Page 1

EN

RAGE3B

Original Instructions

Originalanweisungen

Instructions originales

Istruzioni originali

Originele Instructions

DE

FR

IT

Original written in UK English

NL

Date Published: 01/03/2016

Page 2

Page 3

ENGLISH

Original Instructions

DE

FR

NL

IT

Page 4

www.evolutionpowertools.com

TABLE OF CONTENTS

English Page 2

Deutsch Seite 32

Français Page 62

Italiano Pagina 92

Nederlands Pagina 122

INTRODUCTION Page 5

Guarantee Page 5

Machine Specification Page 6

Labels and Symbols Page 7

Vibration Page 7

Intended use of this Power Tool Page 8

Prohibited use of this Power Tool Page 8

SAFETY PRECAUTIONS Page 9

Electrical Safety Page 9

Outdoor Use Page 9

General Power Tool Safety Instructions Page 11

Additional Safety Instructions Page 13

GETTING STARTED Page 14

Unpacking Page 14

Machine Overview Page 15

Service Parts Diagram Page 16

Assembly and Preparation Page 17

Operating Instructions Page 18

MAINTENANCE Page 29

Environmental Protection Page 29

DECLARATION OF CONFORMITY Page 31

4

Page 5

www.evolutionpowertools.com

EN

(1.2) THIS INSTRUCTION MANUAL

WAS ORIGINALLY WRITTEN IN ENGLISH

(1.3) IMPORTANT

Please read these operating and safety

instructions carefully and completely.

For your own safety, if you are uncertain

about any aspect of using this equipment

please access the relevant Technical Helpline,

the number of which can be found on the

Evolution Power Tools website. We operate

several Helplines throughout our worldwide

organization, but Technical help is also

available from your supplier.

WEB

www.evolutionpowertools.com

(1.4) Congratulations on your purchase

of an Evolution Power Tools Machine.

Please complete your product registration

‘online’ as explained in the A4 online

guarantee registration leaflet included with

this machine. You can also scan the QR code

found on the A4 leaflet with a Smart Phone.

This will enable you to validate your machine’s

guarantee period via Evolutions website by

entering your details and thus ensure prompt

service if ever needed. We sincerely thank

you for selecting a product from

Evolution Power Tools.

EVOLUTION LIMITED GUARANTEE.

Evolution Power Tools reserves the right

to make improvements and modifications

to the product design without prior notice.

Please refer to the guarantee registration

leaflet and/or the packaging for details of

the terms and conditions of the guarantee.

(1.5) Evolution Power Tools will, within

the guarantee period, and from the original

date of purchase, repair or replace any

goods found to be defective in materials or

workmanship. This guarantee is void if the tool

being returned has been used beyond the

recommendations in the Instruction Manual or

if the machine has been damaged by accident,

neglect, or improper service.

This guarantee does not apply to machines

and / or components which have been altered,

changed, or modified in any way, or subjected

to use beyond recommended capacities

and specifications. Electrical components

are subject to respective manufacturers’

warranties. All goods returned defective

shall be returned prepaid freight to

Evolution Power Tools.

Evolution Power Tools reserves the right to

optionally repair or replace it with the same

or equivalent item. There is no warranty –

written or verbal – for consumable accessories

such as (following list not exhaustive) blades,

cutters, drills, chisels or paddles etc. In no

event shall Evolution Power Tools be liable for

loss or damage resulting directly or indirectly

from the use of our merchandise or from any

other cause. Evolution Power Tools is not

liable for any costs incurred on such goods or

consequential damages. No officer, employee

or agent of Evolution Power Tools is authorized

to make oral representations of fitness or

to waive any of the foregoing terms of

sale and none shall be binding on

Evolution Power Tools.

Questions relating to this limited guarantee

should be directed to the company’s head

office, or call the appropriate Helpline number.

DE

FR

IT

NL

5

Page 6

www.evolutionpowertools.com

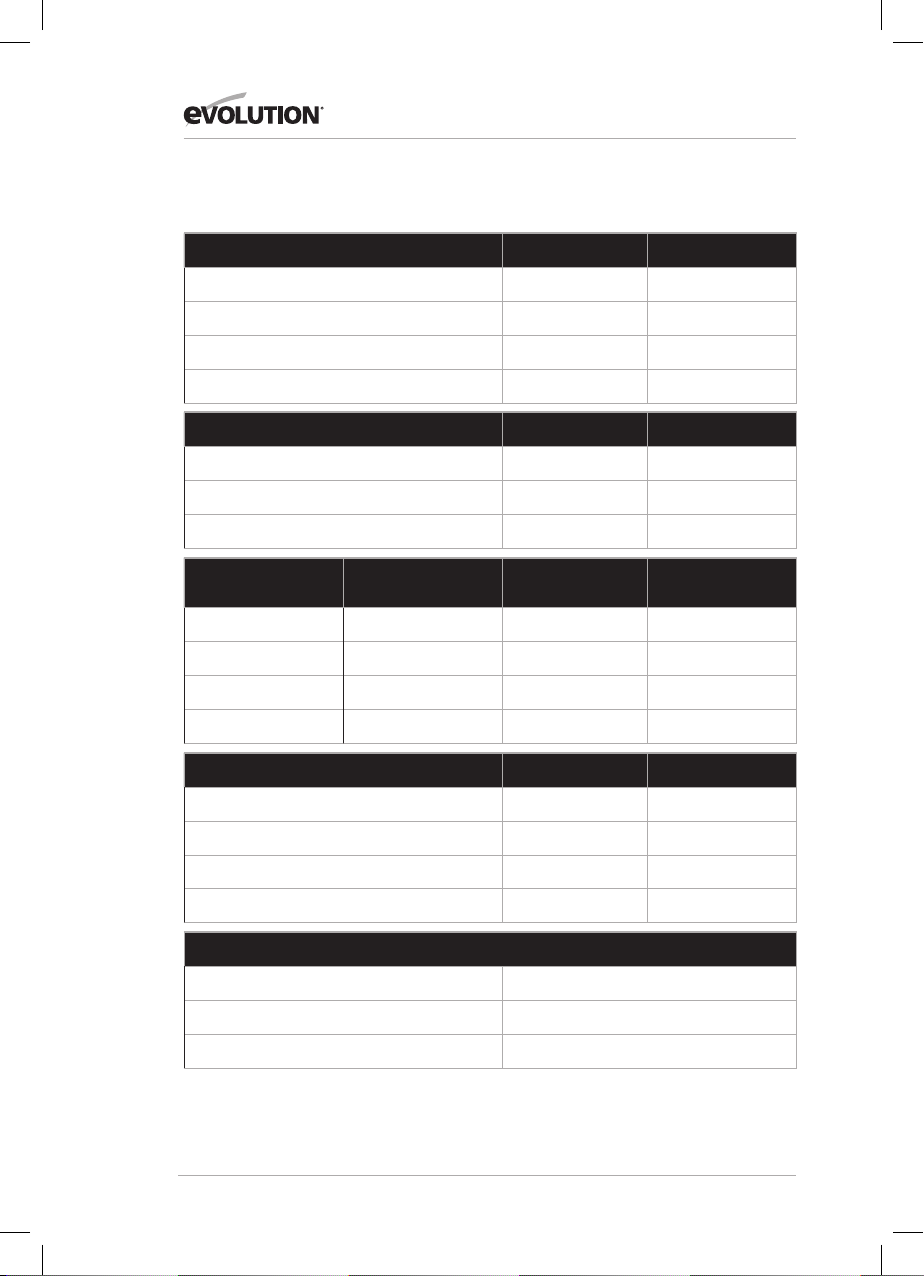

SPECIFICATIONS

MACHINE METRIC IMPERIAL

Motor (230-240V ~ or 110V ~ 50/60 Hz) 1100W 5A

Speed No Load 4000min

Recommended Maximum Duty Cycle 30mins 30mins

Weight 6.4kg 14lb

CUTTING CAPACITIES METRIC IMPERIAL

Mild Steel Plate - Max Thickness 6mm 1/4”

Mild Steel Box Section - Max Wall Thickness 3mm 1/8”

Wood – Max section 50mm x 120mm 2” x 4-3/4””

-1

4000rpm

MITRE BEVEL

MAX WIDTH

OF CUT

MAX DEPTH

OF CUT

0° 0° 120mm (4-3/4”) 50mm (2”)

45L° / 45R° 45° 80mm (3-1/8”) 30mm (1-3/16”)

45L° / 45R° 0° 80mm (3-1/8”) 50mm (2”)

0° 45° 120mm (4-3/4”) 30mm (1-3/16”)

BLADE DIMENSIONS METRIC IMPERIAL

Diameter 210mm 8-1/4”

Bore 25.4mm 1”

Max Speed 4000min

-1

4000rpm

Thickness 1.7mm 1/16”

NOISE & VIBRATION DATA

Sound Pressure LPA 89dB(A) K=3dB(A)

Sound Power Level LWA 102dB(A) K=3dB(A)

Vibration Level 6m/s2 K=1.5m/s

2

6

Page 7

www.evolutionpowertools.com

EN

(1.6) Note: The vibration measurement

was made under standard conditions in

accordance with: BS EN 61029-1:2009.

The declared vibration total value has been

measured in accordance with a standard test

method and may be used for comparing one

tool with another.

The declared vibration total value may also be

used in a preliminary assessment of exposure.

(1.7) VIBRATION

WARNING: When using this machine the

operator can be exposed to high levels of

vibration transmitted to the hand and arm.

It is possible that the operator could develop

“Vibration white finger disease” (Raynaud

syndrome). This condition can reduce the

sensitivity of the hand to temperature as well

as producing general numbness. Prolonged

or regular users of this machine should

monitor the condition of their hands and

fingers closely. If any of the symptoms become

evident, seek immediate medical advice.

• The measurement and assessment of

human exposure to hand-transmitted

vibration in the workplace is given in:

BS EN ISO 5349-1:2001 and

BS EN ISO 5349-2:2002.

Handling

• Handle the machine with care, allowing

the machine to do the work.

• Avoid using excessive physical effort

on any of the machines controls.

• Consider your security and stability,

and the orientation of the machine

during use.

Work Surface

• Consider the work surface material;

its condition, density, strength,

rigidity and orientation.

WARNING: The vibration emission during

actual use of the power tool can differ from

the declared total value depending on the

ways in which the tool is used. The need

to identify safety measures and to protect

the operator are based on an estimation

of exposure in the actual conditions of use

(taking account of all parts of the operating

cycle, such as the times the tool is switched

off, when it is running idle, in addition

to trigger time).

(1.8) LABELS & SYMBOLS

WARNING: Do not operate this machine

if warning and/or instruction labels are

missing or damaged. Contact Evolution

Power Tools for replacement labels.

DE

FR

• Many factors can influence the actual

vibration level during operation e.g. the

work surfaces condition and orientation

and the type and condition of the machine

being used. Before each use, such factors

should be assessed, and where possible

appropriate working practices adopted.

Managing these factors can help reduce

the effects of vibration:

Note: All or some of the following symbols

may appear in the manual or on the product.

7

IT

NL

Page 8

www.evolutionpowertools.com

(1.9) LABELS & SYMBOLS

Symbol Description

V

A

Amperes

Hz

-1

Min

~

n

o

Alternating Current

No Load Speed

Wear Safety Goggles

Wear Ear Protection

Do Not Touch

Wear Dust Protection

Read Instructions

CE certification

Warning

Volts

Hertz

Speed

(1.10) INTENDED USE

OF THIS POWER TOOL

WARNING: This product is a Hand Operated

Compound Mitre Saw and has been designed

to be used with special Evolution blades.

Only use accessories designed for use in

this machine and/or those recommended

specifically by Evolution Power Tools Ltd.

When fitted with an appropriate blade

this machine can be used to cut:

Mild Steel

Aluminium

Wood

(1.11) PROHIBITED USE

OF THIS POWER TOOL

WARNING: This product is a Hand Operated

Compound Mitre Saw and must only be used

as such. It must not be modified in any way,

or used to power any other equipment or

drive any other accessories other than those

mentioned in this Instruction Manual.

(1.13) WARNING: This machine is not

intended for use by persons (including

children) with reduced physical, sensory

or mental capabilities, or lack of experience

and knowledge, unless they have been

given supervision or instruction concerning

the safe use of the machine by a person

responsible for their safety and who

is competent in its safe use.

Children should be supervised to ensure

that they do not have access to, and are

not allowed to play with, this machine.

Waste electrical and

electronic equipment

Double Insulated

8

Page 9

www.evolutionpowertools.com

EN

(1.14) ELECTRICAL SAFETY

This machine is fitted with the correct

moulded plug and mains lead for the

designated market. If the supply cord is

damaged, it must be replaced by a special

cord or assembly available from the

manufacturers or its service agent.

(1.15) OUTDOOR USE

WARNING: For your protection if this

tool is to be used outdoors it should not be

exposed to rain, or used in damp locations.

Do not place the tool on damp surfaces.

Use a clean, dry workbench if available.

For added protection use a residual current

device (R.C.D.) that will interrupt the supply

if the leakage current to earth exceeds 30mA

for 30ms. Always check the operation of the

residual current device (R.C.D.) before using

the machine.

If an extension cable is required it must

be a suitable type for use outdoors and

so labelled. The manufacturers instructions

should be followed when using an

extension cable.

(2.1) POWER TOOL GENERAL SAFETY

INSTRUCTIONS

(These General Power Tool Safety Instructions

are as specified in BS EN 60745-1:2009 &

EN 61029-1:2009)

WARNING: Read all safety warnings and

instructions. Failure to follow the warnings

and instructions may result in electric shock,

fire and/ or serious injury.

Save all warnings and instructions for future

reference. The term “power tool” in the

warnings refers to your mains-operated

(corded) power tool or battery-operated

(cordless) power tool.

(2.2) 1) General Power Tool

Safety Warnings [Work area safety]

a) Keep work area clean and well lit.

Cluttered or dark areas invite accidents.

b) Do not operate power tools in explosive

atmospheres, such as in the presence of

flammable liquids, gasses or dust. Power

tools create sparks which may ignite the

dust or fumes.

c) Keep children and bystanders away

while operating power tool. Distractions

can cause you to lose control.

(2.3) 2) General Power Tool Safety

Warnings [Electrical Safety]

a) Power tool plugs must match the outlet.

Never modify the plug in any way. Do not use

any adapter plugs with earthed (grounded)

power tools. Unmodified plugs and matching

outlets will reduce the risk of electric shock.

b) Avoid body contact with earthed

or grounded surfaces, such as pipes,

radiators, ranges and refrigerators.

There is an increased risk of electric shock

if your body is earthed or grounded.

c) Do not expose power tools to rain or wet

conditions. Water entering a power tool will

increase the risk of electric shock.

d) Do not abuse the cord. Never use the

cord for carrying, pulling or unplugging

the power tool. Keep cord away from heat,

oil, sharp edges or moving parts. Damaged

or entangled cords increase the risk of

electric shock.

e) When operating a power tool outdoors,

use an extension cord suitable for

outdoor use. Use of a cord suitable for

outdoor use reduces the risk of electric shock.

f) If operating a power tool in a damp

location is unavoidable, use a residual

current device (RCD) protected supply.

Use of an RCD reduces the risk

of electric shock.

DE

FR

IT

NL

9

Page 10

www.evolutionpowertools.com

(2.4) 3) General Power Tool Safety

Warnings [Personal Safety].

a) Stay alert, watch what you are doing

and use common sense when operating

a power tool. Do not use a power tool

while you are tired or under the influence of

drugs, alcohol or medication. A moment of

inattention while operating power tools may

result in serious personal injury.

b) Use personal protective equipment.

Always wear eye protection. Protective

equipment such as dust masks, non-skid safety

shoes, hard hat or hearing protection used

for appropriate conditions will reduce

personal injuries.

c) Prevent unintentional starting. Ensure the

switch is in the off-position before connecting

to power source and or battery pack, picking

up or carrying the tool. Carrying power tools

with your finger on the switch or energising

the power tools that have the switch on

invites accidents.

d) Remove any adjusting key or wrench

before turning the power tool on. A wrench

or key left attached to a rotating part of a

power tool may result in personal injury .

e) Do not overreach. Keep proper footing

and balance at all times. This enables

better control of the power tool in

unexpected situations.

f) Dress properly. Do not wear loose clothing

or jewellery. Keep your hair, clothing and

gloves away from moving parts. Loose

clothes, jewellery or long hair can be

caught in moving parts.

g) If devices are provided for the connection

of dust extraction and collection facilities,

ensure that these are connected and

properly used. Use of dust collection can

reduce dust-related hazards.

