Page 1

DISC CUTTER

Original Instructions

Original Bedienungsanleitung

Instructions Originales

Instrucciones Originales

®

Date Published: 01 / 09 / 2016Written in UK English

Page 2

www.evolutionpowertools.com

TABLE OF CONTENTS

English Page 02

Deutsch Seite 20

Français Page 40

Español Página 56

INTRODUCTION Page 03

Guarantee Page 03

Machine Specification Page 04

Vibration Page 04

Labels and Symbols Page 05

Intended use of this Power Tool Page 06

Prohibited use of this Power Tool Page 06

SAFETY PRECAUTIONS Page 06

Electrical Safety Page 06

Outdoor Use Page 06

General Power Tool Safety Instructions Page 06

Additional Safety Instructions Page 10

GETTING STARTED Page 11

Unpacking Page 11

Machine Overview Page 12

Assembly and Preparation Page 13

Operating Instructions Page 13

MAINTENANCE Page 17

Environmental Protection Page 17

DECLARATION OF CONFORMITY Page 18

2

Page 3

www.evolutionpowertools.com

EN

DE

FR

ES

1.2

This Instruction Manual was originally

written in English.

(1.3)

IMPORTANT

Please read these operating and safety

instructions carefully and completely.

For your own safety, if you are uncertain

about any aspect of using this equipment

please access the relevant Technical Helpline,

the number of which can be found on the

Evolution Power Tools website. We operate

several Helplines throughout our worldwide

organization, but Technical help is also

available from your supplier.

WEB

www.evolutionpowertools.com

(1.4)

Congratulations on your purchase of an

Evolution Power Tools Machine. Please

complete your product registration ‘online’

as explained in the A4 online guarantee

registration leaflet included with this

machi ne. You ca n also scan the Q R code

found on the A4 leaflet with a Smart Phone.

This wil l enable you to val idate your

machine’s guarantee period via Evolutions

website by entering your details and thus

ensure prompt service if ever needed. We

sincerely thank you for selecting a product

from Evolution Power Tools.

EVOLUTION LIMITED GUARANTEE.

Evolution Power Tools reserves the right

to make improvements and modifications

to the product design without prior notice.

(1.5)

Evolution Power Tools will, within the

guarantee period, and from the original date of

purchase, repair or replace any goods found to

be defective in materials or workmanship. This

guarantee is void if the tool being returned

has been used beyond the recommendations

in the Instruction Manual or if the machine

has been damaged by accident, neglect, or

improper service. This guarantee does not

apply to machines and / or components which

have been altered, changed, or modified

in any way, or subjected to use beyond

recommended capacities and specifications.

Electrical components are subject to respective

manufacturers’ warranties. All goods returned

defective shall be returned prepaid freight

to Evolution Power Tools. Evolution Power

Tools reserves the right to optionally repair or

replace it with the same or equivalent item.

There is no warranty – written or verbal – for

consumable accessories such as (following list

not exhaustive) blades, cutters, drills, chisels

or paddles etc. In no event shall Evolution

Power Tools be liable for loss or damage

resulting directly or indirectly from the use

of our merchandise or from any other cause.

Evolution Power Tools is not liable for any

costs incurred on such goods or consequential

damages. No officer, employee or agent of

Evolution Power Tools is authorized to make

oral representations of fitness or to waive any

of the foregoing terms of sale and none shall

be binding on Evolution Power Tools.

Questions relating to this limited

guarantee should be directed to the

company’s head office, or call the

appropriate Helpline number.

Please refer to the guarantee registration

leaflet and/or the packaging for details of

the terms and conditions of the guarantee.

3

Page 4

www.evolutionpowertools.com

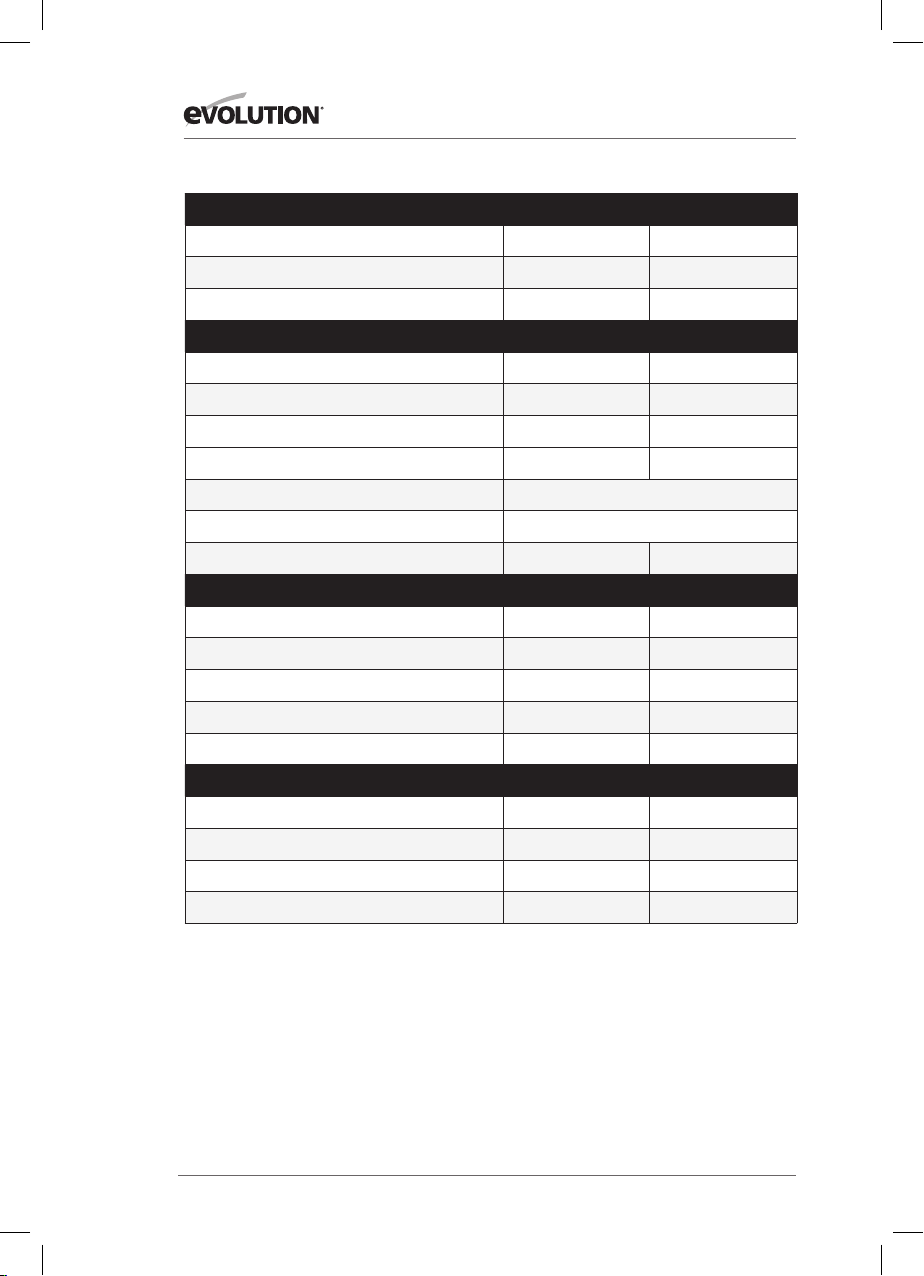

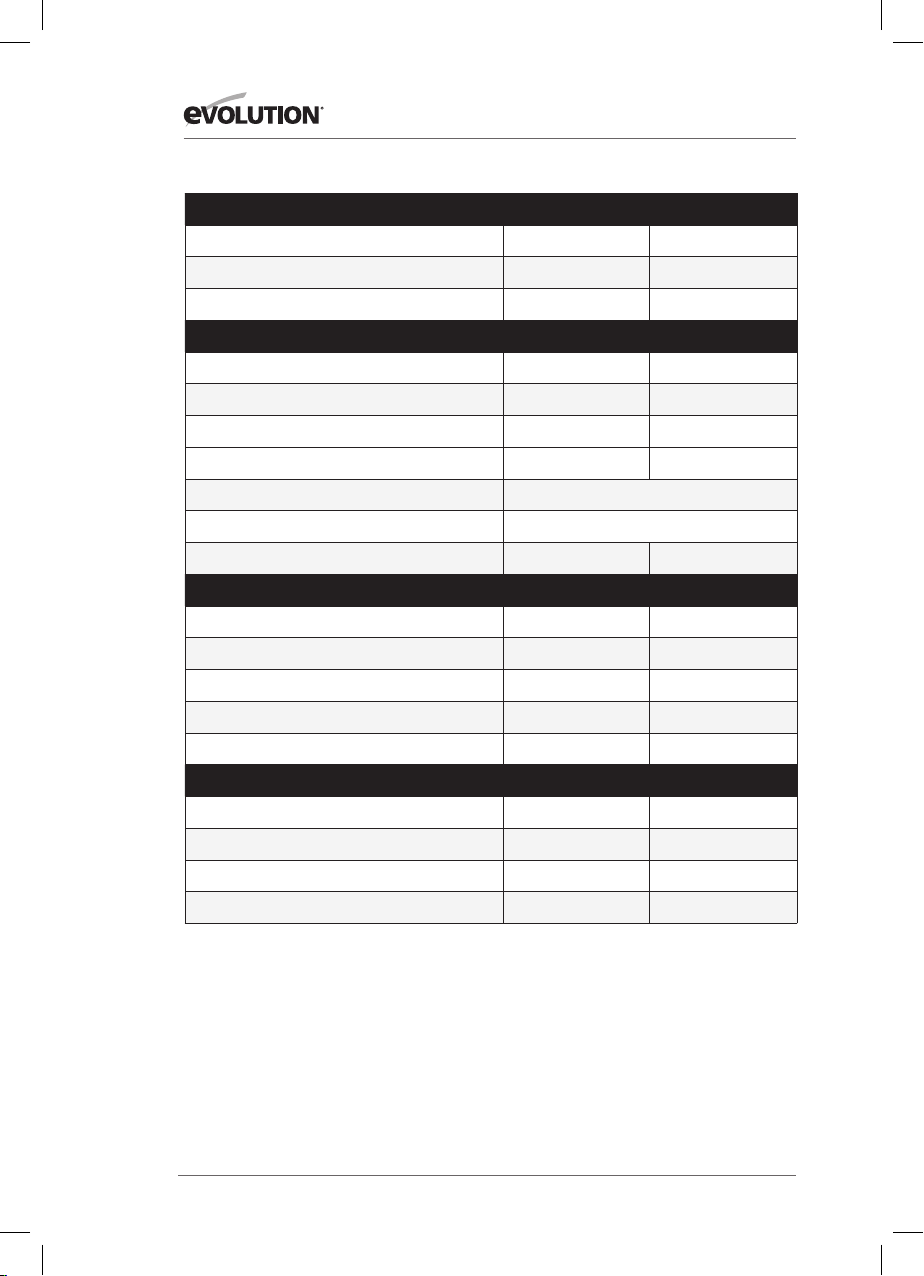

SPECIFICATIONS

POWER METRIC IMPERIAL

UK/EU Motor (230-240V ~ 50Hz) 2400W 10A

UK Motor (110V ~ 50Hz) 2000W 18A

USA Motor (120V ~ 60Hz) 1800W 15A

MACHINE METRIC IMPERIAL

Maximum Depth of Cut

*Progressive/incremental cutting required to obtain maximum cutting depth.

UK/EU Sp eed (No Load) 4500min

USA Speed (No Load) 5000min

AUS Rated Spe ed (No Load) 4900min

Protection Class Class II (UK & EU) / Class I (US)

Degree of Protection IP20

Gross Weight 9.5kg 21lb s

BLADE METRIC IMPERIAL

Diameter 305mm 12”

UK & EU Bore 22.2mm 7/8”

USA Bore 25.4mm 1”

Thickness 3mm 1/8”

Maximum Speed 5500min

NOISE & VIBRATION DATA 110V 120V MODELS 230V 240V MODELS

Sound Pre ssure LPA 96.0dB(A) K=3dB(A) 98.3dB(A) K=3dB(A)

Sound Powe r Level LWA 110.0d B(A) K=3dB(A) 112.0dB(A) K=3dB(A)

Front Handle Vibration Level 3.2 94m/s2 K=1. 5m/s22,273 m/s2 K=1. 5m/s

Rear Handle Vibration Level 3. 611m /s2 K=1. 5m/s23.788m/s2 K=1. 5m/s

*

100mm 4”

-1

-1

-1

-1

4500rpm

5000rpm

4900rpm

5500rpm

2

2

(1.6)

Note: The vibration measurement was made

under standard conditions in accordance with:

BS EN 61029-1:2009

The declared vibration total value has been

measured in accordance with a standard test

method and may be used for comparing one

tool with another.

The declared vibration total value may also be

used in a preliminary assessment of exposure.

(1.7)

VIBRATION

WARNING: When using this machine the

operator can be exposed to high levels of

vibration transmitted to the hand and arm.

It is possible that the operator could develop

“Vibration white finger disease” (Raynaud

syndrome). This condition can reduce the

sensitivity of the hand to temperature as well

as producing general numbness. Prolonged or

regular users of this machine should monitor

4

Page 5

www.evolutionpowertools.com

EN

DE

FR

ES

the condition of their hands and fingers closely.

If any of the symptoms become evident, seek

immediate medical advice.

