PROGRAMABLE CONTROLLERS FOR

AIR HANDLING UNITS

APPLICATION MANUAL

CODE 144AHU0K0E07

C-PRO KILO AHU APPLICATION MANUAL

Important

Please read the instructions herein before installing and using the device. Follow all instructions and

suggestions for installing and connecting the device; keep these instructions in a safe place as you may need

them for future reference.

Ensure that this device is properly discarded in accordance with local government regulations as they

pertain to the disposal of electrical and electronic devices.

Pag. 2

C-PRO KILO AHU APPLICATION MANUAL

Summary

Important....................................................................................................................................2

1 GENERAL.........................................................................................................................6

1.1 Description.................................................................................................................6

2 APPLICATIONS...............................................................................................................8

2.2 Air handling device usage during the summer only ................................................10

2.3 Air handling device usage during the summer and winter, with humidity..................11

2.4 Air handling unit usage during the summer and winter, with humidity and heat

recuperation..........................................................................................................................12

2.5 Air handling unit regulated by 2 coils without dehumidification............................13

2.6 Air handling unit regulated by 3 coils with dehumidification.................................14

2.7 Layout of connection - C-PRO KILO AHU............................................................15

2.8 Layout of connection - EXP KILO..........................................................................17

3 NETWORK COMPONENTS & ACCESSORIES..........................................................20

4 USER INTERFACE ........................................................................................................21

4.1 Display and keyboard ..............................................................................................21

4.1.1 Buit-in interface...............................................................................................21

4.2 Page listing...............................................................................................................22

4.2.1 RTC Menu .............................................................................................................22

4.2.2 General Menu.........................................................................................................23

4.2.3 User Menu..............................................................................................................23

4.2.4 Maintenance Operator Menu .................................................................................24

4.2.5 Menu Installation Operator....................................................................................24

4.2.6 Constructor Menu ..................................................................................................25

4.2.7 Password................................................................................................................26

4.2.8 Main OFF page......................................................................................................26

4.2.9 Main ON page........................................................................................................27

4.2.10 Status page...........................................................................................................27

4.2.11 Alarm pages.........................................................................................................28

4.2.12 History pages .......................................................................................................29

4.2.13 Project and Firmware Versions............................................................................29

5 CONFIGURATION PARAMETERS.............................................................................30

5.1 Directory of configuration parameters.....................................................................31

6 REGULATIONS..............................................................................................................40

6.1 Unit status ................................................................................................................40

6.1.1 Alarm OFF status...................................................................................................41

6.2 Unit Type...................................................................................................................42

6.2.1 Unit in WINTER operating mode (PG00=1).......................................................43

6.2.2 Unit in SUMMER operating mode (PG00=2).......................................................44

6.2.3 Unit operation during WINTER/SUMMER WITH HUMIDITY (PG00=3)........45

6.2.4 Unit for operation in WINTER/SUMMER with humidity and recuperation

(PG00=4) .........................................................................................................................46

6.2.5 Unit with 2 coils without dehumidification (PG00=5)..........................................47

6.2.6 Unit with 3 coils with dehumidification (PG00=6) ...............................................49

6.3 Operating mode during summer/winter...................................................................51

6.4 Setting the RTC........................................................................................................52

6.5 Fans..........................................................................................................................52

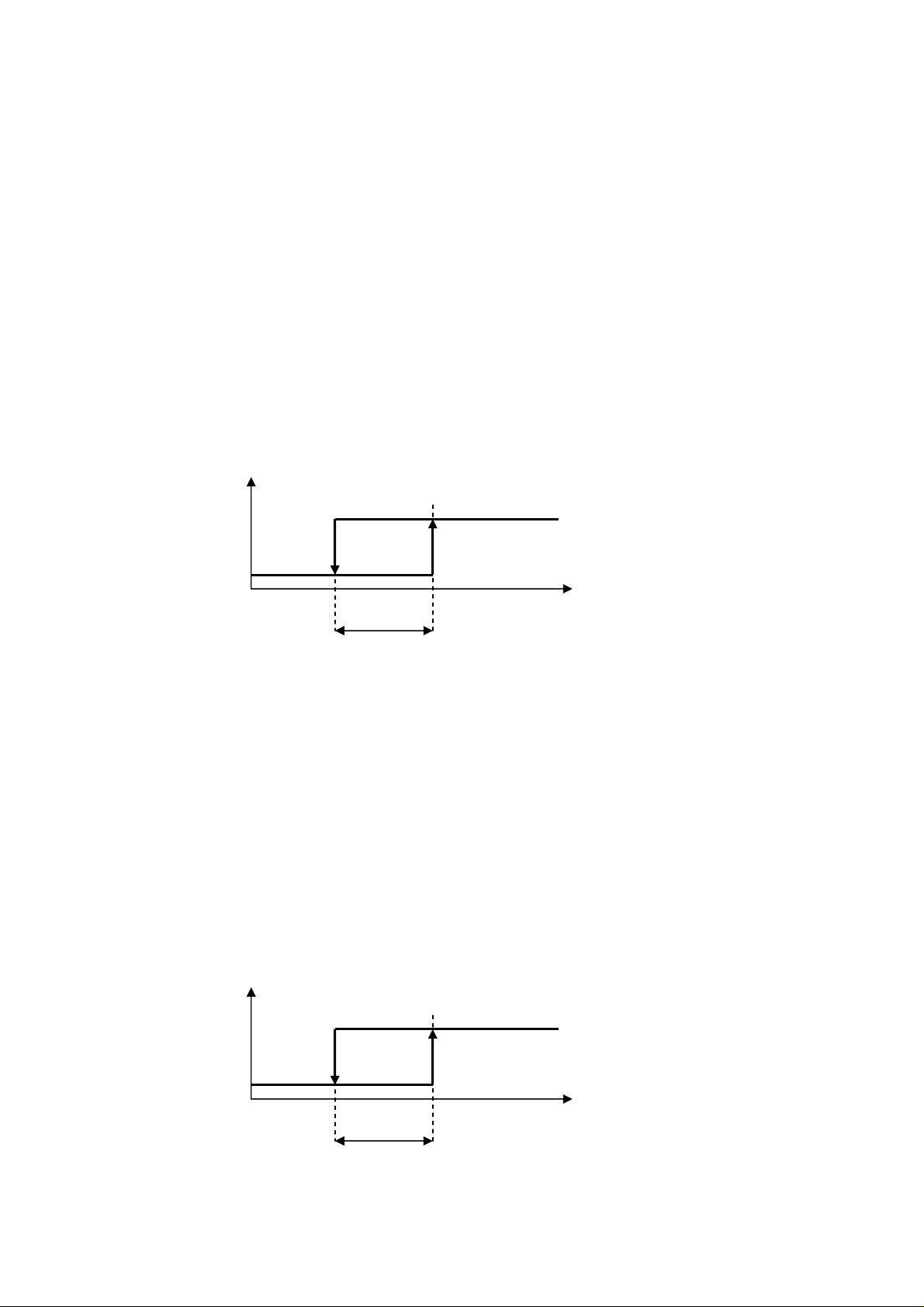

6.5.1 Continuous regulation and On/Off.........................................................................52

Pag. 3

C-PRO KILO AHU APPLICATION MANUAL

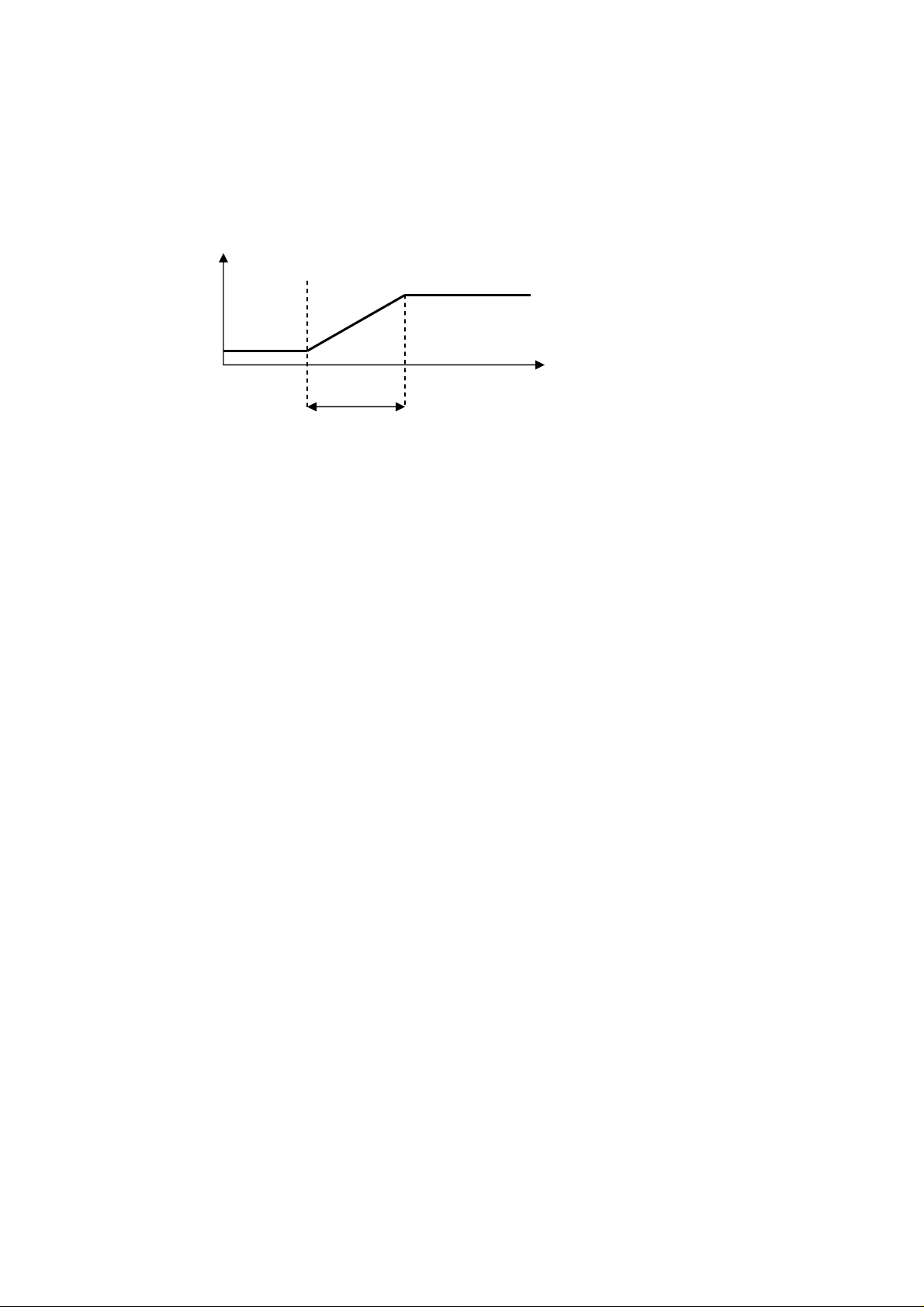

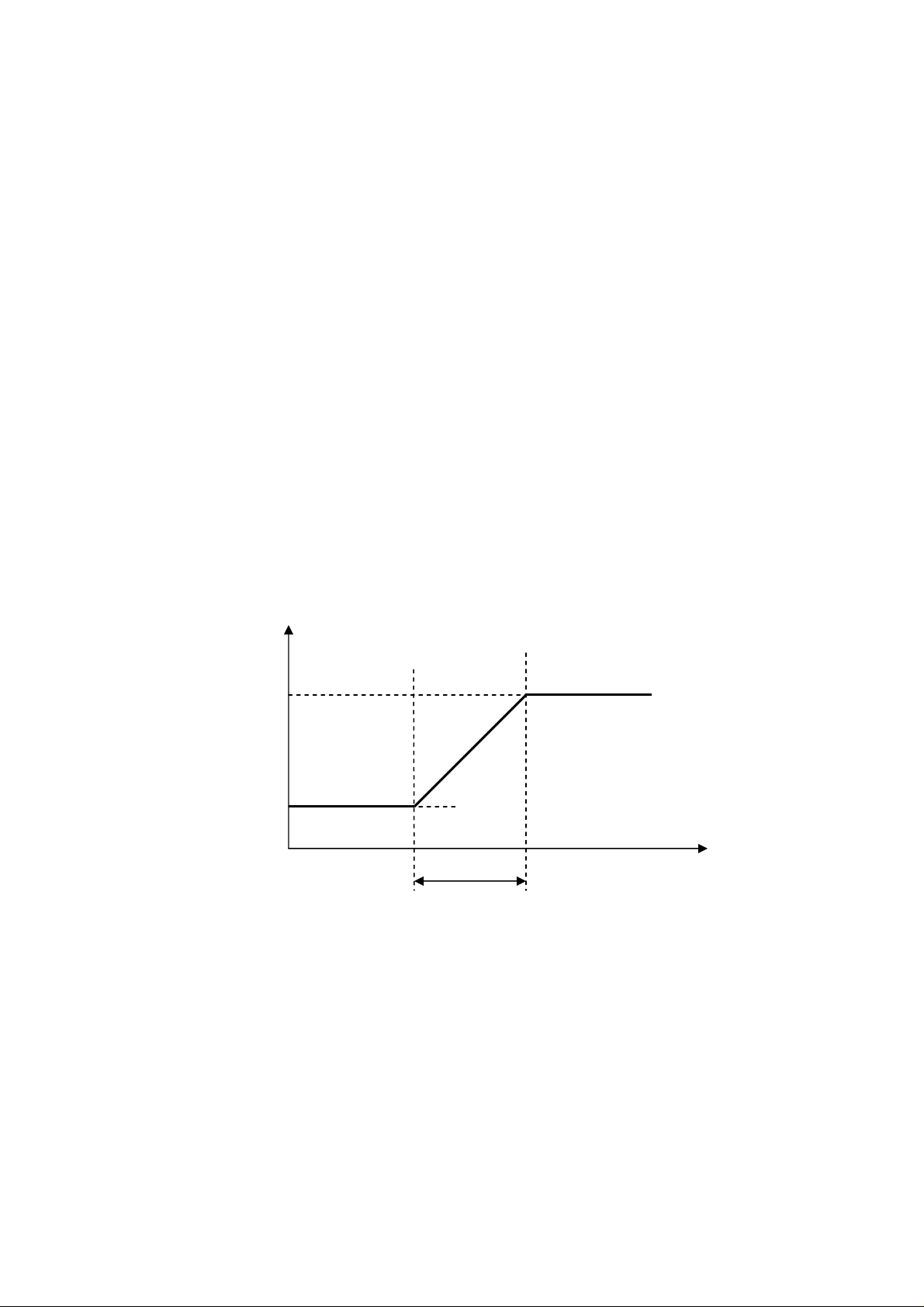

6.5.2 Modulating Regulation ..........................................................................................53

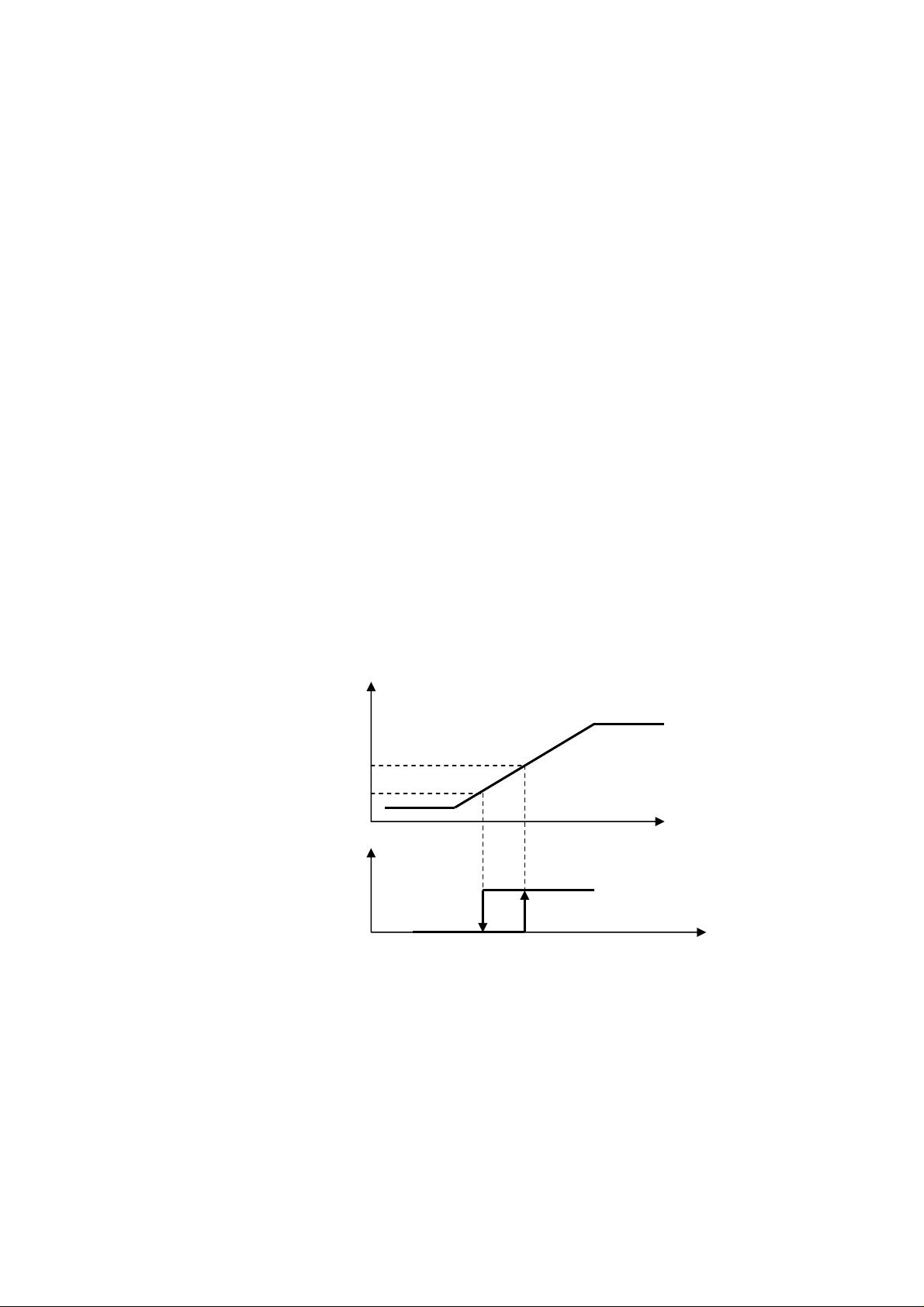

6.5.3 Modulating regulation with steps to enable...........................................................54

6.5.4 Air quality sensor cycles........................................................................................55

