Page 1

®

P O W E R T O O L S

www.evolutionrage.com

255mm (10”) TCT

Multi Purpose

Sliding Mitre S.A.W.

www.evolutionrage.com

Instruction

Manual

Manuel d’Instruction

Instruktionshandbuch

Manual de Instrucción

Handleiding

P O W E R T O O L S

Read instructions before operating this tool.

®

Lisez le mode d’emploi avant d’utiliser cet outil.

Vor Benutzung des Werkzuegs bitte bedienungsanleitungen

sorgfaltig lesen.

Antes de utilizar esta herramienta, lean las instrucciones.

Lees instructies alvorens dit hulpmiddel in werking te stellen.

®

BUILD

Page 2

Important

Please read these operating and safety instructions carefully and

completely. For your own safety, before using this equipment

check that the voltage is correct and that all handles and parts are

rmly secured. If you are uncertain about any aspect of using this

equipment, please contact our Technical Helpline.

Technical Helpline UK: 0870 609 2297

Technical Helpline USA: 1-866-EVO-TOOL

warranty – written or verbal – for saw blades. In no event shall

Evolution Power Tools be liable for loss or damage resulting directly

or indirectly from the use or merchandise or from any other cause.

Evolution Power Tools is not liable for any costs incurred on such

goods or consequential damages. No ofcer, employee or agent of

Evolution Power Tools is authorised to make oral representations of

tness or to waive any of the foregoing terms of sale and none shall

be binding on Evolution Power Tools.

Questions relating to this limited warranty should be directed to the

company’s head ofce, or call the appropriate Helpline number.

Rage 3 Multi Purpose Sliding Mitre Saw

Congratulations on your purchase of an Evolution Power

Tools Rage 3 Sliding Mitre Saw. Please complete and mail

your product registration card. Doing so will validate your

machine’s warranty period and ensure prompt service if

needed. We sincerely thank you for selecting a product

from Evolution Power Tools.

CAUTION: IMPORTANT

SAFETY INSTRUCTIONS

To reduce the risk of electric shock, this equipment is tted

with an approved cord and plug for its intended Country of

use. Do not change the plug in any way.

GENERAL SAFETY RULES

WARNING: For Your Own Safety. Read Instruction Manual Before

Operating Mitre Saw.

1. KEEP GUARDS IN PLACE and in working order.

2. REMOVE ADJUSTING KEYS AND WRENCHES. Form habit of

checking to see that keys and adjusting wrenches are removed from

tool before turning it on.

3. KEEP WORK AREA CLEAN. Cluttered areas and benches invite

accidents.

4. DON’T USE IN DANGEROUS ENVIRONMENT. Don’t use power

tools in damp or wet locations, or expose them to rain. Keep work

area well lit.

5. KEEP CHILDREN AWAY. All visitors should be kept a safe

distance from work area.

6. DON’T FORCE TOOL. It will do the job better and safer at the

rate for which it was designed.

7. USE PROPER EXTENSION CORD. Make sure your extension

cord is in good condition. When using an extension cord, be sure to

use one heavy enough to carry the current your product will draw. An

undersized cord will cause a drop in line voltage resulting in loss of

power and overheating.

8. WEAR PROPER APPAREL. Do not wear loose clothing, gloves,

neckties, rings, bracelets, or other jewellery which may get caught in

moving parts. Nonslip footwear recommended. Wear protective hair

covering to contain long hair.

9. ALWAYS USE SAFETY GLASSES. Also use face or dust mask if

cutting operation is dusty. Everyday eyeglasses only have impact

resistant lenses, they are NOT safety glasses.

10. SECURE WORK. Use clamps to hold work when practical. It’s safer

than using your hand and it frees both hands to operate tool.

11. DON’T OVERREACH. Keep proper footing and balance at all

times.

12. MAINTAIN TOOLS WITH CARE. Keep tools sharp and clean for

best and safest performance. Follow instructions for lubricating and

changing accessories.

13. DISCONNECT TOOLS before servicing and when changing

accessories, such as blades.

14. REDUCE THE RISK OF UNINTENTIONAL STARTING. Make sure

switch is in off position before plugging in.

15. USE RECOMMENDED ACCESSORIES. Only use genuine Evolution

accessories.

