Page 1

C-PRO CLIMA SISTEMA

INSTALLER MANUAL

CODE 144CLIMA0E02

Page 2

C-PRO CLIMA SISTEMA INSTALLER MANUAL

Important

Read these instructions carefully before installation and use and follow all recommendations regarding installation and

for the electric connection; keep these instructions for future reference.

The instrument must be disposed of according to local Standards regarding the collection of electric and

electronic appliances.

Page 2

Page 3

C-PRO CLIMA SISTEMA INSTALLER MANUAL

Summary

1 GENERALITIES ......................................................................................................................................................5

1.1 Description ...................................................................................................................................................... 5

2 APPLICATIONS ......................................................................................................................................................7

2.1 Application layouts.......................................................................................................................................... 8

3 INSTALLATION......................................................................................................................................................9

3.1 Dimensions......................................................................................................................................................9

3.2 Assembly....................................................................................................................................................... 10

3.3 Electric connections.......................................................................................................................................12

3.4 Regulators network configuration .................................................................................................................17

3.5 Displays network configuration..................................................................................................................... 21

4 USER INTERFACE................................................................................................................................................25

4.1 Display and keyboard ....................................................................................................................................25

4.2 Navigation through the applications making up the system ..........................................................................26

5 C-PRO MEGA MCCT REGULATOR...................................................................................................................27

5.1 List of pages................................................................................................................................................... 27

5.2 Alarms/log menu ...........................................................................................................................................28

5.3 Clock menu....................................................................................................................................................29

5.4 Maintenance menu (maintenance technician)................................................................................................29

5.5 Installer menu ................................................................................................................................................ 30

5.6 Main OFF page..............................................................................................................................................31

5.7 Main ON page ...............................................................................................................................................31

5.8 State pages.....................................................................................................................................................32

5.9 Configuration parameters ..............................................................................................................................33

5.10 State of the unit..............................................................................................................................................38

5.11 Summer/winter functioning mode .................................................................................................................39

6 C-PRO MICRO MCZN REGULATOR ................................................................................................................. 40

6.1 List of pages................................................................................................................................................... 40

6.2 Main page...................................................................................................................................................... 41

6.3 Zones status ...................................................................................................................................................41

6.4 Main menu.....................................................................................................................................................42

6.6 System Network page.................................................................................................................................... 44

6.7 Configuration parameters ..............................................................................................................................45

6.8 State of the unit..............................................................................................................................................49

6.9 State of Zone A and Zone B ..........................................................................................................................49

7 C-PRO MICRO MCDE REGULATOR ................................................................................................................. 50

7.1 List of pages................................................................................................................................................... 50

7.2 Main page...................................................................................................................................................... 51

7.3 States..............................................................................................................................................................51

7.4 Main menu.....................................................................................................................................................52

7.5 On/Off pages.................................................................................................................................................. 54

7.6 System Network page.................................................................................................................................... 54

7.7 Configuration parameters ..............................................................................................................................55

7.8 State of the unit..............................................................................................................................................57

8 C-PRO MICRO MCPS REGULATOR ..................................................................................................................58

8.1 List of pages................................................................................................................................................... 58

8.2 Main page...................................................................................................................................................... 59

8.3 State pages.....................................................................................................................................................59

8.4 Main menu.....................................................................................................................................................61

8.5 System Network page.................................................................................................................................... 63

8.6 Configuration parameters ..............................................................................................................................64

8.7 State of the unit..............................................................................................................................................67

9 REGULATION.......................................................................................................................................................68

9.1 Regulation of the zone temperature (MCZN, MCCT modules) .................................................................... 68

9.2 Regulation of the delivery temperature (MCZN, MCCT modules)...............................................................72

9.3 Regulation of the zone humidity (MCZN, MCCT, MCDE modules) ...........................................................77

9.4 Regulation of air quality (recirculation) (MCDE module) ............................................................................79

9.5 Regulation of the DHW tank temperature for the DHW water (MCPS module) ..........................................80

9.6 Management and configuration of the heating solar panel circuits (MCPS module) ....................................83

9.7 Other regulations ...........................................................................................................................................86

Page 3

Page 4

C-PRO CLIMA SISTEMA INSTALLER MANUAL

Page 4

Page 5

C-PRO CLIMA SISTEMA INSTALLER MANUAL

1 GENERALITIES

1.1 Description

The c-pro CLIMA Climatic Modules allow to realise innovative control and regulation networks in

distributed logic, for air-conditioning and heating systems in residential and commercial buildings,

characterised by the most demanding and modern necessity for environmental comfort, system

performance and energy savings.

The Climatic Modules are programmable controllers dedicated specifically to the regulation of the

different parts of the systems:

• c-pro Mega MCCT, for THERMAL POWER PLANT, where there is a boiler, chiller

and/or heat pump present with relative delivery pumps and safety devices.

• c-pro Micro MCZN, for the various ZONES, where it is necessary to control the regulation

of the temperature and humidity in the room, via heated or cooled floors and dehumidifiers.

• c-pro Micro MCDE, can manage the most different types of DEHUMIDIFIERS for every

zone, which also have integration and support systems for heating and/or cooling the room.

• c-pro Micro MCPS, dedicated to the management of the glycoled circuit of the SOLAR

HEAT PANELS and for the circuit of the heating and/or domestic hot water with DHW

tank.

Other specific components of the CLIMA system are dedicated for the completion of the

requirements of every conditioning and heating system:

• Vgraph, ZONE TERMINALS for the user, which allow to display and set the temperature

and room humidity values, the alarms and the time band of each zone.

• EVSET, ZONE SET VARIATOR not displayed, with temperature probe on board, able to

modify the room temperature in order to reach maximum well-being.

• Flow switches, air quality probes (and CO2), temperature and immersion humidity probes,

channel or room.

Some features of the Climatic Modules and the components of the c-pro CLIMA system must be

highlighted:

• Flexibility: allows to design and realise the correct and convenient regulation and control

solution for every type of building, thanks to the capacity of the modules to adapt to the

needs of every type of system.

• Modularity: allows to insert the number and type of modules and components necessary to

satisfy the requirements of every user and every different and specific new system to be

realised, obtaining complete stability of the application software, which must not be realised

or modified for very new system that a plant engineer must build (possibility of modifying

or developing software, which being programmable controllers remains in all cases).

• capacity of communication among modules and some components, via the CANbus field,

which makes the realisation of distributed control network possible in the building, instead

of the traditional centralised system. This has the important and fundamental result of

reducing realisation times and costs of the electric wiring of the air conditioning and heating

system.

Page 5

Page 6

C-PRO CLIMA SISTEMA INSTALLER MANUAL

• Availability of MODBUS communication, from the Modules to a BMS system supervision

system via a serial output, also suitable for the configuration phases or modification of

controller parameters in the system installation or maintenance phases.

All of these features mean an innovative control and regulation system, from high performance

resulting in great system efficiency with consequent maximum energy saving.

Page 6

Page 7

C-PRO CLIMA SISTEMA INSTALLER MANUAL

2 APPLICATIONS

Personal Computer with

supervision software "RICS" installed

CAN network

CAN network

CAN network

CAN network

Page 7

Page 8

C-PRO CLIMA SISTEMA INSTALLER MANUAL

2.1 Application layouts

Below find the application layouts:

solar panels

circuit 1 pump

solar panels

circuit 2 pump

ACS tank

circuit pump

c-pro micro MCPS

ACS tank upper

temperature

ACS tank lower

temperature

alarm

auxiliary circuit pum p

overheating emergency

solar panels

CAN network

circuit 1 dischargin g valve

circuit 2 dischargin g valve

alarm

/

boiler

c-pro mega MCCT

flow switch

circuit 1

summer / winter

chiller / heat pump

circuit 1 discharging pump

circuit 2 discharging pump

thermal power plant

auxiliary plant

temperature

solar panels circuit

temperature

flow switch

circuit 2

circuit 1 discharging temp.

circuit 2 discharging temp.

external temperature

electric valve collector heating / cooling zone A (1) electric valve collector heating / cooling zone B (1)

zone A (1) alarm

c-pro micro MCZN Vgraph

zone A (1)

CAN network

electric valve collector heating / cooling zone A (2) electric valve collector heating / cooling zone B (2)

zone A (2) alarm

zone A (2)

dehumidifier

heat booster dehumidifier

dehumidifier alarm

electric valve collector

heating / cooling zone C (1)

cool booster

dehumidifier

electric valve collector dehumidifier zone B (1)

zone B (1) alarm

c-pro micro MCZN

room temperature zone B (1)room temperature zone A (1)

room humidity zone B (1)room humidity zone A (1)

zone B (1)

CAN network

electric valve collector dehumidifier zone B (2)

zone B (2) alarm

room temperature zone B (2)room temperature zone A (2)

room humidity zone B (2)room humidity zone A (2)

zone B (2)

heat booster dehumidifier 1

dehumidifier 1 alarm

electric valve collector

heating / cooling zone D (1)

zone D (1) alarmzone C (1) alarm

c-pro micro MCZNc-pro micro MCZN

room temperature zone D (1)room temperature zone C (1)

room humidity zone D (1)room humidity zone C (1)

zone D (1)zone C (1)

CAN networkCAN network

electric valve collector heating / cooling zone D (2)electric valve collector heating / cooling zone C (2)

dehumidifier 1

c-pro micro MCDEc-pro micro MCDE

zone C (2) alarm

room temperature zone C (2)

room humidity zone C (2)

Vgraph

zone D (2) alarm

heat booster dehumidifier 2

dehumidifier 2 alarm

room temperature zone D (2)

room humidity zone D (2)

zone D (2)zone C (2)

dehumidifier 2

Page 8

Page 9

C-PRO CLIMA SISTEMA INSTALLER MANUAL

3 INSTALLATION

Below we will show the dimensions, assembly and electric connections of the C-PRO CLIMA

SYSTEM, made up from thermal power plant modules (MCCT), Zones (MCZN), Dehumidifiers

(MCDE), solar panels (MCPS) and graphical displays (Vgraph).

