Page 1

Tattoo User’s Guide part number: KU10E Rev. B0

Ev

olis Car

d Print

er © Sept

ember 2007

USERÕs Guide

Page 2

CCooppyyrriigghhtt IInnffoorrmmaattiioonn

E

volis Card Printer © September 2007. All rights reserved.

CCooppyyrriigghhtt NNoottiiccee

Users must respect the copyright laws applicable in their country. This manual must not be

photocopied, translated, reproduced or transmitted in whole or in part for any reason and by the

means that might be, albeit electronic or mechanical, without the express, written authorisation of the company Evolis Card Printer.

All information contained herein may be subject to modification without prior notice.

Evolis Card Printer accepts no liability for any possible errors herein, nor for any accidental

damage or damage caused through the dissemination or the use of this manual.

TTrraaddeemmaarrkkss

Tattoo is a trademark and Evolis is a registered trademark of Evolis Card Printer.

Windows and MS.DOS are registered trademarks of Microsoft Corp. All other trademarks or

r

egistered trademarks are marks of their respective holders. eMedia Card Designer is a trade-

mark of Mediasoft Technologies.

IIccoonnss

Throughout this manual, different icons highlight important information, as follows:

Indicates information that emphasizes or supplements important points of the main text.

Advises y

ou of information that is essential t

o complete a task, or points out the importance

of specific inf

ormation in the text.

Advises you that failure to take or avoid a specific action could result in physical harm to

you, or could r

esult in physic

al damage to the hardwar

e.

WWaarrrraannttyy IInnffoorrmmaattiioonn

Refer to the Warranty booklet enclosed with your Evolis printer for terms and conditions.

RReettuurrnn MMaatteerriiaallss AAuutthhoorriizzaattiioonn

In or

der t

o mak

e a warr

anty claim you must contact an Evolis Reseller. You will be responsible for

packaging the printer for shipment and the costs of shipping and insurance of the printer from the

point of use of the print

er t

o the Evolis Reseller. The Evolis Reseller will bear the costs of shipping

and insuring the printer from the repair location to the address from which the printer was shipped.

Before returning any equipment for in-warranty or out-of warranty repair, contact an Evolis

Reseller or an Evolis Repair Center (ERC) for a Return Materials Authorization (RMA) number.

Repack the equipment in the original packing material and mark the RMA number clearly on

the outside of the box. For more information about RMA or Evolis warranty statements, refer to

the Warranty booklet enclosed with your Evolis printer.

PPrroodduucctt DDiissppoossaall

WEEE Directive

This symbol indicates that when the last user wishes to discard this product, it must

be sent to appropriate facilities for recovery and recycling.

By not disc

ar

ding this pr

oduct al

ong with other household-type waste, the volume

of waste sent to incinerators or landfills will be reduced and natural resources will

be c

onserved. Your Evolis printer should be recycled according to your local stan-

dards. For more information, please contact Evolis at: info@evolis.com.

Page 3

TThhaannkkss ffoorr cchhoooossiinngg aann

EEvvoolliiss CCaarrdd PPrriinntteerr ttoo

ppeerrssoonnaalliizzee yyoouurr bbaaddggeess

Using the latest printing technologies, Evolis Tattoo offers its

users both performance and quality.

Evolis Tattoo combines user-oriented design, compact size

and ease of use. It is fully adapted to small runs and fields

such as identification, loyalty and leisure.

The ‘Evolis Genuine Product’ line of consumables linked to

the printer was specifically developed and optimized to guarantee the best quality of printing.

Using these consumables increases the lifespan of your

badges and of your Evolis printer.

As for all Evolis products, particular care has been used in

writing this manual. But if an error has still managed to slip

into these pages without our wanting it, please let us know

by sending an e-mail to info@evolis.com. Evolis will then do

everything in its power to correct the problem and give you

complete satisfaction.

Page 4

11

Install the Evolis printer

Technology and benefits .

..........................................

06

Initial approach

.

.....................................................

07

Install your printer

..................................................08

Check the items shipped

Connect the printer to the main power supply

Printer Control panel.

..............................................

10

Stand by ...............................................................10

Install the ribbons

...................................................11

Monochrome or color ribbon

Install the cards .....................................................12

Types of cards

Installation in the feeder

Manual card loading

Remove the personalized cards ..................................13

22

Setting of parameters

Windows print driver ...............................................14

Installation of the print driv

er

Properties of the driver

Card printing configuration in

an office automation application

33

Error messages and diagnostics

Notification of messages...........................................21

Description of the printer control panel

Interpretation of messages .......................................22

Diagnostics assistance

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Print and interpret a test card

Identify the software version installed

C

C

o

o

n

n

t

t

e

e

n

n

t

t

s

s

Page 5

44

Servicing and Maintenance

Ordinary maintenance.

.............................................

25

Clean the card feed module

Service the cleaning rollers

Clean the print head

Maintenance .........................................................30

Replace the cleaning rollers

Replace the print head

Updat

e the Firmware

Update the print driver

Troubleshooting .

....................................................

35

Free a card jammed in the printing unit

Upgrade printing quality

Assistance.

............................................................

38

Network of Evolis partners

Look for inf

ormation on www

.evolis.com

Register your product to benefit from updates

55

Characteristics

Declaration of conformity..........................................39

Printer specifications

...............................................40

List of “Evolis Genuine Product” consumables

...............42

Magnetic encoding

..................................................43

C

C

o

o

n

n

t

t

e

e

n

n

t

t

s

s

Page 6

IIn

nssttaallll

tth

hee

E

Evvoolliiss

p

prrii

n

ntteerr

The aim of this first part is to assist you, step-by-step, in

discovering your new printer and putting it to work for you.

By taking the time to review these few pages, you will get more

detailed knowledge about your printer and its capabilities, while

optimizing the time needed to install and start using the product.

TTeecchhnnoollooggyy aanndd bbeenneeffiittss

Evolis Tattoo is specially designed for users requiring simplicity and quality of printing for their

personalization of badges in monochrome or color.

In a few seconds, the Tattoo personalizes your pre-printed or blank plastic cards, and prints your

texts, barcodes, graphics, logos and pictures.

Truly flexible, this printer can be used for batch printing with the 100-card feeder, or “over-the counter”

runs, with cards inserted manually, one after the other.

Tattoo is one of the most compact of all plastic card printers, and can be integrated in all types of

environment: offices, bank receptions, shop counters.

Ev

olis T

att

oo suits perf

ectl

y applic

ations such as pr

of

es

sional and business cards, identification badges

(employees, visitors…), membership cards, and event cards.

In addition, it perfectly fits applications such as loyalty cards and transportation passes.

1

1

06

Page 7

07

IInniittiiaall aapppprrooaacchh

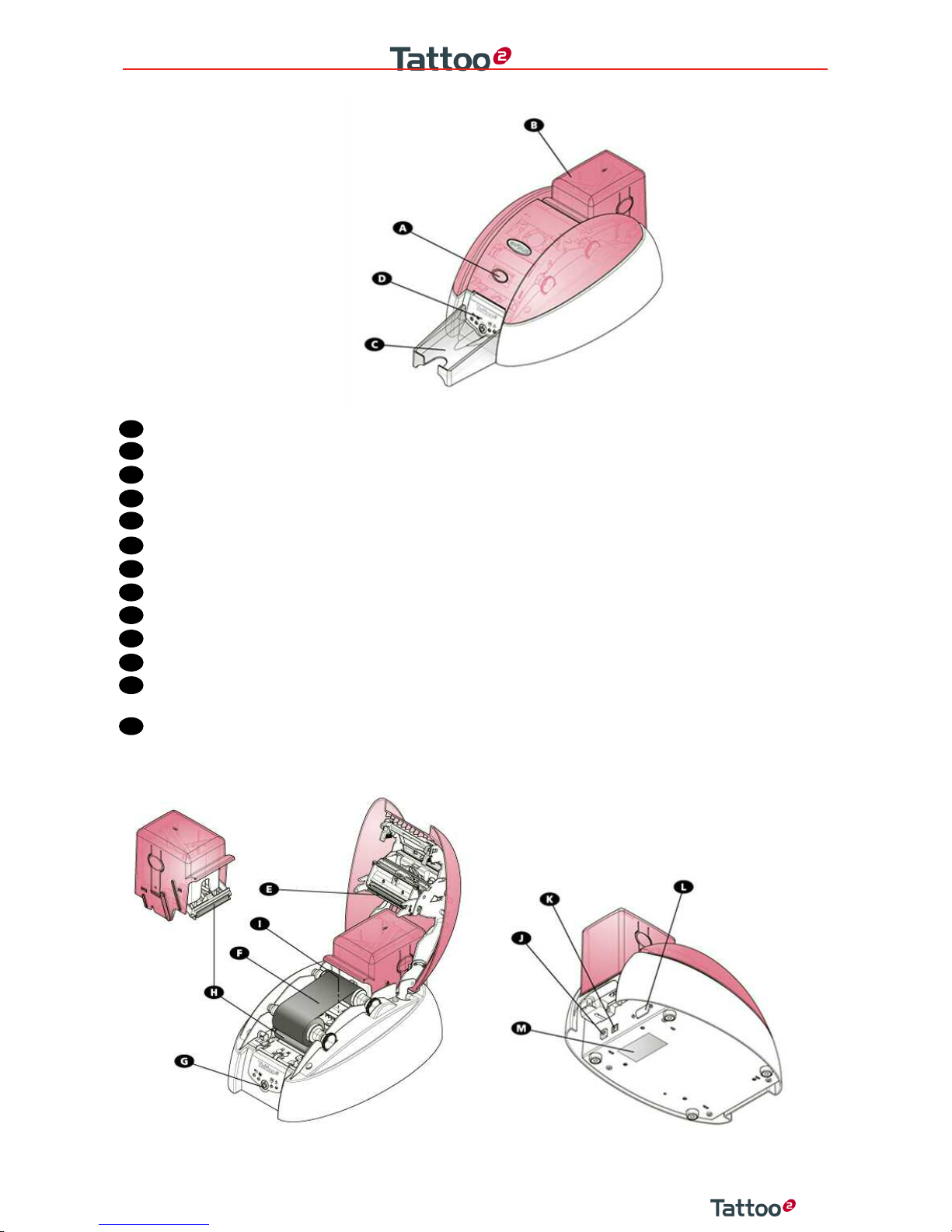

A Cover lever Enables the printer cover to be opened and closed.

