Page 1

Instructions and installation

manual

MODELS:

GOC64 / GOC75 / GOC95

PLEASE READ THIS MANUAL BEFORE

INSTALLING THE COOKTOP.

COD. 04067LM 15.10.2014

Page 2

2

Dear Customer,

Congratulations on purchasing your new product from Euromaid Appliances.

To register your parts and labour warranty (some conditions apply please refer to

your warranty card for more details) please contact out Customer Care team on:

1800 805 300

Our Customer Care centre is there to ensure you get the most out of your

appliance. For example, should you want to learn more about recommended

cooking temperatures, the various cooking functions available, how to set and

program your LED clock, and importantly taking care of your appliance when

cleaning, please call us because we are here to help you.

It is important that you read through the following use and care manual thoroughly

to familiarize yourself with the installation and operation requirements of your

appliance to ensure optimum performance.

We also carry a complete range of spare parts for all Euromaid products. For all

your spare parts enquiries please contact Parts on:

1800 805 300

Again, thank you for choosing an appliance brought to you by Euromaid Appliances

and we look forward to being of service to you

.

Kind regards

Management

Euromaid Appliances

Page 3

3

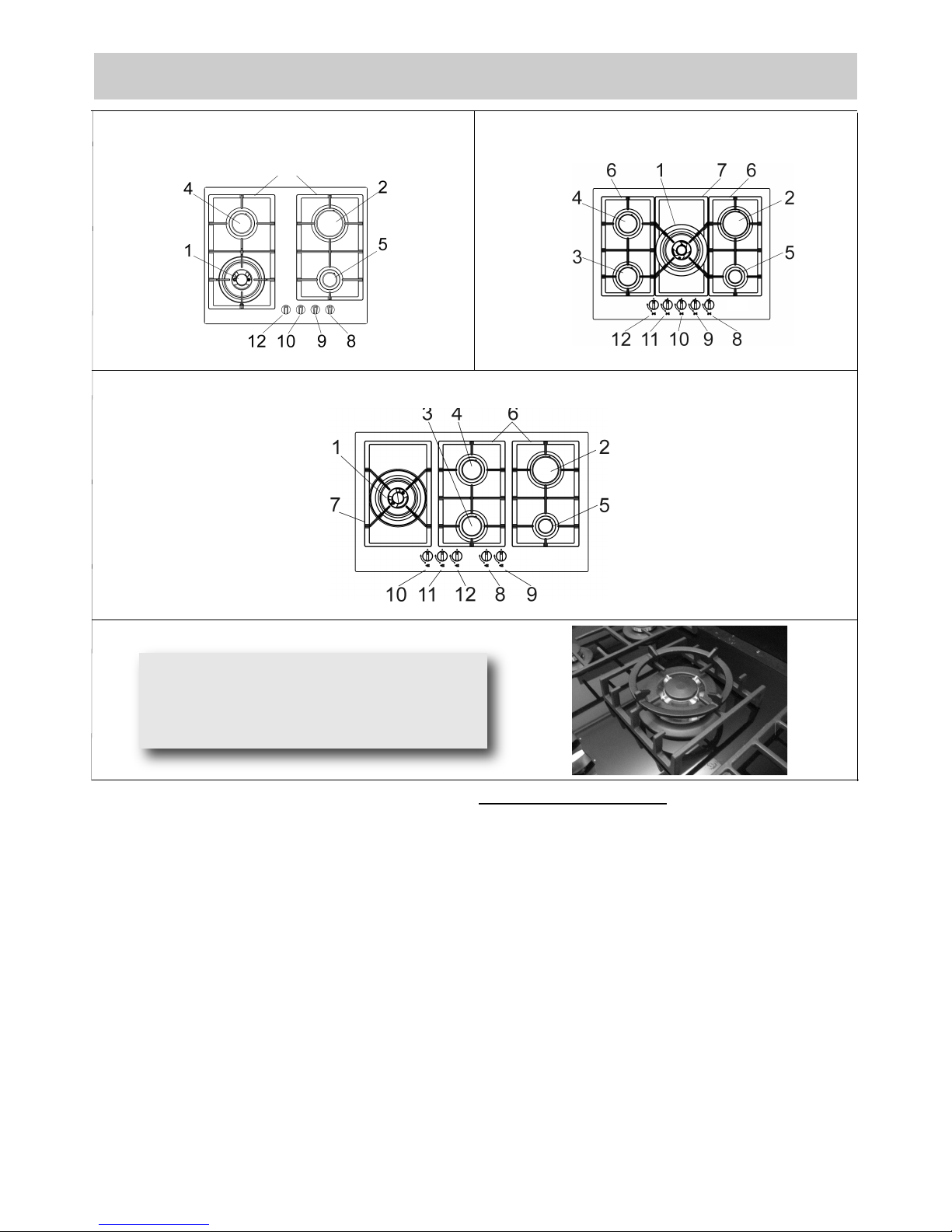

Natural U-LPG

1 Ultra rapid gas burner/WOK 14.5 MJ/h 12.6 MJ/h

2 Rapid gas burner 12.0 MJ/h 10.4 MJ/h

3 Semirapid reduced gas burner 5.4 MJ/h 4.9 MJ/h

4 Semirapid gas burner 7.1 MJ/h 6.3 MJ/h

5 Auxiliary gas burner 4.1 MJ/h 3.6 MJ/h

6 Pan stands support 2F

7 Pan stands support 1F

8 Burner n° 2 control knob

9 Burner n° 5 control knob

10 Burner n° 1 control knob

11 Burner n° 3 control knob

12 Burner n° 4 control knob

Attention: this appliance has been manufactured for domestic use only. Do not modify this

appliance.

