Page 1

RAGE 6

Original Instructions

EN

FR

IT

NL

Date Published: 01/03/2016Written in UK English

Page 2

Page 3

ENGLISH

Original Instructions

NL

Page 4

EN

EN

FR

www.evolutionpowertools.com

TABLE OF CONTENTS

English Page 4

Français Page 30

Italiano Pagina 60

Nederlands Pagina 90

Important Information Page 5

Warranty Page 5

Specification Page 6

Labels & Symbols Page 7

General Safety Rules Page 8

Additional Specific Safety Rules Page 9

Machine Overview Page 12

Service Parts Diagram Page 14

Operation Mitre Saw Page 15

Operation Table Saw Page 21

Maintenance Page 25

Environmental Protection Page 27

EC - Declaration of Conformity Page 28

IT

4

Page 5

www.evolutionpowertools.com

IMPORTANT

Please read these operating and safety

instructions carefully and completely. For

your own safety, if you are uncertain about

any aspect of using this equipment please

access the relevant Technical Helpline,

the number of which can be found on

the Evolution Power Tools website. We

operate several Helplines throughout our

worldwide organization, but Technical

help is also available from your supplier.

WEB

www.evolutionpowertools.com/register

EMAIL

info@evolutionpowertools.com

Congratulations on your purchase

of an Evolution Power Tools Machine.

Please complete your product registration

‘online’ as explained in the A4 online

guarantee registration leaflet included

with this machine. You can also scan the

QR code found on the A4 leaflet with

a Smart Phone. This will enable you to

validate your machine’s guarantee period

via Evolutions website by entering your

details and thus ensure prompt service

if ever needed. We sincerely thank you

for selecting a product from Evolution

Power Tools.

EVOLUTION LIMITED GUARANTEE

Evolution Power Tools reserves the right

to make improvements and modifications

to the product design without prior notice.

Please refer to the guarantee registration

leaflet and/or the packaging for details of

the terms and conditions of the guarantee.

Evolution Power Tools will, within the

guarantee period, and from the original date of

purchase, repair or replace any goods found to

be defective in materials or workmanship. This

guarantee is void if the tool being returned

has been used beyond the recommendations

in the Instruction Manual or if the machine

has been damaged by accident, neglect, or

improper service.

This guarantee does not apply to machines

and / or components which have been altered,

changed, or modified in any way, or subjected

to use beyond recommended capacities

and specifications. Electrical components

are subject to respective manufacturers’

warranties. All goods returned defective shall

be returned prepaid freight to Evolution Power

Tools. Evolution Power Tools reserves the right

to optionally repair or replace it with the same

or equivalent item.

There is no warranty – written or verbal – for

consumable accessories such as (following list

not exhaustive) blades, cutters, drills, chisels

or paddles etc. In no event shall Evolution

Power Tools be liable for loss or damage

resulting directly or indirectly from the use

of our merchandise or from any other cause.

Evolution Power Tools is not liable for any

costs incurred on such goods or consequential

damages. No officer, employee or agent of

Evolution Power Tools is authorized to make

oral representations of fitness or to waive any

of the foregoing terms of sale and none shall

be binding on Evolution Power Tools.

Questions relating to this limited guarantee

should be directed to the company’s head

oce, or call the appropriate Helpline number.

EN

FR

IT

NL

5

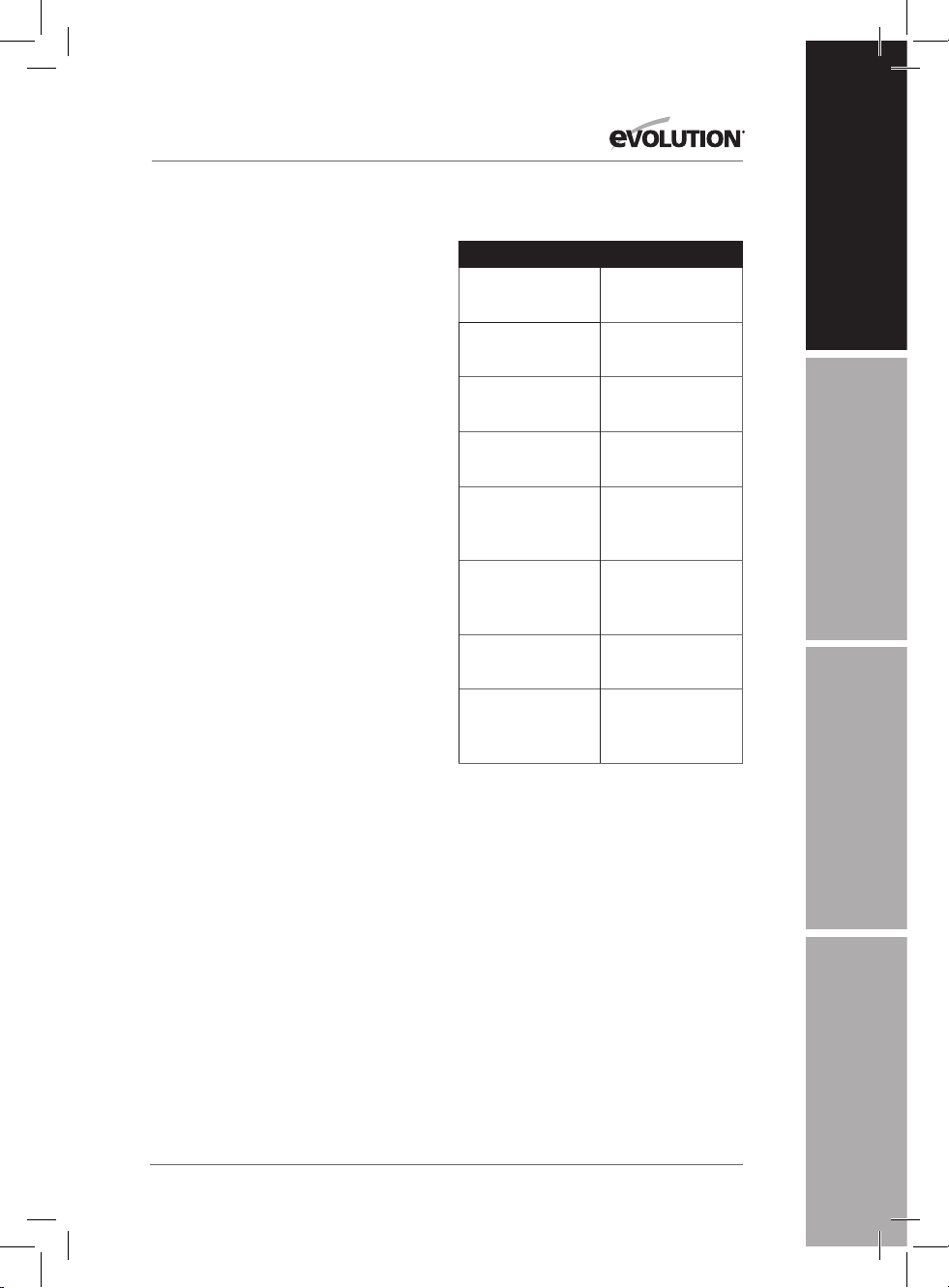

Page 6

www.evolutionpowertools.com

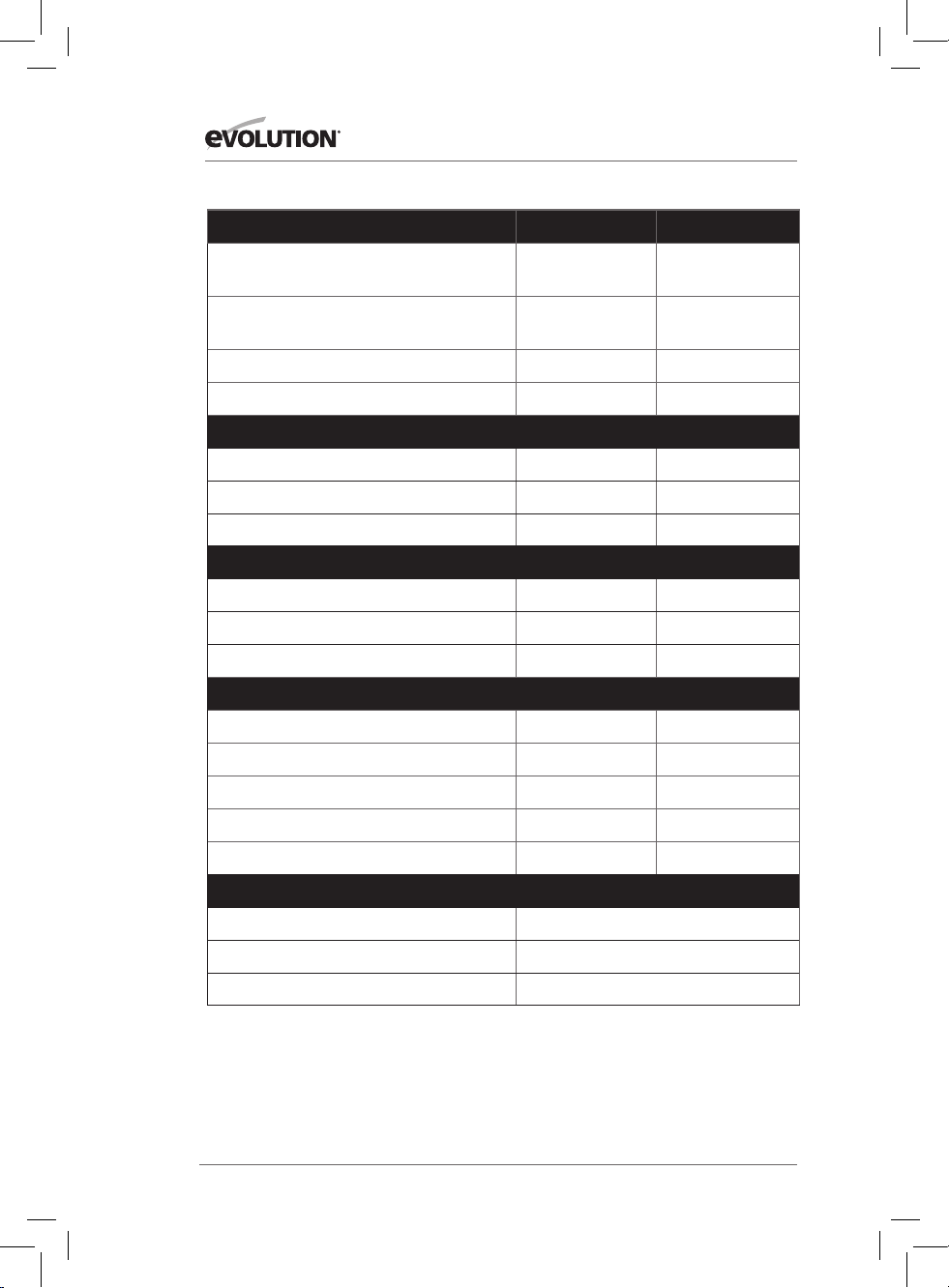

SPECIFICATIONS

DESCRIPTION METRIC IMPERIAL

Motor (UK/EU) 230V-240V ~ 50Hz

Motor (UK) 110V ~ 50Hz

1000W

1000W

Speed (No Load) 2500rpm 2500min

5A

9A

-1

Weight 18kg 40lb

MITRE SAW MODE MAXIMUM CUTTING

Mild Steel 6mm 1/4”

Wood - 90º Mitre x 90º Bevel 150 x 70mm 5-7/8 x 2-3/4”

Wood - 45º Mitre x 45º Bevel 50 x 50mm 2 x 2”

TABLE SAW MODE MAXIMUM CUTTING

Mild Steel 6mm 1/4”

Wood 40mm 1-1/2”

Table Dimensions 570 x 450mm 22-1/2 x 17-3/4”

BLADE

Diameter 255mm 10˝

Number Of Teeth 28 28

Bore Diameter 25.4mm 1”

Kerf 2mm .078”

Max Speed 2750min

-1

2750rpm

NOISE & VIBRATION DATA

Sound Pressure Level L

Sound Power Level L

Vibration Level 2.5 m/s

A 106.3dB(A) K=3dB(A)

P

W

A 119.3dB(A) K=3dB(A)

2

K =1.5dB(A)

6

Page 7

www.evolutionpowertools.com

LABELS & SYMBOLS

Symbol Description

V

Amperes

Alternating current

No load speed

Wear safety goggles

Wear ear protection

Do not touch

Wear dust protection

CE certification

Waste electrical and

electronic equipment

Hz

Min

n

A

-1

~

o

Volts

Hertz

Speed

WARNING: Do not operate machine if

warning and / or instruction labels are missing

or damaged. Contact Evolution Power Tools for

replacement labels.

Only use genuine Evolution replacement

saw blades. Unauthorized blades may

be dangerous! Keep saw blades securely

fastened. Check the blade flanges for debris

before installing any new blade. Do not use

dull, broken or damaged blades. Check the

blade regularly for condition and wear. A

damaged or worn blade should be replaced

immediately. Beware of ejecting chips as

they may be HOT. Always make provision for

the safe handling of excess material. Keep

machine base and rotary table free from dirt

and other debris.