B Card Feeder Receives the cards for printing.

C Detachable output hopper Collects the printed and/or encoded cards.

D Control Panel Shows the printer activity.

E Thermal print head Enables the cards to be printed in 300 dpi.

F Ribbon Monochrome or color ribbon (cf consumable list). E

G Push button

Shows the printer activity (power ON/OFF).

H Cleaning roller Removes all dust before the cards are printed.

I

Magnetic encoding head (option)

Enables cards with magnetic tracks 1, 2 and 3 to be encoded.

J Power supply connector Enables the printer to be connected to its power supply.

K USB computer connector (std) Enables data to be received and sent "from" and "to" the computer.

L DB-9 connector(s) (option) Enables data to be received and sent "from" and "to" the computer.

or a c

oupler to be connected for chip cards personalization.

M Identification label Indicates the model and the serial number of the printer.

Page 8

08

IInnssttaallll yyoouurr pprriinntteerr

The Evolis printer must be set up in a dry, well-ventilated location protected against dust and air

c

urrents.

In addition, make sure you install your printer on a sturdy flat surface that can support its weight of

around 2.4 kg (5.3 lbs).

Finally, it is essential to allow free access to the connectors and to the power plug.

CChheecckk tthhee iitteemmss sshhiippppeedd

The Evolis printer is shipped with a set of accessories that we invite you to examine.

Please take note that this list may vary in terms of the geographic area where you are located.

The printer is shipped in an original container specially designed to ensure that the product is protected against any risk of damage during shipment.

In the event of visible damage at the time of delivery, do not hesitate to carry out all required steps

as far as the shipper is concerned, and immediately contact your Evolis dealer who will provide you

with all necessary assistance.

Evolis has paid particular attention to the quality of this shipping material, and we urge you to keep

it in a clean, dry space.

This packaging material will be required to return equipment.

During the manufacturer’s guarantee period, returning material without the original Evolis

packaging could cause you to lose the benefit of this guarantee !

The following parts are furnished with your Evolis printer:

■ Power suppl

y unit - VP ELECTRONIQUE or SWITCHBO

X Type F10723-A or FDF0503-A

■ Main power cable

■ USB cable (length 1:80 m) - Item # A5017

■ CD-Rom Driv

er

s & Document

ations

■ CD-Rom eMedia Card Designer Trial Version 30 days.

■ Cleaning kit

■ Ev

olis Limit

ed Guar

ant

ee document (mus

t be consulted)

■ Quick start

In the absenc

e of one of these c

omponents, please contact your Evolis dealer.

Only use the power supply delivered with your Tattoo

VP ELECTRONIQUE or SWITCHBOX Type F10723-A or VP ELECTRONIQUE Type EA10723

Only use the same type of USB cable as the one delivered with your Tattoo.

Page 9

09

PPrree--iinnssttaallllaattiioonn aaccttiivvaattiioonn

Before installing the printer, please perform the following operations:

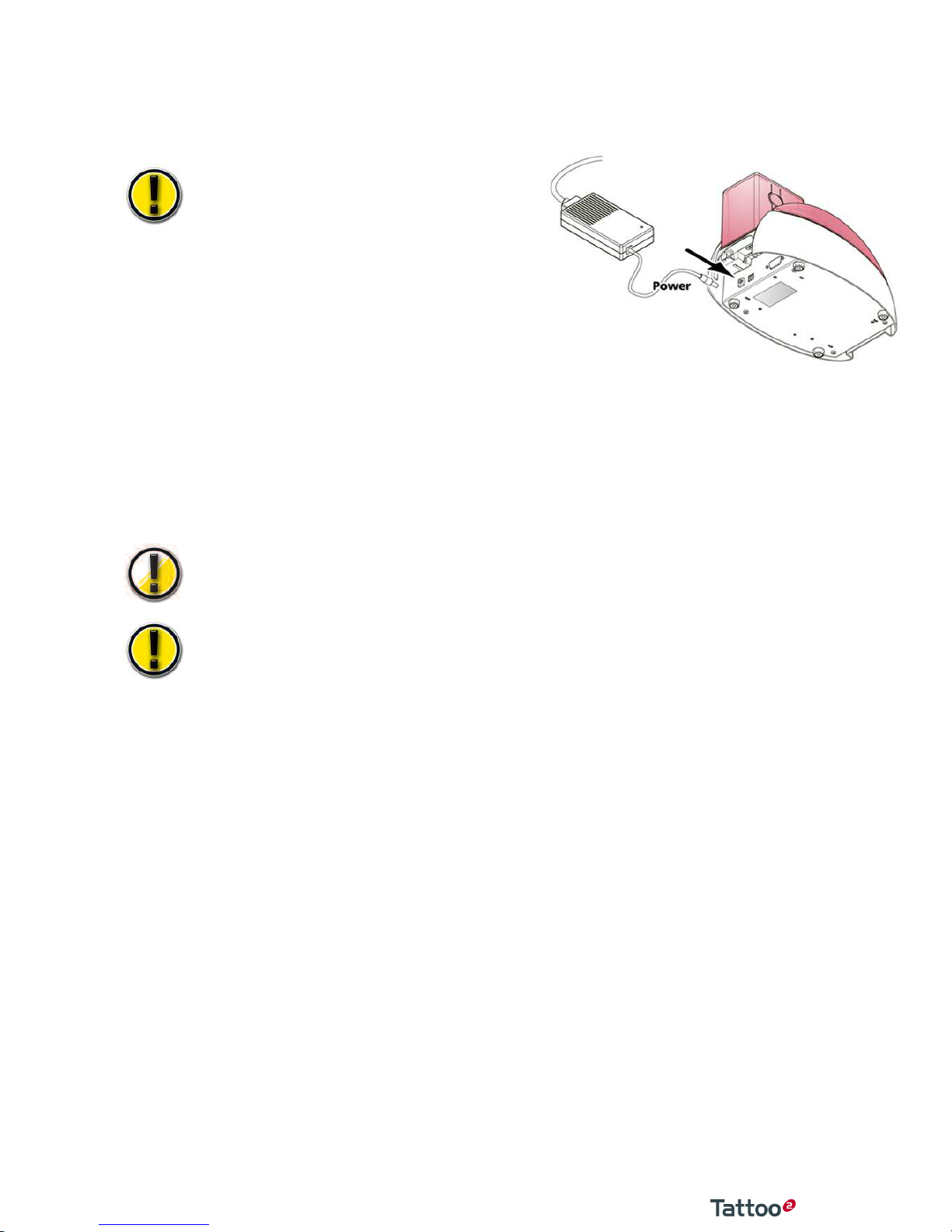

CCoonnnneecctt tthhee pprriinntteerr ttoo tthhee mmaaiinn ppoowweerr

ssuuppppllyy

Turn off the printer by pulling the plug out of the

socket, which must always be accessible.

This product must be connected to an electrical

installation that is correctly protected and grounded.

FI: Laite on liitettävä suojamaadoitus koskettimilla

varustettuun pistorasiaan

NO: Apparatet må tilkoples jordet stikkontakt

SE: Apparaten skall anslutas till jordat uttag

1. Connect the power supply cord to the power supply, then attach the power cord

connector to the printer.

2. Then connect the end of the power supply cord to a grounded system outlet.

3. The printer is under power. The light on the control panel comes on and the

print head rises and falls to indicate the correct mechanical working of the

print

er. If the light fails t

o come on, this means that the installation has not

been carried out correctly or possibly that the printer is not working properly. Check the installation.

Prior to any maintenance action, always disconnect the power supply

cable.

For your own safety, these components must remain accessible at all

times to permit emergency action

This product must be connected to a correctly protected and grounded electrical installation

CCoonnnneecctt tthhee UUSSBB ccaabbllee

The data USB cable must never be connected before the installation of the

printer driver has been completed.

Refer to Chapter 2 and carefully follow these instructions.

Page 10

10

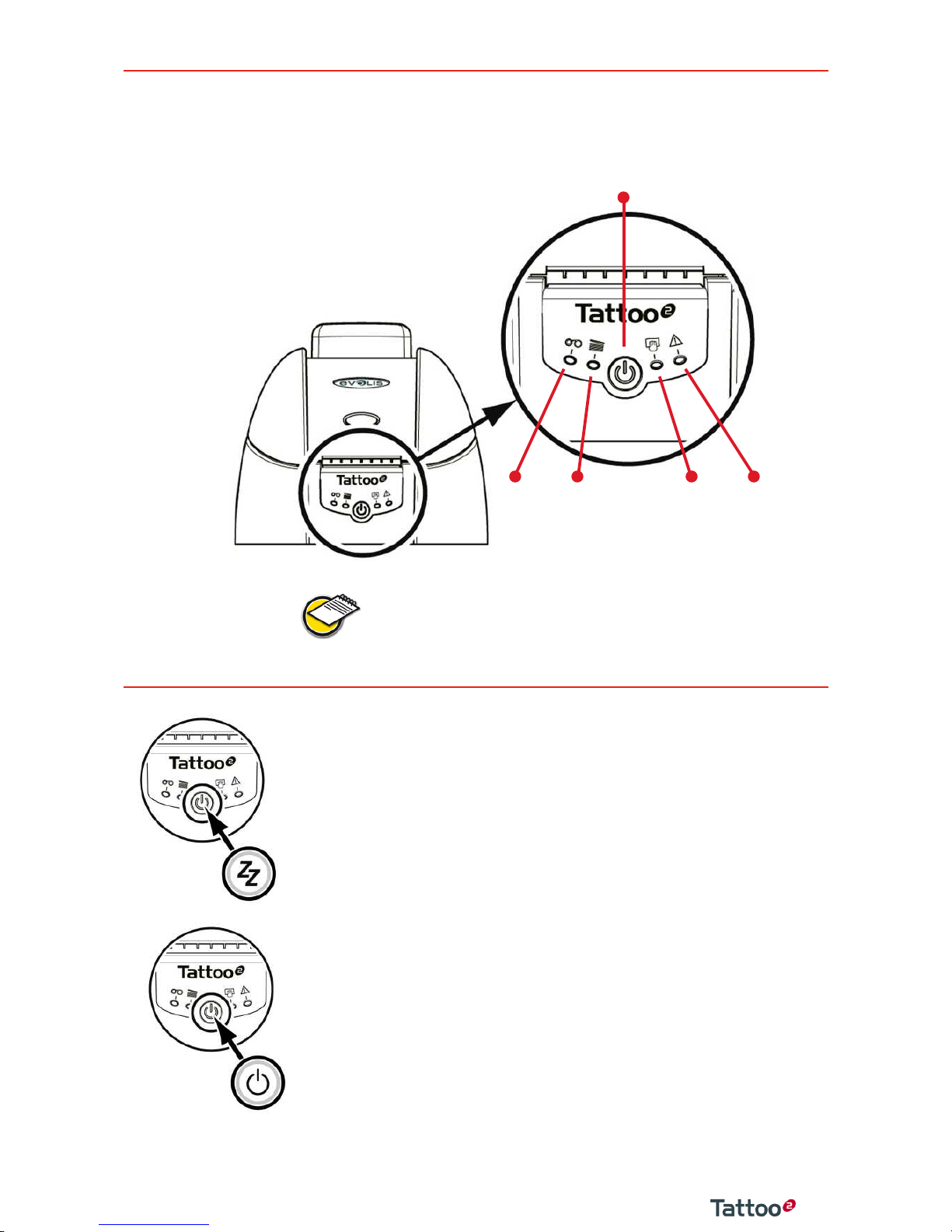

PPrriinntteerr ccoonnttrrooll ppaanneell

A control panel is available in front of the printer.