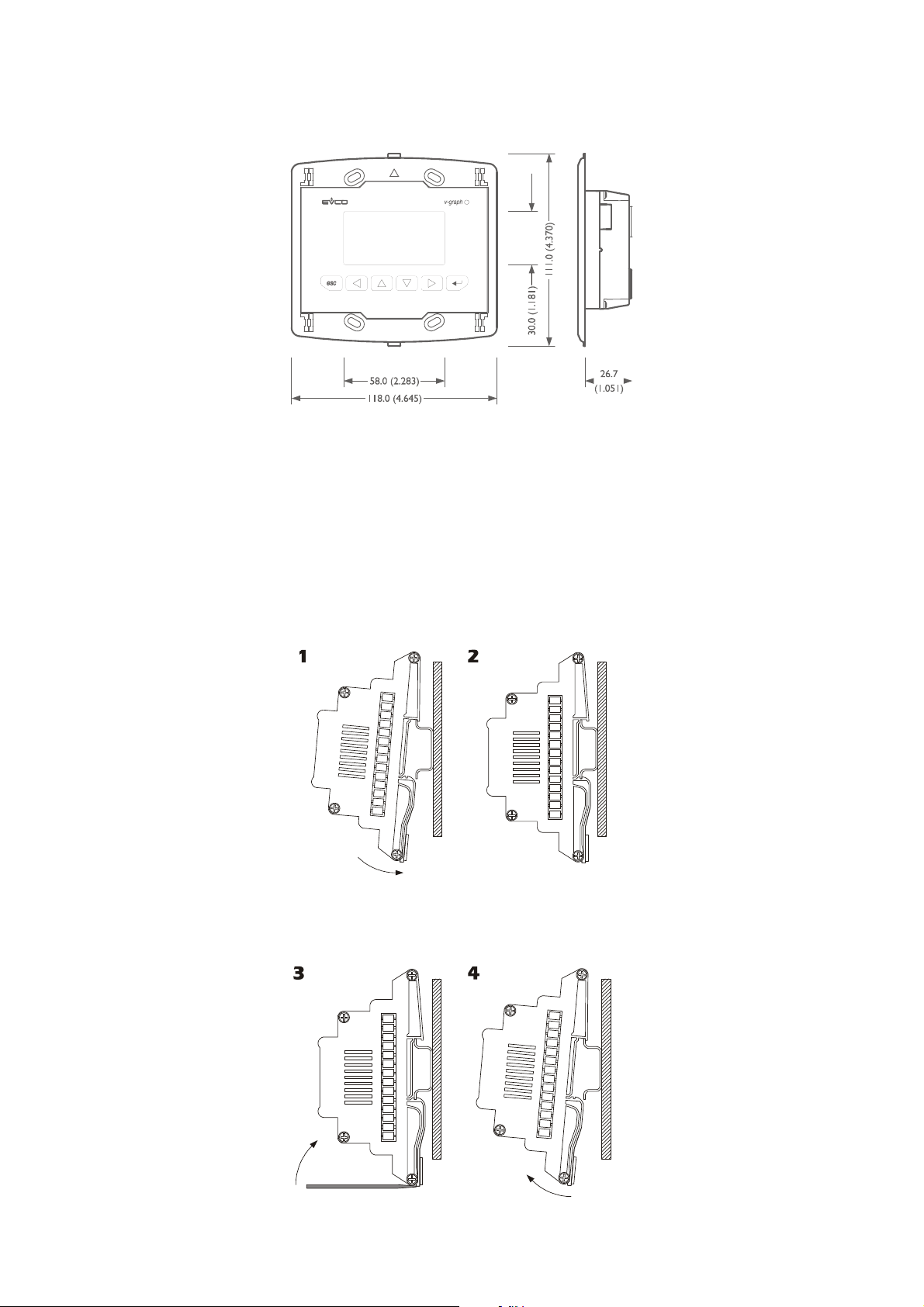

3.1 Dimensions

3.1.1 Thermal power plant module dimensional drawing (MCCT).

3.1.2 Zone modules (MCZN), dehumidifier (MCDE) and solar panels (MCPS)

dimensional drawing.

Page 9

Page 10

C-PRO CLIMA SISTEMA INSTALLER MANUAL

3.1.3 Graphical display dimensional drawing (Vgraph).

3.2 Assembly

3.2.1 Assembly of thermal power plant modules (MCCT), Zone (MCZN),

Dehumidifier (MCDE) and solar panels (MCPS)

To install the thermal power plant, zone, Dehumidifier and solar panels module,

operate as indicated in the diagrams (points 1 and 2).

To remove thermal power plant, zone, dehumidifier and solar panels module, use a screwdriver and

operate as indicated in the diagrams (points 3 and 4).

Page 10

Page 11

C-PRO CLIMA SISTEMA INSTALLER MANUAL

3.2.2 Display Assembly (Vgraph)

There are three possibilities for assembly of the Vgraph graphical display:

3.2.2.1 Wall recessed in 506E box

3.2.3

3.2.3.1 Wall-installation, on Evco CPVW00 support

3.2.3.2 Panel installation

Page 11

Page 12

C-PRO CLIMA SISTEMA INSTALLER MANUAL

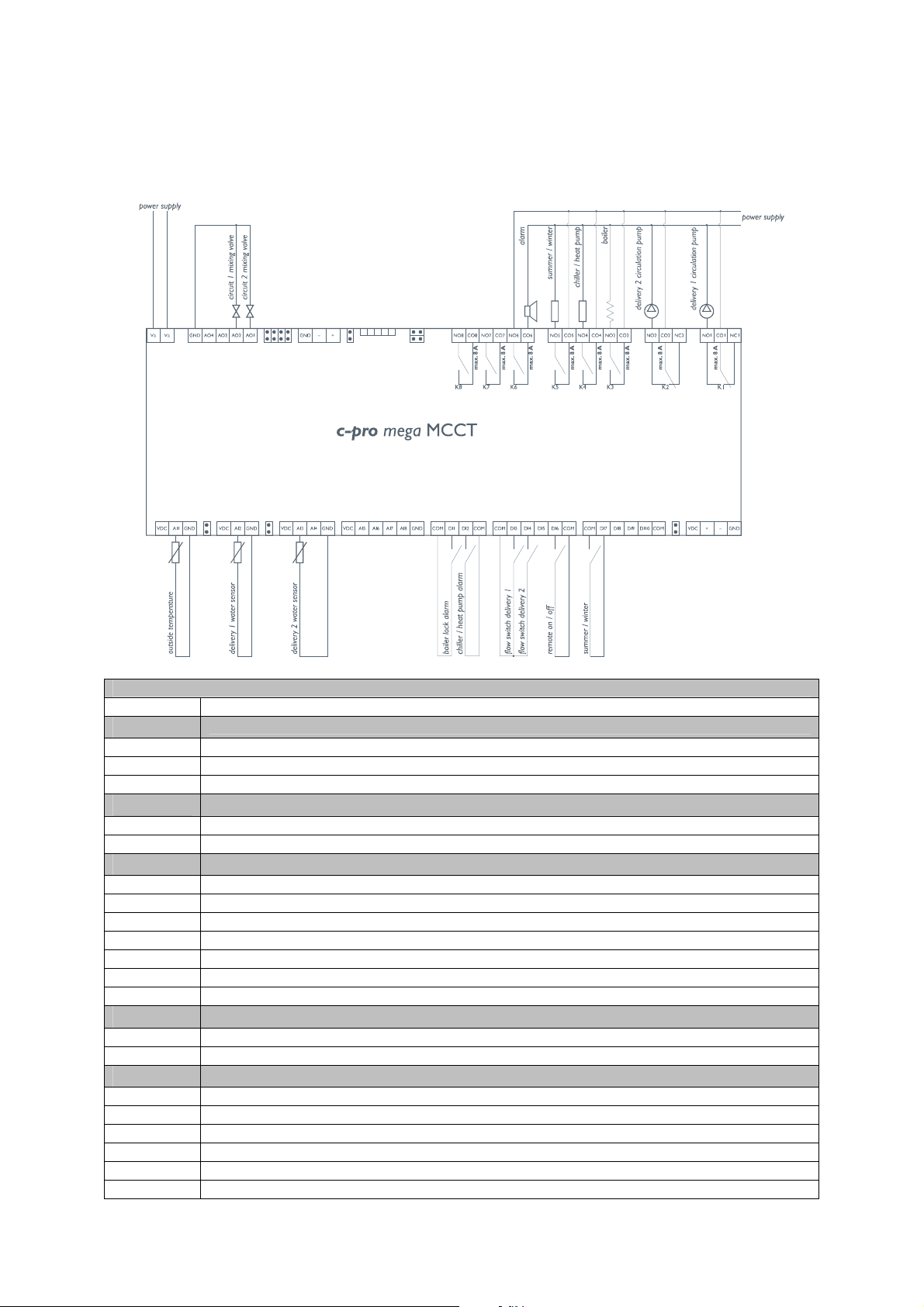

3.3 Electric connections

3.3.1 Thermal power plant electric connections (MCCT).

C-PRO Mega Thermal power plant controller

I/O Description

A/I 1 CT

A/I 2 CT

A/I 3 CT

Rs485

CANbus

D/I 1 CT

D/I 2 CT

D/I 3 CT

D/I 4 CT

D/I 5 CT

D/I 6 CT

D/I 7 CT

A/O 2 CT

A/O 3 CT

D/O 1 CT

D/O 2 CT

D/O 3 CT

D/O 4 CT

D/O 5 CT

D/O 6 CT

Analogue inputs (NTC / 0-5V / 4-20mA)

