Page 1

1

wwww

here barbecuing meets art

here barbecuing meets arthere barbecuing meets art

here barbecuing meets art

ASSEMBLY, OPERATION

& MAINTENANCE INSTRUCTIONS

NEO

NEO GRANDE

NEO NEO

GRANDE &

GRANDEGRANDE

& GROSSO

& &

F O R O U T D O O R U S E O N L Y

F O R O U T D O O R U S E O N L Y

F O R O U T D O O R U S E O N L YF O R O U T D O O R U S E O N L Y

GROSSO

GROSSOGROSSO

Page 2

2

ASSEMBLY, OPERATION AND MAINTENANCE INSTRUCTIONS

ASSEMBLY, OPERATION AND MAINTENANCE INSTRUCTIONS

ASSEMBLY, OPERATION AND MAINTENANCE INSTRUCTIONSASSEMBLY, OPERATION AND MAINTENANCE INSTRUCTIONS

FOR

FOR EVERDURE

FOR FOR

EVERDURE 6666 BURNER GAS BARBECUE RANGE

EVERDURE EVERDURE

BURNER GAS BARBECUE RANGE

BURNER GAS BARBECUE RANGE BURNER GAS BARBECUE RANGE

GRANDE

GRANDE AND

GRANDEGRANDE

CONTENTS

CONTENTS

CONTENTSCONTENTS

SECTION PAGE NO.

General Safety Instructions 3

Appliance Details 4

Gas Connections 4

Outdoor Installation Guide 5

Operating Instructions for Barbecue 6

Lighting Procedure 6

Cooking 7

Cleaning and Storage 7

Operating Instructions for Wok Burner 8

Troubleshooting 9

Maintenance 9

Assembly Instructions 10-17

It is important that you retain these instructions for future reference.

It is important that you retain these instructions for future reference.

It is important that you retain these instructions for future reference.It is important that you retain these instructions for future reference.

Grande Grosso

AND GROSSO

AND AND

GROSSO OUTDOOR BARBECUES

GROSSOGROSSO

OUTDOOR BARBECUES

OUTDOOR BARBECUESOUTDOOR BARBECUES

Page 3

3

!

IMPORTANT SAFETY INSTRUCTIONS

IMPORTANT SAFETY INSTRUCTIONS

IMPORTANT SAFETY INSTRUCTIONSIMPORTANT SAFETY INSTRUCTIONS

IMPORTANT

IMPORTANT: Read the assembly instruction section and safety precautions

IMPORTANTIMPORTANT

Read the assembly instruction section and safety precautions of this

Read the assembly instruction section and safety precautionsRead the assembly instruction section and safety precautions

booklet carefully before removing the contents of this carton.

booklet carefully before removing the contents of this carton.

booklet carefully before removing the contents of this carton.booklet carefully before removing the contents of this carton.

of this

of this of this

1. This barbecue and wok burner is for OUTDOOR USE ONLY

indoors.

2. Unsupervised children or pets should not be near a barbecue while cooking or during warm up or cool

down. Ensure children or pets are kept a distance well away from the barbecue whilst it is in use. Ensure

that young children do not play with the appliance.

3. Particular care must be taken when removing the fat tray. Hot fats can cause serious injury.

4. Turn all gas valves off including cylinder after use. Do not allow build up of unburned gas.

5. Do not use this appliance for any purpose other than what it is intended for.

6. Do not move this barbecue while in use as accessible parts may be very hot.

7. People with flammable clothing such as nylon etc. should keep well away from the barbecue when it is

operating.

8. Never leave burners on high for more than 10 minutes unless actually cooking.

9. Always check for leaks when a gas cylinder is replaced or reconnected. Never store more than one gas

cylinder in the trolley at any one time.

10. Sand, kitty litter and fat absorbers should not be used in the fat tray.

11. In case of fat fire turn cylinder off. Fat drip trays should be cleaned and checked before using the

barbecue. Regular cleaning should reduce the build up of fat and food residues which is combustible

and can result in a fat fire. Fat fires can be prevented with diligence in cleaning your fat tray.

Damage as a result of fat fire is not covered by your warranty and voids it.

Fat fires can be prevented with diligence in cleaning your fat tray.

Fat fires can be prevented with diligence in cleaning your fat tray. Fat fires can be prevented with diligence in cleaning your fat tray.

OUTDOOR USE ONLY. This appliance must NOT

OUTDOOR USE ONLYOUTDOOR USE ONLY

NOT be used

NOT NOT

12. For your safety and enjoyment, read all operating instructions before lighting.

13. Ensure that the product has adequate clearance from combustible materials. The appliance is designed

so that heat will not affect the trolley. All combustible materials must be kept more than 250mm from the

sides of the trolley and more than 1500mm above the cooking surface of the barbecue.

14. If the burner makes a hissing sound when lit, it may be burning inside. Turn the burner off, allow to cool

and try ignition again. Keep your barbecue protected against strong wind – if this cannot be avoided,

always check that the burners remain alight if operating the barbecue in windy conditions.

15. This appliance is not intended for use by young children or infirm persons.

16. When the wok burner is in use or is still hot, the lid must not be placed in the closed position.

17. Do not carry out any servicing on the gas manifold of the barbecue yourself – this must only be done by

authorised technicians.

18. We recommend that you regularly maintain your barbecue and keep it in good condition. This can be

achieved by following the cleaning and maintenance suggestions in this booklet.

DO NOT

DO NOT

DO NOT

DO NOT

DO NOT

DDDDO NOT

DO NOT OPERATE THIS APPLIANCE BEFORE READING THE

DO NOT DO NOT

DO NOT PLACE ARTICLES ON OR AGAINST THIS APPLIANCE

DO NOT DO NOT

DO NOT STORE CHEMICALS OR FLAMMABLE MATERIALS OR

DO NOTDO NOT

DO NOT OPERATE THIS APPLIANCE INDOORS

DO NOTDO NOT

DO NOT ENCLOSE THIS APPLIANCE

DO NOTDO NOT

O NOT LIGHT OR OPERATE WITH COVER ON

O NOTO NOT

INSTRUCTION BOOKLET

SPRAY AEROSOLS NEAR THIS APPLIANCE

Page 4

4

!

