Page 1

Original Instructions

EN

FR

IT

NL

Date Published: 01/03/2016Written in UK English

Page 2

ENGLISH

Original Instructions

EN

FR

NL

IT

Page 3

www.evolutionpowertools.com www.evolutionpowertools.com

TABLE OF CONTENTS

English Page 2

Français Page 22

Italiano Pagina 42

Nederlands Pagina 62

INTRODUCTION

Guarantee Page 5

Machine Specification Page 6

Vibration Page 7

Labels and Symbols Page 7

Intended use of this Power Tool Page 8

Prohibited use of this Power Tool Page 8

SAFETY PRECAUTIONS

Electrical Safety Page 9

Outdoor Use Page 9

General Power Tool Safety Instructions Page 9

Additional Safety Instructions Page 11

GETTING STARTED

Unpacking Page 13

Machine Overview Page 14

Assembly and Preparation Page 15

Operating Instructions Page 17

MAINTENANCE

Environmental Protection Page 19

DECLARATION OF CONFORMITY Page 20

THIS INSTRUCTION MANUAL

WAS ORIGINALLY WRITTEN IN ENGLISH

IMPORTANT

Please read these operating and safety

instructions carefully and completely.

For your own safety, if you are uncertain

about any aspect of using this equipment

please access the relevant Technical Helpline,

the number of which can be found on the

Evolution Power Tools website. We operate

several Helplines throughout our worldwide

organization, but Technical help is also

available from your supplier.

WEB

www.evolutionpowertools.com/register

Congratulations on your purchase of an

Evolution Power Tools Machine. Please

complete your product registration ‘online’

as explained in the A4 online guarantee

registration leaflet included with this machine.

You can also scan the QR code found on the

A4 leaflet with a Smart Phone. This will enable

you to validate your machine’s guarantee

period via Evolutions website by entering your

details and thus ensure prompt service if ever

needed. We sincerely thank you for selecting

a product from Evolution Power Tools.

EVOLUTION LIMITED GUARANTEE

Evolution Power Tools reserves the right

to make improvements and modifications

to the product design without prior notice.

Please refer to the guarantee registration

leaflet and/or the packaging for details of

the terms and conditions of the guarantee.

Evolution Power Tools will, within

the guarantee period, and from the original

date of purchase, repair or replace any

goods found to be defective in materials or

workmanship. This guarantee is void if the

tool being returned has been used beyond the

recommendations in the Instruction Manual or

if the machine has been damaged by accident,

neglect, or improper service.

This guarantee does not apply to machines

and / or components which have been altered,

changed, or modified in any way, or subjected

to use beyond recommended capacities

and specifications. Electrical components

are subject to respective manufacturers’

warranties. All goods returned defective shall

be returned prepaid freight to Evolution Power

Tools. Evolution Power Tools reserves the right

to optionally repair or replace it with the same

or equivalent item.

There is no warranty – written or verbal –

for consumable accessories such as (following

list not exhaustive) blades, cutters, drills,

chisels or paddles etc. In no event shall

Evolution Power Tools be liable for loss or

damage resulting directly or indirectly from

the use of our merchandise or from any other

cause. Evolution Power Tools is not liable

for any costs incurred on such goods

or consequential damages.

No officer, employee or agent of Evolution

Power Tools is authorized to make oral

representations of fitness or to waive any

of the foregoing terms of sale and none

shall be binding on Evolution Power Tools.

Questions relating to this limited

guarantee should be directed to the

company’s head office, or call the

appropriate Helpline number.

EN

FR

IT

4 5

NL

Page 4

www.evolutionpowertools.com www.evolutionpowertools.com

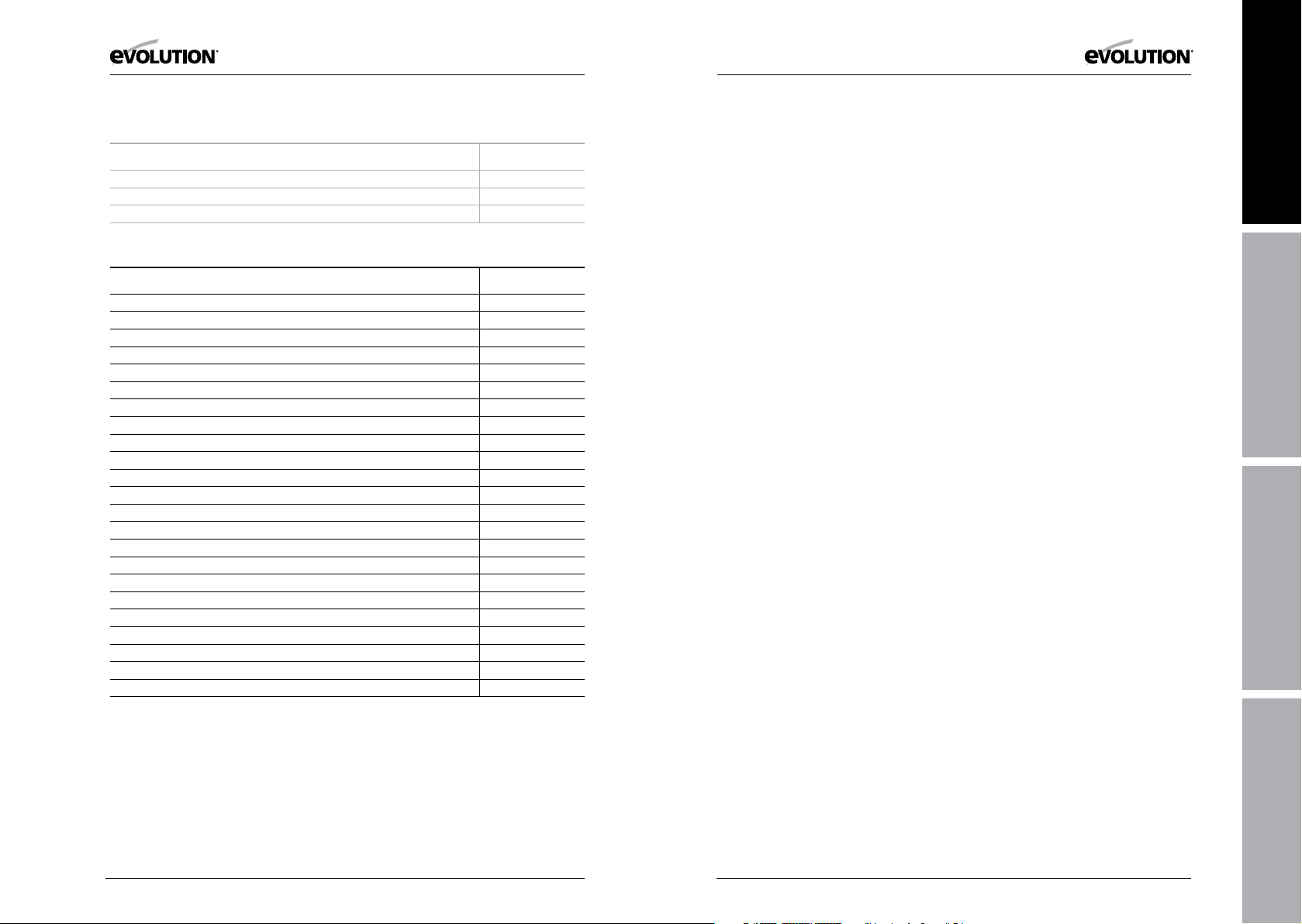

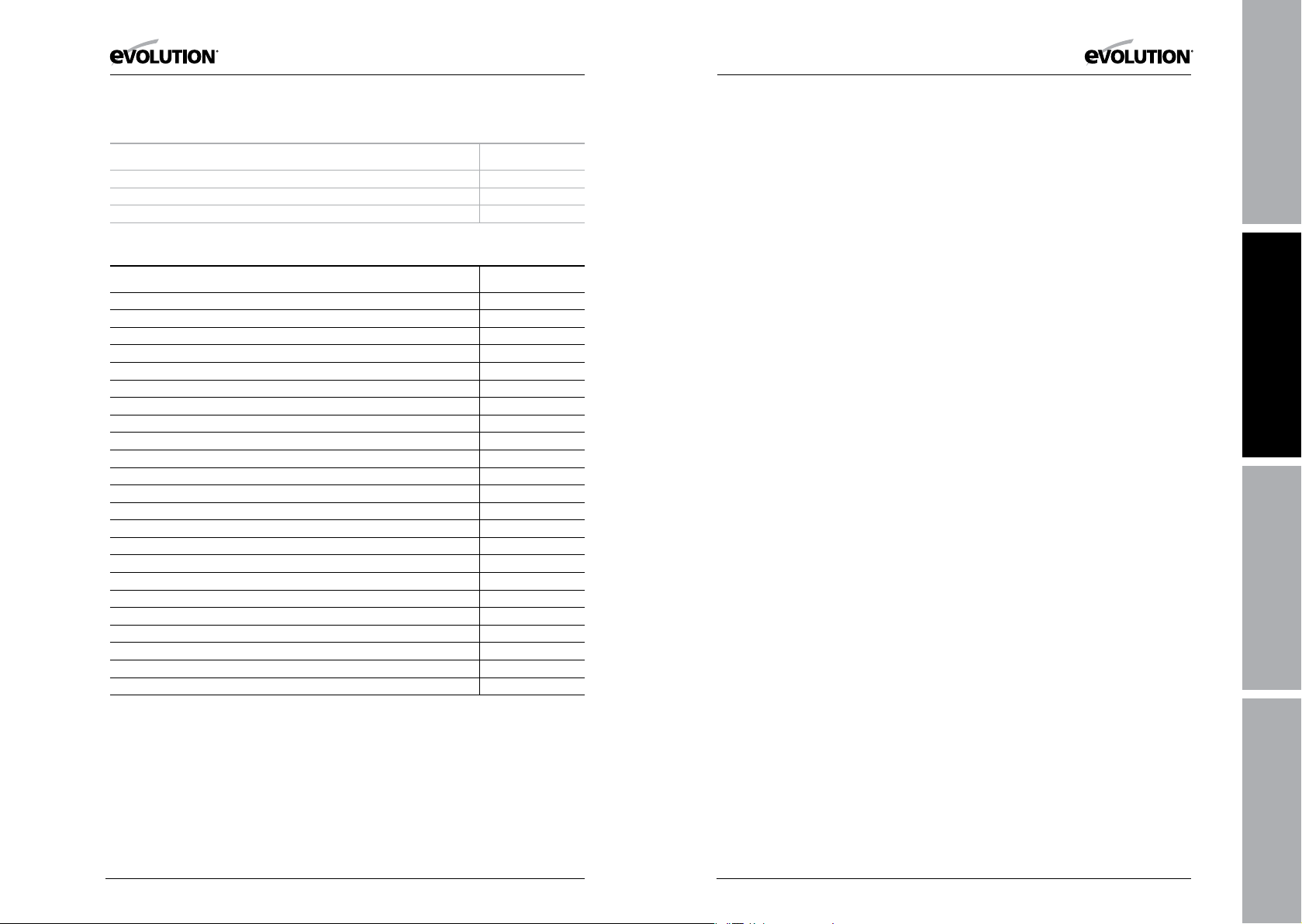

SPECIFICATIONS

MACHINE METRIC IMPERIAL

Motor (USA) 120v ~ 60Hz 1050W 9A

Motor (UK/EU) 230/240v ~ 50Hz 1050W 5A

Motor (UK) 110v ~ 50Hz 1050W 10A

Speed No Load 3500min

-1

Weight 6.5kg 14lbs

CUTTING CAPACITY METRIC IMPERIAL

Mild Steel Plate (Maximum Thickness) 6mm 1/4”

Maximum Cutting at 90

Maximum Cutting at 45

0

0

55mm 2-1/8”

35mm 1-3/8”

BLADE METRIC IMPERIAL

Diameter 185mm 7-1/4”

Bore 20mm 3/4”

Number of Teeth 20 20

Kerf 1.7mm .067”

Speed 3900min

-1

NOISE & VIBRATION DATA

Sound Pressure L

Sound Power Level L

(Under Load) 93 dB(A) K= 3 dB(A)

PA

(Under Load) 104 dB(A) K= 3 dB(A)

WA

Vibration Level (Under Load) 4.99m/s

3500rpm

3900rpm

2

K= 1.5m/s2

Note: The vibration measurement was made

under standard conditions in accordance with:

BS EN 61029-1:2009.

