Evolution Rage Twin, RAGETWIN1251, RAGETWIN1252, RAGETWIN1252EU Original Instructions Manual

Page 1

125mm (5˝) Twin Blade Saw

Original

Instructions

Read instructions before operating this tool.

Manuel D’Instruction Original

Lisez attentivement ces consignes avant

d’utiliser cet outil.

Manual de instrucciones

Lea las instrucciones antes de hacer funcionar

esta herramienta.

www.evolutionbuild.com

FR

ES

Page 2

2

www.evolutionbuild.com

3

www.evolutionbuild.com

®

FIG 1 FIG 2

EC - DECLARATION OF CONFORMITY

EC - Declaration of Conformity 3

Important Information 3

12 Month Limited Warranty 4

General Safety Rules 4

Safety Instructions for all Saws 5

Symbols 6

Additional Specific Safety Rules 6

Specification 7

Assembly 7

Operation 7

Maintenance 9

Environmental Protection 9

Service Parts Lists 10

We, the importer

Evolution Power Tools Ltd.

Venture One

Longacre Close

Sheffield

S20 3FR

Declare that the product

Part numbers: RAGETWIN1251, RAGETWIN1252,

RAGETWIN1252EU

Evolution: RAGE125mm (5˝) Twin Blade Cutter

Complies with the essential requirements of the following

European Directives:

2006/42/EC – Machine Directive

2006/95/EC – Low Voltage Directive

2004/108/EC – EMC Directive

2002/95/EC – Restriction of the use of Certain Hazardous

Substances in Electrical and Electric equipment.

These power tools have been designed in compliance with

the Council Directives:

2006/42/EC

2004/108/EC

2002/95/EC

2002/96/EC

The following standards have been applied:

EN55014-1

EN55014-2

EN61000-3-2 & EN61000-3-3

EN60745-1

EN60745-2-5

NOISE & VIBRATION DATA

LpA (sound pressure) dB(A) 90.0

LwA (acoustic power) dB(A) 101.0

KpA (sound pressure uncertainty) dB(A) 3

KwA (acoustic power uncertainty) dB(A) 3

WEIGHTED RMS ACCELERATION VALUE

Front Handle m/s2 1.383

Rear Handle m/s2 1.5

VIBRATION m/s2 5.18

K m/s2 1.5

The declared vibration value has been measured in

accordance with a standard test method (EN60745) and may

be used for comparing one tool with another. The declared

vibration value may also be used in a preliminary assessment

of exposure.

WARNING: The vibration emission value during actual

use of the power tool can differ from the declared value

depending on the ways in which the tool is used. Identify

safety measures to protect the operator that are based on an

estimation of the exposure in the actual conditions of use.

Take into account all parts of the operating cycle including

the times when the tool is switched off and when it is

running at idle in addition to actual trigger time.

Authorised Signatory

Date: 1/8 /2010

Name: Mr Matthew J Gavins

Position: Managing Director

Year of Manufacture: 2010

IMPORTANT

Please read these operating and safety instructions carefully

and completely. For your own safety, before using this

equipment check that the voltage is correct and that all

handles and parts are firmly secured. If you are uncertain

about any aspect of using this equipment, please contact our

Technical Helpline.

Technical Helpline UK 0870 609 2297

Technical Helpline USA 1-866-EVO-TOOL

TABLE OF CONTENTS

GB

EC - DECLARATION OF CONFORMITY

GB

FIG 5 FIG 6 FIG 7

FIG 8 FIG 9 FIG 10

FIG 11 FIG 12 FIG 13

FIG 3

FIG 4

B

B

A

A

Page 3

4

www.evolutionbuild.com

5

www.evolutionbuild.com

®

14. Maintain tools in good working condition. Keep

cutting tools sharp and clean for better performance and

optimum safety. Follow instructions for lubricating and

changing accessories. Inspect power cables regularly

and, if damaged, have them replaced by an authorised

service centre. Inspect extension cables regularly and

replace immediately if damaged. Keep handles dry, clean

and free from oil and grease at all times.

15. Disconnect tools. Disconnect tools from the power

supply when not in use, before any maintenance

operation and when changing accessories such as

blades, bits, cutters, etc.

16. Remove adjusting keys and spanners. Get into the

habit of checking that adjusting keys and spanners have

been removed from the machine before turning it on.

17. Avoid unintentional starting. Ensure switch is in

“off” position before plugging in the machine.

18. Use proper extension leads. When the tool is used

outdoors, use only extension leads intended for outdoor

use and labelled as such.

19. Stay alert. Concentrate on what you are doing, use

common sense and do not operate the tool when you

are tired.

20. Check that no part is damaged. Before using a tool,

make sure that it is in good working order. Check the

alignment and condition of moving parts, mounting

and any other aspect that may affect its operation. A

guard or other part that is damaged should be properly

repaired or replaced by an authorised service centre

unless otherwise indicated in this instruction manu al. Do

not use the tool

if the switch does not turn on and off.

21. Warning. The use of any accessory or attachment

other than one recommended in this instruct ion manual

may present a risk of personal injury.

22. Have your tool repaired at an authorised service centre.

This electric tool complies with current safety rules. Repairs

should only be carried out by an authorised service centre

using original spare parts. Failing this, the user could

expose themselves to considerable danger.

HEALTH ADVICE

WARNING!

When drilling, sanding, sawing or grinding, dust particles will

be produced. In some instances, depending on the materials

you are working with, this dust can be particularly harmful

to you (e.g. lead from old gloss paint).You are advised to

consider the risks associated with the materials you are

working with and to reduce the risk of exposure.

You should:

-Work in a well-ventilated area.

-Work with approved safety equipment, such as dust masks

that are specially designed to filter microscopic particles.

SAFETY INSTRUCTIONS FOR ALL SAWS

a) DANGER: Keep hands away from cutting area and

the blade. Keep your second hand on the auxiliary handle,

or motor housing. If both hands are holding the saw, they

cannot be cut by the blade.

b) Do not reach underneath the workpiece. The guard

cannot protect you from the blade below the workpiece.

c) Adjust the cutting depth to the thickness of the

workpiece. Less than a full tooth of the blade teeth should

be visible below the workpiece.

d) Never hold piece being cut in your hands or across

your leg. Secure the workpiece to a stable platform. It is

important to support the work properly to minimize body

exposure, blade binding, or loss of control.

e) Hold power tool by insulated gripping surfaces when

performing an operation where the cutting tool may

contact hidden wiring or its own cord. Contact with a

“live” wire will also make exposed metal parts of the power

tool “live” and shock the operator.

f) When ripping always use a rip fence or straight edge

guide. This improves the accuracy of cut and reduces the

chance of blade binding.

g) Always use blades with correct size and shape

(diamond versus round) of arbor holes. Blades that

do not match the mounting hardware of the saw will run

eccentrically, causing loss of control.

h) Never use damaged or incorrect blade washers or

bolt. The blade washers and bolt were specially designed for

your saw, for optimum performance and safety of operation.

Further safety instructions for all saws

Causes and operator prevention of kickback:

Kickback is a sudden reaction to a pinched, bound or

misaligned saw blade, causing an uncontrolled saw to lift up

and out of the workpiece toward the operator:

1. When the blade is pinched or bound tightly by the kerf

closing down, the blade stalls and the motor reaction drives

the unit rapidly back toward the operator;

2. If the blade becomes twisted or misaligned in the cut,

the teeth at the back edge of the blade can dig into the top

surface of the workpiece causing the blade to climb out of

the kerf and jump back towards the operator.

SAFETY INSTRUCTIONS FOR ALL SAWS

GB

HEALTH ADVICE

GB

RAGETWIN

Congratulations on your purchase of an Evolution Power

Tools RAGE125mm Twin Blade Saw. Please complete

your product registration online to validate your machine’s

warranty period and ensure prompt service if needed. We

sincerely thank you for selecting a product from Evolution

Power Tools.

12 MONTH LIMITED WARRANTY. Evolution power tools

reserves the right to make improvements and modifications

to design without prior notice.

Evolution Power Tools will, within twelve (12) months from

the original date of purchase, repair or replace any goods found

to be defective in materials or workmanship. This warranty is

void if the tool being returned has been used to cut materials

beyond the recommendations in the Instruction Manual or if

the saw has been damaged by accident, neglect, or improper

service. This warranty does not apply to machines and / or

components which have been altered, changed, or modified

in any way, or subjected to use beyond recommended

capacities and specifications. Electrical components are

subject to respective manufacturers’ warranties. All goods

returned defective shall be returned prepaid freight to

Evolution Power Tools. Evolution Power Tools reserves

the right to optionally repair or replace it with the same or

equivalent item. There is no warranty – written or verbal

– for saw blades. In no event shall Evolution Power Tools

be liable for loss or damage resulting directly or indirectly

from the use of our merchandise or from any other cause.

Evolution Power Tools is not liable for any costs incurred on

such goods or consequential damages. No officer, employee

or agent of Evolution Power Tools is authorised to make oral

representations of fitness or to waive any of the foregoing

terms of sale and none shall be binding on Evolution Power

Tools. Questions relating to this limited warranty should be

directed to the company’s head office, or call the appropriate

Helpline number.

IMPORTANT SAFETY INSTRUCTIONS

To reduce the risk of electric shock, this equipment is fitted

with an approved cord and plug for its intended country of

use. Do not change the cord or plug in any way.

GENERAL SAFETY RULES

Please read all of these instructions before

attempting to operate this machine.