DESCRIPTION OF COOKTOP

MOD.: GOC64

MOD.: GOC75

MOD.: GOC95

To use the WOK pan support (If present) on

ultra rapid gas burner only.

Put it on the ultra rapid pan support and

make sure of the stability (see fig. A).

Fig. A

Page 4

4

USE

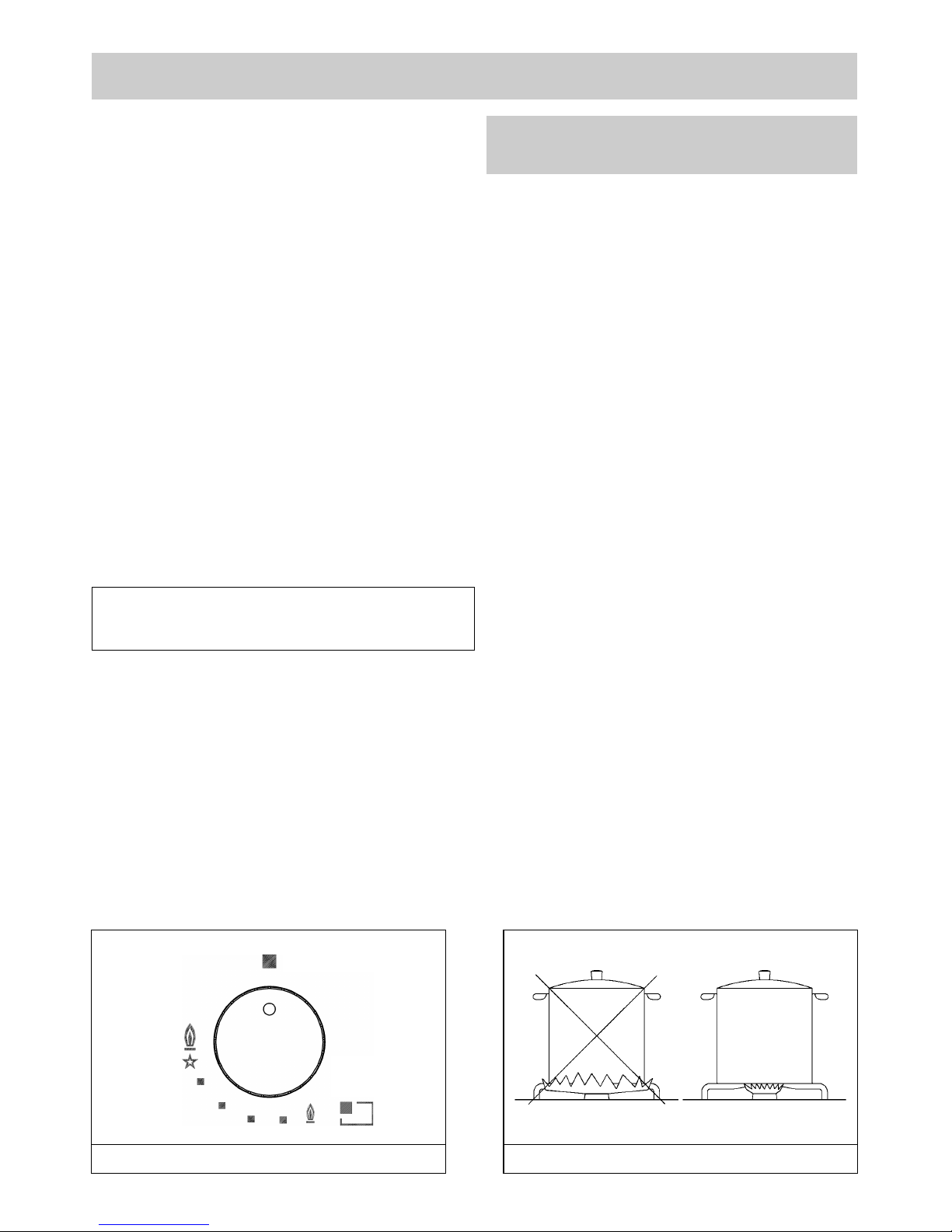

FIG. 1 FIG. 2

1) BURNERS

A diagram is screen-printed above each knob on the

front panel. This diagram indicates to which burner

the knob in question corresponds. After having

opened the gas mains or gas bottle tap, light the

burners as described below:

- automatic electrical ignition

Push and turn the knob corresponding to the

required burner in an anticlockwise direction until it

reaches the full on position (large flame fig. 1), then

depress the knob.