VIBRATION LEVEL

The declared vibration total value has been

measured in accordance with a standard test

method and may be used for comparing one

tool with another.

The declared vibration total value may also be

used in a preliminary assessment of exposure.

WARNING: The vibration emission during

actual use of the power tool can differ from the

declared total value depending on the ways

in which the tool is used. The need to identify

safety measures and to protect the operator

are based on an estimation of exposure in the

actual conditions of use (taking account of all

parts of the operating cycle, such as the times

the tool is switched off, when it is running idle,

in addition to trigger time).

EN

FR

IT

To obtain an additional copy of your manual,

please contact Evolution Power Tools at:

UK: +44 (0)114 251 1022

WEB: www.evolutionpowertools.com

7

NL

Page 8

www.evolutionpowertools.com

IMPORTANT SAFETY INSTRUCTIONS

To reduce the risk of electric shock, this

equipment is fitted with an approved cord and

plug for its intended country of use. Do not

change the cord or plug in any way.

GENERAL SAFETY RULES

Read and understand all instructions before

operating this product. Failure to follow all

instructions listed below may result in electric

shock, fire and / or serious personal injury.

SAVE THESE INSTRUCTIONS

FOR FUTURE REFERENCE.

The term “power tool” in the warnings refers to

your mains-operated (corded) power tool or

battery-operated (cordless) power tool.

WARNING: When using electric tools, basic

safety precautions should always be followed

to reduce the risk of fire, electric shock and

personal injury.

Please read all of these instructions before

attempting to operate this machine. Save this

manual for future reference.

1) Keep work area clear. Cluttered work

areas invite accidents.

2) Consider work area environment. Do not

expose tools to rain. Do not use tools in damp

or wet locations. Keep work area well lit. Never

use tools near flammable liquids or gases.

3) Protect yourself against electric shock.

Avoid body contact with earthed or grounded

surfaces.

4) Keep other people away. Do not let

others, especially children, come close to the

work, and touch the tool or the extension lead.

Keep them away from the work area.

5) Store idle tools. When not in use, tools

should be stored in a dry locked-up place, out

of children’s reach.

6) Never force the tools. Your tools will be

more efficient and safer when used at the rate

for which they were intended.

7) Use the right tool. Do not force small tools

to do the job of a heavy duty tool. Do not use

tools for purposes not intended; for example

do not use circular saws to cut tree limbs or

logs.

8) Dress properly. Do not wear loose clothing

or jewellery which may get caught in moving

parts. Non-skid footwear is recommended

when working outdoors. If you have long hair,

tie it back and wear protective hair covering.

9) Use protective equipment. Use safety

glasses. Use face or dust mask if cutting

operations create dust.

10) Connect dust extraction equipment.

If the machines have a connection for dust

extraction equipment, ensure these are

connected and properly used.

11) Do not damage the cable. Never pull the

power cable to disconnect the machine. Keep

the cable away from heat, oil and sharp edges.

12) Secure workpiece. Where possible, use

clamps or a vice to hold the workpiece. It’s

much safer than using your hands.

13) Don’t over reach. Keep proper footing

and balance at all times.

14) Maintain tools in good working

condition. Keep cutting tools sharp and

clean for better performance and optimum

safety. Follow instructions for lubricating

and changing accessories. Inspect power

cables regularly and, if damaged, have them

replaced by an authorised service centre.

Inspect extension cables regularly and replace

immediately if damaged. Keep handles dry,

clean and free from oil and grease at all times.

15) Disconnect tools. Disconnect tools from

the power supply when not in use, before any

maintenance operation and when changing

accessories such as blades, bits, cutters, etc.

16) Remove adjusting keys and spanners.

Get into the habit of checking that adjusting

keys and spanners have been removed from

the machine before turning it on.

8

Page 9

www.evolutionpowertools.com

17) Avoid unintentional starting.

Ensure switch is in “off” position before

plugging in the machine.

18) Use proper extension leads. When the

tool is used outdoors, use only extension leads

intended for outdoor use and labelled as such.

19) Stay alert. Concentrate on what you are

doing, use common sense and do not operate

the tool when you are tired.

20) Check that no part is damaged.

Before using a tool, make sure that it is in

good working order. Check the alignment and

condition of moving parts, mounting and any

other aspect that may affect its operation. A

guard or other part that is damaged should be

properly repaired or replaced by an authorised

service centre unless otherwise indicated in

this instruction manual. Do not use the tool if

the switch does not turn on and off.

WARNING. The use of any accessory or

21)

attachment other than one recommended in

this instruction manual may present a risk of

personal injury.

22) Have your tool repaired at an

authorised service centre. This electric tool

complies with current safety rules. Repairs

should only be carried out by an authorised

service centre using original spare parts.

Failing this, the user could expose themselves

to considerable danger.

HEALTH ADVICE

WARNING: When drilling, sanding, sawing

or grinding, dust particles will be produced. In

some instances, depending on the materials

you are working with, this dust can be

particularly harmful to you (e.g. lead from

old gloss paint).You are advised to consider

the risks associated with the materials you

are working with and to reduce the risk of

exposure.

You should:

• Work in a well-ventilated area.

• Work with approved safety equipment, such

as dust masks that are specially designed to

filter microscopic particles.

ADDITIONAL SAFETY INSTRUCTIONS FOR

YOUR MITRE SAW

WARNING: Be sure to read and understand

all instructions. Failure to follow all instructions

listed below may result in electric shock, fire

and/or serious personal injury.

1) Know your power tool. Read operator’s

manual carefully. Learn the applications and

limitations, as well as the specific potential

hazards related to this tool.

2) Always wear safety glasses or eye

shields when using this mitre saw. Everyday

eyeglasses have only impact-resistant lenses;

they are not safety glasses.

3) Always protect your lungs. Wear a face

mask or dust mask if the operation is dusty.

4) Always protect your hearing. Wear

hearing protection during extended periods

of operation.

5) Inspect the machines power cord

regularly and if damaged have it repaired

or replaced. Always be aware of the cords

location.

6) Always check for damaged parts. Before

further use of the tool, a guard or other part

that is damaged should be carefully checked

to determine if it will operate properly and

perform its intended function. Check for

misalignment or binding of moving parts,

breakage of parts, and any other condition

that may affect the tool’s operation. A guard or

other part that is damaged should be properly

repaired or replaced at a qualified service

centre. Keep guards in place and in working

order.

7) Do not abuse the cord. Never use the

cord to carry the tool or pull the plug from the

outlet. Keep cord away from heat, oil, sharp

edges or moving parts. Replace damaged

cords immediately. Damaged cords increase

the risk of electric shock.

EN

FR

IT

NL

9

Page 10

www.evolutionpowertools.com

8) Always make sure that your extension

cord is in good condition. When using an

extension cord be sure to use one that is heavy

enough to carry the current that your tool will

draw. An undersized cord will cause a drop

in line voltage, resulting in loss of power and

overheating.

9) Do not use the tool while tired or under

the influence of drugs, alcohol or any

medication. Following this rule will reduce

the risk of electric shock, fire or serious

personal injury.

10) Save these instructions. Refer to

them frequently and use them to instruct

others who may use this tool. If someone

borrows this tool, make sure they have these

instructions also.

11) When the correct blade to cut the

material has been fitted, this saw is

recommended for cutting steel and

ferrous metals, aluminium and nonferrous metals, wood, and plastic only.

12) Do not use saw blades with High Speed

Steel (HSS) or blades that are damaged or

deformed.

13) Replace the table insert when worn.

14) Use only saw blades recommended

by the manufacturer and which are the

exact bore and diameter required for this

machine.

15) Connect your mitre saw to a dust

collecting device (I.D.Ø32mm) when

sawing material likely to cause dust.

16) Select saw blades in relation to

the material to be cut. Use only genuine

Evolution or Evolution recommended

accessories.

17) Check the maximum depth of cut.

18) When sawing long work pieces, always

use extra support to provide better

support, and use clamps or other clamping

devices. To reduce the risk of injury, return

the slide carriage to the full rear position after

each crosscut operation.

19) The operator is adequately trained

in the use adjustment and operation and

operation of the machine.

20) Provide for adequate room lighting at

your workplace or for adequate lighting of

the immediate work area.

21) When fitted with a laser no exchange

with a different type of laser is

permissible. Repairs shall only be carried out

by the laser manufacturer or an authorised

agent.

22) Refrain from removing any cut-offs

or other parts of the workpiece from

the cutting area whilst the machine is

running and the saw head is not in the

rest position. Never reach around the saw

blade. Turn off tool and wait for saw blade to

stop before moving workpiece or changing

settings.

23) Never stand on this tool. Serious injuries

could occur if this tool tips over and you come

into contact with the saw blade.

24) Reduce the risk of unintentional

starting. Make sure switch is in off position

before plugging in.

WARNING: The operation of any mitre saw

can result in foreign objects being thrown

into your eyes, which can result in severe

eye damage. Before beginning power tool

operation, always wear safety goggles or

safety glasses with side shield and a full face

shield when needed.

WARNING: If any parts are missing, do not

operate your mitre saw until the missing parts

are replaced. Failure to follow this rule could

result in serious personal injury.

10

Page 11

www.evolutionpowertools.com

CARRYING YOUR MITRE SAW

Safety Advice

1) Although compact, this saw is heavy.

To reduce the risk of back injury, get

competent help whenever you have to lift the

saw.

2) To reduce the risk of back injury, hold

the tool close to your body when lifting.

Bending your knees so you can lift with your

legs, not your back. Lift by using the handhold

areas at each side of the bottom of the base.

3) Never carry the table mitre saw by

the power cord or the trigger grip of the

handle. Carrying the tool by the power cord

could cause damage to the insulation or the

wire connections resulting in electric shock

or fire.

4) Before moving the saw tighten the mitre

and bevel lock knobs to guard against

sudden movement.

5) Lock the cutting head in its lowest

position. Ensure that the cutting head locking

pin is completely engaged in its socket.

WARNING: Do not use the blade guard

as a ‘lifting point’. The power cord must be

removed from the power supply before

attempting to move the machine.

• Lock down the head using the head locking

pin.

• Loosen the mitre angle lock knob. Push

down the mitre angle lever and rotate the

table to either of its maximum settings.

• Lock the table in position using the locking

knob.

• Use the two carry handle cut-outs

machined into either end of the machine

base, to transport the machine.

Place the saw on a secure stationary work

surface and check the saw over carefully.

Check particularly the operation of all

the machines safety features before

commissioning or operating the machine.

ITEMS SUPPLIED

Description Quantity

Instruction Manual 1

Hold Down Clamp 1

Push Stick 1

Allen Key (Arbor Lock) 1

Allen Key (Blade

Change)

Multi-Purpose Blade

(Fitted)

Rip Fence (Fitted) 1

Auxiliary Lower

Blade Guard

Additional Accessories

In addition to the standard accessories

supplied with this machine, other accessories

are available to improve its performance, these

include the following items:

1) Dust bag – the design of this machine

allows for a dust bag or workshop vacuum

extraction device to be fitted to the rear of the

machine.

2) Specialist cutting blades – use only

Evolution Blades with this machine.

Additional accessories can be obtained by

contacting your local dealer (or Evolution

Power Tools).