Save this manual for future reference.

1. Keep work area clear. Cluttered work areas invite

accidents.

2. Consider work area environment. Do not expose

tools to rain. Do not use tools in damp or wet locations.

Keep work area well lit. Never use tools near flammable

liquids or gases.

3. Protect yourself against electric shock. Avoid body

contact with earthed or grounded surfaces.

4. Keep other people away. Do not let others, especially

children, come close to the work, and touch the tool or the

extension lead. Keep them away from the work area.

5. Store idle tools. When not in use, tools should be

stored in a dry locked-up place, out of children’s reach.

6. Never force the tools. Your tools will be more efficient

and safer when used at the rate for which they were

intended.

7. Use the right tool. Do not force small tools to do the

job of a heavy duty tool. Do not use tools for purposes

not intended; for example do not use circular saws to

cut tree limbs or logs.

8. Dress properly. Do not wear loose clothing or

jewellery which may get caught in moving parts. Nonskid footwear is recommended when working outdoors.

If you have long hair, tie it back and wear protective hair

covering.

9. Use protective equipment. Use safety glasses. Use

face or dust mask if cutting operations create dust.

10. Connect dust extraction equipment.

If the machines have a connection for dust extraction

equipment, ensure these are connected and properly

used.

11. Do not damage the cable. Never pull the power

cable to disconnect the machine. Keep the cable away

from heat, oil and sharp edges.

12. Secure workpiece. Where possible,

use clamps or a vice to hold the workpiece. It’s much safer

than using your hands.

13. Don’t over reach. Keep proper footing and balance

at all times.

Page 4

6

www.evolutionbuild.com

7

www.evolutionbuild.com

®

c) Keep work area clean. Cluttered areas and benches

invite accidents.

d) Don’t use in dangerous environment. Don’t use power

tools in damp or wet locations, or expose them to rain. Keep

work area well lit.

e) Keep children away. All visitors should be kept a safe

distance from the work area.

f) Don’t force the tool. It will do the job better and safer if

used at the rate for which it was designed.

g) Use proper extension cord. Make sure your extension

cord is in good condition. When using an extension cord,

be sure to use one heavy enough to carry the current your

machine will draw. An undersized cord will cause a drop in line

voltage resulting in loss of power and possible overheating.

h) Wear proper apparel. Do not wear loose clothing, gloves,

neckties, rings, bracelets, or other jewellery which may get

caught in moving parts. Nonslip footwear is recommended.

Wear protective hair covering to contain long hair.

i) Always use safety glasses. Also use face or dust mask

if cutting operation is dusty. Everyday eyeglasses only have

impact resistant lenses, they are NOT safety glasses.

j) Secure work. Use clamps to hold work when practical.

k) Don’t overreach. Keep proper footing and balance at all times.

l) Maintain tools with care. Keep tools sharp and clean

for best and safest performance. Follow instructions for

lubricating and changing accessories.

m) Disconnect tools before servicing and when changing

accessories, such as blades.

n) Reduce the risk of unintentional starting. Make sure

switch is in off position before plugging in.

o) Use recommended accessories. Only use genuine

Evolution accessories.

p) Check for damaged parts. Before further use of the tool,

a guard or other part that is damaged should be carefully

checked to determine that it will operate properly and perform

its intended function - check for alignment of moving parts,

binding of moving parts, breakage of parts, mounting, and any

other conditions that may affect its operation. A guard or other

part that is damaged should be properly repaired or replaced.

q) Keep hands out of the path of the saw blades.

r) Never reach around the saw blades.

s) Turn off tool and wait for saw blades to stop before

moving workpiece.

t) Disconnect power before changing blades, servicing

or cleaning.

u) Never carry the tool by the power cord. Carrying the

tool by the power cord could cause damage to the insulation

or the wire connections resulting in the possibility of electric

shock or fire.

SPECIFICATIONS

RAGETWIN 125mm (5˝)

Motor (230V or 110V 50Hz) (Watts): 850W

RPM No Load (min-1): 5500min

-1

Max Cut Depth: 28mm

Weight: 3.2kg

Blade Dimensions

Maximum Diameter: 125mm

Thickness: Blade A: 1.5mm

Blade B: 1.7mm

ASSEMBLY

Your Evolution Power Tools Twin Blade Saw is shipped

complete. Remove all the contents from the box and inspect

to ensure no damage has occurred during shipping, and that

the items listed below are included:

Description Qty

Instruction Manual 1

125mm TCT Blade (Fitted) 1 Pair

Spanner 1

Assist Handle 1

Lubrication Unit (Fitted) 1

CAUTION! ALWAYS DISCONNECT THE TWIN BLADE

SAW FROM THE POWER SOURCE BEFORE MAKING ANY

ADJUSTMENTS.

OPERATION

Before commencing any operations, please check the

following:

1. Power source

Ensure that the power source to be utalized conforms to the

power requirements specified on the machines nameplate.

2. Power Switch

Ensure that the power switch is in the OFF position. If the

plug is connected to a power source with the switch in the

ON position, the machine will start operating immediately.

This could cause a serious accident.

3. Extension cord

When the work is remote from the power source, use an

extension cord of sufficient thickness and rated capacity. The

extension cord should be kept as short as possible, and routed

so that it does not constitute a trip or other safety hazard.

4. Checking the Blades

Check that the blades are the specified ones, and are not

cracked, broken or bent. Do not use the machine if there is

any doubt about the integrity of the blades.

OPERATION

GB

Kickback is the result of saw misuse and/or incorrect

operating procedures or conditions and can be avoided by

taking proper precautions as given below.

a) Maintain a firm grip with both hands on the saw and

position your arms to resist kickback forces. Position

your body to either side of the blade, but not in line with the

blade. Kickback could cause the saw to jump backwards, but

kickback forces can be controlled by the operator, if proper

precautions are taken.

b) If the blades are binding, or when interrupting a cut

for any reason, release the trigger and hold the saw

motionless in the material until the blades come to a

complete stop. Never attempt to remove the saw from the

work or pull the saw backward while the blades are in motion

or kickback may occur. Investigate and take corrective actions

to eliminate the cause of blade binding.

c) When restarting a saw in the workpiece, centre the saw

blade in the kerf and check that saw teeth are not engaged

into the material. If saw blade is binding, it may walk up or

kickback from the workpiece as the saw is restarted.

d) Support large panels to minimise the risk of blade

pinching and kickback. Large panels tend to sag under their

own weight. Supports must be placed under the panel on

both sides, near the line of cut and near the edge of the panel.

e) Blade depth and bevel adjusting locking levers must be

tight and secure before making a cut. If blade adjustment

shifts while cutting. it may cause binding and kickback.

f) Do not use dull or damaged blades. Unsharpened

or improperly set blades produce a narrow kerf causing

excessive friction, blade binding and kickback.

g) Use extra caution when making a “plunge cut” into

existing walls or other blind areas. The protruding blade

may cut objects that can cause kickback.

Safety instructions for saws

a) Check lower guard for proper closing before each use.

Do not operate the saw if lower guard does not move freely

and close instantly. Never clamp or tie the lower guard into

the open position. If saw is accidentally dropped, the lower

guard may be bent. Raise the lower guard with the retracting

handle and make sure it moves freely and does not touch

the blade or any other part, in all angles and depths of cut.

b) Check the operation of the lower guard spring. If the

guard and the spring are not operating properly, they must be

serviced before use. Lower guard may operate sluggishly due

to damaged parts, gummy deposits, or a build-up of debris.

c) Lower guard may be retracted manually only for

special cuts such as “plunge cuts” and “compound

cuts.” Raise lower guard by the retracting handle and as

soon as the blade enters the material, the lower guard

must be released. For all other sawing, the lower guard

should operate automatically.

d) Always observe that the lower guard is covering

the blade before placing saw down on bench or floor.

An unprotected, coasting blade will cause the saw to walk

backwards, cutting whatever is in its path. Be aware of the

time it takes for the blade to stop after switch is released.