- Lighting burners equipped with flame failure

device

The knobs of burners equipped with flame failure

device must be turned in an anticlockwise direction

until they reach the full on position (large flame fig. 1)

and come to a stop. Now depress the knob in

qu estion and repeat the previously in dicated

operations.

Keep the knob depressed for about 10 seconds once

the burner has ignited.

Note: you are advised not to try and light a

burner if the flame divider (burner Cap) is not

correctly placed

HOW TO USE THE BURNERS

Bear in mind the following indications in order to

achieve maximum efficiency with the least possible

gas consumption:

- Use adequate pans for each burner (consult the

following table and fig. 2).

- When the pan comes to the boil, set the knob to

the reduced rate position (small flame fig. 1).

- Always place a lid on the pans.

- Use only pan with a flat bottom.

WARNINGS:

- Burners with flame failure device may only be

ignited when the relative knob has been set to

the Full on position (large flame fig. 1).

- Matches can be used to ignite the burners in a

blackout situation.

- Never leave the appliance unattended when the

burners are being used. Make sure there are no

children in the near vicinity. Particularly make

sure that the pan handles are correctly

positio ned and keep a check on foods

requiring oil and grease to cook since these

products can easily catch fire.

- The appliance must not be used by people

(including children) with impaired mental or

physical capacities, or without experience of

using electrical devices, unless supervised or

instructed by an expert adult responsible for

their care and safety. Children should not be

allowed to play with the equipment.

- Never use aerosols in the vicinity of this appliance

while it is in operation.

- Should a crack appear on the surface of the glass,

disconnect the appliance from the electricity

supply immediately.

- Do not place pans with an unstable or deformed

bottom on the burner, as these may tip or spill their

contents, causing accidents.

- Do not store or use flammable liquids or items

in the vicinity of the cooktop.

- Do not use the hob as a work surface.

- This product is not to be installed in marine

crafts, caravans, or mobile homes.

- Containers wider than the unit are not

recommended.

- Avoid scraping the pans on the glass surface,

as the surface may become scratched.

- Do not modify this appliance.

Burners

Power ratings

Pan Ø

in cm

Natural U-LPG

Ultra rapid/WOK 14.5 MJ/h 12.6 MJ/h

24 ÷ 26

Rapid 12.0 MJ/h 10.4 MJ/h

20 ÷ 22

Semirapid reduced 5.4 MJ/h 4.9 MJ/h

16 ÷ 18

Semirapid 7.1 MJ/h 6.3 MJ/h

16 ÷ 18

Auxiliary 4.1 MJ/h 3.6 MJ/h

10 ÷ 14

In the event of the Burner flames being accidentally

extinguished, turn off the burner control and do not

attempt to re-ignite the burner for a least 1 minute.

Closed position

Full on

position

Reduced rate

position

Page 5

5

USE

WARNINGS AND ADVICE FOR THE USER:

- Do not attempt to change the technical characteristics of the product because it can be dangerous.

- If you decide longer use this appliance any more (or replace an old model), before disposing of it,

make it inoperative in conformity with current law on the protection of health and the prevention of

environmental pollution by making its dangerous parts harmless, especially for children who

might play on an abandoned appliance.

- Do not touch the appliance with wet or damp hands or feet.

- Do not use the appliance barefoot.

- The manufacturer will not be liable for any damage resulting from improper, incorrect or

unreasonable use.

- During, and immediately after operation, some parts of the cooktop are very hot: avoid touching

them.

- After using the cook top, make sure that the knob is in the closed position and close the main tap

of the gas supply or gas cylinder.

- If the gas taps are not operating correctly, call the Customer Care Department.

Abnormal operations:

Any of the following are considered to be anormal operation and may require servicing:

- Yellow tipping of the hob burner flame.

- Sooting up of cooking utensils.

- Burners not igniting properly.

- Burners failing to remain alight.

- Burner extinguished by cupboard doors.

- Gas valves which are difficult to turn.

CAUTION:

In case of hotplate glass breakage:

● shut immediately off all burners and any electrical heating element and isolate the appliance from

the power supply,

● do not touch the appliance surface,

●do not use the appliance.

