Page 1

User’s Guide

Plastic Card Printer

Dualys User’s Guide. Part Number: KU02E. Rev. A2

January 2006 © Evolis Card Printer

1

Page 2

Copyright Information

Evolis Card Printer © January 2006. All rights reserved.

Copyright Notice

Users must respect the copyright laws applicable in their country. This manual must not be photocopied, translated,

reproduced or transmitted in whole or in part for any reason and by the means that might be, albeit electronic or

mechanical, without the express, written authorisation of the company Evolis Card Printer.

All information contained herein may be subject to modification without prior notice.

Evolis Card Printer accepts no liability for any possible errors herein, nor for any accidental damage or damage caused through the dissemination or the use of this manual.

Trademarks

Dualys is a trademark and Evolis is a registered trademark of Evolis Card Printer.

Windows and MS.DOS are registered trademarks of Microsoft Corp. All other trademarks or registered trademarks

are marks of their respective holders. eMedia Card Designer is a trademark of Mediasoft Technologies.

Icons

Throughout this manual, different icons highlight important information, as follows:

Note

Indicates information that emphasizes or supplements important points of the main text.

Important

Advises you of information that is essential to complete a task, or points out the importance of specific information in the text.

Caution

Advises you that failure to take or avoid a specific action could result in physical harm to you, or could

result in physical damage to the hardware.

Warranty Information

Refer to the Warranty booklet enclosed with your Evolis printer for terms and conditions.

Return Materials Authorization

In order to make a warranty claim you must contact an Evolis Reseller. You will be responsible for packaging the printer for shipment and the costs of shipping and insurance of the printer from the point of use of the printer to the

Evolis Reseller. The Evolis Reseller will bear the costs of shipping and insuring the printer from the repair location to

the address from which the printer was shipped.

Before returning any equipment for in-warranty or out-of warranty repair, contact an Evolis Reseller or an Evolis Repair

Center (ERC) for a Return Materials Authorization (RMA) number. Repack the equipment in the original packing material and mark the RMA number clearly on the outside of the box. For more information about RMA or Evolis warranty statements, refer to the Warranty booklet enclosed with your Evolis printer.

Product Disposal

WEEE Directive

This symbol indicates that when the last user wishes to discard this product, it must be sent to

appropriate facilities for recovery and recycling.

By not discarding this product along with other household-type waste, the volume of waste sent

to incinerators or landfills will be reduced and natural resources will be conserved. Your Evolis

printer should be recycled according to your local standards. For more information, please

contact Evolis at: info@evolis.com.

2

Page 3

Table of contents

Introduction .................................................................. 4

Chapter I • Setting out ............................................... 4

Choice of a location

..................................................... 5

Unpacking the printer

................................................... 5

Description of the printer and its functions

.......................... 6

Installation of the interface cable and power supply

................ 7

Stand by

................................................................... 8

Ribbon installation

....................................................... 9

Card management....................................................................... 10

Placing the cards in the feeder

................................ 10

Installing the manual card feeder and loading the cards

.. 11

Adjusting the card thickness

.................................. 12

Using the output hopper.....................................................14

Other stages to the installation .....................................................14

Chapter II • Printing .................................................. 15

Installation of the driver

............................................... 15

Printing parameter setup

............................................. 16

Printing

................................................................... 19

Chapter III • Cleaning ............................................... 22

Cleaning the inside of the printer

.................................... 22

Cleaning of the print head

............................................ 25

Maintenance of the cleaning roller

.................................. 26

Chapter IV • Troubleshooting ................................... 28

Interpretation of the printer control panel

.......................... 28

Printing and interpreting a test card

................................. 31

Printing quality problems

.............................................. 32

Correcting card jamming

.............................................. 34

Changing a print head

................................................. 34

Customer service

........................................................ 37

Chapter V • Technical specifications .......................... 38

Chapter VI • Supplies ................................................ 39

Appendix A • Magnetic encoding ............................. 41

Appendix B • Smart card contact station .................. 44

3

Page 4

Introduction

We congratulate you for choosing a Dualys printer!

Dualys printers are the ideal solution for all printing of plastic cards and badges, student cards, transportation season tickets, employee badges, access control badges, membership cards, and all other applications requiring printing on the two sides of the card …

This product comes with a wide range of assistance services from the Evolis Company and its partners,

specially selected to help you effectively and professionally.

4

Page 5

5

Chap.1

Starting up

Choice of a location

The Dualys printer must be set up on a level surface, in a dust free environment.

It is essential to be able to access the printer from all sides for installation and use.

Unpacking the printer

Proceed as follows in unpacking the printer

1. Remove the upper protection foam.

2. Lift the printer out of its box, remove the protection bag and set it in the chosen place.

3 Remove all adhesive from the outside of the printer.

It is best to keep all the packing materials in case the printer has to be moved or returned for

any reason.

The following elements are supplied with your Dualys printer:

■

USB interface and Centronics parallel cables

■

A Quick Operating Guide)

■

A User’s Guide (this guide)

■

A Dualys CD (Drivers & Documentation)

■

A cleaning kit

■

A warranty booklet

■

A certificate of conformity with CE and FCC safety regulations

If any of the elements are missing from your package, contact your Evolis reseller.

Page 6

6

D

A

B

C

F

G

E

H

I

J

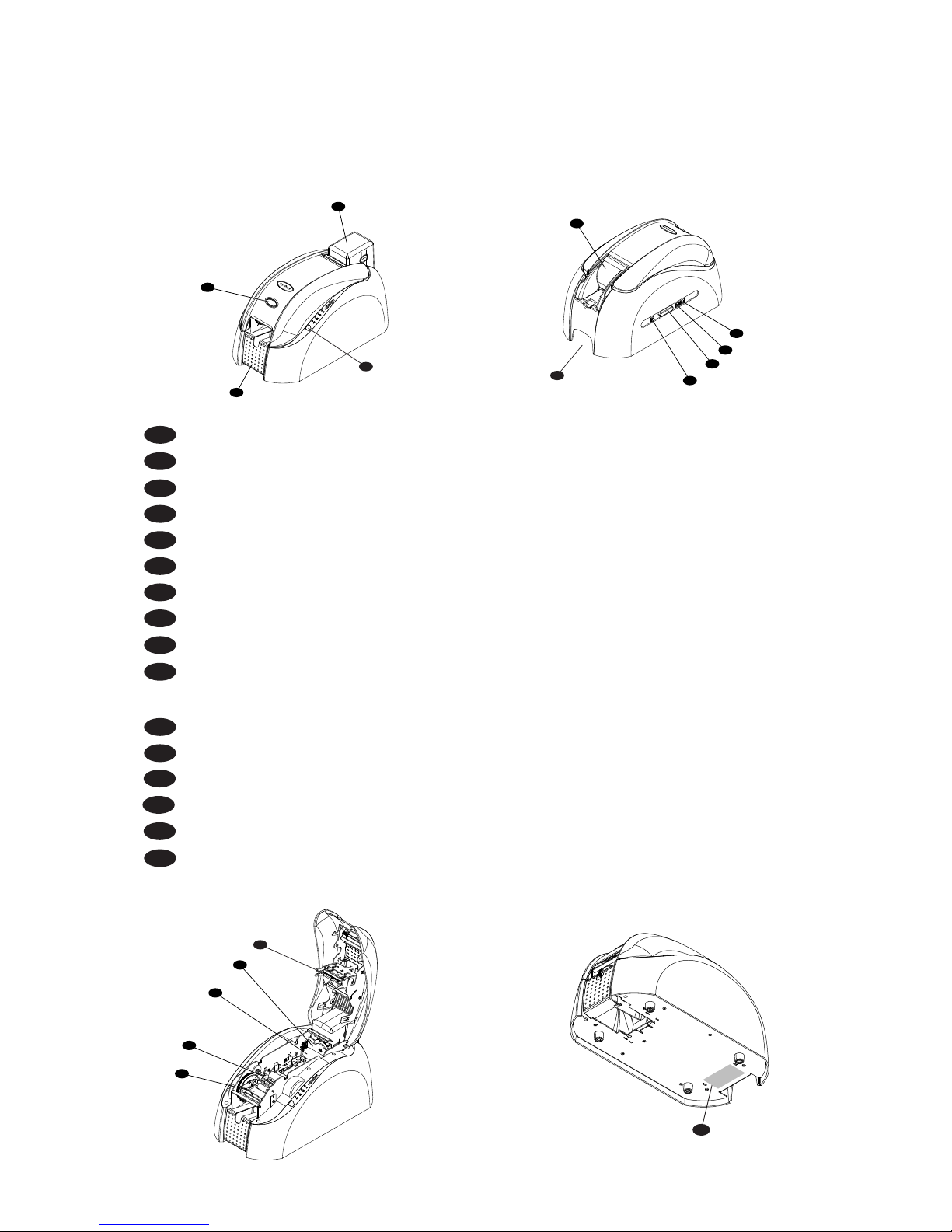

Description of the printer and its functions

We invite you to check the different components of your printer on the following drawings, to which

we will refer in this manual.