6.5.5 Fan status ...............................................................................................................55

6.5.6 Security inputs .......................................................................................................56

6.5.7 Fans in probe error.................................................................................................56

6.6 Main regulations ......................................................................................................57

6.7.1 Set Point flowing from delivery.............................................................................58

6.7.2 Valve module regulation........................................................................................59

6.8 Post-Heating.............................................................................................................60

6.8.1 Post-Heating with coil...........................................................................................60

6.8.2 Post-Heating with resistance.................................................................................60

6.8.3 Status of the resistance..........................................................................................61

6.9 Dehumidification .....................................................................................................62

6.9.1 Dehumidification regulation.................................................................................62

6.9.2 Regulation limit on dehumidification...................................................................62

6.10 Humidification.........................................................................................................63

6.10.1 Enabling humidifier (delivery temperature operation) .......................................64

6.10.2 Humidifier On/Off..............................................................................................64

6.10.3 Modulating humidifier........................................................................................65

6.10.4 Humidifier status.................................................................................................65

6.11 External Air Shutters................................................................................................66

6.11.1 Regulation in fixed opening................................................................................66

6.11.2 Enable Free-Cooling and Free-Heating in temperature......................................66

6.11.3 Enable Free-Cooling and Free-Heating heat exchanger......................................67

6.11.4 Free-Cooling and Free-Heating Regulation........................................................68

6.11.5 Air quality control...............................................................................................69

6.11.6 Shutter Command ...............................................................................................69

6.11.7 Shutter status........................................................................................................70

6.12 Heat Recuperators....................................................................................................71

6.12.1 Recuperators at cross flow..................................................................................71

6.12.2 Recuperator at double coil................................................................................72

6.12.3 Rotating Recuperator..........................................................................................72

6.12.4 Recuperator status...............................................................................................73

6.13 Heating/Cooling Pumps...........................................................................................74

6.13.1 Continuous regulation..........................................................................................74

6.13.2 Regulation On/Off ...............................................................................................74

6.13.3 Pump status..........................................................................................................75

6.13.4 Security Inputs.....................................................................................................75

6.14 Unit at single coil (seasonal)....................................................................................76

16.14.1 Primary regulation ............................................................................................76

6.15 Management (various).............................................................................................77

6.15.1 Single or distinct Set Point..................................................................................77

6.15.2 Compensation for Set Point................................................................................77

6.15.3 Variation Set Point from Digital inputs..............................................................77

6.15.4 Variation Set Point from Supervisor...................................................................78

6.15.5 Variation Set Point in nocturnal time zone.........................................................78

6.15.6 Manual fan operation..........................................................................................78

6.15.7 Last date of maintenance .....................................................................................79

6.15.8 Restoring default parameters ...............................................................................79

Pag. 4

C-PRO KILO AHU APPLICATION MANUAL

6.15.9 Programming key.................................................................................................79

7 DIAGNOSTICS...............................................................................................................80

7.1 Manual and automatic alarms....................................................................................80

7.1.1 Manual alarms........................................................................................................80

7.1.2 Automatic alarms...................................................................................................80

7.2 Table of Alarms .......................................................................................................81

7.2.1 Air Flow Meter Alarm...........................................................................................82

7.2.2 Anti-freeze Alarm..................................................................................................82

7.3 Alarm relay ..............................................................................................................83

7.4 Alarm history...........................................................................................................83

8 MODBUS VARIABLES.................................................................................................84

8.1 ModBus Export Table..............................................................................................84

Pag. 5

C-PRO KILO AHU APPLICATION MANUAL

1 GENERAL

1.1 Description

The air handling units (AHU) contain various programmable application controls providing

the user with the widest range of solutions and combinations which can be modified

according to construction requirements, including the destination in which the plant subject is

installed. The possible configurations vary from the simple use of one coil (utilized for

seasonal heating and cooling) to the most complete solution which includes up to three coils

(for preheating, cooling and dehumidifying, and post-heating) plus a dehumidifier,

recuperator, free-cooling function, shutter controls and the fan pickup and delivery controls.

The AHU are widely configurable with built in sectional components to satisfy any user

installation requirement. The primary objective for each solution is to ensure the well being

of the environment, including air quality control and thermoigometric well being.

The optimal summer temperature is between 24-26°C and 40-60%UR; in winter between 1822°C

40-60%UR.

This application manages AHU with a single coil which is utlilized for heating during the

winter and cooling during the summer. Environmental conditions are controlled from the

central thermal and are reliant on the pre-selection of hot and cold fluids sent by the coil.

The various control functions include:

- Single coil for cooling/heating management

- Manage up to 3 coils (heating, cooling, post-heating)

- Manage up to 3 stages of resistance for the post-heating

- Controlling humidifier - On/Off and modulating

- Controlling dehumidifier

- Controlling external air shutters for free-cooling and free-heating in temperature

- Controlling external air shutters for free-cooling and free-heating heat exchanger

- Controlling external air shutters for air quality

- Manage heat recuperation (cross-flow, at single coil, rotating)

- Manage heating and cooling pumps

- Fan Delivery/Pickup Management - On/Off and at inverter

- Variation Set Point from digital input and supervisor and nocturnal time zone

- Changing modes of functionalilty from digital input and supervisor

- Seasonal Operation - Winter/Summer

- Alarm history

- Navigational User interface divided into four main levels (User, Maintenance

Operator, Installation Operator, and Constructor) each level protected by a different

password.

- Paramater upload/download using EVKEY.

Pag. 6

C-PRO KILO AHU APPLICATION MANUAL

C-PRO KILO AHU

Version with built-in LCD screen display (alfanumeric display with 4 x 20 characters)

C-PRO KILO EXP

Expansion

Pag. 7

C-PRO KILO AHU APPLICATION MANUAL

2 APPLICATIONS

The air handling device can be operated under the following three modes:

1) Air handling unit usage during the winter time only.

2) Air handling unit usage during the summer time only.

3) Air handling unit usage during the summer and winter, with humidity.

4) Air handling unit usage during the summer and winter, with humidity and

heat recuperation.

5) Air handling unit regulated by 2 coils without dehumidification.

6) Air handling unit regulated by 3 coils with dehumidification.

utilizing C-PRO KILO + EXP KILO

Total digital outputs: 14 - of which 7 are on EXP KILO

Total digital inputs: 14 - of which 7 are on EXP KILO

Total analogue inputs: 10 - of which 5 are on EXP KILO

Total analogue ouputs: 6 - of which 3 are on EXP KILO

For viewing purposes it is possible to utilize an alfanumeric display containing 4 x 20

characters which are directly mounted on the controller.

It is also possible to communicate through the Modbus protocol by using the external

optional card (an RS-485).