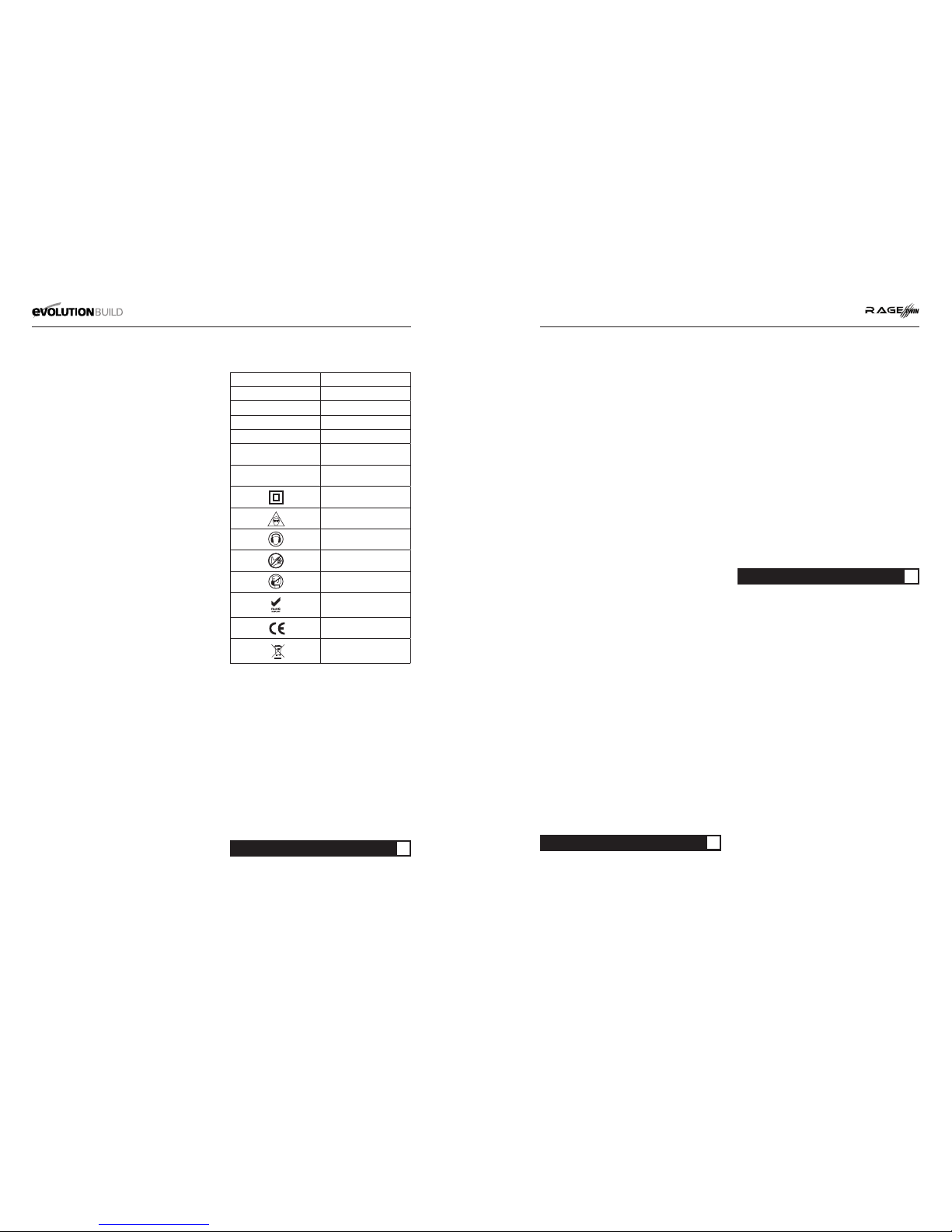

Symbol Description

V Volts

A Amperes

Hz Hertz

min

-1

Speed

~ Alternating Current

No

No Load Speed

Double Insulated

Wear Safety Goggles

Wear Ear Protection

Do Not Touch

Wear Dust Protection

Restriction of Hazardous

Substances Directive

CE certification

Waste electrical and

electronic equipment

Only use genuine Evolution replacement blades. Unauthorised

blades may be dangerous! Keep the blades securely fastened.

Check for debris before installing any new blades and do

not use dull or broken blades. Check the blades regularly

for condition and wear. Damaged or worn blades should be

replaced immediately. Never use any abrasive wheels. Loose

fitting or damaged guards must be replaced immediately.

Beware of ejecting chips as they may be HOT. Always make

provisions for safe handling of excess material.

To obtain an additional copy of your manual, please contact

Evolution Power Tools at:

UK 0870 609 2297

USA 1-866-EVO-TOOL

WEB www.evolutionbuild.com

a) Keep guards in place and in working order.

b) Remove adjusting keys and wrenches. Form the habit

of checking to see that keys and adjusting wrenches are

removed from the machine before turning it on.

SPECIFICATIONS

GB

ADDITIONAL SPECIFIC SAFETY RULES

GB

Page 5

8

www.evolutionbuild.com

9

www.evolutionbuild.com

®

INSTALLING/REMOVING THE TCT BLADES

NOTE: It is recommended that the operator considers

wearing protective gloves when handling the blades during

installation or when changing the blades.

1. Installation

1. Ensure that the machine is not connected to any power

source.

2. Lay the saw down on a bench with the blade arbor

pointing upwards.

3. Open the lower guard (see fig 2)

4. Place blade A onto the flange with the letter ‘A’ clearly

visible (see fig 1)

5. Align the two offset cut-outs in the blade with the drive

pins on the flange and securely fit the blade onto the flange.

6. Place blade ‘B’ onto the adaptor with the letter ‘B’ clearly

visible, and then thread the locknut onto the shaft. (see fig 3)

HAND TIGHTEN only.

7. Turn the blades so that the holes in both blades are lined up.

8. Place the pin (included with the wrench) into the aligned

holes.

9. Tighten the locknut clockwise with a wrench, and then

remove the pin from the blades (see fig 4). This will allow

the blades to rotate freely.

10. Carefully turn the blades by hand to ensure that they

rotate easily in opposite directions.

2. Removal

1. Ensure that the machine is disconnected from the mains

supply.

2. Allow the blades to cool.

3. Rotate the blades until the holes in both blades are in

alignment.

4. Place the pin attached to the wrench through the holes

in the blades.

5. Unscrew the locknut by rotating it counter clockwise, and

remove it (see fig 4).

6. Open the lower guard (see fig 2)

7. Lift and remove blade ‘B’.

8. Lift and remove blade ‘A’.

CUTTING PROCEDURES

1. Mark out the material to be cut (use an appropriate pencil

etc) with clear, precise cutting lines.

2. Offer the saw up to the material to be cut and align the

blades with a pre-marked cutting line. Do not start the

machine until correct alignment has been achieved

3. Ensuring that the blades are not touching the material to be

cut, turn on the machine and allow to run up to full speed.

4. Gently feed the saw blades into the workpiece. Cutting can

be preformed smoothly if you cut straight ahead and allow the

saw time to work without forcing or pressing the blade.

CAUTION

• AlwayschecktheTCTbladesbeforestartingwork.

• Neveruseacracked,brokenorbentTCTblade.

• DonotapplywaterorcoolanttoaTCTblade.

• Startcuttingonlywhenthemachinereachesfulloperating

speed.

• If the blade seizes or there is any abnormal noise,

immediately turn the power off.

• NeveruseaTCTbladetocutzigzagorcurvedlines.

• NeverusethesidesurfaceoftheTCTblade.Neveruseto

perform inclination cutting.

• Ifexcessive force is applied to the TCT bladeto make

it align with a pre-marked line during cutting, this could

overload the motor, cause burn damage and may overheat

the blades and shorten their service life.

• Takecarenottoallowthemachines powercordtocome

into contact with the rotating TCT blades during cutting

operations.

• Supporttheworkpieceinsuchaway thatitispossibleto

predict what will happen, and so that the cut remains open

while cutting.

• Feedthemachinedowninlinewiththeblades.Sideways

pressure on the blades can damage them and can be

dangerous.

• When the work is completed, turn off the power and

disconnect the power plug from the power supply.

CUTTING CROSS SECTIONAL MATERIALS

The life span of the blades and the quality of the cutting edge

is dependent upon vibration being kept to a minimum. For

this reason the material should always be clamped in place

before work begins.

Flat bar iron

The blade is fed at an angle of 900 to the work surface

(see fig 5).

Corner piece

The blade is fed diagonally through the work surface

(see fig 6).

Rectangular pipe

The blade is fed from corner to corner (see fig 7).

U Section

The blade is fed from corner to corner (see fig 8)

Aluminium / Copper

This machine is equipped with a lubricating unit and this

should be used when cutting all kinds of aluminium and copper

(see fig 9). Refer to the section ‘Lubricating Instructions’.

Shaped plate

Plate must always rest on at least three mounts, with one on

either side of the cut (see fig 10).

Pipes

The blade is fed through the object until it reaches the lower

edge, angled as it goes so that the blade hits the material at

an angle of 900 (see fig 11).

Spiral tube and longitudinal cutting

Feed the blade into the material, so that the blade protrudes

through by approximately 10mm. Do not drive the blade

as far as its entire cutting edge. When the blade is through

the materials wall, start to feed the blade forwards and

backwards (see fig 12).

Thin plate

Only feed the blade down approximately 10mm. Then start

cutting (see fig 13)

LUBRICATION INSTRUCTIONS

1. The blades are equipped with ‘Dry Cut’ teeth and as a

general rule these need not be lubricated. However, with

some materials and in some extreme conditions, cutting

paste can be applied.

2. When cutting Aluminium / Copper / Stainless Steel and

Cast Iron, the lubricating device should be used.

3. Insert the cutting paste rod (not included) into the hole in

the lubrication unit. This unit is located on the top of the steel

blade guard. Push the lubricant rod down firmly, and rotate

the lubricant feed hand-wheel until it grips the lubricant rod.

4. Switch on the cutter, and using the feed hand-wheel,

bring the lubricant rod to gently bear on the rotating teeth

of the blades.

5. Operator discretion will be required to determine the

frequency of lubrication application. To apply extra lubricant,

turn the lubricant feed hand wheel.

NOTE: We recommend that you use cutting paste in rod

form, available from your Evolution Power Tool retailer.

MAINTENANCE

1. Inspecting the TCT Blades. A worn blade overloads the

motor and reduces working efficiency. If either blade shows

signs of wear replace with a new pair.

2. Inspecting the mounting screws. Regularly inspect all

mounting screws and ensure they are properly tightened.

Should any of the screws be loose, retighten them immediately.

Failure to do so could result in a serious hazard.

3. Maintenance of the motor. Exercise due care to ensure

that the winding does not become damaged and/or wet with

oil or water.

4. Keep machine clean and free from debris. Avoid using cleaning

products which include benzene, trichloroethylene, chloride or

ammonia as these can damage plastic components.

