Page 1

Original Instructions

Originalanweisungen

RAGE7-S 230V UK (075-0002)

RAGE7-S 230V EU (075-0003)

RAGE7-S 120V US (075-0004)

RAGE7-S BLADES (075-0200)

Originally written in UK English Date Published: 01/03/2016

Page 2

www.evolutionpowertools.com

TABLE OF CONTENTS

English Page 2

Deutsch Seite 20

INTRODUCTION

Important information Page 3

Guarantee Page 3

Jigsaw Specification Page 4

Labels and Symbols Page 5

Vibration Page 5

Intended use of this Power Tool Page 5

Prohibited use of this Power Tool Page 5

SAFETY PRECAUTIONS

Outdoor Use Page 6

General Power Tool Safety Instructions Page 6

Additional Safety Instructions Page 8

Items Supplied Page 9

GETTING STARTED

Machine Overview Page 10

Operating Instructions Page 11

Installing Or Removing A Blade Page 11

On/O Trigger Switch Page 11

Trigger Switch Locking Button Page 12

Cutting Action Selection Switch Page 12

Laser Cutting Guide Page 13

Footplate Angle Adjustment Page 13

Chip Guards Page 14

Parallel Edge Guide Page 15

Air Blower Page 15

Dust Extraction Page 15

Cutting Advice Page 16

MAINTENANCE

Maintenance Page 17

Environmental Protection Page 17

DECLARATION OF CONFORMITY Page 18

2

Page 3

www.evolutionpowertools.com

IMPORTANT

Please read these operating and safety

instructions carefully and completely.

For your own safety, if you are uncertain

about any aspect of using this equipment

please access the relevant Technical Helpline,

the number of which can be found on the

Evolution Power Tools website. We operate

several Helplines throughout our worldwide

organization, but technical help is also

available from your supplier.

WEBSITE

www.evolutionpowertools.com

Congratulations on your purchase of an

Evolution Power Tools Machine. Please

complete your product registration ‘online’

as explained in the A5 online guarantee

registration leaet included with this

machine.

You can also scan the QR code found on

the A5 leaet with a Smart Phone. This

will enable you to validate your machine’s

guarantee period via Evolution’s website by

entering your details and thus ensure prompt

service if ever needed. We sincerely thank you

for selecting a product from Evolution.

EVOLUTION LIMITED GUARANTEE

Evolution Power Tools reserves the right to

make improvements and modications to the

product design without prior notice.

Manual or if the machine has been damaged

by accident, neglect, or improper service. This

guarantee does not apply to machines and

/ or components which have been altered,

changed, or modied in any way, or subjected

to use beyond recommended capacities

and specications. Electrical components

are subject to respective manufacturers’

warranties. All goods returned defective shall

be returned prepaid freight to Evolution Power

Tools. Evolution Power Tools reserves the right

to optionally repair or replace it with the same

or equivalent item. There is no warranty –

written or verbal – for consumable accessories

such as (following list not exhaustive) blades,

cutters, drills, chisels or paddles etc. In no

event shall Evolution Power Tools be liable for

loss or damage resulting directly or indirectly

from the use of our merchandise or from

any other cause. Evolution Power Tools is

not liable for any costs incurred on such

goods or consequential damages. No ocer,

employee or agent of Evolution Power Tools

is authorized to make oral representations of

tness or to waive any of the foregoing terms

of sale and none shall be binding on Evolution

Power Tools.

Questions relating to this limited guarantee

should be directed to the company’s head

oce, or call the appropriate Helpline

number.

Please refer to the guarantee registration leaet

and/or the packaging for details of the terms,

conditions and period of the guarantee.

Evolution Power Tools will, within the

guarantee period, and from the original

date of purchase, repair or replace any

goods found to be defective in materials or

workmanship. This guarantee is void if the

tool being returned has been used beyond

the recommendations in the Instruction

3

Page 4

www.evolutionpowertools.com

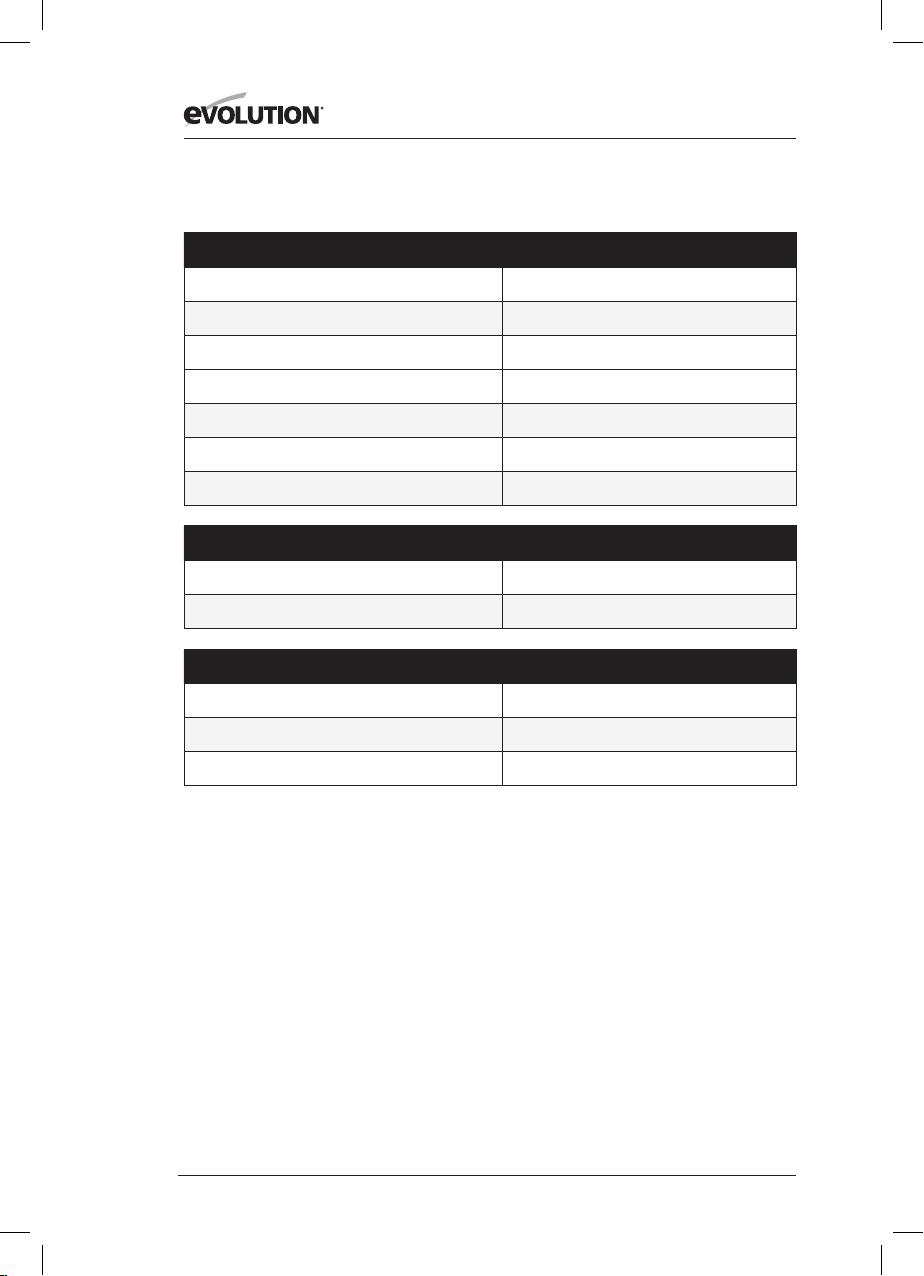

JIGSAW SPECIFICATIONS

MACHINE SPECIFICATIONS

Motor 230V ~ 50Hz 710W (6A)

Motor 110V ~ 60Hz 600 (5.2A

RPM No Load 0 - 3000min

Recommended Max Duty Cycle 30mins

Stroke Length 26mm

Insulation Class II

Weight (Gross) 4.1kg (9lbs)

CUTTING CAPACITIES

Wood 80mm

Metal 8mm

NOISE & VIBRATION DATA

Sound Pressure LPA 87dB(A) K=3dB(A)

-1

(rpm)

Sound Power Level LWA 98dB(A) K=3dB(A)

Vibration Level 3:129 m/s2 K=1.5m/s

4

2

Page 5

www.evolutionpowertools.com

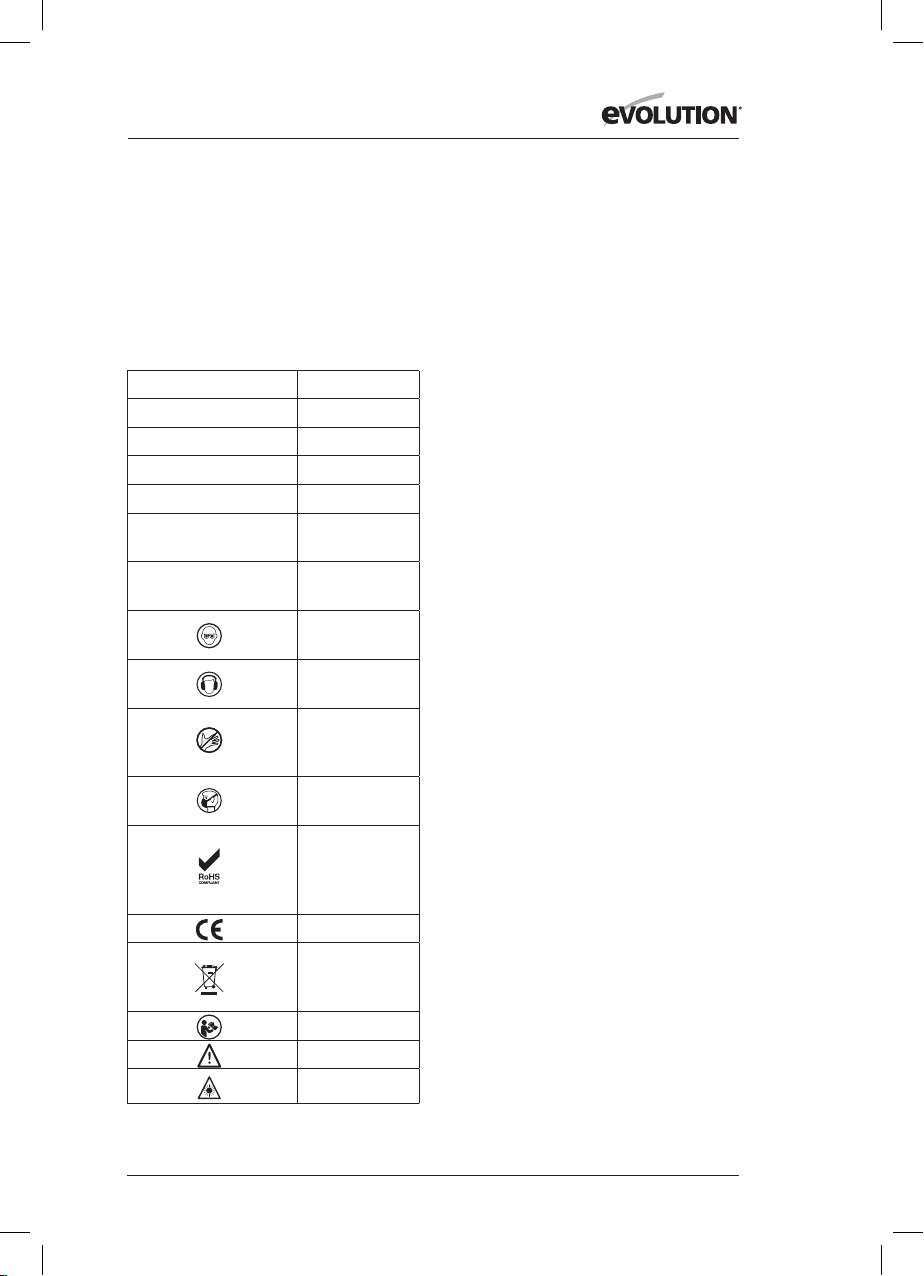

LABELS & SYMBOLS

WARNING: Do not operate machine if warning

and/or instruction labels are missing or

damaged. Contact Evolution Power Tools or

your supplier for replacement labels.

Note: All or some of the following symbols

may appear in the manual or on the product.

Symbol Description

V Volts

A Amperes

Hz Hertz

-1

Min

Speed

~ Alternating

Current

n

o

No Load

Speed

Wear Safety

Goggles

Wear Ear

Protection

Do Not Touch

Keep Hands

Away

Wear Dust

Protection

Restriction

of Hazardous

Substances

Directive

CE certification

Waste Electrical

& Electronic

Equipment

Read Manual

Warning

Laser Warning

VIBRATION

Note: The vibration measurement was made

under standard conditions in accordance with:

BS EN 610291.2009.