Pag. 8

C-PRO KILO AHU APPLICATION MANUAL

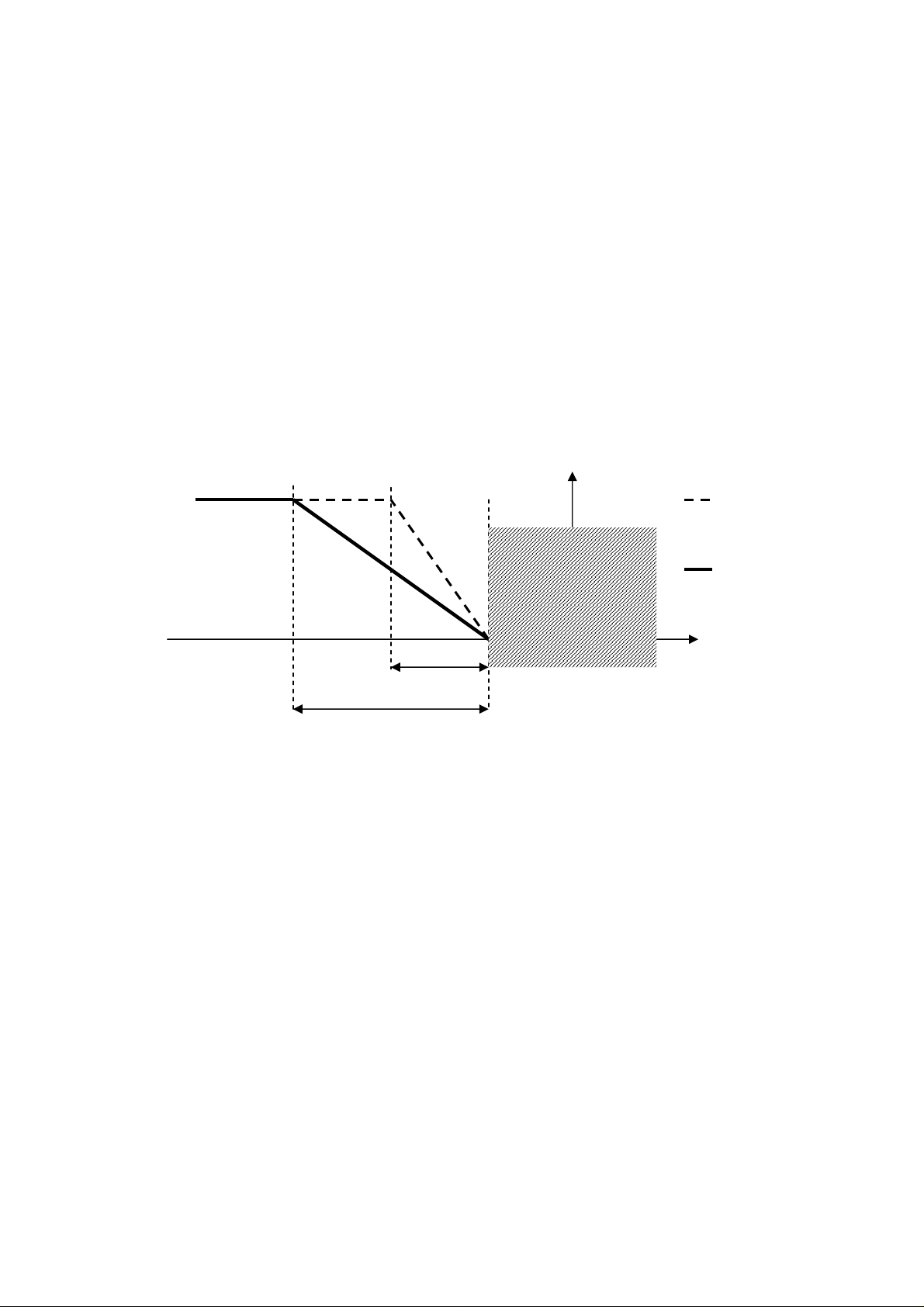

2.1 Air handling device usage during the winter only

Pag. 9

C-PRO KILO AHU APPLICATION MANUAL

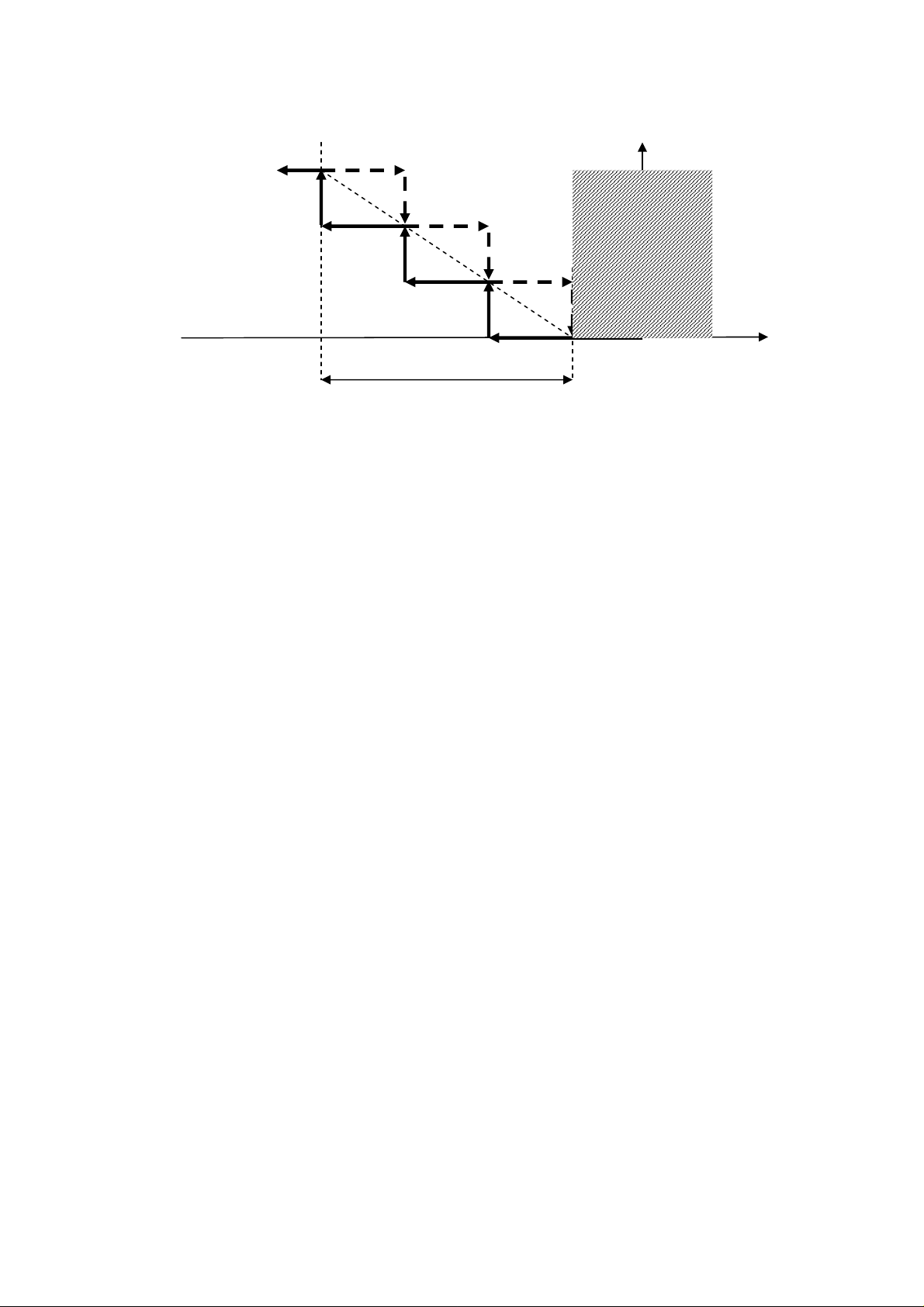

2.2 Air handling device usage during the summer only

Pag. 10

C-PRO KILO AHU APPLICATION MANUAL

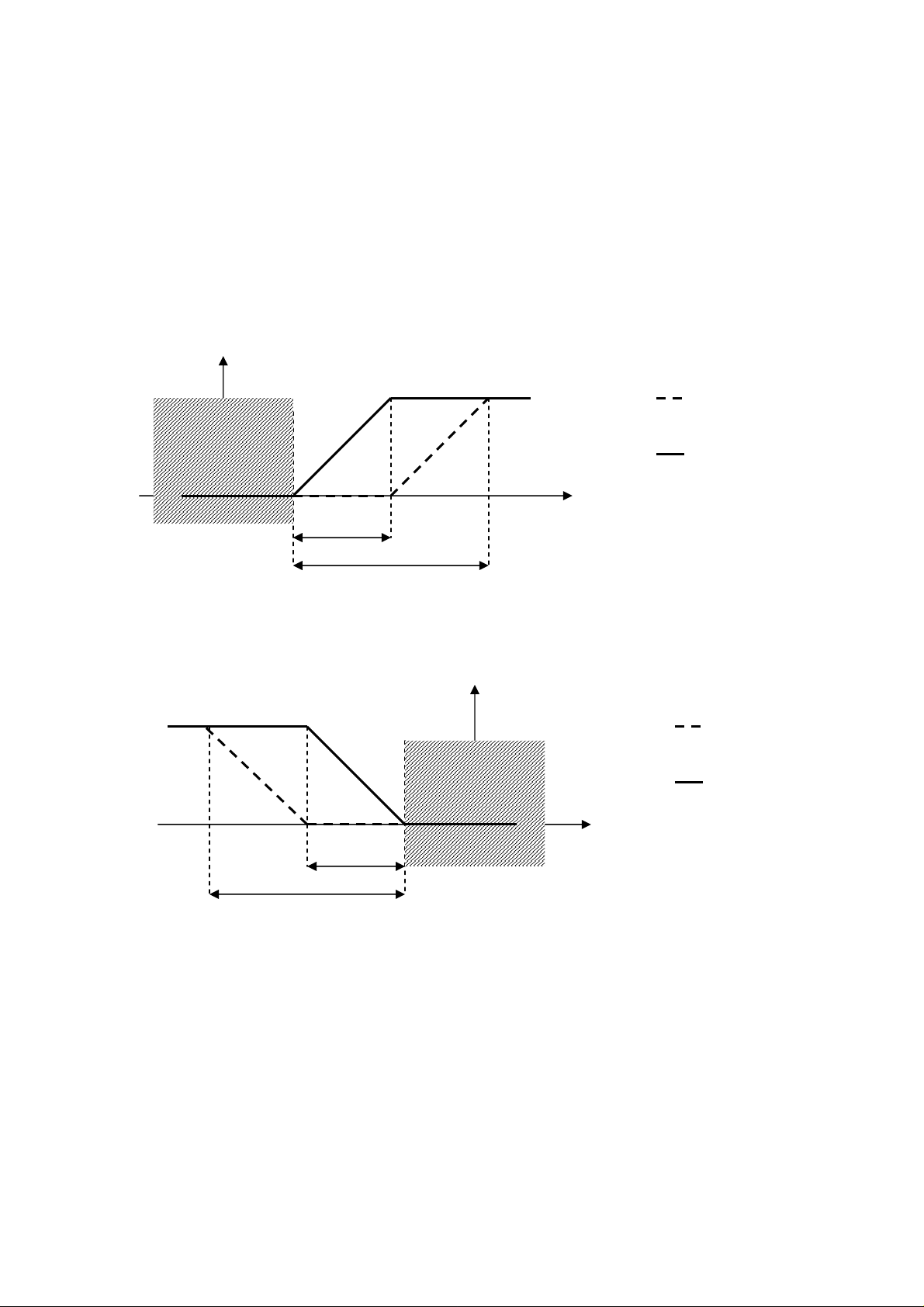

2.3 Air handling device usage during the summer and

winter, with humidity

Pag. 11

C-PRO KILO AHU APPLICATION MANUAL

2.4 Air handling unit usage during the summer and winter,

with humidity and heat recuperation

Pag. 12

C-PRO KILO AHU APPLICATION MANUAL

2.5 Air handling unit regulated by 2 coils without

dehumidification

Pag. 13

C-PRO KILO AHU APPLICATION MANUAL

2.6 Air handling unit regulated by 3 coils with

dehumidification

Pag. 14

C-PRO KILO AHU APPLICATION MANUAL

2.7 Layout of connection - C-PRO KILO AHU

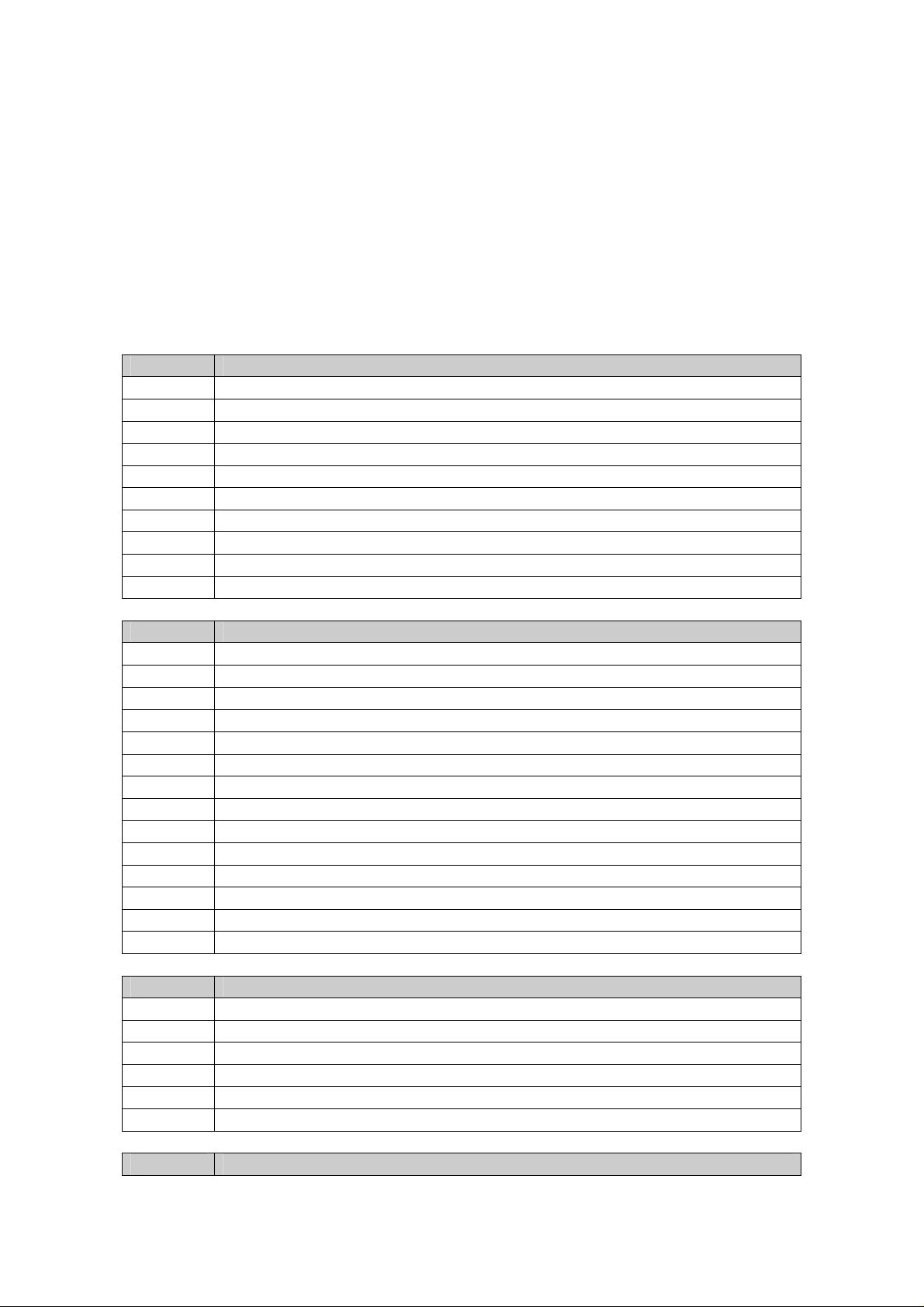

The connection layout of the controller is shown below, with related tables explaining the

significance of inputs and outputs.

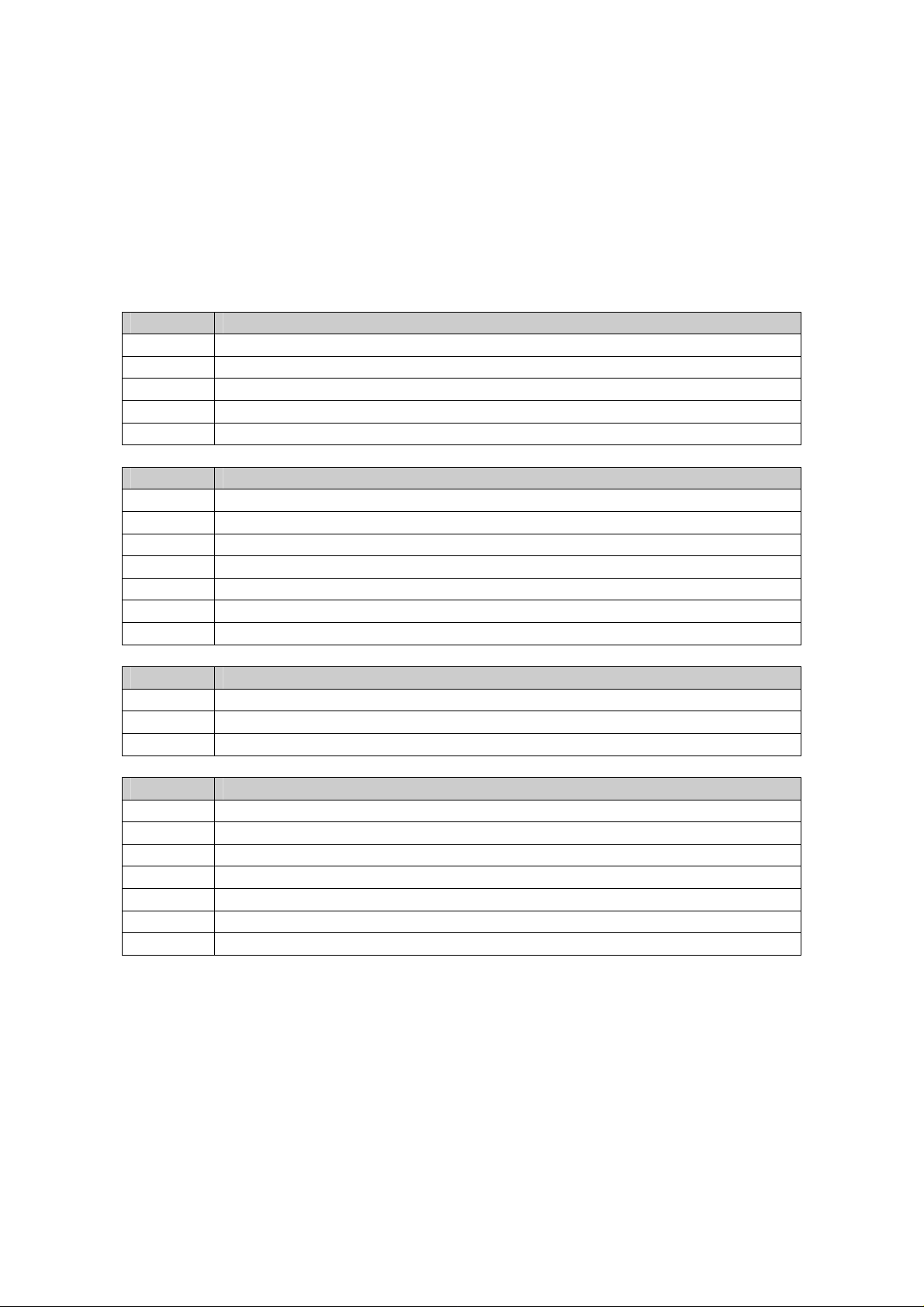

JA Connections for analogue signals

Conn. Label Description

JA-1 AI1 Analogue inputs n.1 (for NTC probe)

JA-2 AI2 Analogue inputs n.2 (for NTC probe)

JA-3 AI3 Analogue inputs n.3 (for NTC probe)

JA-4 AI4 Analogue inputs n.4 (for transducers 4-20 mA); for ratiometric

transducers 0-5 V upon request

JA-5 AI5 Analogue inputs n.5 (for transducers 4-20 mA); for ratiometric

transducers 0-5 V upon request

JA-6 GND Common analogue inputs

JA-7 +5V Supplying power to ratiometric transducers

JA-8 +12V Supplying current to transducers

JB Connections for digital signals

Conn. Label Description

JB-1 DI1 Digital input n.1

JB-2 DI2 Digital input n.2

JB-3 DI3 Digital input n.3

JB-4 DI4 Digital input n.4

JB-5 DI5 Digital input n.5

JB-6 DI6 Digital input n.6

JB-7 DI7 Digital input n.7

JB-8 GND Common digital inputs

JC: Connection for EVKEY (key for upload/download parameters) and outputs for

TTL-RS-485 module.

Pag. 15

C-PRO KILO AHU APPLICATION MANUAL

JD: Connection for the cut-phase output EVDFAN1 (analogue output 1; not utilized)

Conn. Label Description

JD-1 VDC Supplying power to cut-phase module EVDFAN1

JD-2 AO1 Cut-phase output module EVDFAN1

In order to utilize the cut-phase module EVDFAN1, it is necessary to supply power to the

controller in an alternate current; the current that powers the controller must be the same

current as that which is used to power the module.

JE: Connections for analogue outputs 2 and 3 (opto-isolator)

Conn. Label Description (Version V+V)

JE-1 AO2 0-10VDC

JE-2 GND Common analogue outputs

JE-3 AO3 0-10VDC

JF: Connections for controller power supply

Conn. Label Description

JF-1

JF-2

V≅

V≅

Controller power supply (24VAC / 20 … 60 VDC)

Controller power supply (24VAC / 20 … 60 VDC)

JG: Connections for network expansion I/O (not utilized) and for the remote keyboard (not

utilized)

Conn. Label Description

JG-1 VDC Remote keyboard power supply (12VDC, max. 50 mA)

JG-2 GND Common

JG-3 DATA Serial in tension

JM-JL-JI-JH: Connection for digital outputs

Conn. Label Description

JM-4 NO1 Contact normally open - output n.1

JM-3 CO1 Common output n.1

JM-2 NO2 Contact normally open - output n.2

JM-1 CO2 Common output n.2

JL-4 NO3 Contact normally open - output n.3

JL-3 CO3 Common output n.3

JL-2 NO4 Contact normally open - output n.4

JL-1 CO4 Common output n.4

JI-4 NO5 Contact normally open - output n.5

JI-3 CO5 Common output n.5

JI-2 NO6 Contact normally open - output n.6

JI-1 CO6 Common output n.6

JH-3 NO7 Contact normally open - output n.7

JH-2 NC7 Contact normally closed - output n.7

JH-1 CO7 Common output n.7

Pag. 16

C-PRO KILO AHU APPLICATION MANUAL

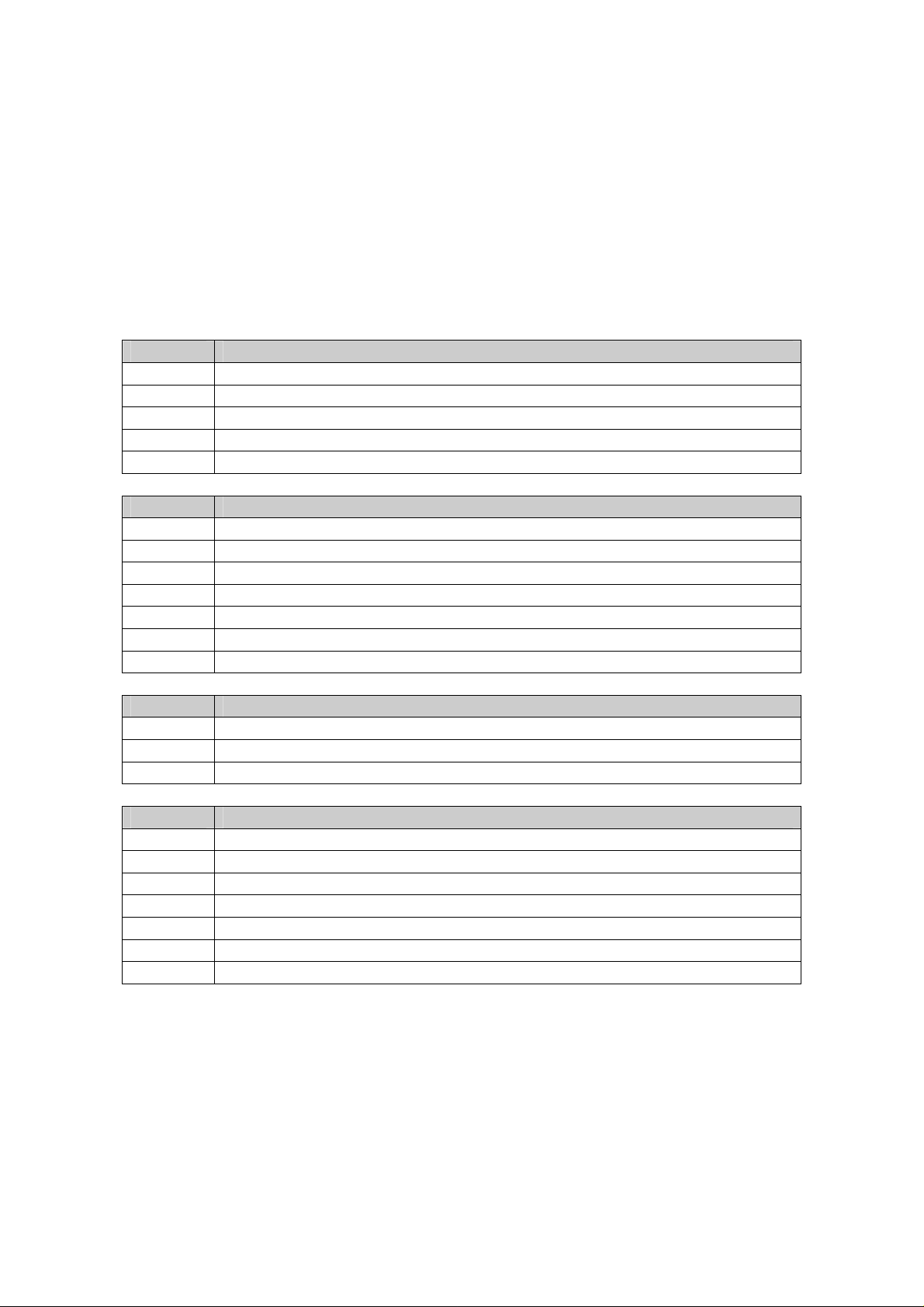

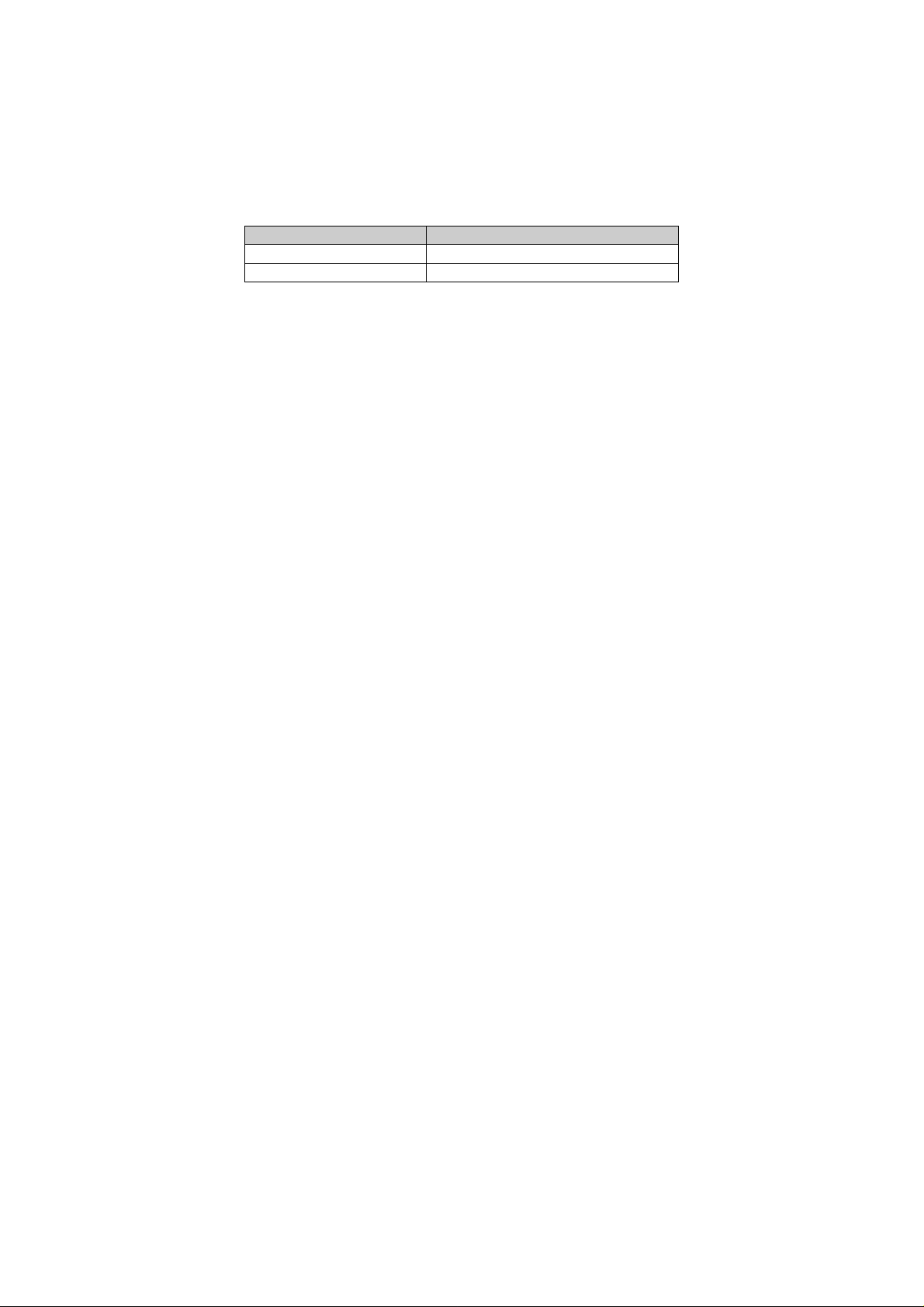

2.8 Layout of connection - EXP KILO

The following presents the connection layout of KILO expansion, with relative tables

indicating inputs and outputs.