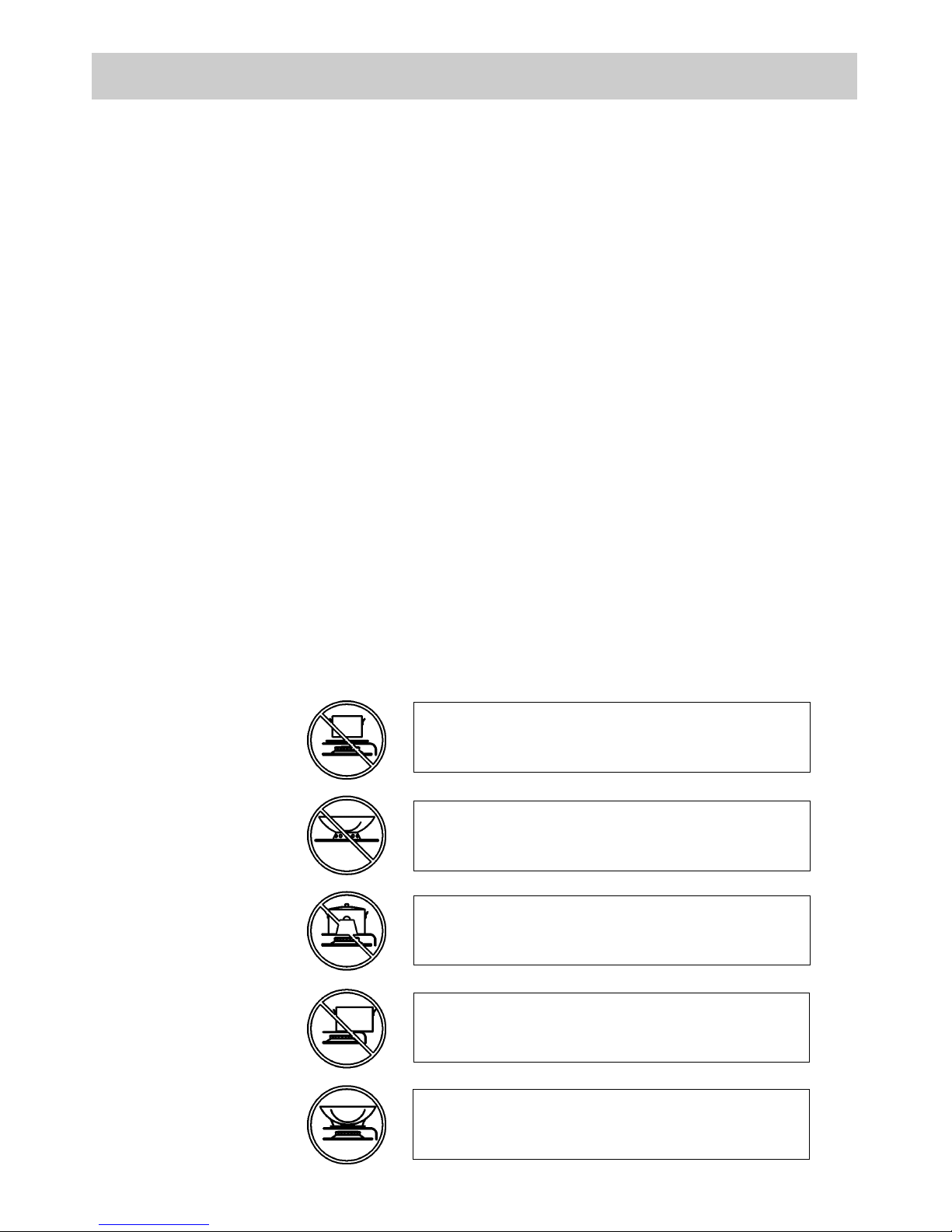

Do not place anything, eg. flame tamer, asbestos

mat, between pan and pan support as ser iou s

damage to the appliance my result.

Do not remove the pan support and enclose the

burner with a wok stand as this will concentrate and

deflect heat onto the cooktop.

Do not use large pots or heavy weights which can

be nd the pan support or de flect flame onto t he

cooktop.

Symbol 1

Symbol 2

Symbol 3

Locate pan centrally over the burner so that it is

stable and does not overhang the appliance.

Use only a wok support supplied or recommended by

the manufacturer of the appliance.

Symbol 4

Symbol 5

Page 6

6

CLEANING

IMPORTANT:

Always disconnect the appliance from the gas and electricity mains before carrying out any

cleaning operation.

2) COOKTOP

Periodically wash the hot plate, the enamelled stell pan support, the enamelled burner caps “A”, “B” and

“C” and the burner heads "T" (see fig. 3 and 3/A) with lukewarm soapy water. They should also be

cleaned plugs "AC" and flame detection "TC" (see fig. 3). Clean them gently with a small nylon brush as

shown (see fig. 3/B) and allow to dry fully. Do not wash in the dishwasher. It is very important to clean the

surface soon after every use, when the glass is still tepid.

Do not allow vinegar, coffee, milk, salted water, lemon or tomato juice from remaining in contact with the

enamelled surfaces for long periods of time.

Do not clean using abrasive metal scourers, powder abrasives or corrosive sprays.

WARNINGS:

Comply with the following instructions, before remounting the parts:

- Check that burner head slots “T” (fig. 3) have not become clogged by foreign bodies.

- Check that the enamelled burner cap “A-B-C” (fig. 3-3/A) has been correctly positioned on the burner head. It

must be steady.

- The pan support must be placed in the appropriate centering pins verifying the perfect stability

- Do not force the taps if they are difficult to open or close. Contact an Authorised Service Centre

for repairs.