APPLIANCE DETAILS

APPLIANCE DETAILS

APPLIANCE DETAILSAPPLIANCE DETAILS

Gas Type:

Gas Type:

Gas Type:Gas Type:

Burner

Burner Pressure:

BurnerBurner

Injector Diameter:

Injector Diameter: Ø0.95 mm Ø1.65 mm

Injector Diameter:Injector Diameter:

Heat Input:

Heat Input: 70 MJ/ hr 75 MJ/ hr

Heat Input:Heat Input:

Wok Injector Diameter:

Wok Injector Diameter: Ø0.90 mm Ø1.65 mm

Wok Injector Diameter:Wok Injector Diameter:

Wok Heat Input:

Wok Heat Input: 10.5MJ/hr 12.5MJ/hr

Wok Heat Input:Wok Heat Input:

Note: The size of the injector diameter is stamped on one of the hexagon faces (e.g. ‘104’ for Ø1.04mm injector).

Pressure: 2.75 kPa 0.95 kPa

Pressure: Pressure:

(Propane and/or Butane gas)

Universal LPG

Natural Gas

Barbecue only

Barbecue only 1004 545 220

Barbecue onlyBarbecue only

Barbecue and

Barbecue and

Barbecue and Barbecue and

Trol

Trolley

ley

TrolTrol

leyley

Grande 1710 640 1220

Grosso 1680 640 1220

LENGTH (mm)

LENGTH (mm) WIDTH (mm)

LENGTH (mm)LENGTH (mm)

WIDTH (mm) HEIGHT (mm)

WIDTH (mm)WIDTH (mm)

HEIGHT (mm)

HEIGHT (mm)HEIGHT (mm)

GAS CONNECTIONS

GAS CONNECTIONS

GAS CONNECTIONSGAS CONNECTIONS

LOCAL AUTHORITY REQUIREMENTS

LOCAL AUTHORITY REQUIREMENTS

LOCAL AUTHORITY REQUIREMENTSLOCAL AUTHORITY REQUIREMENTS

Check Gas Type and specifications plate on the left-hand side of the barbecue. All gas fitting work, service and repairs

can only be performed by an authorised person in accordance with AS5601 / AG601 and local gas regulations.

NATURAL GAS

NATURAL GAS

NATURAL GASNATURAL GAS

Neo 6 burner barbecues can be converted to use natural gas ONLY with a Neo NG 6 burner conversion kit. Fit the NG

manifolds, regulator and NG hose. This conversion can ONLY

with AS5601 / AG601 and local gas regulations.

Note: The burner pressure (as noted on the appliance details) MUST be checked after installation by turning on and

measuring at the regulator output test point. All connections must be checked for leaks.

FOR

FOR GAS

GAS CYLINDER CONNECTION

FOR FOR

1. To achieve the optimum performance from your Barbecue, an approved gas cylinder (POL fitting) of 9kg capacity

must be used.

2. Do not connect gas to a barbecue that is not secured in a trolley.

3. Connect the cylinder to the barbecue, via the hose and regulator. Firmly tighten joints, but do not over-tighten. Take

LEAK TESTING

LEAK TESTING

LEAK TESTINGLEAK TESTING

1. Make sure gas controls are Off

2. Check for leaking joints by brushing with solution of half-liquid detergent and half water. If a leak is present, bubbles

will appear (or you will hear a hissing sound). Retightening connections can generally repair a leaking joint. You must

also check the gas hose and connection at the gas cylinder, and at the wok burner. If a leak cannot be resolved, do

not proceed.

CYLINDER CONNECTION

GASGAS

CYLINDER CONNECTION CYLINDER CONNECTION

care not to damage the regulator fitting.

Off and turn the cylinder valve On

OffOff

LEAK TEST ALL CONNECTIONS, INCL

LEAK TEST ALL CONNECTIONS, INCLUDING THE CONNECTION

LEAK TEST ALL CONNECTIONS, INCLLEAK TEST ALL CONNECTIONS, INCL

TO THE GAS CYLINDER

TO THE GAS CYLINDER.

TO THE GAS CYLINDERTO THE GAS CYLINDER

DO NOT USE NAKED FLAME FOR LOCATING GAS LEAKS.

DO NOT USE NAKED FLAME FOR LOCATING GAS LEAKS.

DO NOT USE NAKED FLAME FOR LOCATING GAS LEAKS.DO NOT USE NAKED FLAME FOR LOCATING GAS LEAKS.

IF A LEAK PERSISTS CALL AN AUTHORISED GAS FITTER.

IF A LEAK PERSISTS CALL AN AUTHORISED GAS FITTER.

IF A LEAK PERSISTS CALL AN AUTHORISED GAS FITTER.IF A LEAK PERSISTS CALL AN AUTHORISED GAS FITTER.

ONLY be performed by an authorised person in accordance

ONLYONLY

On.