A Output hopper Collects the printed and/or encoded cards

B Cover lever Enables the printer cover to be opened and closed

C Card feeder Receives the cards for printing

D Control panel Shows the printer activity

E Manual card feeder Enables the cards to be inserted one by one (optional)

F Carrying handle Enables the printer to be carried

G Electrical connector Enables the printer to be connected to its power supply.

H Centronics parallel port (std) Enables data to be received and sent from and to the computer.

I USB port (std) Enables data to be received and sent from and to the computer.

J DB-9 connector (optional) Enables data to be received and sent from and to the computer

and coupler to be connected for chip cards personalization

K Flip Over module Rotates the card 180°

L Magnetic encoder Enables cards with magnetic tracks 1, 2 and 3 to be encoded

M Cleaning roller Removes all dust before the cards are printed

N Card thickness gauge Enables the thickness of the card to be adjusted from 0.25 mm to 1 mm

O Thermal print head Enables the cards to be printed in 300 dpi

P Identification label This label indicates the model and the serial number of the

printer

O

N

M

K

L

P

Page 7

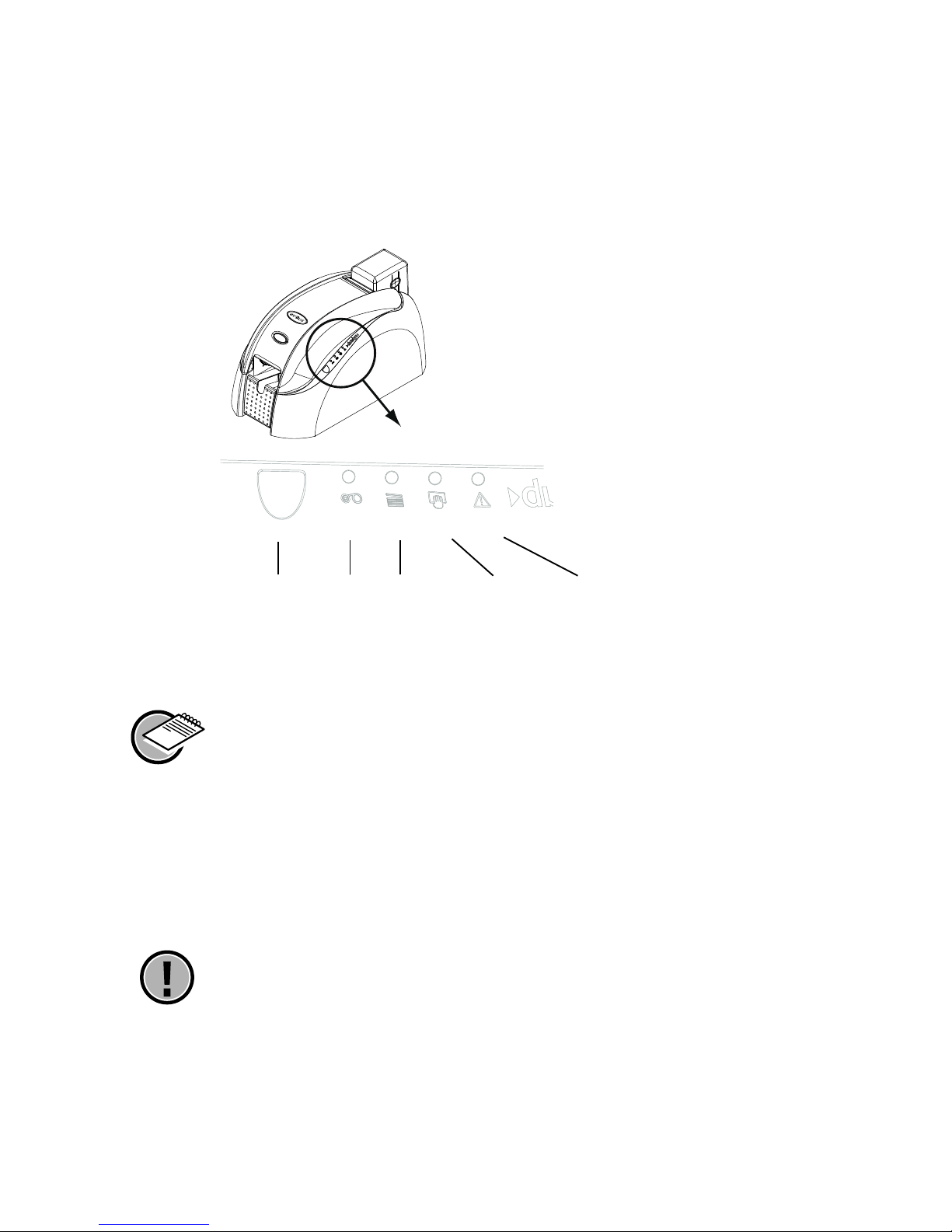

Printer control panel

A control panel is available on the top of the printer. Four lights are associated with symbols indicating

the printer activity. These lights indicate the following:

Refer to chapter 4 of this manual for further information on interpreting the messages of the

control panel.

Installation of the interface cable and

power supply

If you wish to use your Dualys printer with the USB port, install the Windows driver before

connecting this port.

1. Connect the interface cable supplied with your printer as indicated in the following

2. Connect the other end of the cable to the corresponding port on your computer

3. Connect the cable from supply to supply and then connect the power cable to the printer.

7

Turned on

Data

reception

(Pushbutton)

End of

ribbon

No card

in the feeder

or feeder not

present

Cleaning

signal

Cover

open

Page 8

4. Then connect the end of the power supply cable to an earthed socket

5. The printer is under power. The light on the control panel comes on and the print head

rises and falls to indicate the correct mechanical working of the printer. If the light fails to come on,

this means that the installation has not been carried out correctly or possibly that the printer is not

working properly. Check the installation.

Turn off the printer by pulling the plug out of the socket, which must always be accessible.

This product must be connected to an electrical installation that is correctly protected and

grounded.

FI: "Laite on liitettävä suojamaadoitus koskettimilla varustettuun pistorasiaan"

NO: "Apparatet må tilkoples jordet stikkontakt"

SE: "Apparaten skall anslutas till jordat uttag"

Stand by

The Dualys printer may be left in stand-by at any time by pressing the push

button as indicated. The green light on the push button goes out.

To reactivate the printer, press the push button for

one second. The green light on the push button

comes on.

The printer automatically goes into stand-by after 10 minutes of inactivity.

