Page 1

RCP

Original Instructions

Instrucciones originales

Instructions originales

GB2438285

Originally written in UK English Date Published: 20/06/2019

308 7464

Page 2

www.evolutionpowertools.com

TABLE OF CONTENTS

INTRODUCTION

Machine Specification Page 4

Vibration Page 5

Labels and Symbols Page 5

Intended use of this Power Tool Page 6

Prohibited use of this Power Tool Page 6

SAFETY PRECAUTIONS

Electrical Safety Page 7

Outdoor Use Page 7

General Power Tool Safety Instructions Page 7

Additional Safety Instructions Page 9

GETTING STARTED

Unpacking Page 10

Machine Overview Page 11

Operating Instructions Page 12

MAINTENANCE

Environmental Protection Page 17

DECLARATION OF CONFORMITY Page 18

2

Page 3

www.evolutionpowertools.com

EN

THIS INSTRUCTION MANUAL WAS

ORIGINALLY WRITTEN IN ENGLISH

IMPORTANT

Please read these operating and safety

instructions carefully and completely.

For your own safety, if you are uncertain

about any aspect of using this equipment

please access the relevant technical helpline,

the number of which can be found on the

Evolution Power Tools website. We operate

several helplines throughout our worldwide

organization, but technical help is also

available from your supplier.

WEB

www.evolutionpowertools.com

EMAIL

enquiries@evolutionpowertools.com

Congratulations on your purchase of an

Evolution Power Tools Machine. Please

complete your product registration ‘online’

as explained in the A5 online guarantee

registration leaflet included with this machine.

You can also scan the QR code found on the

A5 leaflet with a Smart Phone. This will enable

you to validate your machine’s guarantee

period via Evolutions website by entering your

details and thus ensure prompt service if ever

needed. We sincerely thank you for selecting

a product from Evolution Power Tools.

3

Page 4

www.evolutionpowertools.com

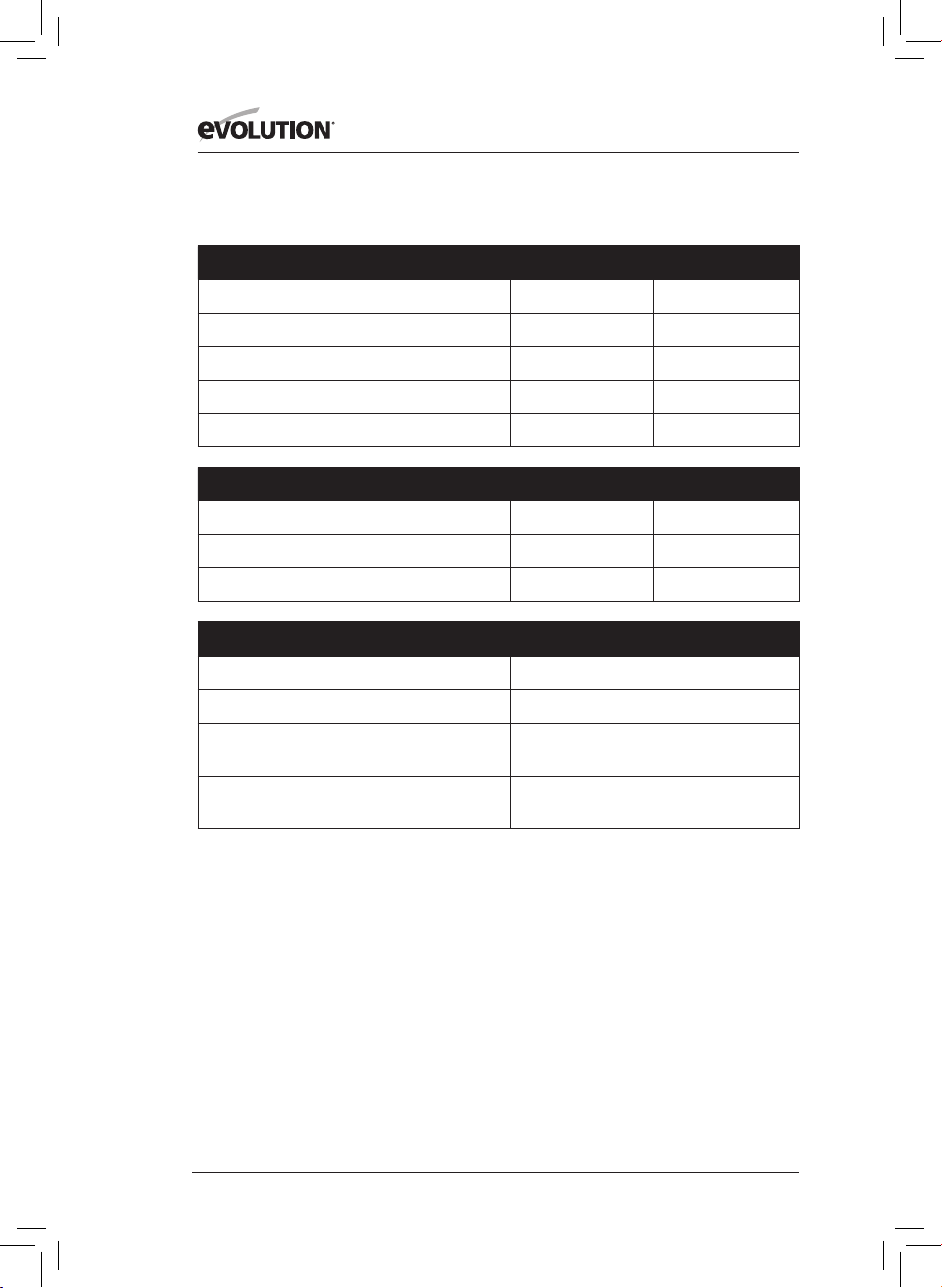

SPECIFICATIONS

MACHINE SPECIFICATIONS METRIC IMPERIAL

Motor EU (230V ~ 50 Hz) 850W 3.7A

Motor USA (120V ~ 60 Hz) 850W 7A

Stroke Length 28mm 1-1/8"

Variable Speed (Strokes Per Minute) 0 - 2800spm 0 - 2800spm

Weight 2.7kg 5.9lbs

CUTTING CAPACITIES METRIC IMPERIAL

Mild Steel (Max Thickness) 20mm 3/4”

Wood (Max Thickness) 230mm 9-1/16”

Plastic (Max Thickness) 150mm 5-7/8”

NOISE & VIBRATION DATA

Sound Pressure L

Sound Power Level L

Vibration Level (Under Load) - Main Handle Wood - 10.357m/s

Vibration Level (Under Load) - Auxiliary Handle Wood - 19.151m/s2 , Metal - 19.905m/s

(Under Load) 90.39 dB(A) K=3dB(A)

PA

(Under Load) 101.39 dB(A) K=3dB(A)

WA

2

, Metal - 21.223m/s

2

K=1.5m/s

2

K=1.5m/s

4

2

2

Page 5

www.evolutionpowertools.com

EN

Note: The vibration measurement was made

under standard conditions in accordance

with: EN 62841-1:2015

The declared vibration total value

has been measured in accordance with

a standard test method and may be used

for comparing one tool with another.

The declared vibration total value may

also be used in a preliminary assessment

of exposure.

VIBRATION

WARNING: When using this machine the

operator can be exposed to high levels of

vibration transmitted to the hand and arm.

It is possible that the operator could develop

“Vibration white nger disease” (Raynaud

syndrome). This condition can reduce the

sensitivity of the hand to temperature as well

as producing general numbness. Prolonged

or regular users of this machine should

monitor the condition of their hands and

ngers closely. If any of the symptoms become

evident, seek immediate medical advice.

• The measurement and assessment of

human exposure to hand-transmitted

vibration in the workplace is given in:

BS EN ISO 5349-1:2001 and

BS EN ISO 5349-2:2002

• Many factors can inuence the actual

vibration level during operation e.g. the

work surfaces condition and orientation

and the type and condition of the machine

being used. Before each use, such factors

should be assessed, and where possible

appropriate working practices adopted.

Managing these factors can help reduce

the eects of vibration:

Handling

• Handle the machine with care, allowing

the machine to do the work.

• Avoid using excessive physical eort on

any of the machines controls.

• Consider your security and stability, and

the orientation of the machine during use.

Work Surface

• Consider the work surface material;

its condition, density, strength,

rigidity and orientation.

WARNING: The vibration emission during

actual use of the power tool can dier from

the declared total value depending on the

ways in which the tool is used. The need

to identify safety measures and to protect

the operator are based on an estimation

of exposure in the actual conditions of use

(taking account of all parts of the operating

cycle, such as the times the tool is switched

o, when it is running idle, in addition to

trigger time).

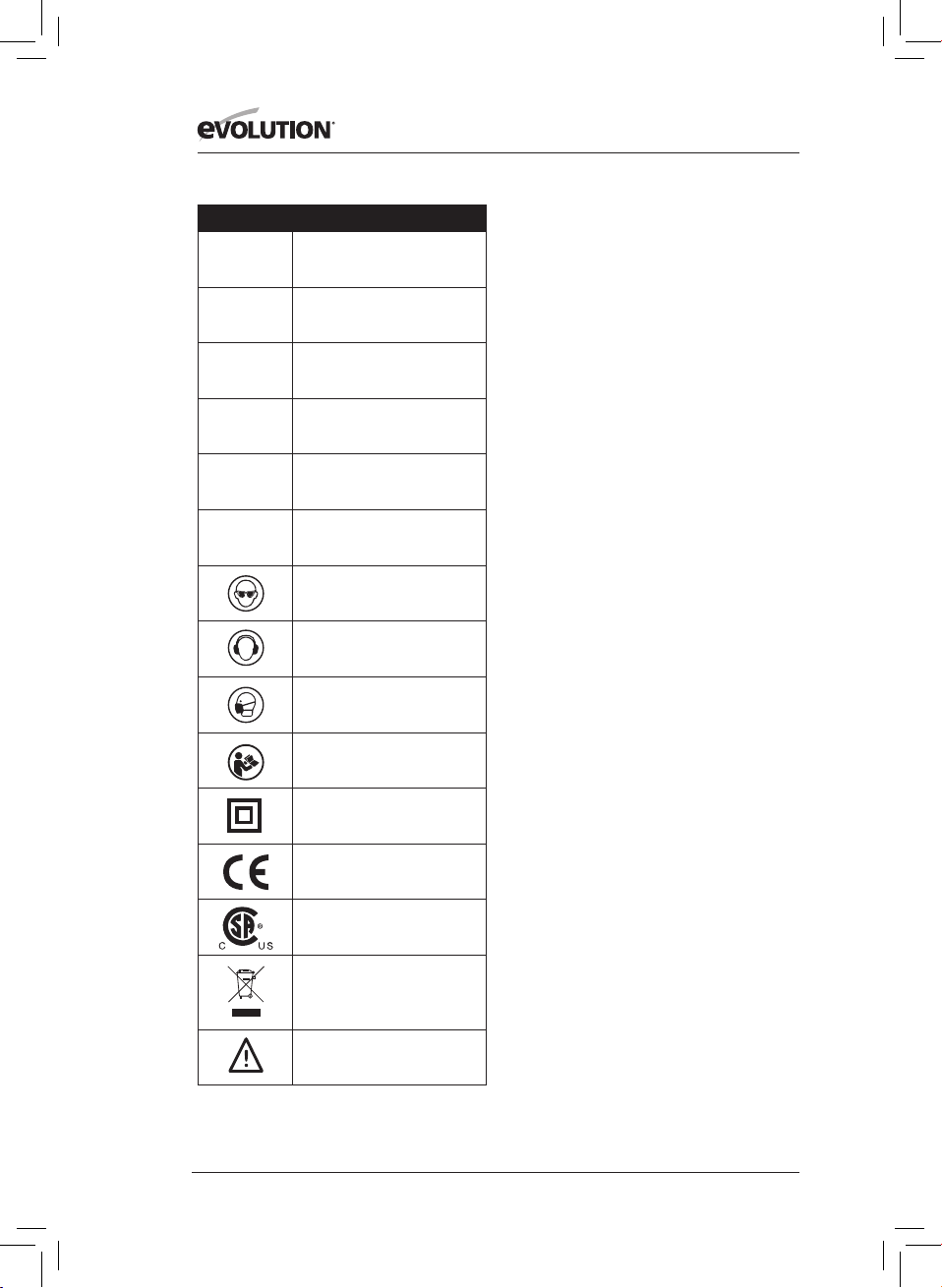

LABELS & SYMBOLS

WARNING: Do not operate this machine

if warning and/or instruction labels are

missing or damaged. Contact Evolution

Power Tools for replacement labels.