External air temperature – NTC

Delivery temperature 1 – NTC

Delivery temperature 2 – NTC

Serial ports

Rs485 modbus

At the c-pro CLIMA system modules

Digital inputs (ON-OFF pocoverial-free contact)

Alarm (block) Boiler

Chiller – Heat pump alarm

Delivery pump 1 flow switch (and/or thermal switch)

Delivery pump 2 flow switch (and/or thermal switch)

ON-OFF remote

Summer/Winter

Analogue outputs (PWM / 0-10 V / 4-20mA)

Delivery 2 modulating valve control (0-10 V)

Delivery 1 modulating valve control (0-10 V)

Digital outputs (Relay)

Delivery 1 circulation pump

Delivery 2 circulation pump

Boiler

Chiller/Heat pump

Summer/winter

Alarm that can be configured

Not used

Page 12

Page 13

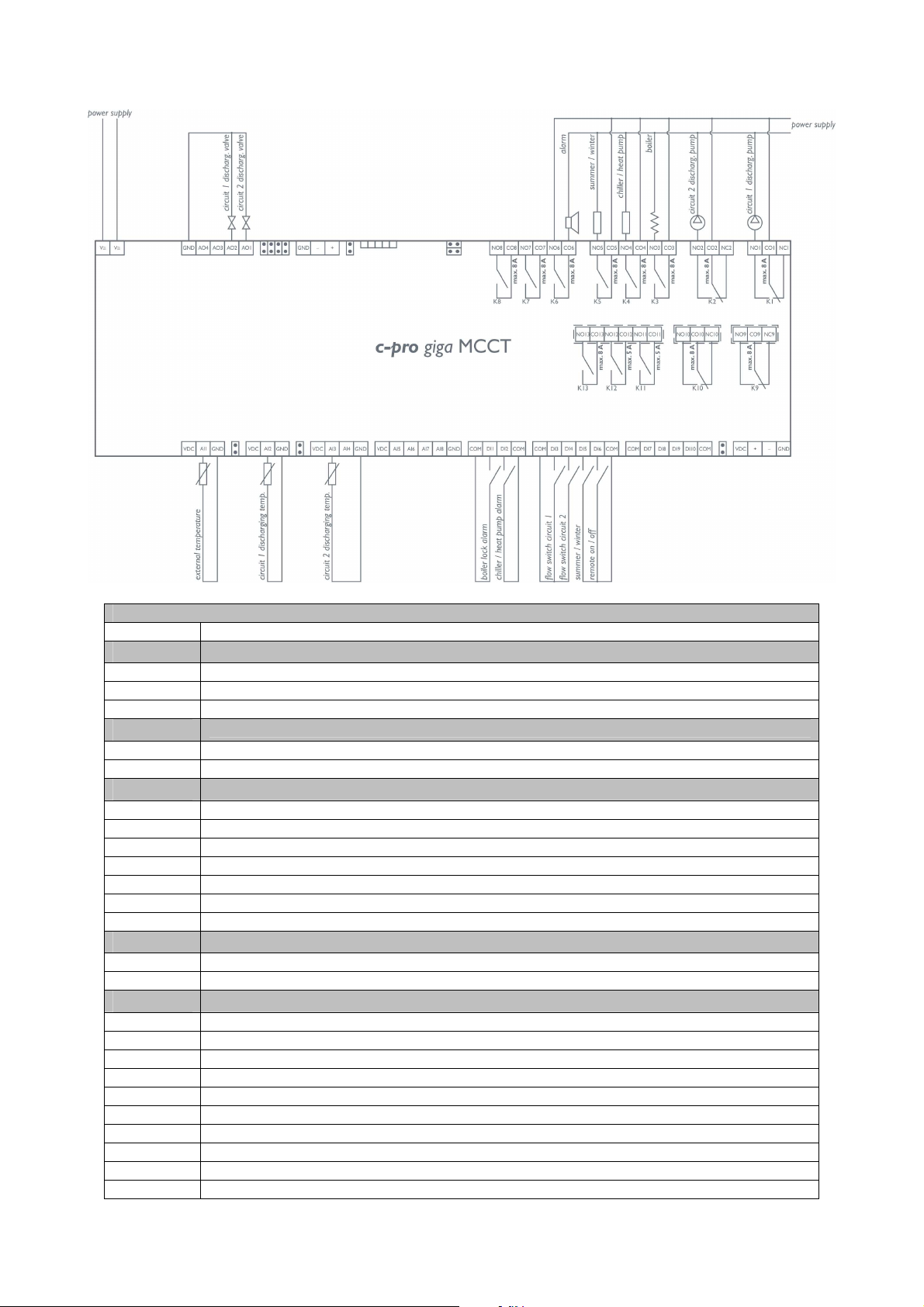

C-PRO CLIMA SISTEMA INSTALLER MANUAL

C-PRO Mega Thermal power plant controller

I/O Description

A/I 1 CT

A/I 2 CT

A/I 3 CT

Rs485

CANbus

D/I 1 CT

D/I 2 CT

D/I 3 CT

D/I 4 CT

D/I 5 CT

D/I 6 CT

D/I 7 CT

A/O 2 CT

A/O 3 CT

D/O 1 CT

D/O 2 CT

D/O 3 CT

D/O 4 CT

D/O 5 CT

D/O 6 CT

D/O 7 CT

D/O 8 CT

D/O 9 CT

D/O 10 CT

Analogue inputs (NTC / 0-5V / 4-20mA)

External air temperature – NTC

Delivery temperature 1 – NTC

Delivery temperature 2 – NTC

Serial ports

Rs485 modbus

At the c-pro CLIMA system modules

Digital inputs (ON-OFF pocoverial-free contact)

Alarm (block) Boiler

Chiller – Heat pump alarm

Delivery pump 1 flow switch (and/or thermal switch)

Delivery pump 2 flow switch (and/or thermal switch)

ON-OFF remote

Summer/Winter

Analogue outputs (PWM / 0-10 V / 4-20mA)

Digital outputs (Relay)

Delivery 1 circulation pump

Delivery 2 circulation pump

Boiler

Chiller/Heat pump

Summer/winter

Alarm that can be configured

Delivery modulating valve 1 open command

Delivery modulating valve 1 close command

Delivery modulating valve 2 open command

Delivery modulating valve 1 close command

Not used

Not used

Not used

Page 13

Page 14

C-PRO CLIMA SISTEMA INSTALLER MANUAL

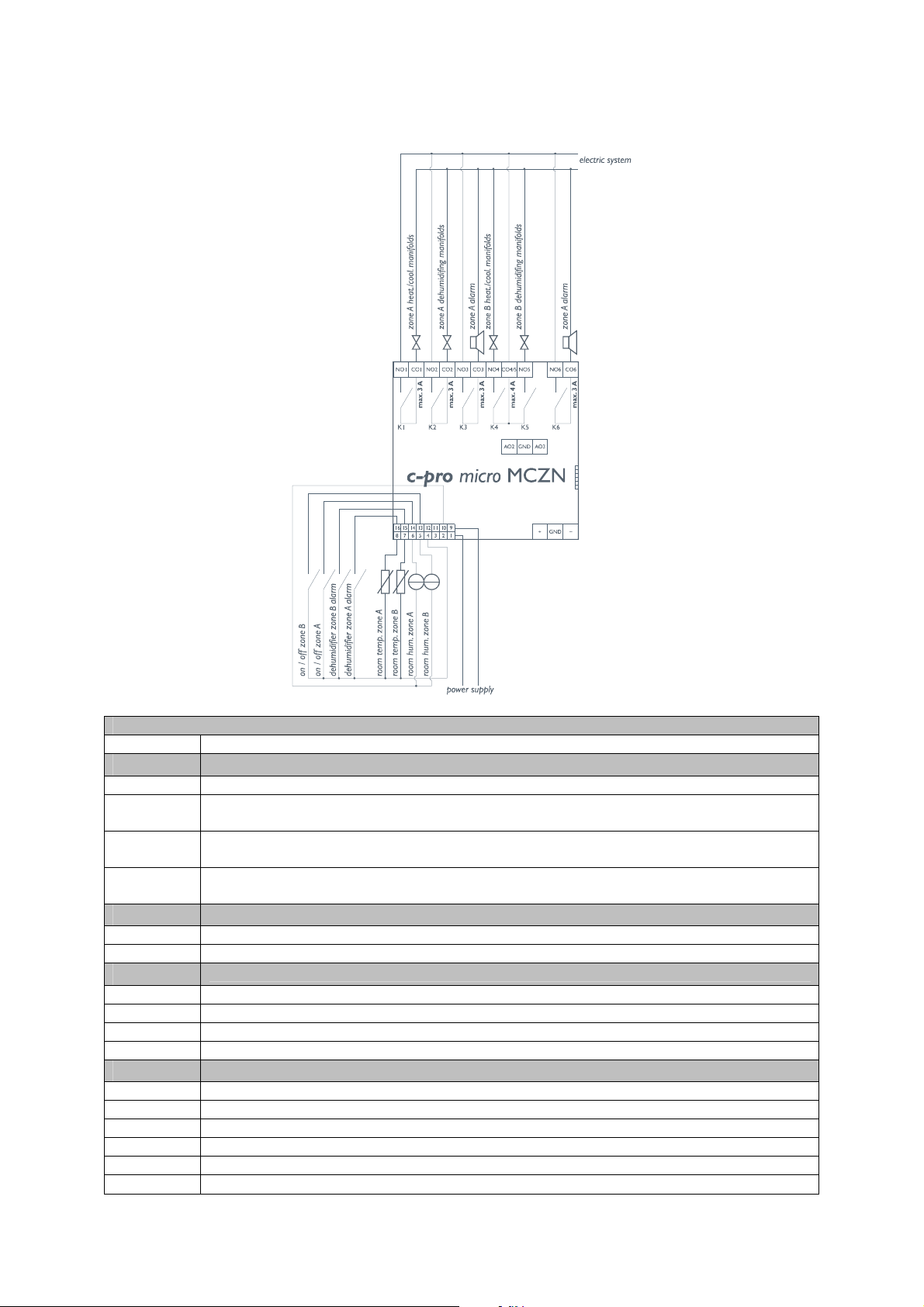

3.3.2 Zones electric connections (MCZN).

C-PRO Micro zones controller

I/O Description

A/I 1 ZN

A/I 2 ZN

A/I 3 ZN

A/I 4 ZN

TTL (485)

