Page 1

Original Instructions

Original written in UK English Date Published: 01 / 04 / 2016

CMS

R210

Page 2

2

www.evolutionpowertools.com

TABLE OF CONTENTS

Introduction Page 3

Guarantee Page 3

Machine Specifications Page 4

Labels and Symbols Page 5

Intended use of this Power Tool Page 6

Prohibited use of this Power Tool Page 6

Safety Precautions Page 6

Electrical Safety Page 6

Outdoor Use Page 6

Power Tool General Safety

Instructions

Page 6

Health Advice Page 8

Mitre Saw Specific Safety Page 9

Blade Safety Page 9

Personal Protective Equipment

(PPE)

Page 9

Safe Operation Page 9

Perform Cuts Correctly and Safely Page 10

Additional Safety Advice Carrying your Mitre Saw

Page 10

Getting Started Page 11

Unpacking Page 11

Serial No. / Batch Code Page 11

Items Supplied Page 11

Additional Accessories Page 11

Machine Overview Page 12

Assembly and Preparation Page 13

Permanently Mounting the

Mitre Saw

Page 13

For Portable Use Page 13

Hold Down Clamp Page 14

The Sliding Upper Fence Section Page 14

Operating Instructions Page 14

Body and Hand Positioning Page 15

Adjustment of Precision Angles Page 15

Bevel Angles Page 15

Cutting Head Travel Page 16

Fence Alignment Page 16

Mitre Angle Scales & Pointer Page 17

Final Adjustment Checks Page 17

Preparing to Make a Cut Page 17

Releasing the Cutting Head Page 17

The Motor On/Off Switch Page 18

Chop Cutting Page 18

Mitre Cutting Page 18

Bevel Cutting

Tilting the Cutting Head

Page 19

Compound Cutting Page 19

Cutting Bowed Material Page 20

Clearing Jammed Material Page 20

Supporting Long Workpieces Page 20

Installing or Removing a Blade Page 20

Use of Optional

Evolution Accessories

Page 21

Dust Bag Page 21

Maintenance Page 22

Environmental Protection page 22

Declaration of Conformity Page 23

Page 3

3

www.evolutionpowertools.com

EN

INTRODUCTION

(1.2)

This instruction manual was

originally written in English.

(1.3)

IMPORTANT

Please read these operating and safety

instructions carefully and completely.

For your own safety, if you are uncertain

about any aspect of using this equipment

please access the relevant technical helpline.

The number of which can be found on the

Evolution Power Tools website. We operate

several helplines throughout our worldwide

organization, but technical help is also

available from your supplier.

WEB:

www.evolutionpowertools.com

EMAIL:

enquiries@evolutionpowertools.com

(1.4)

Congratulations on your purchase of an

Evolution Power Tools machine. Please

complete your product guarantee

registration online as explained in the

guarantee registration leaet included with

this machine. You can also scan the QR code

found on the leaet with a smart phone.

This will enable you to validate your

machine’s guarantee period via Evolution‘s

website by entering your details and thus

ensure prompt service if ever needed. We

sincerely thank you for selecting a product

from Evolution Power Tools.

EVOLUTION LIMITED GUARANTEE

Evolution Power Tools reserves the right to

make improvements and modications to the

product design without prior notice.

Please refer to the guarantee registration leaet

and/or the packaging for details of the terms

and conditions of the guarantee.

The guarantee below is applicable to machines

destined for the UK mainland market only.

Other markets may have specic requirements,

additions or exclusions applied. Consult your

dealer for details of the guarantee applied to

your area/country. All Evolution guarantees are

in addition to your statutory rights.

(1.5)

Evolution Power Tools will, within the guarantee

period, and from the original date

of purchase, repair or replace any goods found

to be defective in materials or workmanship.

This guarantee is void if the tool being returned

has been used beyond the recommendations

in the instruction manual or if the machine

has been damaged by accident, neglect,

or improper service. This guarantee does not

apply to machines and / or components which

have been altered, changed, or modied

in any way, or subjected to use beyond

recommended capacities and specications.

Electrical components are subject to respective

manufacturers’ warranties. All goods returned

defective shall be returned prepaid freight to

Evolution Power Tools. Evolution Power Tools

reserves the right to optionally repair or replace

it with the same or equivalent item. There is no

warranty – written or verbal – for consumable

accessories such as (following list not exhaustive)

blades, cutters, drills, chisels or paddles etc.

In no event shall Evolution Power Tools be

liable for loss or damage resulting directly or

indirectly from the use of our merchandise or

from any other cause. Evolution Power Tools is

not liable for any costs incurred on such goods or

consequential damages. No ocer, employee or

agent of Evolution Power Tools is authorized to

make oral representations of tness or to waive

any of the foregoing terms of sale and none shall

be binding on Evolution Power Tools.

Questions relating to this limited

guarantee should be directed to the

company’s head oce, or call the

appropriate helpline number.