Four lights are associated with symbols indicating the printer activity.

These lights indicate the following:

Refer to chapter 3 of this manual for further information

on interpreting the messages of the control panel.

SSttaanndd bbyy

The printer automatically goes into stand-by after 10 minutes of inactivity.

The light on the push button from the control panel goes out.

To reactivate the printer, press the push button for one second.

The light on the push button comes on.

Tattoo may be left in stand-by at any time by pressing a few seconds the push

button as indicated. The light on the push button goes out.

Turned on

Data reception

(

Pushbutton)

End of

ribbon

No card in

the feeder

or feeder

not present

Cleaning

signal

Cover

open

Page 11

11

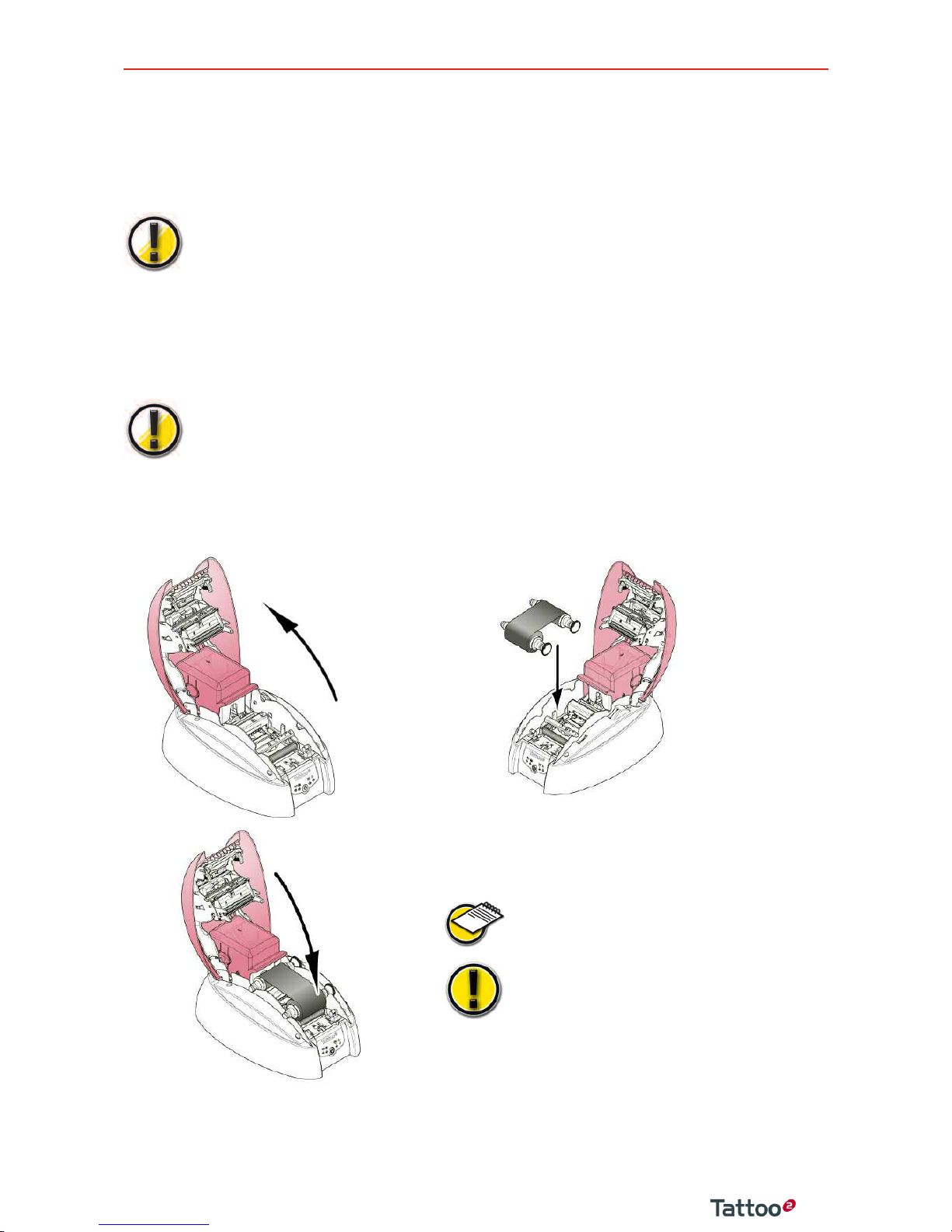

IInnssttaallll tthhee rriibbbboonnss

Tattoo uses two types of ribbons:

■ Color ribbon also called multi-panel ribbon

■ Monochrome ribbons available in different colors: black, red, green, blue, white, gold, silver

The Evolis original ribbons are specially designed to guarantee optimum operation of your

equipment without any risk of damage. The use of ribbons from any other source than Evolis

could seriously damage the print head, consequently entailing the immediate interruption of

the factory warranty.

For optimum printing quality, Evolis recommends cleaning all the equipment each time a ribbon is

changed. It is up to the user to make this determination, provided, however, that he makes sure to

comply with the mandatory cleaning cycles in order to keep the equipment in perfect operating conditions (consult the chapter on Ordinary Maintenance).

The validity of the factory guarantee is conditional upon compliance with these cleaning

cycles (cf. Limited Evolis Warranty document).

MMoonnoocchhrroommee oorr ccoolloorr rriibbbboonn

To install a monochrome or color ribbon in the print module, proceed as follows:

The ribbon will be automatically positionned

when a new printing task is launched.

Installation of the print ribbons must be

accompanied by adequate defining of the

parameters of the print driver.

Please refer to the chapters on

Properties of

the Driver

for additional details.

3. Lo

w

er the c

o

ver

and l

ock it.

1. Open the cover of

the printer by

pressing the

opening lever then

turn it in vertic

al

position.

2. Install the new ribbon

in the position

indic

ated in the

diagram:

• Toothed wheel toward

the right side.

• Part including the

new ribbon located at

the front.

Page 12

12

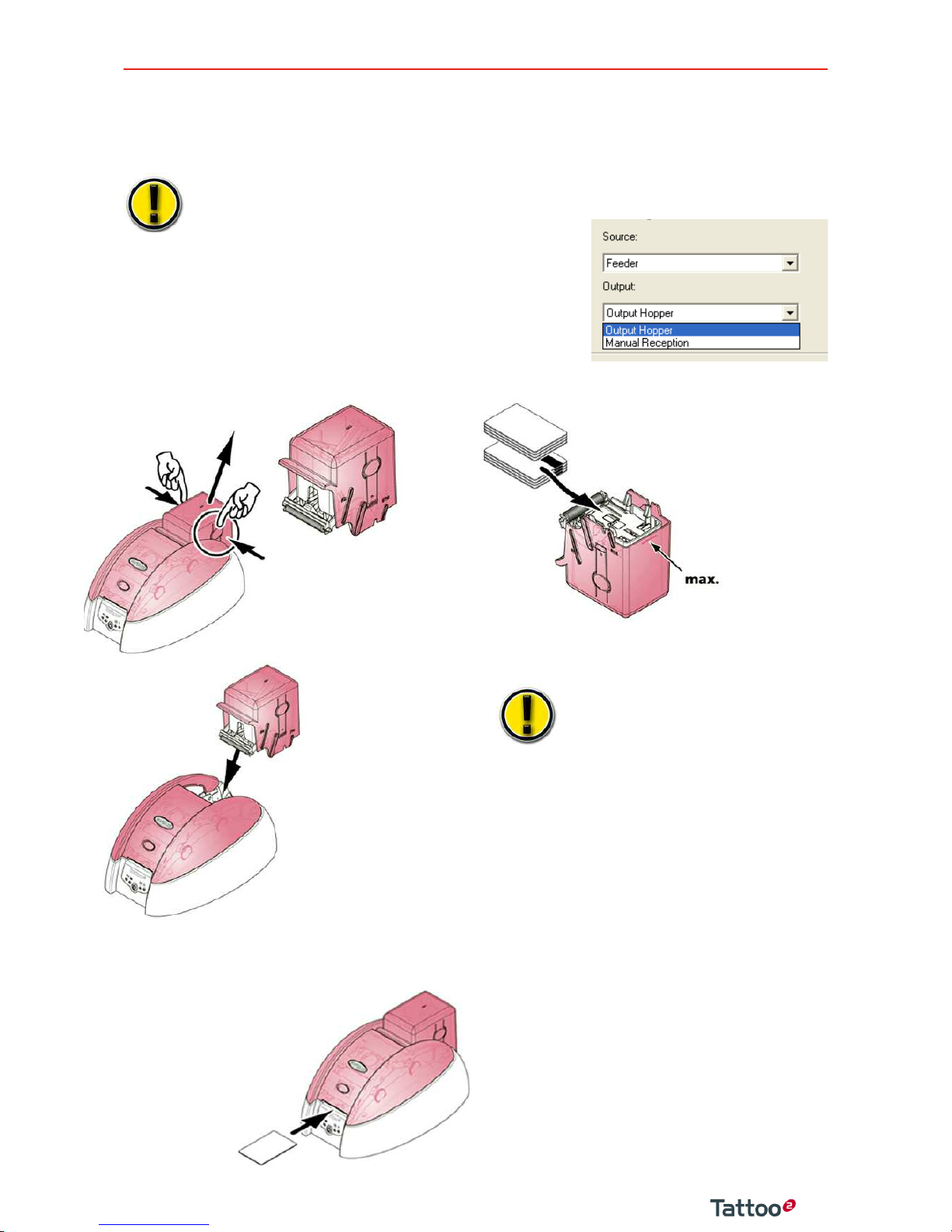

IInnssttaallll tthhee ccaarrddss

TTyyppeess ooff ccaarrddss

T

attoo supports PVC cards varying in thickness between 0.25 mm (10 mil) and 0.76 mm (30 mil).