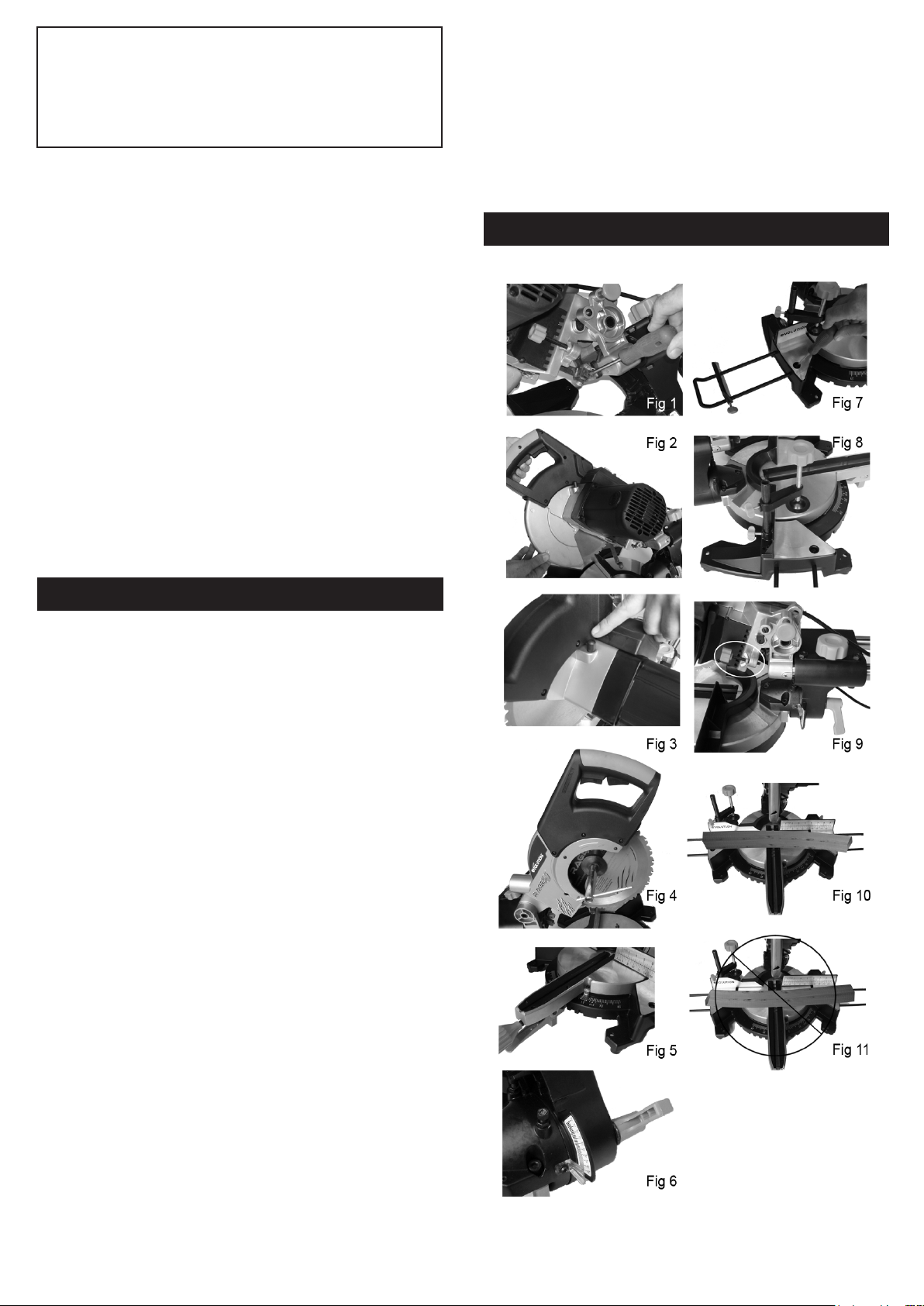

FIGURE ILLUSTRATIONS

2 9

Page 3

20°

25°

30°

35°

40°

45°

50°

55°

60°

65°

70°

75°

80°

85°

90°

M- 43.22°

B- 14.00°

M- 42.19°

B- 17.39°

M- 40.89°

B- 20.70°

M- 39.32°

B- 23.93°

M- 37.45°

B- 27.03°

M- 35.26°

B- 30.00°

M- 32.73°

B- 32.80

M- 29.84°

B- 35.40°

M- 26.57°

B- 37.76°

M- 22.91°

B- 39.86°

M- 18.88°

B- 41.64°

M- 14.51°

B- 43.08°

M- 9.85°

B- 44.14°

M- 4.98°

B- 44.78°

M- 0.00°

B- 45.00°

M- 34.32°

B- 11.60°

M- 33.36°

B- 14.38°

M- 32.18°

B- 17.09°

M- 30.76°

B- 19.70°

M- 29.10°

B- 22.20°

M- 27.19°

B- 24.56°

M- 25.03°

B- 26.76°

M- 22.62°

B- 28.78°

M- 19.96°

B- 30.60°

M- 17.07°

B- 32.19°

M- 13.95°

B- 33.53°

M- 10.65°

B- 34.59°

M- 7.19°

B- 35.37°

M- 3.62°

B- 35.84°

M- 0.00°

B- 36.00°

M- 28.48°

B- 9.85°

M- 27.62°

B- 12.20°

M- 26.57°

B- 14.48°

M- 25.31°

B- 16.67°

M- 23.86°

B- 18.75°

M- 22.21°

B- 20.70°

M- 20.36°

B- 22.52°

M- 18.32°

B- 24.18°

M- 16.10°

B- 25.66°

M- 13.71°

B- 26.95°

M- 11.17°

B- 28.02°

M- 8.50°

B- 28.88°

M- 5.73°

B- 29.50°

M- 2.88°

B- 29.87°

M- 0.00°

B- 30.00°

M- 24.35°

B- 8.53°

M- 23.56°

B- 10.57°

M- 22.64°

B- 12.53°

M- 21.53°

B- 14.41°

M- 20.25°

B- 16.19°

M- 18.80°

B- 17.87°

M- 17.20°

B- 19.41°

M- 15.44°

B- 20.82°

M- 13.54°

B- 22.07°

M- 11.50°

B- 23.16°

M- 9.35°

B- 24.06°

M- 7.10°

B- 24.78°

M- 4.78°

B- 25.30°

M- 2.40°

B- 25.61°

M- 0.00°

B- 25.71°

MAINTENANCE

M- 21.27°

B- 7.52°

M- 20.58°

B- 9.31°

M- 19.73°

B- 11.03°