CANbus

D/I 1 ZN

D/I 2 ZN

D/I 3 ZN

D/I 4 ZN

D/O 1 ZN

D/O 2 ZN

D/O 3 ZN

D/O 4 ZN

D/O 5 ZN

D/O 6 ZN

Analogue inputs (NTC / 0-5V / 4-20mA)

Zone A room temperature (NTC)

Zone B room temperature (NTC)

Zone A remote set variator (10 K ohm)

Zone A room humidity (0-5 V or 4-20 mA) (clamps 6 and 10)

Zone A remote set variator (10 KOhm) (clamps 6 and 4)

Zone B room humidity (0-5 V or 4-20 mA) (clamps 5 and 10)

Zone B remote set variator (10 KOhm) (clamps 5 and 4)

Serial ports

TTL with EVIF external interface becomes RS485 Modbus RTU

At the c-pro CLIMA system modules

Digital inputs (ON-OFF pocoverial-free contact)

Zone A dehumidifier alarm

Zone B dehumidifier alarm

Zone A ON-OFF

Zone B ON-OFF

Digital outputs (Relay)

Zone A Heating/Cooling manifolds

Zone A dehumidifier manifold

Zone A alarm

Zone B Heating/Cooling manifolds

Zone B dehumidifier manifold

Zone B alarm

Page 14

Page 15

C-PRO CLIMA SISTEMA INSTALLER MANUAL

3.3.3 Dehumidifier electric connections (MCDE).

C-PRO Micro zones controller

I/O Description

A/I 1 DE

A/I 2 DE

A/I 3 DE

TTL (485)

CANbus

D/I 1 DE

D/I 2 DE

D/I 3 DE

D/I 4 DE

D/O 1 DE

D/O 2 DE

D/O 3 DE

D/O 4 DE

D/O 5 DE

D/O 6 DE

Analogue inputs (NTC / 0-5V / 4-20mA)

Zone A dehumidifier input temperature

Zone B dehumidifier input temperatures

CO2 transducer (0-5 V or 4-20 mA)

Serial ports

TTL with EVIF external interface becomes RS485 Modbus RTU

At the c-pro CLIMA system modules

Digital inputs (ON-OFF pocoverial-free contact)

Zone A dehumidifier alarm

Zone B dehumidifier alarm

Zone A dehumidifier ON-OFF

Zone B dehumidifier ON-OFF

Digital outputs (Relay)

Dehumidifier (Type 1)

Zone A dehumidifier (Type 2)

Heating integration (Type 1)

Zone A heating/cooling integration (Type 2)

Cooling integration (Type 1)

Zone B dehumidifier (Type 2)

Renew damper

Zone B heating/cooling integration (Type 2)

Zone A dehumidifier alarm

Zone B dehumidifier alarm

Page 15

Page 16

C-PRO CLIMA SISTEMA INSTALLER MANUAL

Solar panels 1 circuit pump (thermal) flow switch

3.3.4 Solar panels electric connections (MCPS).

C-PRO Micro solar panels controller

I/O Description

A/I 1 PS

A/I 2 PS

A/I 3 PS

A/I 4 PS

TTL (485)

CANbus

D/I 1 PS

D/I 2 PS

D/I 3 PS

D/I 4 PS

D/I 5 PS

D/O 1 PS

D/O 2 PS

D/O 3 PS

D/O 4 PS

D/O 5 PS

D/O 6 PS

Analogue inputs (NTC / 0-5V / 4-20mA)

DHW tank temperature (upper) (NTC)

DHW tank lower temperature (NTC)

Auxiliary temperature 1 (NTC)

Solar panel 2 temperature (4-20 mA).

Solar panel 1 temperature (4-20 mA).

Serial ports

TTL with EVIF external interface becomes RS485 Modbus RTU

At the c-pro CLIMA system modules

Digital inputs (ON-OFF pocoverial-free contact)

Solar panels 2 circuit pump (thermal) flow switch

DHW circuit pump (thermal) flow switch

Auxiliary system circuit pump (thermal) flow switch

Digital outputs (Relay)

Solar panels 1 circuit pump

Solar panels 2 circuit pump

DHW circuit pump

Alarm (that can be configured)

Auxiliary 1 circuit pump

Anti-stagnation emergency (cover opening)

Anti-stagnation emergency (heat disposal/cover opening)

Anti-stagnation emergency (cover closing)

Not used

Page 16

Page 17

C-PRO CLIMA SISTEMA INSTALLER MANUAL

3.4 Regulators network configuration

The c-pro CLIMA system is based on the CANbus communication between the various control

modules present in the network, with the following maximum configuration:

• N° 1 c-pro Mega MCCT thermal power plant regulator

• N° 8 c-pro micro MCZN zone regulators

• N° 8 regulators for additional c-pro micro MCDE dehumidifiers

• N° 1 regulator for c-pro micro MCPS solar panels

Every controller present in the network must be assigned with a different and specific CANbus

address, according to the logic position of the controller inside the c-pro CLIMA network,

following the layout given below:

Type of controller Controller code CANbus

address

Thermal power plant regulator c-pro mega MCCT 1 (default)

Zone 1 regulator (zones 1-2) c-pro micro MCZN 2 (default)

Zone 2 regulator (zones 3-4) c-pro micro MCZN 3

Zone 3 regulator (zones 5-6) c-pro micro MCZN 4

Zone 4 regulator (zones 7-8) c-pro micro MCZN 5

Zone 5 regulator (zones 9-10) c-pro micro MCZN 6

Zone 6 regulator (zones 11-12) c-pro micro MCZN 7

Zone 7 regulator (zones 13-14) c-pro micro MCZN 8

Zone 8 regulator (zones 15-16) c-pro micro MCZN 9

Regulator for dehumidif. associated to zone 1 regulator c-pro micro MCDE 22 (default)

Regulator for dehumidif. associated to zone 2 regulator c-pro micro MCDE 23

Regulator for dehumidif. associated to zone 3 regulator c-pro micro MCDE 24

Regulator for dehumidif. associated to zone 4 regulator c-pro micro MCDE 25

Regulator for dehumidif. associated to zone 5 regulator c-pro micro MCDE 26

Regulator for dehumidif. associated to zone 6 regulator c-pro micro MCDE 27

Regulator for dehumidif. associated to zone 7 regulator c-pro micro MCDE 28

Regulator for dehumidif. associated to zone 8 regulator c-pro micro MCDE 29

Regulator for solar panels c-pro micro MCPS 17 (default)

As highlighted in the previous table, the controllers are set by default to be automatically recognised

in network as:

• thermal power plant regulator CANbus 1 address

• zone 1 regulator CANbus 2 address

• regulator for dehumidifiers

added, associated to zone 1 regulator CANbus 22 address

• regulator for solar panels CANbus 17 address

Page 17

Page 18

C-PRO CLIMA SISTEMA INSTALLER MANUAL

Total number of zones controlled

Num

ber of MCZN zone regulators present

Number of zone regulators in the system

3.4.1 MCCT thermal power plant controller network configuration

As the thermal power plant controller is the logical centre of the system controlled, it is first

necessary to set how many MCZN zone regulators will be present in the system, following the

procedure given below:

1. Enter the Installer General parameters menu of the MCCT regulator

2. Set the total number of zones controlled and the number of MCZN zone regulators present in

the system

3. Set the c-pro mega MCCT J4 jumpers in the position corresponding to the communication

speed of 125Kbyte, as given in the figure below.

3.4.2 MCZN zone controllers network configuration

The zone regulator leaves the factory configured as zone 1 regulator (therefore with CANbus 2

address).

Whenever it is necessary to install more than one zone controller in the system, it will be necessary

to configure the regulators present as zone regulators 2, 3, etc…up to a maximum of 8.

To change the network configuration of the MCZN zone controller network, follow the procedure

below:

1. Connect a zone regulator to the CANbus network (leaving all of the other zone regulators

disconnected from the network);the controller connected will be recognised as zone 1

controller

2. Access the MCZN zone regulator application as shown in chapter 5.2.1

3. Enter the Installer General parameters menu

4. Set the number of local zones managed by the MCZN regulator (1 or 2 local zones)

5. Set the number of the last zone regulator that is to be inserted in the system managed (e.g.

zone 4 regulator).

6. The controller will automatically assume the appropriate CANbus address (address 25 for the

regulator of zone 4)

7. Repeat the operation, connecting the next to last zone controller to the CANbus network and

so on, until the first zone regulator is connected (zone 1 regulator).

Number of local zones managed

Page 18

Page 19

C-PRO CLIMA SISTEMA INSTALLER MANUAL

Enabling of regulator for additional dehumidifiers

Number of MCZN regulator to associate

3.4.3 Network configuration of controllers for additional MCDE dehumidifiers

Once the MCZN zone regulators have been configured, if present, it is possible to associate the

relative regulators for additional MCDE dehumidifiers to the same.

The regulator for dehumidifiers leaves the factory configured as regulator associated to zone

1(therefore with CANbus 22 address).

Whenever it is necessary to install more than one controller in the system for dehumidifiers and/or

to vary the association of the controller for dehumidifiers at the zone controller it will be necessary

to configure the regulators present appropriately.