F

or optimum quality, these cards must comply with CR Standard 80.

10 mil cards must be used only for monochrome printings

There are several feeding and ejection modes available.

The driver must be set up accordingly to your needs and choice

(cf Chapter 2)

IInnssttaallllaattiioonn iinn tthhee ffeeeeddeerr

The cards are installed in the feeder as follows:

2. Insert the

cards into the

f

eeder as

indicated,

printable face

do

wn.

3. Put the feeder

back int

o plac

e

in the printer

until it “Clicks”

in place.

1. Remove the

feeder as

indic

ated.

Only use the type of cards appearing

in the Technical Specifications in this

manual

Do not touch the printable surface of

the cards: the printing quality depends

on this.

Do not use cards that are damaged,

bent or that have an embossed texture.

Always store the blank cards in a

clean and dust-free location.

To load a card manually from the feeding mouth :

Insert a c

ard in the feeding mouth.

The card will be automatically taken in and

ejected after the printing process.

Page 13

13

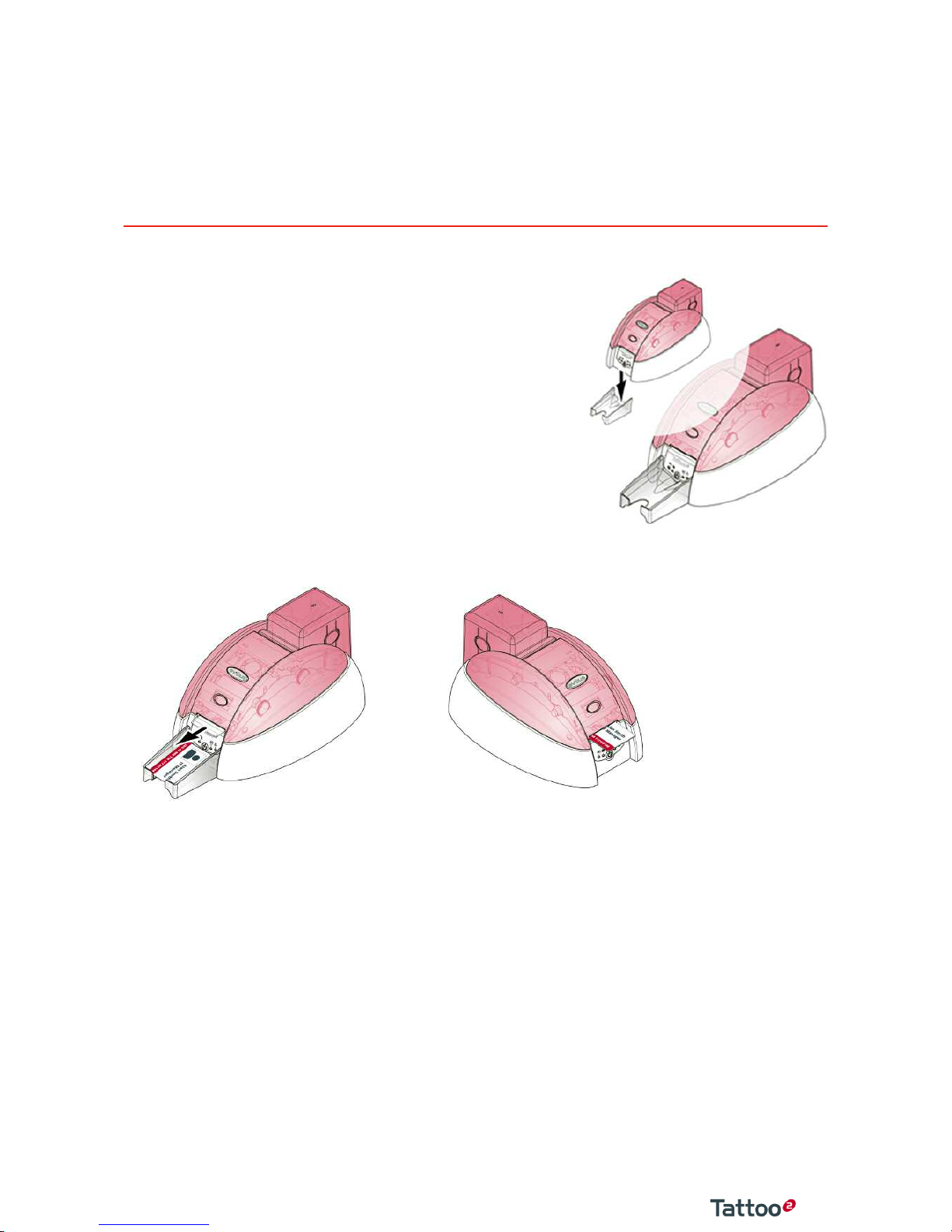

RReemmoovvee tthhee ppeerrssoonnaalliizzeedd ccaarrddss

The printer is delivered with a detachable output hopper with a

capacity of 15 cards in 0.76 mm (30 mil) format. This is intended

to receive the printed cards, and must be installed as follows.

There are 2 different modes for the card reception:

- an automatic ejection mode (in this case, it is recommended to

use the detachable hopper deliv

ered with the printer)

- a manual reception mode (the card must be collected after the

printing process)

OOtthheerr ssttaaggeess ttoo tthhee iinnssttaallllaattiioonn

You have now completed the installation (material) of your Evolis printer. For the moment, we would

urge y

ou to carry on reading this manual and we would inform you that there are still two extra

stages to be followed to make your Evolis printer fully operational:

• Installation of the driver

• Printer cleaning

Page 14

14

S

Seettttii

n

n

g

g

ooff p

paarraa

m

meetteerrss

Defining the parameters of the printer and of its driver is a

highly important step and requires very special attention.

As a matter of fact, improper settings are factors that have a

negative impact on the quality of personalization.

It is therefore essential to proceed in stages, changing the

parameters only when you are completely sure.

Evolis gives you at all times the ability to return to the ‘factory’

settings if the adjustments made do not give the expected results.

Be careful about defining the personalized parameters and do not hesitate to contact your

Evolis dealer to get the necessary advice and assistance prior to any modification.

WWiinnddoowwss pprriinntt ddrriivveerr

The Evolis Tattoo driver operates under Windows XP, Server 2003 and Vista 32 and 64-bits.

IInnssttaallllaattiioonn ooff tthhee pprriinntt ddrriivveerr

T

o ins

tall your print driver, you will need the CD-Rom ‘Drivers and Documentation’ shipped with your

Evolis printer.

Please make sure the USB cable is disconnected before starting this procedure.

The installation program automatically selects the version to be installed in terms of your

operating system.

1. Load the ‘DRIVERS & DOCUMENT

A

TIONS’ CD-Rom in y

our CD drive.

2. W

ait a f

e

w sec

onds until the w

el

c

ome screen asks you to choose your language. If the

CD-Rom does not launch automatically, double click on the setup.exe file located in the DRIVERS

directory on the CD-Rom.

3. Select your language.

4. Click the “Ins

t

all Driv

er” option t

o launch the setup pr

ogr

am.

5. Make sure you stick precisely to the installation guidelines. Some versions of Windows may

require the user to have Administrator rights to install the driver.

2

2

2

2

Page 15

15

Step 1: Accept the limited warranty conditions

Step 2: Make sure the USB cable is disconnected

Step 3: Destination location

Page 16

16

Step 4: USB cable connection

Step 5: Printer Detection

Click 'next' and/or 'continue' if the following windows appear.

Page 17

17

Step 6: End of the process

When the installation process is over, print a test card to make sure your printer operates suitably.

You are now ready to use your printer.

Page 18

18

PPrrooppeerrttiieess ooff tthhee ddrriivveerr

Before using your printer, you must determine your personalized parameters:

■ T

ype of ribbon for printing the cards

■ Default parameter settings

You will find more detailed information on Evolis ribbons in the ‘Evolis Genuine Product’

Consumables List section.

In general, it is recommended to retain the default parameters determined by the print driver.

Modification of these parameters by an uninformed user could lead to a poor quality of personalization as well as to hardware damage.

So, stay alert and contact your Evolis dealer, who will guide you in adjusting these

parameters if applicable.

These printing parameters are accessible:

■ From the Start button located at the bottom left on the Windows task bar: select Printers and Faxes.

■ Choose your printer by left-clicking with the mouse, for example Evolis Tattoo2.

■ Click again but with right mouse k

ey to bring up a menu, and select Properties.

An initial screen for setting the equipment properties parameters now appears.

The principal tabs for defining parameters are ‘Graphic’and ‘Tools’.

‘Graphic’ tab

• Choice of printing mode and of the associated ribbons

• Orient

ation of the printed card

• Number of copies

• Adjustment of the ribbon parameters: color, black panel, overlay panel options

(depend on the print ribbon selected)

Page 19

19

‘Tools’ tab

• Setting parameters and testing

of the magnetic encoding options

•

Testing and diagnostic tools

On-line help

A help file guides you in using each of the parameters of the print driver in terms of the different

print modes and criteria selected.

To familiarize yourself with these different parameters, we recommend that you consult this help

feature before making any changes.

Print a test card (Tools tab)

We recommend that you print a Test Card at the time of the first use, and that you save it.

This card s

tores data that you may be asked to provide if you call Technical Service.