Note: All or some of the following symbols

may appear in the manual or on the product.

5

Page 6

www.evolutionpowertools.com

Symbol Description

Volts

Amperes

Hertz

Speed

Alternating Current

No Load Speed

Wear Safety Goggles

Wear Ear Protection

Wear Dust Protection

Read Instructions

Hz

Min

n

V

A

-1

~

o

INTENDED USE OF THIS POWER TOOL

WARNING: This product is a hand held

reciprocating saw and has been designed

to be used with special Evolution blades.

Only use accessories designed for use in

this machine and/or those recommended

specically by Evolution Power Tools Ltd.

When tted with an appropriate blade,

and with the workpiece contact plate

rmly on the workpiece, this machine can

be used to cut:

Wood

Mild Steel, Aluminium, and

many other non-ferrous metals.

Most plastics.

PROHIBITED USE OF THIS POWER TOOL

WARNING: This product is a hand held

reciprocating saw and must only be used

as such. It must not be modied in any way,

or used to power any other equipment or

drive any other accessories other than those

mentioned in this instruction manual.

WARNING: This machine must not be used to

cut any material that may contain asbestos.

If the presence of asbestos is suspected,

consult the relevant authorities for advice.

Double Insulation Protection

CE Certification

CSA Certification

Waste Electrical &

Electronic Equipment

Warning

WARNING: This machine is not intended

for use by persons (including children) with

reduced physical, sensory or mental capabilities,

or lack of experience and knowledge, unless

they have been given supervision or instruction

concerning the safe use of the machine by a

person responsible for their safety and who is

competent in its safe use.

Children should be supervised to ensure

that they do not have access to, and are not

allowed to play with, this machine.

6

Page 7

www.evolutionpowertools.com

EN

ELECTRICAL SAFETY

This machine is tted with the correct

moulded plug and mains lead for the

designated market. If the mains lead or

the plug are damaged in any way, they

must be replaced with original replacement

parts by a competent technician.

OUTDOOR USE

WARNING: For your protection if this tool is to

be used outdoors it should not be exposed to

rain, or used in damp locations. Do not place

the tool on damp surfaces. Use a clean, dry

workbench if available. For added protection

use a residual current device (R.C.D.) that will

interrupt the supply if the leakage current to

earth exceeds 30mA for 30ms. Always check

the operation of the residual current device

(R.C.D.) before using the machine.

If an extension cable is required it must be a

suitable type for use outdoors and so labelled.

The manufacturers instructions should be

followed when using an extension cable.

POWER TOOL GENERAL

SAFETY INSTRUCTIONS

(These General Power Tool Safety Instructions

are as specified in EN 62841-1:2015,

EN 62841-2-11:2016)

WARNING: Read all safety warnings and

instructions. Failure to follow the warnings and

instructions may result in electric shock, re

and/or serious injury.

of ammable liquids, gasses or dust.

Power tools create sparks which may ignite

the dust or fumes.

c) Keep children and bystanders

away while operating power tool.

Distractions can cause you to lose control.

2) General Power Tool Safety

Warnings [Electrical Safety]

a) Power tool plugs must match the outlet.

Never modify the plug in any way. Do not use

any adapter plugs with earthed (grounded)

power tools. Unmodied plugs and matching

outlets will reduce the risk of electric shock.

b) Avoid body contact with earthed

or grounded surfaces, such as pipes,

radiators, ranges and refrigerators.

There is an increased risk of electric shock

if your body is earthed or grounded.

c) Do not expose power tools to rain or

wet conditions. Water entering a power tool

will increase the risk of electric shock.

d) Do not abuse the cord. Never use the cord

for carrying, pulling or unplugging the power

tool. Keep cord away from heat, oil, sharp

edges or moving parts. Damaged or entangled

cords increase the risk of electric shock.

e) When operating a power tool outdoors, use

an extension cord suitable for outdoor use.

Use of a cord suitable for outdoor use reduces

the risk of electric shock.

f) If operating a power tool in a damp

location is unavoidable, use a residual

current device (RCD) protected supply.

Use of an RCD reduces the risk of electric shock.

Save all warnings and instructions for

future reference. The term “power tool”

in the warnings refers to your mainsoperated (corded) power tool or batteryoperated (cordless) power tool.

1) General Power Tool Safety

Warnings [Work Area Safety]

a) Keep work area clean and well lit.

Cluttered or dark areas invite accidents.

b) Do not operate power tools in explosive

atmospheres, such as in the presence

3) General Power Tool Safety

Warnings [Personal Safety].

a) Stay alert, watch what you are doing

and use common sense when operating

a power tool. Do not use a power tool

while you are tired or under the influence of

drugs, alcohol or medication. A moment of

inattention while operating power tools may

result in serious personal injury.

b) Use personal protective equipment.

Always wear eye protection. Protective

7

Page 8

www.evolutionpowertools.com

equipment such as dust masks, non-skid

safety shoes, hard hat or hearing protection

used for appropriate conditions will reduce

personal injuries.

c) Prevent unintentional starting.

Ensure the switch is in the off-position before

connecting to power source and or battery

pack, picking up or carrying the tool. Carrying

power tools with your finger on the switch

or energising the power tools that have the

switch on invites accidents.

d) Remove any adjusting key or wrench

before turning the power tool on.

A wrench or key left attached to a rotating part

of a power tool may result in personal injury.

e) Do not overreach. Keep proper footing and

balance at all times. This enables better control

of the power tool in unexpected situations.

f) Dress properly. Do not wear loose

clothing or jewelry. Keep your hair, clothing

and gloves away from moving parts. Loose

clothes, jewelry or long hair can be caught in

moving parts.

g) If devices are provided for the

connection of dust extraction and

collection facilities, ensure that these are

connected and properly used. Use of dust

collection can reduce dust-related hazards.

4) General Power Tool Safety Warnings

[Power Tool Use and Care].

a) Do not force the power tool. Use the

correct power tool for your application.

The correct power tool will do the job better

and safer at a rate for which it was designed.

b) Do not use the power tool if the switch

does not turn it on or o. Any power tool

that cannot be controlled with the switch is

dangerous and must be repaired.

c) Disconnect the power tool from the

power source and/or battery pack from

the power tool before making any

adjustments, changing accessories, or

storing power tools. Such preventative

safety measures reduce the risk of starting the

power tool accidentally.

d) Store idle power tools out of the reach of

children and do not allow persons unfamiliar

with the power tool or these instructions

to operate the power tool. Power tools are

dangerous in the hands of untrained users.

e) Maintain power tools. Check for

misalignment or binding of moving parts,

breakage of moving parts and any other

condition that may affect the power tools

operation. If damaged, have the power tool

repaired before use. Many accidents are

caused by poorly maintained power tools.

f) Keep cutting tools sharp and clean.

Properly maintained cutting tools with sharp

cutting edges are less likely to bind and are

easier to control.

g) Use the power tool, accessories and

tool bits, etc, in accordance with these

instructions, taking into account the

working conditions and the work to

be performed. Use of the power tool for

operations dierent from those intended

could result in a hazardous situation.

5) General Power Tool Safety Warnings

[Service]

a) Have your power tool serviced by

a qualied repair person using only

identical replacement parts. This will ensure

that the safety of the power tool is maintained.

HEALTH ADVICE

WARNING: When using this machine, dust

particles may be produced. In some instances,

depending on the materials you are working with,

this dust can be particularly harmful.

If you suspect that paint on the surface of material

you wish to cut contains lead, seek professional

advice. Lead based paints should only be removed

by a professional and you should not attempt

to remove it yourself. Once the dust has been

deposited on surfaces, hand to mouth contact can

result in the ingestion of lead. Exposure to even

low levels of lead can cause irreversible brain and

nervous system damage. The young and unborn

children are particularly vulnerable.

8

Page 9

www.evolutionpowertools.com

EN

You are advised to consider the risks

associated with the materials you are working

with and to reduce the risk of exposure.

As some materials can produce dust that may

be hazardous to your health, we recommend

the use of an approved face mask with

replaceable lters when using this machine.

You should always:

• Work in a well-ventilated area.

• Work with approved safety equipment,

such as dust masks that are specially

designed to lter microscopic particles.

WARNING: The operation of any power tool

can result in foreign objects being thrown

towards your eyes, which could result in

severe eye damage. Before beginning power

tool operation, always wear safety goggles

or safety glasses with side shield or a full face

shield where necessary.

ADDITIONAL SAFETY INSTRUCTIONS

WARNING: Always disconnect the

reciprocating saw from the mains supply

before changing blades, servicing, cleaning

or adjusting the reciprocating saw.

• Keep your hands away from the cutting

area and the cutting blade. Hold the

machine by gripping the insulated hand hold areas with both hands. If both hands

are holding the machine, they cannot come

into contact with the blade.

• Do not use dull or damaged blades. Dull or

damaged blades can break easily and are

prone to ‘jamming’ which can cause ‘kickback’.

• Always check that the blade is correctly

installed within the machines blade holder.

Wear protective gloves when handling a

blade and conduct a ‘tug test’ when a new

blade is installed to ensure the blade has been

successfully ‘captured’ by the blade holder.

• Do not use excessive force. Excessive force

overloads the motor and reduces working

eciency and service life.

• Always wear the relevant PPE (Personal

Protective Equipment) for the job at hand.

This could typically include safety glasses or

eye shields, dust masks, protective clothing

and safety shoes, ear defenders and safety

helmet, etc.

• The operator should always be aware of

the routing of the mains power cable. The

cable should be routed in such a way that

it cannot become a trip or other type of

hazard and cannot come into contact with

the machines blade.

• Always check walls, oors and ceilings for

hidden power cables, water and/or gas

pipes or other services. Striking hidden

services could be extremely dangerous to

the operator, and could cause considerable

property damage. Detectors that can

determine the position of hidden utilities

within or behind a wall, etc, are readily

available at most tool retailers.

• Only withdraw the blade from a cut when

the machine has been switched ‘o’, and

the blade has come to a complete stop.

Withdrawing a moving blade from a cut

could lead to the moving blade striking

a nearby surface causing the operator to

experience severe ‘kick back’.

• If possible, ensure that any work-piece

is rmly clamped to prevent movement

during the cutting operation.

• Never try to stop the cutting blade by

applying sideways pressure to the blade.

Allow the blade come to a halt by turning

the machine ‘O ’, allowing the motor to

slow and stop normally.

• Always check that the mains supply voltage

is the same as the indicated supply voltage

shown on the machines rating plate. Using

this machine with a supply voltage that is

dierent from that shown on the machines

rating plate could damage the machine and

could potentially cause the machine to be

electrically unsafe.

9

Page 10

www.evolutionpowertools.com

• Do not alter or modify the power cord. This

saw is equipped with an approved cord and

plug for its intended country of use. If the

moulded plug or the power cord is damaged

in any way it must be replaced with an

identical type by a competent technician.

WARNING: This machine must not be used to

cut any material that may contain asbestos. If the

presence of asbestos is suspected, consult the

relevant authorities for advice. Do not attempt

to cut any suspect material until it has been

declared safe to do so by the relevant authorities.

GETTING STARTED

UNPACKING

Caution: This packaging contains sharp

objects. Take care when unpacking. Remove

the machine, together with the accessories

supplied from the packaging. Check carefully

to ensure that the machine is in good condition

and account for all the accessories listed in this

manual. Also make sure that all the accessories

are complete. If any parts are found to be

missing, the machine and its accessories should

be returned together in their original packaging

to the retailer. Do not throw the packaging

away; keep it safe throughout the guarantee

period. Dispose of the packaging in an

environmentally responsible manner. Recycle

if possible. Do not let children play with empty

plastic bags due to the risk of suocation.

ITEMS SUPPLIED

Description Quantity

R230RCP Reciprocating Saw 1

Multipurpose Blade 2 Pack

(Includes 1 x Thin Steel

& 1 x Multipurpose Blade)

Wood Cutting Blade 2 Pack

(Includes 1 x Green Wood

& 1 x General Wood Blade)

Instruction Manual 1

ADDITIONAL ACCESSORIES

In addition to the standard items supplied

with this machine, the following accessories

are also available from the Evolution online

shop at www.evolutionpowertools.com

or from your local retailer.