8

USB 1USB 1USB 1

USB 2USB 2USB 2

Page 9

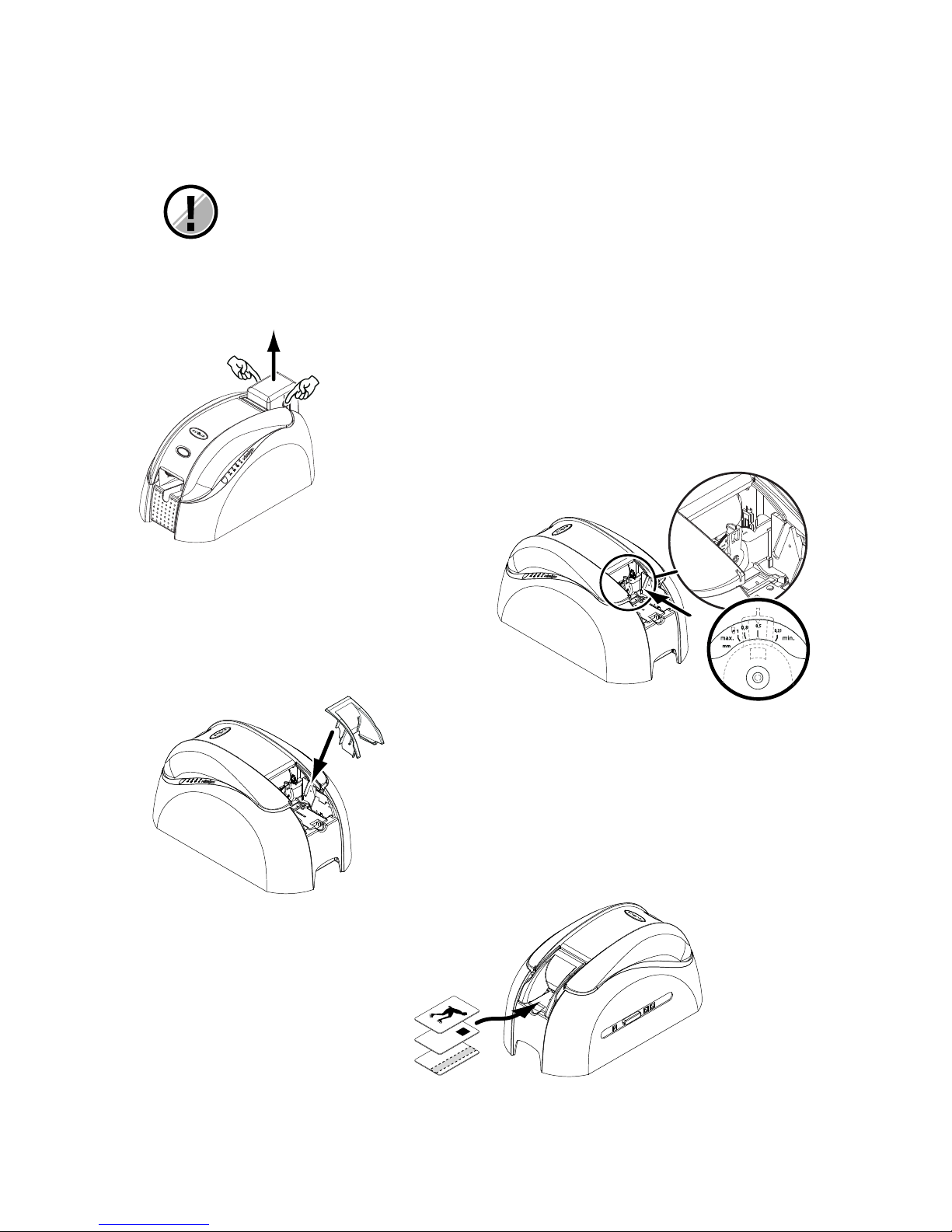

The ribbon must be correctly installed for the printer to work. Only use Evolis ribbons.

Evolis declines all responsibility if the printer or the print head are damaged through the

use of an unapproved ribbon.

The ribbon is automatically positioned each time the cover is opened.

9

Ribbon installation

2. Install the ribbon in the printer as shown.

3. Close the cover of the printer.

1. Open the cover of the printer

by pressing the opening lever

then turn it.

Page 10

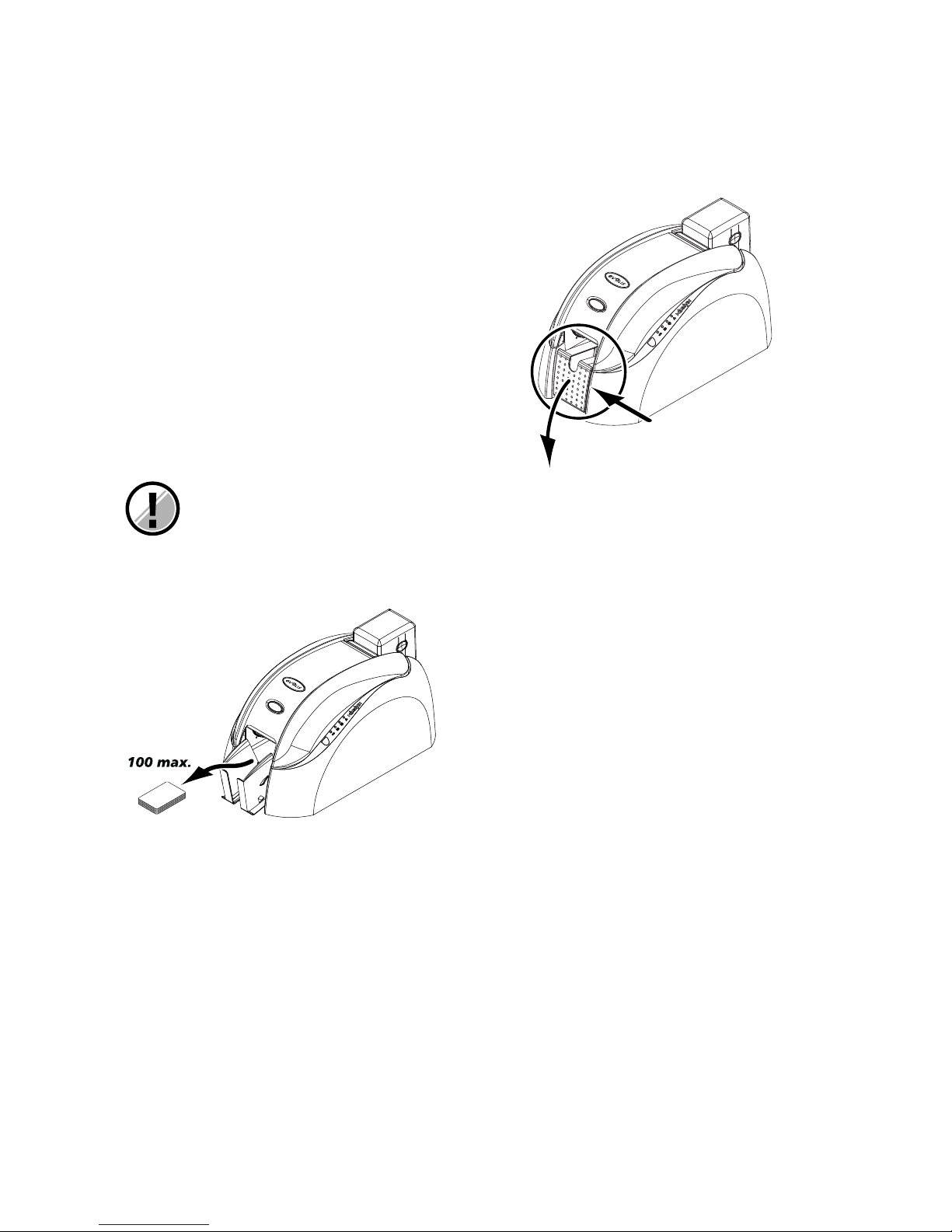

Card management

Placing the cards in the feeder

Card thickness:

• Dualys printers admit cards with a thickness of 0.25 mm to 1 mm.

Advice on card selection:

■ Only use the type of cards appearing in the Technical Specifications in this manual

■ Do not touch the printing surface of the cards, as this would affect the quality of the printing

■ Do not use damaged or folded cards or cards with a raised texture

■ Always keep new cards in a clean, dust-free place

10

1. Remove the feeder from the printer as shown.

2. Lower the spring system as shown and

insert 100 cards of 0.76 mm at most.

3. Put the feeder back in the printer. Then press on

the top of the feeder until it clicks.

max.max.max.

Page 11

Installing the manual card feeder and loading the cards

The Dualys printer may be optionally fitted with a manual card feeder for inserting cards one by one.

Manual card feeder option should be set through the driver Properties. In the Tools tab click

on Dialog box button. Then select Manual feed option in Source Tray menu and in Output

Tray menu choose the option according to the required operation mode for the card exit.

`Click on the Set button to confirm.

The manual card feeder is installed as follows:

11

1. Remove the feeder from the printer as shown.

2. Using the lever, adjust the thickness

of the card to MAX position.

3. Place the manual supply tray in the printer as indicated. Then press on the top of

the feeder until it clicks.

