Page 1

UK FR

P2 P18

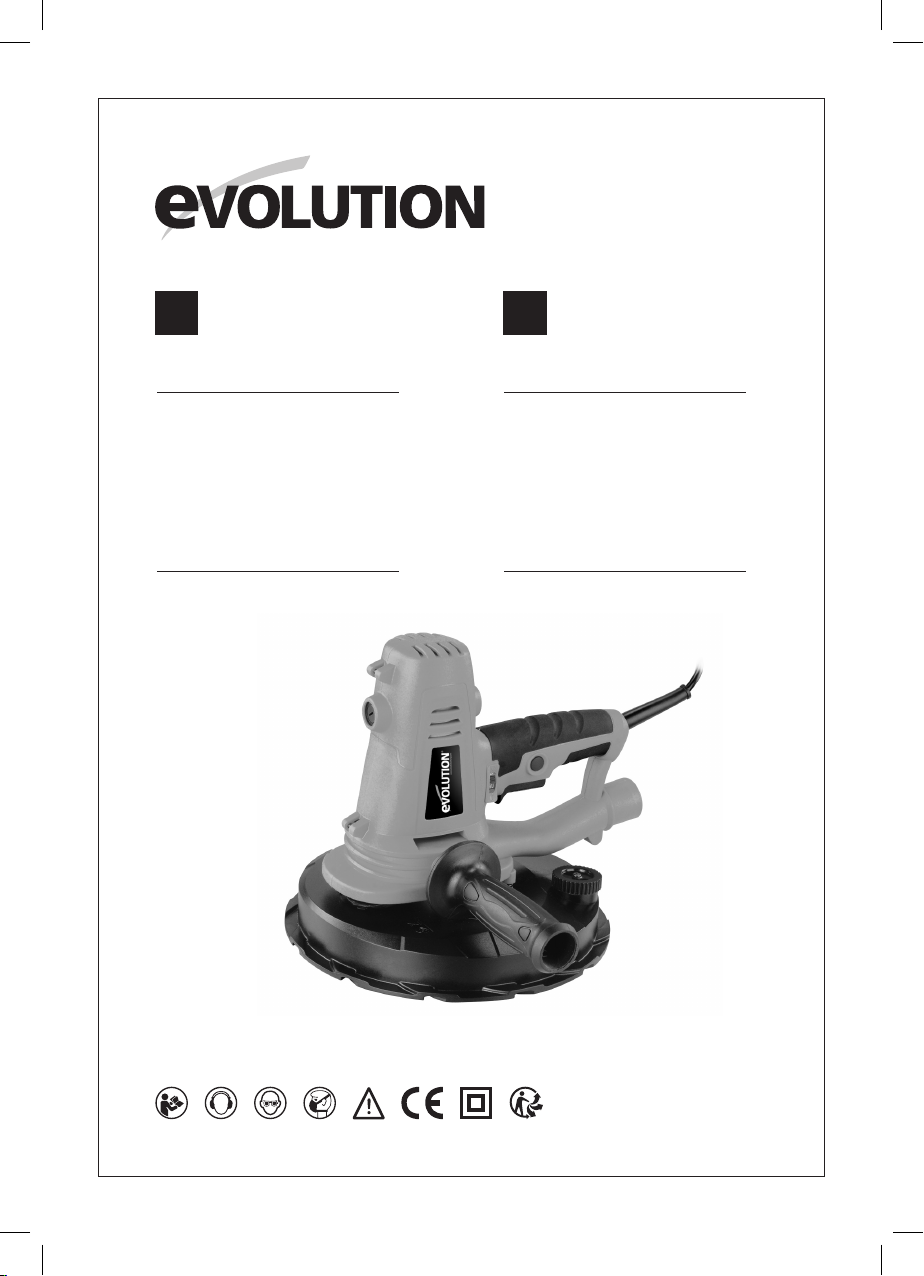

22 5mm HAND-HEL D DRYWAL L SANDE R

PONCEUSE DE CLOISONS SÈCHES À MAIN DE 225 MM

Instruction

Manual

Read instructions before operating this tool.

Manuel

d’Instruction

Merci de lire ces instructions avant d’utiliser l’outil

Original written in UK English Date Published: 01/03/2016

www.evolutionbuild.com

Page 2

®

BUILD

UK

Evolution Power Tools reserves the right to make improvements and modifications

to the design and technical specification of this product without prior notification.

DRYWALL SANDER - SPECIFICATIONS

Power (230V ~ 50Hz) (Watts): 1050

RPM Rated speed (min-1): 1500-2300

Recommended Maximum Duty Cycle (Minutes): 30

Abrasive paper size (Diametre mm): 225

Dust extraction hose length (metres): 2

Weight (kg): 2.8

Noise and Vibration Data:

Sound Pressure LPA: 88dB(A) K=3dB(A)

Sound Power Level LWA: 99dB(A) K=3dB(A)

Vibration Level: 4.915m/s

INFORMATION:

- that the deciared vibration total value has been measured in accordance with

a standard test method and may be used for comparing one tool with another;

- that the deciared vibration total value may also be used in a preliminar y assessment of exposure

WARNING:

- that the vibration emission during actual use of the power tool can differ from the declared

total value depending on the ways in which the tool is used; and

- of the need to identify safety measures to protect the operator that are based on an estimation of

exposure in the actual conditions of use (taking account of all par ts of the operating cycle such as

the times when the tool is switched off and when it is running idle in addition to the trigger time).

2

www.evolutionbuild.com

2

K=1.5m/s

2

Page 3

HAND HELD DRYWALL SANDER

TABLE OF CONTENTS

Important Information 03

Evolution Limited Guarantee 03

General Safety Rules 04

Safety Precautions for Drywall Sanders 06

Labels and Symbols 09

Machine Overview 11

Operation 12

Maintenance 15

Environmental Protection 16

EC - Declaration of Conformity 17

IMPORTANT

IMPORTANT

UK

Please read these operating and

safety instructions carefully and

completely. For your own safety, if

you are uncertain about any aspect of using

this equipment please access the relevant

Technical Helpline, the number of which can be

found on the Evolution Power Tools website.

We operate several Helplines throughout our

worldwide organization, but technical help is

also available from your supplier.

UK: +44 (0)114 251 1022

www.evolutionpowertools.com/register

Congratulations on your purchase of an

Evolution Power Tools Machine. Please

complete your product registration ‘online’

as explained in the A4 online guarantee

registration leaflet included with this

machine. You can also scan the QR code

found on the A4 leaflet with a Smart

Phone. This will enable you to validate your

machine’s guarantee period via Evolution’s

website by entering your details and thus

ensure prompt service if ever needed. We

sincerely thank you for selecting a product

from Evolution Power Tools.

EVOLUTION LIMITED GUARANTEE

Evolution Power Tools reserves the right

to make improvements and modifications

to the product design without prior notice.

Please refer to the guarantee registration

leaflet and /or the packaging for details of

the terms and conditions of the guarantee.

Evolution Power Tools will, within

the guarantee period, and from the original

date of purchase, repair or replace any

goods found to be defective in materials or

workmanship. This guarantee is void if the

tool being returned has been used beyond the

recommendations in the Instruction Manual

or if the machine has been damaged by

accident, neglect, or improper service.

This guarantee does not apply to machines

and / or components which have been altered,

changed, or modified in any way, or subjected

to use beyond recommended capacities

and specifications. Electrical components

are subject to respective manufacturers’

warranties. All goods returned defective shall

be returned prepaid freight to Evolution Power

Tools. Evolution Power Tools reserves the

right to optionally repair or replace it with the

same or equivalent item.

There is no warranty – written or verbal –

for consumable accessories such as

(following list not exhaustive) blades, cutters,

drills, chisels or paddles etc. In no event shall

Evolution Power Tools be liable for loss or

damage resulting directly or indirectly from

the use of our merchandise or from any other

cause. Evolution Power Tools is not liable

for any costs incurred on such goods

or consequential damages.

No officer, employee or agent of Evolution

Power Tools is authorized to make oral

representations of fitness or to waive any

of the foregoing terms of sale and none

shall be binding on Evolution Power Tools.

www.evolutionbuild.com

3

Page 4

BUILD

®

Questions relating to this limited

guarantee should be directed to the

company’s head office, or call the

appropriate Helpline number.

IMPORTANT SAFETY INSTRUCTIONS

IMPORTANT SAFETY INSTRUCTIONS

UK

To reduce the risk of electric shock, this

equipment is fitted with an approved cord

and plug for its intended country of use. Do

not change the cord or plug in any way.

GENERAL SAFETY RULES

GENERAL SAFETY RULES

UK

Read and understand all instructions

before operating this product. Failure

to follow all instructions listed below

may result in electric shock, fire and

/ or serious personal injury. SAVE

THESE INSTRUCTIONS FOR FUTURE

REFERENCE.

WARNING: When using electric tools

basic safety precautions should always be

followed to reduce the risk of fire, electric

shock and personal injury.

POWER TOOL GENERAL SAFETY

INSTRUCTIONS

(These General Power Tool Safety

Instructions are as specified in BS EN

60745-1:2009 & EN 61029-1:2009)

WARNING: Read all safety warnings and

instructions. Failure to follow the warnings

and instructions may result in electric shock,

fire and/ or serious injury.

Save all warnings and instructions for

future reference.

The term “power tool” in the warnings refers

to your mains-operated (corded) power tool

or battery-operated (cordless) power tool.

1) General Power Tool Safety Warnings

[Work area safety]

a) Keep work area clean and well lit.

Cluttered or dark areas invite accidents.

b) Do not operate power tools in

explosive atmospheres, such as in the

presence of flammable liquids, gasses or

dust. Power tools create sparks which may

ignite the dust or fumes.

c) Keep children and bystanders away

while operating power tool. Distractions

can cause you to lose control.

2) General Power Tool Safety Warnings

[Electrical Safety]

a) Power tool plugs must match the

outlet. Never modify the plug in any

way. Do not use any adapter plugs

with earthed (grounded) power tools.

Unmodified plugs and matching outlets will

reduce the risk of electric shock.

b) Avoid body contact with earthed

or grounded surfaces, such as pipes,

radiators, ranges and refrigerators. There

is an increased risk of electric shock if your

body is earthed or grounded.

c) Do not expose power tools to rain or

wet conditions. Water entering a power

tool will increase the risk of electric shock.

d) Do not abuse the cord. Never use the

cord for carrying, pulling or unplugging

the power tool. Keep cord away from

heat, oil, sharp edges or moving parts.

Damaged or entangled cords increase the

risk of electric shock.

e) When operating a power tool outdoors,

use an extension cord suitable for outdoor

use. Use of a cord suitable for outdoor use

reduces the risk of electric shock.

f) If operating a power tool in a damp

location is unavoidable, use a residual

current device (RCD) protected supply.

Use of an RCD reduces the risk of

electric shock.

4

www.evolutionbuild.com

Page 5

HAND HELD DRYWALL SANDER

3) General Power Tool Safety Warnings

[Personal Safety].

a) Stay alert, watch what you are doing

and use common sense when operating a

power tool. Do not use a power tool while

you are tired or under the influence of

drugs, alcohol or medication. A moment of

inattention while operating power tools may

result in serious personal injury.

b) Use personal protective equipment.