Description Part No

Multipurpose Blade Pack 2

(Includes 1 x Thin Steel

& 1 x Multipurpose Blade)

Wood Cutting Blade Pack 2

(Includes 1 x Green Wood

& 1 x General Wood Blade)

1

1

045-0255

045-0254

10

Page 11

www.evolutionpowertools.com

EN

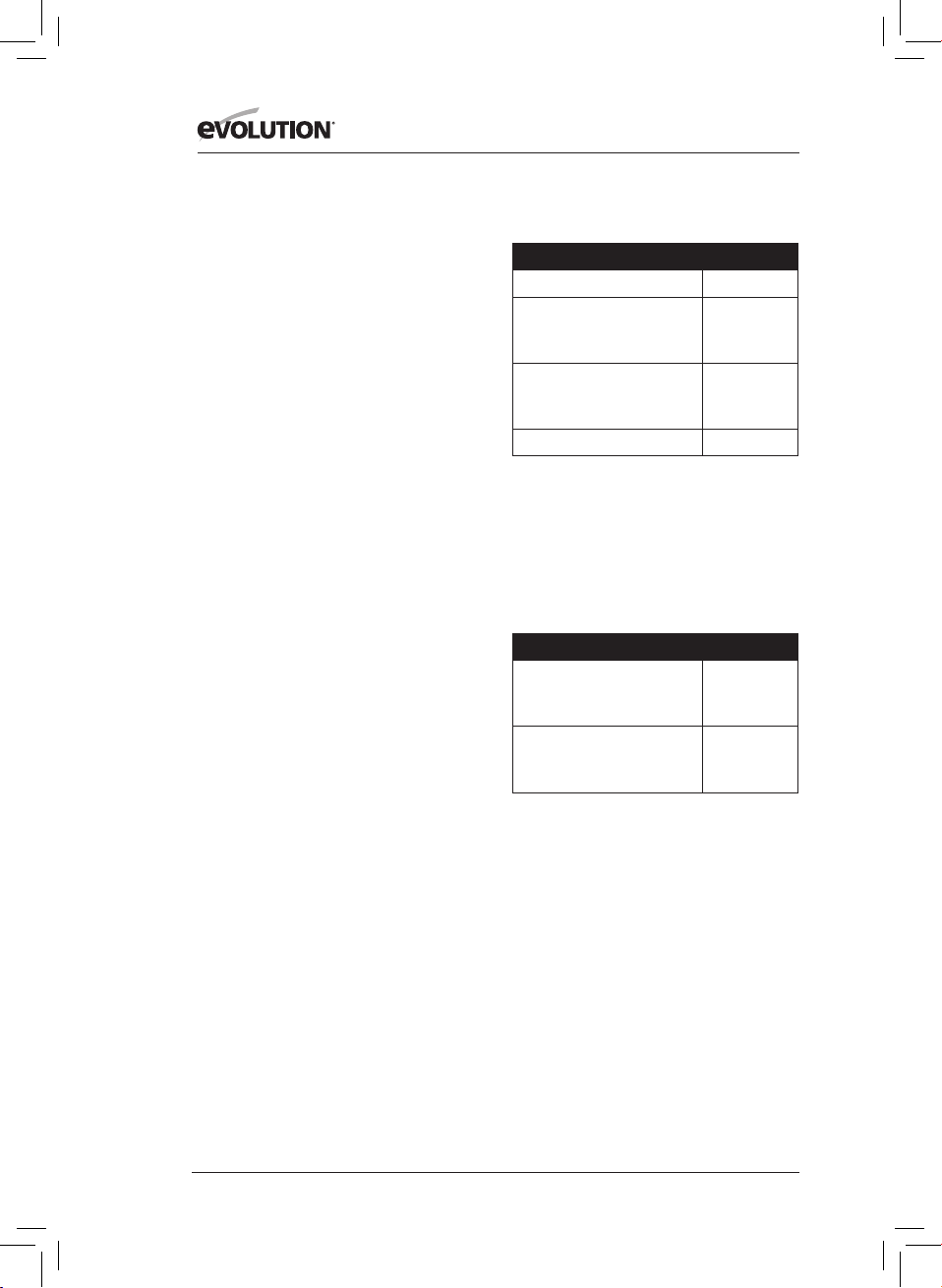

MACHINE OVERVIEW

4

2

1

3

1. Blade

2. Workpiece Contact Plate

3. Contact Plate Locking Lever

4. Blade Clamp Dial

5. Trigger Switch

6. Variable Speed Control

7. Trigger Lock-On Button

8. Handle Rotation Button

8

A. Multipurpose Blade

B. General Wood Blade

C. Green Wood Blade

D. Thin Steel Blade

5

7

6

A

B

C

D

11

Page 12

www.evolutionpowertools.com

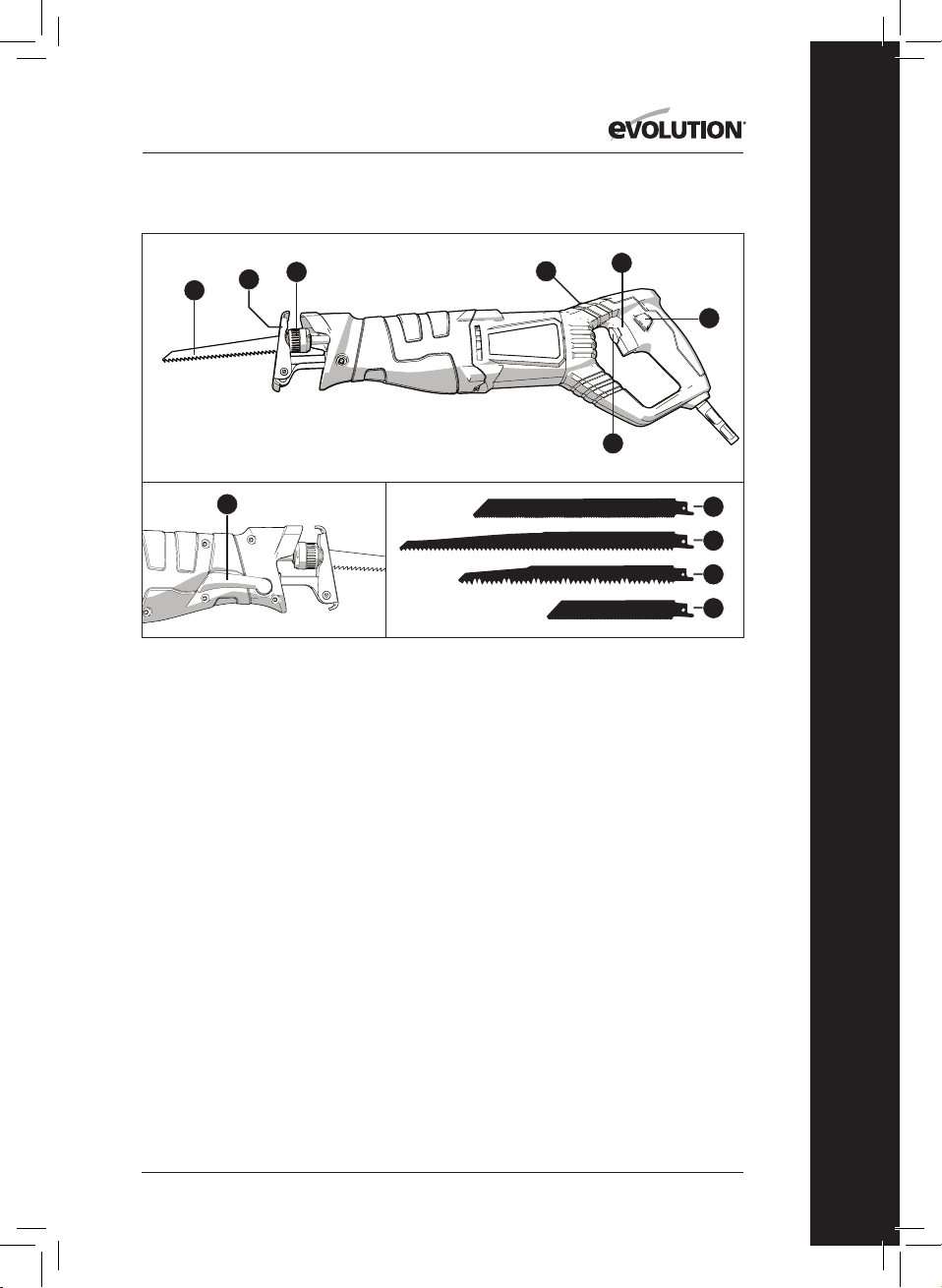

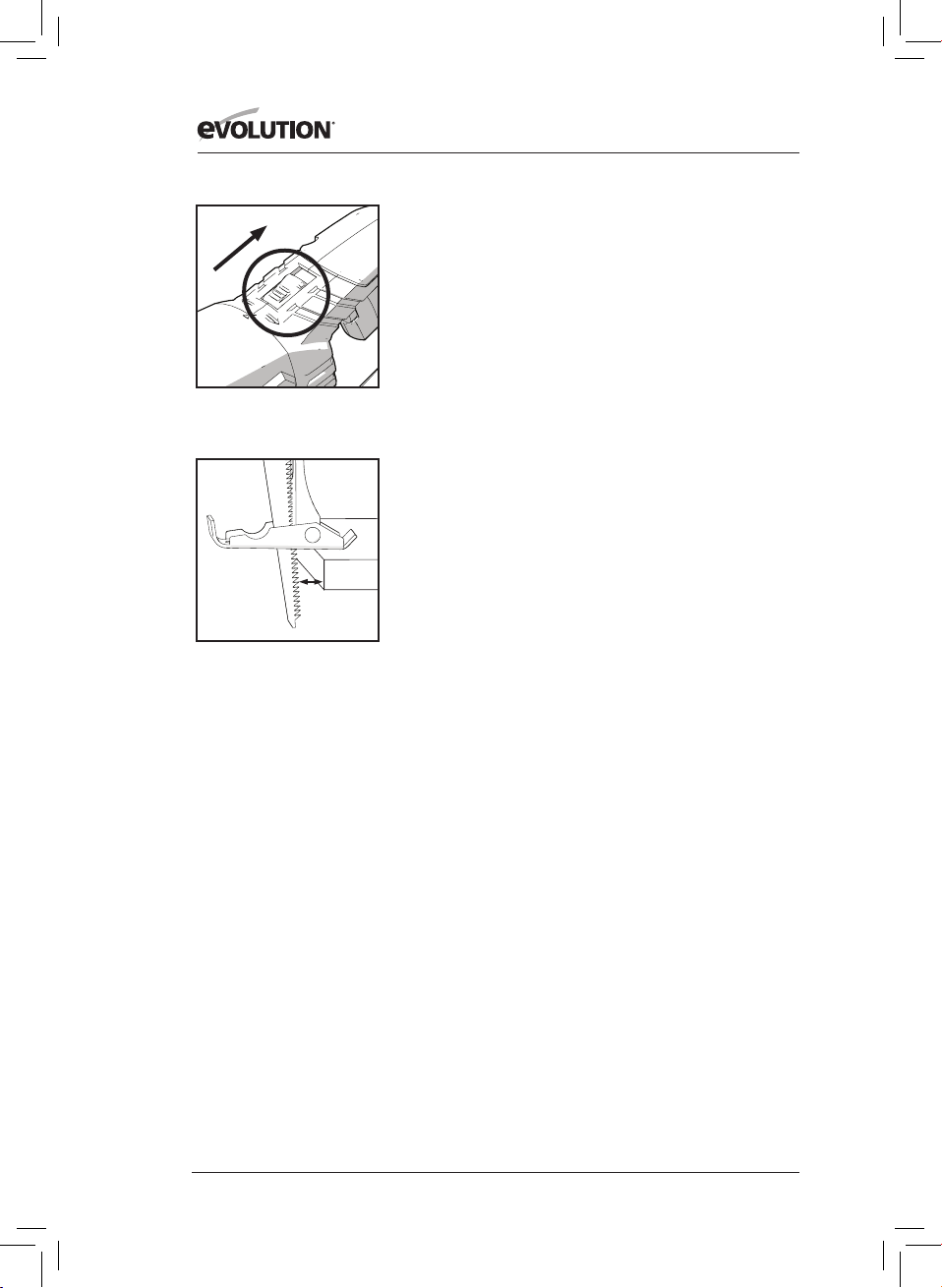

Fig. 1

Fig. 2

INSTALLING OR REMOVING A BLADE

WARNING: Only attempt these procedures with the machine

disconnected from the mains power supply.

