Page 1

PROGRAMMABLE CONTROLLERS

FOR SINGLE OR TWIN-CIRCUIT

CHILLERS - HEAT PUMPS

WITH UP TO 6 COMPRESSORS

APPLICATION MANUAL

CODE 144CHILNUE03

Page 2

C-PRO NANO CHIL AND C-PRO MICRO CHIL – APPLICATION MANUAL

Important Notice

This Instruction Manual should be read carefully before installation and before use, and all warnings relating to

installation and electrical connections should be observed; the Manual should then be kept for future reference.

All devices must be disposed of in accordance with local regulations governing the disposal of electrical and

electronic devices.

Pag. 2

Page 3

C-PRO NANO CHIL AND C-PRO MICRO CHIL – APPLICATION MANUAL

Table of Contents

1 General Information..................................................................................................................................................6

1.1 Description ......................................................................................................................................................6

2 Applications ..............................................................................................................................................................8

2.1 Air-to-air single-circuit chiller units and air-to-air single-circuit chiller units + heat pump..........................10

2.1.1 Air-to-air single-circuit chiller units ....................................................................................................10

2.1.2 Air-to-air single-circuit chiller units + heat pump................................................................................12

2.2 Air-to-water single-circuit chiller units and air-to-water single-circuit chiller units + heat pump ................14

2.2.1 Air-to-water single-circuit chiller units................................................................................................14

2.2.2 Air-to-water single-circuit chiller units + heat pump...........................................................................16

2.3 Water-to-water single-circuit chiller units and water-to-water single-circuit chiller units + heat pump .......18

2.3.1 Water-to-water single-circuit chiller units ...........................................................................................18

2.3.2 Water-to-water single-circuit chiller units + heat pump....................................................................... 20

2.4 Single-circuit motocondensing air-based units and single-circuit motocondensing air-based units with cycle

inversion.......................................................................................................................................................................22

2.4.1 Single-circuit motocondensing air-based units ....................................................................................22

2.4.2 Single-circuit motocondensing air-based units with cycle inversion ...................................................24

2.5 Single-circuit motocondensing water-based units and single-circuit motocondensing water-based units with

cycle inversion .............................................................................................................................................................26

2.5.1 Single-circuit motocondensing water-based units................................................................................ 26

2.5.2 Single-circuit motocondensing water-based units with cycle inversion...............................................28

2.6 Air-to-air twin-circuit chiller units and air-to-air twin-circuit chiller units + heat pump ..............................30

2.6.1 Air-to-air twin-circuit chiller units.......................................................................................................30

2.6.2 Air-to-air twin-circuit chiller units + heat pump..................................................................................32

2.7 Air-to-water twin-circuit chiller units and air-to-water twin-circuit chiller units + heat pump .....................34

2.7.1 Air-to-water twin-circuit chiller units .................................................................................................. 34

2.7.2 Air-to-water twin-circuit chiller units + heat pump .............................................................................36

2.8 Water-to-water twin-circuit chiller units and water-to-water twin-circuit chiller units + heat pump ............ 38

2.8.1 Water-to-water twin-circuit chiller units..............................................................................................38

2.8.2 Water-to-water twin-circuit chiller units + heat pump.........................................................................40

2.9 Twin-circuit motocondensing air-based units and twin-circuit motocondensing air-based units with cycle

inversion.......................................................................................................................................................................42

2.9.1 Twin-circuit motocondensing air-based units......................................................................................42

2.9.2 Twin-circuit motocondensing air-based units with cycle inversion.....................................................44

2.10 Twin-circuit motocondensing water-based units and twin-circuit motocondensing water-based units with

cycle inversion .............................................................................................................................................................46

2.10.1 Twin-circuit motocondensing water-based units..................................................................................46

2.10.2 Twin-circuit motocondensing water-based units with cycle inversion ................................................48

2.11 Connection Layout of C-PRO MICRO CHIL and C-PRO EXP MICRO .....................................................50

2.11.1 Connection layout of C-PRO NANO CHIL and C-PRO MICRO CHIL.............................................50

2.11.2 Connection layout of C-PRO EXP MICRO.........................................................................................53

3 Component Network and Accessories ....................................................................................................................55

3.1 Example of C-PRO NANO CHIL .................................................................................................................55

3.2 Example of C-PRO MICRO CHIL (built-in version)....................................................................................56

3.3 Example of C-PRO MICRO CHIL (blind version) .......................................................................................57

4 USER INTERFACE................................................................................................................................................58

4.1 Displays and Keyboards ................................................................................................................................58

4.2 List of Pages ..................................................................................................................................................62

5 Parameter List .........................................................................................................................................................68

5.1 List of Configuration Parameters...................................................................................................................69

6 REGULATIONS..................................................................................................................................................... 82

6.1 Machine Status ..............................................................................................................................................82

6.2 Unit Type....................................................................................................................................................... 83

6.2.1 Single-circuit air-to-air units ................................................................................................................83

6.2.2 Single-circuit air-to-water units ...........................................................................................................84

6.2.3 Single-circuit water-to-water units.......................................................................................................85

6.2.4 Single-circuit motocondensing air-based units ....................................................................................86

Pag. 3

Page 4

C-PRO NANO CHIL AND C-PRO MICRO CHIL – APPLICATION MANUAL

6.2.5 Single-circuit motocondensing water-based units................................................................................ 87

6.2.6 Twin-circuit air-to-air units.................................................................................................................. 88

6.2.7 Twin-circuit air-to-water units ............................................................................................................. 90

6.2.8 Twin-circuit water-to-water units......................................................................................................... 92

6.2.9 Twin-circuit motocondensing air-based units......................................................................................94

6.2.10 Twin-circuit motocondensing water-based units..................................................................................96

6.3 Configuration of Circuits...............................................................................................................................98

6.4 Operating Mode Control................................................................................................................................99

6.4.1 Heat-pump-only mode ....................................................................................................................... 100

6.4.2 Geothermal heat pumps......................................................................................................................100

6.5 Compressor Regulation ...............................................................................................................................101

6.5.1 Lateral-band (LB) regulation ............................................................................................................101

6.5.2 Neutral-zone (NZ) regulation.............................................................................................................102

6.5.3 Compressor activation from digital input...........................................................................................103

6.6 Compressor Management ............................................................................................................................104

6.6.1 Compressor statuses...........................................................................................................................104

6.6.2 Rotation of compressors.....................................................................................................................104

6.6.3 Pump-down switch-OFF procedure ...................................................................................................105

6.6.4 Relative-threshold pump-down.......................................................................................................... 105

6.6.5 Protection timings ..............................................................................................................................106

6.6.6 Thermal protection inputs .................................................................................................................. 107

6.7 Condensation Regulation.............................................................................................................................108

6.7.1 Fan linear regulation .......................................................................................................................... 108

6.7.2 Condensing valve regulation.............................................................................................................. 110

6.7.3 Condensing fan pre-start at high external temperatures.....................................................................110

6.7.4 Single condensation ........................................................................................................................... 110

6.8 Fan Management .........................................................................................................................................111

6.8.1 Fan status ...........................................................................................................................................111

6.8.2 Fan timings......................................................................................................................................... 111

6.8.3 Thermal Protection Inputs.................................................................................................................. 111

6.9 Circulating Pump Management ...................................................................................................................112

6.9.1 Pump Status........................................................................................................................................113

6.10 Internal Fan Management............................................................................................................................113

6.10.1 Hot-start function...............................................................................................................................113

6.10.2 Recirculating fan status...................................................................................................................... 114

6.11 Flow Meter Management.............................................................................................................................114

6.12 Defrosting Management ..............................................................................................................................116

6.12.1 Defrosting management via external contact .....................................................................................117

6.12.2 Defrosting cycle compensation.......................................................................................................... 117

6.12.3 Defrosting heating coil.......................................................................................................................118

6.13 Anti-frost management / Chilling-support heating coils..............................................................................118

6.14 Free-Cooling Management..........................................................................................................................119

6.14.1 Free-Cooling Enable .......................................................................................................................... 119

6.14.2 Free-cooling regulation......................................................................................................................119

6.14.3 Free-cooling control valves................................................................................................................121

6.15 Temperature Alarm Control ........................................................................................................................122

6.15.1 Low and high temperature alarm management ..................................................................................122

6.15.2 Management of primary exchanger efficiency alarm.........................................................................122

6.16 Pressure Alarm Control ...............................................................................................................................123

6.16.1 Management of high-pressure pressure-switch alarm........................................................................123

6.16.2 Management of high-pressure transducer alarm ................................................................................123

6.16.3 Management of low-pressure pressure-switch alarm (chiller mode) .................................................123

6.16.4 Management of low-pressure transducer alarm (heat pump mode) ...................................................123

6.16.5 Low start-up pressure alarm...............................................................................................................124

6.17 Miscellaneous Management ........................................................................................................................125

6.17.1 Set point variation..............................................................................................................................125

6.17.2 External probe configuration (AI04 / AI05).......................................................................................125

6.17.3 Evaporation-probe configuration .......................................................................................................126

6.17.4 Dynamic set point ..............................................................................................................................126

6.17.5 Forced shutdown................................................................................................................................127

6.17.6 Power limiting....................................................................................................................................128

6.17.7 High-pressure partialisation at high temperatures (chiller) ................................................................128

Pag. 4

Page 5

C-PRO NANO CHIL AND C-PRO MICRO CHIL – APPLICATION MANUAL

6.17.8 Low-pressure partialisation at low temperatures (heat pump) ...........................................................129

6.17.9 Operating limit management (heat pump)..........................................................................................131

6.17.10 Function for chilling/heating on demand.......................................................................................131

6.17.11 Manual operation...........................................................................................................................132

6.17.12 Resetting of default parameters..................................................................................................... 133

6.17.13 Programming key .......................................................................................................................... 133

7 DIAGNOSTICS.................................................................................................................................................... 134

7.1 Manual and Automatic Alarms....................................................................................................................134

7.1.1 Manual-reset alarms...........................................................................................................................134

7.1.2 Automatic-reset alarms ......................................................................................................................134

7.2 Alarm Table................................................................................................................................................. 135

7.3 Alarm Relay.................................................................................................................................................136

8 List of Modbus® Variables....................................................................................................................................137

Pag. 5

Page 6

C-PRO NANO CHIL AND C-PRO MICRO CHIL – APPLICATION MANUAL

1 General Information

1.1 Description

C-PRO NANO CHIL and C-PRO MICRO CHIL are two new families of innovative programmable

controllers, which are both flexible and modular, as well as being capable satisfying all application,

technical and cost requirements of modern single and twin-circuit chillers, with capacity from 4 to

450 KW and up to 6 compressors.

The features of the C-PRO NANO and MICRO CHIL controllers – contained size, I/O availability,

price, etc. – enable, for the very first time, the use of programmable devices even in low-complexity

machines such as chillers - heat pumps with a single circuit, capacity from 4 to 80 KW and up to 3

compressors, where until recently it had only been possible to utilise rigid parameter-based

controllers. By connecting to a C-PRO NANO and MICRO CHIL the C-PRO EXP MICRO I/O

expansion, the advantages in control and price offered by the use of these programmable devices

are also extended to twin-circuit units up to 450 KW and 6 compressors.