(2.5) 4) General Power Tool Safety

Warnings [Power tool use and care].

a) Do not force the power tool. Use the

correct power tool for your application.

The correct power tool will do the job

better and safer at a rate for which

it was designed.

b) Do not use the power tool if the switch

does not turn it on or off. Any power tool

that cannot be controlled with the switch

is dangerous and must be repaired.

c) Disconnect the power tool from the

power source and/or battery pack from the

power tool before making any adjustments,

changing accessories, or storing power tools.

Such preventative safety measures reduce the

risk of starting the power tool accidentally.

d) Store idle power tools out of the reach

of children and do not allow persons

unfamiliar with the power tool or these

Instructions to operate the power tool.

Power tools are dangerous in the hands

of untrained users.

e) Maintain power tools. Check for

misalignment or binding of moving parts,

breakage of moving parts and any other

condition that may affect the power tools

operation. If damaged, have the power

tool repaired before use. Many accidents are

caused by poorly maintained power tools.

f) Keep cutting tools sharp and clean.

Properly maintained cutting tools with sharp

cutting edges are less likely to bind and are

easier to control.

g) Use the power tool, accessories and

tool bits etc. in accordance with these

instructions, taking into account the

working conditions and the work to

be performed. Use of the power tool for

operations different from those intended

could result in a hazardous situation.

10

Page 11

www.evolutionpowertools.com

EN

(2.6) 5) General Power Tool

Safety Warnings [Service]

a) Have your power tool serviced by a qualified

repair person using only identical replacement

parts. This will ensure that the safety of the

power tool is maintained.

(2.7) HEALTH ADVICE

WARNING: When using this machine, dust

particles may be produced. In some instances,

depending on the materials you are working

with, this dust can be particularly harmful.

If you suspect that paint on the surface of

material you wish to cut contains lead, seek

professional advice. Lead based paints should

only be removed by a professional and you

should not attempt to remove it yourself.

Once the dust has been deposited on surfaces,

hand to mouth contact can result in the

ingestion of lead.

Exposure to even low levels of lead can

cause irreversible brain and nervous system

damage. The young and unborn children are

particularly vulnerable. You are advised to

consider the risks associated with the materials

you are working with and to reduce the risk

of exposure. As some materials can produce

dust that may be hazardous to your health,

we recommend the use of an approved face

mask with replaceable filters when using

this machine.

(2.8) WARNING: the operation of any power

tool can result in foreign objects being thrown

towards your eyes, which could result in severe

eye damage. Before beginning power tool

operation, always wear safety goggles

or safety glasses with side shield or a full

face shield where necessary.

(3.5) ADDITIONAL SAFETY

INSTRUCTIONS - MITRE SAWS

The following specific safety instructions

for Mitre Saws are based on the requirements

of EN61029-2-9:2009.

BLADE SAFETY

WARNING: Rotating Circular Saw Blades are

extremely dangerous and can cause serious

injury and amputation. Always keep fingers

and hands at least 150mm away from the

blade at all times. Never attempt to retrieve

sawn material until the cutting head is in the

raised position, the guard is fully closed and

the saw blade has stopped rotating.

Only use saw blades that are recommended

by the manufacturer and as detailed in

this manual and that comply with the

requirements of EN 847-1.

Do Not use saw blades that are damaged or

deformed as they could shatter and cause

serious injury to the operator or bystanders.

DE

FR

You should always:

• Work in a well-ventilated area.

• Work with approved safety equipment,

such as dust masks that are specially

designed to filter microscopic particles.

Do Not use saw blades that are manufactured

from high speed steel (HSS).

If the table insert becomes damaged or

worn it must be replaced with an identical

one available from the manufacturer

as detailed in this manual.

11

IT

NL

Page 12

www.evolutionpowertools.com

(3.6) PERSONAL PROTECTIVE

EQUIPMENT (PPE)

Hearing protection should be worn in order

to reduce the risk of induced hearing loss.

Eye protection should be worn in order to

prevent the possibility of the loss of sight

from ejected chippings.

Respiratory protection is also advised as some

wood and wood type products especially MDF

(Medium Density Fibreboard) can produce

dust that can be hazardous to your health.

We recommend the use of an approved face

mask with replaceable filters when using

this machine in addition to using the dust

extraction facility.

Gloves should be worn when handling blades

or rough material. It is recommended that saw

blades should be carried in a holder wherever

practicable. It is not advisable to wear gloves

when operating the mitre saw.

(3.7) SAFE OPERATION

Always ensure that you have selected the

correct saw blade for the material being cut.

Do Not use this mitre saw to cut materials

other than those specified in this

Instruction Manual.

When transporting a mitre saw ensure that

the cutting head is locked in the 90 degree

down position (if a sliding mitre saw ensure

that the slide bars are locked). Lift the machine

by gripping the outer edges of the base with

both hands (if a sliding mitre saw, transport

using the handles provided). Under no

circumstances shall the machine be lifted

or transported using the retractable guard

or any part of its operating mechanism.

Before each use check the operation

of the retractable guard and its operating

mechanism ensuring that there is no damage,

and that all moving parts operate

smoothly and correctly.

Keep the work bench and floor area clear of all

debris including sawdust, chips and off-cuts.

Always check and ensure that the speed

marked on the saw blade is at least equal to

the no load speed marked on the mitre saw.

Under no circumstances shall a saw blade

be used that is marked with a speed that

is less than the no load speed marked

on the mitre saw.

Where it is necessary to use spacer or reducing

rings these must be suitable for the intended

purpose and only as recommended by

the manufacturer.

If the mitre saw is fitted with a laser it shall not

be replaced with a different type. If the laser

fails to operate it shall be repaired or replaced

by the manufacturer or his authorised agent.

The saw blade shall only be replaced as

detailed in this Instruction Manual.

Never attempt to retrieve off-cuts or any other

part of the work piece until the cutting head is

in the raised position, the guard is fully closed

and the saw blade has stopped rotating.

12

Page 13

www.evolutionpowertools.com

EN

(3.8) PERFORM CUTS

CORRECTLY & SAFELY

Wherever practicable always secure the work

piece to the saw table using the work clamp

where provided.

Always ensure that before each cut the mitre

saw is mounted in a stable position.

If needed the mitre saw can be mounted

on a wooden base or work bench or attached

to a mitre saw stand as detailed in this

Instruction Manual.

Long work pieces should be supported on

the work supports provided or on appropriate

additional work supports.

(3.4) WARNING: If any parts are missing, do

not operate your machine until the missing

parts are replaced. Failure to follow this rule

could result in serious personal injury.

(3.9) ADDITIONAL SAFETY ADVICE

CARRYING YOUR MITRE SAW

Safety Advice

• Although compact, this Mitre Saw is

heavy. To reduce the risk of back injury,

get competent help whenever you have

to lift the saw.

• To reduce the risk of back injury, hold

the tool close to your body when lifting.

Bending your knees so you can lift with

your legs, not your back. Lift by using

the handhold areas at each side of the

machines base.

• Never carry the Mitre Saw by the power

cord. Carrying the Mitre Saw by the power

cord could cause damage to the insulation

or the wire connections resulting in electric

shock or fire.

• Before moving the Mitre Saw tighten the

mitre and bevel locking screws and the

sliding carriage locking screw to guard

against sudden unexpected movement.

• Lock the Cutting Head in its lowest

position. Ensure that the Cutting Head

Locking Pin is completely engaged

in its socket.

WARNING: Do not use the blade guard

as a ‘lifting point’. The power cord must be

removed from the power supply before

attempting to move the machine.

• Lock the Cutting Head in the down position

using the Cutting Head Locking Pin.

• Loosen the Mitre Angle Locking Screw. Turn

the table to either of its maximum settings.

• Lock the table in position using the

Locking Screw.

• Use the two carry handle cut-outs

machined into either side of the machine

base, to transport the machine.

Place the saw on a secure stationary work

surface and check the saw over carefully.

Check particularly the operation of all the

machines safety features before attempting

to operate the machine.

(4.1) GETTING STARTED - UNPACKING

Caution: This packaging contains sharp

objects. Take care when unpacking. Remove

the machine, together with the accessories

supplied from the packaging. Check carefully

to ensure that the machine is in good

condition and account for all the accessories

listed in this manual.

Also make sure that all the accessories are

complete. If any parts are found to be missing,

the machine and its accessories should be

returned together in their original packaging

to the retailer. Do not throw the packaging

away; keep it safe throughout the guarantee

period. Dispose of the packaging in an

environmentally responsible manner. Recycle

if possible. Do not let children play with empty

plastic bags due to the risk of suffocation.

DE

FR

IT

NL

13

Page 14

www.evolutionpowertools.com

(4.2) ITEMS SUPPLIED

Description Quantity

Instruction Manual 1

Multipurpose Cutting Blade 1

Hex Key 6mm (Blade Change) 1

Hex Key 4mm 1

Dust Bag 1

Hold down Clamp 1

Carbon Brush Set 1

4.3 ADDITIONAL ACCESSORIES

In addition to the standard items supplied

with this machine the following accessories

are also available from the Evolution online

shop at www.evolutionpowertools.com or

from your local retailer.

(4.4)

Description Part No

RAGE Blade RAGE210

14

Page 15

www.evolutionpowertools.com

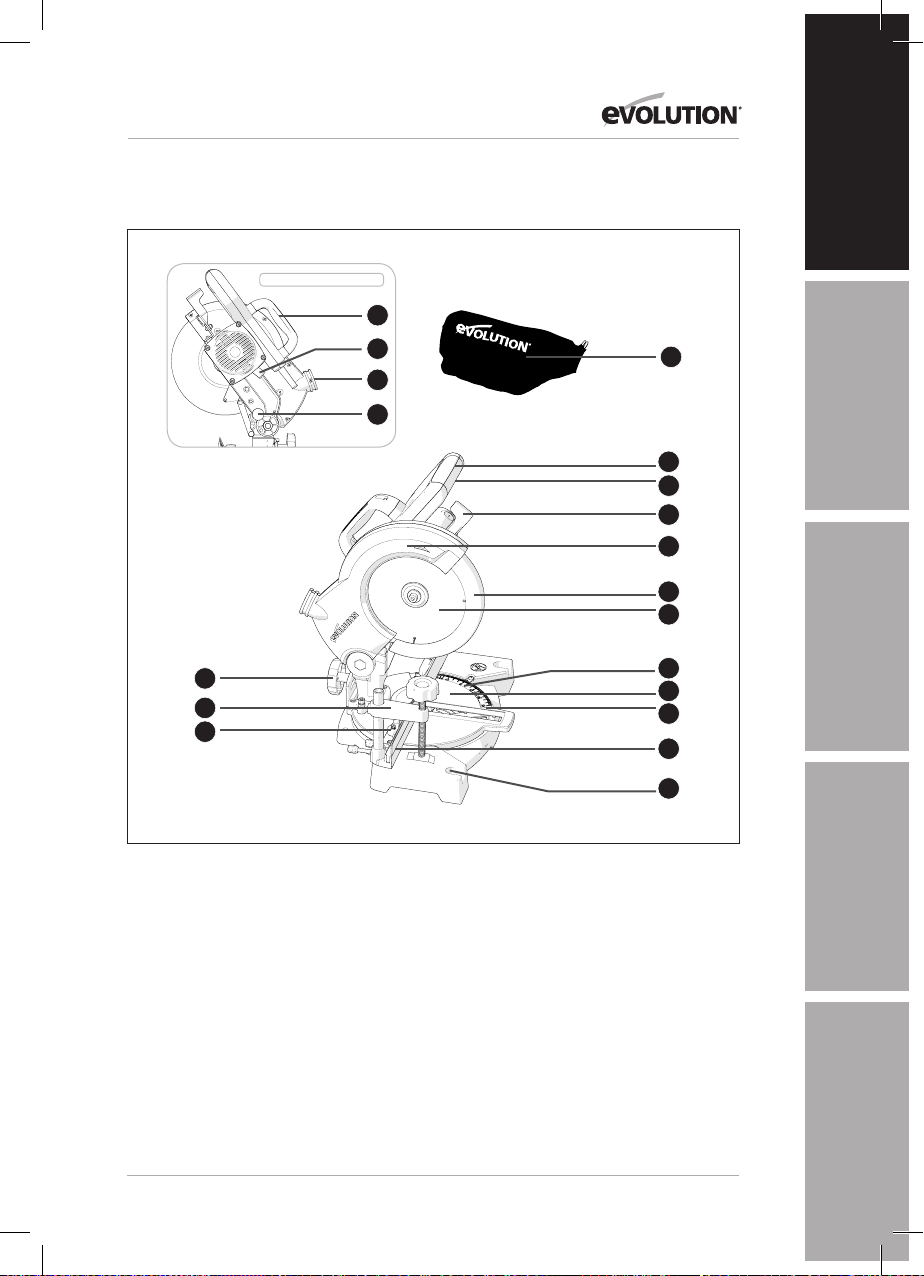

MACHINE OVERVIEW

REVERSE OF MACHINE

10

(10)

19

(19)

(11)

11

15

(15)

16

(16)

17

(17)

18

(18)

(4)

(3)

(1)

(2)

(8)

(7)

(9)

12

(12)

13

(13)

EN

4

DE

3

1

2

8

7

9

FR

6

5

Know your parts

1. On/Off Trigger Switch

2. Blade Guard Locking Lever

3. Cutting Handle

4. Dust Bag

5. Rotary Table

6. Table Top

7. Lower Blade Guard

8. Upper Blade Guard

9. Blade

10. Bevel Locking Screw

11. Mitre Locking Screw

12. Mitre Angle Scale

13. Fence

14. Mounting Hole (x 4 Corners)

15. Carry Handle

16. Arbor Lock

17. Dust Extraction Port

18. Head Latching Pin

19. Hold Down Clamp

15

14

(14)

IT

NL

Page 16

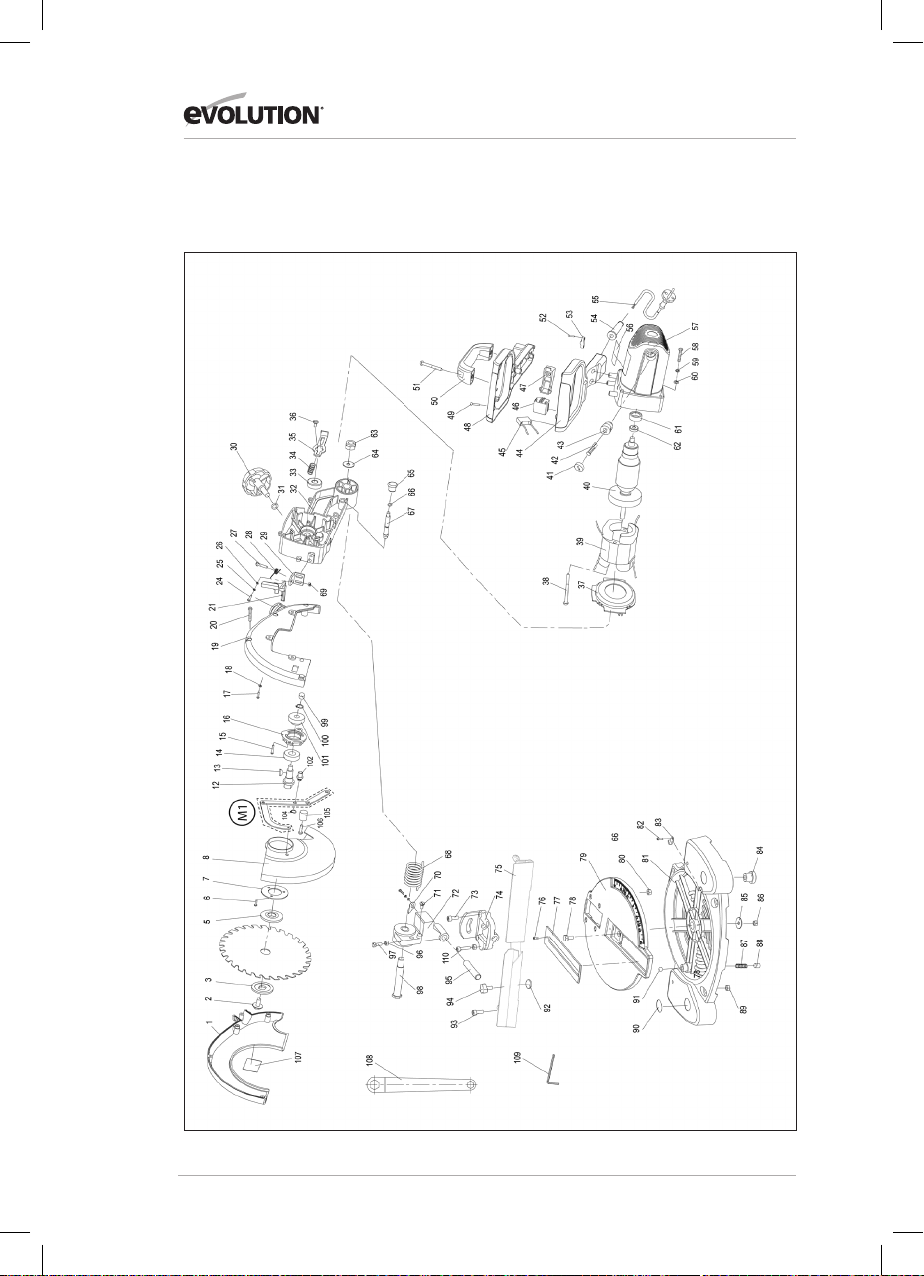

PARTS DIAGRAM

www.evolutionpowertools.com

16

Page 17

www.evolutionpowertools.com

EN

(7.1) ASSEMBLY & PREPARATION

WARNING: Always disconnect the saw from the power source

before making any adjustments.