JA Connector for the analogue signals

Pag. 17

C-PRO KILO AHU APPLICATION MANUAL

Conn. Label Description

JA-1 AI1 Analogue input n.1 (for NTC probe)

JA-2 AI2 Analogue input n.2 (for NTC probe)

JA-3 AI3 Analogue input n.3 (for NTC probe)

JA-4 AI4 Analogue input n.4 (for NTC probe / transducers 0-20 mA /

transducers 4-20 mA); ratiometric transducers 0-5 V upon

request

JA-5 AI5 Analogue input n.5 (for NTC probe / transducers 0-20 mA /

transducers 4-20 mA); ratiometric transducers 0-5 V upon

request

JA-6 GND Common analogue inputs

JA-7 +5V Supplying power to ratiometric transducers

JA-8 +12V Supplying current to transducers

JB Connector for the digital signals

Conn. Label Description

JB-1 ID1 Digital input n.1

JB-2 ID2 Digital input n.2

JB-3 ID3 Digital input n.3

JB-4 ID4 Digital input n.4

JB-5 ID5 Digital input n.5

JB-6 ID6 Digital input n.6

JB-7 ID7 Digital input n.7

JB-8 GND Common digital inputs

JD: Connector for cut-phase output EVDFAN1 (analogue output 1)

Conn. Label Description

JD-1 VDC Supplying power to cut-phase module EVDFAN1

JD-2 AO1 Cut-phase module output EVDFAN1

In order to utilize the cut-phase module EVDFAN1, it is necessary to supply the expansion

with an alternate current; the phase which supplies power to the controller must be the same

as that which is supplied to both the expansion and the module.

JE: Connector for the analogue outputs 2 and 3 (for isolation); upon request, not available in

daytime models

Conn. Label Description (Version V+I)

JE-1 AO2 0-10VDC

JE-2 GND Common analogue outputs

JE-3 AO3 4-20mA

Description (Versione I+I)

JE-1 AO2 4-20 mA

JE-2 GND Common analogue outputs

JE-3 AO3 4-20 mA

Description (Versione V+V)

JE-1 AO2 0-10VDC

JE-2 GND Common analogue outputs

JE-3 AO3 0-10VDC

Pag. 18

C-PRO KILO AHU APPLICATION MANUAL

JF: Connector for supplying power to the expansion

Conn. Label Description

JF-1

JF-2

V≅

V≅

Expansion power supply (24VAC / 20 … 60 VDC)

Expansion power supply (24VAC / 20 … 60 VDC)

JG: Connector for connecting to controllore

Conn. Label Description

JG-1 VDC Power supply (not utilized)

JG-2 GND Common

JG-3 DATA Serial in tension

JM-JL-JI-JH: Connection for the digital outputs (electromechanical relays)

Conn. Label Description

JM-4 NO1 Contact normally open relay n.1

JM-3 CO1 Common relay n.1

JM-2 NO2 Contact normally open relay n.2

JM-1 CO2 Common relay n.2

JL-4 NO3 Contact normally open relay n.3

JL-3 CO3 Common relay n.3

JL-2 NO4 Contact normally open relay n.4

JL-1 CO4 Common relay n.4

JI-4 NO5 Contact normally open relay n.5

JI-3 CO5 Common relay n.5

JI-2 NO6 Contact normally open relay n.6

JI-1 CO6 Common relay n.6

JH-3 NO7 Contact normally open relay n.7

JH-2 NC7 Contact normally closed relay n.7

JH-1 CO7 Common relay n.7

Pag. 19

C-PRO KILO AHU APPLICATION MANUAL

3 NETWORK COMPONENTS & ACCESSORIES

Pag. 20

C-PRO KILO AHU APPLICATION MANUAL

4 USER INTERFACE

4.1 Display and keyboard

Application requires an interface incorporated into the controller (later referred to as

built-in) with an alfanumeric display containing 4 x 20 characters and various keys and

dedicated led.

4.1.1 Buit-in interface

The built-in interface is directly integrated into the controller.

The keyboard contains four keys which are used to navigate pages, modify parameters and/or

values by performing the following functions:

- and (UP and DOWN): these keys modify parameters; otherwise, used to

move cursor.

- (ENTER): used to confirm a value when editing; otherwise, it enters a command

associated to the text where the cursor is currently positioned. If viewing an alarm

page press and hold ENTER key down for about 2 seconds allowing for the alarm to

reset. When viewing an alarm page, with each key pressure, all active alarms are run.

- (ESC): used to cancel a value when editing; otherwise, it requests the default

page associated with the current page in view. If pressed down and held for about 2

seconds, the ESC key enables switching the machine ON and OFF.

Additionally, 2 LED’s are presented:

- : indicates the presence or absence of alarms.

Off: no alarms present

Light on: indicates the presence of new alarms not yet viewed

Access: all active alarms have been viewed

Pag. 21

C-PRO KILO AHU APPLICATION MANUAL

- : ESC key, identifies current state of machine.

Off: machine on

On: machine off (or machine alarms OFF)

Slow flashing light: machine digital inputs off

Quick flashing light: machine supervisor off

4.2 Page listing

The following paragraph presents the principle pages and menus presented in the application

manual. As previously discussed, the general menu is divided into four sections: User,

Maintenance Operator, Installation Operator, and Constructor. In addition, there is a menu

(with additional open access pages) which can be referenced to operate the system clock.

The structure of the menu is as follows:

⋅ Clock Menu-RTC

⋅ General Menu

⋅ User Menu (Level 1, password for level 1)

⋅ Maintenance Operator Menu (Level 2, password for level 2)

o Maintenance Operator Menu – operating branch

o Maintenance Operaror Menu – manual branch

o Maintenance Operator Menu – input/output branch

⋅ Installation Operator Menu (Level 3, password for level 3)

o Installation Operator Menu – regulation branch

o Installation Operator Menu – fans branch

o Installation Operator Menu – coil branch

o Installation Operator Menu – humidity branch

o Installation Operator Menu – recuperation branch

o Installation Operator Menu – external air shutters branch

o Installation Operator Menu – pumps branch

o Installation Operator Menu – security branch

o Installation Operator Menu – various branch

o Installation Operator Menu – default branch (level 4, only when machine is

off)

⋅ Constructor Menu (Level 4, password for level 4, only when machine is off)

o Constructor Menu – implant branch

o Constructor Menu – hardware IN branch

o Constructor Menu – hardware OUT branch

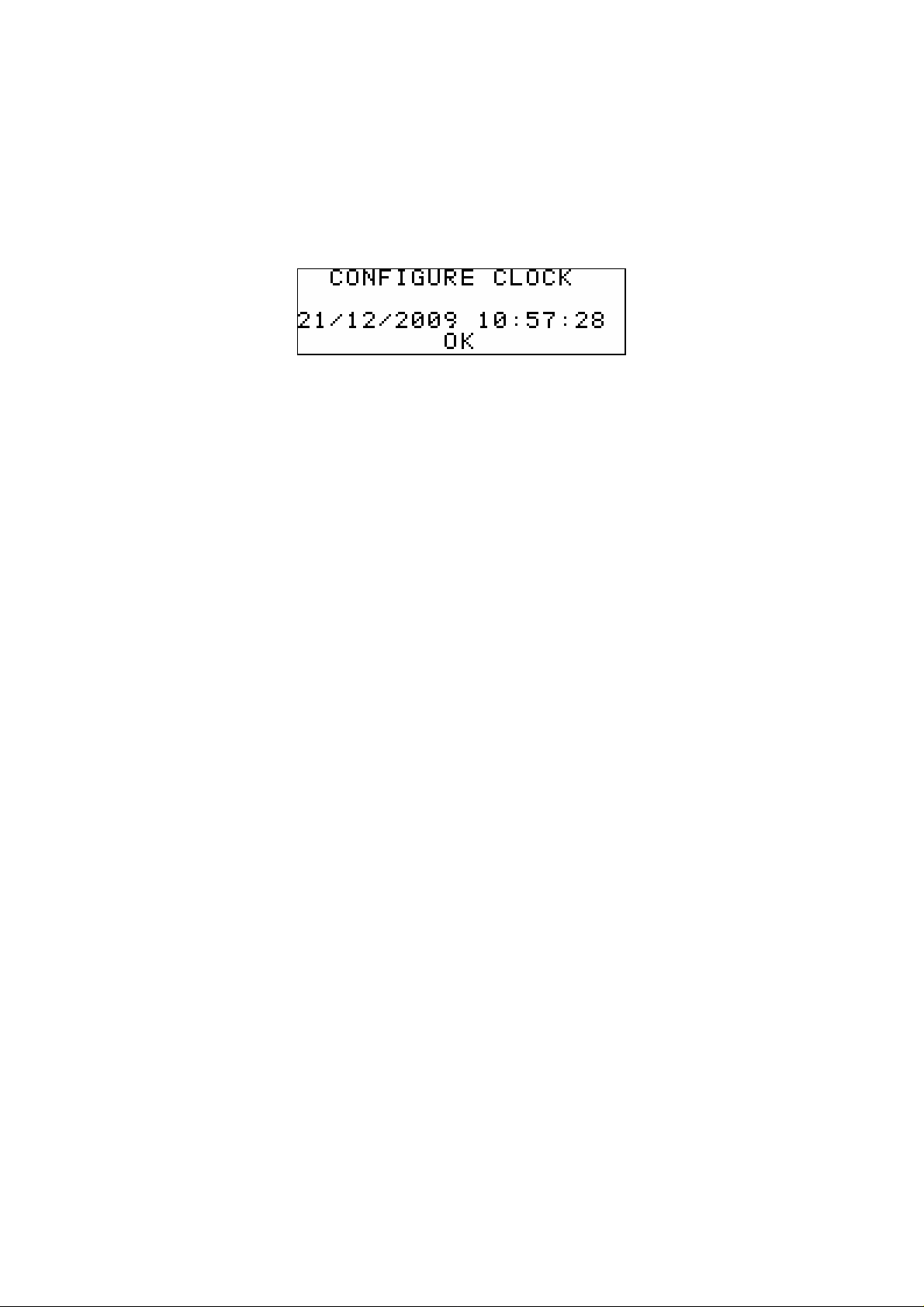

4.2.1 RTC Menu

This menu contains the functionality of the systems’ RTC:

⋅ setting the clock

⋅ setting the clock during evening hours

⋅ setting the clock offset at Set Point to regulate during evening hours

In order to enter into this menu click ENTER on the RTC mask, accessed from the general

menu.

Pag. 22

C-PRO KILO AHU APPLICATION MANUAL

In the upper right hand corner of the above image appears a “>” indicating that you may

navigate to another page. This is done by placing the cursor on the “>” and then pressing

ENTER; this will bring you to the following page.

In the upper left hand corner of the above image appears a “<” indicating that you may

navigate to the preceding page by placing the cursor on the “<” and then pressing ENTER.

4.2.2 General Menu

The general menu has no level and represents the access point for all the other system menus.

It is possible to view this menu from any point within the user interface by pressing ENTER

for approximately 2 seconds. From this menu you can choose the menu you wish to view by

pressing the UP and DOWN keys followed by pressing the ENTER key for confirmation.

In the upper right hand corner of the below image appears a “v” which repsents the focus.

This indication specifies to the user that additional information is contained therin and can be

viewed by pressing the DOWN key (or UP key depending on the direction of the focus)

scrolling to view the contents that is not viewable in the current page. In this specific case,

once the focus is on the line “COSTRUTTORE” (CONSTRUCTOR), press DOWN to

proceed to the subsequent page:

In the same fashion as described in the above two paragraphs, once the focus is placed on the

“RTC” line, press the UP key to return to the preceding page.

4.2.3 User Menu

Access to the user menu for level 1 requires a password from a basic user (or superior) in

order to view/modify the parameters presented in this branch.

The following parameters appear in this branch:

MOdE: Usage during summer/winter by key input

SEtH: Set point for winter operation (or single Set Point)

SEtC: Set point for summer operation

OS01: Offset set point from Digital inputs

OS02: Offset set point from Supervisor

PU01: Set point ambient humidity

PSd1: User password

Pag. 23

C-PRO KILO AHU APPLICATION MANUAL

4.2.4 Maintenance Operator Menu

Access to the Maintenance Operator Menu for level 2 requires a password from a

maintenance operator (or superior) in order to view/modify the parameters presented in this

branch.

In this Menu it is possible to view the status of various devices, inputs and outputs utilized by

the application. By pressing the ENTER key on the text which reads “MENU’

MANUTENTORE” (MAINTENANCE OPERATOR MENU) you will come to a page

allowing you the option to change your password (PSd2).

In the FUNZIONAMENTO (OPERATION) Menu you may view/enable characteristics

relating to the operation of the devices, including the hours of operation or the maximum

threshold of acceptible hours.

Under the MANUALE (MANUAL) Menu you can set the fan and humidifier modes to

manual/automatic. It is also possible to force the outputs in order to test their functionality.

In the STATO I/O (STATUS I/O) Menu you can directly view status of the physical inputs and

outputs of the card and you can set corrections to the analogue inputs to compensate the

required offset for the cables and positioning of the probes.

4.2.5 Menu Installation Operator

The Installation Operator Menu is in level 3 and requires a password from either an

installation operator or constructor in order to view/modify the parameters presented in this

branch.

The Installation Operator Menu contains all the paramaters related to the configuration of all

operations (alarms, regulations, logistics, characteristics) used for this device. By pressing

the ENTER key on the text which reads “MENU’ INSTALLATORE” (INSTALLATION

MENU) you will come to a page allowing you the option to change your password (PSd3).

Pag. 24

C-PRO KILO AHU APPLICATION MANUAL

In the REGOLAZIONI (REGULATIONS) Menu you can set/view parameters for various

specific regulations:

⋅ compensation regulation Set Point

⋅ cycles for air quality sensors

Within the VENTILATORI (FAN), BATTERIE (COIL), UMIDITA’(HUMIDITY),

RECUPERO(RECUPERATION), SERRANDA ARIA (AIR SHUTTER) and POMPE (PUMPS)

menus you may set the the related parameters to manage the devices:

⋅ regulation parameters

⋅ timetable

⋅ operation

In the SICUREZZE(SECURITY) Menu you can find all the paramaters which relate to the

alarms and the management of device security:

⋅ enabling

⋅ signal delays

⋅ type of re-arm…

The VARIE(VARIOUS)Menu contains other general parameters:

⋅ maximum threshold values

⋅ Modbus communication

⋅ enabling On/Off of Digital inputs and supervisor

⋅ enabling secondary Set Point of Digital inputs and supervisor

⋅ enabling summer/winter modes from Digital inputs and supervisor

⋅ enabling probes

⋅ digital input/output logistics

⋅ enable nocturnal operating mode

⋅ cancelling history

⋅ unit of measurment

From the DEFAULT Menu it is possible to restore the default values of all the parameters of

the application and save or redownload a map which contains all the parameters from the key.

This Menu is only accessible when the machine is off.

4.2.6 Constructor Menu

The Constructor Menu appears in level 4 and requires a password from a constructor in order

to view/modify the paramaters presented in this branch. In addition, this Menu is only

accessible when the device is off.

The Constructor Menu contains all the parameters relating to the configuration of the device.

By pressing the ENTER key on the text which reads “MENU’ COSTRUTORE”

(CONSTRUCTOR MENU) you will come to a page allowing you the option to change your

password for all four levels.

Pag. 25

C-PRO KILO AHU APPLICATION MANUAL

The CONFIGURAZIONE(CONFIGURATION) Menu allows you to set/view the parameters

relating to the characteristics used to configure the device.