The display on these products consists of a 4-digit LED display, with function icons, available in

both product families.

The C-PRO NANO and MICRO CHIL controllers feature:

• 9 inputs, three of which are analogue inputs (2 for NTC temperature probes and 1 for

pressure transducers

0-20 / 4-20 mA or for ratiometric transducers, 0-5 V), 5 are digital and 1 is analogue/digital

(i.e. configurable);

• 9 outputs, of which 3 are analogue (one PWM and two 4-20 mA or 0-10 V) and 6 are digital

(electromechanical relays); analogue outputs enable control of inverters for compressors and for

phase-cut speed regulators for fans.

Using the C-PRO EXP MICRO I/O expansion, I/O is doubled.

Thanks to their design and installation features, these controllers are easily installed – the C-PRO

NANO is panel-mounted, while the C-PRO MICRO is DIN-rail-mounted on an electrical board.

Using the EVKEY programming key, it is possible to upload/download parameters; in addition,

these controllers can be connected to RICS monitoring and supervisory systems.

The application software is created with UNI-PRO and is capable of managing air-to-air, air-towater, water-to-water and motocondensing units.

The following are only some of the numerous control functions available:

• free-cooling management

• pump-down management

• dynamic set point compensation

• double set-point that can be enabled from external contact

• possibility of managing up to 3 scroll compressors for each circuit

• possibility of managing compressors with inverter and fans with phase-cut module

• control of condensing pressure / linear or stepped evaporation

• operation as heat pump only

• activation of compressors from motocondensing machine input

• operation as heat pump with low external temperature

• version with one, two or no circulating pumps.

Pag. 6

Page 7

C-PRO NANO CHIL AND C-PRO MICRO CHIL – APPLICATION MANUAL

C-PRO NANO CHIL

C-PRO MICRO CHIL

Built-in version

C-PRO MICRO CHIL

Blind version

C-PRO MICRO CHIL

Open-frame version

Pag. 7

Page 8

C-PRO NANO CHIL AND C-PRO MICRO CHIL – APPLICATION MANUAL

2 Applications

Management of the following unit types is possible:

1) Air-to-air single-circuit chiller units and air-to-air single-circuit chiller units +

heat pump, using C-PRO NANO CHIL (or C-PRO MICRO CHIL).

Total number of analogue inputs: 4.

Total number of digital inputs: 5 (*).

Total number of analogue outputs: 1 + 2 optional.

Total number of digital outputs: 6.

2) Air-to-water single-circuit chiller units and air-to-water single-circuit chiller

units + heat pump, using C-PRO NANO CHIL (or C-PRO MICRO CHIL).

Total number of analogue inputs: 4.

Total number of digital inputs: 5 (*).

Total number of analogue outputs: 1 + 2 optional.

Total number of digital outputs: 6.

3) Water-to-water single-circuit chiller units and water-to-water single-circuit

chiller units + heat pump, using C-PRO NANO CHIL (or C-PRO MICRO CHIL).

Total number of analogue inputs: 4.

Total number of digital inputs: 5 (*).

Total number of analogue outputs: 1 + 2 optional.

Total number of digital outputs: 6.

4) Single-circuit motocondensing air-based units and single-circuit

motocondensing air-based units with cycle inversion, using C-PRO NANO CHIL (or C-PRO

MICRO CHIL).

Total number of analogue inputs: 4.

Total number of digital inputs: 5 (*).

Total number of analogue outputs: 1 + 2 optional.

Total number of digital outputs: 6.

5) Single-circuit motocondensing water-based units and single-circuit

motocondensing water-based units with cycle inversion, using C-PRO NANO CHIL (or C-PRO

MICRO CHIL).

Total number of analogue inputs: 4.

Total number of digital inputs: 5.

Total number of analogue outputs: 1 + 2 optional.

Total number of digital outputs: 6.

(*) Note: The total number of digital inputs is 6, if analogue input AI04 is used as additional digital

input (parameter PH44).

6) Air-to-air single-circuit chiller units and air-to-air single-circuit chiller units +

heat pump, using C-PRO NANO CHIL (or C-PRO MICRO CHIL) and C-PRO EXP

MICRO.

Total number of analogue inputs: 8.

Total number of digital inputs: 10 (*).

Total number of analogue outputs: 2 + 2 optional.

Total number of digital outputs: 12.

Pag. 8

Page 9

C-PRO NANO CHIL AND C-PRO MICRO CHIL – APPLICATION MANUAL

7) Air-to-water twin-circuit chiller units and air-to-water twin-circuit chiller units

+ heat pump, using C-PRO NANO CHIL (or C-PRO MICRO CHIL) and C-PRO EXP MICRO.

Total number of analogue inputs: 8.

Total number of digital inputs: 10 (*).

Total number of analogue outputs: 2 + 2 optional.

Total number of digital outputs: 12.

8) Water-to-water twin-circuit chiller units and water-to-water twin-circuit chiller

units + heat pump, using C-PRO NANO CHIL (or C-PRO MICRO CHIL) and C-PRO EXP

MICRO.

Total number of analogue inputs: 8.

Total number of digital inputs: 10 (*).

Total number of analogue outputs: 2 + 2 optional.

Total number of digital outputs: 12.

9) Twin-circuit motocondensing air-based units and twin-circuit motocondensing

air-based units with cycle inversion, using C-PRO NANO CHIL (or C-PRO MICRO CHIL) and

C-PRO EXP MICRO.

Total number of analogue inputs: 8.

Total number of digital inputs: 10 (*).

Total number of analogue outputs: 2 + 2 optional.

Total number of digital outputs: 12.

10) Twin-circuit motocondensing water-based units and twin-circuit

motocondensing water-based units with cycle inversion, using C-PRO NANO CHIL (or C-PRO

MICRO CHIL) and C-PRO EXP MICRO.

Total number of analogue inputs: 8.

Total number of digital inputs: 10 (*).

Total number of analogue outputs: 2 + 2 optional.

Total number of digital outputs: 12.

(*) Note: The total number of digital inputs is 12, if analogue inputs AI04 and AI08 are used as

additional digital inputs (parameters PH44, PH45).

Pag. 9

Page 10

C-PRO NANO CHIL AND C-PRO MICRO CHIL – APPLICATION MANUAL

2.1 Air-to-air single-circuit chiller units and air-to-air single-

circuit chiller units + heat pump

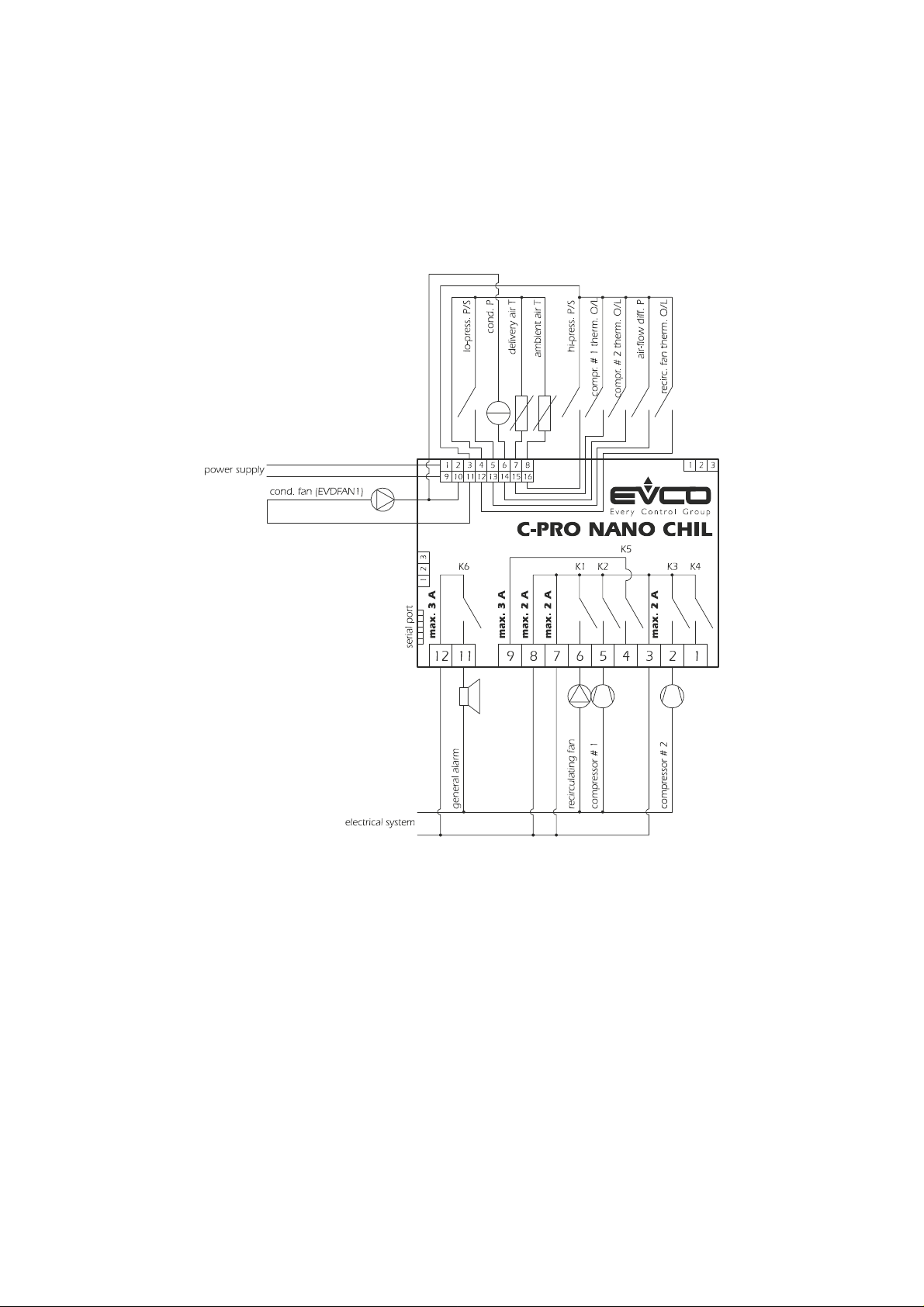

2.1.1 Air-to-air single-circuit chiller units

Using C-PRO NANO CHIL.