The declared vibration total value has been

measured in accordance with a standard test

method and may be used for comparing one

tool with another.

The declared vibration total value may also be

used in a preliminary assessment of exposure.

VIBRATION

WARNING: When using this machine the

operator can be exposed to high levels of

vibration transmitted to the hand and arm.

It is possible that the operator could develop

“Vibration white finger disease” (Raynaud

syndrome). This condition can reduce the

sensitivity of the hand to temperature as

well as producing general numbness.

Prolonged or regular users of this machine

should monitor the condition of their hands

and fingers closely. If any of the symptoms

become evident, seek immediate

medical advice.

• The measurement and assessment of

human exposure to hand-transmitted

vibration in the workplace is given in:

BS EN ISO 5349-1:2001 and

BS EN ISO 5349-2:2002.

• Many factors can influence the actual

vibration level during operation e.g. the

work surfaces condition and orientation

and the type and condition of the machine

being used. Before each use, such factors

should be assessed, and where possible

appropriate working practices adopted.

Managing these factors can help reduce

the effects of vibration:

Handling

• Handle the machine with care, allowing

the machine to do the work.

• Avoid using excessive physical effort on

any of the machines controls.

• Consider your security and stability,

and the orientation of the machine

during use.

Work Surface

• Consider the work surface material;

its condition, density, strength,

rigidity and orientation.

WARNING: The vibration emission during

actual use of the power tool can differ from

the declared total value depending on the

ways in which the tool is used.

The need to identify safety measures

and to protect the operator are based on

an estimation of exposure in the actual

conditions of use (taking account of all parts

of the operating cycle, such as the times the

tool is switched off, when it is running idle,

in addition to trigger time).

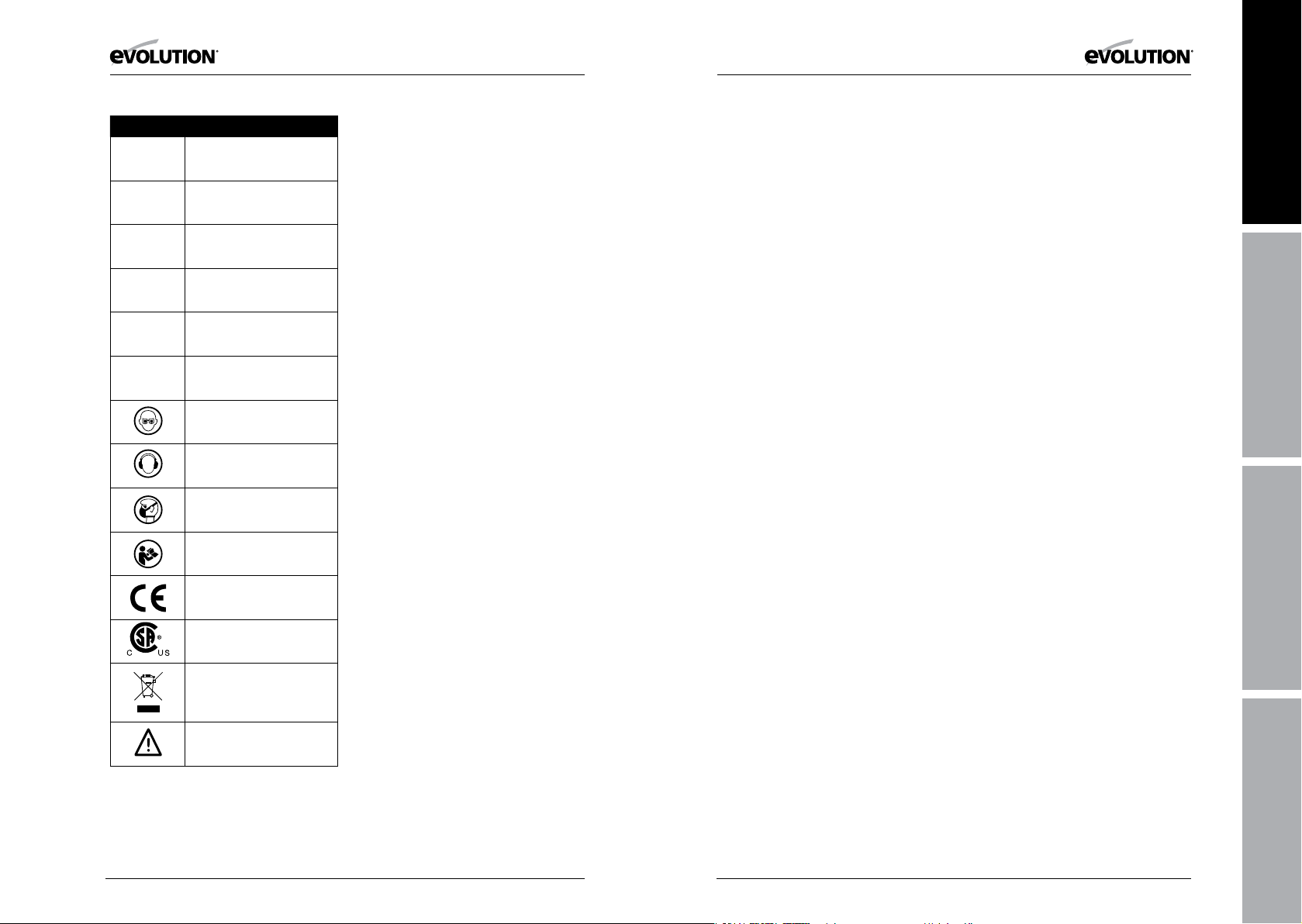

LABELS & SYMBOLS

WARNING: Do not operate this machine

if warning and/or instruction labels are

missing or damaged. Contact Evolution

Power Tools for replacement labels.

Note: All or some of the following symbols

may appear in the manual or on the product.

EN

FR

IT

NL

6 7

Page 5

www.evolutionpowertools.com www.evolutionpowertools.com

Symbol Description

Volts

Amperes

Hertz

Speed

Alternating Current

No Load Speed

Wear Safety Goggles

Wear Ear Protection

Wear Dust Protection

Read Instructions

CE Certification

CSA Certification

Waste Electrical &

Electronic Equipment

Warning

Hz

Min

n

V

A

-1

~

o

INTENDED USE OF THIS POWER TOOL

WARNING: This product is a Hand Operated

Circular Saw and has been designed to be

used with special Evolution blades. Only use

accessories designed for use in this machine

and/or those recommended specifically

by Evolution Power Tools Ltd.

When fitted with an appropriate blade

this machine can be used to cut:

Mild Steel

Aluminium

Wood

PROHIBITED USE OF THIS POWER TOOL

WARNING: This product is a Hand Operated

Circular Saw and must only be used as such.

It must not be modified in any way, or used to

power any other equipment or drive any other

accessories other than those mentioned in this

Instruction Manual.

WARNING: This machine is not intended

for use by persons (including children) with

reduced physical, sensory

or mental capabilities, or lack of experience

and knowledge, unless they have been given

supervision or instruction concerning the safe

use of the machine by a person responsible

for their safety and who is competent

in its safe use.

Children should be supervised to ensure

that they do not have access to, and are

not allowed to play with, this machine.

ELECTRICAL SAFETY

This machine is fitted with the correct

moulded plug and mains lead for the

designated market. If the supply cord is

damaged, it must be replaced by a special

cord or assembly available from the

manufacturers or its service agent.

OUTDOOR USE

WARNING: For your protection if this tool is to

be used outdoors it should not be exposed to

rain, or used in damp locations. Do not place

the tool on damp surfaces. Use a clean, dry

workbench if available. For added protection

use a residual current device (R.C.D.) that will

interrupt the supply if the leakage current to

earth exceeds 30mA for 30ms. Always check

the operation of the residual current device

(R.C.D.) before using the machine.

If an extension cable is required it must be a

suitable type for use outdoors and so labelled.

The manufacturers instructions should be

followed when using an extension cable.

POWER TOOL GENERAL

SAFETY INSTRUCTIONS

(These General Power Tool Safety Instructions

are as specified in BS EN 60745-1:2009

& EN 61029-1:2009).

WARNING: Read all safety warnings and

instructions. Failure to follow the warnings

and instructions may result in electric shock,

fire and/ or serious injury.

Save all warnings and instructions for

future reference. The term “power tool” in

the warnings refers to your mains-operated

(corded) power tool or battery-operated

(cordless) power tool.

1) General Power Tool

Safety Warnings [Work area safety]

a) Keep work area clean and well lit.

Cluttered or dark areas invite accidents.

b) Do not operate power tools in explosive

atmospheres, such as in the presence of

flammable liquids, gasses or dust. Power

tools create sparks which may ignite the

dust or fumes.

c) Keep children and bystanders away while

operating power tool. Distractions can cause

you to lose control.

2) General Power Tool Safety Warnings

[Electrical Safety]

a) Power tool plugs must match the outlet.

Never modify the plug in any way. Do not use

any adapter plugs with earthed (grounded)

power tools. Unmodified plugs and matching

outlets will reduce the risk of electric shock.

b) Avoid body contact with earthed or

grounded surfaces, such as pipes, radiators,

ranges and refrigerators. There is an

increased risk of electric shock if your body

is earthed or grounded.

c) Do not expose power tools to rain or wet

conditions. Water entering a power tool will

increase the risk of electric shock.

d) Do not abuse the cord. Never use the cord

for carrying, pulling orunplugging the power

tool. Keep cord away from heat, oil, sharp edges

or moving parts. Damaged or entangled cords

increase the risk of electric shock.

e) When operating a power tool outdoors,

use an extension cord suitable for outdoor

use. Use of a cord suitable for outdoor use

reduces the risk of electric shock.

f) If operating a power tool in a damp

location is unavoidable, use a residual

current device (RCD) protected supply.

Use of an RCD reduces the risk of

electric shock.

EN

FR

IT

NL

8 9

Page 6

www.evolutionpowertools.com www.evolutionpowertools.com

3) General Power Tool Safety Warnings

[Personal Safety].

a) Stay alert, watch what you are doing and

use common sense when operating a power

tool. Do not use a power tool while you are

tired or under the influence of drugs, alcohol

or medication. A moment of inattention while

operating power tools may result in serious

personal injury.

b) Use personal protective equipment.

Always wear eye protection. Protective

equipment such as dust masks, non-skid safety

shoes, hard hat or hearing protection used

for appropriate conditions will reduce

personal injuries.

c) Prevent unintentional starting. Ensure the

switch is in the off-position before connecting

to power source and or battery pack, picking

up or carrying the tool. Carrying power tools

with your finger on the switch or energising

the power tools that have the switch on

invites accidents.

d) Remove any adjusting key or wrench

before turning the power tool on. A wrench

or key left attached to a rotating part of

a power tool may result in personal injury.

e) Do not overreach. Keep proper footing

and balance at all times. This enables better

control of the power tool in unexpected

situations.

f) Dress properly. Do not wear loose clothing

or jewellery. Keep your hair, clothing and

gloves away from moving parts. Loose clothes,

jewellery or long hair can be caught in

moving parts.

g) If devices are provided for the connection

of dust extraction and collection facilities,

ensure that these are connected and

properly used. Use of dust collection

can reduce dust-related hazards.

4) General Power Tool Safety Warnings

[Power tool use and care].

a) Do not force the power tool. Use the

correct power tool for your application. The

correct power tool will do the job better and

safer at a rate for which it was designed.

b) Do not use the power tool if the switch

does not turn it on or off. Any power tool

that cannot be controlled with the switch

is dangerous and must be repaired.

c) Disconnect the power tool from the

power source and/or battery pack from the

power tool before making any adjustments,

changing accessories, or storing power

tools. Such preventative safety measures

reduce the risk of starting the power

tool accidentally.

d) Store idle power tools out of the reach

of children and do not allow persons

unfamiliar with the power tool or these

Instructions to operate the power tool.

Power tools are dangerous in the hands of

untrained users.

e) Maintain power tools. Check for

misalignment or binding of moving parts,

breakage of moving parts and any other

condition that may affect the power tools

operation. If damaged, have the power tool

repaired before use. Many accidents are

caused by poorly maintained power tools.

f) Keep cutting tools sharp and clean.