WARNING: The vibration emission during

actual use of the power tool can dier from the

declared total value depending on the ways

in which the tool is used. The need to identify

safety measures and to protect the operator

are based on an estimation of exposure in the

actual conditions of use (taking account of all

parts of the operating cycle, such as the times

the tool is switched o, when it is running idle,

in addition to trigger time)

INTENDED USE OF THIS POWER TOOL

WARNING: This product is a Multipurpose

Jigsaw and has been designed to be used with

special Evolution multipurpose blades. Only

use blades designed for use in this machine

and/or those recommended specically by

Evolution Power Tools Ltd.

When tted with a correct blade

this machine can be used to cut:

• Wood

• Wood Derived Products

(MDF, Chipboard, Plywood,

Blockboard, Hardboard. etc)

• Aluminium

• Mild Steel

PROHIBITED USE OF THIS POWER TOOL

WARNING: This product is a Multipurpose

Jigsaw and must only be used as such. It

must not be modied in any way, or used to

power any other equipment or drive any other

accessories other than those mentioned in this

Instruction Manual.

5

Page 6

www.evolutionpowertools.com

WARNING: This machine is not intended

for use by persons (including children)

with reduced physical, sensory or mental

capabilities, or lack of experience and

knowledge, unless they have been given

supervision or instruction concerning the safe

use of the machine by a person responsible for

their safety.

Children should be supervised to ensure

that they do not have access to, and are not

allowed to play with, this machine.

OUTDOOR USE

WARNING: For your protection if this tool is to

be used outdoors it should not be exposed to

rain, or used in damp locations. Do not place

the tool on damp surfaces. Use a clean, dry

workbench if available. For added protection

use a residual current device (R.C.D.) that will

interrupt the supply if the leakage current to

earth exceeds 30mA for 30ms. Always check

the operation of the residual current device

(R.C.D.) before using the machine.

If an extension cable is required it must be a

suitable type for use outdoors and so labelled.

The manufacturers instructions should be

followed when using an extension cable.

POWER TOOL GENERAL

SAFETY INSTRUCTIONS

(These General Power Tool Safety Instructions

are as specied in BS EN 60745-1:2009 & EN

61029-1:2009)

WARNING:

Read all safety warnings and instructions.

Failure to follow the warnings and instructions

may result in electric shock, re and/ or serious

injury.

Save all warnings and

instructions for future reference.

The term “power tool” in the warnings refers to

your mains-operated (corded) power tool or

battery-operated (cordless) power tool.

1) General Power Tool Safety Warnings

[Work area safety]

a) Keep work area clean and well lit.

Cluttered or dark areas invite accidents.

b) Do not operate power tools in explosive

atmospheres, such as in the presence of

ammable liquids, gasses or dust. Power tools

create sparks which may ignite the dust or fumes.

c) Keep children & bystanders away while

operating power tool. Distractions can cause

you to lose control.

2) General Power Tool Safety Warnings

[Electrical Safety]

a) Power tool plugs must match the outlet.

Never modify the plug in any way. Do

not use any adapter plugs with earthed

(grounded) power tools. Unmodied plugs

and matching outlets will reduce the risk of

electric shock.

b) Avoid body contact with earthed or

grounded surfaces, such as pipes, radiators,

ranges and refrigerators. There is an increased

risk of electric shock if your body is earthed or

grounded.

c) Do not expose power tools to rain or wet

conditions. Water entering a power tool will

increase the risk of electric shock.

d) Do not abuse the cord. Never use the

cord for carrying, pulling or unplugging the

power tool. Keep cord away from heat, oil,

sharp edges or moving parts. Damaged or

entangled cords increase the risk of electric shock.

e) When operating a power tool outdoors,

use an extension cord suitable for outdoor

use. Use of a cord suitable for outdoor use reduces

the risk of electric shock.

f) If operating a power tool in a damp

location is unavoidable, use a residual

current device (RCD) protected supply. Use

of an RCD reduces the risk of electric shock.

3) General Power Tool Safety Warnings

[Personal Safety].

a) Stay alert, watch what you are doing

and use common sense when operating a

power tool. Do not use a power tool while

you are tired or under the inuence of

6

Page 7

www.evolutionpowertools.com

drugs, alcohol or medication. A moment of

inattention while operating power tools may

result in serious personal injury.

b) Use personal protective equipment. Always

wear eye protection. Protective equipment such

as dust masks, non-skid safety shoes, hard hat or

hearing protection used for appropriate conditions

will reduce personal injuries.

c) Prevent unintentional starting. Ensure

the switch is in the o-position before

connecting to power source and or battery

pack, picking up or carrying the tool.

Carrying power tools with your nger on the

switch or energising the power tools that have

the switch on invites accidents.

d) Remove any adjusting key or wrench

before turning the power tool on. A wrench

or key left attached to a rotating part of a power

tool may result in personal injury.

e) Do not overreach. Keep proper footing

and balance at all times. This enables better

control of the power tool in unexpected situations.

f) Dress properly. Do not wear loose

clothing or jewellery. Keep your hair,

clothing and gloves away from moving

parts. Loose clothes, jewellery or long hair can

be caught in moving parts.

g) If devices are provided for the connection

of dust extraction and collection facilities,

ensure that these are connected and

properly used. Use of dust collection can

reduce dust-related hazards.

4) General Power Tool Safety Warnings

[Power tool use and care].

a) Do not force the power tool. Use the

correct power tool for your application. The

correct power tool will do the job better and safer

at a rate for which it was designed.

b) Do not use the power tool if the switch

does not turn it on or o. Any power tool

that cannot be controlled with the switch is

dangerous and must be repaired.

c) Disconnect the power tool from the

power source and/or battery pack from the

power tool before making any adjustments,

changing accessories, or storing power

tools. Such preventative safety measures reduce

the risk of starting the power tool accidentally.

d) Store idle power tools out of the reach

of children and do not allow persons

unfamiliar with the power tool or these

Instructions to operate the power tool.

Power tools are dangerous in the hands of

untrained users.

e) Maintain power tools. Check for

misalignment or binding of moving parts,

breakage of moving parts and any other

condition that may aect the power tools

operation. If damaged, have the power

tool repaired before use. Many accidents are

caused by poorly maintained power tools.

f) Keep cutting tools sharp and clean.

Properly maintained cutting tools with sharp

cutting edges are less likely to bind and are easier

to control.

g) Use the power tool, accessories and

tool bits etc. in accordance with these

instructions, taking into account the

working conditions and the work to be

performed. Use of the power tool for operations

dierent from those intended could result in a

hazardous situation.

5) General Power Tool Safety Warnings

[Service]

a) Have your power tool serviced by a

qualied repair person using only identical

replacement parts. This will ensure that the

safety of the power tool is maintained.

HEALTH ADVICE

WARNING: When drilling, sanding, sawing or

grinding, dust particles will be produced. In

some instances, depending on the materials

you are working with, this dust can be

particularly harmful to you (e.g. lead from

old gloss paint).You are advised to consider

the risks associated with the materials you

are working with and to reduce the risk

of exposure. Some wood and wood type

products, especially MDF (Medium Density

Fibreboard), can produce dust that may be

hazardous to your health. We recommend the

7

Page 8

www.evolutionpowertools.com

use of an approved face mask with replaceable

lters when using this machine, in addition to

using the dust extraction facility.

You should always:

• Work in a well-ventilated area.

• Work with approved safety equipment,

such as dust masks that are specially

designed to lter microscopic particles.

WARNING: If you suspect that paint on

surfaces in your home contains lead, seek

professional advice. Lead based paints

should only be removed by a professional

and you should not attempt to remove it

yourself. Once the dust has been deposited

on surfaces, hand to mouth contact can result

in the ingestion of lead. Exposure to even

low levels of lead can cause irreversible brain

and nervous system damage. The young and

unborn children are particularly vulnerable.

ADDITIONAL SAFETY RULES FOR YOUR

EVOLUTION JIGSAW

1. Do not expose to rain or water.

2. Wear hearing protection when necessary.

Exposure to noise can cause hearing loss.

3. Cutting/scraping blades and accessories

can become very hot. Take care when

changing or handling any bits or accessories.

4. Hold the tool by the insulated gripping

surfaces, especially when performing an

operation where the blade may contact

hidden wiring. If the blade contacts a ‘live’

wire, exposed metal parts of the power tool

could become ‘live’ and give the operator an

electric shock.

5. If possible, use clamps or a vice to hold

your work.

6. When cutting into walls, oors or similar

areas, make sure, as far as possible, that

there are no services (gas or water pipes,

electric cables etc) in the path of the blade.

Striking hidden services could cause injury to

the user and damage to the property.

7. Always disconnect the jigsaw from the

power supply before changing the blade.

Never use damaged or distorted blades.

8. Always allow the saw to come to a

complete halt before putting it down. A

running tool may bounce uncontrollably if the

blade tip contacts any surface.

9. Always consider the work environment

and wear the appropriate personal

protection equipment. This could include dust

masks, eye protection, safety footwear etc.

WARNING: the operation of any power tool

can result in foreign objects being thrown

towards your eyes, which could result in

severe eye damage. Before beginning power

tool operation, always wear safety goggles

or safety glasses with side shield or a full face

shield where needed.

WARNING: If any parts are missing, do not

operate your machine until the missing parts

are replaced. Failure to follow this rule could

result in serious personal injury.

VIBRATION

WARNING: When using this machine the

operator can be exposed to high levels of

vibration transmitted to the hand and arm. It

is possible that the operator could develop

“Vibration white nger disease” (Raynaud

syndrome). This condition can reduce the

sensitivity of the hand to temperature as well

as producing general numbness. Prolonged

or regular users of sanding machines should

monitor the condition of their hands and

ngers closely. If any of the symptoms become

evident, seek immediate medical advice.

• The measurement and assessment of

human exposure to hand-transmitted

vibration in the workplace is given in: BS

EN ISO 5349-1:2001 and BS EN ISO 53492:2002.

• Many factors can inuence the actual

vibration level during operation e.g. the

work surfaces condition and orientation

8

Page 9

www.evolutionpowertools.com

and the type and condition of the saw blade

being used. Before each use, such factors

should be assessed, and where possible

appropriate working practices adopted.

Managing these factors can help reduce the

eects of vibration:

HANDLING

• Handle the machine with care, allowing the

machine to do the work.

• Avoid using excessive physical eort on any

of the machines controls.

• Consider your security and stability, and the

orientation of the machine during use.

WORK SURFACE

• Consider the work surface material; its

condition, density, strength, rigidity and

orientation.