Pag. 10

Page 11

C-PRO NANO CHIL AND C-PRO MICRO CHIL – APPLICATION MANUAL

Using C-PRO MICRO CHIL.

Pag. 11

Page 12

C-PRO NANO CHIL AND C-PRO MICRO CHIL – APPLICATION MANUAL

2.1.2 Air-to-air single-circuit chiller units + heat pump

Using C-PRO NANO CHIL.

Pag. 12

Page 13

C-PRO NANO CHIL AND C-PRO MICRO CHIL – APPLICATION MANUAL

Using C-PRO MICRO CHIL.

Pag. 13

Page 14

C-PRO NANO CHIL AND C-PRO MICRO CHIL – APPLICATION MANUAL

2.2 Air-to-water single-circuit chiller units and air-to-water

single-circuit chiller units + heat pump

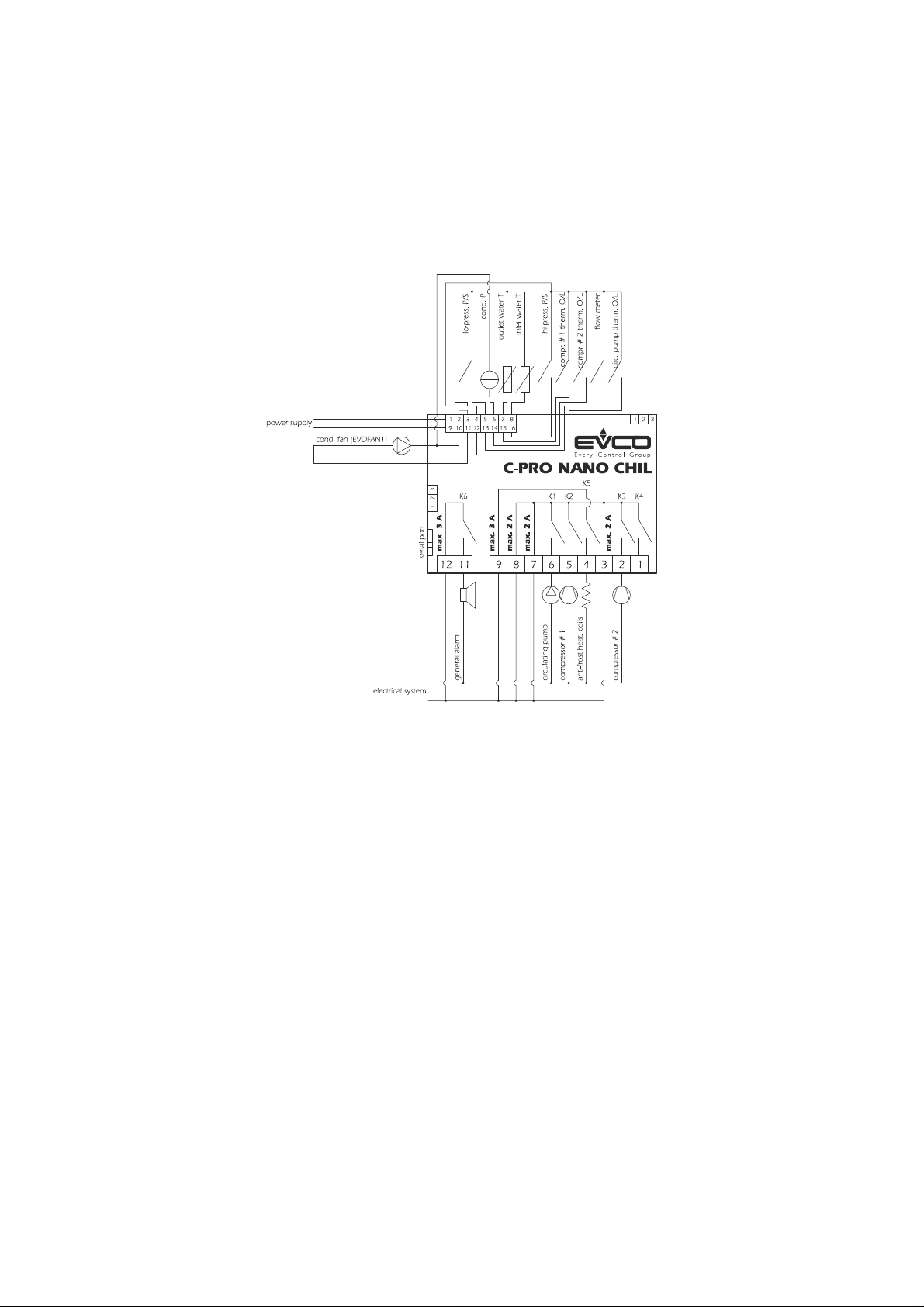

2.2.1 Air-to-water single-circuit chiller units

Using C-PRO NANO CHIL.

Pag. 14

Page 15

C-PRO NANO CHIL AND C-PRO MICRO CHIL – APPLICATION MANUAL

Using C-PRO MICRO CHIL.

Pag. 15

Page 16

C-PRO NANO CHIL AND C-PRO MICRO CHIL – APPLICATION MANUAL

2.2.2 Air-to-water single-circuit chiller units + heat pump

Using C-PRO NANO CHIL.

Pag. 16

Page 17

C-PRO NANO CHIL AND C-PRO MICRO CHIL – APPLICATION MANUAL

Using C-PRO MICRO CHIL.

Pag. 17

Page 18

C-PRO NANO CHIL AND C-PRO MICRO CHIL – APPLICATION MANUAL

2.3 Water-to-water single-circuit chiller units and water-to-

water single-circuit chiller units + heat pump

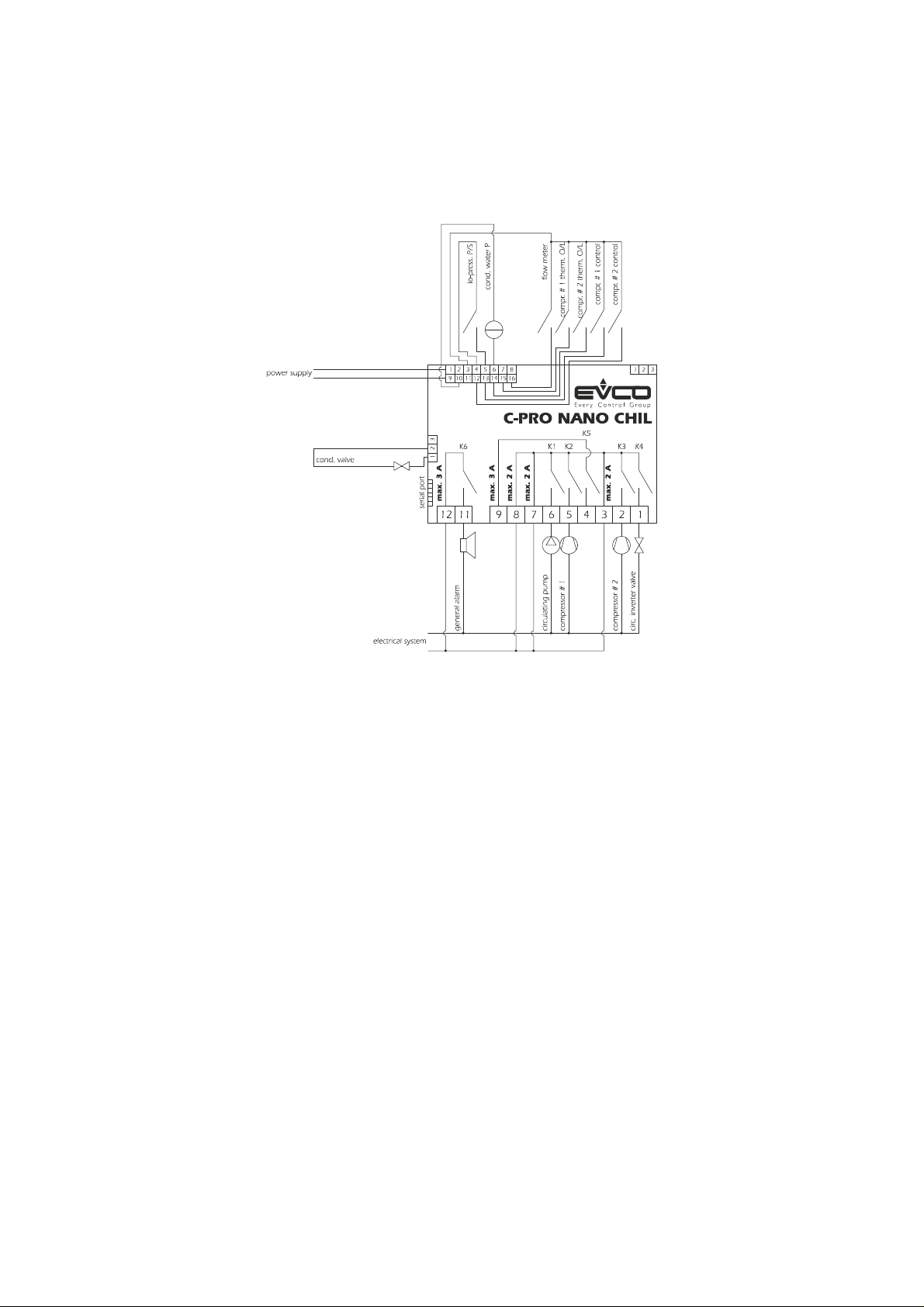

2.3.1 Water-to-water single-circuit chiller units

Using C-PRO NANO CHIL.