OnOn

UDING THE CONNECTION

UDING THE CONNECTION UDING THE CONNECTION

Page 5

5

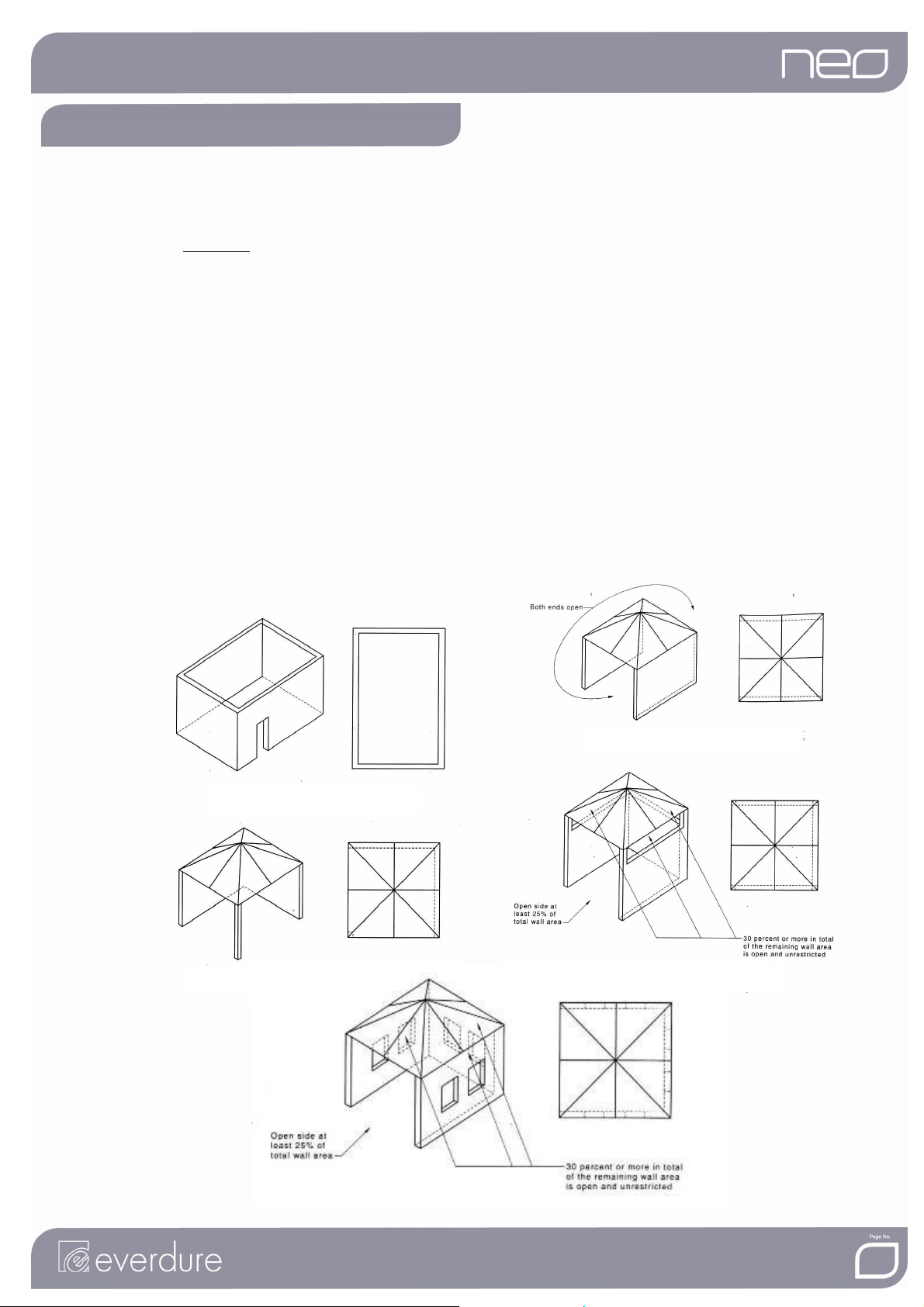

OUTDOOR INSTALLATION GUIDE

OUTDOOR INSTALLATION GUIDE

OUTDOOR INSTALLATION GUIDEOUTDOOR INSTALLATION GUIDE

This Appliance shall only be used in an above ground open-air situation with natural ventilation, without

stagnant areas, where gas leakage and products of combustion are rapidly dispersed by wind and natural

convection.

This appliance

This appliance must not

This appliance This appliance

other enclo

other enclosed areas. The barbecue is not intended to be installed in or used on recreational vehicles

other encloother enclo

(e.g. boats, camping vans) and should not be placed close to or under any surfaces that will burn or

(e.g. boats, camping vans) and should not be placed close to or under any surfaces that will burn or

(e.g. boats, camping vans) and should not be placed close to or under any surfaces that will burn or (e.g. boats, camping vans) and should not be placed close to or under any surfaces that will burn or

are sensitive to heat. Do not block/obstruct the flow of air

are sensitive to heat. Do not block/obstruct the flow of air and combustion around the barbecue

are sensitive to heat. Do not block/obstruct the flow of air are sensitive to heat. Do not block/obstruct the flow of air

housing while in use.

housing while in use.

housing while in use.housing while in use.

Any enclosure in which the appliance is used shall comply with one of the following:

Any enclosure in which the appliance is used shall comply with one of the following:

Any enclosure in which the appliance is used shall comply with one of the following:Any enclosure in which the appliance is used shall comply with one of the following:

• An enclosure with walls on all sides, but at least one permanent opening at ground level and no

overhead cover.

• Within a partial enclosure that includes an overhead cover and no more than two walls

• Within a partial enclosure that includes an overhead cover and more than two walls, the following shall

apply-

In the case of balconies, at least 20% of the total of the side, back and front wall areas shall be and remain

open and unrestricted.

must not be used indoors. Do not use your barbecue in garages, porches, sheds or

must notmust not

sed areas. The barbecue is not intended to be installed in or used on recreational vehicles

sed areas. The barbecue is not intended to be installed in or used on recreational vehicles sed areas. The barbecue is not intended to be installed in or used on recreational vehicles

(i) at least 25% of the total wall area is completely open: and

(ii) at least 30% of the remaining wall area is open and unrestricted.

be used indoors. Do not use your barbecue in garages, porches, sheds or

be used indoors. Do not use your barbecue in garages, porches, sheds or be used indoors. Do not use your barbecue in garages, porches, sheds or

and combustion around the barbecue

and combustion around the barbecue and combustion around the barbecue

Page 6

6

!

OPERATING IN

OPERATING INSTRUCTIONS

OPERATING INOPERATING IN

GAS TYPE AND CONSUMPTION

GAS TYPE AND CONSUMPTION

GAS TYPE AND CONSUMPTIONGAS TYPE AND CONSUMPTION

The barbecue is designed to operate on Universal LP Gas only (Propane and/or Butane gas) and Natural Gas

(using a conversion kit). Gas consumption, Pressure and Injector Orifice size are shown on the Data Plate

found on the left-hand side of the barbecue.

GAS

GAS CONTROL

CONTROL KNOBS

GAS GAS

CONTROLCONTROL

The gas control knob locks in both the Off

clockwise, gas flow will gradually increase until the High

and gas flow will decrease until a simmer level is reached at Low

must be turned clockwise from Low

VAPOURISER

VAPOURISER

VAPOURISERVAPOURISER

Prior to using the barbecue, ensure the vapouriser is located in the correct position below the grill plate.

HOT PLATE, GRILL PLATE

HOT PLATE, GRILL PLATE, BAKING DISH

HOT PLATE, GRILL PLATEHOT PLATE, GRILL PLATE

Prior to using the barbecue, it’s advisable to cure the cooking surface. Wash the hot plate and grill plate, then

cover with olive or vegetable oil, light all burners and leave on until oil is absorbed, then wipe with a dry cloth.

STRUCTIONS

STRUCTIONSSTRUCTIONS

KNOBS

KNOBS KNOBS

Low, depressed at High

LowLow

, BAKING DISH

, BAKING DISH, BAKING DISH

Off and High

OffOff

High positions. By depressing the knob and turning anti-

HighHigh

High position is reached. Continue turning in this direction

High High

Low. To turn gas flow off the gas control knob

LowLow

High and turned until the Off

HighHigh

Off position is reached.

OffOff

DRIP TRAY

DRIP TRAY

DRIP TRAYDRIP TRAY

Prior to use check that the drip tray is clean and lined with aluminium foil.