Always wear eye protection. Protective

equipment such as dust masks, non-skid

safety shoes, hard hat or hearing protection

used for appropriate conditions will reduce

personal injuries.

c) Prevent unintentional starting. Ensure

the switch is in the off-position before

connecting to power source and or

battery pack, picking up or carrying the

tool. Carrying power tools with your finger

on the switch or energising the power tools

that have the switch on invites accidents.

d) Remove any adjusting key or wrench

before turning the power tool on. A

wrench or key left attached to a rotating part

of a power tool may result in personal injury .

e) Do not overreach. Keep proper

footing and balance at all times. This

enables better control of the power tool in

unexpected situations.

f) Dress properly. Do not wear loose

clothing or jewellery. Keep your hair,

clothing and gloves away from moving

parts. Loose clothes, jewellery or long hair

can be caught in moving parts.

g) If devices are provided for the

connection of dust extraction and

collection facilities, ensure that these are

connected and properly used. Use of dust

collection can reduce dust-related hazards.

dangerous and must be repaired.

c) Disconnect the power tool from

the power source and/or battery pack

from the power tool before making any

adjustments, changing accessories, or

storing power tools. Such preventative

safety measures reduce the risk of starting

the power tool accidentally.

d) Store idle power tools out of the

reach of children and do not allow

persons unfamiliar with the power tool

or these Instructions to operate the

power tool. Power tools are dangerous in

the hands of untrained users.

e) Maintain power tools. Check for

misalignment or binding of moving

parts, breakage of moving parts and

any other condition that may affect

the power tools operation. If damaged,

have the power tool repaired before

use. Many accidents are caused by poorly

maintained power tools.

f) Keep cutting tools sharp and clean.

Properly maintained cutting tools with sharp

cutting edges are less likely to bind and are

easier to control.

g) Use the power tool, accessories and

tool bits etc. in accordance with these

instructions, taking into account the

working conditions and the work to

be performed. Use of the power tool for

operations different from those intended

could result in a hazardous situation.

5) General Power Tool Safety Warnings

[Service]

a) Have your power tool serviced by a

qualified repair person using only identical

replacement parts. This will ensure that the

safety of the power tool is maintained.

4) General Power Tool Safety Warnings

[Power tool use and care].

a) Do not force the power tool. Use the

correct power tool for your application.

The correct power tool will do the job better

and safer at a rate for which it was designed.

b) Do not use the power tool if the switch

does not turn it on or off. Any power tool

that cannot be controlled with the switch is

www.evolutionbuild.com

HEALTH ADVICE

HEALTH ADVICE

UK

WARNING: When drilling, sanding, sawing

or grinding, dust particles will be produced.

In some instances, depending on the

materials you are working with, this dust

can be particularly harmful to you (e.g.

lead from old gloss paint).You are advised

to consider the risks associated with the

5

Page 6

BUILD

®

materials you are working with and to

reduce the risk of exposure. Some wood

and wood type products, especially MDF

(Medium Density Fibreboard), can produce

dust that may be hazardous to your health.

We recommend the use of an approved

face mask with replaceable filters when

using this machine, in addition to using the

dust extraction facility.

You should always:

• Workinawell-ventilatedarea.

• Workwithapprovedsafetyequipment,

such as dust masks that are specially

designed to filter microscopic particles.

WARNING: If you suspect that paint on

surfaces in your home contains lead, seek

professional advice. Lead based paints

should only be removed by a professional

and you should not attempt to remove it

yourself. Once the dust has been deposited

on surfaces, hand to mouth contact can result

in the ingestion of lead. Exposure to even

low levels of lead can cause irreversible brain

and nervous system damage. The young and

unborn children are particularly vulnerable.

VIBRATION

VIBRATION

UK

WARNING: When using this machine the

operator can be exposed to high levels

of vibration transmitted to the hand and

arm. It is possible that the operator could

develop “Vibration white finger disease”

(Raynaud syndrome). This condition

can reduce the sensitivity of the hand to

temperature as well as producing general

numbness. Prolonged or regular users

of sanding machines should monitor

the condition of their hands and fingers

closely. If any of the symptoms become

evident, seek immediate medical advice.

• Themeasurementandassessmentof

human exposure to hand-transmitted

vibration in the workplace is given in:

BS EN ISO 5349-1:2001 and BS EN ISO

5349-2:2002

• Manyfactorscaninuencetheactual

vibration level during operation e.g the

work surfaces condition and orientation

and the type and condition of the abrasive

disc being used. Before each use, such

factors should be assessed, and where

possible appropriate working practices

adopted. Managing these factors can help

reduce the effects of vibration:

Handling

Handle the machine with care, allowing

the machine to do the work.

Avoid using excessive physical effort on

any of the machines controls.

Consider your security and stability, and

the orientation of the machine during use.

Work Surface

Consider the work surface material; its

condition, density, strength, rigidity and

orientation.

ADDITIONAL SAFETY INSTRUCTIONS

FOR DRYWALL SANDERS

WARNING: Be sure to read and

understand all instructions. Failure

to follow all instructions listed below

may result in electric shock, fire and/or

serious personal injury.

1. Know your power tool. Read operator’s

manual carefully. Learn the applications and

limitations, as well as the specific potential

hazards related to this tool.

2. Always wear safety glasses or eye

shields when using this machine.

Everyday eyeglasses have only impactresistant lenses; they are not safety glasses.

3. Always protect your lungs. Wear a

face mask or dust mask that is specially

designed to filter microscopic particles. Do

not use any Drywall Sander if it is suspected

that asbestos or lead could be present

in the wall material. Contact the relevant

authorities for advice.

4. Always protect your hearing. Wear

hearing protection during extended periods

of operation. Wear other PPE (Personal

6

www.evolutionbuild.com

Page 7

HAND HELD DRYWALL SANDER

Protection Equipment) as may be necessary

for the job at hand. If unsure, consult

competent advice from a supervisor or

other responsible person.

5. Inspect the machines power cord

regularly and if damaged have it

repaired or replaced. Always be aware

of the power supply cords location and

routing. Ensure that the power cord is safely

routed and cannot be damaged in any way

by contact with sharp or heavy objects etc.

Ensure that the power cord route does not

pose a ‘trip hazard’.

6. Always check for damaged parts.

Before further use of the tool, a guard

or other part that is damaged should be

carefully checked to determine if it will

operate properly and perform its intended

function. Check for misalignment or binding

of moving parts, breakage of parts, and

any other condition that may affect the

tool’s operation. A guard or other part that

is damaged should be properly repaired or

replaced at a qualified service centre.

7. Do not abuse the power supply cord.

Never use the cord to carry the tools or pull

the plug from the outlet. Keep cord away from

heat, oil, sharp edges or moving parts. Replace

damaged cords immediately. Damaged cords

increase the risk of electric shock.

8. Always make sure that any extension

cord you use is in good condition, and if

used outdoors is of a suitable type, and

so labelled. When using an extension cord

be sure to use one that is heavy enough to

carry the current that your tool will draw.

An undersized cord will cause a drop in

line voltage, resulting in loss of power and

possible overheating.

9. Do not use the tool while tired or

under the influence of drugs, alcohol or

any medication. Following this rule will

reduce the risk of electric shock, fire or

serious personal injury.

10. Save these instructions. Refer to

them frequently and use them to instruct

others who may use this tool. If someone

borrows this tool, make sure they have

these instructions also.

11. Ensure that the operator is adequately

trained in the use adjustment and

operation and operation of the machine.

All operators should have read and understood

the instructions contained within this manual,

before commencing operations.

12. Ensure that the workplace lighting

is adequate, and/or provide extra

lighting for the immediate work area.

Poorly illuminated workplaces are inherently

dangerous.

13. Keep the work area well ventilated.

If possible open some windows and put an

exhaust fan in one of them to move air from

the inside to the outside. Post WARNING

notices to alert bystanders that potentially

hazardous operations are taking place nearby.

14. Use a vacuum dust extraction

machine in conjunction with this sander.

The workplace should be kept as clean and

dust free as possible. A dust filled room has

an explosive potential.

15. Ensure that there are no sources of

ignition nearby. Dust suspended in the air

has an explosive potential.

16. Do not connect a domestic vacuum

cleaner to this machine. A domestic

vacuum cleaner is not suitable for the

collection of drywall dust particles.

SAFETY INSTRUCTIONS FOR ALL OPERATIONS

UK

Safety Warnings Common

for Sanding Operations:

a) This power tool is intended to

function as a sander tool. Read

all safety warnings, instructions,

illustrations and specifications

provided with this power tool.

Failure to follow all instructions listed below

may result in electric shock, fire and/or

serious injury.

b) Operations such as grinding, sanding,

wire brushing, polishing or cutting-off

are not recommended to be performed

with this power tool. Operations for

which the power tool was not designed may

create a hazard and cause personal injury.

www.evolutionbuild.com

7

Page 8

BUILD

®

c) Do not use accessories which are not

specifically designed and recommended

by the tool manufacturer. Just because

the accessory can be attached to your

power tool, it does not assure safe

operation.

d) The rated speed of the accessory

must be at least equal to the maximum

speed marked on the power tool.

Accessories running faster than their rated

speed can break and fly apart.

e) The outside diameter and the

thickness of your accessory must be

within the capacity rating of your power

tool. Incorrectly sized accessories cannot

be adequately guarded or controlled.

f) The arbour size of wheels, flanges,

backing pads or any other accessory

must properly fit the spindle of the

power tool. Accessories with arbour holes

that do not match the mounting hardware

of the power tool will run out of balance,

vibrate excessively and may cause loss

of control.

g) Do not use a damaged accessory.

Before each use inspect the accessory

such as abrasive wheels for chips and

cracks, backing pad for cracks, tear

or excess wear, wire brush for loose

or cracked wires. If power tool or

accessory is dropped, inspect

for damage or install an undamaged

accessory. After inspecting and

installing an accessory, position yourself

and bystanders away from the plane

of the rotating accessory and run the

power tool at maximum no-load speed

for one minute.

Damaged accessories will normally break

apart during this test time.

h) Wear personal protective equipment.

Depending on application, use face

shield, safety goggles or safety glasses.

As appropriate, wear dust mask, hearing

protectors, gloves and workshop apron

capable of stopping small abrasive or

workpiece fragments. The eye protection

must be capable of stopping flying debris

generated by various operations . The

dust mask or respirator must be capable

of filtrating particles generated by your

operation. Prolonged exposure to high

intensity noise may cause hearing loss.

i) Keep bystanders a safe distance

away from work area. Anyone entering

the work area must wear personal

protective equipment. Fragments of

workpiece or of a broken accessory may fly

away and cause injury beyond immediate

area of operation.

j) Hold the power tool by insulated

gripping surfaces only, when performing

an operation where the cutting

accessory may contact hidden

wiring or its own cord.