Def

ault printer

Depending on your application, it may be important to define your Evolis printer as a default printing peripheral device.

In that event, all your print work (not just cards but office documentation) will be sent to the Evolis

printer.

To define your default printer, proceed as follows:

■ Using the Start button at the bottom left of the Windows task bar, select Printers and Faxes.

■ Sel

ect y

our print

er with a l

eft mouse click, f

or e

xampl

e

Ev

olis T

att

oo2

.

■ Click again using the right mouse key to bring up a menu, and choose Define as default printer.

Other tabs

> ‘Gener

al

’ t

ab

::

Windo

ws inf

ormation windo

w that all

o

ws you to print a test page to monitor the

c

omput

er-print

er c

ommunication.

> ‘Ports’ tab

:

:

Windows control window that allows you to select the printing port and to validate use

of the appr

opriat

e print driver.

The parameters displayed should be changed only by a person with advanced computer skills.

> ‘Color management’ tab

:

:

This dialog box makes it possible to associate the printing with a specific

color profile.

> ‘Security’, ‘Sharing’, ‘Advanced’ tabs: Windows and Network parameters reserved for the system

administrator of your computer system.

Do not change without prior approval.

Page 20

20

CCaarrdd pprriinnttiinngg ccoonnffiigguurraattiioonn iinn aann ooffffiiccee aauuttoommaattiioonn aapppplliiccaattiioonn

A large number of Windows applications permit the printing of a document (for example, the tools

o

f the Microsoft office suite: MS-Word, MS-Access, MS-Excel, MS-Power Point).

T

o help you familiarize yourself with formatting a card and setting the parameters for its formatting

and printing, we offer the following example:

Using Microsoft®Word

After first setting up the Evolis default printer:

■ Start the MS-Word application.

■ Click File on the menu bar, then click on Formatting.

■ The Paper tab proposes Paper format; select type ‘Card CR80’.

■ Under the Margins tab, set all the margins to

‘0’, then under Orientation, select Landscape.

■ Close the window by clicking on OK.

Your Word window should now look like this:

You are ready to personalize your card by entering

the different composition components:

■ Logo and illustration.

■ Identification photo.

■ Fixed and variable text.

■ Bar code, etc.

EExxaammppllee:

:

Please note that this example does not propose to initiate the operator on operating the

MS-Word application. Its purpose is simply to establish a relationship between the gra

phics of a card and the parameters of the Evolis printer driver that are necessary for the

printing operation.

Setting the parameters of the Evolis print driver from MS-Word:

■ Click on File on the menu bar, then click

on

Print.

■ The dialog box informs you that the

Evolis printer has been selected. Now

click on

Properties. The Evolis printer

drive dialog box appears.

The printing par

amet

er

s f

or this graphics example are:

1.

Graphic

dialog box, select:

■

Type of ribbon: R3411 - 5 Panel color ribbon - YMCKO

■

Orientation: Landscape.

■

Copy (number to be deter

mined).

2.

Advanced settings

dialog box, select:

■

Black panel adjustment: all black dots.

■

Varnish panel adjustment: full varnish.

3. Click on Apply if you modify a parameter

, then on

OK to successively close each dialog box.

4. Having r

etur

ned to the main window

, click

OK to star

t printing.

Consult the help of each dialog box, if necessary.

Page 21

21

E

Errrroorr

m

meessssaa

g

geess

aan

n

d

d

d

diiaa

g

g

n

noossttiiccss

While the Evolis Tattoo was designed to work independently, keeping your

involvement to a minimum, it may nevertheless be useful to become

familiar with the main alert messages.

NNoottiiffiiccaattiioonn ooff mmeessssaaggeess

DDeessccrriippttiioonn ooff tthhee pprriinntteerr ccoonnttrrooll ppaanneell

The control panel includes 1 button and a 4-LED-type diode.

The lights on the control panel are represented in one of the following states:

Switched off Switched on Flashing

The push button returns the control panel to its original state after dealing with the following cases:

■

ABSENCE OF CARD or INTERNAL PRINTER PROBLEM.

■

ERROR IN MAGNETIC ENCODING.

■

CARD EJECTION.

The push button also enables:

■

The printer to be set to stand-by.

■

A test card to be printed.

■

A cleaning cycle to be started.

3

3

Turned on

Data reception

(Push butt

on)

End of

ribbon

No card in

the f

eeder

or feeder

not pr

esent

Cleaning

signal

Cover

open

Page 22

22

IInntteerrpprreettaattiioonn ooff mmeessssaaggeess

Consult the following states of the control panel to determine the activity of your Evolis printer or the nature of

the problem:

State of the lights Interpretation Solution or explanation

The printer is ready to receive data.

The printer receives data from one

or several of its interfaces.

■

There is no ribbon in the printer.

■

The ribbon has finished.

■

The ribbon has been badly installed

in the printer.

■

The ribbon is cut.

Check the state of the ribbon in the

printer. If you are have a printing job in

course, this restarts with a new card.

PRINTER READY

PROCESSING

END OF RIBBON

NO CARD IN FEEDER

OR FEEDER NOT PRESENT

WAITING FOR A CARD TO

BE INSERTED

PRINTER CLEANING

ALERT (AFTER 400

INSERTIONS)

■

There is no card in the feeder.

■

The cards are curved.

■

The cards are stuck together.

■

The feeder is not present in the

printer or is badly inserted.

Check the state of the cards in the feeder or make sure that the feeder is present in the printer and correctly inserted.

Then, press the push button for one

second. The printing restarts

■

The printer is waiting for a card to be

inserted.

The printer is fitted with the manual

card feeder option: insert a card in the

printer. Go to chapter 1 “Install the

Evolis printer”.

■

The print

er has to be cleaned.

Go to chapter 4 “Servicing and

Maintenance”.

Page 23

23

State of the lights Interpretation Solution or explanation

■

The printer must immediately be

cleaned.

G

o to chapter 4 “Servicing and

Maintenance”.

■

The printer cover is open.

Close the cover of the printer.

The activity in course restarts.

■

There is a card jammed in the

printing station.

■

A mechanical part in the printer

is faulty.

Press the push button for one second.

If the problem persists, call your Evolis

reseller for assistance.

■

The orientation of the magnetic

track in the feeder is not correct.

■

The type of encoding has not been

correctly parameterised (HICO or

LOCO).

Go to Chapter 5 of this

manual for more information.

■

The encoded data do not conform

to ISO 7811 or to the parameters

pre-defined in the properties of the

driver.

Go to Chapter 5 of this

manual for more information.

Press the push button for one second.

The printer restarts the magnetic

encoding cycle with a new card.

Please check the data & parameters,

if the problem persists, call your

Evolis reseller for assistance.

■

The print head cooling system is

activated.

The printer stops working for a few

seconds. As soon as the print head

reaches the normal working temperature, the activity starts once more.

PRINTER CLEANING ALERT

(AFTER 500

INSERTIONS)

PRINTER COVER OPEN

MECHANICAL PROBLEM

ENCODING ERROR

COOLING MODE

Page 24

24

DDiiaaggnnoossttiiccss aassssiissttaannccee

In this chapter, you will find all the information required to perform certain simple procedures that you may

be asked to do by your Evolis dealer to provide you with the most effective assistance.

PPrriinntt aa tteesstt ccaarrdd

Printing a test card gives certain technical information about your printer and confirms its correct working.

We advise you to print it when the printer is put into service and to keep it at hand.

1.

Make sure there are a ribbon and a card in the printer.

2.

Press the push button for three seconds. All the lights go out.

3.

Press the push button once more and hold it down.

4.

Release the push button as soon as the light flashes

5.

The test card is printed in a few seconds (in color if the printer has a color ribbon or in monochrome

if it has a monochrome ribbon).

6.

The printed card is ejected into the output hopper.

IInntteerrpprreett aa tteesstt ccaarrdd

The printing of a test card gives the following information:

■

Correct printing.

■

The correct position of the ribbon in the printer.

■

The printer model.

■

The serial number of the printer.

■

The serial number of the head printer.

■

The version of the Firmware installed in the printer.

IIddeennttiiffyy tthhee ssooffttwwaarree vveerrssiioonn iinnssttaalllleedd

As indicated above, you can simply identify the software version loaded into your printer thanks to

the test card (Firmware no.). You can also identify the version of the print driver installed as follows:

■

Go into the driver

properties (on the print

driver l

ogo, right-click

and choose

Pr

operties

)

■ Gr

aphic

tab

■ About

button

Page 25

S

Seerrvviiccii

n

n

g

g

aan

n

d

d

M

Maaii

n

nttee

n

naa

n

nccee

In this chapter, we suggest that you identify the ordinary service

operations for your Evolis printer that will enable you to ensure a

very high quality of personalization of your plastic cards.

Keep your Warranty in effect !

The factory warranty is subject to strict compliance with ordinary maintenance instructions, and specifically to compliance with the equipment cleaning cycle intervals.

Failure to comply with the procedures described in this chapter entails cancellation of

the warranty on your printer and its print head.

Evolis will not be liable if the printer is used under non-approved maintenance conditions.

Indeed, the print head is subject to wear and tear. This is a very sensitive component of

the printer of which lifespan can be shortened in case the neighboring environment of the

printer /print head or the cards is not dust-free.

The cards inserted must be clean, dustproof and with no dirt.

Moreover, the frequency and quality of cleanings are key in helping user extend the print

head lifespan. Stick to the instructions mentioned below.

OOrrddiinnaarryy mmaaiinntteennaannccee

The printer is delivered with a 'starter cleaning kit'.

Evolis also provides you with the following maintenance items, available under the following reference item:

A5011 - UltraClean cleaning kit:

■ Five cleaning cards pre-saturated with 99% isopropyl alcohol.

■ Five 99% isopropyl-based cotton swabs.

■ A dispenser box of 40 pre-saturated cleaning wipes.

CClleeaann tthhee ccaarrdd ffeeeedd mmoodduullee

Cl

eaning cy

cle:

e

v

ery 400 cards inserted

Maximum interval between two cleaning cycles: 500 inserted cards

Maintenance accessory: pre-saturated cleaning cards

When a cleaning of the card feed module is necessary (every 400 cards

print

ed), the cl

eaning light from the control panel comes on as follows:

This message is an alert that indicates to the operator that it is necessary to perform the cleaning cycle.