Note: We recommend that the operator wears protective gloves

when handling blades. Care should be exercised as a recently

used blade could be hot and/or contaminated with debris.

To install a blade:

• Ensure that the blade holder is clean and free from debris or

other contaminates.

• Twist and hold the blade clamping dial anti-clockwise.

(Fig. 1)

• Fully insert the shank of the blade into the blade holder.

• Release the blade clamp so it returns to its original position.

• Check that the blade is secure.

WARNING: It is important that the hole in the tang of the blade

engages with the ‘spigot’ located inside the blade holder.

To remove a blade:

• If recently used allow the blade to cool down.

• Ensure that the machine is facing downwards to allow

any debris to fall out.

• Twist and hold the blade clamping dial anti-clockwise.

• Gently pull the blade from the blade holder.

Note: If a blade is being removed because it is at the end of its

service life eject it straight into a recycling bin.

Fig. 3

WORKPIECE CONTACT PLATE (Fig. 2)

WARNING: To achieve the best cutting eciency, minimise

the risk of vibration, and blade jumping and/or breakage, the

workpiece contact plate must be kept rmly in contact with the

workpiece.

Note: The workpiece contact plate is pivoted and adjustable.

This feature allows the contact plate to adjust and lie ush on a

workpiece surface even when the machines main body is at a

slight angle to that surface.

CUTTING REACH & CAPACITY

By using dierent length blades and/or altering the service

position of the workpiece contact plate, it is possible to increase or

decrease the overall ‘reach’ and cutting capacity of the machine.

(Fig. 3)

12

Page 13

www.evolutionpowertools.com

EN

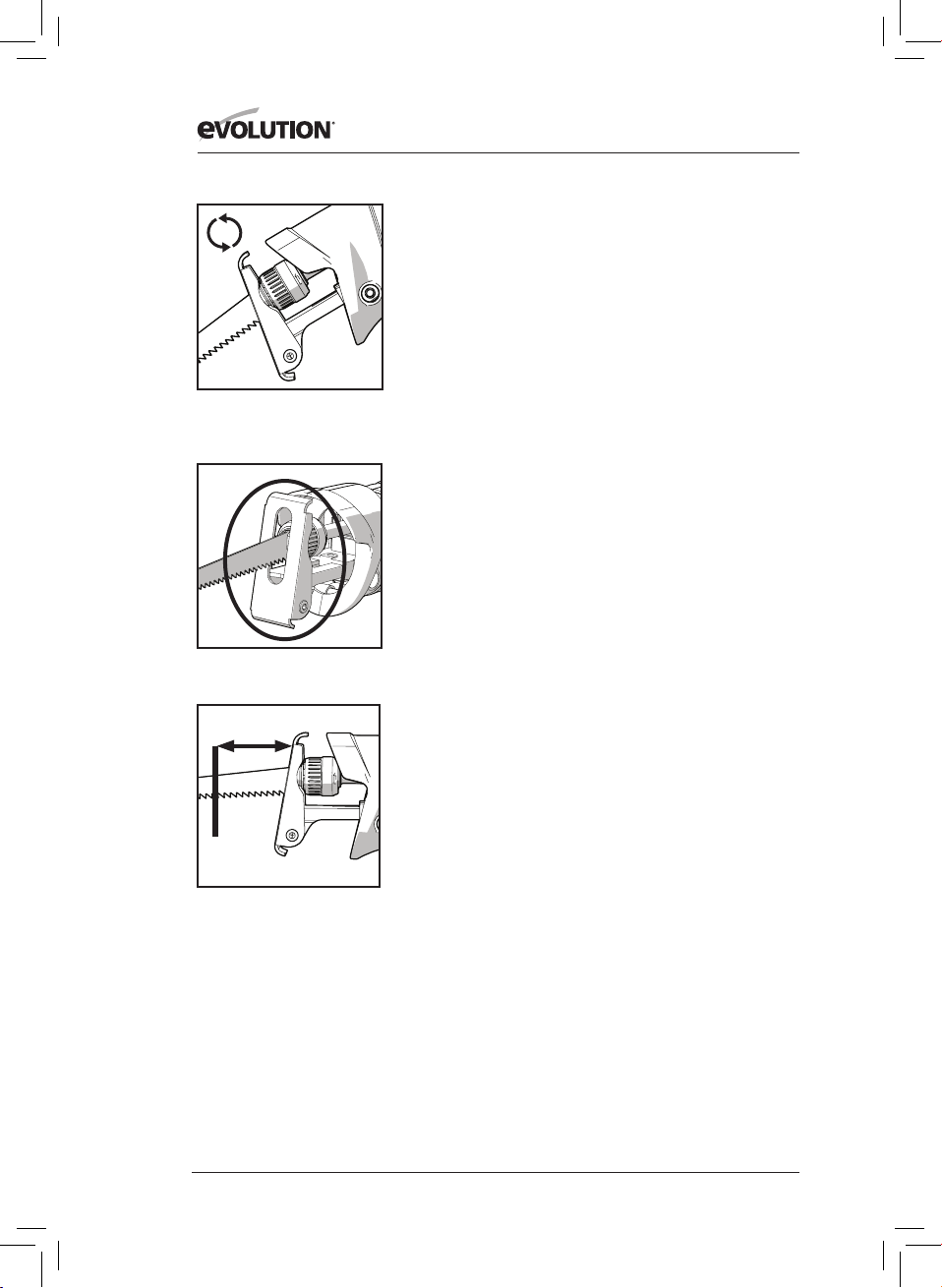

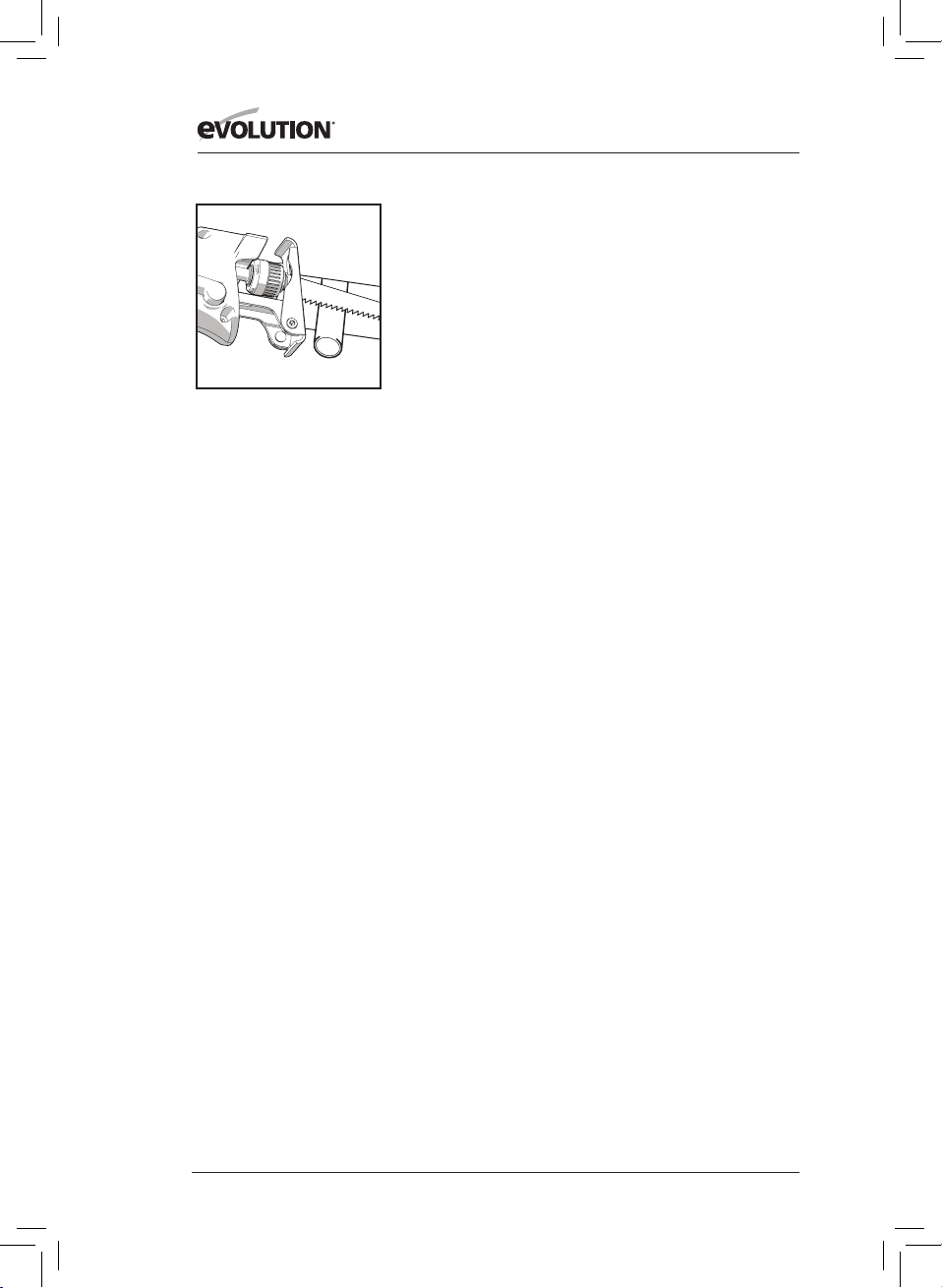

To adjust the position of the contact plate:

• Release the contact plate locking lever. (Fig. 4)

• Pull out or push in the contact plate as required.

• Once the plate is in the desired position, push the locking

lever back into its original position to lock the plate in place.

• Check that it is secure.

THE TRIGGER SWITCH

The ON/OFF trigger switch is located within the machines rear

handle. (Fig. 5).

• Squeeze the trigger switch to start the machines motor.

• Release the trigger switch to stop the machines motor.

LOCK-ON SWITCH

The trigger is equipped with a lock-on switch. To operate the

lock-on feature:

• Fully squeeze the trigger to start the machines motor.

• Press and hold the lock-on switch. (Fig. 6)

• Release the trigger then release the lock-on switch.

WARNING: The motor will run continuously until the trigger is

pressed and the lock-on switch is tripped.

Fig. 4

Fig. 5

THE STROKE RATE CONTROL DIAL

The stroke rate of the machine can be varied. A stroke rate

control dial is located on the trigger. (Fig. 7).

Note: The ergonomic positioning of this control dial allows a

skilled operator to adjust the stroke rate of the machine during

cutting operations.

Rotating this dial will alter the stroke rate of the machine from

approximately 800 strokes a minute up to a maximum of 2800

strokes per minute.

Note: We recommend that the operator begins any cutting

operation using a slow stroke rate, and increases the stroke rate

to achieve optimum performance as cutting progresses.

A practical trial on scrap material may be useful to determine

the best stroke rate for any particular material or application.