Page 4

4

www.evolutionpowertools.com

MACHINE SPECIFICATIONS

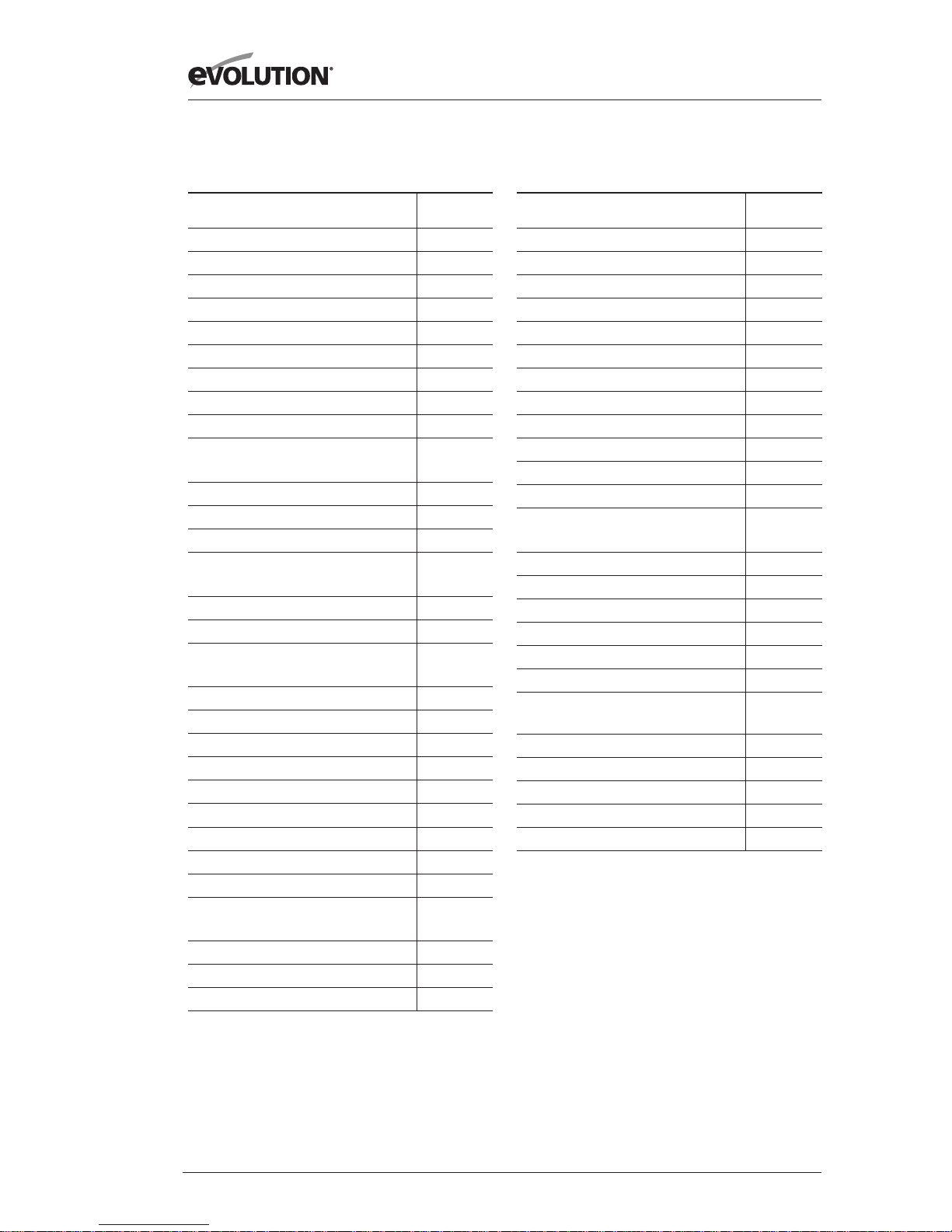

MACHINE METRIC IMPERIAL

Motor (230-240V ~ 50 Hz) 1200W 5A

Motor (110V ~ 50 Hz) 1200W 11A

Speed No Load 3750min

-1

3750rpm

Weight (Net) 5.8 kg 12.8 lb

Dust Port Diameter 35mm 1-3/8 In.

Tool Dimensions (H x W x L) (0° / 0°)

(Note: Dimensions taken with saw head down.)

260 x 393 x 381mm

10-15⁄64 x

15-15⁄ 32 x 15 I n.

Cable Length 2m 6ft 9⁄16 In.

CUTTING CAPACITIES METRIC IMPERIAL

Mild Steel Plate - Max Thickness 6mm 1/4 In.

Mild Steel Box Section - Max Wall Thickness* 4mm 5/32 In.

Wood – Max section 125 x 55mm 4-15/16 x 2-3/16 In.

MAXIMUM CUTTING ANGLES LEFT RIGHT

Mitre 50˚ 50˚

Bevel 0˚ - 45˚ N/A

MITRE BEVEL

MAX WIDTH

OF CUT

MAX DEPTH

OF CUT

0° 0° 125mm (4-15/16 In.) 55mm (2-3/16 In.)

0° 45° 125mm (4-15/16 In.) 35mm (1-3/8 In.)

45° 0° 85mm (3-3/8 In.) 55mm (2-3/16 In.)

45° 45° 85mm (3-3/8 In.) 35mm (1-3/8 In.)

BLADE DIMENSIONS METRIC IMPERIAL

Diameter 210mm 8-1/4 In.

Bore 25.4mm 1 In.

Thickness 1.7mm 1/16 In.

*50mm mild steel box section.

NOISE DATA

Sound Pressure LPA 110v: 96.02dB / 230v: 97.14dB

Sound Power Level LWA 110v: 109.02dB / 230v: 110.14dB

Page 5

5

www.evolutionpowertools.com

EN

Warning: Wear hearing protection!

Handling

• Handlethemachinewithcare,

allowing the machine to do the work.

• Avoidusingexcessivephysicaleort

on any of the machines controls.

• Consideryoursecurityandstability,

and the orientation of the machine

during use.

Work Surface

• Considertheworksurfacematerial;

its condition, density, strength,

rigidity and orientation.

WARNING: The vibration emission during

actualuseofthepowertoolcandierfromthe

declared total value depending on the ways

in which the tool is used. The need to identify

safety measures and to protect the operator

are based on an estimation of exposure in the

actual conditions of use (taking account of all

parts of the operating cycle, such as the times

thetoolisswitchedo,whenitisrunningidle,

in addition to trigger time).

(1.8)

LABELS & SYMBOLS

WARNING: Do not operate this machine if

warning and/or instruction labels are missing

or damaged. Contact Evolution Power Tools

for replacement labels.

Note: All or some of the following symbols

may appear in the manual or on the product.

Manufacturing Date Code

The manufacturing date code is the first part

of the serial number, found on the motor

housing of the machine. Evolution serial

numbers begin with the abbreviation of the

machine followed by a letter. A = January, B =

February and so on. The following 2 numbers

are the year of manufacture. 09 = 2009, 10 =

2010, etc. (Example of batch code: XXX-A10)

(1.9)

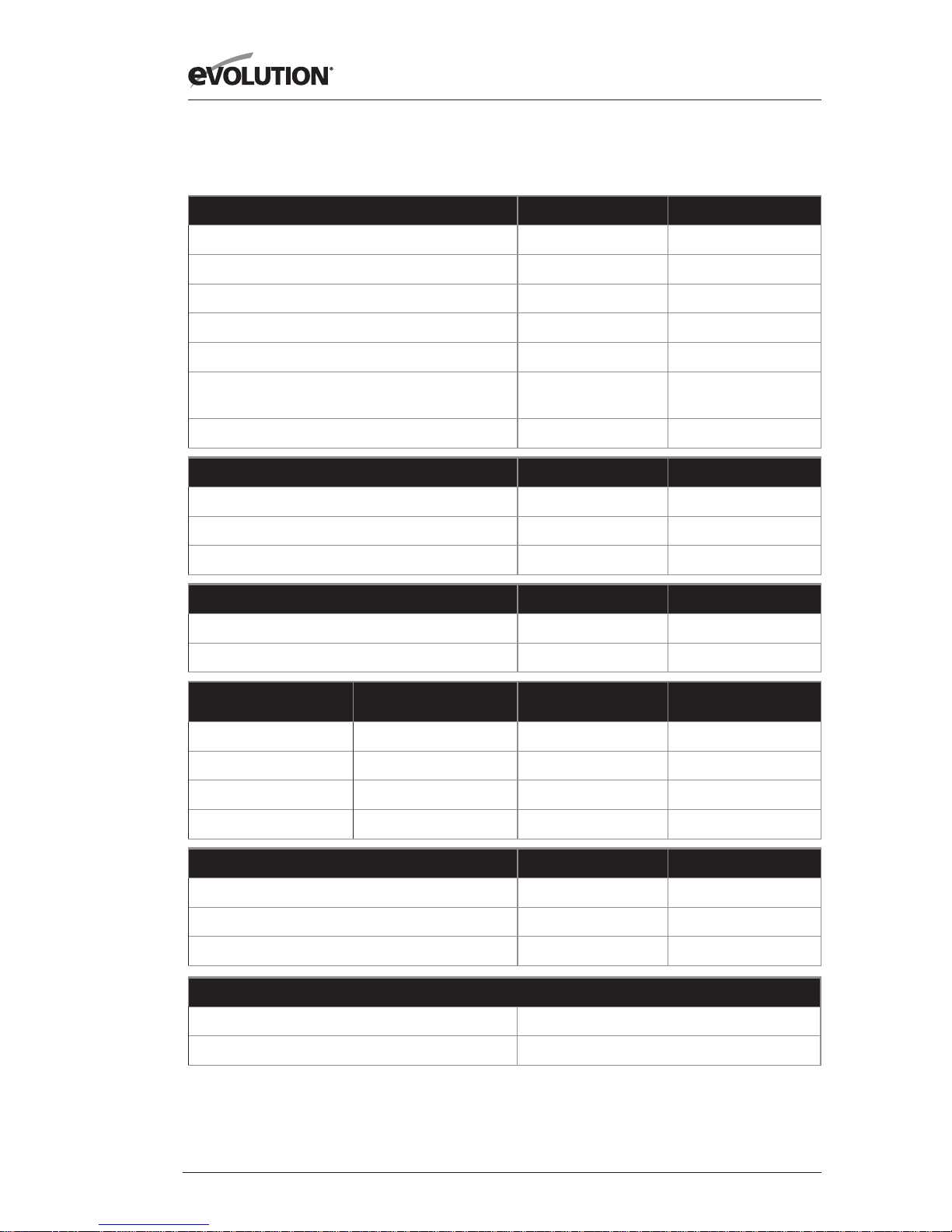

Symbol Description

V

Volts

A

Amperes

Hz

Hertz

min

-1

Speed

~

Alternating Current

n

o

No Load Speed

Wear Safety Goggles

Wear Ear Protection

Do Not Touch

Wear Dust Protection

Wear Safety Gloves

Read Instructions

CE Certification

EAC Certification

Triman - Waste Collection

& Recycling

Waste Electrical &

Electronic Equipment

Warning

Protection Class II

Double Insulated

Page 6

6

www.evolutionpowertools.com

(1.10 )

INTENDED USE OF THIS POWER TOOL

WARNING: This product is a Compound

Mitre Saw and has been designed to be used

with special Evolution blades. Only use

accessories designed for use in this machine

and/or those recommended specically by

Evolution Power Tools Ltd.