1

1

1

EN

FR

IT

NL

11

Page 12

www.evolutionpowertools.com

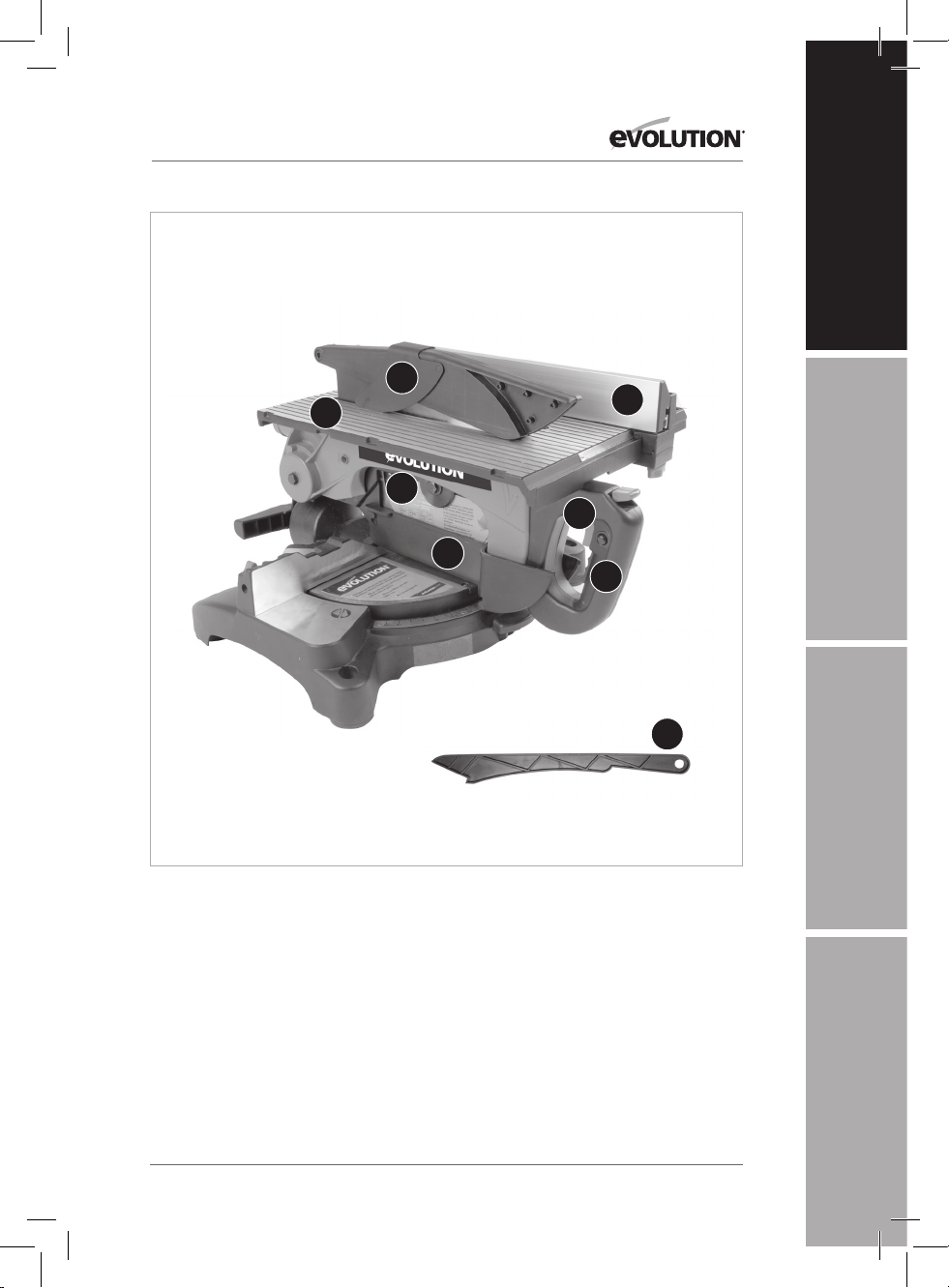

OVERALL VIEW OF RAGE 6 IN MITRE SAW CONFIGURATION

6

1

3

7

5

9

13

12

14

Know your parts

1. On/off trigger switch

2. Cutting head locking pin

3. Cutting handle

4. Rotary table

5. Lower blade guard

6. Upper blade guard

7. Blade

84

11

2

10

8. Mitre lock knob

9. Bevel angle locking lever

10. Mitre angle scale

11. Positive stop locking lever

12. Fence

13. Hold down clamp

14. Mounting hole

12

Page 13

www.evolutionpowertools.com

OVERALL VIEW OF RAGE 6 IN TABLE SAW CONFIGURATION

5

3

EN

7

6

Know your parts

1. On/off trigger switch

2. Cutting handle

3. Table top

4. Auxilliary lower blade guard

5. Upper blade guard

6. Blade

7. Rip fence

8. Push stick

1

4

2

8

FR

IT

NL

13

Page 14

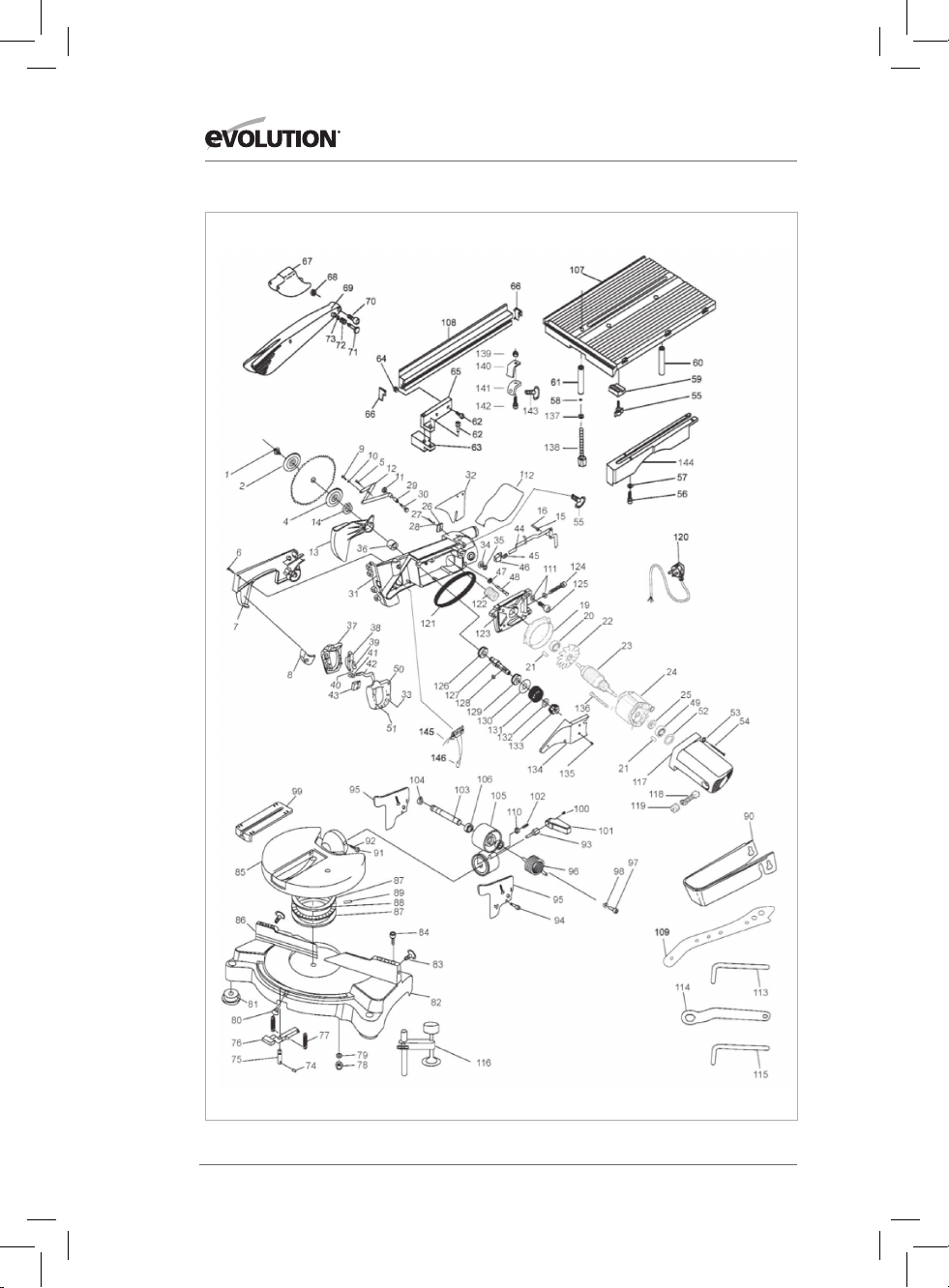

www.evolutionpowertools.com

PARTS DIAGRAM Parts Diagrams can also be downloaded from www.evolutionpowertools.com

14

Page 15

www.evolutionpowertools.com

OPERATION

GETTING STARTED

CAUTION! ALWAYS DISCONNECT THE SAW FROM THE

POWER SOURCE BEFORE MAKING ANY ADJUSTMENTS.

Refer to the “Service Parts List Drawing”. Install a blade as

detailed in the “Installing or Removing the Blade” section.

1. Mounting the Table Mitre Saw

WARNING: To reduce the risk of injury from unexpected saw

movement, place the saw in the desired location either on a

workbench or other recommended leg set. The base of the saw

has four holes to mount the mitre saw. If the saw is to be used in

one location, permanently fasten it to the workbench or leg set

using appropriate bolts with lock washers and nuts.

• Tighten the mitre and bevel locks.

• Position the saw so other people cannot stand behind it.

Thrown debris could injure people in its path.

• Place the saw on a firm, level surface where there is plenty of

room for handling and properly supporting the workpiece.

• Support the saw so that the table is level and the saw does

not rock.

• Bolt or clamp the saw to its support.