Enabling of presence of a MCDE module for additional dehumidifiers associated to the MCZN

regulator

1. Access the MCZN zone regulator to which the regulator for additional dehumidifiers is to be

associated, as shown in chapter 5.2.1

2. Enter the Installer Dehumidifyer menu

3. To enable the control via the appropriate parameter.

The CANBUS address field will automatically show the CANbus address that

the regulator must assume for additional dehumidifiers

CANbus address that the regulator must assume for

additional dehumidifiers

To change the network configuration of the MCDE zone controller network, follow the procedure

below:

1. Connect a regulator for dehumidifiers to the CANbus network (leaving all of the other

dehumidifier regulators disconnected from the network);the controller connected will be

recognised by the system as controller for dehumidifier associated to zone 1

2. Access the application of the regulator for MCDE dehumidifiers associated to zone 1, as

shown in chapter 5.2.2

3. Enter the Installer General parameters menu

4. Set the number of the MCZN zone regulator to which to associate the connected regulator for

additional MCDE dehumidifiers

5. Return to the MCCT thermal power plant regulator main menu

6. Repeat the operation connecting the next controlled for additional dehumidifiers to the

CANbus network and so on, until all regulators for envisioned additional dehumidifiers are

connected.

Page 19

Page 20

C-PRO CLIMA SISTEMA INSTALLER MANUAL

Enable the prsence of MCPS regulator in the system

3.4.4 MCPS solar panels controller network configuration

As the solar panels controller is the only possible controller of this type that can be installed in the

system, in order to configure it just enable the presence of the MCPS regulator from the thermal

power plant application, following the procedure given below:

1. Enter the Installatore Parametri generali (Installer, General parameters) menu of the

MCCT regulator

2. Enable the presence of the MCPS regulator in the system

Page 20

Page 21

C-PRO CLIMA SISTEMA INSTALLER MANUAL

3.5 Displays network configuration

For the final user, the c-pro CLIMA system envisions the use of a series of user terminals installed

in zone, from which it is possible to display temperature, humidity, state of the zone and set the

work set-points, time bands, etc.

The maximum number of user terminals that can be set in the system depends mainly on the

configuration of the terminal selected by the installer, from the following possibilities:

• Public terminal (maximum n°1 display for the entire system)

• Module private terminal (maximum n°8 displays for the entire system)

• Zone private terminal (maximum n°8 displays for the entire system)

Depending on the type of terminal desired, settings must be made in the MCZN zone controller and

in the Vgraph user terminal, illustrated in the following paragraphs.

3.5.1 Public terminal

If the Vgraph display is configured as a public terminal (universal), a unique Vgraph display can

show all MCZN zone controllers present in the system and all zones managed by the MCZN

controllers (called Zone A, Zone B).

A hotel is given as an example.

The unique Vgraph display will be installed in an area with access to authorised staff only, which

will establish the temperatures and time bands predefined for every Zone (hotel room) managed.

The hotel client will only have the possibility to change the room temperature, using the EVSET

remote set-point variator (installed in the room), by ±3-5°C (from parameter).

Vgraph settings:

Below find the network settings to be made on Vgraph to make it a public terminal (for the setting

procedures, consult the Vgraph hardware manual):

CANbus address: 99

CANbus map:

Network node Address

1 2

2 3

3 4

4 5

5 6

6 7

7 8

8 9

10 1

Page 21

Page 22

C-PRO CLIMA SISTEMA INSTALLER MANUAL

MCCT thermal power plant controller settings:

Below find the settings to make on the MCCT regulator to make Vgraph a public terminal:

From the Installer General parameters menu, enable the presence of the public V-graph display

via Enab. V-GRAPH- parameter

MCZN zone controllers settings:

Below find the settings to make on the MCZN regulators to make Vgraph a public terminal:

From the Installer General parameters menu, enable the presence of the public V-graph display

by setting the V-GRAPH mode parameter in UNIV.

3.5.2 Module private terminal

If the Vgraph display is configured as a private module terminal (AB), every Vgraph display will be

able to only show the preselected MCZN zone regulator, managing both zones (called Zone A,

Zone B) managed by the MCZN controller.

A condominium is given as an example.

A Vgraph display will be installed in every apartment, which will establish temperatures and time

bands for the two Zones present in the apartment, (day zone/night zone or apartment/bathroom),

without the possibility to display or modify the settings of the other apartments present.

Vgraph settings:

Below find the network settings to be made on Vgraph to make it a private module terminal (for the

setting procedures, consult the Vgraph hardware manual):

CANbus address: 100 + address of the MCZN zone regulator to which the connection is to be

made

CANbus map:

Network node Address

1 MCZN associated

controller address

Page 22

Page 23

C-PRO CLIMA SISTEMA INSTALLER MANUAL

MCCT thermal power plant controller settings:

Below find the settings to make on the MCCT regulator to make Vgraph a private module:

From the Installer General parameters disable the presence of the public V-graph display via

Enab. V-GRAPH.

MCZN zone controllers settings:

Below find the settings to make on the MCZN regulators to make Vgraph a private module:

From the Installer General parameters menu, enable the presence of the private V-graph display

by setting the V-GRAPH mode parameter in AB.

3.5.3 Zone private terminal

If the Vgraph display is configured as a private zone terminal (A+B), every Vgraph display will be

able to only show the preselected MCZN zone regulator, and only the zone selected (Zone A or

Zone B) managed by the MCZN controller.

As an example, an individually owned villa on two floors.

A Vgraph display will be installed for each zone controlled (living room, bedroom, bathroom),

which will establish temperatures and time bands for the Zone where the display is installed,

without possibility of displaying or modifying the settings of the other zones present.

Vgraph settings:

Below find the network settings to be made on Vgraph to make it a private zone terminal (for the

setting procedures, consult the Vgraph hardware manual):

CANbus address:

For connection to ZONE A: 100 + address of the MCZN zone regulator to which the

connection is to be made

For connection to ZONE B: 110 + address of the MCZN zone regulator to which the

connection is to be made

CANbus map:

Network node Address

1 MCZN associated

controller address

Page 23

Page 24

C-PRO CLIMA SISTEMA INSTALLER MANUAL

MCCT thermal power plant controller settings:

Below find the settings to make on the MCCT regulator to make Vgraph a private zone terminal:

From the Installer General parameters menu, disable the presence of the public V-graph display

via Enab. V-GRAPH parameter.

MCZN zone controllers settings:

Below find the settings to make on the MCZN regulators to make Vgraph a private zone terminal:

From the Installer General parameters menu, enable the presence of the private zone V-graph

display by setting the V-GRAPH mode parameter in A+B.

Page 24

Page 25

C-PRO CLIMA SISTEMA INSTALLER MANUAL

4 USER INTERFACE

4.1 Display and keyboard

A unique incorporated interface is envisioned for the application (herein called built-in) in the

MCCT controller with 4 x 20 characters alphanumerical display and several dedicated keys and

LEDs.

The built-in display of the MCCT controller is the only user interface available for the installer and

the maintenance technician of the c-pro CLIMA system. All settings and configurations of the

modules connected will be performed via a unique display.

4.1.1 Built-in interface

The built-in interface is integrated directly onto the MCCT.

There are 9 navigation and value editing pages present in the keyboard with the following meaning:

- and (UP and DOWN): when editing it modifies the parameters; otherwise moves the

cursor.

- (LEFT): moves the cursor to the left or takes to the previous menu.

- (RIGHT): moves the cursor to the right.

- (ENTER): in editing it confirms the value; otherwise it sends any controls associated to the

text where the cursor is present.

- (ESC): in editing it annuls the value; otherwise request of the default page eventually

associated to the current page. If the ESC key is held for about 2 seconds, the machine can be

switched on/off,

- (K0): used to silence the alarm buzzer.

- and : they are keys not used.

Page 25

Page 26

C-PRO CLIMA SISTEMA INSTALLER MANUAL

There are also 2 LEDs present.

- associated to the ESC key, it identifies the machine state

Off: with machine off.

On: with machine on.

- associated to key K0, it identifies the presence or not of alarms

Off: no alarm present.

Flashing: with alarms present.

4.2 Navigation through the applications making up the system

The c-pro mega MCCT controller represents the heart of the c-pro CLIMA system, also from a user

interface point of view.

To access the other system components, the procedure given in the following paragraphs must be

followed.

4.2.1 Access a c-pro micro MCZN zone regulator

To access one of the c-pro micro MCZN zone regulators present in the system, access the

“Regulators state in serial network” page present in the “States” section and select the regulator to

which access is to be made from the list of regulators available.

4.2.2 Access a regulator for additional c-pro micro MCDE dehumidifiers

Access to the regulators for additional c-pro micro MCDE dehumidifiers takes place from the

MCZN application connected to it. Therefore, not directly from the MCCT thermal power plant

regulator.

From the main menu of the MCZN regulator, access the "system network" page and select the

MCDE regulator available. The system will automatically access the regulator for additional

dehumidifiers associated to the zone controller from which the loading control originated.

4.2.3 Access the regulator for c-pro micro MCPS solar panels

To access the regulator for c-pro micro MCPS solar panels present in the system, the “Solar panels

functioning state” page must be accessed, present in the “States” section and select to access the

MCPS regulator (if configured).

Page 26

Page 27

C-PRO CLIMA SISTEMA INSTALLER MANUAL

5 c-pro mega MCCT regulator

Thermal power plant regulator

5.1 List of pages

This paragraph presents the main pages and menus found in the MCCT application. As shown

previously, the main menu is divided into 3 levels: user, maintenance technician and installer. A

“States” section is also present that can be consulted freely, also necessary for navigation between

modules.

The menus have the following structure:

• Menu

- Alarms/log

- Alarms log

- reset active alarms

- reset alarms log

- Clock

- Maintenance

- general parameters

- delivery lines

- manual

- timer

- Installer

- I/O configuration

- general parameters

- delivery lines

- initialisation

- Program info

• States

- LINE 1 functioning state

- LINE 2 functioning state

- Functioning state and access to the SOLAR PANELS module

- Functioning state and access to the ZONE REGULATORS module.