Properly maintained cutting tools with

sharp cutting edges are less likely to bind

and are easier to control.

g) Use the power tool, accessories and

tool bits etc. in accordance with these

instructions, taking into account the

working conditions and the work to

be performed. Use of the power tool for

operations different fromthose intended

could result in a hazardous situation.

5) General Power Tool

Safety Warnings [Service]

a) Have your power tool serviced by a

qualified repair person using only identical

replacement parts. This will ensure that the

safety of the power tool is maintained.

HEALTH ADVICE

WARNING: When using this machine,

dust particles may be produced. In some

instances, depending on the materials you

are working with, this dust can be particularly

harmful. If you suspect that paint on the

surface of material you wish to cut contains

lead, seek professional advice. Lead based

paints should only be removed by

a professional and you should not

attempt to remove it yourself.

Once the dust has been deposited on

surfaces, hand to mouth contact can result

in the ingestion of lead. Exposure to even

low levels of lead can cause irreversible brain

and nervous system damage. The young and

unborn children are particularly vulnerable.

You are advised to consider the risks

associated with the materials you are working

with and to reduce the risk of exposure.

As some materials can produce dust that may

be hazardous to your health, we recommend

the use of an approved face mask with

replaceable filters when using this machine.

You should always:

• Work in a well-ventilated area.

• Work with approved safety equipment, such

as dust masks that are specially designed to

filter microscopic particles.

WARNING: the operation of any power tool

can result in foreign objects being thrown

towards your eyes, which could result in

severe eye damage. Before beginning power

tool operation, always wear safety goggles

or safety glasses with side shield or a full face

shield where necessary.

ADDITIONAL SAFETY INSTRUCTIONS

a) DANGER: Keep hands away from cutting

area and the blade. Keep your second hand

on auxiliary handle, or motor housing. If both

hands are holding the saw, they cannot be cut

by the blade.

b) Do not reach underneath the workpiece.

The guard cannot protect you from the blade

below the workpiece.

c) Adjust the cutting depth to the thickness

of the workpiece. Less than a full tooth of

the blade teeth should be visible below the

workpiece.

d) Never hold piece being cut in your hands

or across your leg. Secure the workpiece to

a stable platform. It is important to support

the work properly to minimize body exposure,

blade binding, or loss of control.

e) Hold power tool by insulated gripping

surfaces when performing an operation

where the cutting tool may contact hidden

wiring or its own cord. Contact with a “live”

wire will also make exposed metal parts of the

power tool “live” and shock the operator.

f) When ripping always use a rip fence

or straight edge guide. This improves the

accuracy of cut and reduces the chance

of blade binding.

g) Always use blades with correct size and

shape (diamond versus round) of arbor

holes. Blades that do not match the mounting

hardware of the saw will run eccentrically,

causing loss of control.

h) Never use damaged or incorrect blade

washers or bolt. The blade washers and

bolt were specially designed for your saw,

for optimum performance and safety

of operation.

EN

FR

IT

NL

10 11

Page 7

www.evolutionpowertools.com www.evolutionpowertools.com

i) Do not use High Speed Steel (HSS)

saw blades.

j) Inspect the machine and the blade

before each use. Do not use deformed,

cracked, worn or otherwise damaged blades.

k) Never use the saw without the original

guard protection system. Do not lock

the moving guard in the open position.

Ensure that the guard operates freely

without jamming.

l) Only use blades that comply with the

characteristics specified in this manual.

Before using accessories, always compare

the maximum allowed RPM of the

accessory with the RPM of the machine.

Causes and operator

prevention of kickback:

Kickback is a sudden reaction to a pinched,

bound or misaligned saw blade, causing an

uncontrolled saw to lift up and out of the

workpiece toward the operator:

1. When the blade is pinched or bound

tightly by the kerf closing down, the blade

stalls and the motor reaction drives the

unit rapidly back toward the operator;

2. If the blade becomes twisted or

misaligned in the cut, the teeth at the

back edge of the blade can dig into the top

surface of the workpiece causing the blade

to climb out of the kerf and jump back

towards the operator.

Kickback is the result of saw misuse and/

or incorrect operating procedures or

conditions and can be avoided by taking

proper precautions as given below.

a) Maintain a firm grip with both hands

on the saw and position your arms to

resist kickback forces. Position your body

to either side of the blade, but not in line

with the blade. Kickback could cause the

saw to jump backwards, but kickback forces

can be controlled by the operator, if proper

precautions are taken.

b) If the blades are binding, or when

interrupting a cut for any reason, release

the trigger and hold the saw motionless

in the material until the blades come to a

complete stop. Never attempt to remove the

saw from the work or pull the saw backward

while the blades are in motion or kickback may

occur. Investigate and take corrective actions

to eliminate the cause of blade binding.

c) When restarting a saw in the workpiece,

centre the saw blade in the kerf and check

that saw teeth are not engaged into the

material. If saw blade is binding, it may walk

up or kickback from the workpiece as the saw

is restarted.

d) Support large panels to minimise

the risk of blade pinching and kickback.

Large panels tend to sag under their own

weight. Supports must be placed under

the panel on both sides, near the line

of cut and near the edge of the panel.

e) Blade depth and bevel adjusting locking

levers must be tight and secure before

making a cut. If the blade adjustment

shifts while cutting it may cause binding

and kickback.

f) Do not use dull or damaged blades.

Unsharpened or improperly set blades

produce a narrow kerf causing excessive

friction, blade binding and kickback.

g) Use extra caution when making a “plunge

cut” into existing walls or other blind areas.

The protruding blade may cut objects that

can cause kickback.

h) Check lower guard for proper closing

before each use. Do not operate the saw if

lower guard does not move freely and close

instantly. Never clamp or tie the lower guard

into the open position. If saw is accidentally

dropped, lower guard may be bent. Raise the

lower guard with the retracting handle and

make sure it moves freely and does not touch

the blade or any other part, in all angles and

depths of cut.

i) Check the operation of the lower guard

spring. If the guard and the spring are not

operating properly, they must be serviced

before use. Lower guard may operate

sluggishly due to damaged parts, gummy

deposits, or a build-up of debris.

j) Lower guard may be retracted manually

only for special cuts such as “plunge cuts”

and “compound cuts.” Raise lower guard

by retracting handle and as soon as blade

enters the material, the lower guard must be

released. For all other sawing, the lower guard

should operate automatically.

k) Always observe that the lower

guard is covering the blade before

placing saw down on a bench or the floor.

An unprotected, coasting blade will cause the

saw to walk backwards, cutting whatever is in

its path. Be aware of the time it takes for the

blade to stop after switch is released.

WARNING: If any parts are missing, do not

operate your machine until the missing parts

are replaced. Failure to follow this rule could

result in serious personal injury.

GETTING STARTED - UNPACKING

Caution: This packaging contains sharp

objects. Take care when unpacking. Remove

the machine, together with the accessories

supplied from the packaging. Check carefully

to ensure that the machine is in good

condition and account for all the accessories

listed in this manual. Also make sure that all

the accessories are complete.

If any parts are found to be missing,

the machine and its accessories should

be returned together in their original

packaging to the retailer.

Do not throw the packaging away;

keep it safe throughout the guarantee

period. Dispose of the packaging in an

environmentally responsible manner.

Recycle if possible.

Do not let children play with empty plastic

bags due to the risk of suffocation.

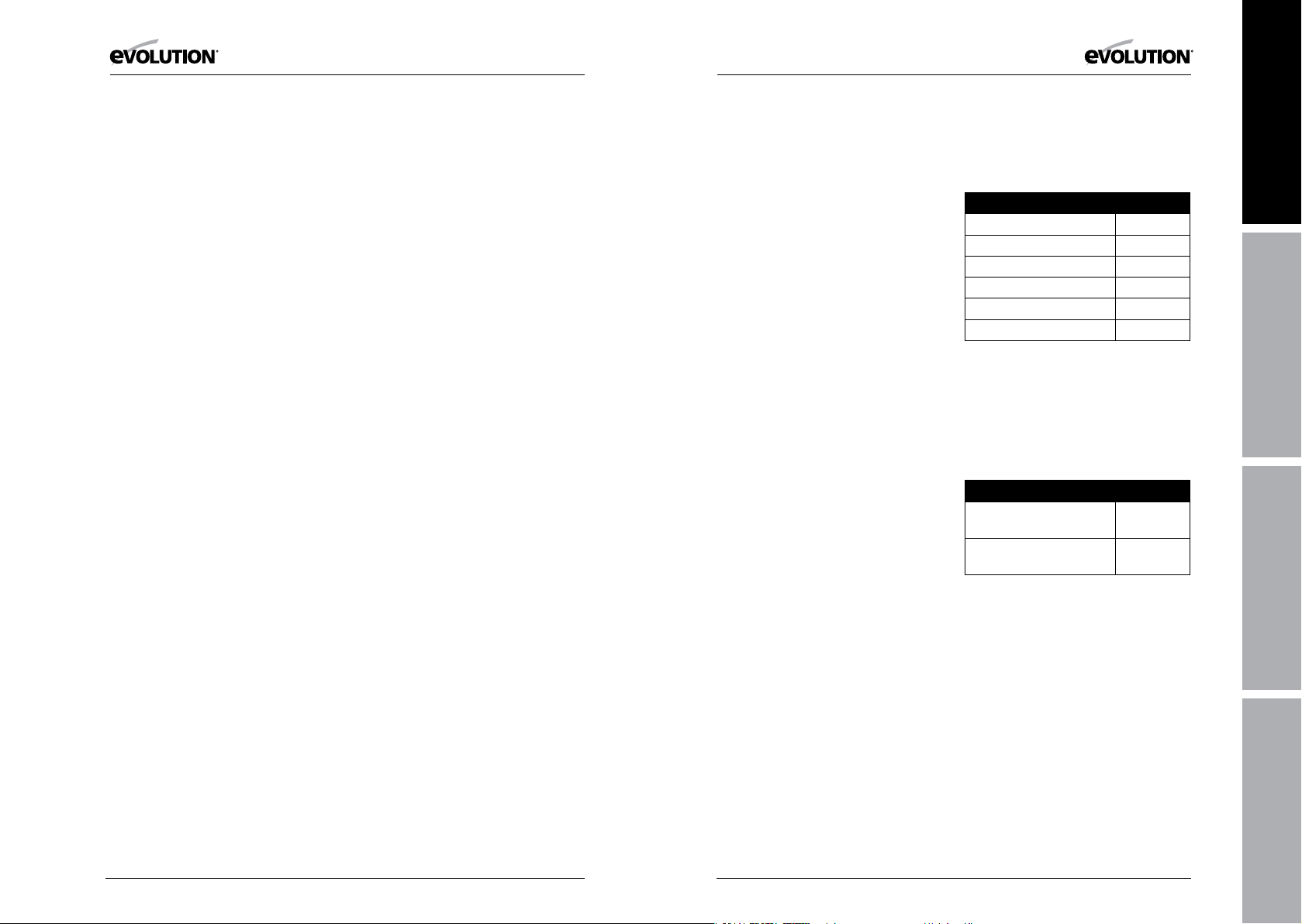

ITEMS SUPPLIED

Description Quantity

Instruction Manual 1

Multipurpose Blade (Fitted) 1

Hex Key (Blade Change) 1

Discharge Port Exhaust 1

Parallel Edge Guide 1

Carry Case 1

ADDITIONAL ACCESSORIES

In addition to the standard items supplied

with this machine the following accessories

are also available from the Evolution online

shop at www.evolutionpowertools.com

or from your local retailer.