If the print

er is not cl

eaned aft

er the LED illuminat

es, the LED will r

emain illuminat

ed and will s

tart

flashing when 100 additional cards have been printed.

In that event, immediately stop the work in progress and proceed with the cleaning.

If there is no maintenance action on your part, the message will remain posted and the

factory warranty will be implicitly invalidated for failure to comply with the contractual

maintenance requirements.

25

4

4

Page 26

3. Insert the cleaning

card in the feeder

as indicated.

2. Remove the cards

that are in the

feeder.

4. Put the

feeder back

int

o the

printer than

press on the

top part of

the feeder

until the

‘click’ is

heard.

To service the printer card feed system, obtain a pre-saturated cleaning card specially designed for

t

he printer.

A

cleaning kit including samples of these cards is shipped with your Evolis printer.

R

epeated running of the card in the printer cleans the card feed rollers, the cleaning rollers, the

p

rint head and the magnetic head (if your device has one).

Proceed as follows:

1.

Remove the

card feeder

as indicated.

5. Open the

cover and

remo

ve the

ribbon fr

om

the printer

as shown.

26

6. Close the cover of

the printer.

7. Press the push

button on the control

panel f

or a second.

The cleaning starts.

8. The used cleaning card is

eject

ed in the output hopper

.

Page 27

Following a cleaning cycle, wait 2 minutes until all the cleaner is completely evaporated

b

efore using the printer.

Take advantage of this interruption to clean the print head (see below).

RReeccoommmmeennddaattiioonns

s

Maintenance of the card feed module ensures a high quality of printing. Evolis recommends

that you perform servicing on each ribbon change. Without waiting for the signal of the light

of the printer, proceed as described above.

27

SSeerrvviiccee tthhee cclleeaanniinngg rroolllleerrss

The function of the cleaning rollers is to eliminate any residual dust of the cards before they enter

the feeder system.

This roller, therefore systematically becomes dirty. This is a sign of its efficacy.

If this roller remains clean, we suggest that you check its quality by contacting your Evolis dealer in

order to replace it, if applicable.

To supplement the servicing of the card feeder system which is intended to clean it, you can obtain

a satur

ated cleaning cloth and clean this component thoroughly.

Frequency: on each ribbon change and after each cleaning cycle of the card feed module

Maintenance accessory: cleaning cloths

Proceed as follows:

1. Open the c

over.

If there is one,

remove the ribbon

and l

ocate the

cleaning roller.

2. Release the cleaning

r

oll

er from its seat.

Page 28

28

CClleeaann tthhee pprriinntt hheeaadd

Frequency: on each ribbon change and after each cleaning cycle of the card feed module

Maintenance accessory: cotton swab saturated with isopropyl alcohol

The print head is cleaned at the time the inside of the printer is cleaned (see above).

However, in order to preserve the original printing quality and to reduce the incidents created by the

presenc

e of surplus ink on the surface of the print head, it is recommended that the print head be clea-

ned regularly (at each ribbon change) using the cotton swabs supplied with the UltraClean cleaning kit.

It is very important to protect the print head and any other related component handled

against any electrostatic discharge.

The print head is a fragile component of your printer. To prevent any damage to it:

■

Before cleaning the print head, disconnect the printer from its power supply.

■

Comply with the cleaning cycles.

■

Never put the print head into contact with pointed and or metal objects.

■

Avoid direct contact between the surface of the print head and the fingers. This could result in

an altered print quality, or even permanent damage to the print head.

3. Clean the roller with a cleaning cloth from your

cleaning kit. Eliminate all dust by rubbing the

cloth lightly over the entire surface of the roller.

7. Clean the roller with the

cleaning cloth & put the feeder

back into place until il clicks.

8. The printer is again available

for use.

4.W

hen it is dry, replace the

roller into the printer, making

s

ure it is properly

positioned.

5. Put the ribbon

back in its place,

lower and close

the cover.

6. Remove the

feeder as

indicated.

After a cleaning cycle, wait 2 minutes for the cleaning fluid to evaporate completely

before using the printer

Page 29

29

After a cleaning cycle, wait 2 minutes until all the cleaning fluid evaporates before using

the printer.

2. Take a cotton swab and

press the middle of the

tube until a click is

heard. The cotton

becomes saturated with

alcohol.

3. Carefull

y rub the c

otton swab

from right to left along the print

head for a few seconds.

4. Close the cover. The printer is

again r

eady f

or operation.

1. O

pen the cover

and locate the

p

rinthead.

Proceed as follows:

Page 30

MMaaiinntteennaannccee

The Evolis printers are designed to offer the user quality of personalization, ease of use and equipment longevity.

H

owever, depending on the type and volume of personalized cards as well as the operating environment,

certain elements are able to be exchanged by the user.

Moreover, it is common in the computer world to do regular upgrades of the software components:

the firmware and the print drivers.

The following chapters provide information on the ordinary maintenance operations that make it

possible to keep your Evolis printer in perfect working order.

RReeppllaaccee tthhee cclleeaanniinngg rroolllleerrss

In the event your cleaning rollers become less efficient despite regular maintenance, they need to

be replaced in order to keep the print head from becoming clogged and ultimately permanently

damaged. (See the chapter on Service the Cleaning Roller).

The cleaning rollers are available as a consumable from your Evolis dealer.

To replace the rollers, proceed as follows:

30

2. Locate the cleaning

roller and release it

fr

om its seat.

4. Remove the

c

ar

d f

eeder as

indic

ated.

5. Remove the cards

that ar

e in the

feeder.

6. Release the cleaning roller

& replace it.

7. Put the cards in the feeder and the

f

eeder back in the print

er

.

8. The printer is ready for operation.

3. Install the new roller into

the printer, making sure

that it is c

orrectly positioned

in its seat.

1. Open the cover. If there is

one, remove the ribbon.

Page 31

31

RReeppllaaccee tthhee pprriinntt hheeaadd

T

he print head is a sensitive component of your equipment. It determines the print quality, and its regu-

lar maintenance as well as the absence of dust in the immediate environment guarantee its longevity.

However, it can happen that this head needs to be replaced. Evolis has designed a unique device that

a

llows the user to proceed to this exchange without using any tools by simply following the instruc-

t

ions very carefully.

Before doing anything else, please contact your Evolis dealer in order to check with him whether it

is advisable to replace the print head.

During the printer warranty period, Evolis has put in place a program for the replacement

of defective print heads. Your equipment is eligible for this program if:

■

You use only Evolis consumables (ribbons and maintenance products).

■

You have scrupulously complied with the equipment maintenance cycles.

■

You work in a dust-free environment in accordance with technical specifications.

■

You use flat cards without any rough areas that could damage the surface of the

print head.

To complete the exchange of the print head, proceed as follows:

Before changing a print head, make sure to disconnect the printer from its power supply.

Step 1 - Removing the defective print head

1. Open the cover and locate

the print head.

2. Pr

es

s on the 2 holding f

orks (1)

and piv

ot them round in order to

pull the lugs fr

om their seat (2).

3. Turn the head

carefully and

disc

onnect the

connector linked

to the cable

without f

or

cing

the mechanism.

Page 32

Step 2 - Installing the new print head

5. Fit in the the head horizontall

y by inserting the ball int

o

its seat.

6. Turn the print head in or

der to insert the lugs into the

lateral forks of the head bracket.

7. The head is put back in plac

e.

8. Close the cover. The new print head is now installed.

1.N

ote the code indicated

on the white ticket affixed

to the print head. You

w

ill be asked for this

code in Step 3.

2.P

ick up the new

print head and

turn it toward

y

ou, with the

white connector

v

isible.

3. Connect the cable into its

seat, making sure it is in

the correct direction. Do

not force the mechanism,

as this part is relatively

sensitive.

4. Turn the head so

that the notice is

visible: the

connector is no

longer visible.

32

Step 3 - Setting the parameters of the new print head

1. P

ower up the printer and make sure it is properly connected to a computer

on which Tattoo print driver is installed.

2. Under print driver “Properties”, click on the “Tools” dialogue box.

3. In the “

Bi dir

ectionnal communication”

portion, ent

er the f

ollowing command:

Pkn;x

X = the print head kit number that you read in Step 2

Example: if the print head kit number is: 379-D760 2028-D, you must enter the command:

Pkn;379-D760 2028-D

If the print head kit number is not entered correctly, printer malfunctions can occur and the

warranty may be canceled.

Page 33

33

Step 4 - Cleaning the printer

O

n the LED control panel, the cleaning light comes on as follows:

Cleaning is absolutely required after a print head change.

No printing should be started before this operation has been completed.

Refer to the Clean Card Feed Module chapter to perform this operation.

Also service the cleaning roller and replace cards and ribbons.

Once the cleaning is done, your Evolis printer is again ready to personalize your cards.

UUppddaattee tthhee FFiirrmmwwaarree

Updating the Firmware is a simple operation, but if is not carried out fully, the result can be a disabled.

Prior to any update, please contact your Evolis dealer who can advise you as to whether or

not it is appropriate to carry out this operation. In general, this type of update is required

only in case of a problem or malfunction clearly identified by your Evolis dealer.

In order to download an update from the www.evolis.com/en/supservices/access.asp site, you must

first have registered your product with Evolis (see chapter

Register your product in order to benefit

from updates).

1. Enter your login and password: a page is displayed.

2. Sel

ect the Tattoo2 printer model and the Firmware selection.

3. Accept the download and register the file in a directory on your hard disk.

The file is stored in compressed zip. file. You must extract it and save it in a temporary directory.

4. Then double-click on the file in the directory to start the download.

5. When ask

ed by the program, click on the Download

butt

on to start the operation.

The downloading is in process, the push button from the control panel flashes.

6. Aft

er about thirty sec

onds, the Firmware has been transferred to the printer, and the operation

is c

ompl

ete. The light from the push button comes on and the print head rises and falls to

indicate the correct transfer of the firmware. If the light fails to come on or flashes, this means

that the transfer has not been carried out correctly or possibly that the printer is not working

pr

operl

y

. Check the c

onnections cables and perform a new transfer.

The update is complete, and your equipment is ready to personalize

your cards.

Never interrupt the transfer between the PC and the printer during the important down

loading phase (by turning off the printer or the PC, or disconnecting a cable). The result

would be the total inability to restart the printer.