• The measurement and assessment of

human exposure to hand-transmitted

vibration in the workplace is given in:

BS EN ISO 5349-1:2001 and

BS EN ISO 5349-2:2002

• Many factors can influence the actual

vibration level during operation e.g. the

work surfaces condition and orientation

and the type and condition of the machine

being used. Before each use, such factors

should be assessed, and where possible

appropriate working practices adopted.

Managing these factors can help reduce

the effects of vibration:

Handling

• Handle the machine with care, allowing

the machine to do the work.

• Avoid using excessive physical effort on

any of the machines controls.

• Consider your security and stability,

and the orientation of the machine

during use.

Work Surface

• Consider the work surface material; its

condition, density, strength, rigidity and

orientation.

(1.8)

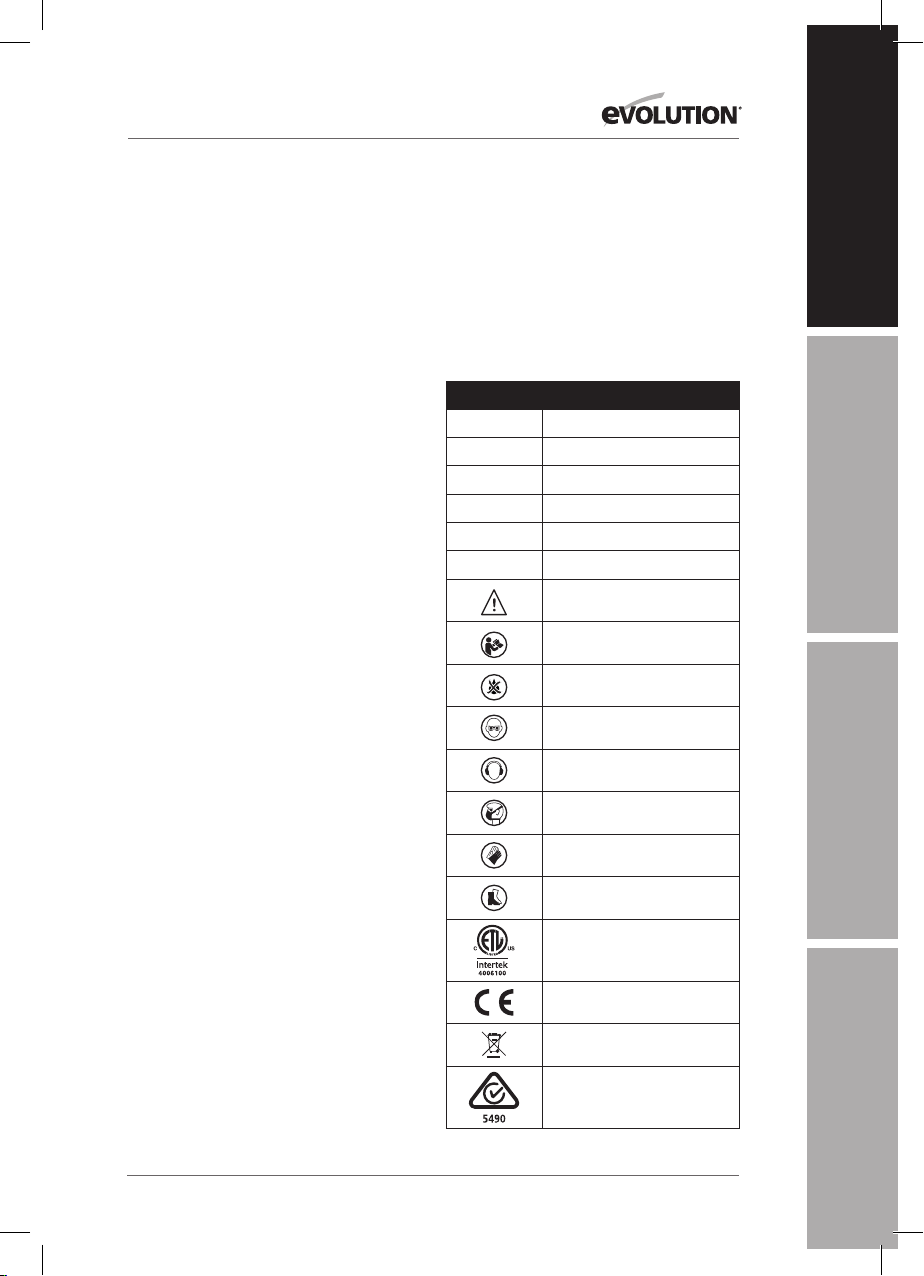

LABELS & SYMBOLS

WARNING: Do not operate this machine if

warning and/or instruction labels are missing

or damaged. Contact Evolution Power Tools

for replacement labels.

Note: All or some of the following symbols

may appear in the manual or on the product.

SYMBOL DESCRIPTION

V Volts

A Amperes

Hz Hertz

-1

Min

~ Alternating Current

n Rated Speed

Speed

Warning!

Read Instructions

Drt Cutting Only

Wear Safety Goggles

Wear Ear Protection

Wear Dust Protection

WARNING: The vibration emission during

actual use of the power tool can differ from

the declared total value depending on the

ways in which the tool is used. The need

to identify safety measures and to protect

the operator are based on an estimation

of exposure in the actual conditions of use

(taking account of all parts of the operating

cycle, such as the times the tool is switched

off, when it is running idle, in addition to

trigger time).

Wear Safety Gloves

Wear Safety Boots

US Certification

CE Certification

Waste Electrical &

Electronic Equipment

(RCM) Regulatory Compliance Mark

for electrical and electronic equipment.

Australian/New Zealand Standard

5

Page 6

www.evolutionpowertools.com

(1.10 )

INTENDED USE OF

THIS POWER TOOL

WARNING: This product is a Hand Operated

Disc Cutter and has been designed to be

used with special Evolution blades. Only use

accessories designed for use in this machine

and/or those recommended specifically by

Evolution Power Tools Ltd.

When fitted with an appropriate blade

this machine can be used to cut:

Brick

Paving

Kerb Stones

Concrete

1.11

PROHIBITED USE OF

THIS POWER TOOL

WARNING: This product is a Hand Operated

Disc Cutter and must only be used as such. It

must not be modified in any way, or used to

power any other equipment or drive any other

accessories other than those mentioned in

this Instruction Manual. (1.11)

WARNING: This machine must not be used to

cut any material that may contain asbestos. If

the presence of asbestos is suspected, consult

the relevant authorities for advice.

(1.13)

WARNING: This machine is not intended

for use by persons (including children)

with reduced physical, sensory or mental

capabilities, or lack of experience and

knowledge, unless they have been given

supervision or instruction concerning the safe

use of the machine by a person responsible

for their safety and who is competent in its

safe use.

Children should be supervised to ensure

that they do not have access to, and are not

allowed to play with, this machine.

(1.14 )

ELECTRICAL SAFETY

This machine is f itted with the correct

moulded plug and mains lead for the

designated market. If the supply cord is

damaged, it must be replaced by a special

cord or assembly available from the

manufacturer or its service agent.

(1.15 )

OUTDOOR USE

WARNING: For your protection if this tool

is to be used outdoors it should not be

exposed to rain, or used in damp locations.

Do not place the tool on damp surfaces.

Use a clean, dry workbench if available. For

added protection use a residual current

device (R.C.D.) that will interrupt the supply

if the leakage current to earth exceeds 30mA

for 30ms. Always check the operation of the

residual current device (R.C.D.) before using

the machine.

If an extension cable is required it must be a

suitable type for use outdoors and so labelled.

The manufacturers instructions should be

followed when using an extension cable.

(2 .1)

GENERAL POWER TOOL

SAFETY INSTRUCTIONS

WARNING: Read all safety warnings and

instructions. Failure to follow the warnings

and instructions may result in electric shock,

fire and/ or serious injury.

Save all warnings and instructions for

future reference.

The term “power tool” in the warnings refers

to your mains-operated (corded) power tool

or battery-operated (cordless) power tool.

(2.2)

1) General Power Tool Safety Warnings

[Work area safety]

a) Keep work area clean and well lit.

Cluttered or dark areas invite accidents.

b) Do not operate power tools in

6

Page 7

www.evolutionpowertools.com

EN

DE

FR

ES

explosive atmospheres, such as in the

presence of flammable liquids, gasses or

dust. Power tools create sparks which may

ignite the dust or fumes.

c) Keep children and bystanders away

while operating power tool. Distractions

can cause you to lose control.

(2.3)

2) General Power Tool Safety Warnings

[Electrical Safety]

a) Power tool plugs must match the

outlet. Never modify the plug in any way

Do not use any adapter plugs with

earthed (grounded) power tools.

Unmodified plugs and matching outlets will

reduce the risk of electric shock.

b) Avoid body contact with earthe d

or grounded surfaces, such as pipes,

radiators, ranges and refrigerators. There

is an increased risk of electric shock if your

body is earthed or grounded.

c) Do not expose power tools to rain or

wet conditions. Water entering a power tool

will increase the risk of electric shock.

d) Do not abuse the cord. Never use the cord

for carrying, pulling or unplugging the power

tool. Keep cord away from heat, oil, sharp

edges or moving parts. Damaged or entangled

cords increase the risk of electric shock.

e) When operating a power tool outdoors,

use an extension cord suitable for

outdoor use. Use of a cord suitable for

outdoor use reduces the risk of electric shock.

f) If operating a power to ol in a damp

location is unavoidable, use a residual

current device (RCD) protected supply. Use

of an RCD reduces the risk of electric shock.

(2.4)

3) General Power Tool Safety Warnings

[Personal Safety].

a) Stay alert, watc h what you are doing

and use common sense when operating

a power tool. Do not use a power tool

while you are tired or under the influence of

drugs, alcohol or medication. A moment of

inattention while operating power tools may

result in serious personal injury.

b) Use personal protective equipment.

Always wear eye protection. Protective

equipment such as dust masks, non-skid

safety shoes, hard hat or hearing protection

used for appropriate conditions will reduce

personal injuries.

c) Prevent unintentional starting. Ensure

the switch is in the off-position before

connecting to power source and or battery

pack, picking up or carrying the tool. Carrying

power tools with your finger on the switch

or energising the power tools that have the

switch on invites accidents.

d) Remove any adjusting key or wrench

before turning the power tool on. A

wrench or key left attached to a rotating part

of a power tool may result in personal injur y .

e) Do not overreach. Keep proper footing and

balance at all times. This enables bet ter control

of the power tool in unexpected situations.

f) Dress properly. Do not wear loose

clothing or jewellery. Keep your hair, clothing

and gloves away from moving par ts. Loose

clothes, jewellery or long hair can be caught

in moving parts.

g) If devices are provided for the

connection of dust extraction and

collection facilities, ensure that these are

connected and properly used. Use of dust

collection can reduce dust-related hazards.

(2.5)

4) Gener al Power Tool Safety War nings

[Power tool use and care].

a) Do not force the power tool. Use the correct

power tool fo r your application. Th e correct

power tool w ill do the job better and s afer at a rate

for which it was d esigned.

b) Do not use t he power tool if t he switch

does not t urn it on or off. Any p ower tool that

cannot be cont rolled with the switch is d angerous

and must be repaired.

c) Disconnect the power tool from the

power source and/or battery pack from the

power tool before making any adjustments,

7

Page 8

www.evolutionpowertools.com

changing accessories, or storing power tools.

Such preventat ive safety measures r educe the risk

of star ting the power tool accide ntally.

d) Store id le power tools o ut of the reach o f

children and do not allow persons unfamiliar

with the power tool or these Instructions

to opera te the power too l. Power tools are

dangerous in t he hands of untrained use rs.

e) Mainta in power tools . Check for

misalignment or binding of moving parts,

breakage of moving parts and any other condition

that may aff ect the power tools op eration. If

damaged, h ave the p ower tool repaired be fore

use. Many accide nts are caused by poorl y

maintained power tools.

f) Keep cutting tools sharp and clean. Properly

maintained cutting tools with sharp cutting edges

are less likely to b ind and are easier to control.

g) Use the power tool, accessories and

tool bits etc. in accordance with these

instructions, taking into account the

working conditions and the work to be

performed. Use of the power to ol for operations

different from those intended could result in a

hazardous situation.

(2.6)

5) Genera l Power Tool Safety War nings

[Service]

a) Have your powe r tool servi ced by a

qualified repair person using only identical

replacement parts. This w ill ensure that the

safet y of the power tool is maintain ed.

(2.7)

HEALTH ADVICE

WARNING: When using this machine, dus t

particl es may be produced. In som e instances,

depending on the materials you are working

with, this dust c an be particularl y harmful. If you

suspect t hat paint on the surface o f material you

wish to cut contai ns lead, seek professio nal advice.

Lead based p aints should only be re moved

by a professio nal and you should not atte mpt

to remove it your self. Once the dust has been

deposite d on surfaces, hand to mo uth contact can

result in the in gestion of lead. Exp osure to even

low levels of lea d can cause irreversibl e brain and

nervous s ystem damage. The youn g and unborn

children are particularly vulnerable. You are

advised to co nsider the risks associ ated with the

materials you ar e working with and to reduce t he

risk of expo sure. As some materials can p roduce

dust that may be ha zardous to your health, we

recommend t he use of an approved face mask

with replace able filters when us ing this machine.

You should always:

• Work i n a well-ventilated area.

• Work w ith approved safet y equipment, such as

dust masks t hat are specially design ed to filter

microscopic particles.