Description Part No

Multipurpose Blade RAGE

185

Diamond Blade DIAMOND

185

EN

FR

IT

NL

12 13

Page 8

www.evolutionpowertools.com www.evolutionpowertools.com

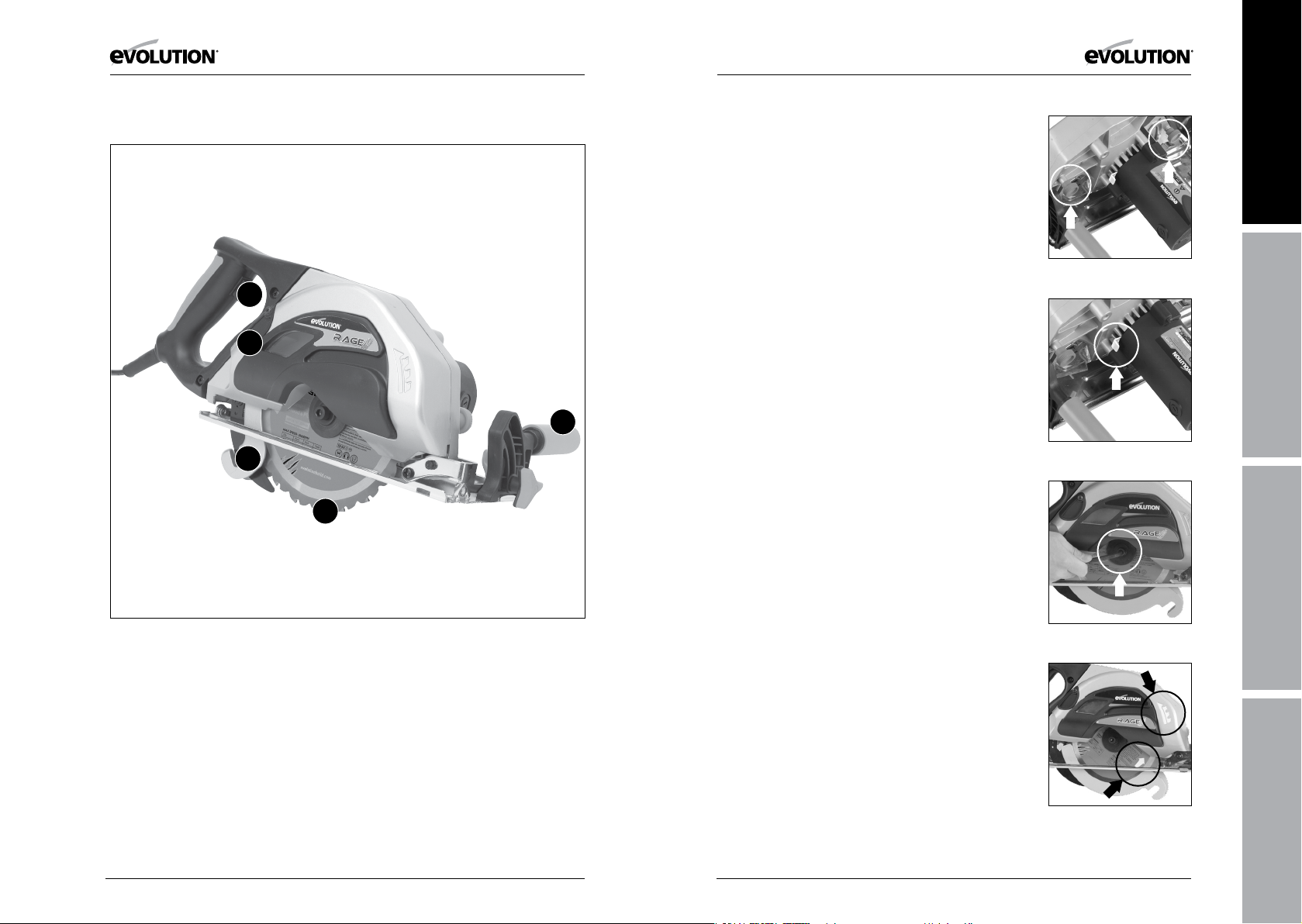

MACHINE OVERVIEW

GETTING STARTED - PREPARATION

WARNING: Always disconnect the saw from the power source

before making adjustments.

WARNING: Never start the saw with the cutting edge of the

saw blade in contact with the workpiece surface. Do not retract

blade guard manually. Guard retracts automatically.

This saw is equipped with an approved cord and plug for its

intended Country of use. Do not alter or modify the power cord.

1

3

2

4

5

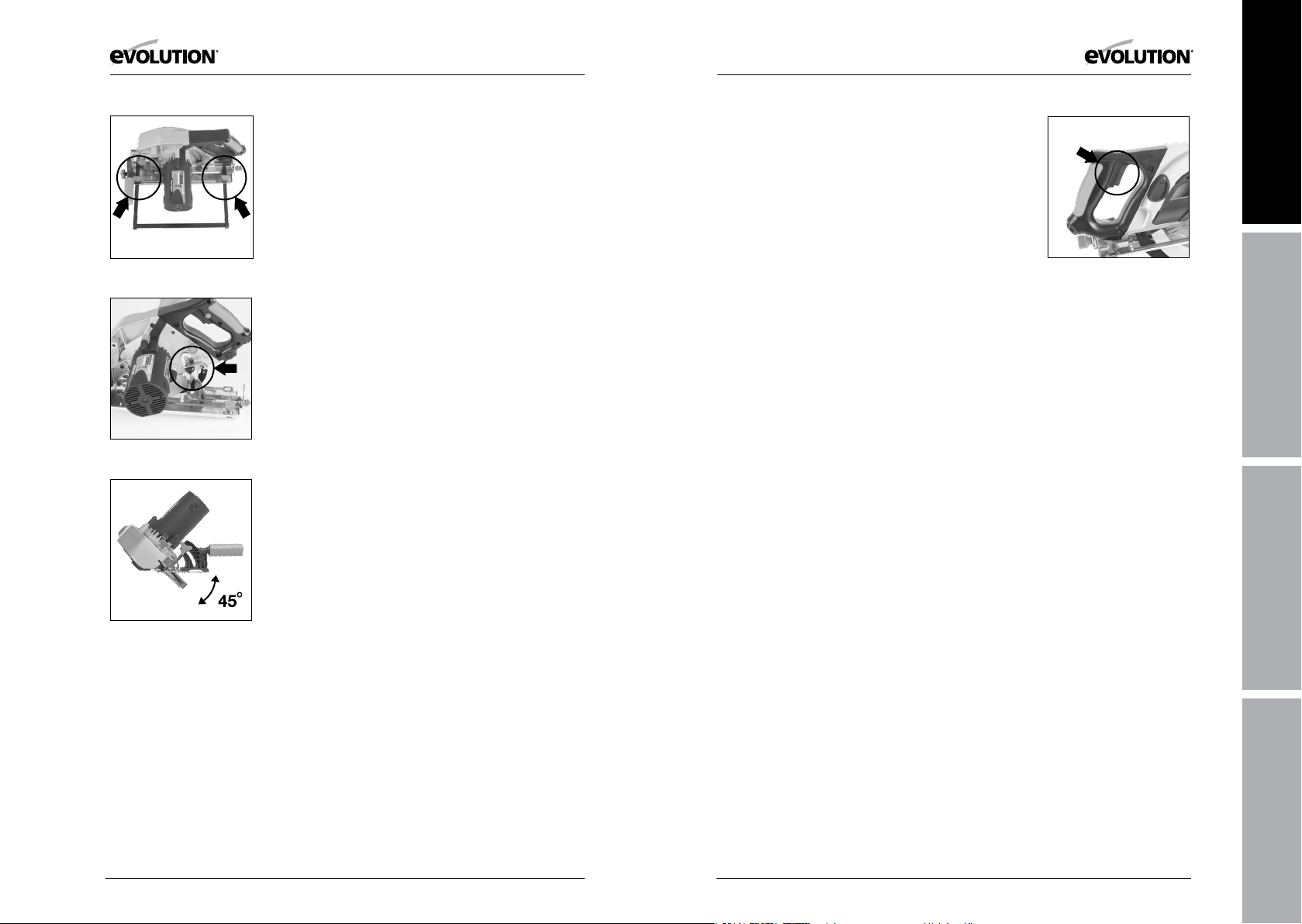

Installing or Removing a Blade

WARNING: Only use genuine Evolution blades which are designed

for this machine. Ensure that the maximum speed of the blade is

compatible with the machine. Only perform this operation with

the machine disconnected from the power supply.

Note: It is recommended that the operator considers wearing

protective gloves when handling the blade during installation

or when changing the machines blade.

1. Place saw on a level, secure surface.

2. Remove the chip collector from the machine by undoing the

(2) large thumb screws. (Fig. 1)

Note: The chip collector thumb screws are ‘captive’ and cannot

be removed from the machine.

Fig. 1

Fig. 2

EN

FR

1. ON/OFF TRIGGER SWITCH

2. AUXILLARY FRONT HANDLE

3. DISCHARGE PORT

4. LOWER BLADE GUARD

5. FITTED BLADE IN SITU

3. Lock the machine arbor by engaging the arbor lock. (Fig. 2)

4. Using the supplied Allen Key loosen and remove the arbor

socket headed screw and outer blade drive flange. (Fig. 3)

5. Remove the saw blade.

6. Thoroughly clean inner and outer blade drive flanges and

blade mounting surface before installing a new blade.

7. Ensure that the direction of rotation arrows printed on the

blade, match the direction of rotation arrow found on the chip

collection cover. (Fig. 4)

8. Reinstall the outer drive flange and the arbor socket headed

screw.

9. Engage the arbor lock and tighten the arbor socket headed

screw securely using the Allen key.

Note : The socket headed arbor screw has a RH thread.

14 15

Fig. 3

Fig. 4

IT

NL

Page 9

www.evolutionpowertools.com www.evolutionpowertools.com

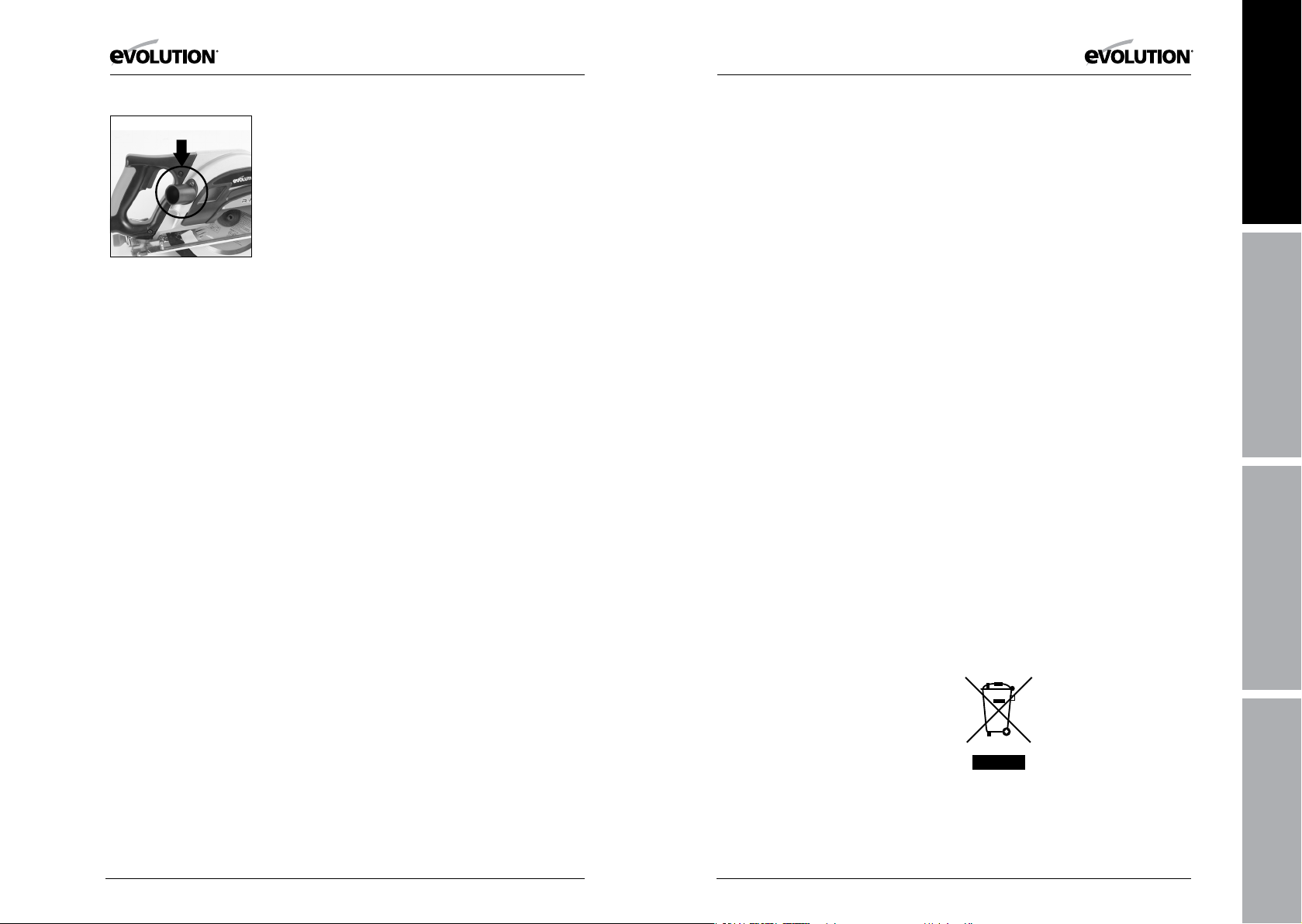

Fig. 5

Fig. 6

Fig. 7

10. Replace the chip collector and securely tighten the two

thumb screws.