Cutting accessory contacting a “live”

wire may make exposed metal parts of

the power tool “live” and could give the

operator an electric shock.

k) Position the cord clear of the spinning

accessory. If you lose control, the cord may

be cut or snagged and your hand or arm

may be pulled into the spinning accessory.

l) Never lay the power tool down until

the accessory has come to a complete

stop. The spinning accessory may grab the

surface and pull the power tool out of your

control.

m) Do not run the power tool while

carrying it at your side. Accidental contact

with the spinning accessory could snag

your clothing, pulling the accessory into

your body.

n) Regularly clean the power tool’s

air vents. The motor’s fan will draw the

dust inside the housing and excessive

accumulation of powdered metal may cause

electrical hazards.

o) Do not operate the power tool near

flammable materials. Sparks could ignite

these materials.

p) Do not use accessories that require

liquid coolants. Using water or other liquid

coolants may result in electrocution or

shock.

8

www.evolutionbuild.com

Page 9

KICKBACK & RELATED WARNINGS

UK

Kickback is a sudden reaction to a pinched

or snagged rotating wheel, backing pad,

brush or any other accessory. Pinching

or snagging causes rapid stalling of the

rotating accessory which in turn causes the

uncontrolled power tool to be forced

in the direction opposite of the accessory’s

rotation at the point of the binding.

HAND HELD DRYWALL SANDER

d) Use special care when working

corners, sharp edges etc. Avoid

bouncing and snagging the accessory.

Corners, sharp edges or bouncing have

a tendency to snag the rotating accessory

and cause loss of control or kickback.

e) Do not attach a saw chain

woodcarving blade or toothed

saw blade. Such blades create frequent

kickback and loss of control.

For example, if an abrasive wheel is

snagged or pinched by the workpiece, the

edge of the wheel that is entering into the

pinch point can dig into the surface of the

material causing the wheel to climb out or

kick out. The wheel may either jump toward

or away from the operator, depending on

direction of the wheel’s movement at the

point of pinching. Abrasive wheels

may also break under these conditions.

Kickback is the result of power tool misuse

and/or incorrect operating procedures or

conditions and can be avoided by taking

proper precautions as given below.

a) Maintain a firm grip on the power

tool and position your body and arm

to allow you to resist kickback forces.

Always use auxiliary handle, if provided,

for maximum control over kickback or

torque reaction during start-up.

The operator can control torque reactions

or kickback forces, if proper precautions

are taken.

b) Never place your hand near the

rotating accessory. Accessory may

kickback over your hand.

c) Do not position your body in the area

where power tool will move if kickback

occurs. Kickback will propel the tool in

direction opposite to the wheel’s

movement at the point of snagging.

SAFETY WARNINGS SPECIFIC FOR SANDING OPERATIONS UK

a) Do not use excessively oversized

sanding disc paper. Follow

manufacturers recommendations,

when selecting sanding paper.

Larger sanding paper extending beyond

the sanding pad presents a laceration hazard

and may cause snagging, tearing of

the disc or kickback.

WARNING: the operation of any sanding

machine can result in foreign objects

being thrown towards your eyes, which

could result in severe eye damage. Before

beginning power tool operation, always wear

safety goggles or safety glasses with side

shield or a full face shield where needed.

WARNING: If any parts are missing, do

not operate your machine until the missing

parts are replaced. Failure to follow this rule

could result in serious personal injury.

SAFETY LABELS & SYMBOLS

WARNING: Do not operate this machine

if warning and /or instruction labels are

missing or damaged. Contact Evolution

Power Tools for replacement labels.

www.evolutionbuild.com

9

Page 10

BUILD

®

Note: All or some of the following symbols

may appear in the manual or on the product.

Symbol Description

V Volts

A Amperes

Hz Hertz

-1

Min

Rated speed

~ Alternating Current

n

o

No Load Rated speed

Double Insulated

Wear Safety Goggles

Wear Ear Protection

INTENDED USE OF THIS POWER TOOL

WARNING: This product is a Drywall

Sanding Machine and has been designed to

be used with most commercially available

sanding discs. Only use sanding discs

designed for use in this machine and/

or those recommended specifically by

Evolution Power Tools Ltd.

When fitted with a correct abrasive

sanding disc this machine can be used

to sand:

• Drywallwallsandceilings.

WARNING: This machine is not suitable for

sanding materials that may contain asbestos

or lead based products.

PROHIBITED USE OF THIS POWER TOOL

WARNING: This product is a Drywall

Sanding Machine and must only be used as

such. It must not be modified in any way,

or used to power any other equipment or

drive any other accessories other than those

mentioned in this Instruction Manual.

WARNING: This product is not intended

for use by persons (including children)

with reduced physical, sensory or mental

capabilities, or lack of experience and

knowledge, unless they have been given

supervision or instruction concerning

the safe use of the product by a person

responsible for their safety and who is

competent in its safe use.

GETTING STARTED

GETTING STARTED

UNPACKING

Caution: This packaging contains sharp

objects. Take care when unpacking. Remove

the machine, together with the accessories

supplied from the packaging. Check carefully

to ensure that the machine is in good

condition and account for all the accessories

listed in this manual. Also make sure that all

the accessories are complete. If any parts

are found to be missing, the machine and

its accessories should be returned together

in their original packaging to the retailer. Do

not throw the packaging away; keep it safe

throughout the guarantee period. Dispose

of the packaging in an environmentally

responsible manner. Recycle if possible. Do

not let children play with empty plastic bags

due to the risk of suffocation.

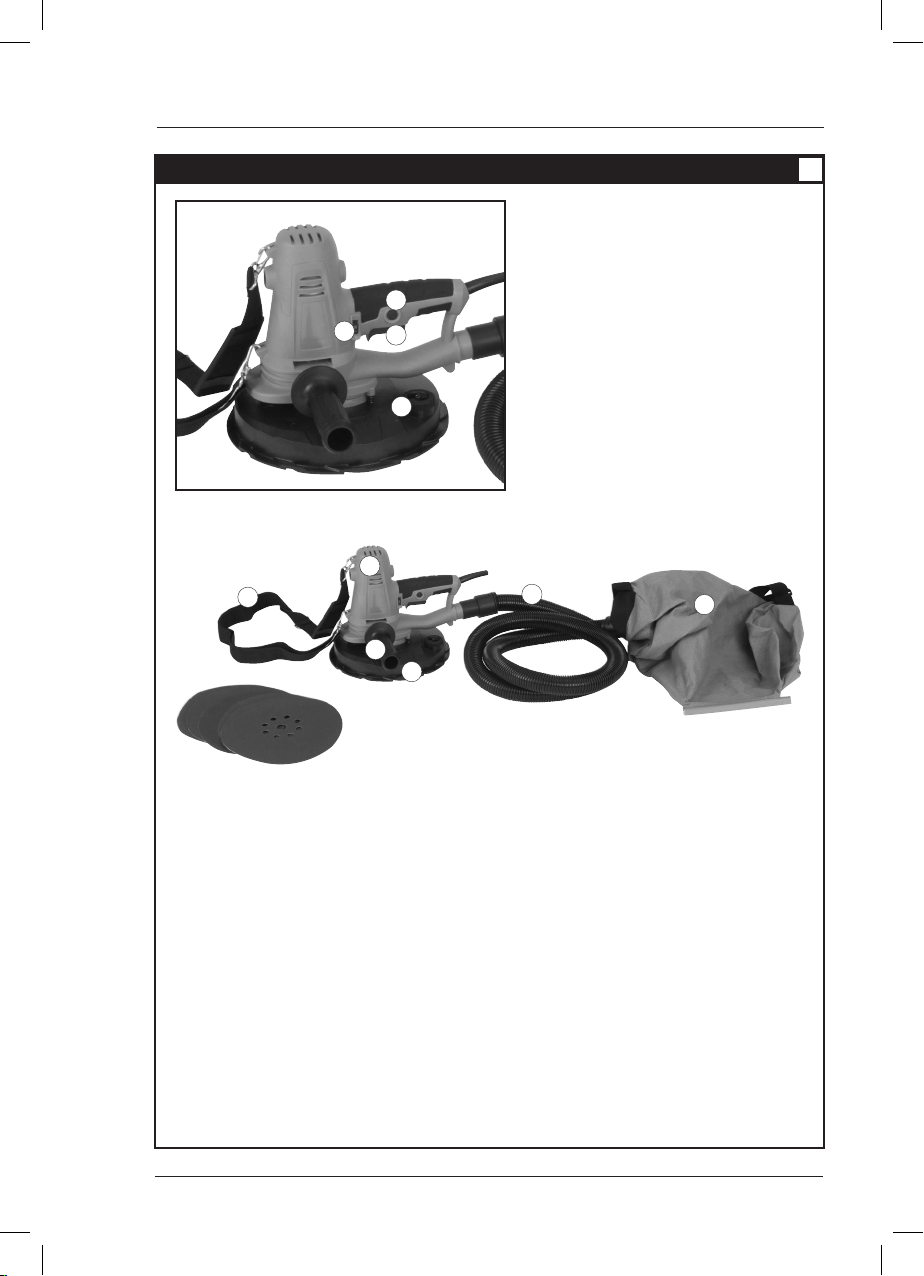

ITEMS SUPPLIED

DESCRIPTION QUANTITY

Instruction Manual 1

Sanding Discs (assorted) 8

Dust Extraction Hose 1

Side Assist Handle 1

Dust Bag 1

Hose Adaptor 1

Carry Belt 1

Replacement Carbon Brush

1

Set (power)