Page 27

Page 28

C-PRO CLIMA SISTEMA INSTALLER MANUAL

Log state

Date and time of the alarm

Progressive number memorised

Alarm code and origin network

node

5.2 Alarms/log menu

This menu contains the functionality linked to the controller alarms and the alarms log of the

system.

5.2.1 Alarms log

To view the system alarms log (MCCT regulator and MCZN regulators), press ENTER on

“hystorical alarms”.

If there are no elements present, “NO ALARMS” is displayed, otherwise the following page is

proposed, where the information of the last element memorised in the log is given:

To view the previous element, press ENTER on “>>”. By repeating this procedure, scroll all log

elements until the first element inserted is reached. From here, on request of the next element, the

last element memorised is re-proposed: the log display is circular.

To exit the log pages, press the ESC key or wait 60 timeout seconds. This level is not protected by a

password.

5.2.2 Reset active alarms

To view the active alarms of the MCCT regulator, press ENTER on “Rst running alarms”.

If there are no alarms present, “no alarms is displayed, otherwise a series of pages appear

containing all possible alarms present in the controller with relative codes and description.

The alarm or the alarms present, will be highlighted by flashing "Rst ALARM", as shown in the

figure below.

Ok: correct reading

Empty: memory empty

Overflow: memory full

Error: log reading failed

If the ESC key is pressed from an alarm page or 60 timeout seconds are allowed to pass, you go

back to the main page of the application. This level is not protected by a password.

5.2.3 Reset alarms log

To reset the memorised alarms log, press ENTER on “Rst hyst. alarms” and take the value of the

“Do you want to erase hystorical alarms memory?” parameter to the “Yes” value.

To exit the alarms log reset pages, press the ESC key or wait 60 timeout seconds. This level is not

protected by a password.

Page 28

Page 29

C-PRO CLIMA SISTEMA INSTALLER MANUAL

5.3 Clock menu

From this menu it is possible to set/modify the value of the date and real time that the c-pro mega

MCCT controller propagates to the entire c-pro CLIMA system.

To set/modify the date and/or real time, press ENTER on “Real time clock” and set the desired

value, as shown in the following figure.

If the ESC key is pressed from a setting page or 60 timeout seconds are allowed to pass, you go

back to the main page of the application. This level is not protected by a password.

5.4 Maintenance menu

The maintenance menu is level 1, i.e. used to insert the maintenance level password or higher in

order to display/modify the parameters present in this branch.

In this menu it is possible to view and set the state of the various devices, inputs and outputs used

by the MCCT application.

Entering the GENERAL PARAMETERS menu, it is possible to view/enable/define the features

relative to functioning of the digital control digital inputs, summer/winter functioning mode

changeover (from keyboard, from digital input, from BMS or automatic), relative to the antigrip

function, management of the flow switches for the delivery pumps and the temporary disabling of

the zone controllers.

Entering the DELIVERY LINES menu, it is possible to view/define the features relative to the

functioning of various utilities present and enabled in the controlled system such as the type of

delivery lines, the management and the presence of the mixing valve, the management of delay

times on activation/deactivation of the utilities, the definition of the standard delivery set-points and

the set-points of the mixing valve, the definition of the temperature and calibration alarms of the

input probes.

The MANUAL menu allows to set the functioning of the utilities managed by the application in

manual/automatic mode, thus forcing the state, to test its functionality.

Finally, the TIME COUNTER menu allows to display, enable, set and reset the functioning hours

and the maintenance requests for the users to manage the MCCT application.

Page 29

Page 30

C-PRO CLIMA SISTEMA INSTALLER MANUAL

5.5 Installer menu

The installer menu is level 2, i.e. used to insert the installer level password or higher in order to

display/modify the parameters present in this branch.

From this menu it is possible to view and set the configuration of the system managed from the

MCCT application.

Entering the I/O CONFIGURATION menu it is possible to set the type of analogue inputs, the

polarity of the digital inputs and the calibration values of the analogue outputs used in the

application.

Entering the GENERAL PARAMETERS menu, it is possible to define the main features present in

the controlled system such as the presence and type of the heating/cooling elements (boiler, chiller,

heat pump), the number of delivery lines and the number of MCZN zone regulators present, the

presence of the MCPS module for the management of the DHW tank and/or the solar panels

system, the presence or not of the public Vgraph display, as well as the possibility of changing the

serial communication parameters both CANbus (c-pro CLIMA controllers network) and Modbus

(towards the RICS supervision system or other BMS systems).

Entering the DELIVERY LINES menu, it is possible to define the main features relative to the

delivery lines present and enabled in the controlled system such as the type of delivery lines

present, the presence of the mixing valve, the management method of the circulation pumps and the

definition of their type of protection digital input.

Finally the PASSWORDS menu allows to display and modify the 3 password levels present in the

application.

Page 30

Page 31

C-PRO CLIMA SISTEMA INSTALLER MANUAL

Summer/Winter functioning mode

Name of the MCCT thermal power plant

5.6 Main OFF page

The main OFF page changes depending on the reason for which the unit is off.

The unit in OFF alarm can be switched off completely using the key, digital input or supervisor.

This type of display is temporary. When the 30 seconds time-out has passed, the controller will go

back to the display of the main ON page, however indicating the OFF state of the unit.

5.7 Main ON page

The main page is displayed during the ON state:

Pressing the DOWN key, it is possible to scroll all information contained in the page (External

Temperature, Delivery Line 1 and 2 Temperature). It is also possible to access the Main Menu and

the States Pages by pressing ENTER once the cursor is positioned on the corresponding wording.

If the machine is OFF, he screen will be identical but with the OFF indication OFF at the side of the

name assigned to the MCCT module by the installer.

Date and real time

External temperature and, in order of

appearance (pressing the DOWN key):

Delivery line 1 temperature

Delivery line 2 temperature

Access to main menu

Access to state pages

Page 31

Page 32

C-PRO CLIMA SISTEMA INSTALLER MANUAL

5.8 State pages

By accessing the state pages from the ON main page, access the following four screens representing

the machine states of the c-pro mega MCCT controller and the entire controlled system.

5.8.1 Delivery line L1 and delivery line L2 state page

Line indicating the state of the L1/L2 delivery line:

P1 = circulation pump P1 activated

Alr = P1 circulation pump block alarm

FL = delivery line 1 flow switch alarm with automatic rearm

The state pages of the Delivery line 1 and 2 show, as well as the state of the line described in the

previous illustration, the opening percentage of the mixing valve, the delivery line water

temperature,the active work set-point and the calculation of the dew point for the corresponding

line.

Pressing ENTER on the “>” access the next state page, corresponding with delivery line 2.

By pressing ENTER on the “>” again, access the next state page, i.e. the SOLAR PANELS

state/access page.

When the 30 seconds time-out has passed or by pressing ESC, the controller will go back to the

display of the main ON page.

5.8.2 State page and access to the MCPS solar panels module

* = delivery line 1 flow switch alarm with manual rearm running

Fs = delivery line 1 flow switch with manual rearm function active

LT = delivery line low water temperature alarm

HT = delivery line high water temperature alarm

Fz = Anti-freeze function active

Ag = Anti-grip function active

Line indicating the state of the MCPS solar panels module

MCPS = MCPS module enabled and on-line

MCPS OFFLine = MCPS module enabled but off-line

No MCPS = MCPS module not enabled

The state page and access to the MCPS solar panels module shows, as well as the network state of

the MCPS regulator, described in the previous element, the temperature of the boiler (DHW tank).

Pressing ENTER on the “>” in the top right of the screen, access the next state page, i.e. the

state/access page to the ZONE REGULATORS modules.

Pressing ENTER on the MCPS module state (with MCPS module enabled and on-line) the MCPS

application can be accessed.

When the 30 seconds time-out has passed or by pressing ESC, the controller will go back to the

display of the main ON page.

Page 32

Page 33

C-PRO CLIMA SISTEMA INSTALLER MANUAL

5.8.3 State and access page of the MCZN zone regulators modules

Indication of the state of the relative MCZN zone module:

+ = zone present, enabled with active zones

+ = zone present, enabled with non-active zones

? = zone present, enabled but off-line

A = zone present, enabled in alarm state

! = zone present but disabled

* = zone not present/not configured

The state and access page to the MCZN zone regulators modules shows the network state of the

MCZN regulators described in the previous illustration.

Pressing ENTER on the “>” in the top right of the screen, returns to the DELIVERY LINE L1 state

page.

Pressing ENTER on the selected MCZN module state (with MCZN module present, enabled and

on-line) the MCZN application can be accessed.

When the 30 seconds time-out has passed or by pressing ESC, the controller will go back to the

display of the main ON page.

5.9 Configuration parameters

Below find a list of all configuration parameters contained in the MAINTENANCE menu

(maintenance technician) and INSTALLER managed by the MCCT application.

A brief description is supplied for every parameter, the range of acceptable values, unit of

measurement and the default value proposed.

The menus are structured following the logic given in the respective description paragraphs 6.4 and

6.5.