ITEMS SUPPLIED

Description Quantity

Instruction Manual 1

Hex Key 4mm 1

Footplate Shoe 1

Jigsaw Blades 1 Pack

Parallel Edge Guide 1

Dust Extraction Adaptor 1

Chip Guard (Front) 1

Chip Guard (Footplate) 1

Batteries ‘AAA’ 2

9

Page 10

www.evolutionpowertools.com

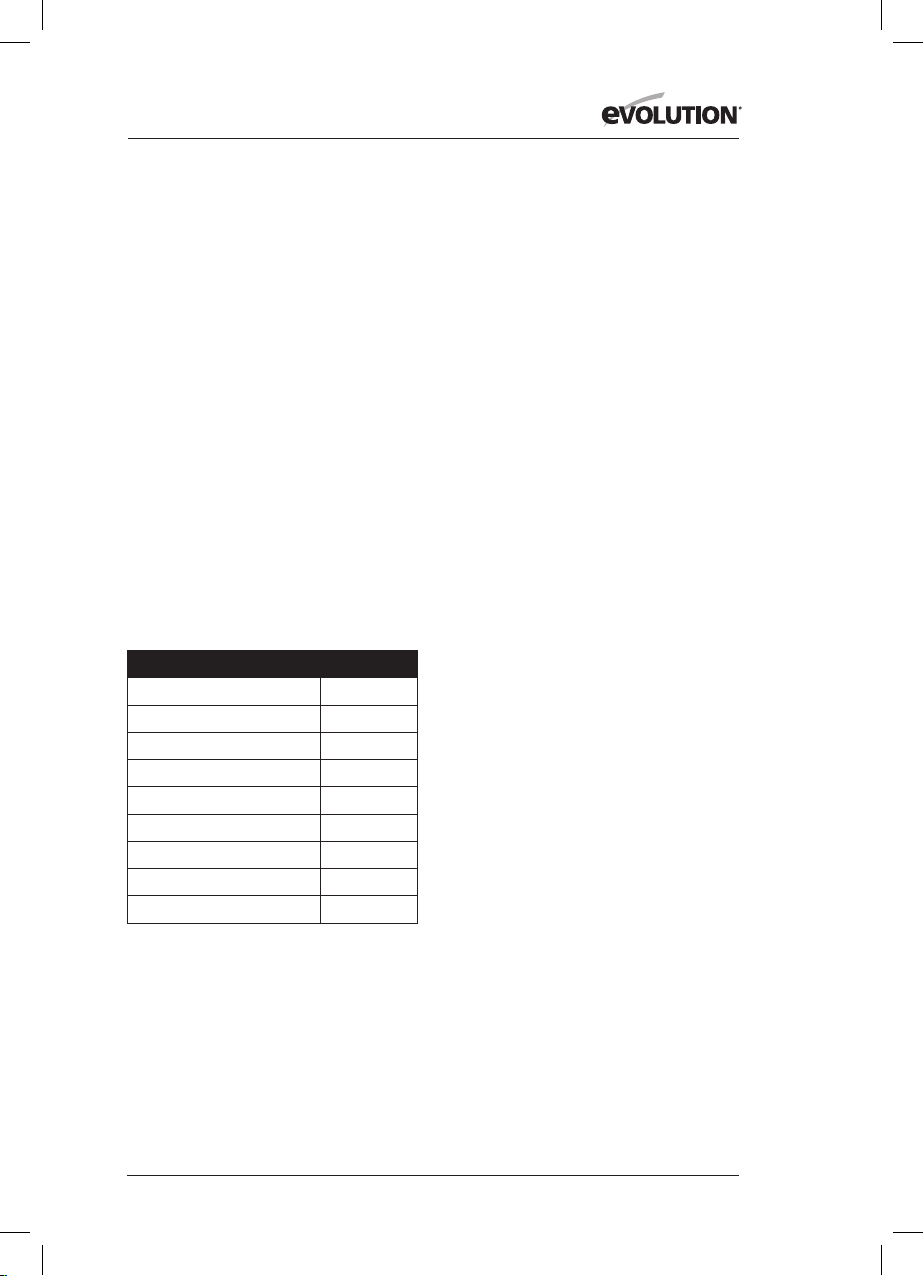

MACHINE OVERVIEW

3

2

4

6

7

8

1

Cutting Blade

1 6

Trigger Switch

2 7

Locking Button

3 8

Rotary Control

4 9

Cutting Action Selection Switch

5 10

5910

Laser Switch

Dust Extraction

Chip Guard

Parallel Edge Guide

Air Blower

10

Page 11

www.evolutionpowertools.com

OPERATION

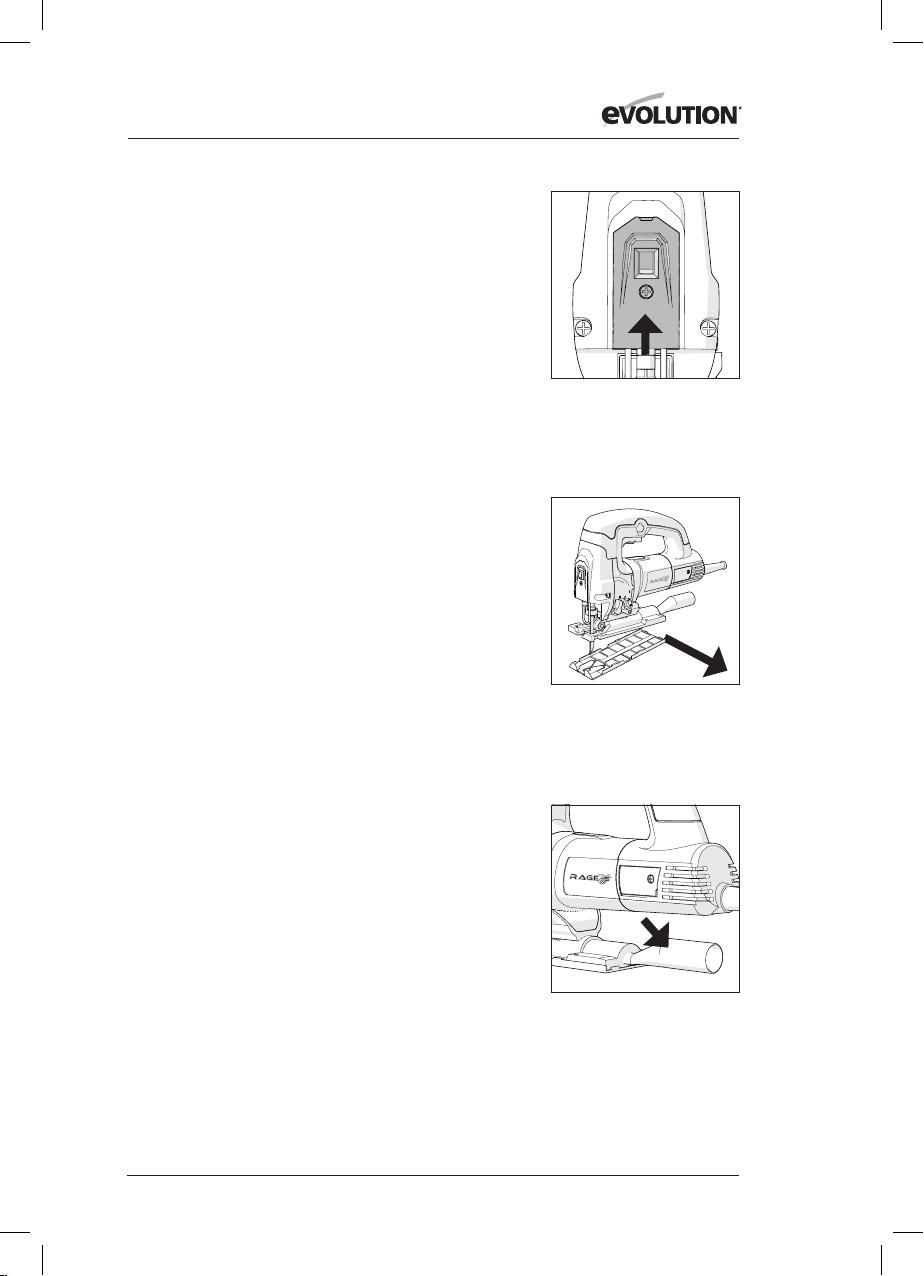

1. INSTALLING OR REMOVING A BLADE (Fig. 1)

WARNING: The jigsaw must be disconnected from the power

supply and the blade must not be facing the operator when

installing or removing the blade.

Installation:

• Check that the jigsaw blade is of the correct type.

• Insert the blade into the chuck ensuring that the blade teeth

face forwards.

• Rotate the chuck locking collar forward and slide the jigsaw

blade fully ‘home’ into the chuck. Ensure that the ‘T’ bar of the

bayonet tting is fully engaged within the chuck. (Fig. 1)

• Release the chuck locking collar.

• Check to ensure the blade is securely gripped by the chuck.

• Check to ensure that the back of the blade has engaged into

the groove in the guide roller. (Fig. 2)

Removal:

Note: A recently used blade can be very hot. Allow such a blade

to cool down before attempting to remove it from the machine.

• Disconnect the machine from the power supply.

• Set the Cutting Action. Selection Switch to position 0.

• Rotate the chuck locking collar forwards.

The blade will automatically eject from the machine.

Note: The blade may eject from the chuck with some force.

Ensure that the ejecting blade will not strike any nearby surface,

bystander or animal. If possible eject a used blade directly into a

scrap recycling bin.

2. ON/OFF TRIGGER SWITCH (Fig. 3a)

This tool is tted with a variable speed Trigger Switch that

delivers higher speed as the trigger pressure is increased.

EXPLANATION OF Fig. 3a NUMBERS:

1 = TRIGGER SWITCH

2 = LOCKING BUTTON

3 = ROTARY CONTROL

The Trigger Switch is also tted with a rotary control (Fig 3b)

that allows the operator to select a constant speed and then

lock the trigger in this position.

Fig 1

Close up view of the quick

t/release chuck with the

blade inserted.

Fig 2

Close up view of the

correctly tted blade with

the back of the blade

engaged into the groove in

the guide roller.

2

1

3

Fig 3 (a)

Close up view of Trigger

Switch, Locking Button

and Rotary Control.

11

Page 12

www.evolutionpowertools.com

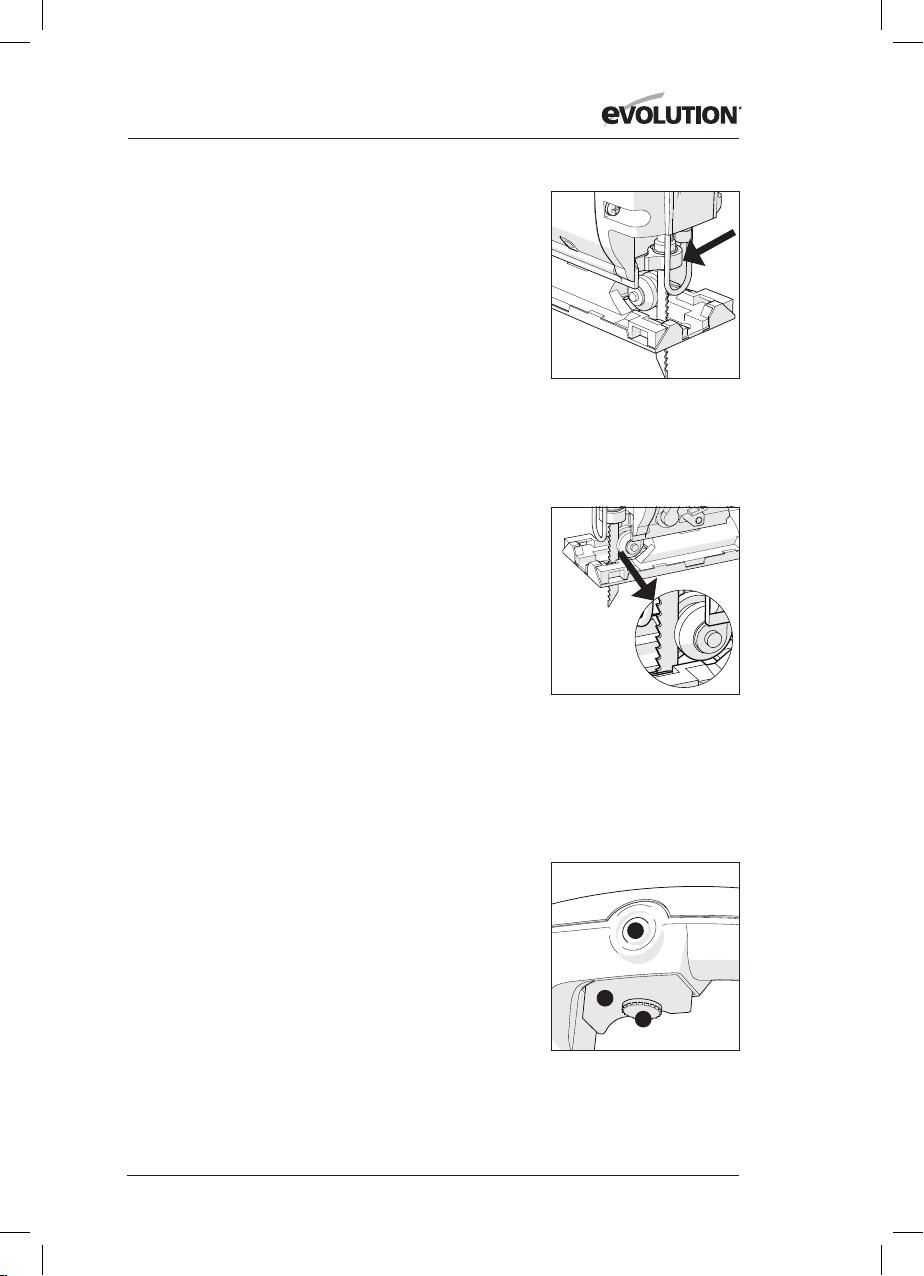

Fig 3 (b)

Close up view

of Rotary Control.

3. TRIGGER SWITCH LOCKING BUTTON (Fig. 3c)

• Pull the trigger fully and rotate the rotary control until the

desired speed is obtained.

• Push in the speed locking button to lock the trigger at the

selected speed.

• Press the trigger switch gently and then release to disengage

the selected speed and to switch the machine o.

4. CUTTING ACTION SELECTION SWITCH (Fig. 4)

This jigsaw has a 4 position switch (0-3) located on the Left

Hand side of the machine just behind the blade. Only operate

this switch when the machine is switched ‘O’ and the blade is

stationary.

Position ‘0’ Straight cutting action

Positions ‘1 – 3’ Orbital cutting actions

Orbital cutting action has an aggressive blade cutting motion

and is especially suited for cutting soft materials.

During orbital cutting the blade moves forwards as well as

up and down. Position 1 is the least aggressive of the orbital

cutting actions, with position 3 being the most aggressive.