EN

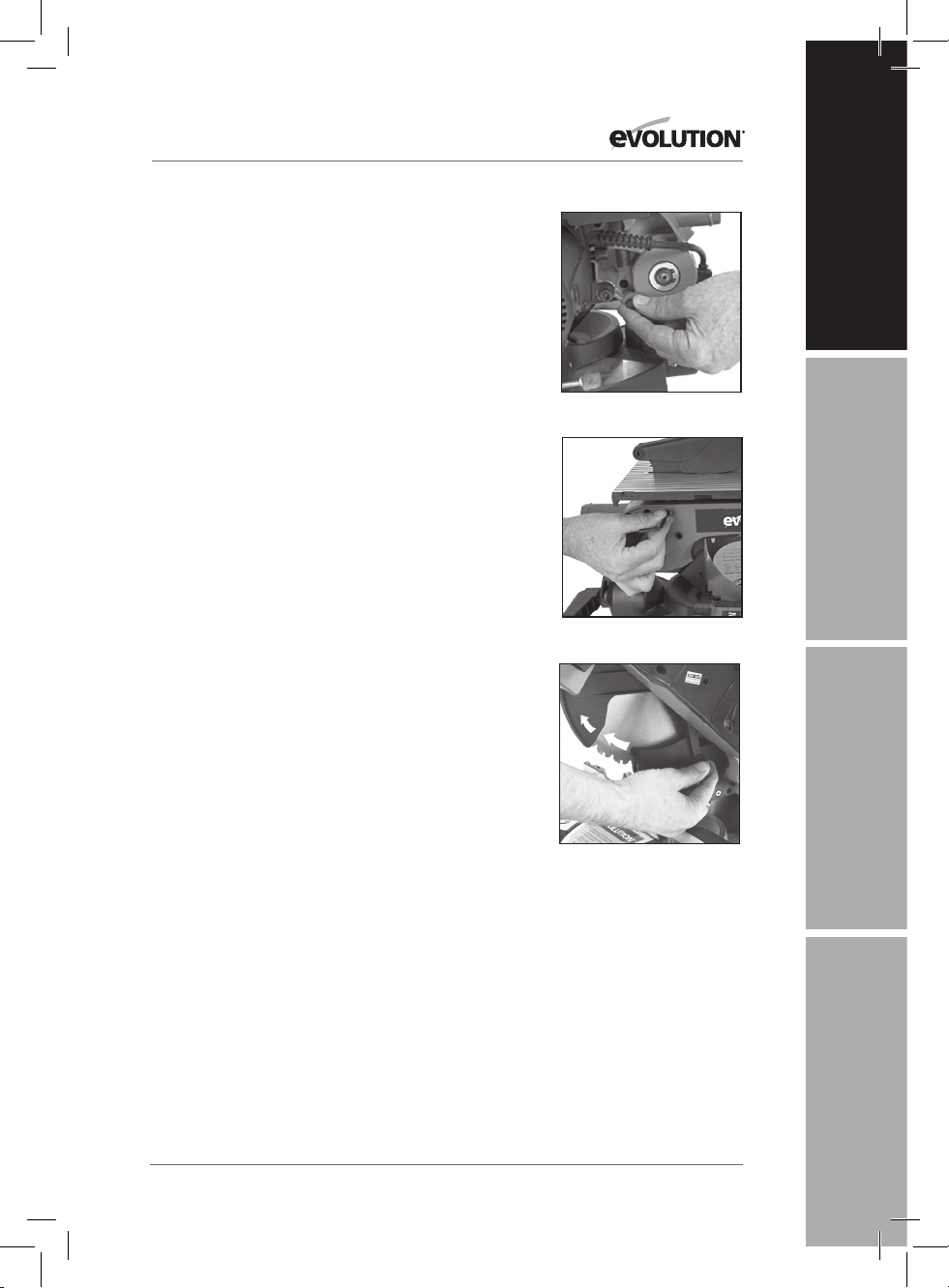

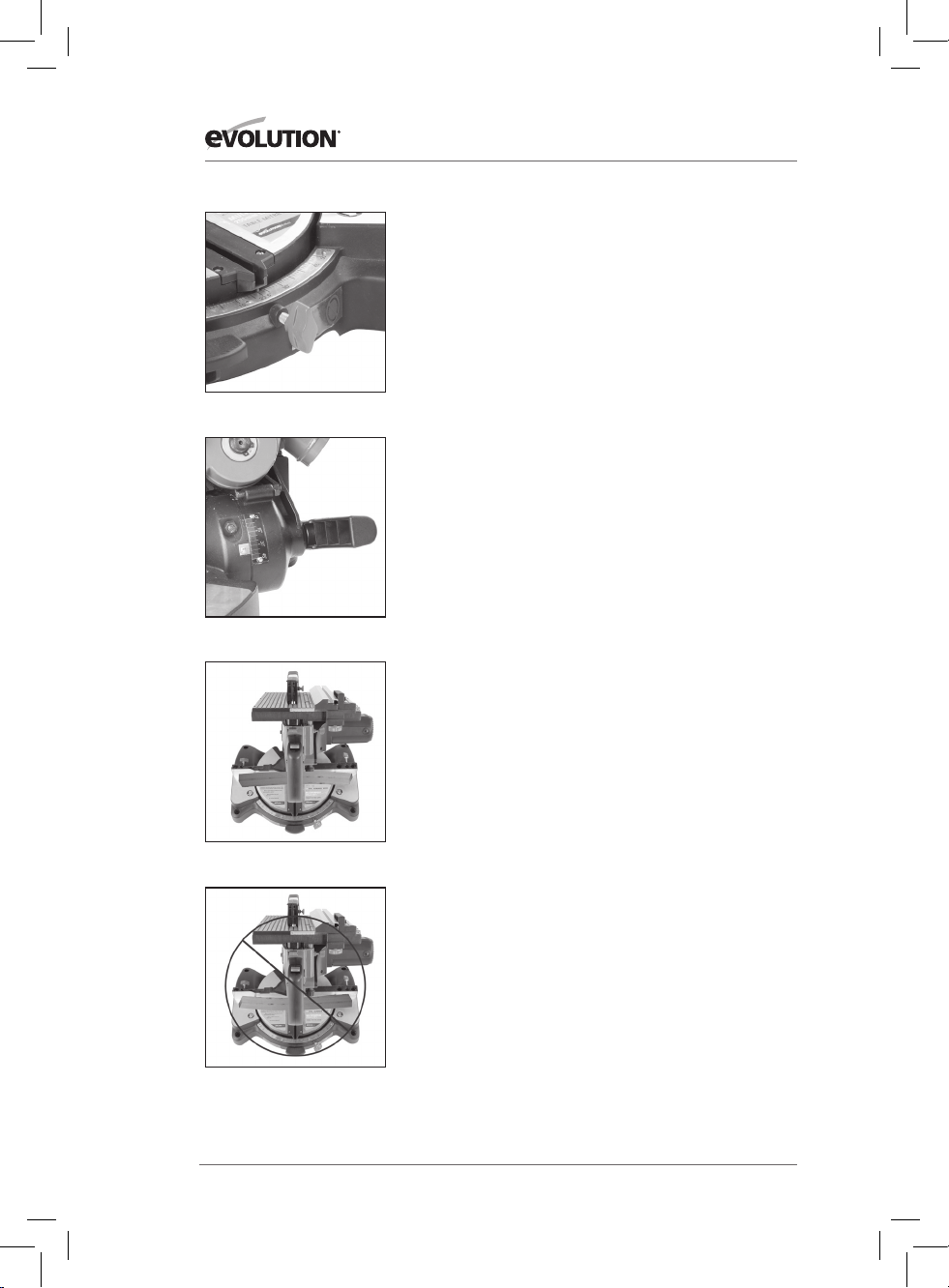

FIG. 1

FR

FIG. 2

2. Installing or Removing the Blade

WARNING: Only use genuine Evolution blades which are

designed for this machine. Ensure that the maximum speed

of the blade is compatible with the machine. Only perform

this operation with the machine disconnected from the mains

supply.

Note: It is recommended that the operator considers wearing

protective gloves when handling the blade during installation

or when changing the machines blade.

• Pull out the cutting head locking pin and allow the cutting

head to rise to its upper position. (Fig. 1)

• Remove the top blade guard with the attached riving knife

by loosening the socket headed fixing screw (Fig. 2) and

withdrawing the riving knife upwards. The riving knife is

slotted for easy removal.

• Push in the sprung loaded lower guard operating pawl and

slide it upwards along the slot. The lower guard will rotate

into the machine exposing the blade. (Fig. 3)

15

IT

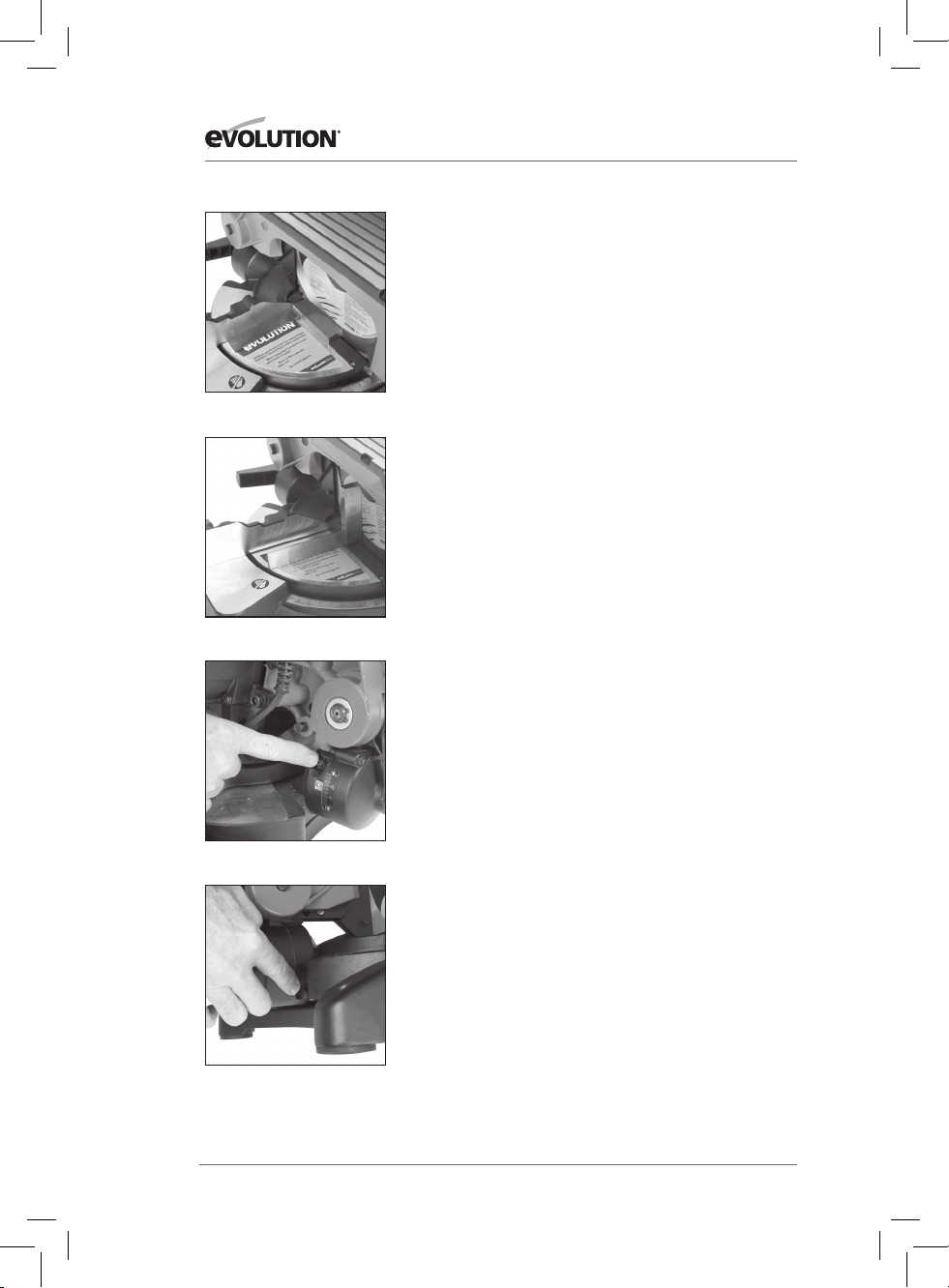

FIG. 3

NL

Page 16

OPERATION

www.evolutionpowertools.com

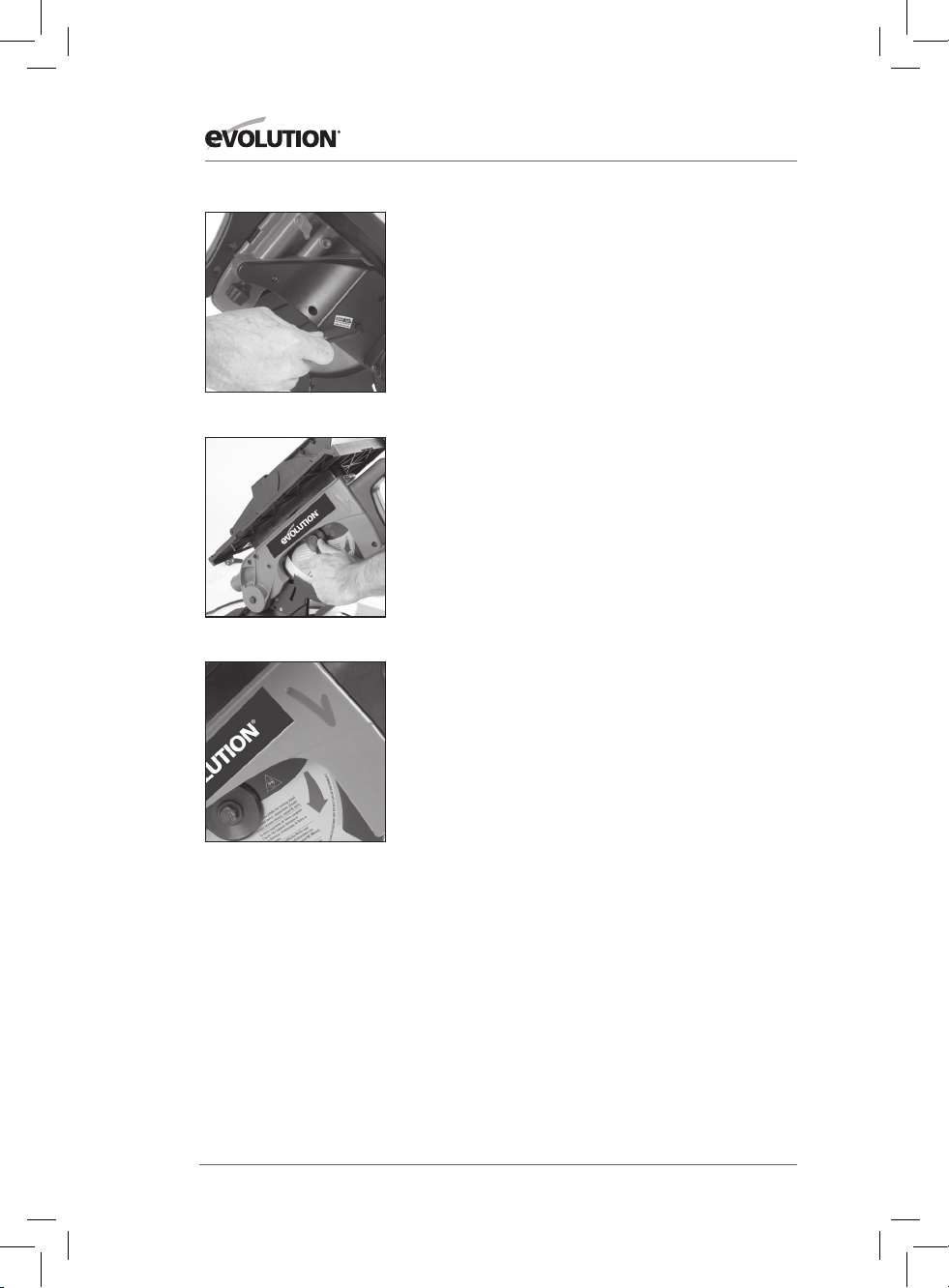

• Insert the supplied hex key into the rear labeled arbor access

port (Fig. 4) Ensure that the hex key engages completely

into the arbor socket. Hold the hex key firmly so that the

machine arbor cannot rotate.

• Using the supplied Blade Change Allen Key, release the blade

arbor screw and remove the outer blade flange and the

blade. (Fig. 4 & 5)

Note: The arbor screw has a LH thread.

FIG. 4

FIG. 5

FIG. 6

• Install the new 255 mm (10”) blade by guiding it down

through the table slot. Make sure the rotation arrow on the

blade matches the clockwise rotation arrow on the upper

guard. (Fig. 6)

Note: The blade teeth should always point downward at the

front of the saw. Be careful and patient, the blade is a very

precise fit within the machine. Sometimes extra clearance

when installing a new blade could be useful. If this is the case

raise the table height of the machine as detailed in Operating

Instructions – Table Saw Configuration – 2 Adjusting the Table

Height.

• Install the outer blade flange and arbor screw. Ensure that

the outer blade flange lugs completely engage into the drive

flats machined on the machine arbor.

• Whilst preventing the arbor from rotating tighten the arbor

screw using moderate force, but do not overtighten.

• Return the lower guard to the ‘safe’ position by sliding the

sprung loaded operating pawl downwards along the slot

until it locks in its operating position.

• Alternatively lower and cutting head to its lowest position.

The lower guard should return automatically to its operating

position with the operating pawl correctly deployed.

• Reinstall the riving knife and top blade guard. Check that

the riving knife is close to, but does not foul, the saw blades

teeth.

• A gap of 3-5mm between the edge of the riving knife and

tips of the blade teeth is ideal.

• Ensure the both Allen Keys are removed and the machines

arbor rotates freely.

• Ensure the blade guards are fully functional before using the

machine.

Note: Spacers and spindle rings should not be used with this

machine and/or blade.

16

Page 17

www.evolutionpowertools.com

OPERATION

3. Debris collection bag (Optional Accessory)

The Debris Collection Bag should be attached at the debris

extraction port.