M- 18.74°

B- 12.68°

M- 17.60°

B- 14.24°

M- 16.32°

B- 15.70°

M- 14.91°

B- 17.05°

M- 13.36°

B- 18.27°

M- 11.70°

B- 19.35°

M- 9.93°

B- 20.29°

M- 8.06°

B- 21.08°

M- 6.12°

B- 21.69°

M- 4.11°

B- 22.14°

M- 2.07°

B- 22.41°

M- 0.00°

B- 22.50°

M- 18.88°

B- 6.72°

M- 18.26°

B- 8.31°

M- 17.50°

B- 9.85°

M- 16.60°

B- 11.31°

M- 15.58°

B- 12.70°

M- 14.43°

B- 14.00°

M- 13.17°

B- 15.19°

M- 11.79°

B- 16.27°

M- 10.31°

B- 17.23°

M- 8.74°

B- 18.06°

M- 7.10°

B- 18.75°

M- 5.38°

B- 19.29°

M- 3.62°

B- 19.68°

M- 1.82°

B- 19.92°

M- 0.00°

B- 20.00°

M- 16.98°

B- 6.07°

M- 16.41°

B- 7.50°

M- 15.72°

B- 8.89°

M- 14.90°

B- 10.21°

M- 13.98°

B- 11.46°

M- 12.94°

B- 12.62°

M- 11.80°

B- 13.69°

M- 10.56°

B- 14.66°

M- 9.23°

B- 15.52°

M- 7.82°

B- 16.26°

M- 6.34°

B- 16.88°

M- 4.81°

B- 17.37°

M- 3.23°

B- 17.72°

M- 1.62°

B- 17.93°

M- 0.00°

B- 18.00°

EC Declaration of Conformity

We: Evolution Power Tools Limited

Evolution House

New Street

Shefeld

S20 3GH

As the supplier of the item listed below:-

Rage 3 255mm (10”) TCT Multi Purpose Sliding Mitre Saw

Part No. RAGE3255

Voltage 110 - 230V

Power 2000W

Declare, under our sole responsibility that the equipment to which

this document relates is in conformity with the following standards

or other normative documents:-

EN 60335-1:1994+A1+A2+A11–A16

EN 55014-1:2000+A1+A2

EN 55014-2:1997+A1

EN 61000-3-2:2000

EN 61000-3-3:1995+A1

EN 61000-3-11:2000

CLEANING

Use only mild soap and damp cloth to clean the tool.