UNDER NO CIRCUMSTANC

UNDER NO CIRCUMSTANCES MUST SAND, FAT AB

UNDER NO CIRCUMSTANCUNDER NO CIRCUMSTANC

OR KITTY LITTE

OR KITTY LITTER BE USED IN THE DRI

OR KITTY LITTEOR KITTY LITTE

LIGHTING PROCEDURE

LIGHTING PROCEDURE

LIGHTING PROCEDURELIGHTING PROCEDURE

ES MUST SAND, FAT ABSORBENTS

ES MUST SAND, FAT ABES MUST SAND, FAT AB

R BE USED IN THE DRIP TRAY

R BE USED IN THE DRIR BE USED IN THE DRI

SORBENTS

SORBENTSSORBENTS

P TRAY

P TRAYP TRAY

READ ALL OPERATING I

MAKE SURE ALL GAS

LIGHTING THE BARBECUE

LIGHTING THE BARBECUE

LIGHTING THE BARBECUELIGHTING THE BARBECUE

The 6 burner barbecue has a rotary ignition system built into the second gas control in from either end, which

ignites the corresponding burner. The remaining burners are ignited by a cross over channel. Pushing either

of these control knobs in, and rotating the control knob in an anti-clockwise direction (starting at off

a spark to ignite an extended pilot flame, which will in turn light the burner in front of the control knob. Once

the knob is released, the pilot flame will extinguish. Visually check to see if the burner has ignited. If the

burner does not light, turn gas control off (turn the control knob clockwise) and allow the unburned gas to

dissipate before attempting ignition again. If ignition continues to fail refer, to the “Trouble shooting” section.

To achieve ignition on the remaining burners, turn an adjacent burner control knob to high

ignite from the first burner.

MANUAL IGNITION

MANUAL IGNITION

MANUAL IGNITIONMANUAL IGNITION

To help light the barbecue manually, a match holder and chain has been provided, and should be attached to

the right hand servery. The right hand burner can then be lit by lighting a match, fitting it into the holder and

pushing the match through to the right hand burner. After the initial burner is lit, the others can be ignited as

described above.

READ ALL OPERATING INSTRUCTIONS BEFORE L

READ ALL OPERATING IREAD ALL OPERATING I

MAKE SURE ALL GAS CONTROL

MAKE SURE ALL GAS MAKE SURE ALL GAS

POSITION AND OPEN CY

POSITION AND OPEN CYLINDER VALVE.

POSITION AND OPEN CYPOSITION AND OPEN CY

NSTRUCTIONS BEFORE LIGHTING.

NSTRUCTIONS BEFORE LNSTRUCTIONS BEFORE L

CONTROL KNOBS ARE IN THE ‘O

CONTROLCONTROL

KNOBS ARE IN THE ‘OFF’

KNOBS ARE IN THE ‘O KNOBS ARE IN THE ‘O

LINDER VALVE.

LINDER VALVE.LINDER VALVE.

IGHTING.

IGHTING.IGHTING.

FF’

FF’ FF’

off), will cause

offoff

high and the burner will

highhigh

Page 7

7

COOKING

COOKING

COOKINGCOOKING

GENERAL COOKING GUIDE

GENERAL COOKING GUIDE

GENERAL COOKING GUIDEGENERAL COOKING GUIDE

A fairly protected location is desirable for pleasant and efficient cooking. IMPORTANT!

drastically reduce cooking efficiency. As a guide, allow 10 minutes with the burners on high, to heat cooking

area. A little cooking fat (or olive oil) on the grill will prevent sticking. Cooking time for a 20mm thick steak cooked

to medium on the char grill is approximately 15 minutes (7.5 minutes per side) with the burners on high. Turn

burners down a little when full heat is not required and to LOW

As a guide for Hood closed

plate, baking dish and vapouriser. Position the grill plate central over the two centre burners. Place either the

roasting dish or a foil baking dish in the centre of the bbq. Fill the dish with 2 cm of water. Place a suitably sized

rack in the dish. Place food on the rack so that any fats will drip into the water in the bottom of the dish. The water

will also keep the food moist during cooking. With the hood open light the bbq as per normal lighting

instructions, then close the hood and turn off the two central burners. Leave the outer two burners on high and

the middle burners on low. This is most important – if left on the two centre burners will cause overheating and

spoil the food. A 10 minute pre-heat time is generally required to get the temperature to the correct level. As a

rough guide to the cooking times for roast beef, allow 30 to 50 minutes cooking time per kilogram for rare to well

done respectively. It is recommended that the food be turned half way through the cooking time, for evenness of

cooking. Remember, never use the roasting hood with all the burners on high as this will cause severe

overheating and may damage the hood and bbq. During cooking, fat and scrapings will drip through to the drip

tray. Do not allow excess fat to build up in the drip tray. Clean the drip tray and replace the aluminium foil before

use. This is a general guide for roasting only – please check www.everdure.com for any updated cooking guides.

AFTER COOKING

AFTER COOKING

AFTER COOKINGAFTER COOKING

1. When finished, make sure burner control knobs are turned OFF

2. TURN OFF THE GAS SUPPLY AT THE CYLINDER

TURN OFF THE GAS SUPPLY AT THE CYLINDER.

TURN OFF THE GAS SUPPLY AT THE CYLINDERTURN OFF THE GAS SUPPLY AT THE CYLINDER

3. Immediately after cooking and whilst the barbecue is still warm, remove scraps from the grill with a scraper.

4. Excess fat and meat scraps can be scraped off the vapouriser by removing the grill to gain access.

WARNING

WARNING: Some surfaces may still be hot.

WARNINGWARNING

5. Clean the fat tray and replace the aluminium foil after or before each use of the appliance.

6. Once the barbecue is cool close the roasting hood and wipe off any fat splatter from the trolley with a clean

rag.

Hood closed cooking, use as per the following instructions: Open hood and remove the solid

Hood closedHood closed

LOW when not cooking.

LOWLOW

OFF.

OFFOFF

IMPORTANT! Strong winds will

IMPORTANT!IMPORTANT!

CLEANING

CLEANING AND STORAGE

CLEANINGCLEANING

AND STORAGE

AND STORAGE AND STORAGE

CLEANING

CLEANING

CLEANINGCLEANING

Painted surfaces can be cleaned using a mild household detergent or cleaner. It is advisable to test cleaners on a

small section of the appliance first. It is recommended to clean the stainless steel surfaces with clean water only

(no detergents to be used) or use a stainless steel cleaner. Failure to follow these instructions may void your

warranty. Over time, stainless steel will be affected by “tea staining” or “bronzing” (brown discoloration of stainless

steel). This can be reduced by washing the surface with mild detergent and warm water, followed by rinsing with

clean cold water. Dry the surface afterwards.