⋅ unit type

⋅ coil number

⋅ device enablement

⋅ utilization of the expansion

In the HARDWARE IN Menu you can set the positions of the digital inputs.

In the HARDWARE OUT Menu you can set the positions of the analogue and digital inputs.

4.2.7 Password

Within each menu (excluding the clock and history menus) is an associated level that has

conditional access. Each level has an associated password which permits access to the

functions within a particular menu. Once the password is typed in, the protected functions

will become accessible to the user. Typing in the correct password will have the following

two effects:

⋅ permits access to the correllated level

⋅ permits access to sub-levels

Each password for each level can be modified from within that level or from a higher level.

For example, all passwords within the constructor level can be modified by levels below the

contructor level.

The following is an example of the password page appearing in the contructor menu:

The range of acceptable values for the password is: -999 / 9999.

If no further action is required in the current page, after a period of 4 minutes, the password

insterted will expire thus requiring a new password to be insterted.

4.2.8 Main OFF page

The main OFF page displays the reason for which the unit is turned off.

When the “Unita’ OFF da alarm” (OFF from alarm) is on, it can be shut down completely by

using either the keys, digital inputs or supervisor.

Pag. 26

C-PRO KILO AHU APPLICATION MANUAL

Mode of operation during summer/winter

Active functions on the unit

4.2.9 Main ON page

When the unit is turned ON the following main pages will appear:

from which you may access the status page, by pressing ENTER on the “>”. By pressing the

ESC key you will able to view the alarm and history pages.

The Set Point viewed is that which is presently in use by the regulations and is calculated by

the relative parameters based on the modes of operation (SEtC, SEtH) and by the possible

variations introduced from the relative functions (compensation, evening time mode, digital

inputs, supervisor).

Additionally, the page includes certain information relating to functions which have yet to

become active:

cR:

tR:

dR:

sR:

sF:

LD:

FC:

FH:

QA:

MX:

MD:

FX:

Compensation Set Point summer

Variation Set Point in nocturnal operating mode

Variation Set Point from digital inputs

Variation Set Point from supervisor

Active fans for cycles of air quality control sensors

The dehumidification functional limit is active

The external air shutters are active for free-cooling

The external air shutters are active for free-heating

The external air shutters are active for air quality control

The external air shutters are active for free-cooling/freeheating and for air quality control (the maximum

requested)

The external air shutters are active for free-cooling/freeheating and for air quality control (the average requested)

The external air shutters are active in a fixed opening

The function is active if the related code is visible in the page.

If ALARM indicates that there are active

alarms

Set Point ambient temperature

Set Point ambient humidity

4.2.10 Status page

From the main page it is possible to scroll through the various pages and have open access to

view the status of each device in operation.

These pages are not password protected and are only accessible when the unit is ON. To

view, press ENTER on “>” on the main ON page.

To scroll the status pages press ENTER on the the label “<” to return to a preceding page or

on the label “>” to view a successive page.

Pag. 27

C-PRO KILO AHU APPLICATION MANUAL

Value of delivery probe and regulation Set Point

Point

The following page summarizes the main values pertaining to the regulation of the delivery

temperature:

Requested heating (and cooling in the case where a

single coil is used) and actual Set Point for heating

Requested cooling and actual Set Point for cooling

The following page summarizes the main values pertaining to the regulation of humidity:

Value of ambient humidity probe and regulation Set Point

Requested humidification and and actual humidification

Set Point

Requested dehumidification and actual dehumidification Set

Note. If certain devices are disabled, the information contained in the parameters for that

particular devices operating status will be substituted by dots (“....”) in order to exclude

information pertaining to any disabled devices from being stored in the status pages. The

same applies for probes which are disabled.

4.2.11 Alarm pages

In order to view the alarms, choose ALARMI (ALARMS) from the general Menu or,

alternatively, from the main pages by pressing ESC to view the following page:

You can press ENTER on “Mostra ALARMI >>”(Show Alarms >>).

If no alarms are present you will see written“NO ALARMI”(NO ALARMS), otherwise, each

time you press ENTER you will view the next active alarm, and so forth.

By pressing the ENTER key for approximately 2 seconds, you will restore the alarms in the

case where the condition of error was restored. If this were not true, the current mask would

remain in view. If from one alarm page you press the ESC key or if you wait for a 60 second

timeout period, you will be brought back to the main page of the application. This level is not

password protected.

Pag. 28

C-PRO KILO AHU APPLICATION MANUAL

Historical status

Alarm date and time

Progressive number memorized

Alarm

code

Pro

ject:

num

ber, version, revision

Controller:

mas

k, version, revision

4.2.12 History pages

In order to view the alarm history, choose STORICO (HISTORY) from the general Menu.

Alternatively, on the main page you can press the ESC key in order to view the following

page:

Press ENTER on “Mostra STORICO >>”(Show History>>).

If no elements are present you will see “NO ALARMI”(NO ALARMS) written on the screen.

Otherwise, you will arrive at the following page which provides information from the most

recent element memorized in history:

where the information is from the last element reported and memorized in the history. To

view the preceding element press ENTER on “>>”. By repeating this procedure you will be

able to run each element contained in history until you arrive at the first inserted element,

from here, at the request of the successive element, you will view the last memorized

element. The history is viewed in a circular manner.

In order to exit the historical page press the ESC key or wait for the 60 second timeout period

to expire. This level is not password protected.

Ok: correct reading

Empty: memory empty

Overflow: memory full

Error: historical reading failed

4.2.13 Project and Firmware Versions

Press down on the UP+DOWN keys simultaneously for approximately two seconds and then

press ENTER on the label InFo. The following information pertaining to the project and

firmware versions of the controller will appear:

To return to the application page press the ESC key.

Pag. 29

C-PRO KILO AHU APPLICATION MANUAL

5 CONFIGURATION PARAMETERS

To follow is a list of all the parameters which are managed by the application. A brief

description will be furnished for each parameter explaining the range of acceptable values,

units of measurement, the reccomended default values and the menus in which they can be

found. The Menus are structured using the following logic:

⋅ OR : Clock Menu

⋅ UT : User Menu

⋅ MA: Maintenance Operator Menu

o MA-F: Maintenance Operator Menu – operating branch

o MA-M: Maintenance Operator Menu – manual branch

o MA-CA: Maintenance Operator Menu – calibration branch

o MA-IO: Maintenance Operator Menu – input/output branch

⋅ IS : Installation Operator Menu

o IS-R: Installation operator Menu – regulations branch

o IS-F: Installation operator Menu – fans branch

o IS-B: installation operator menu – coil branch

o IS-U: installation operator menu – humidity branch

o IS-RH: installation operator menu – recuperation branch

o IS-SE: Installation operator Menu – external air shutters branch

o IS-P: Installation operator Menu – pumps branch

o IS-S: Installation operator Menu – security branch

o IS-V: Installation operator Menu – various parameters branch

o IS-D: Installation operator Menu – default branch

⋅ CO : Constructor Menu

o CO-W: Constructor Menu – implant branch

o CO-HI: Constructor Menu – hardware IN branch

o CO-HO: Constructor Menu – hardware OUT branch.

Pag. 30

C-PRO KILO AHU APPLICATION MANUAL

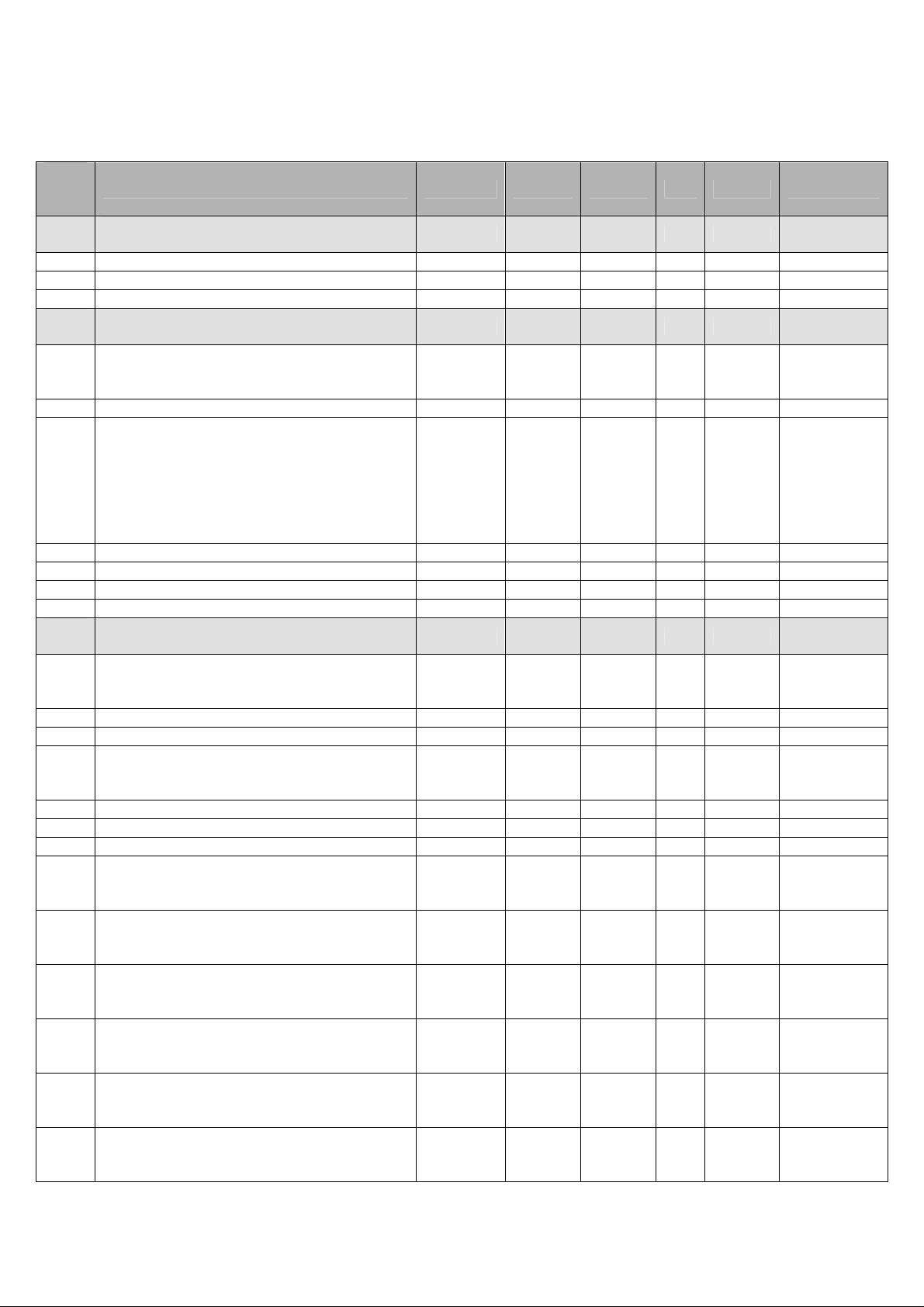

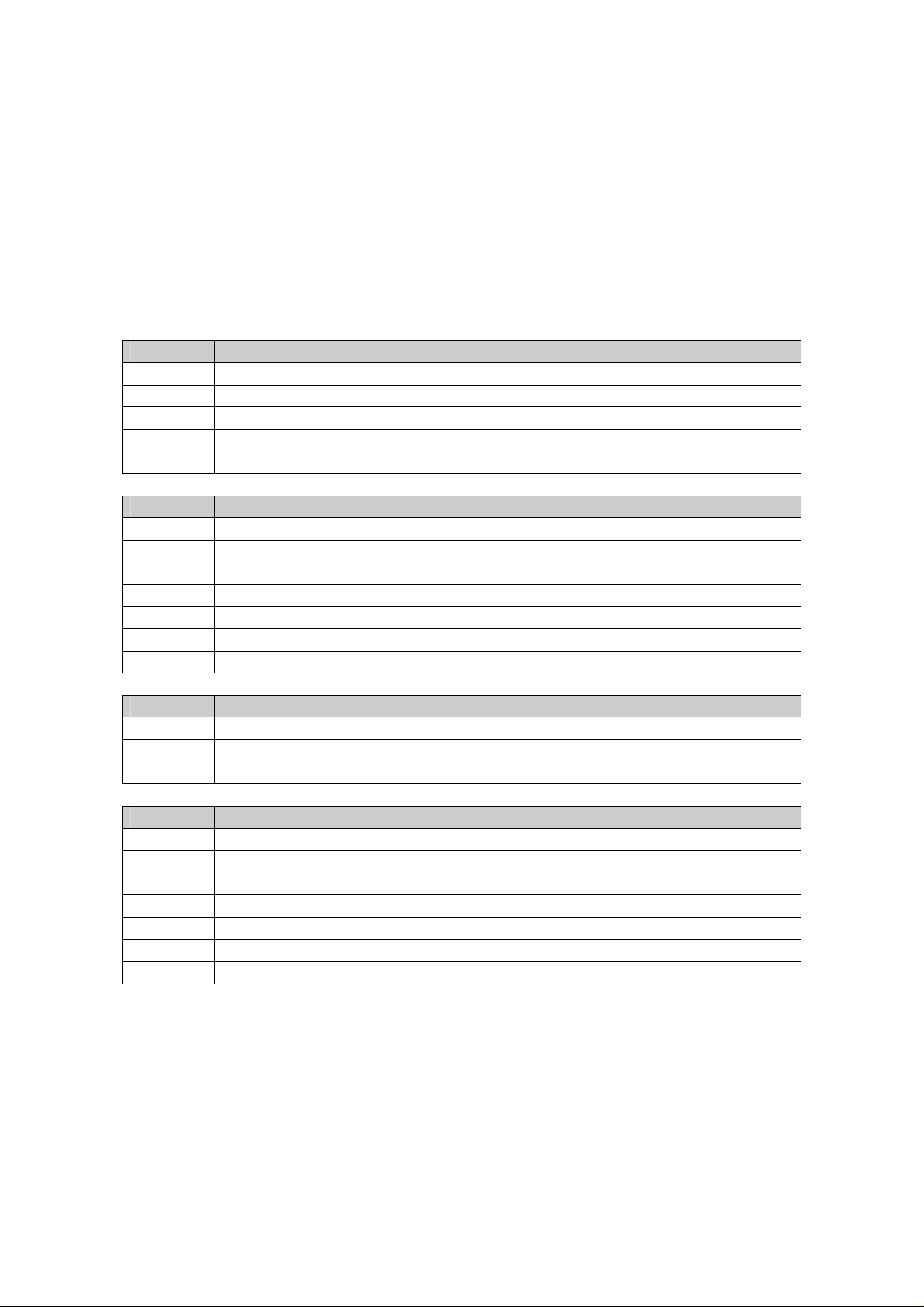

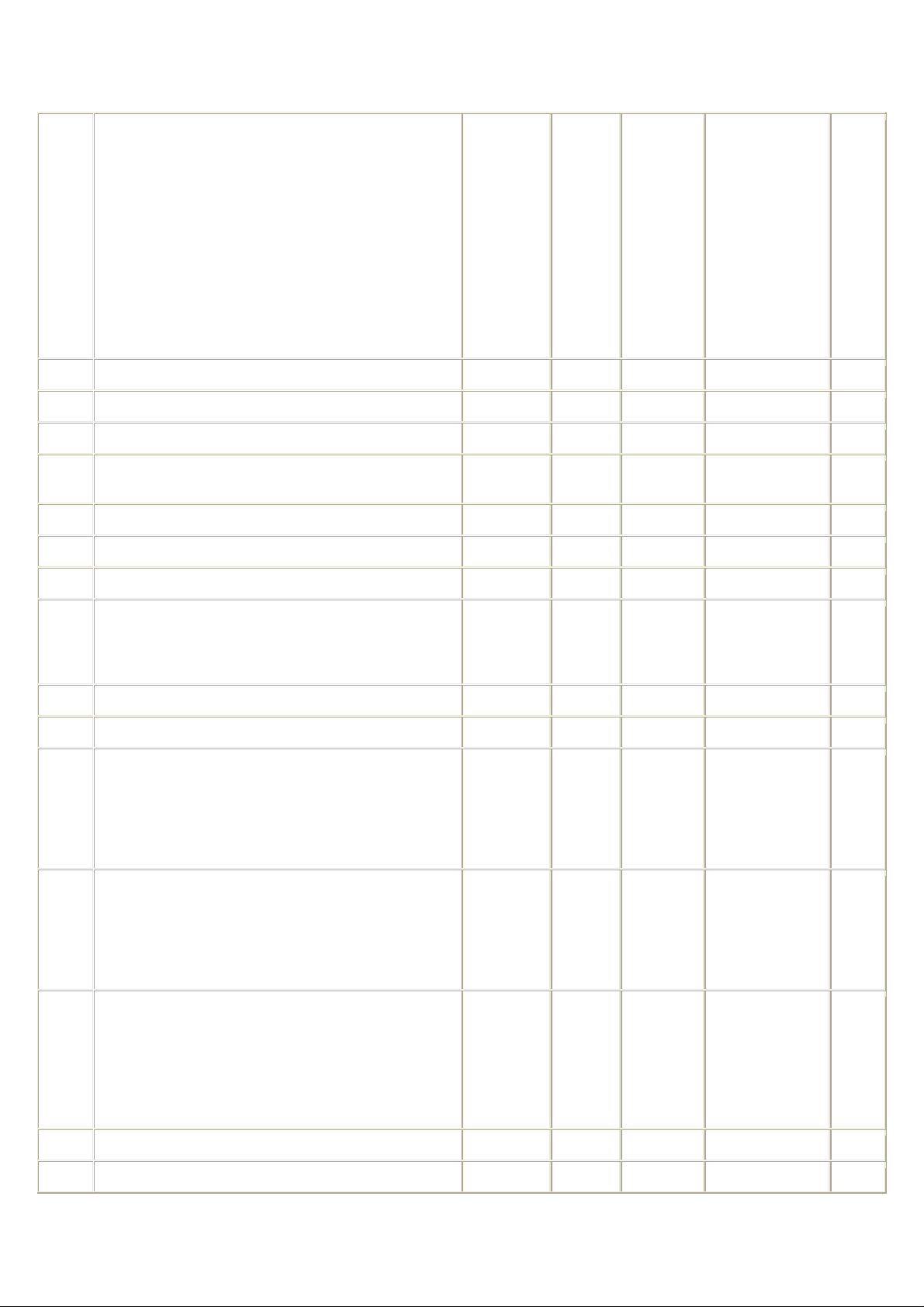

5.1 Directory of configuration parameters

Code Description parameter Default Min Max UM Menu Note

PT01 Begin nocturnal operating mode 00:00:00 00:00:00 23:59:59 - OR

PT02 End nocturnal operating mode 00:00:00 00:00:00 23:59:59 - OR

PT03 Offset of Set Point nocturnal operating mode 0.0 -20.0 20.0 °C OR

Level

1

MOd

E

SEtC Set Point summer 24.0 PH03 PH04 °C

SEtH Set Point winter/single 20.0 PH03 PH04 °C UT

PU01 Set Point for humidity management 55 0 100 % UT

OS01 Offset at regulation Set Point from digital input 0.0 -20.0 20.0 °C UT If PH25=1

OS02 Offset at regulation Set Point from Supervisor 0.0 -20.0 20.0 °C UT If PH26=1

PSd1 Password for User Level (1) 0 -999 9999 - UT

Level

2

PM00

PM01 Hours of fan operation - delivery 0 0 100000 Hrs. MA-F

PM02 Hours of fan operation - pickup 0 0 100000 Hrs. MA-F

PM10

PM11 Hours of cooling pump operation 0 0 100000 Hrs. MA-F

PM12 Hours of heating pump operation 0 0 100000 Hrs. MA-F

PM90 Last date of machine maintenance - MA-F

PM20

PM21 Force the value of the fan in manual operation 0.0 0 100.0 % MA-M

PM23

PM24

PM26

PM27

This menu is accessible only if PG03=1

Operating mode

0: Summer (Cooling)

1: Winter (Heating)

MAINTENANCE OPERATOR MENU

Limit the maximum hours of fan operation.