4. Insert the card as shown.

Page 12

12

Adjusting the card thickness

The Dualys printer is fitted with a manual adjustment system for the thickness of the cards that is acces-

sible either from inside the printer or when the cover is open.

Dualys printers accept card thickness from 0.25 mm (10mil) to 1 mm (40mil).

Factory setting for card thickness is 0.76 mm (30mil).

To adjust the thickness of the cards using the feeder cage

1. Remove the feeder from the

printer as shown.

2. Adjust the thickness of the cards used

by moving the handle from right to left on

the required card thickness.

3. Put the feeder back in the printer. Then press on the

top of the feeder until it clicks.

Page 13

13

To adjust the card thickness from inside the printer

1. Open the cover of the printer by pressing

the opening lever and then turn it.

2. Remove the ribbon if there is one in the

printer. Then adjust the thickness of the

cards used by moving the handle from right

to left on the required card thickness.

3. Reinstall the ribbon in the printer

and close the cover.

Page 14

14

Using the output hopper

The Dualys printer is fitted with an output hopper with a capacity for 100 cards in 0.76 mm format.

This is intended to receive the printed and/or encoded cards.

Other stages to the installation

You have now completed the installation (material) of your Dualys printer. For the moment, we would

urge you to carry on reading this manual and we would inform you that there are still two extra stages

to be followed to make your Dualys printer fully operational:

• Installation of the drivers

• Printer cleaning

1. Locate the output hopper and rotate it.

2. Remove the printed and/or encoded

cards as shown.

The hopper should be completly rotaded until it clicks. The “Cover open” LED will

blink when the hopper stands in middle position.

Page 15

15

Chap. 2

Printing

Installation of the driver

Before using your Dualys printer, you must install its driver.

Remember: the driver and Dualys printer operate under Windows 2000, NT 4.0 and Xp.

The CD provided with the printer includes a utility which automates the installation of the

printer driver. This utility installs the driver the right driver for your

configuration.

• Insert the DRIVERS & DOCUMENTATION CD-Rom reader.

• Wait a few seconds until the CD welcome program tells you to choose your language.

• Click on the flag of your required language.

• Another menu appears telling you to install the printer driver. Follow the instructions below to set up your

Evolis printer.

You use Windows, your printer is connected to the mains, the Parallel cable or USB is not connected.

■ Click on Driver installation.

■ An installation menu appears suggesting you preserve the installations previously performed.

By default the cases are hidden and the installation programme will delete all existing set-ups.

■ Click on Install to start the procedure.

■ When told to do so, choose the type of interface you wish to use to connect your Evolis printer:

USB or Parallel.

The installation programme asks you to turn on the printer. Carefully follow the instructions

below:

■ Connect the USB or Parallel cable between the PC and the printer.

■ The system will automatically detect your peripheral and start the Add Printer

assistant

after a few seconds.

■ Select Next, the Finish.

■ Click OK in the Information window.

■ The installation is complete, click on End.

■ Click on Quit to close the installation programme

Your Evolis printer is ready to personalise your cards once more.

In the event of any incident in the installation, consult the chapter Windows Users - Installation Manual

The installation of a driver under Windows NT, 2000 or Xp may require the authorization of the

system administrator. In the event of any problem, contact this administrator to advise you on the

installation method and associated rights of access.

Page 16

Windows Users - Manual Installation

■ Close all applications before installing the pilot.

■ Do not connect the USB or Parallel cable before the installation is complete.

■ Insert the DRIVERS & DOCUMENTATION CD-Rom in your CD-Rom reader.

■ On the Windows menu bar, click Start, Parameters and then Printers.

■ Double-click on Add printers.

■ Select Local Printer.

■ Select the LPTx printer port (even if you wish to connect the printer on USB).

■ When the assistant displays a series of printer manufacturers,

click on

Disk supplied.

■ Choose the letter of the reader corresponding to the CD-Rom reader

and then click on Next.

■ In the CD-Rom, click on Drivers.

■ Select the directory for your Windows environment:

Windows 2000 and Windows XP: select 2000XP

Windows NT4: select NT4.0

■ Choose the file Youn.inf (or Younbw.inf), click on Open and then OK.

■ The Evolis printer appears on a grey background, click on Next.

■ State whether you wish to use the Evolis printer as your default printer

and then click on

Next.

■ Do not share and then click on Next.

■ Do not print out a test page and click on Next.

■ Click on Finish to install the driver.

For operation on Parallel port, connect the cable between the PC and the printer. The installation is complete.

For a USB connection, the following adjustments must be made:

■ Connect your USB cable between the printer and the PC.

■ Windows detects a new printer and starts the Add Printer Assistant, click on Next.

■ The system looks for a Youngi.dll (or Youbwgi.dll)

■ In the CD-Rom, click on Drivers.

■ Select the directory for your Windows environment:

Windows 2000 and Windows XP: select 2000XP

Windows NT4: select NT4.0

■ Choose the file Youngi.dll file (or Younbwgi.inf), click on Open and then OK.

■ Click on Finish.

A new Evolis driver (Copy1) has been created for the printer on USB port. The installation of the printer driver

is now completed.

16

Page 17

17

Printing parameter setup

Before using your Dualys printer, it is best to check / modify the default parameters of the driver.

Furthermore, if you have options installed, you must declare them to the driver.

Your printer has numerous functions that can be set in the printing manager. These printing parameters are accessible:

■ From Start in the Windows bar, Parameters and then Printers

• Select Evolis Dualys

• In File in the menu bar of Windows, select Default Document

■ From your Windows software:

• In

File in the menu bar of your application, select Print or Printing Set-up.

The procedures vary along with the type of software used and the Operating System.

Before using the printer, make sure that it is correctly selected as the default printer.

Selection of the Dualys printer as default

Proceed as follows to select the Dualys printer by default:

■ Click on Start in the Windows bar, and then select Parameters and then Printers.

■ Click on the Evolis Dualys icon and then point to File in the menu bar.

■ Select Define default and close the window.

Definition of the properties of your Dualys printer

Different dialog boxes enable you:

■ To perform adjustments such as the orientation and the printing quality.

■ To manage the different printing modes and the use of suitable printing ribbons.

■ To select the printing port.

■ To activate the different control and maintenance functions of the printer.

Use of on-line help

A help file guides you in the use of each of the printing management parameters, depending on the

different printing modes and criteria retained. In order to familiarise you with these parameters, we

recommend you consult this help before any modification.

“Main” dialog box

This dialog box enables you to select:

■ Orientation: the orientation of the printout in portrait or

landscape and the rotation of the printout 180º for the

front or/and the backside of the card.

■ Copies: the number of copies required of the card

Page 18

“Graphic” dialog box

This dialog box allows the selection of:

Ribbon: the type of ribbon used

Printing Settings: choice of single-sided or

dual-sided printing, with the possibility to set

the Black and Varnish ribbon panel configuration in the case you previously selected a color

ribbon in the “Ribbon” box above

.

Black panel: the use of the black panel.

Varnish panel: the varnish application of a color

ribbon depending on a deliberate choice or a

kind of card requiring a covering reserve.

The More options button enables action on certain printing parame-

ters, such as the contact and intensity of the colors.

If you previously selected a black ribbon in the

Main

dialog box, the Graphic dialog box allows you to select:

■ Black sensitivity: the placement or more or less ink.

■ Printing quality: the quality of the placement of the

ink.

18

Page 19

“Tools” dialog box

This dialog box offers first level help for your Dualys printer.

If your Dualys printer has an option with a magnetic encoder, now proceed to set it up by clicking on the Encoding

Definition button. For further information concerning this

printer option, consult Annexe A of this manual.

We also recommend you print a Test Card on the first use,

and to keep it. This card records the information you

might be asked for if you call the after-sales service.

Observation: The “Dialog with printer” option is only

available if the driver has been installed with the installation program of the CD.

“General” dialog box

This dialog box is a Windows information window that allows a test page to be printed only to check the

communication between the computer and the printer.

“Details” dialog box

This dialog box is a Windows control window allowing the selection of the printing port and confirming the

use of the correct driver on the printer. Only a person with advanced skills must only modify the displayed

parameters.

“Color management” dialog box

This dialog box enables the printing to be associated with a defined color management profile.

Printing

A large number of Windows applications allow a document to be printed (Word – Access

– Excel, for instance). In order to familiarise you with putting a card on a page and the parameterisation of

the printing, we propose the following example.