Hex Key 5mm 1

UK

10

www.evolutionbuild.com

Page 11

HAND HELD DRYWALL SANDER

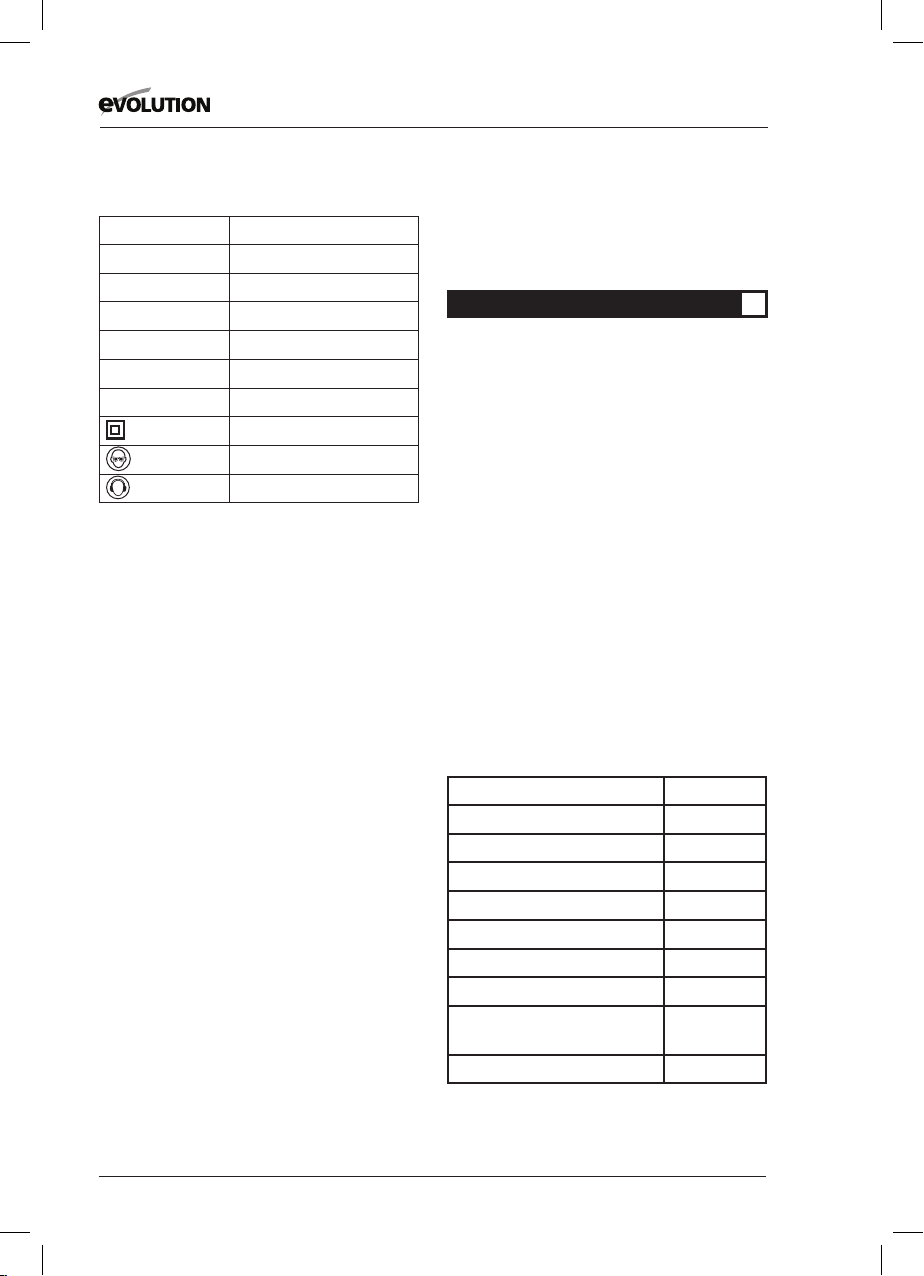

OVERALL VIEW OF DRYWALL SANDER

5

2

10

UK

6

4

9

7

3

1

8

1. Sprung Sanding Head

2. Power

3. Side Assist Handle

4. Power On/Off Trigger

5. Power rated speed control

www.evolutionbuild.com

6. Trigger Locking Button

7. Dust Extraction Hose

8. Dust Collection Bag

9. Suction Regulator

10. Machine Carry Strap

11

Page 12

BUILD

®

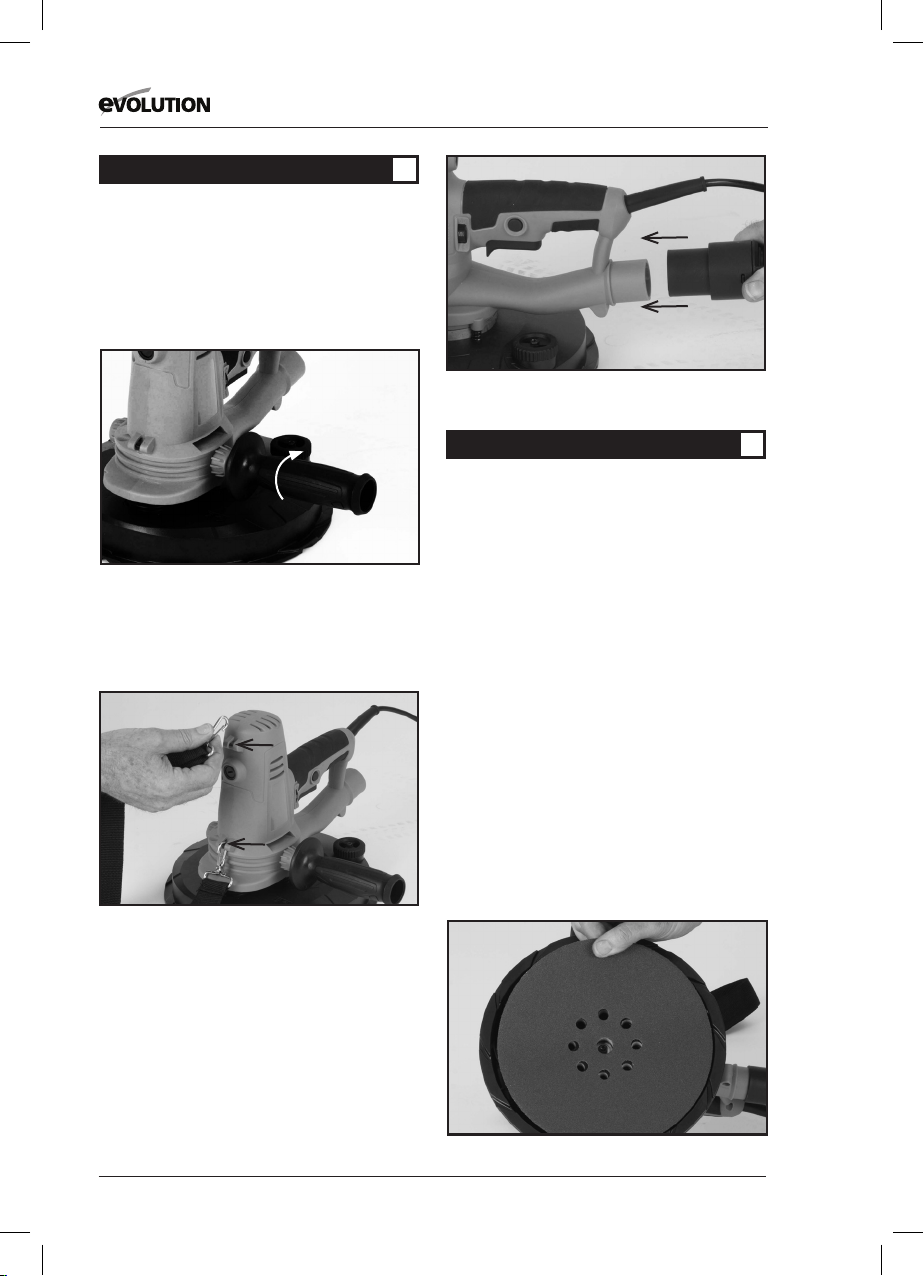

AS SEMBLY

ASSEMBLY

UK

Some minor assembly is required to prepare

the EB225DWSHH for use.

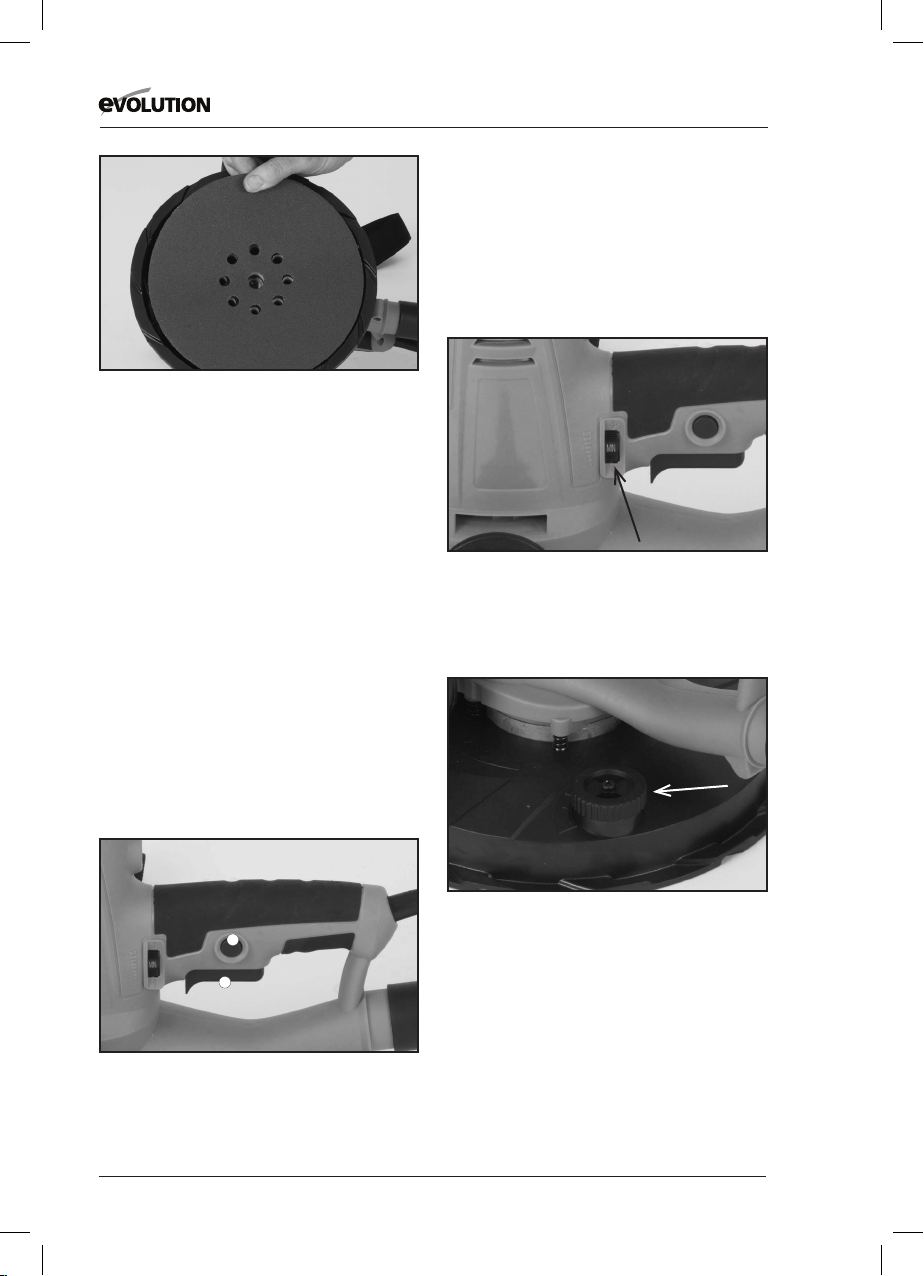

• AttachtheSideAssistHandletothe

machine by screwing it into the preferred

boss on the left hand or right hand side

of the machine. (Fig. 1)

Fig. 1

• AttachtheCarryStraptothemainbody

of the machine (if required) by clipping it

to the dedicated attachment pins. (Fig. 2)

Fig. 3

OPERATION

OPERATION

UK

Fitting or removing an

Abrasive Sanding Disc

WARNING: Only remove or replace an

abrasive sanding disc with the machine

disconnected from the power supply.

Note: Only use sanding discs which are

specifically designed for use in this machine.

This machine uses a hook and loop system

which enables very quick changes of the

abrasive sanding disc. The hooks on the Power

Driven Backing Pad engage with the loops on

the back of the abrasive sanding disc.

Fig. 2

• PushtheDustExtractionHoseontothe

dust extraction port on the machines

main body. (Fig. 3)

12

www.evolutionbuild.com

To fit an abrasive sanding disc:

• Placethenewabrasivediscaccurately

onto the Backing Pad.