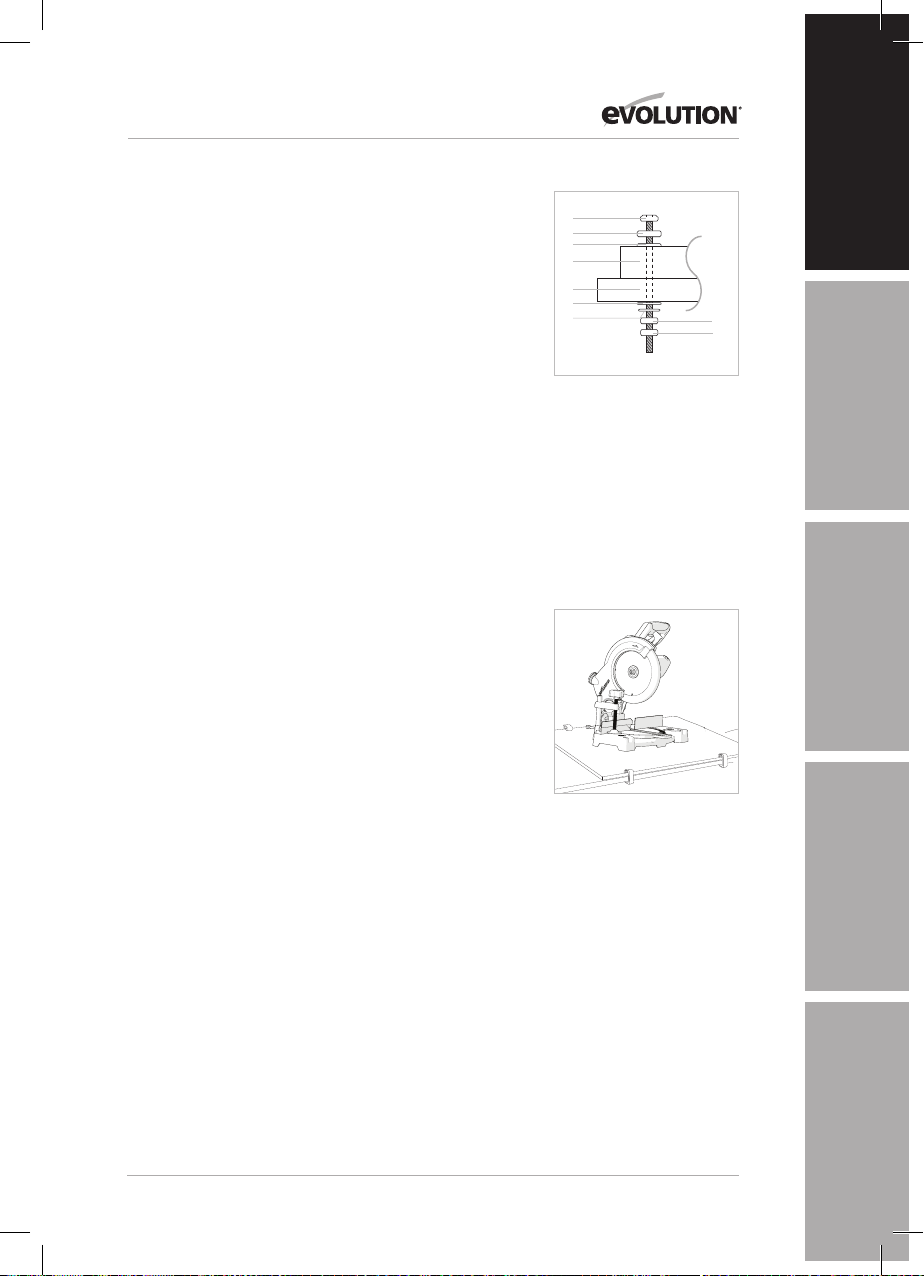

(7.2) PERMANENTLY MOUNTING THE MITRE SAW

To reduce the risk of injury from unexpected saw movement,

place the saw in the desired location either on a workbench

or other suitable machine stand. The base of the saw has four

mounting holes through which suitable bolts (not supplied)

can be placed to secure the miter saw. If the saw is to be used

in one location, permanently fasten it to the workbench using

appropriate fastenings (not supplied). Use locking washers

and nuts on the underside of the workbench. (Fig. 1)

• To avoid injury from flying debris, position the saw so t

hat other people or bystanders cannot stand too close

(or behind) it.

• Locate the saw on a firm, level surface where there is plenty

of room for handling and properly supporting the workpiece.

• Support the saw so the machine table is level and the saw

does not rock.

• Bolt or clamp the saw securely to its support stand

or workbench.

(7.3) FOR PORTABLE USE:

• Mount the saw on a 18mm thick piece of plywood or MDF

(800mm x 500mm min size recommended) using appropriate

fastenings (not supplied).

• It may be necessary to countersink the washers, nuts, etc.

to the underside of the plywood or MDF mounting board

to avoid an uneven work surface.

• Use G-clamps to attach the mounting board to the

work surface. (Fig. 2)

(1)

(2)

(3)

(4)

(5)

(6)

(7)

Fig. 1

1) Hex headed bolt

2) Spring washer

3) Flat washer

4) Mitre saw base

5) Workbench

6) Flat washer

7) Spring washer

8) Hex nut

9) Lock nut

Fig. 2

(8)

(9)

DE

FR

IT

17

NL

Page 18

www.evolutionpowertools.com

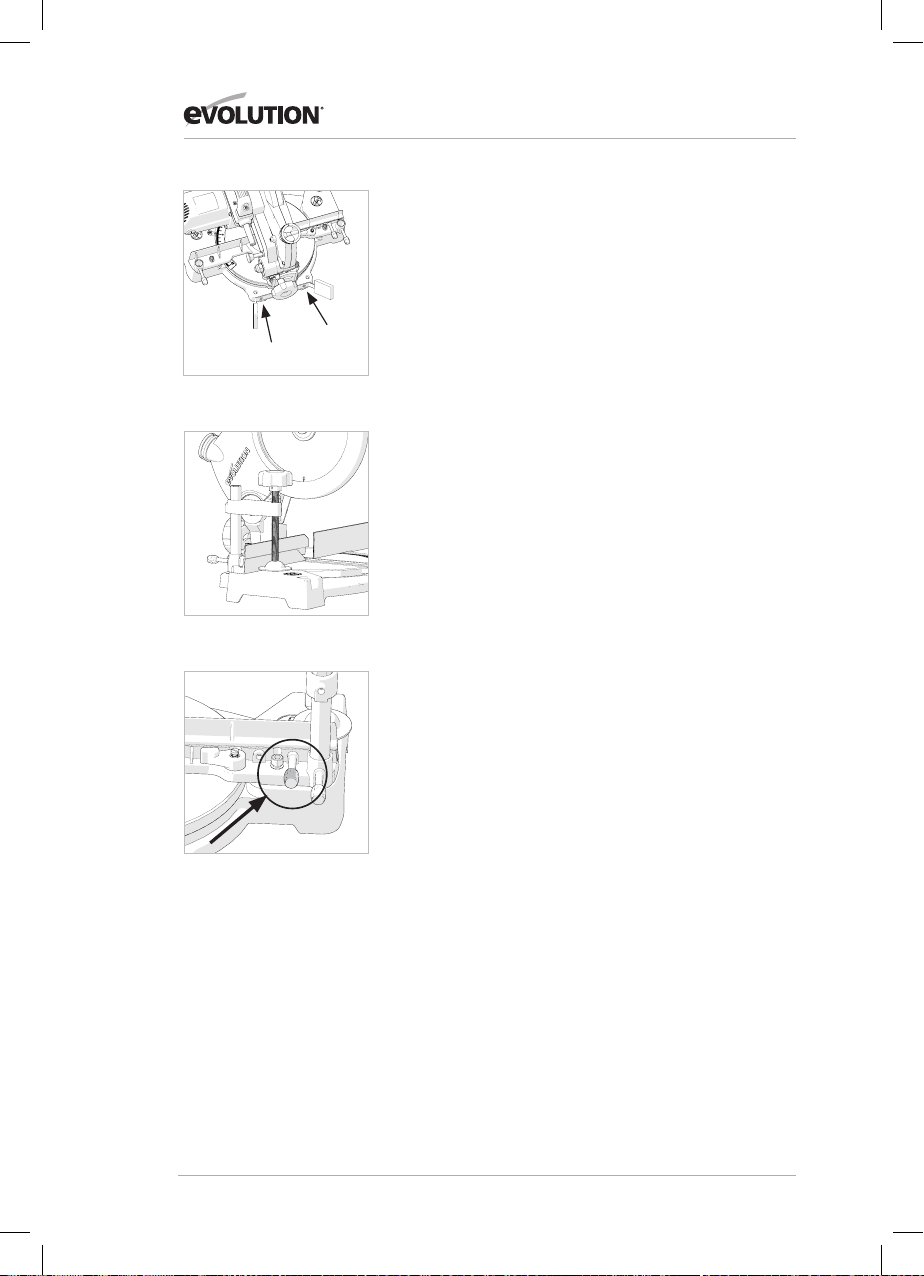

Note: Machines are supplied with a rear stabilising arm, which

attaches to the machines base just below the Bevel Pivot.

If supplied this arm should be attached to the base using the

screws and nuts supplied (Fig. 3)

This arm will provide extra stability to prevent the machine from

toppling in the event of sudden release of the Cutting Head.

Fig. 3

Fig. 4

Fig. 5

(7.4) HOLD DOWN CLAMP (Fig. 4)

Two sockets (one either side) are incorporated into the rear of

the machines fence. These sockets are for positioning the Hold

Down Clamp.

• Fit the clamp to the retaining socket that best suits the

cutting application, ensuring that it is fully pushed down.

• Tighten the fence thumbscrew to lock the pillar of the clamp

into the fence socket.

• Place the workpiece to be cut onto the saw table, against the

fence and in the desired position.

• Adjust the clamp using the thumbscrews and hand-wheel so

that it securely holds the workpiece to the saw table.

Conduct a ‘dry run’ with the power disconnected. Ensure that

the Hold Down Clamp does not interfere with the path of the

blade, or with the path of any other part of the Cutting Head

as it is lowered.

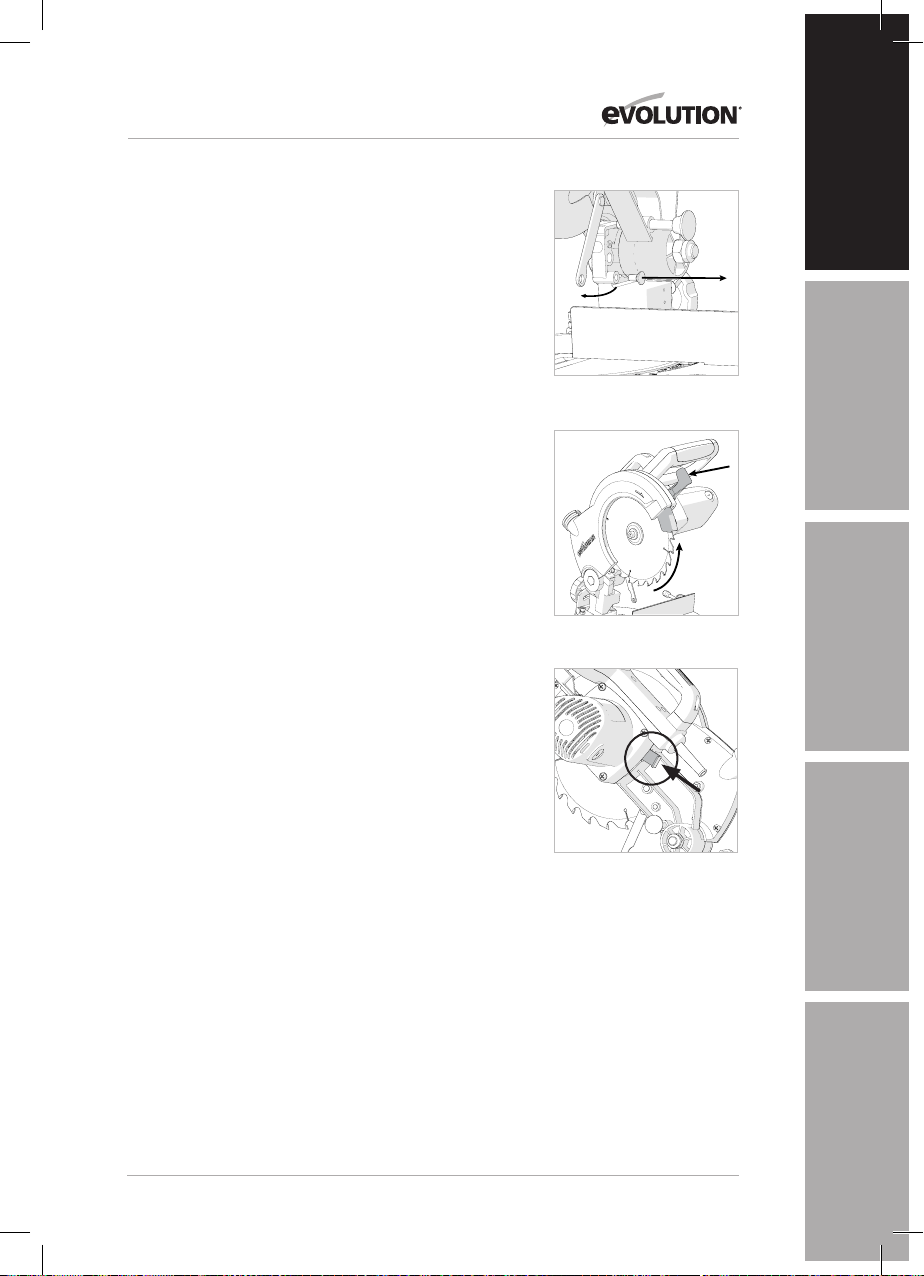

(7.5) THE SLIDING UPPER FENCE SECTION

The Left Hand side of the Fence has an adjustable upper

section. Adjustment may be necessary to provide clearance

for the moving Cutting Head when acute bevel or compound

angles are selected.

To adjust the Fence:

• Loosen the thumbscrew. (Fig. 5)

• Slide the upper section of the Fence leftwards to the required

position and tighten the thumbscrew.

• Conduct a ‘dry run’ with the power off to confirm that there

is no interference between moving parts as the Cutting Head

is lowered.

18

Page 19

www.evolutionpowertools.com

No-Hands ZoneNo-Hands Zone

(8.1) OPERATING INSTRUCTIONS

Caution: The Mitre Saw should be inspected (particularly for

the correct functioning of the safety guards) before each use.

Do not connect the saw to the power supply until a safety

inspection has been carried out.