5. In the case of electrical or mechanical malfunction

immediately switch off the machine and disconnect the plug

from the power supply.

6. Excessive sparking may indicate the presence of dirt in the

motor or worn out carbon brushes. Check the brushes for

wear and replace when they reach ¼ ˝ (6mm)

7. If the supply cord of this power tool is damaged, it must

be replaced by a specially prepared cord available through

the service organisation.

8. For all other service take the machine to your local dealer,

or if bought in the USA to Evolution Power Tools USA, Iowa.

ACCESSORIES

Evolution Blades

2 x 125mm TCT Blades

ENVIRONMENTAL PROTECTION

Waste electrical products should not be disposed of

with household waste. Please recycle where facilities exist.

Check with your Local Authority or retailer for recycling

advice.

Page 6

10

www.evolutionbuild.com

11

www.evolutionbuild.com

®

EC - DECLARATION OF CONFORMITY

Déclaration de conformité CE 11

Informations importantes 11

Garantie limitée de 12 mois 12

Règles de sécurité générales 12

Consignes de sécurité pour toutes les scies 13

Symboles 14

Règles de sécurité particulières supplémentaires 15

Caractéristiques techniques 15

Assemblage 15

Fonctionnement 16

Maintenance 17

Protection environnementale 18

Listes de pièces de rechange 18

Nous, fabricant et importateur,

Evolution Power Tools Ltd.

Venture One

Sheffield

S20 3FR

déclarons que le produit

N° de référence : RAGETWIN1251, RAGETWIN1252,

RAGETWIN1252EU

Evolution : Scie à double lame RAGE125 mm

est conforme aux prescriptions essentielles des directives

européennes suivantes :

2006/42/CE – Directive relative aux machines

2006/95/CE – Directive relative aux basses tensions

2004/108/CE – Directive relative à la compatibilité

électromagnétique

2002/95/CE – Restrictions d’utilisation de certaines

substances dangereuses dans les équipements électriques

et électroniques

Ces outils électriques ont été conçus conformément aux

directives du Conseil suivantes :

2006/42/CE

2004/108/CE

2002/95/CE

2002/96/CE.

Cet outil est conforme aux normes européennes suivantes :

EN55014-1

EN55014-2

EN61000-3-2 et EN61000-3-3

EN60745-1 et EN60745-2-5.

LpA (pression sonore) 90,0 dB(A)

LwA (puissance acoustique) 101,0 dB(A)

KpA (incertitude de pression sonore) 3 dB(A)

KwA (incertitude de puissance acoustique) 3 dB(A)

VIBRATIONS 5,18 m/s

2

K 1,5 m/s2

La valeur de vibrations déclarée a été mesurée selon une

méthode d’essai standard (EN60745) et peut être utilisée

pour comparer un outil avec un autre. La valeur de vibrations

déclarée peut également servir d’évaluation d’exposition

préliminaire.

AVERTISSEMENT : la valeur d’émission de vibrations

pendant l’utilisation de l’outil électrique peut être différente

de la valeur déclarée, selon la façon dont l’outil est utilisé.

Déterminez les mesures de sécurité à adopter pour protéger

l’opérateur en fonction d’une estimation de l’exposition

dans les conditions effectives d’utilisation. Tenez compte

de toutes les parties du cycle d’exploitation, y compris les

périodes d’arrêt de l’outil et ses périodes de ralenti en plus

du temps de déclenchement réel.

Autorisé par

M. Matthew J. Gavins

Directeur général

1er août 2010

Toute la documentation est conservée à l’adresse ci-dessus

et est disponible pour consultation sur demande.

IMPORTANT

Lisez attentivement et intégralement ces consignes

d’utilisation et de sécurité avant toute utilisation de l’outil. Pour

votre sécurité, vous devez vérifier, avant toute utilisation, que la

tension d’alimentation est correcte et que toutes les poignées

et pièces de l’outil sont bien fixées. Si vous avez la moindre

incertitude concernant l’utilisation de cet outil, n’hésitez pas à

contacter notre Service d’assistance technique par téléphone.

Service d’assistance technique par téléphone pour le

Royaume-Uni 0870 609 2297

Service d’assistance technique par téléphone pour les

États-Unis 1-866-EVO-TOOL

RAGETWIN

Nous vous félicitons d’avoir acheté une scie à double lame

RAGE125 mm, d’Evolution Power Tools. Enregistrez votre

produit en ligne pour valider la période de garantie de votre

outil et bénéficier d’un service rapide en cas de besoin.

Nous vous remercions sincèrement d’avoir choisi un produit

Evolution Power Tools.

TABLE DES MATIÈRES

FR

DÉCLARATION DE CONFORMITÉ CE

FR

TWIN BLADE DISC CUTTER SERVICE PARTS LIST (REV. 1. 00)

GB

230V ~ 50Hz

Page 7

12

www.evolutionbuild.com

13

www.evolutionbuild.com

®

12 MONTH LIMITED WARRANTY. Evolution power tools

reserves the right to make improvements and modifications

to design without prior notice.

Evolution Power Tools réparera ou remplacera, dans les

douze (12) mois suivant la date d’achat d’origine, tout article

présentant un vice de matériau ou un défaut de fabrication. La

présente garantie s’annulera si l’outil retourné a été utilisé pour

découper des matériaux non conformes aux recommandations

figurant dans le présent manuel d’utilisation ou si la scie a été

endommagée par accident, par négligence ou en raison d’un

entretien insuffisant. La présente garantie ne s’applique pas aux

machines et/ou aux composants qui ont été altérés, changés ou

modifiés d’une quelconque manière ou qui ont été utilisés sans

respecter les capacités et les spécifications recommandées. Les

composants électriques sont couverts par les garanties offertes

par leurs fabricants respectifs. Tous les articles défectueux

doivent être retournés à Evolution Power Tools en port prépayé.

Evolution Power Tools se réserve le droit de réparer l’outil ou de

le remplacer par un produit identique ou équivalent. Aucune

garantie – écrite ou verbale – ne couvre les lames des scies.

Evolution Power Tools ne saurait en aucun cas être tenue pour

responsable des pertes ou dommages découlant directement ou

indirectement de l’utilisation du produit ou de toute autre cause.

Evolution Power Tools ne saurait être tenue pour responsable

des coûts relatifs à ce produit ou aux dommages accessoires y

afférents. Aucun responsable, employé ou agent de la société

Evolution Power Tools n’est habilité à faire de déclarations

verbales d’adéquation à un usage particulier ou à déroger à

l’une quelconque des conditions de vente qui précèdent :

les déclarations de ce type ne sauraient en aucun cas être

opposées à Evolution Power Tools. Toute question relative à la

présente garantie limitée doit être adressée au siège social de la

société. Vous pouvez également appeler le Service d’assistance

technique par téléphone approprié.

CONSIGNES DE SÉCURITÉ IMPORTANTES

Afin de réduire le risque d’électrocution, cet équipement est

équipé d’un cordon électrique et d’une fiche approuvés pour

le pays d’utilisation auquel il est destiné. Vous ne devez en

aucun cas changer le cordon ou la fiche.

RÈGLES DE SÉCURITÉ D’ORDRE GÉNÉRAL

AVERTISSEMENT ! Lors de l’utilisation

d’outils électriques, les mesures de sécurité

de base devraient toujours être suivies afin

de réduire le risque d’incendie, de décharge

électrique et de blessures.

Lisez toutes ces consignes avant de tenter

d’utiliser cette machine. Conservez ce manuel

pour référence future.

1. Tenez votre lieu de travail propre.

Les endroits encombrés sont propices aux accidents.

2. Pensez à l’environnement de votre lieu de travail.

N’exposez pas les outils à la pluie. N’utilisez pas les outils

dans des endroits humides ou mouillés. Votre lieu de travail

doit être bien éclairé. N’utilisez jamais d’outils à proximité de

liquides ou de gaz inflammables.

3. Protégez-vous contre les décharges électriques. Évitez

le contact du corps avec des surfaces mises à la terre ou à

la masse.

4. Tenez les autres personnes à distance. Ne laissez pas

les autres, les enfants surtout, s’approcher de votre travail et

toucher l’outil ou la rallonge. Tenez-les éloignés de votre lieu

de travail.

5. Rangez les outils quand vous avez fini de vous en servir.

Lorsque vous ne vous en servez pas, rangez les outils dans un

endroit sec fermant à clé, hors de la portée des enfants.

6. Ne forcez jamais les outils. Vos outils seront plus efficaces

et moins dangereux si vous les utilisez à la puissance à

laquelle ils sont censés être utilisés.

7. Utilisez le bon outil. N’utilisez pas un petit outil pour faire

le travail d’un gros outil plus puissant. N’utilisez pas les outils

pour des travaux pour lesquels ils ne sont pas prévus. Par

exemple, n’utilisez pas une scie circulaire pour couper des

arbres ou du bois.

8. Portez une tenue adaptée. Ne portez pas de vêtements

lâches ou de bijoux, car ils pourraient se prendre dans des

composants mobiles. Portez de préférence des chaussures

antidérapantes lorsque vous travaillez à l’extérieur. Si vous

avez des cheveux longs, attachez-les et couvrez-les.

9. Portez un équipement de protection. Portez des

lunettes de sécurité. Portez un masque facial ou un masque à

poussière si le travail prévu va faire de la poussière.

10. Branchez un système d’extraction de la poussière.

Si la machine possède un branchement pour un dispositif

d’extraction de la poussière, branchez-le et utilisez-le

correctement.