5.9.1 List of MAINTENANCE menu configuration parameters

Label

ONOFF dig. input Enable ON OFF digital input No No Yes

W/S keyboard Enabling of Summer/winter from keyboard S S W

W/S d.input Enabling of Summer/winter from digital input No No Yes

W/S BMS Enabling of Summer/winter from BMS Yes No Yes

W/S auto Enabling automatic Summer/winter switch-over No No Yes

T. ext. W (°C)

T. ext. S (°C)

W/S delay (h)

Loads antigrip day Day of the week for performing the antigrip cycle Friday Sunday Saturday

Loads antigrip

Time

Pumps flow switches

start

Parameter description Default Min Max

GENERAL PARAMETERS

Temperature below which automatic summer/winter

switch-over takes place, relative to the external

temperature (expressed in °C)

Temperature above which automatic winter/summer

switch-over takes place, relative to the external

temperature (expressed in °C)

Permanence duration of the external temperature

over/below the threshold established so that

summer/winter switch-over and vice versa takes place

automatically (expressed in hours)

Time of performance of the antigrip cycle 2 0 24

Delay time on activation of the alarms relative to the 1

and 2 delivery flow switches from system start-up

(expressed in seconds)

5.0 -30.0 30.0

30.0 -30.0 30.0

1 0 255

30 0 255

Page 33

Page 34

C-PRO CLIMA SISTEMA INSTALLER MANUAL

Pumps flow switches

Run

Pumps flow switches

Nr. alarms/hour

Network

management

Zone modul.

enabling

Maintenance L1

Pump mode

Maintenance L1

Pump management

Alarm delay

Maintenance L1

Pump management

ON delay

Maintenance L1

Pump management

OFF delay

Maintenance L1

Pump management

Mix.vlv. delay

Maintenance L1

Pump management

CH-HP delay

Maintenance L1

Pump management

Antigrip enab.

Maintenance L1

Temp. regulation

Setpoint S LT

Maintenance L1

Temp. regulation

Setpoint W LT

Maintenance L1

Temp. regulation

Setpoint S HT

Maintenance L1

Temp. regulation

Setpoint W HT

Maintenance L1

T. regulation

Dew offset

Maintenance L1

Mixing valve S

Mode

Maintenance L1

Mixing valve S

Min.Ext.T.

Maintenance L1

Mixing valve S

Max.Ext.T.

Maintenance L1

Mixing valve S

Setpoint 1

Delay time on activation of the alarms relative to the 1

and 2 delivery flow switches with system in normal

conditions (expressed in seconds)

Maximum number of alarms/hour relative to delivery

flow switches 1 and 2 for passage to manual rearm

Temporary MCZN disabling/enabling

X = enabled

O = not enabled

DELIVERY LINES

Functioning mode of the circulation pump 1

CONT. = continuous

TRICH. = on temperature request

Delay time on activation of the alarm relative to the

circulation pump 1 (expressed in seconds)

Delay time on switch on of the circulation pump 1

(expressed in seconds)

Delay time on switch-off value change of mixing valve 1

(expressed in seconds)

Delay time on opening value change of mixing valve 1

(expressed in seconds)

Delay time on activation of the chiller/heat pump

(expressed in seconds)

Enabling of the line 1 antigrip function Yes No Yes

L.T. line 1 summer delivery set-point (expressed in °C) 18.0 7.0 30.0

H.T. line 1 winter delivery set-point (expressed in °C) 30.0 20.0 90.0

H.T. line 1 summer delivery set-point (expressed in °C) 12.0 5.0 30.0

H.T. line 1 winter delivery set-point

(expressed in °C)

Offset (differential) to add to the delivery line 1 dew

point, calculated to obtain the delivery work set-point

value in Summer mode

(expressed in °C)

Summer mixing valve 1 functioning mode

- Closed

- Modulating

- Opened

Minimum external temperature in summer for the

calculation of the delivery 1 floating set-point (expressed

in °C)

Maximum external temperature in summer for the

calculation of the delivery 1 floating set-point (expressed

in °C)

Value of the floating delivery 1 set-point relative to the

minimum external temperature in Summer mode

(expressed in °C)

5 0 255

3 0 255

O X O

TRICH. CONT. TRICH.

0 0 255

30 0 255

30 0 255

30 0 255

60 0 255

60.0 25.0 90.0

3.0 0.0 10.0

MODUL. CLOSED OPENED

10.0 0.0 30.0

30.0 10.0 60.0

12.0 0.0 40.0

Page 34

Page 35

C-PRO CLIMA SISTEMA INSTALLER MANUAL

Maintenance L1

Mixing valve S

Setpoint 2

Maintenance L1

Mixing valve S

Fix setpoint

Maintenance L1

Mixing valve W

Mode

Maintenance L1

Mixing valve W

Min.Ext.T.

Maintenance L1

Mixing valve W

Max.Ext.T.

Maintenance L1

Mixing valve W

Setpoint 1

Maintenance L1

Mixing valve W

Setpoint 2

Maintenance L1

Mixing valve W

Fix setpoint

Maintenance L1

M.Valve regulation

Prop. Band

Maintenance L1

M.Valve regulation

Integr. time

Maintenance L1

M.Valve regulation

Fix opening

Maintenance L1

M.Valve regulation

Opening time

Maintenance L1

M.Valve regulation

Extra time

Maintenance L1

M.Valve regulation

Min variation

Maintenance L1

M.Valve regulation

Antigrip enab.

Maintenance L1

Mix V regulation

Antigrip open

Maintenance L1

Temperature limits

HT setpoint

Maintenance L1

Temperature limits

HT hyst.

Maintenance L1

Temperature limits

LT setpoint

Maintenance L1

Temperature limits

LT hyst.

Value of the floating delivery 1 set-point relative to the

maximum external temperature in Summer mode

(expressed in °C)

Fixed value of the delivery 1 floating set-point in

summer mode if the function is disabled due to alarm

(expressed in °C)

Winter mixing valve 1 functioning mode

- Closed

- Modulating

- Openend

Minimum external temperature in winter for the

calculation of the delivery 1 floating set-point (expressed

in °C)

Maximum external temperature in winter for the

calculation of the delivery 1 floating set-point (expressed

in °C)

Value of the floating delivery 1 set-point relative to the

minimum external temperature in Winter mode

(expressed in °C)

Value of the floating delivery 1 set-point relative to the

maximum external temperature in Winter mode

(expressed in °C)

Fixed value of the delivery 1 floating set-point in winter

mode if the function is disabled due to alarm (expressed

in °C)

Mixing valve 1 regulation proportional band (expressed

in °C)

Integral time for regulation of mixing valve 1 (expressed

in seconds)

Valve 1 opening percentage with fixed opening

regulation (expressed as % opening)

Opening time valve 1 (sec) 150 0 3600

Extra time of limit switch open / close valve 1 (sec) 5 0 600

Percentage of minimum variation of valve 1 to enable

the movement (expressed in % of opening)

Enabling of activation of mixing valve 1 for anti-grip

cycle

Opening percentage of mixing valve 1 during antigrip

cycle (expressed in % of opening)

Delivery 1 high temperature limit for delivery high

temperature alarm activation (expressed in °C)

Hysteresis (differential) relative to delivery 1 high

temperature limit (expressed in °C)

Delivery 1 low temperature limit for delivery 1 low

temperature alarm activation (expressed in °C)

Hysteresis (differential) relative to delivery 1 low

temperature limit (expressed in °C)

7.0 0.0 40.0

7.0 0.0 40.0

MODUL. CLOSED OPENED

5.0 -30.0 30.0

10.0 0.0 30.0

35.0 0.0 90.0

25.0 0.0 90.0

35.0 0.0 90.0

5.0 0.0 10.0

0 0 65535

20.0 0.0 100.0

2.0 0.0 20.0

Yes No Yes

100.0 0.0 100.0

45.0 0.0 90.0

5.0 0.0 10.0

10.0 -10.0 40.0

5.0 0.0 10.0

Page 35

Page 36

C-PRO CLIMA SISTEMA INSTALLER MANUAL

Maintenance L1

Probes calibration

Temperature

5.9.2 List of INSTALLER menu configuration parameters

Label

I/O configuration

Analog In.

I/O configuration

Digital In.

I/O configuration

Analog out.

General parameters

Number of zones

General parameters

Number of MCZN

modules

General parameters

Delivery lines

General parameters

Enable boiler

General parameters

CH-HP type

General parameters

Enable MCPS

General parameters

HP-Boiler switch

Switch temp.

General parameters

HP-Boiler switch

Hysteresis

General parameters

HP-Boiler switch

HP max. time

General parameters

CANBUS network

Node address

General parameters

CANBUS network

Vgraph enab.

General parameters

MODBUS network

Idx

General parameters

MODBUS network

Baud

Delivery 1 temperature probe calibration

(expressed in °C)

* The same menu is also available for the delivery 2 line

Parameter description Default Min Max

I/O CONFIGURATION

Configuration of type of analogue inputs NTC NTC NTC

Digital inputs polarity configuration

NC = normally closed

NA = normally open

Configuration of minimum and maximum calibration

values of the analogue outputs (expressed as % of the

analogue value in output)

GENERAL PARAMETERS

Setting the number of zones present in the system

Setting the number of zone MCZN modules present in

the system

Setting the number of delivery lines present in the

system

Enabling of boiler presence Yes No Yes

Setting the type of cooling unit present

--- = not present

CH = chiller

CHHP = chiller/heat pump

Enabling of MCPS solar panels module presence No No Yes

Minimum temperature threshold relative to the external

temperature for switch functioning from heat pump

functioning at boiler (expressed in °C)

Hysteresis (differential) relative to the external

temperature for return to functioning with heat pump

(expressed in °C)

Heat pump activation continuous maximum time for

automatic switch to boiler (expressed in hours)

MCCT regulator CANBUS address 1 1 127

Enabling of public V-Graph presence Yes No Yes

MCCT regulator MODBUS address 1 1 247

MCCT regulator MODBUS communication speed

1200 baud

2400 baud

0.0 -10.0 10.0

N.O. N.C. N.O.