11. Check that the arbor lock is fully released by manually

rotating the blade.

12. Check the operation of the safety guard.

Parallel Edge Guide

A parallel guide (for help when rip cutting) can be fitted to the

sole plate of the machine The guides arms should be inserted

into the rectangular slots in the turned up edges of the sole

plate, and slid under the locking thumb screws. (Fig. 5)

Note: The edge guide can be fitted to either side of the sole

plate and should only be fitted and adjusted with the machine

disconnected from the power supply.

Adjust the edge guide so that it is at the required distance from

the blade and tighten the two thumb screws. Check that the

edge guide is parallel to the saw blade.

Adjustment of the Cutting Depth

Release the Lever Lock to adjust to the required cutting depth.

Adjust the cutting depth to the thickness of the workpiece.

Less than a full tooth of the blade teeth should be visible below

the workpiece. Tighten the Lever Lock securely to lock in the

required position. (Fig.6)

Adjustment of the Cutting Angle

1. Loosen the Bevel Locking Screw found at the front of the saw.

2. Loosen the Rear Bevel Locking Screw found at the rear of the

machines sole plate.

3. Tilt the blade to the required angle. (Fig. 7)

4. Tighten both Bevel Locking Screws securely

Operating Advice

Carry out routine safety checks each time you use the machine.

Check that all safety guards are operating correctly, and that all

adjustment handles/screws are tightened securely.

Check that the blade is secure and installed correctly. Also check

that it is the correct blade for the material being cut.

Check the integrity of the power cord.

Always clamp the workpiece to a rigid support such as a bench

or saw horse whenever possible.

ON/OFF Trigger Switch

This machine is equipped with a safety start trigger switch.

To start the machine:

• Push in the safety lock button on the side of the

handle with your thumb.

• Depress the main trigger switch to start the motor. (Fig. 8)

Chip Collector

This machine is fitted with a chip collector to capture metal

chips. The chip collector cover plate is provided with a

transparent ‘window’ so that the operator can see the contents

and empty when necessary.

To remove and empty the chip collector:

• Loosen the two chip collector thumb screws.

• Ease the chip collector from the machine.

• Empty the contents of the chip collector by tipping the

collector upside down over a suitable waste container,

allowing the contents to fall out.

EN

Fig. 8

FR

IT

Note: An angle scale (0

O

-45O) is incorporated into the Bevel

Locking quadrant to aid setting.

16 17

Note: To maintain operational efficiency we recommend that

the collector is emptied when approximately 60% full. Dispose

of the contents of the chip collector in an environmentally

responsible manner.

• Replace the chip collector and securely tighten

the (2) thumb screws.

NL

Page 10

www.evolutionpowertools.com www.evolutionpowertools.com

Fig. 9

Discharge Port

When cutting wood the Discharge Port Exhaust should be fitted

to the chip collector cover Discharge Port.

To fit the Discharge Port Exhaust

• Remove the Discharge Port blanking cover by unscrewing

the cross headed screw.

• Pull the blanking cover from the Discharge Port and safely

store for future use.

• Fit the Discharge Port Exhaust in place of the blanking cover.

(Fig. 9) Wood chips will be ejected from the Discharge Port

Exhaust during cutting operations.

When cutting has been completed, remove the Exhaust Port

and replace the blanking cover and tighten the fixing screw

securely.

Cutting Advice

The operator should wear all relevant PPE (Personal Protection

Equipment) necessary for the job at hand. This could include

safety glasses, dust masks, safety shoes etc.

The operator should always be aware of the position and

routing of the power cable.

• Do not force the machine.

• Allow the speed of the saw blade do the work. Cutting

performance will not be improved by applying excessive

pressure to the machine, and blade life will be reduced.

• When using the parallel edge guide, ensure that it is parallel

with the blade. The blade and/or motor could become

damaged if the machine is used with an incorrectly adjusted

parallel edge guide.

• To set the guide, loosen the two retaining screws, and adjust

the guide to the required position. Tighten the locking screws.

• Place front edge of sole plate squarely on the workpiece

before starting the motor.

• When starting a cut, sight the cutting line with the line of

cut guide, taking care to introduce the blade to the material

slowly, so as not to damage its teeth.

• Use both hands to move the saw forwards the work piece.

• Apply smooth, constant pressure to move the saw forwards

through the workpiece.

When a cut has been completed release the

ON/OFF trigger switch and allow the blade to

come to a complete halt. Do not apply lateral

pressure to the blade disc in an attempt to

slow it down more quickly.

WARNING: If the motor should stop or stall

whilst a cut is being attempted release the

trigger switch immediately and disconnect

the machine from the power supply. Remove

the machine from the workpiece before

investigating the cause and attempting to

restart the motor.

Note: This saw is fitted with an overload

protection device. This is designed to prevent

overloading and consequent damage to the

motor. If this feature ‘trips’, the motor stops

and will not operate.

Allow the machine to cool down and then press

the ‘reset switch’ at the base of the main handle.

MAINTENANCE

Note: Any maintenance must be carried

out with the machine switched off and

disconnected from the power supply.

Check that all safety features and guards are

operating correctly on a regular basis. Only use

this machine if all guards/safety features are

fully operational.

All motor bearings in this machine are

lubricated for life. No further lubrication

is required.

Use a clean, slightly damp cloth to clean

the plastic parts of the machine. Do not use

solvents or similar products which could

damage the plastic parts.

WARNING: Do not attempt to clean by

inserting pointed objects through openings

in the machines casings etc. The machines air

vents should be cleaned using compressed

dry air.

Excessive sparking may indicate the presence of

dirt in the motor or worn out carbon brushes.

Brush Checking and Replacement

To replace the motor brushes:

• Disconnect the machine from the

power supply.

• Place the machine on a level, secure surface.

• Remove the (2) motor brush retainer

cap screws.

• Withdraw the brushes.

Note: If the Carbon rod is less than 6mm long

or if there are signs of burning or damage,

replace the brushes.

• Fit the new brushes.

• Refit the motor brush retainer caps.

• Run the saw without load for several

minutes after brush replacement to aid the

‘bedding in’ process.

ENVIRONMENTAL PROTECTION

Waste electrical products should not be

disposed of with household waste. Please

recycle where facilities exist. Check with your

Local Authority or retailer for recycling advice

EN

FR

IT

NL

18 19

Page 11

www.evolutionpowertools.com www.evolutionpowertools.com

EC DECLARATION OF CONFORMITY

In accordance with EN ISO 17050-1:2004

The manufacturer of the product covered by this Declaration is:

Evolution Power Tools, Venture One, Longacre Close, Holbrook Industrial Estate, Sheffield, S20 3FR.

The manufacturer hereby declares that the machine as detailed in this declaration fulfils all the

relevant provisions of the Machinery Directive and other appropriate directives as detailed below.

The manufacture further declares that the machine as detailed in this declaration, where

applicable, fulfils the relevant provisions of the Essential Health and Safety requirements.

The Directives covered by this Declaration are as detailed below:

2006/42/EC. Machinery Directive.

2004/108/EC. (until Apr 19th 2016) Electromagnetic Compatibility Directive.

2014/30/EU. (starting from Apr 20th 2016) Electromagnetic Compatibility Directive.

93/68/EC. The CE Marking Directive.

2011/65/EU. The Restriction of the Use of certain Hazardous

Substances in Electrical Equipment (RoHS) Directive.

2002/96/EC as The Waste Electrical and Electronic Equipment (WEEE) Directive.

amended by

2003/108/EC .

And is in conformity with the applicable requirements of the following documents:

EN55014-1 : 2006 • EN55014-2 : 1997+A1 • EN61000-3-2 : 2006 • EN61000-3-3 : 1995+A1+A2

EN60745-1 : 2003+A1 • EN60745-2-5 : 2003 • EN60825-1 : 1994+A1+A2

Product Details

Description: RAGE 185mm (7-1/4”) MULTIPURPOSE CIRCULAR SAW

Evolution Model No: RAGE1851 / RAGE1852 / RAGE1852EU

Brand Name: EVOLUTION

Voltage: 110V / 230V ~ 50Hz

Input: 1050W

NOTES

EN

FR

IT

The technical documentation required to demonstrate that the product meets the requirements

of directive has been compiled and is available for inspection by the relevant enforcement

authorities, and verifies that our technical file contains the documents listed above

and that they are the correct standards for the product as detailed above.

Name and address of technical documentation holder.

Signed: Print: Matthew Gavins - Group Chief Executive

Date: 01/03/2016

20 21

NL

Page 12

EN

FRANçAIS

Traduction D’original

FR

IT

NL

Page 13

www.evolutionpowertools.com www.evolutionpowertools.com

TABLE DES MATIERES

English Page 2

Français Page 22

Italiano Pagina 42

Nederlands Pagina 62

INTRODUCTION

Garantie Page 25

Spécifications de l’outil Page 26

Vibrations Page 27

Etiquettes et symboles Page 27

Utilisation prévue pour cet outil électrique Page 28

Utilisation prohibée pour cet outil électrique Page 28

PRECAUTIONS DE SECURITE

Sécurité électrique Page 29

Utilisation extérieure Page 29

Instructions générales concernant les outils électriques Page 29

Instructions de sécurité supplémentaires Page 31

COMMENCER AVEC L’OUTIL

Déballage Page 33

Présentation de l’outil Page 34

Assemblage et préparation Page 35

Instructions d’utilisation Page 37

ENTRETIEN

Protection de l’environnement Page 39

DECLARATION DE CONFORMITE Page 40

LA LANGUE D’ORIGINE DE CE MANUEL

EST L’ANGLAIS

IMPORTANT

Merci de lires ces instructions d’utilisation et

de sécurité avec attention et en totalité. Pour

votre sécurité personnelle et si vous n’êtes

pas sûr de connaître l’un des aspects de cet

outil, contactez le ser vice technique dont le

numéro se trouve sur le site web de Evolution

Power Tools. Nous disposons de plusieurs

services techniques à travers le monde, mais

une assistance technique est également

disponible auprès de votre distributeur.

ADRESSE WEB

www.evolutionpowertools.com/register

Félicitations pour votre achat d’un outil

Evolution Power Tools. Merci de remplir le

formulaire de garantie en ligne décrit dans le

dépliant A5 livré avec cet outil. Vous pouvez

également scanner le code QR qui se trouve

sur le dépliant A4 avec votre smartphone.

Ceci vous permettra de valider votre garantie

sur le site Evolution Power Tools et vous

assurera un service rapide en cas de besoin.

Nous vous remercions sincèrement d’avoir

choisi un outil Evolution Power Tools.

GARANTIE LIMITEE EVOLUTION

Evolution Power Tools se réserve le droit

d’apporter des améliorations ou des

modications dans la conception du produit

sans notication préalable.

Merci de vous référer au prospectus

d’enregistrement de garantie et/ou à

l’emballage pour plus d’informations sur les

conditions de garantie.

Pendant la période de garantie et à compter

de la date d’achat, Evolution Power Tools

réparera ou remplacera les outils défectueux,

pièces et main d’œuvre comprises. Cette

garantie ne s’applique pas si l’outil qui nous est

renvoyé a été utilisé dans un cadre qui dépasse

les recommandations du manuel d’utilisation

ou si l’outil a été endommagé par accident,

négligence ou utilisation inappropriée.

Cette garantie ne s’applique pas aux outils et/ou

aux éléments de l’outil qui ont été modiés ou

utilisés hors des capacités et des spécications

prescrites. Les éléments électriques sont soumis

aux garanties de leurs fabricants. Les outils qui

nous sont retournés le seront port payé et à

l’attention d’Evolution Power Tools.