Fig 3 (c)

Close up view of

Locking Button.

Fig 4

Close up view of

Selection Switch Lever.

The Table below gives some typical examples of the use of the

orbital cutting facility. We recommend that the operator always

practices on a piece of unwanted material to determine the

most suitable selection for the task at hand.

POSITION TYPICAL APPLICATION

0 Thin materials. Fine cuts. Tight curves. All metals.

1 Hard materials such as chipboard, MDF, Plywood etc.

2 Thick materials such as constructional timber and

3 Fast cuts when cutting with the grain in softwood

plastic.

material.

12

Page 13

www.evolutionpowertools.com

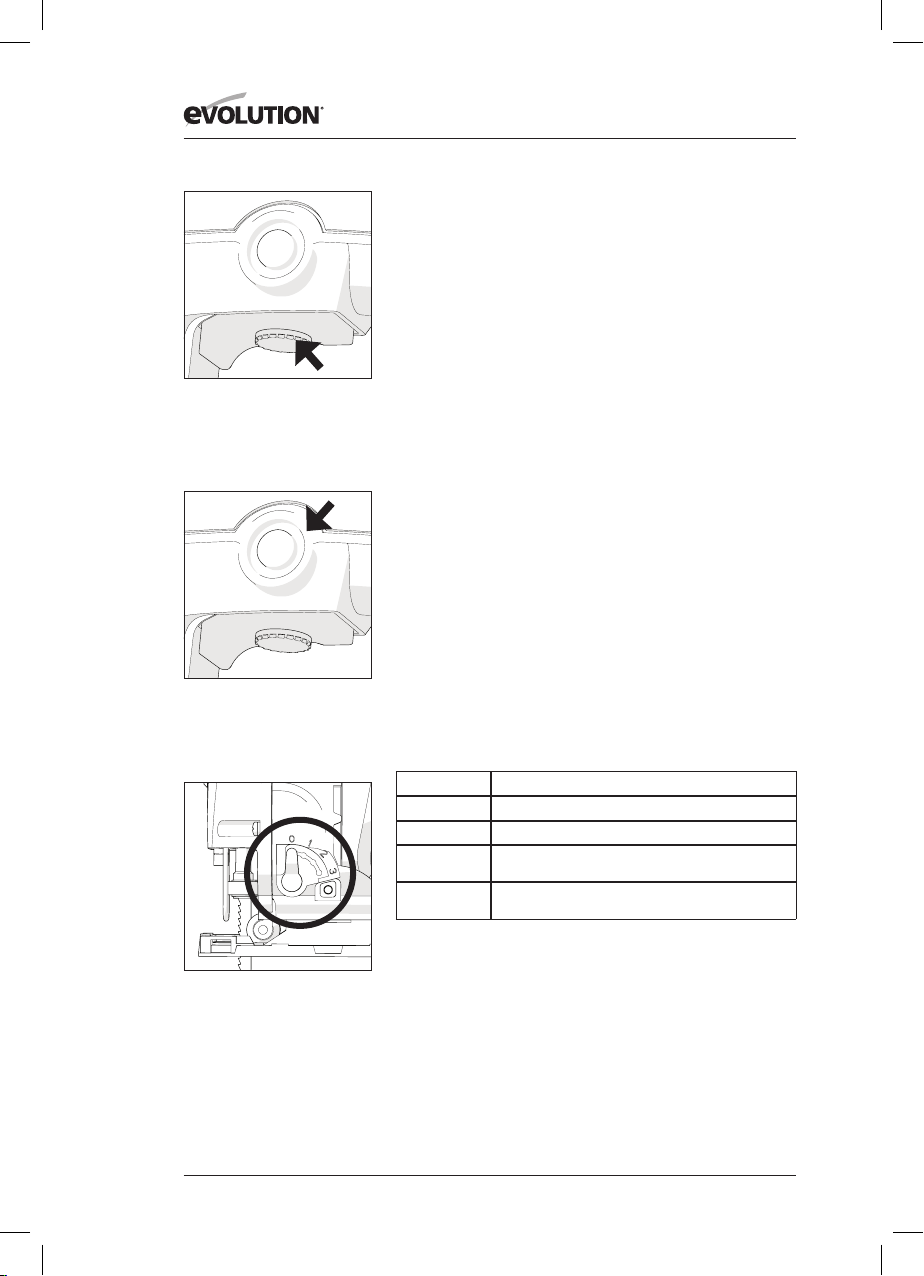

5. LASER CUTTING GUIDE

This jigsaw is tted with a Laser Guide which can be useful when

cutting straight lines. Only switch the Laser Guide on when you

are about to make a straight cut, and switch it o when the cut

has been completed. The switch is located on the front of the

machine. Press the ‘I’ side of the rocker switch to turn the Laser

Guide ‘On’. Press the ‘O’ side of the rocker switch to turn the

Laser Guide ‘O ’.

WARNING: Do not stare directly at the laser beam. A hazard

may exist if you deliberately stare into the beam. Please observe

all of the following safety rules.

• The laser beam must not be deliberately aimed at personnel

and must be prevented from being directed towards the eyes

of a person or animal.

• Always ensure that the laser beam is used only on workpieces

that have non-reective surfaces, i.e natural wood or matt

surfaces etc.

• Never exchange the laser module assembly for a dierent

type or class of laser.

• Repairs to the laser module must only be conducted by

Evolution Power Tools or their authorized agent.

REPLACEMENT OF LASER BATTERIES

Power for the Laser Guide is provided by two (2) ‘AAA’ Cells.

When exhausted these should be replaced.

Access to the battery compartment is gained by loosening the

screw and removing the battery compartment cover.

(Fig. 5)

Observe the polarity of the cells and replace the cover after cell

replacement.

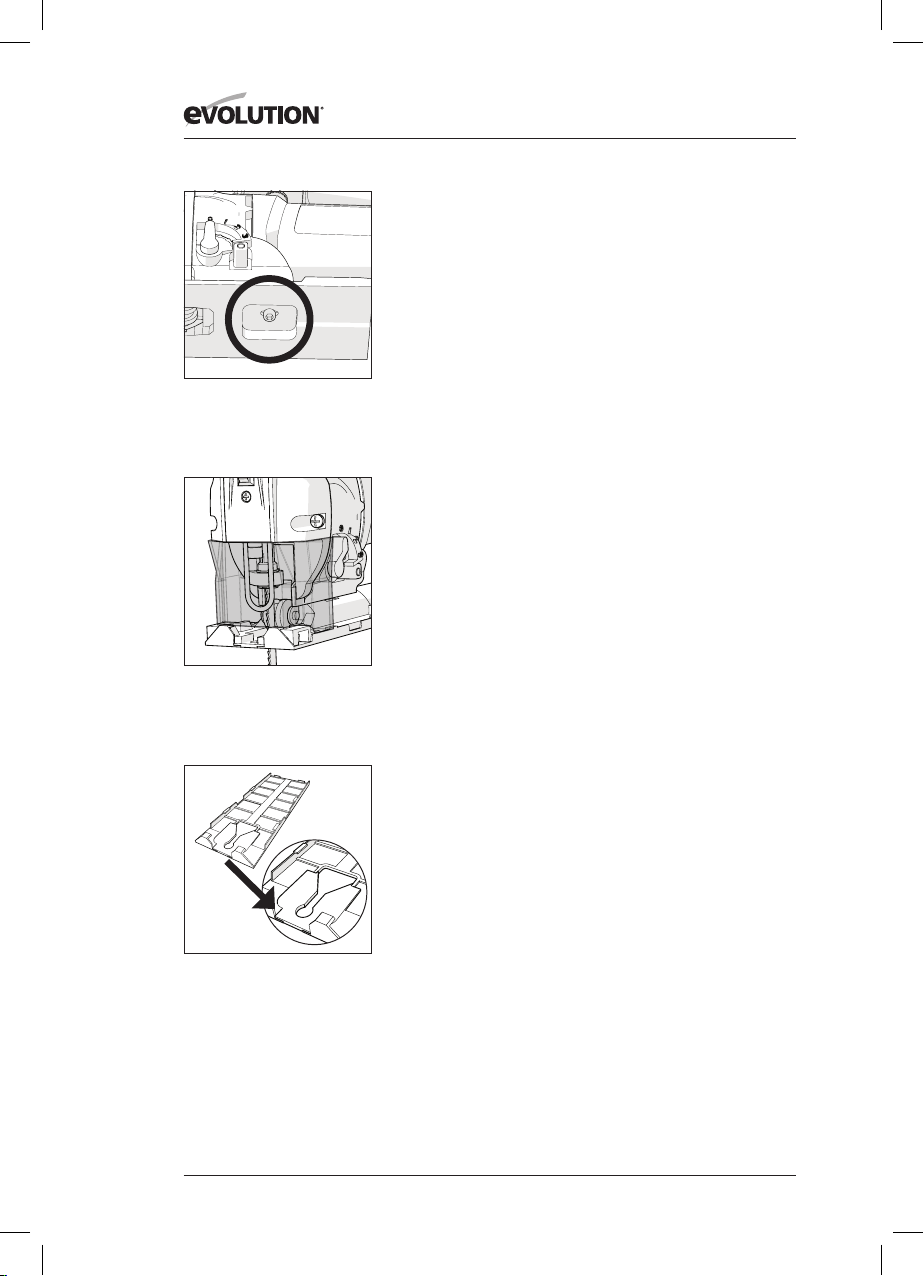

Fig 5

Close up view of battery

compartment cover

and xing screw.

Fig 6

View of footplate shoe

being unclipped and

removed from footplate.

6. FOOTPLATE ANGLE ADJUSTMENT

Note: The footplate is factory set and adjusted so that the blade

cuts at 900 to the footplate.

The footplate may be tilted to an angle of up to 450 to either

side with positive location stops at 150, 300 and 450.

To adjust the footplate:

WARNING: Disconnect the jigsaw from the power supply before

attempting to adjust the footplate.

• Unclip the plastic footplate shoe and store safely for future

installation. (Fig. 6)

• Withdraw the Dust Extraction Adaptor tube, if tted, and

store safely for future installation. (Fig. 7)

13

Fig 7

View of Adaptor tube in

service position.

Page 14

www.evolutionpowertools.com

Fig 8

Close up view of socket

headed screw.

Fig 9

Close up view of Front

Guard in service position.

• Loosen the socket headed screw that holds the footplate to

the machine. (Fig. 8)

• Tilt the footplate to the desired angle. To engage one of

the positive stops it will be necessary to slide the footplate

backwards or forwards depending upon the stop required.

• Tighten the socket-headed screw carefully so as not to

damage the threads.

• Re-install the Dust Extraction Adaptor tube.

• Ret the plastic footplate shoe ensuring that all six (6)

securing lugs (2 to the front of the footplate and 2 either side)

are correctly seated.

Note: The positive location stops are intended as a guide only.

For accurate setting of the footplate we recommend the use of a

vernier angle gauge (not supplied).

7. CHIP GUARDS

Two (2) plastic chip guards are provided. The Front Chip Guard

should always be tted and the Footplate Chip Guard can be

tted to the machine as and when required.

To t the Front Chip Guard:

• Ensure that the machine is disconnected from the power supply

• The front guard (Fig. 9) clips over the front of the machine,

below the laser guide and in front of the steel blade guard.

Note: This guard is precisely engineered and designed to just

clip into place. There is sucient ‘spring’ in the design to allow

the guard to be carefully positioned into its service position.

The operator should use care and ensure that the guard is not

‘forced’ into place with the attendant risk of damage to the

guard. Seat the guard carefully in its service position.

Fig 10

Close up view of Footplate

Guard in service position

before installation of

footplate shoe.

The Footplate Chip Guard (Fig. 10) can be useful when cutting

long straight lines. The use of this guard will help prevent the

sawblade from swinging during a cut.

To t the Footplate Chip Guard:

• Ensure that the machine is disconnected from the power supply.

• Unclip the plastic Footplate Shoe from the Footplate.

• Clip the Footplate Chip Guard into the inside of the Footplate

Shoe with the ‘Vee’ pointing towards the rear of the shoe, and

the raised platform positioned within the throat of the shoe.

Ensure positive location within the shoe. The guard should lie

‘ush’ with both surfaces of the shoe.

• Carefully replace the Footplate Shoe with the attached Chip

Guard onto the Footplate.

14

Page 15

www.evolutionpowertools.com

8. PARALLEL EDGE GUIDE

The supplied Parallel Edge Guide can be tted to either side of

the machine. It can be a useful aid when cutting straight lines

that are parallel to an existing edge.

To t the Parallel Edge Guide:

• Loosen the cross-head screw found in the Parallel Edge Guide

clamp and slide the clamp from the arm of the guide.