Never let any liquid get inside the tool; never immerse

any part of the tool into a liquid.

Regularly clean the tool’s air vents with compressed dry air.

DO NOT ATTEMPT TO CLEAN BY INSERTING POINTED

OBJECTS THROUGH OPENINGS.

LUBRICATION

All of the bearings in this tool are lubricated with a

sufcient amount of high grade lubricant for the life of

the unit under normal operating conditions. Therefore,

no further lubrication is required.

12 MONTHS WARRANTY

12 MONTH LIMITED WARRANTY. EVOLUTION POWER TOOLS

RESERVES THE RIGHT TO MAKE IMPROVEMENTS AND

MODIFICATIONS TO DESIGN WITHOUT PRIOR NOTICE.

Evolution Power Tools will, within twelve (12) months from the

original date of purchase, repair or replace any goods found to

be defective in materials or workmanship, provided the product

warranty registration card has been returned to Evolution Power

Tools within thirty (30) days of purchase date. This warranty is void

if the tool being returned has been used to cut materials beyond the

recommendations in the Instruction Manual or if the saw has been

damaged by accident, neglect, or improper service. This warranty

does not apply to machines and / or components which have been

altered, changed, or modied in any way, or subjected to use beyond

recommended capacities and specications. Electrical components

are subject to respective manufacturers’ warranties. All goods

returned defective shall be returned prepaid freight to Evolution

Power Tools. Evolution Power Tools reserves the right to optionally

repair or replace it with the same or equivalent item. There is no

And thereby conforms to the protection requirements of

Council Directive 73/23/EC amended by 93/68/EC relating

to the Low Voltage Directive, Council Directive 98/37/EC

relating to the Machinery Directive and Council Directive

89/336/EC relating to the EMC Directive, and is compliant

with EU Directive 2002/95/EC in relation to the Restriction of

Hazardous Substances in Electrical & Electronic Equipment

(ROHS).

Guaranteed Sound Power Level: 98 dB(A)

Conformity assessment method to annex V of Directive

2000/14/EC

Relevant technical documentation kept at Evolution Power

Tools Ltd, Shefeld

Authorised by:

Mr M J Gavins

Managing Director

19th June 2006

06

(Year of afxation)

8 3

Page 4

16. NEVER STAND ON TOOL. Serious injury could occur if the tool is

tipped or if the cutting tool is unintentionally contacted.

17. CHECK DAMAGED PARTS. Before further use of the tool, a guard or

other part that is damaged should be carefully checked to determine

that it will operate properly and perform its intended function – check

for alignment of moving parts, binding of moving parts, breakage of

parts, mounting, and any other conditions that may affect its operation.

A guard or other part that is damaged should be properly repaired or

replaced.

18. Wear eye protection.

19. Keep hands out of path of saw blade.

20. Do not operate saw without guards in place.

21. Never reach around saw blade.

22. Turn off tool and wait for saw blade to stop before moving workpiece

or changing settings.

23. Disconnect power before changing blade, servicing or cleaning.

24. To reduce the risk of injury, return carriage to the full rear position after

each crosscut operation.

SAVE THESE INSTRUCTIONS

FOR FUTURE REFERENCE

ADDITIONAL SAFETY INSTRUCTION

1. Although compact, this saw is heavy. To reduce the risk of back injury,

get help whenever you have to lift the saw.

2. To reduce the risk of back injury, hold the tool close to your body when

lifting. Bending your knees so you can lift with your legs, not your

back. Lift by using the handhold areas at each side of the bottom of

the base.

3. Never carry the mitre saw by the power cord or the trigger grip of the

handle. Carrying the tool by the power cord could cause damage to

the insulation or the wire connections resulting in electric shock or

re.