0.0 0.0 100.0

1 0 16

1 0 8

1 0 2

CH --- CHHP

7.0 -20.0 30.0

5.0 0.0 10.0

3 0 65535

9600 1200 19200

Page 36

Page 37

General parameters

MODBUS network

Parity

General parameters

MODBUS network

Stop bit

Line 1 configuration

Line type

Line 1 configuration

M.Valve enable

Configure line 1

Pump DIn alr

C-PRO CLIMA SISTEMA INSTALLER MANUAL

4800 baud

9600 baud

19200 baud

Type of MODBUS communication parity EVEN NO EVEN

MODBUS communication Bit Stop position 1b 1b 2b

DELIVERY LINES

Type of delivery line 1

H.T. = High temperature (radiators)

L.T. = Low temperature (floor)

Enabling of mixing valve 1 Yes No Yes

Type of digital input for protection of circulation pump 1

LOCK = protection input

FLOW = Flow switch

* The same menu is also available for the delivery 2 line

L.T. H.T. L.T.

FLOW LOCK FLOW

Page 37

Page 38

C-PRO CLIMA SISTEMA INSTALLER MANUAL

5.10 State of the unit

There are several procedures for switching the unit on/off:

1) Via the relative On/Off key

Switch-on: press the relative key for about 2 seconds: if all of the other conditions enabled

are present, the machine goes to "ON".

Switch-off: press the relative key for about 2 seconds: the machine goes to "OFF" mode.

2) Via the On/Off from digital input control (ONOFF d.input = 1 parameter)

Switch-on: close the remote On/Off contact: if all of the other conditions enabled are

present, the machine goes to "ON".

Switch-off: if the remote On/Off contact is open, the machine goes to “OFF from digital

input” (also signalled by “OFF digital in.”).

3) Via supervision protocol

Switch-on: to activate the switch-on state from protocol: if all of the other conditions

enabled are present, the machine goes to "ON".

Switch-off: if the ignition state is deactivated from protocol, the machine goes to “OFF from

supervision protocol” (also indicated by “OFF supervisor”).

The On/Off state from key has priority with respect to the other two. In fact, the On/Off states from

digital input and supervision protocol can only be reached with machine on from key.

A machine switched off from digital input can:

⋅ pass to the OFF state from key (by pressing the ESC key).

⋅ pass to the OFF state from supervisor if the OFF condition from digital input returns and the

OFF state from supervisor is set.

⋅ pass to the ON state if the OFF condition from digital input returns and the OFF state from

supervisor is not set.

A machine switched off from supervision protocol can:

⋅ pass to the OFF state from key (by pressing the ESC key).

⋅ pass to the OFF state from digital input if the OFF condition from supervisor returns and the

OFF state from digital input is tripped.

⋅ pass to the ON state if the OFF condition from supervisor returns and the OFF condition

from digital input is not present.

The machine On/Off key is the ESC key, pressed for about 2 seconds.

The remote On/Off input (when present) can be configured via the parameters:

- ONOFF D input: Enables the function

- D In 6 : Sets the NC, NO logic for the digital contact

5.10.1 OFF state due to alarm

When the machine is on, a further state exists OFF due to alarm, which switches the nit and all

devices off until the alarm condition has been reset. If digital consent is missing in this state from

Page 38

Page 39

C-PRO CLIMA SISTEMA INSTALLER MANUAL

supervisor or switch-off is requested from key, the power plant goes into the relative OFF state. The

alarms that cause this state are:

- Delivery 1 probe alarm

- Delivery 2 probe alarm

The machine works normally again when the alarm has been reset.

5.11 Summer/winter functioning mode

The operational mode can assume the following values:

E/I keyboard parameter Description

S= SUMMER Summer functioning mode

W= WINTER Winter functioning mode

There are procedures that allow to set the c-pro CLIMA system functioning mode:

1) Via the parameter regarding S/W keyboard in the maintenance menu

Setting - Be positioned on the S/W keyboard parameter and, pressing the ENTER key,

modify the value using the UP and DOWN keys. Confirm by pressing ENTER again.

2) Via supervision protocol (function enabled by parameter S/W BMS)

Setting - Send the operational mode change control via relative state from protocol.

This control has priority with respect to the S/W control from keyboard

3) Using the Estate/Inverno da ingresso digitale (Summer/winter from digital input) control

(function enabled from S/W D. Input parameter.

Setting - With contact open the unit is in “winter” functioning mode, with contact closed in

“summer” functioning mode.

This control has priority with respect to the S/W control from supervision protocol

4) Using summer/winter automatic switch-over function (function enabled from S/W Auto

parameter)

Setting - Switch-over from summer to winter takes place when the external temperature

remains above the value established with the T.Ext S parameter for the time established by

the W/S delay parameter

Vice versa, switch-over from winter to summer takes place when the external temperature

remains below the value established with the T.ext W parameter for the time established by

the W/S delay parameter

This control has priority with respect to the S/W control from digital input

As well as selection of the operational mode, a digital output is linked to the summer/winter

functioning mode, which functions as follows:

Functioning mode State of the digital input

S= SUMMER Summer/Winter output ACTIVE

W= WINTER Summer/Winter output OFF

A typical application of the summer/winter relay is to automatically inform the chiller/heat pump

unit of the system functioning mode.

Note. For the two manual summer/winter change modes (procedures 1 and 2) it is recommended to

carry out the summer/winter change with the machine off.

Page 39

Page 40

C-PRO CLIMA SISTEMA INSTALLER MANUAL

6 c-pro micro MCZN regulator

Zone regulator

6.1 List of pages

This paragraph presents the main pages and menus found in the MCZN application. As shown

previously, the general menu is divided into 2 levels: maintenance technician and installer are also

present along with "Zones State", “ON/OFF” and "System Network" sections for free consultation.

The latter is also necessary for navigation among modules.

The menus have the following structure:

• Zones status

- Zone A functioning status

Zone B functioning status

• Main menu

- Alarms

- Setpoint

- Zone A active setpoint pages

- Zone B active setpoint pages

- Maintenance

- Zones

- Zone A

- Zone B

- Manual

- Installer

- I/O configuration

- General parameters

- Zones

- Zone A

- Zone B

- Passwords

- Program info

• ON/OFF

- MCZN zone regulator status

• System Network

- MCZN system local network

Page 40

Page 41

C-PRO CLIMA SISTEMA INSTALLER MANUAL

Name of the MCZN regulator to which access has been

Summer/Winter operational mode

Alarm present in Zone A (consult alarms menu)

Zone A room temperature

Zone A roo

m humidity

Zone A

room

temperature set

point active

Zone A

room

humidity set

point active

6.2 Main page

The main page is displayed during the ON state:

MCZN regulator state:

ON = regulation in progress

By pressing the DOWN key, it is possible to select whether to access the Zones State pages of the

Main Menu, the On/Off pages or System Network pages, described below.

By pressing ESC key, the controller will go back to the main display of the MCCT thermal power

plant controller.

OFF = regulator OFF

ALARM = MCZN regulator general alarm

CT ALARM = MCCT regulator alarm off-line

6.3 Zones status

By accessing the state pages from the “Main Page” access the state pages relative to Zone A and

Zone B controlled by the MCZN zone regulator.

The Zone A/B state page will contain the following information:

Status of the temperature/humidity regulation

* = regulation in progress

- = regulation not requested/satisfied

Page 41

Page 42

C-PRO CLIMA SISTEMA INSTALLER MANUAL

Time

period

active

Work set

point relative

to the time

period

indicated

"Real" work set

-

point

6.4 Main menu

By accessing the pages of the main menu from the “Main Page” of the MCZN regulator, access the

setting pages of all regulator functioning parameters organised in the following sub-menu:

6.4.1 Alarms menu

This menu contains the information linked to the alarms present/active in the MCZN controller.

The MCZN regulator alarms log is contained in the MCCT thermal power plant regulator alarms

log.

To view the MCZN regulator active alarms, press ENTER on “Alarms”.

If there are no alarms present, “no alarms” is displayed, otherwise a series of pages appear

containing all possible alarms present in the controller with relative codes and description.

The alarm or the alarms present, will be highlighted by flashing "Rst ALARM", as shown in the

figure below.

If the ESC key is pressed from an alarm page or 60 timeout seconds are allowed to pass, you go

back to the main page of the application. This level is not protected by a password.

6.4.2 Setpoint menu

From this menu it is possible to display the temperature and humidity work setpoints for the zones

controlled by the zone regulator.

As well as the possibility to view and modify all work setpoints, the pages will also show the “real”

work setpoints, indicating by the effect of which type of regulation the work setpoint is different to

that set by the user .

The screens will be displayed as follows:

Work zone setpoint variation active function:

r = remote setpoint variator

Te = climatic curve with respect to the ext. temperature

rTe = remote variator + climatic curve

If the ESC key is pressed from a setting page or 240 timeout seconds are allowed to pass, you go

back to the main page of the application. This level is not protected by a password.

Page 42

Page 43

C-PRO CLIMA SISTEMA INSTALLER MANUAL

6.4.3 Maintenance menu

The maintenance menu is level 1, i.e. used to insert the maintenance level password or higher in

order to display/modify the parameters present in this branch.

From this menu it is possible to enable and set all features relative to the special control functions of

the zones contained in the MCZN application and precisely:

Entering the ZONES (Zone A / Zone B) menu, the temperature and humidity regulations are

enabled/disabled and the work setpoint remote variation functions, the room climatic curve setpoint

and heating/cooling integration are enabled/disabled and defined via external batteries (present in

the MCDE module), as well as the setting of all user work set-points (including the anti-freeze

setpoint and the regulation hysteresis) and the possibility to calibrate the signals coming from the

measurement inputs.

The MANUAL menu allows to set the functioning of the utilities managed by the application in

manual/automatic mode, thus forcing the state, to test its functionality.

6.4.4 Installer menu

The installer menu is level 2, i.e. used to insert the installer level password or higher in order to

display/modify the parameters present in this branch.

From this menu it is possible to view and set the configuration of the system managed from the

MCZN application.

Entering the I/O CONFIGURATION menu it is possible to set the type of analogue inputs and the

polarity of the digital inputs used in the application.

Entering the GENERAL PARAMETERS menu, the main features present in the controlled zone