• Locate the clamp in the required service position on either

the right or left hand side of the machines footplate just

ahead of the blade. (Fig. 11).

• Slide the arm of the Parallel Edge Guide through the clamp

and through the two (2) rectangular slots in the footplate.

• Set the Edge Guide at the required distance and then tighten

the cross-head screw to lock the Edge Guide securely in place.

Note: The Front Chip Guard can be tted to this machine when

the Parallel Edge Guide is tted.

9. AIR BLOWER

This Jigsaw is equipped with an Air Blower. This can be used

to blow away dust created by the blade from the cutting area

thereby keeping the cutting line(s) clear and visible.

Note: We recommend that the Air Blower is used in conjunction

with a suitable workshop dust extraction machine connected to

the Dust Extraction Adaptor of the jigsaw.

Clamp

Fig 11

Parallel Edge Guide.

Fig 12

Close up view of Air

Blower Slide control lever.

We recommend that the Air Blower is not used when cutting

metal or when cutting materials that require a lubricant.

Mechanical vacuum dust extraction using the Adaptor tube will

always work better with the Air Blower turned ‘OFF’.

To switch the Air Blower ‘ON’:

• Push the ‘Air Blower’ control slide fully to the right (as seen

from the operators viewpoint) (Fig 12)

To switch the Air Blower ‘OFF’:

• Push the ‘Air Blower’ control slide fully to the left.

10. DUST EXTRACTION

This jigsaw is tted with a Dust Extraction Adaptor tube.

(Fig. 13)

Whenever possible it is good practice to connect the Adaptor

tube to a workshop dust extraction machine. The Air Blower

should be in the ‘OFF’ position.

15

Fig 13

Close up view of adaptor

tube with vacuum hose

about to be connected.

Page 16

www.evolutionpowertools.com

During operations the use of a dust extraction

machine will help keep the workplace clean

and dust free, enhancing operator safety and

comfort and aiding operator cutting accuracy.

CUTTING ADVICE

Note: Always ensure that the footplate of the

jigsaw is in close contact with the workpiece

throughout the cutting procedure. If the

footplate is allowed to ‘lift’ away from the

workpiece operator control and accuracy will

be compromised.

• Clearly mark out the cutting line to be

followed on the workpiece (use a pencil or

other suitable marking device).

• Small workpieces should be secured in a

vice or clamped to a workbench. Check that

the passage of the blade is not obstructed.

• Larger workpieces should be clamped to

sawhorses or similar. Check that the passage

of the blade is not obstructed.

• Set the Cutting Action Selection Lever to the

desired position.

• Align the saw with the cutting line and rest

the front of the footplate on the workpiece.

Note: Ensure that the blade is not in contact

with the workpiece at this stage.

• Switch the machine ‘On’ and gently feed the

jigsaw into the workpiece. Be careful to hold

the jigsaw rmly and keep full control as the

blade contacts the workpiece.

• Adjust the speed of the blade as necessary

to achieve optimum cutting performance.

• Use the Laser guide if necessary, but only on

non-reective materials.

Note: Do not force the blade. Let the blade do

the work by adjusting the speed and feed rates

to achieve best performance.

CUTTING METAL

When cutting any metal a suitable cutting

lubricant/coolant should be used. Cast Iron and

Brass can be cut without a cutting lubricant.

Always use a blade that is capable of cutting

metal, and secure the workpiece securely,

if practicable, in a vice or similar clamping

device.

WARNING: When cutting metal the Cutting

Action Selection Lever must be set to the ‘0’

position.

CUTTING CIRCLES OR CURVES

When cutting curves, particularly tight

curves, start with a reasonably slow speed,

and gradually increase the speed until the

optimum performance is achieved. Do not

force the blade, as in curved cutting this can

lead to the blade deection, and possible

blade breakage.

To cut a circle from a workpiece:

• Mark out the circle in the required postion.

• Drill a Ø12 mm hole near the centre of the

circle.

• Insert the jigsaw blade into the ø12 mm

hole. Ensure that there is clearance between

the blade and the workpiece.

• Begin cutting towards the outside of the

circle, slowly in a spiral fashion, until the

blade is following the required cutting line.

• Advance the jigsaw slowly to avoid cutting

a slanted surface or experiencing blade

deection.

ANGLED CUTTING

Angled cutting, whatever the material, is

always more dicult than general straight

cutting. With angled cutting it is very important

to allow the saw blade to do the work. Do

not ‘force’ the blade. A trial run on unwanted

material to determine the best combination of

blade feed and speed is recommended.

Return to the factory setting when angled

cutting is completed. Recheck the security of

the blade.

BLADES

Choose blades carefully. Use only a blade that

is suitable for this machine and for the material

to be cut.

16

Page 17

www.evolutionpowertools.com

The ability of any jigsaw to follow curves,

provide smooth nishes or faster cutting is

directly related to the type of blade employed.

MAINTENANCE

Your Evolution Jigsaw requires no major

additional lubrication or maintenance.

Occasionally apply a drop of light machine oil

to the blade guide spindle. There are no user

serviceable parts in your Evolution Jigsaw.

Keep the tool clean, but do not use chemical

cleaners which may damage the plastic parts.

Clean with a dry cloth. Ensure that the motor

ventilation slots are kept clean.

ENVIRONMENTAL PROTECTION

Waste electrical products should not be

disposed of with household waste. Please

recycle where facilities exist. Check with your

Local Authority or retailer for recycling advice.

17

Page 18

www.evolutionpowertools.com

EC DECLARATION OF CONFORMITY

In accordance with EN ISO 17050-1:2004

The manufacturer of the product covered by this Declaration is:

Evolution Power Tools, Venture One, Longacre Close, Holbrook Industrial Estate, Sheeld, S20 3FR

The manufacturer hereby declares that the machine as detailed in this declaration fulls all the

relevant provisions of the Machinery Directive and other appropriate directives as detailed below.

The manufacture further declares that the machine as detailed in this declaration, where applicable,

fulls the relevant provisions of the Essential Health and Safety requirements.

The Directives covered by this Declaration are as detailed below:

2006/42/EC Machinery Directive

2014/30/EU Electromagnetic Compatibility Directive

2002/95/EC The Restriction of the Use of certain Hazardous Substances in Electrical Equipment (RoHS)

Directive

2002/96/EC As amended by 2003/108/EC. The Waste Electrical and Electronic Equipment (WEEE) Directive

And is in conformity with the applicable requirements of the following documents

EN 60745-1:2009+A11:2010

EN 60825-1:2007

EN 60745-2-3:2011

EN 55014-1: 2006+A1+A2

EN 55014-2: 2015

EN 61000-3-2:2006/+A1:2009/+A2:2009

EN 61000-3-3:2008

Product Details

Description: RAGE7-S 710W Corded Jigsaw With Variable Speed Control

Evolution Model No: RAGE7-S1 (075-0002) / RAGE7-S2EU (075-0003)

Factory Model No: HDA1110

Brand Name: EVOLUTION

Voltage: 110V / 230V ~ 50Hz / 60Hz

Input: 710W

The technical documentation required to demonstrate that the product meets the requirements of

directive has been compiled and is available for inspection by the relevant enforcement authorities,

and veries that our technical le contains the documents listed above and that they are the correct

standards for the product as detailed above.

Name and address of technical documentation holder.

Signed: Print: Matthew Gavins - Group Chief Executive

Date: 01/03/16

18

Page 19

www.evolutionpowertools.com

19

Page 20

Page 21

EN

DEUTSCH

Originalanweisungen

DE

Page 22

www.evolutionpowertools.com

INHALTSVERZEICHNIS

English Page 2

Deutsch Seite 20

INHALT

Wichtige Informationen Seite 23

Garantie Seite 23

Technische Daten Seite 24

Schilder und Symbole Seite 25

Vibration Seite 25

Zur bestimmungsgemäßen Verwendung dieses Elektrowerkzeug Seite 25

Verbotene Nutzung dieser Elektrowerkzeug Seite 25

SICHERHEITSHINWEISE

Verwendung Im Freien Seite 26

Allgemeine Sicherheitsvorschriften Seite 26

Weitere spezielle Sicherheitsvorschriften Seite 29

Mitgelieferte Seite 31

ANFANGEN

Maschinenübersicht Seite 30

Bedienungsanleitung Seite 32

Montieren Oder Demontieren Eines Sägeblatts Seite 32

Ein-/Aus-Betätigungsschalter Seite 32

Drehzahlverriegelungsknopf Des Betätigungsschalters Seite 33

Schnitt-Auswahlschalter Seite 33

Laser-Schnittführung Seite 34

Einstellung Des Fussplattenwinkels Seite 34

Splitterschutz Seite 35

Parallelkantenführung Seite 36

Gebläse Seite 36

Staubabsaugung Seite 37

Hinweise Zum Schneiden Seite 37

WARTUNG

Wartung Seite 39

Sicherheitsvorkehrungen für die Umwelt Seite 39

EG - KONFORMITÄTSERKLÄRUNG Seite 40

Diese Bedienungsanleitung wurde ursprünglich in Englisch verfasst

22

Page 23

www.evolutionpowertools.com

WICHTIG

Bitte lesen Sie die folgende

Bedienungsanleitung und die

Sicherheitshinweise vollständig durch.

Wenden Sie sich zu Ihrer eigenen Sicherheit

an die entsprechende Technische Helpline,

deren Nummer Sie auf der Webseite von

Evolution Power Tools nden, wenn Sie über

irgendeinen Aspekt bei der Verwendung

dieses Geräts unsicher sind. Wir betreiben

mehrere Helplines in unserer weltweiten

Organisation, aber sie erhalten Technische

Hilfe auch von Ihrem Lieferanten.

WEBSEITE

www.evolutionpowertools.com

Glückwunsch zum Kauf einer Maschine

von Evolution Power Tools. Bitte füllen

Sie Ihre Produktregistrierung ‘online’

wie es in der A5-Broschüre zur OnlineGarantieregistrierung erklärt ist, die dieser

Maschine beiliegt.

Sie können auch den QR-Code, der sich

auf der A5-Broschüre bendet, mit einem

Smartphone scannen. Damit können Sie

die Garantielaufzeit Ihrer Maschine über die

Webseite von Evolution validieren, indem

Sie Ihre Angaben eingeben und somit einen

umgehenden Service sicherstellen, falls dieser

einmal notwendig werden sollte. Vielen Dank

für die Wahl eines Evolution-Produkts.

EVOLUTION BESCHRÄNKTE GARANTIE

Evolution Power Tools behält sich das Recht

vor, Verbesserungen und Veränderungen

am Produktdesign ohne Vorankündigung

vorzunehmen.

innerhalb der Garantielaufzeit und ab

Originalkaufdatum alle Waren, die Materialoder Verarbeitungsmängel aufweisen.

Diese Garantie ist ungültig, wenn das

zurückgeschickte Werkzeug zum Schneiden

von Werkstoen verwendet wurde, die

außerhalb der in dieser Betriebsanleitung

enthaltenen Empfehlungen liegen, oder

wenn die Maschine aufgrund eines Unfalls,

durch Nachlässigkeit oder durch falsche

Wartung beschädigt wurde. Diese Garantie

gilt nicht bei Maschinen und/oder Teilen,

die in irgendeiner Weise verändert oder

jenseits der empfohlenen Kapazitäten

und Spezikationen verwendet wurden.

Elektroteile unterliegen den Garantien der

jeweiligen Hersteller. Alle als schadhaft

zurückzugebenden Waren sind frachtfrei

an Evolution Power Tools zu retournieren.

Evolution Power Tools behält sich das Recht

vor, sie nach eigenem Ermessen zu reparieren

oder durch identische oder gleichwertige

Artikel zu ersetzen. Es besteht weder eine

schriftliche noch eine mündliche Garantie für

Verbrauchsmaterialien, wie (folgende Liste

ist nicht vollständig) Sägeblätter, Schneiden,

Bohrer, Meißel oder Schaufeln, etc. In keine

Fall ist Evolution Power Tools haftbar für

Verluste oder Beschädigungen, die direkt

oder indirekt durch die Verwendung unserer

Waren oder aus irgendeinem anderen Grund

entstehen. Evolution Power Tools haftet für

keine bei derartigen Waren entstandenen

Kosten oder Folgeschäden. Kein Bediensteter,

Mitarbeiter oder Vertreter von Evolution

Power Tools ist befugt, mündliche Erklärungen

zur Eignung abzugeben oder auf jedwede

der vorgenannten Verkaufsbedingungen zu

verzichten, und für Evolution Power Tools sind

keine bindend.

Sehen Sie in die

Produktregistrierungsbroschüre und/oder

auf die Verpackung für Einzelheiten zu

den Bedingungen, Voraussetzungen und

Laufzeiten der Garantie.