Related alarms will sound if maximum hours are

exceeded.

Limit the maximum hours of pump operation.

Related alarms will sound if maximum hours are

exceeded.

Manual/automatic fan operation - delivery

0: Auto – automatic operation

1: Manu – manual operation

Manual/automatic fan operation - pickup

0: Auto –automatic operation

1: Manu –manual operation

Force the value of the fan pickup module in

manual operation

Manual/automatic humidifier operation

0: Auto –automatic operation

1: Manu –manual operation

Force the value of the humidifier in manual

operation

CLOCK MENU

USER MENU

1 0 1 - UT

20000 0 100000 Hrs. MA-F

20000 0 100000 Hrs. MA-F

0 (Auto) 0 (Auto) 1 (Manu) - MA-M

0 (Auto) 0 (Auto) 1 (Manu) - MA-M

0.0 0 100.0 % MA-M

0 (Auto) 0 (Auto) 1 (Manu) - MA-M

0 0 100 % MA-M

If PH27=1

(single Set

Point), the

single Set

Point utilized

for regulation

and SEtH.

If fan On/Off

set PM21>0 to

activate

If fan On/Off

set PM24>0 to

activate

If humidifier

On/Off set

PM27>0 to

Pag. 31

C-PRO KILO AHU APPLICATION MANUAL

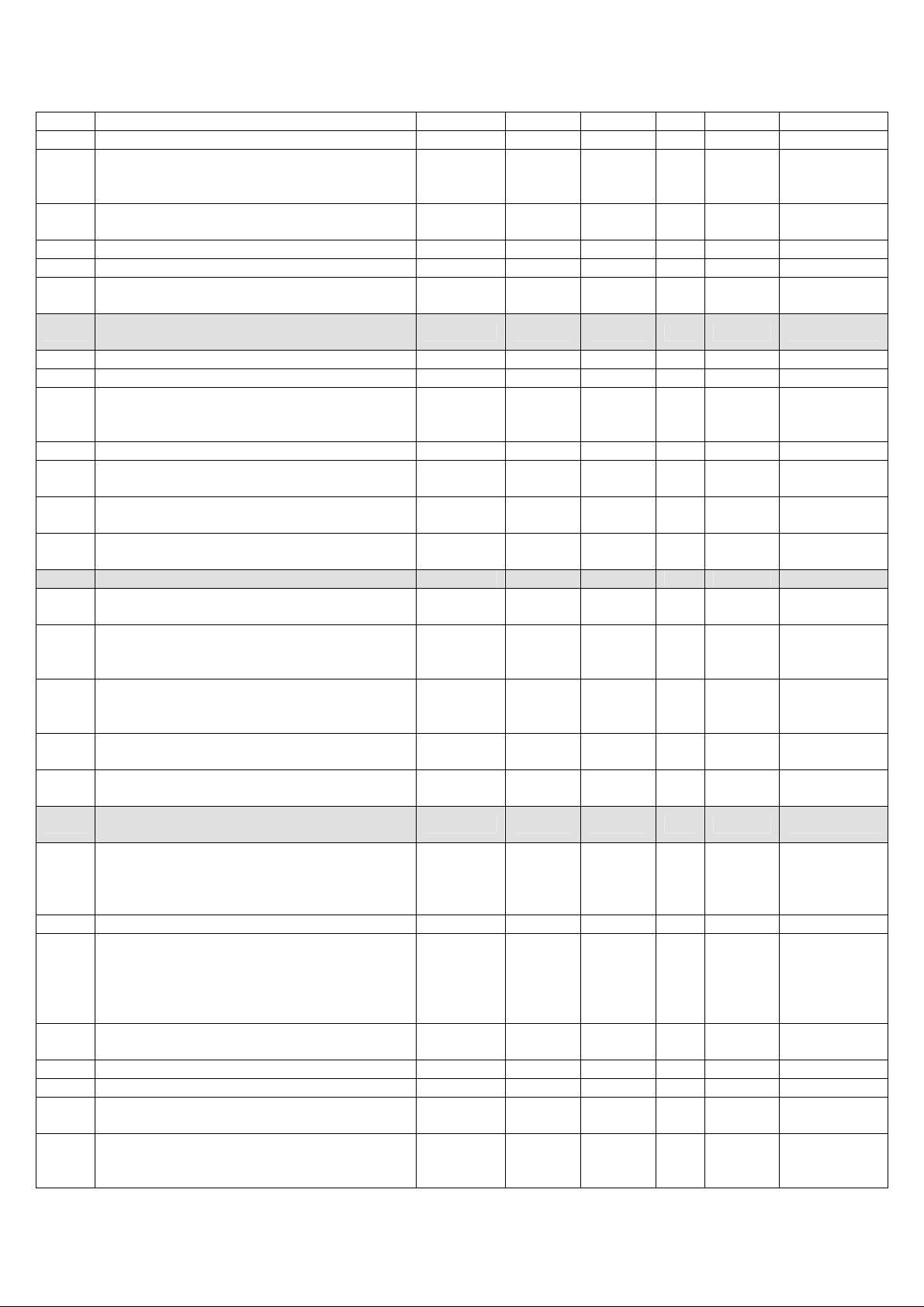

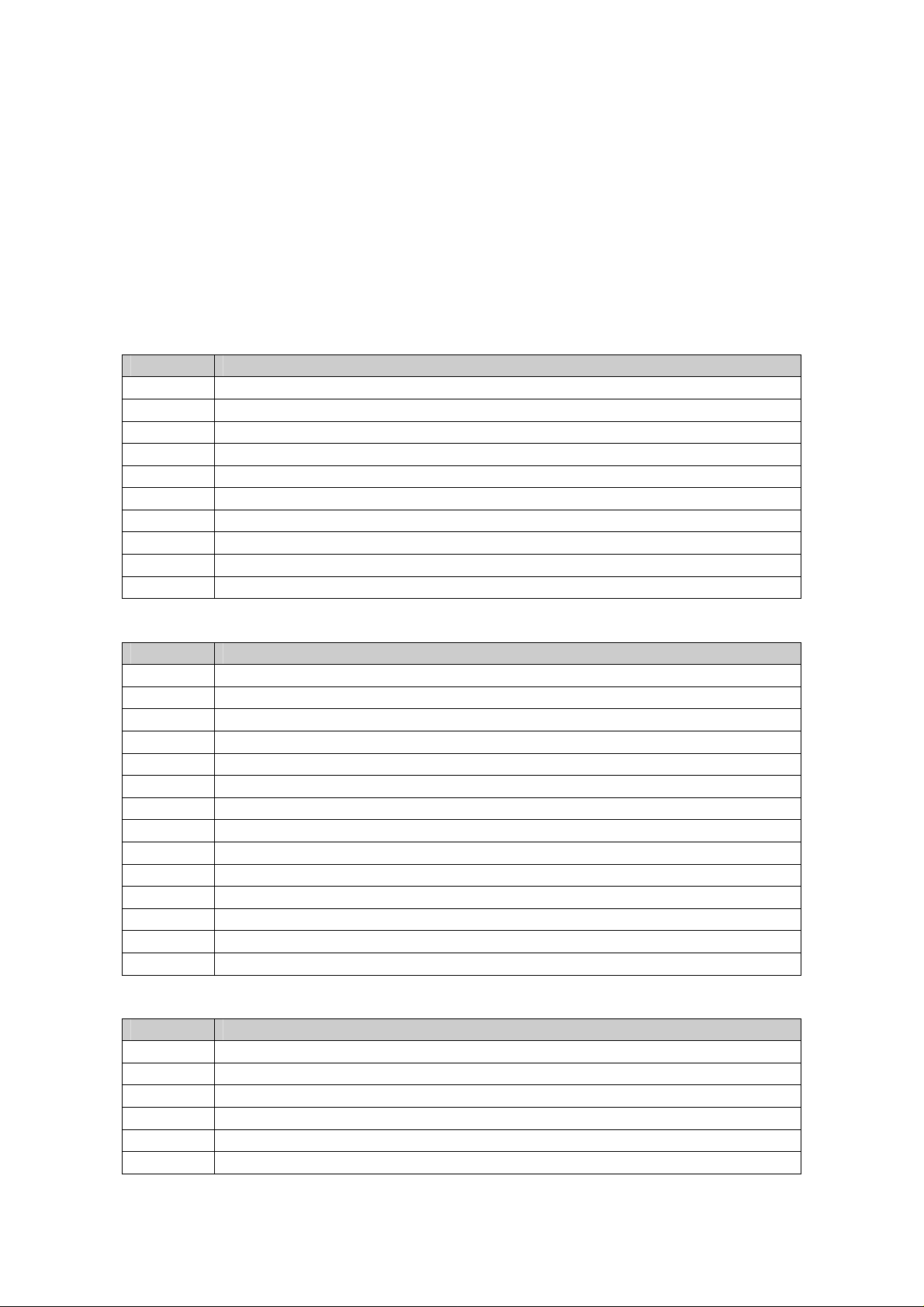

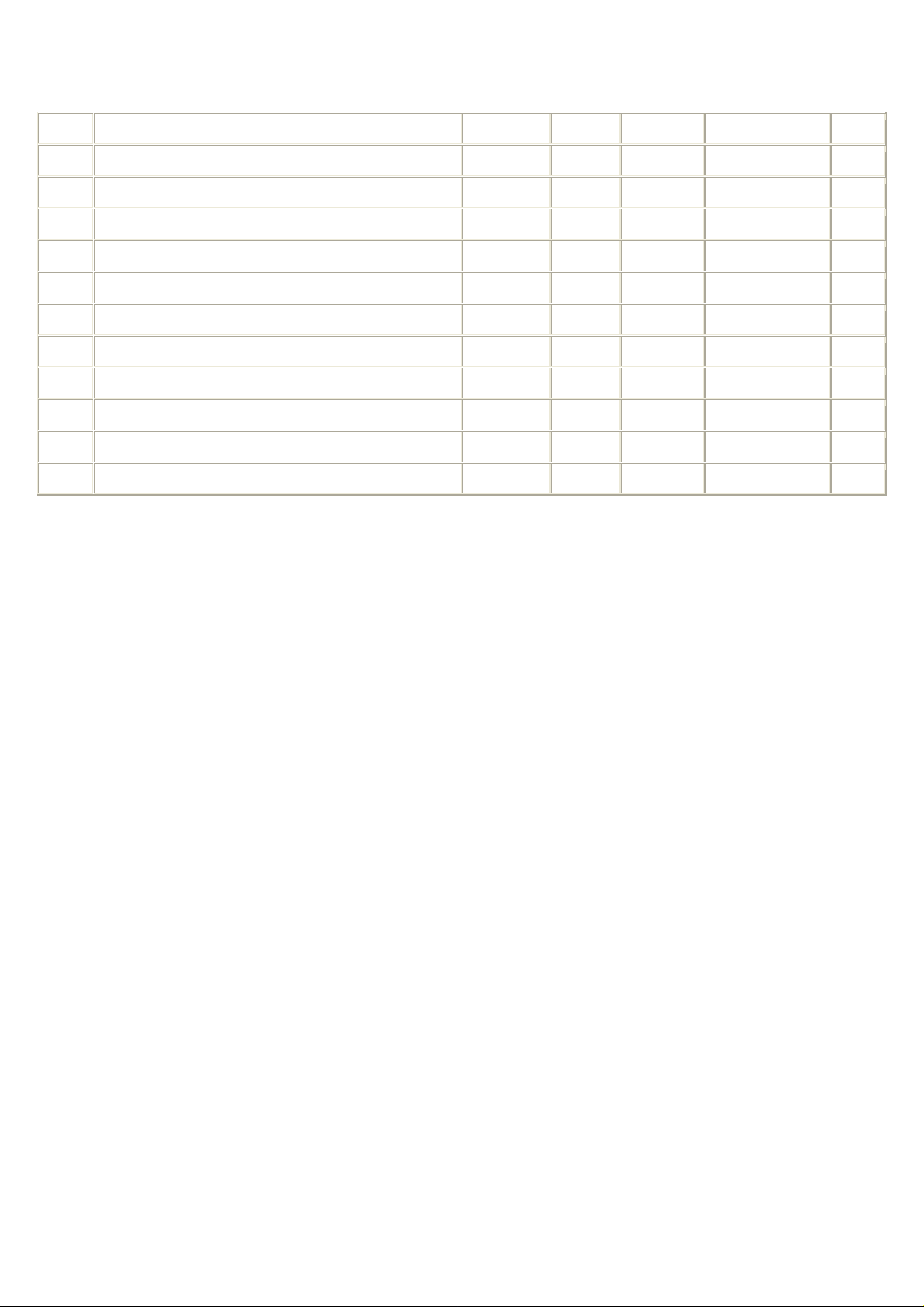

PM80 Calibration of the ambient air temperature probe 0.0 -10.0 10.0 °C MA-IO

PM81 Calibration of the delivery air temperature probe

PM82 Calibration of the external air temperature probe 0.0 -10.0 10.0 °C MA-IO

PM83 Calibration of the ambient humidity probe 0 -10 10 °C MA-IO

PM84

PM85 Calibration of the anti-freeze temperature probe 0.0 -10.0 10.0 °C MA-IO

PM87

PM88 Calibration of the air quality probe (CO2/VOC) 0 -100 100 ppm MA-IO

PM89 Calibration of the external air humity probe 0 -10 10 % MA-IO

PSd2 Password Maintenance Operator Level (2) 0 -999 9999 - MA

Level

3

PC01 Enable compensation Set Point summer NO (0) NO (0) YES (1) - IS-R

PC02 Set Point maximum for summer compensation 28.0 SEtC PH04 °C IS-R

PC03

PC04

PC05

PC06

PC07 Fan activation time for air quality sensors 2 1 30 Min IS-R

PC08

PF01

PF02 Differentials for fan regulation 5.0 0.0 30.0 °C IS-F

PF03

PF04

PF05

PF08

PF09

PF10

Pb01

Pb02

Calibration of the air temperature expulsion

probe

Calibration of the pre-heating air temperature

probe

INSTALLATION OPERATOR MENU

REGULATION

Set Point (on external t.) from begining

compensation

Differential for the summer compensation of Set

Point

Enable cycles for air quality sensors for ambient

temperature (when probe is restarting)

Wait time prior to fan activation for air quality

sensors

Activate both fans for air quality sensors

0 : NO – Only activate pickup fan

1 : YES – Activate both fans

FANS

Types of regulations for fans:

0: Continuous Regulation

1: On/Off Regulation

2: Module Regulation

3: Module Regulation with steps to enable

On/Off

Minimum speed for the regulation of fan

modules

Maximum speed for the regulation of fan

modules

Minimum time between the startup of pickup

and delivery fans.