Ensure that the operator is adequately trained in the use,

adjustment and maintenance of the machine, before

connecting to the power supply and operating the saw.

(8.2) WARNING: To reduce the risk of injury, always unplug

the saw before changing or adjusting any of the machines parts.

Compare the direction of the rotation arrow on the guard to

the direction arrow on the blade. The blade teeth should always

point downward at the front of the saw. Check the tightness

of the arbor screw.

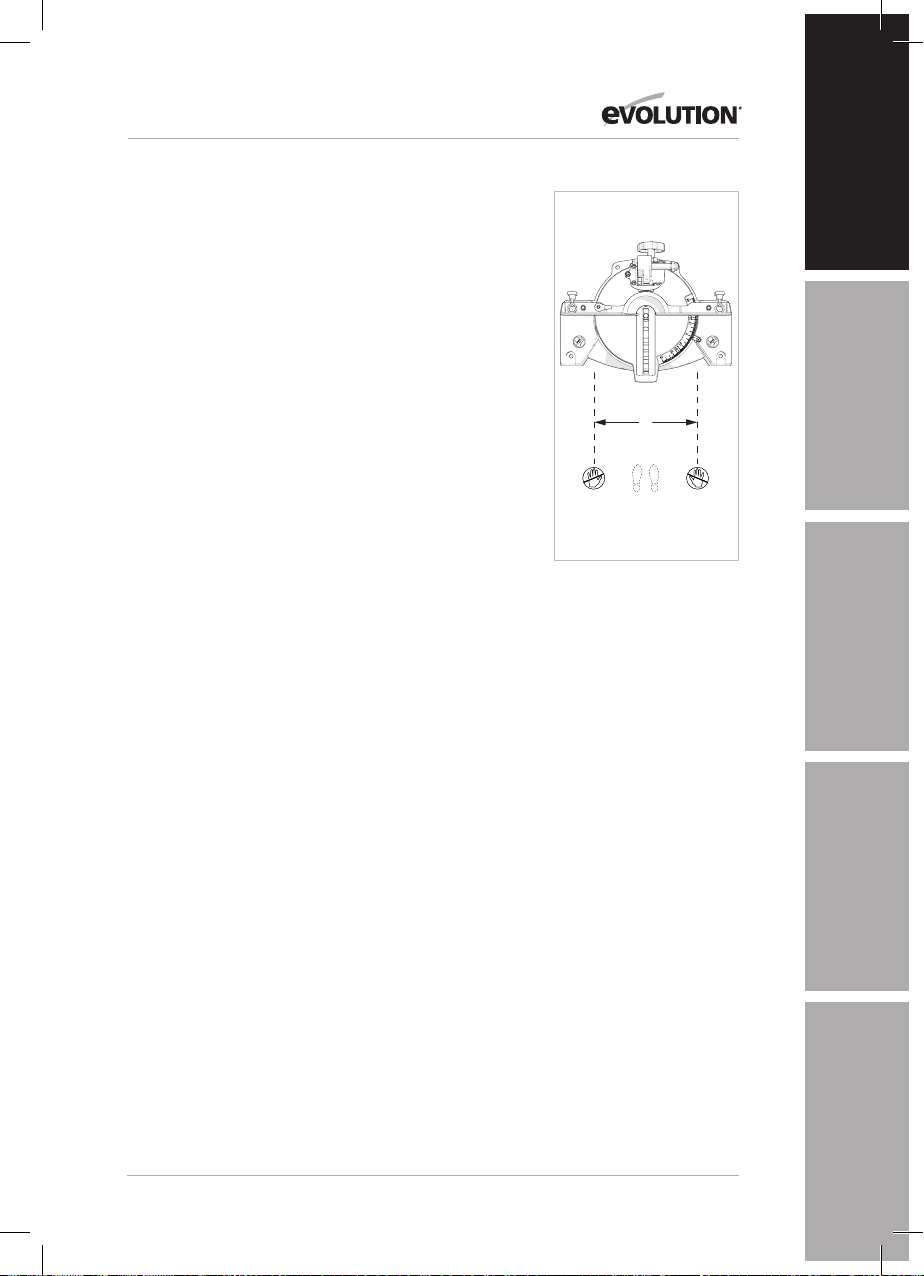

(8.3) BODY & HAND POSITIONING (Fig. 6)

• Never place your hands within the ‘no hands zone’ (at least

150mm away from the blade). Keep hands away from the

path of the blade.

• Secure the workpiece firmly to the table and against the

fence to prevent any movement.

• Use a Hold Down Clamp if possible but check that it is so

positioned that it does not interfere with the path of the

blade or other moving machine parts.

• Avoid awkward operations and hand positions where

a sudden slip could cause your fingers or a hand to move

into the blade.

• Before attempting a cut, make a ‘dry run’ with the power

off so that you can see the path of the blade.

• Keep your hands in position until the ON/OFF trigger switch

has been released and the blade has completely stopped.

EN

DE

Fig. 6

FR

IT

(8.4) ADJUSTMENT of PRECISION ANGLES

Several checks/adjustments are possible on this machine.

The operator will require a 450/450/900. Square (not supplied)

to carry out these checks and adjustments.

WARNING: Checks/adjustments must only be conducted

with the machine disconnected from the power supply.

NL

19

Page 20

Fig. 7

Fig. 8

www.evolutionpowertools.com

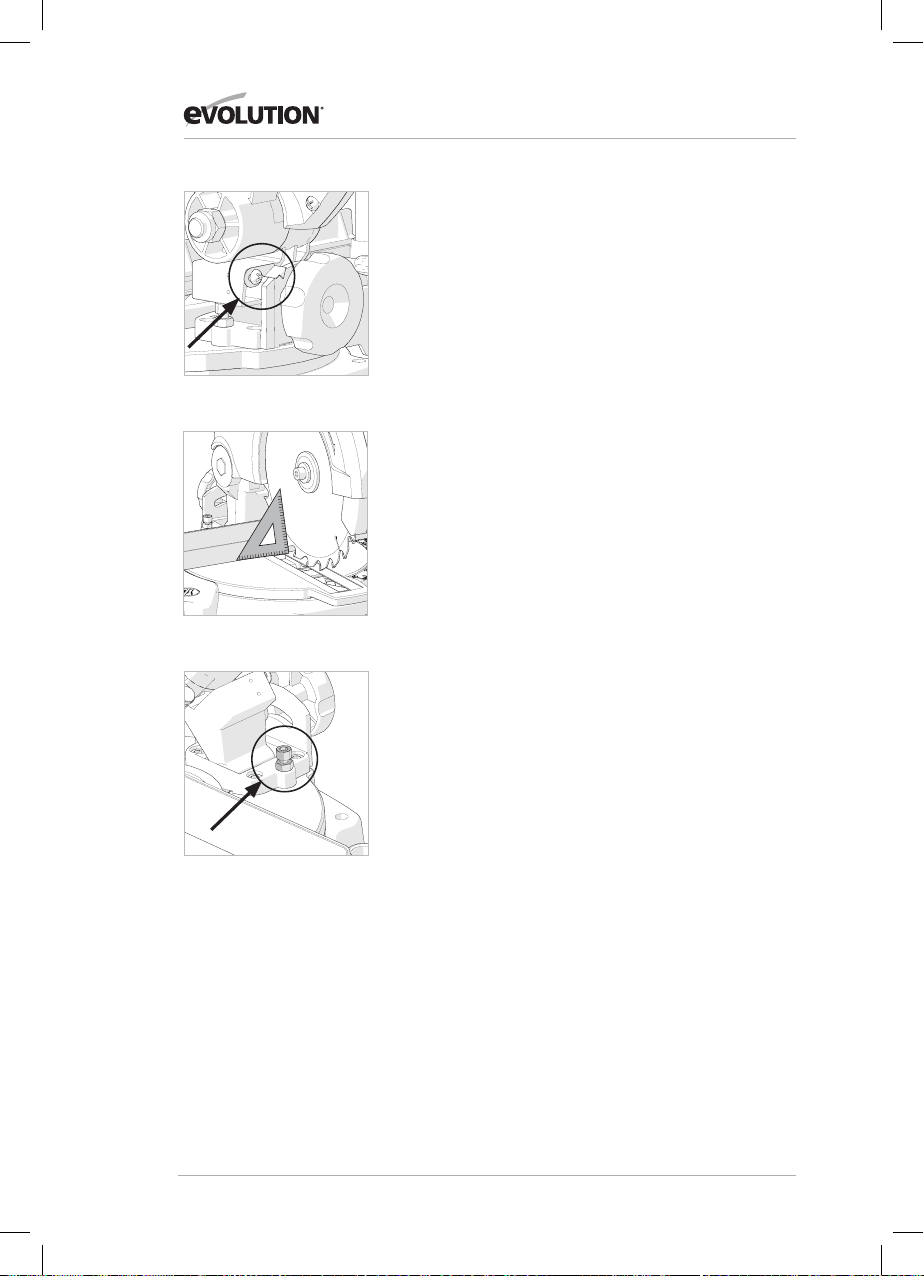

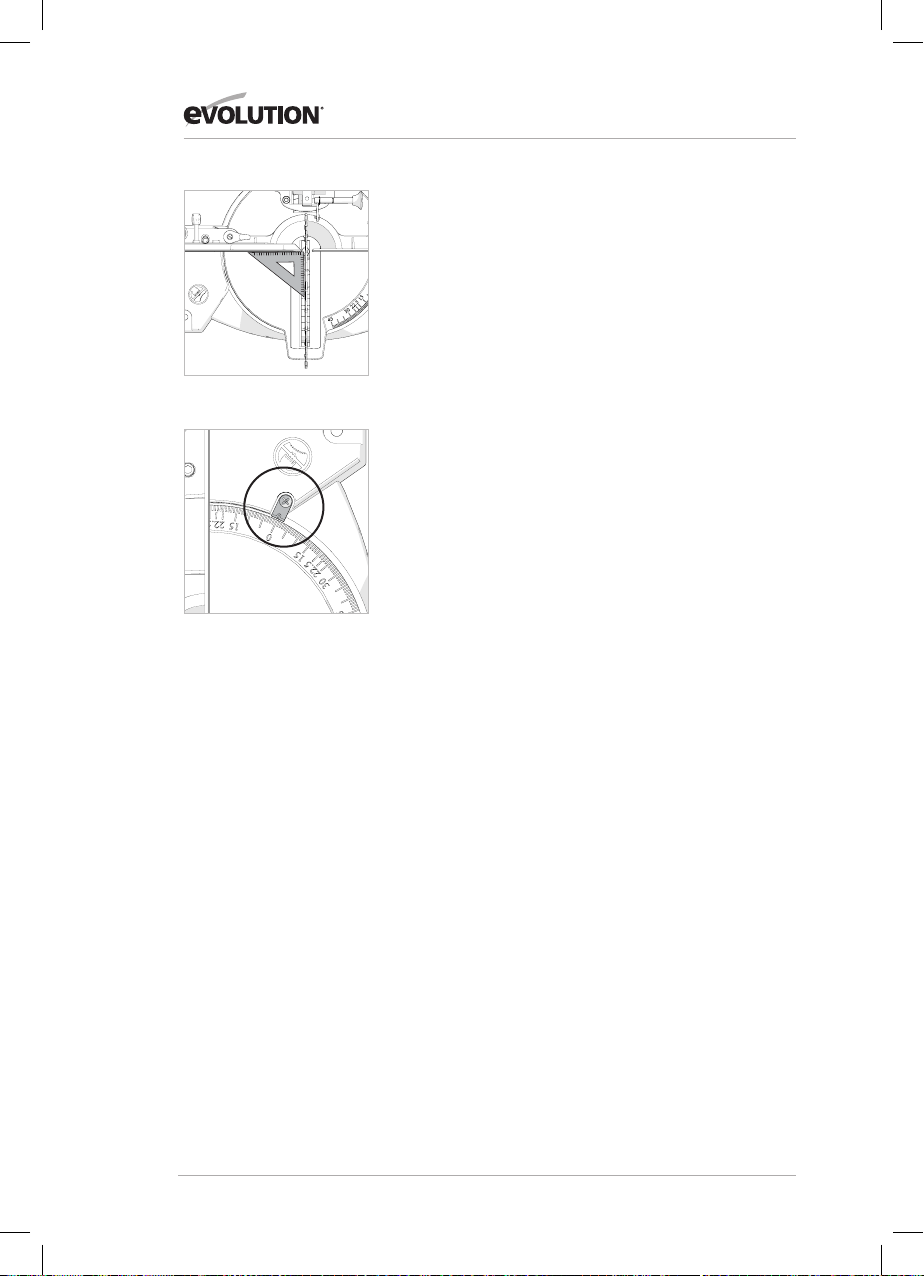

BEVEL ANGLES (00 AND 450)

00 Bevel Stop Adjustment

• Ensure that the Cutting Head is in the locked down position

with the latching pin fully engaged in its socket. (see Fig.15)

• Ensure that the Cutting Head is upright, against its stop and

the bevel pointer is indicating 00 on the scale. (Fig. 7)

• Place the Set Square on the table with one short edge

against the table and the other short edge against the blade

(avoiding the TCT tips). (Fig. 8)

• If the blade is blade is not 900 square with the mitre table

adjustment is required.

• Loosen the Bevel Lock Handle and tilt the Cutting Head

to the left.

• Loosen the locknut on the Bevel Angle Adjustment Screw. (Fig. 9)

• Use a Hex Key to turn the screw in or out to adjust the

blade angle.

• Return the Cutting Head to its upright position and recheck

the angular alignment against the Set Square.

• Repeat the above steps until correct angular

alignment is achieved.

• Tighten the Bevel Angle Adjustment locknut securely.

Fig. 9

20

Page 21

www.evolutionpowertools.com

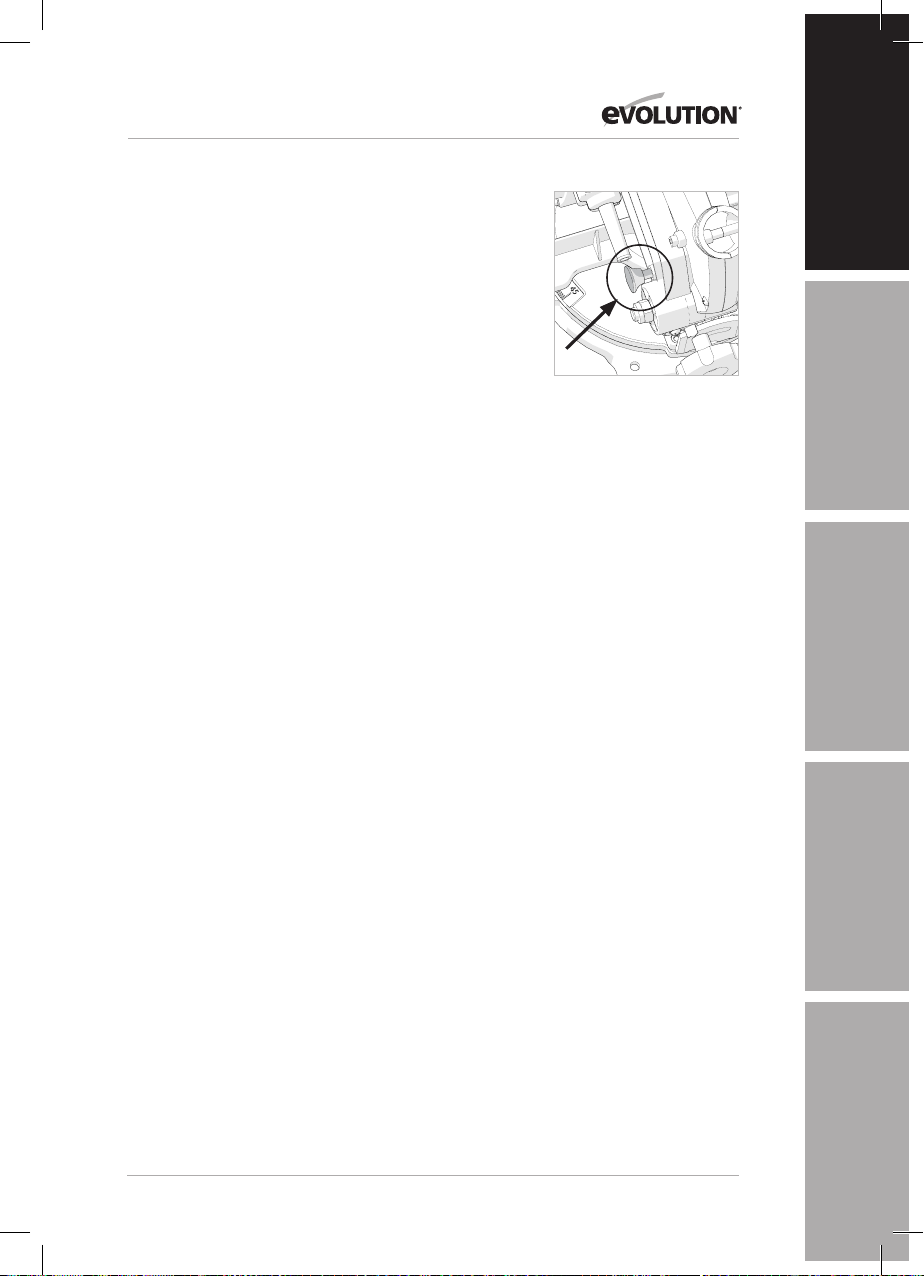

00 Bevel Pointer Adjustment

NOTE: The operator must be satisfied that the blade is set

exactly perpendicular to the table when in the upright position

and against its stop.