Evolution Power Tools repariert oder ersetzt

Fragen zu dieser beschränkten Garantie

richten Sie bitte an die Zentrale des

Unternehmens, oder rufen Sie die

entsprechende Helpline-Nummer an.

23

Page 24

www.evolutionpowertools.com

TECHNISCHE DATEN DER STICHSÄGE

MASCHINE TECHNISCHE DATEN

Motor 230V ~ 50Hz 710W (6A)

Motor 110V ~ 60Hz 600 (5.2A

UPM ohne Last 0 - 3000min

Empfohlene maximale Einschaltdauer 30 min

Hublänge 26mm

Isolationsklasse 2

Gewicht (Brutto) 4.1kg (9lbs)

SCHNITTLEISTUNG

Holz 80mm

Metall 8mm

GERÄUSCH- UND VIBRATIONSDATEN

Schalldruck LPA 87dB(A) K=3dB(A)

-1

(upm)

Schalldruckpegel LWA 98dB(A) K=3dB(A)

Vibrationspege 3:129 m/s2 K=1.5m/s

24

2

Page 25

www.evolutionpowertools.com

AUFKLEBER UND SYMBOLE

WARNUNG: Bedienen Sie die Maschine nicht,

wenn Warn- und/oder Hinweisschilder fehlen

oder beschädigt sind. Für Ersatzaufkleber

wenden Sie sich bitte an Evolution Power Tools

oder Ihren Lieferanten.

Hinweis: Alle oder einige der folgenden

Symbole können im Handbuch oder auf dem

Produkt erscheinen.

Symbol Description

V Volt

A Ampere

Hz Hertz

-1

Min

~ Wechselstrom

n

o

Drehzahl

Leerlaufdrehzahl

Schutzbrille

tragen

Gehörschutz

tragen

Nicht berühren

Hände fern

halten

Staubschutz

tragen

Richtlinie zur

Beschränkung

von Gefahrstoffen

CE-Zertifizierung

Elektro- und

Elektronikaltgeräte

Anleitungen lesen

VIBRATION

HINWEIS: Die Vibrationsmessung erfolgte

unter Standardbedingungen gemäß:

BS EN 610291.2009.

WARNUNG: Die Vibrationsemission

während der eigentlichen Verwendung des

Elektrowerkzeugs kann sich vom erklärten

Gesamtwert unterscheiden – je nachdem, auf

welche Weise das Werkzeug benutzt wird. Die

Notwendigkeit, Sicherheitsmaßnahmen zu

identizieren und den Bediener zu schützen,

beruht auf einer Schätzung der Exposition bei

den eigentlichen Nutzungsbedingungen (unter

Berücksichtigung aller Teile des Betriebszyklus

wie z. B. Abschaltzeiten des Werkzeugs, wenn es

leer läuft, zusätzlich zur Auslösezeit).

BESTIMMUNGSGEMÄSSE VERWENDUNG

DIESES ELEKTROWERKZEUGS

WARNING: Dieses Produkt ist eine Vielzweck-

Stichsäge und sie wurde für die Verwendung

mit speziellen Vielzweck-Sägeblättern von

Evolution entwickelt. Verwenden Sie nur

Sägeblätter, die für die Verwendung in dieser

Maschine entwickelt wurden und/oder solche,

die speziell dafür empfohlen werden von

Evolution Power Tools Ltd.

Wenn diese Maschine mit einem richtigen

Sägeblatt ausgerüstet ist, kann diese

Maschine verwendet werden zum

Schneiden von:

• Holz

• Holzwerkstoe (MDF, Spanplatten,

Sperrholz, Stabplatten,

Hartfaserplatten, etc.)

• Aluminium

• Baustahl

Warnung

Laser-Warnung

25

Page 26

www.evolutionpowertools.com

VERBOTENE VERWENDUNG DIESES

ELEKTROWERKZEUGS

WARNUUNG: Dieses Produkt ist eine

Vielzweck-Stichsäge und darf nur als solche

verwendet werden. Es darf in keinster Weise

modiziert oder zum Antrieb anderer Geräte

verwendet werden oder irgendwelches

anderes Zubehör antreiben, als solches, das in

dieser Bedienungsanleitung erwähnt ist.

WARNUNG: Dieses Gerät ist nicht dafür

geeignet, dass es von Personen (einschließlich

Kindern) mit eingeschränkten körperlichen,

sensorischen oder geistigen Fähigkeiten bzw.

Personen, die unerfahren sind und nicht über

die hierfür nötigen Kenntnisse verfügen,

verwendet wird, es sei denn, diese werden

zuvor in der sicheren Benutzung des Geräts

von einer für ihre Sicherheit verantwortlichen

Person betreut oder angeleitet.

Kinder sollten beaufsichtigt werden, um zu

gewährleisten, dass sie zu dem Gerät keinen

Zugang haben; ihnen darf auf keinen Fall

erlaubt werden, mit dem Gerät zu spielen.

VERWENDUNG IM FREIEN

WARNUNG: Bei einer Verwendung im

Freien sollte dieses Werkzeug zu Ihrem

Schutz nicht Regen ausgesetzt oder an

feuchten Orten verwendet werden. Stellen

Sie das Werkzeug nicht auf feuchte Flächen.

Verwenden Sie wenn möglich eine saubere,

trockene Werkbank. Verwenden Sie für

einen zusätzlichen Schutz eine FehlerstromSchutzeinrichtung (RCD), welche die

Versorgung unterbricht, wenn der Fehlerstrom

gegen Erde 30 mA für 30 ms übersteigt. Prüfen

Sie immer die Funktion der FehlerstromSchutzeinrichtung (RCD) bevor Sie die

Maschine verwenden.

Die Anweisungen des Herstellers sind bei

Verwendung eines Verlängerungskabels zu

befolgen.

ALLGEMEINE ELEKTROWERKZEUGSICHERHEITSHINWEISE

(Diese Allgemeinen Sicherheitshinweise für

Elektrowerkzeuge sind angegeben in der BS

EN 60745-1:2009 & EN 61029-1:2009)

WARNUNG: Lesen Sie alle

Sicherheitshinweise und Anweisungen.

Wenn die Warnungen und Anweisungen nicht

befolgt werden, so kann dies Stromschlag,

Feuer und/oder schwere Verletzungen zur

Folge haben.

Speichern Sie alle Warnungen und

Anweisungen für die Zukunft.

Der in den Warnungen enthaltene Begri

„Elektrowerkzeug“ bezieht sich auf Ihr

netzbetriebenes Elektrowerkzeug (mit Kabel)

oder Ihr batteriebetriebenes (schnurloses)

Elektrowerkzeug.

1) Allgemeine Sicherheitswarnungen

für Elektrowerkzeuge

[Arbeitsbereichssicherheit]

a) Halten Sie Ihren Arbeitsbereich sauber

und gut beleuchtet.

Unordnung und unbeleuchtete Arbeitsbereiche

können zu Unfällen führen.

b) Arbeiten Sie mit dem Elektrowerkzeug

nicht in explosionsgefährdeter Umgebung,

in der sich entammbare Flüssigkeiten,

Gase oder Stäube benden. Elektrowerkzeuge

erzeugen Funken, die den Staub oder die Dämpfe

entzünden können.

c) Halten Sie Kinder und andere

Personen während der Benutzung eines

Elektrowerkzeugs fern. Bei Ablenkung können

Sie die Kontrolle über das Gerät verlieren.

Wenn ein Verlängerungskabel erforderlich

ist, muss es für die Verwendung im Freien

geeignet und so gekennzeichnet sein.

2) Allgemeine Warnungen für

Elektrowerkzeuge [Elektrische Sicherheit]

a) Der Anschlussstecker des Geräts muss in

26

Page 27

www.evolutionpowertools.com

die Steckdose passen. Der Stecker darf in

keiner Weise verändert werden. Verwenden

Sie bei schutzgeerdeten Elektrowerkzeugen

keine Adapterstecker.

Unveränderte Stecker und passende Steckdosen

verringern das Risiko eines Stromschlags.

b) Vermeiden Sie direkten Körperkontakt

mit geerdeten Oberächen, wie z.B.

Rohren, Heizungen, Herden und

Kühlschränken. Es besteht ein erhöhtes

Stromschlagrisiko, wenn Ihr Körper geerdet ist.

c) Halten Sie Elektrowerkzeuge von Regen

oder Nässe fern. Das Eindringen von Wasser

in ein Elektrowerkzeug erhöht das Risiko eines

Stromschlags.

d) Zweckentfremden Sie das Netzkabel

nicht. Verwenden Sie das Kabel nie, um

das Elektrowerkzeug damit zu tragen,

zu schleppen oder um den Stecker daran

aus der Steckdose zu ziehen. Halten Sie

das Kabel von Hitze, Öl, scharfen Kanten

und bewegten Teilen fern. Beschädigte oder

verwickelte Kabel erhöhen das Risiko eines

Stromschlags.

e) Wenn Sie mit einem Elektrowerkzeug

im Freien arbeiten, verwenden Sie nur

Verlängerungskabel, die auch für den

Außenbereich zugelassen sind. Die

Verwendung eines für den Außenbereich

geeigneten Verlängerungskabels verringert das

Risiko eines Stromschlags.

f) Falls sich der Betrieb des

Elektrowerkzeugs in einer feuchten

Umgebung nicht vermeiden

lässt, verwenden Sie unbedingt

eine Stromversorgung mit

Fehlerstromschutzeinrichtung. Durch Einsatz

einer Fehlerstromschutzeinrichtung wird das

Risiko eines Stromschlags verringert.

3) Allgemeine Warnungen für

Elektrowerkzeuge [Persönliche Sicherheit]

a) Seien Sie wachsam, achten Sie darauf,

was Sie tun, und gebrauchen Sie Ihren

gesunden Menschenverstand, wenn Sie mit

einem Elektrowerkzeug arbeiten. Benutzen

Sie das Gerät nicht, wenn Sie müde sind

oder unter dem Einuss von Drogen,

Alkohol oder Medikamenten stehen. Ein

Moment der Unachtsamkeit beim Gebrauch

eines Elektrowerkzeugs kann zu schweren

Verletzungen führen.

b) Tragen Sie persönliche Schutzausrüstung.

Verwenden Sie immer eine Schutzbrille. Das

Tragen von persönlicher Schutzausrüstung, wie

z.B. Staubmasken, rutschfeste Sicherheitsschuhe,

Schutzhelm oder Gehörschutz, je nach Art und

Einsatz des Elektrowerkzeugs, verringert das Risiko

von Verletzungen.

c) Vermeiden Sie eine unbeabsichtigte

Inbetriebnahme. Vergewissern Sie sich,

dass der Ein/Aus-Schalter in der Position

„AUS“ ist, bevor Sie den Stecker in die

Steckdose stecken, den Akku einsetzen

bzw. das Werkzeug hoch heben oder

tragen. Wenn Sie beim Tragen des Geräts den

Finger am Ein/Aus-Schalter haben oder das

Gerät eingeschaltet an die Stromversorgung

anschließen, kann dies zu Unfällen führen.

d) Entfernen Sie Einstellwerkzeuge

oder Schraubenschlüssel, bevor Sie das

Werkzeug einschalten. Ein Handwerkzeug

oder Schlüssel, das bzw. der sich in einem

drehenden Teil eines Elektrowerkzeugs bendet,

kann zu Verletzungen führen.

e) Übernehmen Sie sich nicht. Achten Sie

auf jederzeit sicheren Stand und gutes

Gleichgewicht. Dadurch können Sie das

Elektrowerkzeug in unerwarteten Situationen

besser kontrollieren.

f) Tragen Sie geeignete Kleidung.

Tragen Sie keine lockere Kleidung oder

Schmuck. Halten Sie Haare, Kleidung und

Handschuhe von beweglichen Teilen fern.

Lockere Kleidung, Schmuck oder lange Haare

können von sich bewegenden Teilen erfasst

werden.

g) Wenn Staubabsaug- und

-auangeinrichtungen zur Verfügung

stehen, vergewissern Sie sich, dass diese

angeschlossen sind und richtig verwendet

werden. UDas Verwenden dieser Einrichtungen

verringert Gefährdungen durch Staub.