SAFET Y INSTRU CTIONS F OR ABRAS IVE

CUTTING OFF OPERATIONS

Cut-off machine safety warnings

a) The guard p rovided wit h the tool must

be securely attached to the power tool and

posit ioned for max imum safet y, so the least

amount of wheel is exposed towards the

operator. Position yourself and bystanders

away from the plane of the rotating wheel. The

guard helps to p rotect operator fr om broken wheel

fragments and accidental contact with wheel.

b) Use only bonded reinforced or diamond

cut- off wheels f or your power too l. Just

because an a ccessory can be att ached to your

power tool, i t does not assure safe ope ration.

c) The rate d speed of the ac cessory mu st be at

least e qual to the max imum speed m arked on

the powe r tool. Accessories r unning faster than

their rated sp eed can break and f ly apart.

d) Wheels must be used only for recommended

applications. For example: do not grind with

the sid e of cut-of f wheel. Abrasive cut-off wheels

are intended for peripheral grinding, side forces

applied to th ese wheels may cause them to s hatter.

e) Always use undamaged wheel flanges

that are of correct diameter for your selected

wheel. Proper wheel f langes support t he wheel

thus reducing the possibility of wheel breakage.

f) Do not use worn down reinforced wheels

from lar ger power tool s. Wheels intended

for a larger p ower tool are not suitable f or the

8

Page 9

www.evolutionpowertools.com

EN

DE

FR

ES

higher spe ed of a smaller tool and may bu rst.

g) The outside diameter and the

thickness of your accessory must be

within the capacity rating of your power

tool. Incorrectly si zed accessories cannot

be adequately guarded or controlled.

h) The arbour size of wheels and flanges must

prope rly fit the spi ndle of the powe r tool.

Wheels and f langes with arbou r holes that do not

match the mounti ng hardware of the power too l

will run out of b alance, vibrate excessive ly and may

cause loss of con trol.

i) Do not use damaged wheels. Before each

use, inspect the wheels for chips and cracks.

If power t ool or wheel is d ropped, in spect for

damage

or install an undamaged wheel. After

inspecting and installing the wheel, position

yourself and bystanders away from the plane

of the rotating wheel and run the power tool

at maxi mum no load spe ed for one minu te.

Damaged wheels will normally break apart during

this test time.

j) Wear personal protective equipment.

Depending on application, use face shield,

safet y goggles or sa fety glass es. As

appropriate, wear dust mask, hearing

protectors, gloves and shop apron capable of

stopping small abrasive or workpiece

fragments. The eye p rotection must be c apable

of stopping flying debris generated by various

operatio ns. The dust mask or respir ator must be

capable of f iltrating parti cles generated by your

operatio n. Prolonged expo sure to high intensity

noise may cause h earing loss.

k) Keep byst anders a safe d istance away fr om

work area. Anyone entering the work

area must wear personal protective

equipment. Fragments of wo rkpiece or of a

broken whe el may fly away and cause injur y beyond

immediate area of operation.

l) Hold th e power tool by ins ulated grip ping

surfaces only, when performing an operation

where the cutting accessory may contact

hidden wiring or its own cord.

Cutting access ory contacting a “ live” wire may make

expose d metal parts of the p ower tool “live” and

could give the op erator an electri c shock.

m) Position the cord clear of the spinning

accessory. If you lose control, the cor d may be

cut or snagge d and your hand or arm may be pul led

into the spinning wheel.

n) Never lay th e power tool down u ntil the

accessory has come to a complete stop.

The spinnin g wheel may grab the sur face and pull

the power too l out of your control.

o) Do not run t he power tool whi le carryin g it at

your side. Accidental contact w ith the

spinning access ory could snag your clo thing, pulling

the accessor y into your body.

p) Regula rly clean the p ower tool’s air ve nts.

The motor ’s fan w ill draw the dust inside the hou sing

and excessive acc umulation of powdered m etal may

cause electrical hazards.

q) Do not operate the power tool near

flammable materials. Sparks could igni te these

materials.

r) Do not use accessories that require liquid

coolants. Using water or other liq uid coolants may

result in ele ctrocution or shoc k.

FURTHER SAFETY INSTRUCTI ONS FOR

ABRASIVE CUTTING OFF OPERATIONS

Kickback and related warnings

Kickba ck is a sudden reaction to a pi nched or

snagged rotating wheel. Pinching or snagging

causes rapi d stalling of the rotatin g wheel which in

turn causes th e uncontrolled power to ol to be forced

in the direc tion opposite of the wh eel’s rotation at

the point of th e binding. For example, i f an abrasive

wheel is sna gged or pinched by the wor kpiece, the

edge of the w heel that is entering into the p inch

point can dig i nto the surface of the mater ial causing

the wheel to c limb out or kick out. The w heel may

either jump tow ard or away from the operato r,

dependin g on direction of the wh eel’s movement

at the point of p inching. Abrasive whe els may also

break under t hese conditions. Kick back is the result

of power tool m isuse and/or incorrect op erating

procedure s or conditions and can be avoid ed by

taking proper precautions as given below.

a) Mainta in a firm grip on t he power tool an d

posit ion your body an d arm to allow you to

resist kickback forces. Always use auxiliary

9

Page 10

www.evolutionpowertools.com

handle , if provided , for maximum c ontrol over

kickback or torque reaction during startup. The operator can control torque reactions or

kickba ck forces, if proper pre cautions are taken.

b) Never place your hand near the rotating

accessory. Accessory may kick back over your hand.

c) Do not pos ition your bo dy in line with t he

rotating wheel. Kickback w ill propel the tool in

directi on opposite to the wheel ’s move ment at the

point of snag ging.

d) Use special care when working corners,

sharp edges etc. Avoid bouncing and snagging

the accessory. Corners, sharp edges or bouncing

have a tendenc y to snag the rotating accesso ry and

cause loss of con trol or kickback.

e) Do not attach a saw chain, woodcarving

blade, segmented diamond wheel with a

peripheral gap greater than 10 mm or toothed

saw blad e. Such blades create fr equent kickback

and loss of contro l.

f) Do not “jam” the wheel or apply excessive

pressure. Do not attempt to make an excessive

depth o f cut. Overstressing the wheel increases the

loading and susceptibility to twisting or binding of

the wheel i n the cut and the possibilit y of kickback or

wheel breakage.

g) When wheel is binding or when interrupting

a cut for any r eason, swit ch off the powe r tool

and hold the power tool motionless until the

wheel c omes to a compl ete stop. Never at tempt

to remove t he wheel from t he cut while t he

wheel is in motion otherwise kickback may

occu r. Investigate and take corre ctive action to

eliminate the c ause of wheel binding .

h) Do not restart the cutting operation in the

workpiece. Let the wheel reach full speed and

carefully re-enter the cut. The whe el may bind,

walk up or kic kback if the power tool is r estarted in

the workpi ece.

i) Support panels or any oversized workpiece to

minimize the risk of wheel pinching

and kickback. Large work pieces tend to sag unde r

their own weig ht. Supports must b e placed under

the workpi ece near the line of cut and ne ar the edge

of the workp iece on both sides of the wh eel.

j) Use extra caution when making a “pocket

cut” i nto existin g walls or othe r blind areas .

The protru ding wheel may cut gas or wate r pipes,

electr ical wiring or objec ts that can cause kick back.

(2.8)

WARNING: the operation of any powe r

tool can resul t in foreign object s being thrown

towards your eyes , which could result in severe eye

damage. Be fore beginning power to ol operation,

always wear saf ety goggles or saf ety glasses with

side shield o r a full face shield where n ecessary.

ADDITIONAL SAFETY INSTRUCTIONS

WARNING: Always disconnect the Disc Cutter

from the mains s upply before changin g discs,

servi cing, cleaning or adjusti ng the Disc Cutter.

• Ke ep your hands away from cut ting area and

the cuttin g disc. Keep your second ha nd on

the auxiliar y handle or motor housi ng. If both

hands are holding the machine, they cannot

come into contac t with the diamond disc .

• N ever engage the spindle l ock button while

the machine is running. Serious damage could

occur to the mach ine and potentially a ver y

hazardo us situation arise for the op erator.

• O nly use diamond discs or o ther approved

cutting di scs as specified by t he manufacturer.

Do not oper ate the cutter while app lying water.

The cutting discs are ‘dry cut’ discs.

• A lways check the diamond dis c before startin g

the machine. I f it is cracked, broken or be nt,

do not use it. C arefully start th e machine and

check for any unu sual noises, vibratio n or other

abnormalities.

• B e careful when cutt ing metal. Using the

diamond disc to cut metal (reinforcing rods

embedde d in concrete) will shorten i ts service

life and could l ead to disc damage.

• A llow the Cutting Disc to reach f ull speed

before beginning a cut. Start working only

when maxi mum speed is reached.

• D o not use excessive force. Exce ssive force

overloads th e motor and reduces worki ng

eff iciency and ser vice life. Always cut concrete ,

tile or stone t o a maximum cutting dep th of

50mm or less . If the cutting depth is mo re than

50mm, cut the wo rkpiece 2 or 3 times. I f the

workpie ce is cut with a cutting dept h of more

than 50mm, th e service life of the diam ond disc

will be re¬ duced and the motor may sei ze.

10

Page 11

www.evolutionpowertools.com

EN

DE

FR

ES

• I nstall the dust extr action port cover w hen

a dust collec tion hose is not in use. Dur ing

cutting operations if sparks could be generated,

cover the dust ex traction por t with its rubber

cap and be sure to w ear protective glasses .

• N ever use a damaged or incor rect arbor bolt

or disc fla nges. The disc flan ges and arbor bolt

were specia lly designed for your mac hine to

provide opt imum performance an d safety of

operation.

• T his saw is equipped with an a pproved cord

and plug for i ts intended Country of u se. Do not

alter or modi fy the power cord. If th e moulded

plug or the p ower cord is damaged in any way

it must be rep laced with an identical t ype by a

competent technicia n.

WARNING: This machine must not be us ed to

cut any material th at may contain asbestos. If th e

presence of as bestos is suspected , consult the

relevant authorities for advice.

PPE (Personal Protective Equipment)

Note: If using th is equipment on a construc tion

site it is impor tant that the operato r conforms to

any site rules/re gulations that may apply. Consult

the site forem an or other responsible p erson for

details.

a. Wear suitable clothing. This could include a

Boiler Suit o r Padded Coverall and Hi Vis jacket etc.

b. Wear suitable footwear. Safet y shoes with

steel toecaps and anti-slip soles are recommended.

c. Wear suitable Safety Glasses. A Full Face

Safety Shield or Saf ety Goggles with si de shields

which provide protection from thrown debris is

recommended.

d. Protect you hearing. Wear suitable ear

protectors.

e. Wear sui table gloves. H igh grip gloves are

recommended.

f. Wear respiratory protection. A dust mask

with replace able filters which pr ovide protection

against f ine toxic dust, fibres and vapour s is

recommended.

g. Wear a Saf ety Helmet . The use of a Safety

Hat may be compulsory on co nstruction sites to

protect th e operator from potential overhead

dangers.

(4.1) GETTING STARTED - UNPACKING

Caution: This pack aging contains sharp obj ects.

Take care when unpack ing. Remove the machine,

together w ith the accessories suppl ied from the

packagin g. Check carefully to ensu re that the

machine is in go od condition and account fo r all

the accessori es listed in this manual. Also m ake

sure that all the acce ssories are complete. If a ny

parts a re found to be missing, the mac hine and its

accessories s hould be returned tog ether in their

original pa ckaging to the retaile r. Do not th row

the packag ing away; keep it safe throug hout the

guarantee p eriod. Dispose of the p ackaging in

an environmentally responsible manner. Recycle

if possible . Do not let children play wit h empty

plastic ba gs due to the risk of suffoc ation.

(4.2)

ITEMS SUPPLIED

DESCRIPTION QUANTITY

Instruction Manual

Blade (Fitted)

Spanner (blade change)

Rubber Cap

(extraction port)

1

1

1

1

4.3

ADDITIONAL ACCESSORIES

In addition to the standard items supplied

with this machine the following accessories

are also available from the Evolution online

shop at www.evolutionpowertools.com or

from your local retailer.

(4.4)

DESCRIPTION PART NO

Specialist cutting blades

(use only Evolution Blades

or Evolution approved blades

with this machine)

Not suitable for resharpening.

Specific to

blade type

11

Page 12

www.evolutionpowertools.com

MACHINE OVERVIEW

6

7

5

3

2

1

4

1. Safety Lock Button

2. Trigger Switch

3. Dust Extraction Port

4. Cutting Disc

5. Adjustable Disc Guard

6. Arbor Lock Button

7. Anti-vibration Front handle

12

Page 13

www.evolutionpowertools.com

EN

DE

FR

ES

FIG. 1

FIG. 2

OPERATING INSTRUCTIONS

The tool is recommended to always be supplied via a residual

current device with a rated residual current of 30 mA or less.

INSTALLING/REMOVING A DISC

WARNING: Always disconnect the machine from the power

supply before attempting to install or remove a Cutting Disc.

• Ensure that the machines arbor and the blade flanges are

clean and free from dust and debris.

• Ensure that the direction of rotation marked on the blade

matches the direction of rotation marked on the machines

guard.

