usually , into a drain or trap, where the washer drains, the pool, or

any outside that has sufficient size and space for percolation. You can be flexible or creative. Do not connect the backwash line

to an air conditioning drain line. Do not freeze.

Air gap must be used, if connecting to a drain line or sewer trap, to prevent possible back siphoning into the tank.

Backwash is a mechanical way of turning over the filtration media. The discharge is only water and not a brine. The water

discharge can go anywhere, may be used, or recycled, and does not have the legal restrictions or issues of brine discharge.

5 - GO TO SYSTEM START-UP PROCEDURES

www.EWSWATER.com office: 702-256-8182 (m-f; 8:30-4:30, pst) fax: 702-256-3744 customerservice@ewswater.com

Loading...

Loading...