• Slide the frame of the collection bag on to the outlet of the

extraction port, ensuring that it is firmly connected.

• To release the bag, slide the frame in the opposite direction.

Note: To ensure optimal dust collection, empty the dust bag

when it becomes approximately 60% full.

WARNING: Before cutting metal materials, the collection bag

should be removed and replaced with a blanking plug

(not supplied).

Reinstate the dust bag when cutting wood.

EN

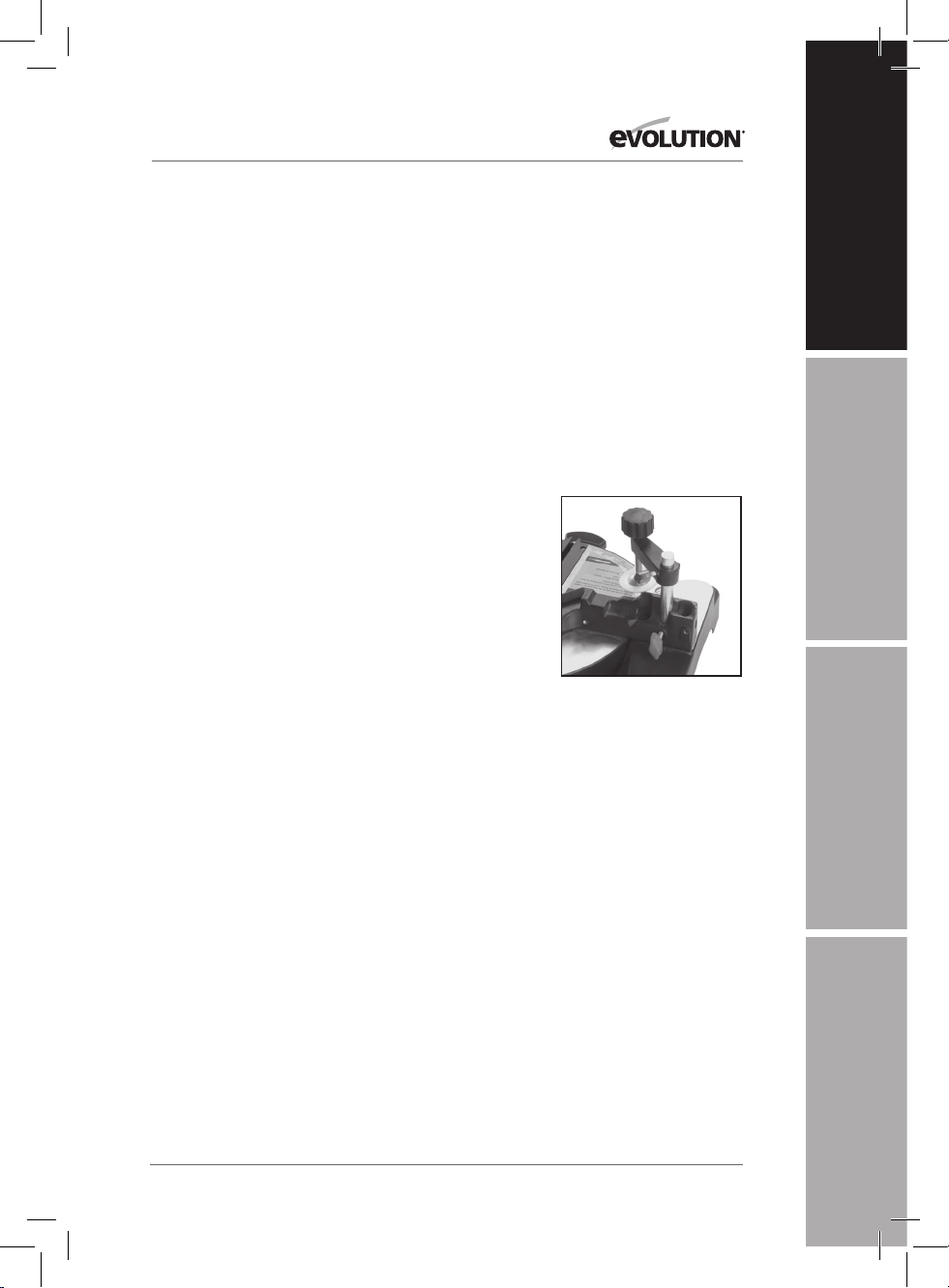

4. Fitting the Hold Down Clamp (Fig. 7)

Two sockets (one either side) are incorporated into the rear of

the machines fence.

• Fit the clamp to the retaining socket that best suits the

cutting application, ensuring that it is fully pushed down.

• Tighten the fence thumbscrew to lock the pillar into the

socket.

• Put the workpiece to be cut onto the saw rotary table.

• Adjust the clamp using the thumbscrew and hand-wheel so

that it securely holds the workpiece to the saw table. Ensure

that the clamp does not foul the blade or any other moving

machine parts.

FR

FIG. 7

IT

17

NL

Page 18

OPERATION

www.evolutionpowertools.com

OPERATING INSTRUCTIONS

MITRE SAW CONFIGURATION

Disconnect the Table Mitre Saw from the mains supply and

inspect your Saw before each use.

Note: It is important that the operator is adequately trained

in the use, adjustment and operation of the machine and has

read this instruction and safety manual before commencing

operations.

WARNING: To reduce the risk of injury, always unplug the

saw before changing or adjusting any of the machines parts.

Compare the direction of rotation arrow on the guard to

direction arrow on the blade. The blade teeth should always

point downward at the front of the saw. Check the tightness of

the arbor screw.

In mitre saw configuration the lower auxiliary guard should be

removed from the machine and safely stored for future use.

The upper blade guard must be secured to the riving knife

using the sprung loaded locating pin.

The table should be adjusted so that it is in its upper most

position. See section 2 Table Saw Configuration for adjusting

procedure. In this position the upper blade guard will be

effectively locked down over the crown of the blade.

FIG. 8

1. Releasing the saw head

• Gently press down on the cutting handle.

• Pull out the head stop latching knob and allow the head to

rise to its upper position. (Fig. 8)

Note: The cutting head will automatically lock in the upper

position.

We recommend that when the machine is not in use the cutting

head is locked in its down position, and the latching knob fully

engaged in its socket.

2. Preparing to make a cut

• Avoid awkward operations and hand positions where a

sudden slip could cause fingers or hands to move into

the blade.

• Cut only one workpiece at a time.

• Clear everything except the workpiece and related support

devices away from the blade before turning the mitre

saw on.

• Secure workpiece using clamps to hold the workpiece

securely.

18

Page 19

www.evolutionpowertools.com

OPERATION

3. Body and Hand Position

• Never place hands near the cutting area and keep hands

away from the path of the blade.

• Hold the workpiece firmly to the fence to prevent

movement. Use a clamp if necessary but check that it is

positioned so that it does not foul the blade.

• Before making a cut. Make a dry run with the power off so

you can see the path of the blade.

• Keep hands in position until the ON/OFF trigger has been

released and the blade has completely stopped.

4. On/Off Switch Operation

The On/Off switch is located in the cutting handle (Fig. 9) and

incorporates several safety features to guard against accidental

actuation.

To switch ‘On’

• Grasp the saw handle.

• Slide the trigger switch safety locking slide downwards.

• Press the trigger switch. The machine will start.To release the

lower safety guard and cutting head, press the head release

thumb button on the top of the saw handle. (Fig. 10)

• Gently lower the cutting head through the workpiece to

make a cut.

To switch ‘Off’

• Allow the cutiing head to rise to its upper position.

• Release the trigger switch, thumb button and safety locking

slide.

• Wait for the saw blade to completely stop before removing

your hand from the cutting handle.

• The safety locking slide and head release button will

automatically deploy to ‘safety mode’.

EN

FR

FIG. 9

IT

5. Chop Cutting

The saw handle is gently pushed down to cut through a

workpiece.

• Place the workpiece on the table and against the fence in the

desired position. Secure with clamps if necessary.

• Grasp the saw handle.

• Turn on the saw using the trigger switch and allow the blade

to reach full operating speed.

• Press the cutting head release button to release the saw

head.

• Gently push the saw head down and cut through the

workpiece.

• After the cut is completed, turn off the saw by releasing the

trigger switch, and allow the blade to come to a complete

halt before removing your hands or the workpiece from the

machine.

19

FIG. 10

NL

Page 20

OPERATION

FIG. 11

www.evolutionpowertools.com

6. Mitre Cutting

Any angle from 50º left to 50º right is available, and a protractor

scale can be found on the front of the machine table.

Positive stops are provided at 0º and 15º, 22.5º, 30º and 45º to

the RH and LH side.

• Loosen the mitre angle locking screw. This is situated on the

RH side of the machine table just above the 22.5º index mark.

• Push down the positive stop locking lever and turn the table

to the desired angle as indicated on the mitre protractor

scale by using the cutting handle. Lock in the required

position by tightening the mitre angle locking screw.

(Fig. 11) A small index pointer can be found under the table

insert to aid accurate setting.

• If utilizing the positive stop facility it is still good practice to

lock the table into position using the mitre locking screw

• Start the saw and allow it to reach full operating speed

before making the cut.

7. Bevel Cutting

The cutting head can be set at any angle up to a 45º to the LH

side only.

FIG. 12

FIG. 13

FIG. 14

The bevel angle locking lever is found at the rear of the

machine and a protractor guide and pointer is incorporated

into the casting to the front of the locking lever to aid setting.

(Fig. 12)

• Loosen the bevel lock lever.

• Tilt the saw head to the desired angle. Use the protractor

guide provided to the front of the lever to aid setting.

• Ensure the locking lever is tightened securely when the

required angle has been achieved.

• Stand to the left hand side of the handle to make the cut.

8. Compound Cutting

A compound cut is a combination of a mitre cut and a bevel cut.

• Select the required mitre angle as previously described.

• Select the required bevel angle as previously described.

• Ensure the tightness of all adjustment/locking screws before

making a cut.

9. Cutting Bowed Material

Before cutting any workpiece, check to see if it is bowed. If it is

bowed the workpiece must be positioned and cut as shown.

(Fig. 13 & Fig. 14)

Do not position the workpiece incorrectly or cut the workpiece

without the support of the fence.

20

Page 21

www.evolutionpowertools.com

OPERATION

10. Clearing Jammed Material

• Turn mitre saw “OFF” by releasing the trigger switch.

• Allow the blade to come to a complete halt and the cutting

to rise to its upper position if possible.

• Unplug the mitre saw from the mains supply.

• Carefully remove any jammed material from the unit.

11. Supporting Long Workpieces

The free end of a long workpiece should be supported at the

same height as the machines rotary table. The operator should

consider using a remote workpiece support stand or enlisting

competent trained help if thought necessary.

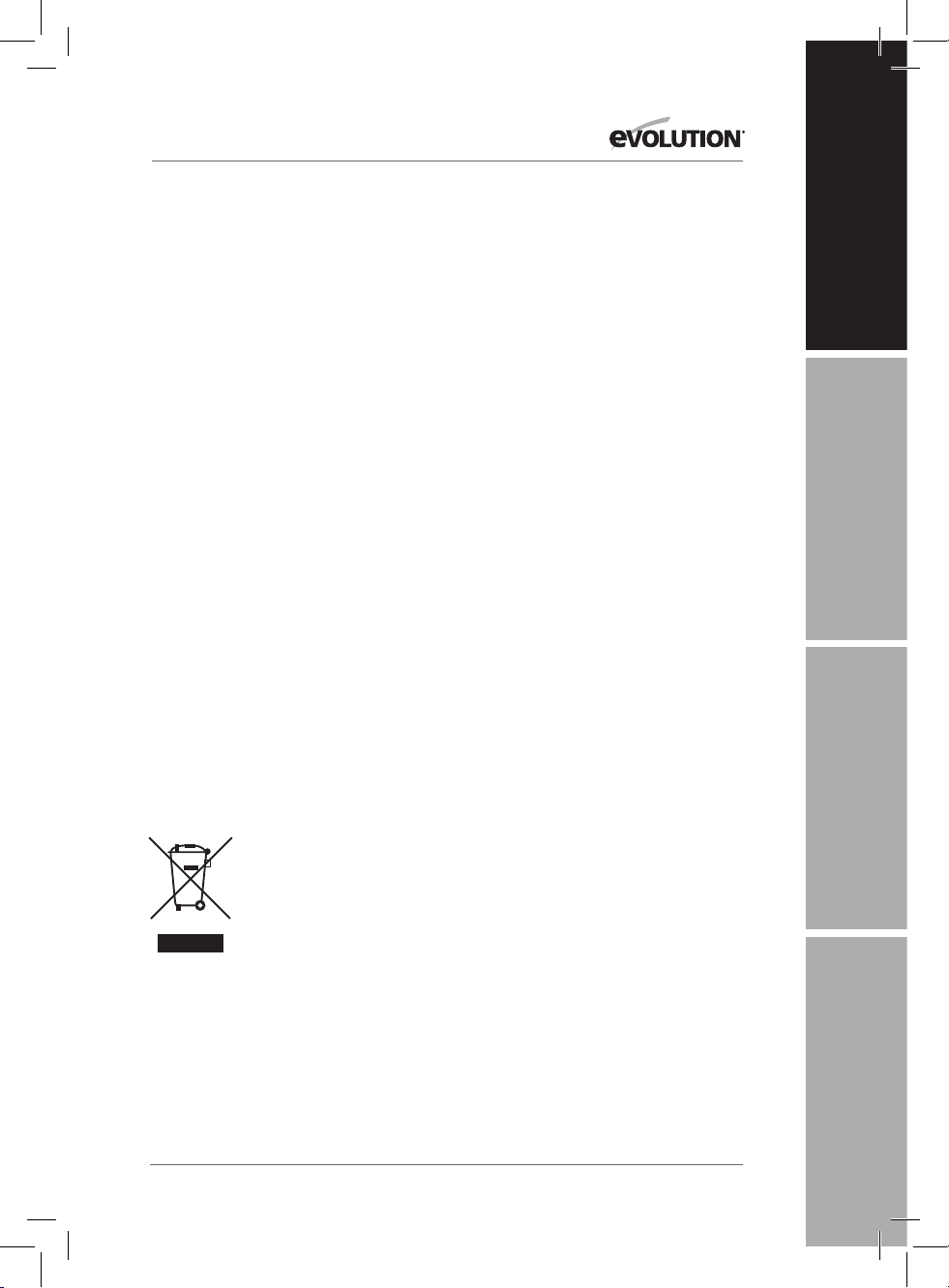

TABLE SAW CONFIGURATION

EN

WARNING: To operate as a table saw certain adjustments/

checks must be carried out to ensure that the machine is

configured correctly. Optimally the table saw is best suited to

the Rip Cutting of sheet material.