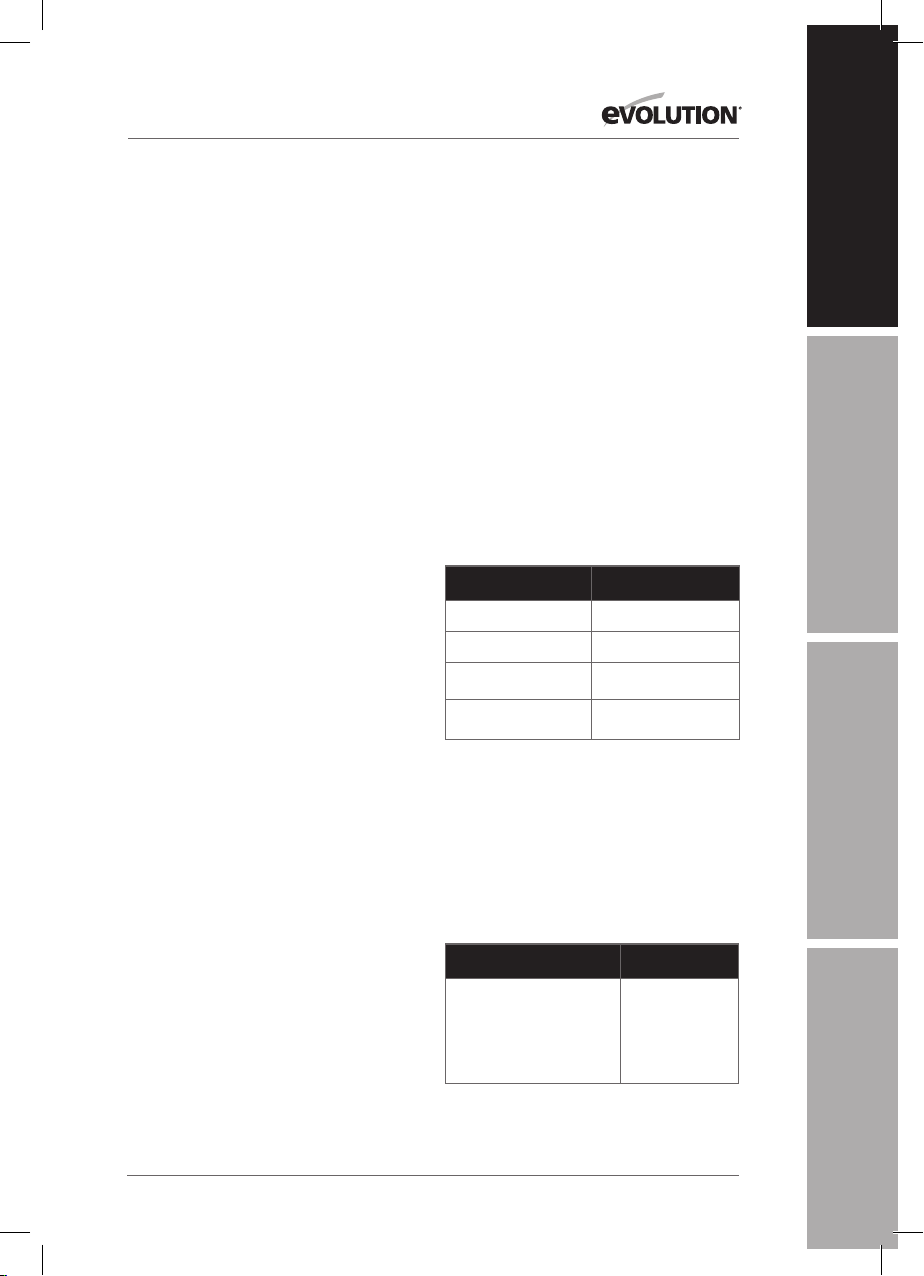

Note: This machine is supplied with two (2) blade f langes. These

can accommodate blades with either a ø20mm (ø3/4”) or ø22.2

(ø7/8”) arbor hole depending upon how they are installed.

• Install blade flange ‘A’ on the inner side when the arbor hole

in the cutting disc is ø22.2mm (ø7/8”). FIG. 1

• Install the blade flange ‘B’ on the inner side when the arbor

hole in the cutting disc is ø20mm (ø3/4”) FIG. 2

• Install the cutting blade and outer blade flange, washer and

arbor bolt.

• Press the arbor lock to lock the machines arbor.

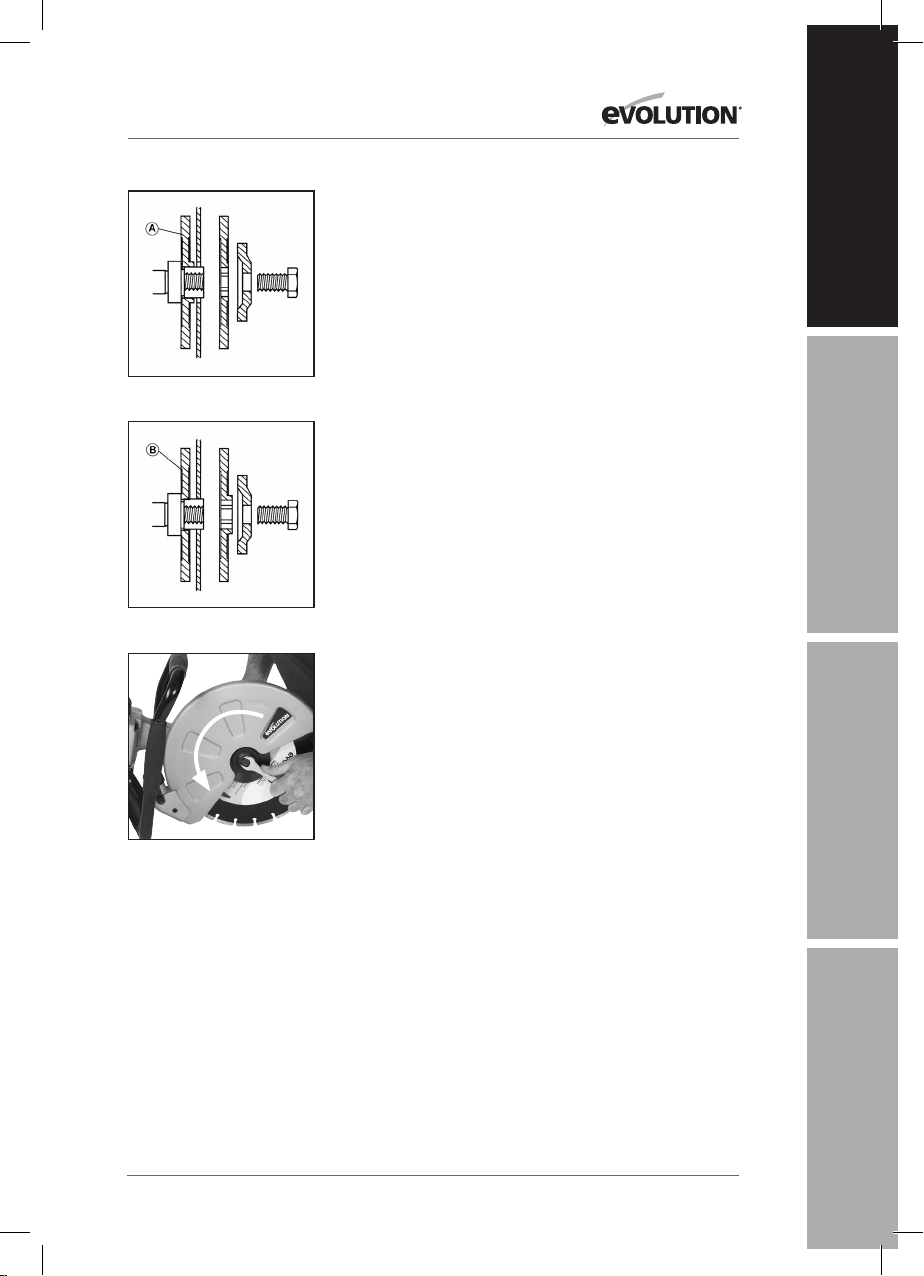

• Tighten the arbor bolt using the supplied spanner. FIG. 3

• Release the arbor lock and check by hand that the Cutting

Disc is secure and correctly positioned on the arbor and that

if rotates freely.

FIG. 3

Note: The arbor bolt has a Left Hand thread. Turn

counterclock wise to tighten the arbor bolt. Turn clockwise to

loosen the arbor bolt.

To remove a Cutting Disc, reverse the above Installation

procedure.

13

Page 14

www.evolutionpowertools.com

USING A DUST EXTR ACTION MACHINE

A workshop dust extraction machine can be attached to the

Evolution Disc Cutter.

WARNING: Dust can be very dangerous. We strongly

recommend that a suitable dust extraction machine (not

supplied) is used with this machine to keep the workplace as

clean and safe as possible.

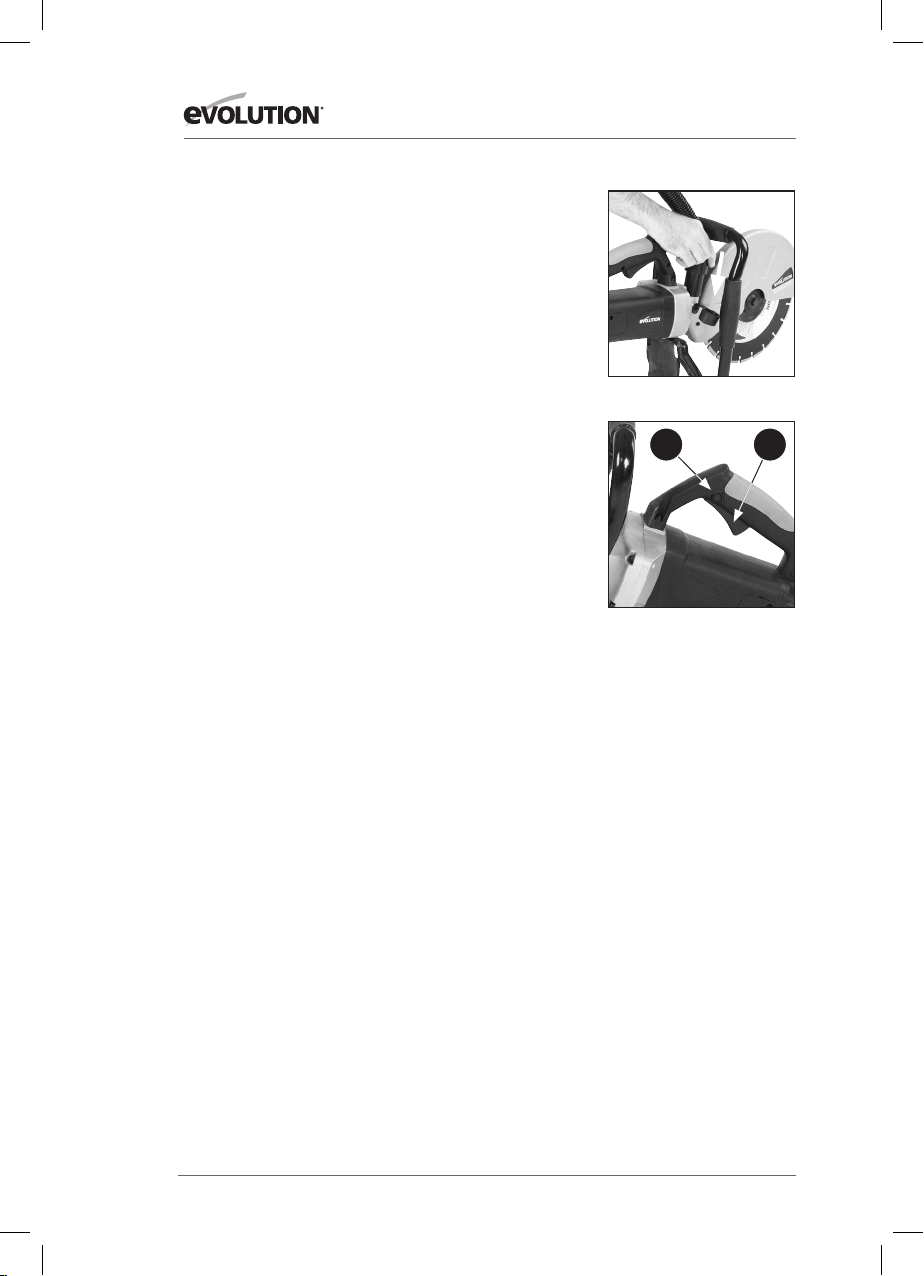

The suction hose from the dust extraction machine should be

attached to the dust ex traction port of the Disc Cutter.

• Remove the rubber cap from the dust extraction port and

store it safely for future use.

• Push the connection hose from the dust extraction machine

into the dust extraction port of the Disc Cutter. FIG. 4

• Follow all instructions supplied with the dust extraction

machine when using such with this Disc Cutter.

• Ensure that the hose and power cable of any attached dust

extraction machine do not pose or cause a trip or any other

form of hazard to the operator.

• When the dust extraction machine is no longer required,

remove it from the Disc Cutter and replace the rubber cap to

the dust extraction port.

THE ON/OFF TRIGGER SWITCH

This machine is equipped with a safet y start trigger switch.

FIG. 4

a b

FIG. 5a & 5b

To start the tool:

• Push in the safety lock button (Fi g. 5a) on the side of the

handle with your thumb.

• Depress the main trigger switch (Fig. 5b) to start the motor.

WARNING: Never start the saw with the cutting edge of the

saw blade in contact with the workpiece surface.

14

Page 15

www.evolutionpowertools.com

EN

DE

FR

ES

FIG. 6

CUTTING ADVICE

PRE-CUTTING ADVICE

• Ensure that the power supply matches the requirements

specified on the machines rating plate.

• Ensure that the machines trigger switch is in the ‘OFF’

position. If the machine is connected to a power source with

the trigger switch in the ‘ON’ position, the machine could

start operating immediately with the possibility of a serious

accident occurring.