Under Microsoft® Word

After installing the Dualys printer as default:

1. Start Word and in File click on Page setup.

2. The Paper dialog box proposes Paper format; select

Youn Card.

19

Page 20

3. In the Margin dialog box, select 0 cm for all mar-

gins, then in

Orientation, select Landscape

4.

Close the window by clicking OK

Your Word window should now be like this:

You are ready to personalize your card by entering the

different composition elements:

■ Logo and Illustration

■ Identity photo

■ Constant and variable texts

■ Barcode, etc.

Example:

Note that this example does not intend

to teach the operator about the

working of the Word application.

The only aim is to establish a relationship between the design of a card and

the parameters management of the

Dualys necessary for its printing.

20

Page 21

Setting the Evolis Dualys Driver

To access the parameters from the Word window:

1. In the menu bar, point to File and select Print

2.

The dialog box tells you that the Evolis printer has been selected. Then click on Properties. The dia-

log box of the Evolis Dualys driver opens.

To access the printing parameters from the Word window:

1. In the menu bar, point on File and select Print.

2. The dialog box indicates that the Evolis printer has been selected.

3. Click on Properties. The dialog box of the Evolis Dualys driver opens.

The printing parameters for this graphic example are:

1. In the “Main” dialog box select:

■ Orientation – Front side: landscape

■ Orientation – Back side: landscape

■ Copy (number to be determined)

2. In the “Graphic” dialog box, select:

■ In Ribbon type: “6 panel ribbon (YMCKOK)”

■ In Printer settings: “Print on both sides”

3. Click on Apply if you change a parameter, then on OK to close each successive dialog box.

4. Once back in the main window, click OK to run printing.

Consult the help of each dialog box, if necessary. See the « Use of on-line help » paragraph above for further information.

21

Page 22

Chap. 3

Cleaning

Keep your warranty valid!

Failure to observe the procedures concerning maintenance in this chapter may lead annuls

the warranty of your Dualys printer and the print head. The company Evolis declines all liability if the printer is used under unapproved conditions of cleaning.

Evolis provides the following cleaning articles under the reference article A5011 – UltraClean

cleaning kit:

■ Five pre-saturated cleaning cards with isopropyl alcohol 99%

■ Five swabs with isopropyl alcohol 99%

■ One dispenser of 40 pre-saturated cleaning lint-free wipes

Cleaning the inside of the printer

Cleaning cycle: every 1000 cards inserted

Use: pre-saturated cleaning cards

When interior cleaning of the printer is necessary (every 1000 cards inserted) the cleaning light comes

on as follows:

22

Status after the insertion of 1000 cards

Page 23

23

If the printer has not been cleaned after the cleaning light has come on, it will begin to flash when a

further 200 cards have been inserted. In this case, the cleaning light flashes as follows:

Status after the insertion of 1200 cards

When the light flashes, the interior of the printer must be cleaned without delay (under 5

cards). Otherwise, the warranty of the cleaning head will be cancelled.

How to proceed

This simple cleaning system requires the use of pre-saturated cleaning cards specially conceived for the

printer. A cleaning kit with samples of these cards is provided with your Dualys printer. By repeatedly

passing the card inside the printer, the card transport rollers, the cleaning roller, the print head and the

magnetic head (option) are all cleaned.

1. Remove the feeder from the

printer as shown.

2. Remove the cards in the feeder.

3. Take a new cleaning card and insert it in

the feeder as shown.

Page 24

24

4. Using the lever, adjust the thick-

ness of the card to MAX position.

5. Put the feeder back in the printer.

Then press on the top of the feeder until it clicks.

6. Open the cover and remove the

ribbon from the printer as shown.

7. Close the cover of the printer.

8. Press the push button on the control panel

for a second. The cleaning starts.

9. The used cleaning card is ejected

in the output hopper.

Page 25

25

Following a cleaning cycle, wait two minutes for the cleaner to evaporate completely

before using the printer again.

Although the cleaning alert might have been triggered, the printer will continue

to work.

It is also possible to trigger a cleaning sequence without waiting for the signal of the

light of the printer. This is carried out by pressing the push button of the Control

Panel for a few seconds.

In this case, first repeat all the operations described above.

Cleaning the print head

Cleaning cycle: on each ribbon change

Use: cleaning swabs

The print head is cleaned when the inside of the printer is also cleaned (see preceding section).

However, in order to preserve the original printing quality and to reduce the incidents caused by the

excessive presence of ink on the surface of the print head, it is advised to clean it regularly (on each

change of the ribbon) using the swabs supplied with the UltraClean cleaning kit.

It is very important to protect the print head and all other related components that are handled from any electrostatic discharge.

The print head is a very fragile component of your printer. To void it being damaged:

■ Before cleaning the print head, disconnect the printer from the power supply.

■ Observe the cleaning cycles.

■ Never place the print head in contact with sharp or metal objects.

■ Avoid the surface of the print head coming into direct contact with fingers. The result could

be altered printing quality or even damage to the print head.

How to proceed

1. Take a new swab and press on the middle of the stick to

let the liquid out in the foam.

Page 26

26

2. Open the cover of the printer and

locate the print head. Then, gently rub

the swab along over the print head for

several seconds.

Following a cleaning cycle, wait two minutes for the cleaner to evaporate completely

before using the printer again.

Maintaining the cleaning roller

Cleaning cycle: on each ribbon change

Use: cleaning wipes

Your Dualys printer has a cleaning roller. Its adhesive surface holds the dust caused by the cards.

Although this roller is maintained when cleaning the inside of the printer, it is nevertheless advised to

clean it regularly and simply with a wipe provided in the cleaning kit to ensure that the surface of the

cards is perfectly clean.

How to proceed

1. Open the cover of the printer. If

there is one, remove the printer ribbon

and locate the cleaning roller.

2. Remove the cleaning roller from the printer.

Page 27

27

3. Clean the roller with a wipe from your cleaning kit.

Eliminate all dust by lightly rubbing the wipe on the surface

of the roller.

4. When the roller is dry, put it back in the printer

and close the cover.

Following a cleaning cycle, wait two minutes for the cleaner to evaporate completely before

using the printer again

.

Page 28

Chap. 4

Troubleshooting

To satisfy the demands of its customers, Evolis provides a complete range of technical assistance services in this manual and on the website www.evolis.com

This section includes information concerning first level repairs on the Dualys printer.

Interpreting the messages of the control panel

Although the Dualys printer has been conceived to work extremely reliably, problems may however

arise. What follows helps you to identify the cause of the possible problems on the installation or use

of the printer and to find the means of resolving them.

Description of the printer control panel

A Control Panel is available on the top of the printer.

Four lights are associated with symbols indicating the printer activity.

These lights indicate the following:

28

Turned on

Data r

eception

(Pushbutton)

End of ribbon

No card in the

feeder or

feeder not

present

Cleaning signal

Cover open

Page 29

29

The lights on the control panel are represented in one of the following states:

SWITCHED OFF SWITCHED ON FLASHING

The push button returns the control panel to its original state after dealing with the following cases:

■ ABSENCE OF CARD or INTERNAL PRINTER PROBLEM

■ ERROR IN MAGNETIC ENCODING

■ CARD EJECTION

The push button also enables:

■ The printer to be set to stand-by

■ A test card to be printed

■ A cleaning cycle to be started

Consult the following states of the control panel to determine the activity of the Dualys printer or the

nature of the problem:

State of the lights Interpretation Solution or explanation

The printer is r

eady to r

eceive data.

The printer r

eceives data from one

or several of its interfaces.

■ Ther

e is no ribbon in the printer

■ The ribbon has finished

■ The ribbon has been badly installed

in the printer

■ The ribbon is cut

Check the state of the ribbon in

the printer. If you are have a printing

job in course, this restarts with a new

card.

PRINTER READY

PROCESSING

END OF RIBBON

Page 30

State of the lights Interpretation Solution or explanation

30

■ There is no card in the feeder

■ The thickness of the cards has not been cor

rectly adjusted

■ The cards are curved

■ The cards are stuck together

■ The feeder is not pr

esent in the printer or is

badly inser

ted

Check the state of the car

ds in the feeder or make

sure that the feeder is present in the printer and correctly inserted Then, press the push button for one

second. The printing restarts

■ The printer is waiting for a card to be inserted

The printer is fitted with the manual feed tray

option: insert a card in the printer. Go to chapter

1 « Starting up ».