• The cutting head must be in the locked down position with

the locking pin completely engaged in its socket.

• The rotary table should be set at 0

with the mitre locking screw.

• The cutting head should be locked at 0

locking lever securely tightened.

º

and locked in position

º

bevel with the bevel

• The auxiliary lower blade guard must be fitted.

Note: Ensure that these checks/adjustments are carried out with

the machine disconnected from the mains supply.

1. Fitting the Auxiliary Lower Blade Guard

• Ensure that the cutting head is in its upper position.

• Position the lower auxiliary guard over the rotary table insert

and slide it to the rear. Narrow end of the guard to the rear,

open wide end to the front.

• Ensure that the RH and LH sides of the guard engage with

their respective locating pins on the lower rear fixed blade

guard, and that the cut out slot on the RH side of the auxiliary

guard straddles the machine fence. (Fig. 15)

• When satisfied that the lower auxiliary guard is correctly

positioned, lower the cutting head to its lowest position and

securely lock in place with the locking pin.

• Check the integrity of the installation, and that the machine

handle has trapped the auxiliary guard in place. (Fig. 16)

WARNING: The Auxiliary Blade Guard must be fitted when

this machine is used as a Table Saw. Do not operate this machine

if the Auxiliary Blade Guard is damaged or missing.

FIG. 15

FIG. 16

FR

IT

NL

21

Page 22

OPERATION

www.evolutionpowertools.com

2. Adjusting the Table Height

The height of the machine table top above the machine motor

can be adjusted. This enables your Evolution Table/Mitre Saw

to mimic the rise and fall facility found on many conventional

table saws. The cutting depth of the blade can thereby be

adjusted from 0mm to 50mm.

WARNING: Only adjust the height of the table with the

machine disconnected from the mains power supply.

FIG. 17

FIG. 18

FIG. 19

To adjust:

• Loosen the two table pillar wing nuts, one to the front, and

one to the rear underneath the machine table. (Fig. 17)

• Turn the height adjustment screw (Fig. 18) clockwise or

counter-clockwise until the saw blade protrudes through the

table by the required amount.

• Tighten the two table pillar wing nuts securely.

Note: The upper blade guard can be rotated backwards to

allow access to the table top so that a machinist ruler can be

used to measure the height of the blade above the table.

To gain access –

• Pull out the sprung loaded locating pin at the rear of the

upper guard (Fig. 19)

• Rotate the guard backwards.

WARNING: Always return the guard to its operational

position with the locating pin fully engaged in its hole in the

riving knife when measuring has been completed.

Never use the machine without the upper guard in its

operational position. Check the operation of the upper guard

after every adjustment.

Return the table to its original (lowest) position when cutting is

completed.

22

Page 23

www.evolutionpowertools.com

OPERATION

3. The Rip Fence

An adjustable Rip Fence is positioned to the RH side of the

blade. The Rip Fence can be locked into the desired position by

tightening a wing nut found underneath the Rip Fence Carrier.

(Fig. 20)

The Rip Fence rail is an integral part of the machine table and

contains a measurement scale to aid setting.

Do not position the Rip Fence to the LH side of the blade.

Forwards and backwards adjustment of the rip fence is possible.

Loosen the two socket headed screws with a suitable Allen

key and slide the aluminium extrusion to the desired position.

Tighten the socket screws firmly. (Fig. 21)

Note: We recommend that normally the rip fence be adjusted

so that the rear of the guide is level with the rear of the blade

where it emerges from the table.

The aluminium fence guide can be attached to the fence carrier

in a ‘Hi’ and a ‘Lo’ position. The ‘normal’ and factory supplied

position is with the fence set to the ‘Hi’ setting.

The ‘Lo’ setting can be useful when cutting very thin sheet

material.

To re-position the Rip Fence to the ‘Lo’ setting:

• Loosen the two socket headed screws.

• Slide the aluminium extrusion from the carrier.

• Re-attach the aluminium extrusion to the carrier in the ‘Lo’

position.

• Tighten the two socket headed screws with the fence in the

required position. (Fig. 22)

BASIC TABLE SAW OPERATIONS

EN

FIG. 20

FR

FIG. 21

IT

WARNING: Never attempt freehand cuts on this machine.

Always use the Rip Fence Guide to minimise the possibility

of the blade binding and kickback. We recommend that

the saw blade protrudes through the material to be cut by

approximately 3mm.

Adjust the cutting height of the blade by adjusting the height

of the machine table as previously described. This machine is

not suitable for cutting rebates or stopped grooves.

A workshop dust extraction device can be connected to the

extraction port found at the rear of the machine if required.

23

FIG. 22

NL

Page 24

OPERATION

FIG. 23

www.evolutionpowertools.com

1. On/Off Switch Operation

To start the machine:

• Slide the trigger switch safety locking slide downwards.

• Press the trigger switch. The machine will start.

• Push in the trigger locking button (Fig. 23) for continuous

motor operation.

When cutting is completed, gently press the trigger switch to

release the trigger locking button. The machine will stop and

the safety locking slide will automatically deploy.

2. Rip cutting

Rip cutting is cutting along the length of a piece of material

rather than across it.

Rip cutting should always be done with the Rip Fence set to the

desired width and on the RH side of the machines table.

Note: Check that the rip fence is locked in position and is

parallel to the saw blade. Check that the riving knife is properly

aligned with the saw blade.

When ripping small section material a push stick should be

used to feed/guide the final 300mm of the material past the

blade. A push stick should always be used when making cuts of

less than 300mm.

When ripping long boards or large panels always use a remote

work support or enlist competent trained help.

Feed the workpiece through the saw keeping it indexed against

the rip fence. Use smooth, steady pressure and employ a push

stick if necessary. Hands should never be in line with the blade.

24

Page 25

www.evolutionpowertools.com

MAINTENANCE

WARNING:

the mains supply before any maintenance tasks or adjustments

are attempted.

Cleaning

After each use the machine should be cleaned. Remove all

sawdust etc from the visible parts of the machine with a

vacuum cleaner. A vacuum cleaner can also be connected to

the machine dust extraction port at the rear of the machine.

This should remove debris from the inside of the machine.

Never use solvents to clean plastic parts, as solvents can

damage them. Clean only with a soft damp cloth.

Riving Knife

The riving knife is a very important component and comes

factory fitted and correctly aligned and adjusted. The riving

knife prevents the work from binding as it passes through the

blade. Inspect the riving knife at regular intervals and replace it

if it is worn or damaged.

Note: Use only a genuine Evolution Riving Knife, as this is a

dedicated component for this machine. Non genuine parts

could be dangerous. If in any doubt, please contact the

Helpline.

Push Stick

A plastic push stick is provided with the machine. When not in

use store the push stick on the machine.

Note: If the push stick becomes damaged it should be replaced.

If the operator makes their own push stick, we recommend that

it follows the same pattern as that supplied.

Ensure that the machine is disconnected from

EN

FR

IT

Replacement push sticks are available from Evolution

Power Tools.

25

NL

Page 26

MAINTENANCE

FIG. 24

FIG. 25

www.evolutionpowertools.com

PRECISION SETTING OF ANGLES

WARNING: Before making any adjustments, or carrying out

maintenance to the saw, make sure that it is disconnected from

the mains supply.

When all adjustments, settings or maintenance have been

completed, make sure that all keys or wrenches have been

removed, and that all screws, bolts and other fittings are

securely tightened.

While the machine has been factory set, it is advisable that the

0º setting of the rotary table and the 90º perpendicular setting

of the tilt head be checked, as these positions may have moved

in transit.

To confirm the 0º rotary table setting:

• Set the rotary table at 0

handle.

º

and tighten the rotary table lock

• Use an engineers square (not supplied) to check that the

angle between the machines fence guide and the blade is

90º. (Fig. 24)

• If the angle requires adjustment, loosen the four fence

guide clamp screws and align the fence guide against the

engineers square. Retighten the clamp screws.

Similarly check that the angle of the saw blade to the face of the

table is 90º. (Fig. 25)

To adjust:

• Loosen the locknut

• Using a suitable allen key/screwdriver turn the 90

adjustment screw clockwise or counter clockwise until

correct alignment has been achieved. (Fig. 26)

º

• Retighten the locknut.

FIG. 26

FIG. 27

The 45º bevel setting can also be adjusted.

• Set the cutting head to 45

the blade and the machine table with a 45º set square (not

provided).

• To adjust, loosen the 45

a suitable allen key/screwdriver turn the adjusting screw

clockwise or anti- clockwise until the correct alignment is

achieved. (Fig. 27)

º

and check the angle between

º

adjusting screw locknut and using

• Retighten the locknut.

26

Page 27

www.evolutionpowertools.com

MAINTENANCE

PLUG REPLACEMENT

The fuse in the main plug of your power tool should always be

replaced with one of identical rating.

Check the voltage given on your power tool matches the supply

voltage.

The power tool is supplied with a fitted plug, however if you

should need to fit a new plug follows the instruction below.

IMPORTANT

The wire in the mains lead are coloured in accordance with the

following code:

Blue - Neutral

Brown - Live

Green/Yellow - Earth

The wire that is coloured blue must be connected to the terminal

that is marked with the letter N. The wire that is coloured brown

must be connected to the terminal that is marked with the letter

L. The wire that is coloured green/yellow must be connected to

the terminal that is marked with the letter E.

A 13AMP (BS1363 or BS1363/A) plug must be used and a 5 AMP

fuse must be fitted.

EN

FR

ENVIRONMENTAL PROTECTION

Waste electrical products should not be disposed of with

household waste. Please recycle where facilities exist. Check

with your Local Authority or retailer for recycling advice.

27

IT

NL

Page 28

www.evolutionpowertools.com

EC DECLARATION OF CONFORMITY

In accordance with EN ISO 17050-1:2004

The manufacturer of the product covered by this Declaration is:

Evolution Power Tools, Venture One, Longacre Close, Holbrook Industrial Estate, Sheffield, S20 3FR.

The manufacturer hereby declares that the machine as detailed in this declaration fulfils all the

relevant provisions of the Machinery Directive and other appropriate directives as detailed below.

The manufacture further declares that the machine as detailed in this declaration, where

applicable, fulfils the relevant provisions of the Essential Health and Safety requirements.

The Directives covered by this Declaration are as detailed below:

2006/42/EC. Machinery Directive.

2004/108/EC. (until Apr 19th 2016) Electromagnetic Compatibility Directive.

2014/30/EU. (starting from Apr 20th 2016) Electromagnetic Compatibility Directive.

93/68/EC. The CE Marking Directive.

2011/65/EU. The Restriction of the Use of certain Hazardous

Substances in Electrical Equipment (RoHS) Directive.

2002/96/EC as The Waste Electrical and Electronic Equipment (WEEE) Directive.

amended by

2003/108/EC .

And is in conformity with the applicable requirements of the following documents:

EN 61000-6-3:2007 • EN 55014-1:2006 • EN 55014-2+A2:2008

EN 60745-1:2009 • EN 60745-2-11+A12:2009

Product Details

Description: RAGE6 255mm (10”) MULTIPURPOSE MITRE/TABLE SAW

Evolution Model No: RAGE62551 / RAGE62552 / RAGE62552EU

Brand Name: EVOLUTION

Voltage: 110V / 230V ~ 50Hz

Input: 1000W

The technical documentation required to demonstrate that the product meets the requirements

of directive has been compiled and is available for inspection by the relevant enforcement

authorities, and verifies that our technical file contains the documents listed above

and that they are the correct standards for the product as detailed above.