• If an extension cable is required it must be a suitable type

for use outdoors and so labelled.

• The manufacturers instructions should be followed when

using an extension cable.

• Route any extension cable so that it does not pose a trip (or

any other) hazard to the operator or any bystanders.

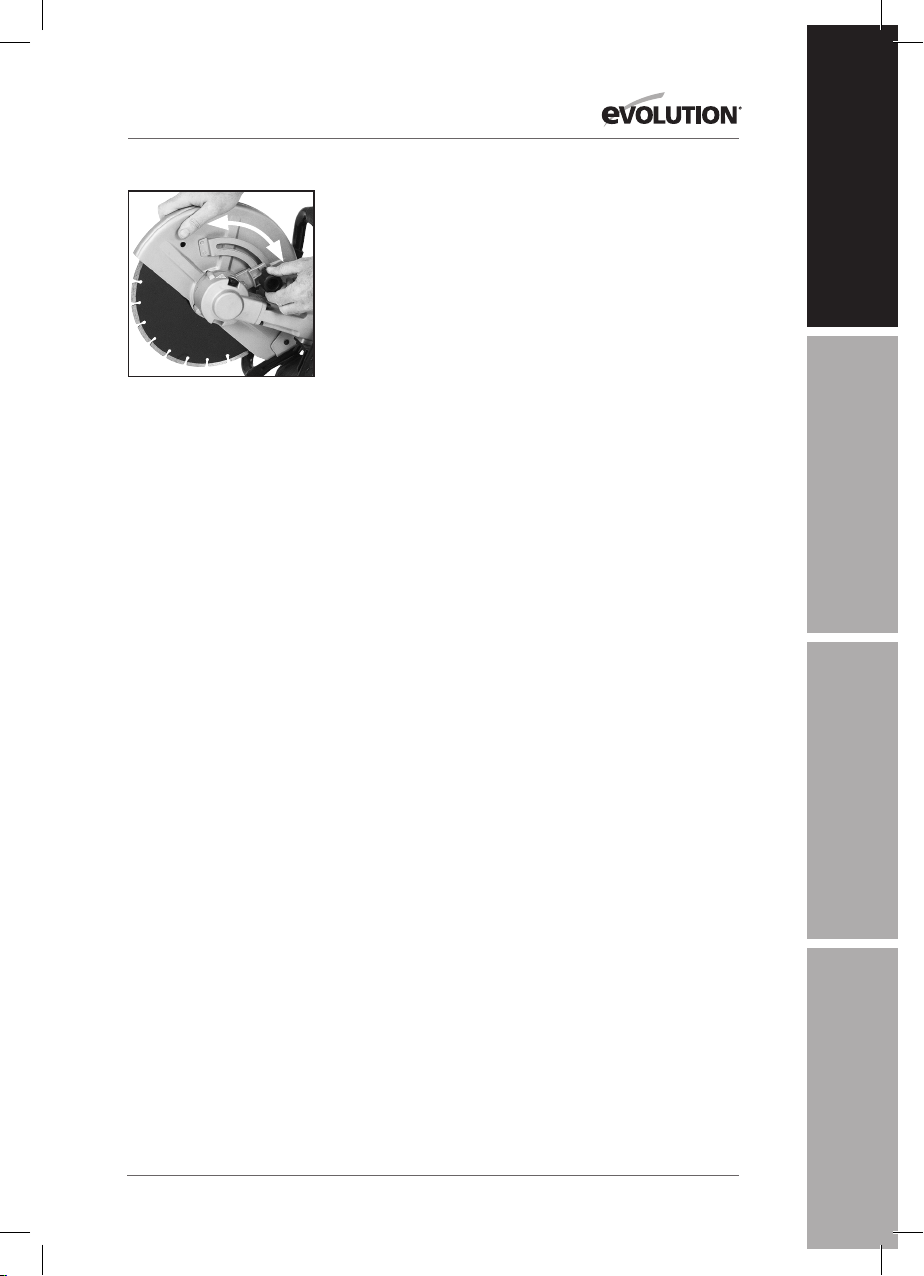

WHEEL GUARD ADJUSTMENT

The Wheel Guard is adjustable and should be positioned to

provide the operator with the best combination of personal

protection and visibility of the cutting area.

WARNING: Ensure that the machine is disconnected from the

power supply before adjusting the Wheel Guard.

• Loosen the Wheel Guard locking knob and rotate the Guard

to the required position. FIG. 6

• Securely tighten the Wheel Guard locking knob to lock the

Guard in place.

Note: The tightness of this locking knob and the security of

the Wheel Guard should be checked regularly when operations

commence.

15

Page 16

www.evolutionpowertools.com

CUTTING ADVICE

Mark out all the cutting lines on the workpiece using suitable

media – pencil, crayon, chalk etc. All cutting lines should be

clear and readily visible.

• If possible support the workpiece in such a way that it is

possible to predict what will happen, and that the cut will

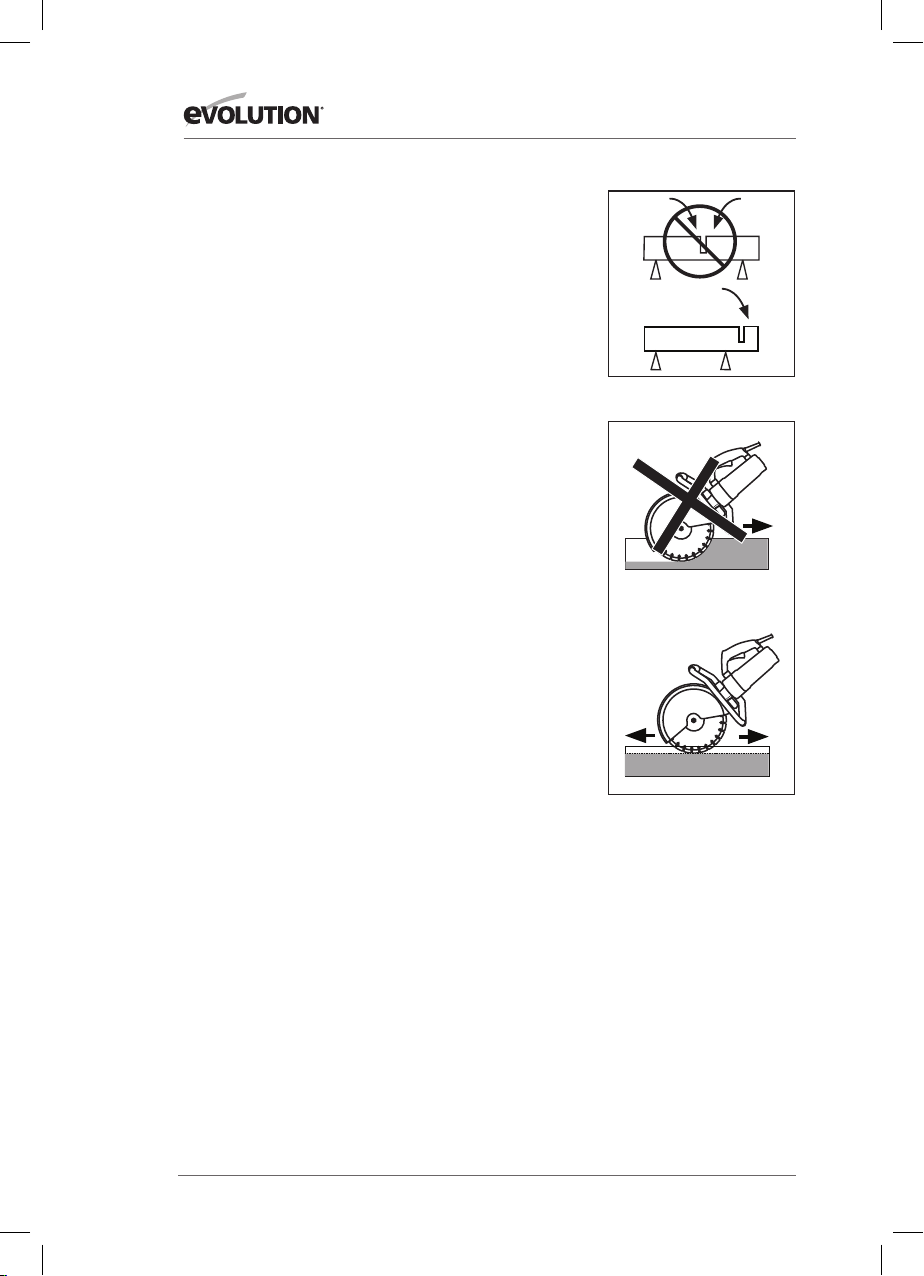

remain stable and open while cutting. (FIG. 7)

• Always align the diamond wheel with a pre-marked cutting

line before beginning operations, but ensure that the

diamond wheel is not touching the workpiece.

• Switch the machine ‘ON’ and allow the blade to reach its full

operational speed.

• Gently feed the blade into the workpiece. Cutting

performance is best when you cut straight ahead along the

pre-marked cutting line. Do not cut a depth of greater than

50mm (2”). FIG. 8 If a cut of greater than 50 mm (2”) is

required make several passes.

• Cut smoothly, allowing the machine to work without forcing

the blade.

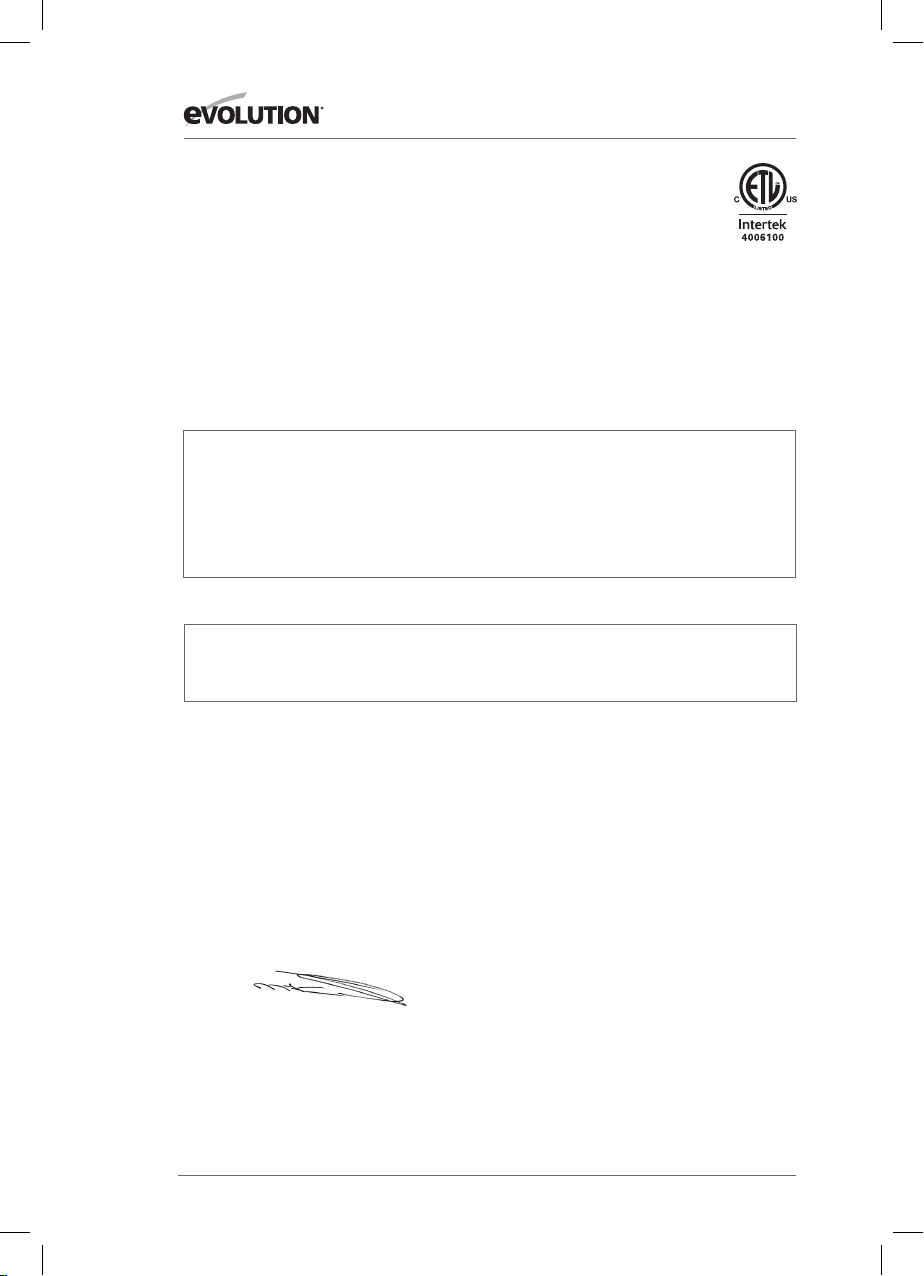

WARNING: Do not attempt to cut curved or zig zag lines.

Never use the side of the blade as a cutting surface. Never use

to perform inclination cutting.

• Do not apply water or coolant to the diamond blade.

• Move the blade slowly backwards and forwards and try to

achieve a small contact area between the blade and the

workpiece being cut. This reduces the temperature of the

blade and ensures efficient cutting.

• If the blade seizes or there is any abnormal noise,

immediately turn the power ‘OFF’ and investigate the

cause. Determine the cause of any noise or stoppage. Only

recommence cutting if it is safe to do so.

• Feed the machine down in line with the blade. Sideways

pressure on the blade disc can damage it and can be very

dangerous.