NEVER

NEVER use paint thinners or similar solvents for cleaning and NEVER

NEVERNEVER

STORAGE

STORAGE

STORAGESTORAGE

WARNING

WARNING:::: When the appliance is not in use, the cylinder valve must be turned OFF,

WARNINGWARNING

cylinder together must be stored outdoors in a well ventilated area. However it is permissible to store the

appliance (but not the cylinder) indoors. Ensure a small amount of fat or oil is on the barbecue plates to prevent

rust.

STORE CYLINDER IN A WELL VENTILATED AREA

STORE CYLINDER IN A WELL VENTILATED AREA OUT OF REACH OF CHILDREN

STORE CYLINDER IN A WELL VENTILATED AREASTORE CYLINDER IN A WELL VENTILATED AREA

NEVER pour cold water over hot surfaces.

NEVERNEVER

OFF, the appliance and the

OFF, OFF,

OUT OF REACH OF CHILDREN

OUT OF REACH OF CHILDRENOUT OF REACH OF CHILDREN

Page 8

8

When the gas cylinder is disconnected, replace the plug or cap on the valve outlet.

For extended storage it is suggested that the primary air port of the burners be covered against the

penetration of insects or vermin. Spiders and small insects can spin webs or nest in the burner rails/tubes,

which could lead to obstruction in the gas and air flow, resulting in a fire in an around the burner rails/tubes.

This type of fire is called a flash-back and can cause serious damage to your barbecue and create an unsafe

operating condition. To prevent this, regularly inspect and clean the burners. A barbecue cover can be

placed over the appliance for extra protection, and to reduce this.

To extend the life of your barbecue and trolley and to keep it looking great, we recommend using a

Weatherproof Cover.

GAS SUPPLY

GAS SUPPLY

GAS SUPPLYGAS SUPPLY

1. Inspect the gas supply hose for any deterioration and replace it if necessary.

2. Test the gas circuit for leaks and remedy any found. See leak testing instruction.

TROLLEY

TROLLEY

TROLLEYTROLLEY

1. Check all fasteners for tightness and re tighten where necessary to ensure rigidity of the structure.

2. Wipe over barbecue trolley with a clean cloth.

OPERATING INSTRUCTIONS FOR

OPERATING INSTRUCTIONS FOR WOK BURNER

OPERATING INSTRUCTIONS FOROPERATING INSTRUCTIONS FOR

WOK BURNER

WOK BURNER WOK BURNER

GAS CONNECTION

GAS CONNECTION

GAS CONNECTIONGAS CONNECTION

Attach small hose from wok burner gas valve to barbecue manifold. Connect gas hose and regulator to the

cylinder. Before turning gas cylinder on please ensure that the gas valves on the barbecue and wok burner

are in the off position.

Turn gas supply on and check for leaks by applying a soap solution to all connections with a brush. If a leak

is detected, retighten the connection and test for leaks again. Never check for leaks with the use of a flame.

BEFORE IGNITING T

BEFORE IGNITING THE BARBECUE ENSURE T

BEFORE IGNITING TBEFORE IGNITING T

BARBECUE AND THE WOK

BARBECUE AND THE WOK BURNER

BARBECUE AND THE WOKBARBECUE AND THE WOK

LIGHTING INSTRUCTION

LIGHTING INSTRUCTIONSSSS

LIGHTING INSTRUCTIONLIGHTING INSTRUCTION

Important: The lid must be open when lighting the burner and during normal operation.

Important: The lid must be open when lighting the burner and during normal operation.

Important: The lid must be open when lighting the burner and during normal operation.Important: The lid must be open when lighting the burner and during normal operation.

1. Push in and turn the control knob to HIGH.

2. The built-in ignitor will light the burner.

3. If burner does not light, return knob to the OFF position and retry 5 times.

4. If the burner does not light, leave the knob in the OFF position, and wait 5 minutes before retrying.

HE BARBECUE ENSURE THAT ALL VALVES ON TH

HE BARBECUE ENSURE THE BARBECUE ENSURE T

BURNER ARE IN THE OFF POSIT

BURNER BURNER

HAT ALL VALVES ON THE

HAT ALL VALVES ON THHAT ALL VALVES ON TH

ARE IN THE OFF POSITION.

ARE IN THE OFF POSITARE IN THE OFF POSIT

ION.

ION.ION.

E

E E

CARE AND CLEANING

CARE AND CLEANING

CARE AND CLEANINGCARE AND CLEANING

Before cleaning, ensure the appliance has cooled down and is safe to touch. Remove the trivet plate and

wipe down the burner and spill bowl with a clean damp cloth. Do not use harsh detergents or scourers as

damage may occur to the surfaces.

Page 9

9

TROUBLESHOOTING

TROUBLESHOOTING

TROUBLESHOOTINGTROUBLESHOOTING

Burner will no

Burner will not ignite when using the igniter:

Burner will noBurner will no

Cylinder valve is not on Turn cylinder valve on

Cylinder is empty Replace with a full cylinder

Igniter button is not working Check connections

Igniter is not sparking Remove plate and visually check ignition box for a spark. If there is no

Injector is blocked Clean injector with a toothbrush. Do not drill out or use wire. Do not

Burner flame is erratic:

Burner flame is erratic:

Burner flame is erratic:Burner flame is erratic:

Burner is blocked Remove burner and check for obstruction

t ignite when using the igniter:

t ignite when using the igniter:t ignite when using the igniter:

spark contact, check connections.

remove injector.

Contact authorised service agent

Flame is burning inside burner

(hissing sound)

Regulator is faulty Contact authorised service agent

Injector is partially blocked Clean injector with a toothbrush. Do not drill out or use wire. Do not

Gas is leaking from connections:

Gas is leaking from connections:

Gas is leaking from connections:Gas is leaking from connections:

Connections are loose Tighten loose connections (do not over-tighten) and leak test under

Hose has deteriorated Replace hose and leak test after replacement.

Gas valve is faulty Contact an authorised service agent

Threads are damaged Contact an authorised service agent

MAINTENANCE

MAINTENANCE

MAINTENANCEMAINTENANCE

It is recommended that, at the commencement of each barbecue season, the following maintenance be

conducted.

BURNERS

BURNERS

BURNERSBURNERS

1. Remove the burner and inspect the port holes, primary air inlet and mixing throat for any signs of

blockage. Clean out with compressed air or a length of wire if necessary.