• Pressitrmlybyhandintoplace.

• Becarefultoensurethatthenine(9)

holes in the abrasive sanding disc line up

perfectly with the nine ( 9) holes in the

Backing Pad. (Fig. 4)

Fig. 4

Page 13

HAND HELD DRYWALL SANDER

To remove an Abrasive Sanding Disc:

• Lifttheabrasivediscatanypointalong

its edge, and gently peel upwards and

away from the Backing Pad.

To switch the machine ‘On’:

• PresstheTriggerSwitch. (Fig. 5A)

Note: For operator convenience the On/Off

Trigger Switch can be locked in the

‘On’ position.

• Pushinthe‘TriggerLockingButton’(Fig. 5B)

to lock the Trigger in the ‘On’ position.

B

A

Fig. 5A +B

To switch ‘Off’:

• PresstheTriggerslightlyandthenrelease.

The Power Rated speed Control (Fig. 6)

Rotate the thumb wheel until the required

rated speed is obtained.

Sanding Head Suction Regulator Control

(Fig. 7)

Fig. 7

The Suction Control Regulator allows the

operator to adjust the power of the suction

provided by the inbuilt dust extraction system.

Extra air can be allowed into the Sanding

Head, reducing the suction power. This may

be necessary as at maximum suction the

Sanding Head may become difficult to move

or sweep over the work surface. Regulating

the volume of air admitted to the Sanding

Head can reduce operator workload by

reducing the effort required to sweep the

Sanding Head over the work surface.

To adjust the suction:

• RotatetheRegulatorcounterclockwise

fully, for reduced suction.

• RotatetheRegulatorclockwisefullyfor

maximum suction.

Note: The Regulator has three (3) positive

stop positions.

Fig. 6

The Sprung Sanding Head

The Sanding Head is attached to the

machine by four (4) sprung loaded pins.

This allows the Sanding Head to move

slightly in multiple directions.

When in use the Sanding Head can

effectively ‘float’ over the work surface

compensating automatically for uneven

wall surfaces. This action enables the user

to sweep the work surface with minimal

changes to their stance and foot position,

allowing greater security and better balance

for the operator.

www.evolutionbuild.com

13

Page 14

BUILD

®

OPERATION

OPERATION

Holding the Drywall Sander

The Drywall Sander should always be held

with both hands, one on the Trigger Switch

Handle, and the other on the Side Assist

Caution: If ‘reach’ or access considerations

UK

necessitate the use by the operator of a

‘stand – on’ platform, such a platform must

be suitable and stable in use e.g. a folding

inside scaffold or ‘hop on’ work platform.

The operator must NEVER overstretch.

Handle. (Fig. 8)

SANDING – Operating Advice

Note: Attach the Side Assist Handle to

that side of the machine that best suits the

operator or the application.

• Connectthedustextractionhosetothe

machine by pushing it onto the machines

dust extraction port. (Fig. 9).

Fig. 8 Fig. 9

Note: Although the sander is a light weight

design, the user should be aware that

Note: The Dust Extraction Hose is permanently

attached to the Dust Collection Bag.

prolonged use can cause operator muscle

fatigue.

We recommend a maximum operator duty

cycle of 10 – 12 minutes, after which the

operator should rest for 5 minutes before

resuming sanding operations.

• AdjusttheCarryStrapsforoperator

convenience and comfort.

• Ensurethatthemainsleadanddust

collection hose do not pose a ‘trip’ or

any other hazard to the operator or any

bystanders.

Carry Straps

Carry straps are provided for both the

Sanding Machine and the Dust Collection

Bag. These should be used whenever

necessary to aid operator comfort and safety.

• Adoptthecorrectstancefortheoperation.

• Switchthemachine‘On’andposition

the Drywall Sander Sanding Head lightly

against the work surface, and apply just

enough pressure to align the Sanding

Head with the work surface.

Operator Stance

The operator should adopt a comfortable

stance with their feet apart and firmly

balanced.

Both feet should be on the ground or floor.

It is not acceptable to have one foot on the

floor and the other on a stand or ladder rung

etc. as this precludes the operator from

achieving a proper balanced stance.

• Gentlyapplymorepressuretoengage

the rotating abrasive disc onto the work

surface.

• MovetheSanderacrossthework

surface in long overlapping sweeps.

Apply only enough pressure to keep

the abrasive disc flat against the work

surface. Excessive pressure should be

avoided as it can cause swirl marks and

unevenness in the work surface.

14

www.evolutionbuild.com

Page 15

HAND HELD DRYWALL SANDER

• KeeptheSanderinconstantmotion

whilst the abrasive disc is in contact with

the work surface. Use a steady, sweeping

motion, allowing the rotating abrasive disc

to ‘float’ over the work surface. Moving

the Sander erratically or concentrating

for too long on one area can cause swirl

marks or unevenness in the work surface.

Caution: Always keep your hands away

from the Sanding Head. The Sanding Head

swivels in multiple directions and could

pinch your hands.

WARNING: Do not allow the rotating

abrasive disc to contact sharp objects such

as protruding nails, screws etc, or wall

architecture such as electrical boxes or

switch plates. Damage to the Sander or the

wall fittings could result.

Dust Collection

Dust collection is automatic. Wall dust will

sucked from the Sanding Head, along the

dust extraction hose and deposited in the

Dust Collection Bag.

Note: We recommend for operational

efficiency that the Dust Collection Bag is

emptied when it is approximately 2/3 full.

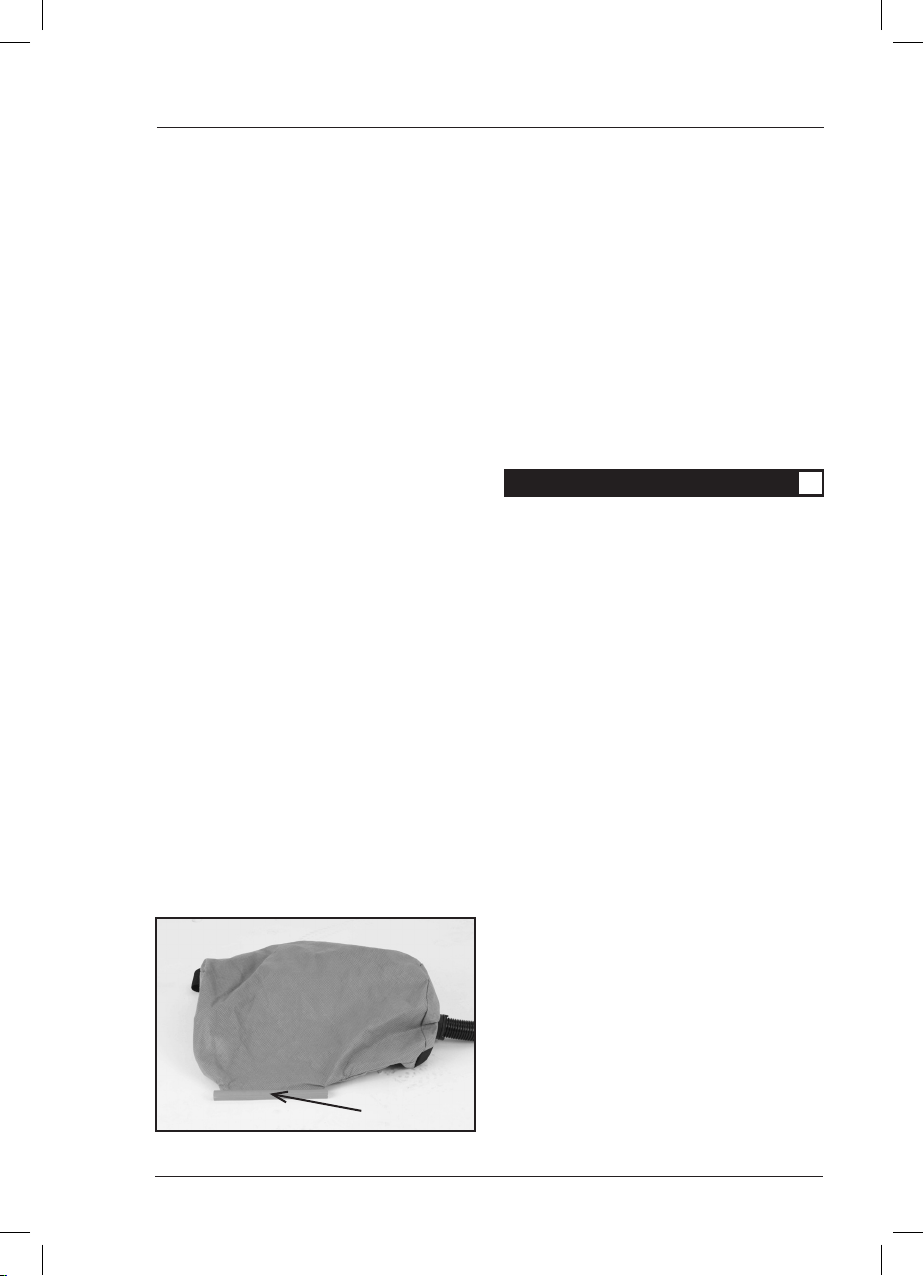

Emptying the Dust Collection Bag

WARNING: Only empty the Dust Collection

Bag when the machine is switched ‘Off’.

The Dust Collection Bag has an open seam

which is sealed by a plastic slide fastener.

(Fig. 10)

Slide this fastener from the Dust Collection

Bag to open the seam.

Dispose of the contents of the Dust

Collection Bag in an environmentally

responsible way.

Note: It may be necessary for the

operator to wear a dust mask and other

PPE (Personal Protection Equipment) as

necessary when disposing of the contents

of the Dust Bag.

Reseal the seam by sliding the plastic

fastener back onto the Dust Collection Bag.

MAINTENANCE

MAINTENANCE

UK

Note: Any maintenance must be carried

out with the machine switched off and

disconnected from the mains/battery

power supply. Check that all safety features

and guards are operating correctly on a

regular basis. Only use this machine if all

guards/safety features are fully operational.

All power bearings in this machine are lubricated

for life. No further lubrication is required.

Use a clean, slightly damp cloth to clean

the plastic parts of the machine. Do not use

solvents or similar products which could

damage the plastic parts.

WARNING: Do not attempt to clean by

inserting pointed objects through openings in

the machines casings etc. The machines air

vents should be cleaned using compressed

dr y air.

Fig. 10

Excessive sparking may indicate the

presence of dirt in the power or worn out

carbon brushes.

www.evolutionbuild.com

15

Page 16

BUILD

®

Checking and replacing the

Carbon Brushes

WARNING: Disconnect the machine from

the power supply before attempting to

check or replace the Carbon Brushes.

To remove the brushes:

• Unscrewthe2plasticcapsfound

towards the base of either side of the

motor housing. Be careful as the caps are

spring-loaded.

1 2

• Youmustreplacebothcarbonbrushes

if one has less than 6mm length of

carbon remaining, or if the spring or wire

is damaged or burned.

• Withdrawthebrusheswiththeirsprings.