WHEN FITTED WITH A CORRECT

BLADE THIS MACHINE CAN BE

USED TO CUT:

•Wood,Woodderivedproducts

(MDF, Chipboard, Plywood, Blockboard,

Hardboard etc),

•Woodwithnails,

•50mmmildsteelboxsectionwith4mm

wall at HB 200-220,

•6mmmildsteelplateatHB200-220.

Note: Wood containing non galvanised nails

or screws, with care, can be safely cut.

Note: Not recommended for cutting

galvanised materials or wood with embedded

galvanised nails. For cutting stainless steel

we recommend Evolution dedicated stainless

steel blades.

(1.11)

PROHIBITED USE OF THIS POWER TOOL

WARNING: This product is a Compound

Mitre Saw and must only be used as such.

It must not be modied in any way, or used

to power any other equipment or drive any

other accessories other than those mentioned

in this Instruction Manual.

(1.13)

WARNING: This machine is not intended

for use by persons (including children) with

reduced physical, sensory or mental capabilities,

or lack of experience and knowledge, unless

they have been given supervision or instruction

concerning the safe use of the machine by

a person responsible for their safety and who

is competent in its safe use.

Children should be supervised to ensure

that they do not have access to, and are

not allowed to play with, this machine.

SAFETY PRECAUTIONS

(1.14 )

ELECTRICAL SAFETY

This machine is tted with the correct moulded

plug and mains lead for the designated market.

If the mains lead or the plug are damaged in

any way, they must be replaced with original

replacement parts by a competent technician.

(1.15 )

OUTDOOR USE

WARNING: For your protection if this tool is to

be used outdoors it should not be exposed to

rain, or used in damp locations. Do not place

the tool on damp surfaces. Use a clean, dry

workbench if available. For added protection

use a residual current device (R.C.D.) that will

interrupt the supply if the leakage current to

earth exceeds 30mA for 30ms. Always check

the operation of the residual current device

(R.C.D.) before using the machine.

If an extension cable is required it must be a

suitable type for use outdoors and so labelled.

The manufacturers instructions should be

followed when using an extension cable.

(2 .1)

POWER TOOL GENERAL

SAFETY INSTRUCTIONS

WARNING: Read all safety warnings and

instructions. Failure to follow the warnings

and instructions may result in electric shock,

re and/ or serious injury.

Note: This power tool should not be powered

on continuously for a long time.

Save all warnings and instructions for

future reference.

The term “power tool” in the warnings refers

to your mains-operated (corded) power tool

or battery-operated (cordless) power tool.

Page 7

7

www.evolutionpowertools.com

EN

(2.2)

1) General Power Tool Safety Warnings

[Work area safety]

a) Keep work area clean and well lit. Cluttered

or dark areas invite accidents.

b) Do not operate power tools in explosive

atmospheres, such as in the presence

of ammable liquids, gasses or dust. Power

tools create sparks which may ignite

the dust or fumes.

c) Keep children and bystanders away while

operating power tool. Distractions can cause

you to lose control.

d) Do not use this machine in an enclosed

room.

(2.3)

2) General Power Tool Safety Warnings

[Electrical Safety]

a) Power tool plugs must match the outlet.

Never modify the plug in any way. Do

not use any adapter plugs with earthed

(grounded) power tools. Unmodied plugs

and matching outlets will reduce the risk

of electric shock.

b) Avoid body contact with earthed or

grounded surfaces, such as pipes, radiators,

ranges and refrigerators.

There is an increased risk of electric shock

if your body is earthed or grounded.

c) Do not expose power tools to rain or wet

conditions. Water entering a power tool will

increase the risk of electric shock.

d) Do not abuse the cord. Never use the cord

for carrying, pulling or unplugging the power

tool. Keep cord away from heat, oil, sharp

edges or moving parts. Damaged or entangled

cords increase the risk of electric shock.

e) When operating a power tool outdoors, use

an extension cord suitable for outdoor use. Use

of a cord suitable for outdoor use reduces the

risk of electric shock.

f) If operating a power tool in a damp location

is unavoidable, use a residual current device

(RCD) protected supply.

Use of an RCD reduces the risk of electric shock.

(2.4)

3) General Power Tool Safety Warnings

[Personal Safety].

a) Stay alert, watch what you are doing

and use common sense when operating a

power tool. Do not use a power tool while

you are tired or under the influence of

drugs, alcohol or medication. A moment of

inattention while operating power tools may

result in serious personal injury.

b) Use personal protective equipment.

Always wear eye protection to prevent

injury from sparks and chippings. Protective

equipment such as dust masks, non-skid

safety shoes, hard hat or hearing protection

used for appropriate conditions will reduce

personal injuries.

c) Prevent unintentional starting. Ensure

theswitchisintheo-positionbefore

connecting to power source and or battery pack,

picking up or carrying the tool. Carrying

power tools with your nger on the switch or

energising the power tools that have the switch

on invites accidents.

d) Remove any adjusting key or wrench

before turning the power tool on. A wrench or

key left attached to a rotating part of a power

tool may result in personal injury .

e) Do not overreach. Keep proper

footing and balance at all times.

This enables better control of the

power tool in unexpected situations.

f) Dress properly. Do not wear loose

clothing or jewellery. Keep your hair,

clothing and gloves away from moving parts.

Loose clothes, jewellery or long hair can be

caught in moving parts.

g) If devices are provided for the connection of

dust extraction and collection facilities, ensure

that these are connected and properly used.

Use of dust collection can reduce dust-related

hazards.

h) When cutting metal, gloves should be worn

before handling to prevent from getting burnt

from hot metal.

Page 8

8

www.evolutionpowertools.com

(2.5)

4) General Power Tool Safety Warnings

[Power tool use and care].

a) Do not force the power tool. Use the

correct power tool for your application. The

correct power tool will do the job better and

safer at a rate for which it was designed.

b) Do not use the power tool if the switch

doesnotturnitonoro.Anypowertool

that cannot be controlled with the switch is

dangerous and must be repaired.

c) Disconnect the power tool from the power

source and/or battery pack from the power

tool before making any adjustments,

changing accessories,

or storing power tools. Such preventative

safety measures reduce the risk of starting

the power tool accidentally.

d) Store idle power tools out of the reach of

children and do not allow persons unfamiliar

with the power tool or these Instructions

to operate the power tool. Power tools are

dangerous in the hands of untrained users.

e) Maintain power tools. Check for

misalignment or binding of moving parts,

breakage of moving parts and any other

conditionthatmayaectthepowertools

operation. If damaged, have the power tool

repaired before use. Many accidents are

caused by poorly maintained power tools.

f) Keep cutting tools sharp and clean.

Properly maintained cutting tools with sharp

cutting edges are less likely to bind and are

easier to control.

g) Use the power tool, accessories and tool

bits etc. in accordance with these instructions,

taking into account the working conditions

and the work to be performed. Use of the

powertoolforoperationsdierentfrom

those intended could result in a hazardous

situation.