2. Wire brush the outside of the burner to remove rust and dirt.

3. Replace the burner.

GAS SUPPLY

GAS SUPPLY

GAS SUPPLYGAS SUPPLY

1. Inspect the gas supply hose for any deterioration and replace it if necessary.

2. Test the gas circuit for leaks and remedy any found.

TROLLEY

TROLLEY

TROLLEYTROLLEY

1. Check all fasteners for tightness and re-tighten where necessary to ensure rigidity of the structure.

2. Wipe over barbecue trolley with a clean cloth.

Turn off burner, allow to cool and re-ignite

remove injector. Contact authorised service agent.

pressure with soapy water solution. Refer to leak testing instructions

Page 10

10

Phillips Screwdriver

Phillips ScrewdriverPhillips Screwdriver

Phillips Screwdriver

Spanner

SpannerSpanner

Spanner

BARBECUE ASSEMBLY

BARBECUE ASSEMBLY

BARBECUE ASSEMBLYBARBECUE ASSEMBLY

CHECK AND REMOVE THE BBQ PARTS FRON THE CARTONS

CHECK AND REMOVE THE BBQ PARTS FRON THE CARTONS

CHECK AND REMOVE THE BBQ PARTS FRON THE CARTONSCHECK AND REMOVE THE BBQ PARTS FRON THE CARTONS

NEO

2.FAT TRAY HANDLE

1.FAT TRAY

25.BURNERS

23.WOK SERVERY

NEO Grande

NEONEO

6.COOKING PLATE

Grande

GrandeGrande

26.BAKING DISH

3.WARMING RACK

4.GRILL

5.VAPOURISER

7.SIDE SERVERY

AND DRAWER

27.SERVERY BRACKET

24.MATCH HOLDER

8.BODY AND HOOD ASS'Y

9.TROLLEY TOP PANEL

10.MAGNETS (2PCS)

22.REAR PANEL

21.LEFT SIDE PANEL

11.RIGHT SIDE PANEL

12.DOORPOSTS (2PCS)

13.DOOR HANDLES (2PCS)

14.RIGHT DOOR

20.AXLE

19.WHEELS (2PCS)

18.WHEEL DECALS (2PCS)

PARTS REQU

PARTS REQUIRED

PARTS REQUPARTS REQU

Make sure you thoroughly inspect parts before assembly and do not assemble or operate a barbecue that

appears damaged.

IRED / INVENTORY

/ INVENTORY

IREDIRED

/ INVENTORY / INVENTORY

17.LEFT DOOR

15.TROLLEY BOTTOM PANEL

16.CASTOR (2PCS)

ITEM

ITEM

ITEMITEM

A

B

C

D

E

The use of an adjustable spanner and a Phillips screwdriver will be required.

PICTURE

PICTURE NAME AND QUANTITY

PICTUREPICTURE

NAME AND QUANTITY ITEM

NAME AND QUANTITYNAME AND QUANTITY

SCREW M6X16…......14PCS F

SCREW M5X15….…..36PCS G

SCREW M4X8…….......8PCS H

SCREW M3X12….…....4PCS I

FLAT HEAD SCREW.....4PCS J

ITEM PICTURE

ITEMITEM

PICTURE NAME AND QUANTITY

PICTUREPICTURE

NAME AND QUANTITY

NAME AND QUANTITYNAME AND QUANTITY

NUT M6........................ 14PCS

LOCK NUT M10….…...…2PCS

LOCK NUT M3……....…..4PCS

SPRING WASHER D6.....14PCS

FIBRE WASHER M5.........4PCS

Page 11

11

Phillips Screwdriver

Phillips ScrewdriverPhillips Screwdriver

Phillips Screwdriver

Spanner

SpannerSpanner

Spanner

NEO Grosso

2.FAT TRAY HANDLE

1.FAT TRAY

25.BURNERS

23.WOK SERVERY

22.REAR PANEL

21.LEFT SIDE PANEL

6.COOKING PLATE

26.BAKING DISH

3.WARMING RACK

4.GRILL

5.VAPOURISER

7.SIDE SERVERY

24.MATCH HOLDER

8.BODY AND HOOD ASS'Y

9.TROLLEY TOP PANEL

10.MAGNETS (2PCS)

11.RIGHT SIDE PANEL

12.DOORPOSTS (2PCS)

13.DOOR HANDLES (2PCS)

20.AXLE

14.RIGHT DOOR

15.TROLLEY BOTTOM PANEL

19.WHEELS (2PCS)

18.WHEEL DECALS (2PCS)

16.CASTOR (2PCS)

17.LEFT DOOR

PA

PARTS REQUIRED

RTS REQUIRED / INVENTORY

PAPA

RTS REQUIREDRTS REQUIRED

Make sure you thoroughly inspect parts before assembly and do not assemble or operate a barbecue that

appears damaged.

/ INVENTORY

/ INVENTORY / INVENTORY

ITEM

ITEM

ITEMITEM

A

B

C

D

E

The use of an adjustable spanner and a Phillips screwdriver will be required.

PICTURE

PICTURE NAME AND QUANTITY

PICTUREPICTURE

NAME AND QUANTITY ITEM

NAME AND QUANTITYNAME AND QUANTITY

SCREW M6X16….…..14PCS F

SCREW M5X15….…..36PCS G

SCREW M4X8…….......6PCS H

SCREW M3X12….…....4PCS I

FLAT HEAD SCREW..…4PCS J

ITEM PICTURE

ITEMITEM

PICTURE NAME AND QUANTITY

PICTUREPICTURE

NAME AND QUANTITY

NAME AND QUANTITYNAME AND QUANTITY

NUT M6........................ 14PCS

LOCK NUT M10….…...…2PCS

LOCK NUT M3……....…..4PCS

SPRING WASHER D6.....14PCS

FIBRE WASHER M5.........4PCS

Page 12

12

STEP 1: Fitting the wheels and castors to the trolley bottom plate.

STEP 1: Fitting the wheels and castors to the trolley bottom plate.

STEP 1: Fitting the wheels and castors to the trolley bottom plate.STEP 1: Fitting the wheels and castors to the trolley bottom plate.