Name and address of technical documentation holder.

Signed: Print: Matthew Gavins - Group Chief Executive

Date: 01/03/16

28

Page 29

www.evolutionpowertools.com

NOTES

EN

FR

29

IT

NL

Page 30

®

30

Page 31

EN

FRANÇAIS

Traduction de manuels d’instruction d’origine

FR

IT

31

NL

Page 32

www.evolutionpowertools.com

TABLE DES MATIÈRES

English Page 4

Français Page 30

Italiano Pagina 60

Nederlands Pagina 90

Informations importantes Page 33

Garantie Page 33

Spécifications Page 34

Étiquettes et symboles Page 35

Règles de sécurité générales Page 35

Règles de sécurité particulières supplémentaires Page 38

Présentation de l’appareil Page 42

Schéma des pièces de rechange Page 44

Utilisation de la scie à onglets Page 45

Utilisation de la scie circulaire à table Page 51

Entretien Page 55

Protection de l’environnement Page 57

Déclaration CE de Conformité Page 58

32

Page 33

www.evolutionpowertools.com

IMPORTANT

S’il vous plaît lire les instructions de

fonctionnement et de sécurité attentivement

et complètement. Pour votre propre

sécurité, si vous êtes incertain à propos de

n’importe quel aspect de l’utilisation de cet

équipement s’il vous plaît accéder à la ligne

d’assistance technique concerné, dont le

nombre peut être trouvé sur le site Evolution

Power Tools. Nous exploitons plusieurs

lignes d’assistance téléphonique au long

de notre organisation mondiale, mais l’aide

technique est également disponible auprès

de votre fournisseur.

WEB

www.evolutionpowertools.com/register

EMAIL

info@evolutionpowertools.com

Félicitations pour votre achat d’une machine

Power Tools Evolution. S’il vous plaît remplir

«en ligne» enregistrement de votre produit

comme expliqué dans la brochure A4 garantie

d’inscription en ligne fournis avec l’appareil.

Vous pouvez également scanner le code QR

trouvé sur le dépliant A4 avec un téléphone

intelligent. Cela vous permettra de valider la

période de garantie de votre machine via le

site Evolutions en entrant vos coordonnées

et ainsi assurer un service rapide si

jamais nécessaire. Nous vous remercions

sincèrement de choisir un produit Evolution

Power Tools.

Evolution Power Tools sera, dans la période de

garantie, et à partir de la date d’achat originale,

réparer ou remplacer tout produit reconnu

défectueux dans les matériaux ou de fabrication.

Cette garantie est nulle si l’outil retournées

a été utilisé au-delà des recommandations

contenues dans le manuel d’instructions ou

si l’appareil a été endommagé par accident,

négligence ou une mauvaise utilisation. Cette

garantie ne s’applique pas aux machines et / ou

des composants qui ont été altérés, modifiés ou

modifié de quelque manière, ou soumis à une

utilisation au-delà des capacités et spécifications

recommandées. Les composants électriques

sont soumis aux garanties fabricants respectifs.

Tous les produits défectueux retournés doivent

être retournés franco de port pour Evolution

Power Tools. Evolution Power Tools se réserve

le droit de réparer ou de le remplacer par

un élément identique ou équivalent. Il n’y

a pas de garantie - écrite ou verbale - pour

les accessoires consommables tels que (liste

non exhaustive ci-dessous) lames, fraises,

forets, ciseaux ou des palettes etc En aucun

cas, Evolution Power Tools peut être tenu

responsable des pertes ou dommages résultant

directement ou indirectement de l’ l’utilisation

de nos marchandises ou de toute autre cause.

Evolution Power Tools n’est pas responsable des

frais engagés sur ces biens ou les dommages

indirects. Aucun agent, employé ou agent de

Evolution Power Tools est autorisé à présenter

des observations orales de remise en forme ou

de renoncer à l’une des conditions précédentes

de la vente et n’est nullement lié par Evolution

Power Tools.

EN

FR

IT

GARANTIE LIMITÉE EVOLUTION

Evolution Power Tools se réserve le droit

d’apporter des améliorations et des

modifications à la conception du produit sans

préavis. S’il vous plaît se référer à la notice

d’enregistrement de la garantie et / ou

l’emballage pour plus de détails sur les termes

et conditions de la garantie.

Les questions relatives à cette garantie limitée

doivent être envoyées au siège social de

l’entreprise, ou composez le numéro assistance

approprié.

NL

33

Page 34

www.evolutionpowertools.com

CARACTÉRISTIQUES

DESCRIPTION MÉTRIQUE IMPÉRIAL

Motor (UK / EU) 230V-240V ~ 50Hz

Motor (UK) 110V ~ 50Hz

1000W

1000W

Vitesse (sans charge) 2500rpm 2500min

5A

9A

-1

Poids 18kg 40lb

SCIE MODE COUPE MAXIMALE

Acier Doux 6mm 1/4”

º

Mitre x 90º Bevel 150 x 70mm 5-7/8 x 2-3/4”

Bois - 90

º

x 45º Mitre Bevel 50 x 50mm 2 x 2”

Bois - 45

SCIE MODE COUPE MAXIMALE

Acier Doux 6mm 1/4”

Bois 40mm 1-1/2”

Dimensions De La Table 570 x 450mm 22-1/2 x 17-3/4”

LAME

Diamètre 255mm 10˝

Nombre De Dents 28 28

Diamètre D'alésage 25.4mm 1”

Trait 2mm .078”

Vitesse Maximale 2750min

-1

2750rpm

DONNÉES DE BRUIT ET DE VIBRATION

Niveau De Pression Acoustique L

Niveau De Puissance Acoustique L

Niveau De Vibration 2.5 m/s

A 106.3dB(A) K=3dB(A)

P

W

A 119.3dB(A) K=3dB(A)

2

K =1.5dB(A)

34

Page 35

www.evolutionpowertools.com

ÉTIQUETTES ET SYMBOLES

Symbole Description

Volts

Amperes

Hertz

Vitesse

Courant alternatif

No vitesse à vide

Ne pas toucher

poussière

Certification CE

Déchets électriques et

équipement électronique

& Recyclage

Hz

Min

n

V

A

-1

~

o

Portez des lunettes de sécurité

Portez des protections auditives

Portez des protections contre la

Triman - Collecte des déchets

AVERTISSEMENT : N’utilisez pas la

machine si les étiquettes d’avertissement

et / ou d’instructions sont absentes ou

endommagées. Contactez Evolution Power

Tools pour le remplacement des étiquettes.

N’utilisez que des lames de scie de rechange

Evolution. Des lames non autorisées peuvent

être dangereuses ! Gardez les lames de la

scie bien serrées. Vérifiez s’il y a des débris

dans les brides de lame avant d’installer

une nouvelle lame. N’utilisez pas de lames

émoussées, cassées ou endommagées.

Vérifiez régulièrement la lame pour voir si

elle est usée et constater de son état. Une

lame endommagée ou usée devrait être

immédiatement remplacée. Faites attention

à la projection de copeaux qui pourraient

être CHAUDS. Veillez toujours à manipuler

l’excédent de matériau de manière sécurisée.

Gardez la base de la machine et la table

tournante propres et libres de tout débris.

NIVEAU DE VIBRATION

La valeur totale des vibrations déclarée a été

mesurée conformément à la méthode de test

standard et peut être utilisée pour comparer

un outil à un autre.

La valeur totale des vibrations déclarée peut

également être utilisée lors d’une évaluation

préliminaire d’exposition.

AVERTISSEMENT : L’émission de

vibrations durant l’utilisation effective de

l’outil électrique peut différer de la valeur

totale déclarée en fonction de la manière dont

l’outil est utilisé. La nécessité d’identifier les

mesures de sécurité et de protéger l’utilisateur

sont basées sur l’estimation d’exposition en

conditions réelles d’utilisation (en prenant

en compte toutes les phases du cycle de

fonctionnement telles que les périodes où

l’outil est éteint, lorsqu’il est allumé mais

inactif, en plus du temps de déclenchement).

EN

FR

IT

Pour obtenir un exemplaire supplémentaire

de votre manuel, veuillez contacter Evolution

Power Tools au :

UK: +44 (0)114 251 1022

WEB: www.evolutionpowertools.com

35

NL

Page 36

www.evolutionpowertools.com

CONSIGNES DE SÉCURITÉ IMPORTANTES

Afin de réduire le risque d’électrocution, cet

appareil a été pourvu d’un cordon et d’une

fiche approuvés pour l’usage dans le pays

pour lequel ils sont prévus. Ne changez pas le

cordon ou la fiche.

RÈGLES DE SÉCURITÉ GÉNÉRALES

Veuillez bien lire et comprendre toutes les

instructions avant d’utiliser ce produit. Le

non-respect des instructions répertoriées cidessous peut entraîner des électrocutions, des

incendies et/ou des blessures graves.

VEUILLEZ CONSERVER CES INSTRUCTIONS

POUR POUVOIR VOUS Y RÉFÉRER

ULTÉRIEUREMENT.

Le terme « outil électrique » dans les

avertissements fait référence aux outils

électriques fonctionnant sur secteur (avec fil)

ou sur batterie (sans fil).

AVERTISSEMENT : Lorsque vous utilisez

des outils électriques, vous devez toujours

prendre les précautions élémentaires de

sécurité suivantes afin de réduire le risque

d’incendie, d’électrocution et de blessures.

Veuillez bien lire toutes ces instructions avant

d’essayer d’utiliser cette machine. Veuillez

conserver ce manuel pour pouvoir vous y

référer ultérieurement.

1) Gardez l’espace de travail propre.

Les espaces de travail encombrés sont

propices aux accidents.

2) Tenez compte de l’environnement de

votre lieu de travail. N’exposez pas les outils

à la pluie. N’utilisez pas les outils dans des

endroits humides ou mouillés. L’espace de

travail doit être suffisamment éclairé. N’utilisez

jamais les outils près de liquides ou de gaz

inflammables.

3) Protégez-vous contre les électrocutions.

Évitez tout contact du corps avec des surfaces

mises à la terre.

4) Tenez les autres personnes éloignées.

Ne laissez pas d’autres personnes, en

particulier les enfants, s’approcher du travail,

et toucher l’outil ou la rallonge. Tenez-les

éloignés de l’espace de travail.

5) Rangez tous les outils non utilisés.

Lorsqu’ils ne sont pas utilisés, les outils

devraient être rangés dans un endroit sec

fermé à clé, hors de portée des enfants.

6) Ne forcez jamais sur les outils. Vos outils

seront suffisamment efficaces et sûrs lorsqu’ils

seront utilisés de la façon pour laquelle ils ont

été conçus.

7) Utilisez le bon outil. Ne forcez pas sur

les petits outils pour effectuer le travail d’un

outil puissant. N’utilisez pas les outils à des

fins pour lesquelles ils n’ont pas été conçus ;

par exemple, n’utilisez pas de scies circulaires

pour découper des branches d’arbres ou des

rondins.

8) Portez une tenue appropriée. Ne portez

pas de vêtements ni de bijoux pendants

qui pourraient être happés par les parties

mouvantes. Des chaussures antidérapantes

sont recommandées lorsque vous travaillez

à l’extérieur. Si vous avez de longs cheveux,

attachez-les et portez un filet de protection

pour cheveux.

9) Utilisez un équipement de protection.

Utilisez des lunettes de sécurité. Utilisez

un masque facial ou anti-poussières si les

découpes génèrent de la poussière.

10) Branchez un équipement d’extraction

de poussière. Si les machines sont pourvues

d’un raccord pour un équipement d’extraction

de la poussière, veuillez à ce qu’il soit raccordé

et utilisé correctement.

36

Page 37

www.evolutionpowertools.com

11) N’endommagez pas le câble. e tirez

jamais sur le câble pour débrancher la

machine. Gardez le câble éloigné de la chaleur,

de l’huile et des bords tranchants.

12) Sécurisez la pièce à usiner. Si possible,

utilisez des pinces ou un étau pour coincer la

pièce à usiner. C’est beaucoup plus sûr que de

vous servir de vos mains.

13) Ne vous penchez pas trop. Gardez un

bon appui et un bon équilibre à tout moment.

14) Gardez les outils en bon état. Gardez

les outils de découpe affutés et propres

pour un meilleur rendement et une

sécurité optimale. Suivez les instructions

sur la lubrification et le changement

d’accessoires. Inspectez régulièrement les

câbles d’alimentation et, si endommagés,

faites-les remplacer par un centre d’entretien

autorisé. Inspectez régulièrement les

rallonges et remplacez-les immédiatement si

endommagées. Gardez toujours les poignées

sèches, propres et libres de toute huile et

graisse.

15) Débranchez les outils. Débranchez

les outils de l’alimentation électrique

lorsqu’ils ne sont pas utilisés, avant chaque

opération d’entretien et lors du changement

d’accessoires tels que des lames, des forets,

des couteaux, etc.

16) Retirez les clavettes et clés de calage.

Prenez l’habitude de vérifier que les clavettes

et clés de calage aient bien été retirées de la

machine avant de la mettre en marche.

17) Évitez les démarrages impromptus.