13

Fig. 6

Fig. 7

Page 14

www.evolutionpowertools.com

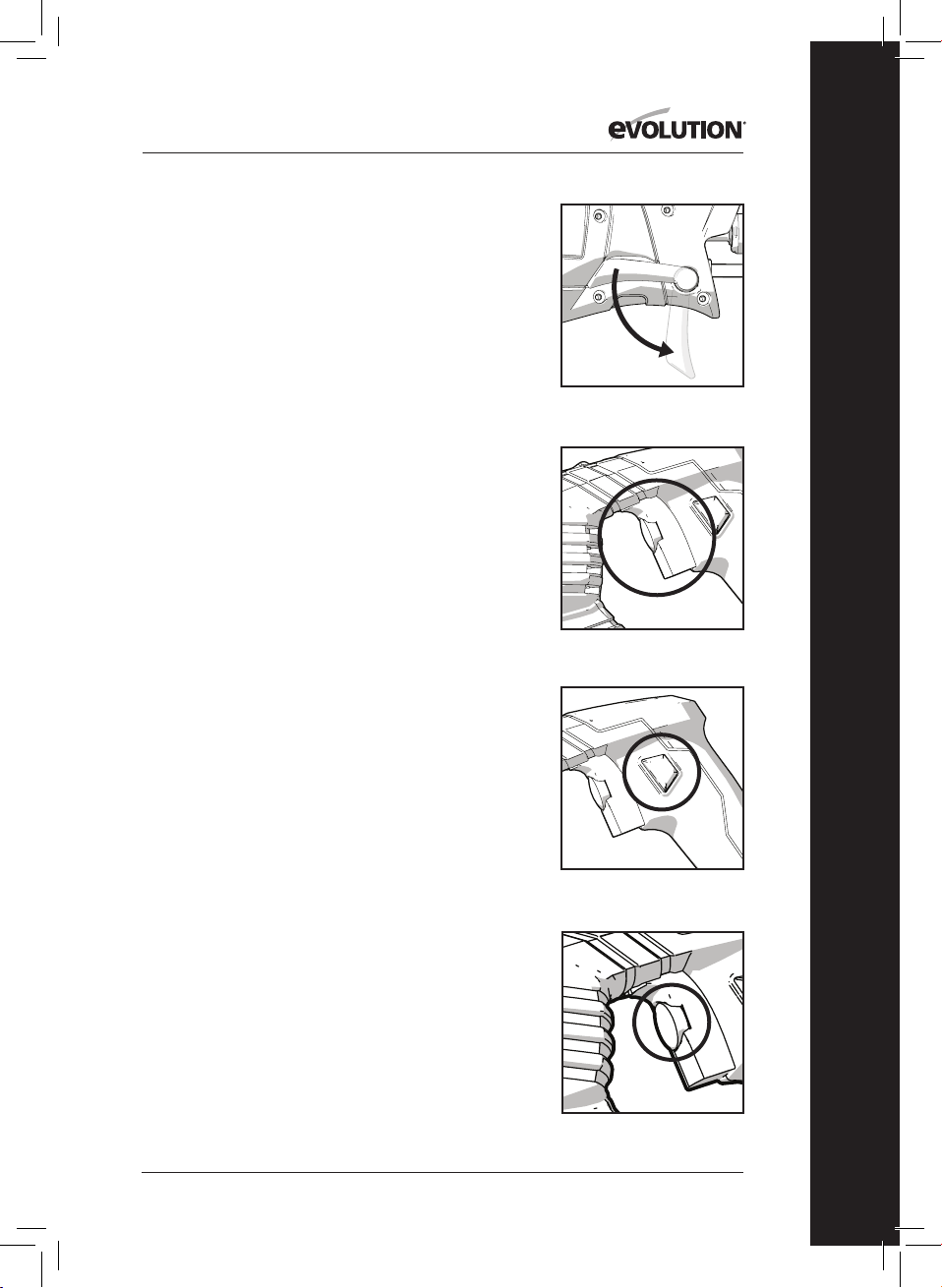

Fig. 8

Fig. 9

180˚ ROTATING HANDLE

The handle of the machine can be rotated through 180˚ and has

3 positions to achieve maximum control during cutting.

To rotate the handle:

• Slide and hold the handle rotation button backwards.

(Fig. 8)

• Twist the handle through 90˚ into the desired position.

• Release the rotation button.

• Check the handle is secure and the button is fully engaged.

WARNING: Handle adjustments must only be made when the

motor is o. Adjusting the handle while the tool is in use can

lead to serious injury.

GENERAL CUTTING

WARNING: Never start the machine with the blade in contact

with the workpiece.

• Select a low stroke rate.

• Hold the machine with both hands.

• Ensure that the workpiece contact plate is rmly in contact

with the workpiece but that the blade is not. (Fig. 9).

• Switch on the machine.

• Very gradually, and holding the machine rmly, introduce the

blade into the workpiece until it is cutting successfully.

• Operate the stroke rate control dial until optimum cutting

performance is achieved.

• Never ‘force’ the blade. Allow the blade to cut through the

workpiece without applying undue pressure. Forcing the

blade will reduce blade life, increase the likelihood of blade

breakage, and put strain on the machines motor.

WARNING: If the saw blade should jam, switch o the machine

immediately and disconnect from the mains supply.

JAMMED BLADES

WARNING: Jammed blades may be very hot and/or

contaminated with debris. The operator should exercise great

caution when attempting to remove a ‘jammed’ blade,

and employ all necessary PPE.

To remove a jammed blade the kerf (the saw cut made by the

blade) will have to be widened.

• Remove the machine from the blade by operating the blade

clamping dial, and carefully easing the machine from the

jammed blade.

• Widen the kerf with a suitable tool until the blade can be

pulled from the workpiece.

14

Page 15

www.evolutionpowertools.com

EN

PLUNGE CUTTING

WARNING: Plunge cutting is a technique that must only be

used on soft building materials such as plasterboard etc. It is

not a suitable procedure for use on harder materials, and must

never be employed on metallic materials.

Note: This technique should not be attempted by

inexperienced operatives.

Note: Only dedicated plunge cutting blades must be used

when attempting a plunge cut.

Note: To reduce the risk of blade kickback when plunge cutting.

It is recommended to drill a pilot hole and plunge cut into the

hole as a starting point, giving you extra control and stability.

To plunge cut:

• Complete any/all marking out of the cutting lines using

a pencil, marker pen, etc, on the workpiece before

commencing operations.

• Hold the machine at an angle to the workpiece with the

bottom edge of the workpiece contact plate resting rmly

against the workpiece. (Fig. 10).

Note: The blade must not be in contact with the workpiece at this

stage. The operator must also be satised that the blade will not

contact the workpiece immediately the machine is switched on.

• Set stroke rate to its maximum setting.

• Switch the machine on.

• Very slowly rotate the machine using the bottom edge of

the workpiece contact plate as a fulcrum. Allow the blade

to very gradually ingress into the workpiece.

• When the contact plate is lying at against the workpiece

continue cutting as normal.

• Adjust the stroke rate for optimum cutting performance.

Fig. 10

FLUSH CUTTING

Flush cutting is cutting very close to a surface such as a oor,

wall or ceiling etc. This technique allows the operator to cut

o unwanted protruding material such as redundant joists,

brackets pipes, etc, from a building.

WARNING: The operator should ensure that any redundant

architectural objects etc, are not ‘live’ and it is safe to cut

through them.

Note: Flush cutting is only possible when using highly exible

bi-metal blades.

15

Page 16

www.evolutionpowertools.com

Fig. 11

To ush cut:

• Select and insert the correct saw blade into the machine.

• Position the side of saw blade directly against the oor, wall, etc.

• A side edge of the workpiece contact plate should be in

contact with the oor, wall, etc.

• Switch on the machine and gradually introduce the blade

into the workpiece.

• Adjust the stroke rate for optimum perfomance.

• Cut through the workpiece slowly allowing the exible blade

to curve as required. (Fig. 11).

• Allow the side of the exible blade to gently glide across the

oor, wall, etc.

CLEANING

WARNING: Any cleaning must only be attempted with the

machine disconnected from the mains power supply.

Clean the saw blade holder and remove any dirt and/or debris

build up. The saw blade should be removed from the machine

to facilitate proper and thorough cleaning.

Remove any contaminants by using a soft haired brush.

Compressed air can also be used. If this is the case the operator

should take all the necessary safety precautions to safeguard the

surrounding environment and any bystanders that may be present.

The operator should use all relevant PPE.

Safety glasses should be worn to protect the operators eyes

from blown debris.

MAINTENANCE

WARNING: Any maintenance must be carried out with the

machine switched o and disconnected from the mains/battery

power supply.

Check that all safety features and guards are operating correctly

on a regular basis. Only use this machine if all guards/safety

features are fully operational.

All motor bearings in this machine are lubricated for life. No further

lubrication is required.

Use a clean, slightly damp cloth to clean the plastic parts of the

machine. Do not use solvents or similar products which could

damage the plastic parts.

16

Page 17

www.evolutionpowertools.com

EN

WARNING: Do not attempt to clean by inserting

pointed objects through openings in the

machines casings, etc. The machines air vents

should be cleaned using compressed dry air.

Excessive sparking may indicate the presence of

dirt in the motor or worn out carbon brushes.

If this is suspected have the machine serviced and

the brushes replaced by a qualied technician.

ENVIRONMENTAL PROTECTION

Waste electrical products should not be

disposed of with household waste. Please

recycle where facilities exist.

Check with your local authority or retailer for

recycling advice.

17

Page 18

www.evolutionpowertools.com

EC DECLARATION OF CONFORMITY

In accordance with EN ISO 17050-1:2004

The manufacturer of the product covered by this declaration is:

UK: Evolution Power Tools Ltd, Venture One, Longacre Close, Holbrook Industrial Estate, Sheeld, S20 3FR.

FR: Evolution Power Tools SAS, 61 Avenue Lafontaine, 33560, Carbon-Blanc, Bordeaux, France.

The manufacturer hereby declares that the machine as detailed in this declaration fulfils all

the relevant provisions of the Machinery Directive and other appropriate directives as detailed

below. The manufacture further declares that the machine as detailed in this declaration, where

applicable, fulfils the relevant provisions of the Essential Health and Safety requirements.

The Directives covered by this Declaration are as detailed below:

2006/42/EC Machinery Directive.

2014/30/EU Electromagnetic Compatibility Directive.

The Restriction of the Use of certain Hazardous

2011/65/EU. &

2015/863/EU.

Substances in Electrical Equipment (RoHS) Directive.

2002/96/EC as The Waste Electrical and Electronic Equipment (WEEE) Directive.

amended by

2003/108/EC

And is in conformity with the applicable requirements of the following documents:

EN 62841-1:2015, EN 62841-2-11:2016, EN 55014-1:2017, EN 55014-2:2015,

EN 61000-3-2:2014, EN 61000-3-3:2013

Product Details

Description: R230RCP RECIPROCATING SAW

Evolution Model No: 0450001 230V UK, 0450003 230V EU, 045 0004 120V US

Brand Name: EVOLUTION

Voltage: 230V ~ 50 Hz, 120V ~ 60 Hz

Input: 850W

The technical documentation required to demonstrate that the product meets the requirements

of directive has been compiled and is available for inspection by the relevant enforcement

authorities, and verifies that our technical file contains the documents listed above

and that they are the correct standards for the product as detailed above.

Name and address of technical documentation holder.

Signed: Print: Barry Bloomer - Supply Chain & Procurement Director

Date: 20/06/2019

UK: Evolution Power Tools Ltd, Venture One, Longacre Close, Holbrook Industrial Estate, Sheeld, S20 3FR.

FR: Evolution Power Tools SAS, 61 Avenue Lafontaine, 33560, Carbon-Blanc, Bordeaux, France.

18

Page 19

www.evolutionpowertools.com

EN

Notes

19

Page 20

www.evolutionpowertools.com

ÍNDICE

INTRODUCCIÓN

Características técnicas de la máquina Página 22

Vibraciones Página 23

Etiquetas y símbolos Página 23

Uso previsto de esta herramienta eléctrica Página 24

Uso prohibido de esta herramienta eléctrica Página 24

PRECAUCIONES DE SEGURIDAD

Seguridad eléctrica Página 25

Uso en exteriores Página 25

Instrucciones generales de seguridad de la herramienta eléctrica Página 25

Instrucciones adicionales de seguridad Página 27

PRIMEROS PASOS

Desembalaje Página 28

Descripción general de la máquina Página 29

Instrucciones de funcionamiento Página 30

MANTENIMIENTO

Protección medioambiental Página 35

DECLARACIÓN DE CONFORMIDAD Página 36

20

Page 21

www.evolutionpowertools.com

ES

ESTE MANUAL DE INSTRUCCIONES SE

ESCRIBIÓ ORIGINALMENTE EN INGLÉS.

IMPORTANTE

Lea estas instrucciones de uso y seguridad

detenidamente y por completo.

Por su propia seguridad, si no está seguro

de algún aspecto sobre el uso de este equipo

contacte con el servicio de asistencia técnica.

Puede encontrar el número de teléfono en la

página web de Evolution Power Tools. Nuestra

organización dispone de varios teléfonos de

asistencia en todo el mundo. Su proveedor

también puede ofrecerle asistencia técnica.

PÁGINA WEB

www.evolutionpowertools.com

CORREO ELECTRÓNICO

enquiries@evolutionpowertools.com

Enhorabuena por adquirir una máquina de

Evolution Power Tools. Complete el registro

de su producto en línea como se explica

en el formulario de registro de garantía en

línea A5 que acompaña a esta máquina.

También puede escanear el código QR

impreso en el formulario A5 con un Smart

Phone. Esto le permitirá validar el periodo

de garantía de su máquina a través de la

página web de Evolution al introducir sus

datos y, así, disponer de un servicio rápido

si fuera necesario. Le estamos sinceramente

agradecidos por escoger

uno de nuestros productos Evolution Power

Tools.