PARTS REQUIRED

PARTS REQUIRED

PARTS REQUIRED PARTS REQUIRED

ITEM

ITEM

ITEMITEM

A

I

FIGURE

FIGURE NAME AND QUANTITY

FIGUREFIGURE

NAME AND QUANTITY ITEM

NAME AND QUANTITYNAME AND QUANTITY

SCREW M6X16…..….14PCS F

SPRING WASHER......14PCS G

ITEM FIGURE

ITEMITEM

FIGURE NAME AND QUANTITY

FIGUREFIGURE

NAME AND QUANTITY

NAME AND QUANTITYNAME AND QUANTITY

NUT M6........................14PCS

LOCK NUT M10……...…2PCS

Fix the axle to the trolley bottom panel using six screws, spring washers and nuts. Fit the wheels onto the axle

with the large lock nuts, and cover with the wheel decals. Fix the castors to the trolley bottom panel using

eight screws, spring washers and nuts. Tighten all nuts firmly.

STEP 2: Fitting the door magnets to the trolley top and bottom pa

STEP 2: Fitting the door magnets to the trolley top and bottom pannnneeeelllls.

STEP 2: Fitting the door magnets to the trolley top and bottom paSTEP 2: Fitting the door magnets to the trolley top and bottom pa

PARTS REQUIRED

PARTS REQUIRED

PARTS REQUIRED PARTS REQUIRED

ITEM

ITEM

ITEMITEM

D

FIGURE

FIGURE NAME AND QUANTITY

FIGUREFIGURE

NAME AND QUANTITY ITEM

NAME AND QUANTITYNAME AND QUANTITY

SCREW M3X12…........4PCS H

ITEM FIGURE

ITEMITEM

FIGURE NAME AND QUA

FIGUREFIGURE

s.

s.s.

NAME AND QUANTITY

NAME AND QUANAME AND QUA

LOCK NUT M3…….....…4PCS

NTITY

NTITYNTITY

Place a door magnet on the trolley bottom panel (over the mounting bracket) and fix in place using two M3

screws and two M3 nuts. Repeat for the trolley top panel.

10

D

H

9

15

Page 13

13

STEP 3: Fitting the trolley rear panel to the trolley bottom pa

STEP 3: Fitting the trolley rear panel to the trolley bottom pannnneeeellll....

STEP 3: Fitting the trolley rear panel to the trolley bottom paSTEP 3: Fitting the trolley rear panel to the trolley bottom pa

PARTS REQUI

PARTS REQUIRED

PARTS REQUIPARTS REQUI

ITEM

ITEM

ITEMITEM

B

FIGURE

FIGURE NAME AND QUANTITY

FIGUREFIGURE

RED

RED RED

NAME AND QUANTITY

NAME AND QUANTITYNAME AND QUANTITY

SCREW M5X15…..............2PCS

Align the trolley rear panel over the rear edge of the trolley bottom panel and fix into place with two M5 screws

(the edges should be flush). Tighten the screws firmly.

STEP 4: Fitting the trolley side panels to the trolley bottom p

STEP 4: Fitting the trolley side panels to the trolley bottom panel

STEP 4: Fitting the trolley side panels to the trolley bottom pSTEP 4: Fitting the trolley side panels to the trolley bottom p

PARTS REQUIRED

PARTS REQUIRED

PARTS REQUIRED PARTS REQUIRED

ITEM

ITEM

ITEMITEM

B

FIGURE

FIGURE NAME AND QUANTITY

FIGUREFIGURE

NAME AND QUANTITY

NAME AND QUANTITYNAME AND QUANTITY

SCREW M5X15…..............8PCS

anel....

anelanel

Align the left hand trolley side panel (with the access hole for the hose and regulator to the top front corner) on

top of the left hand edge of the trolley bottom panel and in front of the trolley rear panel. Fix into place using

four M5 screws. Repeat for the right hand trolley side panel. Tighten the screws firmly.

Page 14

14

STEP 5: Fitting the

STEP 5: Fitting the door posts

STEP 5: Fitting the STEP 5: Fitting the

door posts to th

door postsdoor posts

to the trolley bottom panel

to th to th

e trolley bottom panel and side panels

e trolley bottom panele trolley bottom panel

and side panels....

and side panels and side panels

PARTS REQUIRED

PARTS REQUIRED

PARTS REQUIRED PARTS REQUIRED

ITEM

ITEM

ITEMITEM

B

Align a door post so that the larger face is at the front, and the large return is against the trolley side panel. Fix

into place with two M5 screws through the bottom of the door panel into the trolley bottom panel, and two M5

screws through the front edge of the side panel and into the door post. Repeat for the other door post.

Tighten the screws firmly.

FIGURE

FIGURE NAME AND QUANTITY

FIGUREFIGURE

NAME AND QUANTITY

NAME AND QUANTITYNAME AND QUANTITY

SCREW M5X15…..............8PCS

STEP

STEP 6666: Fitting the trolley

STEP STEP

: Fitting the trolley top

: Fitting the trolley : Fitting the trolley

PARTS REQUIRED

ITEM

ITEM

ITEMITEM

B

FIGURE

FIGURE NAME AND QUANTITY

FIGUREFIGURE

NAME AND QUANTITY

NAME AND QUANTITYNAME AND QUANTITY

SCREW M5X15…..............10PCS

top panel.

panel.

toptop

panel. panel.

Place the trolley top panel (door magnet to the front) on a protected surface and align the rest of the trolley on

top of it. Fix the trolley top panel to the 5 panels with ten M5 screws. Tighten the screws firmly.

Page 15

15

STEP

STEP 7777: Fitting

STEP STEP

PARTS REQUIRED

PARTS REQUIRED

PARTS REQUIRED PARTS REQUIRED

ITEM

ITEM

ITEMITEM

C

: Fitting the

: Fitting: Fitting

FIGURE

FIGURE NAME AND QUANTITY

FIGUREFIGURE

the door handles and doors

door handles and doors....

the the

door handles and doorsdoor handles and doors

NAME AND QUANTITY

NAME AND QUANTITYNAME AND QUANTITY

SCREW M4X8..…..............4PCS

Screw the two door handles to the fronts of the doors using two M4 screws each. To fit the doors into

the trolley, firstly place the bottom (fixed) hinge into the door hole in the trolley bottom panel, then fit the

top hinge by squeezing the spring hinge down and angling the door into place (the spring hinge will

extend to fit the hole in the trolley top panel).

STEP 8: Fitting the

STEP 8: Fitting the barbecue body to the trolley

STEP 8: Fitting the STEP 8: Fitting the

barbecue body to the trolley....

barbecue body to the trolleybarbecue body to the trolley

PARTS REQUIRED

PARTS REQUIRED

PARTS REQUIRED PARTS REQUIRED

ITEM

ITEM

ITEMITEM

E

Place the barbecue body onto the trolley and line up the four mounting holes. Place a thin fiber washer

onto each of the four flat head screws, and screw the two parts down together. Keep the face of the

screws as flush as possible to the edge of the barbecue body, to help the fat tray slide. Take the four

cast iron burners and remove the wire clips. Fit the burners by placing its throat over a gas valve (behind

each control knob). Lower the tab at the rear of the burner into the hole in the rear of the barbecue body.