- Don’t use steam jets for cleaning the cooktop.

Not e: cont inuo us use could caus e t he

burners to change colour due to the high

temperature.

FIG. 3/B

FIG. 3/AFIG. 3

Page 7

7

CLEANING

COOKTOP CERAMIC GLASS

If you wish to maintain the shine of the ceramic surface, treat the glass with a silicon-based film product

before use to protect the surface against water and dirt.

This protective film is not durable, so it is advisable to repeat the application of the product frequently.

It is very important to clean the hob every time you use it, while the glass is still warm.

Do not clean using abrasive metal scourers, powder abrasives or corrosive sprays.

Depending on the degree of dirt, we recommend:

- for light stains, a damp sponge is sufficient.

- Tough, encrusted dirt is easily eliminated using a scraper (fig.3/C), not supplied with the hob, but easy to

find in local stores. Use the scraper carefully to avoid damaging the hob.

- Traces of liquid spilled from pans can be eliminated with vinegar or lemon juice.

- Never allow sugar or sugary foods to fall on the hob while cooking. Should this occur, switch off the

hob and clean it immediately with hot water, using a scraper on hot spills.

- As time goes by metallic reflections, colouring or scratches may appear due to poor cleaning and the

incorrect movement of pans. Scratches are hard to eliminate but do not affect the correct operation of your

hob.

- Do not use jets of steam to clean the appliance.

PREVENTATIVE MAINTENANCE

This cooktop should not require ongoing maintenance provided you ensure:

- all spillages are cleaned up as soon as they occur.

- Burner are kept clean.

- Burner ports are free of debris, food or anything else that may cause an obstruction.

- Electrode and thermocouples are kept clean.

- Burners are re-assembled correctly.

- Do not get water in the area where the injectors are located.

FIG. 3/C

Page 8

8

INSTALLATION

FIG. 4

COMPLY WITH THE DIMENSIONS

(in mm)

A B C D E

4F (60) 553 473 63.5 63.5 173.5 min.

5F (70) 645 475 63.5 63.5 173.5 min.

5F (90) 833 475 62.5 62.5 73.5 min.

TECHNICAL INFORMATION

FOR THE INSTALLER

This appliance shall be installed only by authorised

personnel and in accordance with the

manufacturer’s installation instructions, local gas

fitting regulations, municipal codes, electrical wiring

regulations, NZS5261:2003, AS 5601 - Gas

Installation and any other statutory regulations.

Ventilation must be in accordance with AS 5601,

NZS5261:2003 - Gas installation. In general, the

appliance should have adequate ventilation for

complete combustion of gas, proper flueing and

to maint ain te mperature of imme diate

surroundings safe limits.

The wall and bench surfaces must be capable of

sustaining temperatures of 75 °C. All laminates,

fixing adhesive and surfacing materials should

be certified suitable for this temperature.

3) INSTALLING THE COOKTOP

Check that the appliance is in a good condition after

having removed the outer packaging and internal

wrappings from around the various loose parts. In

case of doubt, do not use the appliance and contact

qualified personnel.

Never leave the packaging materials (cardboard,

bags, polystyrene foam, nails, etc.) within

children’s reach since they could become

potential sources of danger.

The measurements of the opening made in the top of

the modular cabinet and into which the cooktop will be

installed are indicated in fig. 4. The maximum overall

dimensions are shown either in Figures 4/A - 4/B - 4/C.

Always comply with the measurements given for

the hole into which the appliance will be recessed

(see fig. 4)

.

The app liance bel ongs t o class 3 and i s

there for e s ubject to all the pro vis ions

established by the provisions governing such

appliances.

Any adjoining wall surface situated within 200 mm

from the edge of any hob burner must be a suitable

non - combustible material for a height of 150 mm

for the entire length of the hob. Any combustible

construction above the top of the burner and no

construction shall be within 450 mm above the top

of the burner. A minimum depth of 70 mm from the

top of the work surface must be provided for this

appliance.

CAUTION:

the installer shall test the appliance

bef ore le avin g. Te st the s afet y

operation of the ignition system on all

burners individually and combined.

IMP ORTAN T: a perf ect inst alla tion ,

adjustment or transformation of the cook top

to use other gases requires a QUALIFIED

INSTALLER: a failure to follow this rule will

void the warranty.

Fig.4/A Mod.:GOC64

Fig.4/B Mod.:GOC75

Fig.4/C Mod.:GOC95

Page 9

9

4) FIXING THE COOKTOP

The cooktop has a special seal which prevents

liquid from getting into the cabinet. Strictly comply

with the following instructions in order to correctly

apply this seal:

- Take off all the movable parts of the hob.

- Cut the seal in 4 parts of the necessary lenght to

positionning it on the 4 edges of the glass.

- Overturn the cooktop and correctly position seal

“E” (fig. 5) under the edge of the cooktop itself,

so t hat the outer side of t he s eal perfectly

matches the outer edge of the cooktop. The ends

of the strips must fit together without overlapping.