Veillez à ce que l’interrupteur soit sur la

position « arrêt » avant de brancher la

machine.

18) Utilisez les bonnes rallonges.

Lorsque l’outil est utilisé à l’extérieur, utilisez

uniquement des rallonges spéciales usage

extérieur et étiquetées comme telles.

19) Restez sur vos gardes. Concentrez-vous

sur ce que vous êtes en train de faire, restez

pragmatique et n’utilisez pas l’outil si vous êtes

fatigué.

20) Vérifiez qu’aucune pièce ne soit

endommagée. Avant d’utiliser un outil, veillez

à ce qu’il fonctionne bien. Vérifiez l’alignement

et l’état des pièces mouvantes, du montage

et d’autres aspects qui pourraient affecter son

fonctionnement. Tout carter ou autres pièces

endommagées devraient être correctement

réparées ou remplacées par un centre

d’entretien autorisé sauf si autrement indiqué

dans ce manuel d’instructions. N’utilisez pas

l’outil si l’interrupteur ne peut pas être mis sur

marche ou sur arrêt.

AVERTISSEMENT : L’utilisation de

21)

tout accessoire autre que celui recommandé

dans ce manuel d’instructions pourrait

présenter un risque de blessure.

22) Faites réparer votre outil dans un

centre d’entretien autorisé. Cet outil

électrique se conforme aux règles de sécurité

en vigueur. Les réparations devraient

uniquement être effectuées par un centre

d’entretien autorisé utilisant des pièces de

rechange d’origine. Dans le cas contraire,

l’utilisateur pourrait s’exposer à des risques

considérables.

CONSEILS DE SANTÉ

AVERTISSEMENT : Lors du perçage,

ponçage, sciage ou meulage, des particules

de poussière sont générées. Dans certains

cas, en fonction des matériaux avec lesquels

vous travaillez, cette poussière peut être

particulièrement dangereuse pour votre santé

(ex. plomb d’anciennes peintures brillantes).

Nous vous recommandons de tenir compte

des risques associés aux matériaux avec

lesquels vous travaillez et de réduire le risque

d’exposition.

EN

FR

IT

NL

37

Page 38

www.evolutionpowertools.com

Vous devriez :

• Travailler dans un endroit bien aéré.

• Travailler en portant un équipement de

protection agréé tel que des masques antipoussières spécialement conçus pour filtrer

les particules microscopiques.

INSTRUCTIONS DE SÉCURITÉ

COMPLÉMENTAIRES POUR VOTRE SCIE À

ONGLETS

AVERTISSEMENT : Veuillez bien lire

et comprendre toutes les instructions. Le

non-respect des instructions répertoriées cidessous peut entraîner des électrocutions, des

incendies et/ou des blessures graves.

1) Connaissez votre outil sur le bout

des doigts. Veuillez bien lire le manuel

de l’opérateur. Renseignez-vous sur les

applications et les limites, ainsi que les risques

potentiels spécifiques reliés à cet outil.

2) Portez toujours des lunettes de sécurité

ou des protections oculaires lorsque vous

utilisez cette scie à onglets. Des lunettes

normales ne sont pourvues que de verres

résistants aux impacts ; il ne s’agit donc pas de

lunettes de sécurité.

3) Protégez toujours vos voies

respiratoires. Portez un masque facial ou

anti-poussières si l’opération génère de la

poussière.

4) Protégez toujours vos oreilles. Portez

une protection auditive en cas d’utilisations

prolongées.

5) Inspectez régulièrement le câble

d’alimentation de la machine et,

si endommagé, faites-le réparer

ou remplacez-le. Localisez toujours

l’emplacement des cordons.

6) Vérifiez toujours s’il y a des pièces

endommagées. Avant d’utiliser l’outil,

tout carter ou autres pièces endommagées

devraient être soigneusement vérifiées

afin de déterminer si elles fonctionneront

correctement et exécuteront la fonction

pour laquelle elles ont été conçues. Vérifiez

qu’aucune pièce ne soit décalée ou bloquée,

qu’aucune pièce ne soit brisée et assurez-vous

qu’aucun autre problème risque d’affecter

le bon fonctionnement de l’outil. Tout carter

ou autre pièce endommagée devrait être

correctement réparée ou remplacée dans un

centre d’entretien qualifié. Laissez les carters

en place et gardez-les en bon état.

7) Ne maltraitez pas le cordon

d’alimentation. N’utilisez jamais le cordon

pour transporter l’outil ni pour le débrancher

de la prise. Gardez le cordon à l’écart de la

chaleur, de l’huile, des objets tranchants

et des pièces en mouvement. Remplacez

immédiatement les cordons endommagés.

Un cordon endommagé accroît le risque

d’électrocution.

8) Veillez toujours à ce que votre rallonge

soit en bon état. Lorsque vous utilisez

une rallonge, veillez à en utiliser une ayant

un calibre adapté au transport du courant

vers votre outil. Une rallonge d’un calibre

insuffisant entraînera une chute de tension,

qui entraînera à son tour une perte de

puissance et une surchauffe.

9) N’utilisez pas l’outil en état de fatigue

ou sous l’influence de l’alcool, de drogues

ou de médicaments. Le respect de cette

règle réduira le risque d’électrocution,

d’incendie ou de blessure grave.

10) Conservez ces instructions. Consultezles régulièrement et servez-vous en pour

instruire les autres personnes susceptibles

d’utiliser cet outil. Si vous prêtez cet outil à

quelqu’un, veillez également à lui donner ces

instructions.

38

Page 39

www.evolutionpowertools.com

11) Une fois la lame appropriée au

matériau installée, cette scie peut couper

de l’acier et du fer, de l’aluminium et

des métaux non ferreux, du bois et du

plastique uniquement.

12) N’utilisez pas les lames de la scie avec

de l’acier haute vitesse (HSS) ou des lames

endommagées ou déformées.

13) Remplacez l’insert de la table lorsqu’il

est usé.

14) Utilisez uniquement les lames de scie

recommandées par le fabricant et ayant le

même alésage et diamètre que celui requis

pour cette machine.

15) Branchez la scie à onglets à un

dispositif de récupération de la poussière

(D.I. Ø32 mm) lorsque vous sciez un

matériau générant de la poussière.

16) Sélectionnez les lames de la scie en

fonction du matériau à découper. Utilisez

uniquement des accessoires Evolution

d’origine ou des accessoires recommandés par

Evolution.

17) Contrôlez la profondeur de découpe

maximum.

18) Lorsque vous sciez des pièces à usiner

longues, utilisez toujours un support

supplémentaire afin de garantir un

meilleur soutien, et utilisez des pinces

ou d’autres dispositifs de fixation. Pour

réduire le risque de blessure, remettez le

chariot complètement en arrière après chaque

découpe.

19) L’opérateur a été formé de manière

adéquate à l’ajustement et à l’utilisation

de la machine.

20) Éclairez votre espace de travail ou

zone de travail immédiate de manière

adéquate.

21) Lorsqu’elle est pourvue d’un laser,

aucun échange avec un type de laser

différent n’est autorisé. Les réparations

devront uniquement être faites par le fabricant

du laser ou un agent autorisé.

22) Évitez de retirer toute pièce de

découpe ou autres parties de la pièce à

usiner de la zone de découpe lorsque la

machine fonctionne et lorsque la tête de la

scie n’est pas en position de repos. Ne vous

approchez jamais de la lame de la scie. Arrêtez

l’outil et attendez que la lame de la scie s’arrête

avant de déplacer la pièce à usiner ou modifier

les réglages.

23) Ne montez jamais sur cet outil. Des

blessures graves pourraient survenir si cet outil

basculait et si vous entriez en contact avec la

lame de la scie.

24) Réduisez le risque de démarrage

impromptu. Veillez à ce que l’interrupteur soit

sur la position arrêt avant le branchement.

AVERTISSEMENT : l’utilisation d’une

scie à onglets peut entraîner une projection

d’objets étrangers, qui peuvent être à

l’origine de lésions oculaires graves. Avant de

commencer à utiliser l’outil électrique, portez

constamment des lunettes de protection

munies d’écrans latéraux et un masque facial

intégral si nécessaire.

AVERTISSEMENT : S’il manque des

pièces, n’utilisez pas la scie à onglets jusqu’à ce

que les pièces manquantes soient remplacées.

Le non-respect de cette règle pourrait

provoquer des blessures graves.

EN

FR

IT

NL

39

Page 40

www.evolutionpowertools.com

TRANSPORT DE VOTRE SCIE À ONGLETS

Conseils de sécurité

1) Bien que compacte, cette scie est

lourde. Pour réduire le risque de blessures au

dos, demandez à une personne compétente

de vous aider à chaque fois que vous devez

porter la scie.

2) Afin de réduire le risque de blessures

au dos, tenez l’outil près de votre corps

lorsque vous le soulevez. Pliez les genoux

de manière à soulever avec les jambes et non

avec le dos. Soulevez en utilisant les poignées

de chaque côté au bas de la base.

3) Ne portez jamais la scie à onglets/

circulaire à table par le cordon

d’alimentation ou la prise à gâchette

de la poignée. Le transport de l’outil par

son cordon d’alimentation peut détériorer

l’isolation ou les raccordements de câbles et

provoquer une électrocution ou un incendie.

4) Avant de déplacer la scie, serrez les

boutons de verrouillage de l’onglet et

du biseau sur le carter afin d’éviter tout

mouvement soudain.

5) Verrouillez la tête de coupe le plus

bas possible. Veillez à ce que la broche de

fixation de la tête de coupe soit complètement

enclenchée dans sa douille.

AVERTISSEMENT : Ne vous servez pas du

carter de lame comme d’un « point de levage

». Le cordon d’alimentation doit être retiré de

l’alimentation électrique avant d’essayer de

déplacer la machine.

• Verrouillez la tête en utilisant la broche de

fixation de la tête.

• Desserrez le bouton de verrouillage de

l’angle de l’onglet. Abaissez le levier de

l’angle de l’onglet et tournez la table vers

l’un de ses deux réglages maximum.

• Verrouillez la table en utilisant le bouton de

verrouillage.

• Utilisez les deux découpes de la poignée

de transport usinées à chaque extrémité de

la base de la machine, pour transporter la

machine.

Placez la scie sur une surface de travail fixe et

sûre et vérifiez soigneusement le dessus de

la scie.

Vérifiez en particulier le fonctionnement de

toutes les fonctions de sécurité de la machine

avant la mise en service ou l’utilisation.

40

Page 41

www.evolutionpowertools.com

ÉLÉMENTS FOURNIS

Description Quantité

Manuel d’instructions 1

Pince de verrouillage 1

Poussoir 1

Clé Allen

(Verrouillage de l’arbre)

Clé Allen

(Changement de lame)

Lame polyvalente

(Installée)

Guide de refend

(Installé)

Carter de lame

inférieur auxiliaire

EN

1

FR

1

1

1

1

IT

Accessoires complémentaires

En plus des accessoires standards fournis

avec cette machine, d’autres accessoires sont

disponibles pour améliorer ses performances,

ceux-ci incluent les articles suivants :

1) Sac à poussière – cette machine peut être

équipée d’un sac à poussière ou d’un dispositif

d’extraction d’atelier à l’arrière.

2) Lames spéciales – utilisez uniquement des

Lames Evolution sur cette machine.

Vous pouvez obtenir d’autres accessoires

en contactant votre distributeur local (ou

Evolution Power Tools).

NL

41

Page 42

www.evolutionpowertools.com

VUE D’ENSEMBLE DE LA CONFIGURATION DE LA SCIE À ONGLETS RAGE 6

6

1

3

7

5

9

13

12

14

Pièces de la scie circulaire d’établi

1. Interrupteur à gâchette marche/arrêt

2. Broche de verrouillage de la tête de coupe

3. Poignée de découpe

4. Table tournante

5. Carter de lame inférieur

6. Carter de lame supérieur

7. Lame

84

11

2

10

8. Bouton de verrouillage de l’onglet

9. Levier de verrouillage de l’angle du biseau

10. Graduation de l’angle de l’onglet

11. Levier de verrouillage de l’arrêt positif

12. Guide

13. Pince de verrouillage

14. Trou de montage

42

Page 43

www.evolutionpowertools.com

VUE D’ENSEMBLE DE LA CONFIGURATION DE LA SCIE À ONGLETS RAGE 6

5

3

7

EN

6

Pièces de la scie circulaire d’établi

1. Interrupteur-gâchette marche/arrêt

2. Poignée de découpe

3. Haut de la table

4. Carter de lame inférieur auxiliaire

5. Carter de lame supérieur

6. Lame

7. Guide de refend

8. Poussoir

1

4

2

8

FR

IT

NL

43

Page 44

SCHÉMA DES PIÈCES DE RECHANGE

www.evolutionpowertools.com

44

Page 45

www.evolutionpowertools.com

UTILISATION

DÉMARRAGE

ATTENTION ! DÉBRANCHEZ TOUJOURS LA SCIE DE

L’ALIMENTATION ÉLECTRIQUE AVANT DE FAIRE DES

RÉGLAGES.

Veuillez vous référer au « Schéma de la liste des pièces de