(2.6)

5) General Power Tool Safety Warnings

[Service]

a) Have your power tool serviced by a qualied

repair person using only identical replacement

parts. This will ensure that the safety of the

power tool is maintained.

(2.7)

HEALTH ADVICE

WARNING: When using this machine, dust

particles may be produced. In some instances,

depending on the materials you are working

with, this dust can be particularly harmful.

If you suspect that paint on the surface

of material you wish to cut contains lead,

seek professional advice. Lead based paints

should only be removed by a professional

and you should not attempt to remove it

yourself. Once the dust has been deposited

on surfaces, hand to mouth contact can result

in the ingestion of lead. Exposure to even

low levels of lead can cause irreversible brain

and nervous system damage. The young and

unborn children are particularly vulnerable.

You are advised to consider the risks associated

with the materials you are working with and to

reduce the risk of exposure. As some materials

can produce dust that may be hazardous to

your health, we recommend the use of an

approved face mask with replaceable lters

when using this machine.

You should always:

• Workinawell-ventilatedarea.

• Workwithapprovedsafetyequipment,

such as dust masks that are specially

designed to lter microscopic particles.

(2.8)

WARNING: the operation of any power tool

can result in foreign objects being thrown

towards your eyes, which could result in

severe eye damage. Before beginning power

tool operation, always wear safety goggles

or safety glasses with side shield or a full face

shield where necessary.

Page 9

9

www.evolutionpowertools.com

EN

(3.5)

MITRE SAW SPECIFIC SAFETY

The following specic safety instructions for

Mitre Saws are based on the requirements of

EN 61029-2-9:2012+A11.

BLADE SAFETY

WARNING: Rotating circular saw blades are

extremely dangerous and can cause serious

injury and amputation. Always keep ngers

and hands at least 150mm away from the

blade at all times. Never attempt to retrieve

sawn material until the cutting head is in the

raised position, the guard is fully closed and

the saw blade has stopped rotating.

Only use saw blades that are recommended

by the manufacturer and as detailed in

this manual and that comply with the

requirements of EN 847-1

Do Not use saw blades that are damaged or

deformed as they could shatter and cause

serious injury to the operator or bystanders.

Do Not use saw blades that are manufactured

from high speed steel (HSS).

If the table insert becomes damaged or worn

it must be replaced with an identical one

available from the manufacturer as detailed

in this manual.

(3.6)

PERSONAL PROTECTIVE EQUIPMENT (PPE)

Hearing protection should be worn in order

to reduce the risk of induced hearing loss.

Eye protection should be worn in order to

prevent the possibility of the loss of sight

from ejected chippings.

Respiratory protection is also advised as some

wood and wood type products especially

MDF (Medium

Density Fibreboard) can

produce dust that ca

n be hazardous to

your health. We recommend the use

of

an

approved face mask with replaceable lters

whe

n using this machine in addition to using

the dust extraction facility.

Gloves should be worn when handling blades

or rough material. It is recommended that

saw blades should be carried in a holder

wherever practicable. It is not advisable to

wear gloves when operating the mitre saw.

(3.7)

SAFE OPERATION

Always ensure that you have selected the

correct saw blade for the material being cut.

Do Not use this mitre saw to cut materials other

than those specied in this Instruction Manual.

When transporting a mitre saw ensure that

the cutting head is locked in the 90 degree

down position (if a sliding mitre saw ensure

that the slide bars are locked). Lift the

machine by gripping the outer edges of the

base with both hands (if a sliding mitre saw,

transport using the handles provided). Under

no circumstances shall the machine be lifted

or transported using the retractable guard or

any part of its operating mechanism.

Bystanders and other colleagues must be

kept at a safe distance from this saw. Cut

debris can, in some circumstances, be ejected

forcibly from the machine, posing a safety

hazard to people standing nearby.

Before each use check the operation of the

retractable guard and its operating mechanism

ensuring that there is no damage, and that all

moving parts operate smoothly and correctly.

Keep the work bench and oor area clear of all

debrisincludingsawdust,chipsando-cuts.

Always check and ensure that the speed marked

on the saw blade is at least equal to the no

load speed marked on the mitre saw. Under no

circumstances shall a saw blade be used that

is marked with a speed that is less than the no

load speed marked on the mitre saw.

Where it is necessary to use spacer or reducing

rings these must be suitable for the intended

purpose and only as recommended by

the manufacturer.

If the mitre saw is tted with a laser it shall not

bereplacedwithadierenttype.Ifthelaser

Page 10

10

www.evolutionpowertools.com

fails to operate it shall be repaired or replaced

by the manufacturer or his authorised agent.

The saw blade shall only be replaced as

detailed in this Instruction Manual.

Neverattempttoretrieveo-cutsoranyother

part of the work piece until the cutting head is

in the raised position, the guard is fully closed

and the saw blade has stopped rotating.

(3.8)

PERFORM CUTS CORRECTLY

AND SAFELY

Wherever practicable always secure the work

piece to the saw table using the work clamp

where provided.

Always ensure that before each cut the mitre

saw is mounted in a stable position.

If needed the mitre saw can be mounted on

a wooden base or work bench or attached

to a mitre saw stand as detailed in this

Instruction Manual.

Long work pieces should be supported on the

work supports provided or on appropriate

additional work supports.

(3.9)

ADDITIONAL SAFETY ADVICE CARRYING YOUR MITRE SAW

• Althoughcompact,thisMitreSawisheavy.

To reduce the risk of back injury,

get competent help whenever you

have to lift the saw.

• Toreducetheriskofbackinjury,holdthe

tool close to your body when lifting. Bending

your knees so you can lift with your legs, not

your back. Lift by using the handhold areas at

each side of the machines base.

• NevercarrytheMitreSawbythepower

cord. Carrying the Mitre Saw by the power

cord could cause damage to the insulation

or the wire connections resulting in electric

shock or re.

• BeforemovingtheMitreSawtightenthe

mitre and bevel locking screws and the

sliding carriage locking screw to guard

against sudden unexpected movement.

• LocktheCuttingHeadinitslowestposition.

Ensure that the Cutting Head Locking Pin is

completely engaged in its socket.

WARNING: Do not use the blade guard as

a ‘lifting point’. The power cord must be

removed from the power supply before

attempting to move the machine.

• LocktheCuttingHeadinthedownposition

using the Cutting Head Locking Pin.

• LoosentheMitreAngleLockingScrew.

Turn the table to either of its

maximum settings.

• Lockthetableinpositionusingthe

Locking Screw.

• Usethetwocarryhandlecut-outs

machined into either side of the machine

base, to transport the machine.

Place the saw on a secure stationary work

surface and check the saw over carefully.

Check particularly the operation of all the

machines safety features before attempting

to operate the machine.

Page 11

11

www.evolutionpowertools.com

EN

(4 .1)

GETTING STARTED

UNPACKING

Caution: This packaging contains sharp

objects. Take care when unpacking.

Remove the machine, together with the

accessories supplied from the packaging.

Check carefully to ensure that the machine

is in good condition and account for all the

accessories listed in this manual. Also make

sure that all the accessories are complete.

If any parts are found to be missing, the

machine and its accessories should be

returned together in their original packaging

to the retailer. Do not throw the packaging

away;keepitsafethroughouttheguarantee

period. Dispose of the packaging in an

environmentally responsible manner.

Recycle if possible. Do not let children play

with empty plastic bags due to the risk of

suocation.