21

Page 22

www.evolutionpowertools.com

ESPECIFICACIONES

CARACTERÍSTICAS TÉCNICAS

MÉTRICO IMPERIAL

DE LA MÁQUINA

Motor UE (230V ~ 50 Hz) 850W 3,7 A

Motor EE. UU. (120V ~ 60Hz) 850W 7A

Longitud de desplazamiento 28mm 1-1/8"

Velocidad variable (carreras por minuto) 0 - 2800cpm 0 - 2800cpm

Peso 2,7kg 5,9 lbs

CAPACIDADES DE CORTE MÉTRICO IMPERIAL

Acero dulce (grosor máximo) 20mm 3/4”

Madera (grosor máximo) 230mm 9-1/16”

Plástico (grosor máx.) 150mm 5-7/8”

DATOS DE RUIDO Y VIBRACIÓN

Nivel de presión acústica L

Potencia acústica L

Nivel de vibración (bajo carga) - Mango principal Madera - 10,357 m/s

Nivel de vibración (bajo carga) - Mango adicional Madera - 19,151 m/s2 , metal - 19,905 m/s

(bajo carga) 90,39 dB(A) K=3dB(A)

PA

(bajo carga) 101,39 dB(A) K=3dB(A)

WA

2

, metal - 21,223 m/s

K=1,5m/s

K=1,5m/s

2

2

2

2

22

Page 23

www.evolutionpowertools.com

ES

Nota: La medición de la vibración se hizo

en condiciones normales de acuerdo con la

norma EN 62841-1:2015

El valor total de vibración citado

se ha medido según un

método normal de examen y puede usarse

para comparar una herramienta con otra.

El valor total de vibración citado también

puede usarse en la evaluación preliminar

de la exposición humana

.

VIBRACIONES

ADVERTENCIA: al utilizar esta máquina, el

operario puede estar expuesto a altos niveles

de vibración transmitidos a la mano y al brazo.

Es posible que el operario pueda desarrollar

la «enfermedad de los dedos blancos» debido

a la vibración (síndrome de Raynaud). Esta

enfermedad puede reducir la sensibilidad de

la mano a la temperatura, así como producir

entumecimiento general. Los usuarios que

utilicen esta máquina de manera prolongada

o regular deben vigilar de cerca el estado de

sus manos y dedos. Si aparece alguno de los

síntomas, busque atención médica inmediata.

• La medición y la evaluación de la exposición

humana a las vibraciones transmitidas por

la mano en el lugar de trabajo se indican en

las normas:

BS EN ISO 5349-1:2001 y

BS EN ISO 5349-2:2002

• Muchos factores pueden inuir en

el nivel de vibración real durante el

funcionamiento, p. ej., el estado y la

orientación de las supercies de trabajo,

y el tipo y el estado de la máquina que se

está usando. Antes de cada uso, se deben

evaluar dichos factores y adoptar prácticas

de trabajo adecuadas donde sea posible. La

gestión de estos factores puede ayudar a

reducir los efectos de la vibración:

Manipulación

• Manipule la máquina con cuidado,

permitiendo que esta haga el trabajo.

• Evite un esfuerzo físico excesivo en

cualquiera de los controles de las

máquinas.

• Tenga en cuenta su seguridad y

estabilidad, así como la orientación de la

máquina durante su uso.

Supercie de trabajo

• Tenga en cuenta el material de la

supercie de trabajo, su estado,

densidad, resistencia, rigidez y

orientación.

ADVERTENCIA: la emisión de vibraciones al

usar la herramienta eléctrica puede variar del

valor total citado en función de la forma en

la que se use la herramienta. La necesidad de

identicar medidas de seguridad y de proteger

al operario se basa en una estimación de las

condiciones reales de uso (teniendo en cuenta

todas las partes del ciclo operativo, como las

veces que se desconecta la máquina

y cuando está en reposo, además del tiempo

que está funcionando de forma continuada).

ETIQUETAS Y SÍMBOLOS

ADVERTENCIA: no utilice la máquina

si faltan etiquetas de instrucciones y/o

advertencia, o si están dañadas. Póngase en

contacto con Evolution

Power Tools para sustituir las etiquetas.

Nota: todos o algunos de los siguientes

símbolos pueden aparecer en el manual o en

el producto.

23

Page 24

www.evolutionpowertools.com

Símbolo Descripción

Voltios

Amperios

Hercios

Velocidad

Corriente alterna

Velocidad sin carga

Utilice gafas protectoras

Utilice protección auditiva

Lea las instrucciones

Certificado CE

Certificado CSA

Residuos de Aparatos

Eléctricos y Electrónicos

Advertencia

Hz

Min

n

V

A

-1

~

o

Utilice protección contra el polvo

Protección de doble aislamiento

USO PREVISTO DE ESTA HERRAMIENTA

ELÉCTRICA

ADVERTENCIA: Este producto es una sierra

manual de movimiento alternativo y ha sido

diseñada para usarse con hojas especiales

de Evolution. Solamente utilice accesorios

diseñados para el uso de esta máquina y/o

aquellos recomendados especícamente por

Evolution Power Tools Ltd.

Esta máquina se puede usar para cortar,

si está equipada con una hoja adecuada,

y con la placa de contacto de la pieza de

trabajo rmemente sobre la pieza de

trabajor:

Madera

Acero dulce, aluminio y

muchos otros metales no ferrosos.

La mayoría de los plásticos.

USO PROHIBIDO DE ESTA HERRAMIENTA

ELÉCTRICA

ADVERTENCIA: Este producto es una sierra

manual de movimiento alternativo y debe

usarse solo como tal. No debe ser modicada

de ninguna manera ni usada para alimentar

ningún otro equipo, tampoco debe llevar

ningún otro accesorio que no aparezca en el

manual de instrucciones.

ADVERTENCIA: esta máquina no se debe

usar para cortar ningún material que pueda

contener amianto.

Si se sospecha de la presencia de amianto,

pida consejo a las autoridades pertinentes.

ADVERTENCIA: esta máquina no está

diseñada para ser utilizada por personas

(niños incluidos) con discapacidad psíquica,

sensorial o mental, o con falta de experiencia

y conocimiento, a no ser que hayan sido

supervisadas o instruidas en el uso seguro de

la máquina por una persona responsable de

su seguridad y competente en el uso seguro

de esta.

Debe supervisarse a los niños para asegurarse

de que no tienen acceso a la máquina ni

pueden jugar con ella.

24

Page 25

www.evolutionpowertools.com

ES

SEGURIDAD ELÉCTRICA

Esta máquina está equipada con el

enchufe moldeado y el cable de red

correctos para el mercado designado. Si

los hilos del cable de alimentación o

el enchufe están dañados de cualquier

modo, los debe sustituir un técnico

cualicado con repuestos originales.

USO EN EXTERIORES

ADVERTENCIA: para su protección, si va

a usar esta herramienta en exteriores no

debe exponerla a la lluvia o usarla en lugares

húmedos. No coloque la herramienta en

supercies húmedas. Si es posible, use un

banco de trabajo limpio y seco. Para obtener

una mayor protección, utilice un dispositivo

de corriente residual que interrumpa el

suministro si la corriente de fuga a tierra es

superior a 30 mA durante 30 ms. Compruebe

siempre el funcionamiento del dispositivo de

corriente residual antes de usar la máquina.

Si es necesario un alargador, debe ser de un

tipo adecuado para exteriores y etiquetado

para tal n.

Se deben seguir las instrucciones de los

fabricantes al utilizar un alargador.

INSTRUCCIONES GENERALES DE

SEGURIDAD PARA HERRAMIENTAS

ELÉCTRICAS

(Estas instrucciones generales de seguridad

para herramientas eléctricas son las que se

especifican en las normas EN 62841-1:2015, EN

62841-2-11:2016)

ADVERTENCIA: lea todas las advertencias e

instrucciones de seguridad. El no seguir las

instrucciones y advertencias puede provocar

una descarga eléctrica, incendios y/o lesiones

graves.

Guarde todas las advertencias e

instrucciones para poder consultarlas

en el futuro. El término «herramienta

eléctrica» de las advertencias se reere

a la herramienta alimentada por la

red eléctrica (con cable) o con baterías

(inalámbrica).

1) Advertencias generales de seguridad de

la herramienta eléctrica

[seguridad en la zona de trabajo]

a) Mantenga la zona de trabajo limpia y

bien iluminada. Las zonas desordenadas u

oscuras pueden provocar accidentes.

b) No utilice las herramientas eléctricas en

atmósferas explosivas, como cuando haya

líquidos inamables, gases o polvo.

Las herramientas eléctricas producen chispas

que pueden incendiar el polvo o los gases.

c) Mantenga a los niños y transeúntes

alejados cuando utilice una herramienta

eléctrica.

Las distracciones pueden hacerle perder el

control.

2) Advertencias generales de seguridad de

la herramienta eléctrica

[Seguridad eléctrica]

a) Los enchufes de la herramienta eléctrica

deben coincidir con las tomas de corriente.

No modique el enchufe de ningún modo.

No utilice adaptadores de enchufe con

las herramientas eléctricas conectadas

a tierra. Si las tomas de corriente coinciden

y los enchufes no se modican, se reduce

el riesgo de que se produzca una descarga

eléctrica.

b) Evite el contacto corporal con

supercies conectadas a tierra tales

como tuberías, radiadores, estufas y

refrigeradores.

El riesgo de descarga eléctrica aumenta

si su cuerpo está conectado a tierra.

c) No exponga las herramientas eléctricas

a la lluvia o a la humedad. Si se introduce

agua en una herramienta eléctrica aumentará

el riesgo de descarga eléctrica.

d) No utilice cable de forma incorrecta.

Nunca use el cable para transportar, tirar

o desenchufar la herramienta eléctrica.

Mantenga el cable lejos del calor, el aceite,

las esquinas cortantes o piezas móviles.

Los cables dañados o enredados aumentan

el riesgo de que se produzca una descarga

eléctrica.

e) Cuando trabaje con una herramienta

eléctrica en exteriores, use un alargador

adecuado para uso en exteriores. El uso

de un cable adecuado para uso en exteriores

reduce el riesgo de que se produzca una

descarga eléctrica.

f) Si es inevitable tener que usar una

herramienta eléctrica en un lugar húmedo,

es necesario utilizar una toma de corriente

residual (RCD) protegida.

El uso de un dispositivo de corriente residual

reduce el riesgo de que se produzca una

descarga eléctrica.

3) Advertencias generales de seguridad de

25

Page 26

www.evolutionpowertools.com

la herramienta eléctrica

[Seguridad personal].

a) Manténgase alerta, tenga cuidado

con lo que hace y use el sentido común

al utilizar una herramienta eléctrica. No

utilice una herramienta eléctrica cuando

esté cansado o haya tomado alcohol, o algún

tipo de fármaco o medicación. Un momento

de distracción mientras utiliza herramientas

eléctricas puede ocasionar lesiones personales

graves.

b) Utilice el equipo de protección

individual. Utilice siempre protección para

los ojos. El uso del equipo de seguridad, como

máscaras para el polvo, calzado antideslizante,

casco o protección auditiva para condiciones

adecuadas reducirá el riesgo de que se

produzcan lesiones personales.

c) Evite el encendido accidental.

Compruebe que el interruptor está en la

posición off (apagado) antes de conectar a la

fuente de alimentación o a las baterías, o de

coger o transportar la herramienta. Transportar

herramientas eléctricas con el dedo sobre el

interruptor o enchufar herramientas eléctricas

con el interruptor encendido puede ocasionar

accidentes.

d) Quite las llaves de ajuste o inglesa antes

de encender la herramienta eléctrica.

Una llave, por ejemplo una llave inglesa,

colocada en una pieza giratoria de la

herramienta eléctrica puede ocasionar

lesiones personales.

e) No se extralimite. Mantenga una

postura y equilibrio adecuados en todo

momento. Esto permitirá un mejor control

de la herramienta eléctrica en situaciones

inesperadas.

f) Vístase de manera adecuada. No use

ropa suelta ni joyas. Mantenga el pelo,

la ropa y los guantes alejados de las piezas

móviles. Las joyas, la ropa holgada y el cabello

largo pueden quedar atrapados en las piezas

móviles.

g) Si se proporcionan dispositivos para

la conexión de unidades de extracción y

recogida de polvo, asegúrese de que están

conectados y de que se usan de forma

adecuada. El uso de estos dispositivos puede

reducir los riesgos derivados del polvo.