• If the pointer is not in exact alignment with the 00 mark on

the protractor scale adjustment is necessary.

• Loosen the Bevel Pointer screw using a #2 Phillips

screwdriver. (Fig. 10)

• Adjust the Bevel Pointer so that it is in alignment

exactly with the 00 mark.

• Retighten the screw.

450 Bevel Stop Adjustment

• Loosen the Bevel Lock Handle and tilt the Cutting Head

completely to the left until it rests against the 450 stop.

• Use a Set Square to see if the blade is at 450 to the table

(avoiding the TCT tips).

• If the saw blade is not in exact alignment adjustment

is necessary.

• Return the Cutting Head to its upright position.

• Loosen the locknut on the 450 Bevel Adjustment Screw.

• Use a Hex Key to adjust the Adjustment Screw in or out

as required. (Fig. 11)

• Tilt the Cutting Head to the 450 setting and recheck for

alignment with the Set Square.

• Repeat the above steps until the correct angular alignment

is achieved.

• Tighten the Adjustment Screw locknut securely once

alignment is achieved.

Fig. 10

Fig. 11

EN

DE

FR

Fence Alignment

The fence must be aligned at 900 (square) to a correctly installed

blade The rotary table must be set at ‘00’ miter angle.

The Fence is fastened to the table with two socket head Hex

screws positioned at either side of the fence in elongated slots.

(Fig. 12)

21

IT

Fig. 12

NL

Page 22

Fig. 13

www.evolutionpowertools.com

• Ensure that the Cutting Head is in the locked down position

with the latching pin fully engaged in its socket.

• Place a Set Square on the table with one short edge against

the Fence and the other short edge against the Blade

(avoiding the TCT tips). (Fig. 13)

• If adjustment is necessary, loosen the four Fence adjustment

screws using a Hex Key.

• Re-position the Fence in its elongated slots until alignment

is achieved.

• Securely tighten the socket head Hex screws.

Mitre Angle Pointer Adjustment

NOTE: There are dual miter angle scales cast into the front of

the machines base. A small pointer attached to the rotary table

indicates the angle selected.

If necessary the pointer can be repositioned by loosening

its fastening screw using a #2 Phillips screwdriver. Adjust as

necessary, and then securely tighten the fixing screw. (Fig. 14)

Fig. 14

FINAL ADJUSTMENT CHECKS

With the machine switched OFF and disconnected

from the mains supply carry out the following;

When all adjustments have been made, set the

machine at each of the maximum settings.

Lower the blade to its lowest position and rotate the blade

by hand, (it is advisable to wear gloves whilst doing this),

and ensure that the blade does not foul on any part

of the machine castings or guards.

22

Page 23

www.evolutionpowertools.com

(8.5) PREPARING TO MAKE A CUT

DO NOT OVER-REACH

Keep good footing and balance. Stand to one side so that your

face and body are out of line of a possible kickback.

Freehand cutting is a major cause of

accidents and should not be attempted.

EN

• Ensure that the workpiece is always firmly resting against

the fence, and where practical is clamped with the Hold

Down Clamp to the table.

• The saw table should be clean and free from any sawdust etc.

before the workpiece is clamped into position.

• Ensure that the ‘cut-off’ material is free to move sideways

away from the blade when the cut is completed. Ensure that

the ‘cut-off’ piece cannot become ‘jammed’ in any other

part of the machine.

• Do not use this saw to cut small pieces. If the workpiece

being cut would cause your hand or fingers to be within

150mm of the sawblade, the workpiece is too small.

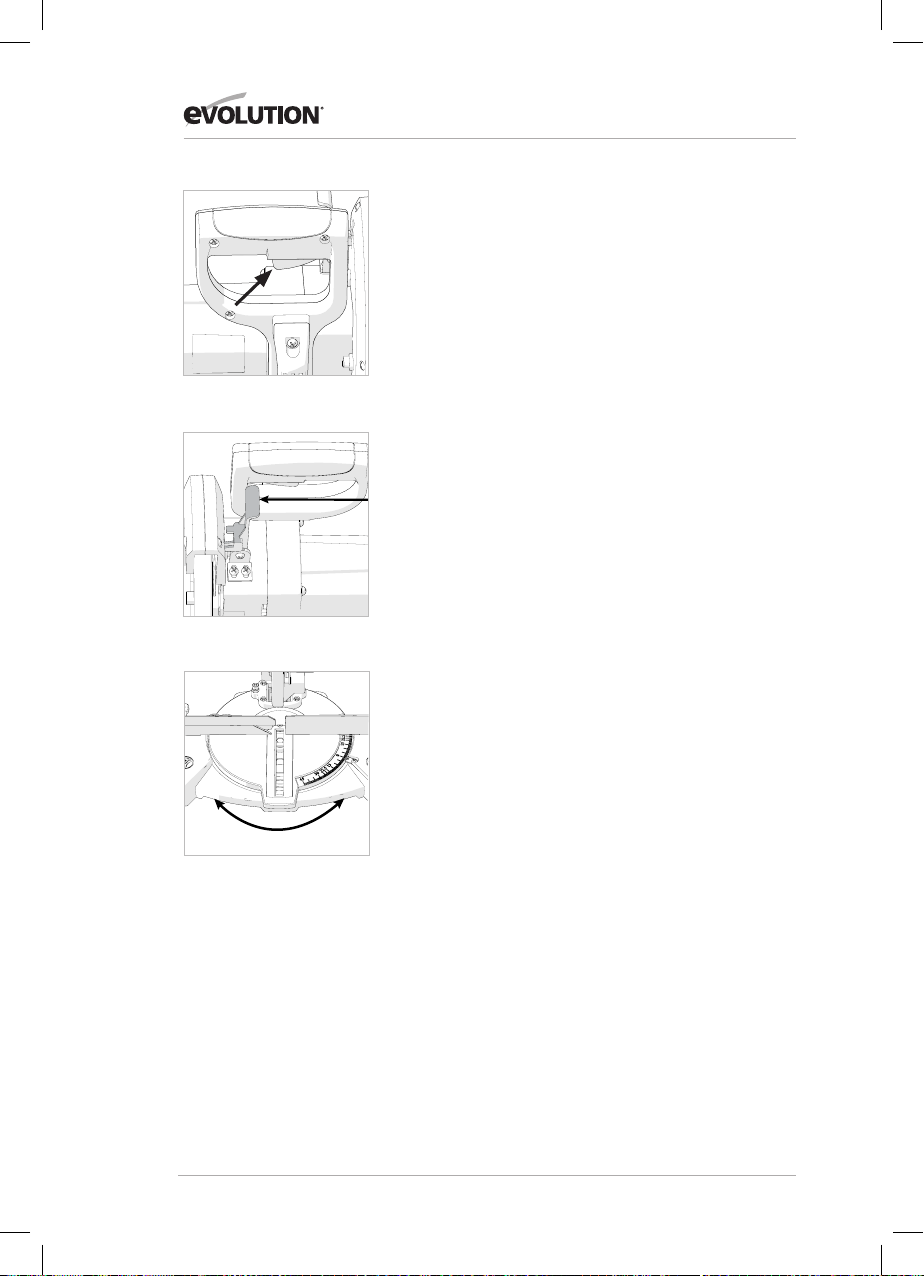

(8.6) RELEASING THE CUTTING HEAD

The Cutting Head will automatically rise to the upper position

once it is released from the locked down position.

It will automatically lock in the upper position.

To Release the Cutting Head

from the Locked Down position:

• Gently press down on the Cutting Handle.

• Pull out the head latching pin (Fig. 15) and allow

the Cutting Head to rise to its upper position.

If Release is Difficult:

• Gently rock the Cutting Head up and down.

• At the same time twist the Head Latching Pin

clockwise and pull outwards.

Fig. 15

DE

FR

IT

Note: We recommend that when the machine is not in use

the Cutting Head is locked in its down position with the

latching pin fully engaged in its socket.

23

NL

Page 24

Fig. 16

Fig. 17

www.evolutionpowertools.com

THE MOTOR ON/OFF SWITCH (Fig. 16)

The ON/OFF Motor Trigger Switch is a non-latching type.

It is positioned inside the Cutting HANDLE.

• Press the switch to start the motor.

• Release the switch to turn off the motor.

CHOP CUTTING

This type of cut is used mainly for cutting small or narrow

section material. The Cutting Head is gently pushed down to

cut through the workpiece.

• Place the workpiece on the table and against the fence and

secure with clamp(s) as appropriate.

• Grasp the saw handle.

• Turn the motor on and allow the saw blade to reach full speed.

• Press the lower guard locking lever to release

the Cutting Head. (Fig. 17)

• Lower the Cutting Handle downwards and cut through

the workpiece.

• Allow the speed of the blade to do the work, there is no need

to apply undue pressure to the Cutting Handle.

• When the cut has been completed, release the

ON/OFF trigger switch.

• Allow the blade to come to a complete stop.

• Allow the Cutting Head to rise to its upper position,

with the lower blade guard completely covering the

blade teeth, and the Cutting Head locked in the upper

position, before releasing the Cutting Handle.

• Remove the workpiece.

Fig. 18

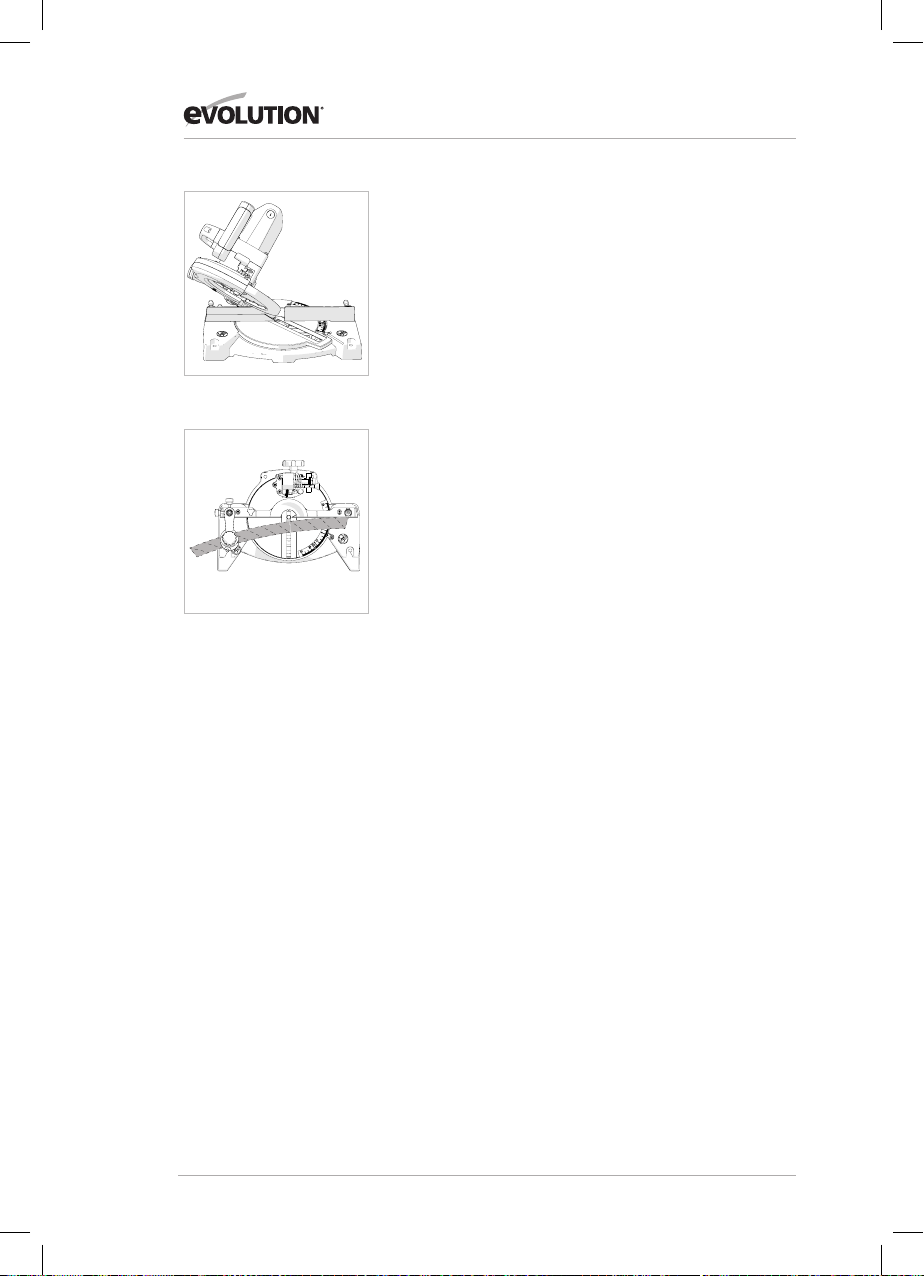

MITRE CUTTING (Fig. 18)

The rotary table of this machine can be turned through 450

to the left or right from the normal cross-cut (00) position.

Positive stops are provided at 450, 400, 350, 300, 22.50, 150,

100 and 50 to both the right hand and left hand sides.

24

Page 25

www.evolutionpowertools.com

• Loosen the Mitre Locking Screw (Fig. 19) by turning

it anti-clockwise.

• Turn the rotary table to the desired angle. A mitre angle

protractor scale is incorporated into the rotary table

to aid setting.

• Tighten the Mitre Locking Screw when the desired

angle is achieved.

Note: It is important to tighten the Mitre Locking

Screw even if a Positive Stop has been selected.

Note: The Mitre Locking Screw has a sprung loaded

repositionable lever. Repositioning may be necessary

to avoid interference with other parts of the machine

when certain mitre angles are selected.

To reposition:

• Lift up the lever and turn to a convenient position.

• Release the lever.

BEVEL CUTTING TILTING THE CUTTING HEAD

A bevel cut (Fig. 20) is made with the rotary table set at 00 mitre.

Note: It may be necessary to adjust the upper section of

the Fence to provide clearance for the moving Cutting Head.

Fig. 19

Fig. 20

EN

DE

FR

The Cutting Head can be tilted from the normal 00

(perpendicular position) to a maximum angle of 450

from the perpendicular to the left hand side only.

To tilt the Cutting Head to the left:

• Loosen the bevel locking screw. (Fig. 21a)

• Tilt the Cutting Head to the required angle. A protractor scale

is provided as an aid to setting. (Fig 21b)

• Tighten the bevel locking screw when the desired angle has

been selected.

25

Fig. 21A

Fig. 21B

IT

NL

Page 26

www.evolutionpowertools.com

When cutting is completed:

• Release the ON/OFF trigger switch, but keep your hands

in position and allow the blade to completely stop.

• Allow the Cutting Head has to rise to its upper position,

with the lower blade guard completely deployed before

removing yours hand(s).

• Return the Cutting Head to the perpendicular position.

• Tighten the bevel lock lever.

Fig. 22

Fig. 23

(8.7) COMPOUND CUTTING (Fig. 22)

A compound cut is a combination of a mitre

and bevel cut employed simultaneously.

When a compound cut is required, select the desired

bevel and mitre positions as previously described.