- Evenly and securely fix the seal to the cooktop,

pressing into place with the fingers and remove

the strip of protective paper from the seal and set

the plate into the hole made in the cabinet.

- Position the hob in the hole in the unit and fasten it in

place using the appropriate screws “F” and the

fastening hooks “G” (fig. 6).

- When the appliance is installed so that the base

can be to uched, we recommend fi tti ng a

protecting shield. This shield must be at least

70 mm below the base of the bench top (fig. 4).

Timber or other suitable material may be used

provi ded it is ca pable of wit hstan din g the

appliance temperatures. Ensure that the supply

connection point is accessible with the appliance

installed. To facilitate shield may need to be

removable.

NOTE: do not fix the cooktop into the bench

with sealant (ie silicon) as this may void the

warranty. Use only the seals provided.

INSTALLATION

FIG. 5

FIG. 6

FIG. 4/A

Caution: Do not allow the glass (A)

lay directly on the work top. it is the

bottomshelf (B) “carter” that has to

be in touch with the work top (see

fig. 4/A).

Page 10

10

5) GAS CONNECTION

The gas connection is located in the rear and on

the underside of the appliance 100 mm from the

right hand side.

There are two ways to carry out the connection to

the main gas line:

A. The cooktop can be connected with rigid pipe

as specified in AS5601 table 3.1.

B. If installing with a hose assembly, install with a

hose assembly that complies with AS/ANZ 1869

(AGA Approved), 10 mm ID, class B or D, no more

than 1.2 m long and in accordance with AS5601.

Ensure that the hose does not contact the hot

surfaces of the cooktop, oven, dishwasher or any

other appliance that may be installed underneath

or next to the cooktop. The hose should not be

subjected to abras ion, ki nking or permanent

deformation and should be able to be inspected

along its entire length with the cooktop in the

installed position.

Unions compatible with the hose fittings must be

used and all connections tested for gas leaks.

The gas supply connection for the hose assembly

must be accessible.

Wa rning: ens ure tha t the hos e assem bly is

restrained from accidental contact with the flue or

flue outlet of an underbench oven.

Natural Gas

Natural Gas installations require the connection of

a gas regulator at the appliance. This regulator is

supplied with the appliance on purchase.

Assemble the regulator (noti ng t he g as f low

direction) and transition pieces (supplied with the

appliance), in accordance with figure 7.

The transition piece on the supply side of the

regulator must be provided by the installer.

Liquified Petroleum Gas.

In a Uni ver sal LP Gas i nstalla tion the g as

reg ulat ion is made at the gas cyli nder a nd

regulation at the appliance is not required. To

connect supply to the appliance use transition

pieces as shown in figure 8. These pieces are

supplied with the appliance on purchase.

WARNING:

THE BURNER FLAME MUST BE ADJUSTED BY

THE INSTALLER.

FAULTY I NSTAL LATION W ILL NO T BE

COVERED UNDER WARRANTY.

THE A PPLI ANCE IS FA CTORY SET F OR

NATURAL GAS. THE TEST POINT PRESSURE

SHOULD BE ADJUSTED TO 1.00kPa WITH THE

WOK BURNER OPERATING AT MAXIMUM.

INSTALLATION

FIG. 7

FIG. 8

Page 11

11

6) ELECTRICAL CONNECTION

The appliance is supplied with a 1800 mm long

flexible supply lead.

The point of attachment for this lead is located at

the rear and on the underside of the appliance

380 mm from the right hand side.

The voltage and power consumption are detailed on

the underside of the appliance. Ensure that the

appliance is correctly rated to the supply.

Connect appliance by way of a switched power

point.

THE APPLIANCE MUST BE EARTHED

Ensure that this power point is properly earthed.

Loo k a t the conn ecti on wiri ng dia gram s

(fig. A and Fig.B).

Warning: in order to avoid any hazard, any

electrical work performed on this equipment or

its associated wiring, should only be done by

persons a qualified by the supplier or similarly

qualified persons.

The socket outlet for this cooktop shall be

installed near the cooktop and shall be easily

accessible.

The electrical connections of the appliance

must be carried out in compliance with the

provisions and standards in force.

Before connecting the appliance, check that:

- The voltage matches the value shown on the

specification plate and the section of the wires of

the electrical system can support the load, which

is also indicated on the specification plate.

- The electrical capacity of the mains supply and

current sockets suit the maximum power rating of

the appliance (consult the data label applied to the

underside of the cooktop).

- The socket or system has an efficient earth

connection in compliance with the provisions and

standards in force. The manufacturer declines all

responsibility for failing to comply with these

provisions.

When the ap pli ance is con nec ted to the

electricity main by a socket:

- Fit a standard plug suited to the load indicated on

the data label to the cable.

- Fit the wires following figure n.9, taking care of

respecting the following correspondences:

Letter L (live) = brown wire;

Letter N (neutral) = blue wire;

Earth symbol = green - yellow wire.