4. Before removing the saw from the carton tighten the slide lock knob

to guard against sudden movement.

5. Place the saw on a secure stationary work surface and check the saw

over carefully.

6. Warning. Do not stare directly at the laser beam. A hazard may exist

if you deliberately stare into the beam, please observe all safety rules

as follows.

- The laser shall be used and maintained in accordance with the

manufacturer instructions.

- The laser beam shall not be deliberately aimed at personnel

and shall be prevented from being directed towards the eyes of a

person.

- Always ensure the laser beam is aimed at the workpiece

without reective surfaces, i.e. wood or rough coated surfaces are

acceptable.

- Do not change the laser light assembly with a different type.

SPECIFICATIONS

Model Rage 3

Motor (230v-240v ~ or 110v ~ 50/60 Hz) (Watts): 2000

RPM No Load (min-1): 2500

Recommended Maximum Duty Cycle (Minutes): 30

Sound Pressure Level (Under Load) (dB(A)): 98

Vibration Level (Under Load) (m/s2): 1.98

Weight: 19.6Kg

Blade Dimensions

Maximum Diameter: (10”) 255mm

Bore Diameter: (1”) 25.4mm

Thickness: (1/16”) 2mm

Maximum Cutting Capacity

Mitre Bevel Max Width of Cut Max Depth of Cut

90º 90° 300mm (11.81””) 75mm (2.95”)

45°L / 45°R 45° 210mm (8.26””) 40mm (1.57”)

45°L / 45°R 90° 210mm (8.26””) 75mm (2.95”)

90° 45° 300mm (11.81””) 40mm (1.57”)

5. Turn on saw and allow the saw to reach full speed.

6. Press the lower guard unlock lever for saw head release.

7. Push the saw handle down and cut the workpiece.

8. After cut is complete turn off saw, allow blade to completely stop.

WARNING: For your convenient use, the saw has a blade brake. Never

rely on it to replace proper use of the guard on your saw.

BODY AND HAND POSITION

1. Never place hands near cutting area and keep hand away from the

path of blade.

2. Hold workpiece rmly to the fence to prevent movement toward the

blade.

3. Before making a cut. Make a dry run with the power off so you can

see the path of the blade.

5. Keep hands in position until trigger has been released and the blade

has completely stopped.

MITRE CUT

An angle of up to 45° left or right can be obtained using the unit.

1. Loosen the mitre angle lock.

2. Pull up the mitre angle set lever.

3. Turn the table unit to the desired angle is indicated on the mitre angle

pointer.

4. Tighten the angle lock knob to hold the desired angle.

5. Start the saw and allow it to reach full speed before commencing the

cut.

BEVEL CUT

1. Loosen the bevel angle lock.

2. Move the blade to desired bevel angle.

3. Stand to the left side of the handle to make the cut.

COMPOUND CUT

When a compound cut is required. Select the desired bevel and mitre

positions.

CUTTING BOWED MATERIAL (Fig 10 & 11)

Before cutting a workpiece, check to make sure it is not

bowed. If it is bowed, the workpiece must be positioned

and cut as illustrated. Do not position workpiece

incorrectly or try to cut the workpiece without the

support of the fence. This will cause pinching of the

workpiece on the blade. The workpiece could suddenly

jump or move and your hand could hit the blade.

CUTTING COMPOUND MITRES

To aid in making the correct settings, the compound

angle setting chart below has been provided. Since

compound cuts are the most difcult to accurately

obtain, trial cuts should be made in scrap material, and

much thought and planning made, prior to making your

required cut.

WARNING: Always unplug the tool before making any

assembly, adjustments or changing accessories.