11. N’endommagez pas le cordon électrique. Ne tirez

jamais sur le cordon électrique pour débrancher la machine.

Conservez le cordon éloigné de la chaleur, de l’huile et des

bords tranchants.

12. Bloquez la pièce. Si possible, utilisez des pinces ou un

étau pour la bloquer. Cela est nettement moins dangereux que

d’utiliser vos mains.

13. N’essayez pas d’atteindre les endroits inaccessibles.

Veillez à toujours garder votre équilibre.

14. Gardez vos outils en bon état de marche. Gardez vos

outils propres et affûtés pour des résultats optimaux et pour

travailler en toute sécurité. Suivez les consignes de graissage

et de changement des accessoires. Inspectez régulièrement

les cordons d’alimentation. En cas de dommage, faites-les

remplacer par un réparateur agréé. Inspectez les rallonges

périodiquement. Si elles sont abîmées, remplacez-les. Gardez

toujours les poignées propres, sèches et sans huile ni graisse.

15. Débranchez les outils. Débranchez les outils de la prise

électrique lorsque vous ne vous en servez pas, avant les

révisions/réparations et lors du changement d’accessoires

(lames, embouts, disques de coupe, etc.).

16. Retirez les clavettes et clés de réglage. Prenez pour

habitude de contrôler que les clavettes et clés de réglage ont

été retirées de l’outil avant de le mettre en marche.

17. Évitez les démarrages accidentels. Contrôlez que

l’interrupteur Marche/Arrêt est sur la position Arrêt avant de

brancher l’outil.

18. Utilisez des rallonges adaptées. Si vous utilisez l’outil

à l’extérieur, utilisez uniquement une rallonge adaptée à une

utilisation à l’extérieur, ce qui doit être indiqué sur l’étiquette

de la rallonge.

19. Restez alerte. Concentrez-vous sur ce que vous faites,

faites preuve de bon sens et n’utilisez pas l’outil si vous êtes

fatigué.

20. Contrôlez qu’aucun composant n’est endommagé.

Avant d’utiliser un outil, assurez-vous qu’il est en bon état

de marche. Contrôlez l’alignement et l’état des pièces

en mouvement, les fixations et tous les autres aspects

susceptibles d’affecter son fonctionnement. Si un carter de

protection ou un autre composant est endommagé, faites-le

réparer ou remplacer dans un centre de réparation agréé, sauf

indication contraire figurant dans ce manuel. N’utilisez pas

l’outil si l’interrupteur ne le met pas en marche et à l’arrêt.

21. Avertissement. L’utilisation d’accessoires autres que ceux

recommandés dans ce manuel peut entraîner un risque de

dommage corporel.

22. Faites réparer votre outil dans un centre de réparation

agréé. Cet outil électrique est conforme aux règles de sécurité

en vigueur. Les réparations ne doivent être effectuées que par

un réparateur agréé et avec des pièces de rechange d’origine.

Le non-respect de cette consigne pourrait mettre l’utilisateur

de l’outil dans une situation très dangereuse.

Tenez

AVERTISSEMENT !

Lorsque vous percez, poncez, sciez ou meulez, des particules de

poussières sont produites. Dans certains cas, selon le matériau

utilisé, ces poussières peuvent être très dangereuses pour la

santé (plomb contenu dans les anciennes peintures brillantes,

par exemple). Il est conseillé de réfléchir aux risques associés

aux matériaux utilisés et de réduire le risque d’exposition.

Vous devriez :

- Travailler dans un endroit bien aéré.

- Travailler avec l’équipement de sécurité approuvé, comme,

par exemple, les masques à poussière spécialement conçus

pour filtrer les particules microscopiques.

a) DANGER : tenez vos mains éloignées de la zone de

coupe et de la lame. Placez votre seconde main sur la poignée

auxiliaire ou sur le bloc moteur. En tenant la scie des deux

mains, vous ne courrez aucun risque d’être blessé par la lame.

b) Ne mettez pas vos mains sous la pièce à couper. Le

carter de protection ne peut pas vous protéger de la lame

dans ce cas.

c) Réglez la profondeur de coupe en fonction de

l’épaisseur de la pièce à couper. Moins d’une dent entière

de la lame devrait être visible sous la pièce à couper.

d) Ne tenez jamais la pièce à couper dans vos mains ou

sur votre jambe. Bloquez la pièce à couper sur un établi

stable. Il importe de soutenir correctement la pièce de façon

à réduire au minimum l’exposition du corps et le risque de

blocage de la lame ou de perte de contrôle.

e) Tenez votre outil électrique par ses surfaces de prise

isolées lorsqu’il est possible que l’outil de coupe entre

en contact avec des fils cachés ou son propre cordon

électrique. Le contact avec un fil « sous tension » peut

également mettre les parties métalliques exposées de

l’outil électrique « sous tension » et vous risqueriez alors de

recevoir une décharge électrique.

f) Pour le sciage en long, utilisez toujours un guide

longitudinal ou un guide de chant. Vous obtiendrez ainsi une

coupe plus précise et la lame risquera moins de se bloquer.

g) Utilisez toujours des lames avec des trous d’arbre de

la taille correcte et de la forme appropriée (en losange/

ronds). Les lames qui ne sont pas adaptées au dispositif de

montage de la scie tourneront excentriquement, ce qui vous

fera perdre le contrôle de l’outil.

h) N’utilisez jamais de rondelles ou de boulons de lame

endommagés ou inadaptés. Les rondelles et le boulon de

lame ont été spécialement conçus pour votre scie et pour

lui permettre d’offrir des performances et une sécurité

d’utilisation optimales.

Autres consignes de sécurité pour toutes les scies

Causes des reculs et comment les éviter :

Le recul est une réaction soudaine à une lame de scie

pincée, bloquée ou mal alignée, qui amène une scie non

contrôlée à se soulever vers l’opérateur :

1. Lorsque la lame est pincée ou complètement bloquée

dans la saignée qui se referme, la lame cale et la réaction du

moteur ramène rapidement la scie vers l’opérateur.

2. Si la lame se déforme ou devient mal alignée dans la

coupe, les dents du bord arrière de la lame peuvent entrer

dans la surface supérieure de la pièce, ce qui peut amener la

lame à sortir de la saignée et à sauter vers l’opérateur.

Le recul est le résultat d’une mauvaise utilisation de la scie et/ou

de conditions ou procédures d’utilisation incorrectes. Il peut être

évité en prenant les mesures de précaution décrites ci-dessous.

a) Vérifiez que le protecteur inférieur soit bien fermé avant

chaque utilisation. Ne mettez pas la scie en marche si le

protecteur inférieur ne se déplace pas librement et ne se ferme

pas instantanément. Ne serrez jamais ou n’attachez jamais

le protecteur inférieur en position ouverte. Si la scie tombe

accidentellement, le protecteur inférieur peut se tordre. Soulevez

le protecteur inférieur avec la poignée rétractive et assurez-vous

qu’il bouge librement et n’est pas en contact avec la lame ou

toute autre partie, à tous les angles et profondeurs de coupe.

NOTE Une autre formulation peut remplacer «poignée

rétractive».

b) Vérifiez le fonctionnement du ressort du protecteur

inférieur. Si le protecteur et le ressort ne fonctionnent

pas correctement, ils doivent être révisés avant utilisation.

CONSEILS DE SANTÉ

FR

CONSIGNES DE SÉCURITÉ POUR

TOUTES LES SCIES

FR

Page 8

14

www.evolutionbuild.com

15

www.evolutionbuild.com

®

une éventuelle surchauffe de votre outil.

h) Portez une tenue adaptée. Ne portez pas de vêtements

flottants, de gants, de foulards, de bagues, de bracelets ou

autres bijoux susceptibles de se prendre dans les pièces en

mouvement. Il est conseillé de porter des chaussures non

glissantes. Portez quelque chose sur la tête pour maintenir

vos cheveux attachés s’ils sont longs.

i) Portez toujours des lunettes de sécurité. Portez

également un masque facial ou un masque à poussière si le

travail prévu va faire de la poussière. Les verres des lunettes

ordinaires offrent une résistance aux chocs uniquement. Ce

NE sont PAS des lunettes de sécurité.

j) Bloquez la pièce à découper. Utilisez des pinces pour

bloquer la pièce à découper lorsque cela est possible.

k) N’essayez pas d’atteindre les endroits inaccessibles.

Veillez à toujours garder votre équilibre.

l) Prenez soin de vos outils. Gardez vos outils propres et

affûtés pour des résultats optimaux et pour travailler en

toute sécurité. Suivez les consignes de graissage et de

changement des accessoires.

m) Débranchez l’outil avant toute réparation et avant de

changer des accessoires (lames, etc.).

n) Réduisez le risque de démarRAGEaccidentel. Contrôlez

que l’interrupteur Marche/Arrêt est sur la position Arrêt avant

de brancher l’outil.

o) Utilisez les accessoires recommandés. Utilisez

uniquement des accessoires d’origine Evolution garantie.

p) Contrôlez qu’il n’y a pas de composants endommagés.