Il n’existe aucune garantie, écrite ou verbale,

sur les consommables tels que (sans que

cette liste soit exhaustive) : les lames, les

cutters, les mèches, les burins, etc. En aucune

circonstance Evolution Power Tools ne

pourra être tenu pour responsable des pertes

ou dommages résultant directement ou

indirectement de l’utilisation de nos produits

ou de toute autre cause.

Aucun employé o u agent d’Evolution Power

Tools n’est autorisé à établir de décla ration

de convenance ora le ou à renoncer l’une des

conditions de vente et de tels en gagements ne

pourront être opposé s à Evaluation Power Tools.

Les questions relatives à la présente

limitation de garantie seront directement

adressées au siège de l’entreprise ou par

appel téléphonique au numéro du service

technique approprié.

EN

FR

IT

24 25

NL

Page 14

www.evolutionpowertools.com www.evolutionpowertools.com

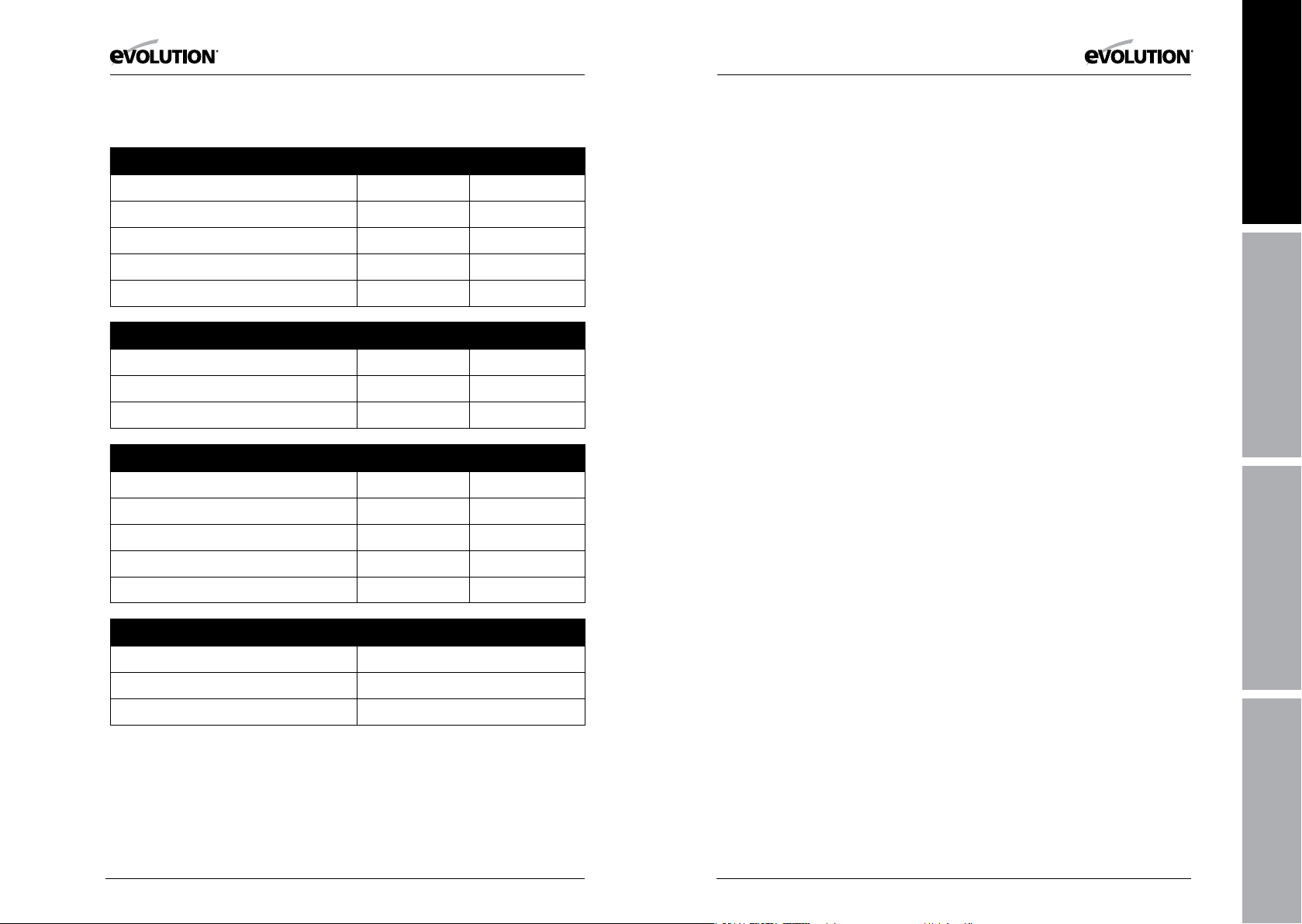

SPECIFICATIONS

MACHINE METRIQUE IMPERIAL

Moteur (USA) 120v ~ 60Hz 1050W 9A

Moteur (UK/EU) 230/240v ~ 50Hz 1050W 5A

Moteur (UK) 110v ~ 50Hz 1050W 10A

Vitesse hors charge 3500min

-1

Poids 6.5kg 14lbs

CAPACITE DE COUPE METRIQUE IMPERIAL

Plaque d’acier doux (Epaisseur maximum) 6mm 1/4”

Coupe maximum à 90

Coupe maximum à 45

0

0

55mm 2-1/8”

35mm 1-3/8”

LAME METRIQUE IMPERIAL

Diamètre 185mm 7-1/4”

Alésage 20mm 3/4”

Nombre de dents 20 20

Saignée 1.7mm .067”

Vitesse 3900min

-1

BRUIT ET VIBRATIONS

Pression acoustique L

Niveau sonore L

(en charge) 93 dB(A) K= 3 dB(A)

PA

(en charge) 104 dB(A) K= 3 dB(A)

WA

Niveau de vibrations (en charge) 4.99m/s

3500rpm

3900rpm

2

K= 1.5m/s2

Note: Les mesures de vibrations ont été

eectuées en conditions normales selon la

norme BS EN 61029-1:2009.

La valeur totale de vibrations déclarée a

été mesurée selon des méthodes de test

standards et peuvent être utilisées pour

comparer les outils entre eux.

La valeur totale de vibrations déclarée peut

également être utilisée dans le cadre d’une

évaluation préliminaire d’exposition.

VIBRATIONS

ATTENTION : Lors de l’utilisation de cet

outil, l’utilisateur peut être soumis à de forts

niveaux de vibrations transmises par les

mains et par les bras.

Il est possib le que l’utilisateur développe un

syndrom e de blanchiment des doigts suite aux

vibrations, ou syndrome de Raynaud. Cet état est

susceptible de réduire la sensibilité des mains à la

température et de créer des engourdissements.

Les utilisateurs réguliers et sur de longues

périodes de cet outil doivent contrôler l’état de

leurs mains et de leurs doigts régulièrement.

En cas d’apparition de tels symptômes,

consultez immédiatement un médecin.

• La mesure et l’évaluation de l’exposition

humaine aux vibrations transmises par les

mains est donnée par les documents de

référence suivants : BS EN ISO 5349-1:2001

et BS EN ISO 5349-2:2002

• De nombreux facteurs peuvent inuencer

le niveau réel de vibrations pendant

l’utilisation tel que l’état des surfaces

usinés, l’orientation et le type ou l’état

de l’outil utilisé. Ces facteurs doivent être

évalués avant utilisation et de bonnes

pratiques de travail doivent être adoptées

à chaque fois que possible. Une bonne

gestion des facteurs suivants peut aider à

réduire les eets des vibrations.

Manutention

• Utilisez l’outil avec précaution en le

laissant eectuer le travail.

• Evitez d’utiliser trop de force sur l’un

quelconque des contrôles de l’outil.

• Pensez à votre sécurité et à votre

stabilité, ainsi qu’à l’orientation de la

machine lors de son utilisation.

Surface usinée

• Prenez en considération la surface du

matériau : son état, sa densité, sa force

et sa rigidité et son orientation.

ATTENTION : Les émissions de vibrations lors

de l’utilisation de la machine peuvent varier

de la valeur totale déclarée selon l’utilisation

qui est faite de l’outil.

Le besoin d’identier les mesures de sécurité

et de protéger l’opérateur se basent sur

une estimation de l’exposition dans des

conditions d’utilisation réelles (prenant en

considération tous les éléments du cycle

d’utilisation, tels que les moments pendant

lesquels l’outil est éteint, les moments

pendant lesquels il est inutilisé, et les

moments pendant lesquels on allume l’outil).

ETIQUETTES ET SYMBOLES

ATTENTION : N’utilisez pas cet outil si les

étiquettes de signalisation et/ou d’instructions

manquent ou sont endommagées. Contactez

Evolution Power Tools pour recevoir des

étiquettes de remplacement.

Note: Tous ou certains des symboles suivants

sont susceptibles d’apparaître dans le manuel

ou sur le produit.

EN

FR

IT

NL

26 27

Page 15

www.evolutionpowertools.com www.evolutionpowertools.com

Symbole Description

Volts

Ampères

Hertz

Vitesse

Courant alternatif

Vitesse hors charge

Portez des protections

anti poussières

Lire les instructions

Certification CE

Certification CSA

Déchet électrique et

Hz

Min

n

V

A

-1

~

o

Portez des lunettes de protection

Portez une protection des oreilles

d’équipement électronique

Triman - Collecte des déchets

& Recyclage

Attention

UTILISATION PREVUE DE CET OUTIL

ELECTRIQUE

ATTENTION : Cet outil est une scie circulaire

à main, conçue pour une utilisation avec des

lames Evolution multi usages. N’utilisez que

des lames conçues pour cet outil et/ou des

accessoires recommandés spéciquement

par Evolution Power Tools Ltd.

Equipé d’une lame appropriée, cet outil peut

être utilisé pour couper :

Acier doux,

aluminium,

bois

UTILISATION PROHIBEE DE CET OUTIL

ELECTRIQUE

ATTENTION : Cet outil est une scie circulaire

à main qui ne doit être utilisée qu’à cet eet. Il

ne doit être modié en aucune façon ni utilisé

pour entrainer un autre outil ou un accessoire

autre que ceux mentionnés dans le présent

manuel d’instruction.

ATTENTION : Cette machine n’est pas conçue

pour une utilisation par des personnes

aux capacités physiques, sensorielles ou

intellectuelles réduites, y compris les enfants,

ni par des personnes manquant d’expérience

ou de connaissance de l’outil, à moins qu’ils

n’aient été formés et qu’ils soient supervisés

quant à l’utilisation sécurisée de l’outil par

une personne responsable de leur sécurité et

compétente en la matière.

Les enfants doivent être surveillés pour

s’assurer qu’ils n’ont pas accès à et ne sont pas

autorisés à jouer avec cet outil.

SECURITE ELECTRIQUE

Cet outil est équipé d’une prise moulé

et d’un câble d’alimentation adaptés au

marché désigné. Si le câble d’alimentation

est endommagé, il doit être remplacé par un

câble et un assemblage spécial disponible

auprès du fabricant ou de son distributeur.

UTILISATION EXTERIEURE

ATTENTION : Dans le cas où cet outil serait

utilisé en ex térieur et pour votre protection, il

ne doit pas être exposé à la pluie ni utilisé dans

un environnement humide. Ne placez pas l’outil

sur une surf ace humide. Utilisez si possible

un établi propre et sec. Pour une protection

supplémentaire, utilisez un disjonc teur

diérentiel qui coupera l’alimentation si la fuite

vers la terre dépasse 30mA p our 30ms. Vériez

toujours le bon fonctionnement du disjoncteur

diérentiel avant d’utiliser cet outil.

Si une rallonge est nécessaire, elle doit être

d’un modèle adapté pour une utilisation

extérieure et marquée comme telle. Les

instructions des fabricants doivent être

respectées lors de l’utilisation d’une rallonge.

INSTRUCTIONS GENERALES DE SECURITE

POUR LES OUTILS ELECTRIQUES

(Ces instructions générales de sécurité pour

outils électriques sont celles décrites dans les

documents BSEN60745-1:2009 &

EN 61029 -1:20 09)

ATTENTION : Lisez tous les aver tissements

et toutes les instructions de sécurité. Le

fait de ne pas suivre les avertissements et

les instructions de sécurité peut avoir pour

conséquence une décharge électrique, un

incendie et/ou des blessures graves.