Always check that the path of the blade does not interfere

with the machines fence or any other parts of the machine.

Adjust the upper left hand section of the fence if necessary.

(8.8) CUTTING BOWED MATERIAL (Fig. 23)

Before cutting any workpiece, check to see if it is bowed.

If it is bowed the workpiece must be positioned

and cut as shown.

Do not position the workpiece incorrectly or

cut the workpiece without the support of the fence.

(8.9) CLEARING JAMMED MATERIAL

• Turn mitre saw “OFF” by releasing the trigger switch.

• Allow the blade to come to a complete halt.

• Unplug the mitre saw from the mains supply.

• Carefully remove any jammed material from the machine.

• Check the condition and operation of the safety guard.

• Check for any other damage to any part of the

machine e.g. the blade.

• Have any damaged parts replaced by a competent

technician and a safety inspection carried out before

using the machine again.

26

Page 27

www.evolutionpowertools.com

(8.10) SUPPORTNG LONG WORKPIECES

The free end of a long workpiece should be supported at the

same height as the machine table. The operator should consider

using a remote workpiece support if thought necessary.

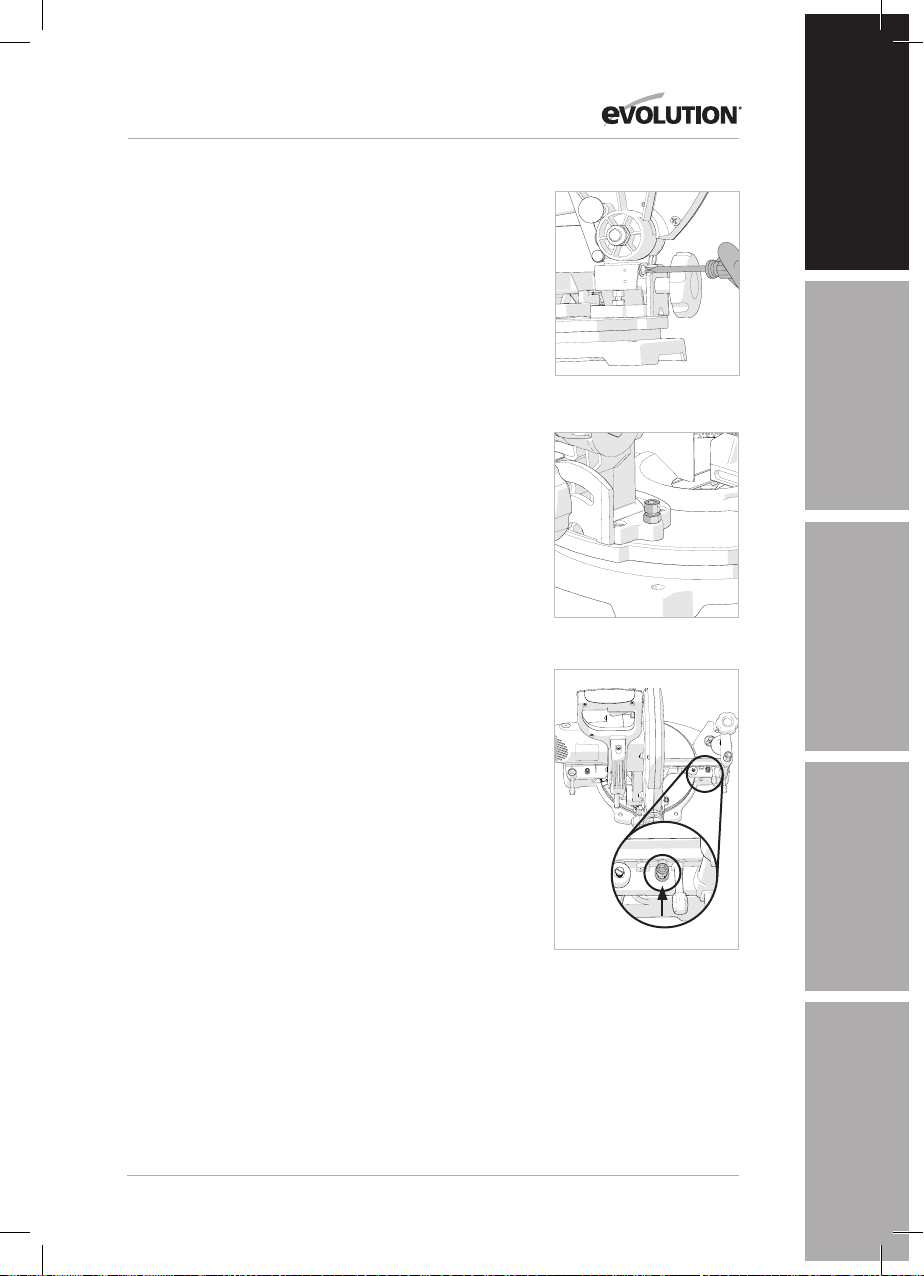

(8.11) INSTALLING or REMOVING a BLADE

WARNING: Only carry out this operation with the machine

disconnected from the mains supply.

WARNING: Only use genuine Evolution blades which are

designed for this machine. Ensure that the maximum speed

of the blade is higher than the speed of the motor.

Note: It is recommended that the operator considers wearing

protective gloves when handling the blade during installation

or when changing the blade.

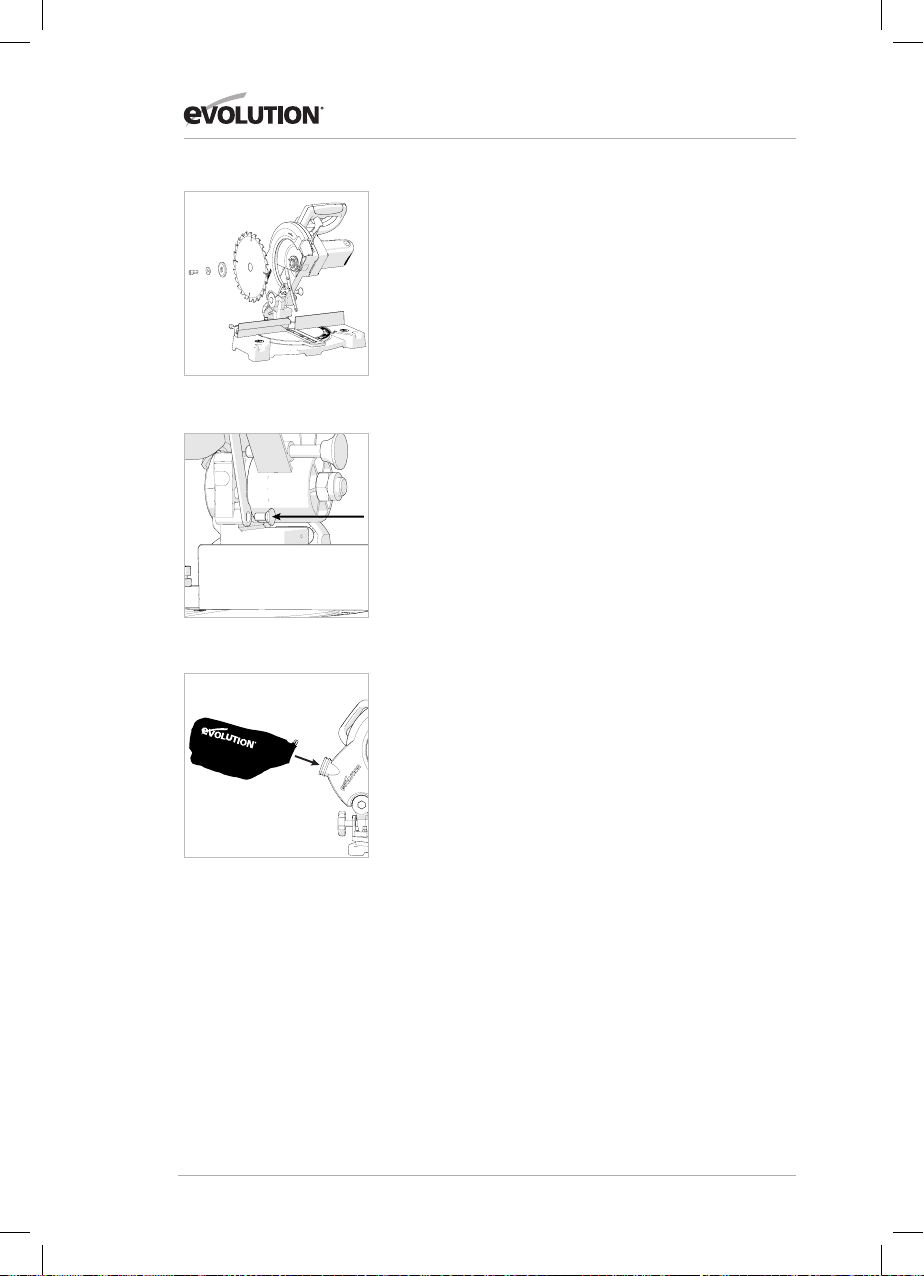

• Ensure the Cutting Head is in its upper position.

• Remove the lower guard operating arm from the machine

by removing the pivot screw. (Fig. 24) Store this screw

safely for future use.

• Press the lower blade guard locking lever (a) and rotate the lower

blade guard (b) up and into the upper blade guard. (Fig. 25)

• Press the black arbor lock button to lock the arbor. (Fig. 26)

Fig. 24

Fig. 25

EN

DE

FR

27

Fig. 26

IT

NL

Page 28

Fig. 27

Fig. 28

www.evolutionpowertools.com

• Using the supplied Hex Key, release the arbor screw and

remove the washer and blade flange and the blade from

the arbor. (Fig. 27)

Note: The arbor screw has a LH thread. Turn clockwise to

loosen. Turn counterclockwise to tighten.

• Install the new ø210 mm blade. Make sure the rotation arrow

on the blade matches the clockwise rotation arrow on the

upper guard.

Note: The blade teeth should always point downward at the

front of the saw.

• Install the blade flange, washer and arbor screw.

• Lock the arbor and tighten the arbor screw using moderate

force, but do not overtighten.

• Replace the guard operating arm and its retaining pivot

screw. (Fig. 28)

• Ensure the Hex Key is removed and the arbor lock has

released before operating.

• Ensure the blade guard is fully functional before using

the machine.

If required, Blade Bore Reducing Inserts should only be used

in accordance with the manufacturers instructions.

Fig. 29

(8.12) USE OF OPTIONAL EVOLUTION ACCESSORIES

(not supplied as original equipment –

see Additional Accessories)

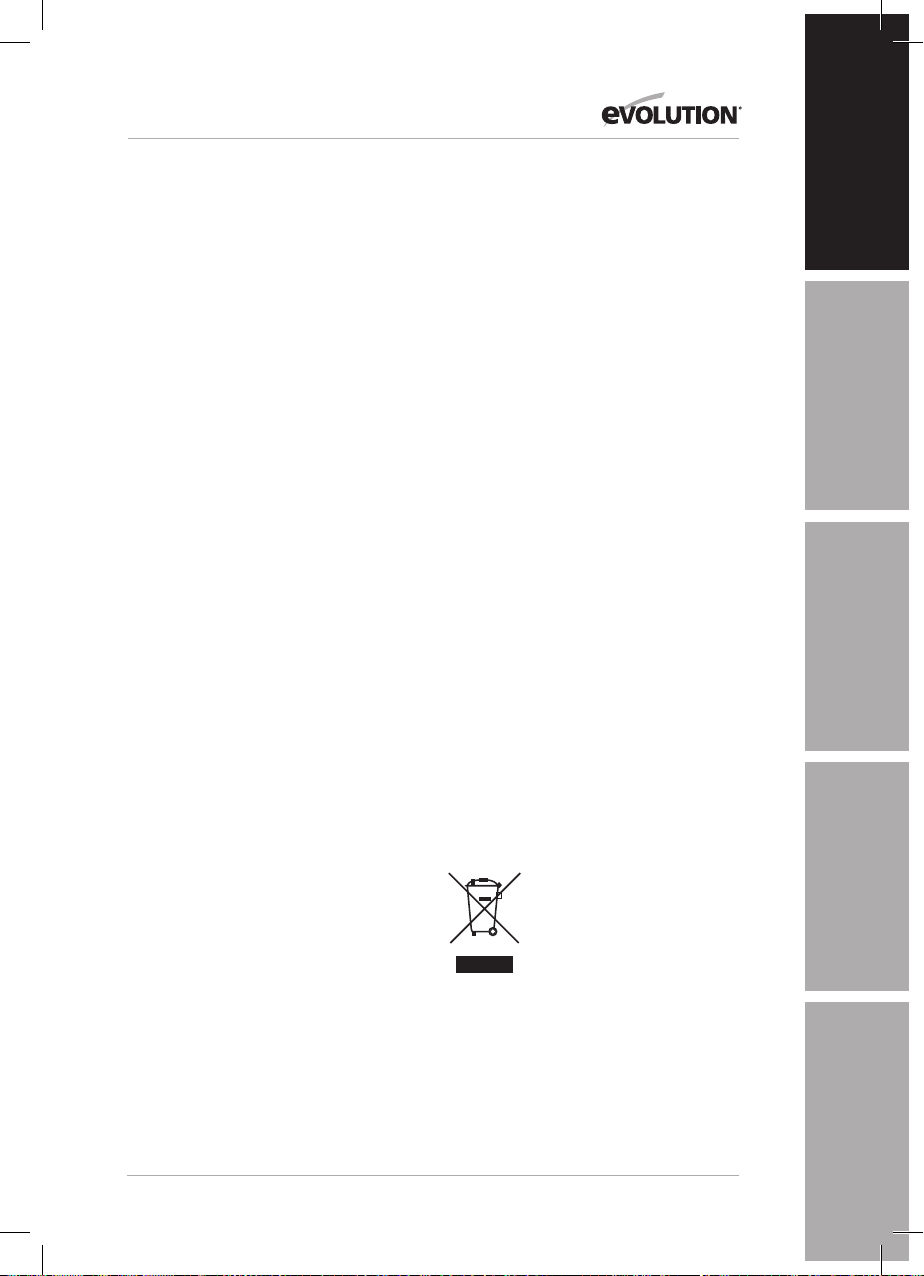

(8.13) DUST BAG

A Dust Bag can be fitted to the extraction port at the rear of

the machine. The Dust Bag is for use when cutting wooden

materials only.

• Slide the Dust Bag over the dust extraction port, ensuring

that the spring clip grips the port holding the Dust Bag

securely in place. (Fig. 29)

28

Page 29

www.evolutionpowertools.com

EN

Note: For operational efficiency empty

the Dust Bag when it becomes 2/3 full.

Dispose of the contents of the Dust Bag in an

environmentally responsible way. It may be

necessary to wear a dust mask when

emptying the Dust Bag.

Note: A workshop vacuum extraction machine

can be attached to the dust extraction

port if required. Follow the manufacturers

instructions if such a machine is fitted.

WARNING: Do not use the Dust

Bag when cutting metallic materials.

(6.1) MAINTENANCE

Note: Any maintenance must be carried

out with the machine switched off and

disconnected from the mains/battery

power supply.

Check that all safety features and guards

operating correctly on a regular basis.

Only use this machine if all guards/safety

features are fully operational.

All motor bearings in this machine are lubricated

for life. No further lubrication is required.

Use a clean, slightly damp cloth to clean

the plastic parts of the machine. Do not use

solvents or similar products which could

damage the plastic parts.

WARNING: Do not attempt to clean by

inserting pointed objects through openings

in the machines casings etc. The machines air

vents should be cleaned using compressed

dry air. Excessive sparking may indicate the

presence of dirt in the motor or worn out

carbon brushes.

(6.2) If this is suspected have the machine

serviced and the brushes replaced by

a qualified technician.

Table Insert

A one piece table insert is fitted to this

machine. If it is damaged or worn, it must be

replaced. Replacement inserts are available

from Evolution Power Tools.

To replace the table inserts:

• Remove the cross-head screw that secures

the insert to the rotary table.

Note: It may be necessary to temporarily

remove or reposition the fence to gain access

to the fixing screw.

• Lift the insert from the table.

• Remove any debris that may have

accumulated under the insert.

• Fit the replacement insert, and replace the

fixing screw.

• If necessary replace and re-align the fence.

(see Fence Alignment and Figs 12 & 13)

• Check that the insert is lying flush and level

within the table.