FIG. 7

FIG. 8

16

Page 17

www.evolutionpowertools.com

EN

DE

FR

ES

(6 .1) MAINTENANCE

Note: Any maintenance must be carried out with the machine

switched off and disconnected from the mains/battery power

supply.

Check that all safety features and guards are operating

correctly on a regular basis. Only use this machine if all guards/

safety features are fully operational.

All motor bearings in this machine are lubricated for life. No

further lubrication is required.

Use a clean, slightly damp cloth to clean the plastic parts of the

machine. Do not use solvents or similar products which could

damage the plastic parts.

WARNING: Do not attempt to clean by inserting pointed

objects through openings in the machines casings etc. The

machines air vents should be cleaned using compressed dry air.

Excessive sparking may indicate the presence of dirt in the

motor or worn out carbon brushes.

(6.2)

If this is suspected have the machine serviced and the brushes

replaced by a qualified technician.

(6.4)

ENVIRONMENTAL PROTECTION

Waste electrical products should not be disposed of with

household waste. Please recycle where facilities exist. Check

with your Local Authority or retailer for recycling advice.

17

Page 18

www.evolutionpowertools.com

DECLARATION OF CONFORMITY

The manufacturer of the product covered by this Declaration is:

Evolution Power Tools, Venture One, Longacre Close, Holbrook Industrial Estate, Shef field, S20 3FR

The manufacturer hereby declares that the machine as detailed in this declaration fulfils all the

relevant provisions of the Machinery Directive and other appropriate directives as detailed below.

The manufacture further declares that the machine as detailed in this declaration, where

applicable, fulfils the relevant provisions of the Essential Health and Safety requirements.

The Directives covered by this Declaration are as detailed below:

200 6/42/EC. Machinery Directive.

2014/30/EU. Electromagnetic Compatibility Directive.

93/68/EC. The CE Mark ing Directive .

20 11/6 5/E U. The Rest riction of the Us e of certain Haz ardous Substan ces in Electric al Equipment (Ro HS) Directive.

2002/96/EC. as amend ed by 2003/108/EC The Waste E lectrical an d Electronic Equ ipment (WEEE) Di rective.

And is in conformity with the applicable requirements of the following documents

EN 60745-1/A11:2010 • EN IS O 12100: 2010 • EN 55014-1: 2017 • EN 55014-2: 2015 •

EN61000-3 -2: 2014 • EN61000-3 -3: 2013

Product Details

Description: Evolution 305mm (12”) Multipurpose Electric Disc Cutter

Brand Name: Evolution Build

Voltage: 110V / 230-240V ~ 50Hz / 60Hz

Input: 1800W (120v) 2000W (110v) 2400W (230v)

The technical documentation required to demonstrate that the product meets the requirements

of directive has been compiled and is available for inspection by the relevant enforcement

authorities, and verifies that our technical file contains the documents listed above and that they

are the correct standards for the product as detailed above.

Name and address of technical documentation holder.

Signed: Print: Matthew Gavins - Operations Director

Date: 01/03/16

18

Page 19

www.evolutionpowertools.com

EN

DE

FR

ES

Notes

19

Page 20

www.evolutionpowertools.com

INHALTSVERZEICHNIS

English Page 02

Deutsch Seite 20

Français Page 40

Español Página 56

EINLEITUNG Seite 21

Garantie Seite 21

Python Programming Seite 22

Vibration Seite 22

Kennzeichnungen und Symbole Seite 23

Bestimmungsgemäßer Gebrauch des Elektrowerkzeugs Seite 24

Python Programming Gebrauch des Elektrowerkzeugs Seite 24

SICHERHEITSVORKEHRUNGEN Seite 24

Elektrische Sicherheit Seite 24

Verwendung im Freien Seite 24

Allgemeine Sicherheitsanweisungen zu Elektrowerkzeugen Seite 24

Zusätzliche Sicherheitsanweisungen Seite 29

ERSTE SCHRITTE Seite 30

Auspacken Seite 30

Maschinenübersicht Seite 32

Montage und Vorbereitung Seite 33

Betriebsanleitung Seite 33

INSTANDHALTUNG Seite 16

Umweltschutz Seite 37

KONFORMITÄTSERKLÄRUNG Seite 38

20

Page 21

www.evolutionpowertools.com

EN

DE

FR

ES

1.2

DIESES BEDIENUNGSHANDBUCH

WURDE URSPRÜNGLICH IN ENGLISCHER

SPRACHE ERSTELLT.

(1.3)

WICHTIG

Lesen Sie diese Betriebs- und Sicherheitsanweisungen bitte sorgfältig und vollständig

durch.

Sollten Sie sich hinsichtlich der Anwendung

des Elektrowerkzeugs unsicher fühlen,

kontaktieren Sie zu Ihrer eigenen Sicherheit

unsere technische Helpline, deren Nummer

auf der Website von Evolution Power Tools zu

finden ist. Wir bieten weltweit eine Vielzahl von

Helplines an, technische Hilfe ist jedoch auch

über Ihren Einzelhändler verfügbar.

WEB

www.evolutionpowertools.com

(1.4)

Wir gratulieren Ihnen zum Kauf einer

Evolution Power Tools-Maschine.

Bitte f olgen Sie den Anw eisungen des

beiliegenden A4-Merkblattes zur OnlineGarantieregistrierung und registrieren Sie

Ihr Produkt „online“. Sie können ebenfalls

den auf dem A4-Merkblatt enthaltenen QRCode mithilfe eines Smartphones scannen.

Hierdurch aktivieren Sie die Garantiefrist

Ihrer Maschine über die Evolution-Website.

Geben S ie zu diesem Zwec k einfach Ihr e

Kontaktdaten ein und sichern Sie sich

schnellen Kundenservice, wann immer Sie

ihn brauchen. Wir danken Ihnen, dass Sie

sich fü r ein Produkt vo n Evolution Power

Tools entschieden haben.

BEGRE NZTE GARANTIE VON EVOLUTION.

Evolution Power Tools behält sich das

Recht vor, ohne vorherige Mitteilung

konstruktive Verbesserungen und

Änderungen am Produkt vorzunehmen.

Die Garantiebedingungen finden Sie auf

dem Garantieregistrierungs-Merkblatt

und/oder der Verpackung.

(1.5)

Evolution Power Tools repariert oder

ersetzt innerhalb der Garantiefrist und ab

ursprünglichem Kaufdatum alle Waren,

bei denen Mängel im Material oder in der

Ausführungsqualität auftreten.

Diese Garantie ist nichtig, wenn die

zurückgegebene Maschine entgegen den

Empfehlungen des Bedienungshandbuchs

verwendet haben oder sie durch Unfall,

Fahrlässigkeit oder unsachgemäße Wartung

beschädigt worden ist.

Diese Garantie gilt nicht für Maschinen und/

oder Komponenten, die in irgendeiner Form

geändert oder modifiziert oder außerhalb der

empfohlenen Kapazitäten und Spezifikationen

eingesetzt worden sind. Elektrische

Komponenten werden durch die Garantien

der jeweiligen Hersteller abgedeckt. Alle

retournierten defekten Waren sind frachtfrei an

Evolution Power Tools zu senden.

Evolution Power Tools behält sich das

Recht vor, optional eine Reparatur oder

eine Ersatzlieferung mit gleichen oder

gleichwertigen Posten vorzunehmen.

Der Hersteller übernimmt keine Garantie,

weder schriftlich noch mündlich, für

Verbrauchsmaterialien und Zubehör,

einschließlich, jedoch nicht beschränkt auf:

Schneideblätter, Schneider, Bohrer, Meißel,

Rührer usw.

Evolution Power Tools haf tet nicht für direkte

oder indirekte Schäden oder Verluste, die aus

der Verwendung unserer Produkte oder aus

irgendwelchen anderen Gründen entstehen.

Evolution Power Tools haf tet weder für jegliche

Kosten, die für solche Waren entstehen, noch

für Folgeschäden.

Angestellte oder Vertreter von Evolution Power

Tools sind nicht bevollmächtigt, mündliche

Erklärungen zur Eignung abzugeben

oder auf irgendeine der vorstehenden

Geschäftsbedingungen zu verzichten;

derartige Erklärungen haben keinerlei

bindende Wirkung für Evolution Power Tools.

Fragen zu dieser begrenzten Garantie

sind an die Firmenzentrale zu richten

oder über eine n Anruf über die jeweilige

Helpline-Nummer zu klären.

21

Page 22

www.evolutionpowertools.com

TECHNISCHE DATEN

STROM METRISCH IMPERIAL

UK/EU Motor (230-240V ~ 50Hz) 2400 W 10 A

UK Motor (110V ~ 50Hz) 2000 W 18 A

USA Motor (120V ~ 60Hz) 1800 W 15 A

MASCHINE METRISCH IMPERIAL

Maximale Schnitttiefe

*PDie maximale Schnitttiefe kann nur durch progressives/inkrementelles Schneiden erzielt werden.

Geschwindigkeit GB/EU (Leerlauf ) 4500min

Geschwindigkeit USA (Leerlauf ) 5000min

Geschwindigkeit AUS (Leerlauf) 4900min

Schutzklasse Klasse II (GB und EU)/Klasse I (USA)

Schutzgrad IP20

Bruttogewicht 9,5kg 21Pf und

BL ATT METRISCH IMPERIAL

Durchmesser 305mm 12 ”

Bohrun g GB und EU 22.2mm 7/8”

Bohrun g USA 25.4mm 1 ”

Breite 3mm 1/8”

Höchstgeschwindigkeit 5500min

LÄRM UND VIBRATIONSBEZOGENE DATEN

Schalldruck LPA 96.0dB(A) K=3dB(A) 98.3dB(A) K=3dB(A)

Schallleistungspegel LWA 110.0dB(A) K=3dB(A) 112.0dB(A) K=3dB(A)

Vibration des Vordergriffs 3.2 94m/s2 K=1. 5m/s22,273 m/s2 K=1. 5m/s

Vibration des hinteren Griffs 3. 611m /s2 K=1. 5m/s23.788m/s2 K=1. 5m/s

*

100mm 4”

-1

-1

-1

-1

MODELLE MIT

110 V120 V

4500U/min

5000U/min

4900U/min

5500U/min

MODELLE MIT

230 V240 V

2

2

(1.6)

Hinweis: Die Ermittlung des Vibrationspegels

geschah unter Standardbedingungen in

Übereinstimmung mit: BS EN 61029-1:2009

Der angegebene Vibrationswert wurde im

Einklang mit einer Standard-Prüfmethode

gemessen und kann verwendet werden, um

verschiedene Maschinen miteinander zu

vergleichen.

Ebenso kann er für eine erste

Gefahrenbewertung herangezogen werden.

(1.7)

VIBRATION

WARNUNG: Beim Betrieb der Maschine ist der

Bediener u. U. starken Vibrationen (Hand und

Arm) ausgesetzt. Möglicherweise tritt dadurch

beim Bediener die „Weißfingerkrankheit“

(Raynaud-Syndrom) auf. Dies kann die

Temperaturempfindlichkeit der Hand

22

Page 23

www.evolutionpowertools.com

EN

DE

FR

ES

beeinträchtigen und ein allgemeines

Taubheitsgefühl erzeugen. Personen, die

längere Zeit oder regelmäßig mit diesem Gerät

arbeiten, sollten den Zustand ihrer Hände

und Finger aufmerksam beobachten. Falls die

vorgenannten Symptome auftreten, sollte

unverzüglich ärztlicher Rat eingeholt werden.

• Die Messung und Bewertung von

Auswirkungen von Schwingungen auf das

Hand-Arm-System am Arbeitsplatz wird in

folgenden Normen beschrieben:

BS EN ISO 5349-1:2001 und

BS EN ISO 5349-2:2002

• Die Stärke der Vibration wird von einer

Vielzahl von Faktoren beeinflusst,

wie z. B. Beschaffenheit und Ausrichtung

der Arbeitsfläche und Typ und Zustand der

verwendeten Maschine. Diese Faktoren

sollten vor jedem Gebrauch in Betracht

gezogen werden. Wenn möglich, ist für

angemessene Arbeitsbedingungen zu

sorgen. Folgende Einstellungen können

Vibrationen vermindern:

Gebrauch

• Bedienen Sie die Maschine mit

Sorgfalt, lassen Sie sie die Arbeit für Sie

verrichten.

• Wenden Sie nicht unnötig viel Kraft auf

die Bedienelemente der Maschine an.

• Berücksichtigen Sie Sicherheit und

Stabilität sowie die Ausrichtung der

Maschine während Inbetriebnahme.

Arbeitsfläche

• Berücksichtigen Sie das Material Ihrer

Arbeitsfläche; ihren Zustand, Dicke,

Robustheit, Härte und Ausrichtung.

WARNUNG: Die Vibrationen, die bei

der Verwendung des Elektrowerkzeugs

auftreten, können je nach Art und Weise der

Nutzung der Maschine vom angegebenen

Wert abweichen. Das Ausmaß an

Sicherheitsmaßnahmen und Maßnahmen

zum Schutz des Verwenders basiert auf dem

geschätzten Ausmaß an Beanspruchung

(unter Berücksichtigung aller Abschnitte des

Betriebs, wie z. B. Ausschalten der Maschine,

Leerlauf sowie Auslösezeit).

(1.8)

KENNZEICHNUNGEN UND SYMBOLE

WARNUNG: Verwenden Sie die Maschine

nicht, wenn Warnhinweise und/oder

Hinweisschilder fehlen oder beschädigt sind.

Für Ersatz wenden Sie sich an Evolution Power

Too ls.