Gardez tous les avertissements et toutes les

instructions de sécurité pour pouvoir vous y

reporter.

Le terme «Outil électrique» mentionné

dans les avertissements concerne vos outils

branchés sur secteur (câblés) ou fonctionnant

sur piles (non câblés).

1) Avertissements de sécurité générale

[Sécurité de la zone de travail]

a) Travaillez dans un espace de travail

propre et bien éclairé. Les zones de travail

encombrées ou sombres attirent les accidents.

b) N’utilisez pas d’outil électrique

dans un environnement explosif tel

qu’en présence de liquides, de gaz ou

de poussières inammables. Les outils

électriques sont susceptibles de créer

des étincelles qui peuvent enammer la

poussières ou les fumées.

c) Eloignez les enfants et les spectateurs

lors de l’utilisation d’un outil électrique.

Une distraction peut vous faire perdre le

contrôle de l’outil.

2) Avertissements de sécurité générale

[Sécurité électrique]

a) Les ches élec triques doivent

correspondre aux prises murales. Ne

modiez jamais la che en aucune façon.

N’utilisez pas d’adaptateur de prise avec des

outils mis à la terre. Des ches non modiées

sur des prises correspondantes minimisent les

risques de décharge électrique.

b) Evitez de toucher les su rfaces mises à la

terre, telles que les tuyaux, les radiateurs,

les cuisinières et les réfrigérateurs. Le

risque de décharge électrique augmente si

votre corps est relié à la terre.

c) N’exposez pas les outils élect riques à

la pluie ou à l’humidité. L’eau qui pénètre

dans un outil électrique augmente le risque

de décharge électrique.

d) Ne maltraitez pas le câble électrique.

N’utilisez jamais le câble électrique pour

transporter, tirer ou débrancher l’outil.

Eloignez le câble des sources de chaleur, des

graisses, des bords tranchants et des parties

mobiles. Un câble endommagé ou emmêlé

augmente le risque de décharge électrique.

e) Lors de l’utilisation d’un outil électrique

en extérieur, utilisez une rallonge adaptée

à une utilisation extérieure. L’utilisation

d’un câble adapté à une utilisation extérieure

diminue le risque de décharge électrique.

f) Lors de l’utilisation d’un outil

électrique dans un environnement

humide, si cela est inévitable, utilisez un

disjoncteur diérentiel. L’utilisation d’un

disjoncteur diérentiel réduit le risque de

décharge électrique.

EN

FR

IT

NL

28 29

Page 16

www.evolutionpowertools.com www.evolutionpowertools.com

3) Avertissements de sécurité générale

[Sécurité personnelle].

a) Restez éveillé, regardez ce que vous

faites et utilisez votre bon sens lors de

l’utilisation d’un outil électrique. N’utilisez

pas d’outil électrique lorsque vous êtes fatigué

ou sous l’inuence de drogues, d’alcool ou de

médicaments. Un moment d’inattention lors

de l’utilisation d’un outil électrique peut être la

cause de blessures graves.

b) Utilisez des équipements de

protection individuelle. Portez toujours

des lunettes de protection. Un équipement

de protection personnelle tel qu’un masque

anti poussières, des chaussures de sécurité

antidérapantes, un casque ou une protection

auditive utilisé dans les bonnes conditions

réduit les risques de blessures.

c) Evitez les démarrages intempestifs.

Assurez-vous que l’interrupteur est bien sur

la position arrêt avant de brancher l’outil

au secteur et/ou à une batterie, et avant de

soulever ou de transporter l’outil. Le fait de

porter l’outil avec un doigt sur l’interrupteur

ou de brancher un outil électrique dont

l’interrupteur est sur la position marche est

susceptible de provoquer des accidents.

d) Retirez toutes les clés et clés de

réglage avant d’allumer l’outil électrique.

Une clé ou une clé de réglage xée à une

partie mobile d’un outil électrique peut être

la cause de blessures.

e) Ne vous penchez pas trop. G ardez

une bonne position des pieds et un bon

équilibre à tout moment. Ceci permet un

meilleur contrôle de l’outil électrique en cas

de situation inattendue.

f) Portez des vêtements adaptés. Ne

portez pas de vêtements lâches ni de bijoux.

Eloignez vos cheveux, vos vêtements et vos

gants des par ties mobiles. Les vêtements

lâches, les bijoux et les cheveux longs

peuvent être pris dans les parties mobiles.

g)Si des équ ipements so nt fournis pour

le branchement de systèmes d›extraction

et de ramassage des poussières, faites

en sorte qu›ils soient branchés et utilisés

correctement. L’utilisation de collec teurs de

poussières réduit les risques liés aux poussières.

4) Avertissements de sécurité générale

[Utilisation et soin de l’outil électrique].

a) Ne forcez pas l’outil électrique. Utilisez

l’outil électrique adapté à votre utilisation.

L’outil électrique adapté fera un meilleur travail

dans de meilleures conditions de sécurité à la

puissance pour laquelle il a été conçu.

b) N’utilisez pas l’outil électrique si

l’interrupteur ne l’allume ou ne l’éteint

pas. Tout outil électrique qui ne peut être

contrôlé au niveau de l’interrupteur est

dangereux et doit être réparé.

c) Débranchez l’outil électrique

du secteur ou de la batte rie avant

d’effectuer un réglage, de changer un

accessoire ou de ranger l’outil. De telles

mesures de sécurité préventives réduisent le

risque d›un démarrage intempestif de l›outil.

d) Rangez les outils électriques que vous

n’utilisez pas hors de portée des enfants

et ne permettez pas aux personnes qui

ne sont pas familiarisées avec ces outils

de les utiliser. Les outils électriques sont des

outils dangereux entre les mains d’utilisateurs

non avertis.

e) Prenez s oin de vos outils é lectrique s.

Vériez les alignements des parties mobiles, le

fait qu’elles ne soient pas cassées et toute autre

situation qui p ourrait en altérer l’utilisation. En

cas de dégâts, faites réparer l’outil électrique

avant de l’utiliser. De nombreux accidents sont

causés par de s outils électriques mal entretenus.

f) Maintenez les outils de coupe propres

et bien aiguisés. Des outils de coupe bien

entretenus et bien aiguisés sont moins

susceptibles de se tordre et sont plus

faciles à contrôler.

g) Utilisez l’outil électrique, les accessoires

et les él éments de l’outi l en respect ant ces

instructions d’utilisation et en prenant

en considération les conditions de travail

ainsi que le travail à eectuer. Le fait

d’utiliser un outil électrique dans un cadre pour

lequel il n’a pas été conçu pourrait avoir pour

conséquence une situation dangereuse.

5) Avertissements de sécurité générale

[Entretien]

a) Faites entretenir votre outil électrique

par un réparateur qualié et n’utilisez que

des pièces identiques aux pièces d’origine.

Ceci garantira que l’outil électrique est

correctement entretenu.

CONSEILS CONCERNANT LA SANTE

ATTENTION : Lorsque vous utilisez cet

outil, des particules de poussières peuvent

être éjectées. Dans certains cas et selon les

matériaux que vous utilisez, cette poussière

peut être particulièrement dangereuse. Si

vous suspectez que la peinture présente sur

les surfaces des murs de votre maison contient

du plomb, demandez l’avis d’un professionnel.

Les peintures à base de plomb ne doivent être

retirées que par un professionnel et vous ne

devez pas essayer de les retirer vous-mêmes.

Une fois la poussière déposée sur les surfaces,

un contact entre les mains et la bouche peut

résulter en une ingestion de plomb. Une

exposition au plomb, même à faible taux,

peut être la cause de dommages irréversibles

au cerveau et au système nerveux. Les

enfants en bas âge et les enfants à naître y

sont particulièrement sensibles.

ATTENTION : L’utilisation d’un outil électrique

quel qu’il soit peut provoquer la projection

de corps étrangers vers vos yeux. Avant de

commencer à utiliser un outil électrique,

assurez-vous que vous por tez bien des lunettes

de protection équipées de protections latérales

ou un casque intégral si nécessaire.

CONSEI LS SUPPLEMEN TAIRES D E SÉCURITE

Etant donné que certains matériaux p euvent

produire des poussières dangereuses pour

votre santé, nous vous recommandons d’utiliser

un masque facial agréé équipé de ltres

remplaçables lorsque vous utilisez cet outil.

Vous devez toujours:

• Travailler dans un endroit bien aéré.

• Travailler avec un équipement de sécurité

agréé tel qu’un masque anti poussières

conçu spécialement pour ltrer les

particules microscopiques.

a) DANGER: El oignez vos mai ns de la zone

de coup e et de la lame. Gardez votre deuxième

main sur la poig née auxiliaire ou sur le carter du

moteur. Si les deux mains tiennent la scie, elles n e

peuvent pas ê tre coupées par la lame.

b) Ne vous pen chez pas sous l a pièce à

usiner. La protection ne p eut pas vous protéger

de la lame en dessous de la piè ce à usiner.

c) Ajustez la profondeur de coupe à

l’épaisseur de la pièce à usiner. Moins

d’une dent entière de la lame doit apparaître

sous la pièce à usiner.

d) Ne tene z jamais la piè ce que vous êtes en

tarin de c ouper avec vos main s ou entre vos

jambes. Sécurisez la pièce sur une plateforme

stable. Il est impor tant de bien soutenir la pièce

pour minimiser les risques corporels, de blocage

de la lame ou de perte de contrôle.

e) Tenez l’outil électrique par ses surfaces

de prise isolées lorsque vous réalisez

une opération pendant laquelle l’outil

de coupe peut entrer en contact avec un

câble électrique caché ou avec son propre

câble. Un contact avec un câble alimenté

alimentera également les parties métalliques

exposées de l’outil électrique et peut

provoquer une décharge pour l’utilisateur.

f) Lors du déplacement de l’outil, utilisez

toujours un guide à refendre ou une

règle. Ceci améliore la précision de la coupe

et limite les risques de blocage de la lame.

g) Utilisez toujours des lames de la

bonne dimension et de la bonne forme

d’alésage (diamant ou rond). Les lames

qui ne correspondent pas à l’équipement sur

lequel elles sont montées tourneront de façon

excentrée, conduisant à une perte de contrôle.

h) N’utilisez jamais de joints ou de boulons

endommagés ou inadaptés. Les joints et les

boulons de la lame ont été spécialement conçus

pour votre scie, an d’assurer des p erformances

et une sécurité optimales.

EN

FR

IT

NL

30 31

Page 17

www.evolutionpowertools.com www.evolutionpowertools.com

i) N’utilisez pas de lame pour acier rapide.

j) Inspectez la machine et la lame avant

chaque utilisation. N’utilisez pas de lames

déformées, fêlées, usées ou endommagées

d’une façon quelconque.

k) N’utilisez jamais la scie sans son

système de protection d’origine. Ne

bloquez pas la protection mobile en position

ouverte. Assurez-vous que la protection

fonctionne librement sans se bloquer.

l) N’utilisez que des lames dont les

spécications correspondent à celles

indiquées dans ce manuel. Avant d’utiliser

des accessoires, comparez toujours le nombre

de tours minute maximum autorisé pour

l’accessoire et pour l’outil.

Causes et prévention des retours de lame

par l’utilisateur :

Un retour de lame est une réaction soudaine

au pincement, au blocage ou au mauvais

alignement de la lame, provoquant un bond

non contrôlé de la scie hors de la pièce à

usiner et en direction de l’utilisateur.

1. Lorsque la lame est pincée ou bloquée par

la fermeture de la saignée, la lame cale et la

réaction du moteur renvoie rapidement l’outil

en direction de l’utilisateur;

2. Si la lame se tord ou perd son alignement

avec la saignée, les dents qui se situent au

dos de la lame peuvent creuser la partie

supérieure de la pièce à usiner et provoquer

le saut de la lame hors de la saignée en

direction de l’utilisateur.