(6.4) ENVIRONMENTAL PROTECTION

Waste electrical products should not be

disposed of with household waste. Please

recycle where facilities exist. Check with your

Local Authority or retailer for recycling advice.

DE

FR

IT

29

NL

Page 30

www.evolutionpowertools.com

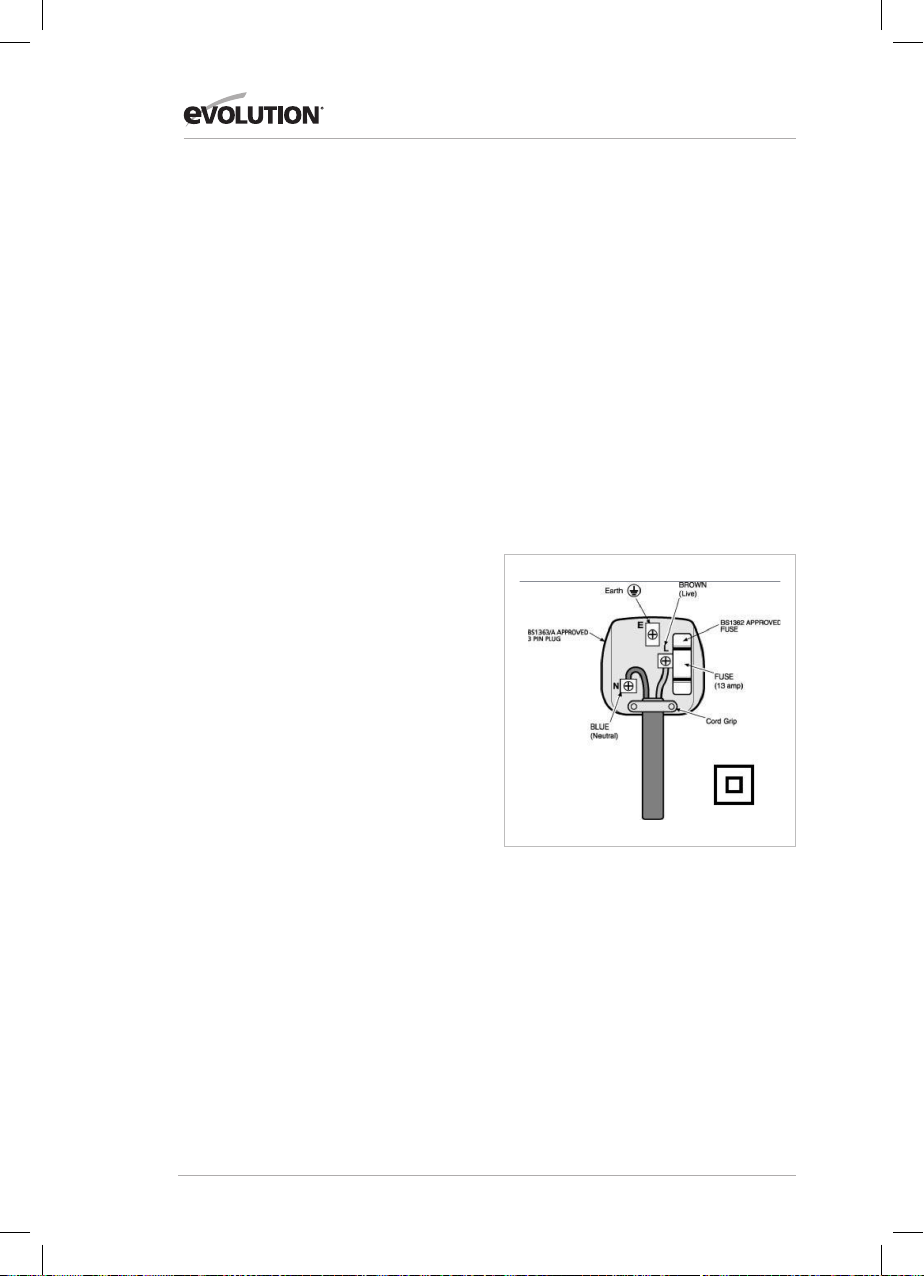

ELECTRICAL SAFETY - UK PLUG

REPLACEMENT CONNECTION OF

THE DOUBLE INSULATED MAINS

PLUG - UK ONLY

IMPORTANT: The wires in the mains

lead fitted to this product are coloured

in accordance with the following code:

Brown: Live (L) or Red

Blue: Neutral (N) or Black

THIS PRODUCT IS DOUBLE INSULATED

AND THEREFORE DOES NOT REQUIRE

A CONNECTION TO EARTH.

• THE3PINPLUGMUST

COMPLY TO BS1363/A.

• THEFUSEMUSTCOMPLYTOBS1362.

If for any reason the 13 amp moulded plug

fitted to this product requires replacing, the

replacement must be wired in accordance

with the following instructions:

• ConnecttheBluewiretothe

terminal marked Neutral (N).

Ensure that the outer insulation is gripped

by the cord grip and that the wires are not

trapped when replacing the plug cover.

A 13 amp (BS1362) fuse must

be fitted in the plug.

Do not connect any wire to the earth pin

MARKED E on the 3 pin plug.

If in any doubt consult a qualified electrician.

There are no user serviceable parts inside

this product except those referred to in the

manual. Always refer servicing to qualified

service personnel. Never remove any part

of the casing unless qualified to do so;

this unit contains dangerous voltages.

• ConnecttheBrownwiretothe

terminal marked Live (L).

30

Page 31

www.evolutionpowertools.com

EC DECLARATION OF CONFORMITY

In accordance with EN ISO 17050-1:2004

The manufacturer of the product covered by this Declaration is:

Evolution Power Tools, Venture One, Longacre Close, Holbrook Industrial Estate, Sheeld, S20 3FR

The manufacturer hereby declares that the machine as detailed in this declaration fulls all the

relevant provisions of the Machinery Directive and other appropriate directives as detailed below.

The manufacture further declares that the machine as detailed in this declaration, where

applicable, fulls the relevant provisions of the Essential Health and Safety requirements.

The Directives covered by this Declaration are as detailed below:

2006/42/EC. Machinery Directive.

2004/108/EC. (valid until Apr 19th 2016) Electromagnetic Compatibility Directive,

2014/30/EU. (eective from Apr 20th 2016) Electromagnetic Compatibility Directive,

93/68/EC. The CE Marking Directive.

2011/65/EU. The Restriction of the Use of certain Hazardous

Substances in Electrical Equipment (RoHS) Directive

2002/96/EC The Waste Electrical and Electronic Equipment (WEEE) Directive.

as amended

by 2003/108/EC.

And is in conformity with the applicable requirements of the following documents:

EN61029-1•EN61029-2•EN55014-1•EN55014-2

EN61000-3-2•EN61000-3-3•EN60825-1

EN

DE

FR

Product Details

Description: RAGE3-B 210mm MULTIPURPOSE COMPOUND MITRE SAW

Evolution Model No: RAGE3B2102 / RAGE3B2102EU

Factory Model No: J1X-KZ5-210L

Brand Name: EVOLUTION

Voltage: 230-240V~ 50Hz

Input: 1100W

The technical documentation required to demonstrate that the product meets the requirements

of directive has been compiled and is available for inspection by the relevant enforcement

authorities, and veries that our technical le contains the documents listed above and that they

are the correct standards for the product as detailed above.

Name and address of technical documentation holder.

Date: 01/03/2016

Signed: Print: Matthew Gavins - Group Chief Executive

31

IT

NL

Page 32

Page 33

EN

DEUTSCH

Übersetzung Original Bedienungsanleitungen

DE

FR

IT

NL

Page 34

www.evolutionpowertools.com

KAPP-UND GEHRUNGSSÄGE

English Page 2

Deutsch Seite 32

Français Page 62

Italiano Pagina 92

Nederlands Pagina 122

INHALTSVERZEICHNIS Seite 35

Garantie Seite 35

Technische Daten Seite 36

Kennzeichnungen und Symbole Seite 37

Vibration Seite 37

Bestimmungsgemäßer Gebrauch des Elektrowerkzeugs Seite 38

Nicht zulässiger Gebrauch des Elektrowerkzeugs Seite 38

SICHERHEITSVORKEHRUNGEN Seite 39

Elektrische Sicherheit Seite 39

Verwendung im Freien Seite 39

Allgemeine Sicherheitsanweisungen zu Elektrowerkzeugen Seite 41

Zusätzliche Sicherheitsanweisungen Seite 43

ERSTE SCHRITTE Seite 44

Auspacken Seite 44

Überblick Seite 45

Diagramm Ersatzteile Seite 46

Montage und Vorbereitung Seite 47

Betriebsanleitung Seite 48

WARTUNG Seite 49

Umweltschutz Seite 49

KONFORMITÄTSERKLÄRUNG Seite 60

34

Page 35

www.evolutionpowertools.com

EN

(1.2) Dieses Bedienungshandbuch wurde

ursprünglich in englischer Sprache erstellt.

(1.3) WICHTIG

Bitte lesen Sie diese Sicherheitsanweisungen

sorgfältig und vollständig durch. Falls Sie sich

über irgendeinen Aspekt der Nutzung dieser

Ausrüstung unsicher sind, kontaktieren Sie

zu Ihrer eigenen Sicherheit bitte unseren

Technischen Service, dessen Nummer Sie auf

der Website von Evolution Power Tools finden.

Zusätzlich zu unserem weltweit angebotenen

Kundendienst können Sie für Technischen Service

auch Ihren örtlichen Fachhändler kontaktieren.

WEB

www.evolutionpowertools.com

(1.4) Gratulation zum Kauf einer Evolution

Power Tools-Maschine. Bitte lassen Sie Ihr

Produkt online registrieren, indem Sie die

Anweisungen zur Onlineregistrierung auf

der beiliegenden A4-Broschüre befolgen

oder scannen Sie den auf der A4-Broschüre

befindlichen QR-Code mit einem Smart

Phone, um die Garantie Ihrer Maschine über

die Evolutions-Website eintragen zu lassen

und sicherzustellen, dass die entsprechenden

Leistungen ggf. sofort zur Verfügung stehen.

Wir danken Ihnen, dass Sie sich für ein Produkt

von Evolution Power Tools entschieden haben.

BEGRENZTE GARANTIE VON EVOLUTION

Evolution Power Tools behält sich das Recht

vor, ohne vorherige Mitteilung konstruktive

Verbesserungen und Änderungen an

Produkten vorzunehmen.

Genaue Details zur Garantiefrist Ihres Produkts

finden Sie auf dem A4-Garantie-Merkblatt

bzw. der Verpackung.

(1.5) Evolution Power Tools repariert oder

ersetzt innerhalb der Garantiefrist vom

ursprünglichen Kaufdatum alle Waren,

bei denen Mängel im Material oder in der

Ausführungsqualität auftreten. Diese Garantie

ist nichtig, wenn die zurückgegebene

Maschine entgegen den Empfehlungen des

Bedienungshandbuchs verwendet oder durch

Unfall, Fahrlässigkeit oder unsachgemäße

Wartung beschädigt worden ist. Diese

Garantie gilt nicht für Maschinen und / oder

Komponenten, die in irgendeiner Form

geändert oder modifiziert oder außerhalb der

empfohlenen Kapazitäten und Spezifikationen

eingesetzt wurden. Elektrische Komponenten

werden durch die Garantien der jeweiligen

Hersteller abgedeckt.

Alle als mangelhaft zurückgegebenen Waren

sind als vorausbezahlte Fracht an Evolution

Power Tools zurückzusenden. Evolution Power

Tools behält sich das Recht vor, optional eine

Reparatur oder einen Austausch mit gleichen

oder gleichwertigen Posten vorzunehmen.

Zubehör wie Verschleißteile wie z. B. (die

folgende Liste ist nicht vollständig) Blätter,

Klingen, Bohrer, Meißel oder Paddel sind

von jeglicher Garantie – schriftlich oder

mündlich – ausgeschlossen. Evolution

Power Tools übernimmt keinerlei Haftung

für Verlust oder Schaden aus direkter oder

indirekter Verwendung unserer Ware oder aus

irgendeinem sonstigen Grund. Evolution Power

Tools haftet weder für Kosten, die für besagte

Waren auflaufen, noch für Folgeschäden.

Angestellte oder Vertreter von Evolution Power

Tools sind nicht bevollmächtigt, mündliche

Erklärungen zur Eignung abzugeben

oder auf irgendeine der vorstehenden

Geschäftsbedingungen zu verzichten; derartige

Erklärungen haben keinerlei bindende Wirkung

für Evolution Power Tools.

DE

FR

IT

Fragen zu dieser begrenzten Garantie

müssen an die Firmenzentrale gerichtet

oder über einen Anruf an die jeweilige

Service-Nummer geklärt werden.

35

NL

Page 36

www.evolutionpowertools.com

TECHNISCHE SPEZIFIKATION

MASCHINE METRIC KAISERLICHE

Motor (230-240V ~ oder 110V ~ 50/60 Hz) 1100W 5A

Geschwindigkeit unbelastet 4000min

Empfohlene maximale Kapazität 30mins 30mins

Gewicht 6.4kg 14lb

ZUM SCHNEIDEN VON METRIC KAISERLICHE

Weiche Stahlplatten - Max Dicke Zoll 6mm 1/4”

-1

4000rpm

Kastenquerschnitte aus weichem

3mm 1/8”

Stahl - Max Dicke Zoll

Holz - Abschnitt Max Zoll 50mm x 120mm 2” x 4-3/4””

GEHRUNG

GRAD

NEIGUNG

GRAD

MAX

SCHNITTBREITE

ZOLL

MAX

SCHNITTTIEFE

ZOLL

0° 0° 120mm (4-3/4”) 50mm (2”)

45L° / 45R° 45° 80mm (3-1/8”) 30mm (1-3/16”)

45L° / 45R° 0° 80mm (3-1/8”) 50mm (2”)

0° 45° 120mm (4-3/4”) 30mm (1-3/16”)

BLATTABMESSUNGEN METRIC KAISERLICHE

Durchmesser Zoll 210mm 8-1/4”

Bohrung Durchmesser Zoll 25.4mm 1”

Max Drehzahl 4000min

-1

4000rpm

Dicke 1.7mm 1/16”

SCHALL& SCHWINGUNGSDATEN

Schalldruckpegel LPA 89dB(A) K=3dB(A)

Schallleistungspegel LWA 102dB(A) K=3dB(A)

Schwingungspegel 6m/s2 K=1.5m/s

2

36

Page 37

www.evolutionpowertools.com

EN

(1.6) Hinweis:Die Vibrationsmessung wurde

unter Standardbedingungen, gemäß

BS EN 61029-1:2009, durchgeführt. Der

angegebene Vibrationswert wurde im

Einklang mit einer Standardprüfmethode

gemessen und kann verwendet werden, um

verschiedene Maschinen miteinander zu

vergleichen. Ebenso kann er für eine erste

Gefahrenbewertung herangezogen werden.

(1.7) VIBRATION

WARNUNG: Beim Betrieb der Maschine ist

der Bediener u. U. starken Vibrationen (Hand

und Arm) ausgesetzt. Es ist möglich, dass sich

beim Bediener Symptome einer mangelnden

Durchblutung (Raynaud-Syndrom) zeigen.

Dies kann die Temperaturempfindlichkeit der

Hand beeinträchtigen und ein allgemeines

Taubheitsgefühl erzeugen. Personen,

die längere Zeit oder regelmäßig mit

Magnetbohrmaschinen arbeiten, sollten den

Zustand ihrer Hände und Finger aufmerksam

beobachten. Falls die vorgenannten

Symptome auftreten, sollte unverzüglich

ärztlicher Rat eingeholt werden.

• DieMessungundBewertungvon

Auswirkungen von Schwingungen auf

das Hand-Arm-System am Arbeitsplatz

wird in folgenden Normen beschrieben:

BS EN ISO 5349-1:2001 and

BS EN ISO 5349-2:2002

• DietatsächlicheVibrationsstärke

während des Betriebs wird durch viele

Faktoren beeinflusst, z.B. dem Zustand

und der Ausrichtung der Arbeitsflächen

und der Art und dem Zustand der

verwendeten Maschine. Diese Faktoren

sollten vor jedem Einsatz bewertet

werden; ggf. sind die Arbeitspraktiken

anzupassen. Ein umsichtiger Umgang

mit diesen Faktoren kann dazu

beitragen, die Auswirkungen von

Vibrationen zu reduzieren:

Handhabung

• Gehen Sie umsichtig mit der Maschine

um und überlassen Sie der Maschine

die Arbeit.