Si vous constatez qu’un carter de protection ou un autre

composant est endommagé, examinez-le soigneusement afin

de déterminer s’il fonctionnera correctement et s’acquittera de

sa fonction avant de continuer à utiliser l’outil. Contrôlez que les

pièces en mouvement sont correctement alignées et qu’elles

ne sont pas bloquées, qu’il n’y a pas de composants de cassés,

que la monture est en parfait état et qu’il n’y a pas d’autres

problèmes susceptibles de nuire au fonctionnement. Si un

carter de protection ou un autre composant est endommagé,

faites-le réparer par un réparateur agréé ou remplacez-le.

q) Éloignez vos mains du parcours de la lame de la scie.

r) N’approchez jamais vos mains de la lame.

s) Mettez l’outil hors tension et attendez que la lame se soit

arrêtée avant de changer les pièces à découper de position.

t) Débranchez l’outil de la prise électrique avant de changer

la lame, d’effectuer des réparations ou de nettoyer l’outil.

u) Ne portez jamais l’outil en le tenant par le cordon

électrique. Si vous le portez par le cordon, vous risquez

d’endommager l’isolation ou les branchements des fils, ce

dont il peut résulter une électrocution ou un incendie.

CARACTÉRISTIQUES TECHNIQUES

Scie circulaire RAGETwin 125 mm

Moteur (230 V ou 110 V, 50 Hz) (Watts) : 850 W

Vitesse de rotation à vide (min-1) : 5 500 min-1

Profondeur de coupe max. : 28 mm

Poids : 3,2 kg

Dimensions de la lame

Diamètre maximal : 125 mm

Épaisseur : Lame A : 1,5 mm

Lame B : 1,7 mm

ASSEMBLAGE

Votre scie à double lame Evolution Power Tools est livrée

complète. Videz le carton et inspectez-en le contenu afin de

vous assurer qu’il n’a pas été endommagé lors du transport et

qu’aucun des composants énumérés ci-dessous ne manque.

DESCRIPTION QTÉ

MANUEL D’UTILISATION 1

LAME TCT (MONTÉE) de 125 mm 1 paire

CLÉ 1

POIGNÉE AUXILIAIRE 1

DISPOSITIF DE GRAISSAGE (MONTÉ) 1

MISE EN GARDE ! DÉBRANCHEZ TOUJOURS LA SCIE

À DOUBLE LAME DU SECTEUR AVANT DE PROCÉDER

AU MOINDRE RÉGLAGE.

Avant de commencer à utiliser votre outil, contrôlez ce qui suit :

1. Alimentation

Assurez-vous que la source d’alimentation utilisée est

conforme aux spécifications électriques indiquées sur la

plaque signalétique de l’outil.

2. Interrupteur marche/arrêt

Assurez-vous que l’interrupteur marche/arrêt est en position

OFF (arrêt). Si l’interrupteur marche/arrêt est en position

ON (marche) lorsque le cordon d’alimentation de l’outil est

branché sur la prise murale, l’outil se mettra en marche

immédiatement. Il pourra en résulter un accident grave.

3. Rallonge électrique

Lorsque la zone de travail est éloignée de la source

d’alimentation, utilisez une rallonge électrique d’une

épaisseur et d’une capacité nominale suffisantes. La rallonge

électrique doit être aussi courte que possible. Évitez de la

faire passer à un endroit où il est possible de se prendre

dedans ou présentant tout autre risque.

4. Contrôle des lames

Vérifiez que les lames utilisées sont bien du modèle indiqué et

qu’elles ne sont pas fissurées, cassées ou tordues. N’utilisez

pas cet outil si vous doutez de l’intégrité des lames.

INSTALLATION/RETRAIT DES LAMES TCT

REMARQUE : il est conseillé à l’opérateur d’envisager le

port de gants de protection lors de la manipulation des lames

pendant la pose ou le changement des lames.

SYMBOLES DE SÉCURITÉ

FR

RÈGLES DE SÉCURITÉ PARTICULIÈRES

SUPPLÉMENTAIRES

FR

Le protecteur inférieur peut fonctionner lentement en

raison d’éléments endommagés, de dépôts collants ou de

l’accumulation de débris.

c) Le protecteur inférieur peut revenir se loger manuellement

uniquement pour les coupes particulières telles que les

«coupes plongeantes» et les «coupes complexes». Soulevez

le protecteur inférieur par la poignée rétractive et dès que la lame

entre dans le matériau, le protecteur inférieur doit être relâché.

Pour toutes les autres découpes, il convient que le protecteur

inférieur fonctionne automatiquement.

NOTE Une autre formulation peut remplacer « poignée

rétractive ».

d) Vérifiez toujours que le protecteur inférieur recouvre

la lame avant de poser la scie sur un établi ou sur le sol.

Une lame non protégée et continuant à fonctionner par inertie

entraînera la scie en arrière, et coupera alors tout ce qui se

trouve sur sa trajectoire. Soyez conscient du temps nécessaire

à la lame pour s’arrêter après que l’interrupteur est relâché.

e) Contrôlez que les leviers de verrouillage du réglage du

biseau et de la profondeur de la lame sont bien serrés et

bloqués avant de couper. Si le réglage de la lame change

pendant la coupe, il pourra y avoir blocage et recul.

f) N’utilisez jamais de lames émoussées ou endommagées.

Des lames de scie mal affutées ou mal posées produiront une

saignée étroite, ce dont il résultera une friction excessive. La

lame se bloquera alors et reculera.

g) Faites extrêmement attention pendant le « sciage en

plongée » dans des murs ou autres zones aveugles. La lame

en saillie peut couper des objets, ce qui peut provoquer un recul.

AVERTISSEMENT !

N’utilisez en aucun cas la scie s’il manque des autocollants

contenant des avertissements et/ou des consignes ou si ces

autocollants sont endommagés. Contactez Evolution Power

Tools pour obtenir des autocollants de rechange.

Symbole Description

V Volts

A Ampères

Hz Hertz

Min

-1

Vitesse

~

Courant alternatif

No Vitesse à vide

Double isolation

Portez des lunettes

de sécurité

Portez des protections

auditives

Ne pas toucher

Portez une protection

contre la poussière

Directive relative à la

restriction d'utilisation

de certaines substances

dangereuses

Certification CE

Déchets d'équipements

électriques et électroniques

Utilisez uniquement des lames de rechange d’origine Evolution

garantie. Les lames non autorisées peuvent être dangereuses

! Les lames de la scie doivent être solidement fixées. Avant de

poser de nouvelles lames, contrôlez qu’il n’y a pas de débris.

N’utilisez pas des lames émoussées ou cassées.

Vérifiez fréquemment l’état et le degré d’usure des lames.

Les lames endommagées ou usées doivent être remplacées

immédiatement. Si un carter est mal ajusté ou endommagé,

il faut le remplacer immédiatement. N’ulitisez jamais des

disques abrasifs. Faites attention aux copeaux qui sont

éjectés. Ils sont peut-être CHAUDS. Manipulez toujours

l’excédent de matériau avec précaution.

Pour obtenir un nouvel exemplaire du présent manuel

d’utilisation, contactez Evolution Power Tools à :

Royaume-Uni 0870 609 2297

États-Unis 1-866-EVO-TOOL

SITE WEB www.evolutionbuild.com

a) Conservez tous les carters de protection en place et en

bon état de marche.

b) Retirez les clavettes et clés de réglage. Prenez pour

habitude de contrôler que les clavettes et clés de réglage ont

été retirées de l’outil avant de le mettre en marche.

c) Tenez votre lieu de travail propre. Les endroits et les

établis encombrés sont propices aux accidents.

d) N’utilisez pas l’outil dans les lieux dangereux. N’utilisez

pas les outils électriques dans des endroits humides ou

mouillés et ne les exposez pas à la pluie. Votre lieu de travail

doit être bien éclairé.

e) Tenez les enfants à l’écart. Tous les visiteurs devraient

être tenus à bonne distance du lieu de travail.

f) Ne forcez pas l’outil. Il fera un meilleur travail et sera

moins dangereux s’il est utilisé à la puissance pour laquelle

il a été conçu.

g) Utilisez une rallonge appropriée. Si vous utilisez une

rallonge, contrôlez qu’elle est en bon état. Si vous utilisez

une rallonge, assurez-vous qu’elle est suffisamment forte

pour transporter le courant que votre outil tirera. Si elle

est trop faible, cela entraînera une chute de la tension

sectorielle, ce qui se traduira par une perte de puissance et

CARACTÉRISTIQUES TECHNIQUES

FR

FONCTIONNEMENT

FR

Page 9

16

www.evolutionbuild.com

17

www.evolutionbuild.com

®

Tube en hélice et découpe longitudinale

Faites entrer la lame dans le matériau de façon telle que la

lame dépasse d’environ 10 mm. Ne faites pas entrer la lame

sur tout son bord de coupe. Lorsque la lame a entièrement

traversé la paroi du matériau, commencez à faire avancer et

reculer la lame (cf. fig. 12).

Tôle plate

Faites entrer la lame dans le matériau d’environ 10 mm

seulement. Puis commencez la découpe (cf. fig. 13).

CONSIGNES DE GRAISSAGE

1. Les lames sont munies de dents de type « à sec ». En

règle générale, elles ne nécessitent aucun graissage. Il est

toutefois possible d’appliquer de la pâte de coupe avec

certains matériaux et dans des conditions extrêmes.

2. Il faut utiliser le dispositif de graissage lorsque vous découpez

de l’aluminium, du cuivre, de l’acier inoxydable ou de la fonte.

3.Insérez la tige de lubrification dans le trou prévu à cet effet.

Cette unité est placée sur le sommet de la protection de la

lame. Poussez la tige de lubrifiant en bas fermement et faites

tourner la roue d’alimentation du lubrifiant manuellement

jusqu’à ce qu’il saisisse la tige de lubrifiant.