■ The printer has to be cleaned

Go to chapter 3 « Cleaning ».

■ The printer has to be cleaned

Go to chapter 3 « Cleaning ».

■ The printer cover is open

Close the cover of the printer. The activity in course restarts.

■ The output hopper is midway between opened

and closed positions.

Close or open the output hopper. The activity in

course restarts.

■ There is a card jammed in the printing sta

tion or in the flip over module

■ A mechanical par

t in the printer is faulty

Press the push button for one second. If the problem persists, call your Evolis r

eseller for assistance.

■ The orientation of the magnetic track in the

feeder is not cor

r

ect

■ The type of encoding has not been cor

rectly

parameterised (HICO or LOCO). Go to Annexe A

of this manual for more information.

■ The encoded data do not confor

m to ISO 7811

or to the parameters pr

e-defined in the properties

of the driver. Go to Annexe A of this manual for

mor

e infor

mation.

Press the push button for one second. The printer

r

estar

ts the magnetic encoding cycle with a new

car

d. If the pr

oblem persists, call your Evolis r

esel

-

ler for assistance.

■ The print head cooling system is activated.

The printer stops working for a few seconds. As

soon as the print head reaches the normal working temperatur

e, the activity starts once more

NO CARD IN FEEDER

OR FEEDER NOT PRESENT

WAITING FOR A CARD TO BE

INSERTED

PRINTER CLEANING ALERT

(AFTER 1000 INSERTIONS)

PRINTER CLEANING ALERT

(AFTER 1200 INSERTIONS)

PRINTER COVER OPEN

OUTPUT HOPPER POSITION

MECHANICAL PROBLEM

ENCODING ERROR

COOLING MODE

Page 31

31

Printing and interpreting a test card

Printing a test card gives certain technical information about your printer and confirms its correct working.

We advise you to print it when the printer is put into service and to keep it at hand.

Printing a test card

1. Make sure there are a ribbon and a card in the printer.

2. Press the push button for three seconds. All the lights go out.

3. Press the push button once more and hold it down.

4. The green light of the push button comes on.

5. Release the push button as soon as the green light flashes.

6. The test card is printed in a few seconds (in color if the printer has a color ribbon or in monochro-

me if it has a black ribbon).

7. The printed card is ejected into the output hopper.

Interpreting a test card

The printing of a test card gives the following information:

■

Correct printing of the colors and black

■

The correct position of the ribbon in the printer

■

The printer model

■

The serial number of the printer

■

The version of the Firmware installed in the printer

Page 32

Printing quality problem

The following information will help you to resolve any problems of printing quality that might arise in

using your printer. If despite this information you are unable to resolve the problem, contact your Evolis

reseller.

Nothing prints

1. Check the power supply.

Make sure:

■

The power supply cable is correctly connected to the printer and connected to a mains socket

that works.

■

The printer is under power. The green light of the control panel is on.

■

The power supply used is that delivered with the printer

2. Check the card feeder and the card in the printer

■

Make sure there are cards in the feeder

■

Make sure there is no jamming.

See this chapter

3. Check the ribbon

■

Make sure that the ribbon has been correctly installed and that the printer cover is well closed.

4. Printing a test card

See the point “Printing and interpreting a test card” in this chapter.

5. Check the printer interface cable

■

Check the connection with the computer and to the printer.

■

Test with another cable of the same type.

6. Check the driver

■

Make sure there is a driver on your Dualys printer in the Windows parameters

7. Check the printing parameters of the computer

■

Make sure that the Dualys printer has been selected as the default printer.

See” Setting up the printing parameters” in the Printing chapter.

8. Check the network configuration

If your printer is connected in a network, make sure that it is correctly set up in the network environment. See the documentation on your network for more information.

A blank card is ejected from the printer

1. Check the ribbon

■

Make sure the ribbon is not finished or cut. Replace or reinstall the ribbon, if necessary.

2. Check the printer interface cable

■

Check the printer interface cable.

■

Check the connection with the computer and the printer.

■

Test with another cable of the same type.

32

Page 33

3. Elements of the print head may be damaged.

■

Print a test card.

See the point “Printing and interpreting a test card” in this chapter.

If the test card fails to print, contact your reseller for a new print head.

The printing quality is not sufficient

1. The contrast and luminosity parameters must be modified

■

Lack of contrast and color saturation, increase the contrast and luminosity parameters in the

setup of the driver.

2. The type of cards used is maybe unsuitable

■

Check whether the type of cards used corresponds to the specifications required.

See the ”Technical Specifications” chapter in this manual for further information.

■

The texture of the card is rough or not perfectly flat.

■

Try printing with another kind of card.

Partial or incorrect printing

1. Check the parameters defined for the printing

■

Make sure that no element of your page setup is outside the printing margins

■

Check the orientation of the document selected in the configuration of the driver (Landscape or

Portrait)

2. Check the printer interface cable

■

If unusual characters are printed, make sure you are using the right interface cable for your printer.

■

Check the connection with the computer and the printer.

■

Test with another cable of the same type.

3. Check that the printer is clean

■

Clean the interior of the printer, the cleaning rollers and the print head if necessary.

See the ”Cleaning” chapter in this manual.

4. Check that the cards are clean

■

Check that the cards are stored in a dust-free place.

5. Check that the print head is clean

■

See the procedure for cleaning the print head in the ”Cleaning” chapter of this manual.

6. Check the ribbon

■

Its position in the printer.

■

Its correct run

7. Check the print head

■

If horizontal lines (white) appear on the card, elements of the print head might be blocked or

damaged.

■

Clean the print head.

See the ”Cleaning” chapter for further information.

■

If the problem is not solved after cleaning, contact your reseller for a new print head.

33

Page 34

34

Correcting card jamming

Remove the card as follows:

1. Open the cover of the printer and remove the ribbon.

2. Remove the card by pressing the push button and/or pushing it manually towards the printer oulet.

If there are several cards, push the top one first.

3. Replace the ribbon then close the printer cover.

4. Press the push button on the control panel for one second.

To prevent card jamming:

1. Make sure the cards are correctly adjusted with the right thickness.

2. Make sure that the card thickness corresponds to the specifications in the ”Technical Specifications”

section of this manual.

3. Check that the cards are not curved.

4. Make sure that the cards are not stuck together.

Changing a print head

Dualys printer print heads may be changed simply and effectively without any tools or special

adjustments.

Wait until the head is cool before working on it. Before changing a print head, make sure

the printer is turned off.

Stage 1 – Removal of the faulty print head

1. Open the cover of the printer and

locate the print head.

Page 35

35

Stage 2 – Installation of the new print head

3. Disconnect the cable from behind the print head

2. With one hand, push the metal part at the

back under the cover and with the other turn

the two forks to remove the print head from

the head arm.

1. Take the new print head and insert

the cable in its housing.

2. Insert the head vertically in the two guides

3. Turn the print head to « clip » it in the metal part.

2

1

2

1

3

Page 36

4. Close the cover of the printer. The print head is

now installed.

Stage 3 – Setting the new print head

1. Make sure that the printer is turned on and connected to a computer where the Dualys driver has

been installed.

2. In the driver properties, click on the « Tools » dialog box.

3. In the part « Dialog with printer » enter the following: Pkn;x

x =

the kit number of the print head recorded on a transparent label on the print head

Example: if the kit number of the print head is: 179-004-00048, the following command must

be entered: Pkn;179-004-00048

If the print head kit number has not been correctly entered, it may cause printer malfunctioning.

Two LEDs flash simultaneously on the printer control panel. They indicate that the

printer interior needs cleaning. No printing may be started until this operation is

done. For cleaning procedure, see

Chapter 3 Maintenance - Cleaning the inside of

the printer

. Following this cleaning cycle, make sure the cleaning roller is properly

cleaned (for cleaning roller maintenance, see

Chapter 3 Maintenance – Maintaining

the cleaning roller

). Then, reinstall the ribbon and the cards.

The new print head is now set up. You can reuse your Dualys printer.