Hinweis: Manche oder alle der folgenden

Symbole können in der Betriebsanleitung

oder auf dem Produkt abgebildet sein.

SYMBOL BESCHREIBUNG

V Volt

A Ampere

Hz Hertz

-1

Min

~ Wechselstrom

n Nenngeschwindigkeit

RCM REGULATORY COMPLIANCE

AUSTRALISCHE/NEUSEELÄNDISCHE

Drehzahl

Warnung!

Anleitung lesen

Nur Trockenzerspanung

Schutzbrille tragen

Gehörschutz tragen

Staubmaske tragen

Schutzhandschuhe tragen

Sicherheitsstiefel tragen

US-Zertifizierung

CE-Zertifizierung

Entsorgung als Elektro- und

Elektronikschrott

MARK FÜ R ELEKTR ISCHE UND

ELEKTRONISCHE GERÄTE.

NORM

23

Page 24

www.evolutionpowertools.com

(1.10 )

BESTIMMUNGSGEMÄSSER

GEBRAUCH DES

ELEKTROWERKZEUGS

WARNUNG: Dieses Produkt ist ein von

Hand betriebener Trennschleifer und wurde

für den Einsatz mit speziellen EvolutionTrennscheiben entwickelt. Verwenden

Sie ausschließlich für den Gebrauch mit

dieser Maschine entwickeltes und/oder

ausdrücklich von Evolution Power Tools Ltd

empfohlenes Zubehör.

Mit geeigneter Trennscheibe kann diese

Maschine zum Schneiden der folgenden

Materialien verwendet werden:

Ziegel

Pflastersteine

Bordsteinkanten

Beton

1.11

UNZULÄSSIGER GEBRAUCH DES

ELEKTROWERKZEUGS

WARNUNG: Dieses Produkt ist ein von Hand

betriebener Trennschleifer und ist nicht

anderweitig zu verwenden. Es dürfen keinerlei

Modifikationen vorgenommen werden.

Weiterhin darf die Maschine nicht mit anderer

Ausrüstung oder anderem Zubehör als dem in

dieser Betriebsanleitung erwähnten in Betrieb

genommen werden. (1.11)

WARNUNG: Diese Maschine darf nicht zum

Schneiden von potenziell asbesthaltigem

Material verwendet werden. Sollte der

Verdacht bestehen, dass sich im Material

Asbest befindet, holen Sie sich Rat von der

zuständigen Behörde ein.

(1.13)

WARNUNG: Diese Maschine ist nicht

bestimmt zur Nutzung durch Personen

(einschließlich Kindern) mit eingeschränkten

körperlichen, sensorischen bzw. geistigen

Fähigkeiten, mangelnder Erfahrung bzw.

fehlendem Wissen, sofern diese nicht durch

eine für ihre Sicherheit verantwor tliche Person

eine Beaufsichtigung bzw. Anweisung für

die sichere Nutzung der Maschine er fahren

haben.

Kinder müssen beaufsichtigt werden, um

sicherzustellen, dass sie keinen Zugang zu der

Maschine haben und nicht mit ihr spielen.

(1.14 )

ELEKTRISCHE SICHERHEIT

Diese Maschine ist ausgestattet mit den auf

dem Zielmarkt jeweils verwendeten Stecker

und Anschlusskabel. Bei Beschädigung des

Anschlusskabels ist dieses durch ein vom

Hersteller oder dessen Händler zur Verfügung

gestelltes Kabel zu ersetzen.

(1.15 )

VERWENDUNG IM FREIEN

WARNUNG: Zu Ihrer eigenen Sicherheit

sollte diese Maschine bei Verwendung im

Freien nicht Regen ausgesetzt werden und

nicht in einer feuchten Umgebung eingesetzt

werden. Platzieren Sie die Maschine nicht auf

feuchtem Untergrund.

Wenn verfügbar, arbeiten Sie auf einer

sauberen, trockenen Fläche. Verwenden Sie

für zusätzlichen Schutz eine FehlerstromSchutzeinrichtung (R.C.D.), die bei Leckstrom

von über 30 mA über einen Zeitraum von

30 ms die Stromzufuhr unterbricht.

Überprüfen Sie vor Verwendung der

Maschine jedes Mal die FehlerstromSchutzeinrichtung (R.C.D.).

Ist ein Verlängerungskabel notwendig, muss

dieses für den Gebrauch im Freien geeignet

und entsprechend gekennzeichnet sein.

Folgen Sie den Anweisungen des Herstellers

bei Verwendung mit Verlängerungskabel.

(2 .1)

ALLGEMEINE

SICHERHEITSANWEISUNGEN ZU

ELEKTROWERKZEUGEN

WARNUNG: Lesen Sie sorgfältig alle

Warnhinweise und Anweisungen.

Nichtbeachtung der Warnhinweise und

Anweisungen kann zu Stromschlag, Brand

und/oder schweren Verletzungen führen.

Bewahren Sie alle Warnhinweise und

Anweisungen zu Referenzzwecken auf.

24

Page 25

www.evolutionpowertools.com

EN

DE

FR

ES

Der Begriff „Elektrowerkzeug“ in

den Warnhinweisen bezieht sich auf

Ihr netzbetriebenes (verkabeltes)

Elektrowerkzeug oder Ihr Batteriebetriebenes (kabelloses) Elektrowerkzeug.

(2.2)

1) Allgemeine Sicherheitswarnungen

zum Elektrowerkzeug [Sicherheit am

Arbeitsplatz]

a) Halten Sie den Arbeitsbereich sauber

und sorg en Sie für eine gute Beleuchtu ng.

Zugestellte oder dunkle Bereiche

begünstigen Unfälle.

b) Verwenden Sie das E lektrowerk zeug

nicht in explosionsgefährdeten

Bereichen wie z. B. bei Vorhandensein

brennbarer Flüssigkeit, Gase oder Staub.

Elektrowerkzeuge erzeugen Funken, die

Staub oder Gase entzünden können.

c) Halten Sie Kinder und Unbeteiligte

während Inbetriebnahme vom

Elektrowerkzeug fern. Ablenkungen

können dazu führen, dass Sie die Kontrolle

über das Werkzeug verlieren.

(2.3)

2) Allgemeine Sicherheitswarnungen zum

Elektrowerkzeug [Elektrische Sicherheit]

a) Der Stecker des Elektrowerk zeugs

muss zur Steckdose passen. Den Stecker

niemals modifizieren. Verwenden

Sie keine Adapter mit geerdeten

Elektrowerkzeugen. Nicht modifizierte

Stecker und dazu passende Steckdosen

verringern das Risiko eines Stromschlags.

b) Vermeiden Sie den Kontakt mit

geerdeten Oberflächen wie z. B. Rohren,

Heizungen, Herden oder Kühlschränken.

Das Risiko auf Stromschlag steigt, wenn Ihr

Körper geerdet ist.

c)Setzen Sie Elektrowerkzeuge nie Regen

oder nassen Bedingungen aus. Wasser, das

in ein Elektrowerkzeug eindringt, erhöht das

Risiko eines Stromschlags.

d) Verwenden Sie das Kabel nicht

unzweckmäßig. Verwenden Sie das

Kabel nicht, um das Elektrowerk zeug zu

transportieren oder zu ziehen oder den Stecker

herauszuziehen. Halten Sie das Netzkabel

fern von Hitze, Öl, scharfen Kanten oder sich

bewegenden Geräteteilen. Beschädigte oder

verwickelte Kabel erhöhen das Risiko eines

Stromschlags.

e) Verwenden Sie ein geeignetes

Verlängerungskabel, wenn Sie das

Elektrowerk-zeugs im Freien betreiben.

Die Verwendung eines für den Gebrauch im

Freien vorgesehenen Verlängerungskabels

vermindert das Risiko eines Stromschlags.

f) Ist die Verwendung des

Elektrowerkzeugs in feuchter Umgebung

unumgänglich, verwenden Sie eine

Fehlerstrom-Schutzeinrichtung (R.C.D.).

Die Verwendung einer FehlerstromSchutzeinrichtung verringert das Risiko eines

Stromschlags.

(2.4)

3) Allgemeine Sicherheitswarnungen

zum Elektrowerkzeug [Persönliche

Sicherheit].

a) Seien Sie beim Be trieb des

Geräts immer aufmerksam und

verantwortungsbewusst. Verwenden

Sie das Elektrowerkzeug nicht bei

Müdigkeit oder unter Einfluss von Drogen,

Alkohol oder Medikamenten. Kurze

Unachtsamkeit während der Verwendung

dieses Elektrowerk zeugs kann zu schweren

körperlichen Verletzungen führen.

b) Verwenden Sie persönliche

Schutzausrüstung. Tragen Sie stets

eine Schutzbrille. Das Tragen von

Schutzausrüstung wie Staubmaske,

rutschfesten Sicherheitsschuhen, Schutzhelm

oder Gehörschutz verringert das Risiko von

Verletzungen.

c) Vermeiden Sie unbeabsichtigte

Inbetriebnahme. Vergewissern Sie sich,

dass das Werkzeug ausgeschaltet ist, bevor Sie

es an die Stromquelle und/oder an die Batterie

anschließen, anheben oder transportieren.

Das Tragen von Elektrowerkzeugen mit dem

Finger am Schalter oder die Aktivierung der

Stromversorgung einer Maschine, deren

Schalter in der Stellung „ON“ (An) steht, kann

zu Unfällen führen.

d) Entfernen Sie alle Einstell- und

sonstigen Schlüssel, bevor Sie das

25

Page 26

www.evolutionpowertools.com

Elektrowerkzeug einschalten.

Schraubenschlüssel oder andere

Schlüssel, die in sich bewegenden Teilen

des Elektrowerkzeugs stecken, können

körperliche Verletzungen verursachen.

e) Nicht zu weit hinauslehnen. Achten

Sie stets auf guten Stand bzw. gute Balance.

Dies sorgt für eine bessere Kontrolle des

Elektrowerkzeugs in unerwarteten Situationen.

f) Tragen Sie angemessene Kleidung.

Tragen Sie keine weite Kleidung oder

Schmuck. Halten Sie Haare, Kleidung und

Handschuhe fern von sich bewegenden

Teilen. Weite Kleidung, Schmuck oder langes

Haar kann sich in sich bewegenden Teilen

verfangen.

g) Falls Vorrichtungen zum Absaugen

und Sammeln von Staub vorhanden sind,

schließen Sie diese an und verwenden

Sie sie ordnungsgemäß. Die Verwendung

eines Staubabscheiders vermindert durch

Staub verursachte Gefahren.

(2.5)

4) Allgemeine Sicherheitswarnungen

zum Ele ktrowerk zeug [Gebrauc h und

Instandhaltung].

a) Wenden Si e keine Gewalt a n.

Verwenden Si e ein für Ihre Zwecke geeigne tes

Elektrowerkzeug. Das passende Elektrowerkzeug

erledigt die Arbeit besser und sicherer in

angemessenem Tempo.

b) Verwenden Sie das Elektrowerkzeug

nicht, wenn der Schalter nicht ein- und

ausschaltet. Jedes Elektrowerkzeug, dessen

Ein-/Ausschalter nic ht funktionier t, stellt eine

Gefahr dar und muss repariert werden.

c) Trennen Sie das Elektrowerkzeug von der

Netzquelle und/oder der Batterie, bevor

Sie Änderungen vornehmen, Zubehör

auswechseln oder das Elektrowerkzeug

lagern. Derartige vorbeugende Maßnahmen

verringern das Risiko, dass das Elektrowerkzeug

unbeabsichtigt starte.t

d) Bewahren Sie unbenutzte Geräte

außerhalb der Reichweite von Kindern auf

und lassen Sie Personen, die mit dem Gerät

nicht vertraut sind oder diese Anweisungen

nicht gelesen haben, das Gerät nicht

benutzen. Das Gerät kann gefährlich sein, wenn

es von unerfahrenen Personen benutzt wird.

e) Halten Sie Elektrowerkzeuge instand.

Stellen Sie sicher, dass sich alle beweglichen Teile

in der richtigen Position befinden, keine Teile

gebrochen sind oder sonstige Fehler vorliegen,

um den reibungslosen Betrieb des Geräts

sicherzustellen. Sollten Schäden vorliegen, lassen

Sie das Elektrowerkzeug vor Gebrauch reparieren.

Viele Unf älle werden von schlecht in stand

gehaltenen Elektrowerkzeugen verursacht.

f) Halten Sie Schneidewerkzeug scharf

und saub er. Angemessen gepflegtes

Schneidewerkzeug mit scharfen Klingen läuft

geschmeidiger und ist leichter zu kontrollieren.

g) Verwenden Sie das Elektrowerkzeug,

Zubehör und Werkzeugteile usw.

in Übereinstimmung mit diesen

Anweisungen unter Berücksichtigung der

Arbeitsumstände und der auszuführenden

Arbeit. Unzweckmäßige Verwendung des

Elektrowerkzeu gs kann zu Gefahr führe n.

(2.6)

5) Allgemeine Sicherheitswarnungen zum

Elektrowerkzeug [Wartung]

a) Lassen Sie Ihr Elektrowerkzeug von

qualifiziertem Fachpersonal und nur

mit identischen Ersatzteilen reparieren.

Dadurch wird die fortwährende Sicherheit des

Elektrowerkzeugs gewährleistet.

(2.7)

GESUNDHEITSHINWEISE

WARNUNG: WBei Arbeiten mit dieser Maschine

können Staubpartikel entstehen. Je nachdem,

mit welchem Material Sie arbeiten, kann dieser

Staub beson ders schädlich sein. Su chen Sie

professionelle Hilfe auf, wenn Sie vermuten, dass

die Farbe auf dem Material, das Sie schneiden

wollen, Blei enthält.