4. Allumez la machine et utilisez la roue d’alimentation

manuellement, amenez la tige de lubrifiant en appuyant

doucement afin d’atteindre les dents des lames .

5. La vigilence de l’opérateur sera exigée afin de déterminer

la fréquence d’application du lubrifiant. Pour appliquer le

lubrifiant supplémentaire, tournez la roue d’alimentation de

lubrifiant manuellement.

NOTEZ : Nous recommandons que vous utilisiez le lubrifiant

sous forme de tige, disponible chez votre détaillant qui

distribue la marque Evolution Power Tools.

MAINTENANCE

1. Inspection des lames TCT. Une lame usée surcharge le

moteur et réduit l’efficacité de l’outil. Si une des lames présente

des signes d’usure, remplacez les lames par une paire neuve.

2. Inspection des vis de montage. Inspectez régulièrement

toutes les vis de montage et assurez-vous qu’elles sont

bien serrées. Si l’une des vis est desserrée, resserrez-la

immédiatement. Le non-respect de cette consigne peut

mettre l’utilisateur dans une situation dangereuse.

3. Entretien du moteur. Veillez tout particulièrement à ce que

le bobinage ne soit pas endommagé et/ou exposé à de l’eau

ou à de l’huile.

4. Veillez à ce que l’outil soit toujours propre et exempt de

débris. Évitez d’utiliser des produits de nettoyage contenant

du benzène, du trichloréthylène, du chlorure ou de l’ammoniac

: ces substances risquent d’endommager les composants en

plastique.

5. En cas de dysfonctionnement électrique ou mécanique,

éteignez immédiatement l’outil et débranchez-le de la prise

murale.

6. Des projections d’étincelles trop importantes peuvent

indiquer un encrassement du moteur ou une usure des

balais en carbone. Contrôlez le degré d’usure des balais et

remplacez-les lorsqu’ils ne font plus que 6 mm.

7. Si le cordon électrique de l’outil est endommagé, il doit être

remplacé par un cordon spécialement étudié. Contactez le

centre de réparation à ce sujet.

8. Pour toute autre réparation, portez la machine à votre

revendeur local ou à Evolution Power Tools USA, Iowa, si vous

l’avez achetée aux États-Unis.

ACCESSOIRES

Lames Evolution

2 X Lames TCT 125mm

PROTECTION ENVIRONNEMENTALE

Les produits électriques usés ne doivent pas être

jetés avec les ordures ménagères. Recyclez-les si possible.

Contactez les autorités locales ou votre revendeur pour tous

conseils sur le recyclage.

1. Installation

1. Contrôlez que la machine n’est branchée sur aucune

source d’alimentation électrique.

2. Posez la scie sur l’établi en veillant à ce que l’arbre de la

lame soit dirigé vers le haut.

3. Ouvrez le carter inférieur (cf. fig. 2).

4. Posez la lame A sur la flasque portant la lettre « A » (cf. fig. 1).

5. Alignez les deux trous présents sur la lame avec les ergots

d’entraînement de la flasque, puis mettez la lame solidement

en place sur la flasque (cf. fig. 3).

6. Posez la lame B sur l’adaptateur portant la lettre « B » et serrez

le contre-écrou sur l’arbre. SERREZ À LA MAIN uniquement.

7. Faites tourner les lames de façon à ce que les trous des

deux lames soient alignés.

8. Insérez la goupille (fournie avec la clé) dans les trous alignés.

9. Serrez le contre-écrou dans le sens des aiguilles d’une

montre à l’aide d’une clé, puis retirez la goupille des lames

(cf. fig. 4). Cela permettra aux lames de tourner librement.

10. Tournez délicatement les lames manuellement pour vous

assurer qu’elles tournent facilement dans les deux sens opposés.

2. Retrait

1. Contrôlez que la machine est débranchée du secteur.

2. Laissez les lames refroidir.

3. Faites tourner les lames jusqu’à ce que les trous des deux

lames soient alignés.

4. Insérez la goupille fixée sur la clé dans les trous des lames.

5. Dévissez le contre-écrou en le tournant dans le sens

contraire des aiguilles d’une montre et déposez-le (cf. fig. 4).

6. Ouvrez le carter inférieur (cf. fig. 2).

7. Soulevez la lame « B » et retirez-la.

8. Soulevez la lame « A » et retirez-la.

PROCÉDURES DE DÉCOUPE

1. Tracez des lignes de coupe claires et précises sur la pièce à

découper (à l’aide d’un crayon de bois approprié, etc.).

2. Amenez la scie près du matériau à découper et placez les lames

dans l’alignement de la ligne de coupe tracée. Ne démarrez pas

la machine avant d’avoir obtenu l’alignement correct.

3. En veillant à ce que les lames ne touchent pas le matériau

à découper, mettez la machine en marche et attendez qu’elle

ait atteint la vitesse de pleine marche.

4. Mettez délicatement les lames de la scie en contact avec la

pièce. La coupe se déroulera dans les meilleures conditions si

vous coupez droit devant et laissez à la scie le temps de faire

son travail sans forcer la lame.

MISE EN GARDE

• Vérieztoujoursl’étatdeslamesTCTavantdecommencer

le travail.

• N’utilisezjamaisunelameTCTssurée,casséeoutordue.

• N’appliquezjamaisd’eauoudeliquidederefroidissement

sur une lame TCT.

• Commencezàcouperuniquementlorsquelascieaatteint

sa vitesse de pleine marche.

• Silalamesebloqueousivousentendezunbruitanormal,

éteignez immédiatement la machine.

• N’utilisez jamais une lame TCT pour effectuer des

découpes en zigzag ou incurvées.

• N’utilisez jamais la surface latérale de la lame TCT.

N’effectuez jamais de découpes en inclinant la machine.

• SipendantladécoupevousforceztropsurlalameTCTpour

l’aligner avec la ligne tracée, vous risquez non seulement de

surcharger le moteur, mais aussi d’entraîner une surchauffe

des lames et de raccourcir leur durée de vie.

• Veillezà ceque le cordond’alimentation n’entrepas en

contact avec les lames TCT pendant la découpe.

• Soutenezlapièceàdécouperdemanièreàpouvoirprévoir

ce qui va se passer et à ce que la découpe reste ouverte

pendant le travail.

• Faitesavancer la machinedans l’alignement deslames.

Une pression latérale sur les lames peut les endommager et

s’avérer dangereux.

• Une fois la découpe terminée, éteignez la machine et

débranchez la fiche d’alimentation de la prise murale.

COUPE DE SECTIONS

Pour garantir la durée de vie des lames et la qualité du

tranchant, le niveau de vibration doit être réduit au minimum.

C’est la raison pour laquelle le matériau doit toujours être fixé

solidement avant de commencer le travail.

Fer plat

La lame avance selon un angle de 90º par rapport à la surface

de travail (cf. fig. 5).

Pièce présentant une encoignure

La lame avance en diagonale sur la surface de travail (cf. fig. 6).

Tuyau de section rectangulaire

La lame avance d’un coin à l’autre (cf. fig. 7).

Profilé en U

La lame avance d’un coin à l’autre (cf. fig. 8).

Aluminium / cuivre

Cette machine est équipée d’un dispositif de graissage qui

devrait être utilisé pour la découpe de l’aluminium et du

cuivre en tous genres (cf. fig. 9). Reportez-vous à la section

« Consignes de graissage ».

Tôle ondulée

La plate doit toujours reposer sur au moins trois points, dont

un de chaque côté de la découpe (cf. fig. 10).

Tuyaux

La lame avance dans l’objet jusqu’à ce qu’elle atteigne le

bord inférieur, selon un angle permettant d’attaquer le

matériau selon un angle de 90º (cf. fig. 11).

Page 10

18

www.evolutionbuild.com

19

www.evolutionbuild.com

®

NOMENCLATURE DES PIECES DE RECHANGE DE LA SCIE CIRCULAIRE A DOUBLE LAME (REV. 1. 00)

FR

230V ~ 50Hz

EC - DECLARATION OF CONFORMITY

CE – Declaración de conformidad 19

Información importante 19

Garantía limitada de 12 meses 20

Normas de seguridad generales 20

Instrucciones de seguridad para todas las sierras 22

Símbolos 23

Normas de seguridad específicas adicionales 23

Especificaciones 24

Montaje 24

Funcionamiento 24

Mantenimiento 26

Protección medioambiental 26

Listas de piezas de servicio 27

Nosotros, los importadores,

Evolution Power Tools Ltd.

Venture One

Longacre Close

Sheffield

S20 3FR

Declaramos que el producto

Números de referencia: RAGETWIN1251, RAGETWIN1252,

RAGETWIN1252EU

Evolution: Cortadora de doble hoja RAGE125mm (5˝)

Cumple los requisitos fundamentales de las siguientes

directrices europeas:

2006/42/CE – Directriz de máquinas

2006/95/CE – Directriz de bajo voltaje

2004/108/CE – Directriz de EMC

2002/95/CE – Restricción del uso de ciertas sustancias

peligrosas en equipos eléctricos y electrónicos

Estas herramientas mecánicas se han diseñado cumpliendo

las directivas del consejo:

2006/42/EC

2004/108/EC

2002/95/EC

2002/96/EC

Se han aplicado las normas siguientes:

EN55014-1

EN55014-2

EN61000-3-2 & EN61000-3-3

EN60745-1

EN60745-2-5

La valeur de vibrations déclarée a été mesurée selon une

méthode d’essai standard (EN60745) et peut être utilisée pour

comparer un outil avec un autre. La valeur de vibrations déclarée

peut également servir d’évaluation d’exposition préliminaire.