SERIAL NO. / BATCH CODE

Note: The serial number can be found on

the motor housing of the machine. For

instructions on how to identify the batch

code, please contact the Evolution Power

Tools helpline or go to:

www.evolutionpowertools.com

(4.2 )

ITEMS SUPPLIED

Description Quantity

Instruction Manual 1

RAGE Multipurpose TCT Blade 1

Top Hold Down Clamp 1

6mm Blade Change Allen Key 1

(4.3)

ADDITIONAL ACCESSORIES

In addition to the standard items supplied

with this machine the following accessories

are also available from the Evolution online

shop at www.evolutionpowertools.com or

from your local retailer.

(4.4 )

Description Part No

RAGE Multipurpose

TCT Blade

RAGEBLADE210MULTI

Dust Bag 030-0309

Page 12

12

www.evolutionpowertools.com

PREZENTARE GENERALĂ

1. COMUTATOR PORNIRE/OPRIRE

2. MANETA DE BLOCARE A APĂRĂTORII

INFERIOARE A LAMEI DE TĂIERE

3. ȘURUB DE BLOCARE RAPORTOR

4. BOLȚUL CAPULUI DE TĂIERE

5. RAPORTOR

6. ȘURUB DE BLOCARE APĂRĂTOARE

7. ȘURUB BLOCARE CAP TĂIERE

8. CONEXIE EXTRACTOR PRAF

9. MÂNER

10. ELEMENT FIXARE APĂRĂTOARE

11. APĂRĂTOARE SUPERIOARĂ

12. APĂRĂTOARE CULISANTĂ

13. APĂRĂTOARE INFERIOARĂ

14. MASĂ ROTATIVĂ

15. BAZA MESEI FIERĂSTRĂULUI

16. CARCASA MOTORULUI

17. ACCES CĂRBUNI

18. GĂURI MONTARE

9

10

8

7

13

14

15

16

11

12

6

4 5

1

2 3

18

18

17

Page 13

13

www.evolutionpowertools.com

RO

(7.1)

ASAMBLAREA ȘI PREGĂTIREA

AVERTISMENT: Deconectați întotdeauna fierăstrăul de la

sursa de alimentare înainte de a face ajustări.

(7. 2)

MONTAREA FIERĂSTRĂULUI DE O MASĂ

Pentru a reduce riscul de accidentări cauzate de mișcări

neașteptate ale fierăstrăului, așezați fierăstrăul în poziția

dorită, fie pe o bancă de lucru, fie pe un alt tip de suport

adecvat. Baza fierăstrăului are patru găuri de montare prin

care pot fi montate șuruburi adecvate (nu sunt furnizate).

Utilizați șaibe de blocare și piulițe pe partea inferioară

a bancului de lucru (FIg. 1).

• Pentru a evita rănirea cauzată de resturi, poziționați

fierăstrăul astfel încât alte persoane să nu stea prea

aproape (sau în spatele acestuia).

• Fixați fierăstrăul pe o suprafață fermă, nivelată, unde

există suficient spațiu pentru manipularea și susținerea

suficientă a piesei de prelucrat.

• Montați fierăstrăul astfel încât masa este stabilă și

fierăstrăul nu se clatină.

Înșurubați sau fixați fierăstrăul ferm de suportul său sau de

bancul de lucru.

(7. 3)

PENTRU UTILIZARE PORTABILĂ

• Montați fierăstrăul pe o bucată de placaj sau MDF

(Dimensiuni minime recomandate 800mm x 500mm)

cu grosimea de 18mm, folosind elemente de fixare

(nu sunt furnizate).

• Este posibil să fie nevoie de fixarea fierăstrăului de

partea inferioară a placajului sau a plăcii de montaj MDF

cu ajutorul a unor șaibe sau piulițe de fixare pentru a

evita o suprafață de lucru instabilă.

• Folosiți cleme G pentru a fixa placa de montaj pe

suprafața de lucru (Fig. 2).

Notă: Unele fierăstraie sunt dotate cu un braț stabilizator

aflat chiar sub articulația circularului.

Dacă acest tip de element este prezent, el ar trebui să fie

eliberat/retras de pe suprafața de lucru, în special în cazul

în care fierăstrăul este folosit fără a fi fixat (Fig. 3).

Acest braț va oferi o stabilitate suplimentară pentru a împiedica

fierăstrăul să se miște sau capul de tăiere să se clatine.

Fig. 1

(1) Șurub cu cap Hex

(2) Șaibă grower

(3) Șaibă

(4) Baza fierăstrăului

(5) Masă de lucru

(6) Șaibă

(7) Șaibă grower

(8) Piuliță Hex

(9) Piuliță blocare

Fig. 2

Fig. 3

(1)

(2)

(3)

(4)

(5)

(6)

(7)

(8)

(9)

Page 14

14

www.evolutionpowertools.com

(7. 4)

CLEMĂ DE FIXARE (Fig. 4)

Două orificii (câte una pentru fiecare parte) sunt încorporate în

în spatele apărătorii. Acestea sunt destinate poziționării clemei de

susținere.

• Montați clemele la orificiile în care se potrivesc cel mai bine

aplicației de tăiere, asigurându-vă că sunt împinse până la capăt.

• Așezați piesa de prelucrat ce urmează a fi tăiată de masa rotativă

a fierăstrăului și sprijiniți-o de apărătoare încât să fie plasată

în poziția dorită.

• Reglați clema folosind roata de mână astfel încât aceasta să fie

fixată în siguranță.

Faceți o testare în timp ce fierăstrăul este deconectat de la sursa

de alimentare. Asigurați-vă că clema de susținere de sus nu intră

în contact cu traiectoria lamei sau cu traiectoria oricărei alte părți a

capului de tăiere când este coborât.

APĂRĂTOAREA CULISANTĂ

Notă: Partea stângă a apărătorii are o secțiune superioară

reglabilă. Atunci când sunt selectate unghiuri mari de tăiere poate

fi necesar să glisați partea superioară a apărătorii spre stânga.

Acest lucru ar trebui să creeze un spațiu suficient încât capul de

tăiere și lama să fie coborâte fără ca acestea fie blochate de alte

elemente ale fierăstrăului.

Pentru ajustarea apărătorii:

• Slăbiți șurubul cu cap crestat (Fig. 5).

• Glisați partea superioară a apărătorii spre stânga în poziția

dorită și strângeți șurubul.

• Faceți o testare în timp ce fierăstrăul este deconectat de la sursa

de alimentare pentru a confirma că nu există interferențe între

piesele fierăstrăului în timp ce capul de tăiere este coborât.

(8 .1)

INSTRUCȚIUNI DE UTILIZARE

Atenție: Fierăstrăul ar trebui verificat(în special pentru

funcționarea corectă a dispozitivelor de protecție) înainte de

fiecare utilizare. Nu conectați fierăstrăul la sursa de alimentare

până nu a fost efectuată o inspecție de siguranță.

Asigurați-vă că operatorii acestui produs sunt instruiți în mod

corespunzător în legătură cu utilizarea, reglarea și întreținerea

fierăstrăului înainte de a îl conecta la sursa de alimentare.

(8.2)

AVERTIZARE: Pentru a reduce riscul rănirii, deconectați

întotdeauna dispozitivul înainte de a schimba sau regla oricare

din piesele mașinii. Comparați direcția săgeții de rotație a

dispozitivului de protecție cu săgeata de direcție a lamei.

Dinții lamei trebuie să fie întotdeauna în jos spre partea din

față a fierăstrăului (Fig. 6). Verificați etanșeitatea șurubului

de fixare a lamei de tăiere.

Fig. 4

Fig. 5

Fig. 6

A B

Page 15

15

www.evolutionpowertools.com

EN

F

ig. 7

No-Hands Zone

No-Hands Zone

No-Hands Zone

No Hand s

Zone

(8.3)

POZIȚIONAREA CORPULUI ȘI A MÂINILOR (Fig. 7)

• Nu așezați niciodată mâinile în zona "NU ATINGEȚI"

(NO HANDS ZONE) (la cel puțin 150mm de lamă)

Țineți-vă mâinile departe de lamă.