- The power supply cable must be positioned so that no

part of it is able to reach an overtemperature of 90 °C.

- Never use reductions, adapters of shunts for

connection since these could create false contacts

and lead to dangerous overheating.

When the appliance is connected straight to the

electricity main:

- Install an omnipolar circuit-breaker between the

appliance and the electricity main. This circuitbreaker should be sized according to the load

rating of the appliance and possess a minimum 3

mm gap between its contacts.

- Remember th at t he earth w ire must no t be

interrupted by the circuit-breaker.

-The electrical connection may also be protected by

a high sensitivity differential circuit- breaker.

You are strongly advised to fix the relative yellowgreen earth wire to an efficient earthing system.

Before performing any service on the electrical

part of the appliance, it must absolutely be

disconnected from the electrical network.

INSTALLATION

IMPORTANT: the appliance must be installed

following the manufacturer's instructions. The

manufacturer will not be liable for injury to

persons or animals or property damage caused

by an incorrect installation.

If the installation requires modifications to

the h ome' s electri cal sys tem or if t he

socket is incompatible with the appliance's

plu g, hav e chan ges or r epla ceme nts

per formed by profess iona lly -qua lified

person. In particular, this person must also

make sure that the section of the wires of

the s ocke t is su itab le for the po wer

absorbed by the appliance.

220-240 V~

220-240 V~

A

B

FIG. 9

Page 12

12

ADJUSTMENTS

Always disconnect the appliance from the

electricity main before making any adjustments.

All seals must be replaced by the technician at

the end of any adjustments or regulations.

Our b urners d o not re qui re primary air

adjustment.

a) Data Label

The Data Label is located on the underside of the

cooktop. A duplicate Data Label is supplied to

adhere in an accessible area next to the cooktop.

Th is cookt op is suitable for Natural Ga s and

Universal LP Gas; ensure that the available gas

supply matches the Data Label.

b) Before Leaving

Check that there are no gas leaks, but do not use a

naked flame to detect gas leaks. Ignite all burners

to ensure correct operation of gas valves, burners,

ignition and if fitted, flame failure valves. Turn gas

taps to low flame position and observe stability of

the flame. When satisfied with the cooktop, please

instruct the user on the correct method of operation.

In case the appliance fails to operate correctly after

all checks have been carried out, refer to the

authorised service provider in your area.

7) TAPS

Our taps are suitable for all gas, they are male

conical type.

“Reduced rate” adjustment

- Switch on the burner and turn the relative knob to the

“Reduced rate” position (small flame fig.1- pag. 3).

- Remove knob “M” (fig. 10 and 10/A) of the tap,

which is simply pressed on to its rod. The by-pass

for minimal rate regulation can be: beside the tap

(fig. 10) or inside the shaft. In any case, to access

to regulation, it can be done through the insertion

of a small screwdriver ‘’D’’ beside the tap (fig. 10)

or in the hol e ‘ ’C’’ insi de th e s haft of ta p

(fig 10/A). Turn the throttle screw to the right or left

un til the burne r flame has been adequatel y

regulated to the “Reduced rate” position.

The flame should not be too low: the lowest small

flame should be continuous and steady. Reassemble the several components.

It is understood that only burners operating

with Natural gas should be subjected to the

above mentioned adjustments.

FIG. 10

FIG. 10/A

Page 13

13

CONVERSIONS

8) UNIVERSAL LP GAS TO NATURAL GAS

CONVERSION PROCEDURE

Appliance models: Gas stainless steel cooktop

models:

1. Remove each burner cap and burner skirt.

2. Remove the Universal LP Gas main injector with

a 7 mm/VF tube spanner and replace with the

appropriate size Natural Gas injector for each

burner. The following injector sizes are required for

Natural Gas:

Burner Main injector

Wok 1.75 B mm

Rapid 1.55 mm

Semi Rapid Reduced 1.05 mm

Semi Rapid 1.20 mm

Auxiliary 0.90 mm

3. Shut off gas supply to the appliance.

4. Disconnect gas inlet pipe from the Universal LP

Gas test point inlet fitting.

5. Remove the Universal LP Gas test point inlet

fitting from the appliance.

6. Fit the Natural Gas Regulator supplied in the

conversion kit.

7. Connect the gas supply to the Regulator.

8. Check for gas leaks. Do not use a naked flame

to check for gas leaks.

9. Adjust the gas pressure to 1.00 kPa.

10. Remove the control knob, with a thin shaft blade

screwdriver down the centre of each gas valve

shaft, screw the by-pass injector anti-clockwise.

Test the appliance on both high and low flame for

each burner. If the burner fails to remain alight or

the flame is not stable on the simmer setting, adjust

the by-pass screw, until flame is stable.

11. If not already removed, remove the “Only for

use with Universal LP Gas” label adhered to the

bottom panel near the gas connection.

12. Fit the new data label included in the gas

conversion kit.