> 6mm

To replace the Power Driven Backing Pad

WARNING: Only attempt this procedure

with the machine disconnected from the

power supply.

• Removeanyinstalledsandingdiscto

reveal the Backing Pad and the centrally

located socket headed screw that

attaches it to the power drive spindle.

• HoldingtheBackingPadwiththepalm

of one hand, loosen the socket headed

screw using the supplied 5mm Hex Key

with the other hand. (Fig. 11)

Fig. 11

• Removethesocketheadedscrewand

lift away the Backing Pad.

Note: The two (2) flats machined on the

power spindle that engage in the Backing

Pad to provide positive drive and location.

(Fig. 12)

• Ifreplacementisnecessar yrenewthe

brushes and replace the caps.

• Ensurethecapsscrewbackfreely.

Note: Used but serviceable brushes can

be replaced, but only as long as they are

returned to the same position, and inserted

the same way round, as they were removed

from the machine.

• Runnewbrusheswithoutloadfor

approximately 5 minutes. This will help

the bedding-in process.

16

www.evolutionbuild.com

Fig. 12

ENVIRONMENTAL PROTECTION

UK

Waste electrical products should not be

disposed of with household waste. Please

recycle where facilities exist. Check with

your Local Authority or retailer for recycling

advice.

Page 17

HAND HELD DRYWALL SANDER

EC DECLARATION OF CONFORMITY

In accordance with EN ISO 17050-1:2004

®

EB225DWSHH

The manufacturer of the product covered by this Declaration is:

Evolution Power Tools, Venture One, Longacre Close, Holbrook Industrial Estate, Sheffield, S20

3FR

The manufacturer hereby declares that the machine as detailed in this declaration fulfils all the

relevant provisions of the Machinery Directive and other appropriate directives as detailed below.

The manufacture further declares that the machine as detailed in this declaration, where

applicable, fulfils the relevant provisions of the Essential Health and Safety requirements.

The Directives covered by this Declaration are as detailed below:

2006/42/EC. Machinery Directive.

2004/108/EC. (until Apr 19th 2016) Electromagnetic Compatibility Directive

2014/30/EU. (starting from Apr 20th 2016) Electromagnetic Compatibility Directive

93/68/EC. The CE Marking Directive

2011/65/EU. The Restriction of the Use of certain Hazardous Substances

in Electrical Equipment (RoHS) Directive

2002/96/EC as amended by 2003/108/EC. The Waste Electrical and Electronic Equipment (WEEE) Directive

And is in conformity with the applicable requirements of the following documents:

EN 60745-1:2009+A11:2010

EN 60745-2-3:2011

EN 55014-1:2006/+A1:2009

EN 55014-2:1997/+A1:2001/+A2:2008

EN 61000-3-2:2006/+A1:2009/+A2:2009

EN 61000-3-3:2008

EN 62321:2009

Product Details

Description: 225MM HAND HELD DRYWALL SANDER

Evolution Model No: EB225DWSHH

Factory Model No: R7235A, R7235B

Brand Name: EVOLUTION

Voltage: 230-240V ~ 50Hz

Input: 1050W

The technical documentation required to demonstrate that the product meets the requirements of directive has

been compiled and is available for inspection by the relevant enforcement authorities, and verifies that our technical

file contains the documents listed above and that they are the correct standards for the product as detailed above.

Name and address of technical documentation holder.

Signed: Print: Matthew Gavins - Group Chief Executive

Date: 01/03/16

www.evolutionbuild.com

17

Page 18

®

BUILD

FR

Evolution Power Tools se réserve le droit d’apporter des améliorations et des

modifications à la conception et à la spécification technique de ce produit sans

préavis.

PONCEUSE DE CLOISONS SÈCHES - SPÉCIFICATIONS

Puissance (230 V ~ 50Hz) (Watts) :

RPM Vitesse nominale (min-1) :

Cycle de fonctionnement maximal recommandé

1050

1500-2300

30

(minutes) :

Format du papier abrasif (diamètre, mm) :

Longueur du tuyau d’aspiration des poussières

225

2

(mètres) :

Poids (kg) :

2.8

Données de bruit et de vibration :

Niveau de pression acoustique (LPA) : 88dB(A) K=3dB(A)

Niveau de puissance acoustique (LWA) : 99dB(A) K=3dB(A)

Niveau de vibration : 4.915m/s

INFORMATION:

- La valeur totale des vibrations déclarées a été mesurée à partir d’une méthode

d’essai normalisée et peut être utilisée pour comparer un outil par rapport à un autre.

- La valeur totale des vibrations déclarées peut être également utilisée en tant qu’évaluation

préliminaire du degré exposition.

AVERTISSEMENT:

- L’émission de vibrations émises par l’outil en usage normal peut différer de la valeur

déclarée en fonction de la façon dont celui- ci est utilisé.

- Les mesures adéquates doivent être prises pour protéger l’utilisateur en se basant sur une

estimation du degré d’exposition en usage normal de l’outil (en prenant en compte toutes les

étapes du cycle d’utilisation: mise à l’arrêt, fonctionnement à vide, temps de travail réel avec l’outil)

2

K=1.5m/s

2

18

www.evolutionbuild.com

Page 19

PONCEUSE DE CLOISONS SÈCHES À MAIN

TABLE DES MATIÈRES

Informations importantes 19

Garantie Limitée Evolution 19

Règles générales de sécurité 20

Consignes de sécurité pour la

ponceuse de cloisons sèches 23

Étiquettes et symboles 25

Aperçu de la machine 26

Fonctionnement 29

Entretien 31

Protection de l’environnement 32

CE - Déclaration de conformité 33

IMPORTANT

IMPORTANT

FR

Merci de lires ces instructions

d’utilisation et de sécurité avec

attention et en totalité. Pour votre

sécurité personnelle et si vous n’êtes pas

sûr de connaître l’un des aspects de cet

outil, contactez le service technique dont le

numéro se trouve sur le site web de Evolution

Power Tools. Nous disposons de plusieurs

services techniques à travers le monde, mais

une assistance technique est également

disponible auprès de votre distributeur.

Service d’assistance téléphonique.

Royaume-Uni : + 33 (0) 5 57 30 61 89

www.evolutionpowertools.com/register

Félicitations pour votre achat d’un outil

Evolution Power Tools. Merci de remplir le

formulaire de garantie en ligne décrit dans

le dépliant A4 livré avec cet outil. Vous

pouvez également scanner le code QR

qui se trouve sur le dépliant A4 avec votre

smartphone. Ceci vous permettra de valider

votre garantie sur le site Evolution Power

Tools et vous assurera un service rapide

en cas de besoin. Nous vous remercions

sincèrement d’avoir choisi un outil Evolution

Power Tools.

GARANTIE LIMITÉE EVOLUTION

Evolution Power Tools se réserve le droit

d’apporter des améliorations ou des

modifications dans la conception du produit

sans notification préalable.

Merci de vous référer au prospectus

d’enregistrement de garantie et/ou à

l’emballage pour plus d’informations sur les

conditions de garantie.

Pendant la période de garantie et à compter

de la date d’achat, Evolution Power Tools

réparera ou remplacera les outils défectueux,

pièces et main d’œuvre comprises. Cette

garantie ne s’applique pas si l’outil qui nous

est renvoyé a été utilisé dans un cadre qui

dépasse les recommandations du manuel

d’utilisation ou si l’outil a été endommagé

par accident, négligence ou utilisation

inappropriée. Cette garantie ne s’applique

pas aux outils et/ou aux éléments de l’outil

qui ont été modifiés ou utilisés hors des

capacités et des spécifications prescrites.

Les éléments électriques sont soumis aux

garanties de leurs fabricants. Les outils qui

nous sont retournés le seront port payé et à

l’attention d’Evolution Power Tools. Evolution

Power Tools se réserve le droit de réparer ou

de remplacer l’outil par un outil identique ou

équivalent. Il n’existe aucune garantie, écrite ou

verbale, sur les consommables tels que (sans

que cette liste soit exhaustive) : les lames,

les cutters, les mèches, les burins, etc. En

aucune circonstance Evolution Power Tools

ne pourra être tenu pour responsable des

pertes ou dommages résultant directement ou

indirectement de l’utilisation de nos produits

ou de toute autre cause. Evolution Power

Tools ne peut être tenu pour responsable

des coûts découlant de telles pertes ou de

tels dommages. Aucun employé ou agent

d’Evolution Power Tools n’est autorisé à établir

de déclaration de convenance orale ou à

renoncer l’une des conditions de vente et de

www.evolutionbuild.com

19

Page 20

BUILD

®

tels engagements ne pourront être opposés à

Evolution Power Tools.

Les questions relatives à la présente

limitation de garantie seront directement

adressées au siège de l’entreprise ou par

appel téléphonique au numéro du service

technique approprié.

INSTRUCTIONS DE SÉCURITÉ IMPORTANTES

IMPORTANT SAFETY INSTRUCTIONS

FR

Pour réduire le risque de choc électrique, ce

matériel est doté d’un câble et d’une prise

approuvés pour son pays d’utilisation. Ne

modifiez pas le câble ou la prise de quelque

façon que ce soit.

RÈGLES GÉNÉRALES DE SÉCURITÉ

GENERAL SAFETY RULES

FR

Veillez lire et comprendre toutes

les instructions avant d’utiliser ce

produit. Le non-respect de toutes les

instructions ci-dessous peut provoquer

des blessures graves, un incendie et/

ou un choc électrique. CONSERVEZ CES

INSTRUCTIONS POUR POUVOIR VOUS

Y RÉFÉRER ULTÉRIEUREMENT.

AVERTISSEMENT : lorsque vous utilisez

des outils électriques, des précautions

de sécurité de base doivent toujours être

suivies pour réduire le risque d’incendie, de

choc électrique et de blessures.

INSTRUCTIONS DE SÉCURITÉ

IMPORTANTES POUR LES OUTILS

ÉLECTRIQUES

(Ces instructions générales de sécurité des

outils électriques sont spécifiées dans BS

EN 60745-1:2009 & EN 61029-1:2009.)

AVERTISSEMENT : lisez tous les

avertissements et consignes de

sécurité. Le non-respect des instructions

et des avertissements peut provoquer des

blessures graves, un incendie et/ou un choc

électrique.

Conservez tous ces avertissements et

instructions pour pouvoir vous y référer

ultérieurement.

Le terme « outil électrique » mentionné dans

les avertissements se rapporte à votre outil

électrique alimenté sur secteur (avec fil) ou

fonctionnant sur batterie (sans fil).

1) Avertissements généraux de sécurité

des outils électriques

[sécurité de la zone de travail]

a) Maintenez la zone de travail bien

éclairée et propre.

Des lieux de travail encombrés ou sombres

favorisent les accidents.

b) N’utilisez pas d’outils électriques

dans des atmosphères explosives,

comme en présence de liquides, gaz

ou poussières inflammables. Les

outils électriques génèrent des étincelles

susceptibles d’enflammer la poussière ou

les vapeurs.

c) Tenez les enfants et autres personnes

éloignés lorsque vous faites fonctionner

des outils électriques. Des distractions

peuvent vous faire perdre le contrôle.