Auf Blei basierte Farben sind von professionellen

Fachkräften zu entfernen. Von Selbstversuchen

ist abzuraten . Hat sich der Staub auf Ober flächen

abgesetzt, k ann Hand- Mund-Kontakt zur

Aufnahme von Blei führen. Schon geringe

Mengen an Blei können unwiderrufliche

Schäden an Hirn und Nervensystem verursachen.

Junge und ungeborene Kinder sind besonders

gefährdet. Ziehen Sie die Risiken verbunden

mit dem Material, mit dem Sie arbeiten, in

26

Page 27

www.evolutionpowertools.com

EN

DE

FR

ES

Erwägung und verringern Sie das Risiko, sich dem

auszusetzen. Da manche Materialien potenziell

gesundheitsschädliche n Staub produz ieren,

empfehlen wir die Verwendung von geprüften

Schutzmasken mit austaus chbaren Filtern

während der Verwendung der Maschine.

Sie sollten stets:

• in gut belüfteten Bereichen arbeiten.

• ge prüfte Schutz ausrüstung tragen, z . B.

Staubmasken f ür die Filterung mikroskop isch

kleiner Partikel.

SICHERHEITSANWEISUNGEN FÜR

TRENNSCHLEIFVERFAHREN

Sicherheitshinweise zu Schneidegeräten

a) Die mit dem Werkzeug bereitgestellte

Schutzvorrichtung muss für maximale

Sicherheit fest am Elektrowerkzeug

angebracht und so positioniert sein, dass

der Anteil des gegenüber des Verwenders

freigelegten Schneideblatts so gering

wie möglich ausfällt. Positionieren Sie

sich selbst und Umstehende nicht in der

Ebene des rotierenden Schneideblatts. Die

Schutzvorrichtung schützt den Verwender vor

Schneideblattfragmenten und versehentlichem

Kontakt mit der Trennscheibe.

b) Verwende n Sie für Ihr Ele ktrowerk zeug

ausschließlich verstärkte Verbund- oder

Diamanttrennscheiben. Nur weil si ch

ein Zubehörteil am Werkzeug befestigen

lässt, be deutet das nicht, dass es sich

auch für einen sicheren Betrieb eignet.

c) Die auf dem Zubehörteil angegebene

Geschwindigkeit muss mindestens der

Höchstgeschwindigkeit des Elektrowerkzeugs

entsprechen. Zubehörteile, die mit einer

Geschwindigkeit betrieben werden, die ihre

Nenngeschwindigkeit übertrifft, können zerbrechen

und auseinanderfliegen.

d) Trennscheibe n dürfen nur für die

empfohlenen Zwecke eingesetzt werden.

Beispiel: Mit der Seite einer Trennscheibe

nicht schleifen. Trennscheiben eignen sich nur

zum Umfangschleifen. Werden Seitenkräf te auf sie

ausgeübt, können sie zerbrechen.

e) Verwenden Sie nur unbeschädigte

Scheibenflansche mit dem passenden

Durchmesser für die ausgewählte Scheibe.

Die passenden Scheibenflansche stützen die

Trennscheibe und senken die Wahrscheinlichkeit,

dass sie zerbricht.

f) Verwenden Sie keine abgenutzten,

verstärkten Scheiben größerer

Elektrowerkzeuge. Für größere

Elektrowerkzeuge gefertigte Scheiben eignen

sich nicht für di e hohen Geschwindigke iten

kleinerer Geräte und können zerbrechen.

g) Der Außendurchmesser und die Stärke Ihres

Zubehörteils müssen innerhalb der für Ihr

Elektrowerkzeug angegebenen Grenzwerte

liegen. Zubehörteile der falschen Größe lassen

sich nicht ausreichend steuern oder schüt zen.

h) Das Dornmaß der Scheiben und

Flansche muss mit dem der Spindel des

Elektrowerkzeugs übereinstimmen.

Scheiben und Flansche, deren Dornbohrungen nicht

zu den Maßen der Hardware des Elektrowerk zeugs

passen, sin d beim Betrieb nicht ausg ewuchtet,

erzeugen übermäßige Vibrationen und können zum

Kontrollverlust führen.

i) Verwenden Sie keine beschädigten

Scheiben. Prüfen Sie die Scheiben vor jedem

Einsatz auf Absplitterungen und Risse.

Sollte das Elektrowerkzeug oder die Scheibe

herunterfallen, müssen Sie sie auf Schäden

untersuchen oder eine unbeschädigte

Scheibe einsetzen. Positionieren Sie sich und

Umstehende nach der Prüfung und Installation

nicht in der Ebene der sich drehenden Scheibe

und bet reiben Sie da s Elektro werkzeug

eine Minute mit der maximalen

Leerlaufgeschwindigkeit. Beschädigte Scheiben

zerbrechen meist während dieses Prüfzeitraums.

j) Tragen Sie persönliche Schutzausrüstung.

Verwenden Sie, abhängig von der

auszuführenden Arbeit, einen Gesichtsschutz

oder eine Schutzbrille. Tragen Sie bei Bedarf

eine Staubmaske, einen Gehörschutz,

Handschuhe und eine Arbeitsschürze, die

kleine Fragmente der Trennscheibe oder

des Werk stücks auf hält. Der verwendete

Augenschutz muss umherfliegende Teile

abhalten können, die durch unterschiedlichste

Prozesse ents tehen. Die Staubmaske bz w. das

Atemgerät muss d azu in der Lage sein, dur ch die

vorgenommenen Arbeiten erzeugte Partikel aus der

27

Page 28

www.evolutionpowertools.com

Luft zu f iltern. Eine langfris tige Lärmbelast ung kann

zum Gehörverlust führen..

k) Umstehende müssen Sicherheitsabstand

zum Arbeitsbereich einhalten. Personen,

die den Arbeitsbereich betreten, müssen

persönliche Schutzausrüstung tragen.

Fragmente des Werks tücks oder einer beschädigten

Scheibe kön nen davonfliegen un d auch außerhalb

der unmittelbaren Arbeitsumgebung zu

Verletzungen führen.

l) Führen Si e das Elekt rowerkzeu g nur mit Hilfe

von isoli erten Gri ffen, wenn Si e eine Arbeit

durchführen, bei der die Zubehörteile nicht

sichtbare Kabel oder das eigene Netzkabel

berühren könnten.

Beim Kontakt des Schneidzubehörs mit einem

stromführenden Kabel können nicht isolierte

Bauteile des Elektrowerkzeugs ebenfalls Strom leiten

und dem Verwender einen elektrischen Schlag

versetzen.

m) Halten Sie das Kabel vom sich drehenden

Zubehö r fern. Falls Sie die Kontroll e verlieren,

könnte das Kab el durchschnitten werde n oder sich

verhaken und Ih re Hand oder Ihr Arm könnte in di e

Trennscheibe gezogen werden.

n) Legen Si e das Elekt rowerkzeu g erst ab, wenn

das Zubehör stillsteht. Die sich drehende Scheibe

könnte sich in der O berfläche ver haken und das

Elektrowerkzeug aus Ihren Händen ziehen.

o) Schalten Sie das Elektrowerkzeug nicht

ein, wenn Sie es transportieren. Beim

versehentlichen Kontakt mit der sich drehenden

Scheibe könnte diese sich in der Kleidung verhaken

und das Gerä t in Ihren Körper ziehen .

p) Reinigen Sie die Lüftunge n des

Elektrowerkzeugs regelmäßig. Der Lüfter des

Elektromotors zieht Staub ins Gehäuseinnere und

große Ansammlungen von Metallpulver führen zu

einer erhöhten Stromschlaggefahr.

q) Betre iben Sie das E lektrower kzeug nic ht

in der Umgebung brennbarer Stoffe. Diese

könnten sich durch Funken entzünden.

r) Verwende n Sie kein Zube hör, für das

Kühlflüssigkeiten benötigt werden. De r Einsatz

von Wasser oder anderen Kühlflüssigkeiten kann zu

Stromschlägen oder gar zum Tod durch Stromschlag

führen.

WEITERE SICHERHEITSANWEISUNGEN FÜR

TRENNSCHLEIFVERFAHREN

T

Hinweise zu Ausschlagbewegungen und

Ähnlichem

Beim Ausschla gen handelt es sich um eine p lötzliche

Reaktion, hervorgerufen durch eine eingeklemmte

oder sich verhakende rotierende Scheibe. Wird eine

sich drehende Scheibe eingeklemmt oder verhakt

sie sich, wird ih re Bewegung abrupt geb remst,

sodass das unkontrollierte Elektrowerkzeug am

entsprechenden Klemmpunkt in die Richtung

gedrückt wird, die der Drehrichtung der Scheibe

entgegengesetzt ist. Verklemmt oder verhakt sich

eine Trennscheibe beispielsweise im Werkstück,

kann sich die K ante, die sich in diesen Kle mmpunkt

hineinbew egt, in die Oberf läche des Werkstof fs

graben und s o dazu führen, dass die Sch eibe

ausschlägt oder sich anhebt.

Die Scheibe kann entweder auf den Verwender zu

oder von ihm we g springen, abhängig d avon, i n

welche Richt ung sich die Scheibe am Kl emmpunkt

bewegt. Unter diesen Umständen können

Trennscheiben auch zerbrechen. Ausschlagen

bzw. Ausreißen eines Elektrowerk zeugs ist das

Ergebnis unsachgemäßer Verwendung und/oder

ungeeigneter Arbeitsverfahren oder -bedingungen

und kann mit Hilfe der nachfolgenden

Vorkehrungen vermieden werden.

a) Halten Sie das Elek trowerkze ug

immer gut fest und positionieren

Sie Arm un d Körper so, dass Si e

Ausschlagbewegungen entgegenwirken

können. Verwenden Sie für maximale

Kontrolle über Ausschlagbewegungen

oder Drehmomentreaktionen während des

Startens immer den Zusatzgriff, falls ein

solcher vorhanden ist. Der Verwender kann durch

entsprechende Vorsichtsmaßnahme n Ausschlag und drehmomentbedingte Bewegungen unter

Kontrolle bringen.

b) Legen Sie Ihre Hand niemals neben das

rotierende Zubehör. Das Zubehör kann beim

Ausschlagen über Ihre Hand fahren.

c) Positionieren Sie Ihren Körper nicht auf der

Linie der sich drehenden Scheibe. Bei einer

Ausschlagbewegung wird das Werkzeug in die

Richtung beschleunigt, die der Bewegungsrichtung

der Scheibe am Klemmpunkt entgegengesetzt ist.

28

Page 29

www.evolutionpowertools.com

EN

DE

FR

ES

d) Gehe n Sie bei der Bea rbeitung von

Ecken, scharfen Kanten usw. vorsichtig vor.

Vermeiden Sie ein Federn oder Verkanten der

Scheibe. Ecken, scharfe Kanten oder federnde

Bewegungen führen häuABB dazu, dass sich

das rotierende Zubehörteil verkantet, was zum

Kontrollverlust oder zu Ausschlagbewegungen

führen kann.

e) Verwenden Sie keinesfalls eine Sägekette,

Schnitzklinge, segmentierte Diamantscheibe

mit ein em peripher en Spalt von me hr als

10 mm oder ei n gezahntes S ägeblatt . Solche

Blätter führen häufig zu Ausschlagbewegungen und

Kontrollverlust.

f) Blockieren Sie die Scheibe nicht und üben Sie

nicht zu viel Kraft darauf aus. Versuchen Sie

nicht, eine zu große Schnitttiefe zu erzwingen.

Bei einer Überbelastung kann die Scheibe im

Schnittbereich verbiegen oder sich verformen, was

unter Umständen zu Ausschlagbewegungen oder

zum Zerbrechen der Scheibe führen kann.

g) Sollte sich die Scheibe festfressen oder wird

der Schneidvorgang aus einem beliebigen

Grund unterbrochen, schalten Sie das

Elek trowerkze ug ab und beweg en Sie es nicht ,

bis es zum Stillstand kommt. Versuchen Sie

keinesfalls, die Scheibe aus dem Schnitt zu

ziehen, solange sie sich noch dreht, da dies zu

Ausschlagbewegungen führen kann. Stellen Sie

den Grund f ür das Festfressen fe st und sorgen Sie

für Abhilfe.

h) Beginnen Sie den Schneidevorgang

nicht i m Werkstück . Starten Sie e rst das

Werkzeug und warten Sie, bis die Scheibe ihre

Betriebsgeschwindigkeit erreicht hat, bevor

Sie sie wieder in den Schnitt einführen. Wird

das Elekt rowerkzeug im Werk stück gestartet , kann

dies zum Fest fressen, einer Auf wärtsbewegun g oder

zum Ausschlagen führen.

i) Stützen Sie Platten oder andere

große Wer kstücke ab, u m das Risiko

des Einklemmens und Ausschlagens zu

minimieren. Große Werkstücke geben häufig unter

ihrem eigen en Gewicht nach. Stütze n Sie solche

Werkstücke auf beiden Seiten der Scheibe sowohl in

der Nähe der S chnittlinie als auch an de n Enden ab.

j) Seien Sie besonders vorsichtig, wenn Sie

einen „Aufsetzschnitt“ an vorhandenen

Wänden oder sonstigen Blindflächen

vornehmen. Die hervorstehende Scheibe

kann Gas- oder Wasserrohre, Stromleitungen

oder Objekte beschädigen, die zu einer