Pag. 18

Page 19

C-PRO NANO CHIL AND C-PRO MICRO CHIL – APPLICATION MANUAL

Using C-PRO MICRO CHIL.

Pag. 19

Page 20

C-PRO NANO CHIL AND C-PRO MICRO CHIL – APPLICATION MANUAL

2.3.2 Water-to-water single-circuit chiller units + heat pump

Using C-PRO NANO CHIL.

Pag. 20

Page 21

C-PRO NANO CHIL AND C-PRO MICRO CHIL – APPLICATION MANUAL

Using C-PRO MICRO CHIL.

Pag. 21

Page 22

C-PRO NANO CHIL AND C-PRO MICRO CHIL – APPLICATION MANUAL

2.4 Single-circuit motocondensing air-based units and single-

circuit motocondensing air-based units with cycle inversion

2.4.1 Single-circuit motocondensing air-based units

Using C-PRO NANO CHIL.

Pag. 22

Page 23

C-PRO NANO CHIL AND C-PRO MICRO CHIL – APPLICATION MANUAL

Using C-PRO MICRO CHIL.

Pag. 23

Page 24

C-PRO NANO CHIL AND C-PRO MICRO CHIL – APPLICATION MANUAL

2.4.2 Single-circuit motocondensing air-based units with cycle inversion

Using C-PRO NANO CHIL.

Pag. 24

Page 25

C-PRO NANO CHIL AND C-PRO MICRO CHIL – APPLICATION MANUAL

Using C-PRO MICRO CHIL.

Pag. 25

Page 26

C-PRO NANO CHIL AND C-PRO MICRO CHIL – APPLICATION MANUAL

2.5 Single-circuit motocondensing water-based units and single-

circuit motocondensing water-based units with cycle

inversion

2.5.1 Single-circuit motocondensing water-based units

Using C-PRO NANO CHIL.

Pag. 26

Page 27

C-PRO NANO CHIL AND C-PRO MICRO CHIL – APPLICATION MANUAL

Using C-PRO MICRO CHIL.

Pag. 27

Page 28

C-PRO NANO CHIL AND C-PRO MICRO CHIL – APPLICATION MANUAL

2.5.2 Single-circuit motocondensing water-based units with cycle inversion

Using C-PRO NANO CHIL.

Pag. 28

Page 29

C-PRO NANO CHIL AND C-PRO MICRO CHIL – APPLICATION MANUAL

Using C-PRO MICRO CHIL.

Pag. 29

Page 30

C-PRO NANO CHIL AND C-PRO MICRO CHIL – APPLICATION MANUAL

2.6 Air-to-air twin-circuit chiller units and air-to-air twin-circuit

chiller units + heat pump

2.6.1 Air-to-air twin-circuit chiller units

Using C-PRO NANO CHIL and C-PRO EXP MICRO.

The power supplies of C-PRO NANO CHIL and C-PRO EXP MICRO must be galvanically isolated from each

other.

Pag. 30

Page 31

C-PRO NANO CHIL AND C-PRO MICRO CHIL – APPLICATION MANUAL

Using C-PRO MICRO CHIL and C-PRO EXP MICRO.

The power supplies of C-PRO MICRO CHIL and C-PRO EXP MICRO must be galvanically isolated from each

other.

Pag. 31

Page 32

C-PRO NANO CHIL AND C-PRO MICRO CHIL – APPLICATION MANUAL

2.6.2 Air-to-air twin-circuit chiller units + heat pump

Using C-PRO NANO CHIL and C-PRO EXP MICRO.

The power supplies of C-PRO NANO CHIL and C-PRO EXP MICRO must be galvanically isolated from each

other.

Pag. 32

Page 33

C-PRO NANO CHIL AND C-PRO MICRO CHIL – APPLICATION MANUAL

Using C-PRO MICRO CHIL and C-PRO EXP MICRO.

The power supplies of C-PRO MICRO CHIL and C-PRO EXP MICRO must be galvanically isolated from each

other.

Pag. 33

Page 34

C-PRO NANO CHIL AND C-PRO MICRO CHIL – APPLICATION MANUAL

2.7 Air-to-water twin-circuit chiller units and air-to-water twin-

circuit chiller units + heat pump

2.7.1 Air-to-water twin-circuit chiller units

Using C-PRO NANO CHIL and C-PRO EXP MICRO.

The power supplies of C-PRO NANO CHIL and C-PRO EXP MICRO must be galvanically isolated from each

other.

Pag. 34

Page 35

C-PRO NANO CHIL AND C-PRO MICRO CHIL – APPLICATION MANUAL

Using C-PRO MICRO CHIL and C-PRO EXP MICRO.

The power supplies of C-PRO MICRO CHIL and C-PRO EXP MICRO must be galvanically isolated from each

other.

Pag. 35

Page 36

C-PRO NANO CHIL AND C-PRO MICRO CHIL – APPLICATION MANUAL

2.7.2 Air-to-water twin-circuit chiller units + heat pump

Using C-PRO NANO CHIL and C-PRO EXP MICRO.

The power supplies of C-PRO NANO CHIL and C-PRO EXP MICRO must be galvanically isolated from each

other.

Pag. 36

Page 37

C-PRO NANO CHIL AND C-PRO MICRO CHIL – APPLICATION MANUAL

Using C-PRO MICRO CHIL and C-PRO EXP MICRO.

The power supplies of C-PRO MICRO CHIL and C-PRO EXP MICRO must be galvanically isolated from each

other.

Pag. 37

Page 38

C-PRO NANO CHIL AND C-PRO MICRO CHIL – APPLICATION MANUAL

2.8 Water-to-water twin-circuit chiller units and water-to-water

twin-circuit chiller units + heat pump

2.8.1 Water-to-water twin-circuit chiller units

Using C-PRO NANO CHIL and C-PRO EXP MICRO.

The power supplies of C-PRO NANO CHIL and C-PRO EXP MICRO must be galvanically isolated from each

other.

Pag. 38

Page 39

C-PRO NANO CHIL AND C-PRO MICRO CHIL – APPLICATION MANUAL

Using C-PRO MICRO CHIL and C-PRO EXP MICRO.

The power supplies of C-PRO MICRO CHIL and C-PRO EXP MICRO must be galvanically isolated from each

other.

Pag. 39

Page 40

C-PRO NANO CHIL AND C-PRO MICRO CHIL – APPLICATION MANUAL

2.8.2 Water-to-water twin-circuit chiller units + heat pump

Using C-PRO NANO CHIL and C-PRO EXP MICRO.

The power supplies of C-PRO NANO CHIL and C-PRO EXP MICRO must be galvanically isolated from each

other.

Pag. 40

Page 41

C-PRO NANO CHIL AND C-PRO MICRO CHIL – APPLICATION MANUAL

Using C-PRO MICRO CHIL and C-PRO EXP MICRO.

The power supplies of C-PRO MICRO CHIL and C-PRO EXP MICRO must be galvanically isolated from each

other.

Pag. 41

Page 42

C-PRO NANO CHIL AND C-PRO MICRO CHIL – APPLICATION MANUAL

2.9 Twin-circuit motocondensing air-based units and twin-

circuit motocondensing air-based units with cycle inversion

2.9.1 Twin-circuit motocondensing air-based units

Using C-PRO NANO CHIL and C-PRO EXP MICRO.

The power supplies of C-PRO NANO CHIL and C-PRO EXP MICRO must be galvanically isolated from each

other.

Pag. 42

Page 43

C-PRO NANO CHIL AND C-PRO MICRO CHIL – APPLICATION MANUAL

Using C-PRO MICRO CHIL and C-PRO EXP MICRO.

The power supplies of C-PRO MICRO CHIL and C-PRO EXP MICRO must be galvanically isolated from each

other.

Pag. 43

Page 44

C-PRO NANO CHIL AND C-PRO MICRO CHIL – APPLICATION MANUAL

2.9.2 Twin-circuit motocondensing air-based units with cycle inversion

Using C-PRO NANO CHIL and C-PRO EXP MICRO.

The power supplies of C-PRO NANO CHIL and C-PRO EXP MICRO must be galvanically isolated from each

other.

Pag. 44

Page 45

C-PRO NANO CHIL AND C-PRO MICRO CHIL – APPLICATION MANUAL

Using C-PRO MICRO CHIL and C-PRO EXP MICRO.

The power supplies of C-PRO MICRO CHIL and C-PRO EXP MICRO must be galvanically isolated from each

other.

Pag. 45

Page 46

C-PRO NANO CHIL AND C-PRO MICRO CHIL – APPLICATION MANUAL

2.10 Twin-circuit motocondensing water-based units and twin-

circuit motocondensing water-based units with cycle

inversion

2.10.1 Twin-circuit motocondensing water-based units

Using C-PRO NANO CHIL and C-PRO EXP MICRO.

The power supplies of C-PRO NANO CHIL and C-PRO EXP MICRO must be galvanically isolated from each

other.

Pag. 46

Page 47

C-PRO NANO CHIL AND C-PRO MICRO CHIL – APPLICATION MANUAL

Using C-PRO MICRO CHIL and C-PRO EXP MICRO.

The power supplies of C-PRO MICRO CHIL and C-PRO EXP MICRO must be galvanically isolated from each

other.

Pag. 47

Page 48

C-PRO NANO CHIL AND C-PRO MICRO CHIL – APPLICATION MANUAL

2.10.2 Twin-circuit motocondensing water-based units with cycle inversion

Using C-PRO NANO CHIL and C-PRO EXP MICRO.

The power supplies of C-PRO NANO CHIL and C-PRO EXP MICRO must be galvanically isolated from each

other.

Pag. 48

Page 49

C-PRO NANO CHIL AND C-PRO MICRO CHIL – APPLICATION MANUAL

Using C-PRO MICRO CHIL and C-PRO EXP MICRO.

The power supplies of C-PRO MICRO CHIL and C-PRO EXP MICRO must be galvanically isolated from each

other.

Pag. 49

Page 50

C-PRO NANO CHIL AND C-PRO MICRO CHIL – APPLICATION MANUAL

c

o

n

n

e

c

t

o

r

#

3

(

i

f

r

e

q

u

e

s

t

e

d

)

connector # 5

connector # 4

connector # 1

C-PRO NANO CHIL

m

a

x

.