2) Avertissements généraux de sécurité

des outils électriques

[sécurité électrique]

a) Les prises des outils électriques

doivent être adaptées à la prise de

courant. Ne modifiez jamais la prise de

quelque façon que ce soit. N’utilisez pas

d’adaptateurs avec des outils électriques

mis à la terre (la masse). Des prises non

modifiées et des prises de courant adaptées

réduisent le risque de choc électrique.

b) Évitez tout contact corporel avec des

surfaces mises à la terre ou à la masse,

par exemple des tuyaux, radiateurs,

cuisinières et réfrigérateurs. Il y a un

risque accru de choc électrique si votre

corps est mis à la terre ou à la masse.

c) N’exposez pas les outils électriques à

la pluie ou à des conditions d’humidité.

L’eau qui pénètre dans un outil électrique

augmente le risque de choc électrique.

20

www.evolutionbuild.com

Page 21

PONCEUSE DE CLOISONS SÈCHES À MAIN

d) Ne maltraitez pas le câble. N’utilisez

jamais le câble pour transporter l’outil,

le tirer ou le débrancher. Tenez le câble

éloigné de la chaleur, de l’huile, des bords

coupants ou des pièces mobiles. Les câbles

endommagés ou emmêlés augmentent le

risque de choc électrique.

e) Lorsque vous utilisez un outil

électrique à l’extérieur, utilisez une

rallonge adaptée à une utilisation en

extérieur. L’utilisation d’un câble adapté à

une utilisation en extérieur réduit le risque

de choc électrique.

f) Si l’utilisation d’un outil électrique

dans un endroit humide est inévitable,

utilisez une alimentation protégée à

dispositif différentiel résiduel (DDR).

L’utilisation d’un DDR réduit le risque de

choc électrique.

3) Avertissements généraux de sécurité

des outils électriques

[sécurité personnelle]

a) Restez vigilant, surveillez ce que vous

faites et faites preuve de bon sens lorsque

vous utilisez un outil électrique. N’utilisez

pas un outil électrique si vous êtes fatigué(e)

ou sous l’influence de drogues, d’alcool ou

de médicaments. Un moment d’inattention

pendant l’utilisation d’outils électriques peut

entraîner des blessures graves.

b) Utilisez un équipement de protection

personnelle. Portez toujours des

lunettes de protection. Travailler avec

un équipement de protection approuvé,

comme les masques à poussière, des

chaussures de sécurité antidérapantes,

un casque ou une protection acoustique

pour les conditions appropriées, réduira les

blessures personnelles.

c) Évitez tout démarrage involontaire.

Assurez-vous que l’interrupteur soit sur

la position OFF avant de brancher l’outil à

une source de courant ou une batterie, de

prendre ou de transporter l’outil. Si vous

transportez des outils électriques en ayant

votre doigt sur l’interrupteur ou si vous

branchez des outils électriques alors que

l’interrupteur est sur la position ON, vous

risquez d’avoir des accidents.

d) Retirez toute clé de réglage ou

de serrage avant de mettre l’outil

électrique en marche. Une clé laissée

attachée à une partie tournante d’un outil

électrique peut entraîner des blessures.

e) Ne tendez pas votre bras trop loin.

Maintenez un bon appui et restez en

équilibre à tout moment. Cela permet un

meilleur contrôle de l’outil électrique dans

des situations inattendues.

f) Habillez-vous de façon appropriée.

Ne portez pas de vêtements amples ni de

bijoux. Tenez vos cheveux, vêtements et

gants éloignés des parties mobiles. Les

vêtements amples, bijoux ou cheveux

longs peuvent se prendre dans les parties

mobiles.

g) Si on a fourni des dispositifs pour la

connexion des installations d’aspiration

et du captage des poussières, assurezvous que ces installations sont

connectées et correctement utilisées.

L’utilisation d’une installation de captage de

poussières peut réduire les risques liés à la

poussière.

4) Avertissements généraux de sécurité

des outils électriques

[utilisation et entretien des outils

électriques]

a) Ne forcez pas l’outil électrique. Utilisez

l’outil électrique approprié pour votre

application. L’outil électrique approprié

permettra d’effectuer un travail meilleur et plus

sûr à la vitesse pour laquelle il a été conçu.

b) N’utilisez pas l’outil électrique si

l’interrupteur ne l’allume pas ou ne l’éteint

pas. Tout outil électrique qui ne peut pas être

contrôlé par son interrupteur est dangereux et

doit être réparé.

c) Débranchez l’outil électrique de la

source d’alimentation et/ou de la batterie

avant de faire des réglages, de changer

les accessoires ou de ranger les outils

électriques. Ces mesures de sécurité

préventives réduisent le risque de démarrage

de l’outil électrique accidentellement.

www.evolutionbuild.com

21

Page 22

BUILD

®

d) Rangez les outils électriques

inutilisés hors de la portée des enfants

et ne permettez pas aux personnes peu

familières avec l’outil électrique ou les

présentes instructions d’utiliser l’outil

électrique. Les outils sont dangereux dans les

mains d’utilisateurs inexpérimentés.

e) Entretenez les outils électriques.

Recherchez des défauts d’alignement ou

un grippage des parties mobiles, la casse

de parties mobiles et toute autre condition

qui peut affecter le fonctionnement des

outils électriques. Si endommagé, assurez-

vous que l’outil électrique soit réparé avant

utilisation. Beaucoup d’accidents sont causés

par des outils électriques mal entretenus.

f) Maintenez les outils de coupe aiguisés et

propres. Des outils de coupe bien entretenus

avec des bords bien affûtés sont moins

susceptibles de coincer et sont plus faciles à

contrôler.

g) Utilisez l’outil électrique, les accessoires

et les outils rapportés, etc. en conformité

avec ces instructions, en tenant compte

des conditions de travail et du travail à

ef fectuer. L’utilisation de l’outil électrique pour

des travaux différents de ceux pour quoi il est

prévu peut entraîner une situation dangereuse.

5) Avertissements généraux de sécurité

des outils électriques

[entretien]

a) Faites réparer votre outil électrique

par un réparateur qualifié qui utilisera

seulement des pièces de rechange

identiques. Cela permettra d’assurer que la

sécurité de l’outil électrique est maintenue.

HEALTH ADVICE

CONSEILS SUR LA SANTÉ

FR

AVERTISSEMENT : lors du perçage, du

ponçage, du sciage ou du broyage, des

particules de poussière seront produites.

Dans certains cas, en fonction des

matériaux avec lesquels vous travaillez,

cette poussière peut être particulièrement

dangereuse pour vous (par exemple, le

plomb de peinture brillante ancienne).

Il est conseillé de prendre en considération

les risques associés aux matériaux avec

lesquelles vous travaillez et de réduire le

risque de l’exposition. Certains produits

en bois et de type bois et, en particulier

en MDF (fibres à densité moyenne),

peuvent produire de la poussière qui

peut être dangereuse pour votre santé.

Nous recommandons l’utilisation d’un

masque facial approuvé avec des filtres

remplaçables lors de l’utilisation de

cette machine, en plus de l’utilisation de

l’installation d’aspiration de la poussière.

Vous devriez toujours :

• travaillerdansunendroitbienventilé;

• travailleravecunéquipementdesécurité

approuvé, comme les masques à

poussière qui sont spécialement conçus

pour filtrer les particules microscopiques.

AVERTISSEMENT :si vous pensez que la

peinture sur les surfaces dans votre domicile

contient du plomb, demandez des conseils

professionnels. Les peintures à base de

plomb doivent seulement être retirées par un

professionnel et vous ne devriez pas tenter

de les retirer vous-même. Une fois que la

poussière a été déposée sur des surfaces,

le contact entre la main et la bouche peut

entraîner l’ingestion de plomb. L’exposition

à des niveaux de plomb, même faibles,

peut causer des dommages irréversibles au

cerveau et au système nerveux. Les jeunes

enfants et les fœtus sont particulièrement

vulnérables.

22

www.evolutionbuild.com

Page 23

VIBRATION

FR

AVERTISSEMENT : lorsqu’il utilise cette

machine, l’opérateur peut être exposé

à des niveaux élevés de vibrations

transmises à la main et au bras. Il

est possible que l’opérateur puisse

développer “la maladie des doigts

morts” (le syndrome de Raynaud). Cette

condition peut réduire la sensibilité

de la main à la température ainsi que

produire un engourdissement général.

Les utilisateurs prolongés ou réguliers de

ponceuses devrait surveiller l’état de leurs

mains et de leurs doigts de près. Si l’un

quelconque des symptômes se manifeste,

consulter immédiatement un médecin.

• Lamesureetl’évaluationdel’exposition

humaine aux vibrations transmises aux

mains dans le lieu de travail est donnée

dans : BS EN ISO 5349-1:2001 et BS EN

ISO 5349-2:2002

• Denombreuxfacteurspeuventinuencer

le niveau de vibration réelle lors du

fonctionnement, par exemple l’état et

l’orientation des surfaces de travail ainsi

que le type et l’état du disque abrasif

utilisé. Avant chaque utilisation, ces

facteurs devraient être évalués et, si

possible, des pratiques appropriées de

travail devraient être adoptées. La gestion

de ces facteurs peut aider à réduire les

effets des vibrations.

Manipulation

Manipulez la machine avec soin, permettez

à la machine de faire le travail. Évitez

d’utiliser un effort physique excessif sur

les commandes des machines. Considérez

votre sécurité et stabilité, et l’orientation de

la machine lors de l’utilisation.

Surface de travail

Tenez compte du matériau de la surface

de travail; de son état, de sa densité, de

sa résistance, de sa rigidité et de son

orientation.

PONCEUSE DE CLOISONS SÈCHES À MAIN

CONSIGNES DE SÉCURITÉ

SUPPLÉMENTAIRES POUR LES

PONCEUSES DE CLOISONS SÈCHES

AVERTISSEMENT : assurez-vous de lire

et de comprendre toutes les instructions.

Le non-respect de toutes les instructions

ci-dessous peut provoquer des blessures

graves, un incendie et/ou un choc

électrique.

1. Familiarisez-vous avec votre outil

électrique. Lisez le manuel d’instructions

soigneusement. Prenez connaissance des

applications et des limites, ainsi que des

risques potentiels spécifiques liés à cet

outil.

2. Veuillez à toujours porter des lunettes

de sécurité ou des protecteurs oculaires

lors de l’utilisation de cette machine.

Les lunettes ordinaires ont seulement des

verres résistants aux chocs, ce ne sont pas

des lunettes de sécurité.

3. Veuillez toujours protéger vos

poumons. Portez un masque facial ou un

masque à poussière qui soit spécialement

conçu pour filtrer les particules

microscopiques. N’utilisez pas de ponceuse

de cloisons sèches si vous soupçonnez que

de l’amiante ou du plomb pourraient être

présents dans le matériau de la cloison.

Contactez les autorités pertinentes pour leur

demander conseil.

4. Veuillez toujours protéger votre

audition. Portez des protections

acoustiques lors d’une utilisation de longue

durée. Portez d’autres EPI (équipements

de protection individuelle) qui peuvent être

nécessaires pour le travail en question. En

cas de doute, consultez un avis compétent

d’un superviseur ou d’une autre personne

responsable.