COMPOUND ANGLE SETTINGS FOR POPULAR STRUCTURES

Each B (Bevel) and M (Mitre) Setting is given to the closest 0.005°

PITCH

OF

SIDE

0°

5°

10°

15°

4 5 6 7 8 9 10

M- 45.00°

B- 0.00°

M- 44.89°

B- 3.53°

M- 44.56°

B- 7.05°

M- 44.01°

B- 10.55°

N U M B E R O F S I D E S

M- 36.00°

B- 0.00°

M- 35.90°

B- 2.94°

M- 35.58°

B- 5.86°

M- 35.06°

B- 8.75°

M- 30.00°

B- 0.00°

M- 29.91°

B- 2.50°

M- 29.62°

B- 4.98°

M- 29.15°

B- 7.44°

M- 25.71°

B- 0.00°

M- 25.63°

B- 2.17°

M- 25.37°

B- 4.32°

M- 24.95°

B- 6.95°

M- 22.50°

B- 0.00°

M- 22.42°

B- 1.91°

M- 22.19°

B- 3.81°

M- 21.81°

B- 5.68°

M- 20.00°

B- 0.00°

M- 19.93°

B- 1.71°

M- 19.72°

B- 3.40°

M- 19.37°

B- 5.08°

M- 18.00°

B- 0.00°

M- 17.94°

B- 1.54°

M- 17.74°

B- 3.08°

M- 17.42°

B- 4.59°

4 7

Page 5

DEPTH STOP (Fig. 9)

Use of the depth stop feature means that the blade will not cut completely

through the workpiece depending on the depth that it is set to. This allows

the operator to cut slots in the workpiece. NOTE: It is advisable that the

depth of cut is checked using a scrap piece of timber prior to undertaking

the workpiece. By making a cut in the workpiece and then slightly moving

the workpiece to the left or right before repeating, it is possible to perform

trenching cuts in the workpiece.

To use the depth stop feature follow these steps:

1. Loosen the wing nut.

2. Adjust the thumb knob to the required depth.

3. Once set to the desired depth, tighten the wing nut against the

retaining bracket to lock the depth stop and ensure that there is no

movement.

Standard Equipment Supplied With Unit: 1 MultiBlade, 1 Box Spanner, 1

Operating Instructions.

ASSEMBLY

MOUNTING THE MITRE SAW

WARNING: To reduce the risk of injury from unexpected saw movement,

place the saw in the desired location either on a workbench or other

recommended leg set. The base of the saw has four holes to mount the

mitre saw. If the saw is to be used in one location, permanently fasten it to

the workbench or leg set.

CLEARING JAMMED MATERIAL:

1. Turn mitre saw “OFF” by releasing trigger switch.

2. Wait for all moving parts to stop.

3. Unplug the mitre saw.

4. Remove jammed material from the unit.

OPERATING INSTRUCTION

DISCONNECT THE MITRE SAW AND INSPECT YOUR

SAW BEFORE EACH USE.

WARNING: To reduce the risk of injury, always unplug the saw before

changing or adjusting anything. Compare the direction of rotation arrow on

the guard to direction arrow on the blade. The blade teeth should always

point downward at the front of the saw. Tighten the arbor screw. Tighten

the cover plate screw.

PREPARING TO MAKE THE CUT

CAUTION: NEVER pull the saw toward you during a cut. The blade can

suddenly climb up on top of the workpiece and force itself toward you.

- Avoid awkward operations and hand positions where a sudden slip

could cause ngers or hand to move into the blade.

- Cut only one workpiece at a time.

- Clear everything except the workpiece and related support devices

away from the blade before turning the mitre saw on.

- Secure workpiece using clamps to hold the workpiece securely.

MAKING COMMON SLIDE COMPOUND CUTS

There are two types of cuts that can be made with the slide compound

mitre saw.

Slide Cutting

Loosen the side lock knob and move the cutting head towards the operator.

The saw blade is lowered into the workpiece and then pushed to the rear of

the saw to complete the cut. Used for cutting wide pieces. It should not be

used for cutting metal materials.

1. Put wood against fence and secure with clamp as appropriate.

2. Loosen the slide lock knob.

3. Grasp the saw handle and pull the carriage until the arbor (centre of

saw blade) is over the front edge of the workpiece.

4. Press the lower guard unlock lever for saw head release.

5. Switch on the saw and allow the saw to reach full speed.

6. Push the saw handle all the way down and cut through the leading

edge of the workpiece.

7. Gently push the saw handle towards the fence completing the cut.

8. Push power head to full rear position after each cut.

9. Release the trigger to switch off the saw and allow blade to come to

a complete stop before moving hands or remove the workpiece.

CHOP CUTTING

The slide lock knob is tightened and the saw handle is pushed down to cut

through the workpiece. This type of cut is used mainly for narrow pieces

and all metals.