2

A

m

a

x

.

3

A

m

a

x

.

3

A

m

a

x

.

2

A

m

a

x

.

2

A

connector # 1

connector # 4

connector # 5

C-PRO MICRO CHIL

c

o

n

n

e

c

t

o

r

#

2

213

2.11 Connection Layout of C-PRO MICRO CHIL and C-PRO

EXP MICRO

2.11.1 Connection layout of C-PRO NANO CHIL and C-PRO MICRO CHIL

The connection layout of C-PRO NANO CHIL and C-PRO MICRO CHIL is shown below, with

related tables explaining the meaning of inputs and outputs.

C-PRO NANO CHIL:

connector # 2

C-PRO MICRO CHIL:

5136

4

10311

2

1

K6 K1 K2

12

14715816

K5

4 2

3 157 69 81112

1192

K3 K4

233

1

42 3 5 76 98 112112

K1 K2 K3 K4 K5 K6

16

15

7

8

max. 3 A

1461351241131029

max. 3 A

1

max. 3 A

connector # 3 (if requested)

max. 4 A

max. 3 A

3

Pag. 50

Page 51

C-PRO NANO CHIL AND C-PRO MICRO CHIL – APPLICATION MANUAL

Connector 1: Connection for relay outputs

C-PRO NANO CHIL

Conn. Label Description

C1-1 DO4 Normally open contact relay # 4

C1-2 DO3 Normally open contact relay # 3

C1-3 COMMON 1 Common relays # 1, 2, 3, 4

C1-4 DO5 Normally open contact relay # 5

C1-5 DO2 Normally open contact relay # 2

C1-6 DO1 Normally open contact relay # 1

C1-7 COMMON 1 Common relays # 1, 2, 3, 4

C1-8 COMMON 1 Common relays # 1, 2, 3, 4

C1-9 COMMON DO5 Common relay # 5

C1-10 Not in use

C1-11 DO6 Normally open contact relay # 6

C1-12 COMMON DO6 Common relay # 6

C-PRO NANO CHIL

Connector 1: Connection for relay outputs

Conn. Label Description

C1-1 DO1 Normally open contact relay # 1

C1-2 COMMON DO1 Common relay # 1

C1-3 DO2 Normally open contact relay # 2

C1-4 COMMON DO2 Common relay # 2

C1-5 DO3 Normally open contact relay # 3

C1-6 COMMON DO3 Common relay # 3

C1-7 DO4 Normally open contact relay # 4

C1-8 COMMON 1 Common relays # 4, 5

C1-9 DO5 Normally open contact relay # 5

C1-10 Not in use

C1-11 DO6 Normally open contact relay # 6

C1-12 COMMON DO6 Common relay # 6

Connector 2: Connection for EVKEY (parameter upload/download key) and output for

TTL-RS-485 module.

Connector 3: Connector for optional analogue outputs (AO2 and AO3)

Conn. Label Description (Version V+I)

C3-1 OUT1 0-10 V dc

C3-2 GND Common analogue output

C3-3 OUT2 0(4)-20 mA

Description (Version I+I)

C3-1 OUT1 0(4)-20 mA

C3-2 GND Common analogue output

C3-3 OUT2 0(4)-20 mA

Description (Version V+V)

C3-1 OUT1 0-10 V dc

C3-2 GND Common analogue output

C3-3 OUT2 0-10 V dc

Pag. 51

Page 52

C-PRO NANO CHIL AND C-PRO MICRO CHIL – APPLICATION MANUAL

Connector 4: Connector for low-voltage signals

Conn. Label Description

C4-1 12 V AC (power

supply)

C4-2 Not connected Not connected

C4-3 GND Common analogue and digital inputs

C4-4 GND Common analogue and digital inputs

C4-5 AI4 Analogue input # 4 (NTC probe, 0-20 or 4-20 mA transducer)

C4-6 AI3 Analogue input # 3 (NTC probe, 0-20 or 4-20 mA transducer)

C4-7 AI2 Analogue input # 2 (NTC probe)

C4-8 AI1 Analogue input # 1 (NTC probe)

C4-9 12 V AC (power

supply)

C4-10 12 V DC Power supply for current transducers and EVCO’s EVDFAN1 phase-cut

C4-11 AO1 Output for EVCO’s EVDFAN1 phase-cut module

C4-12 DI5 Digital input # 5

C4-13 DI4 Digital input # 4

C4-14 DI3 Digital input # 3

C4-15 DI2 Digital input # 2

C4-16 DI1 Digital input # 1

To enable the use of the EVDFAN1 phase-cut module, the controller must be powered by an alternating

current supply; the controller’s powering phase must be the same one that supplies the module.

Connector 5: Connector for EVCO remote keyboard / expansion

Conn. Label Description

C5-1 12 V DC Power supply for remote keyboard (12 V DC, 50 mA max.)

C5-2 GND Common

C5-3 SERIAL EVCO live serial port

Instrument power supply (12 V AC/DC)

Instrument power supply (12 V AC/DC)

module (12 V DC)

The power supplies of the controller and the expansion must be galvanically isolated from each other.

Pag. 52

Page 53

C-PRO NANO CHIL AND C-PRO MICRO CHIL – APPLICATION MANUAL

11

12

connector # 1

connector # 3

connector # 5

CONTROLLER

2.11.2 Connection layout of C-PRO EXP MICRO

The connection layout of C-PRO EXP MICRO is shown below, with related tables explaining the

meaning of inputs and outputs.

1

K7 K8 K9 K10 K11 K12

42 3 5 76 98

max. 3 A

max. 3 A

max. 3 A

max. 4 A

max. 3 A

C-PRO MICROEXP

1681571461351241131029

connector # 2

1

221

3

1

3

Connector 1: Connection for relay outputs

Conn. Label Description

C1-1 DO7 Normally open contact relay # 7

C1-2 COMMON DO7 Common relay # 7

C1-3 DO8 Normally open contact relay # 8

C1-4 COMMON DO8 Common relay # 8

C1-5 DO9 Normally open contact relay # 9

C1-6 COMMON DO9 Common relay # 9

C1-7 DO10 Normally open contact relay # 10

C1-8 COMMON 1 Common relays # 10, 11

C1-9 DO11 Normally open contact relay # 11

C1-10 Not in use

C1-11 DO12 Normally open contact relay # 12

C1-12 COMMON DO12 Common relay # 12

Connector 2: Connector for low-voltage signals

Conn. Label Description

C2-1 12 V AC (power

supply)

C2-2 Not connected Not connected

C2-3 GND Common analogue and digital inputs

C2-4 GND Common analogue and digital inputs

C2-5 AI8 Analogue input # 8 (4-20 mA transducer)

C2-6 AI7 Analogue input # 7 (4-20 mA transducer)

C2-7 AI6 Analogue input # 6 (NTC probe)

C2-8 AI5 Analogue input # 5 (NTC probe)

Instrument power supply (12 V AC/DC)

Pag. 53

Page 54

C-PRO NANO CHIL AND C-PRO MICRO CHIL – APPLICATION MANUAL

C2-9 12 V AC (power

supply)

C2-10 12 V DC Power supply for current transducers and EVCO’s EVDFAN1 phase-cut

C2-11 AO4 Output for EVCO’s EVDFAN1 phase-cut module

C2-12 DI11 Digital input # 11

C2-13 DI10 Digital input # 10

C2-14 DI9 Digital input # 9

C2-15 DI8 Digital input # 8

C2-16 DI7 Digital input # 7

To enable the use of the EVDFAN1 phase-cut module, the expansion must be powered by an alternating

current supply; the expansion’s powering phase must be the same one that supplies the module.

Connector 3: Connector for the controller

Conn. Label Description

C3-1 12 V DC Power supply (12 V DC, 50 mA max.)

C3-2 GND Common

C3-3 SERIAL EVCO live serial port

Instrument power supply (12 V AC/DC)

module (12 V DC)

The power supplies of the controller and the expansion must be galvanically isolated from each other.

Pag. 54

Page 55

C-PRO NANO CHIL AND C-PRO MICRO CHIL – APPLICATION MANUAL

3 Component Network and Accessories

3.1 Example of C-PRO NANO CHIL

Pag. 55

Page 56

C-PRO NANO CHIL AND C-PRO MICRO CHIL – APPLICATION MANUAL

3.2 Example of C-PRO MICRO CHIL (built-in version)

Pag. 56

Page 57

C-PRO NANO CHIL AND C-PRO MICRO CHIL – APPLICATION MANUAL

3.3 Example of C-PRO MICRO CHIL (blind version)

Pag. 57

Page 58

C-PRO NANO CHIL AND C-PRO MICRO CHIL – APPLICATION MANUAL

4 USER INTERFACE

4.1 Displays and Keyboards

For the application, two types of interface are provided:

⋅ a built-in 4-display interface with 7 segments;

⋅ a remote 4-display interface with 7 segments.

Both interfaces feature 4 keys for navigation/page editing, and differ in their display mode of

certain associated statuses, i.e. via icons (built-in version) or LED (remote version).

For both versions, a description is provided of the keys and LEDs used by the application; indeed,

according to the interface in use, it is possible to manage a different number of keys and LEDs.

Local built-in interface

The built-in interface is integrated into the controller being in use.

C-PRO NANO CHIL

C-PRO MICRO CHIL

(built-in version)

Pag. 58

Page 59

C-PRO NANO CHIL AND C-PRO MICRO CHIL – APPLICATION MANUAL

The keyboard features 4 page navigation and value editing keys, which have the following

functions:

- UP and DOWN: in editing, it modifies parameters; otherwise, it moves the cursor. If

pressed down and held for about 2 seconds during the display of the main page, the UP key

enables the display of the other probes, according to the following table.

tin

tou1

PrS1

tou2

PrS2

tEXt

Evp1

Evp2

tAcc

Inlet temperature probe (---, if disabled)

Circuit 1 outlet temperature probe (---, if disabled)

Circuit 1 condensing pressure probe (---, if disabled)

Circuit 2 outlet temperature probe (---, if disabled)

Circuit 2 condensing pressure probe (---, if disabled)

External temperature probe (---, if disabled)

Circuit 1 evaporating pressure probe (---, if disabled)

Circuit 2 evaporating pressure probe (---, if disabled)

Accumulation temperature probe (---, if disabled)

- SET / ENTER: During editing, it confirms the value; otherwise, it sends any

commands associated to the text where the cursor is positioned. If pressed down and held for

about 2 seconds, the ENTER key enables access to the main menu. If held down during

display of an alarm page, this key enables resetting of the alarm. If alarm pages are being

displayed, every key press scrolls all active alarms.