5. Inspectez régulièrement le câble

électrique de la machine et, s’il est

endommagé, faites-le réparer ou

remplacer par un centre de service

autorisé. Soyez toujours conscient de

l’emplacement du câble d’alimentation et

de son acheminement. Assurez-vous que le

câble d’alimentation est acheminé en toute

www.evolutionbuild.com

23

Page 24

BUILD

®

sécurité et ne peut pas être endommagé de

quelque façon par contact avec des objets

tranchants ou lourds, etc. Assurez-vous que

l’acheminement du câble d’alimentation ne

pose pas de « danger de trébuchement ».

6. Veuillez toujours vérifier si des pièces

sont endommagées. Avant toute autre

utilisation de l’outil, il faut soigneusement

examiner si une protection ou autre partie

est endommagée afin de déterminer si

l’outil peut fonctionner correctement et

effectuer la fonction prévue. Recherchez

des défauts d’alignement ou un grippage

des parties mobiles, la casse de parties

mobiles et toute autre condition qui peut

affecter le fonctionnement de l’outil.

Une protection ou toute autre pièce

endommagée doit être correctement

réparée ou remplacée par un centre de

service autorisé.

7. Ne maltraitez pas le câble

d’alimentation. N’utilisez jamais le câble

pour transporter l’outil ou le débrancher

de la prise d’alimentation. Tenez le câble

éloigné de la chaleur, de l’huile, des bords

coupants ou des pièces mobiles. Remplacez

immédiatement les câbles endommagés.

Les câbles endommagés augmentent le

risque de choc électrique.

8. Veillez à ce que toute rallonge que

vous utilisez soit en bon état, et si

utilisée à l’extérieur, qu’il s’agisse

d’un type approprié, et étiqueté de la

sorte. Lorsque vous utilisez une rallonge,

assurez-vous d’en utiliser une qui soit assez

large pour transporter le courant dont votre

outil aura besoin. Une rallonge trop petite

provoquera une chute de tension, entraînant

une perte de puissance et une possible

surchauffe.

9. N’utilisez pas l’outil si vous êtes

fatigué(e) ou sous l’influence de

drogues, d’alcool ou de médicaments.

Si vous suivez cette règle, ce réduira le

risque de choc électrique, d’incendie ou de

blessure grave.

10. Conservez ces instructions.

Consultez-les fréquemment et utilisezles pour instruire d’autres personnes qui

pourraient utiliser cet outil. Si quelqu’un

emprunte cet outil, assurez-vous qu’il a ces

instructions.

11. Veillez à ce que l’opérateur ait une

formation adéquate pour le réglage,

l’utilisation et le fonctionnement de la

machine. Tous les opérateurs devraient

avoir lu et compris les instructions

contenues dans ce manuel, avant de

commencer à travailler.

12. Assurez-vous que l’éclairage dans le

lieu de travail est adéquat, et/ou fournir

un éclairage supplémentaire pour la

zone de travail. Les lieux de travail mal

éclairés sont intrinsèquement dangereux.

13. Maintenez la zone de travail bien

ventilée. Si possible, ouvrez des fenêtres et

mettez un ventilateur d’extraction dans l’une

d’elles pour déplacer l’air de l’intérieur vers

l’extérieur. Affichez des AVERTISSEMENTS

pour alerter les passants que des opérations

potentiellement dangereuses se déroulent

à proximité.

14. Utilisez une machine d’aspiration

de poussières en conjonction avec

cette ponceuse. Le lieu de travail doit être

maintenu aussi propre et sans poussière

que possible. Une salle remplie de

poussière a un potentiel explosif.

15. Assurez-vous qu’il n’y a pas de

sources d’allumage à proximité. De la

poussière flottant dans l’air a un potentiel

explosif.

16. Ne connectez pas un aspirateur

domestique à cette machine. Un

aspirateur domestique n’est pas approprié

pour le captage de particules de poussière

de cloisons sèches.

CONSIGNES DE SÉCURITÉ POUR L’ENSEMBLE DES OPÉRATIONS

FR

Avertissements de sécurité

communes pour poncage opérations :

a) Cet outil électrique est concu pour

fonctionner comme une ponceuse.

Lire tous les avertissements de sécurité,

des instructions, des illustrations et

24

www.evolutionbuild.com

Page 25

PONCEUSE DE CLOISONS SÈCHES À MAIN

spécifications fourni avec cet outil électrique.

Le non-respect des instructions ci-dessous

peut entraîner un choc électrique, un incendie

et / ou des blessures graves.

b) Les opérations telles que le meulage,

le ponçage, le brossage, le polissage ou

de coupe-off ne sont pas recommandé

d’effectuer avec cet outil électrique. Les

opérations pour lesquelles le pouvoir

outil n’a pas été conçu peut être dangereuse

et provoquer des blessures.

c) Ne pas utiliser d’accessoires qui ne

sont pas spécifiquement conçus et

recommandés par le fabricant de l’outil.

Tout simplement parce que l’accessoire peut

être attaché à votre outil électrique, il

ne garantit pas un fonctionnement sûr.

d) La vitesse de rotation nominale de

l’accessoire doit être au moins égale à

la vitesse maximale marqué sur l’outil

électrique. Les accessoires fonctionnant plus

vite que leur vitesse nominale peuvent se

briser et de voler en éclats.

e) Le diamètre extérieur et l’épaisseur

de votre accessoire doit être dans la

Note capacité de votre outil électrique.

Accessoires mal de taille ne peut pas être

adéquatement surveillé ou contrôlé.

f) La taille meules, brides, de ponçage

ou tout autre accessoire doit s’adapter

correctement à la broche de l’outil

électroportatif. Accessoires avec le trou

central qui ne sont pas correspondre au

matériel de montage de l’outil électrique

seront hors d’équilibre, vibrer excessivement

et peut entraîner une perte de contrôle.

g) Ne pas utiliser un accessoire

endommagé. Avant chaque utilisation,

inspectez l’accessoire tel que meules

abrasives pour les puces et les fissures,

tapis de sauvegarde pour les fissures, l’usure

ou la déchirure excès, brosse métallique

pour câbles desserrés ou fissurés. Si l’outil

de puissance ou un accessoire est tombé,

inspecter en cas de dommages ou d’installer

un accessoire en bon état. Après l’inspection

et l’installation d’un accessoire, positionnezvous et les spectateurs hors du plan de la

rotation accessoires et exécuter l’outil de

puissance au maximum à vide pendant

une minute. Accessoires endommagés

normalement cassent pendant ce temps

d’essai.

h) Porter des équipements de protection

individuelle. Selon l’application, utiliser

un écran facial, lunettes de sécurité ou des

lunettes de sécurité. Si nécessaire, porter un

masque antipoussière, l’ouïe protecteurs, des

gants et un tablier atelier capable d’arrêter

abrasif petite ou fragments de la pièce à

usiner. La protection oculaire doit être capable

d’arrêter les débris volant générés par les

activités diverses. Le masque antipoussières

ou un respirateur doit être capable de filtrer

particules générées par votre opération.

Une exposition prolongée à un bruit de forte

intensité peut entraîner une perte auditive.

i) Tenir les spectateurs à une distance

sécuritaire de la zone de travail. Tou te

personne entrant dans le travail zone doit

porter un équipement de protection. Des

fragments de pièce ou d’un cassé accessoire

peut s’envoler et causer des blessures delà de

la zone immédiate de l’opération.

j) Tenir l’outil par les surfaces de prise

isolées uniquement lorsque vous effectuez

une opération où l’accessoire de coupe

peut toucher des câbles électriques cachés

ou son propre cordon. Couper accessoire

communiquant avec un “live” fil peut mettre

les parties métalliques exposées de la

puissance outil de «vivre» et pourrait donner à

l’opérateur un choc électrique.

k) Placez le cordon loin de l ‘accessoire en

rotation. Si vous perdez le contrôle, le cordon

peut être coupure ou de déchirure et votre

main ou le bras peut être tiré dans l’accessoire

en rotation.

l) Ne posez jamais l’outil vers le bas

jusqu’à ce que l’accessoire est venu à un

arrêt complet. La tourner accessoire peut

saisir la surface et l ‘outil électrique hors de

votre contrôle.

m) Ne pas faire fonctionner l’appareil

lorsque vous le transportez à vos côtés.

Contact accidentel avec la tourner accessoire

pourrait accrocher vos vêtements, en tirant

l’accessoire dans votre corps.

www.evolutionbuild.com

25

Page 26

BUILD

®

n) Nettoyer régulièrement les orifices

de ventilation d’alimentation. Le

ventilateur du moteur va attirer la poussière

à l’intérieur du le logement et l’accumulation

excessive de poudre métallique peut

entraîner des risques électriques.

o) Ne pas utiliser l’outil électrique à

proximité de matériaux inflammables.

Les étincelles pourraient enflammer ces

matériaux.

p) Ne pas utiliser d’accessoires

qui nécessitent des liquides de

refroidissement. Utiliser de l’eau ou tout

autre liquide liquides de refroidissement

peut entraîner une électrocution ou de choc.

CONSIGNES DE SÉCURITÉ SUPPLÉMENTAIRES

POUR TOUTES LES OPÉRATIONS

FR

Rebond et avertissements liés. Le

rebond est une réaction soudaine à

une roue tournante pincé ou accroché,

plateau de ponçage, brosse ou tout

autre accessoire.

Pincement ou un accrochage rapide des

causes de décrochage de l’accessoire

en rotation qui provoque à son tour

l’outil d’alimentation non contrôlée

d’être forcé dans la direction opposée

de l’Accessoire de rotation au niveau du

point de la liaison.

Par exemple, si une roue abrasive est

accrochée ou pincée par la pièce à

usiner, le bord de l’meule qui entre dans

le point de pincement peut s’enfoncer

dans la surface de la matière provoquant

la roue de sortir ou mettre dehors.

La roue peut soit aller vers ou loin de

l’opérateur, en fonction de la direction

du mouvement de la roue au point de

pincement. Meules abrasives peuvent

également se rompre sous

ces conditions.

a) Tenir fermement sur l’outil électrique

et positionnez votre corps et vos bras

pour vous permettre de résister aux

forces de recul. Utilisez toujours la poignée

auxiliaire, le cas échéant, pour un maximum

de le contrôle de rebond ou de réaction

de couple lors du démarrage. L’opérateur

peut contrôler les réactions du couple ou

les forces de rebond, si les précautions

nécessaires sont prises.

b) Ne placez jamais votre main près de

l’accessoire en rotation. Accessoire peut

rebond sur votre main.

c) Ne pas placer son corps dans la zone

où l’outil électrique se déplacera en cas

de rebond se produit. Le rebond

va propulser l’outil en direction opposée

au mouvement de la roue à l’point

d ‘accrochage.

d) Prendre des précautions spéciales

en travaillant des coins, des bords

coupants etc éviter de rebondir et de

accrocher l’accessoire. Angles, les arêtes

ou les rebonds ont tendance à s’accrocher

à la rotation accessoire et causer une perte

de contrôle ou un rebond.