4) Advertencias generales de seguridad de

la herramienta eléctrica

[Uso y cuidado de la herramienta

eléctrica].

a) No fuerce la herramienta eléctrica.

Utilice la herramienta eléctrica correcta

para su aplicación. La herramienta correcta

realizará el trabajo de una forma más precisa y

segura al ritmo para el que ha sido diseñada.

b) No utilice la herramienta eléctrica si el

interruptor no se enciende ni se apaga.

Las herramientas eléctricas que no se puedan

controlar con el interruptor son peligrosas y se

deben reparar.

c) Desconecte la herramienta eléctrica

de la fuente de alimentación y/o el

paquete de baterías de la herramienta

eléctrica antes de efectuar algún tipo de

ajuste, cambiar accesorios o almacenar

las herramientas eléctricas. Este tipo de

medidas de seguridad preventivas reducen

el riesgo de que la herramienta eléctrica

arranque por accidente.

d) Guarde las herramientas eléctricas

fuera del alcance de los niños y no permita

que personas que no estén familiarizadas

con la herramienta eléctrica o estas

instrucciones la usen. Las herramientas

eléctricas son peligrosas en manos de

personas inexpertas.

e) Realice un mantenimiento regular de

las herramientas eléctricas. Compruebe la

alineación incorrecta y la fijación de las piezas

móviles, la rotura de las piezas móviles y

cualquier otra condición que pueda afectar al

funcionamiento de las herramientas eléctricas.

Si está dañada, repare la herramienta

eléctrica antes de usarla. Muchos accidentes

se producen debido a un mantenimiento

deciente de las herramientas eléctricas.

f) Mantenga las herramientas de corte

limpias y aladas. Las herramientas de corte

con buen mantenimiento y bordes de corte

alados son menos propensas a trabarse y son

más fáciles de controlar.

g) Use la herramienta eléctrica, accesorios

y útiles, etc., de acuerdo con estas

instrucciones y teniendo en cuenta las

condiciones de funcionamiento y el

trabajo que se va a realizar. El uso de

la herramienta eléctrica para operaciones

diferentes a las previstas podría provocar una

situación peligrosa.

5) Advertencias generales de seguridad de

la herramienta eléctrica

[Servicio técnico]

a) Lleve la herramienta eléctrica a reparar

a un experto cualicado que utilice

solo piezas de repuesto originales. Esto

garantizará que se mantenga la seguridad de

26

Page 27

www.evolutionpowertools.com

ES

la herramienta eléctrica correctamente.

CONSEJOS PARA SU SALUD

ADVERTENCIA: al utilizar esta máquina

se pueden producir partículas de polvo. En

ocasiones, según los materiales con los que

trabaje, este polvo puede ser especialmente

perjudicial.

Si sospecha que la pintura de la supercie del

material que desea cortar contiene plomo,

busque ayuda profesional. No intente quitar

pintura a base de plomo. Solamente un

profesional debería hacerlo. Una vez que el

polvo se ha depositado en una supercie,

el contacto de la mano con la boca puede

llevar a la ingestión de plomo. Incluso la

exposición a niveles bajos de plomo puede

causar daños irreversibles en el cerebro y el

sistema nervioso. Los niños y los nonatos son

especialmente vulnerables.

Se recomienda que considere el riesgo

asociado a los materiales con los que trabaja

para reducir el riesgo de exposición.

Algunos materiales pueden producir polvo

dañino para su salud. Recomendamos el

uso de mascarillas reguladas con ltros

reemplazables cuando use esta máquina.

Siempre debe:

• Trabajar en una zona bien ventilada.

• Trabajar con un equipo de seguridad

aprobado, como mascarillas para el polvo

que hayan sido diseñadas especialmente

para ltrar partículas microscópicas.

ADVERTENCIA: la manipulación de cualquier

herramienta eléctrica puede provocar que se

lancen objetos externos contra los ojos, lo que

puede ocasionar daños graves en los mismos.

Antes de empezar a utilizar una herramienta

eléctrica, póngase siempre gafas con

protección lateral o una máscara que cubra

toda la cara cuando sea necesario.

INSTRUCCIONES ADICIONALES DE

SEGURIDAD

ADVERTENCIA: desconecte siempre la sierra

de movimiento alternativo de la red eléctrica

antes de cambiar las hojas, realizar el servicio

técnico, la limpieza o el ajuste de la sierra de

movimiento alternativo.

• Mantenga las manos lejos de la zona

de corte y de la hoja de corte. Sujete la

máquina agarrando las zonas de sujeción

aisladas con ambas manos. Si sujeta la sierra

con las dos manos, estas no podrán entrar

en contacto con la hoja.

• No use hojas desaladas o dañadas. Las

hojas dañadas o desaladas pueden

romperse fácilmente y son propensas

a atascarse, lo cual puede provocar

contragolpes.

• Compruebe siempre que la hoja está

instalada correctamente dentro del soporte

de hoja de la sierra. Lleve guantes de

protección al manipular una hoja y realice

una prueba dando un «tirón» cuando se

instale una nueva hoja para asegurarse de

que esta se ha «encajado» correctamente

en el soporte de la hoja.

• No use demasiada fuerza. El uso de fuerza

excesiva sobrecarga el motor y reduce la

eciencia de trabajo y la vida útil.

• Lleve siempre el EPI (Equipo de Protección

Individual) necesario para el trabajo que

vaya a realizar. Normalmente, este incluiría

gafas de seguridad o máscaras que cubren

toda la cara, máscaras para el polvo, ropa

de protección y calzado de seguridad,

protección para los oídos y casco de

seguridad, etc.

• El operario debe tener siempre en cuenta

el tendido del cable de alimentación de la

red eléctrica. El cable se debe tender de

modo que no pueda suponer un peligro de

tropiezo ni de ninguna otra clase y de modo

que no pueda entrar en contacto con la

hoja de la máquina.

• Compruebe siempre las paredes, los

suelos y los techos en busca de cables

eléctricos ocultos, tuberías de gas y/o agua

u otros servicios. El contacto con servicios

ocultos podría ser extremadamente

peligroso para el operario y podría causar

daños importantes en la propiedad. En la

mayoría de proveedores de herramientas

hay disponibles detectores que pueden

determinar la posición de los servicios

ocultos dentro o detrás de una pared, etc.

• Retire la hoja de un corte solamente cuando

la máquina se haya apagado y la hoja se

haya detenido completamente. La retirada

de una hoja en movimiento de un corte

podría provocar que la hoja en movimiento

golpee una supercie cercana, haciendo

que el operario experimente un fuerte

retroceso.

• A ser posible, asegúrese de que cualquier

pieza de trabajo esté rmemente sujeta

27

Page 28

www.evolutionpowertools.com

para evitar movimientos durante la

operación de corte.

• Nunca intente detener la hoja de corte

aplicando presión lateral a la hoja. Permita

que la hoja se detenga completamente

apagando la máquina y permita que el

motor se ralentice y se detenga de forma

normal.

• Compruebe siempre que la tensión del

suministro eléctrico es igual que la tensión

de suministro indicada en la placa de

características de la máquina. El uso de esta

máquina con una tensión de suministro

distinta a la que se indica en la placa de

características de la máquina podría dañar

la máquina y hacer que no fuera segura

desde el punto de vista eléctrico.

• No altere ni modique el cable de

alimentación. Esta sierra está equipada con

cable y enchufe aprobados para su país de

uso previsto. Si el cable de alimentación

o el enchufe moldeado están dañados de

cualquier modo, un técnico cualicado

debe sustituirlos por un modelo idéntico.

ADVERTENCIA: esta máquina no se debe

usar para cortar ningún material que pueda

contener amianto. Si se sospecha de la

presencia de amianto, pida consejo a las

autoridades pertinentes. No intente cortar

ningún material sospechoso hasta que las

autoridades pertinentes hayan declarado que

es seguro.

PRIMEROS PASOS

DESEMBALAJE

Precaución: este paquete contiene objetos

punzantes. Tenga cuidado al desembalarlo.

Saque la máquina del embalaje junto con

los accesorios suministrados. Revise con

atención para comprobar que la máquina

está en buenas condiciones y que cuenta con

todos los accesorios que se enumeran en este

manual. Asegúrese también de que todos los

accesorios estén completos. Si falta alguna

de las piezas, la máquina y los accesorios se

deben devolver juntos en su embalaje original

a su distribuidor. No tire el embalaje, guárdelo

durante todo el período de garantía. Deseche

el embalaje de forma respetuosa con el medio

ambiente. Si fuese posible, recíclelo. No

deje que los niños jueguen con las bolsas de

plástico vacías debido al riesgo de asxia.

ITEMS SUPPLIED

Descripción Cantidad

Sierra de movimiento

alternativo R230RCP

Paquete de 2 hojas

multiusos

(Incluye 1 hoja de acero fina

y 1 hoja multiusos)

Paquete de 2 hojas de

corte para madera

(Incluye 1 hoja para madera

verde

y 1 hoja para madera

general)

Manual de instrucciones 1

ACCESORIOS ADICIONALES

Además de los elementos estándar

suministrados con esta máquina, también

ponemos a su disposición los siguientes

accesorios que encontrará en la tienda en línea

de Evolution en

www.evolutionpowertools.com o en su

distribuidor local.

Descripción N.º de

Paquete de 2 hojas

multiusos

(Incluye 1 hoja de acero fina

y 1 hoja multiusos)

Paquete de 2 hojas de

corte para madera

(Incluye 1 hoja para madera

verde

y 1 hoja para madera

general)

1

1

1

pieza

045-0255

045-0254

28

Page 29

www.evolutionpowertools.com

ES

DESCRIPCIÓN GENERAL DE LA MÁQUINA

4

2

1

3

1. Hoja

2. Placa de contacto de la pieza de trabajo

3. Palanca de bloqueo de la placa de contacto

4. Selector de sujeción de la hoja

5. Gatillo interruptor

6. Control de la velocidad variable

7. Botón de bloqueo del gatillo

8. Botón de rotación del mango

8

5

6

A. Hoja multiusos

B. Hoja para madera general

C. Hoja para madera verde

D. Hoja de acero fina

7

A

B

C

D

29

Page 30

www.evolutionpowertools.com

Fig. 1

Fig. 2

INSTALAR O DESMONTAR UNA HOJA

ADVERTENCIA: realice estos procedimientos tan solo cuando

la máquina esté desconectada de la red de alimentación

eléctrica.

Nota: se recomienda que el operario lleve guantes protectores

cuando manipule las hojas. Se debe tener cuidado, ya que

una hoja usada recientemente podría estar caliente y/o

contaminada con residuos.

Para instalar una hoja:

• Asegúrese de que el soporte de la hoja está limpio y que no

contiene residuos u otros contaminantes.

• Gire hacia la izquierda y sujete el selector de sujeción de la

hoja.

(Fig. 1)

• Inserte completamente el vástago de la hoja en el soporte de

la hoja.

• Suelte la mordaza de la hoja para que vuelva a su posición

original.

• Compruebe que la hoja está segura.

ADVERTENCIA: es importante que el oricio en la espiga de

la hoja engrane con la espiga situada dentro del soporte de la

hoja.

Para desmontar una hoja:

• Si se ha usado recientemente, deje que la hoja se enfríe.

• Asegúrese de que la máquina está apuntando hacia abajo

para permitir que cualquier posible residuo se caiga.

• Gire hacia la izquierda y sujete el selector de sujeción de la

hoja.

• Tire suavemente de la hoja para sacarla del soporte de la

hoja.

Fig. 3

Nota: si se está sustituyendo la hoja porque ha llegado al nal

de su vida útil, échela directamente a un cubo de reciclaje.

PLACA DE CONTACTO DE LA PIEZA DE TRABAJO (Fig. 2)

ADVERTENCIA: para lograr la mayor ecacia de corte,

minimizar el riesgo de vibración y de saltos y/o rotura de la hoja,

la placa de contacto de la pieza de trabajo se debe mantener

rmemente en contacto con la pieza de trabajo.

Nota: la placa de trabajo de la pieza de trabajo se puede girar

y ajustar. Esta característica permite que la placa de contacto

se ajuste y esté a ras sobre la supercie de la pieza de trabajo,

incluso cuando el cuerpo principal de la máquina está situado

con un ligero ángulo respecto a dicha supercie.