• Poziționați piesa de lucru ferm pe masă și sprijiniți-o de

de apărătoare pentru a preveni orice mișcare.

• Dacă este posibil, utilizați o clemă de susținere, dar

verificați dacă este poziționată astfel încât să nu

interfereze traiectoria lamei sau a altor piese în mișcare.

• Evitați operarea din poziții incomode ale mâinilor; o

alunecare ar putea determina ca degetele sau o mână sa

intre în traiectoria lamei.

•

Înainte de a încerca o tăietură, faceţi o testare având

fierăstrăul decuplat de la alimentare pentru a observa

traiectoria lamei.

•

Ţineţi mâinile în poziţie până când comutatorul ON/OFF

a fost eliberat şi lama s-a oprit complet.

(8.4)

AJUSTAREA UNGHIURILOR DE PRECIZIE

Acest fierăstrău permite mai multe verificări/ajustări.

Este necesar un echer la unghi de 45°/45°/90° pentru a face

astfel de verificări(nu este inclus).

AVERTIZARE: Verificările/ajustările trebuiesc efectuate

numai cu fierăstrăul deconectat de la sursa de alimentare.

TĂIERE ÎN UNGHI (0° şi 45°)

0° AJUSTAREA UNGHIULUI

• Asigurați-vă că poziția capului de tăiere este închisă, cu

știftul de blocare cuplat la priză (Fig. 16)

• Asigurați-vă că poziția capului de tăiere este verticală,

în poziție oprit, iar indicatorul de înclinare indică 0° (Fig. 8).

• Așezați echerul cu o muchie scurtă pe masă și cu cealaltă

muchie scurtă spre lamă (fără a atinge dinții TCT) (Fig. 9).

• Dacă este la un unghi de 90° cu masa fierăstrălui, este

necesară ajustarea.

• Slăbiți mânerul de blocare și înclinați capul de tăiere

spre stânga.

• Slăbiți piulița de fixare a unghiului de tăiere cu o cheie de

10mm și o cheie Hex de 3mm (nu sunt incluse) (Fig. 10).

• Utilizați o cheie Hex pentru a înșuruba sau a ajusta

unghiul de tăiere al lamei.

• Întoarceți capul de tăiere în poziția verticală și verificați

din nou alinierea unghiului de tăiere cu echerul.

• Repetați pașii de mai sus până când se atinge un unghi

de tăiere corect.

• Strângeți bine piulița de blocare a unghiului de tăiere.

Fig. 8

Fig. 9

Fig. 10

Page 16

16

www.evolutionpowertools.com

45° Ajustarea Capului De Tăiere

• Slăbiți mânerul de blocare și înclinați capul de tăiere spre

stânga până când acesta se sprijină pe opritoul de 45°.

• Utilizați un echer(evitând vârfurile TCT ale lamei de tăiere) și

verificați dacă lama este la 45° față de masă.

• Faceți ajustările de rigoare dacă lama de fierăstrău nu este

poziționată la unghiul dorit.

•Întoarceți capul de tăiere în poziția verticală.

• Slăbiți piulița de fixare pentru înclinarea la 45° cu ajutorul

unei chei de 10mm și a unei chie Hex de 3mm (nu sunt furnizate).

• Utilizați o cheie Hex pentru a regla sau a înșuruba șurubul de

reglare, după cum este necesar (Fig. 11).

• Înclinați capul de tăiere la un unghi de 45° și verificați din nou

alinierea cu ajutorul unui raportor.

• Repetați pașii de mai sus până când a-ți aliniat capul de tăiere

la un unghi potrivit.

• Strângeți bine piulița de fixare dupa ce ați terminat alinierea.

DEPLASAREA CAPULUI DE TĂIERE

Ajustarea Mișcării În Jos A Capului De Tăiere

Pentru a preveni ca lama de tăiere să intre în contact cu orice

alt component al fierăstrăului, mișcarea în jos a capului de tăiere

poate fi ajustată. Coborâți capul de tăiere și verificați orice

contact al lamei de tăiere cu baza fierăstrăului.

Dacă este necesară reglarea deplasării în jos a capului de tăiere:

• Slăbiți piulița de blocare a deplasării în jos cu ajutorul unei chei

de 10mm (nu este furnizată) (Fig. 12A).

• Rotiți șurubul de reglare (Fig. 12b) înspre afară (în sens contrar

acelor de ceasornic) cu o cheie Hex de 5mm (nu este furnizată)

pentru a reduce deplasarea în jos a capului de tăiere.

• Rotiți șurubul de reglare (în sensul acelor de ceasornic) pentru

a crește lungimea de deplasare în jos a capului de tăiere.

• Strângeți șurubul de breglare atunci când deplasarea capului

este una pe placul dumneavoastră.

ALINIEREA APĂRĂTORII

Apărătoarea trebuie aliniată la un unghi de 90° având o lamă de

tăiere instalată corect. Masa rotativă trebuie setată la un unghi

de tăiere de 0°.

Notă: Apărătoarea este fixată de baza fierăstrăului cu două șuruburi

Hex poziționate la fiecare capăt al apărătorii (Fig. 13).

• Asigurați-vă că poziția capului de tăiere este cea în blocare,

știftul de blocare complet cuplat în soclul său (Fig. 16).

• Plasați un echer cu o margine scurtă de apărătoare și cealaltă

de lamă (evitând vârfurile TCT ale dinților lamei) (Fig. 14).

• Acest proces se repetă pentru ambele părți ale lamei.

Fig. 11

Fig. 12A + 12B

Fig. 13

Fig. 14

A

B

Page 17

17

www.evolutionpowertools.com

EN

•Pentru ajustări, slăbiți cele două șuruburi de fixare a

apărătorii folosind o cheie Hex de 5mm (nu este furnizată).

• Repoziționați apărătoarea în fantele sale până când

alinierea este completă.

• Strângeți ferm șuruburile Hex.

RAPORTORUL ȘI IDICATORULUI UNGHIULUI

Note: Un raportor ce măsoară două unități de măsură este

încastrat la baza mesei de tăiere a fierăstrăului(pe dreapta).

O mică săgeată indică unghiul selectat (Fig. 15).

VERIFICĂRILE FINALE

Parcurgeți următorii pași având fierăstrăul oprit și decuplat

de la sursa de alimentare(după efectuarea tuturor

ajustărilor);

• Ridicați capul de tăiere până la maxim.

• Coborâți capul de tăiere până în poziția cea mai joasă

și rotiți manual lama(este recomandat sa purtați mănuși)

și asigurați-vă că lama nu intră în contact cu nici o altă

piesă a fierăstrăului, inclusiv cu apărătoarea.

(8.5)

PREGĂTIREA PENTRU O TĂIERE

AVERTISMENT: Nu vă întindeți.

Mențineți-vă echilibrul. Poziționați-vă într-o parte, astfel încât

fața și corpul dumneavoastră să fie ferite de un recul al

capului de tăiere.

Tăierile realizate folosind o singură mână sunt o cauză

principală a accidentărilor și nu trebuie încercate.

• Asigurațivă că piesa de prelucrat este intotdeauna sprijinită

de apărătoare și, dacă este posibil, este de asemenea

fixată de masă cu ajutorul clemei de susținere.

• Masa de fierăstrău trebuie să fie curată și lipsită de rumeguș

înainte ca piesa de prelucrat să fie fixată în poziție.

• Asigurați-vă că materialul tăiat se poate mișca departe de

lamă după tăiere. Asigurați-vă că piesa tăiată nu se poate

înțepeni între piesele fierăstrăului.

• Nu folosiți acest fierăstrău pentru a prelucra piese de mici

dimensiuni. Dacă este nevoie să vă apropiați degetele la

o distanță de 150mm înseamnă că piesa de prelucrat

este prea mică.