- STAND-BY / ESC: During editing, it cancels the value; otherwise, it requests any default

page that might be associated with the current page. If pressed down and held for about 2

seconds, the ESC key enables ON/OFF switching of the machine. If pressed in the main

page, this key enables access to the list of al active alarms.

In addition , the following icons are also used:

- Summer icon: This identifies the summer operating mode (chiller): if there is a request from

the thermoregulator, the icon remains lit, otherwise it flashes (stand-by). When the heat

pump is operating, it remains off. Its significance may be exchanged with that of the winter

icon, via parameter PH53.

- Winter icon: This identifies the winter operating mode (heat pump): it the thermoregulator

requests its, it remains lit, otherwise it flashes (stand-by). When the chiller is operating, it

remains off, unless free-cooling is enabled, in which case it flashes rapidly. The significance

may be exchanged with the summer icon via the PH53 parameter.

- Fan icon: This identifies the status of fans. If it is lit, at least one fan is on; if it flashes

slowly, at least one fan is in alarm condition; if it flashes rapidly, at least one fan is

operating in manual mode; otherwise, it remains off.

- Pump icon: This identifies the status of the pump or of the delivery fan. If it is lit, at least

one pump is on; if it flashes rapidly, this indicates that a timing is enabled; if it flashes

slowly, this indicates that at least in one of the two pumps (or delivery fan) thermal

protection has been triggered.

Pag. 59

Page 60

C-PRO NANO CHIL AND C-PRO MICRO CHIL – APPLICATION MANUAL

- Maintenance icon: This identifies a maintenance request. If it is lit, at least one compressor

or fan is operating manually; if it flashes, at least one compressor or fan has exceeded the

number of operating hours; otherwise, it remains off.

- Alarm icon: This identifies the presence of any alarms. If it is lit, alarms are present,

otherwise it remains off. If flashing, it indicates the presence of a new alarm that has yet to

be displayed. When the machine is shut down, the icon flashes in the presence of any

alarms.

- Icons 1, 2 ,3: These identify the status of the individual compressors. If it is lit, the

compressor is on; if it flashes slowly, the compressor is in an alarm condition; rapid flashing

indicates a current timing for an imminent shutdown or start-up; otherwise, it remains off. In

the case of a twin circuit, only icons 1 and 2 are used, to signify the following: lit means that

at least one compressor in that circuit is on; slow flashing means that at least one compressor

is in alarm condition; rapid flashing means that at least one compressor is operating

manually; otherwise, it remains off. These icons are enabled/disabled via the PH51

parameter.

- Anti-frost resistor icon: This identifies the status of setting and of the anti-frost alarm. If it

is lit, resistors are enabled; flashing indicates an active alarm; otherwise, it remains off.

- Stand-by icon: This is linked to the ESC key and identifies the machine status.

Off: The machine is off.

Lit: The machine is on.

Slow flashing: The machine has been shut down by a digital input.

Rapid flashing: The machine has been shut down by a supervisor.

- Defrosting icon: This identifies the defrosting status. If it is lit, a defrosting cycle is in

progress; slow flashing indicates a current timing cycle to start defrosting; rapid flashing

indicates dripping; otherwise, it remains off.

- °C/°F icon: This indicates the temperature measurement unit of the selected probe.

Pag. 60

Page 61

C-PRO NANO CHIL AND C-PRO MICRO CHIL – APPLICATION MANUAL

Remote interface

V LEDi

Panel-mounted version

V WALL

Wall-mounted version

The keyboard features 4 page-navigation and value-editing keys, which have the following

functions:

- UP and DOWN: During editing, it modifies parameters; otherwise, it moves the cursor. If

pressed down and held for about 2 seconds during the display of the main page, the UP key

enables the display of the other probes.

- SET / ENTER: During editing, it confirms the value; otherwise, it sends any commands

associated to the text where the cursor is positioned. If pressed down and held for about 2

seconds, the ENTER key enables access to the main menu. If held down during display of

an alarm page, this key enables resetting of the alarm. If alarm pages are being displayed,

every key press scrolls all active alarms.

- STAND-BY / ESC: During editing, it cancels the value; otherwise, it requests any default

page that might be associated with the current page. If pressed and held down for about 2

seconds, the ESC key enables switching on/freezing of the machine; if pressed in the main

page, it enables access to the list of all active alarms.

In addition, the following LEDs are also used:

- L1 = Summer LED: This identifies the summer operating mode (chiller): in case of a request

from the thermoregulator, it remains lit, otherwise it flashes (stand-by). When the heat pump

is operating, it remains off.

- L2 = Defrosting LED: This identifies the status of defrosting. If it is lit, a defrosting cycle is

in progress; slow flashing indicates a current timing cycle to start defrosting; rapid flashing

indicates dripping; otherwise, it remains off.

- L3 = Winter LED: This identifies the winter operating mode (heat pump): if there is a

request from the thermoregulator, it remains lit, otherwise it flashes (stand-by). When the

chiller is operating, it remains off, unless free-cooling is enabled, in which case it flashes

rapidly.

- L4 = Compressor LED: This identifies the status of compressors. If it is lit, at least one

compressor is on; if it flashes slowly, at least one compressor is in alarm condition; if it

Pag. 61

Page 62

C-PRO NANO CHIL AND C-PRO MICRO CHIL – APPLICATION MANUAL

flashes rapidly, at least one compressor is operating in manual mode; otherwise, it remains

off.

- L5 = Pump LED: This identifies the status of the pump or of the delivery fan. If it is lit, at

least one pump is on; if it flashes rapidly, this indicates that a timing is enabled; if it flashes

slowly, this indicates that at least in one of the two pumps (or delivery fan) a thermal

protection has been triggered.

- L6 = Alarm LED: This identifies the presence of any alarms. If it is lit, alarms are present,

otherwise it remains off. If flashing, it indicates the presence of a new alarm that has yet to

be displayed. When the machine is switched off, the LED flashes in the presence of any

alarms.

4.2 List of Pages

This chapter describes the main pages and menus featured in the application. As already described

earlier, the general menu is subdivided into four levels: user, maintenance operator, installation

operator, and constructor.

The menu structure is the following:

⋅ General Menu

⋅ User menu (Level 1)

⋅ Maintenance operator menu (Level 2)

o Operating branch maintenance menu

o Manual branch maintenance menu

o Calibration branch maintenance menu

o Input/output branch maintenance menu

⋅ Installation operator menu (Level 3)

o Compressor branch installation menu

o Setting branch installation menu

o Condensation branch installation menu

o Defrosting branch installation menu

o Pump branch installation menu

o Anti-frost branch installation menu

o Free-cooling branch installation menu

o Safety device branch installation menu

o Miscellaneous branch installation menu

⋅ Constructor menu (Level 4)

o Plant branch constructor menu (configuration wizard)

o Hardware branch constructor menu

o Parameter branch installation menu

Password

Each menu is assigned a level, which affects the accessibility of the various menus.

Each level is assigned a password, which enables access to the various functions featured in that

menu; once the correct password has been entered, protected functions become accessible. Entering

of the correct password has two consequences:

⋅ unlocking of the related level;

Pag. 62

Page 63

C-PRO NANO CHIL AND C-PRO MICRO CHIL – APPLICATION MANUAL

⋅ unlocking of its sublevels.

All level passwords can be modified from the same level or from higher levels. For example, from

the constructor level it will be possible to modify all passwords of underlying levels, by using the

appropriate page.

The range of values that can be set for a password is -999 / 9999.

After 4 minutes have elapsed without any key being pressed, the password expires and it is

necessary to reset it.

Main Page

The main display page varies according to the machine status, i.e. on or off:

- If the machine is switched OFF, OFF is displayed, or OFFd, if the cause for the

shutdown is a lack of consensus from digital input; otherwise OFFS is displayed, if

the shutdown is due to supervisor.

- If the machine is switched ON, the inlet temperature value is displayed (PC11=0),

the outlet value (PC11=1), or the required power (PC11=2), according to the setting

type (parameter PC11). In twin-circuit units, the average value of the two outlet

temperatures is displayed. If the probe is faulty o disconnected, “Err” is displayed.

From this page, by pressing the DOWN key for about 2 seconds, it is possible to display all

configured probes. In case of fault status of the probes, the value field of the corresponding probe

displays Err, or else --- if the probe is disabled.

Pressing the ESC key from this page brings the user back to the main page.

General Menu

The general menu has no levels and represents the access point to all other system menus.

USEr (USER Menu)

MAin ( MAINTENANCE Menu)

InSt (INSTALLATION Menu)

CoSt (CONSTRUCTOR Menu)

StAt (MACHINE STATUS Menu)

This menu can be displayed from any point of the user interface, holding down the ENTER key for

about 2 seconds. From this page, it possible to choose which menu to access via the UP and DOWN

keys, and then pressing the ENTER key to confirm the choice.

Pressing the ESC key from this menu, the user returns to the initial page, if the machine is switched

ON; or else to the OFF page, if the machine is OFF.

Pag. 63

Page 64

C-PRO NANO CHIL AND C-PRO MICRO CHIL – APPLICATION MANUAL

StAt Menu

Selecting the StAt item from the general menu, the user enters the display of some of the plant’s

main statuses:

Unit: indicates the machine’s current operating status (OFF, ChIL, pdC, dEFr, dRIp, F-

C).

tdF1: accumulated waiting time for a defrosting cycle of circuit # 1.

dFr1: duration time of defrosting of circuit # 1.

tdF2: accumulated waiting time for a defrosting cycle of circuit # 2.

dFr2: duration time of defrosting of circuit # 2.

SEtC: current set point for summer operation.

SEtH: current set point for winter operation.

PREq: power requirement [%]

PSup: power output [%]

CMP1, CMP2 .. CMP6: status of compressors (dIS, OFF, tOn, On, tOFF, ALAr,

MAnU).