If this ever occurs, please contact your Evolis dealer, who will replace your printer’s processor card.

Page 34

34

UUppddaattee tthhee pprriinntt ddrriivveerr

The updating of the print driver is required in order to solve malfunction problems or to benefit of new

options.

Prior to any update, contact your Evolis dealer who can advise you as to whether or not it is

appropriate to carry out this operation.

In order to download an update from the www.evolis.com/en/supservices/access.asp site, you must

first have registered your product with Evolis (see chapter

Register your product in order to benefit

from updates).

1. Enter your login and password: a page is displayed.

2. Select the Tattoo2 printer model and the Drivers selection.

3. Accept the download and register the file in a directory on your hard disk.

The file is stored in compressed zip. file. You must extract it and save it to a temporary directory.

4. Then double-click on the file (Setup.exe) that you have just extracted in order to start the

downloading process.

F

or more details on procedures, please consult the chapter on

Ins

tall the Print Driver

.

Page 35

TTrroouubblleesshhoooottiinngg

I

n this chapter, you will find out how to resolve certain problems that can arise while you are working.

Never use a metal tool or object to work on your equipment: you run the risk of hurting

yourself or damaging all or part of the equipment.

FFrreeee aa ccaarrdd jjaammmmeedd iinn tthhee pprriinnttiinngg uunniitt

When a card is jammed in the printing unit, the LEDS from the

control panel are as shown:

Work is interrupted.

Do not turn off the unit: this would lead to a loss of the printing jobs in progress that are

stored in the printer’s memory.

Remove the card as follows:

1. Open the cover of the printer and remove the ribbon.

2. Press the push button from the Control Panel to run the transportation rollers. If the card is still

stuck inside the print

er, push it manually towar

ds the printer outlet. If ther

e are several cards,

always push the top one first.

3. Replace the ribbon then close the printer cover.

To prevent card jamming:

1. Mak

e sur

e that the c

ar

d thickness corresponds to the specifications in the ”Technical

Specific

ations”

section of this manual.

2. Check that the cards are not curved or stuck together.

35

Page 36

UUppggrraaddee tthhee pprriinntt qquuaalliittyy

The following information will help you solve potential print quality problems that can arise when using

y

our printer. If, despite this information, you cannot solve the problem, contact your Evolis dealer.

NNootthhiinngg pprriinnttss

1. Check your equipment’s power supply

Make sure that:

■ The power cord is correctly connected to the printer and to a working outlet.

■ The printer is powered. The button must be illuminated.

■ The power supply used is the one shipped with the printer.

2. Check the card feeder and the card in the printer itself

■ Verify the presence of cards in the feeder.

■ Check that there is no jamming.

3. Check the ribbon

■ Make sure the ribbon is correctly installed and that the the cover is closed.

4. Print a test card

See the chapter “Print and interpret a test card”.

5. Check the printer’s interface cable

■ Check the connection to the computer and to the printer.

■ Try using another cable of the same type.

6. Check the print driver

■ Check for the pr

esence of the print driver of the Tattoo printer in the Windows

parameter

s.

■ Check the computer’s printing parameters.

■ Make sure the Tattoo printer is selected as the default printer.

AA bbllaannkk ccaarrdd iiss eejjeecctteedd ffrroomm tthhee pprriinntteerr

1. Check the ribbon

■ Make sure the ribbon is not finished or cut. Replace or reinstall the ribbon, if applicable.

2. Check the printer connection

■ Check the printer’s interface cable.

■ Check the connection to the computer and to the printer.

■ T

ry using another c

abl

e of the same type.

3. Components of the print head ar

e perhaps damaged

■ Print a test card.

If the test card does not print, contact your dealer for a replacement for the print head.

36

Page 37

TThhee pprriinntt qquuaalliittyy iiss nnoott ssuuffffiicciieenntt

The type of card used may be inappropriate

■ Make sure the type of cards used corresponds to the required specifications.

See the “Characteristics” chapter in this manual for more information.

TThhee tteexxttuurree ooff tthhee ccaarrdd iiss rroouugghh oorr nnoott ppeerrffeeccttllyy ffllaatt

■ Try to print using another type of card.

PPaarrttiiaall oorr iinnccoorrrreecctt pprriinnttiinngg

1. Check the parameters defined for the printing

■ Make sure no element of your formatting is outside the print margins.

■ Check the orientation of the document selected in the configuration of the print driver

(Landscape or Portrait).

2. Check the printer interface cable

■ If some unusual characters print out, make sure you are using the interface cable

appropriate for your printer.

■ Check the connection to the computer and to the printer.

■ Try using another cable of the same type.

3. Make sure the printer is clean

■ Clean the inside of the printer, the cleaning rollers and the print head, if necessary.

See the “Maintenance” chapter of this manual.

4. Make sure the cards are clean

■ Make sure they are stored in a dust-free location.

5. Check the ribbon

■ Make sure its position in the printer is correct.

■ Make sure it is unrolling correctly.

■ Make sure the ribbon is selected in the printer's driver (Graphics Tab).

6. Check the print head

■ If horizontal (white) lines appear on the card, some components of the print head

may be dirty or damaged.

■ Cl

ean the print head.

Consult the “Maintenance” chapter for more information.

■ If the pr

oblem is not solved after cleaning, contact your Evolis reseller for a new print head.

37

Page 38

AAssssiissttaannccee

In order to assist you on a day-to-day basis, Evolis has structured its customer service

a

round a network of specialized partners.

Moreover, to let you get answers to your questions 24/7, the Internet site www.evolis.com

includes a number of elements linked to the day-to-day operation of your Tattoo.

NNeettwwoorrkk ooff EEvvoolliiss ppaarrttnneerrss

For any unresolved technical problem, contact an Evolis dealer. If you do not know of an Evolis dealer, go onto the

www.evolis.com site and send us your request. Evolis will give you the address of

the Evolis dealer closest to you. When you call an Evolis dealer, you must be next to your computer

and be prepared to provide the following information:

■ The type and serial number of your printer

■ The type of configuration and the operating system you are using

■ A description of the problem that has occurred

■ A description of the steps you have taken to solve the problem.

LLooookk ffoorr iinnffoorrmmaattiioonn oonn wwwwww..eevvoolliiss..ccoomm

If you need additional technical aid, you will find a large amount of information relative to the utilization and tr

oubleshooting of the Evolis print

ers under the heading

Support & Serviceson the Ev

olis

Internet site.

This item off

er

s the downl

oading of the mos

t recent versions of Firmware, print drivers and user

manuals, Evolis printer use and maintenance and an FAQ* item to provide answers to the most frequently-asked questions.

*FAQ : Frequently-asked Questions

RReeggiisstteerr yyoouurr pprroodduucctt ttoo bbeenneeffiitt ffrroomm uuppddaatteess

To benefit from driver and Firmware updates, you must pre-register on the www.evolis.com site.

Ent

er the f

oll

o

wing address into your browser in order to get access to the registration form.

http://www.evolis.com/en/supservices/profile.asp

Please fill out the entire form, making sure

to complete correctly the fields in red.

You will receive a return confirmation e-mail

including your personal access codes.

38

Page 39

C

C

h

haarraacctteerriissttiiccss

This chapter covers technical specifications and certifications

for the Evolis printer

DDeeccllaarraattiioonn ooff CCoonnffoorrmmiittyy

Concerning Safety and Electromagnetic Compatibility

Manufacturer’s Name: Evolis Card Printer

Manufacturer’s Address: 14, avenue de la Fontaine

Z.I. Angers Beaucouzé

49070 Beaucouzé - France

Material Designation: Tattoo2

Year of Manufacture: 2007

I, the undersigned, Serge Olivier,

Declare that I have received the assumption of the above material(s), used and installed in accordance with the notice, with the essential requirements

of Directives 2006/95/EC and 2004/108/EC by the application of the following regulations:

EN 60950-1 of 2001

EN 55022 Clas

s B of 1998: A1 (2000), A2 (2003)

EN 55024 of 1998: A1 (2001), A2 (2003)

EN 61000-3-2 of 2000

EN 61000-3-3 of 2000 +A1 of 2001

Full name: Serge Olivier

Title: Technical Manager

Date: September 2007

Signature:

EEUURROOPPE

E

- Norway Only: This product is designed for IT power system with phase-to-phase voltage 230V. Earth grounding is via the polarized, 3-wire power cord.

FI: “Laite on liitettävä suojamaadoitus koskettimilla varustettuun pistorasiaan” - SE: “Apparaten skall anslutas till jordat uttag” - NO: “Apparatet må tilkoples jordet stikkontakt”

FCC Statement (for U.S.A.)

Federal Communications Commission Radio Frequency Interferences Statement

Tattoo2 model conforms to the following specifications: FCC Part 15, Subpart A, Section 15.107(a) and Section 15.109(a) Class B digital device.

Supplemental information:

This equipment has been tested and finds to comply with the limits for a Class B digital device, pursuant to part 15 of the FCC Rules. These limits are

designed to provide reasonable protection against harmful interference in a residential installation. This equipment generates uses and can radiate radio

frequency energy and, if not installed and used in accordance with the instructions, may cause harmful interference to radio communications. However,

ther

e is no guar

ant

ee that interference will not occur in a particular installation. If this equipment does cause harmful interference to radio or television

r

eception, which can be determined by turning the equipment off and on, the user is encouraged to try to correct the interference’s by one or more of

the following measures:

- Reorient or r

el

oc

at

e the r

ec

eiving ant

enna.

- Incr

ease the separ

ation betw

een the equipment and the r

eceiver.

- Connect the equipment into an outlet on a circuit different from that to which the receiver is connected.

- Consult the dealer or an experienced radio/TV technician for help.

Use of a shielded cable is required to comply within Class B limits of Part 15 of FCC Rules.

Pursuant to Part 15.21 of the FCC Rules, any changes or modifications to this equipment not expressly approved by Evolis Card Printer may cause, harmful int

erference and void the FCC authorization to operate this equipment.

VCCI (for Japan)

This is a Class B product

based on the standard of the

Voluntary Control Council for

Interference from Information

Technology Equipment (VCCI).

If this is used near a radio or television receiver

in a domestic environment, it may cause radio

interference. Install and use the equipment

according to the instruction manual.