(8.6)

ELIBERAREA CAPULUI DE TĂIERE

Capul de tăiere va urca automat în poziția sa superioară

odată ce este eliberat din poziția de blocat. Capul de tăiere

se va putea bloca astfel în poziția sa superioară.

Fig. 15

Fig. 16

Page 18

18

www.evolutionpowertools.com

Pentru a elibera capul de tăiere din poziția sa de blocare

în jos:

• Apăsați ușor pe mânerul de tăiere.

• Trageți de bolțul blocant (Fig. 16) și lăsați capul de tăiere

să se ridice.

Dacă aveți dificultăți în a elibera capul de tăiere:

• Mișcați repetat capul de tăiere de sus în jos.

• În același timp răsuciți bolțul blocant în sensul acelor de

ceasornic și trageți-l în înspre exterior.

Notă: Vă recomandam ca atunci când nu folosiți fierăstrăul

capul de tăiere să fie blocat în poziția sa în jos, cu bolțul

blocant este introdus complet în soclul său.

BUTONUL DE PORNIRE/OPRIRE AL MOTORULUI (Fig. 17)

Butonul de PORNIRE/OPRIRE al motorului funcționează ca

un comutator ce nu se blochează.

El este poziționat în mânerul capului de tăiere.

• Apăsați butonul pentru a pune în funcțiune motorul.

• Eliberați butonul pentru a scoate din funcțiune motorul.

TĂIEREA DREAPTĂ

Acest tip de tăiere este destinat secționării materialelor de

mici dimensiuni sau a celor subțiri. Capul de tăiere este

împins ușor în jos pentru a realiza tăietura.

• Așezați piesa de lucru pe masa rotativă sprijinind-o de

apărătoare și fixați-o cu clema.

• Apucați mânerul capului de tăiere.

• Porniți motorul și lăsați lama de tăiere să iși atingă

viteza maximă.

• Apăsați pe maneta de blocare a apărătorii inferioare a

capului de tăiere (Fig. 18).

• Coborâți capul de tăiere în jos și tăiați piesa de lucru.

• Lăsați viteza lamei de tăiere să pătrundă prin piesa de

prelucrat, nu este nevoie să apăsați pe capul de tăiere.

• Când tăietura a fost finalizată, eliberați comutatorul de

PORNIRE/OPRIRE.

• Lăsați lama să se oprească complet.

• Lăsați capul de tăiere să se ridice în poziția sa superioară și

ca protecția inferioară a lamei să o acopere complet. Lăsați

capul de tăiere să se blocheze în poziția sa superioară

înainte de a lua mâinile de pe mânerul capului de tăiere.

• Scoateți piesa de prelucrat.

TĂIEREA LA UNGHI (Fig. 19)

Masa rotativă poate fi rotită poate fi rotită la un unghi de 50°

la stânga sau la dreapta de la poziția normală de tăiere (0°).

Fig. 17

Fig. 18

Fig. 19

Fig. 20

Page 19

19

www.evolutionpowertools.com

EN

Masa rotativă se oprește automat la unghiurile de 45

°, 30°,

22.5°, 15° și 0° și permite utilizarea cu mâna stângă și cea

dreaptă.

• Slăbiți șurubul de blocare al mesei rotative (Fig. 20)

rotindu-l în sens invers acelor de ceasornic.

• În acest moment masa rotativă se poate roti la unghiul

dorit. Un raportor ce ajută la setarea unghiurilor este

încorporat în masa rotativă.

• Strângeți șurubul de blocare al mesei rotative după ce

selectați unghiul dorit.

AVERTISMENT: Este important să strângeți șurubul de

blocare a mesei rotative chiar li dacă ea s-a blocat automat.

ÎNCLINAREA PE LATERALĂ A CAPULUI DE TĂIERE

Tăieturile drepte(Fig. 21) sunt realizate atunci când capul de

tăiereie se află la un unghi de inclinație de 0°.

Notă: Pentru a asigura un spațiu suficient între lamă,

apărătoare și șanțul din masa rotativă, ar putea fi necesar

să ajustați secțiunea superioară a apărători (Vezi Pag. 16).

Capul de tăiere poate fi înclinat de la unghiul normal de 0°

(poziție perpendiculară) până la un unghi maxim de 45°

spre partea stângă.

Pentru a înclina capul de tăiere spre stânga:

• Slăbiți șurubul de blocare al capului de tăiere (Fig. 22).

• Înclinați capul de tăiere la unghiul dorit. O scală de

măsurare este încastrată pentru a vă ajuta la reglarea

unghiului de tăiere (Fig. 23).

• Strângeți șurubul de blocare al capului de tăiere odată

ce unghiul de tăiere dorit a fost selectat.

După ce tăierea a fost finalizată.

• Eliberați comutatorul ON/OFF, însă păstrați-vă mâinile

în aceeași poziție până când lama s-a oprit complet.

• Lăsați capul de tăiere să se ridice în poziția superioară

și protecția lamei să o acopere înainte de a vă îndepărta

mâinile de fierăstrău.

• Reglați capul de tăiere înapoi în poziția sa perpendiculară

de masa rotativă.

• Strângeți șurubul de blocare al capului de tăiere.

(8.7) TĂIERILE COMBINATE (Fig. 24)

O tăiere combinată este o tăiere în care se modifică unghiurile de tăiere ale capului de tăiere și a mesei rotative. Atunci

când este necesară o tăiere combinată, selectați pozițiile

dorite așa cum a fost descris anterior.

AVERTISMENT:

Verificați întotdeauna dacă lama de tăiere intră în contact

cu apărătorii sau ale altor piese. Faceți o probă având fieră-

străul deconectat de la sursa de alimentare.

Ajustați secțiunea superioară a apărătorii dacă este necesar.

Fig. 21

Fig. 22

Fig. 23

Fig. 24

Page 20

20

www.evolutionpowertools.com

(8.8)

TĂIEREA OBIECTELOR ÎNDOITE (Fig. 25)

Înainte de a realiza tăieturi, verificați dacă piesa de prelucrat

este îndoită. Dacă piesa este îndoită, ea trebuie poziționată și

tăiată după cum se arată în imagine. Nu poziționați incorect

piesa și nu o tăiați fără a o sprijini de apărătoare.

(8.9)

CURĂȚAREA DE MATERIALE BLOCATE

• Opriți fierăstrăul eliberând comutatorul de pornire.

• Lăsați lama să se oprească complet.

• Decuplați fierăstrăul de la sursa de alimentare.

• Îndepărtați cu grijă orice material blocat.

• Verificați în ce condiție se află apărătoarea.

• Verificați orice alt tip de deteriorare a oricărui component

al fierăstrăului (ex. lama de tăiere).

• Apelați la un tehnician competent pentru a înlocui

componente defecte și realizați o inspecție de siguranță

înainte de a reporni fierăstrăul.

(8.10)

SUSȚINEREA PIESELOR DE LUCRU LUNGI

Capătul piesei de prelucrat care nu este fixat ar trebui să fie

susținut la aceeași înălțime cu masa de prelucrat a fierăstrăului.

Operatorul fierăstrăului trebuie să ia în considerare utilizarea

unui suport suplimentar, dacă acest lucru este necesar.

(8 .11)

INSTALAREA SAU ÎNLĂTURAREA LAMELOR

Avertisment: Realizați această operațiune numai atunci

când fierăstrăul este deconectat de la sursa de alimentare.

Notă: Este recomandat ca operatorul să poarte mănuși

de protecție atunci când schimbă lama de tăiere.

Avertisment: Utilizați numai lame de tăiere marca Evolution

sau lame recomandate de Evolution Power Tools și care

sunt proiectate special pentru acest fierăstrău. Asigurați-vă

că viteza maximă de rotație a lamei o depășește pe cea a

motorului fierăstrăului.