FAn1, FAn 2: status of fans (dIS, OFF, tOn, On, tOFF, ALAr, MAnU).

InF1,InF2: speed of condensing fans [%]

InFC: value of free-cooling fan [%] (with separate air circuit, otherwise 0).

PMP1, PMP2: status of pumps (dIS, OFF, On, ALAr).

Pressing the ENTER key over the label, the corresponding status value is displayed, while pressing

the ESC key the display returns to the general menu. This menu has no password protection.

User Menu

The user menu is a Level 1 menu, i.e. it requires entering of the user level (or higher) password, in

order to be able to display/modify the parameters contained in this branch.

MOdE (summer/winter operating mode)

SPC1 (summer set point)

SPH1 (winter set point)

SSC1 (summer set point offset)

SSH1 (winter set point offset)

PSd1 (USER password)

It is possible to modify the various set points and offsets for the secondary set point.

Maintenance Operator Menu

The user menu is a Level 2 menu, i.e. it requires entering of the maintenance operator level (or

higher) password, in order to be able to display/modify the parameters contained in this branch.

Func (OPERATION menu)

MAnu (MANUAL menu)

CAL (CALIBRATION menu)

I-O (I/O STATUS menu)

PSd2 (MAINTENANCE OPERATOR password)

In this menu, it is possible to view the status of the various devices, inputs and outputs utilised by

the application.

Pag. 64

Page 65

C-PRO NANO CHIL AND C-PRO MICRO CHIL – APPLICATION MANUAL

In the OPERATION menu, it is possible to view/enable the features relating to the operation of

compressors, fans and pumps. Some examples of these are the hours of operation, the enabling of

the corresponding alarm and the threshold of maximum allowable hours.

In the MANUAL menu, it is possible to set to manual/automatic operation compressors and fans,

whose outputs can be forced, in order to test their functionality.

In the CALIBRATION menu, it is possible to set the corrections to be applied to analogue inputs, to

compensate the offsets due to cabling and probe positioning.

In the I/O STATUS menu, it is possible to view directly the card’s physical inputs and outputs.

Installation Operator Menu

The installation operator menu is a Level 3 menu, i.e. it requires entering of the installation operator

level (or higher) password, in order to be able to display/modify the parameters contained in this

branch.

CoMP (COMPRESSORS menu)

rEG (REGULATION menu)

Cond (CONDENSATION menu)

dEFr (DEFROSTING menu)

PuMP (PUMPS menu)

A-Fr (ANTI-FROST menu)

F-C (FREE-COOLING menu)

SEcu (SAFETY DEVICES menu)

PAr (VARIOUS PARAMETERS menu)

MAP (PARAMETER MAPS menu)

PSd3 (INSTALLATION OPERATOR password)

The installation operator menu contains all the parameters connected with the configuration of all

functionalities (alarms, settings, logic, rotation type, etc.) of the machine.

In the COMPRESSORS menu, it is possible to set the parameters connected with the management of

devices:

⋅ rotation

⋅ timings

⋅ maximum number of start-ups.

In the REGULATIONS menu, it is possible to set the parameters connected with lateral-band and

neutral-zone thermal regulation of compressors.

In the CONDENSATION menu, it is possible to set the parameters connected with the control of

condensation pressure, via the fans.

In the PUMPS menu, it is possible to set the parameters connected with operation and protection of

pumps.

In the DEFROSTING menu, it is possible to set the parameters connected with the activation and

duration of heat pump defrosting.

Pag. 65

Page 66

C-PRO NANO CHIL AND C-PRO MICRO CHIL – APPLICATION MANUAL

In the ANTI-FROST menu, it is possible to set the parameters connected with the thermal

regulation of resistors and control of the anti-frost alarm.

In the FREE-COOLING menu, it is possible to set the parameters connected with the enabling,

operation and activation of the free-cooling function.

The SAFETY DEVICES menu contains all parameters connected with alarms and management of

safety devices which protect the refrigerating circuit:

⋅ activations

⋅ reporting delays

⋅ type of resetting …

The VARIOUS PARAMETERS menu contains other general parameters connected with the

management of Modbus communications, transducer full-scale values and other configurable

activations.

The PARAMETER MAPS menu is accessible only with the machine in OFF mode. In this menu, it

is possible to re-establish factory-set parameters and to save or reload parameters from a

programming key. After each operation, it is necessary to switch OFF and then back ON the device.

Constructor Menu

The constructor menu is a Level 4 menu, i.e. it requires entering of the constructor level password,

in order to be able to display/modify the parameters contained in this branch. Furthermore, this

level is only accessible with the machine in OFF mode.

ConF (PLANT menu)

Hard (INPUT AND OUTPUT HARDWARE menu)

PSd4 (CONSTRUCTOR password)

This menu contains all the machine’s configuration parameters, which determine its operation mode

and which functionalities are to be enabled or disabled, according to the constructor’s requirements.

The PLANT menu contains a plant configuration wizard, which is used to set the number of circuits,

the number of compressors, the number of fans and the number of protection devices to be used

Once the configuration has been completed, a summary page is displayed, showing the configured

relays and digital inputs, with an indication of any need to use an expansion.

HARDWARE menus contain all parameters used for setting the positions to which the various

devices are to be connected.

⋅ Position of digital outputs of pumps, compressors and fans;

⋅ Position of inverter to be connected to analogue outputs;

⋅ Position of digital inputs/outputs of alarms.

Note: By setting the position of the various alarm inputs, their functionality is also enabled. Indeed,

an alarm is only enabled if the parameter which identifies its actual physical position on the

terminal has been set and is different from zero. If an alarm is not to be used, it is sufficient to leave

its corresponding parameter set to zero.

The same system is used to manage outputs, e.g. those of alarm relays: if position parameters have a

zero value, relay commands are disabled.

Pag. 66

Page 67

C-PRO NANO CHIL AND C-PRO MICRO CHIL – APPLICATION MANUAL

Project and Firmware Versions

Press simultaneously the UP+DOWN keys for about 2 seconds, then press the ENTER key on the

InFo label.

Information on the project and controller firmware versions is displayed sequentially, namely:

Project Number <-> Project Version <-> Project Revision <->

Firmware Number <-> Firmware Version <-> Firmware Revision <->

To scroll this information, use the UP and DOWN keys. To return to the application pages, press

the ESC key.

Pag. 67

Page 68

C-PRO NANO CHIL AND C-PRO MICRO CHIL – APPLICATION MANUAL

5 Parameter List

All parameters managed by the application are listed below. Each parameter is accompanied by a

brief description, the range of its admissible values, units of measure, the assigned default value and

the menu containing the parameter. Menu are structured on the basis of the following logic:

⋅ UT : User menu

⋅ MA: Maintenance operator menu

o MA-F: Operation branch maintenance menu

o MA-M: Manual branch maintenance menu

o MA-CA: Calibration branch maintenance menu

o MA-IO: Input/output branch maintenance menu

⋅ IS : Installation operator menu

o IS-R: Regulation branch installation menu

o IS-C: Compressor branch installation menu

o IS-F: Condensing fan branch installation menu

o IS-D: Defrosting branch installation menu

o IS-P: Pump branch installation menu

o IS-A: Anti-frost branch installation menu

o IS-FC: Free-cooling branch installation menu

o IS-S: Protection device branch installation menu

o IS-V: Various parameter branch installation menu

⋅ CO : Constructor menu

o CO-W: Plant branch construction menu

o CO-Hw: Hardware branch construction menu

o CO-Pa: Parameter branch installation menu

Pag. 68

Page 69

C-PRO NANO CHIL AND C-PRO MICRO CHIL – APPLICATION MANUAL

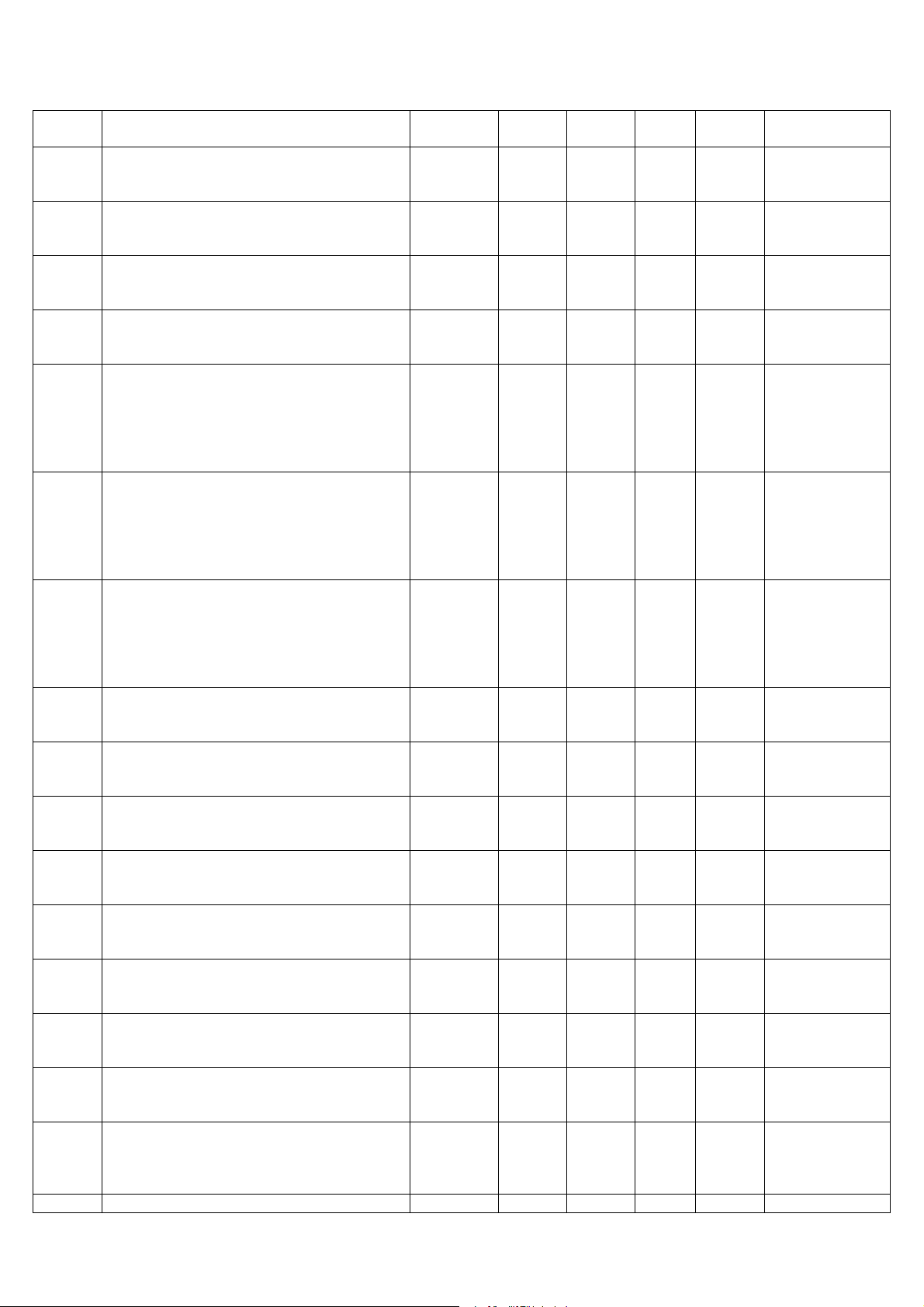

5.1 List of Configuration Parameters

Code

It sets the operating mode:

ModE

0: CooL, (Chiller/summer)

1: hEAt (Heat pump/winter)

SPC1

SSC1

SPH1

SSH1

It sets the value of the summer set point

(chiller)

It sets the offset value for the utilisation of the

secondary summer set point.