AVERTISSEMENT : la valeur d’émission de vibrations

pendant l’utilisation de l’outil électrique peut être différente

de la valeur déclarée, selon la façon dont l’outil est utilisé.

Déterminez les mesures de sécurité à adopter pour protéger

l’opérateur en fonction d’une estimation de l’exposition

dans les conditions effectives d’utilisation. Tenez compte

de toutes les parties du cycle d’exploitation, y compris les

périodes d’arrêt de l’outil et ses périodes de ralenti en plus

du temps de déclenchement réel.

DATOS DE RUIDO Y VIBRACIONES

LpA (presión sonora) dB(A) 90,0

LwA (presión acústica) dB(A) 101,0

KpA (incertidumbre de presión acústica) dB(A) 3

KwA (incertidumbre de potencia acústica) dB(A) 3

Valor de aceleración ponderado efectivo

Asa delantera m/s2 1,383

Asa trasera m/s2 1,56

K m/s2 1,5

VIBRACIÓN m/s2 5,18

El valor declarado de vibración ha sido medido de acuerdo

con un método de prueba estándar (EN60745) y puede

utilizarse para comparar una herramienta con otra. El valor

de vibración declarado también puede utilizarse en una

evaluación preliminar de la exposición.

ADVERTENCIA: El valor de emisión de vibración durante el

uso real de la herramienta mecánica puede diferir del valor

declarado dependiendo de las formas en las cuales se utilice

la herramienta. Identifique las medidas de seguridad para

proteger al operador que se basan en una estimación de la

exposición en las condiciones de uso reales. Tenga en cuenta

todas las piezas del ciclo operativo, incluidos los tiempos en

los que la herramienta está desconectada y cuando está

funcionando al ralentí además del tiempo de activación real.

Firmante autorizado

Fecha: 1/8/2010

Nombre: Sr. Matthew J Gavins

Cargo: Director general

Año de fabricación: 2010

IMPORTANTE! Por favor, lea estas instrucciones de

funcionamiento y seguridad atentamente y hasta el final. Por

su propia seguridad, antes de utilizar este equipo, compruebe

que el voltaje sea correcto y que todas las asas y piezas

estén firmemente fijadas. Si no está convencido de algún

aspecto de la utilización de este equipo, por favor póngase

en contacto con nuestra línea de asistencia telefónica.

ÍNDICE

ES

CE – DECLARACIÓN DE CONFORMIDAD

ES

Page 11

20

www.evolutionbuild.com

21

www.evolutionbuild.com

®

Línea de asistencia telefónica en el Reino Unido

0870 609 2297

Línea de asistencia telefónica en los Estados Unidos

1-866-EVO-TOOL

RAGETWIN

Felicidades por su compra de una sierra de doble hoja

Evolution Power Tools Rage de 125mm. Complete su registro

del producto online para validar el período de garantía de su

máquina y para asegurarse de recibir un rápido servicio en

caso de necesitarlo. Le agradecemos sinceramente que se

haya decidido por un producto de Evolution Power Tools.

GARANTÍA LIMITADA DE 12 MESES. Evolution Power Tools

se reserva el derecho a realizar mejoras y modificaciones en

el diseño sin previo aviso.

Evolution Power Tools, en los doce (12) meses siguientes

a la fecha de compra original, reparará o cambiará cualquier

producto donde sea patente que hay un defecto de

material o de mano de obra. Esta garantía no es válida si

la herramienta que se está devolviendo ha sido utilizada

para cortar materiales más allá de las recomendaciones

del manual de instrucciones o si la sierra ha sufrido daños

por accidentes, negligencia o un servicio inadecuado. Esta

garantía no se aplica a las máquinas y / o componentes que

se hayan alterado, cambiado o modificado de alguna forma, o

hayan estado sujetos a uso más allá de las especificaciones

y capacidades recomendadas. Los componentes eléctricos

están sujetos a las garantías respectivas de los fabricantes.

Todos los productos defectuosos que se devuelvan se

devolverán con portes pagados a Evolution Power Tools.

Evolution Power Tools se reserva el derecho a repararlos

o cambiarlos opcionalmente por el mismo elemento o uno

equivalente. No hay garantía – escrita ni verbal – para las

hojas de sierra. Evolution Power Tools no será en ningún

caso responsable de las pérdidas o daños resultantes

directa o indirectamente del uso de nuestras mercancías

o por cualquier otra causa. Evolution Power Tools no es

responsable de ningún coste en el que hayan incurrido

dichos productos o daños derivados. Ningún directivo,

empleado o agente de Evolution Power Tools está autorizado

para realizar declaraciones verbales sobre la idoneidad o no

aplicar alguno de los términos de venta siguientes y ninguno

será vinculante para Evolution Power Tools. Las cuestiones

referentes a esta garantía limitada deberían dirigirse a las

oficinas centrales de la empresa o llamando al número de

asistencia telefónica apropiado.

IMPORTANTES INSTRUCCIONES DE SEGURIDAD

Para reducir el riesgo de descarga eléctrica, este equipo dispone

de un cable y un enchufe autorizados para el país de uso

deseado. No cambie el enchufe ni el cable de ninguna forma.

NORMAS DE SEGURIDAD GENERALES

ADVERTENCIA: Por su propia seguridad,

leael manual de instrucciones antes de

poner en funcionamiento la sierra de ingletes.

1. MANTENGA LAS PROTECCIONES EN SU LUGAR y en

buen funcionamiento.

2. RETIRE LAS LLAVES DE MONTAJE Y DE AJUSTE.

Adquiera el hábito de comprobar que las llaves de montaje

y de ajuste se encuentran fuera de la herramienta antes de

encenderla.

3. MANTENGA LIMPIO EL LUGAR DE TRABAJO. Una

mesa y zona de trabajo abarrotadas invitan a los accidentes.

4. NO UTILICE EN AMBIENTES PELIGROSOS. No utilice

herramientas eléctricas en lugares húmedos o mojados, ni las

exponga a la lluvia. Mantenga el lugar de trabajo bien iluminado.

5. MANTENGA ALEJADO DEL ALCANCE DE LOS NIÑOS.

Cualquier visitante debe guardar una distancia de seguridad

con la zona de trabajo.

6. NO FUERCE LA MÁQUINA. Trabajará mejor y más segura

al ritmo para el que fue diseñada.

7. UTILICE UNA ALARGADERA APROPIADA. Asegúrese

de que la alargadera está en buen estado. Al utilizar una

alargadera, cerciórese de que tiene la resistencia suficiente

para transportar la corriente del producto. Un cable corto

causará cortes de corriente resultando en la pérdida de

energía y sobrecalentamiento.

8. UTILICE LA INDUMENTARIA APROPIADA. No lleve

ropas holgadas, guantes, corbatas, anillos, pulseras u otras

piezas de bisutería que pudiesen engancharse en partes en

movimiento. Se recomienda utilizar calzado anti-deslizante.

Utilice protección para el pelo si lo tiene largo.

9. UTILICE SIEMPRE GAFAS DE SEGURIDAD. Utilice

también careta o máscara contra el polvo si el proceso de

cortado emite residuos. Las gafas habituales sólo poseen

lentes resistentes a impactos, NO son gafas de seguridad.

10. TRABAJE SEGURO. Utilice abrazaderas para sujetar la

pieza de trabajo cuando resulte práctico. Será más seguro

que utilizar la mano y tendrá las dos manos libres para operar

la máquina.

11. NO INTENTE HACER DEMASIADO. Mantenga el

balance apropiado y una posición firme en todo momento.

12. CUIDE LAS HERRAMIENTAS. Mantenga las

herramientas afiladas y limpias para un rendimiento más

seguro y óptimo. Siga las instrucciones sobre lubricación y

cambio de accesorios.

13. DESCONECTE LAS HERRAMIENTAS antes de realizar

tareas de mantenimiento y al cambiar accesorios, como

hojas.

14. REDUZCA EL RIESGO DE INICIO INVOLUNTARIO.

Asegúrese de que el interruptor se encuentra en posición de

apagado antes de conectar la máquina.

15. UTILICE LOS ACCESORIOS RECOMENDADOS. Utilice

sólo accesorios Evolution originales.

16. NUNCA SE COLOQUE SOBRE LA HERRAMIENTA. El

operador podría sufrir lesiones graves si la herramienta se

inclina o si la herramienta de corte se activa de manera no

intencionada.

17. COMPRUEBE LAS PARTES DAÑADAS. Antes de volver

a utilizar la herramienta, debe comprobar cuidadosamente

las protecciones o cualquier otra pieza dañada para

determinar si funcionará correctamente y si ofrecerá la

función deseada; compruebe la alineación y la unión de las

partes en movimiento, rotura de piezas, montaje y cualquier

otra condición que pueda afectar su funcionamiento. Una

protección u otra pieza que haya resultado dañada deben

repararse o sustituirse oportunamente.

18. Mantenga las manos fuera del paso de la hoja de la sierra.

19. Nunca rodee la hoja de la sierra con los brazos.

20. Apague la herramienta y espere a que la hoja de la sierra

se detenga antes de mover la pieza de trabajo o realizar

cambios.

21. Desconecte el suministro eléctrico antes de cambiar,

reparar o limpiar la hoja.