Le retour de lame est la conséquence d’une

mauvaise utilisation de la scie et/ou d’une

mauvaise procédure d’utilisation et/ou

de mauvaises conditions d’utilisation et

peut être évité en prenant les précautions

nécessaires décrites ci-dessous:

a) Maintenez une bonne prise des deux

mains sur la scie et positionnez vos bras

pour pouvoir résister à la force d ’un

retour de lame. Positionnez votre corps des

deux côtés de la lame et non en alignement

avec la lame. Un retour de lame peut

provoquer un saut de la lame vers l’arrière,

mais les forces en présence dans un retour de

lame peuvent être maitrisées par l’utilisateur

si les bonnes précautions sont prises.

b) En cas de bl ocage de la lame, ou lors

de l’arrêt d’une coupe pour une raison

quelconque, relâchez la gâchette et ne

bougez pas la lame dans le m atériau avant

que la lame ne soit complètement arrêtée.

Ne tentez jamais de retirer la lame de la pièce à

usiner ou de tirez la lame vers l’arrière lorsque

la lame est en mouvement ou qu’elle n’est pas

engagée dans le matériau, un retour de lame

pourrait intervenir. Recherchez et éliminez la

cause du blocage de la lame.

c) Lors du redémarrage de la scie dans

la pièc e à usiner, centre z la lame dans la

saign ée et vériez que l es dents de la sc ie

ne sont pa s engagées dan s le matériau. Si la

lame de la scie se bloque, elle peut ressortir de

la pièce à usiner lors du redémarrage de la scie.

d) Soutenez les grands panneaux pour

limiter le risque de pincement de la lame

et de retour de lame. Les grands panneaux

ont tendance à plier sous leur propre poids.

Un support doit être placé des deux côtés

sous le panneau, près de la ligne de coupe, et

proche du bord du panneau.

e) Les leviers de réglage de profondeur

de lame et de biseau doivent être serrés

et bloqués avant de réaliser une coupe. Si

les réglages de la lame changent pendant une

coupe, la lame peut se bloquer et un retour

de lame peut se produire.

f) N’utilisez pas de lames émoussées ou

endommagées. Les lames mal aiguisées

ou en mauvais état produisent une saignée

étroite résultant en une friction excessive, en

un blocage de la lame et en un retour de lame.

g) Faites particulièrement attention

lorsque vous réalisez une saignée dans un

mur ou dan s un endroit aveug le. La partie

de la lame qui dépasse peut couper des objets

qui peuvent causer des retours de lame.

h) Vériez que la protection inférieure

est bien fermée avant chaque utilisation.

N’utilisez pas la scie si la prote ction inférieure

ne fonctionne pas lib rement et ne se ferme

pas instant anément. Ne bloque z ou n’attac hez

jamais le protection inférieure en position

ouverte. Si la scie tombe accidentellement,

la protection inférieure peut être tordue.

Soulevez la protection inférieure avec la poignée

rétract able et assurez-vous qu’elle b ouge

librement et ne touche pas la lame ou une

autre par tie de l’outil, quels que soit l ’angle u la

profondeur de coupe.

l) Vériez le fonctionnement du

ressort de la protection inférieure. Si la

protection et le ressort ne fonctionnent pas

correctement, ils doivent être révisées avant

utilisation. La protection inférieure peut être

molle en raison d’éléments endommagés, de

dépôts collants ou d’un bourrage de débris.

k) La protection inférieure ne peut être

rétractée manuellement que dans le cas

de coupes spéciales telles que les coupes

«en plongée» ou les coupes «combinées».

Soulevez la protection inférieure en rétractant

la poignée et, dès que la scie pénètre dans le

matériau, relâchez la protection. Pour toutes

les autres coupes, la protection inférieure doit

fonctionner automatiquement.

l) Vériez toujours que la protection

inférieure recouvre bien la lame avant de

placer la scie sur l’établi ou sur le sol. Une

lame non protégée et en roue libre déplacera

la scie vers l’arrière, coupant tout sur son

passage. Prenez conscience du temps d’arrêt

complet de la lame après que le bouton de

marche ait été relâché.

ATTENTION : Si un élément est manquant

, n’utilisez pas l’outil avant que les éléments

manquants aient été remplacés. Ne pas

suivre cette instruction pourrait résulter en

blessures graves.

DEMARRAGE – DEBALLAGE

Attention: Ce colis contient des objets

coupants. Faites attention lors du déballage.

Retirez l’outil et les accessoires fournis dans

le colis. Vériez soigneusement que l’outil

est en bon état et vériez l’état de tous les

accessoires listés dans ce manuel. Vériez

également qu’ils sont tous bien présents.

Si un ou plusieurs éléments sont manquants,

l’outil est ses accessoires doivent être renvoyés

au fournisseur dans leur carton d’origine.

Ne jetez pas le carton, gardez le à l’abri

pendant toute la période de garantie. Jetez le

carton en respectant l’environnement.

Recyclez si possible.

Ne laissez pas les enfants jouer avec les sacs

en plastique vides pour éviter les risques

d’asphyxie.

ELEMENTS FOURNIS

Description Quantité

Manuel d’utilisation 1

Lame multi-usages

(Montée)

Clé anglaise

(changement de lame)

Echappement de l’orifice

d’évacuation

Guide de bord parallèle 1

Valise transport 1

ACCESSOIRES SUPPLÉMENTAIRES

En plus des éléments standards fournis

avec cet outil, les accessoires suivants sont

disponibles auprès de la boutique en ligne

d’Evolution à l’adresse suivante:

www.evolutionpowertools.com ou auprès de

votre distributeur.

Description Pièce No

Lame multi-usages RAGE

Lame diamant DIAMOND

1

1

1

185

185

EN

FR

IT

NL

32 33

Page 18

www.evolutionpowertools.com www.evolutionpowertools.com

DESCRIPTION DE L’APPAREIL

1

3

4

DEMARRAGE - PRE PARATION

ATTENTION : Débranchez toujours l’outil du secteur avant

d’eectuer un réglage.

ATTENTION : Ne démarrez jamais la scie avec le bord de

coupe de la scie en contact direct avec la surface de la pièce

à usiner. Ne rentrez pas la protection de lame à la main.

La protection se rétracte automatiquement. Cette scie est

équipée d’un câble d’alimentation et d’une prise homologués

dans le pays d’utilisation. Ne changez pas ou ne modiez pas

le câble d’alimentation.

INSTALLATION ou R ETRAIT D’UNE LAME.

ATTENTION : N’utilisez que des lames Evolution d’origine

ou des lames approuvées par Evolution et conçues pour

cet outil. Assurez-vous que la vitesse maximum de la lame

est compatible avec celle de l’outil. Ne réalisez cette opération

2

5

qu’une fois l’outil débranché du secteur.

Note: Le port de gants protecteurs est recommandé lors

de la manutention de la lame et pendant l’installation ou le

changement de lame.

1) Placez la scie sur une surface plate et stable.

2) Retirez de l’outil le collecteur de poussières en desserrant les

(2) deux gros écrous moletés. (Fig. 1).

Fig. 1

Fig. 2

EN

FR

1. INTERRUPTEUR MARCHE/ARRÊT

2. POIGNÉE AVANT AUXILIAIRE

3. ORIFICE D’EVACUATION

4. PROTECTION INFERIEURE DE LAME

5. LAME EN PLACE

Note: Les écrous moletés sont captifs et ne peuvent être

retirés de l’outil.

3) Bloquez le mandrin en embrayant le verrou de mandrin.

(Fig. 2)

4) Avec la clé hexagonale fournie, desserrez et retirez la vis à

tête creuse du mandrin et l’embase extérieure de l’arbre de la

lame. (Fig. 3)

5) Retirez la lame de la scie.

6) Nettoyez soigneusement les embases intérieures et

extérieures de lame ainsi que les surfaces de montage de la

lame avant d’installer une nouvelle lame.

7) Assurez-vous que la direction des èches de rotation

imprimées sur la lame correspond au sens de rotation des èches

qui se trouvent sur le collec teur de poussières. (Fig. 4)

8) Réinstallez l’embase extérieure et la vis de mandrin.

9) Embrayez le verrou de mandrin et resserrez la vis à tête

creuse avec la clé hexagonale.

34 35

Fig. 3

Fig. 4

IT

NL

Page 19

www.evolutionpowertools.com www.evolutionpowertools.com

Fig. 5

Fig. 6

Fig. 7

Note : La vis à tête creuse du mandrin est letée à droite.

10) Replacez le collecteur de poussières et resserrez

fermement les deux écrous moletés.

11) Vériez que le verrou du mandrin est bien libéré en faisant

tourner la lame à la main.

12) Vériez le bon fonctionnement de la protection.

Guide de bordure parallèle

Un guide parallèle (pour les coupes en long) peut être xé sur

le sabot de l’outil. Les bras du guide doivent être insérés dans

les fentes rectangulaires qui se trouvent sous le sabot et glissés

sous les vis de xation. (Fig. 5)

Note: Le guide parallèle peut être xé des deux côtés du

sabot et ne doivent être xés et réglés que lorsque l’outil est

débranché du secteur.

Ajustez le guide parallèle à la bonne distance de la lame et

resserrez les deux écrous moletés. Vériez que le guide est

parallèle à la lame de la scie.

Réglage de la profondeur de coupe.

Relâchez le verrou de levier pour ajuster la lame à la

profondeur de coupe désirée. Ajuster la profondeur de coupe à

l’épaisseur de la pièce à usiner. Moins d’une pleine dent des dents

de la lame soit visible sous la pièce. Resserrez le verrou de levier

fermement pour le bloquer dans la position requise. (Fig. 6)

Réglage de l’angle de coupe

• Desserrez la vis de blocage du biseau située à l’avant de

l’outil.

• Desserrez la vis de blocage arrière du biseau située à

l’arrière du sabot.

• Basculez la lame à l’angle désiré (Fig. 7).

• Resserrez les deux vis de blocage fermement.

Note: Un rapporteur (0° à 45°) est incorporé au quadrant de

blocage du biseau pour permettre un bon réglage.

CONSEILS D’UTILISATION

Faites des vérications de routine de sécurité à chaque fois

que vous utilisez l’outil. Vériez que toutes les protections

fonctionnent correctement et que toutes les poignées de

réglage ainsi que toutes les vis sont serrées correctement.

Vériez que la lame est bien xée et installée correctement.

Vériez également que vous utilisez une lame adaptée au

matériau que vous coupez.

Vériez l’état du cordon d’alimentation.

Fixez toujours la pièce à usiner sur un support rigide tel qu’un

établi ou un tréteau.

Interrupteur Marche/Arrêt (Fig. 10)

Cet outil est équipé d’un interrupteur de sécurité.

Pour démarrer l’outil:

• Poussez l’interrupteur de sécurité situé sur le côté de l’outil

avec votre pouce.

• Appuyez sur l’interrupteur principal pour lancer le moteur.

(Fig. 8)

Collecteur de poussière

Cet outil est équipé d’un collecteur de poussière qui récupère

les copeaux de métal. La plaque supérieure du collecteur est

équipée d’une fenêtre transparente qui permet à l’utilisateur

d’en vérier le remplissage et de le vider lorsque nécessaire.

Pour retirer et vider le collecteur:

• Desserrez les deux écrous moletés du collecteur.

• Séparez le collecteur de l’outil.

• Videz le collecteur en le retournant au- dessus d’un conteneur

à déchets approprié pour faire tomber les copeaux.

Note: Pour lui garder toute son ecacité, nous recommandons

de vider le collecteur lorsqu’il est plein à environ 60%. Jetez les

déchets du collecteur de façon responsable.

• Replacez le collecteur et resserrez fermement les deux (2)

écrous moletés.

Orice d’évacuation

Lors de la coupe de bois, l’échappement de l’orice d’évacuation

doit être monté sur l’échappement du collecteur de copeaux.

EN

Fig. 8

FR

IT

NL

36 37

Page 20

www.evolutionpowertools.com www.evolutionpowertools.com

Fig. 9

Pour monter l’échappement de l’orice d’évacuation:

• Retirez le couvercle de l’orice d’évacuation en dévissant la

vis cruciforme.

• Tirez le couvercle de l’orice d’évacuation et rangez-le

soigneusement pour une future utilisation.

• Montez l’échappement de l’orice d’évacuation à la place du

couvercle (Fig. 9). Les copeaux de bois seront é jectés à travers

l’échappeme nt de l’orice d’évacuation lors de la coupe.

Lorsque la coupe est terminée, retirez l’échappement et