It sets the value of the winter set point (heat

pump).

It sets the offset value for the utilisation of the

secondary summer set point.

PSd1 It modifies the password at User level. 0 -999 9999 UT

It sets – in tens – the maximum number of

PM00

operating hours of compressors. When this

limit is exceeded, the connected alarm is

triggered.

PM01

PM02

PM03

PM04

PM05

It shows – in tens – the number of operating

hours of compressors. One parameter for each

compressor.

PM06

It sets – in tens – the maximum number of

PM30

operating hours of pumps / delivery fan. When

this limit is exceeded, the connected alarm is

triggered.

PM31

PM32

It shows – in tens – the number of operating

hours of the first pump / delivery fan.

It shows – in tens – the number of operating

hours of the second pump.

It sets – in tens – the maximum number of

PM40

operating hours of fans. When this limit is

exceeded, the connected alarm is triggered.

It shows – in tens – the number of operating

PM41

hours of the first fan or of the inverter in

Circuit # 1.

It shows – in tens – the number of operating

PM42

hours of the second fan or of the inverter in

Circuit # 2.

PM91

PM92

PM93

PM11

PM12

It sets the date (year) when the last plant

maintenance was carried out.

It sets the date (month) when the last plant

maintenance was carried out.

It sets the date (day) when the last plant

maintenance was carried out.

It enables the manual/automatic operation of

the compressor.

Parameter Description Default Min. Max. M.U. Menu Notes

USER PARAMETERS

0 0 1 UT

8.5 PC21 PC22 °C UT

0.0 -20.0 20.0 °C UT

44.0 PC23 PC24 °C UT

0.0 -20.0 20.0 °C UT

MAINTENANCE PARAMETERS

hours

2000 0 9999

x

10

MA-F

hours

0 0 9999

x

10

MA-F

hours

2000 0 9999

x

10

MA-F

hours

0 0 9999

x

10

MA-F

hours

0 0 9999

x

10

MA-F

hours

2000 0 9999

x

10

MA-F

hours

0 0 9999

x

10

MA-F

hours

0 0 9999

x

10

MA-F

MA-

2007 2007 2060

F«

1 1 12 MA-F

1 1 31 MA-F

0 0 1 MA-M

Modifiable only

if the units is a

chiller + heat

pump:

(PG00=2,4,6,8,1

0 e PG08=0)

Pag. 69

Page 70

C-PRO NANO CHIL AND C-PRO MICRO CHIL – APPLICATION MANUAL

PM13

PM14

PM15

0: Auto – normal operation

1: Manu – manual operation

One for each compressor.

PM16

PM21

PM22

PM23

PM24

PM25

PM26

During manual operation, it forces the start-

up/shutdown of the compressor. 0: switches

the compressor OFF

1: switches the compressor ON

One for each compressor.

0 0 1 MA-M

It enables the manual/automatic operation of

PM51

the condensing fan in Circuit # 1.

0: Auto – normal operation

0 0 1 MA-M

1: Manu – manual operation

It enables the manual/automatic operation of

PM52

the condensing fan in Circuit # 2.

0: Auto – normal operation

0 0 1 MA-M

1: Manu – manual operation

PM61

PM62

During manual operation, it forces the value of

the condensing fan in Circuit # 1.

During manual operation, it forces the value of

the condensing fan in Circuit # 2.

0.0 0.0 100.0 % MA-M

0.0 0.0 100.0 % MA-M

It enables the manual/automatic operation of

PM71

the free-cooling fan.

0: Auto – normal operation

0.0 0.0 100.0 % MA-M

1: Manu – manual operation

PM72

PM81

PM82

PM83 Calibration of condensing probe in Circuit # 1 0.0 -20.0 20.0 Bar

PM84 Calibration of the AI04 probe 0.0 -20.0 20.0 Bar/°C

PM85 Calibration of the AI05 probe 0.0 -20.0 20.0 °C

PM86

PM87 Calibration of AI07 pressure probe 0.0 -20.0 20.0 Bar

PM88 Calibration of AI08 pressure probe 0.0 -20.0 20.0 Bar

PSd2

During manual operation, it forces the value of

the free-cooling fan.

Calibration of the input (ambient) temperature

probe

Calibration of outlet (delivery) temperature

probe # 1

Calibration of outlet (delivery) temperature

probe # 2

It modifies the password at Maintenance

Operator level.

0.0 0.0 100.0 % MA-M

0.0 -20.0 20.0 °C

0.0 -20.0 20.0 °C

0.0 -20.0 20.0 °C

MA-CA

MA-CA

MA-CA

MA-CA

MA-CA

MA-CA

MA-CA

MA-CA

0 -999 9999 MA-F

INSTALLATION OPERATOR PARAMETERS

COMPRESSOR PARAMETERS

Rotation type used for compressor

management:

PC01

0: FIFO

1: LIFO

0 0 3 IS-C

2: FIFO + hours

3: LIFO + hours

Enabling mode of compressors in the two

PC02

circuits:

0: Circuit balancing

0 0 1 IS-C

1: Circuit saturation

Min. time for which the compressor must

PC04

remain ON, even if a shutdown has been

20 0 999 Sec. IS-C

requested.

Min. time for which the compressor must

PC05

remain OFF, even if a start-up has been

120 0 999 Sec. IS-C

requested.

PC06 Min. time which must elapse between two 360 0 999 Sec. IS-C

Only on twin

circuits

Pag. 70

Page 71

C-PRO NANO CHIL AND C-PRO MICRO CHIL – APPLICATION MANUAL

start-ups of the same compressor.

PC07

PC08

PC09

PC10

PC11

PC12

PC14

PC15 Min. value of compressor neutral zone 1.0 0.1 10.0 °C IS-R

PC16 Max. value of compressor neutral zone 5.0 0.1 10.0 °C IS-R

PC17

PC18

PC21

PC22

PC23

PC24

PC30 Enabling of power limiting from digital input No (0) No (0) Yes (1) IS-R

PC31 Power limiting for summer 50 0 100 % IS-R

PC32 Power limiting for winter 50 0 100 % IS-R

PC35 Enabling of forced shutdown of compressors No (0) No (0) Yes (1) IS-R

PC36 Summer forced shutdown set point 3.5 -30.0 23.0 °C IS-R

PC37 Winter forced shutdown set point 52.0 26.0 75.0 °C IS-R

PC41

PC42 Compressor shutdown time in pump-down 5 0 240 Sec. IS-R

PC43 Relative threshold for pump-down disabling 1.5 0.0 5.0 Bar IS-R

PC45

PC46

PC47

PC48

PC49

PC50

PC51 3.2 0.0 10.0 Bar IS-R

PC52

PC53 External low temperature threshold for -5.0 -10.0 5.0 °C IS-R

Min. time which must elapse between startups of two different compressors.

Min. time which must elapse between

shutdowns of two different compressors.

Max. number of start-ups for every hour (only

for adaptive regulation).

Number of compressors per circuit which will

be forced in case of a regulating-probe alarm.

It sets the regulation type for compressor

management:

0: Lateral band

1: Neutral zone

2: From digital inputs

Proportional band for lateral-band regulation

of compressors

Zone value for neutral-zone regulation of

compressors

Enabling/release time for subsequent

compressor step outside the neutral zone

Enabling for auto-adaptive control of the

compressors’ neutral zone

Min. value of summer set point

(chiller)

Max. value of summer set point

(chiller)

Min. value of winter set point

(heat pump)

Max. value of winter set point

(heat pump)

Enabling of pump-down

0 : No

1 : Yes, with timing

2 : Yes, with relative threshold

Enabling of high-temperature pressure-switch

control (chiller)

Pressure set point for high-temperature

pressure-switch control

Pressure differential for high-temperature

pressure-switch control

External high temperature threshold for

pressure-switch control

Min. time for maintaining pressure-switch

partialisation

Enabling of low-temperature pressure-switch

control (heat pump)

Pressure differential for low-temperature

pressure-switch control

10 0 999 Sec. IS-C

20 0 999 Sec. IS-C

8 4 12 IS-C

1 0 PG03 IS-C

1 0 2 IS-R

2.5 1.0 20.0 °C IS-R

3.0 PC15 PC16 °C IS-R

20 0 999 Sec. IS-R

No (0) No (0) Yes (1) IS-R

5.0 -15.0 SPC1 °C IS-R

20.0 SPC1 35.0 °C IS-R

30.0 10.0 SPH1 °C IS-R

44.0 SPH1 70.0 °C IS-R

0 0 2 IS-R

No (0) No (0) Yes (1) IS-R

27.0 0.0 45.0 Bar IS-R

2.0 0.0 5.0 Bar IS-R

12.0 -30.0 23.0 °C IS-R

10 0 99 Min. IS-R

No (0) No (0) Yes (1) IS-R

2.0 0.0 10.0 Bar IS-R

Pag. 71