End of life product disposal

This symbol indic

at

es that W

as

t

e Electrical and Electronic Equipment (WEEE) must be disposed of separately from normal household

was

t

e in or

der t

o pr

omote reuse, recycling and other forms of recovery and to reduce the quantity of waste to be eliminated though land-

fill. WEEE includes ac

c

es

sories such as r

emot

e control, batteries, AC adaptor, etc. When you dispose of such products, please contact

y

our dis

tribut

or or Ev

olis at inf

o@evolis.com

5

5

39

Page 40

40

PPrriinntteerr ssppeecciiffiiccaattiioonnss

GGeenneerraall SSppeecciiffiiccaattiioonnss

■ Color or monochrome printing module

■ 3

00 dpi print head (11.8 dots/mm)

■ USB connection

■ 16 MB RAM

■ Detachable feeder with a capacity of 100 cards (0.76 mm or 30 mil)

■ Detachable Output hopper with a capacity of 15 cards (0.76 mm or 30mil)

■ 1-Button and 4-LED control panel

■ Available in Fire red colour

CCaarrdd llooaaddiinngg mmooddeess

■ Automatic with feeder and/or hand-feed

PPrriinntt MMooddeess

■ Color dye sublimation and monochrome thermal transfer

■ Integrated ribbon saver for monochrome printing

PPrriinnttiinngg ssppeeeedd

Personalization throughput will depend on card design and printer settings

■ YMCKO: 40 sec

onds/cards

1

■ Monochrome: 7 seconds/card

1

SSuupppplliieedd ssooffttwwaarree

■ Windows

TM

XP, Server 2003 and Vista (32 & 64 bits)

SSuuppppoorrtteedd ppllaattffoorrmmss

■ eMedia Trial - 30 days e

valuation

RRiibbbboonn ttyyppeess

■ 5-panel YMCK

O c

olor ribbon - up to 100 cards/roll

■ Monochrome ribbons (available in black, red, green, blue) - Up to 600 cards/roll.

■ Monochr

ome ribbons (av

ailabl

e in whit

e, gold and sil

v

er) - Up t

o 500 cards/roll.

■ BlackWAX monochrome ribbon (for ABS & special varnished plastic cards) - up to 600 cards / roll.

OOppttiioonnss

■ 100-card additional feeder

■ Cleaning kits.

WWaarrrraannttyy

Use Ev

olis Genuine pr

oducts for best performance and extended lifespan of your printer

■ Printer, print head: 1 year warranty, unlimited number of passes

2

Page 41

41

C

ard types

All PVC, Composite PVC cards, PET, ABS1& Varnished1cards

C

ard format

I

SO CR-80 - ISO 7810 (53.98 mm x 85.60 mm - 3.375" x 2.125")

Card thickness From 0.25 mm (10 mil)3to 0.76 mm (30 mil)

Card feeder capacity 100 cards (0.76 mm-30 mil), 300 cards (0,25mm-10 mil)

Card output hopper capacity 15 cards (0.76 mm-30 mil), 45 cards (0,25mm-10 mil)

Printer size Height 166 mm (6.53")

Lenght 290 mm (11.42") / 368 mm (14.49") with the detachable hopper

Width 187 mm (7.36")

Printer weight 2.4 kg (5.3 lbs)

Connections USB (Cable supplied)

Electrical Power supply: 100-240 V, 50-60Hz, 1.5 or 1.8 A

Printer: 24 Volts DC, 3 A

Environmental Min/Max operating temperature: 15° / 30°C (59° / 86° F)

Humidity: 20% to 65% non-condensing

Min/Max storage temperature: -5° / +70°C (23° / 158° F)

Storage humidity: 20% to 70% non-condensing

Operating ventilation: free air

1 Under specific conditions

2 Subject to observance of specific conditions and use of Evolis Genuine Consumables

3 0.25 mm (10 mil) cards must be used only for monochrome printings

Page 42

42

LLiisstt ooff ““EEvvoolliiss GGeennuuiinnee PPrroodduucctt”” ccoonnssuummaabblleess

Part Number Description

M

ulti Panels Color Ribbon

R3411 5-Panel Color Ribbon (YMCKO) - Up to 100 cards / roll

Monochrome Ribbons

R2211 Black Monochrome Ribbon - Up to 600 cards / ribbon

R2212 Blue Monochrome Ribbon - Up to 600 cards / ribbon

R2213 Red Monochrome Ribbon - Up to 600 cards / ribbon

R2214 Green Monochrome Ribbon - Up to 600 cards / ribbon

R2215 White Monochrome Ribbon - Up to 500 cards / ribbon

R2216 Gold Monochrome Ribbon - Up to 500 cards / ribbon

R2217 Silver Monochrome Ribbon - Up to 500 cards / ribbon

Special Ribbon

R2219 BlackWAX Monochrome Ribbon - Up to 600 cards / ribbon

Aimed at printing on ABS and rough surface

LLiisstt ooff PPllaassttiicc CCaarrddss

P

art Number Description

C4001 Classic Blank White plastic cards - 0.76 mm (30 mil)

5 packs of 100 cards

C4002 Classic Blank White plastic cards - 0.50 mm (20 mil)

5 packs of 100 car

ds

C4003

Classic Blank White plastic cards with a HICO Magnetic Stripe - 0.76 mm (30 mil)

5 packs of 100 cards

C4004 Classic Blank Whit

e plas

tic cards with a L

OCO Magnetic Stripe - 0.76 mm (30 mil)

5 packs of 100 cards

C1001 Premium Blank White plastic cards - 0.76 mm (30 mil)

5 packs of 100 cards

C1003

Pr

emium Blank Whit

e plas

tic cards with a HICO Magnetic Stripe - 0.76 mm (30 mil)

5 packs of 100 cards

C1004 Premium Blank White plastic cards with a LOCO Magnetic Stripe - 0.76 mm (30 mil)

5 packs of 100 cards

LLiisstt ooff EEvvoolliiss TTaattttoooo AAcccceessssoorriieess

Part Number Description

A5011

Ultr

a Cl

ean cl

eaning kit

5 pre-saturated cleaning cards, 5 swabs, 1 box of 40 pre-saturated cleaning cloths

S5304FR

Additionnal 100-c

ar

d feeder

A5017

USB interface cable

A5008 Power supply

A5009 Power cord, 220V

A5010

P

o

w

er c

or

d, 110V

A5019 Power cord, UK

Page 43

43

MMaaggnneettiicc eennccooddiinngg

Tattoo printer with a magnetic stripe card encoder is called Tattoo Mag. The operating mode of a

T

attoo Mag printer is identical to that of a Tattoo Basic printer.

The magnetic encoder encodes tracks ISO 1, 2, 3 and custom in a single passage and then checks the data.

S

et in high coercivity (HICO) or in low coercivity (LOCO) with a simple click from the Windows driver,

however, the encoders of the Tattoo Mag are sent adjusted to high coercivity (HICO) by default,

unless specifically requested on the order.

LLooccaattiioonn ooff tthhee mmaaggnneettiicc eennccooddeerr

The magnetic encoder is a module installed in the factory on

Tattoo Mag printers. The writing and reading head is placed

under the path of the cards and after the print head.

The encoding sequence of a card is still carried out

before printing.

Only use cards with magnetic tracks conform to ISO

7810 and ISO 7811. To work properly, the magnetic

track must be moulded in the card. Never use a card

with a glued magnetic track.

CCaarrdd oorriieennttaattiioonn

Cards with a magnetic track must be installed in the feeder so the magnetic strip faces upwards, as

foll

ows:

SSeettttiinngg tthhee WWiinnddoowwss DDrriivveerr

When fir

st installing the Windows driver, it is necessary to parameterise the functions of the magne-

tic encoder. The functions of the magnetic encoder are accessible from the

Tools dialog box of the

driver by clicking the

Magnetic Encoding button.

43

2. Lower the spring

system as shown

and insert 100

magnetic cards of

0.76 mm (30mil) at

most.

1. Remove the

feeder from the

printer as

shown.

3. Put the feeder back in

the printer. Then press

on the top of the feeder

until it clicks.

Page 44

44

““MMaaggnneettiicc EEnnccooddiinngg”” ddiiaalloogg bbooxx

Track settings allows us to choose the ISO stand

ard required for each track. See the table in this

Chapter for the information concerning the ISO

7

811 standards.

C

oercivityparameterises the magnetic encoder

in high (HICO) or low (LOCO) coercivity. A magnetic track encoded in high coercivity is more resistant to exterior disturbances than a magnetic

track encoded in low coercivity.

Direct encoding allows the direct encoding of

one or more magnetic tracks from this window

simply by selecting them and entering the data

to be encoded. Click on the “

Execute encoding”

button to start the encoding cycle.

Automatic extraction allows cards with magnetic tracks to be encoded from Windows applications

(such as Word or Card 5 for example). A text field surrounded by the characters ”|” and ”|” (or another character to be defined by the user) may be interpreted as an encoding command by the driver.

CClleeaanniinngg ooff tthhee mmaaggnneettiicc eennccooddeerr

The head of a magnetic encoder needs regular cleaning to be able to assure the integrity of the data

encoded in the c

ards.

The magnetic encoder is cl

eaned when the printer is the object of a cleaning sequenc

e with the pre-satu-

rated cards (refer to the “Servicing and Maintenance” chapter in this manual for further information).

Repeated pas

sages of the cl

eaning card inside the printer clean the card transport rollers, the clea-

ning roller and the reading / writing head of the magnetic encoder.

If between two print

er cleaning sessions (every 400 cards printed), the reading/writing process has

failed with more than one card, it is recommended to manually start a printer cleaning process (refer

to the “Servicing and Maintenance” chapter of this manual for the procedure to be followed).

IISSOO 77881111--22 eennccooddiinngg ssttaannddaarrddss

1

Bit(s) per inch

2

Except the “?” character

3

Including the Star

t, Stop and LRC characters. The magnetic encoder generates these characters automatically.

Track no. Field separatorTrack density Types of characters Number of characters

T

r

ack 1

^

210 bpi

1

Alphanumeric

al

79

3

(ASCII 20- 95)

2

Track 2 = 75 bpi

1

Numerical 40

3

(ASCII 48-62)

2

Track 3 = 210 bpi

1

Numerical 107

3

(ASCII 78-62)

2

Page 45

Loading...

Loading...