27

Page 28

www.evolutionpowertools.com

4) Allgemeine Sicherheitswarnungen für

Elektrowerkzeuge [Verwendung und Pege

des Elektrowerkzeugs].

a) Überlasten Sie das Elektrowerkzeug

nicht. Verwenden Sie für Ihre Arbeit das

richtige Elektrowerkzeug. Mit dem passenden

Elektrowerkzeug arbeiten Sie besser und sicherer

im angegebenen Leistungsbereich.

b) Benutzen Sie kein Elektrowerkzeug,

dessen Ein/Aus-Schalter defekt ist. Ein

Elektrowerkzeug, das sich nicht mehr ein- oder

ausschalten lässt, ist gefährlich und muss

repariert werden.

c) Trennen Sie das Elektrowerkzeug von

der Steckdose bzw. nehmen Sie den

Akku aus dem Elektrowerkzeug, bevor

Sie Geräteeinstellungen vornehmen,

Zubehörteile wechseln oder das

Elektrowerkzeug verstauen. Diese

Vorsichtsmaßnahmen verhindern den

unbeabsichtigten Start des Elektrowerkzeugs.

d) Bewahren Sie unbenutzte

Elektrowerkzeuge außerhalb der

Reichweite von Kindern auf. Lassen Sie

keine Personen das Werkzeug benutzen,

die nicht damit vertraut sind oder die

diese Anweisungen nicht gelesen haben.

Elektrowerkzeuge sind gefährlich, wenn sie von

unerfahrenen Personen benutzt werden.

e) Pegen Sie das Elektrowerkzeug.

Stellen Sie sicher, dass bewegliche

Geräteteile einwandfrei funktionieren

und nicht klemmen, gebrochen oder so

beschädigt sind, dass die Funktion des

Elektrowerkzeugs beeinträchtigt ist. Lassen

Sie beschädigte Teile vor dem Einsatz des

Elektrowerkzeugs reparieren. Viele Unfälle

haben ihre Ursache in schlecht gewarteten

Elektrowerkzeugen.

f) Halten Sie Schneidwerkzeuge scharf und

sauber. Sorgfältig gepegte Schneidwerkzeuge

mit scharfen Schneidkanten verklemmen sich

weniger und sind leichter zu führen.

g) Verwenden Sie Elektrowerkzeug,

Zubehör, Werkzeugeinsätze usw.

entsprechend diesen Anweisungen und

so, wie es für diesen speziellen Gerätetyp

vorgeschrieben ist. Berücksichtigen

Sie dabei die Arbeitsbedingungen

und die auszuführende Tätigkeit. Der

Einsatz von Elektrowerkzeugen für andere

als die vorgesehenen Anwendungen kann zu

gefährlichen Situationen führen.

5) Allgemeine Sicherheitswarnungen für

Elektrowerkzeuge [Wartung]

Lassen Sie Ihr Elektrowerkzeug von einem

qualizierten Techniker warten, der nur

identische Ersatzteile verwendet. Dies stellt

sicher, dass die Sicherheit des Elektrowerkzeugs

aufrecht erhalten wird.

HINWEISE ZUM GESUNDHEITSSCHUTZ

WARNUNG: Beim Bohren, Polieren, Sägen

oder Schleifen werden Staubpartikel

erzeugt. Je nach Material, mit dem Sie

arbeiten, kann dieser Staub in einigen Fällen

für Sie besonders gesundheitsschädlich

sein (z. B. in altem Glanzlack enthaltenes

Blei). Ihnen wird geraten, die mit den

von Ihnen bearbeiteten Materialien

verbundenen Risiken zu berücksichtigen

und das Expositionsrisiko zu verringern.

Einige Holz- und holzähnliche Produkte,

besonders MDF (Mitteldichte Faserplatten),

können gesundheitsgefährdenden Staub

entwickeln. Wir empfehlen die Verwendung

einer zugelassenen Gesichtsmaske mit

austauschbaren Filtern bei der Verwendung

dieser Maschine zusätzlich zu einer

Staubabsaugvorrichtung.

Sie sollten immer:

• In einem gut belüfteten Bereich arbeiten.

• Mit zugelassener Schutzausrüstung

wie z. B. Staubschutzmasken arbeiten,

die besonders für das Herausltern

mikroskopischer Partikel konstruiert sind.

WARNUNG: Wenn Sie den Verdacht haben,

dass Farbe auf den Oberächen eines

Materials in Ihrer Wohnung Blei enthält,

ersuchen Sie um fachkundigen Rat. Farbe

auf Bleibasis sollte nur von einem Fachmann

28

Page 29

www.evolutionpowertools.com

entfernt werden uns Sie sollten nicht

versuchen, sie selbst zu entfernen. Sobald

sich der Staub auf Oberächen abgesetzt hat,

kann ein Kontakt von der Hand zum Mund

zur Aufnahme von Blei führen. Schon die

Aufnahme von geringen Mengen Blei kann

zu einer irreversiblen Schädigung des Gehirns

und des Nervensystems führen. Kleine und

ungeborene Kinder sind besonders gefährdet.

ZUSÄTZLICHE

SICHERHEITSVORKEHRUNGEN FÜR IHRE

EVOLUTION STICHSÄGE

1. Von Regen oder Nässe fernhalten.

2. Wenn erforderlich Gehörschutz tragen.

Aussetzung von Lärm kann zum Verlust des

Gehörs führen.

3. Säge-/Schabeblätter und Zubehör

können sehr heiß werden. Beim Wechseln

oder Handhaben irgendwelcher Teile oder

Zubehörteile vorsichtig vorgehen.

4. Das Werkzeug nur an den isolierten

Griächen festhalten, besonders wenn

Sie Arbeiten ausführen, bei denen das

Sägeblatt verborgene Stromleitungen

treen könnte. Wenn das Sägeblatt einen

‘stromführenden’ Draht berührt, können

oene Metallteile des Elektrowerkzeugs

‘stromführend’ werden und dem Bediener

einen elektrischen Schlag erleiden lassen

5. Wenn möglich, Klemmen oder einen

Schraubstock benutzen, um Ihre Arbeit zu

halten.

6. Beim Sägen in Mauern, Böden oder

ähnliche Bereiche so weit wie möglich

sicherstellen, dass sich im Weg des

Sägeblatts keine Einrichtungen (Gasoder Wasserrohre, elektrische Kabel,

etc.) benden. Das Treen versteckter

Einrichtungen Verletzungen des Bedieners

und Sachschäden verursachen.

7. Die Stichsäge vor dem Tausch des

Sägeblatts immer von der Stromversorgung

trennen. Niemals stumpfe oder beschädigte

Sägeblätter verwenden.

8. Vor dem Niederlegen die Säge immer

zum vollständigen Stillstand kommen

lassen. Ein laufendes Werkzeug kann

unkontrollierbar springen, wenn das Sägeblatt

irgendeine Fläche berührt.

9. Immer die Arbeitsumgebung

berücksichtigen und die erforderliche

persönliche Schutzausrüstung tragen.

Dies kann Staubmasken, Schutzbrillen,

Sicherheitsschuhe, etc. beinhalten.

WARNUNG: Der Betrieb jedes

Elektrowerkzeugs kann zur Folge haben, dass

Fremdkörper in Ihre Augen geschleudert

werden; dies kann in schweren Augenschäden

resultieren. Vor Beginn der Arbeit mit

Elektrowerkzeugen: legen Sie stets eine

Schutzbrille bzw. eine Schutzbrille mit

Seitenschutz oder eine Vollmaske an, falls

erforderlich.

WARNUNG: Wenn irgendwelche Teile fehlen,

bedienen Sie Ihre Maschine erst, wenn die

fehlenden Teile wieder angebracht sind. Wird

diese Vorschrift nicht beachtet, könnte dies

schwere Körperverletzung zur Folge haben.

VIBRATION

WARNUNG: Beim Verwenden dieser Maschine

kann der Bediener starken Vibrationen

ausgesetzt sein, die auf die Hand und den Arm

übertragen werden. Es ist möglich, dass der

Bediener die “ Vibrations-Weißngerkrankheit”

(Raynaud-Syndrom) bekommt. Dieser Zustand

kann die Temperaturempndlichkeit der

Hand herabsetzen sowie eine allgemeine

Taubheit erzeugen. Längere oder regelmäßige

Anwender von Schleifmaschinen sollten

den Zustand ihrer Hände und Finger genau

überwachen. Suchen Sie sofort einen Arzt auf,

wenn eines der Symptome auftaucht.

• Die Messung und Beurteilung der

Aussetzung eines Menschen gegenüber

handübertragenen Vibrationen am

Arbeitsplatz ist geregelt in: BS EN ISO 53491:2001 und BS EN ISO 5349-2:2002.

29

Page 30

www.evolutionpowertools.com

• Viele Faktoren können das tatsächliche

Vibrationsniveau beeinussen, z.B.

der Zustand und die Orientierung der

Bearbeitungsächen und die Art und der

Zustand des verwendeten Sägeblatts. Solche

Faktoren können vor jeder Verwendung

beurteilt werden und wenn erforderlich

können entsprechende Arbeitsrichtlinien

umgesetzt werden. Eine Kontrolle dieser

Faktoren kann dabei helfen, die Auswirkungen

der Vibrationen zu reduzieren.

HANDHABUNG

• Gehen Sie mit der Maschine vorsichtig um

und lassen Sie die Maschine die Arbeit

machen.

• Üben Sie keine übermäßige körperliche Kraft

auf irgendwelche Bedienelemente der

Maschine aus.

• Berücksichtigen Sie Ihre Sicherheit und

Standfestigkeit sowie die Ausrichtung der

Maschine während der Verwendung.

BEARBEITUNGSFLÄCHE

• Berücksichtigen Sie das Material der

Bearbeitungsäche, ihren Zustand, Dichte,

Festigkeit, Steigkeit und Ausrichtung.

MITGELIEFERTE

Beschreibung Menge

Bedienungsanleitung 1

Innensechskantschlüssel

4 mm

Fußplattenschuh 1

Stichsägeblätter 1 Packung

Parallelkantenführung 1

Staubabsaugadapter 1

Splitterschutz (vorne) 1

Splitterschutz (Fußplatte) 1

Batterien ‘AAA’ 2

1

30

Page 31

www.evolutionpowertools.com

MASCHINENÜBERSICHT

3

2

4

6

7

8

1

Schneidmesser

1 6

Trigger Schalter

2 7

Verriegelungstaste

3 8

Drehstell

4 9

Schneidwirkung Wahlschalter

5 10

5910

Laser-Schalter

Staubabsaugung

Splitterschutz

Parallel Kantenführung

Luftgebläse

31

Page 32

www.evolutionpowertools.com

Abb. 1

Detailansicht des

Schnellspannerfutters mit

eingesetztem Sägeblatt.

Abb. 2

Detailansicht des richtig

eingesetzten Sägeblatts

mit der Rückseite des

Sägeblatts eingelegt in die

Nut der Führungsrolle.

BEDIENUNGSANLEITUNG

1. MONTIEREN ODER DEMONTIEREN EINES SÄGEBLATTS (Abb. 1)

WARNUNG: Zum Montieren oder Demontieren eines Sägeblatts

muss die Stichsäge von der Stromversorgung getrennt werden.

Einbau:

• Prüfen, ob das Stichsägeblatt vom richtigen Typ ist.

• Das Sägeblatt in das Futter einsetzen und sicherstellen, dass

die Zähne nach vorne zeigen.

• Den Schließring des Futters nach vorne drehen und

das Stichsägeblatt vollständig in das Futter schieben.

Sicherstellen, dass der T-Bügel des Bajonettverschlusses

vollständig im Futter eingerastet ist. (Abb. 1)

• Den Schließring des Futters lösen.

• Prüfen, ob das Sägeblatt sicher vom Futter gegrien wird.

• Prüfen, um sicherzustellen, dass die Rückseite des Sägeblatts

richtig in die Nut der Führungsrolle eingesetzt ist. (Abb. 2)

Ausbau:

Hinweis: Ein kürzlich verwendetes Sägeblatt kann sehr heiß

sein. Lassen Sie so ein Sägeblatt abkühlen bevor Sie versuchen,

es aus der Maschine zu entfernen.

• Die Maschine von der Stromversorgung trennen.

• Schnitt einstellen. Wahlschalter auf Position 0.

• Den Schließring des Futters nach vorne drehen.

Das Sägeblatt wird automatisch aus der Maschine ausgeworfen.

Hinweis: Das Sägeblatt kann mit einiger Kraft aus dem Futter

ausgeworfen werden. Stellen Sie sicher, dass das Sägeblatt

keine nahen Oberächen, Umstehende oder Tiere treen

kann. Wenn möglich, ein gebrauchtes Sägeblatt direkt in einen

Schrott-Wertstobehälter auswerfen.

2

1

3

Abb. 3(a)

Detailansicht von

Betätigungsschalter,

Drehzahlverriegelungsknopf

und Drehzahlregelung. Pfeile

zu den Teilen.

2. EIN-/AUS-BETÄTIGUNGSSCHALTER (Abb. 3a)

Das Werkzeug ist mit einer Drehzahlregelung am

Betätigungsschalter ausgestattet, der bei stärkerem Druck auf

den Betätigungsschalter die Drehzahl erhöht.