Differentials of On/Off steps on ramp of

regulation of fan modules

Wait time (on and off) of On/Off steps on ramp

of regulation of fan modules

Pickup and delivery fan speed in ambient probe

alarm

COILS

Proportional band for regulation of valves

(cooling/heating)

Integral time for regulation of valves

(cooling/heating)

0.0 -10.0 10.0 °C MA-IO

0.0 -10.0 10.0 °C MA-IO

0.0 -10.0 10.0 °C MA-IO

26.0 PH03 PH04 °C IS-R

4.0 0.0 20.0 °C IS-R

NO (0) NO (0) YES (1) - IS-R

6 1 99 Min IS-R

NO (0) NO (0) YES (1) - IS-R

1

0.0 0.0 PF04 % IS-F

100.0 PF03 100.0 % IS-F

20 0 999 Sec IS-F

8.0 PF03 60.0 % IS-F

10 0 999 Sec IS-F

30.0 0.0 100.0 % IS-F

10.0 0.0 20.0 °C IS-B

0 0 999 Sec IS-B

Continuo

us (0)

Inverter+

OnOff

(3)

- IS-F

activate

Only with

PG05=1

Only if

PF01=3

Only if

PF01=3

If fans

On/Off set

PF10 > 0 to

activate in

probe error

If Pb02=0

integral action

Pag. 32

C-PRO KILO AHU APPLICATION MANUAL

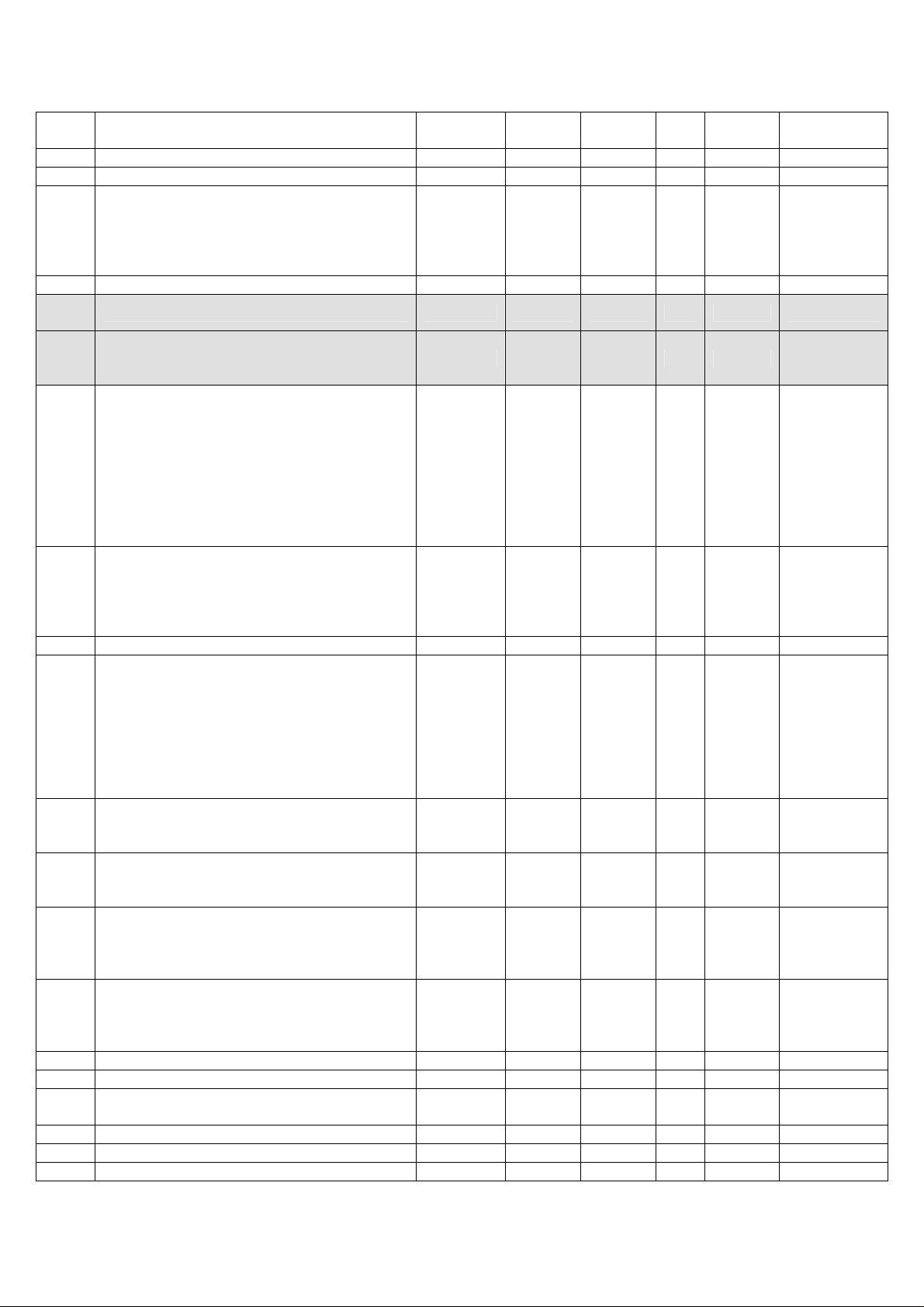

Pb03 Neutral zone for the regulation of temperature 4.0 0.0 20.0 °C IS-B

Pb05

Pb06

Pb10 Opening of heating valves alarm probe delivery 30.0 0.0 100.0 % IS-B

Pb11 Opening of cooling valves alarm probe delivery 30.0 0.0 100.0 % IS-B

Pb20

PU02 Neutral zone for the regulation of humidity 6 0 100 % IS-U

PU03 Differential for the regulation of humidity 10 0 100 % IS-U

PU04

PU05 Enable functional limit for the dehumidification NO (0) NO (0) YES (1) - IS-U

PU10

PU11

PU12

PV01

PV02

PV05

PV06

PV10

PS01

PS02 Enable air quality control NO (0) NO (0) YES (1) - IS-SE

PS03

PS04

PS05 Minimum opening for the external air shutters 0.0 0.0 PS06 % IS-SE

PS06 Maximum opening for the external air shutters 100.0 PS05 100.0 % IS-SE

PS07

PS08

Maximum shifting for Set Point calculation

running of delivery

Proportional band for the Set Point calculation

running of delivery

Insertion/release time single stage of resistance

for the post-heating

VALVES

Menu accessible only if PG06>0 or PG12=1

Integral time for the regulation of

dehumidification (with cold coil)

Enable humidifier control with delivery

temperature

Set Point on the delivery temperature to enable

the humidifier

Differential on the delivery temperature to

enable the humidifier

Proportional band for regulation of valves

(cooling/heating)

Integral time for regulation of valves

(cooling/heating)

Maximum shifting for Set Point calculation

running of delivery

Proportional band for the Set Point calculation

running of delivery

Opening cooling/heating valves alarm probe

delivery

EXTERNAL AIR SHUTTERS

Menu accessible only if PG07>0

Type of Free-Cooling / Free-Heating

0: Disabled

1: Free-Cooling / Free-Heating in temperature

2: Free-Cooling / Free-Heating heat exchanger

Shutter command type

0: Only for Free-Cooling/Free-Heating

1: Only for controlling air quality

2: Priority to the greater of the two requests

3: Average of the two requests

Proportional band for the modulation of the

external air shutters

Run time for the external air shutters from 0% to

100%

Maximum time to maintain signal until end run

time on relay for external air shutters. Signal

will shut off once maximum time is reached

HUMIDITY

0.0 0.0 20.0 °C IS-B

5.0 0.0 20.0 °C IS-B

60 0 999 Sec IS-B

0 0 999 Sec IS-U

YES (1) NO (0) YES (1) - IS-U

22.0 PH03 PH04 °C IS-U

3.0 0.0 20.0 °C IS-U

10.0 0.0 30.0 °C IS-Va

0 0 999 Sec IS-Va

0.0 0.0 10.0 °C IS-Va

5.0 0.0 20.0 °C IS-Va

30.0 0.0 100.0 % IS-Va

1 0 2 - IS-SE

0 0 3 - IS-SE

8.0 0.0 30.0 °C IS-SE

120 0 3600 Sec IS-SE

5 0 600 Sec IS-SE

not present

If Pb05=0

function not

enabled

If PU04=0

ntegral action

not present

Only if

PU10=1

Only if

PU10=1

If PV02=0

integral action

not present

If PV05=0

function not

enabled

Pag. 33

C-PRO KILO AHU APPLICATION MANUAL

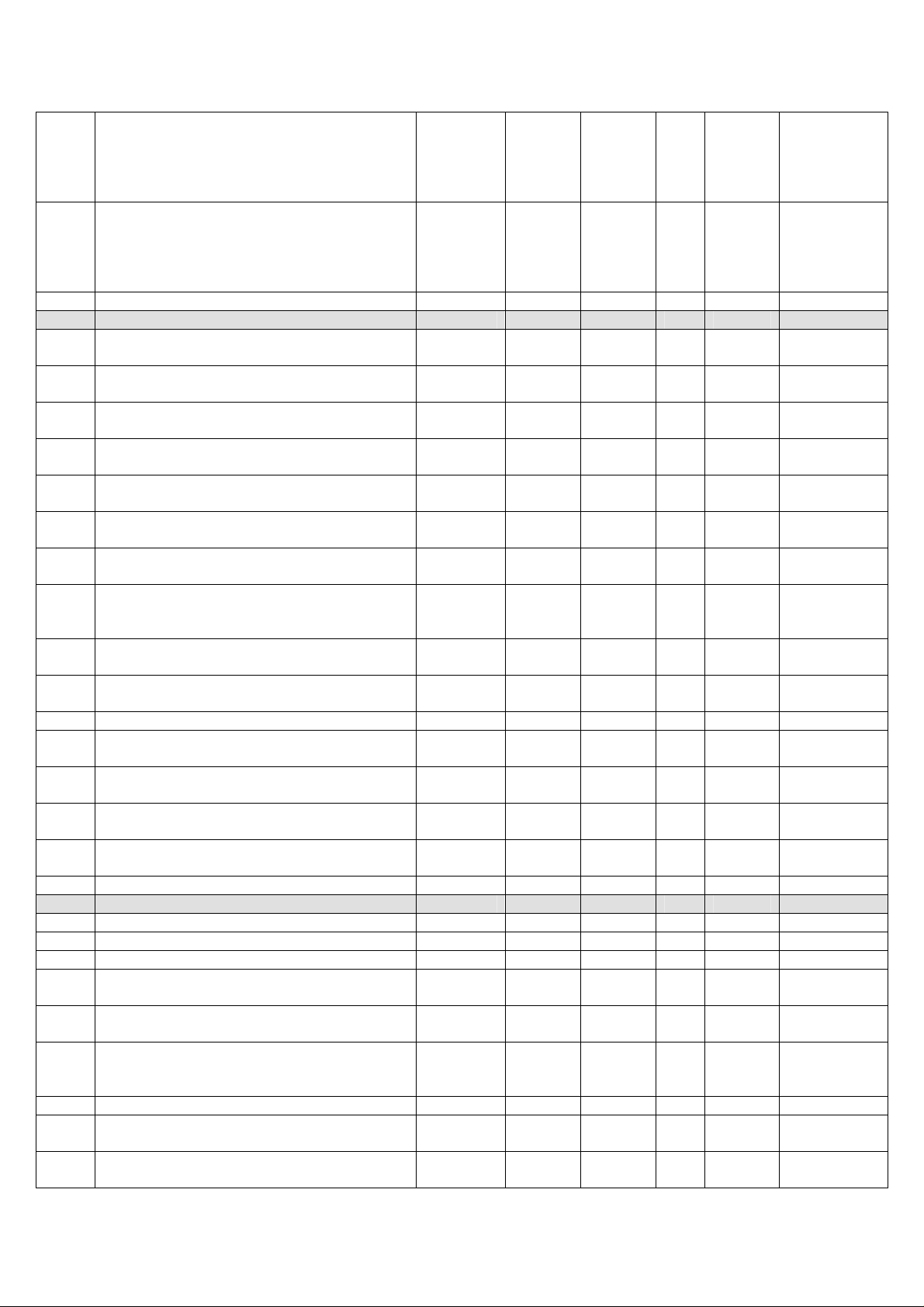

PS09

PS10 Fixed value for opening external air shutters 50.0 0.0 100.0 % IS-SE

PS11

PS12

PS13

PS15

PS16

PS20 Set Point – Air Quality Control 600 0 10000 ppm IS-SE

PS21 Differential – Air Quality Control 100 0 2000 ppm IS-SE

Pr01

Pr02 Differential of regulation of recuperator 3.0 0.0 20.0 °C IS-RH

Pr03 Minimum Set Point expulsion temperature 1.0 PH03 PH04 °C IS-RH

Pr04 Differential minimum expulsion temperature 4.0 0.0 20.0 °C IS-RH

Pr05

Pr07

Pr08

PP01

PP02

PP03

PP04

PU02

PU03 Differential for the regulation of the humidifier 10 0 100 % IS-U

PU10

PU11

PU12

Minimum variation regulation for operating the

external air shutters

Offset at Set Point during winter (at ambient

temp.) until the external air shutters remain

closed during winter operating mode

Differential enabling free-cooling and freeheating in temperature

Differential Set Point enabling free-cooling and

free-heating in temperature

Differential enabling free-cooling and freeheating heat exchanger

Differential Set Point enabling free-cooling and

free-heating heat exchanger

Differential Set Point for regulation of

recuperator

By pass cycle time of recuperators at cross flow

for melting

Minimum velocity of rotating heat recuperator

velocity

Maximum velocity of rotating heat recuperator

velocity

ALARM PARAMETERS

Menu accessibile only if PG10=1 or PG11=1

Types of pump regulation

0: Continuous regulation

1: Regulation On/Off

Set Point on the regulation ramp for pump

startup

Set Point on the regulation ramp for pump

shutdown

Wait time for pump shutdown (only with

PP01=1)

This menu is accessible only if PG06=1

Type of regulation for humidifier

0: ON/OFF Regulation

1: Module Regulation

Enable humidifier control with temperature of

delivery

Set Point at temperature of delivery enabling

humidifier

Differential on the temperature of delivery to

enable humidifier

RECUPERATORS

Menu accessible only if PG13>0

PUMPS

HUMIDIFIER

0.0 0.0 90.0 % IS-SE

2.0 0.0 30.0 °C IS-SE

2.0 0.0 20.0 °C IS-SE

4.0 0.0 20.0 °C IS-SE

8.0 1.0 100.0

10.0 1.0 200.0

5.0 0.0 20.0 °C IS-RH

5 1 99 Min IS-RH

0.0 0.0 Pr08 % IS-RH

100.0 Pr07 100.0 % IS-RH

0 0 1 - IS-P

5.0 PP03 90.0 % IS-P

2.0 1.0 PP02 % IS-P

10 1 99 Min IS-P

0 0 1 - IS-U

YES (1) NO (0) YES (1) - IS-U

22.0 PH03 PH04 °C IS-U

3.0 0.0 20.0 °C IS-U

KJ/

Kg

KJ/

Kg

IS-SE

IS-SE

Enabled if

PS09>0

Only with

fixed

regulation

(PG07=2)

Only with

regulation

module

(PS01=1)

Only if

PG13=4

Only if

PP01=1

OFF – Unit

immediately

shuts down

pump

Only if

PU10=1

Only if

PU10=1

Pag. 34

C-PRO KILO AHU APPLICATION MANUAL

PA01 Enable alarms during hours of fan operation YES (1) NO (0) YES (1) - IS-S

PA02 Enable alarms during hours of pump operation NO (0) NO (0) YES (1) - IS-S

PA03

PA04 Probe alarm delay 10 0 240 Sec IS-S

PA05 Signal alarm probe on alarm relay YES (1) NO (0) YES (1) - IS-S

PA06 Expansion alarm delay 5 0 999 Sec IS-S

PA08 Signal delivery fan alarm on alarm relay YES (1) NO (0) YES (1) - IS-S

PA09 Signal pickup fan alarm on alarm relay YES (1) NO (0) YES (1) - IS-S

PA10 Alarm delay thermal fans 2 0 999 Sec IS-S

PA11 Alarm delay inverter fans 2 0 999 Sec IS-S

PA15 Alarm delay thermal pumps 2 0 999 Sec IS-S

PA16 Signal alarms thermal pumps on alarm relay YES (1) NO (0) YES (1) - IS-S

PA20

PA21 Pressure switch alarm delay (dirty recuperator) 30 0 999 Sec IS-S

PA24

PA25 Pressure switch air filter alarm delay 30 0 999 Sec IS-S

PA26

PA28 Reset airflow meter alarm delay 30 0 999 Sec IS-S

PA29 Airflow meter alarm delay 5 0 999 Sec IS-S

PA30 Signal alarm air flow meter on alarm relay YES (1) NO (0) YES (1) - IS-S

PA31

PA32 Humidifier alarm delay 2 0 999 Sec IS-S

PA33 Signal alarms humidifier on alarm relay YES (1) NO (0) YES (1) - IS-S

PA35

PA36 Alarm delay anti-freeze 5 0 999 Sec IS-S

PA37 Signal alarm anti-freeze on alarm delay YES (1) NO (0) YES (1) - IS-S

PA38

PA39

PA40 Enable RTC alarm YES (1) NO (0) YES (1) IS-S

PA41

PA42 Signal RTC alarms on alarm relay YES (1) NO (0) YES (1) - IS-S

PA45 Signal alarms fire/smoke on alarm relay YES (1) NO (0) YES (1) - IS-S

PH01

PH02

PH03 Minimum temperature value for the Set Point -5.0 -15.0 PH04 °C IS-V

PH04 Maximum temperature value for the Set Point 40.0 PH03 70.0 °C IS-V

PH05

PH06 Enable the change in summer/winter operating YES (1) NO (0) YES (1) - IS-V

Signal alarms during hours of operation on

alarm relay

Type of pressure switch alarm re-arm (dirty

recuperator)

0: Auto - Automatic

1: Manu - Manual

Type of alarm re-arm pressure switch air filter

0: Auto - Automatic

1: Manu - Manual

Signal alarms pressure switch air filter alarm

relay

Type of humidifier alarm re-arm

0: Auto - Automatic

1: Manu - Manual

Type of anti-freeze alarm management:

0: Disabled

1: From digital contact

2: From anti-freeze probe

Activation Set Point for anti-freeze alarm from

transducer

Activation differential for anti-freeze alarm from

transducer

Type of RTC alarm restoration

0: Auto - Automatic

1: Manu - Manual

VARIOUS PARAMETERS

Minimum value threshold for the pressure

probe

Maximum value threshold for the pressure

probe

Enable machine start-up/shut-down by pressing

the ESC/Stand-By key

YES (1) NO (0) YES (1) - IS-S

Manu (1) Auto (0) Manu (1) - IS-S

Manu (1) Auto (0) Manu (1) - IS-S

YES (1) NO (0) YES (1) - IS-S

Auto (0) Auto (0) Manu (1) - IS-S

1 0 2 - IS-S

2.0 PH03 PH04 °C IS-S

3.0 0.0 10.0 °C IS-S

Manu (1) Auto (0) Manu (1) - IS-S

0 -10.0 PH02 Bar IS-V

30.0 PH01 45.0 Bar IS-V

YES (1) NO (0) YES (1) - IS-V

Pag. 35

C-PRO KILO AHU APPLICATION MANUAL

modes utilizing the keyboard (ModE parameter)