• Vermeiden Sie übermäßigen Kraftaufwand

bei der Bedienung der Maschine.

• Achten Sie während des Betriebs der

Maschine auf deren Ausrichtung und auf

Ihre persönliche Sicherheit und Stabilität.

Arbeitsfläche

• Stellen Sie die Maschine auf eine saubere,

stabile Arbeitsfläche im guten Zustand und

achten Sie auf die korrekte Ausrichtung.

WARNUNG: Der Vibrationswert, der bei

der Verwendung des Elektrowerkzeugs

auftritt, kann je nach Art und Weise der

Nutzung der Maschine vom angegebenen

Wert abweichen. Sicherheitsmaßnahmen

zum Schutz des Bedieners müssen auf einer

Abschätzung der Gefährdung unter realen

Nutzungsbedingungen basieren (Beachten Sie

hierbei sämtliche Phasen des Betriebszyklus

einschließlich der Zeiten, in denen die

Maschine abgeschaltet ist oder sich im

Leerlauf befindet bzw. anläuft).

(1.8) KENNZEICHNUNGEN UND SYMBOLE

WARNUNG: Verwenden Sie die Maschine

nicht, wenn Warn- und / oder Hinweisschilder

fehlen oder beschädigt sind. Erkundigen

Sie sich bei Evolution Power Tools, um

Ersatzschilder anzufordern.

Hinweis: Alle oder einige der folgenden

Symbole finden sich möglicherweise

im Handbuch oder auf dem Produkt.

DE

FR

IT

NL

37

Page 38

www.evolutionpowertools.com

(1.9) KENNZEICHNUNGEN UND SYMBOLE

Symbol Bedeutung

Volts

Ampere

Hertz

Beschleunigen

Wechselstrom

Leerlaufdrehzahl

Schutzbrille

Gehörschutz tragen

Do Not Touch

Hz

Min

n

V

A

-1

~

o

(1.10) BESTIMMUNGSGEMÄSSER

GEBRAUCH DES ELEKTROWERKZEUGS

WARNUNG: Dieses Produkt ist eine manuelle

Kapp- und Gehrungssäge, die speziell zum

Gebrauch in Verbindung mit speziellen

Evolution-Sägeblättern konstruiert wurde.

Verwenden Sie nur Zubehör, das speziell

für diese Maschine konstruiert wurde bzw.

speziell von Evolution Power Tools Ltd.

empfohlen wurde.

Wenn diese Maschine mit dem richtigen

Sägeblatt bestückt ist, eignet sie sich zum

Schneiden folgender Materialien:

Weicher Stahl

Aluminium

Holz

(1.11) NICHT ZULÄSSIGER GEBRAUCH

DES ELEKTROWERKZEUGS

WARNUNG: Dieses Produkt ist eine manuelle

Kapp- und Gehrungssäge und sollte nur als

solche verwendet werden. Sie darf in keiner

Weise modifiziert werden oder entgegen den

Empfehlungen des Bedienungshandbuchs mit

anderem Zubehör verwendet werden.

Tragen Staubschutz

Lesen Sie die Anweisungen

CE-Zertifizierung

Warnung

Elektro-und

Elektronik

Doppelt Isoliert

(1.13) WARNUNG: Dieses Gerät ist

nicht für die Verwendung durch Personen

vorgesehen (Kinder eingeschlossen), die

verminderte körperliche, sensorielle oder

geistige Fähigkeiten haben oder nicht über

ausreichende Erfahrung und Kenntnisse

verfügen, außer sie haben von einer Person,

die für ihre Sicherheit verantwortlich ist,

Anweisungen für den Gebrauch dieses Gerätes

erhalten oder werden von dieser beaufsichtigt.

Achten Sie darauf dass Kinder nicht in die

Nähe dieser Maschine gelangen oder

mit ihr spielen.

38

Page 39

www.evolutionpowertools.com

EN

(1.14) ELEKTRISCHE SICHERHEIT

Diese Maschine ist mit dem für den

ausgewiesenen Markt passenden angeformten

Stecker und Netzkabel ausgerüstet. Wenn das

Netzkabel beschädigt ist, muss es durch ein

spezielles Kabel oder Montage beim Hersteller

oder seinen Kundendienst ersetzt werden.

(1.15) VERWENDUNG IM FREIEN

WARNUNG: Zu Ihrer eigenen Sicherheit

sollte die Maschine beim Einsatz im Freien

weder Regen ausgesetzt noch an feuchten

Standorten verwendet werden. Platzieren

Sie das Werkzeug nicht auf feuchten

Oberflächen und verwenden Sie möglichst

eine saubere, trockene Werkbank. Verwenden

Sie als zusätzlichen Schutz eine FehlerstromSchutzeinrichtung (RCD), die bei einem

Fehlerstrom von über 30 mA, der länger als

30 ms auftritt, die Maschine abschaltet. Prüfen

Sie die Fehlerstrom-Schutzeinrichtung (RCD)

auf korrekte Funktion, bevor Sie mit der

Maschine arbeiten. Ist ein Verlängerungskabel

erforderlich, muss es für die Verwendung

im Freien geeignet und entsprechend

gekennzeichnet sein. Bei Verwendung

eines Verlängerungskabels sollten die

Empfehlungen des Herstellers befolgt werden.

(2.1) ALLGEMEINE

SICHERHEITANWEISUNGEN

FÜR ELEKTROWERKZEUGE

(Diese Allgemeinen Sicherheitsanweisungen

entsprechen BS EN 60745-1:2009

& EN 61029-1:2009).

WARNUNG: Lesen Sie sämtliche

Sicherheitshinweise und -Anweisungen.

Eine Nichtbeachtung der Warnhinweise und

Anweisungen kann zu elektrischem Schlag,

Feuer und/oder ernster Verletzung führen.

Bewahren Sie sämtliche Warnhinweise

und Anleitungen gut auf. Die Bezeichnung

“Elektrowerkzeug“ in den Warnhinweisen

bezieht sich sowohl auf netzbetriebene

(mit Kabel) als auch auf batteriebetriebene

(ohne Kabel) Elektrowerkzeuge.

(2.2) Allgemeine Sicherheitshinweise

für Elektrowerkzeuge [Sicherheit

im Arbeitsbereich]

a) Der Arbeitsbereich muss sauber und gut

beleuchtet sein. In unaufgeräumten oder

dunklen Bereichen kann es leicht zu

Unfällen kommen.

b) Elektrowerkzeuge dürfen nicht

in explosiven Atmosphären, z.B. bei

Vorhandensein von entflammbaren

Flüssigkeiten, Gasen oder Stäuben

betrieben werden. Elektrowerkzeuge

erzeugen Funken, die Staub oder Gase

entzünden könnten.

c) Achten Sie beim Betrieb eines

Elektrowerkzeugs darauf, dass keine

Kinder oder sonstige Unbeteiligte

in der Nähe sind. Ablenkungen

können zu Kontrollverlust führen.

(2.3) 2) Allgemeine Sicherheitshinweise für

Elektrowerkzeuge [Elektrische Sicherheit]

a) Die Stecker des Elektrowerkzeugs

müssen zu den Steckdosen passen. Der

Stecker darf auf keinen Fall modifiziert werden.

Verwenden Sie keine Zwischenstecker für

geerdete Elektrowerkzeuge. Originalstecker

und passende Steckdosen reduzieren die

Gefahr, einen elektrischen Schlag zu erhalten.

b) Vermeiden Sie die Berührung von

geerdeten Oberflächen (Rohre, Heizungen,

Herde und Kühlschränke). Das Risiko eines

elektrischen Schlages ist größer, wenn Ihr

Körper mit Erde bzw. Masse verbunden ist.

c) Elektrowerkzeuge sollten weder Regen

noch Feuchtigkeit ausgesetzt werden.

Wenn Wasser in ein Elektrowerkzeug

eindringt, erhöht sich die Gefahr eines

elektrischen Schlags.

DE

FR

IT

NL

39

Page 40

www.evolutionpowertools.com

d) Das Kabel darf nicht zweckentfremdet

werden. Verwenden Sie das Kabel niemals

zum Tragen, Ziehen oder Ausstecken des

Elektrowerkzeugs. Halten Sie das Kabel

fern von Hitze, Öl, scharfen Kanten oder

sich bewegenden Teilen Beschädigte oder

verknäuelte Kabel erhöhen die Gefahr eines

elektrischen Schlags.

e) Beim Betrieb eines Elektrowerkzeugs

im Freien muss ein für den Außeneinsatz

geeignetes Verlängerungskabel verwendet

werden. Die Verwendung eines für den

Außeneinsatz geeigneten Kabels verringert

das Risiko eines elektrischen Schlags.

f) Ist der Betrieb eines Elektrowerkzeugs

in feuchter Umgebung unvermeidlich,

verwenden Sie eine Stromversorgung mit

Fehlerstrom-Schutzeinrichtung (RCD).

Diese verringert das Risiko eines

elektrischen Schlags.

(2.4) 3) Allgemeine Sicherheitshinweise

für Elektrowerkzeuge

[Persönliche Sicherheit].

a) Seien Sie beim Umgang mit einem

Elektrowerkzeug vorsichtig und

nutzen Sie Ihren gesunden

Menschenverstand. Arbeiten Sie nicht

mit einem Elektrowerkzeug, wenn Sie

übermüdet sind oder unter dem Einfluss

von Drogen, Alkohol oder Medikamenten

stehen. Ein Moment der Unaufmerksamkeit

während der Arbeit mit Elektrowerkzeugen

kann zu ernsten Verletzungen führen.

b) Tragen Sie angemessene

Schutzausrüstung. Tragen Sie stets eine

Schutzbrille. Auf die Arbeitsbedingungen

abgestimmte Schutzausrüstung wie

Staubmaske, Schuhe mit rutschfester Sohle,

Helm oder Gehörschutz reduziert das

Verletzungsrisiko.

c) Vermeiden Sie unbeabsichtigtes

Einschalten. Vergewissern Sie sich, dass

der Schalter auf „Aus“ steht, bevor Sie

die Maschine an Netz oder Batterie

anschließen, aufheben bzw transportieren.

Wird ein Elektrowerkzeug mit dem Finger am

Schalter getragen oder

eingesteckt, während der Schalter auf „Ein“

steht, erhöht sich das Unfallrisiko.

d) Entfernen Sie sämtliche

Einstellwerkzeuge (z.B. Schlüssel), bevor

Sie das Elektrowerkzeug einschalten.

Ein Schrauben- oder Inbusschlüssel, der an

einem rotierenden Teil des Elektrowerkzeugs

vergessen wurde, kann zu

Verletzungen führen.

e) Greifen Sie nicht über. Achten Sie stets

auf guten Stand bzw. gute Balance. Dadurch

haben Sie bei unerwarteten Situationen eine

bessere Kontrolle über das Elektrowerkzeug.

f) Tragen Sie angemessene Kleidung. Tragen

Sie keine lose Kleidung oder Schmuckstücke.

Halten Sie Ihre Haare, Kleidung und

Handschuhe von beweglichen Teilen fern.

Lose Kleidung, Schmuckstücke oder lange

Haare können von beweglichen Teilen

erfasst werden.

g) Sind Geräte für den Anschluss von

Staubabzugs-und-Auffangeinrichtungen

vorhanden, so sind diese vorschriftsmäßig

anzuschließen und zu betreiben.

Der Einsatz derartiger Geräte kann

staubspezifische Risiken reduzieren.

(2.5) 4) Allgemeine Sicherheitshinweise

für Elektrowerkzeuge [Verwendung

und Pflege von Elektrowerkzeugen]

a) Überlasten Sie das Elektrowerkzeug

nicht. Verwenden Sie ein für Ihre

Anwendung geeignetes Elektrowerkzeug.

Ein geeignetes Elektrowerkzeug, das mit

Nennlast eingesetzt wird, arbeitet besser

und sicherer.

40

Page 41

www.evolutionpowertools.com

EN

b) Verwenden Sie das Elektrowerkzeug

nicht, wenn der Schalter nicht ein- und

ausschaltet. Ein Elektrowerkzeug, das nicht

über den Schalter bedient werden kann, ist

gefährlich und muss repariert werden.

c) Trennen Sie das Elektrowerkzeug

vom Netz und/oder Batteriesatz

bevor Sie Einstellungen vornehmen,

Zubehör wechseln oder die Maschine

einlagern. Derartige präventive

Sicherheitsmaßnahmen verringern das

Risiko, das Elektrowerkzeug versehentlich

eingeschaltet zu lassen.

d) Lagern Sie nicht benutzte

Elektrowerkzeuge außerhalb der

Reichweite von Kindern und lassen Sie

nicht zu, dass Personen, die nicht mit dem

Elektrowerkzeug oder dieser Anleitung

vertraut sind mit dem Elektrowerkzeug

arbeiten. Elektrowerkzeuge in den Händen

unerfahrener Nutzer stellen eine Gefahr dar.

e) Warten Sie die Elektrowerkzeuge. Prüfen

Sie bewegliche Teile auf Fehlstellung und

Kleben und achten Sie auf Bruch von Teilen

und sonstige Umstände, die den Betrieb

des Elektrowerkzeugs beeinträchtigen

könnten. Ist das Elektrowerkzeug beschädigt,

lassen Sie es vor der Verwendung reparieren.

Viele Unfälle sind auf unzureichend gewartete

Elektrowerkzeuge zurückzuführen.

f) Sorgen Sie dafür, dass Schneidwerkzeuge

scharf und sauber sind. Vorschriftsmäßig

gepflegte Schneidwerkzeuge mit

scharfen Kanten neigen weniger zum Kleben

und sind leichter zu kontrollieren.

g) Verwenden Sie das Elektrowerkzeug,

Zubehör, Werkzeug etc. im Einklang mit

dieser Anleitung, und zwar unter

Berücksichtigung der Arbeitsbedingungen

und der auszuführenden Arbeit. Die

nichtspezifizierte Verwendung des

Elektrowerkzeugs könnte zu gefährlichen

Situationen führen.

(2.6) 5) Allgemeine Sicherheitshinweise

für Elektrowerkzeuge [Wartung]

a) Überlassen Sie die Instandhaltung Ihres

Elektrowerkzeugs einem qualifizierten

Reparaturdienst, der ausschließlich

identische Ersatzteile verwendet.

Dadurch wird der gleichbleibend sichere

Betrieb des Elektrowerkzeugs garantiert.

(2.7) GESUNDHEITSSCHUTZ

WARNUNG: Beim Betrieb dieser Maschine

können Staubpartikel entstehen. Je nachdem,

mit welchen Materialien Sie arbeiten, kann

dieser Staub besonders schädlich sein. Holen

Sie sich professionellen Rat ein, wenn Sie

vermuten, dass die Oberflächenfarbe des

Materials, das Sie bearbeiten möchten, Blei

enthält. Bleihaltige Farben dürfen nur von

einer Fachkraft entfernt werden. Versuchen

Sie nie, diese selbst zu entfernen. Wenn sich

der Staub an einer Oberfläche abgelagert

hat, kann der Hand-zu-Mund-Kontakt zur

Einnahme von Blei führen. Die Exposition

selbst niedriger Bleimengen kann irreversible

Schäden des Gehirns und Nervensystems

verursachen. Kleinkinder und Ungeborene

sind besonders gefährdet.

Es wird empfohlen, dass Sie die Risiken,

die mit den jeweiligen Materialien verbunden

sind, gut abwägen, um ein mögliches

Gesundheitsrisiko und eine Exposition

zu reduzieren. Einige Materialien können

gesundheitschädlichen Staub erzeugen.

Wir empfehlen zusätzlich zur StaubabsaugVorrichtung die Verwendungeiner

zugelassenen Atemmaske mit austauschbaren

Filtern während der Benutzung

dieser Maschine.

Sie sollten immer:

• in gut belüfteten Bereichen arbeiten;

• geprüfte Schutzausrüstung tragen, z.B. eine

Staubmaske für die Filterung mikroskopisch

kleiner Partikel.

DE

FR

IT

NL

41

Page 42

www.evolutionpowertools.com

(2.8) ACHTUNG: Beim Betrieb von

Elektrowerkzeugen besteht Verletzungsgefahr