ALCANCE Y CAPACIDAD DE CORTE

Al usar hojas de diferentes longitudes o alterar la posición de

mantenimiento de la placa de contacto de la pieza de trabajo,

es posible aumentar o disminuir el «alcance» general y la

capacidad de corte de la máquina.

(Fig. 3)

30

Page 31

www.evolutionpowertools.com

ES

Para ajustar la posición de la placa de contacto:

• Suelte la palanca de bloqueo de la placa de contacto. (Fig. 4)

• Empuje hacia dentro o tire hacia fuera de la placa de

contacto, según se requiera.

• Una vez que la placa esté en la posición deseada, empuje

la palanca de bloqueo de vuelta a su posición original para

bloquear la placa en posición.

• Compruebe que sea seguro.

EL GATILLO INTERRUPTOR

El gatillo interruptor on/o está situado dentro del mango

trasero de la máquina. (Fig. 5).

• Presione el gatillo interruptor para arrancar el motor de la

máquina.

• Suelte el gatillo interruptor para detener el motor de la

máquina.

INTERRUPTOR DE BLOQUEO

El gatillo está equipado con un interruptor de bloqueo. Para

utilizar la función de bloqueo:

• Presione completamente el gatillo para arrancar el motor de

la máquina.

• Mantenga presionado el interruptor de bloqueo. (Fig. 6)

• Suelte el gatillo y después suelte el interruptor de bloqueo.

Fig. 4

ADVERTENCIA: el motor funcionará de forma continua hasta

que se presione el gatillo y se active el interruptor de bloqueo.

EL SELECTOR DE CONTROL DEL ÍNDICE DE

DESPLAZAMIENTO

Se puede modicar el índice de desplazamiento de la máquina.

Hay un selector de control del índice de desplazamiento en el

gatillo. (Fig. 7).

Nota: la ubicación ergonómica de este selector de control

permite que un operario cualicado pueda ajustar el índice

de desplazamiento de la máquina durante las operaciones de

corte.

Al girar este selector se modicará el índice de desplazamiento

de la máquina desde aproximadamente 800 carreras por

minuto hasta un máximo de 2800 carreras por minuto.

Nota: recomendamos que el operario empiece cualquier

operación de corte usando un índice de desplazamiento lento

y que aumente el índice de desplazamiento para lograr un

rendimiento óptimo a medida que progrese el corte.

Una prueba práctica en un resto de material puede ser útil para

determinar la mejor tasa de carrera para cualquier aplicación o

material particular.

31

Fig. 5

Fig. 6

Fig. 7

Page 32

www.evolutionpowertools.com

Fig. 8

Fig. 9

MANGO GIRATORIO DE 180˚

El mango de la máquina se puede girar 180˚ y tiene 3 posiciones

para lograr el máximo control durante el corte.

Para girar el mango:

• Deslice y sujete el botón de rotación del mango hacia atrás.

(Fig. 8)

• Gire el mango 90˚ hasta la posición deseada.

• Suelte el botón de rotación.

• Compruebe que el mango es seguro y que el botón está

completamente enganchado.

ADVERTENCIA: los ajustes del mango solamente se pueden

realizar cuando el motor está apagado. Ajustar el mango

mientras se está usando la herramienta puede provocar

lesiones graves.

CORTE GENERAL

ADVERTENCIA: nunca arranque la máquina con la hoja en

contacto con la pieza de trabajo.

• Seleccione un índice de desplazamiento bajo.

• Sujete la máquina con ambas manos.

• Asegúrese de que la placa de contacto de la pieza de trabajo

está tocando rmemente la pieza de trabajo, pero no la hoja.

(Fig. 9).

• Encienda la máquina.

• Sujetando la máquina rmemente, introduzca muy poco

a poco la hoja en la pieza de trabajo hasta que corte

correctamente.

• Utilice el selector de control del índice de desplazamiento

hasta lograr el rendimiento de corte óptimo.

• Nunca «fuerce» la hoja. Permita que la hoja corte la pieza de

trabajo sin aplicar demasiada presión. Forzar la hoja reducirá

la vida útil de la misma, aumentará la probabilidad de rotura

de la hoja y sobrecargará el motor de la máquina.

ADVERTENCIA: si se atasca la hoja de la sierra, apague la

máquina de inmediato y desconéctela de la red eléctrica.

HOJAS ATASCADAS

ADVERTENCIA: las hojas atascadas pueden estar muy calientes

y/o contaminadas con residuos. El operario debe tener mucho

cuidado al intentar sacar una hoja atascada y emplear todo el

EPI necesario.

Para sacar una hoja atascara, habrá que ensanchar la ranura (el

corte de la sierra hecho por la hoja).

• Separe la máquina de la hoja usando el selector de sujeción

de la hoja y aoje la máquina con cuidado alejándola de la

hoja atascada.

• Ensanche la ranura con una herramienta apropiada hasta

que se pueda sacar la hoja de la pieza de trabajo.

32

Page 33

www.evolutionpowertools.com

ES

CORTE DE INMERSIÓN

ADVERTENCIA: el corte de inmersión es una técnica que solo

debe usarse en materiales de construcción blandos, como

placas de yeso, etc. No es un procedimiento adecuado para

materiales más duros y nunca se debe emplear en materiales

metálicos.

Nota: operarios no experimentados no deben intentar realizar

esta técnica.

Nota: solo se pueden usar hojas de corte de inmersión

especicas para tal n al intentar realizar un corte de inmersión.

Nota: Para reducir el riesgo de retroceso al realizar un corte de

inmersión. Se recomienda taladrar un agujero piloto y hacer el

corte de inmersión en el agujero como punto de partida, lo que

proporciona control y estabilidad adicional.

Para realizar cortes de inmersión:

• Complete cualquier marcado o todos los marcados de las

líneas de corte usando un lapicero, un marcador, etc. en la

pieza de trabajo antes de comenzar las operaciones.

• Sujete la máquina en ángulo respecto a la pieza de trabajo

con el borde inferior de la placa de contacto de la pieza

de trabajo apoyado rmemente contra la pieza de trabajo.

(Fig. 10).

Nota: la hoja no debe estar en contacto con la pieza de trabajo

en este momento. El operario también debe estar seguro de

que la hoja no entrará en contacto con la pieza de trabajo de

inmediato cuando se encienda la máquina.

• Ajuste la tasa de carrera al máximo.

• Encienda la máquina.

• Gire muy despacio la máquina usando el borde inferior de

la placa de contacto de la pieza de trabajo como apoyo.

Permita que la hoja entre gradualmente en la pieza de

trabajo.

• Cuando la placa de contacto descanse de forma plana sobre

la pieza de trabajo, prosiga con el corte de la forma habitual.

• Ajuste el índice de desplazamiento para un rendimiento de

corte óptimo.

Fig. 10

CORTE A RAS

El corte a ras es un corte muy cerca de una supercie como el

suelo, la pared o el techo, etc. Esta técnica permite al operario

cortar un material no deseado que sobresale, como vigas

redundantes, tuberías de soporte, etc. de un edicio.

ADVERTENCIA: el operario debe asegurarse de que cualquier

objeto arquitectónico redundante, etc. no esté «sometido a

corriente eléctrica» y que sea seguro cortarlo.

Nota: el corte a ras solo es posible con las hojas bimetálicas

superexibles.

33

Page 34

www.evolutionpowertools.com

Fig. 11

Para realizar un corte a ras:

• Seleccione e inserte la hoja de sierra correcta en la máquina.

• Coloque el lateral de la hoja de sierra directamente contra el

suelo, la pared, etc.

• Un borde lateral de la placa de contacto de la pieza de

trabajo debe estar en contacto con el suelo, la pared, etc.

• Encienda la máquina e introduzca poco a poco la hoja en la

pieza de trabajo.

• Ajuste el índice de desplazamiento para un rendimiento

óptimo.

• Corte la pieza de trabajo lentamente, permitiendo que la

hoja exible se curve según sea necesario. (Fig. 11).

• Permita que el lateral de la hoja exible se deslice

suavemente por el suelo, la pared, etc.

LIMPIEZA

ADVERTENCIA: la limpieza solo se puede realizar con la

máquina desconectada de la red de alimentación eléctrica.

Limpie el soporte de la hoja de la sierra y retire la suciedad

y/o residuos acumulados. Se debe retirar la hoja de la sierra

de la máquina para poder realizar una limpieza adecuada y

minuciosa más fácilmente.

Retire cualquier contaminante usando un cepillo de cerdas

blandas.

También se puede usar aire comprimido. En este caso, el

operario debe tomar todas las precauciones de seguridad

necesarias para salvaguardar el entorno circundante y a

cualquier persona que pueda estar presente. El operario debe

usar todo el EPI relevante.

El operario deben llevar gafas de protección para proteger sus

ojos de los residuos soplados.

MANTENIMIENTO

ADVERTENCIA: cualquier actividad de mantenimiento se debe

llevar a cabo con la máquina apagada y desconectada de la red

de suministro de energía eléctrica o de la batería.

Compruebe que todas las características de seguridad y las

protecciones están funcionando correctamente de forma

regular. Solo utilice esta máquina si las protecciones o

características de seguridad funcionan por completo.

Todos los cojinetes del motor de esta máquina están lubricados

de forma permanente. No es necesario volver a lubricarlos.

Utilice un paño limpio y ligeramente húmedo para limpiar

las partes de plástico de la máquina. No utilice disolventes ni

productos similares que podrían dañarlas.

34

Page 35

www.evolutionpowertools.com

ES

ADVERTENCIA: no intente limpiar

introduciendo objetos puntiagudos a través

de las aberturas de las cubiertas de las

máquinas, etc. Los conductos de ventilación se

deben limpiar con aire comprimido seco.

El exceso de chispas puede indicar que el

motor está sucio o que las escobillas de

carbono están desgastadas.

Si se tiene alguna sospecha de que esto

ocurra, lleve la máquina a servicio técnico

para que el personal cualicado reemplace los

cepillos.

PROTECCIÓN MEDIOAMBIENTAL

Los productos eléctricos no se deben tirar

con la basura doméstica. Recicle en los sitios

destinados para este n.

Consulte con la autoridad local o el

distribuidor para obtener información sobre

el reciclaje.

35

Page 36

www.evolutionpowertools.com

DECLARACIÓN DE CONFORMIDAD DE LA CE

De conformidad con EN ISO 17050-1:2004

El fabricante del producto cubierto por esta declaración es el siguiente:

UK: Evolution Power Tools Ltd, Venture One, Longacre Close, Holbrook Industrial Estate, Sheeld, S20 3FR.

FR: Evolution Power Tools SAS, 61 Avenue Lafontaine, 33560, Carbon-Blanc, Bordeaux, France.

El fabricante declara que la máquina, tal como se detalla en la presente declaración, cumple todas

las disposiciones pertinentes de la Directiva de Máquinas y otras directivas apropiadas, como

se detalla a continuación. El fabricante declara además, que la máquina, según se indica

detalladamente en la presente declaración, en los casos en los que sea aplicable, cumple con las

disposiciones pertinentes sobre los requisitos esenciales de seguridad y salud.

Las Directivas incluidas en esta declaración son las que se detallan a continuación:

2006/42/CE Directiva de máquinas.

2014/30/UE Directiva de Compatibilidad Electromagnética.

Directiva sobre las restricciones a la utilización de determinadas

2011/65/UE. y

2015/863/UE.

sustancias peligrosas en aparatos eléctricos y electrónicos (RoHS).

2002/96/CE como Directiva de Residuos de Aparatos Eléctricos y Electrónicos (WEEE).

Modificada por

2003/108/CE

Y está en conformidad con los requisitos aplicables de los siguientes documentos:

EN 62841-1:2015, EN 62841-2-11:2016, EN 55014-1:2017, EN 55014-2:2015, EN 610003-2:2014, EN 61000-3-3:2013

Detalles del producto

Descripción: SIERRA RECIPROCANTE R230RCP

N.º de modelo Evolution: 0450001 230V REINO UNI DO, 0450003 230V UE, 0450004 120V EE.UU.

Marca comercial: EVOLUTION

Voltaje: 230V ~ 50 Hz, 120V ~ 60 Hz

Entrada: 850 W

La documentación técnica necesaria para demostrar que el producto cumple con los requisitos de

la directiva se ha elaborado y está disponible para su inspección por las autoridades pertinentes, y

verifica que nuestro archivo técnico contiene los documentos enumerados anteriormente

y que estas son las regulaciones normales para el producto, como se detalla antes.