PH07

PH08

PH09

PH10

PH11 Modbus card address 1 1 247 - IS-V

PH12

PH13 ModBus parity (0=none, 1=Odd, 2=Even) 2 0 2 - IS-V

PH14 Stop Bit ModBus (0=1bit, 1=2bit) 0 0 1 - IS-V

PH18 Cancel alarm history NO (0) NO (0) YES (1) - IS-V

PH25 Enable variation Set Point from Digital inputs NO (0) NO (0) YES (1) - IS-V

PH26 Enable variation Set Point as Supervisor NO (0) NO (0) YES (1) - IS-V

PH27

PH28

PH32

PH33

PH34 Value of the Atmospheric Pressure 1013 0 10000 hPa IS-V

PH37 PPM transducer minimum value CO2/VOC 0 0 10000 ppm IS-V

PH38 PPM transducer maximum value CO2/VOC 2000 0 10000 ppm IS-V

PH40 Enable external temperature probe NO (0) NO (0) YES (1) - IS-V

PH41

PH42 Enable air expulsion temperature probe YES (1) NO (0) YES (1)

PH43 Enable anti-freeze temperature probe NO (0) NO (0) YES (1)

PH45 Enable pre-heating air temperature probe NO (0) NO (0) YES (1)

PH46

PH47

PH50

PH51 Logistics of Digital inputs used for the alarms NO (0) NO (0) NC (1) - IS-V

Enable machine start-up/shut-down using the

Digital inputs

Enable the change in summer/winter operating

modes utilizing the Digital inputs

Enable machine start-up/shut-down as

supervisor

Enable the change in summer/winter operating

modes as supervisor

Baud Rate of comunication for the card

(0=1200, 1=2400, 2=4800, 3=9600, 4=19200)

Enable distinct/single Set Point for

heating/cooling:

0: Set Point distinct

1: Set Point single

Enable nocturnal operating mode for the

modification of the Set Point regulation

Unit of measurement of temperature:

0: °Celsius

1: °Fahrenheit

Unit of measurement of pressure:

0: Bar

1: psi

Enable ambient air humidity probe

0: Disabled

1: Enabled with sensor 4..20mA

2: Enabled with sensor 0..5V

Enable air quality probe (CO2/VOC)

0: Disabled

1: Enabled with sensor 4..20mA

2: Enabled with sensor 0..5V

Enable external air humidity probe

0: Disabled

1: Enabled with sensor 4..20mA

2: Enabled with sensor 0..5V

Logistics of Digital inputs for:

- change in summer/winter modes

- On/Off remote

- change in Set Point of regulation

YES (1) NO (0) YES (1) - IS-V

NO (0) NO (0) YES (1) - IS-V

NO (0) NO (0) YES (1) IS-V

NO (0) NO (0) YES (1) IS-V

3 0 4 -

0 0 1 - IS-V

NO (0) NO (0) YES (1) - IS-V

0 (°C) 0 (°C) 1 (°F) - IS-V

0 (Bar) 0 (Bar) 1 (psi) - IS-V

1 0 2 - IS-V

0 0 2 - IS-V

0 0 2 - IS-V

NO (0) NO (0) NC (1) - IS-V

Set SI (1) and

wait for value

NO (0)

If PH27=1

(single Set

Point), the

single Set

Point utilized

for the

regulation is

SEtH.

- IS-V

- IS-V

- IS-V

Pag. 36

C-PRO KILO AHU APPLICATION MANUAL

PH52

PH53 Logistics of Digital inputs for alarm fire-smoke NC (1) NO (0) NC (1) - IS-V

PH60 Logistics of alarm relay NO (0) NO (0) NC (1) - IS-V

PH15 Restoring the manufacturers’ defualt parameters NO (0) NO (0) YES (1) - IS-D

PSd3 Password Installation Operator Level (3) 0 -999 9999 - IS

Level

PG00

PG01

PG02 Enable the presence of the expansion NO (0) NO (0) YES (1) - CO-W

PG03 Enable RTC system clock YES (1) NO (0) YES (1) - CO-W

PG04

PG05

PG06

PG07

PG08 Enable delivery fans YES (1) NO (0) YES (1) - CO-W

PG09 Enable pickup fans YES (1) NO (0) YES (1) - CO-W

PG10

PG11 Enable cooling circulation pump NO (0) NO (0) YES (1)

PG12 Enable dehumidification NO (0) NO (0) YES (1)

PG13 Manage heating recuperator 0 0 4 - CO-W

Logistics of Digital inputs used for the alarm

flux status

4

Upon modification of these parameters it is

Unit type:

1: Winter operating mode only

2: Summer operating mode only

3: Winter and summer operating mode with

humidity

4: Winter and summer operating mode with

humidity and heat recuperation

5: Two coils without dehumidification

6: Three coils with dehumidification

Number of coils

1: Heating/Cooling (Unit with single coil)

2: Heating, Cooling

3: Heating, Cooling, Post-Heating

Primary types of regulation:

0: On fan

1: On valves

Positioning probe of regulation:

0: Ambient probe

1: Probe in restart channel

Enable humidifier

0: Disabled

1: Regulation ON-OFF

2: Regolation Modulating

Enabled external air shutters

0: Disabled

1: Modulating regulation

2: Fixed opening

Enable heating circulation pump (or single pump

for the unit at single coil)

CONSTRUCTOR MENU

CONFIGURATION PARAMETERS

advised to remove and delete the card feed

NC (1) NO (0) NC (1) - IS-V

3 1 6 - CO-W

1 1 3 - COW

Valv. (1) Fan (0) Valv. (1) - CO-W

Amb. (0) Amb. (0) Rest. (1) - CO-W

1 0 2 - CO-W

1 0 2 - CO-W

NO (0) NO (0) YES (1) - CO-W

- CO-W

- CO-W

Wait for the

value NO(0)

upon

completion of

restore

If PG01=1 the

MOdE

parameter

decides if hot

or cold

If PG03=0,

history does

not memorize

elements and

the nocturnal

operating

mode is

disabled

Pag. 37

C-PRO KILO AHU APPLICATION MANUAL

0: Disabled

1: At cross flow

2: Using two coils

3: Rotating On/Off (DO)

4: Rotating Modulating (AO)

Post-heating with electrical resistance:

0: Operation disabled

PG14

PSd4 Password for Constructor Level (4) 0 -999 9999 - CO

Hd01

Hd02

Hd03

Hd05

Hd06

Hd07

Hd08

Hd10

Hd11

Hd13

Hd15 Positioning of Digital inputs of alarm humidifier 0 0 7 - CO-HI

Hd16

Hd17

Hd18

Hd19

Hd20 Positioning of Digital inputs of alarm fire-smoke 0 0 7 - CO-HI

HF01 Positioning of Digital outputs of delivery fans 1 0 7 - CO-HO

HF02 Positioning of Digital outputs of pickup fans 2 0 7 - CO-HO

HU01 Positioning of Digital outputs of humidifier 0 0 7 - CO-HO

HS01

HS02

HP01

HP02 Position of digital output of the cooling pump 0 0 14 - CO-HO

Hr01

HE01

1: One stage of resistance

2: Two stages of resistance

3: Three stages of resistance

HARDWARE IN PARAMETERS

Positioning of Digital inputs while machine is

On/Off

Positioning of Digital inputs for the changes in

operating mode (summer/winter)

Positioning of Digital inputs for the variations of

Set Point ambient

Positioning of Digital inputs of alarm thermal

delivery fan

Positioning of Digital inputs of alarm inverter

delivery fan

Positioning of Digital inputs of alarm thermal

pickup fan

Positioning of Digital inputs of alarm inverter

pickup fan

Position of digital input of thermal heating pump

alarm (or single circulation pump for the unit at

single coil)

Position of digital input of thermal cooling

pump alarm

Position of digital input of thermal resistance

pump alarm

Positioning of Digital inputs of alarm air

flowmeter

Positioning of Digital inputs of alarm anti-freeze

thermostat

Positioning of Digital inputs of alarm air filter

pressure switch

Position of digital input of pressure switch

recuperator alarm

HARDWARE OUT PARAMETERS

Positioning of Digital outputs to control the

opening of external air shutters

Positioning of Digital outputs to control the

closing of external air shutters

Position of digital ouput of the heating pump (or

single circulation pump for the unit at single

coil)

Position of the digital output dedicated to the

recuperator

Position of the digital output of the first stage of

electrical resistance

0 0 3 - CO-W

1 0 7 - CO-HI

0 0 7 - CO-HI

0 0 7 - CO-HI

3 0 7 - CO-HI

0 0 7 - CO-HI

0 0 7 - CO-HI

0 0 7 - CO-HI

0 0 14 - CO-HI

0 0 14 - CO-HI

0 0 14 - CO-HI

6 0 7 - CO-HI

5 0 7 - CO-HI

4 0 7 - CO-HI

0 0 14 - CO-HI

4 0 7 - CO-HO

5 0 7 - CO-HO

0 0 14 - CO-HO

0 0 14 - CO-HO

0 0 14 - CO-HO

Pag. 38

C-PRO KILO AHU APPLICATION MANUAL

HE02

HE03

HA01 Position of the digital output of the alarm relay 7 0 14 - CO-HO

HA02

HA04

HA05

HA06

HA07

HA08

HA09

Position of the digital output of the second stage

of electrical resistance

Position of the digital output of the third stage of

electrical resistance

Position of the digital output for dirty filter

indicator alarm or dirty recuperator

Position of the analogue output of the heating

valves (or single for heating/cooling in case the

unit is at single coil)

Position of the analogue output of the

cooling/dehumidifying valve

Position of the analogue output of the postheating valves

Positioning of Analogue outputs for the inverter

fans

Positioning of Analogue outputs for the

humidifier module

Position of the analogue output dedicated for the

rotating recuperator

0 0 14 - CO-HO

0 0 14 - CO-HO

6 0 14 - CO-HO

2 0 6 - CO-HO

0 0 6 - CO-HO

0 0 6 - CO-HO

3 0 6 - CO-HO

0 0 6 - CO-HO

0 0 6 - CO-HO

Note. In order to accurately configure the machine parameters, it is advised that the card feed

be removed/deleted once the machine parameters have been configured and for each

subsequent modification to the “ parametri di configurazione” (configuration parameters).

Pag. 39

C-PRO KILO AHU APPLICATION MANUAL

6 REGULATIONS

6.1 Unit status

There are additional procedures for the start-up/shut-down of the unit:

1) Using the On/Off key (parameter, PH05=1)

Startup: press the related key for approximately 2 seconds: if all the other enabled

conditions are present, the machine will turn “ON”.

Shutdown: press the related key for approximately 2 seconds: the machine will turn

“OFF”.

2) Using the On/Off command from the Digital inputs (parameter, PH07=1)

Startup: close the remote On/Off contact: if all the other enabled conditions are

present, the machine will turn “ON”.

Shutdown: if the remote On/Off contact opens, the machine will turn “OFF from

Digital inputs” (as also indicated by the dictation “OFF_D”).

3) Using the supervision protocol (parameter, PH09=1)

Startup: activate from protocol the startup status: if all the other enabled conditions

are present, the machine will turn “ON”.

Shutdown: if the startup status becomes deactivated from the protocol, the machine

will turn “OFF da protocollo di supervisione” (OFF from supervision protocol) (as

also indicated by the dictation “OFF_S”).

The status of the On/Off key has priority with respect to the other two keys. In fact, the

status of the On/Off from Digital Inputs and from supervision protocol are accessible only

when the machine’s keyboard is turned on.

A machine with its Digital inputs shut off can:

⋅ Change to OFF status by pressing the ESC key.

⋅ Change to OFF status as supervisor if you re-enter the conditions of OFF from Digital

inputs and set the status of OFF from supervisor.

⋅ Change to ON status if you re-enter the conditions of OFF from Digital inputs and do

not set the status of OFF from supervisor.

A machine with its supervision protocol shut off can:

⋅ Change to OFF status by pressing the ESC key.

⋅ Change to status OFF from Digital inputs if you re-enter the conditions of OFF from

supervisor and switch the status of OFF from Digital inputs.

⋅ Change to ON status if you re-enter the conditions of OFF from supervisor and the

conditions of OFF from Digital inputs are not present.

The machines On/Off key is the ESC key, which needs to be pressed down for approximately

2 seconds.

The remote On/Off inputs (if present) can be configured through the following parameters:

- PH07: Enable the function

- PH50: Set the logic NC, NO for the digital contacts

- Hd01: Set the position for the Digital inputs

Pag. 40

C-PRO KILO AHU APPLICATION MANUAL

6.1.1 Alarm OFF status

When the machine is turned on an additional status, OFF da alarm (Alarm Off) exists. This

shuts down the unit, all devices, and closes the external air shutters completely until the alarm

conditions are restored. The central alarm will shut down to OFF status if there is no digital /

supervisor consent or shut down is requested via the keyboard. The alarms which provoke

this status are as follows:

- Fan thermal alarm

- Fan inverter alarm

- Air Flow Meter alarm

- Fire/smoke alarm

Once alarm conditions have been restored the machine will return to normal operation.

Pag. 41

C-PRO KILO AHU APPLICATION MANUAL

6.2 Unit Type

While the machine is turned off, using the parameter PG00 in the COSTRUTTORE

(CONSTRUCTOR) Menu, it is possibile to choose the type of unit that you wish to utilize.

Based on the value of the parameters, different defualts become available for the positioning

of inputs and outputs. The regulation and other parameters which correspond to diverse

funtionalities can be modified manually according to user requirements.

To follow is a list of the machines which are managed by the respective configurations of

inputs and outputs.

Note. The default configurations can also be modified according to user requirements by

entering modifications to the paramaters manually.

ATTENTION. When changing the machine type (through modification of parameter PG00)

it is necessary to shutdown and then restart the card to ensure the unit has been correctly

configured; in order to allow the card to assign all the parameters contained therein it is

advisable to wait a few seconds (3 seconds should be more than sufficient) before removing

the tension.

Pag. 42

C-PRO KILO AHU APPLICATION MANUAL

6.2.1 Unit in WINTER operating mode (PG00=1)

The MOdE parameter can be setup by default in INVERNO (WINTER).

Unit at single coil PG01=1.

The fan regulations can be setup by default in On/Off (PF01=1).

The primary regulation can be setup by default on the valve (PG04=1).

The regulation of the shutter is fixed (PG07=2).

PIN ANALOGUE INPUTS

AI1 Ambient air temperature probes (NTC)

AI2 Air delivery temperature probes (NTC)

AI3 Not utilized

AI4 Not utilized

AI5 Not utilized

PIN DIGITAL INPUTS

DI1 On/Off remote

DI2 Not utilized

DI3 Thermal delivery fan

DI4 Air filter pressure switch

DI5 Anti-freeze thermostat

DI6 Airflow status

DI7 Not utilized

PIN ANALOGUE OUTPUTS

AO 1 Not utilized

AO 2 Heating valve control (0-10V)

AO 3 Not utilized

PIN DIGITAL OUTPUTS

DO1 Delivery fan

DO2 Pickup fan

DO3 Not utilized

DO4 Opening external air shutters

DO5 Closing external air shutters

DO6 Dirty filter indicator

DO7 Alarm

RTC system clock present.

Pag. 43

C-PRO KILO AHU APPLICATION MANUAL

6.2.2 Unit in SUMMER operating mode (PG00=2)

The MOdE parameter can be setup by default in ESTATE (SUMMER).

Unit at single coil PG01=1.

The fan regulations can be set up by default in On/Off (PF01=1).

The primary regulation can be set up by default on the valve (PG04=1).

The regulation of the shutter is fixed (PG07=2).

PIN ANALOGUE INPUTS

AI1 Ambient air temperature probes (NTC)

AI2 Air delivery temperature probes (NTC)

AI3 Not utilized

AI4 Not utilized

AI5 Not utilized

PIN DIGITAL INPUTS

DI1 On/Off remote

DI2 Not utilized

DI3 Thermal delivery fan

DI4 Air filter pressure switch

DI5 Anti-freeze alarms

DI6 Air flow status

DI7 Not utilized

PIN ANALOGUE OUTPUTS

AO 1 Not utilized

AO 2 Cooling valve control (0-10V)

AO 3 Not utilized

PIN DIGITAL OUTPUTS

DO1 Delivery fan

DO2 Pickup fan

DO3 Not utilized

DO4 Opening external air shutters

DO5 Closing external air shutters

DO6 Dirty filter indicator

DO7 Alarm

RTC system clock present.

Pag. 44

C-PRO KILO AHU APPLICATION MANUAL

6.2.3 Unit operation during WINTER/SUMMER WITH

HUMIDITY (PG00=3)

The MOdE parameter can be set up by default in INVERNO (WINTER).

Unit at single coil PG01=1.

The fan regulations can be set up by default in inverter with On/Off (PF01=3).

The primary regulation can be set up by default on the valve (PG04=1).

The primary regulation starts with valves set on default (PG04=1).

The regulation of the shutter is enabled for free-cooling/free-heating (PG07=1, PS01=1).

PIN ANALOGUE INPUTS

AI1 Ambient air temperature probes (NTC)

AI2 Air delivery temperature probes (NTC)

AI3 External air temperature (NTC)

AI4 Humidity probe (4..20 mA)

AI5 Air expulsion temperature probe (NTC)

PIN DIGITAL INPUTS

DI1 On/Off remote