Notă: Inserțiile folosite pentru montarea unor discuri

cu un diametru interior mai mic decât al celui aprovizionat

trebuiesc folosite în concordanță cu instrucțiunile oferite

de către producător(nu sunt aprovizionate).

Avertisment: Axul fierăstrăului prezintă un șurub de blocare

ce poate fi rotit cu mâna stângă. Rotiți șurubul în sensul acelor

de ceasornic pentru a îl elibera și împotriva sensului acelor

de ceasornic pentru a îl strânge. Țineți apăsat pe butonul de

blocare al axului (aflat pe carcasa motorului) în timp ce rotiți

imbusul aprovizionat până când butonul de blocare intră până la

capăt în carcasa motorului și blochează axul său (Fig. 26).

Continuați să deșurubați șurubul de strângere până ce acesta

iese din carcasa motorului împreuna cu șaiba sa (Fig. 27).

Eliberați butonul de blocare al axului.

Fig. 25

Fig. 26

Fig. 27

Page 21

21

www.evolutionpowertools.com

EN

• Asigurați-vă că lama de tăiere și marginile sale sunt

curate și lipsite de impurități.

• Șaiba interioară ar trebui lăsată în poziția sa. Dacă

aceasta trebuie curățată ea trebuie montată în poziția

sa inițială.

Pentru a monta o lamă, apăsați piedica de eliberare a

protecției inferioară a lamei (A) și rotiți protecția inferioară (B)

până când ajunge în protecția superioară a lamei (Fig. 28).

Montați noua lamă în locul său asigurându-vă că aceasta

este așezată corect și apoi eliberați încet protecția inferioară

a lamei de tăiere.

Asigurați-vă că săgeata de rotație a lamei (A) este aceași

cu cea aflată pe suprafața protecției superioare a lamei.

Notă: Dinții lamei trebuiesc întotdeauna să fie îndreptați

în jos către partea frontală a fierăstrăului.

Montați șaiba exterioară (1) (cu partea lată spre fierăstrău),

șaiba interioară (2) și șurubul axului (3) (Fig. 30).

Țineți apăsat pe buton de blocare al axului poziționat pe

carcasa motorului în timp ce strângeți șurubul axului folosind

imbusul aprovizionat până când butonul intră în întregime

locul său și blocând axul (Fig. 26).

Strângeți șurubul axului cu ajutorul imbusului aplicând o

forță moderată, fără a strânge prea tare. Asigurați-vă că

imbusul este scos și că butonul de eliberare al axului

este eliberat. Asigurați-vă că protecția inferioară a lamei

este funcțională înainte de a folosi fierăstrăul.

(8 .12)

FOLOSIREA DE ACCESORII OPȚIONARE

MARCA EVOLUTION

Nu sunt aprovizionate împreuna cu pachetul de livrare

(vezi Accesorii Opționale).

(8 .13) SACUL DE PRAF

Un sac de praf poate fi montat în orificiul de extracție al

reziduurilor aflat în spatele fierăstrăului. Sacul de praf

poate fi utilizat numai pentru tăierea lemnului.

• Sacul de praf poate fi montat deasupra orificiului de

extracție a prafului având clema de strângere fixată

ferm (Fig. 31).

Notă: Pentru a avea eficiență în lucru, goliți sacul de

praf atunci când este plin în proporție de 2/3. Scoateți

conținutul sacului de praf într-un mod responsabil față de

mediu. În unele cazuri ar putea fi necesar să purtați o mască

de praf atunci când goliți sacul.

Notă: Orificiul de extracție al reziduurilor poate fi conectat

la un aspirator special dacă este nevoie. Urmați instrucțiunile

producătorului aspiratorului dacă doriți acest lucru.

AVERTISMENT: Nu utilizați sacul de praf atunci când

tăiați materiale metalice.

Fig. 28

Fig. 31

A

B

Fig. 29

A B

(1)

(2) (3)

Fig. 30

(1)

(2) (3)

Page 22

22

www.evolutionpowertools.com

(6 .1)

MAINTENANCE

Note: Any maintenance must be carried

outwiththemachineswitchedoand

disconnected from the mains/battery power

supply. Check that all safety features and

guards operating correctly on a regular basis.

Only use this machine if all guards/safety

features are fully operational. All motor

bearings in this machine are lubricated for life.

No further lubrication is required.

Use a clean, slightly damp cloth to clean

the plastic parts of the machine. Do not use

solvents or similar products which could

damage the plastic parts.

WARNING: Do not attempt to clean by

inserting pointed objects through openings

in the machines casings etc. The machines air

vents should be cleaned using compressed

dry air. Excessive sparking may indicate the

presence of dirt in the motor or worn out

carbon brushes.

(6.2)

If this is suspected have the machine serviced

and the brushes replaced by a qualied

technician.

(6.4)

ENVIRONMENTAL PROTECTION

Waste electrical products should not be

disposed of with household waste.

Please recycle where facilities exist.

Check with your local authority or retailer for

recycling advice.

Page 23

23

www.evolutionpowertools.com

EN

EC DECLARATION OF CONFORMITY

The manufacturer of the product covered by this Declaration is:

Evolution Power Tools, Venture One, Longacre Close, Holbrook Industrial Estate, Sheffield, S20 3FR.

The manufacturer hereby declares that the machine as detailed in this declaration fulfils all the

relevant provisions of the Machinery Directive and other appropriate directives as detailed below.

The manufacture further declares that the machine as detailed in this declaration, where applicable,

fulfils the relevant provisions of the Essential Health and Safety requirements.

The Directives covered by this Declaration are as detailed below:

2006/42/EC. Machinery Directive.

2014/30/EU. Electromagnetic Compatibility Directive.

2011/65/EU. The Restriction of the Use of certain Hazardous

Substances in Electrical Equipment (RoHS) Directive.

2012/19/EU. The Waste Electrical and Electronic Equipment (WEEE) Directive.

And is in conformity with the applicable requirements of the following documents:

EN61029-1:2009+A11 • EN 61029-2-9:2012+A11 • EN55014-1:2006+A1+A2

EN55014-2: 2015 • EN61000-3-2:2014 • EN61000-3-11: 2000 • EN ISO 12100:2010

Product Details

Description: R210CMS 210mm MULTIPURPOSE COMPOUND MITRE SAW

Evolution Model No: 230v: R210CMS / F210CMS / 0460001 / 0460001A / 0460003

0460003A / 0460006 / 0460008

110V: 0460002 / 0460002A / 0460007

Brand Name: EVOLUTION

Voltage: 230-240V / 110V ~ 50 Hz

Input: 1200W

The technical documentation required to demonstrate that the product meets the requirements

of directive has been compiled and is available for inspection by the relevant enforcement

authorities, and verifies that our technical file contains the documents listed above

and that they are the correct standards for the product as detailed above.

Name and address of technical documentation holder.

Signed: Print: Matthew Gavins: Group Chief Executive.

Date: 01/04/2016

The place of keeping technical documents: Venture One, Longacre Close, Sheffield, S20 3FR

Page 24

Discover Evolution Power Tools

Visit: www.evolutionpowertools.com

or download a QR Reader App on your

smart phone and scan the QR code (right).

UK

Evolution Power Tools Ltd

Venture One

Longacre Close

Holbrook Industrial Estate

Sheffield

S20 3FR

+44 (0)114 251 1022

US

Evolution Power Tools LLC

8363 Research Drive

Davenport

Iowa

52806

+1 866-EVO-TOOL

EU

Evolution Power Tools SAS

61 Avenue Lafontaine

33560

Carbon-Blanc

Bordeaux

+ 33 (0)5 57 30 61 89

V1.1

R210CMS QR CODE

Loading...

Loading...