Remove the barbecue rear panel (4 screws) and clip the burners into place with the clips. Replace the

rear panel.

FIGURE

FIGURE NAME AND QUANT

FIGUREFIGURE

NAME AND QUANTITY

NAME AND QUANTNAME AND QUANT

FLAT HEAD SCREW M5..4PCS J

ITY ITEM

ITYITY

ITEM FIGURE

ITEMITEM

FIGURE NAME AND QUANTITY

FIGUREFIGURE

NAME AND QUANTITY

NAME AND QUANTITYNAME AND QUANTITY

FIBRE WASHER M5.........4PCS

Page 16

16

STEP 9: Fitting the fat tray handle and fat tray.

STEP 9: Fitting the fat tray handle and fat tray.

STEP 9: Fitting the fat tray handle and fat tray.STEP 9: Fitting the fat tray handle and fat tray.

PARTS REQUIRED

PARTS REQUIRED

PARTS REQUIRED PARTS REQUIRED

ITEM

ITEM

ITEMITEM

C

FIGURE

FIGURE NAME AND QUANTITY

FIGUREFIGURE

NAME AND QUANTITY

NAME AND QUANTITYNAME AND QUANTITY

SCREW M4X8…..............2PCS

Screw the fat tray handle to the fat tray, and slide the fat tray into the bottom of the barbecue body.

STEP 10A

STEP 10A ((((GRANDE

STEP 10A STEP 10A

PART

PARTS REQUIRED

S REQUIRED

PARTPART

S REQUIRED S REQUIRED

ITEM

ITEM

ITEMITEM

B

GRANDE MODEL ONLY

GRANDEGRANDE

FIGURE

FIGURE NAME AND QUANTITY

FIGUREFIGURE

MODEL ONLY)))) Fitting the wok servery, and the servery and drawer.

MODEL ONLY MODEL ONLY

NAME AND QUANTITY ITEM

NAME AND QUANTITYNAME AND QUANTITY

SCREW M5X15…............8PCS C

Fitting the wok servery, and the servery and drawer.

Fitting the wok servery, and the servery and drawer. Fitting the wok servery, and the servery and drawer.

ITEM FIGURE

ITEMITEM

FIGURE NAME AND QUANTITY

FIGUREFIGURE

NAME AND QUANTITY

NAME AND QUANTITYNAME AND QUANTITY

SCREW M4X8……..........2PCS

Secure the wok servery to the left hand side of the barbecue body by threading four M5 screws through the

mounting holes in the wok servery, screwing them into the body. Tighten them all firmly. Connect the wok

hose to the main manifold (the hose should loop around & not kink

kink), and tighten carefully with an adjustable

kinkkink

spanner or correctly sized spanner (leak test as per page 4 before using the appliance). Attach the servery

bracket to the bottom of the right hand servery using the two M4 screws. Repeat the mounting method for

the right hand side servery and fit the drawer into the slides. NOTE: The drawer can be removed by turning the

switches on each of the slides; take care, as the drawer is NOT permanently attached to the servery. Attach

the match holder chain to the bottom of the right hand servery.

Page 17

17

STEP 10B

STEP 10B ((((GROSSO

STEP 10B STEP 10B

PARTS REQUIRED

PARTS REQUIRED

PARTS REQUIRED PARTS REQUIRED

ITEM

ITEM

ITEMITEM

B

Secure the wok servery to the left hand side of the barbecue body by threading four M5 screws through the

mounting holes in the wok servery, screwing them into the body. Tighten them all firmly. Connect the wok

hose to the main manifold (the hose should loop around & not kink

spanner or correctly sized spanner (leak test as per page 4 before using the appliance). Repeat the mounting

method for the right hand side servery. Attach the match holder chain to the bottom of the right hand servery.

GROSSO MODEL ONLY

GROSSOGROSSO

FIGURE

FIGURE NAME AND QUANTITY

FIGUREFIGURE

MODEL ONLY)))) Fitting the

MODEL ONLY MODEL ONLY

NAME AND QUANTITY

NAME AND QUANTITYNAME AND QUANTITY

SCREW M5X15…..............8PCS

Fitting the wok servery, and the servery.

Fitting the Fitting the

wok servery, and the servery.

wok servery, and the servery.wok servery, and the servery.

kink), and tighten carefully with an adjustable

kinkkink

STEP 11: Fitting the vapouriser, grill plate and hot plate.

STEP 11: Fitting the vapouriser, grill plate and hot plate.

STEP 11: Fitting the vapouriser, grill plate and hot plate.STEP 11: Fitting the vapouriser, grill plate and hot plate.

Place the hot plate on the left hand side of the barbecue body, and the vapouriser inside the right hand side of

the barbecue body with the grill plate over it. The baking dish handles should be fitted at either end and the

baking dish fitted between the plate and grill. Run the gas hose through the access hole in the left hand

trolley side. The gas cylinder sits in the recess within the trolley bottom panel. Set all control knobs to Off

before connecting the regulator to the cylinder and turning on the gas. See page 4 for leak testing instructions.

NOTE: The warming rack can be fitted onto the four brackets inside the hood.

Off

Off Off

Page 18

18

Fully Assembled Product

Fully Assembled Product (

Fully Assembled ProductFully Assembled Product

(Grande

Grande))))

( (

GrandeGrande

Page 19

19

Fully Assembled Product (

Fully Assembled Product (Grosso

Fully Assembled Product (Fully Assembled Product (

Grosso))))

GrossoGrosso

Page 20

20

All Service, Assembly and Warranty Enquiries:

All Service, Assembly and Warranty Enquiries:

All Service, Assembly and Warranty Enquiries:All Service, Assembly and Warranty Enquiries:

Telepho

Telephone: 1300 766 066

TelephoTelepho

ne: 1300 766 066

ne: 1300 766 066ne: 1300 766 066

Neo by Everdure

Neo by Everdure

Neo by EverdureNeo by Everdure

A division of Shriro Australia Pty Ltd

23-27 Chaplin Drive Lane Cove NSW 2066

Telephone: 1300 766 066

Telephone: 1300 766 066

Telephone: 1300 766 066Telephone: 1300 766 066

Loading...

Loading...