36

Page 37

37

Customer service

If the suggestions given above in this section do not allow you to resolve the problem/s, connect to

evolis.com for larger information or contact your Evolis reseller.

Evolis website

If you need extra technical help, you will find much information on the use and breakdown of Evolis

printers under Support & Services in the Evolis website.

This section suggests that you download the latest versions of Firmware, of drivers and user manuals,

videos for the use and cleaning of Evolis printers and FAQ* giving replies to the most common questions.

*FAQ: Frequently Asked Questions

Access to an Evolis reseller

For all technical problems unresolved, contact an Evolis reseller. If you do not know any Evolis resellers,

connect to

www.evolis.com and send us your order.

Evolis will give you the address of the nearest Evolis reseller to you.

When you call an Evolis reseller, you must be close to your computer and be prepared to give the following information:

■

The type and serial number of your printer

■

The type of setup and the operating system you use

■

A description of the incident

■

A description of what you have done to solve the problem

Page 38

38

Chap. 5

Technical specifications

Print mode Color dye sublimation and monochr

ome thermal transfer

Edge-to-edge printing standard

Printer specifications Module for dual sided printing

Integrated ribbon saver for monochrome printing

Printing speed 150 cards/hour in full color (YMCKO), one side

125 cards/hour in full color (YMCKO/K), two sides

Up to 1000 cards/hour in monochrome

1

, one side

Up to 350 cards/hour in monochrome1, two sides

Resolution 300 dpi (11,8 dots/mm)

Software supplied eMedia Card Designer Software for designing and editing badges

Compatible with Windows™ NT 4.0 / 2000 and Xp

Warranty Printer: 2 years

Print head: 2 years, unlimited number of prints

2

Consult the guarantee booklet supplied with your Evolis printer for more information

Ribbon types Monochrome: 1000 cards/roll

Monochrome colors: black, blue, red, green, white, gold, silver and scratch off

BlackWAX monochrome ribbon (for ABS and special varnished cards): 1000

cards/roll

2 panel black monochrome ribbon (KO): 500 cards/roll

5 panel color ribbon (YMCKO): 200 cards/roll

Half-panel color ribbon (YMCKO): 400 cards/roll

6 panel color ribbon (YMCKOK): 200 cards/roll

Hologram ribbon: 350 cards/roll

Card loading modes Automatic with feeder or hand-feed

Options Serial por

t (available upon study)

Hand-feed cartridge

100-cards additional feeder

Cleaning kits

Other models Dualys Mag

Printer with HICO/LOCO magnetic stripe encoder - ISO 7811 or JIS2

Dualys Smart

Printer with smart card contact station - ISO 7816-2 and EMV 2000 encoder

Dualys Contactless

Printer with Contactless smar

t car

d coupler - ISO 14443 - ISO 15693 (other stan

dards upon request)

Other specifications:

Card types: All PVC, Composite PVC, PET, ABS and special varnished cards - Card format: ISO CR-80 - ISO 7810 (53,98 mm x 85,60

mm - 3.375" x 2.125") -

Car

d thickness:from 0,25 mm (10 mil) to 1 mm (40 mil) –

Car

d feeder capacity:

300 car

ds (0,25 mm - 10

mil) - 100 car

ds (0,76 mm - 30 mil) -

Car

d output hopper capacity

: 300 car

ds (0,25 mm - 10 mil) - 100 car

ds (0,76 mm - 30 mil) -

Printer size: Height: 235 mm (9.25") – Length: 447 mm (17.59") – W

idth:

237 mm (9.33") - Printer weight: 7,4 Kg (16.31 lbs) -

Connections: USB and parallel Centronics ports (cables supplied) - Electrical: 110~230 Volts CA, 60~50 Hertz - Environmental: Min

/ Max operating temperatur

e: 15

°

/ 30

°

C (59

°

/ 86

°

F) - Humidity: 20% to 65% non-condensing - Min / Max storage temperatur

e: -5°

/ +70° C (23° / 158° F) - Storage humidity: 20% to 70% non-condensing - Operating ventilation: free air

1

- Under specific conditions2- Clause governing the use of Evolis consumables

Page 39

39

Chap. 6

Supplies

Evolis has a large choice of cards and ribbons as well as various accessories. In the following you

will find the list of supplies available from an Evolis reseller.

Monochrome ribbons

P/N: R2011 Black ribbon

1000 car

ds/roll

P/N: R2012 Blue ribbon

1000 cards/roll

P/N: R2013 Red ribbon

1000 cards/roll

P/N: R2014 Green ribbon

1000 cards/roll

P/N: R2015 White ribbon

1000 cards/roll

P/N: R2016 Gold ribbon

1000 cards/roll

P/N: R2017 Silver ribbon

1000 cards/roll

P/N: R2018 Scratch off ribbon

1000 cards/roll

P/N: R2019 BlackWAX Black ribbon

1000 cards/roll

Multi-panel ribbons

P/N: R3314 6 Panel Color Ribbon – YMCKOK (Yellow, Magenta, Cyan, Black TT, Varnish and Black TT)

200 cards/roll

P/N: R3011

5 Panel Color Ribbon – YMCKO (Yellow, Magenta, Cyan, Black TT and Varnish)

200 cards/roll

P/N: R3012 2 Panel Color Ribbon – KO (Black TT and Varnish)

500 cards/roll

P/N: R3013 5 Panel Color Ribbon – 1/2 YMCKO (Yellow, Magenta, Cyan, Black TT and Varnish)

400 cards/roll

Hologram ribbon

P/N: R4001 Optoseal® Hologram Ribbon

350 cards/roll

Page 40

40

Cleaning accessories

P/N: A5011 UltraClean Cleaning Kit (for complete cleaning of the printer)

5 pre-saturated cleaning cards, 5 swabs, 1 box of 40 pre-saturated wipes

P/N: A5002 PrinterClean Cleaning kit (for cleaning of the transport rollers)

50 pre-saturated cleaning cards

Ref. A5003

HeadClean Cleaning kit (for cleaning the print head)

25 swabs

Ref. A5004 DustClean Cleaning kit (for maintaining the cleaning roller)

1 box of 40 pre-saturated wipes

Software

P/N: L8001 eMedia Pro Software

Software for conceiving and editing badges with connection to databases

Plastic Cards

P/N: C4001 Classic Blank White plastic cards – 0.76 mm (30mil)

5 packs of 100 cards

P/N: C4002 Classic Blank White Plastic Cards – 0.50 mm (20mil)

5 packs of 100 cards

P/N: C4003 Classic Blank White Plastic Cards with a HICO Magnetic Stripe – 0.76 mm (30mil)

5 packs of 100 cards

P/N: C4004 Classic Blank White Plastic Cards with LOCO Magnetic Stripe – 0.76 mm (30mil)

5 packs of 100 cards

P/N: C1001 Premium Blank White Plastic Cards – 0.76 mm (30mil)

5 packs of 100 cards

P/N: C1003 Premium Blank White Plastic Cards with HICO Magnetic Stripe – 0.76 mm (30mil)

5 packs of 100 car

ds

P/N: C1004

Premium Blank White Plastic Cards with LOCO Magnetic Stripe – 0.76 mm (30mil)

5 packs of 100 cards

Printer accessories

P/N: S3304 Additional Card Feeder (capacity for 100 cards in 0.76 mm (30mil))

P/N: S6305

Manual Car

d Feeder (for a car

d by car

d loading)

P/N: A5007 Centronics parallel interface cable

P/N: A5017 USB interface cable

P/N: A5008 Power supply

P/N: A5009

Power cor

d, 220V

P/N: A5010 Power cord, 110V

P/N: A5019

Power cord, UK

Page 41

41

Annexe A

Magnetic encoding

Introduction

Dualys printers with a magnetic stripe card encoder are called Dualys Mag printers. The operating

mode of a Dualys Mag printer is identical to that of a Dualys printer.

The magnetic encoder encodes tracks ISO 1, 2 and 3 in a single passage and then checks the data.

Set in high coercivity (HICO) or in low coercivity (LOCO) with a simple click from the

Windows driver, however, the encoders of the Dualys Mag are sent adjusted to high coercivity (HICO)

by default, unless specifically requested on the order.

Location of the magnetic encoder

The magnetic encoder is a module installed in the factory

on Dualys Mag printers. The writing and reading head is

placed under the path of the cards and after the print

head.