1. Slide the cutting head to the rear as far as it will go.

2. Lock slide lock knob.

3. Place the workpiece on table and against fence and secure with

clamp as appropriate.

4. Grasp the saw handle.

1. Tighten the sliding rail, mitre and bevel locks.

2. Place the saw so other people cannot stand behind it. Thrown debris

could injure people in its path.

3. Place the saw on a rm, level surface where there is plenty of room

for handing and properly supporting the workpiece.

4. Support the saw so the table is level and the saw does not rock.

5. Bolt or clamp the saw to its support.

INSTALLING OR REMOVING THE BLADE

WARNING: Only use genuine Evolution blades which are designed for

this machine.

1. Ensure cutting head is up.

2. Remove the guard screw. (Fig. 1)

3. Press safety lock button in and lift up the lower blade guard. (Fig. 2)

4. Press the black lock button to lock the arbor. (Fig. 3)

5. Using the supplied spanner, release the arbor screw to remove the

blade. (Fig. 4)

6. Install the new 255 mm (10”) blade. Make sure the rotation arrow on

the blade matches the clockwise rotation arrow on the upper guard.

The blade teeth should always point downward at the front of the

saw.

7. Install the blade washer and arbor screw.

8. Turn box spanner to secure the blade.

9. Tighten arbor screw using moderate force, but do not overtighten.

10. Replace the guard screw. (Fig. 1)

ADJUSTMENT OF THE CUTTING ANGLES.

MITRE ANGLE: (Fig. 5)

1. Loosen the sliding rail locking knob, push the saw handle back

as far as it will go and lock the handle.

2. Loosen the mitre angle lock knob.

3. Pull up the angle set lever and turn the table until the angle pointer

reach to the desired angle on angle mitre guide (g 5).

4. Tighten the mitre angle lock knob.

BEVEL ANGLE: (Fig. 6)

1. Lock the cutting head down with the cutting lock knob.

2. Loosen the bevel lock.

3. Adjust angle until the bevel angle point reaches the desired bevel

angle.

4. Tighten the bevel lock.

FITTING THE REPEAT STOP

1. Loosen the thumb screw to allow the arms of the workpiece

supports into the holes in the repeat stops.

2. Tighten the thumb screws rmly to minimize movement on the

workpiece support.

3. Attach the workpiece support as detailed below.

NOTE: By loosening the thumb screws the repeat stop can be

adjusted to required widths for each application.

FITTING THE WORKPIECE SUPPORT (Fig.7)

1. Loosen the support retaining screw located on the turntable.

2. Insert the workpiece support into the retaining holes in the base.

3. Tighten the retaining screw.

FITTING THE WORKPIECE CLAMP (Fig.8)

1. Fit the clamp to the retaining hole that best suits the cutting

application, ensuring that it is fully pushed down.

2. Tighten the thumbscrew to lock the pillar.

3. Put the workpiece to be cut onto the saw bed.

4. Adjust the clamp so that it securely holds the workpiece.

6 5

Page 6

REV. 1.00

91

98

29

4

149

149

30

31

28

151

152

10

10

32

113

113

66

48

46

61

65

55

44

80

79

78

81

76

74

75

74

59

4

3

61

67

68

67

68

64

70

71

61

60

3

59

4

3

59

55

4

73

16

49

72

49

63

69

64

63

61

60

113

4

4

4

112

102

145

145

146

147

148

32

141

140

146

147

148

150

10

10

143

144

142

32

141

140

139

138

137

132

133

134

131

130

129

128

4

127

126

110

109

108

107

106

105

104

123

122

121

101

100

99

97

96

95

94

93

88

118

119

120

114

116

117

116

115

114

87

86

84

83

82

3

58

57

56

52

54

53

50

49

4

47

4

45

43

40

42

41

41

40

39

39

40

27

27

40

39

38

27

37

36

35

34

4

24

25

16

16

16

16

18

16

19

17

16

16

15

23

21

22

16

20

14

12

8

9

1

1

2

2

2

575

6

11

10

51

4

4

136

33

29

62

103

125

124

4

4

4

13

3

4

4

3

4

3

77

92

135

27

27

26

89

90

111

RAGE 3

D u a l R a i l S l i d e M i t r e S a w

®

S e r v i c e P a r t s L i s t

Loading...

Loading...