ERKLÄRUNG Abb. 3a ZAHLEN:

1 = AUSLÖSESCHALTER

2 = VERRIEGELUNGSKNOPF

3 = DREHREGLER

Der Betätigungsschalter ist mit einem Drehregler (Abb. 3b)

ausgestattet, der es dem Bediener ermöglicht, eine konstante

Drehzahl auszuwählen und dann den Schalter in dieser Position

zu verriegeln.

32

Page 33

www.evolutionpowertools.com

3. DREHZAHLVERRIEGELUNGSKNOPF DES

BETÄTIGUNGSSCHALTERS (Abb. 3c)

• Drücken Sie den Betätigungsschalter vollständig und drehen

Sie den Drehregler bis Sie die gewünschte Drehzahl erhalten.

• Drücken Sie den Drehzahlverriegelungsknopf hinein, um den

Betätigungsschalter bei der gewählten Drehzahl zu verriegeln.

• Drücken Sie den Betätigungsschalter leicht und lassen Sie ihn

los, um die gewählte Drehzahl zu entriegeln und die Maschine

abzuschalten.

4. SCHNITT-AUSWAHLSCHALTER (Abb. 4)

Diese Stichsäge hat einen 4-Positionen-Schalter (0-3) an der linken

Seite der Maschine direkt hinter dem Sägeblatt. Betätigen Sie

diesen Schalter nur, wenn die Maschine ausgeschaltet ist und das

Sägeblatt steht.

Position ‘0’ Gerader Schnitt

Positionen ‘1 - 3’ Bahnschnitte

Bahnschnitte haben eine aggressive Sägeblatt-Schnittbewegung

und sind besonders für das Sägen weicher Materialien geeignet.

Beim Bahnschnitt bewegt sich das Sägeblatt sowohl nach

vorne als auch nach oben und unten. Position 1 ist der am

wenigsten aggressive der Bahnschnitte während Position 3 der

aggressivste ist.

Die Tabelle unten zeigt einige typische Beispiele für die

Verwendung der Bahnschnittfunktion. Wir empfehlen, dass der

Bediener an einem Stück Abfallmaterial übt, um die am besten

geeignete Auswahl für die jeweilige Aufgabe herauszunden.

POSITION TYPISCHE ANWENDUNG

0 Dünne Materialien. Feine Schnitte. Enge Kurven. Alle

1 Harte Materialien wie Spanplatten, MDF, Sperrholz, etc.

2 Dicke Materialien wie Bauholz und Kunststoff.

3 Schnelle Schnitte in Faserlaufrichtung in Weichholzma-

Metalle.

terialien.

Abb. 3(b)

Detailansicht von

Betätigungsschalter,

Drehzahlverriegelungsknopf

und Drehzahlregelung.

Pfeile zu den Teilen.

Abb. 3 (c)

Detailansicht von

Betätigungsschalter,

Drehzahlverriegelungsknopf

und Drehzahlregelung. Pfeile

zu den Teilen.

33

Abb. 4

Detailansicht des

Wahlschalterhebels.

Page 34

www.evolutionpowertools.com

5. LASER-SCHNITTFÜHRUNG

Die Stichsäge ist mit einer Laser-Führung ausgestattet, die

beim Sägen gerade Linien hilfreich sein kann. Schalten Sie die

Laser-Führung nur ein, wenn Sie einen geraden Schnitt machen

möchten und schalten Sie sie wieder aus, wenn der Schnitt

beendet ist. Der Schalter bendet sich an der Vorderseite der

Maschine. Drücken Sie die ‘I’-Seite des Wippschalters, um die

Laser-Führung einzuschalten. Drücken Sie die ‘O’-Seite des

Wippschalters, um die Laser-Führung auszuschalten.

Abb. 5

Detailansicht auf

Batteriefachabdeckung und

Befestigungsschraube

Abb. 6

Ansicht auf den

Fußplattenschuh, wie

er gelöst und von der

Fußplatte entfernt wird.

WARNUNG: Blicken Sie nicht direkt in den Laserstrahl. Es kann

gefährlich sein, wenn Sie direkt in den Strahl blicken. Beachten

Sie bitte die folgenden Sicherheitsvorkehrungen.

• Der Laserstrahl darf nicht absichtlich auf Personal gerichtet

werden; außerdem muss verhindert werden, dass er auf die

Augen einer Person oder eines Tiers gerichtet wird.

• Stellen Sie immer sicher, dass der Laserstrahl nur bei

Werkstücken verwendet wird, die nicht-reektierende

Oberächen haben, d.h natürliches Holz oder matte

Oberächen, etc.

• Ersetzen Sie niemals das Laser-Modul durch einen anderen Typ

oder eine andere Laser-Klasse.

• Reparaturen des Lasermoduls dürfen nur von Evolution Power

Tools oder seiner autorisierten Vertretung durchgeführt werden.

AUSTAUSCH DER BATTERIEN LASER

Die Stromversorgung der Laser-Führung erfolgt durch zwei

(2) ‘AAA’-Batterien. Diese sollten ersetzt werden, wenn Sie

aufgebraucht sind.

Der Zugang zum Batteriefach erfolgt durch Lösen der Schraube

und Entfernen der Batteriefachabdeckung. (Abb. 5)

Beachten Sie die Polarität der Batterien und bringen Sie die

Abdeckung nach dem Austausch wieder an.

6. EINSTELLUNG DES FUSSPLATTENWINKELS

Hinweis: Die Fußplatte ist ab Werk so eingestellt, dass das

Sägeblatt in einem Winkel von 90º zur Fußplatte schneidet.

Die Fußplatte kann gekippt werden in einem Winkel von bis zu

450 auf jede Seite mit Raststellungen bei 15º, 30º und 45º.

Einstellen der Fußplatte:

WARNUNG: Die Stichsäge vor der Einstellung der Fußplatte von

der Stromversorgung trennen.

34

Page 35

www.evolutionpowertools.com

• Den Fußplattenschuh aus Kunststo lösen und für den späteren

Wiederanbau sicher aufbewahren. (Abb. 6)

• Das Staubabsaug-Adapterrohr wenn montiert entfernen und für

den späteren Wiederanbau sicher aufbewahren. (Abb. 7)

• Die Innensechskantschraube lösen, welche die Fußplatte an der

Maschine befestigt. (Abb. 8)

• Die Fußplatte auf den gewünschten Winkel kippen. Um eine der

Raststellungen einzurasten, wird es notwendig sein, die Fußplatte

vor und zurück zu schieben je nach erforderlicher Stellung.

• Die Innensechskantschraube vorsichtig anziehen, um die

Gewinde nicht zu beschädigen.

• Das Staubabsaug-Adapterrohr wieder anbringen.

• Den Fußplattenschuh aus Kunststo wieder anbringen und dabei

sicherstellen, dass alle sechs (6) Befestigungsbügel (2 vorne an der

Fußplatte und 2 an jeder Seite) richtig sitzen.

Hinweis: Die Raststellungen dienen nur als Orientierung: Für

die genaue Einstellung der Fußplatte empfehlen wir, eine

Winkellehre zu verwenden (nicht mitgeliefert).

7. SPLITTERSCHUTZ

Es stehen zwei (2) Splitterschutzabdeckungen zur Verfügung.

Der vordere Splitterschutz sollte immer angebracht werden und

der Fußplatten-Splitterschutz kann wenn erforderlich an die

Maschine angebracht werden.

Anbringen des vorderen Splitterschutz:

• Sicherstellen, dass die Maschine von der Stromversorgung

getrennt ist.

• Der vordere Schutz (Abb. 9) steckt auf der Vorderseite

der Maschine unter der Laser-Führung und vor dem

Sägeblattschutz aus Stahl.

Abb. 7

Ansicht auf das Adapterrohr

in Betriebsposition.

Abb. 8

Detailansicht der

Innensechskantschraube

Hinweis: Dieser Schutz ist exakt gefertigt und entwickelt,

nur um an Ort und Stelle zu stecken. Die Konstruktion hat

genug ‘Federkraft’, damit der Schutz vorsichtig in seiner

Betriebsposition positioniert werden kann. Der Bediener sollte

vorsichtig vorgehen und sicherstellen, dass der Schutz nicht ‘mit

Gewalt’ an Ort und Stelle gedrückt wird mit dem dazugehörigen

Risiko den Schutz zu beschädigen. Den Schutz vorsichtig in

seine Betriebsposition aufsetzen.

Der Fußplatten-Splitterschutz (Abb. 10) kann beim Sägen

langer gerader Linien hilfreich sein. Die Verwendung dieses

Schutz hilft, das Schwingen des Sägeblatts bei einem Schnitt zu

verhindern.

35

Abb. 9

Detailansicht auf den

vorderen Schutz in

Betriebsposition.

Page 36

www.evolutionpowertools.com

Abb. 10

Detailansicht auf den

Fußplattenschutz

in Betriebsposition

vor Montage des

Fußplattenschuhs.

Clamp

Abb. 11

Parallelkantenführung.

Anbringen des Fußplatten-Splitterschutz:

• Sicherstellen, dass die Maschine von der Stromversorgung

getrennt ist.

• Den Fußplattenschuh aus Kunststo lösen und für den

späteren Wiederanbau sicher aufbewahren.

• Den Fußplatten-Splitterschutz so positionieren, dass das ‘V’

zur Rückseite der Maschine zeigt und die erhöhte Plattform

im Hals der Maschine positioniert ist. Das Einrasten in der

Maschine sicherstellen und dann den Fußplattenschuh wieder

über der Fußplatte anbringen.

8. PARALLELKANTENFÜHRUNG

Die mitgelieferte Parallelkantenführung kann an jeder Seite der

Maschine angebracht werden. Sie kann ein hilfreiches Werkzeug

beim Schneiden gerader Linien sein, die parallel zu einer

vorhandenen Kante sind.

Montieren der Parallelkantenführung:

• Die Kreuzschlitzschraube in der Klemme der

Parallelkantenführung lösen und die Klemme vom Arm der

Führung schieben.

• Die Klemme in der erforderlichen Betriebsposition entweder

an der rechten oder linken Seite der Fußplatte der Maschine

direkt vorm Sägeblatt positionieren.(Abb. 11).

• Den Arm der Parallelkantenführung durch die Klemme und die

beiden (2) rechteckigen Schlitze in der Fußplatte schieben.

• Die Kantenführung auf den erforderlichen Abstand einstellen

und dann die Kreuzschlitzschraube anziehen, um die

Kantenführung sicher an Ort und Stelle zu verriegeln.

Hinweis: Der vordere Splitterschutz kann an der Maschine

angebracht werden, wenn die Parallelkantenführung montiert ist.

9. GEBLÄSE

Die Stichsäge ist mit einem Gebläse ausgestattet. Dieses kann

verwendet werden, um vom Sägeblatt erzeugten Staub aus

dem Schnittbereich zu blasen und dabei die Schnittlinie(n) frei

und sichtbar zu halten.

Hinweis: Wir empfehlen, das Gebläse in Verbindung mit

einer geeigneten Werkstatt-Staubabzugsvorrichtung zu

verwenden, die an den Staubabsaugadapter der Stichsäge

angeschlossen ist. Wir empfehlen, das Gebläse beim Sägen von

Metall oder Materialien, die ein Schmiermittel erfordern, nicht

zu verwenden. Mechanische Vakuumstaubabsaugung unter

Verwendung des Adapterrohrs funktioniert immer besser, wenn

das Gebläse ausgeschaltet ist.

36

Page 37

www.evolutionpowertools.com

Wir empfehlen, dass das Luftgebläse wird nicht verwendet,

wenn das Schneiden von Metall oder beim Schneiden von

Materialien, die ein Schmiermittel erforderlich. Mechanische

Staubabsaugung mit dem Adapter Rohr wird immer besser mit

dem Luftgebläse eingeschaltet “AUS”.

Einschalten des Gebläses:

• Den ‘Gebläse’-Schiebeschalter ganz nach rechts (vom

Bediener aus gesehen) schieben (Abb. 12)

Ausschalten des Gebläses:

• Den ‘Gebläse’-Schiebeschalter ganz nach links schieben.

10. STAUBABSAUGUNG

Diese Stichsäge ist mit einem Staubabsaugungs-Adapterrohr

ausgestattet. (Abb. 13)

Wenn immer möglich ist es eine gute Vorgehensweise, das

Adpaterrohr an eine Werkstatt-Staubabsaugungseinrichtung

anzuschließen. Das Gebläse sollte ausgeschaltet sein.

Bei der Arbeit hilft die Verwendung einer

Staubabsaugeinrichtung dabei, den Arbeitsplatz sauber und

staubfrei zu halten, was Bediensicherheit und -komfort erhöht

und der Sägegenauigkeit durch den Bediener hilft.

HINWEISE ZUM SCHNEIDEN

Hinweis: Immer sicherstellen, dass die Fußplatte der Stichsäge

während dem ganzen Sägevorgang in engem Kontakt mit