The encoding sequence of a card is still

carried out before printing.

Card orientation

Cards with a magnetic track must be installed in the feeder

so the magnetic strip faces upwards, as follows:

1. Remove the feeder from the printer as shown.

Page 42

42

2. Lower the spring system as shown and insert 100

magnetic cards of 0.76 mm (30mil) at most.

3. Put the feeder back in the printer. Then press on

the top of the feeder until it clicks.

Setting the Windows Driver

When first installing the Windows driver, it is necessary to parameterise the functions of the magnetic

encoder. The functions of the magnetic encoder are accessible from the

Tools dialog box of the driver

by clicking the

Encoding Definition button.

“Magnetic Encoder” dialog box

The Magnetic Encoder dialog box opens on

selecting the

Encoding Definition button.

Track format allows us to choose the ISO stan-

dard required for each track. See the table in this

Annexe for the information concerning the ISO

7811 standards.

Coercivity parameterises the magnetic encoder in

high (HICO) or low (LOCO) coercivity. A magnetic

track encoded in high coercivity is more resistant

to exterior disturbances than a magnetic track

encoded in low coercivity.

Direct encoding allows the direct encoding of one or more magnetic tracks from this window simply

by selecting them and entering the data to be encoded. Click on the «

Execute encoding » button

to start the encoding cycle.

max.max.max.

Page 43

43

Automatic extraction allows cards with magnetic tracks to be encoded from Windows applications

(such as Word for example). A text field surrounded by the characters ”|” and ”|” (or another character to be defined by the user) may be interpreted as an encoding command by the driver.

Only use cards with magnetic tracks conform to ISO 7810 and ISO 7811.

To work properly, the magnetic track must be moulded in the card. Never use a card

with a glued magnetic track.

Cleaning of the magnetic encoder

The head of a magnetic encoder needs regular cleaning to be able to assure the integrity of the data

encoded in the cards.

The magnetic encoder is cleaned when the printer is the object of a cleaning sequence with the presaturated cards (refer to the « Cleaning » chapter in this manual for further information.

Repeated passages of the cleaning card inside the printer clean the card transport rollers, the cleaning

roller and the reading / writing head of the magnetic encoder.

If between two printer cleaning sessions (every 1000 cards inserted), the reading / writing process has

failed with more than one card, it is recommended to manually start a printer cleaning process (refer to

the « Cleaning » chapter of this manual for the procedure to be followed).

ISO 7811 encoding standards

1

Bit(s) per inch

2

Except the “?” character

3

Including the Star

t, Stop and LRC characters. The magnetic encoder generates these characters automatically

.

Track no. Field separator Track density Types of characters Number of characters

Track 1 ^ 210 bpi

1

Alphanumerical 79

3

(ASCII 20- 95)

2

Track 2 = 75 bpi

1

Numerical 40

3

(ASCII 48-62)

2

Track 3 = 210 bpi

1

Numerical 107

3

(ASCII 78-62)

2

Page 44

Annexe B

Smart Card Contact Station

Introduction

Dualys printers with a Smart Card Contact Station are called Dualys Smart printers. The working mode

of a Dualys Smart printer is identical to that of a Dualys printer.

The Smart Card Contact Station of the Dualys Smart enables the chips to be programmed to the ISO

7816-2 standards.

Location of the contact station

The Contact Station is a module installed in the factory on

Dualys Smart printers.

The Contact Station is positioned over the path of the cards and

before the print head. To contact the Station, the chip card is

placed under it and is pushed up.

The programming sequence of a chip is always carried

out before the card is printed.

Only use chip cards conform to ISO 7816-2.

Never print on the chip.

Card orientation

Chip cards must be installed in the card feeder so that the chip is downwards, as shown below:

44

1. Remove the feeder from the printer as

shown.

Page 45

45

Interface of the Contact Station

The Dualys is fitted with a DB-9 female connector on the back of the printer. This connector, directly

connected to the Contact Station inside the printer, is also connected to an external coupler to program the chip.

2. Lower the spring system as shown and insert 100 chip

cards of 0.76 mm (30mil) at most (chip downwards).

3.

Put the feeder back in the printer. Then press

on the top of the feeder until it clicks.

DB-9 Connector

USB or Parallel Port

External Coupler

Serial Port, USB, …

max.max.max.

Page 46

46

DB-9 Connector pins Chip card contact points

1 C1 (V c.c.)

2 C2 (reset to 0)

3 C3 (Clock)

4 C4 (reserved)

5 C5 (Ground)

6 C6 (Vpp)

7 C7 (E-S)

8 C8 (reserved)

9 C9 Ground when the chip is commuted with

the Contact Station

A sequence of commands must be sent via the interface of the printer to insert a card in the printer

and then place it under the Station to establish contact

The command sequence is the following:

Sending the “Sis” sequence

■

One card is moved from the feeder to the Contact Station and stops under it.

■

The card is pushed up to come into contact with the Station.

■

The printer connects the Contact Station to the DB-9 connector.

■

The chip may be programmed via the serial or USB interface of the computer and the external coupler.

Check the Programming Guide of the Dualys printer to obtain more complete information

on how to program a chip card.

Page 47

Declarations of Conformity

Concerning Safety and Electromagnetic Compatibility

Manufacturer’s Name: Evolis Card Printer

Manufacturer’s Address: 29, avenue de la Fontaine

Z.I. Angers Beaucouzé

49070 Beaucouzé, France

Material Designation: Dualys

Year of Manufacture: 2006

I, the undersigned, Serge Olivier,

Declare that I have received the assumption of the above material, used and installed in accordance with the notice, with

the essential requirements of Directives 73/23/CEE and 89/336/CEE, modified by 92/31/CEE and 93/68/CEE by the application of the following regulations:

EN 60950-1 of 2001

EN 55022 Class B of 1998

EN 55024 of 1998

EN 61000-3-2 of 2000

EN 61000-3-3 of 2000 +A1 of 2001

EUROPE:

Norway Only: This product is designed for IT power system with phase-to-phase voltage 230V. Earth grounding

is via the polarized, 3-wire power cord.

FI: “Laite on liitettävä suojamaadoitus koskettimilla varustettuun pistorasiaan”

SE: “Apparaten skall anslutas till jordat uttag”

NO: “Apparatet må tilkoples jordet stikkontakt”

Full name: Serge Olivier Signature:

Title: Technical Manager

Date: January 2006

FCC Statement (For U.S.A.)

Federal Communications Commission Radio Frequency Interferences Statement

Dualys model conforms to the following specifications: FCC Part 15, Subpart A, Section 15.107(a) and

Section 15.109(a) Class B digital device.

Supplemental information:

This equipment has been tested and finds to comply with the limits for a Class B digital device, pursuant to par

t 15 of the

FCC Rules. These limits ar

e designed to pr

ovide r

easonable pr

otection against har

mful interference in a residential installation. This equipment generates uses and can radiate radio frequency energy and, if not installed and used in accordance

with the instr

uctions, may cause harmful interference to radio communications. However, there is no guarantee that inter-

fer

ence will not occur in a par

ticular installation. If this equipment does cause har

mful inter

fer

ence to radio or television

r

eception, which can be deter

mined by tur

ning the equipment of

f and on, the user is encouraged to tr

y to cor

r

ect the inter

-

fer

ence’s by one or more of the following measures:

- Reorient or r

elocate the r

eceiving antenna.

- Incr

ease the separation between the equipment and the r

eceiver

.

- Connect the equipment into an outlet on a cir

cuit different from that to which the receiver is connected.

- Consult the dealer or an experienced radio/TV technician for help.

Use of a shielded cable is required to comply within Class B limits of Part 15 of FCC Rules.

Pursuant to Par

t 15.21 of the FCC Rules, any changes or modifications to this equipment not expr

essly appr

oved by Evolis

Car

d Printer may cause, har

mful inter

fer

ence and void the FCC authorization to operate this equipment.

VCCI (For Japan)

This equipment complies with the Class B category for information technology equipment based on the rules of Voluntary

Contr

ol Council for Inter

fer

ences by Information Technology Equipment. When used in a residential area, radio interferen-

ce may be caused. In this case, the user may be r

equir

ed to take appr

opriate cor

r

ective actions.

Loading...

Loading...