9) NATURAL GAS TO UNIVERSAL LP GAS

CONVERSION PROCEDURE

Appliance models: Gas stainless steel cooktop

models:

1. Remove each burner cap and burner skirt.

2. Remove the Natural Gas main injector with a 7

mm /VF tube spanne r and replace wit h the

appropriate size Universal LP Gas main injector for

each burner. The following injector sizes are required

for Universal LP Gas:

Burner Main injector

Wok

1.00 B

mm

Rapid 0.91 mm

Semi Rapid Reduced 0.60 mm

Semi Rapid 0.70 mm

Auxiliary 0.53 mm

3. Remove the control knob, with a thin shaft blade

screwdriver down the centre of each gas valve

shaft, screw the by-pass injector fully clockwise.

4. Shut off gas supply to the appliance.

5. Disconnect gas inlet pipe from the Natural Gas

Regulator.

6. Remove the Natural Gas Regulator from the

appliance.

7. Fit the Universal LP Gas test point inlet fitting

supplied in the conversion kit.

8. Connect the gas supply to the inlet fitting.

9. Check for gas leaks. Do not use a naked flame

to check for gas leaks.

10. Adjust the gas pressure to 2.75 kPa.

11. Test the appliance on both high and low flame

for each burner and check the gas pressure. If the

burner fails to remain alight or the flame is not

stable on the simmer setting, adjust the by-pass

screw, until flame is stable.

12. If not already removed, remove the “Only for

use with Natural Gas” label adhered to the bottom

panel near the gas connection.

13. Fit the new data label included in the gas

conversion kit.

GOC64

4 Burners

GOC75

5 Burners

GOC95

5 Burners

GOC64

4 Burners

GOC75

5 Burners

GOC95

5 Burners

Page 14

14

CONVERSIONS

10) REPLACING THE INJECTORS

The burners can be adapted to different types of

gas by installing injectors suited to the type of gas

required. To do this, first remove the burner tops

using a wrench “B”. Now unscrew injector “A” (see

fig. 11) and fit a injector corresponding to the type of

gas required.

It is advisable to tighten the injector in place.

After the injectors have been replaced, the

burners must be regulated as explained in

paragraphs 7. The technician must reset any

seals on the regulating or pre-regulating devices

and affix the label corresponding to the new gas

regulation on the appliance instead of the already

existing one. This label is supplied in the packet

containing the spare injectors.

The envelope with the injectors and the labels can

be included in the kit, or at disposal to the

authorised Customer Care Department .

For the sake of convenience, the nominal rate chart

also l ists the heat inpu ts of t he burners, the

diameter of the injectors and the working pressures

of the various types of gas.

BURNER ARRANGEMENT ON THE COOKTOP

TABLE 1

BURNERS

GAS

NORMAL

PRESSURE

(kPa)

INJECTOR

DIAMETER

(1/100 mm)

N O MI N AL

HEAT

INPUT (MJ/h)

MAX.

N°

DESCRIPTION

1

ULTRA RAPID

U-LPG

NATURAL

2.75

1.00

100 B

1.75 B

12.6

14.5

2

RAPID

U-LPG

NATURAL

2.75

1.00

91

155

10.4

12.0

3

SEMIRAPID

REDUCED

U-LPG

NATURAL

2.75

1.00

60

105

4.9

5.4

4 SEMIRAPID

U-LPG

NATURAL

2.75

1.00

70

120

6.3

7.1

5

AUXILIARY

U-LPG

NATURAL

2.75

1.00

53

90

3.6

4.1

FIG. 11

Page 15

15

FIG. 12

SERVICING

Gas cooktop H05 RR - F Section 3 x 0.75 mm

2

TYPE OF TYPE OF SINGLE - PHASE

COOKTOP CABLE POWER SUPPLY

CABLE TYPES AND SECTIONS

ATTENTION!!!

If the power supply cable is replaced, the installer should leave the ground wire longer than the phase

conductors (fig. 12) and comply with the recommendations given in paragraph 6.

TECHNICAL ASSISTANCE AND SPARE PARTS

Before leaving the factory, this appliance will have been tested and regulated by expert and specialised

personnel in order to guarantee the best performances.

Any repairs or adjustments which may be subsequently required may only be carried out by qualified

personnel with the utmost care and attention.

For this reason, always contact your Dealer or our nearest After Sales Service Centre whenever repairs or

adjustments are required, specifying the type of fault and the model of the appliance in your possession.

Please also note that genuine spare parts are only available from our After Sales Service Centres and a

qualified retail outlets.

The above data are printed on the data label put on the inferior part of the appliance and on the packing

label.

The above informations give to the technical assistant the possibility to get fit spare parts and a heaven-sent

intervention. We suggest to fill the table below.

MARK: ........................................................

MODEL: .....................................................

SERIES: .....................................................

Page 16

Euromaid Appliances Pty Ltd.

20 Carlotta Street Artarmon

NSW 2064 Australia

please call sales and service on

1800 805 300

Website

www.euromaid.com.au

16

Loading...

Loading...